Prepn. of magnetic molecular pellets by complex emulsion process (W1/0/W2 type)

A polymer microsphere and polymer technology, applied in the field of magnetic polymer microspheres and their preparation, can solve problems such as limiting the application of magnetic polymer microspheres

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

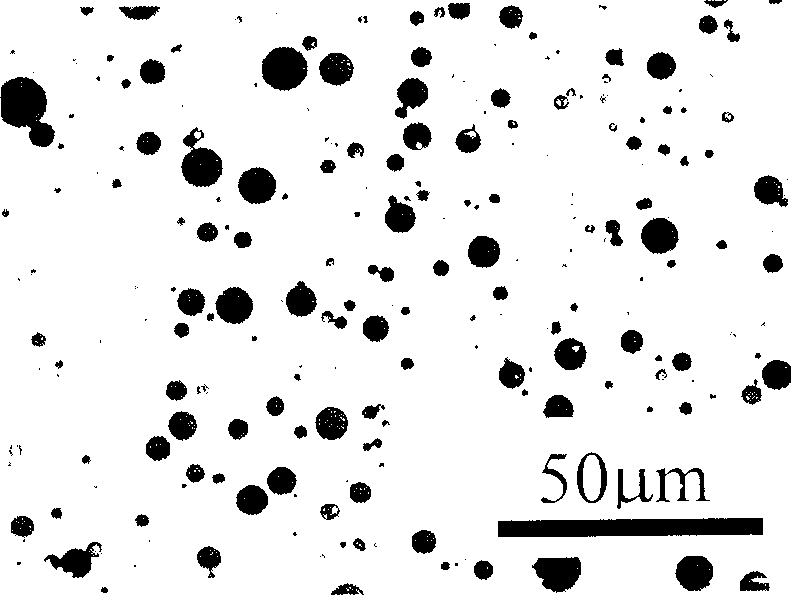

[0036] Take 0.30 g of PSt and 0.06 g of Span85 (sorbitan trioleate) and dissolve them in 6.50 mL of toluene to form oil phase O. Will W 1 (0.40mL of FeCl with a concentration of 1.00mol / L 3aqueous solution and 0.20ml of FeSO with a concentration of 1.00mol / L 4 Aqueous solution) was added to the oil phase O, stirred with an emulsifying homogenizer for 2min at a speed of 10000rpm to form a stable W 1 / O colostrum emulsion. The prepared W 1 / O type colostrum emulsion is slowly poured into 250mL external water phase W 2 (H 2 O is 250.0g, PVA-217 is 1.0g), stirring in the rotating speed is 400rpm, forming W 1 / O / W 2 Type double emulsion, then add 50mL triethylamine to the external water phase, stir for 2hr under nitrogen protection, then raise the temperature to 45°C and stir for 6hr, then naturally cool down to room temperature and stir for 18hr to completely volatilize the toluene. Finally, it is separated in an external magnetic field, washed, and vacuum-dried to obtain ...

Embodiment 2

[0038] Take 0.30 g of PSt and 0.06 g of Aracel83 (sorbitan sesquioleate), and dissolve them in 6.00 mL of dichloromethane to form oil phase O. Will W 1 (0.30mL of FeCl with a concentration of 0.80mol / L 3 aqueous solution and 0.3ml of FeCl with a concentration of 0.80mol / L 2 aqueous solution) into the oil phase O, emulsified by ultrasonic emulsification, the emulsification power is 200W, and the time is 2min to form a stable W 1 / O colostrum emulsion. The prepared W 1 / O type colostrum emulsion is slowly poured into 350mL external water phase W 2 (H 2 O is 350.0g, PVA-217 is 1.75g), stirring in the rotating speed is 400rpm, forming W 1 / O / W 2 Type double emulsion, then add 25mL potassium hydroxide solution with a concentration of 2mol / L to the external water phase, stir for 2hr under the protection of nitrogen, then naturally cool down to room temperature and stir for 24hr to completely volatilize the dichloromethane. Finally, it is separated in an external magnetic fie...

Embodiment 3

[0040] Take 0.30 g of PSt and 0.08 g of Span85 (sorbitan trioleate) and dissolve them in 5.50 mL of toluene and 1.00 mL of dichloromethane to form oil phase O. Will W 1 (0.30mL of FeCl with a concentration of 0.50mol / L 3 aqueous solution and 0.30ml of FeCl with a concentration of 0.50mol / L 2 Aqueous solution) was added to the oil phase O, stirred with an emulsifying homogenizer for 2min, and the speed was 9000rpm to form a stable W 1 / O colostrum emulsion. The prepared W 1 / O type colostrum emulsion is slowly poured into 300mL external water phase W 2 (H 2 O is 300.0g, PVA-217 is 3.0g), stir with a homogeneous emulsifier, the speed is 600rpm, and form W 1 / O / W 2 Type double emulsion emulsion, then use mechanical stirring, the speed is 400rpm, then add 50mL triethylamine to the external water phase, stir for 2hr under the protection of nitrogen, then raise the temperature to 45°C and stir for 6hr, and then reduce the pressure to make the toluene and diethylamine Chlorom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com