Low-temperature coal carbonization kiln

A technology of coal dry distillation and low temperature, which is applied in the field of dry distillation furnaces, can solve the problems of affecting product output and quality, affecting the service life of the furnace, and difficult temperature control, etc., and achieves the effect of convenient regulation, easy operation, and uniform discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

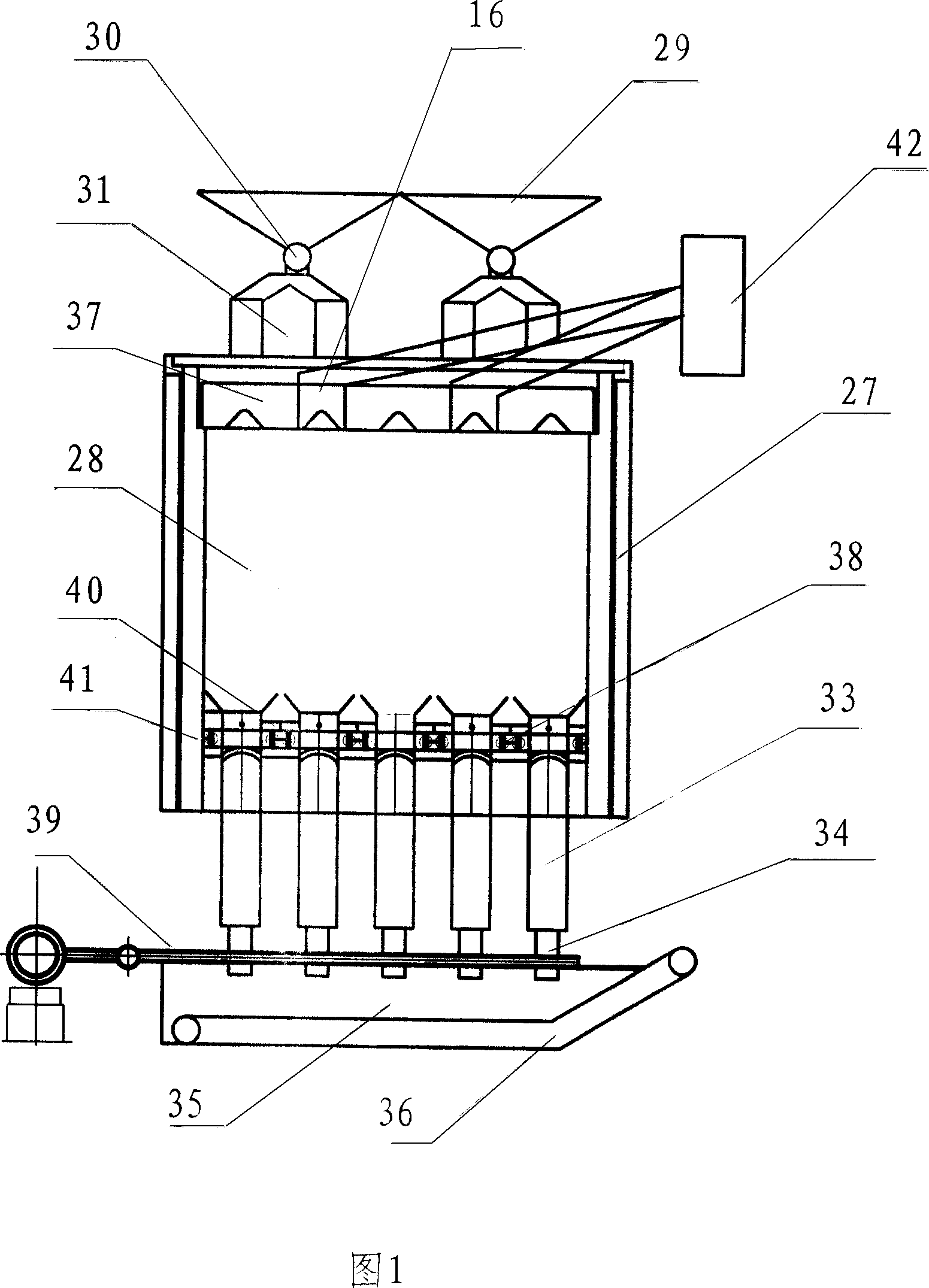

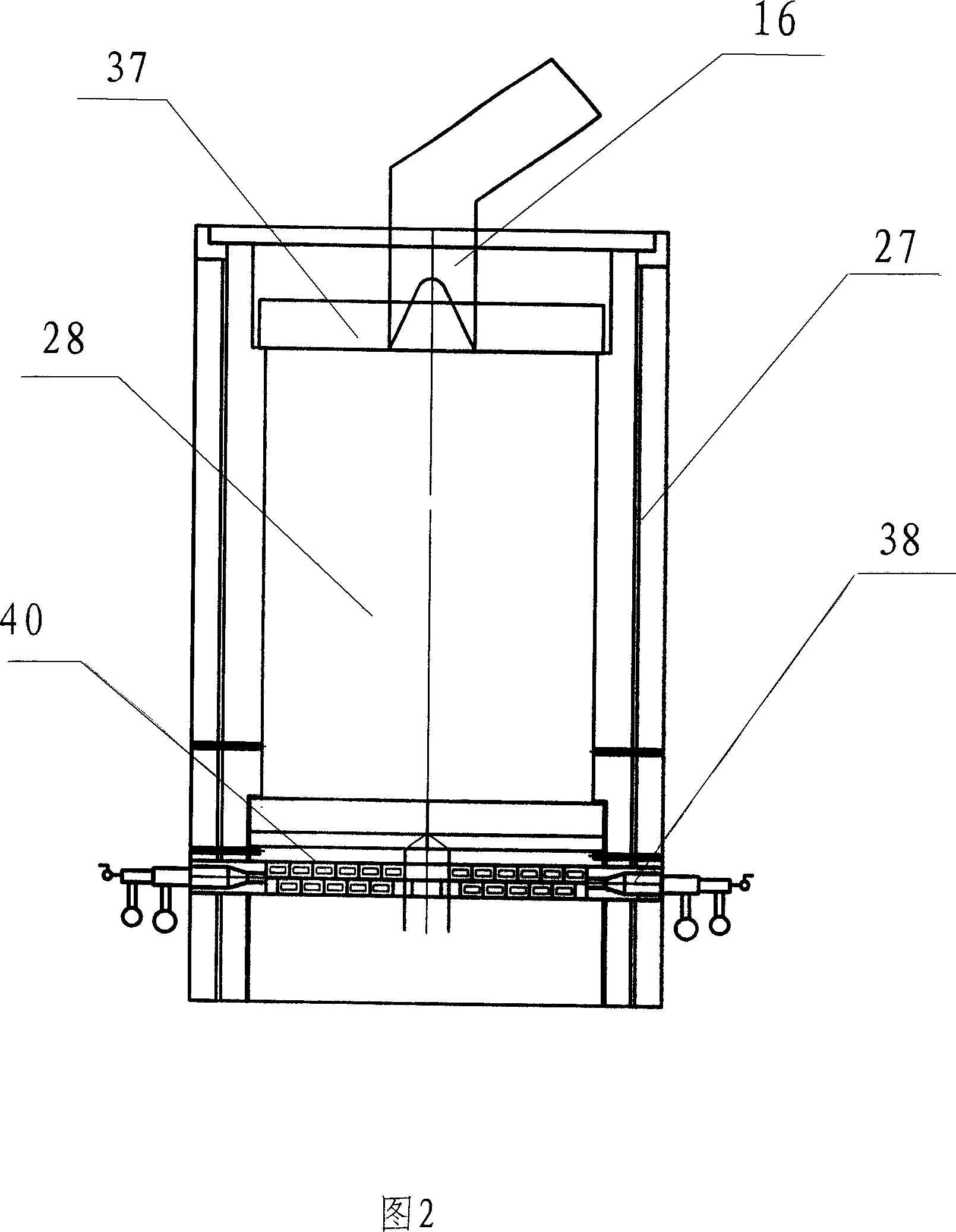

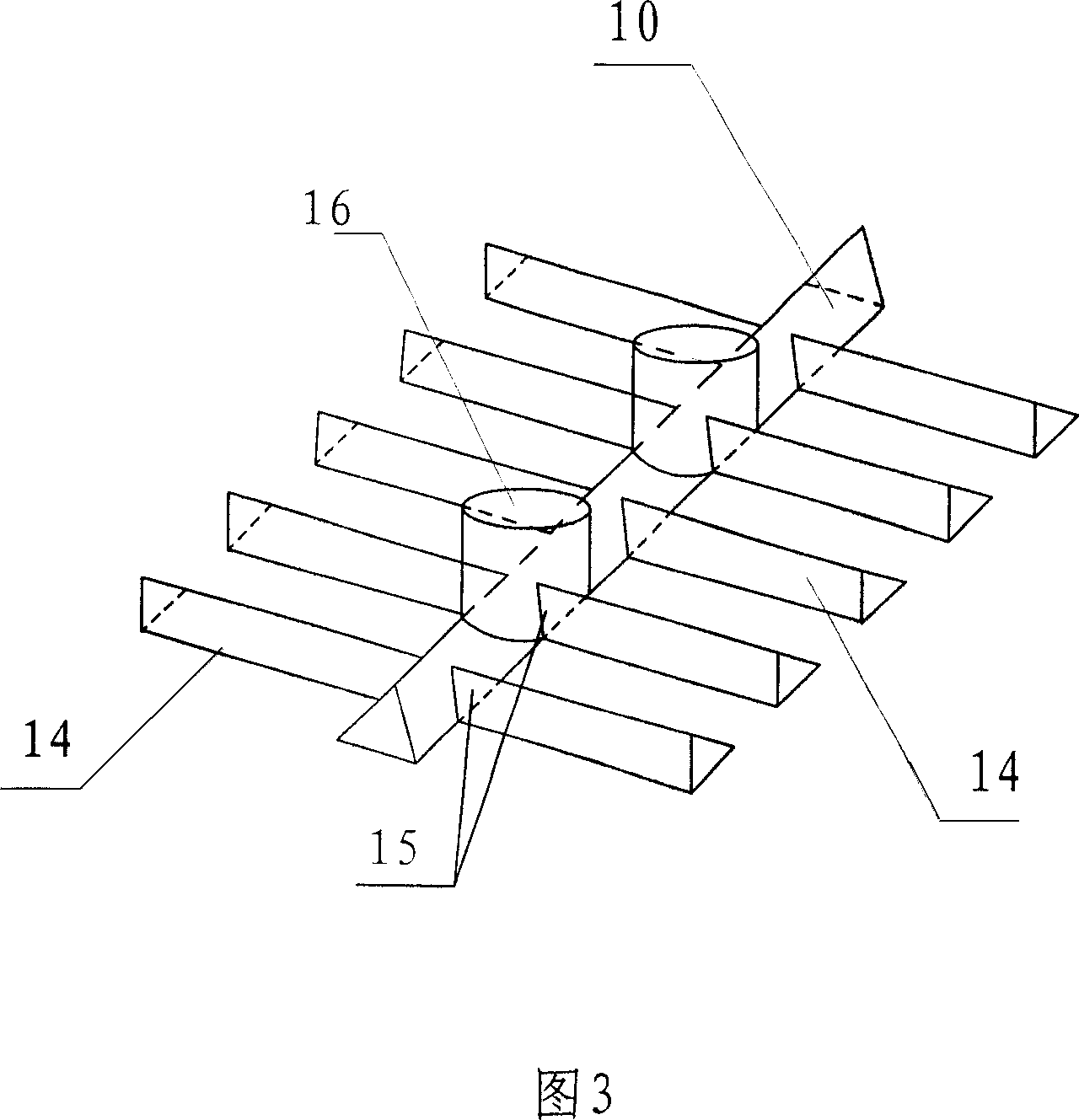

[0020] As shown in Figures 1 and 2, a low-temperature coal dry distillation square furnace includes a furnace body 27, a coal hopper 29, a coke pusher 39, and a branch pipe mixer 38, wherein a gas-collecting array umbrella 37 is installed on the top of the furnace chamber 28 The air-collecting array umbrella 37 comprises a main umbrella 10, an auxiliary umbrella 14, and a rising pipe 16, and there are 10 auxiliary umbrellas 14, which are symmetrically connected to both sides of the main umbrella 10. The parachute channel 15 is convenient to collect the raw gas collected by the parachute 14 into the main parachute 10; the top of the main parachute 10 is communicated with two ascending pipes 16, and the ascending pipes 16 extend out of the furnace cavity and are connected with the bridge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com