Microfluidic device capable of rapidly preparing emulsion in multiple dimensions

A microfluidic device, multi-dimensional technology, applied in the preparation of test samples, laboratory equipment, chemical instruments and methods, etc., can solve the problems of limited dimensions of emulsion splitting, complex channel processing of emulsion splitting devices, etc., and achieve the goal of building Fewer steps, increased emulsion yield, simple channel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

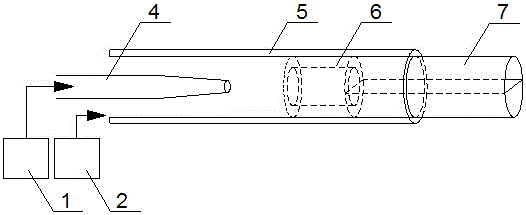

[0034] Example 1: Using figure 1 The microfluidic device shown is implemented according to the implementation steps to realize the division of a single emulsion into two.

example 2

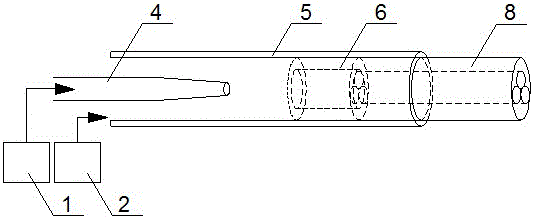

[0035] Example 2: Using figure 2 The microfluidic device shown is implemented according to the implementation steps, and the experimental single emulsion is divided into three.

example 3

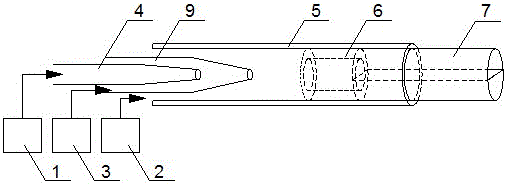

[0036] Example 3: Using image 3 The microfluidic device shown is implemented according to the implementation steps, and the experimental double emulsion is divided into two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com