Patents

Literature

1890results about How to "Guaranteed output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flow control arrangement in a network switch based on priority traffic

InactiveUS6981054B1Avoid congestionMaintain reliabilityError preventionFrequency-division multiplex detailsTraffic capacityFrame based

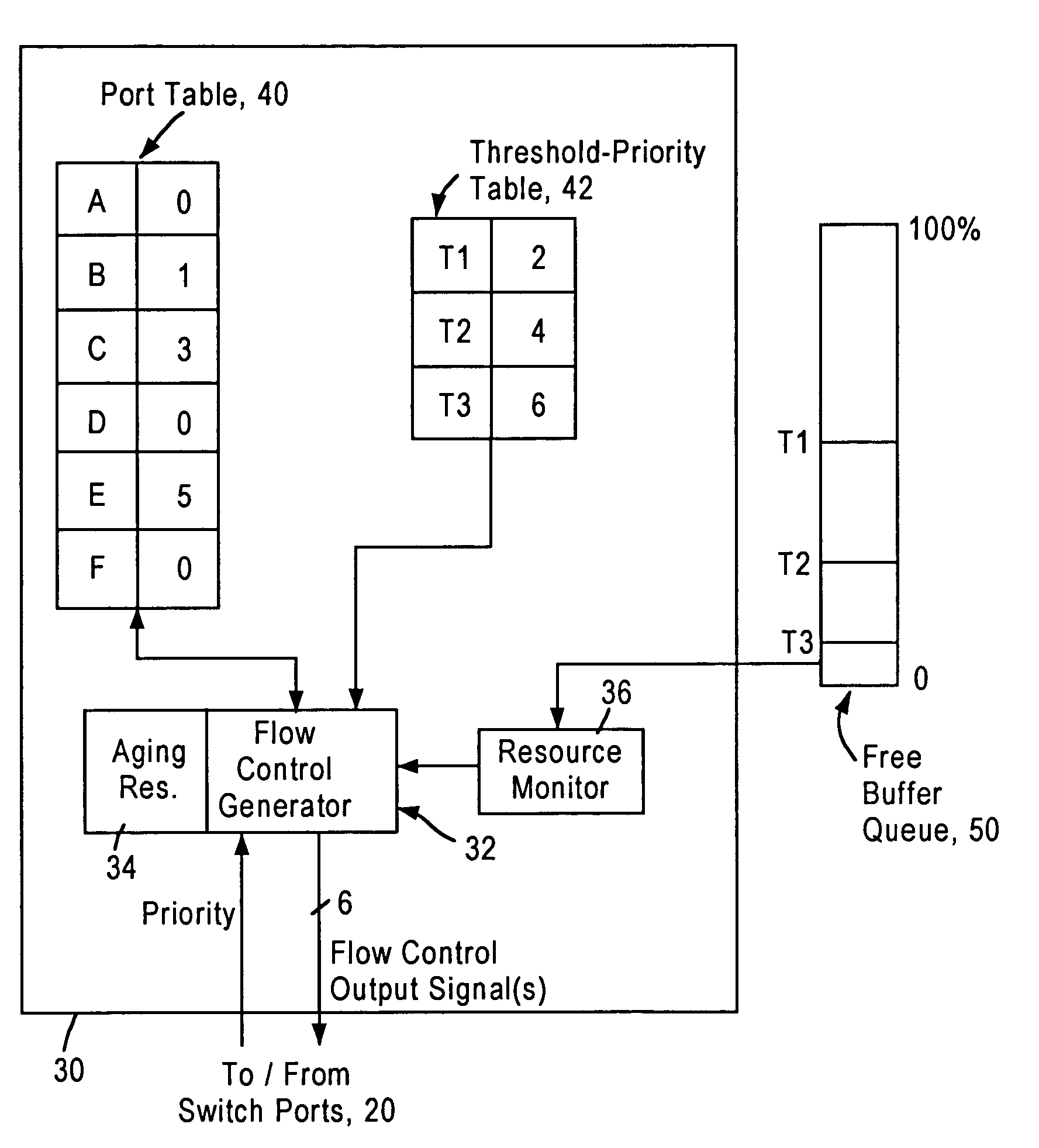

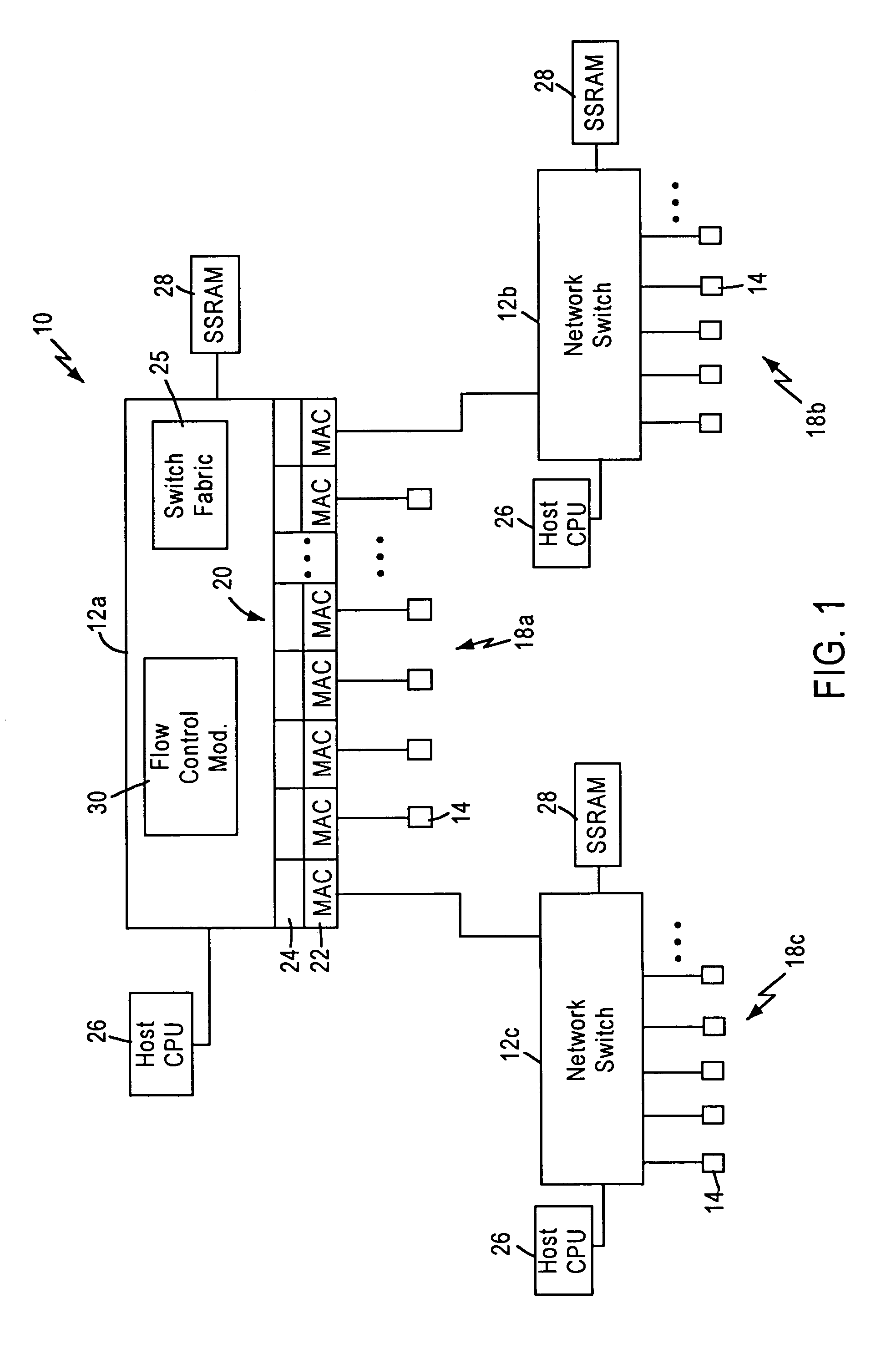

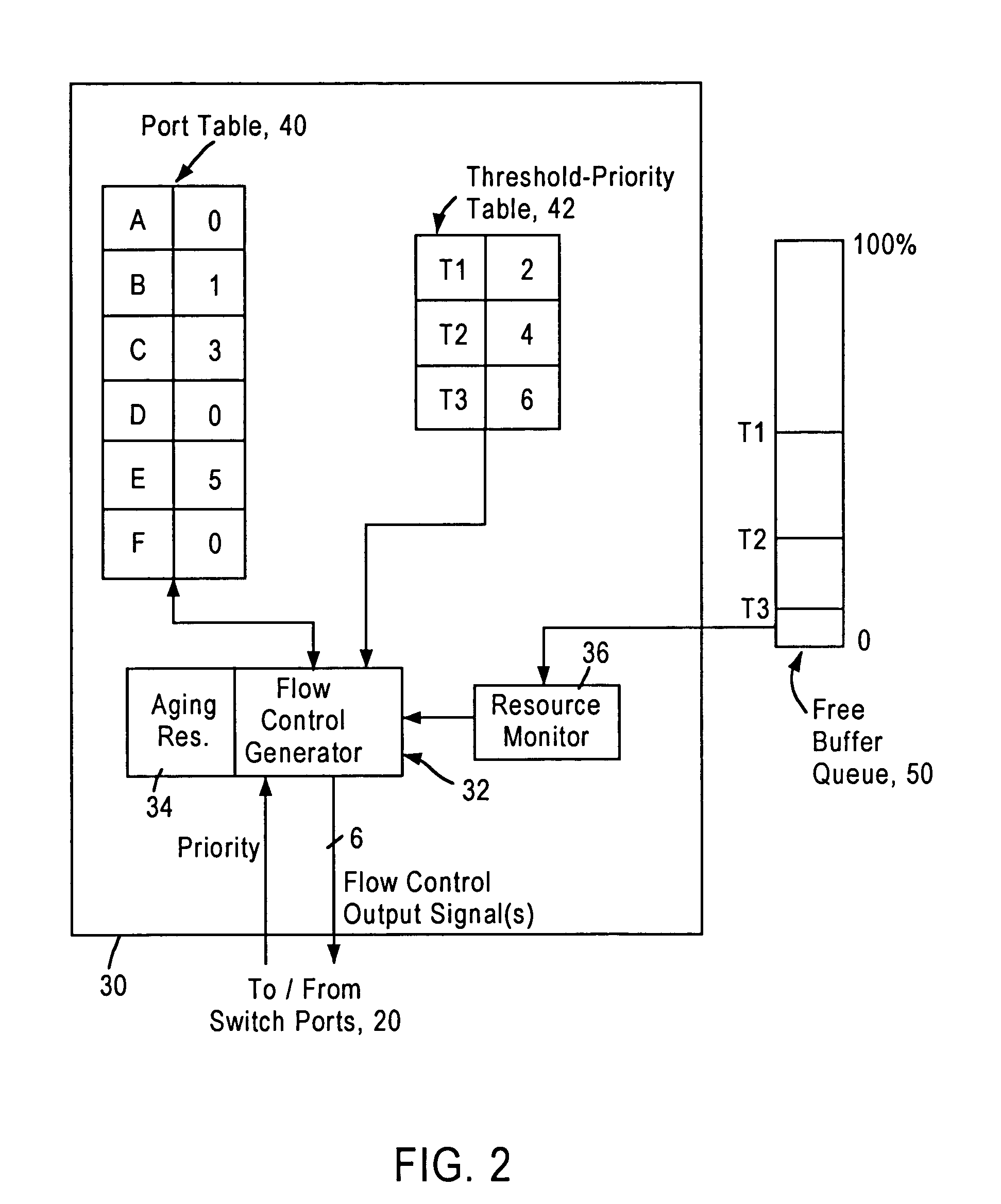

A network switch includes network switch ports, each including a port filter configured for detecting user-selected attributes from a received layer 2 frame. Each port filter, upon detecting a user-selected attribute in a received layer 2 frame, sends a signal to a switching module indicating the determined presence of the user-selected attribute, for example whether the data packet has a prescribed priority value. The network switch includes a flow control module that determines which of the network switch ports should output a flow control frame based on the determined depletion of network switch resources and based on the corresponding priority value of the network traffic on each network switch port. Hence, any network switch port that receives high priority traffic does not output a flow control frame to the corresponding network station, enabling that network station to continue transmission of the high priority traffic. In most cases, the congestion and depletion of network switch resources can be alleviated by sending flow control frames on only those network switch ports that receive lower priority traffic, enabling the network switch to reduce congestion without interfering with high priority traffic.

Owner:GLOBALFOUNDRIES US INC

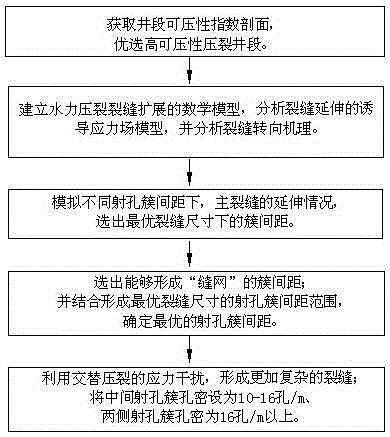

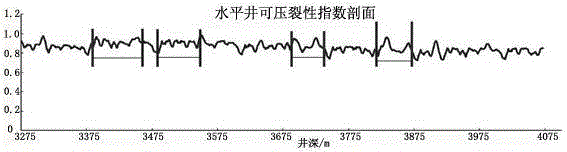

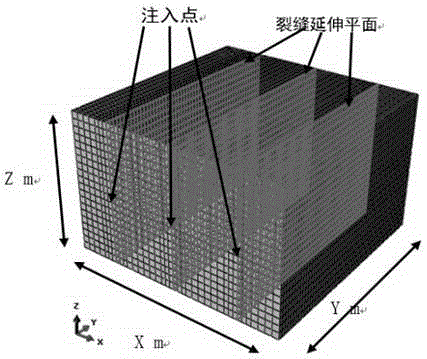

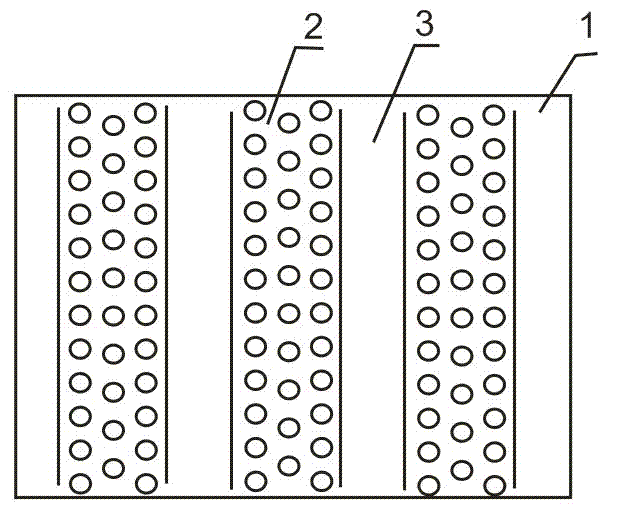

Optimum design method for staged fracturing perforation cluster parameters of horizontal well of shale reservoir

ActiveCN105201479AGuaranteed outputAchieve mutual interferenceFluid removalSpecial data processing applicationsPrincipal stressHigh fracture

The invention relates to an optimum design method for staged fracturing perforation cluster parameters of a horizontal well of a shale reservoir. The optimum design method includes the following steps of S1, selecting high-fracture-performance fracturing well sections; S2, building a mathematical model for hydrofracture fracture progressing, analyzing an induction stress field model for fracture extension, and analyzing a fracture diverting mechanism; S3, analyzing extending conditions of main fractures, and selecting cluster distances capable of allowing the main fractures to evenly extend forwards; S4, analyzing change conditions of stress fields around the main fractures, selecting the perforation cluster distances with the horizontal principal stress ratios smaller than 1.3, and determining the optimal perforation cluster distances in cooperation with the step S3; S5, further improving the complexity of the fractures through an alternate fracturing principle, and setting the perforation density of perforation clusters in the middle to range from 10 to 16 per m and the perforation density of perforation clusters in the two sides to be larger than 16 per m. By means of the optimum design method, the perforation cluster distances can be optimized, largest fracture transforming sizes can be obtained, the practical effect of reservoir transforming can be improved, and high construction cost and the poor fracturing effect which are caused by aimlessly setting the perforation cluster distances can be avoided.

Owner:SOUTHWEST PETROLEUM UNIV

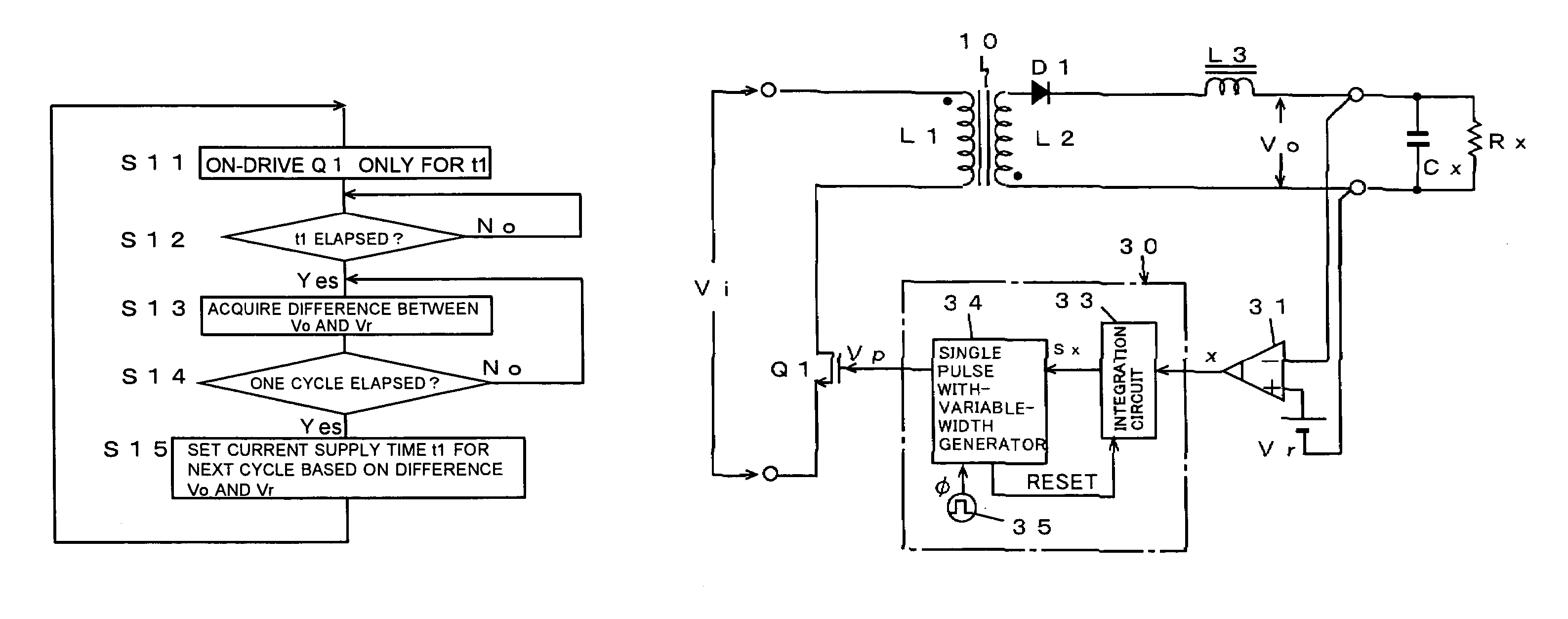

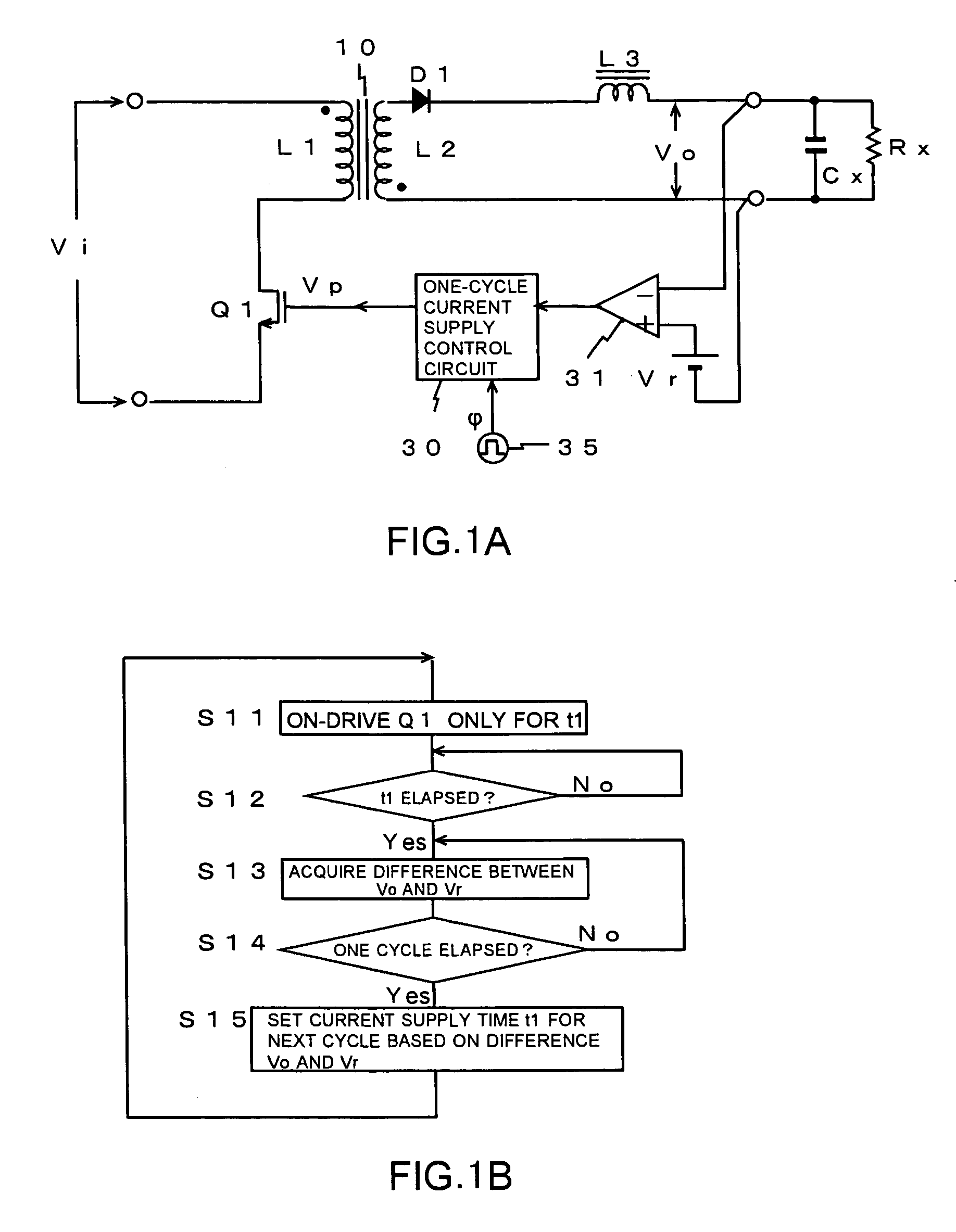

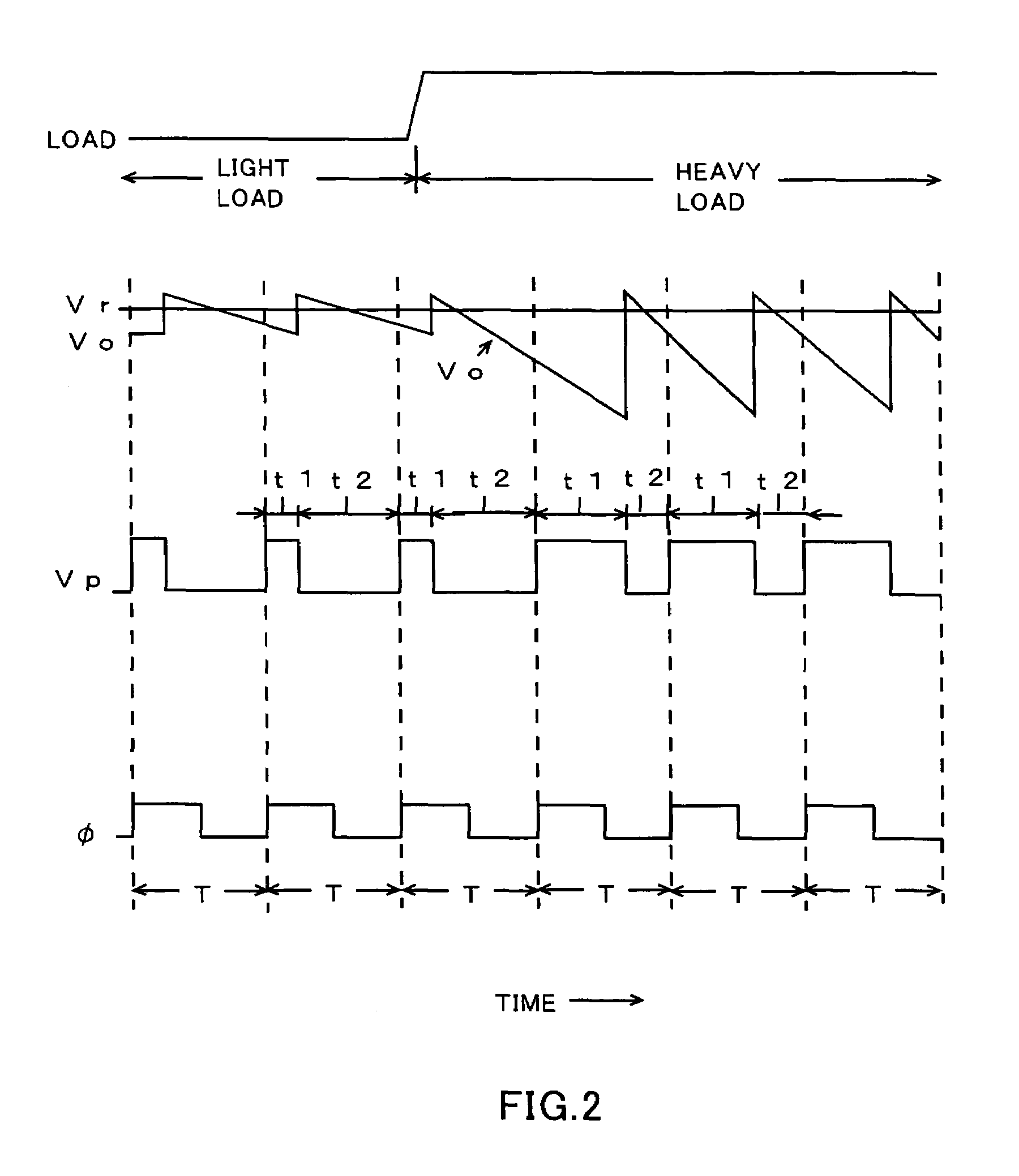

Switching power source circuit for independent per cycle control of ON/OFF time ratio

InactiveUS7072191B2Rapid and large change in the load quickly and stablyGuaranteed outputEfficient power electronics conversionApparatus with intermediate ac conversionCycle controlEngineering

A switching power supply circuit, which can respond to a rapid and large change in a load quickly and stably and ensure a power supply output having a predetermined voltage, is provided. In the power supply circuit which supplies an input current to a load while switching the input current periodically and controls an output voltage Vo supplied to the load to a predetermined target value by controlling an ON / OFF time ratio (t1 / t2) of the switching variably, a control of the ON / OFF time ratio is performed for every one current supply cycle T independently.

Owner:FDK CORP

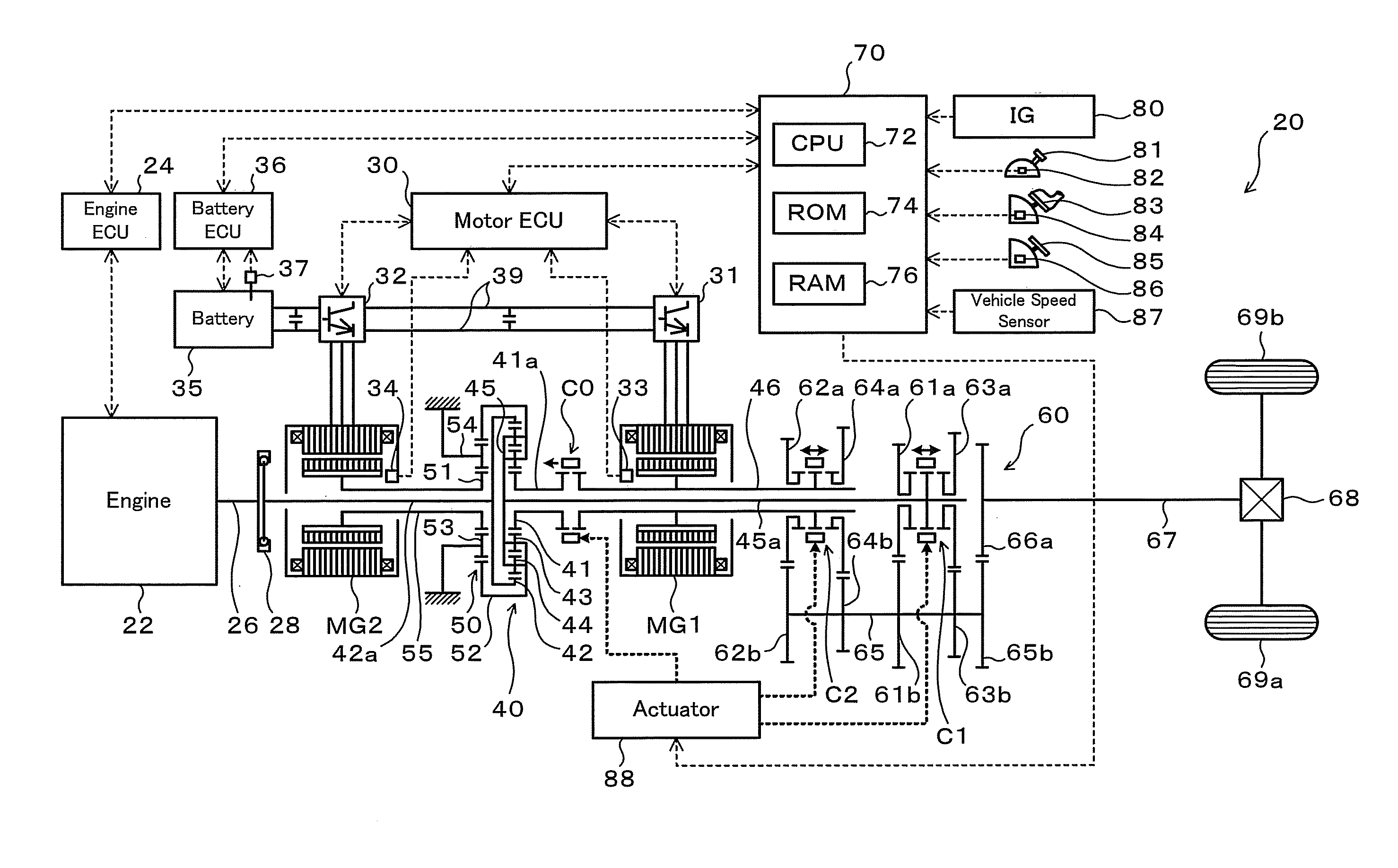

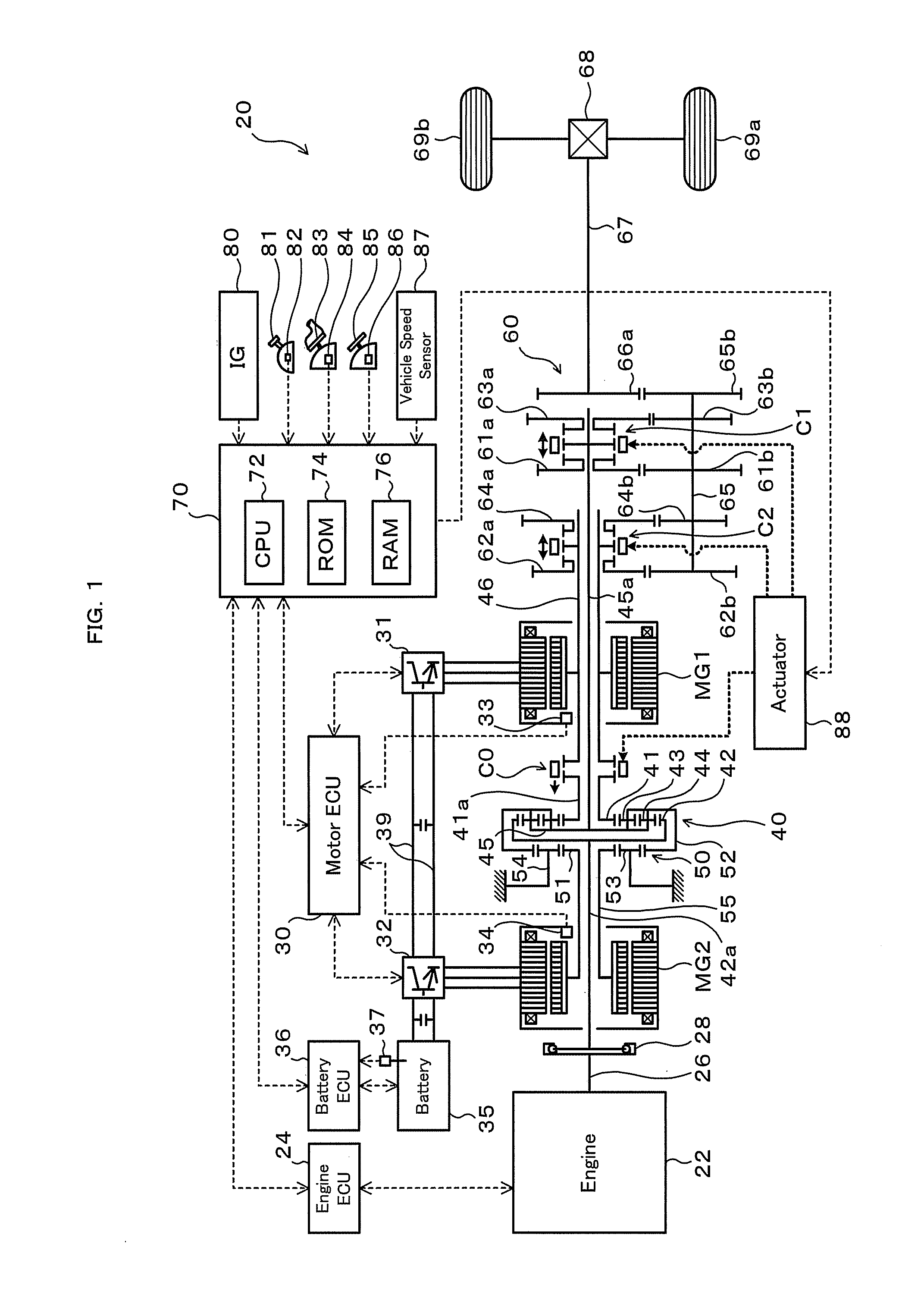

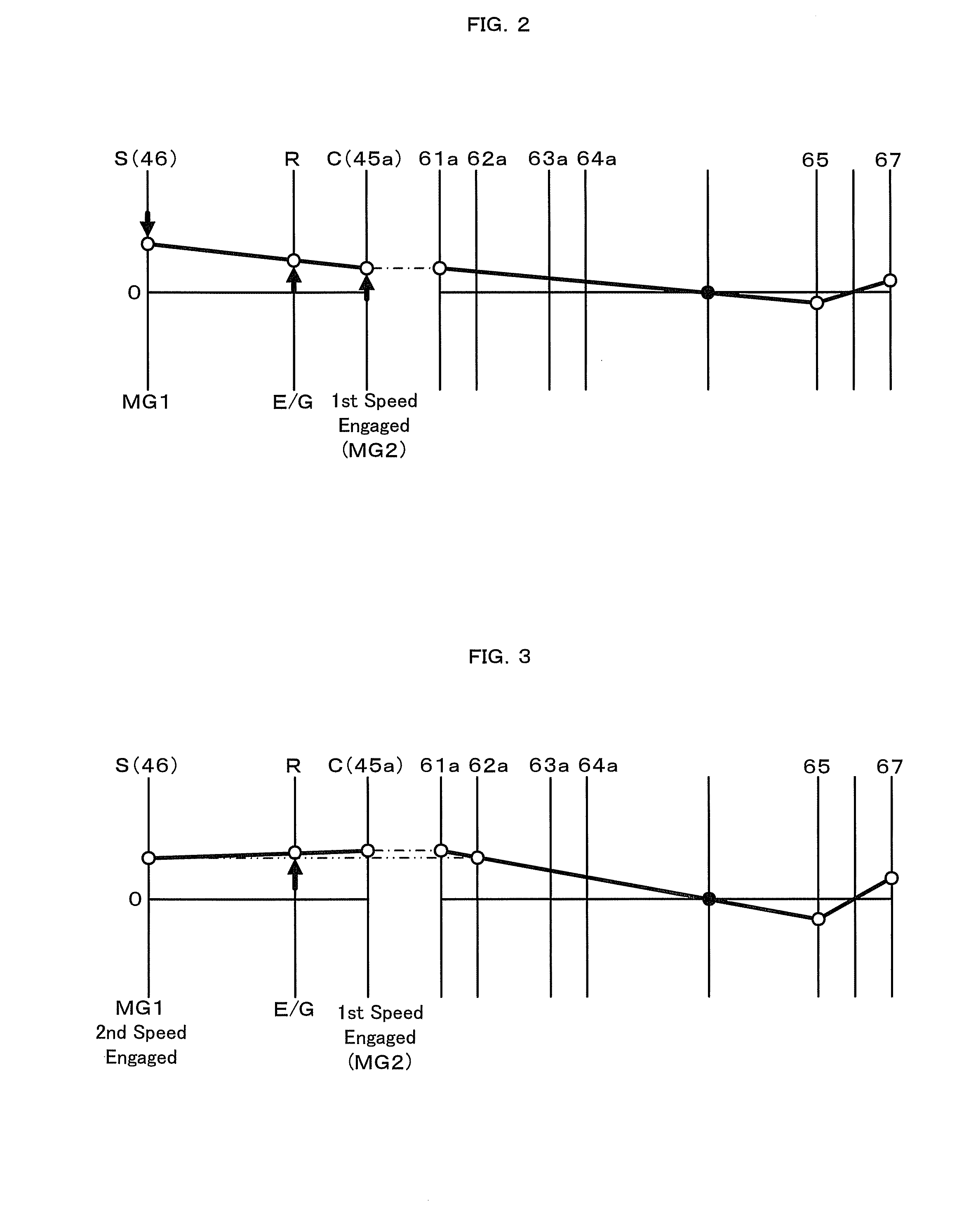

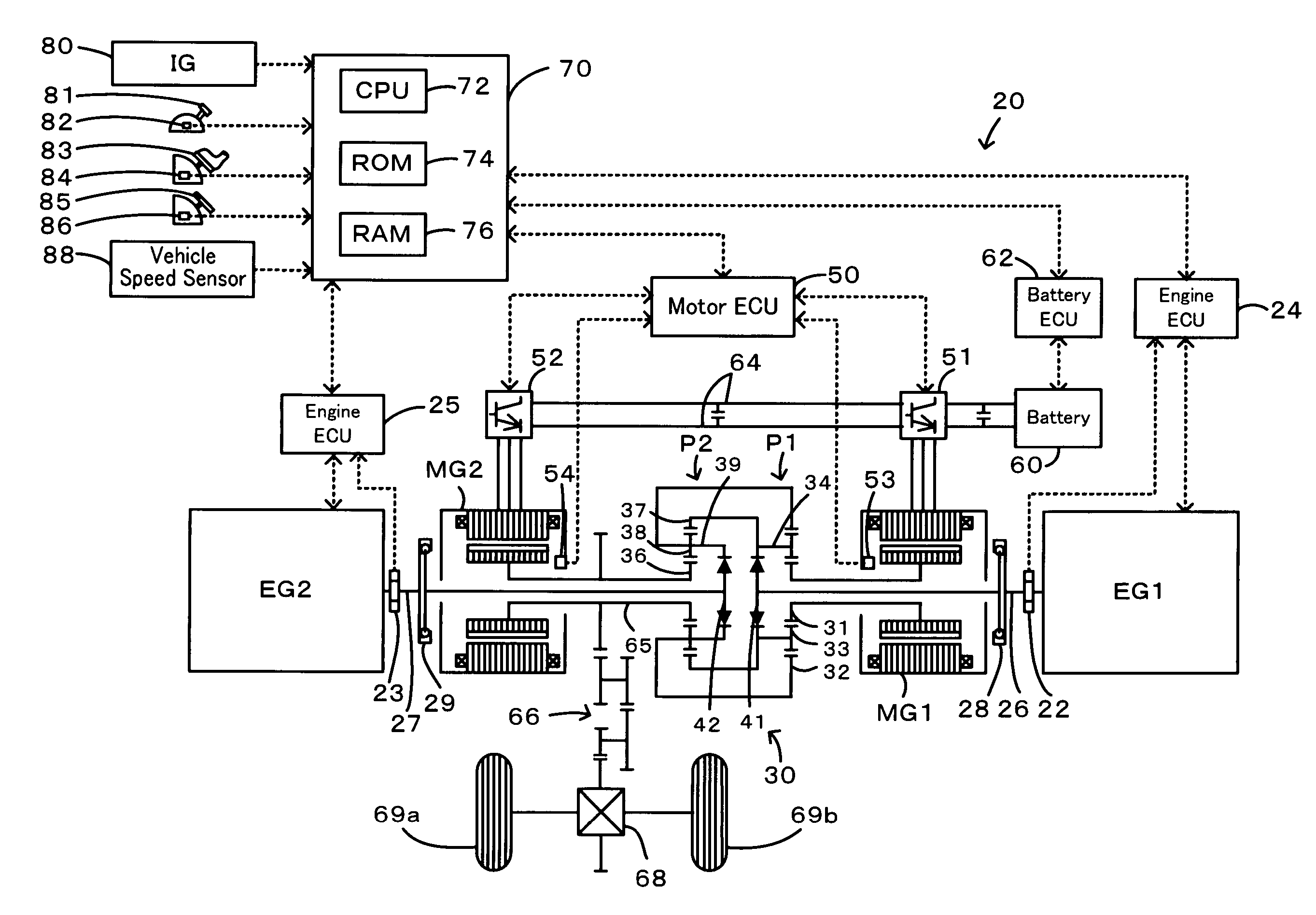

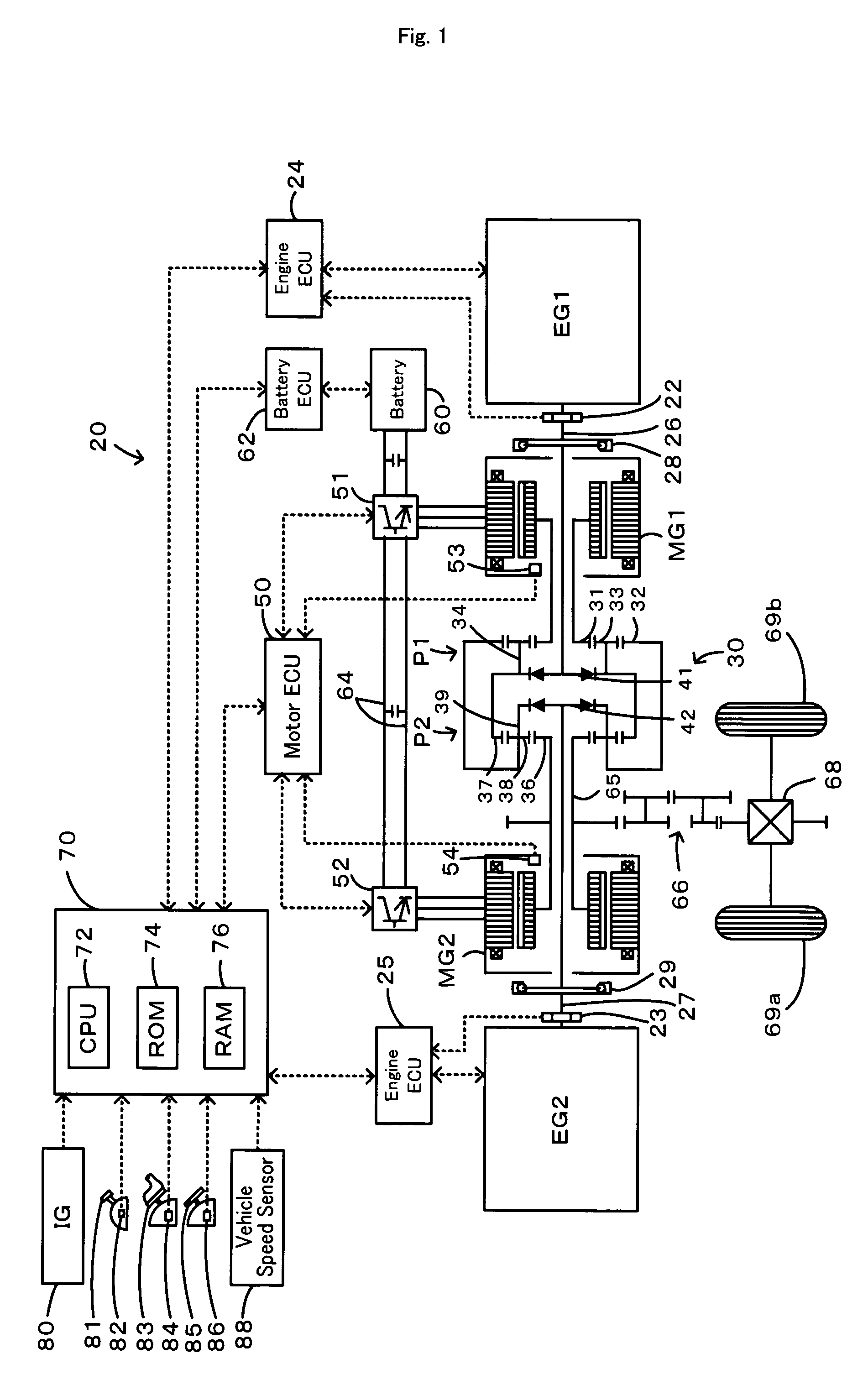

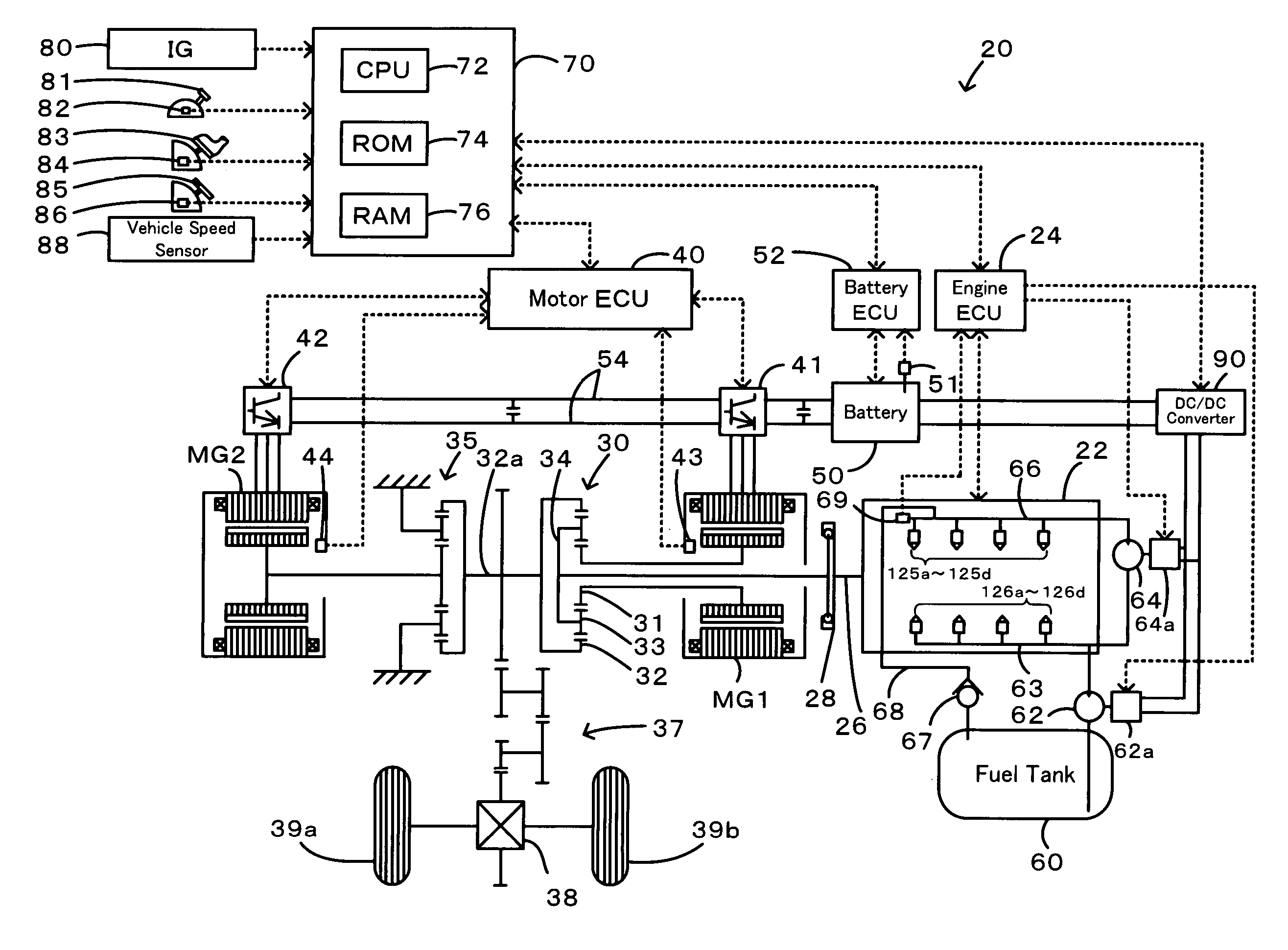

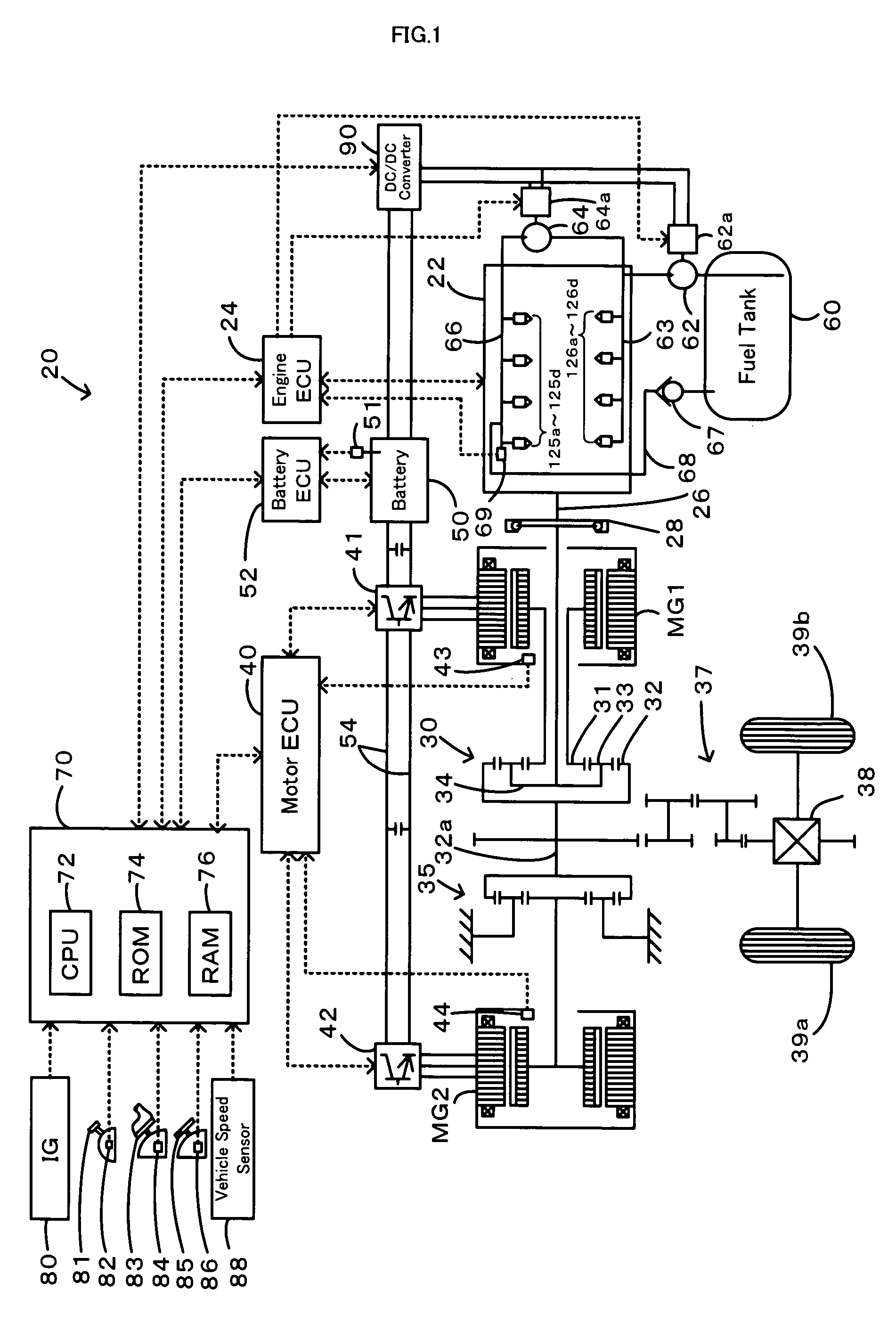

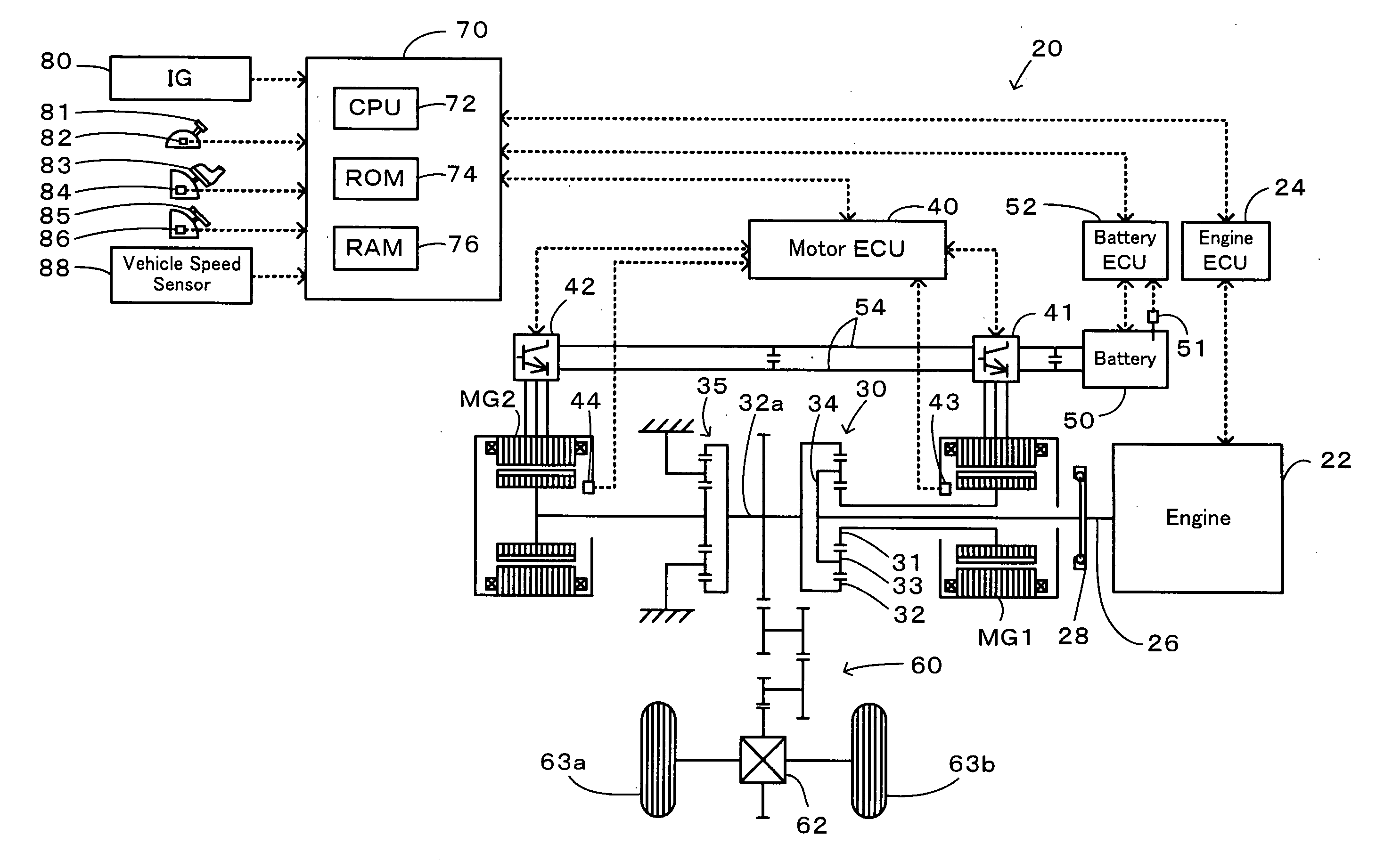

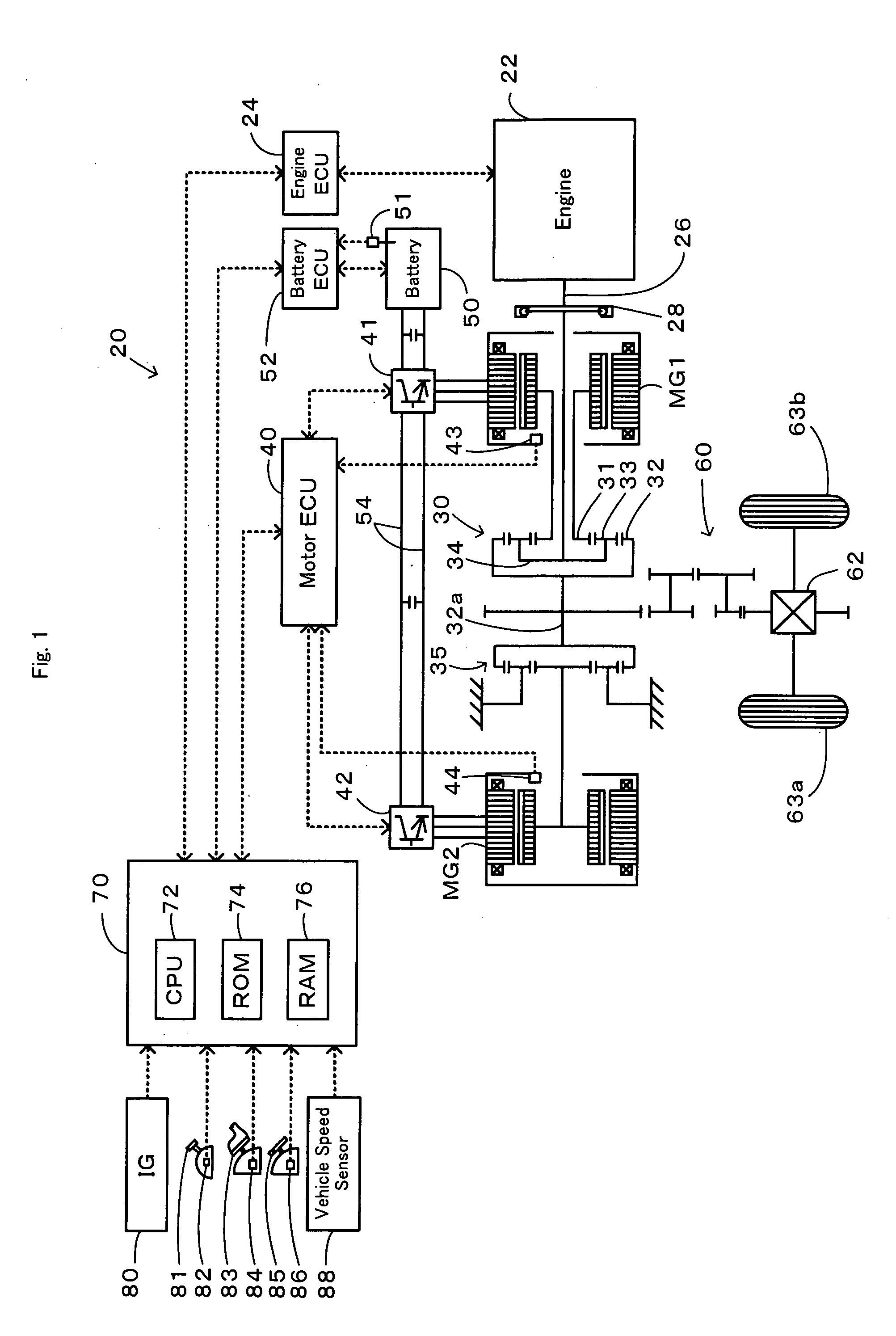

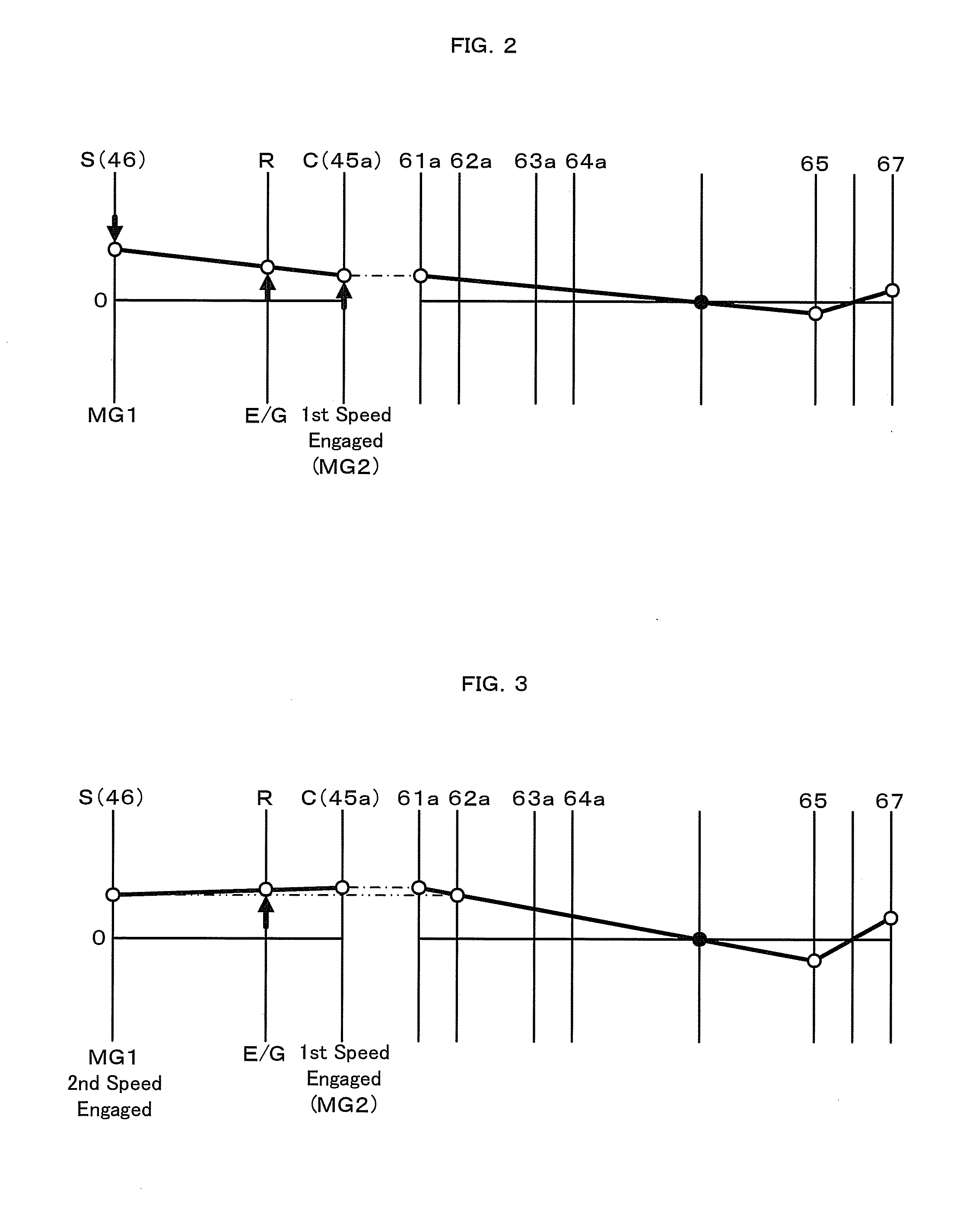

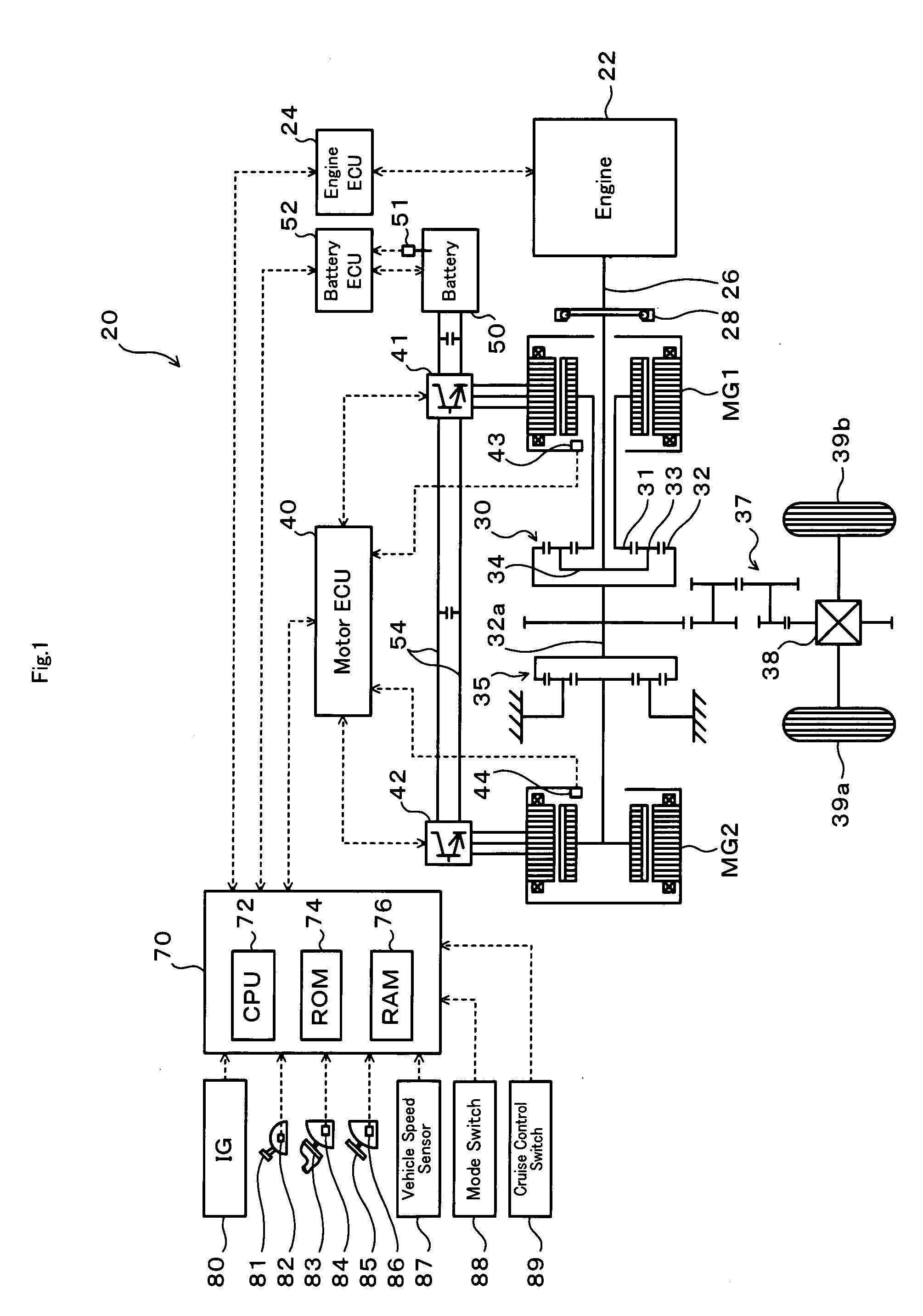

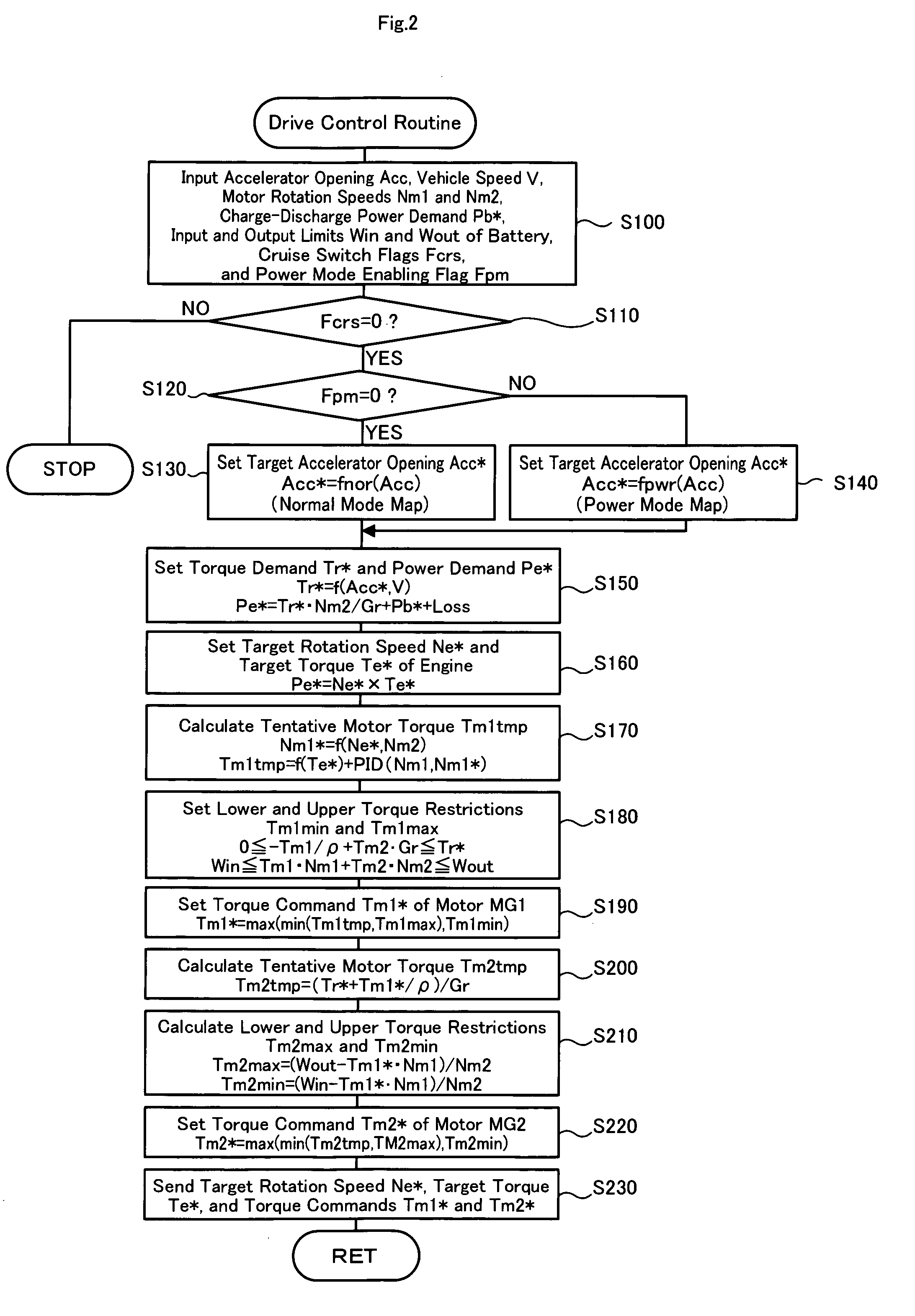

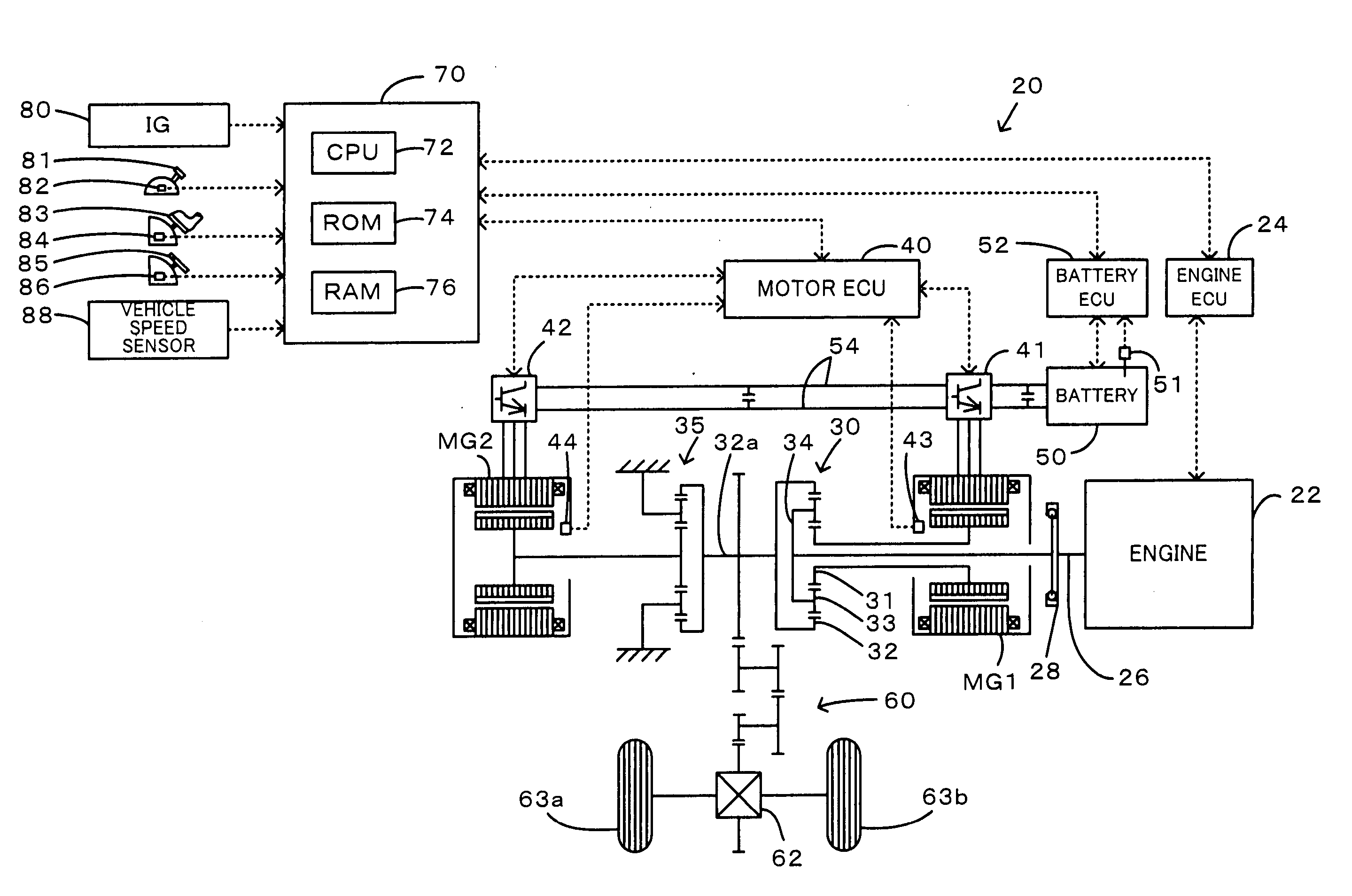

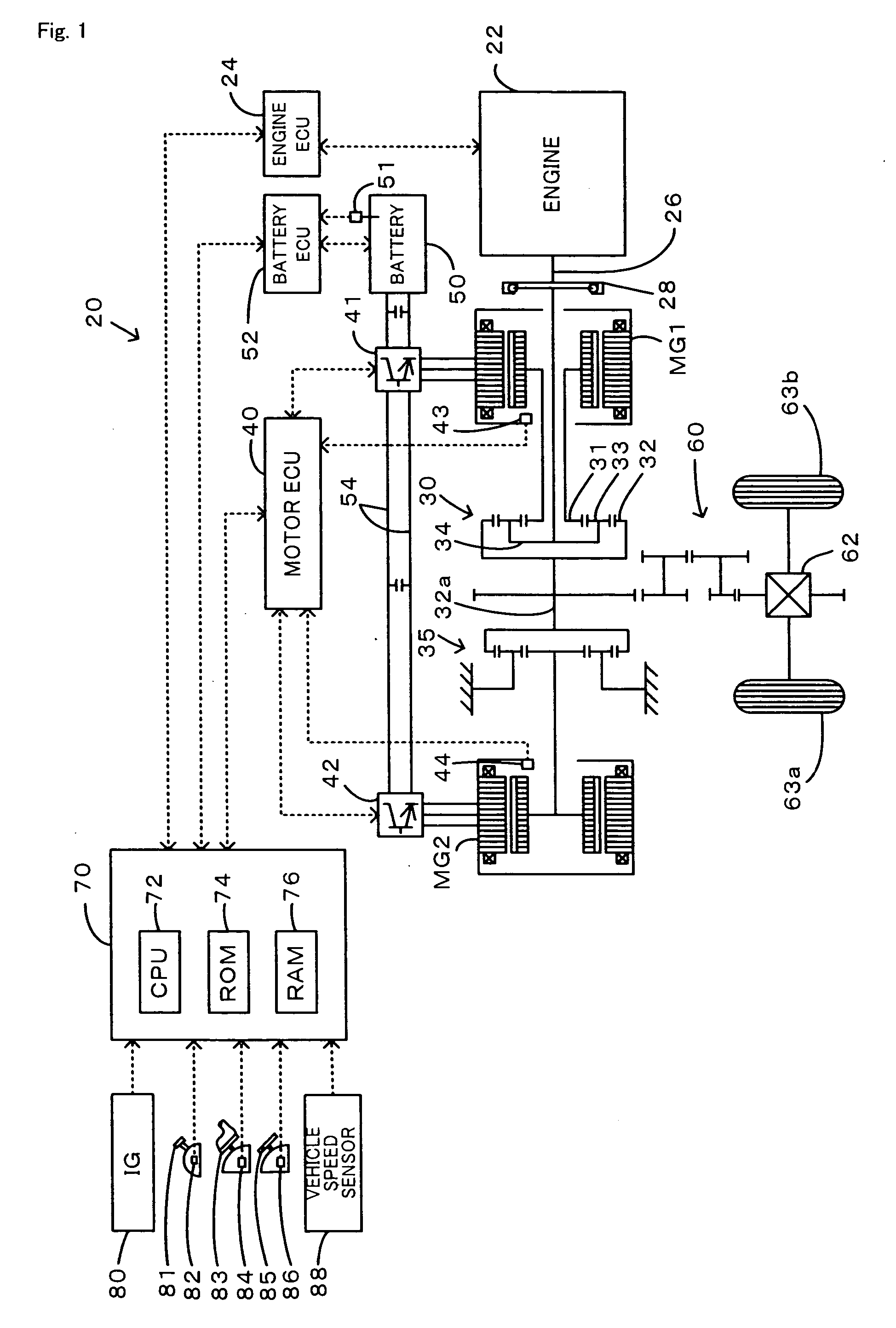

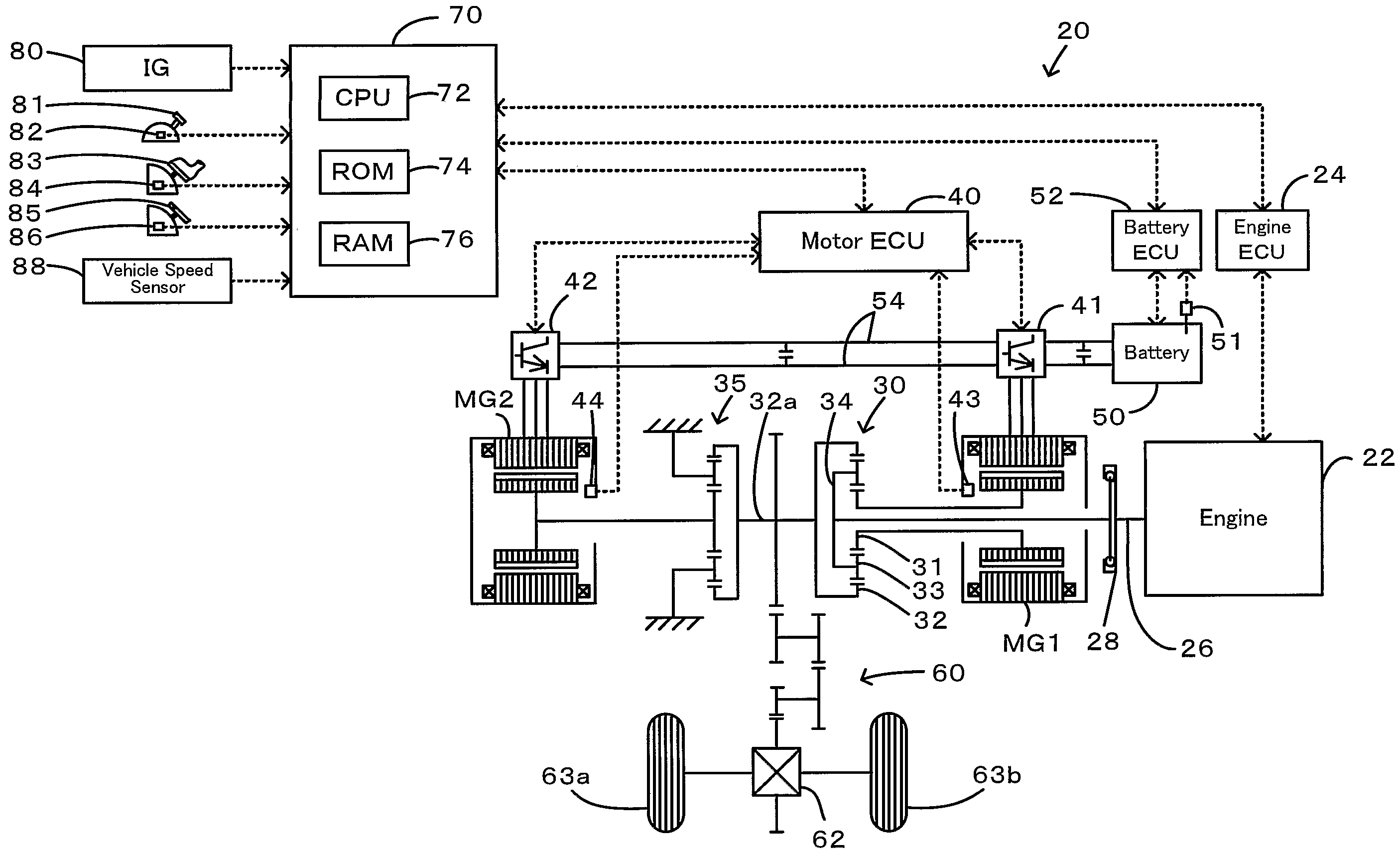

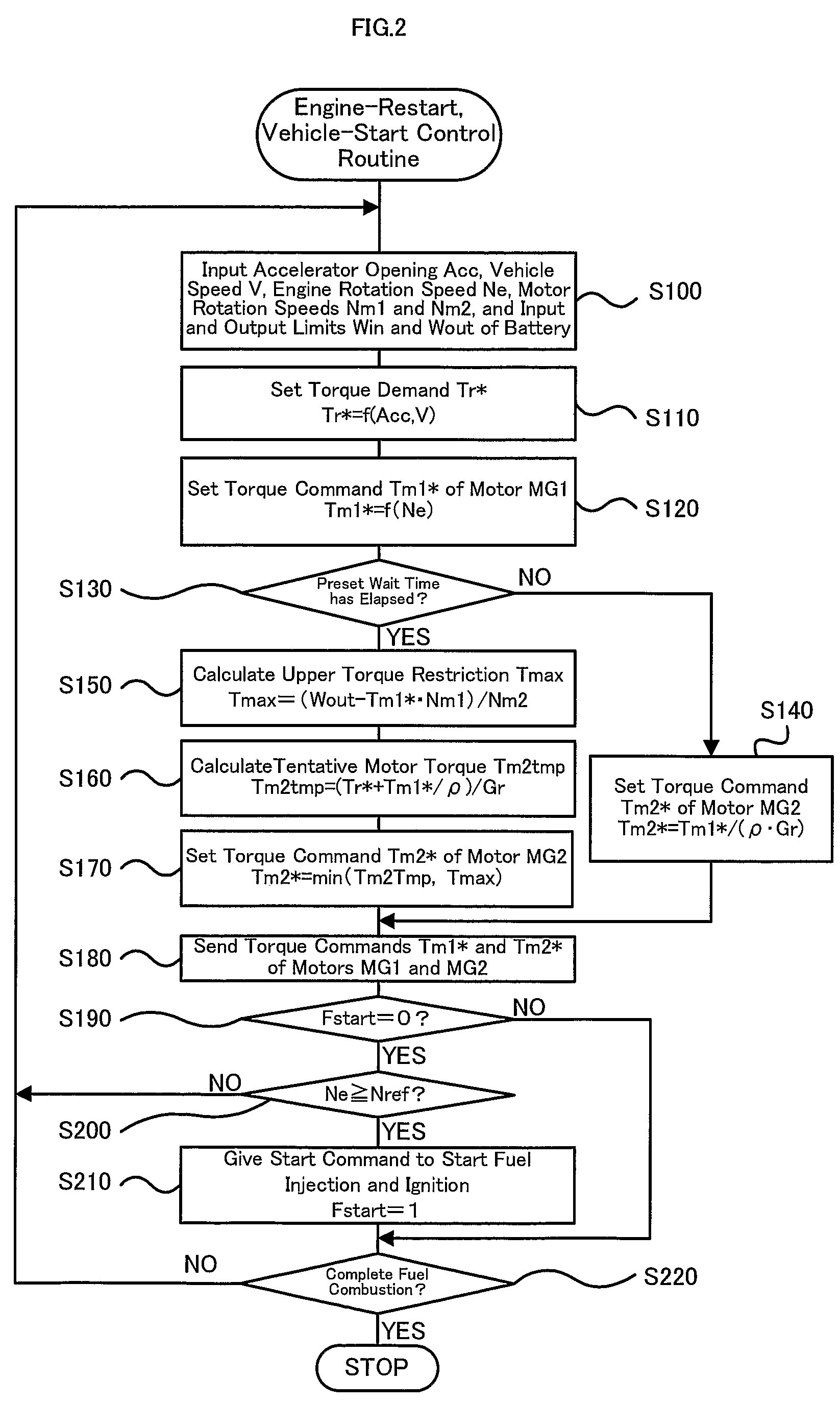

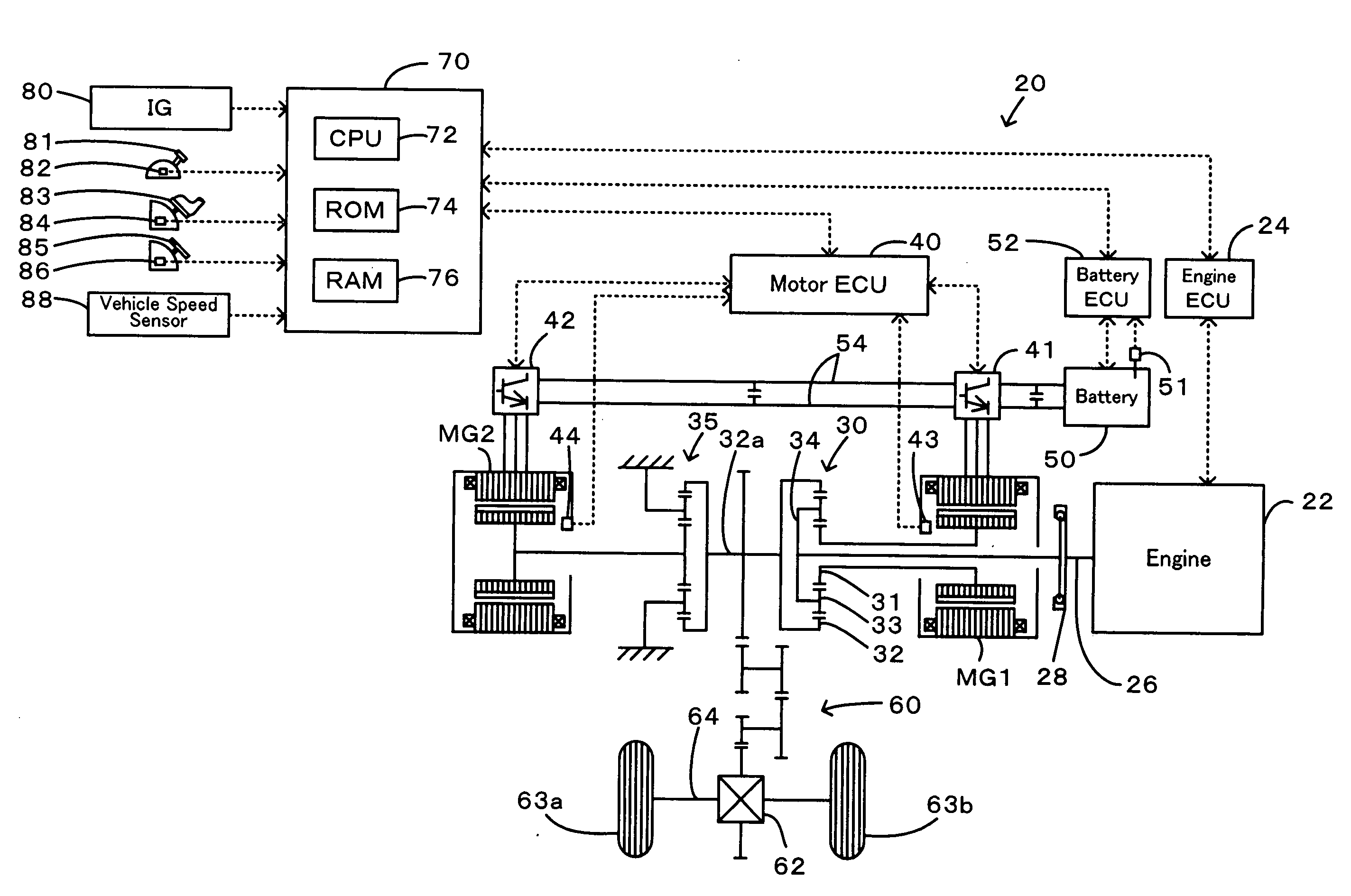

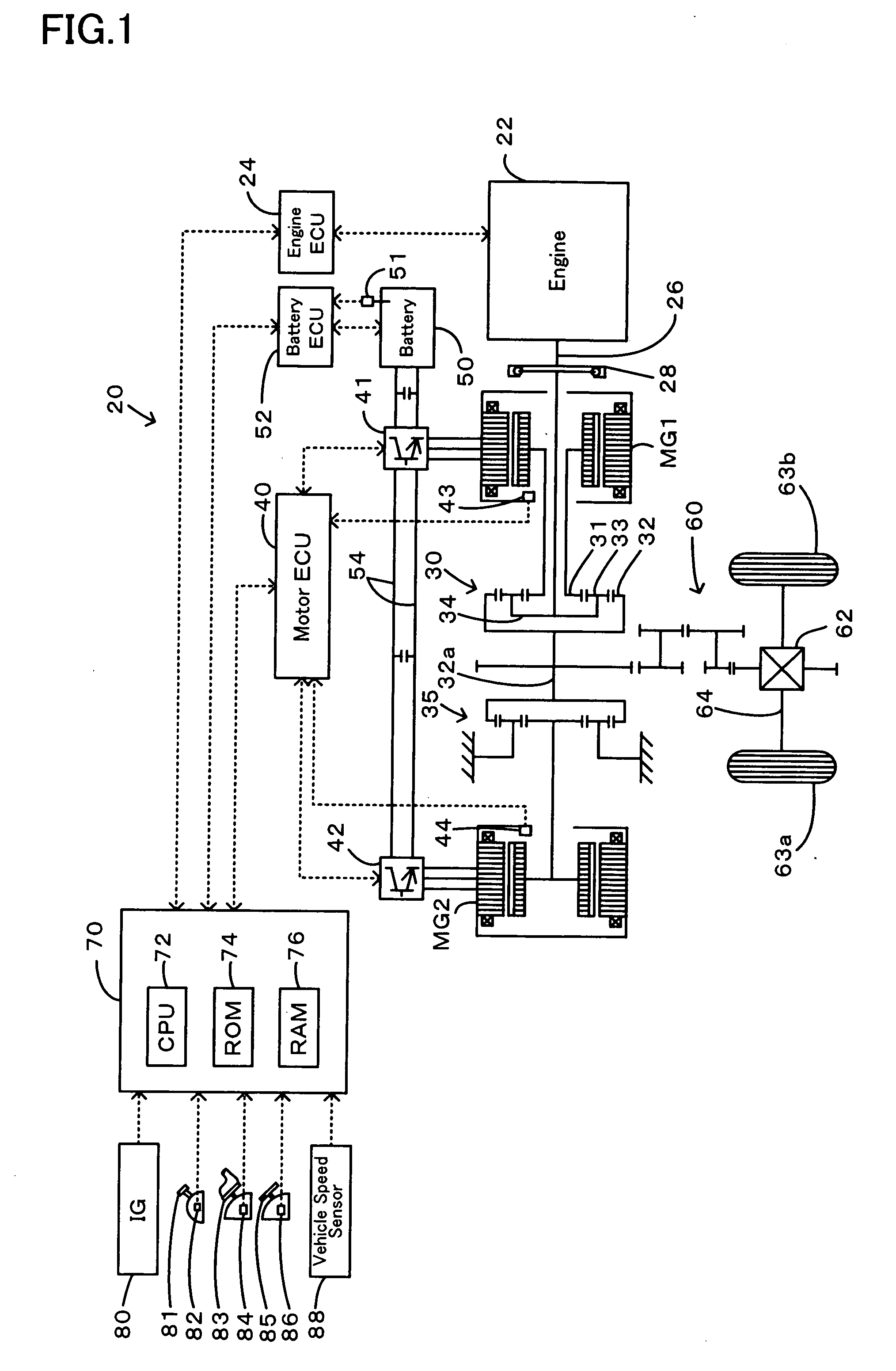

Power output apparatus, vehicle equipped with power output apparatus, and control method of power output apparatus

InactiveUS20100051361A1High torqueAvoid overall overheatingHybrid vehiclesSpeed controllerMotor driveHybrid vehicle

In a 2-motor drive mode with connection of both motors with a driveshaft by means of a transmission, a hybrid vehicle sets torque commands of the motors to substantially equalize an output torque of the second motor with an output torque of the first motor and to ensure output of a torque equivalent to a preset torque demand to the driveshaft. This arrangement ensures continuous output of a relatively large torque.

Owner:TOYOTA JIDOSHA KK

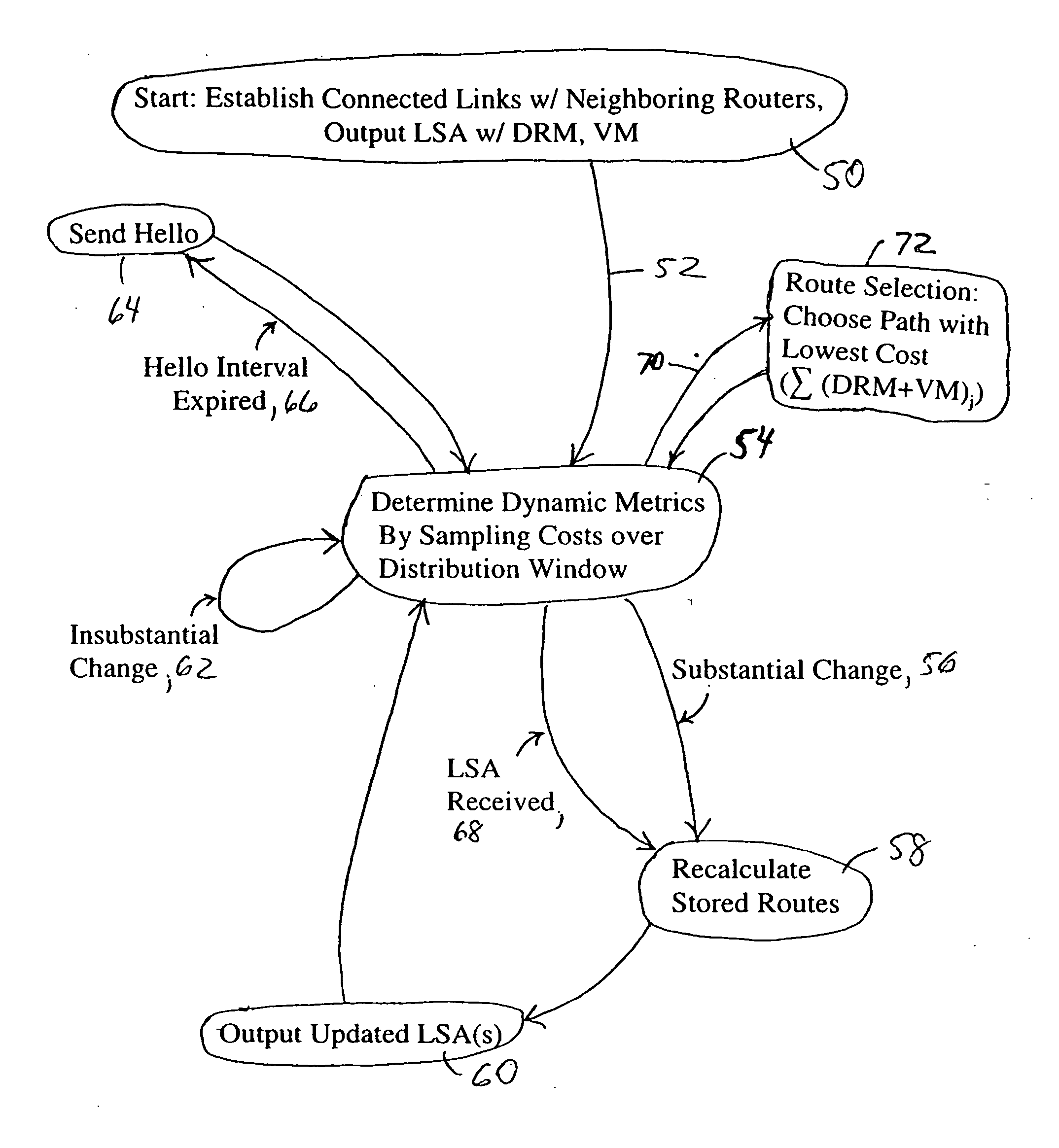

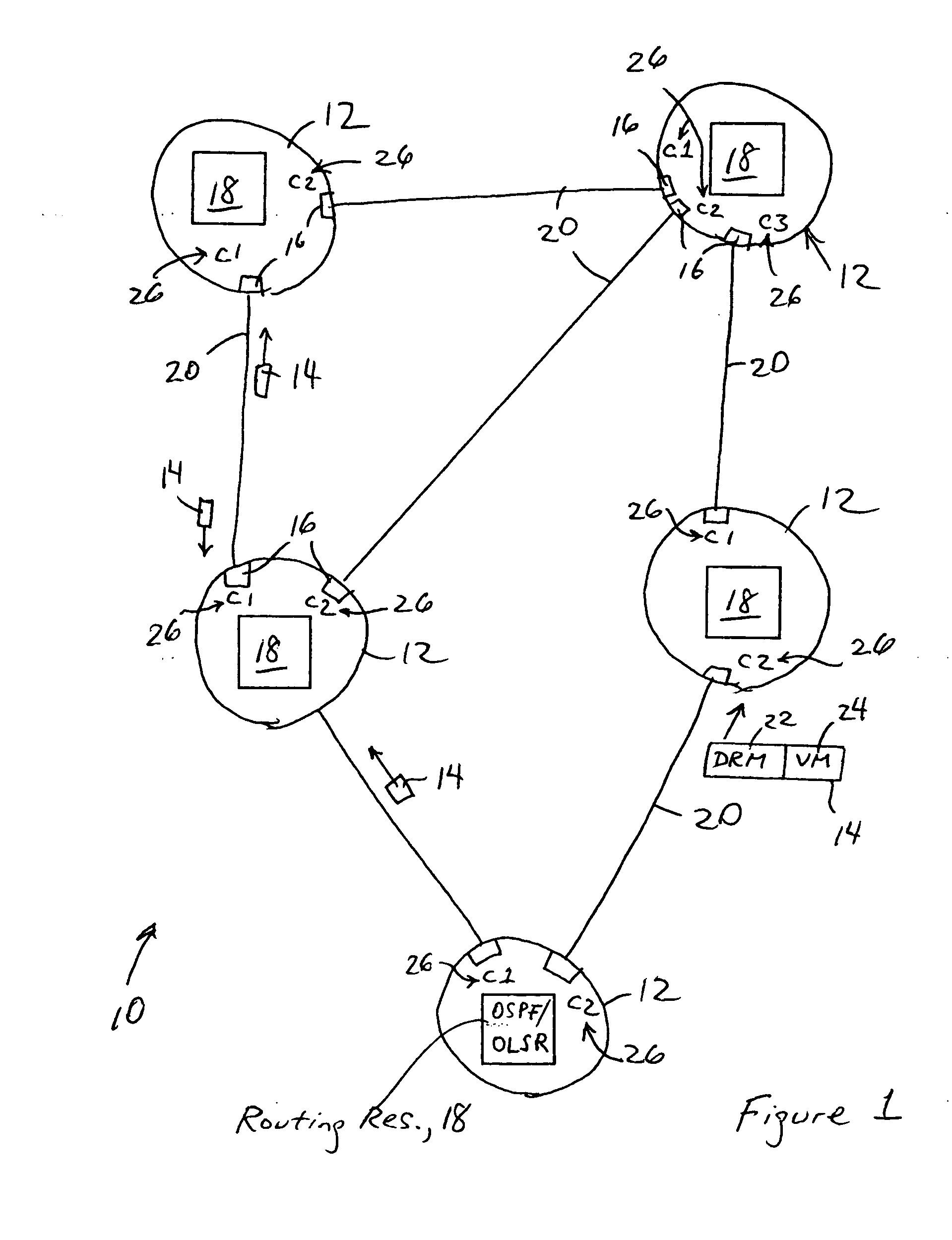

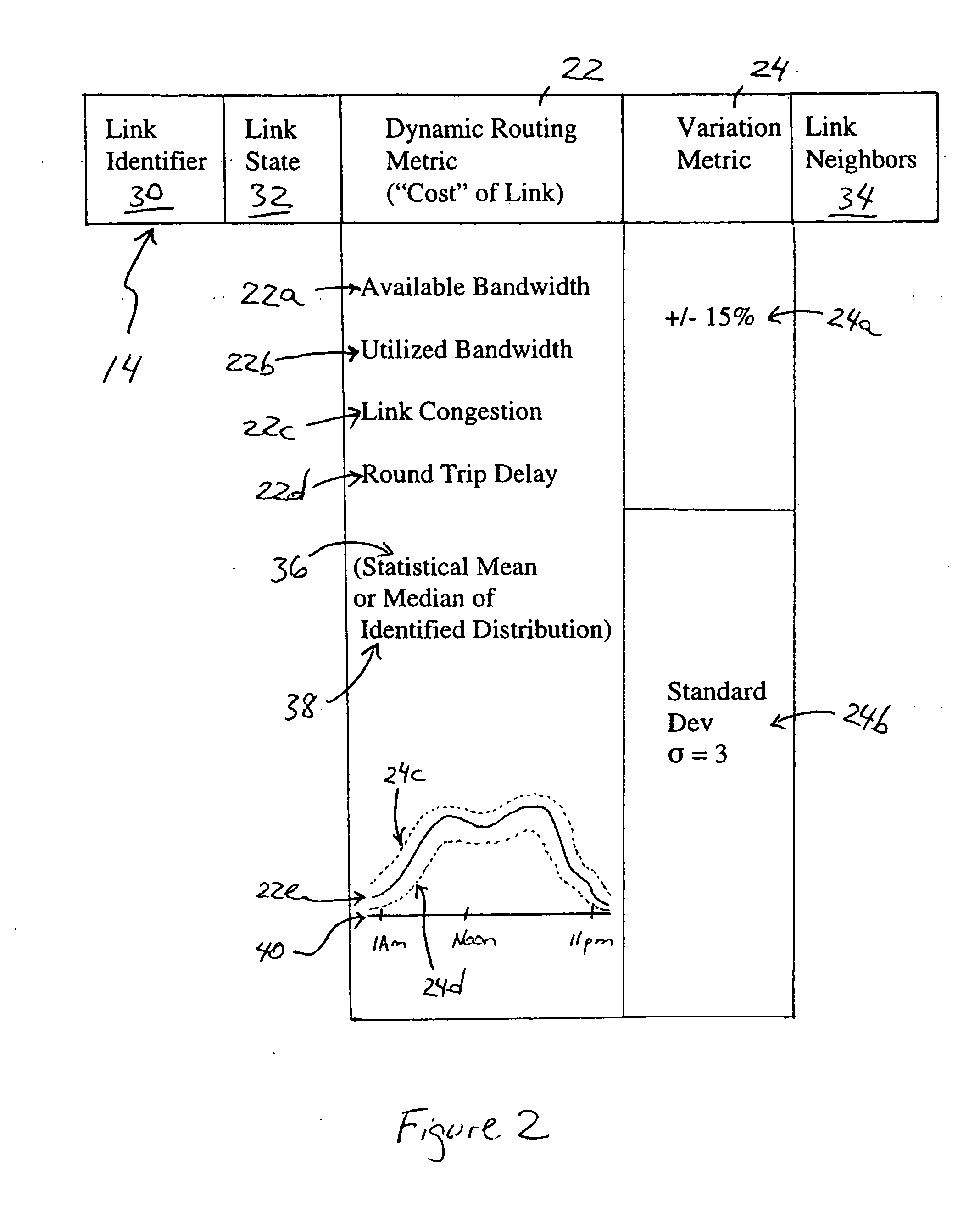

Link state advertisements specifying dynamic routing metrics and associated variation metrics and selective distribution thereof

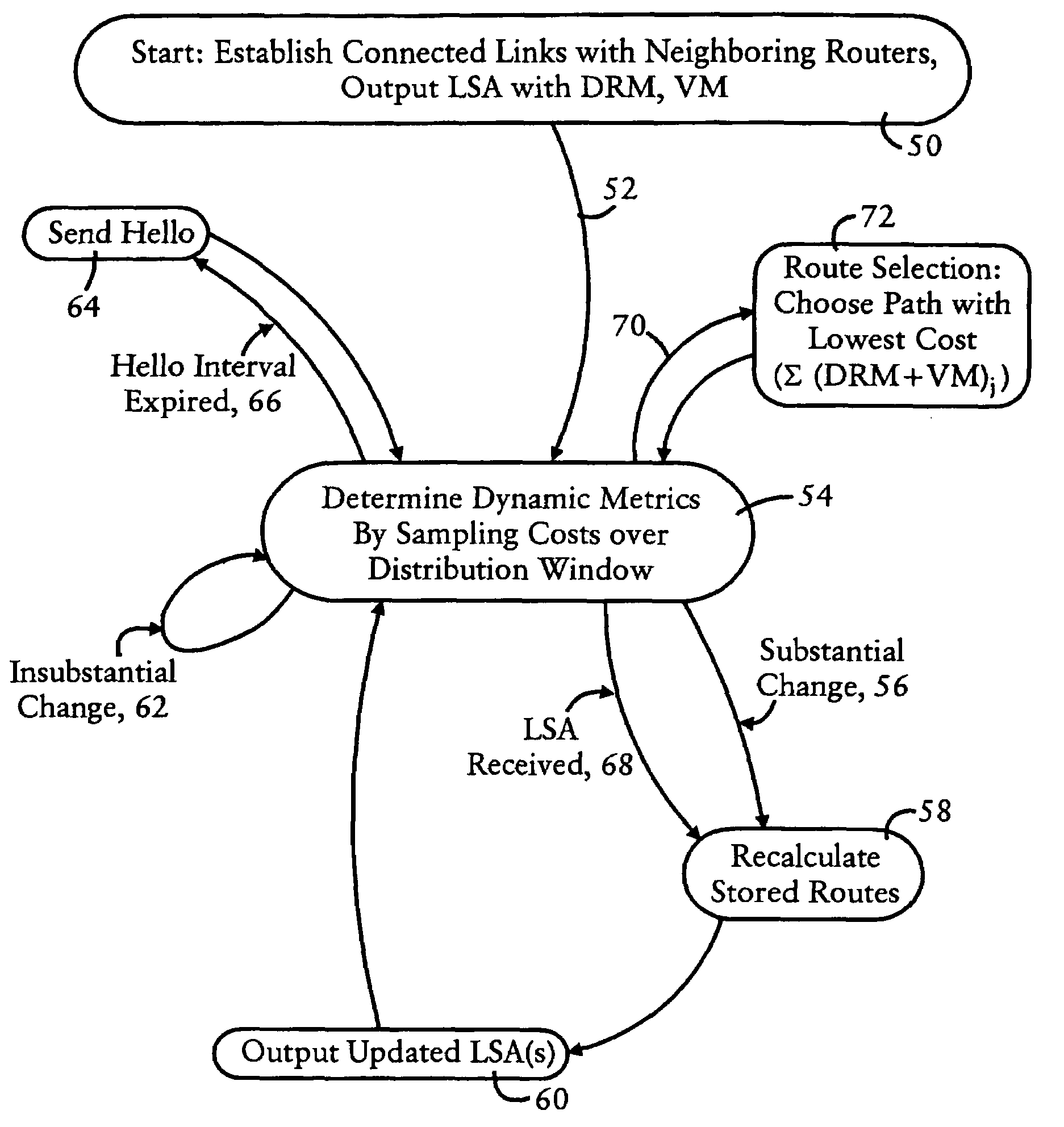

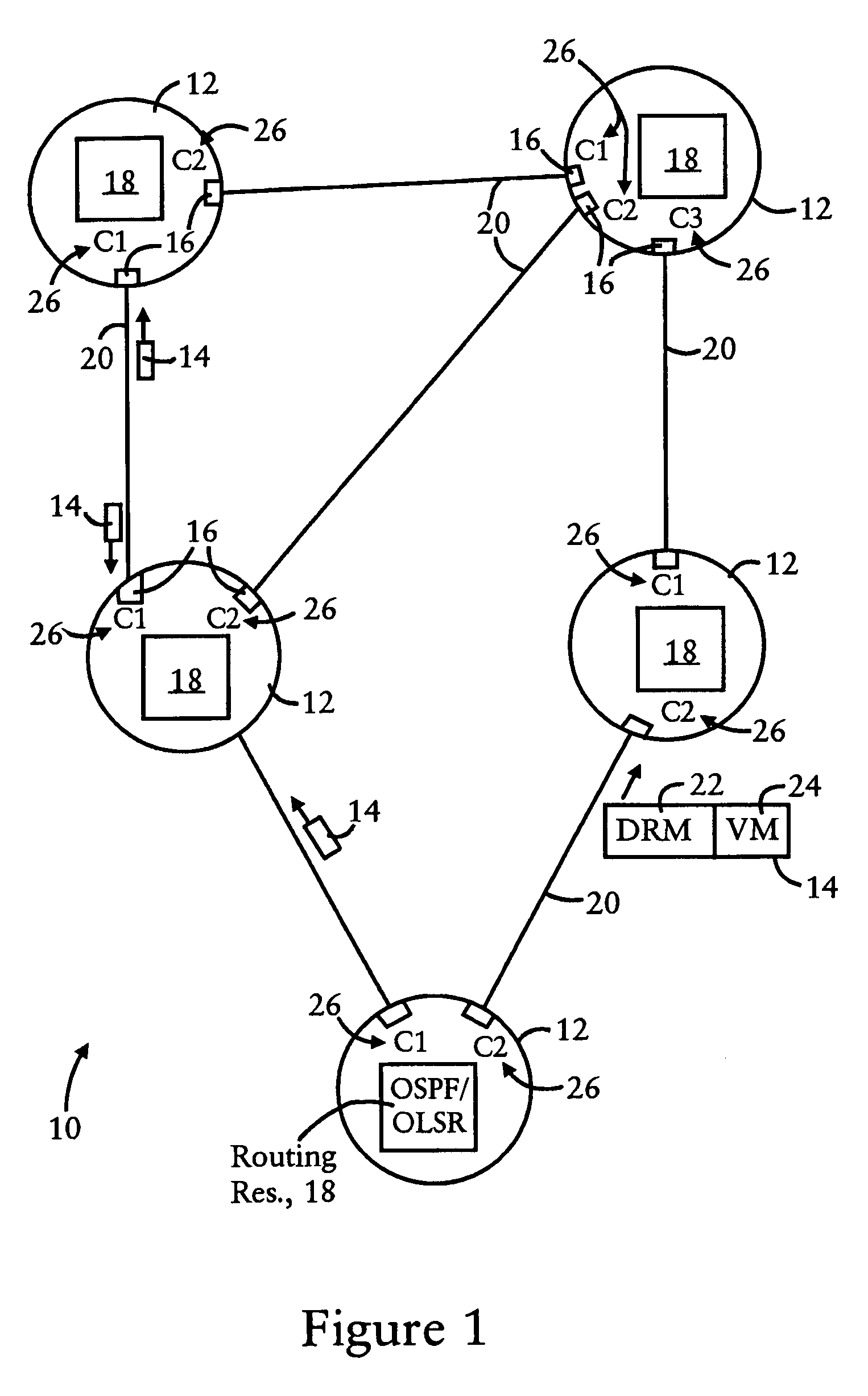

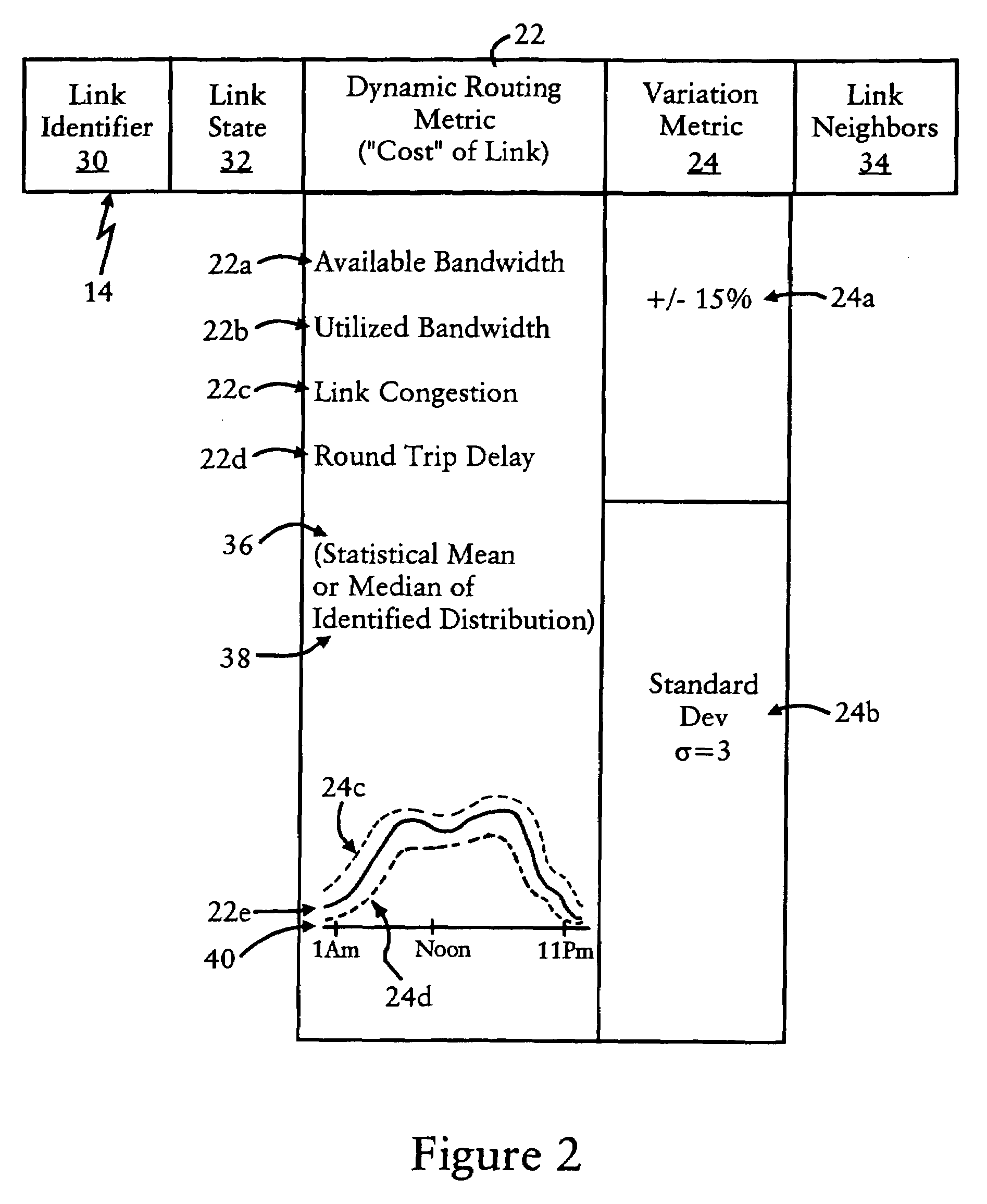

InactiveUS20060291485A1Respond effectivelyIntroduce instabilityError preventionFrequency-division multiplex detailsLink-state advertisementAdaptive routing

Each router in a network is configured for executing a link state routing protocol based on outputting a corresponding first link state advertisement message describing a connected link of the router and that specifies a first dynamic routing metric identifying a first cost of the connected link, and a corresponding variation metric identifying a statistical variation of the dynamic routing metric. Each router also is configured for selectively outputting a corresponding second link state advertisement message describing the connected link and that specifies the corresponding variation metric and an updated dynamic routing metric identifying an updated cost of the connected link relative to the first cost, the second link state advertisement message selectively output based on the updated dynamic routing metric differing from the first dynamic routing metric by more than the variation metric, or the router having received another link state advertisement from another router in the network.

Owner:CISCO TECH INC

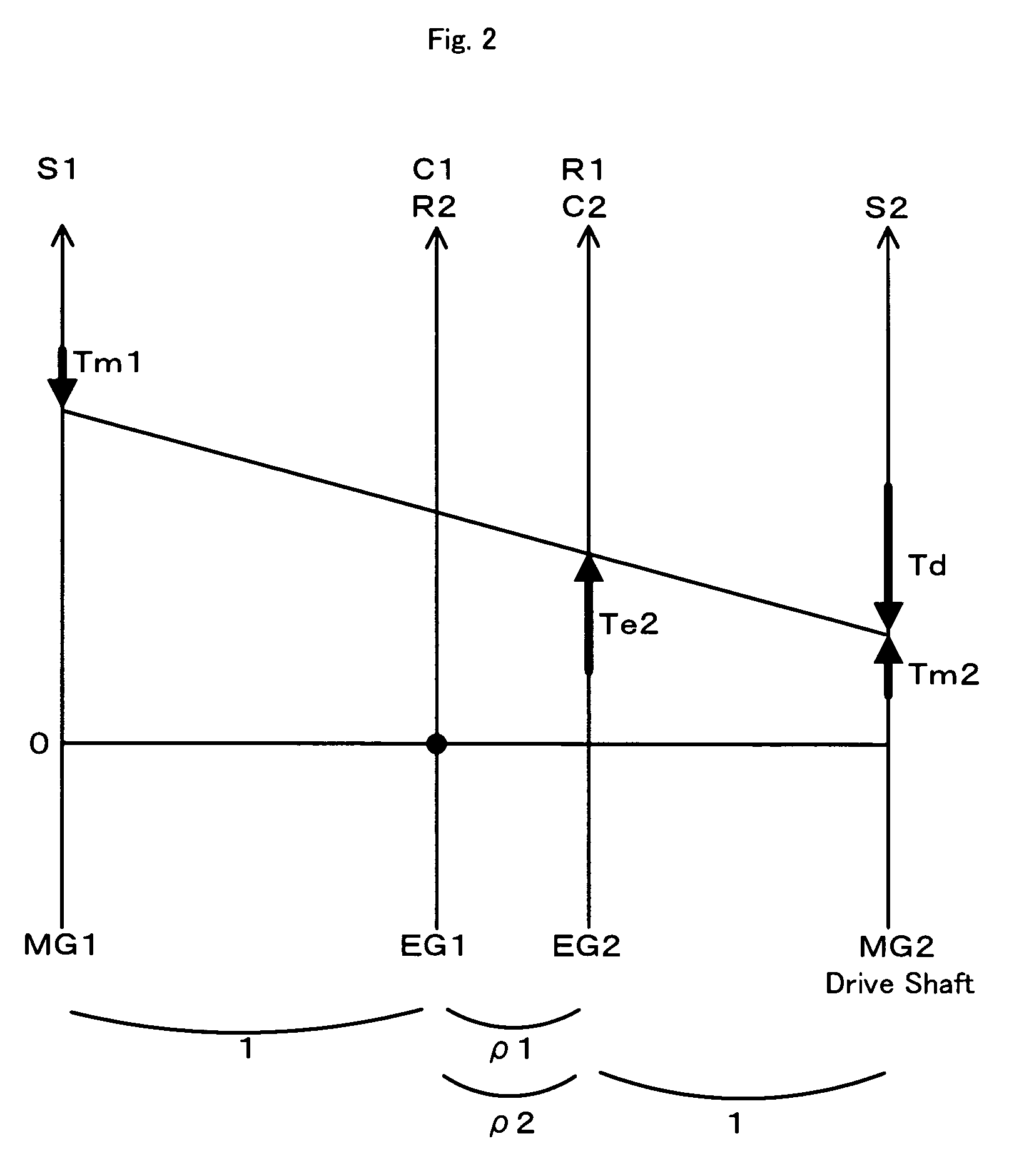

Power output apparatus and motor vehicle equipped with power output apparatus

InactiveUS7317259B2Improve energy efficiencyIncrease freedomHybrid vehiclesAuxillary drivesMobile vehicleDrive shaft

A motor (MG1) is connected to a sun gear (31) of a first planetary gear (P1) of a power distribution / unification mechanism (30), an engine (EG1) is connected to a carrier (34) of the first planetary gear (P1) and a ring gear (37) of a second planetary gear (P2), an engine (EG2) is connected to a ring gear (32) of the first planetary gear (P1) and a carrier (39) of the second planetary gear (P2), and a motor (MG2) and a drive shaft (65) are connected to a sun gear (36) of the second planetary gear (P2). Drive control is made by selecting an operation pattern from the following operation patterns, the operation pattern to be selected is the pattern enabling efficient operation according to a demand by an operator: a first operation pattern where power is outputted from the engine (EG2) to the drive shaft (65), a second operation pattern where power is outputted from the engine (EG1) to the drive shaft (65), a third operation pattern where power is outputted from both engines (EG1, EG2) to the drive shaft (65), and a motor operation mode where the engines (EG1, EG2) are stopped and power is outputted from the motor (MG2) to the drive shaft (65).

Owner:TOYOTA JIDOSHA KK

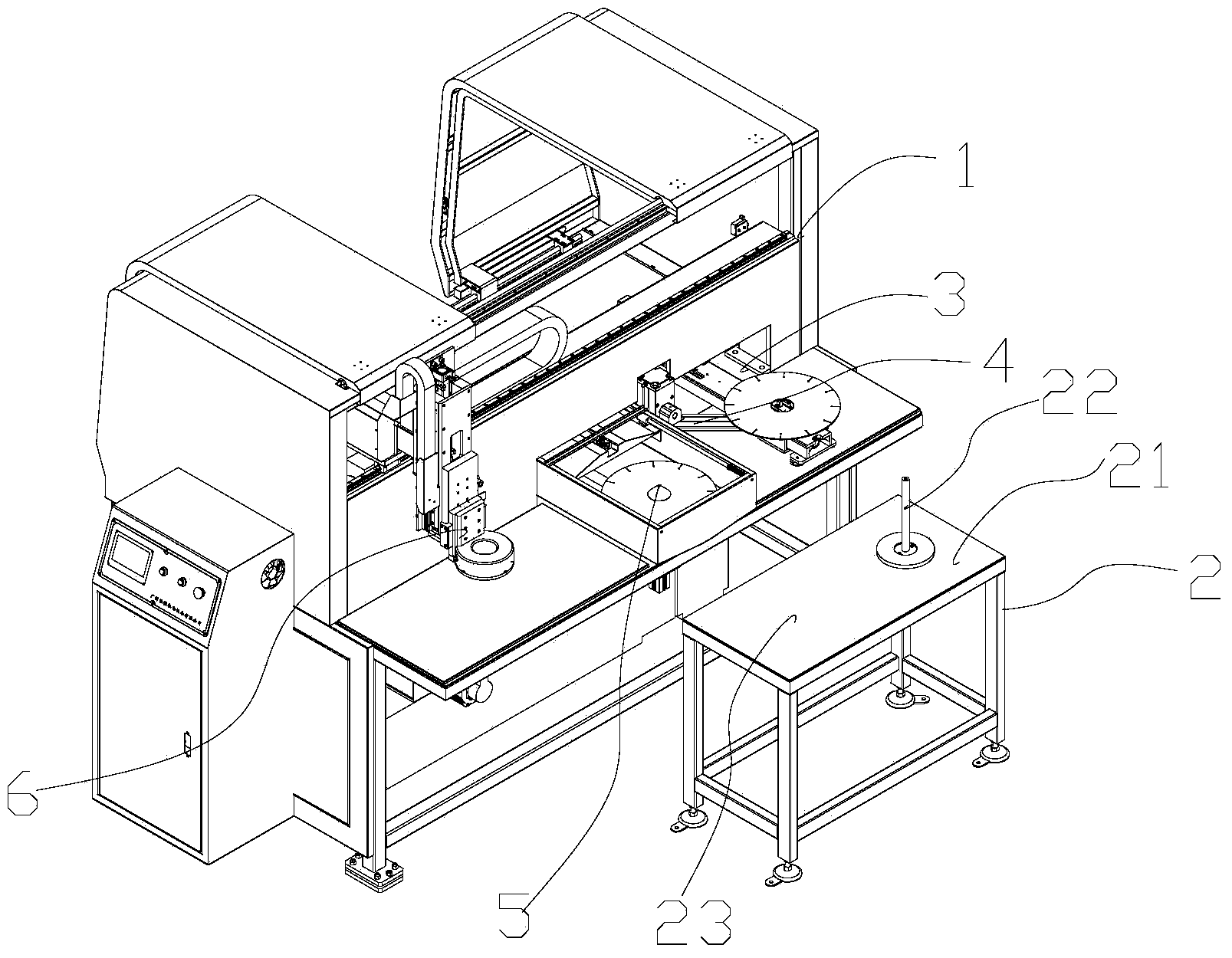

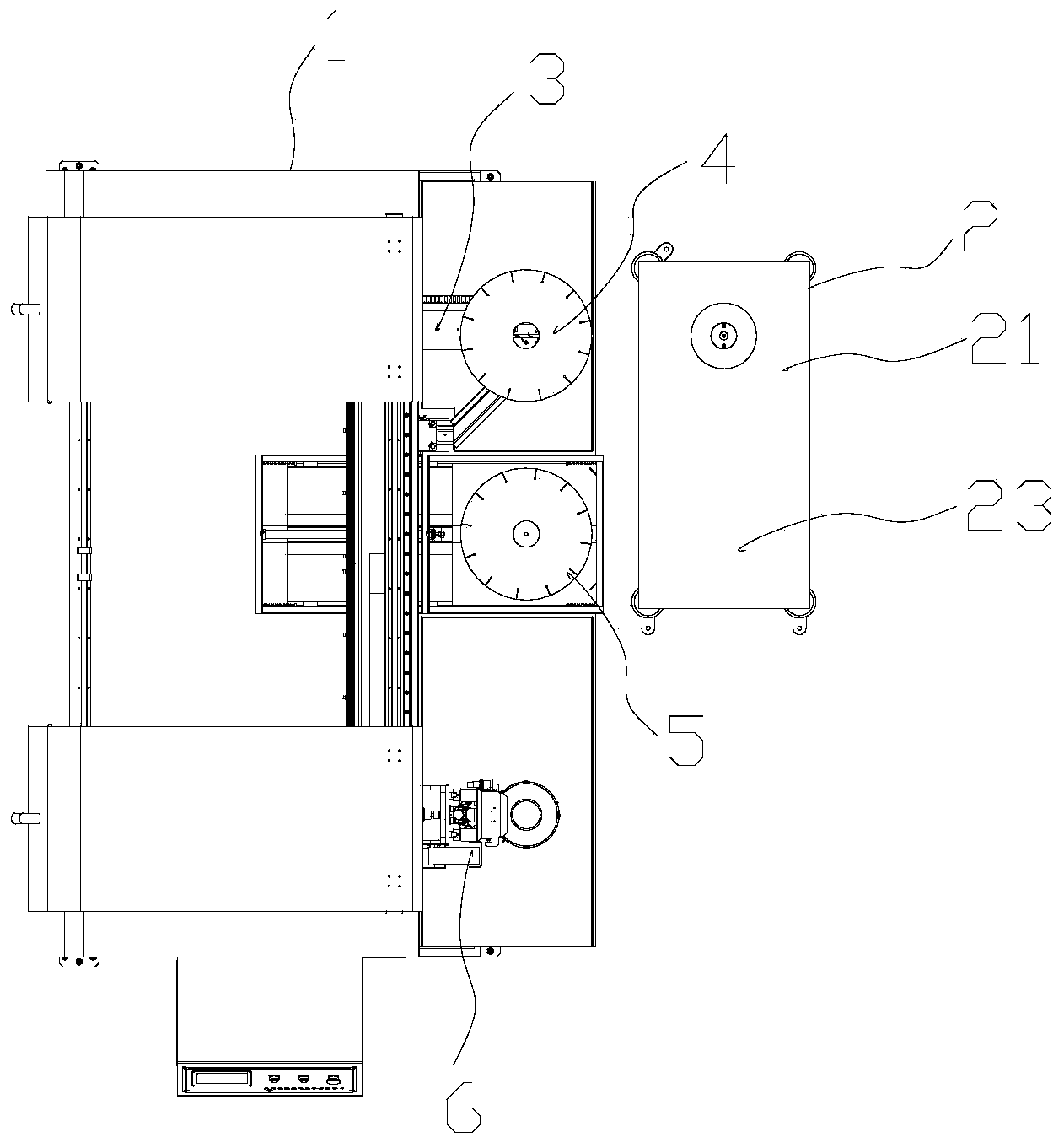

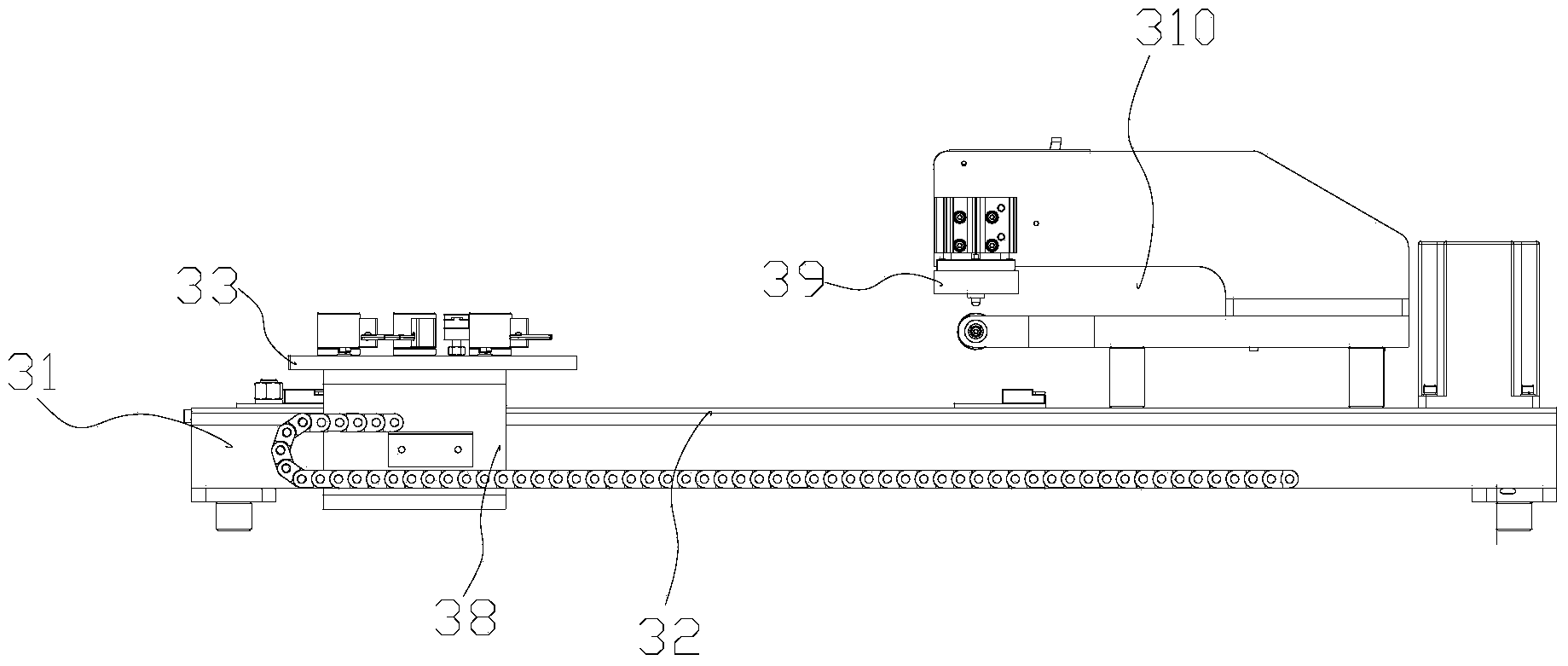

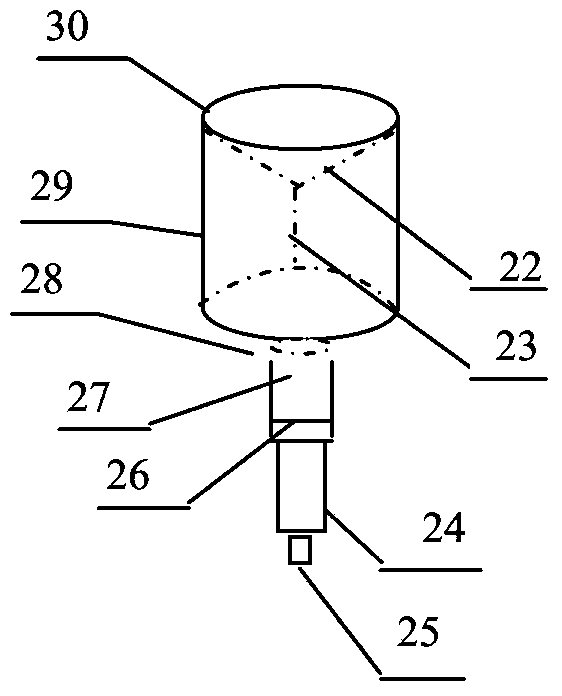

Full-automatic horizontal surface grinding machine mechanical arm

ActiveCN103831680AReduce labor costsImprove pass rateProgramme-controlled manipulatorGripping headsWork periodNumerical control

The invention discloses a full-automatic horizontal surface grinding machine mechanical arm which comprises a machine table and a product containing table. An automatic detection device, a turning device, a cleaning device and a grabbing mechanical arm body are arranged on the machine table. The product containing table and the machine table are arranged side by side. The automatic detection device, the turning device, the cleaning device and the grabbing mechanical arm body are all installed on the machine table, and an automatic grinding machine device is connected with the machine table. By means of the automatic detection device, the turning device, the cleaning device, the grabbing mechanical arm body and the automatic grinding machine device, saw blades are fed, discharged, detected, cleaned and ground in a full-automatic mode, full-automatic operation of the whole process is achieved, and labor cost of an enterprise is greatly reduced; by means of accurate numerical control operation, cost is reduced, the yield is improved, and the production loss rate is reduced; production efficiency is improved, and working time is shortened; by means of full-automatic production, guarantees can be provided for workers on the aspects of mechanical contusion, tiny dust and exhaust gas inhalation and metal dirty water corrosion to human bodies.

Owner:GUANGZHOU HENGWEI ELECTROMECHANICAL EQUIP CO LTD

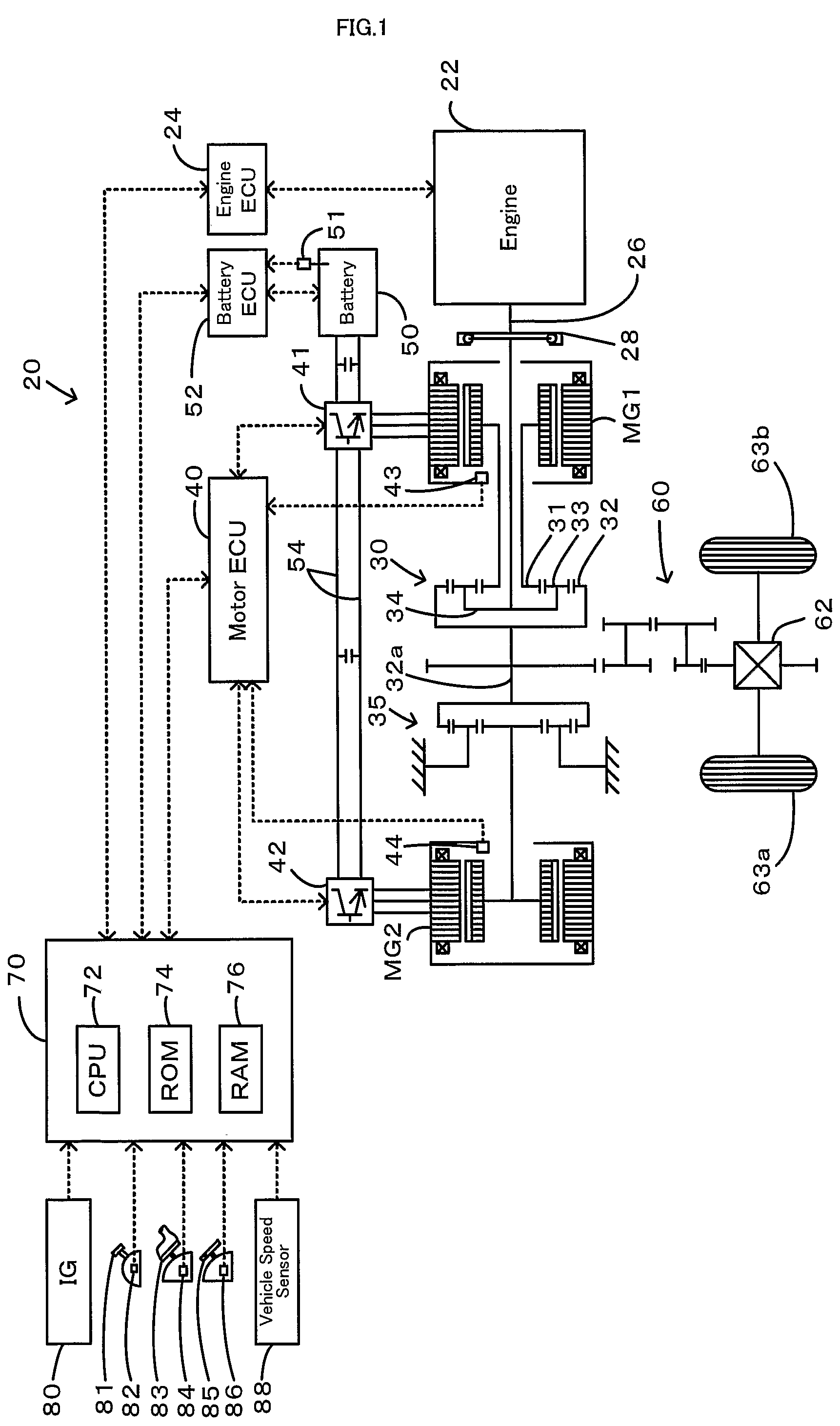

Power output apparatus, vehicle equipped with power output apparatus, and control method of power output apparatus

InactiveUS7448981B2Efficient and appropriate operationGuaranteed outputHybrid vehiclesElectrical controlElectric machinePort fuel injection

Owner:TOYOTA JIDOSHA KK

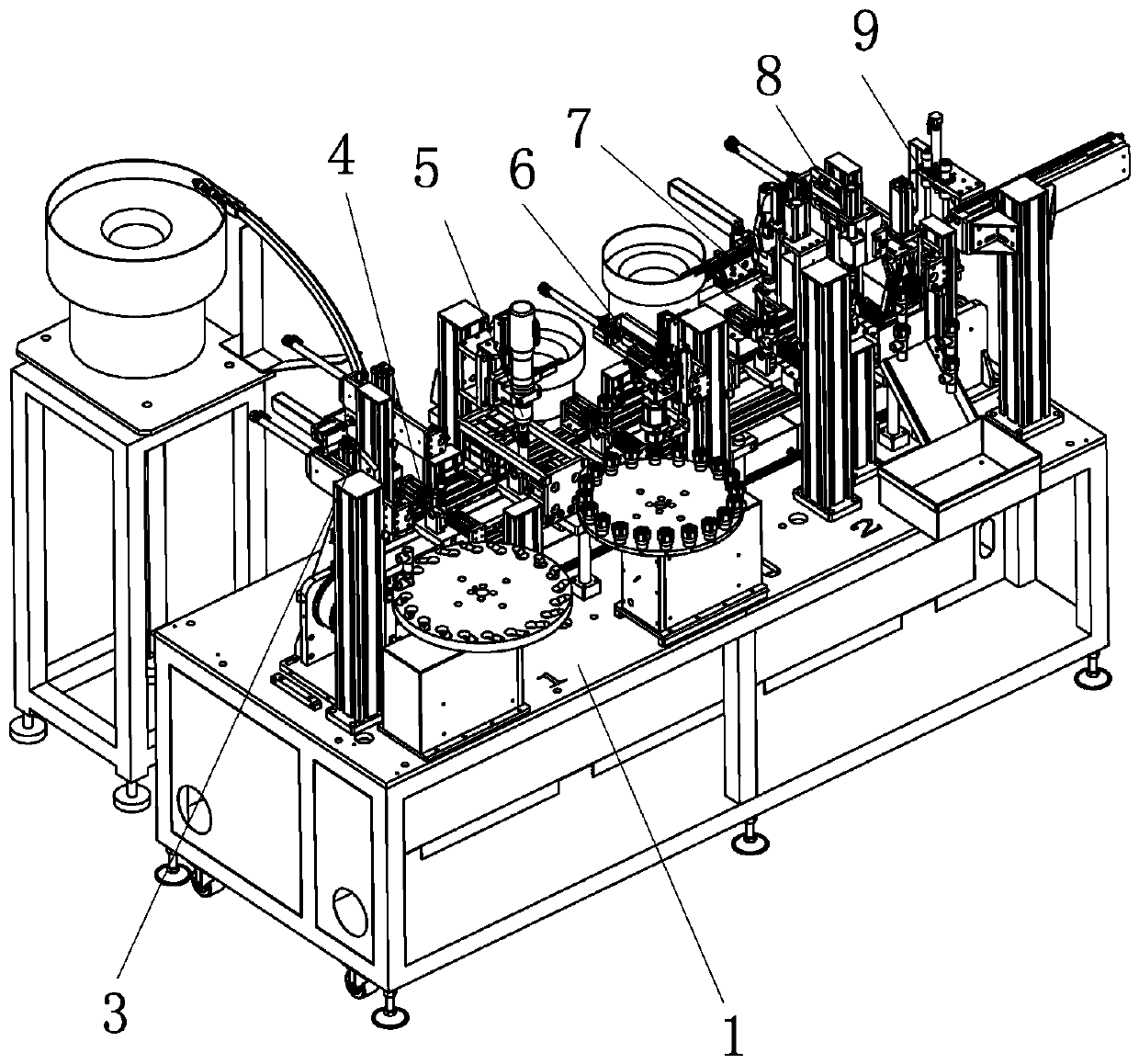

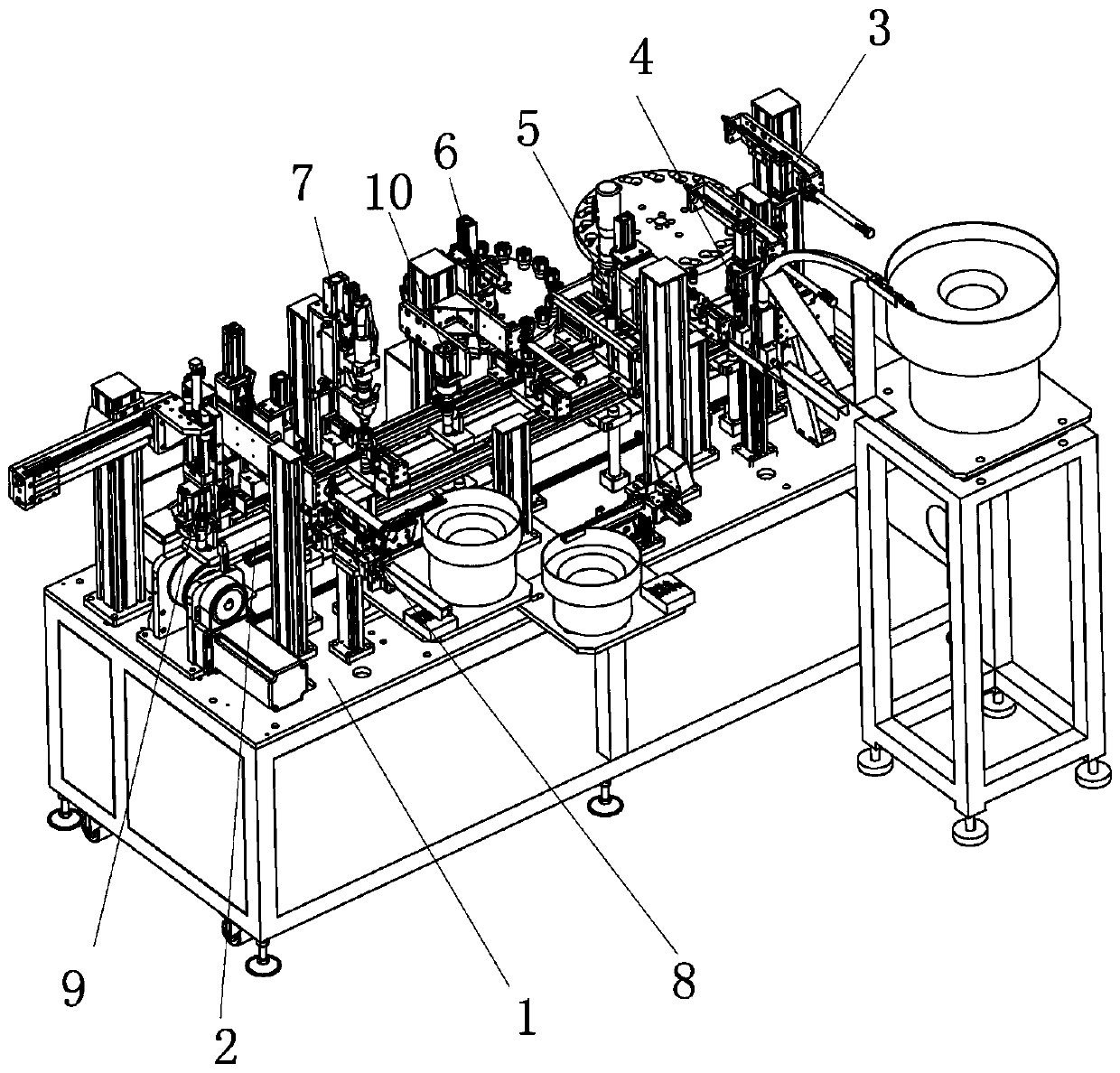

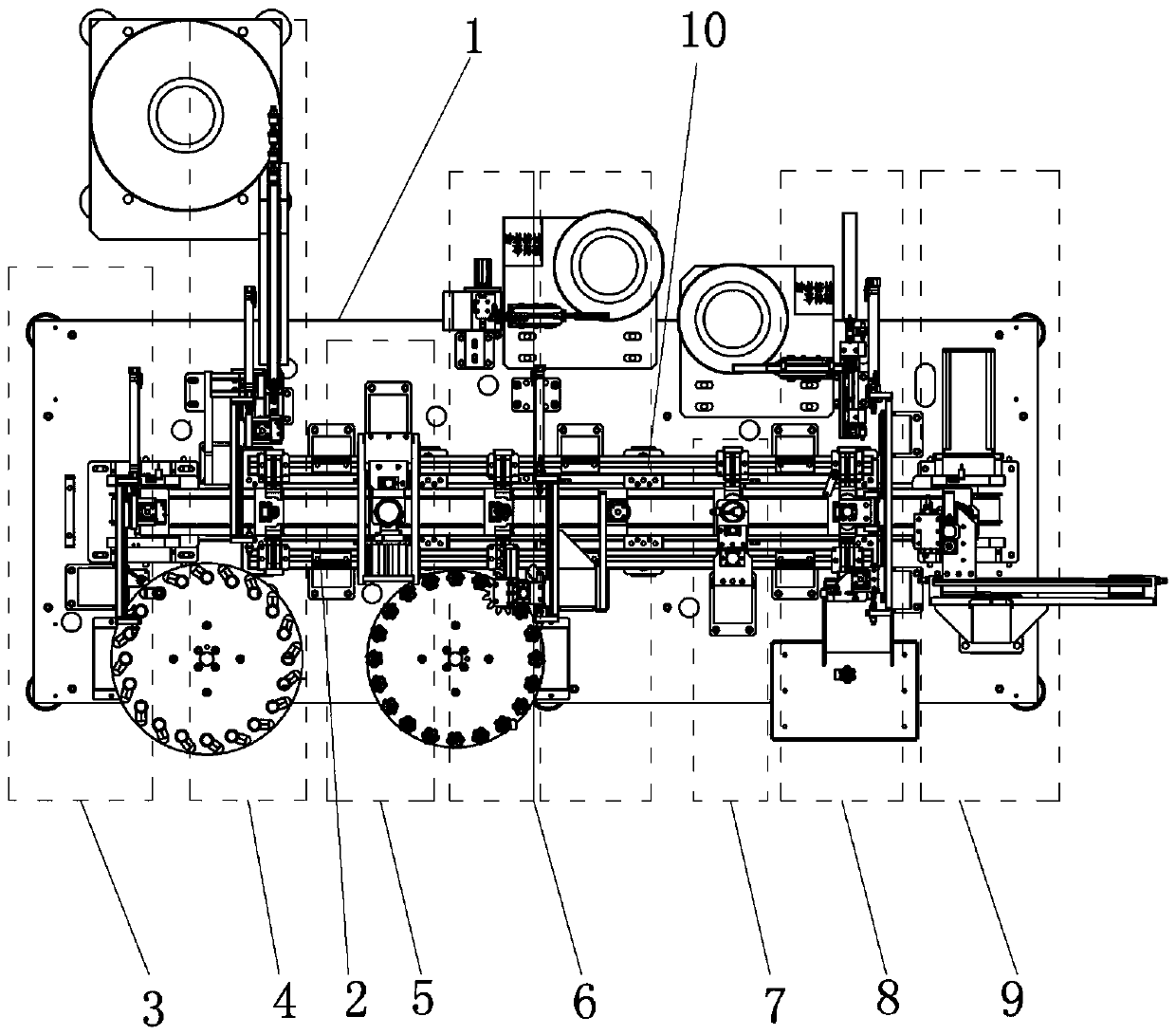

Full automatic angle valve assembly machine

PendingCN108015536ASimple structureReduce manufacturing costAssembly machinesMetal working apparatusLocking mechanismEngineering

The invention discloses a full automatic angle valve assembly machine which is characterized in that the full automatic angle valve assembly machine comprises a main frame and a material shifting andlocating mechanism arranged above the main frame; a valve body charging mechanism, a valve core charging mechanism, a valve core tightening mechanism, a handle charging mechanism, a screw locking mechanism, a valve cap assembly mechanism and a finished product taking mechanism are sequentially arranged above the material shifting and locating mechanism, wherein the material shifting and locating mechanism comprises a synchronous belt and a plurality of locating seats arranged on the synchronous belt; the synchronous belt is driven to rotate by a servo motor and then drives the locating seats to sequentially enter the various assembly mechanisms; locating rods are arranged above and below the synchronous belt; and guide grooves in the bottoms of the locating seats are located in the surfaces of the locating rods to slide. The full automatic angle valve assembly machin has the beneficial effects that by employing the multiple assembly mechanisms, automatic charging and assembly of various fittings of an angle valve are realized, and when full automatic assembly is realized, the assembly quality of products can be ensured since a standardized flow and operation sequences are adopted.

Owner:FOSHAN SUCCEED AUTOMATIC TECH

Passion fruit planting method

InactiveCN104542152AImprove survival rateIncrease productionSeed and root treatmentGraftingPondingRootstock

The invention relates to technical field of agroforestry planting, in particular to a passion fruit planting method. The method is characterized in that passion fruit seeds are soaked; the soaked seeds are sterilized with a sterilizing agent; germination of the soaked seeds is accelerated in order that buds are taken as scions; seedlings are grafted and cultured as rootstocks, so that the planting and seedling culturing processes of the passion fruit become an artificial control environment condition; in a continuous culturing process, the passion fruit adapts to the environment; the passion fruit seedlings obtained by grafting and seedling culturing are planted; in a planting process, a base is treated in order that the ponding amount is small, and moisture supply is appropriate. Therefore, the survival rate of the passion fruit is increased, the yield of the passion fruit is increased, the planting cost of the passion fruit is lowered, and the influence of introduction temperature difference on the quality and yield of passion fruit is avoided.

Owner:GUIZHOU TAIJIN AGRI TECH DEV

Hybrid Vehicle and Control Method Thereof

ActiveUS20090120699A1Effectively controls deteriorationDeterioration can be suppressedAuxillary drivesInternal combustion piston enginesLimit valueHybrid vehicle

A hybrid vehicle 20 sets a tentative limit value Win0 of determining a fuel increase relation with respect to a selected gearshift position SP for driving (S220,S230,S350), and performs increasing correction of a fuel injection amount according to either a first OT increase factor setting map or a second OT increase factor setting map that is enabled based on a relation of an input limit Win of the battery 50 to the tentative limit value Win0. Prohibition of fuel cutoff may be cancelled, based on a relation of the input limit Win to a driving force demand in an accelerator-off state set at the selected gearshift position SP. Even in this case, the increasing correction enables temperature regulation of an exhaust gas purification catalyst, with a view to controlling deterioration of the exhaust gas purification catalyst in an actual fuel cutoff condition after cancellation of the prohibition of the fuel cutoff. The deterioration of the exhaust gas purification catalyst is thus favorably controlled, irrespective of the selected gearshift position SP.

Owner:TOYOTA JIDOSHA KK

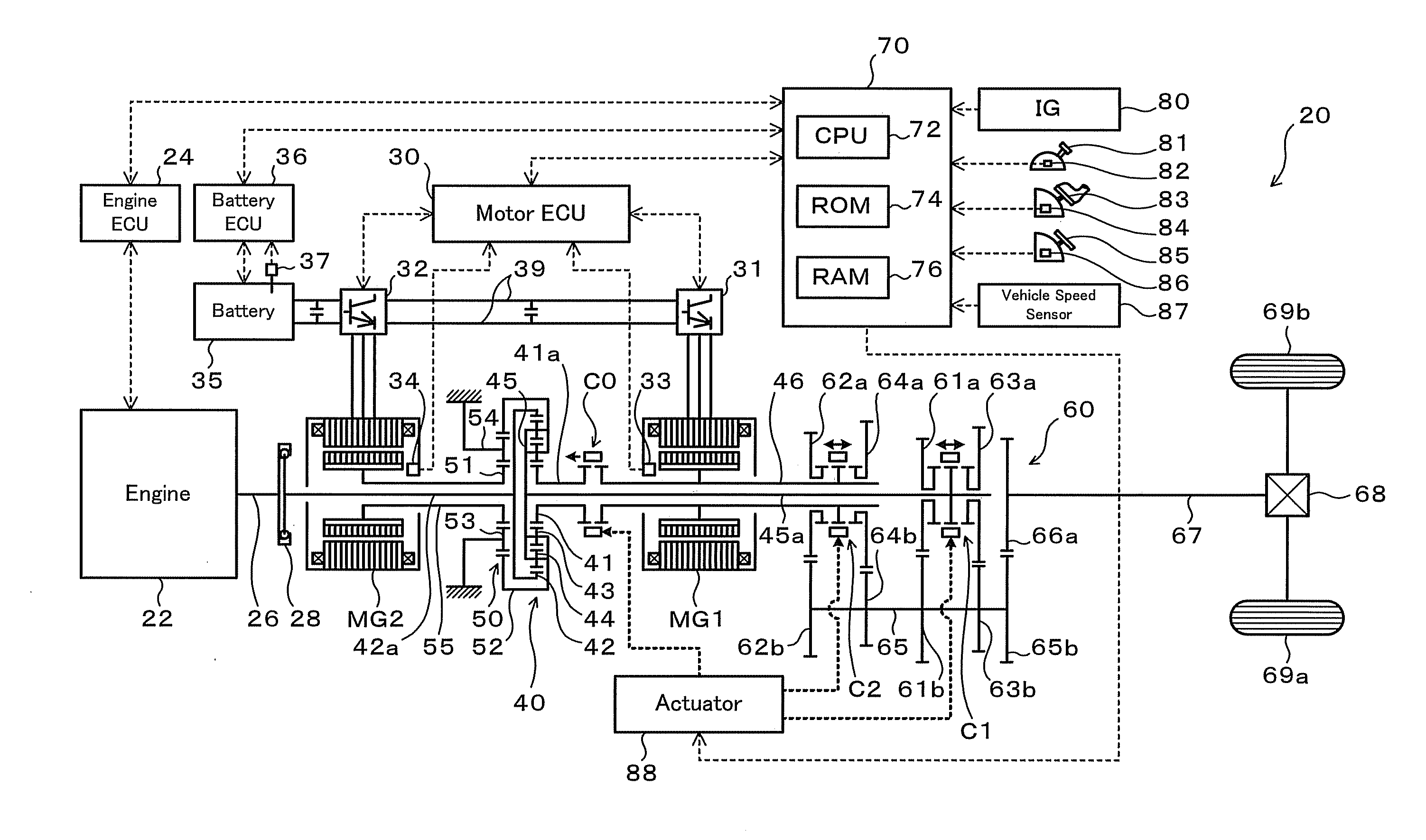

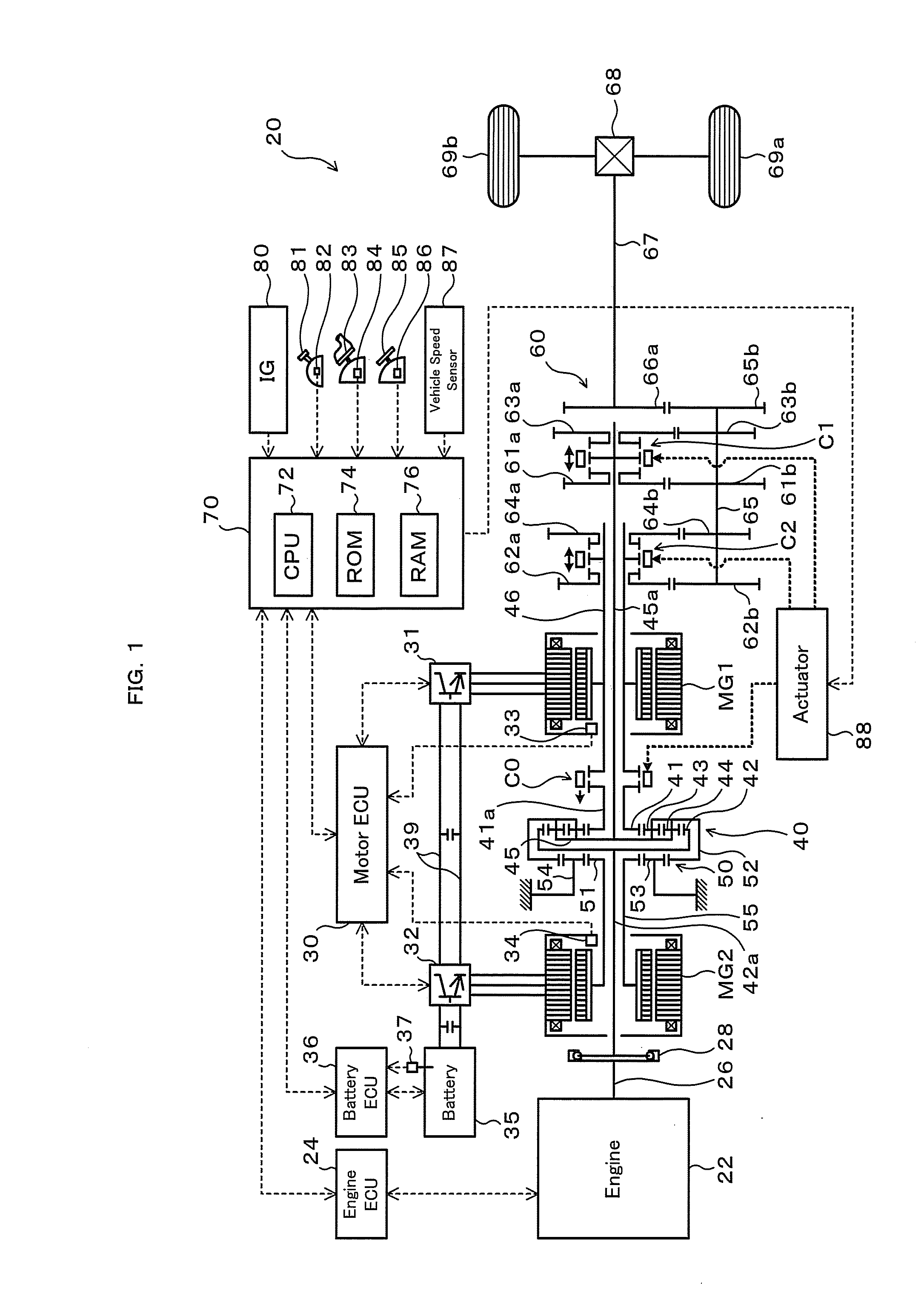

Power output apparatus, vehicle equipped with power output apparatus, and control method of power output apparatus

InactiveUS20100000814A1Large torquePrevent excessive heatingHybrid vehiclesEngine controllersVariatorMotor drive

In a 2-motor drive mode with connection of both motors to a driveshaft by means of a transmission, a hybrid vehicle sets torque commands of the motors to make a work performed by the second motor substantially equal to a work performed by the first motor and to ensure output of a torque equivalent to a preset torque demand to the driveshaft. This arrangement connects both motors to the driveshaft by means of the speed change-transmission assembly and ensures continuous output of a relatively large torque.

Owner:TOYOTA JIDOSHA KK

High-quality and high-output planting method for hot pepper

InactiveCN104396530AReduce the use of peatImprove seedling qualitySeed and root treatmentGrowth substratesSaw dustAgriculture

The invention discloses a high-quality and high-output planting method for hot pepper. The method is characterized in that the seeds are dried and soaked through a clean plastic basin 2 to 5 days before sowing; the seed is disinfected before sowing; the seed which is expanded in water is transferred to a proper temperature to prompt the seed germination; the germination prompting temperature is controlled to be 20 to 30 DEG C, and the relative humidity is controlled to be about 90%; when seedlings grow from the seed coat and the roots of the seedlings are as long as the seed, the seed can be sowed; the culture medium soil for culture of seedling comprises vermiculite, wormcast, decomposed cow dung, straw bran, saw dust and sieved soil; the land is leveled, the fertilizer is applied, then the seedlings are transplanted and planted to the field. According to the method, the components of the culture medium soil are changed; in addition, the grass carbon is decreased; lots of wormcast, decomposed cow dung, straw bran and other unused wastes in the agricultural planting and breeding industry are effectively utilized to form a composite culture medium which improves the seedling culture quality and lowers down the cost of seedling culture; compared with the original planting method, the planting method has the advantages that the seeds are scientifically treated, the management after field planting is scientific, and therefore, the output of the hot pepper is ensured and reaches 5,000g / mu, and the output is increased by about 20 to 30%.

Owner:JIANGXI YANGQISHAN ECOLOGICAL AGRI DEV CO LTD

Low-temperature coal carbonization kiln

ActiveCN1966609AIncrease effective volumeHigh yieldRetortsDischarging devicesAutomatic controlCarbonization

The invention disclosed a kind of low temperature coal dry distillating square stove which includes stove body, coal cup, dant-pushing machine and branch admixer. On the top of the hearth there is installed the gas collecting umbrella, inside the stove it is cavity structure; on the bottom of the cavity there are installed several rows of emitting gas walls, every row of emitting gas wall is parallel to the interval between two side umbrella of the gas collecting umbrella; the consecutive emitting gas walls are pedestalled by arch wall; on both sides of the emitting gas walls there are two branch admixer respectively; the bottom of the stove connects the dant discharging box, the bottom of which connects the dant leading slot; the bottom of the dant leading slot is dant-pushing machine, the bottom of which is aqua sealing slot, in the slot there is scraper machine. The invention adopts the heating scheme of endo-burnning and calor internus which can heat uniformly. The gas collecting umbrella and accessory coalbox can make the material and gas-collecting uniformly while the dant-pushing machine can make the product uniform. The advantage of the invention: it can bring into full play of the producing ability and decrease the investment as well as increase the benefits; besides, it is easy to operate, it needs less people and can be controlled automatically.

Owner:SHAANXI SHENMU SAN JIANG COAL CHEM

Hybrid vehicle and control method thereof

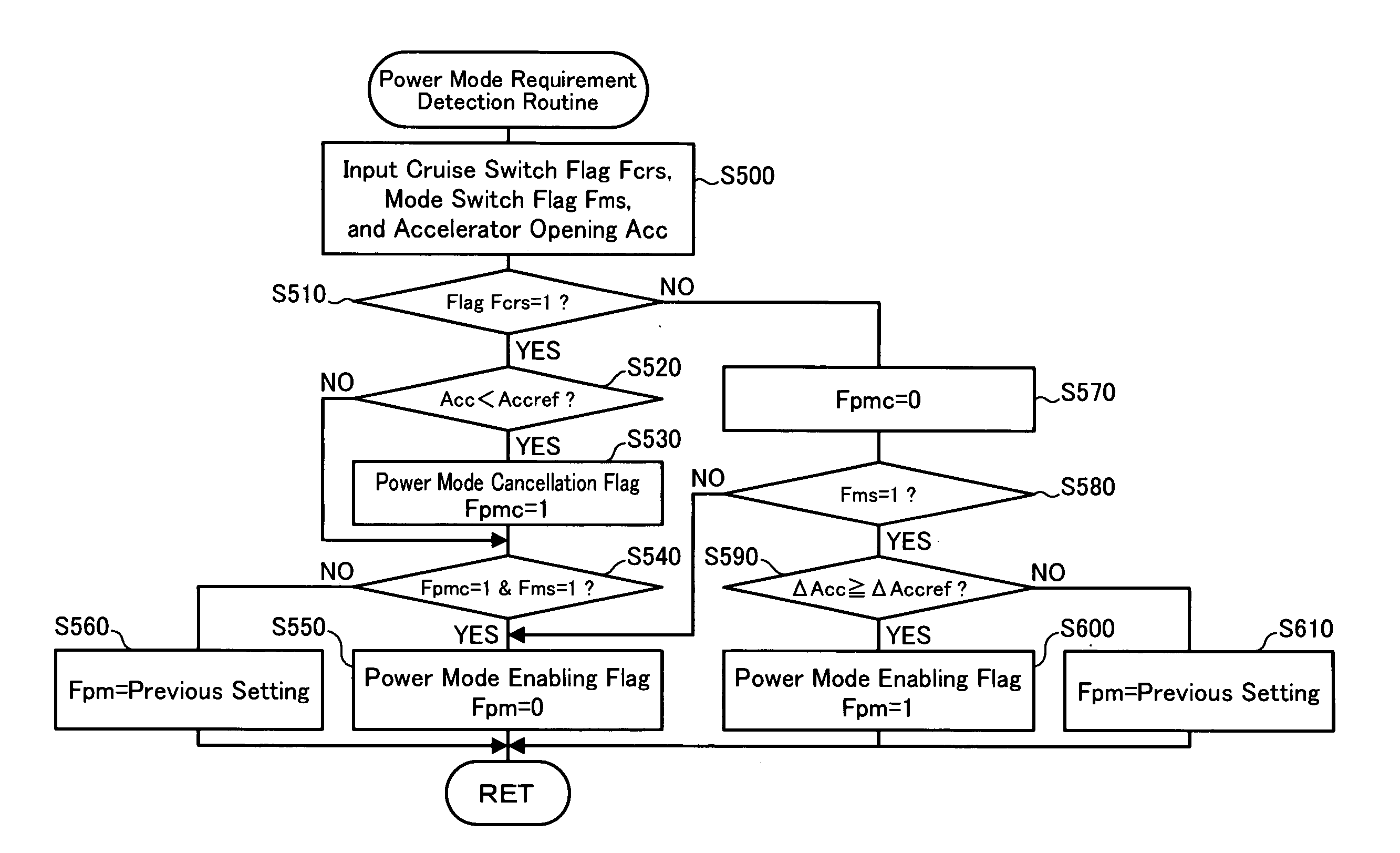

ActiveUS20080228334A1Executed sufficientlyPrevented from feelingVehicle fittingsDigital data processing detailsPower modeEngineering

During execution of an auto cruise function, in response to selection of a power mode, when an measured accelerator opening Acc is less than a preset opening Accref, a hybrid vehicle of the invention sets a power mode cancellation flag Fpmc to 1 and a power mode enabling flag Fpm to 0 (steps S540 and S550). This prohibits the use of an accelerator opening setting map in the power mode for execution of the auto cruise function. In the power mode, in response to an instruction for enabling the auto cruise function, the hybrid vehicle keeps the power mode enabling flag Fpm to the setting of 1 (step S560) as long as the measured accelerator opening Acc is not less than the preset opening Accref. This allows the use of the accelerator opening setting map in the power mode for execution of the auto cruise function.

Owner:TOYOTA JIDOSHA KK

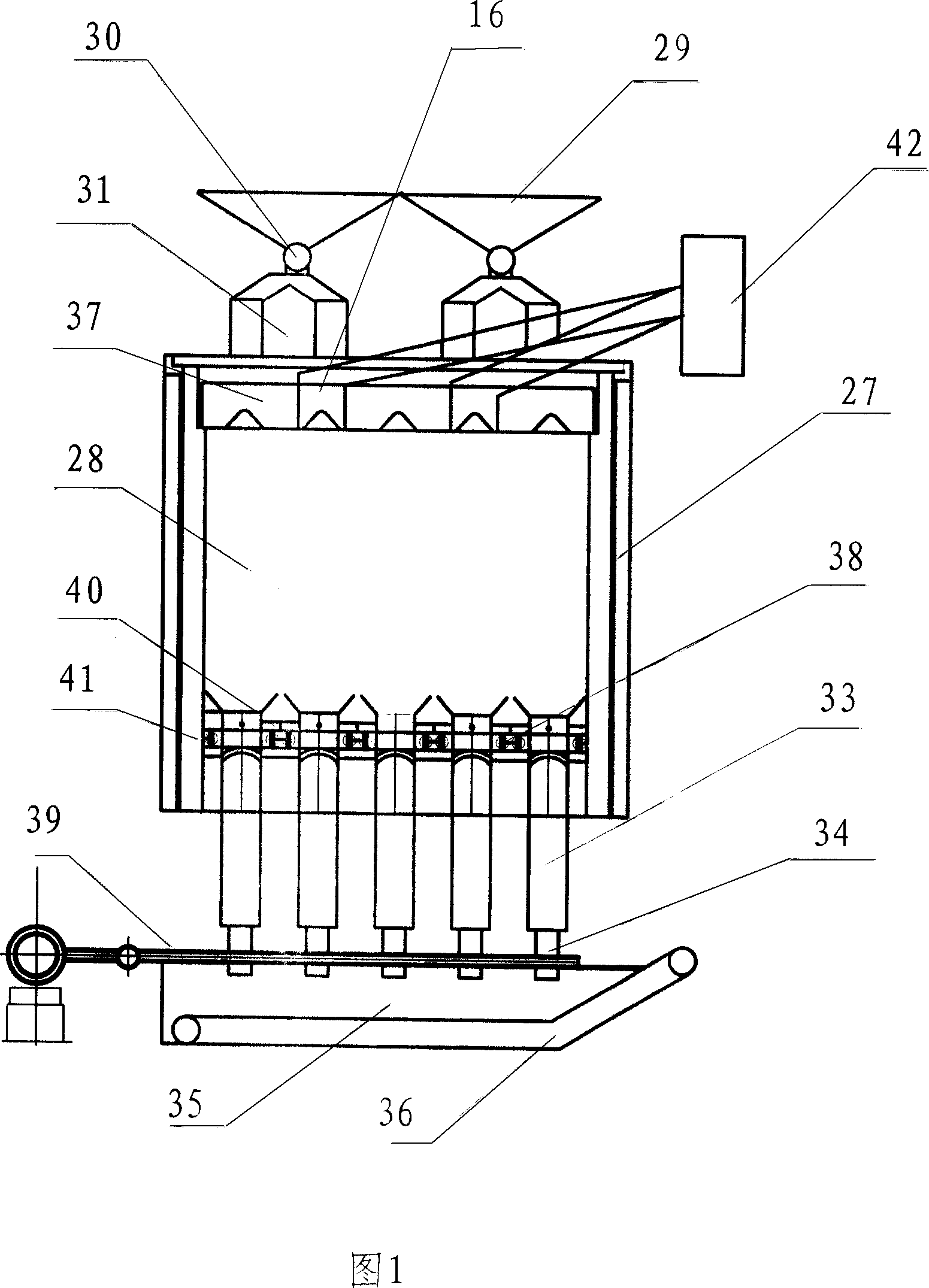

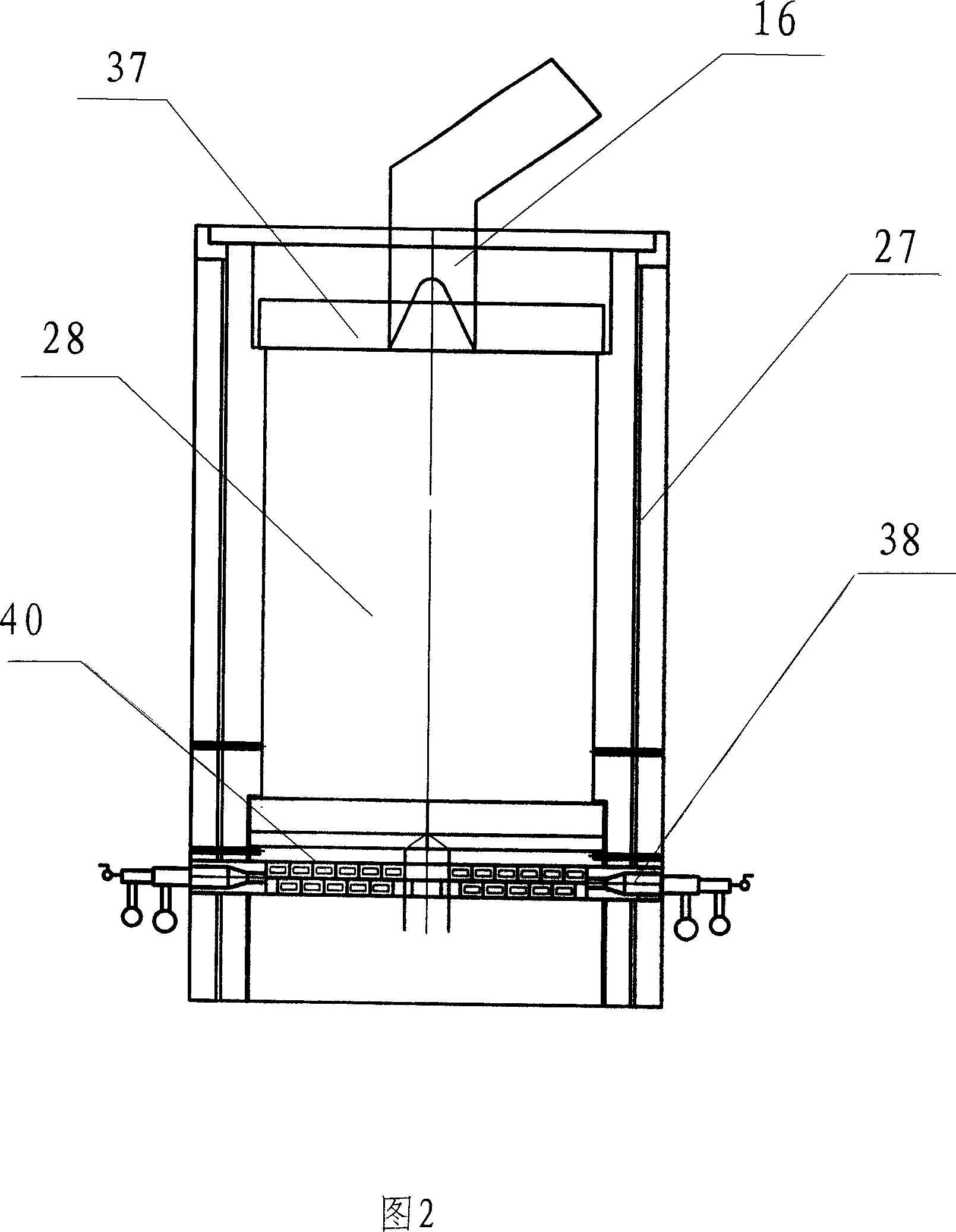

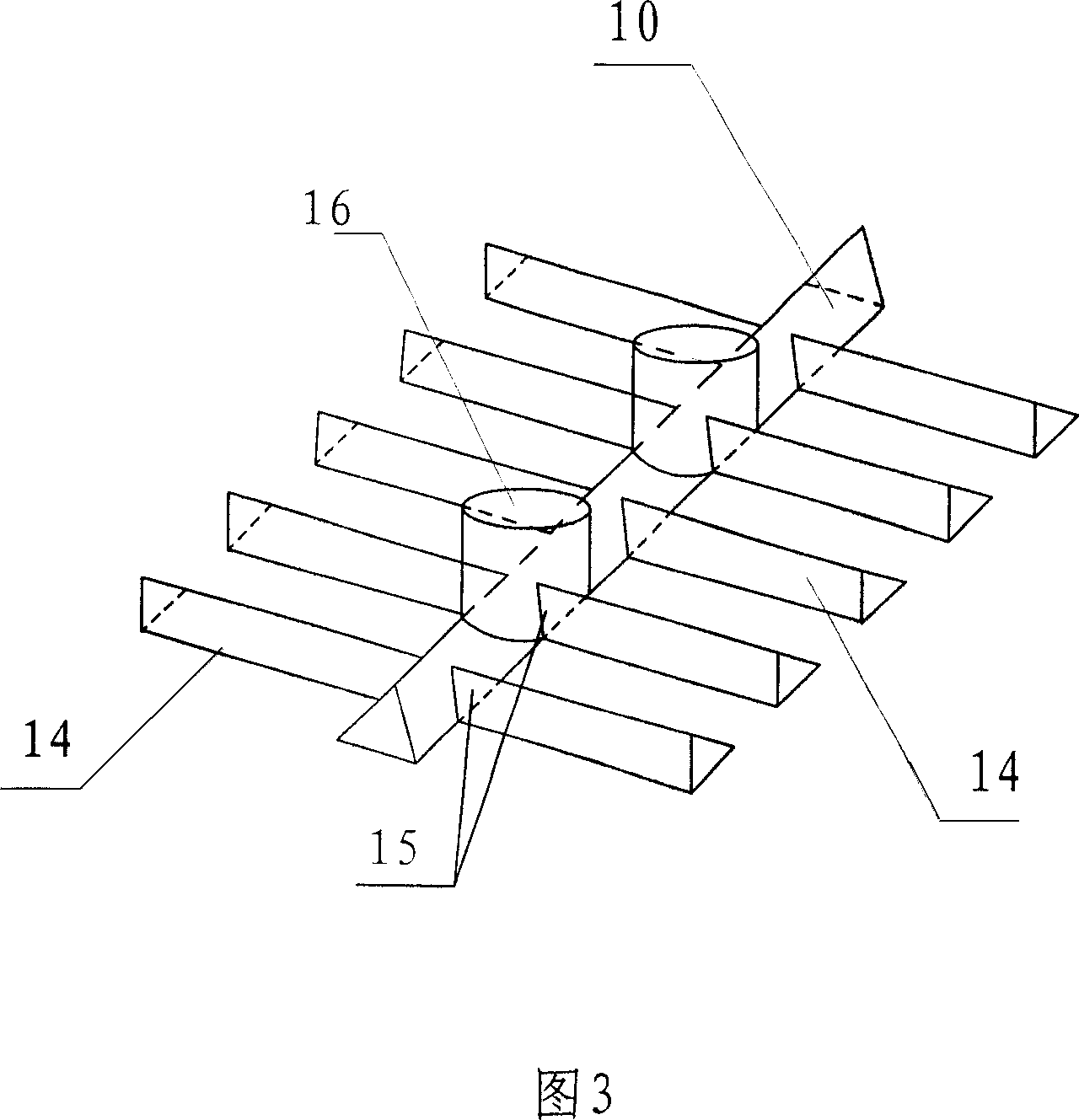

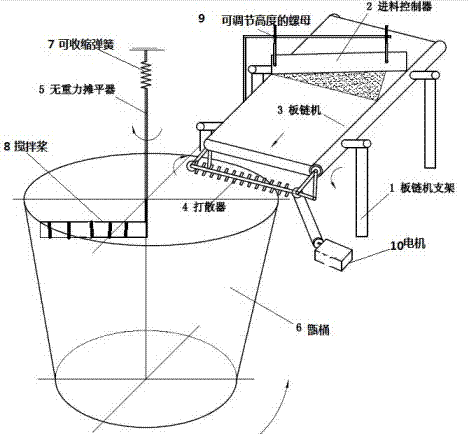

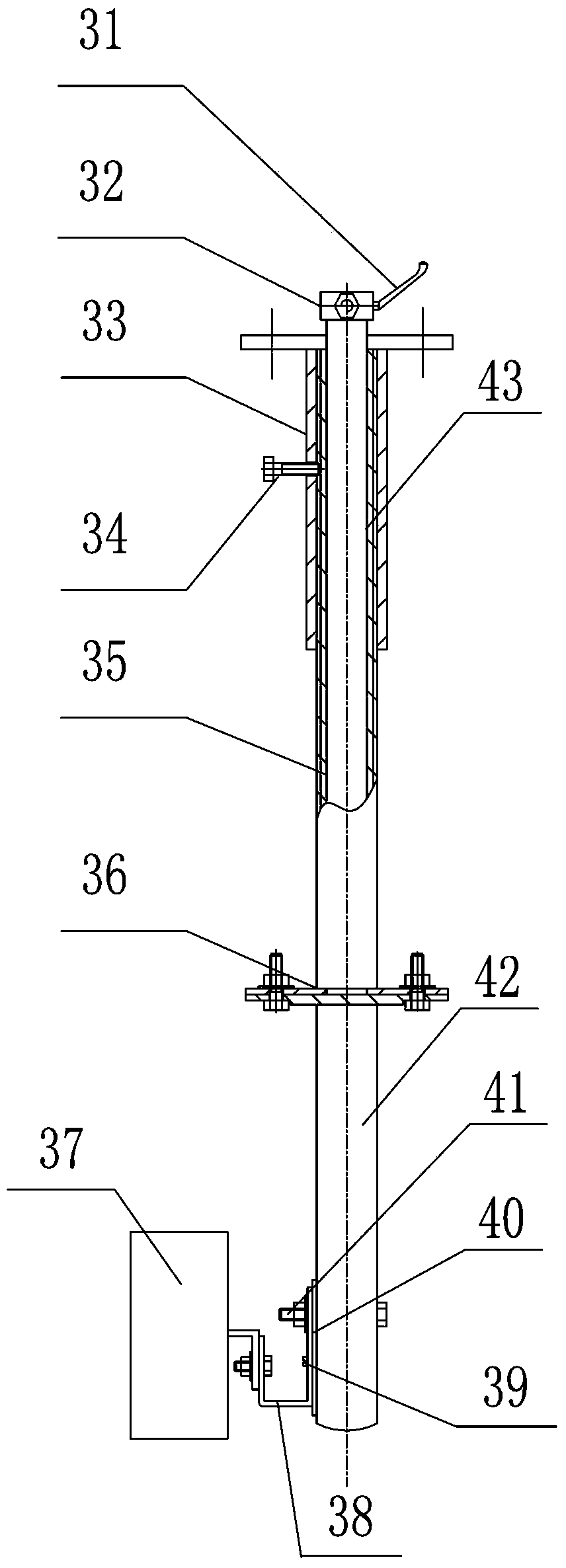

Method and device for automatically and uniformly loading materials into white spirit steaming barrel

The invention provides an automatic and uniform material loading method and an automatic and uniform material loading device which is used in the process of producing white spirit, and aims to achieve effects that the process which is manually performed in the prior art is completely or partially replaced by the method, the uniformity and the looseness of loading fermented grains are simultaneously guaranteed, and the shortcomings of the prior art are overcome. The automatic and uniform material loading device comprises a steaming barrel, a loading device and a uniformizing device, wherein the steaming barrel comprises a steaming barrel body and a bottom pot which are separable; the bottom of the steaming barrel is supported by a rotary supporting piece and can rotate; the loading device consists of a material conveying device, a charging controller and a scattering device; the uniformizing device consists of an agravic levelling device which is provided with a stirring paddle and liftable. By matching the steaming barrel, the loading device and the uniformizing device, materials are automatically loaded, and the uniform and stable looseness of loading the materials is guaranteed.

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD +2

Method for hatching leeche and raising seedling of leeche

InactiveCN101627747AShorten germination cycleHigh concentration of germinationAnimal husbandryConcentration ratioSeedling

The invention discloses an artificial breeding method for hatching leeches and raising seedlings of leeches, aiming to provide a method for hatching leeches and raising seedlings of the leeches, which has leech hatching rate as high as 95 percent, shortened seedling emergence period and concentrated seedling emergence. The method sequentially comprises the following steps: 1, breed selection; 2, leech breed disinfection; 3, breed input; 4, mating and spawning; 5, cocoon classification; 6, hatching in a hatching room; and 7, hatching and seedling emerging. The invention has shortened seedling emergence period of the leeches and high seedling emergence concentration ratio, is convenient to artificial breeding, ensures the quality and indirectly increases the output of the commodity leeches by 150 kg each mu, enhances the benefit by 2000-3000 yuan each mu, and the like.

Owner:陆如明 +1

Link state advertisements specifying dynamic routing metrics and associated variation metrics and selective distribution thereof

InactiveUS7567577B2Introduce instabilityEnsure responsivenessDigital computer detailsData switching by path configurationLink-state advertisementAdaptive routing

Each router in a network is configured for executing a link state routing protocol based on outputting a corresponding first link state advertisement message describing a connected link of the router and that specifies a first dynamic routing metric identifying a first cost of the connected link, and a corresponding variation metric identifying a statistical variation of the dynamic routing metric. Each router also is configured for selectively outputting a corresponding second link state advertisement message describing the connected link and that specifies the corresponding variation metric and an updated dynamic routing metric identifying an updated cost of the connected link relative to the first cost, the second link state advertisement message selectively output based on the updated dynamic routing metric differing from the first dynamic routing metric by more than the variation metric, or the router having received another link state advertisement from another router in the network.

Owner:CISCO TECH INC

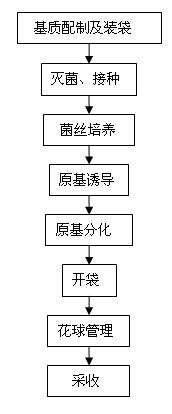

Formula of culture medium for industrial production of sparasis crispa and production process

ActiveCN101955392AWide range of sources and cheapFast growthHorticultureFertilizer mixturesBiotechnologySparassis crispa

The invention provides a formula of a culture medium for industrial production of sparasis crispa and a production process. The formula of the culture medium comprises the following components in percentage by dry weight: 65 to 75 percent of pine sawdust, 10 to 20 percent of husk, 5 to 10 percent of potato powder, 5 to 10 percent of flour, 0.1 to 0.5 percent of peptone, 0.1 percent of ammonium sulfate and 1.2 to 1.8 percent of brown sugar. The production process comprises the following steps of: preparing and bagging the culture medium; sterilizing and inoculating; culturing hypha; inducing a primodium; differentiating the primodium; opening the bag; managing balls; and harvesting. The invention provides a formula of a culture medium for industrial production of sparasis crispa, which has the advantages of rich nutrition, balanced proportion, good ventilation, and capacity of meeting the requirement of industrial production. The production process has the advantages of short hypha culturing time, uniform fruiting at bag openings, good fruiting consistency, convenience of management, contribution to industrial culture, white mushroom body, high yield, and high biological transformation rate of over 43 percent.

Owner:FUQING CITY FIRE KIRIN EDIBLE FUNGUS TECH DEV +1

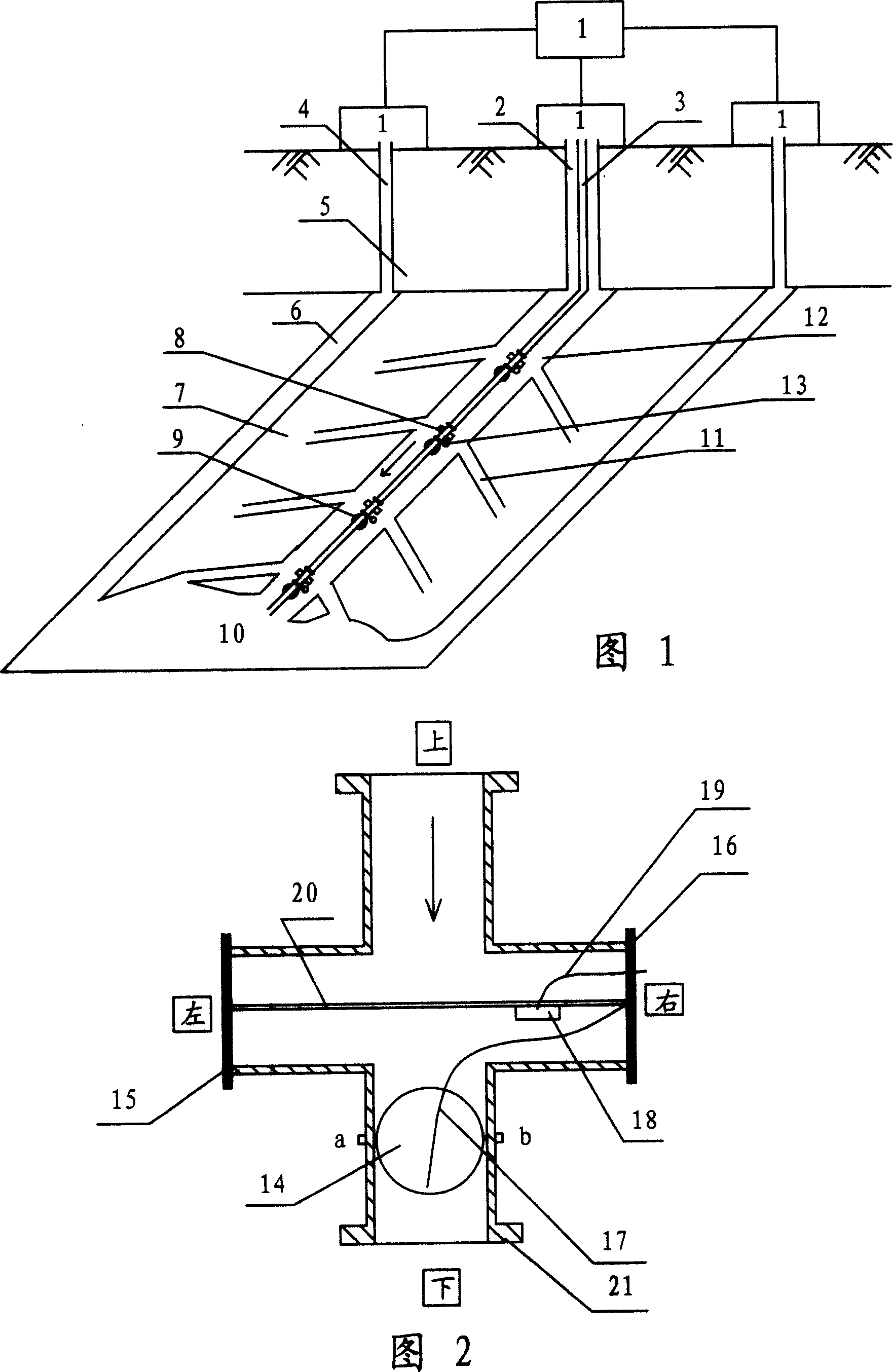

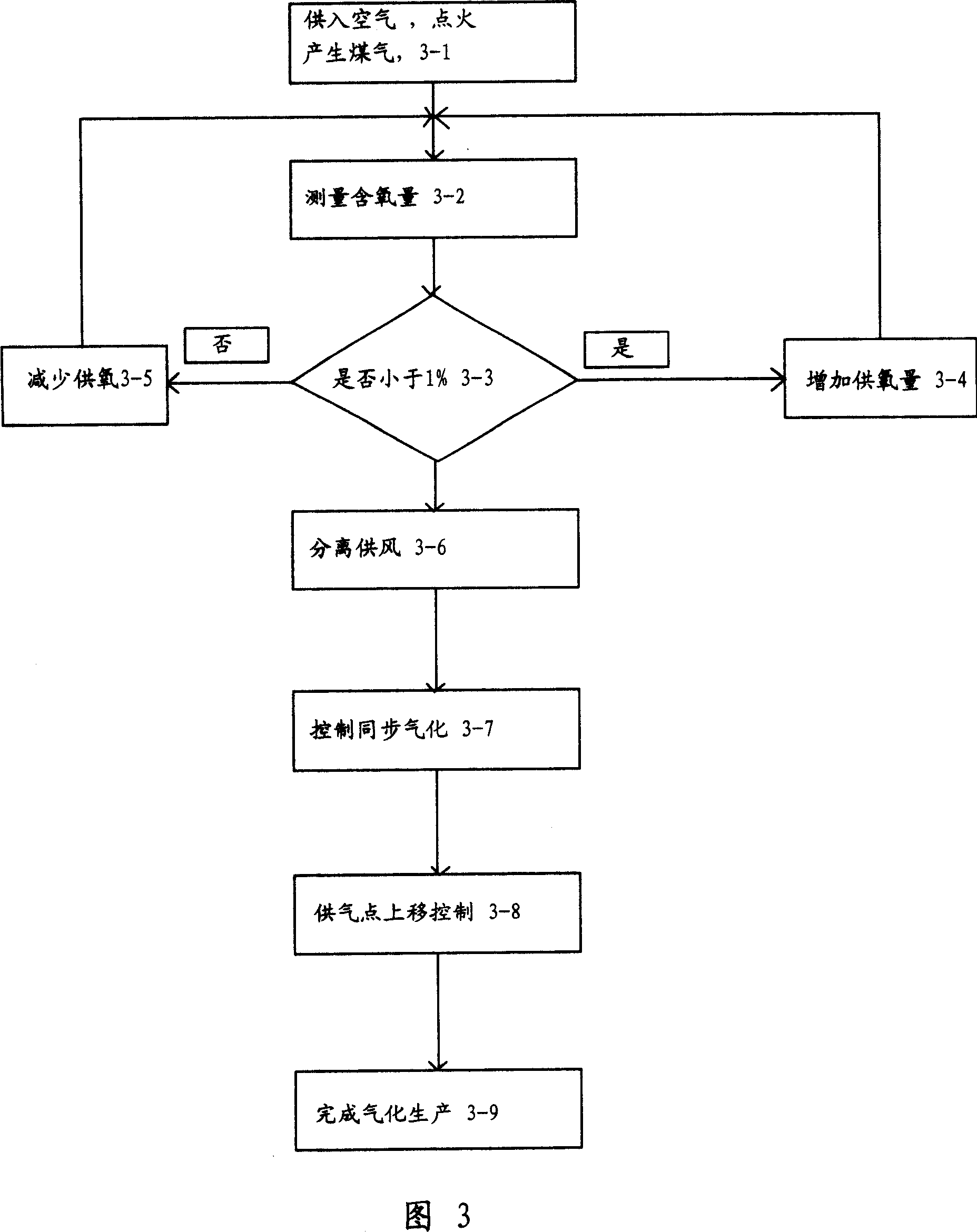

Underground coal gasifier with air-lift point separating control and its process

InactiveCN1982647AAvoid caving and cloggingGuarantee gas production and qualityConstructionsCoal gasificationDrill holeCoal gasifier

A separately controlled gas injection point coal underground gasifier and techniques, the method is achieved in the separately controlled gas injection point coal underground gasifier, the gasifier is installed with the wind hole (2) and wind tunnel (12), air gate (4) and the gas channel(6), oxygen tubes (3) are laid between the wind hole (2) and wind tunnel(12), the oxygen tubes (3) connects several certain distance separated of gas injection point controlling four-way pipe(8); a temperature sensor (13) is set at the four-way pipe position; blind hole (11)is set corresponding to the shutter A (25) and the shutter B (20) on the four-way pipe (8) position, along the coal bed both sides of the wind tunnel (12). The invention overcomes the coal wall combustion phenomena of bottom holes produced by the gasification of oxygen-enriched watered steam, avoid the wind tunnel plugging-up of bottom tunnels, ensure yield and quality of the gas; prevent the wind tunnel directly supply oxygen, guarantee the safety of gasification system; increase of controllability and stability of the gasification process through control to gas injection point and the corresponding loosened blind hole.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Artificial breeding technology of beeves

InactiveCN104472423AGuaranteed outputQuality assuranceAnimal feeding stuffAnimal housingImproved survivalGravidities

The invention relates to an artificial breeding technology of beeves. The artificial breeding technology of the beeves includes steps: completing construction of a beef house according to environment requirements; selecting the beeves, and paying attention to the breeding density in a pasture; selecting healthy beef breeds, separately feeding the healthy beef breeds, and promoting estrus copulation of the healthy beef breeds; separately breeding mother beeves after gravidity of the mother beeves, paying attention to nutrition in a suckling period, and managing the feeding of calves; promoting a group of the beeves to fatten and performing timely hybridization. The artificial breeding technology of the beeves can effectively improve survival rate and growth rate of artificial breeding of the beeves, increases a beef yield of the beeves, improves economic benefit, and promotes development of beef breeding industry in an alpine region.

Owner:CHONGQING MUWEN AGRI

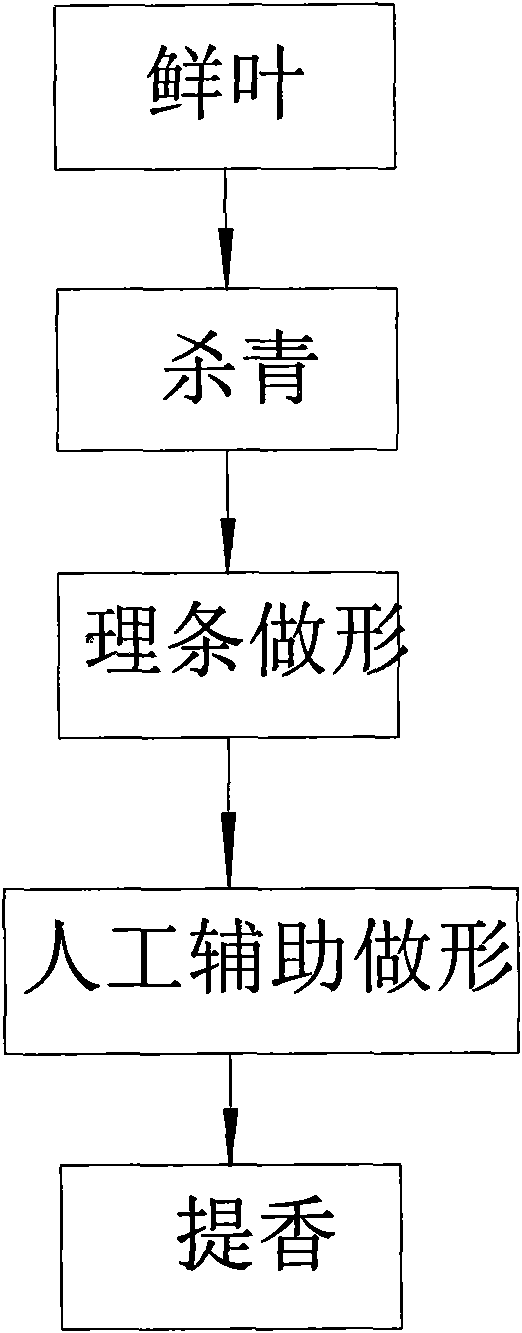

Processing method of tea-leaf like sparrow tongue

InactiveCN101606556AContinuous productionFully convertedPre-extraction tea treatmentEngineeringTea leaf

The invention relates to a processing method of tea-leaf like sparrow tongue, including main steps of water-removing, wire tidying and shaping, artificial assist shaping and deoiling. The tea leaves like sparrow tongue prepared by adopting the invention have flat, tall and graceful and smooth tea wires, like a sparrow tongue in appearance, are green You Run in colour, are dark green, clear and bright in soup colour, and possess of strong long-lasting fragrance, fresh, pure, daintily and unforgettable taste, light green, uniform and bright colour and complete leaves. Green ingredients in the tea leaves are fixed through water removing by a microwave water removing machine, and alcoholization sterilization is carried out on the tea leaves, thus achieving 'three greens' of product and safety and sanitation; a microwave dryer and a far infrared deoiling machine are used and intermediate temperature intermediate speed alcoholization fragrance improving technology is adopted to promote full inversion and polymerization of inclusion and fragrance ingredients, thus the tea leaves are fragrant in smell and rich and pure in taste. In addition, owing to addition of the microwave water removing machine, the microwave dryer and the far infrared deoiling machine, influence caused by man-induced factor is reduced in production of the tea leaves like sparrow tongue, continuous and clean processing is realized, and product quality and yield are ensured.

Owner:SICHUAN WENG TEA IND

Power output apparatus and control method of the same

InactiveUS20050266957A1Easy to limitGuaranteed outputHybrid vehiclesReciprocating combination enginesHigh densityState of charge

When an actual output power level of an engine is greater than a preset engine power demand due to the higher density of intake air in a cold environment, the control procedure of the invention controls a motor to raise a rotation speed of the engine with a throttle opening TH kept at a current level, so as to make the actual output power level of the engine substantially equal to the engine power demand (this is attained by, for example, a change of a target drive point from a point A to a point B). This arrangement effectively restrains a battery from being charged with an unexpectedly large electric power and prevents frequent changeover between the stop and the start of the engine with a significant variation in current state of charge (SOC) of the battery.

Owner:TOYOTA JIDOSHA KK

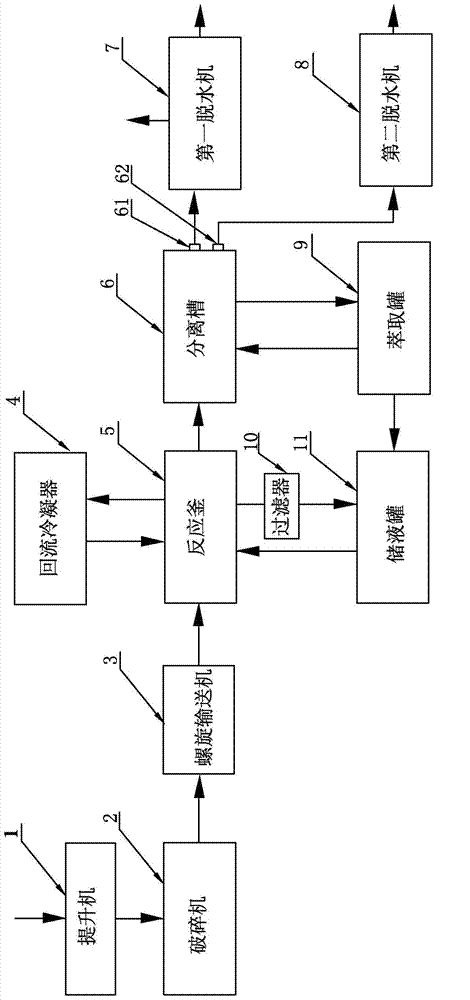

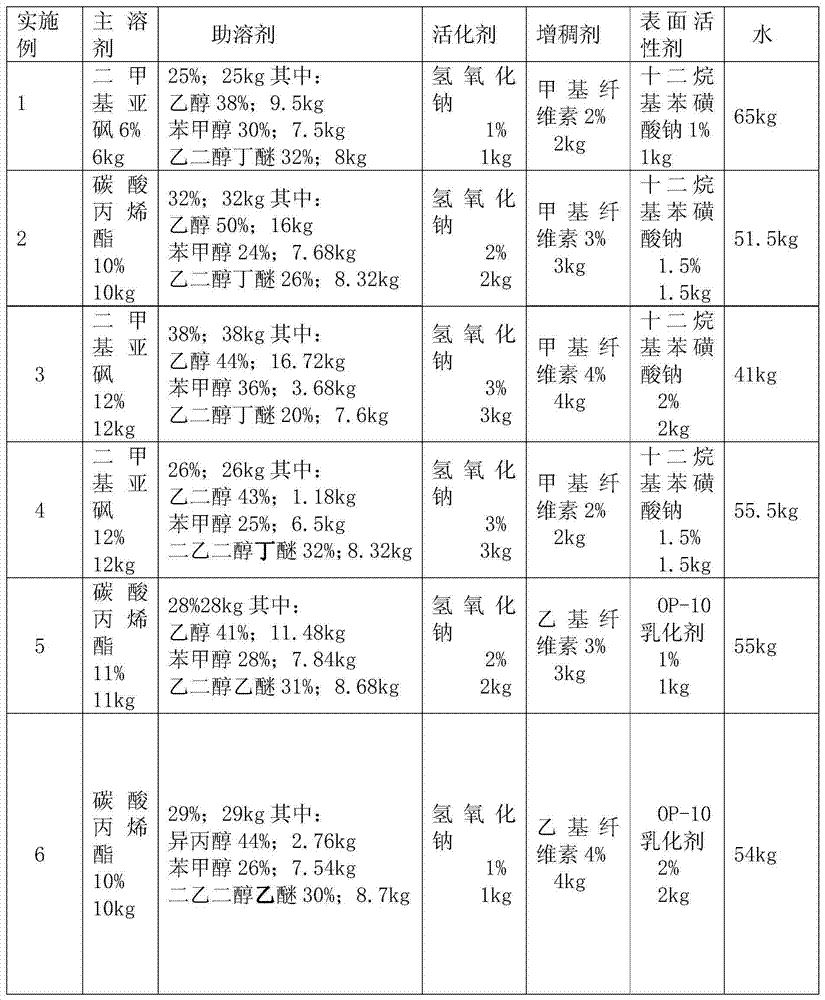

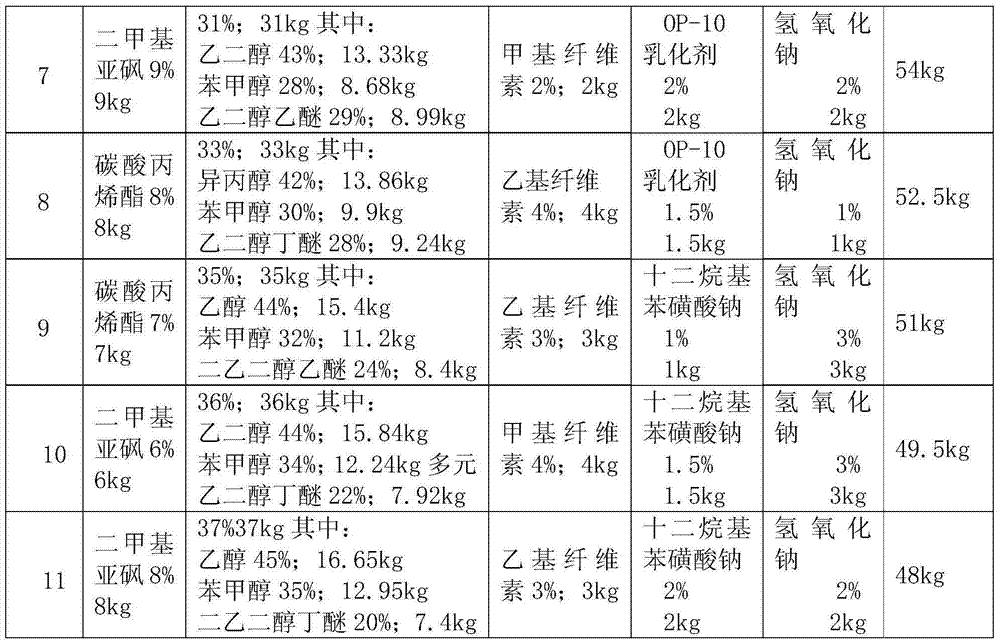

Plastic adhesion layer cleaning agent as well as plastic cleaning process and equipment adopting same

The invention relates to a plastic adhesion layer cleaning agent as well as a plastic cleaning process and equipment adopting the same. The cleaning agent comprises the following components in percentage by mass: 6-12 percent of a master solvent, 25-38 percent of a cosolvent, 1-3 percent of an activating agent, 2-4 percent of a thickener, 1-2 percent of a surfactant and the balance of water, wherein the master solvent is dimethyl sulfoxide or propylene carbonate; the cosolvent comprises the following components in percentage by mass: 38-50 percent of monohydric alcohol or polyhydric alcohol, 24-36 percent of phenylcarbinol and 20-32 percent of polyhydric alcohol ether. The cleaning process comprises the following steps: crushing plastic to form plastic fragments; putting the plastic fragments and the cleaning agent into a reaction kettle according to a mass ratio of 1: 2; heating to 65-75 DEG C in a sealed manner and stirring for 20-40 minutes; leading the cleaning agent out for recycling; separating and dehydrating the plastic fragments and stripped substances of the adhesion layer to obtain a recycled plastic finished-product; and periodically extracting liquid in a separating tank and recovering the cleaning agent. The equipment comprises the reaction kettle, the separating tank, an extracting pot, a liquid storage pot and a reflux condenser.

Owner:天津市生态环境科学研究院

Real-time monitoring method for growth characters of tea trees in intensive cultivation

ActiveCN103439265AAchieve high quality and high yieldImprove qualityUsing subsonic/sonic/ultrasonic vibration meansColor/spectral properties measurementsBudTea leaf

The invention discloses a real-time monitoring method for growth characters of tea trees in intensive cultivation. The method comprises the following steps: performing real-time data acquisition by a tea tree living body growth character data acquisition device based on online location, transmitting the acquired data to an artificial comprehensive management center through a wireless communication way to process, wherein the acquired data comprises current location data acquired by a locating mechanism, fresh tea leaves spectrum data acquired by a high spectrum imaging sensor, and average growth height of fresh tea leaves measured by an ultrasonic wave sensor, and judging the best fresh tea leaf picking time based on that the data and a picking judgment model established off line are combined by the artificial comprehensive management center. The picking judgment model comprises a bud size growth measurement model based on average growth height, a yield correlation model and a quality correlation model based on the high spectrum image data. The real-time monitoring method for the growth characters of the tea trees in intensive cultivation is beneficial to realizing of intensive cultivation and automation in planting of the tea trees.

Owner:湖南星索尔航空科技有限公司

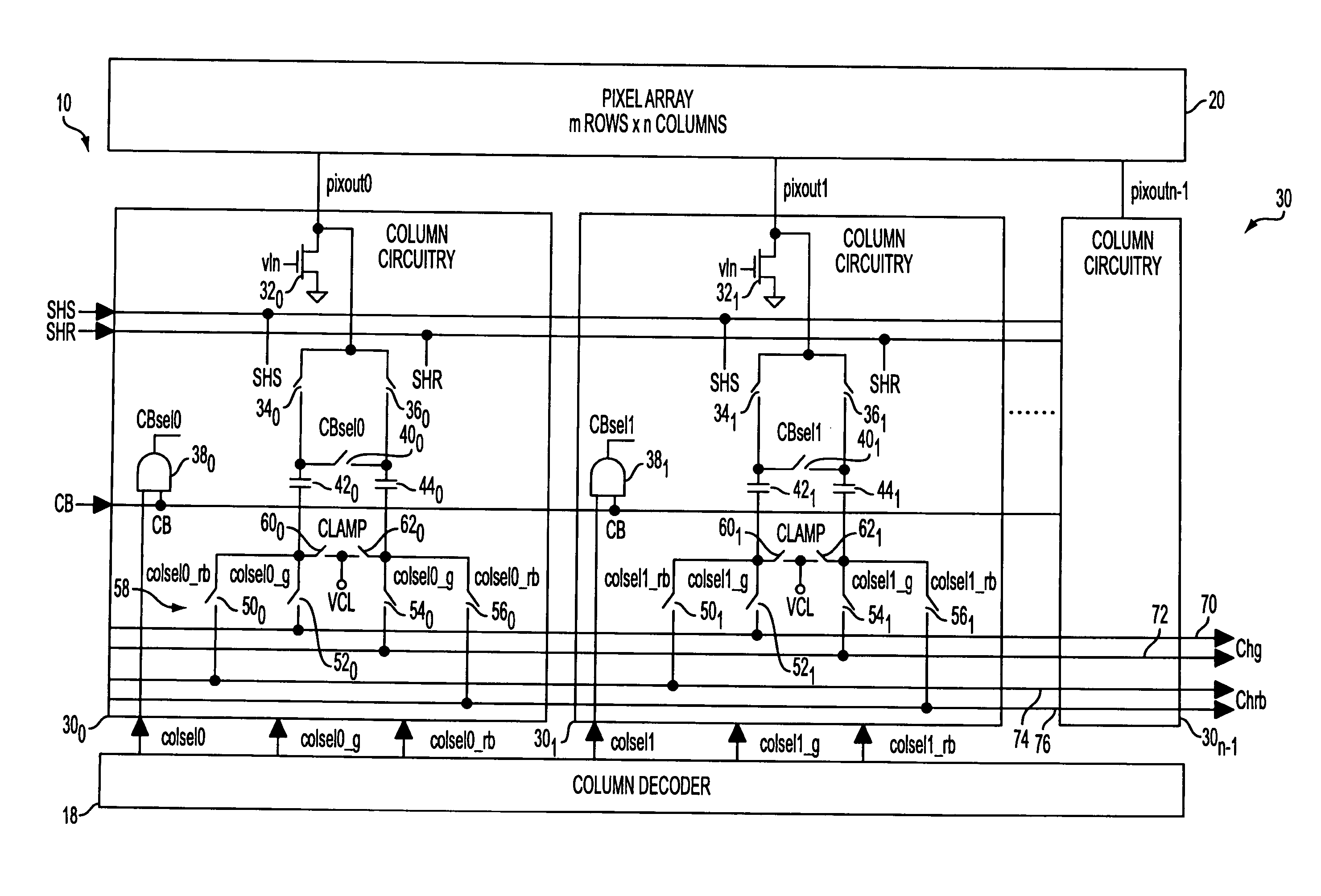

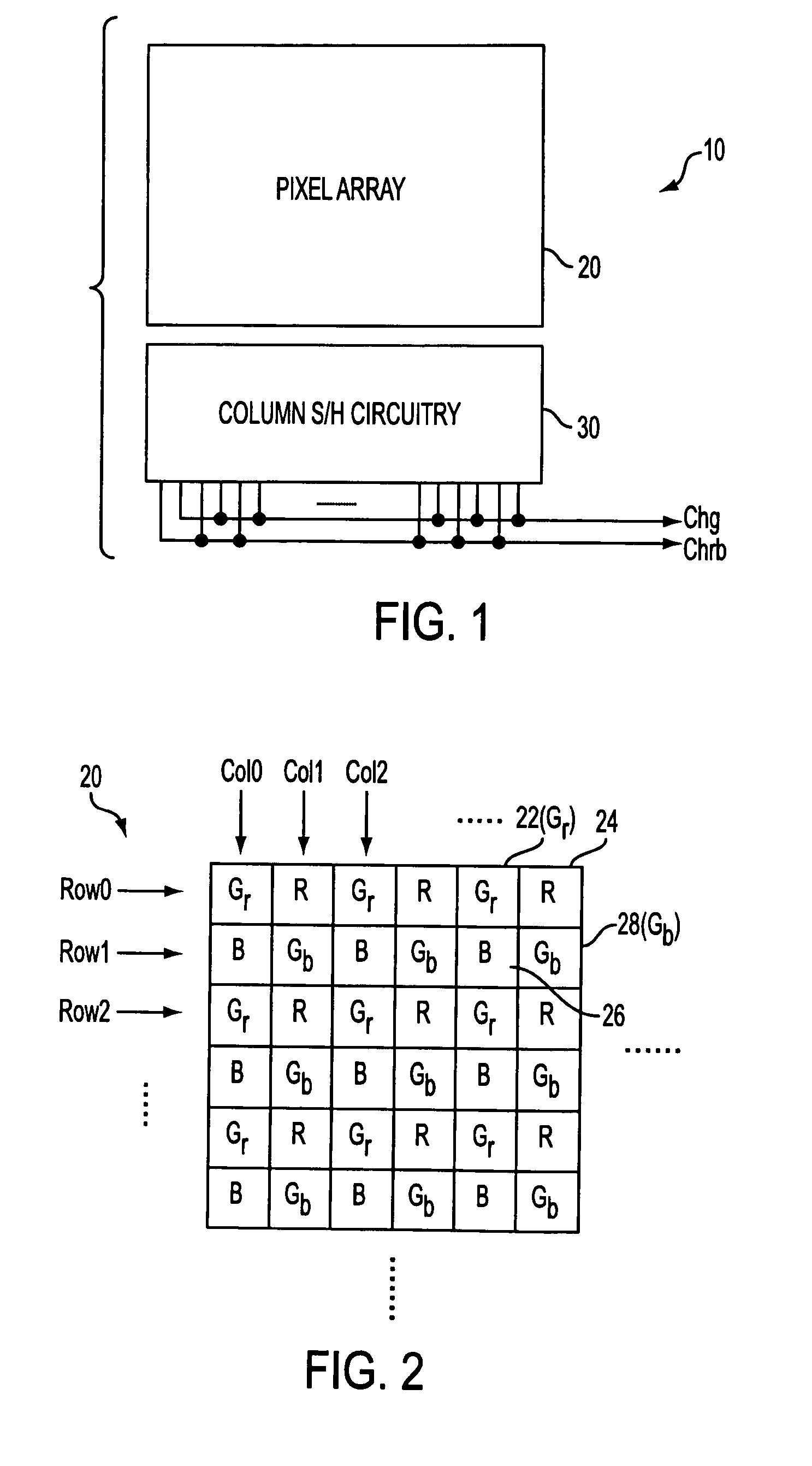

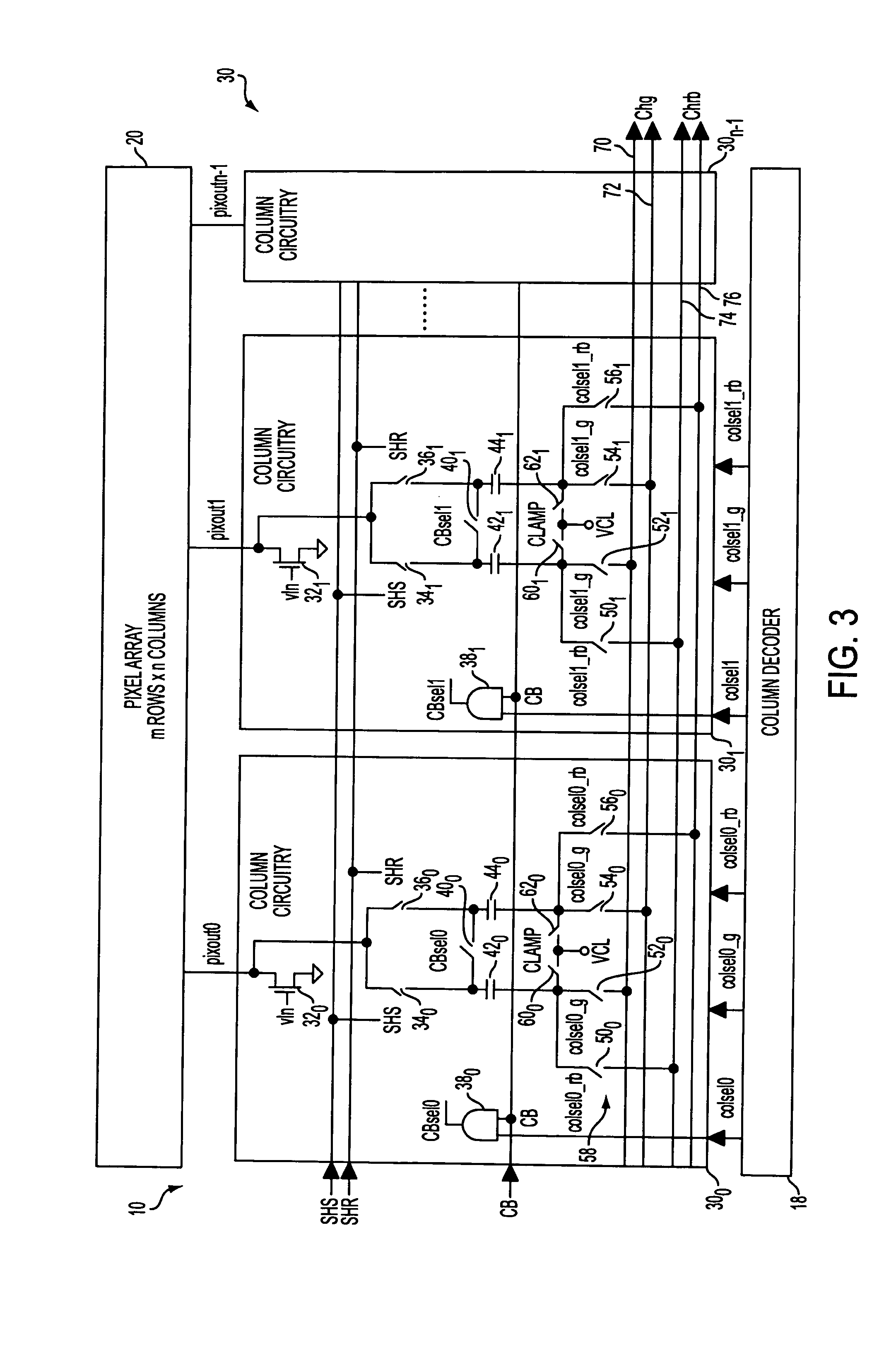

Multiplexed pixel column architecture for imagers

InactiveUS20050062866A1Faster readout speedLower readout noiseTelevision system detailsTelevision system scanning detailsMultiplexingMultiplexer

An imager with a multiplexer located at the pixel output line connected to associated column sample and hold circuitry. The multiplexer ensures that signals from pixels within a column are output to the correct output channels in the readout path. By having the multiplexer at the pixel output line, before any sample and hold circuitry, the imager can use simplified column select circuitry when signals are being read out to the output channels. As such, parasitic capacitance at the readout path is reduced, which produces faster readout speeds than typical imagers. In addition, the imager achieves lower readout noise and less power consumption than typical imagers.

Owner:MICRON TECH INC

Plant maca growing method in lower altitude areas

InactiveCN102884935AExpand the scope of plantingEasy plantingCultivating equipmentsSeed immunisationSocial benefitsGreenhouse

The invention discloses a plant maca growing method in lower altitude areas. The method comprises the steps of soaking seeds in warm water and sterilizing; growing seedlings in a greenhouse and then transplanting the seedlings to an exposed field for professional field management; and finally harvesting. The maca growing method disclosed by the invention has the advantages of simple steps, strong operability and high breeding budding rate and qualification rate. Through the improvement and the specification of each step of the growing method, the requirement of the maca on the planting altitude is reduced from 3500-4000m of a source area to 2600-3600m, so that the planting range of the maca is greatly increased, and a whole set of effective planting method is provided; thus, the maca is convenient to spread and plant in suitable areas and the industrial development of the maca is accelerated, so that more people can enjoy the maca and good economic and social benefits are obtained.

Owner:KUNMING DIANRAN BIOLOGICAL TECH

Hybrid vehicle and control method of hybrid vehicle

ActiveUS7677341B2Stable outputAvoid discomfortHybrid vehiclesInternal combustion piston enginesEngineeringHybrid vehicle

When the driver heavily depresses an accelerator pedal to start a hybrid vehicle in an engine stop condition, the control of the invention waits until elapse of a preset wait time and then starts outputting a torque equivalent to a preset torque demand to a ring gear shaft or a driveshaft. The preset wait time is determined not to make the driver feel uncomfortable with a poor response. This arrangement desirably shortens a time period when the vehicle acceleration is restricted due to insufficient power output until the engine starts to output sufficient power and make significant contribution to the vehicle acceleration. The control of the invention thus desirably prevents the driver from feeling the unexpectedly slow acceleration.

Owner:TOYOTA JIDOSHA KK

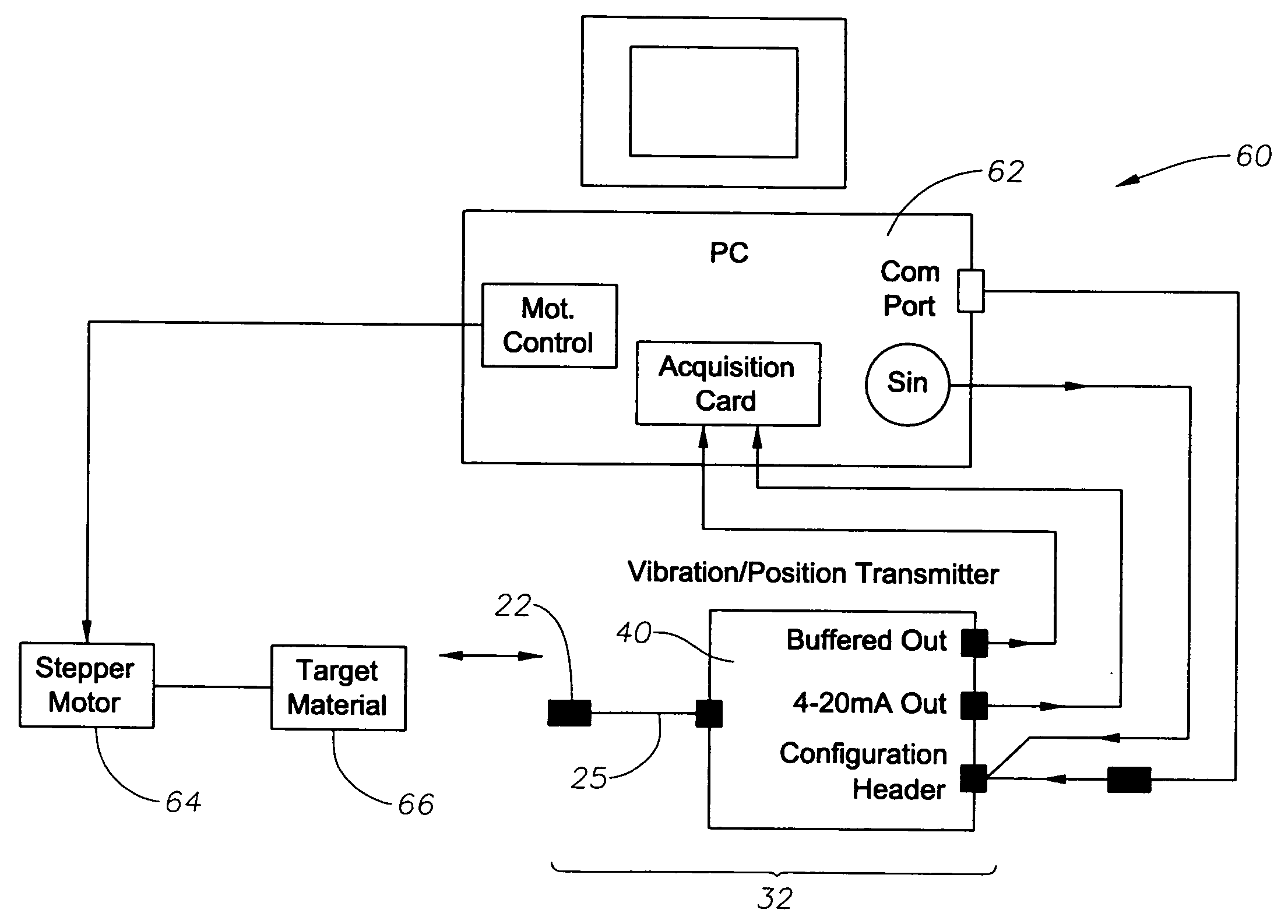

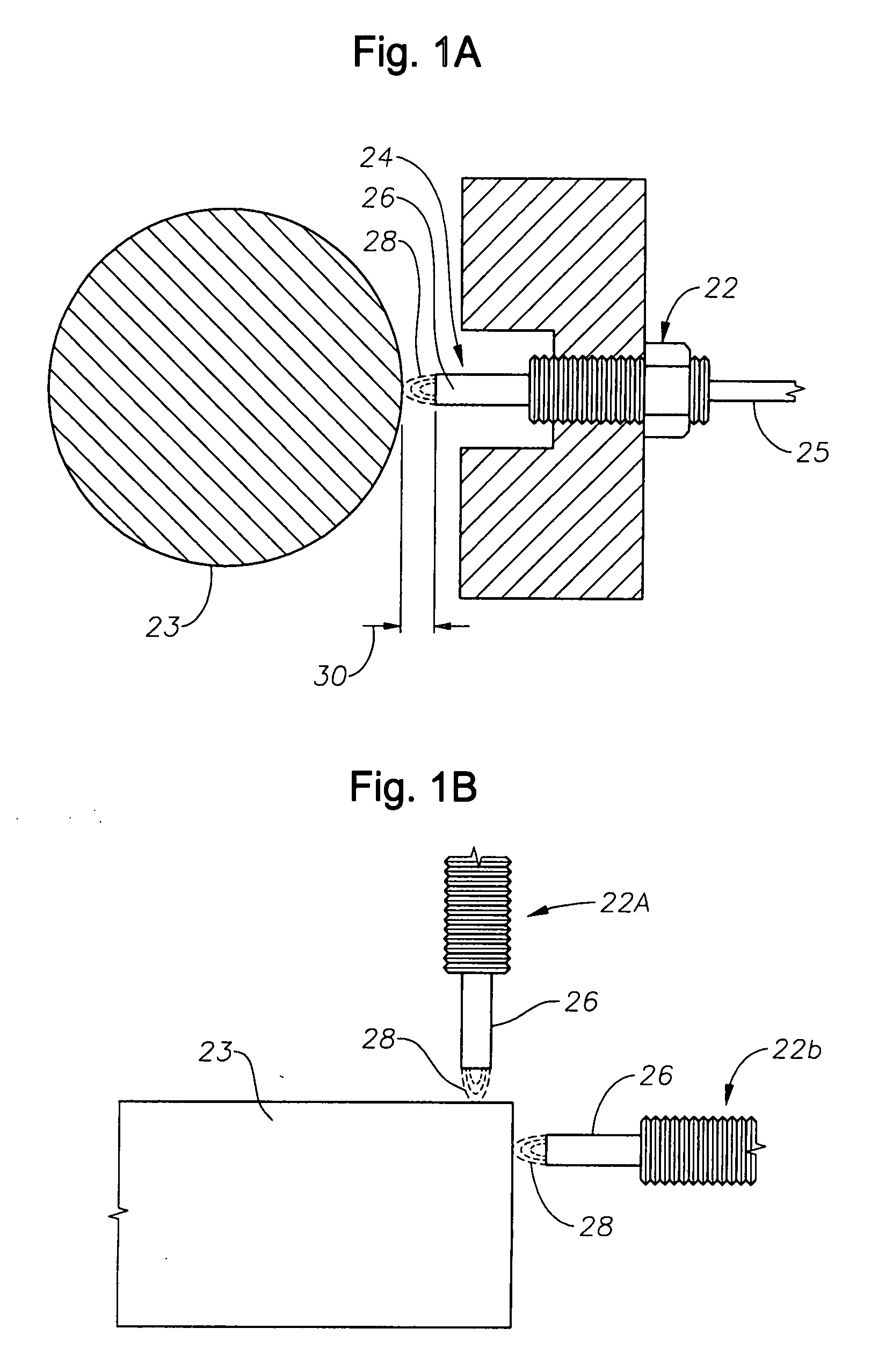

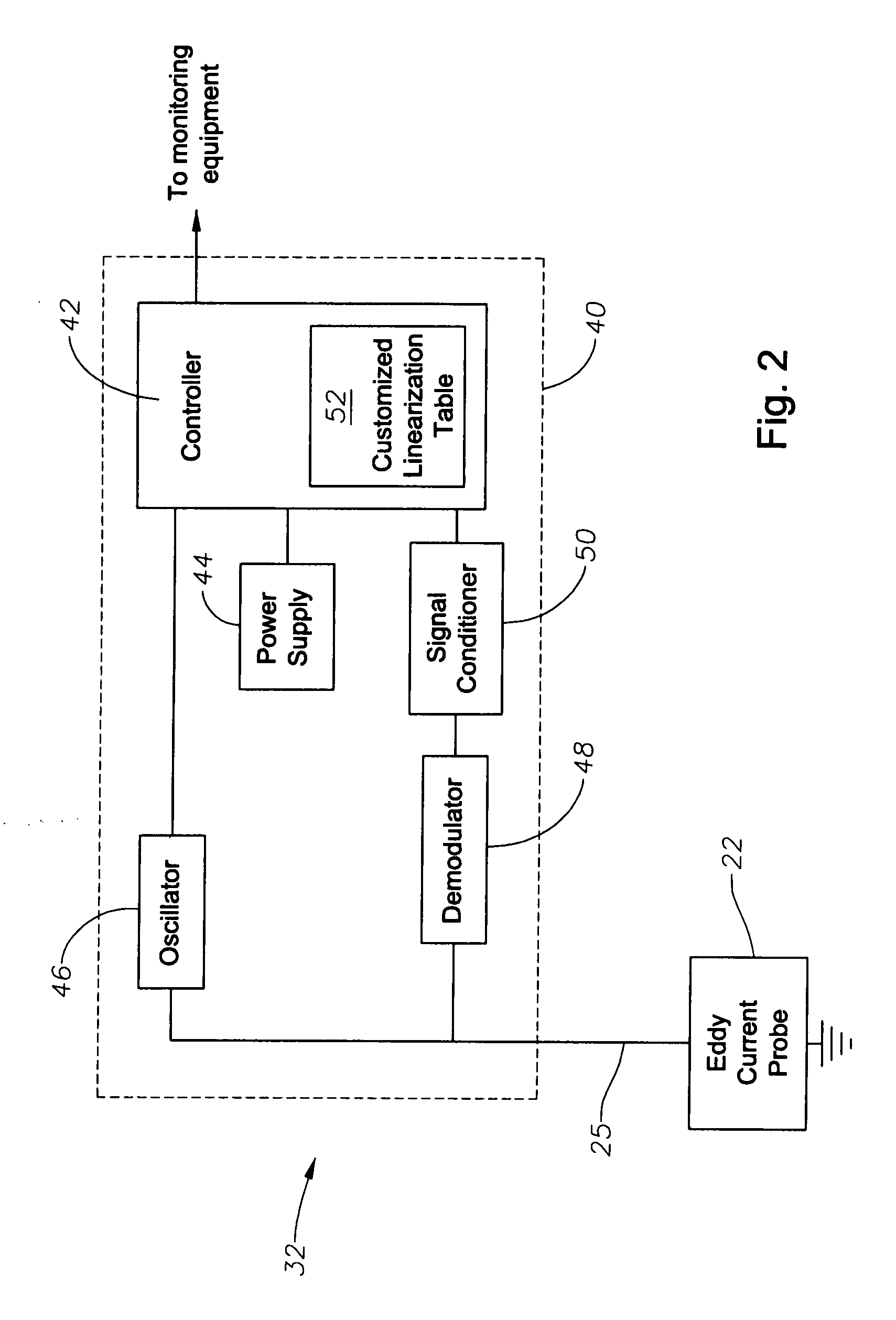

Proximity probe transmitter

ActiveUS20080054891A1Eliminate power consumptionEliminate needVibration measurement in solidsUsing electrical meansCoaxial cableImpedance properties

A digital based two wire proximity transmitter system and a method for calibrating the system, wherein the transmitter includes a customized linearization table uniquely generated during calibration to take into account the unique impedance properties of a particular probe / coaxial cable configuration. During calibration, the probe is positioned adjacent a calibration target. The calibration target is selected to have the same material characteristics as the target to be monitored during actual operation of the transmitter in the field. At a fixed distance between the probe and calibration target, the resonant frequency of the probe / cable system is determined. Thereafter, utilizing this resonant frequency to excite the probe, the voltage response of the probe / cable system is determined as the distance between the probe and the target material is incrementally changed. The voltage output is used to build a table for incremental distances, wherein each distance is characterized by a non-linear output that has been equated to a linear output. This uniquely generated table is subsequently downloaded into the transmitter for reference during monitoring.

Owner:METRIX INSTR

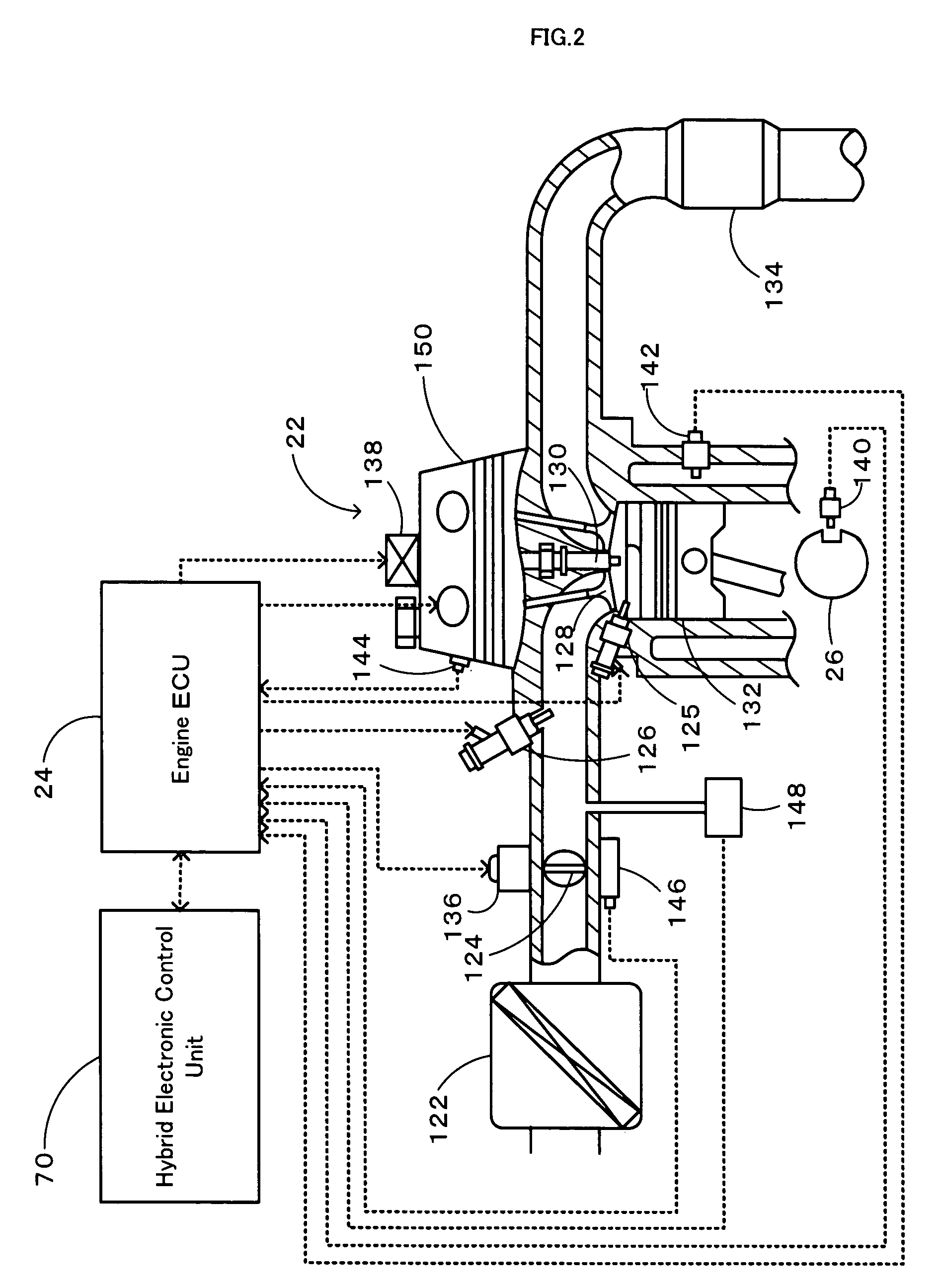

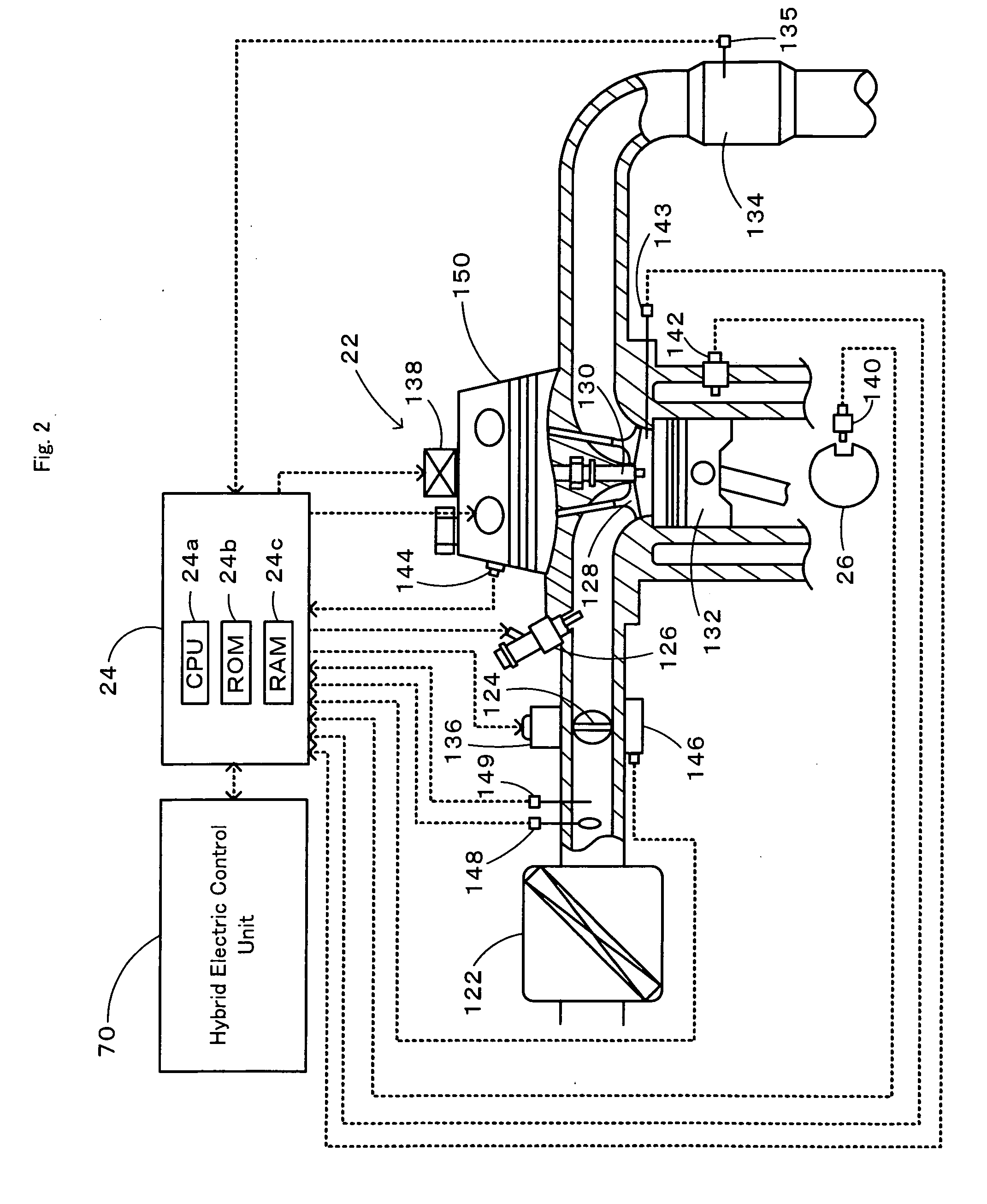

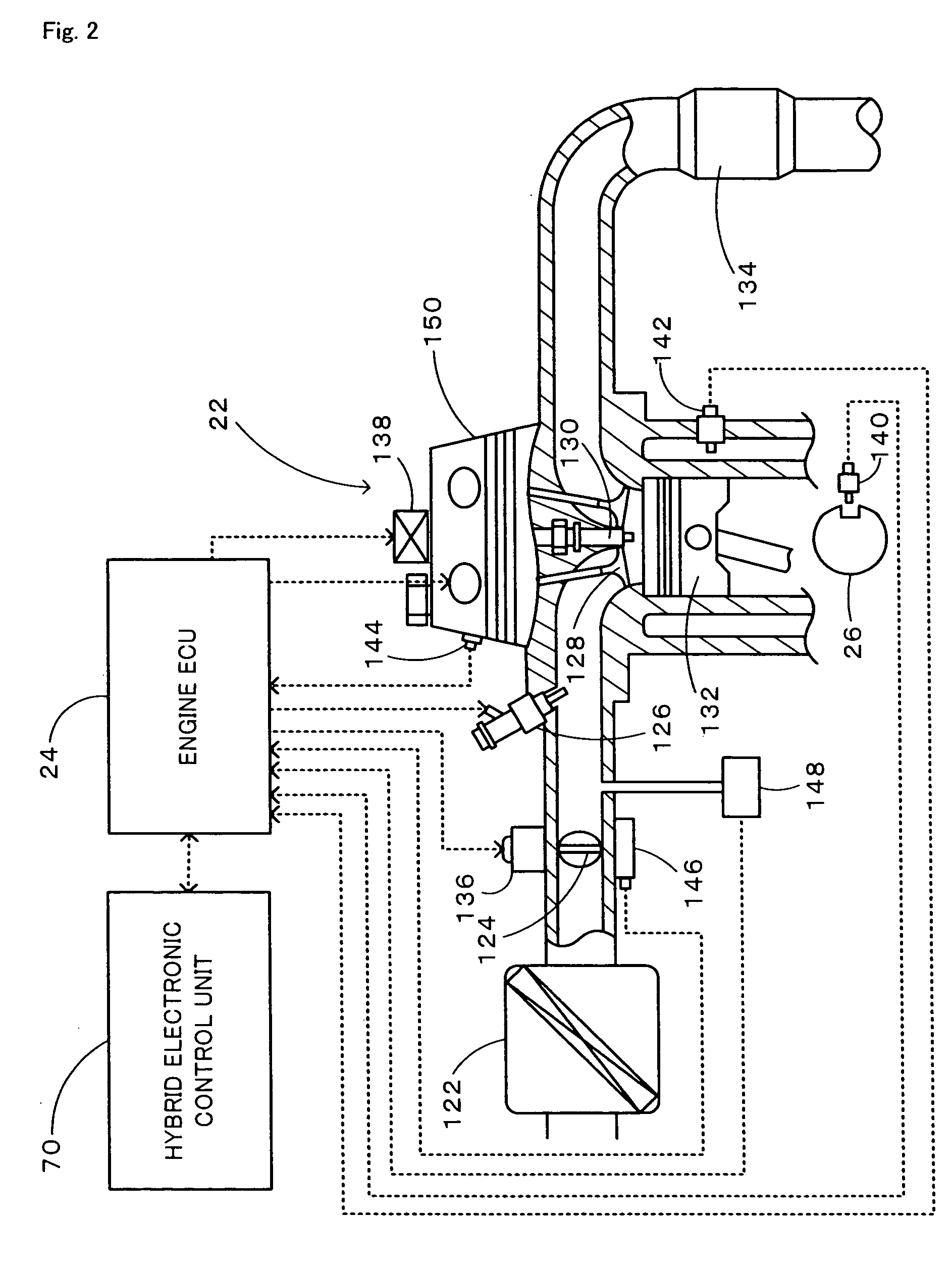

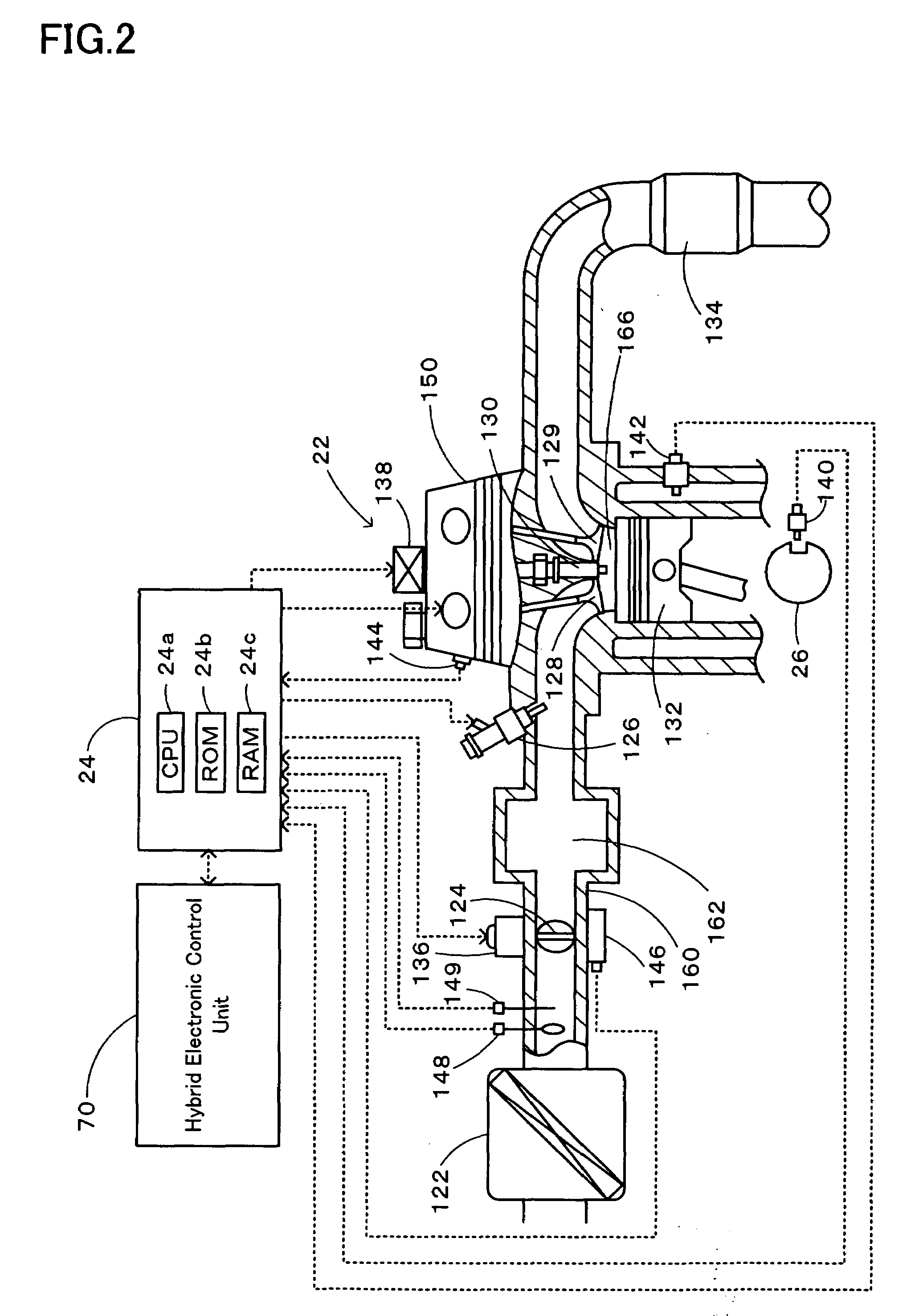

Power output apparatus, vehicle equipped with power output apparatus, and control method of power output apparatus

InactiveUS20090256513A1Reducing potential torque shock torqueReducing torque torque shock-induced vibrationInternal combustion piston enginesElectric ignition installationIgnition timingControl theory

A hybrid electronic control unit sends a combustion start command to an engine ECU when the rotation speed of an engine reaches a combustion start rotation speed by engine cranking. The engine ECU sends an initial explosion advance notification to the hybrid electronic control unit when the crank position of the engine reaches a specific position prior to an ignition timing of an initial explosion cylinder by a preset crank angle θec. Ignition of the initial explosion cylinder is performed at a timing when the crank position is further rotated by the preset crank angle θec. The hybrid electronic control unit sends a torque command in view of a counter torque Tα to a motor ECU after elapse of a preset time period tv. The preset time period tv is the sum of a first time period t1 between reception of the initial explosion advance notification and the ignition timing of the initial explosion cylinder in the engine and a second time period t2 between the ignition timing of the initial explosion cylinder in the engine and appearance of torque effect caused by the ignition of the initial explosion cylinder on a driveshaft. Such control timely reduces the torque effect caused by the initial explosion of the engine on the driveshaft.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com