Patents

Literature

325results about How to "Uniform cloth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

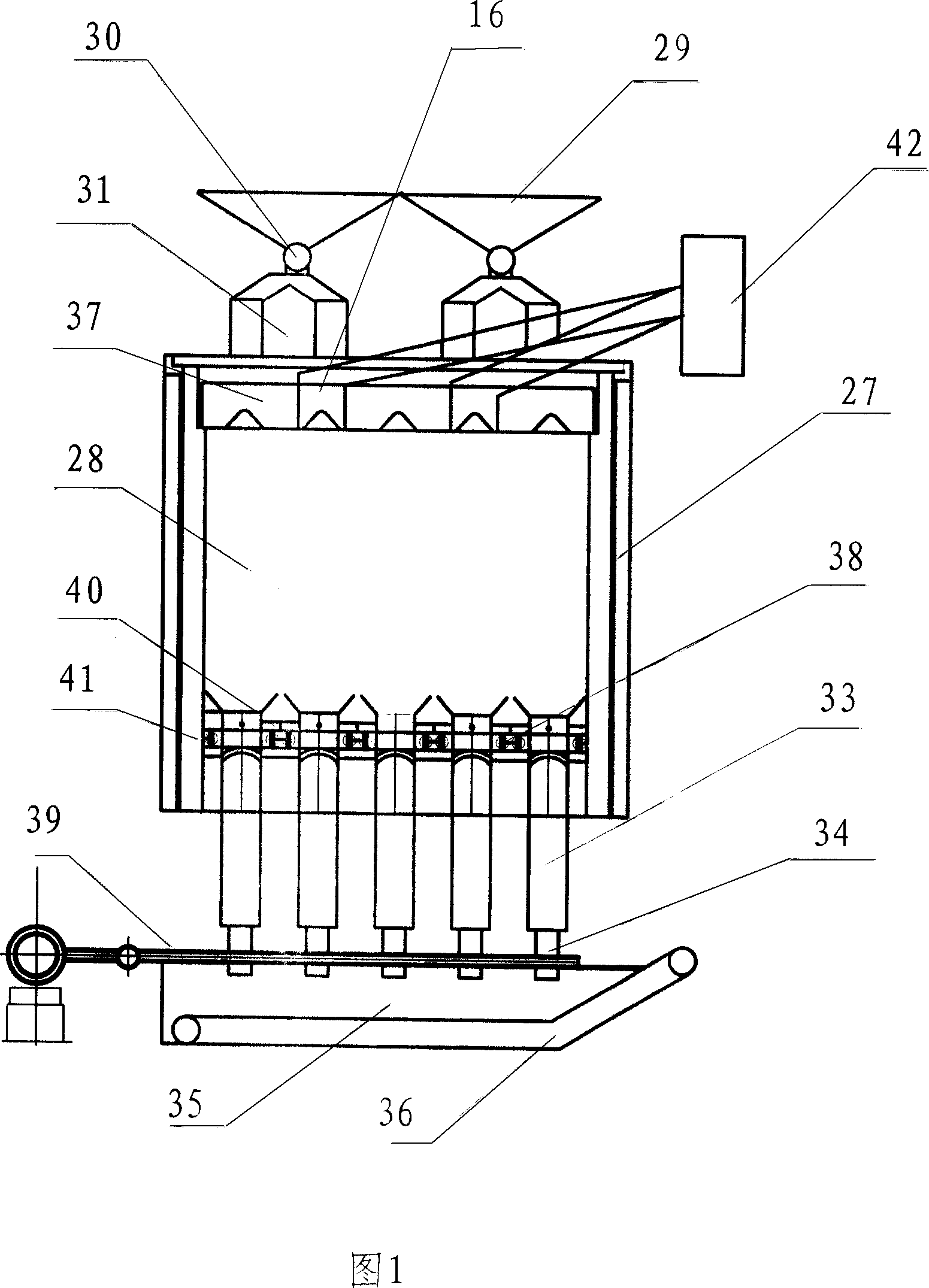

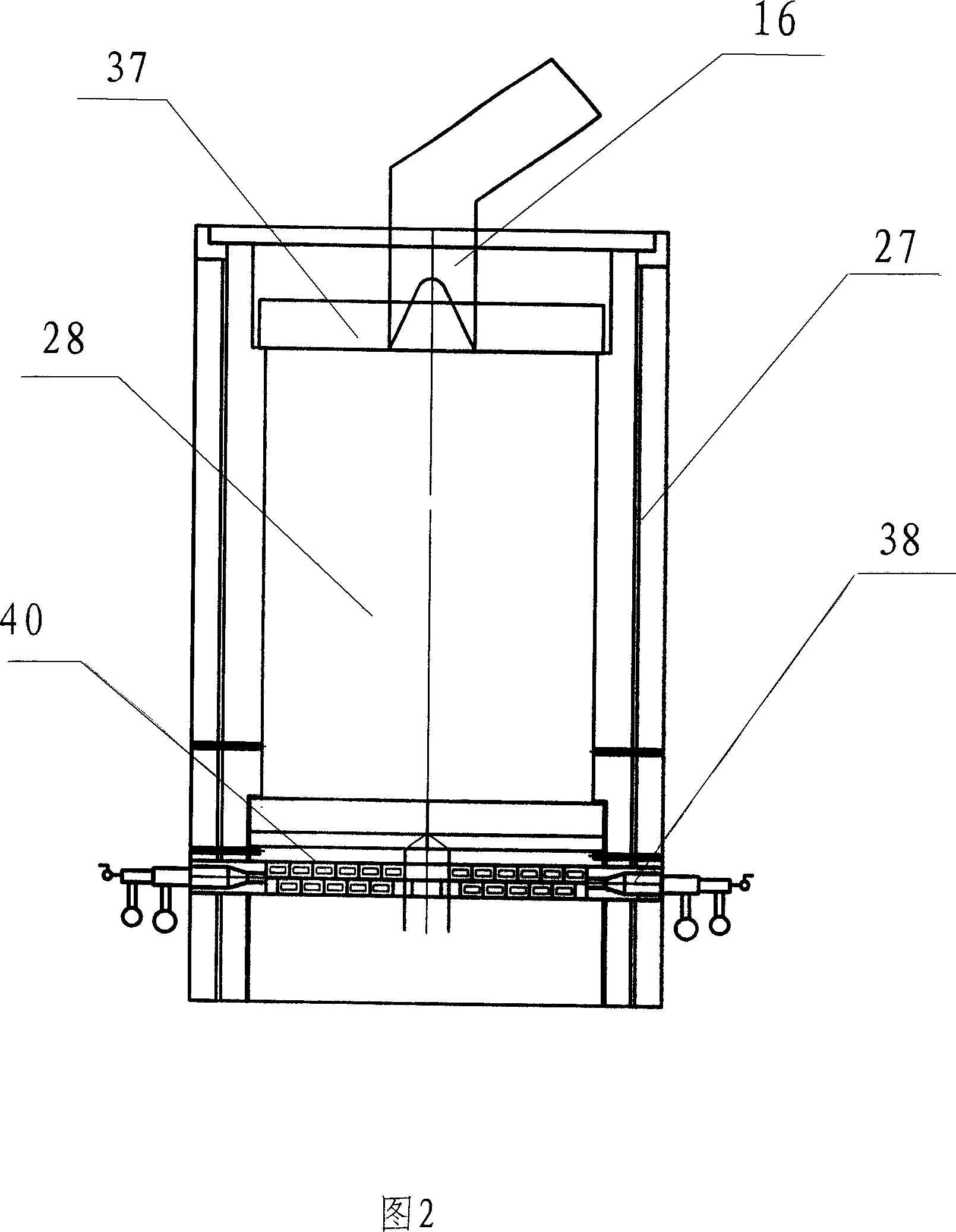

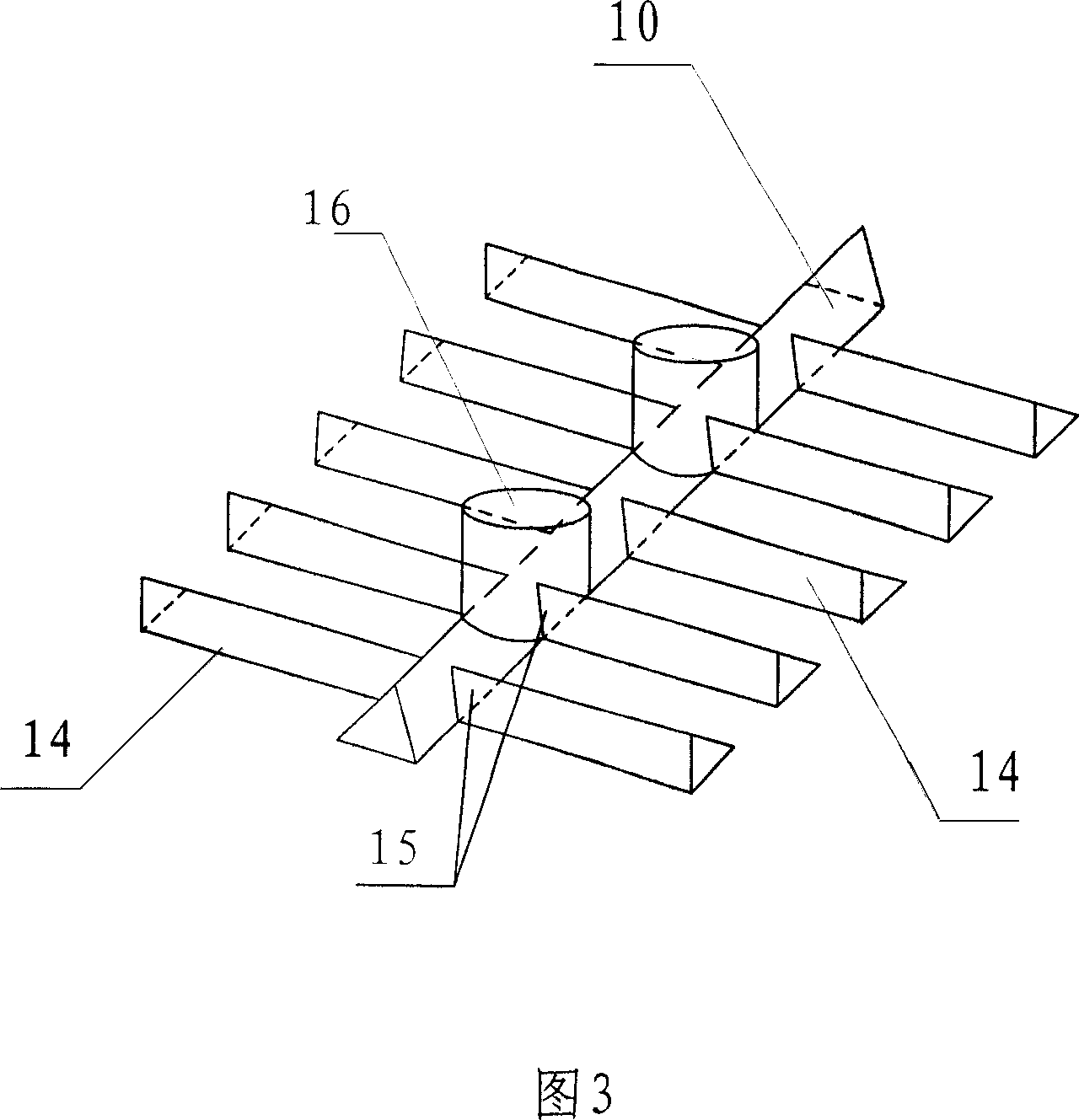

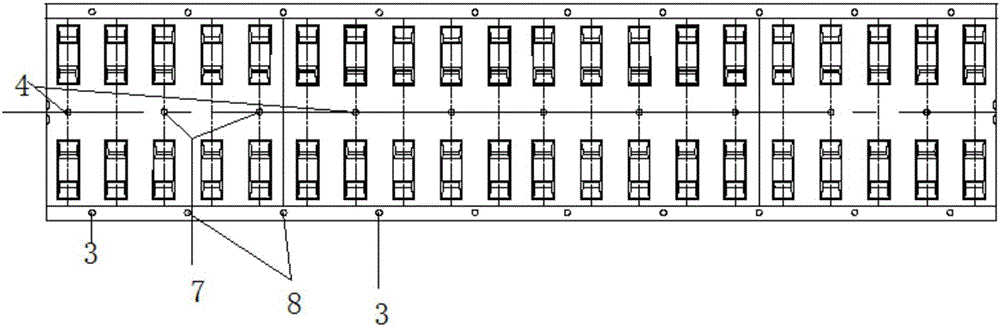

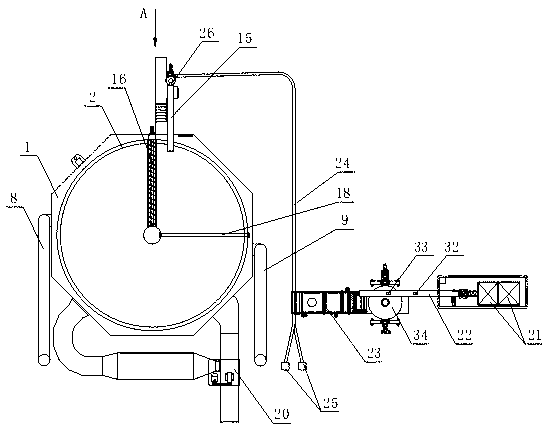

Low-temperature coal carbonization kiln

ActiveCN1966609AIncrease effective volumeHigh yieldRetortsDischarging devicesAutomatic controlCarbonization

The invention disclosed a kind of low temperature coal dry distillating square stove which includes stove body, coal cup, dant-pushing machine and branch admixer. On the top of the hearth there is installed the gas collecting umbrella, inside the stove it is cavity structure; on the bottom of the cavity there are installed several rows of emitting gas walls, every row of emitting gas wall is parallel to the interval between two side umbrella of the gas collecting umbrella; the consecutive emitting gas walls are pedestalled by arch wall; on both sides of the emitting gas walls there are two branch admixer respectively; the bottom of the stove connects the dant discharging box, the bottom of which connects the dant leading slot; the bottom of the dant leading slot is dant-pushing machine, the bottom of which is aqua sealing slot, in the slot there is scraper machine. The invention adopts the heating scheme of endo-burnning and calor internus which can heat uniformly. The gas collecting umbrella and accessory coalbox can make the material and gas-collecting uniformly while the dant-pushing machine can make the product uniform. The advantage of the invention: it can bring into full play of the producing ability and decrease the investment as well as increase the benefits; besides, it is easy to operate, it needs less people and can be controlled automatically.

Owner:SHAANXI SHENMU SAN JIANG COAL CHEM

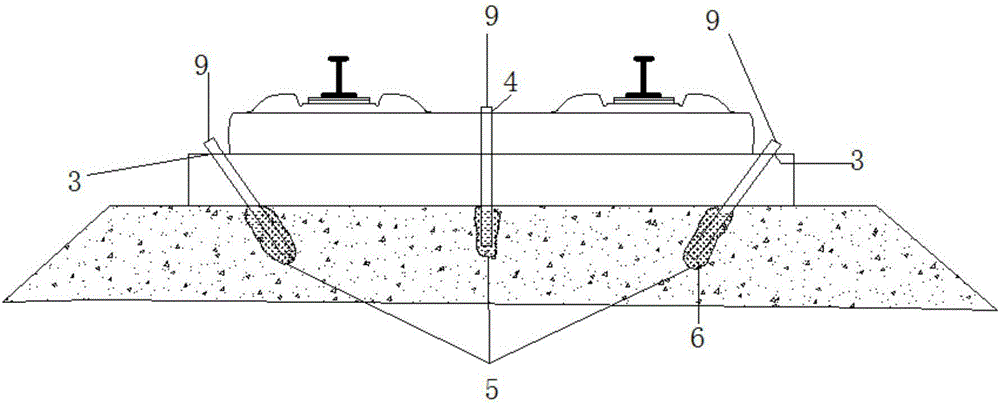

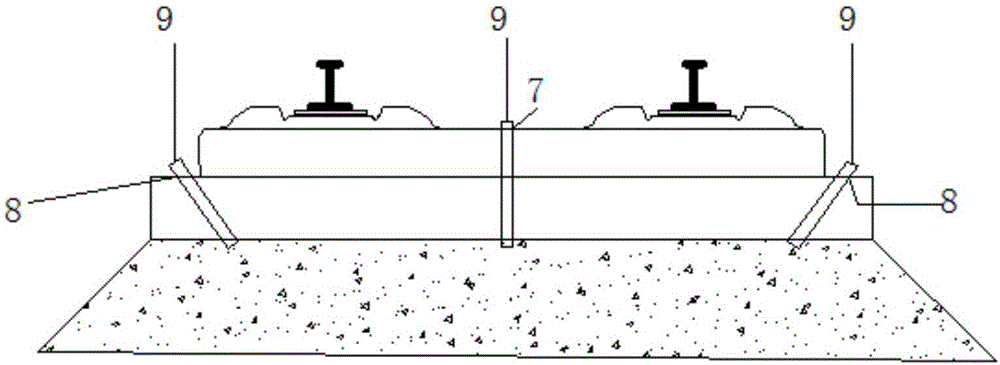

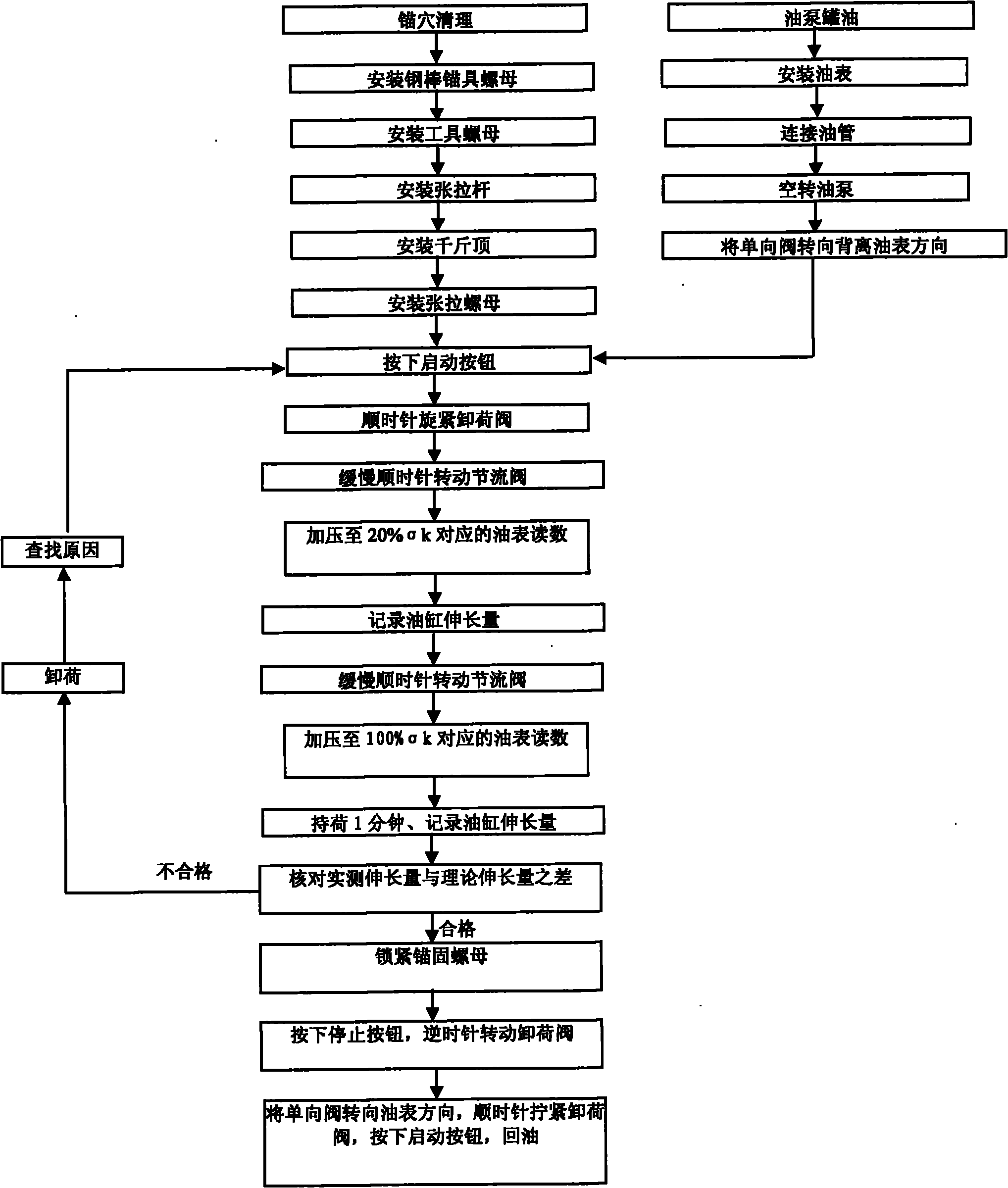

Ballastless track grouting lifting and lifting correcting method

InactiveCN106758591AFast constructionPractical and reliableRailway track constructionEngineeringHigh polymer

The invention discloses a ballastless track grouting lifting and lifting correcting method. The method comprises the following steps: step 1: before lifting, using a high-precision level gauge to measure the track surface and under-track empty area, according to the measuring result, determining the lifting position and lifting quantity of a track board, and determining the arrangement position, space distance, hole diameter and hole depth of a grouting hole; step 2: calculating and determining the cutting position of a closing layer, and cutting the closing layer; step 3: arranging the grouting holes in the position to be lifted, preparing a polymer bag and arranging holes in the polymer bag; step 4: inserting a grouting pipe into the polymer bag, and fixing; step 5: installing the grouting pipe and the polymer bag in the grouting hole; step 6: executing the grouting lifting, monitoring in real time during the lifting process, and guaranteeing the track lifting elevation; and step 7: after executing certain amount of the grouting lifting, correcting the part to be corrected, monitoring the correcting process in real time, and guaranteeing the correcting displacement of the track. After completing the grouting, the high polymer bag and a grouting material carry out the compaction with the surrounding soil so as to form a self-formation pile. The solution is capable of realizing the rapid and accurate lifting of the upper structure of the track.

Owner:BEIJING RUIWEI TIEKE HIGH SPEED RAIL ENG CO LTD

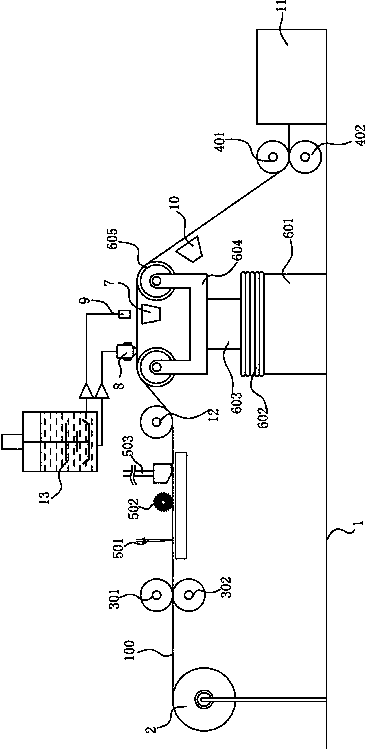

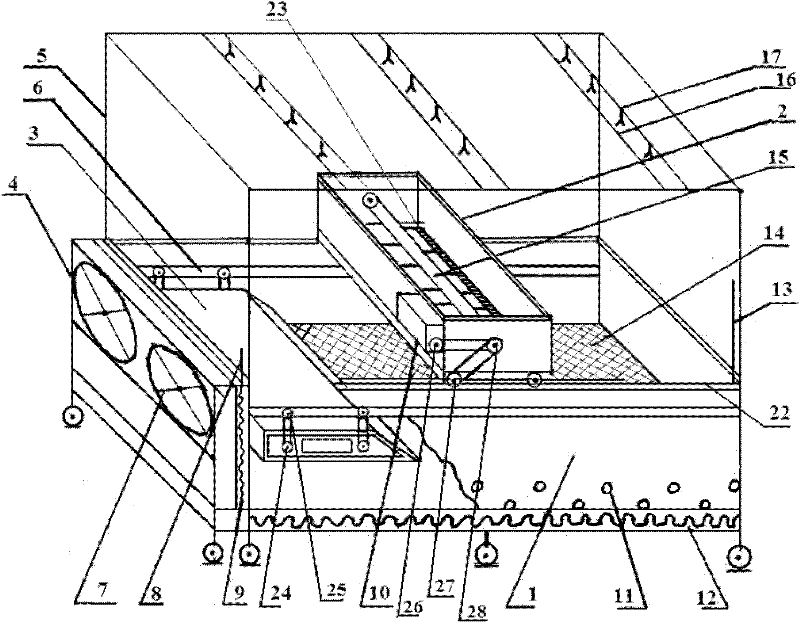

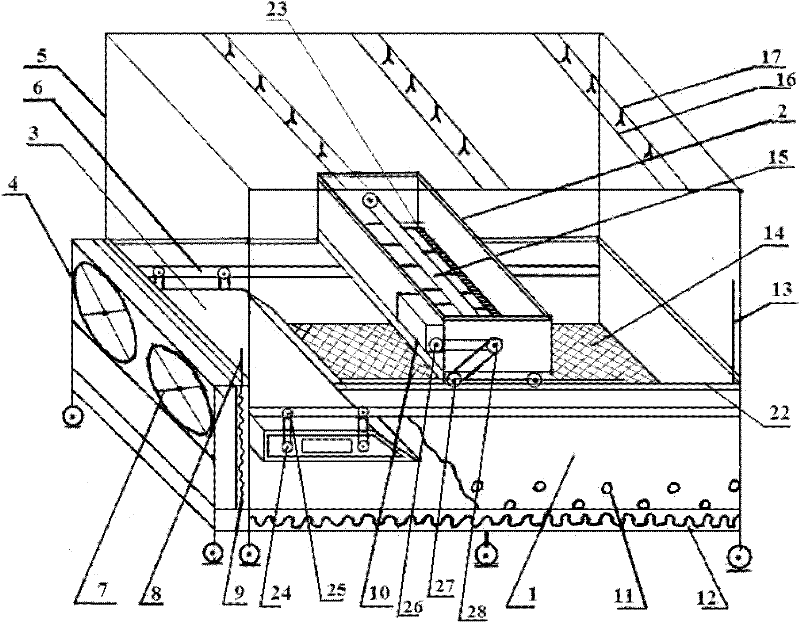

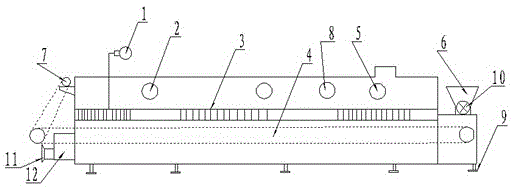

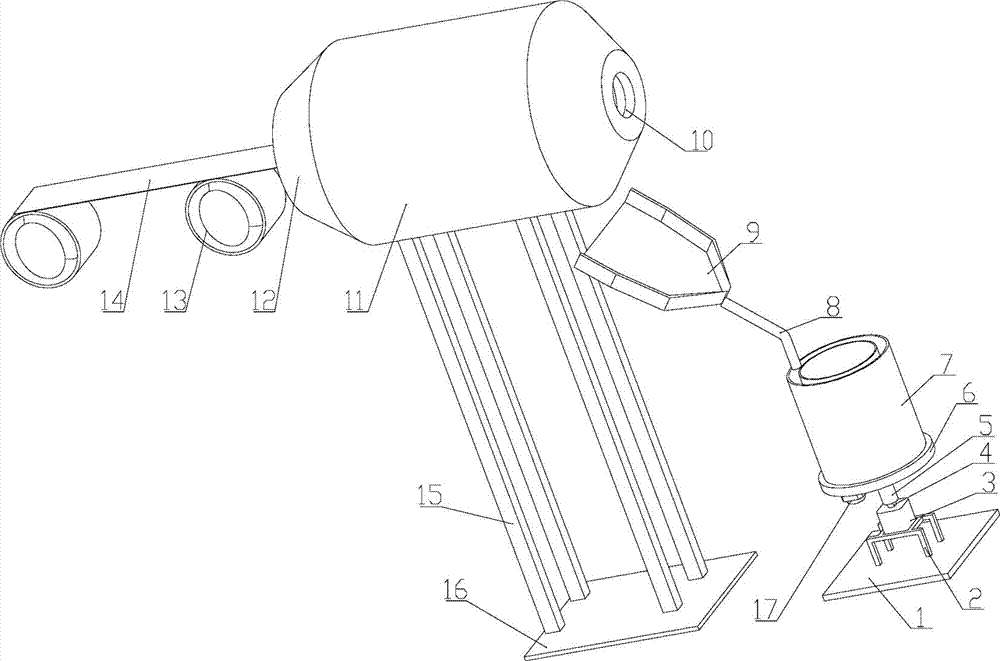

Graphene coating aluminum foil coating machine

ActiveCN105944920AUniform coatingClose contactLiquid surface applicatorsCoatingsGraphene coatingEngineering

The invention relates to a graphene coating aluminum foil coating machine. The machine comprises a base, and an aluminum foil coil, a front tension mechanism, a dust removing mechanism, a transmission mechanism, a vibration mechanism, a coating mechanism, a heating mechanism, a spraying mechanism, a drying mechanism, a back tension mechanism and a storage device arranged on the base; the dust removing mechanism, the transmission mechanism, the coating mechanism and the spraying mechanism are arranged rightly above the section of aluminum foil basal plate in a walking direction of the aluminum foil basal plate; the vibration mechanism and the heating mechanism are arranged below the section of aluminum foil basal plate; the vibration mechanism is perpendicular and corresponding to the coating mechanism and the spraying mechanism; and the heating mechanism is perpendicular and corresponding to the spraying mechanism. The machine is uniform in obtained product coatings, tight in contact with aluminum foil substrates, stable in performance, high in continuity of whole coating process and high in machining efficiency.

Owner:FOSHAN SINO SCI NANO TECH MATERIAL CO LTD

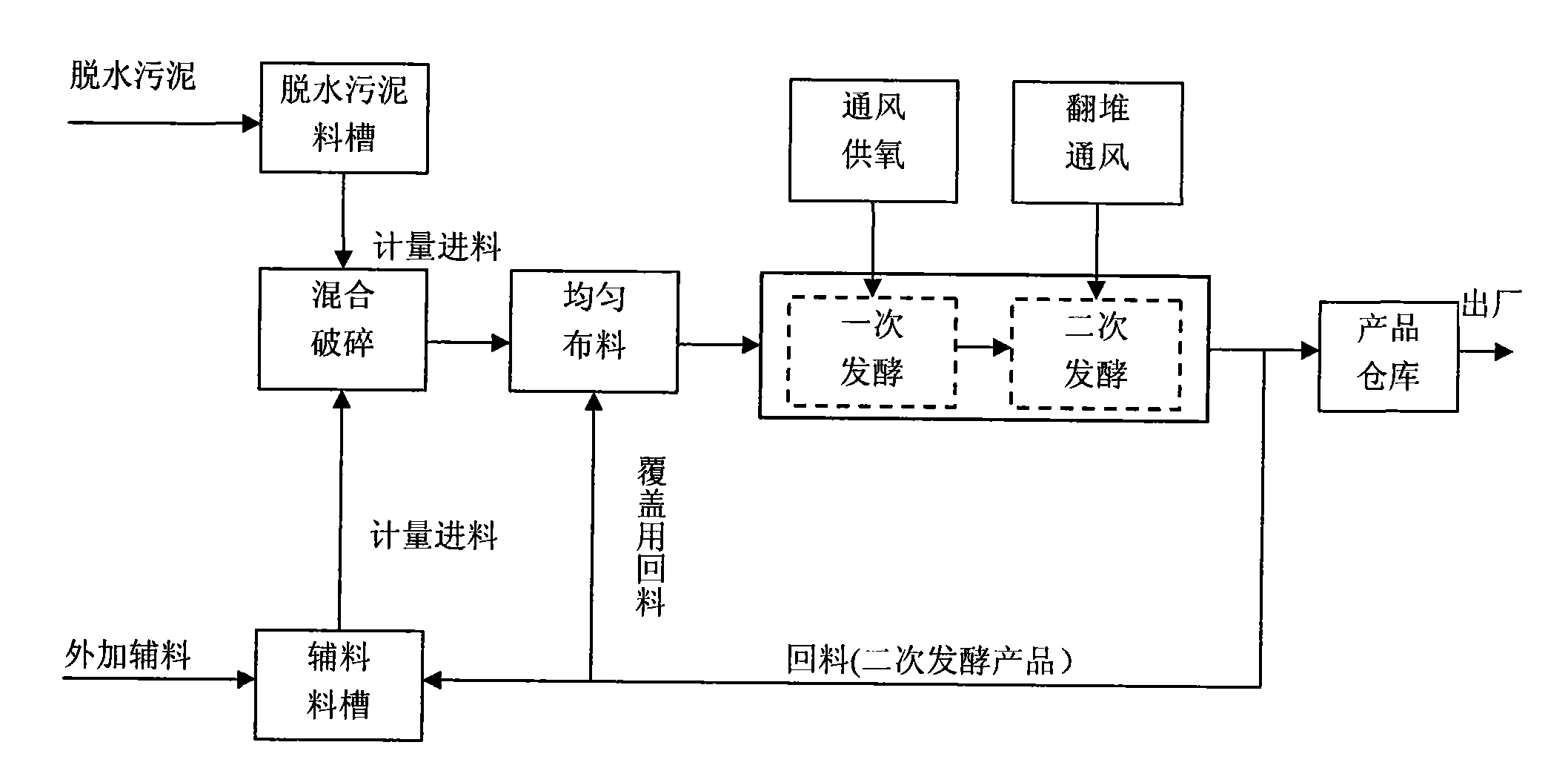

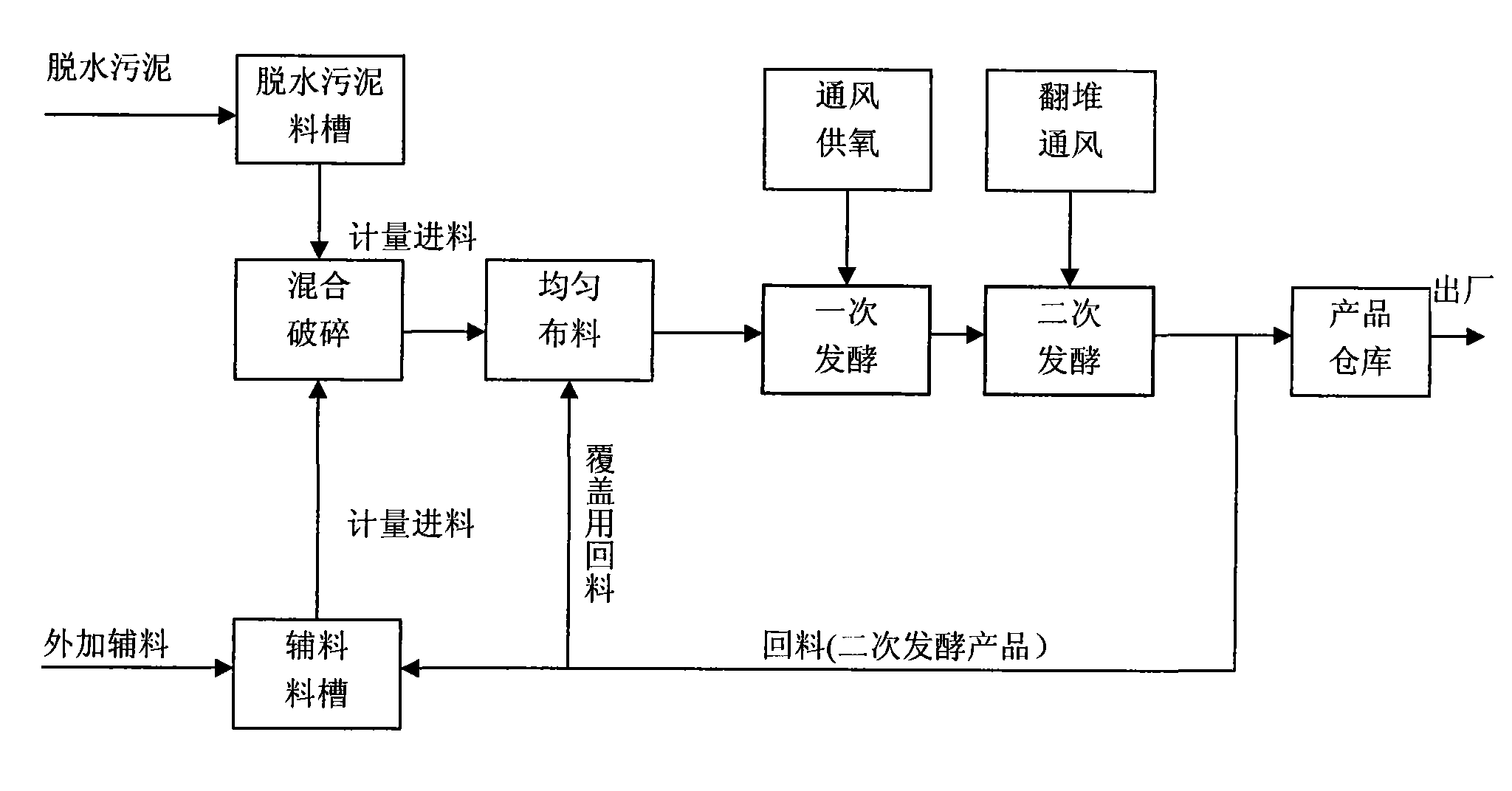

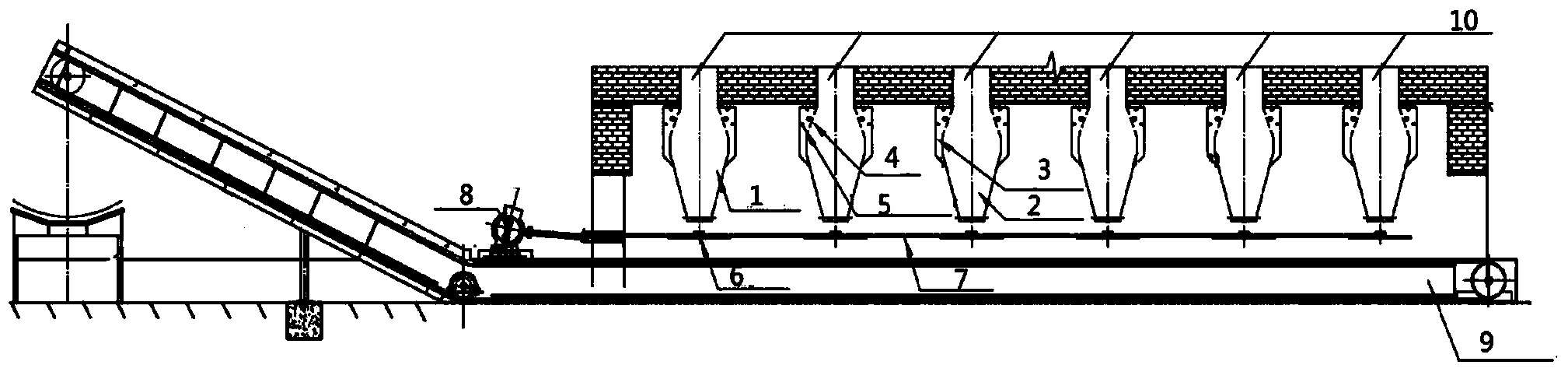

High-temperature aerobic fermentation process for sludge with low energy consumption and no pollution

InactiveCN101618977AAvoid pollutionPromote fermentationBio-organic fraction processingClimate change adaptationReduction treatmentIndustrial waste water

The invention discloses a high-temperature aerobic fermentation process for sludge with low energy consumption and no pollution, and relates to the technology for aerobic fermentation treatment on dewatered sludge. The process is used for decontamination, stabilization and reduction treatment of town sewage sludge, sewage sludge, organic industrial wastewater sludge and organic sludge. In the process, the dewatered sludge and auxiliary materials are mixed, the mixture is crushed into composting particles with the diameter less than or equal to 20mm, the composting particles are evenly distributed into a pile with the height of 2m by a spreader, and the pile is covered by fermented decaying products to effectively reduce the odor emitted by the composting. A fermentation bin with two combined or separated bins is provided with a ventilation and oxygen supply system which is detachable, is easy to clear, prevents blockage and has even gas distribution, and a pile turning device inside; and the oxygen concentration, fermentation temperature, water ratio of the pile in the fermentation bin are controlled, so that sludge fermented products meet national standard. The process facilitates air supply and aerobic fermentation of the pile due to small diameter of the composting particles and the loose pile, has thorough fermentation of the particles of the sludge mixture, improves the quality of the sludge fermented products, makes the sludge fermented products meet the decontamination, stabilization and reduction index requirements specified by the national standard, and greatly saves electric energy consumption and reduces operating cost.

Owner:城市污染控制国家工程研究中心 +2

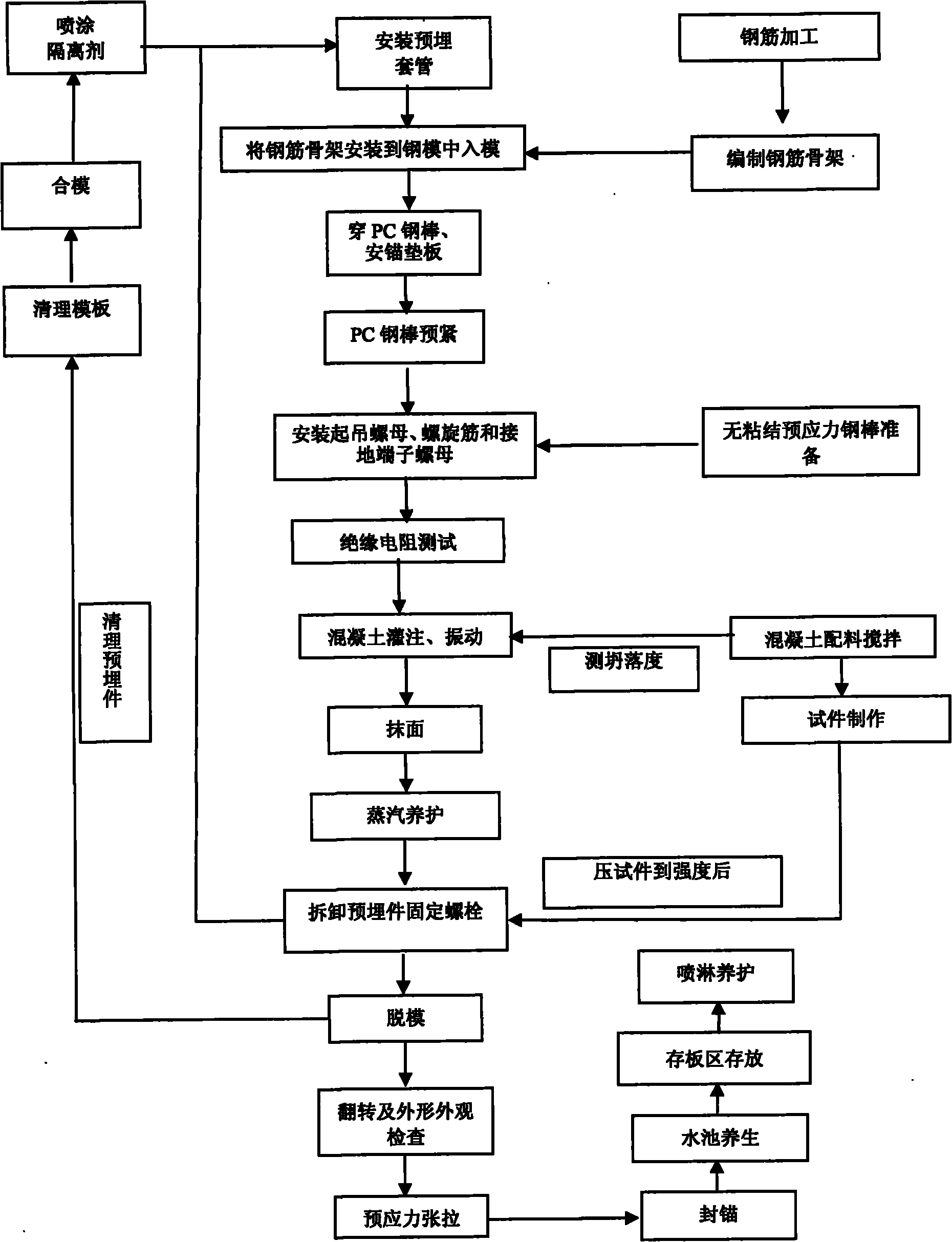

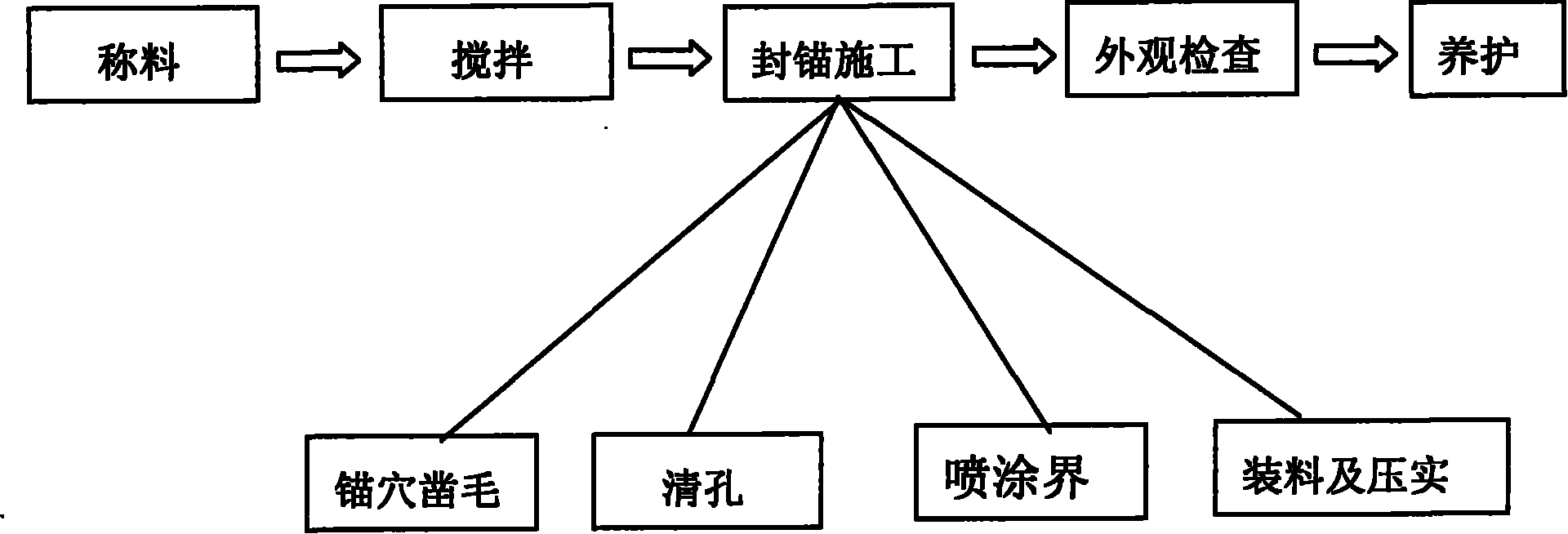

Concrete track slab prefabricating construction method of CRTS I type slab ballastless track

InactiveCN101830036AImprove cutting efficiencyUniform clothCeramic shaping apparatusRebarInsulation resistance

The invention relates to a concrete track slab prefabricating construction method of a CRTS I type slab ballastless track. The method comprises the following steps of: (1) weaving a steel reinforcement framework; (2) mounting the steel reinforcement framework in a steel mould, wherein the steel mould is internally sprayed with a separant and provided with a pre-embedded sleeve; (3) penetrating a PC (Prestressed Concrete) steel rod and mounting an anchor backing slab; (4) pre-tightening the PC steel rod; (5) mounting a hoisting nut, a spiral bar and a grounding terminal nut; (6) testing an insulation resistor; (7) pouring concrete and vibrating; (8) plastering the surface; (9) maintaining by using steam; (10) dismounting fixing bolts of a pre-embedded piece; (11) demoulding: cleaning the pre-embedded piece and a template, closing the mould, spraying the separant in the steel mould and mounting the pre-embedded sleeve for later use; (12) overturning and examining shape: turning over the CRTS I type slab ballastless track contrete track slab obtained in the step (11) and examining the shape and the appearance; (13) stretching by prestress; (14) sealing the anchor; (15) maintaining in a water pool; and (16) storing in a slab storage area.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

Sludge incineration method

ActiveCN103256608ALow costAvoid affecting the combustion effectIncinerator apparatusBrickResource utilization

The invention relates to a sludge incineration method which comprises the following steps: incineration, secondary incineration, incinerator bottom blast, cooling, ash discharging, waste-heat utilization, desulfuration and dedusting treatment. According to the sludge incineration method, sludge burns off completely through the methods of high temperature and multiple incineration, and germs, causative agents and the like in the sludge are killed. The waste heat produced in incineration can be further used for producing steam, and the ash after incineration can be used for making building materials such as bricks and cement. Therefore, the sludge incineration method provides an effective path for follow-up resource utilization of the sludge.

Owner:杭州国泰环保科技股份有限公司

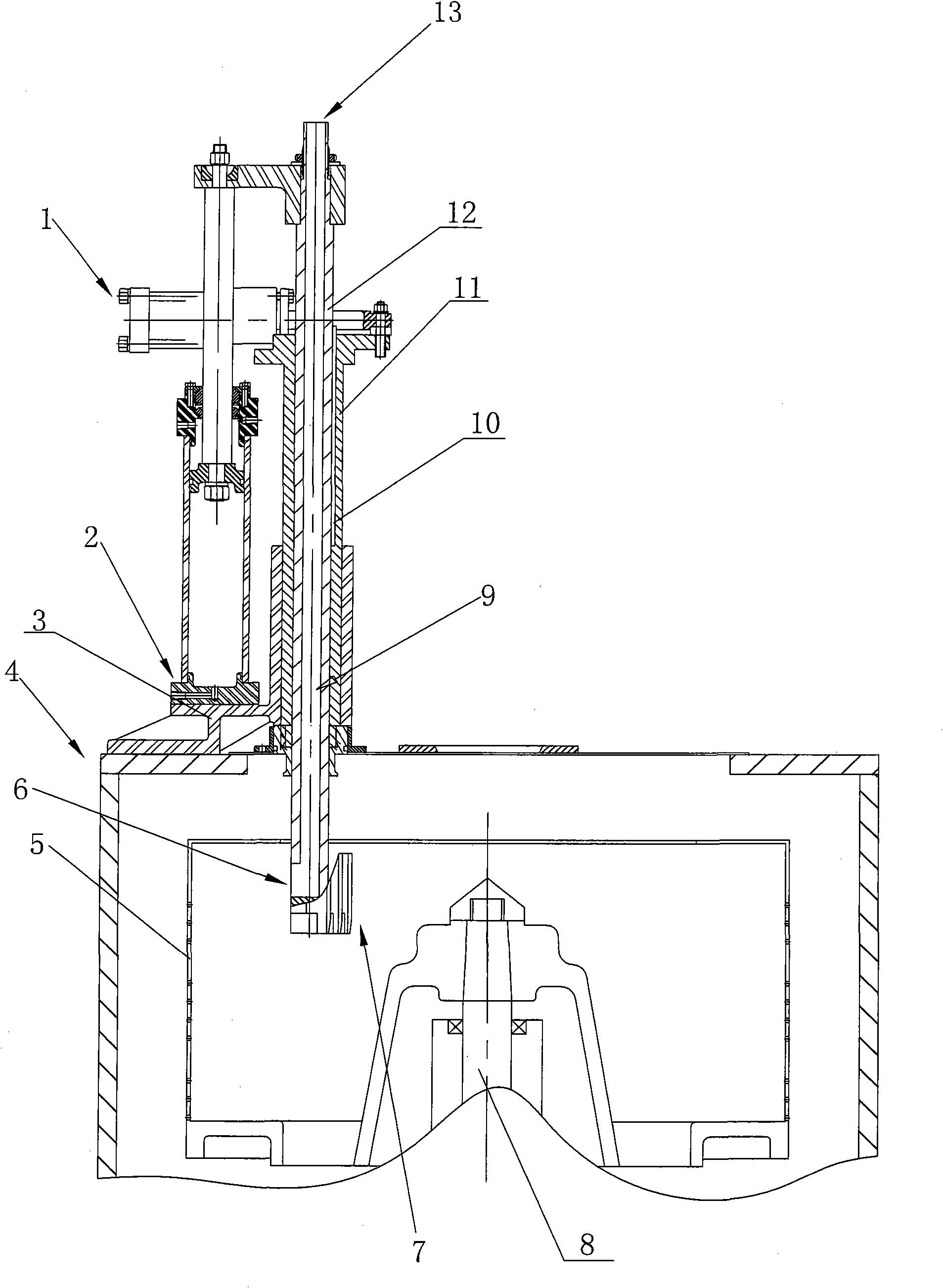

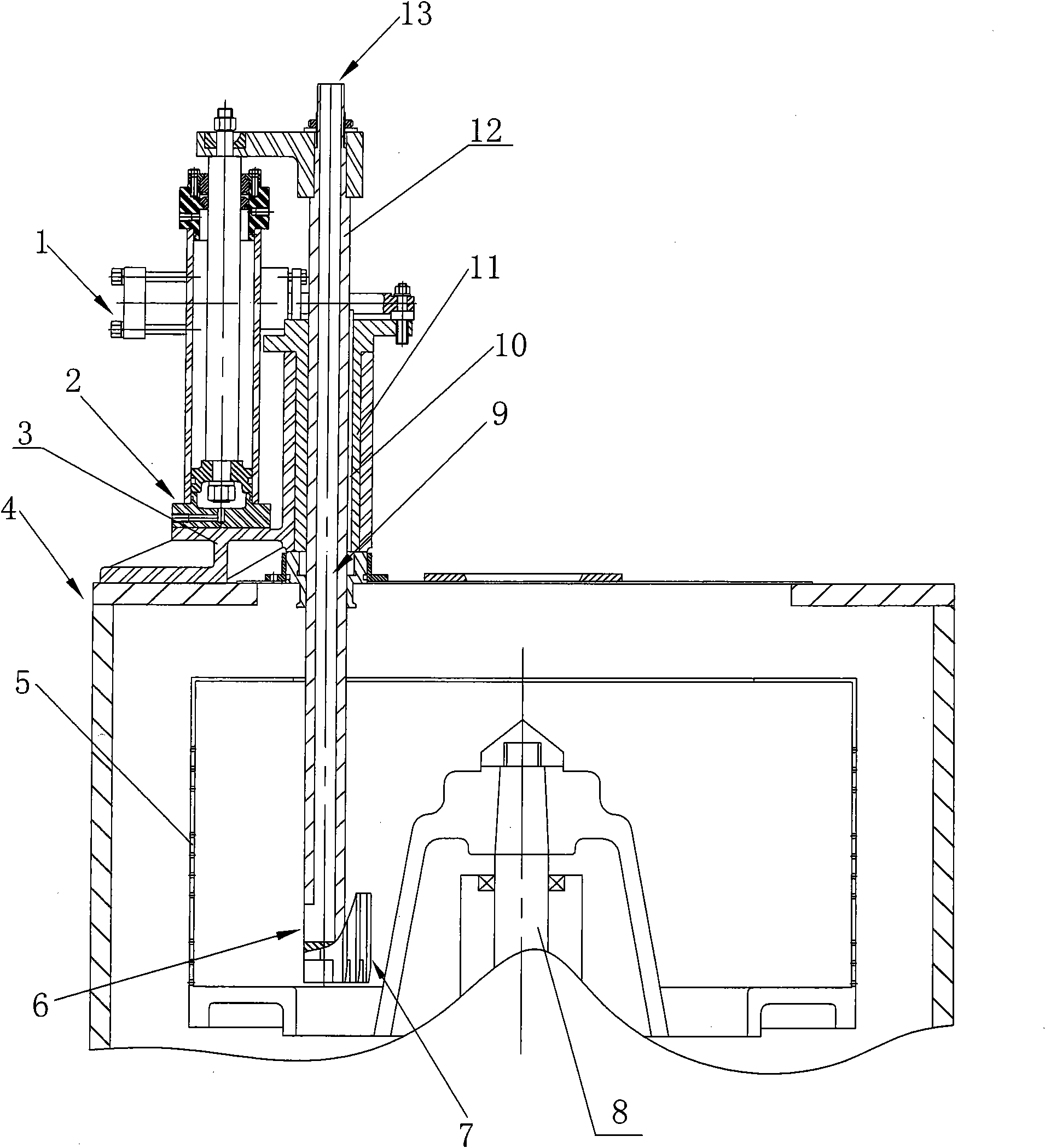

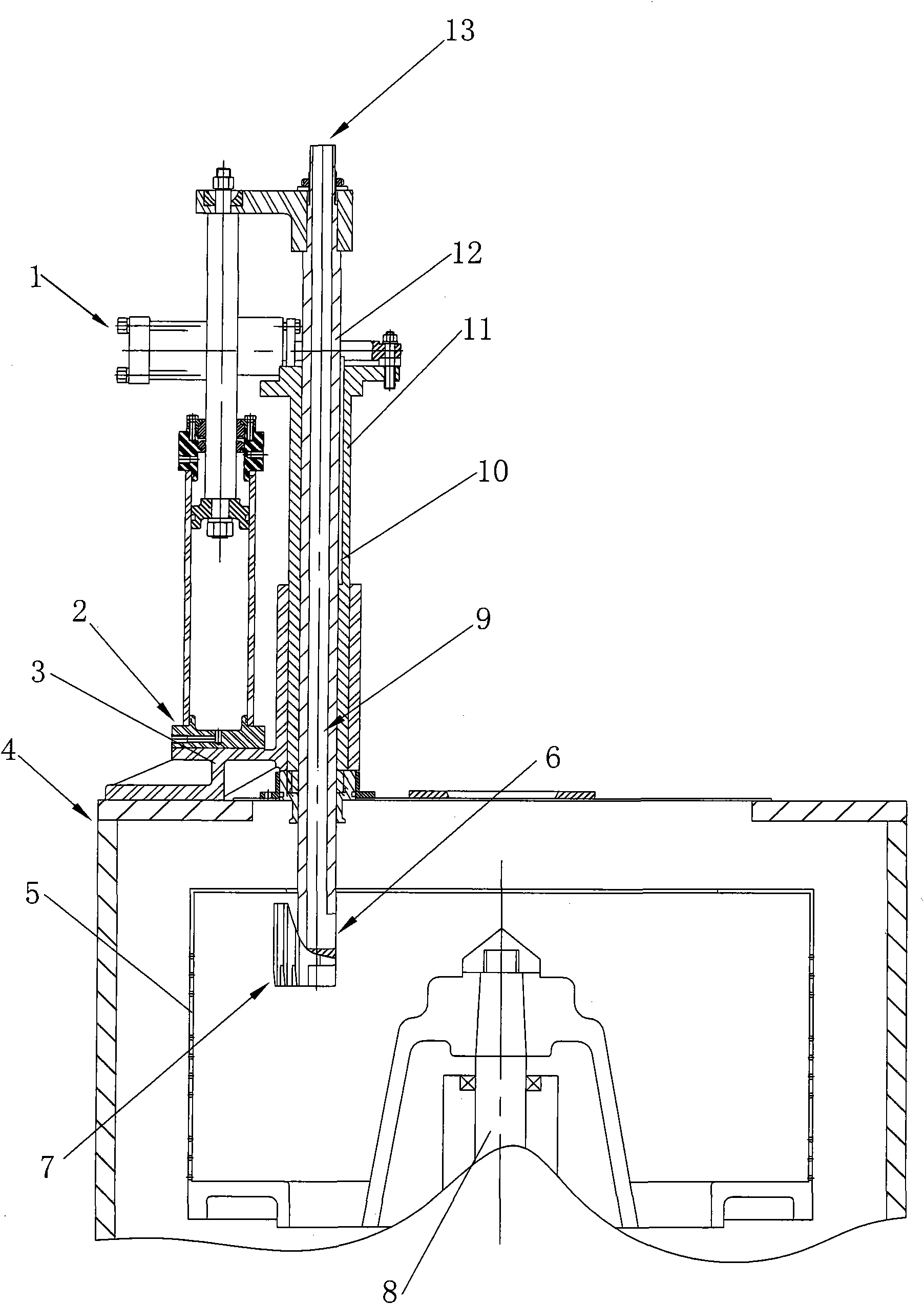

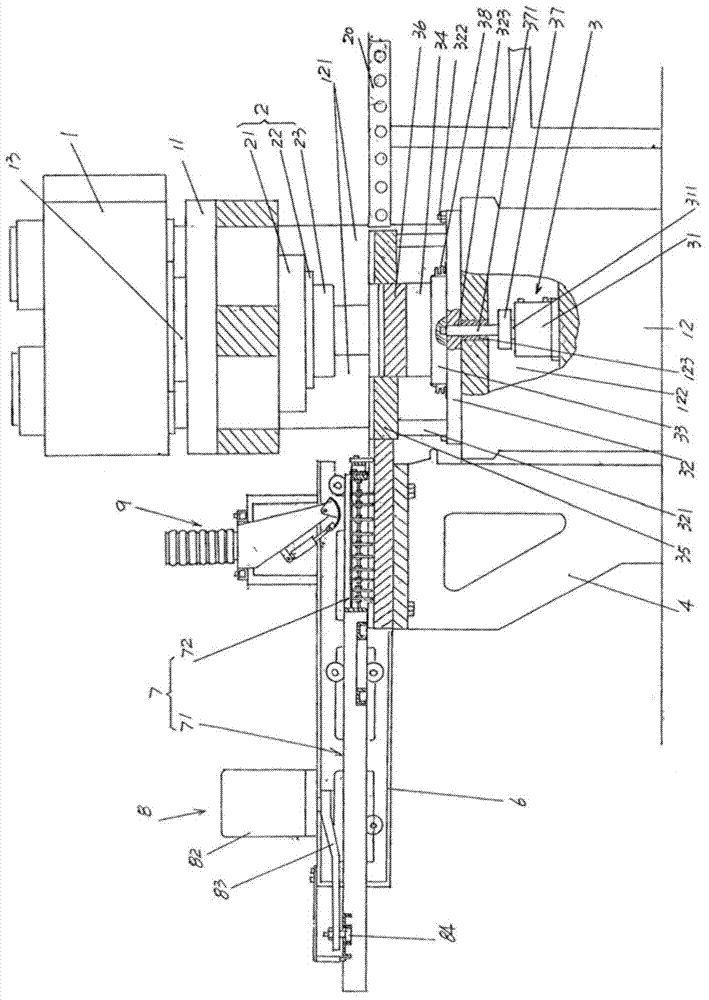

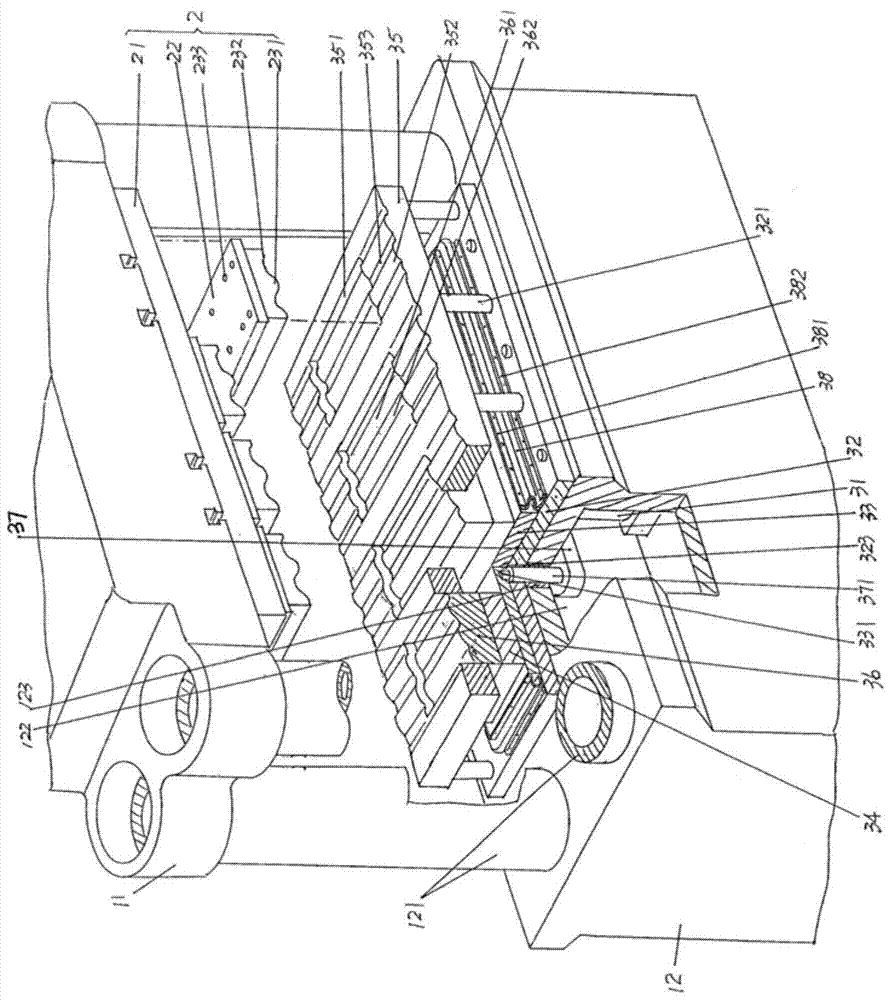

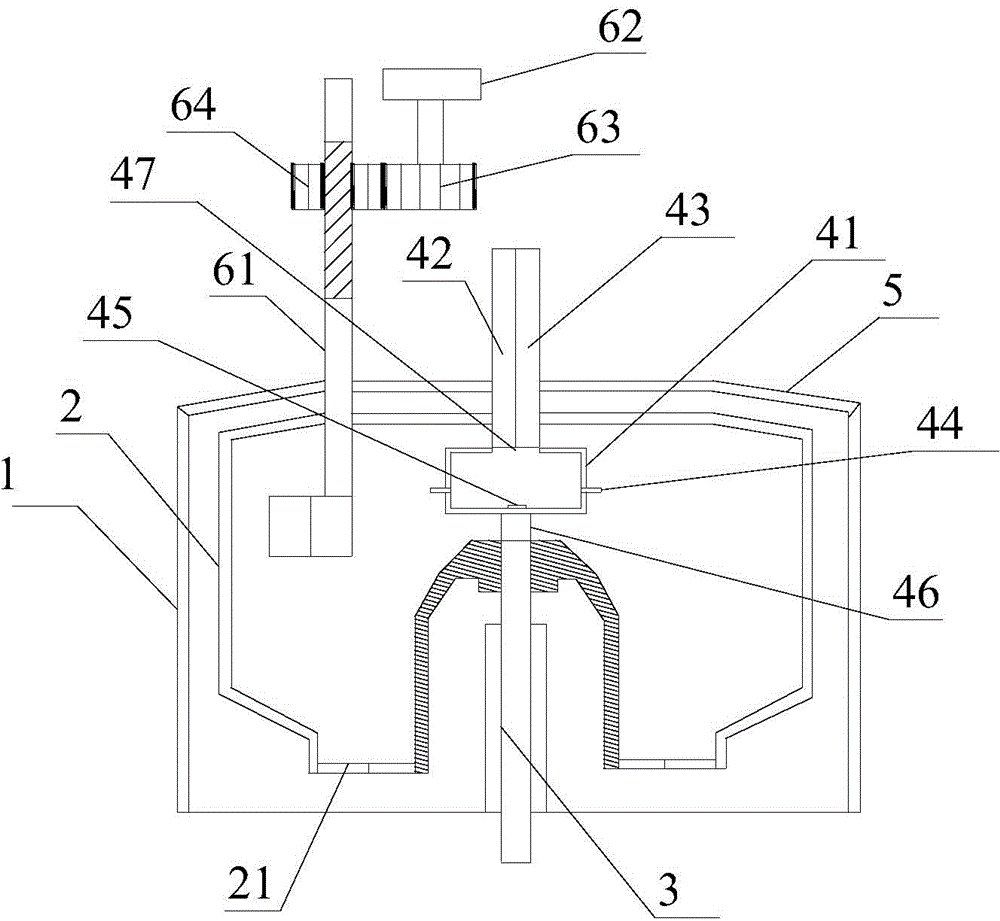

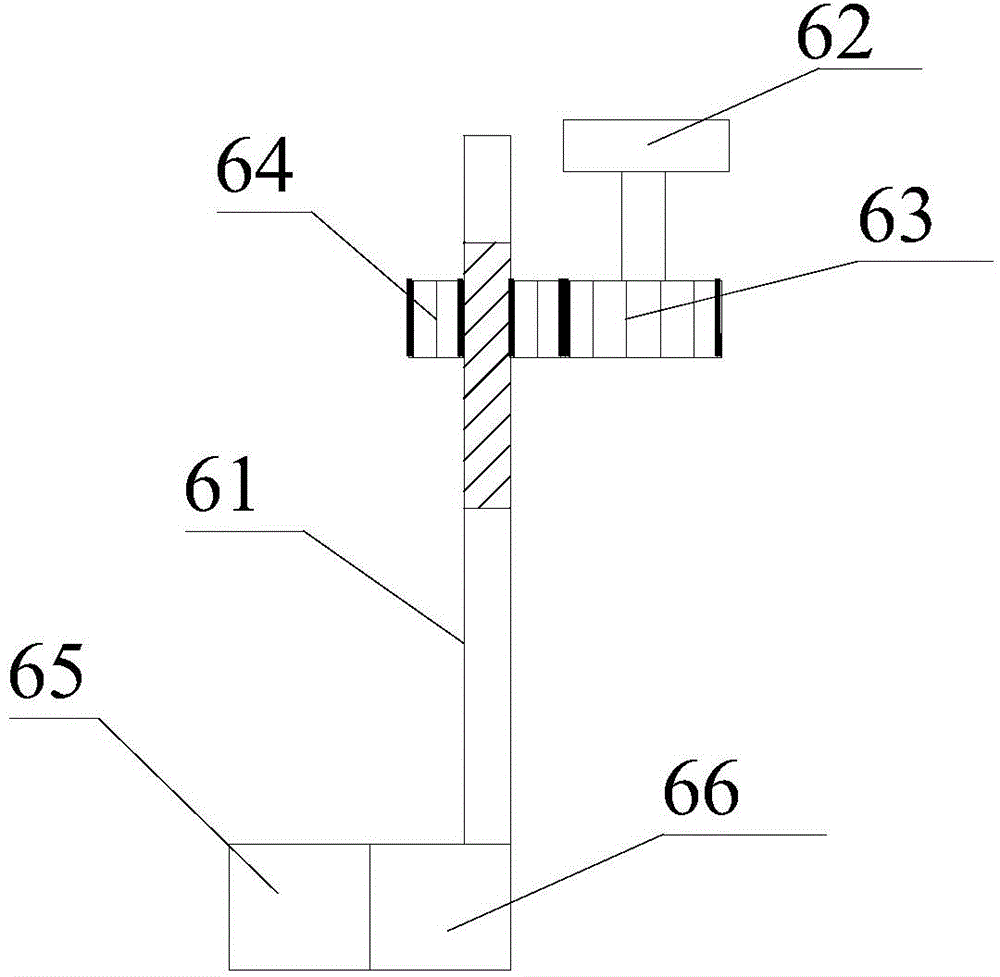

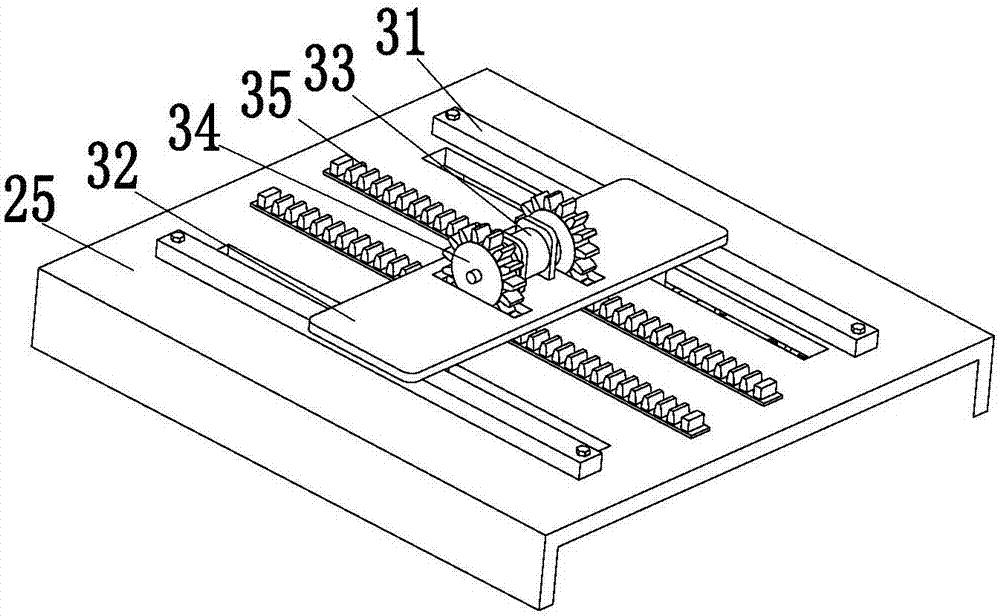

Distributing and discharging device for centrifuge

The invention relates to a distributing and discharging device for a centrifuge. The device comprises a shell, a base, a drum, a feeding pipe and a scraper blade; the feeding pipe comprises a feeding hole outside the shell and a distributing hole in the shell; the base comprises a lifting drive device for driving the feeding pipe to move along the axial direction thereof, a rotating drive device for driving the feeding pipe to rotate along the axis thereof, and a supporting seat for connecting the shell, the lifting drive device and the rotating drive device; the scraper blade is positioned on the outer side of the distributing hole of the feeding pipe, and the edge of the scraper blade is staggered with the distributing hole in the circumferential direction encircling the axis of the feeding pipe; and when the feeding pipe rotates to the edge of the scraper blade and faces the inner wall of the drum, the distributing hole faces a main shaft. By adopting the structure, the distributing range can be controlled so that the distribution is uniform; and the distributing device and the scraper device are integrated so as to facilitate the operations such as installation, repair, later maintenance and the like and quickly, repeatedly and automatically distribute and scrape materials.

Owner:JIANGSU PEONY CENTRIFUGE MFG

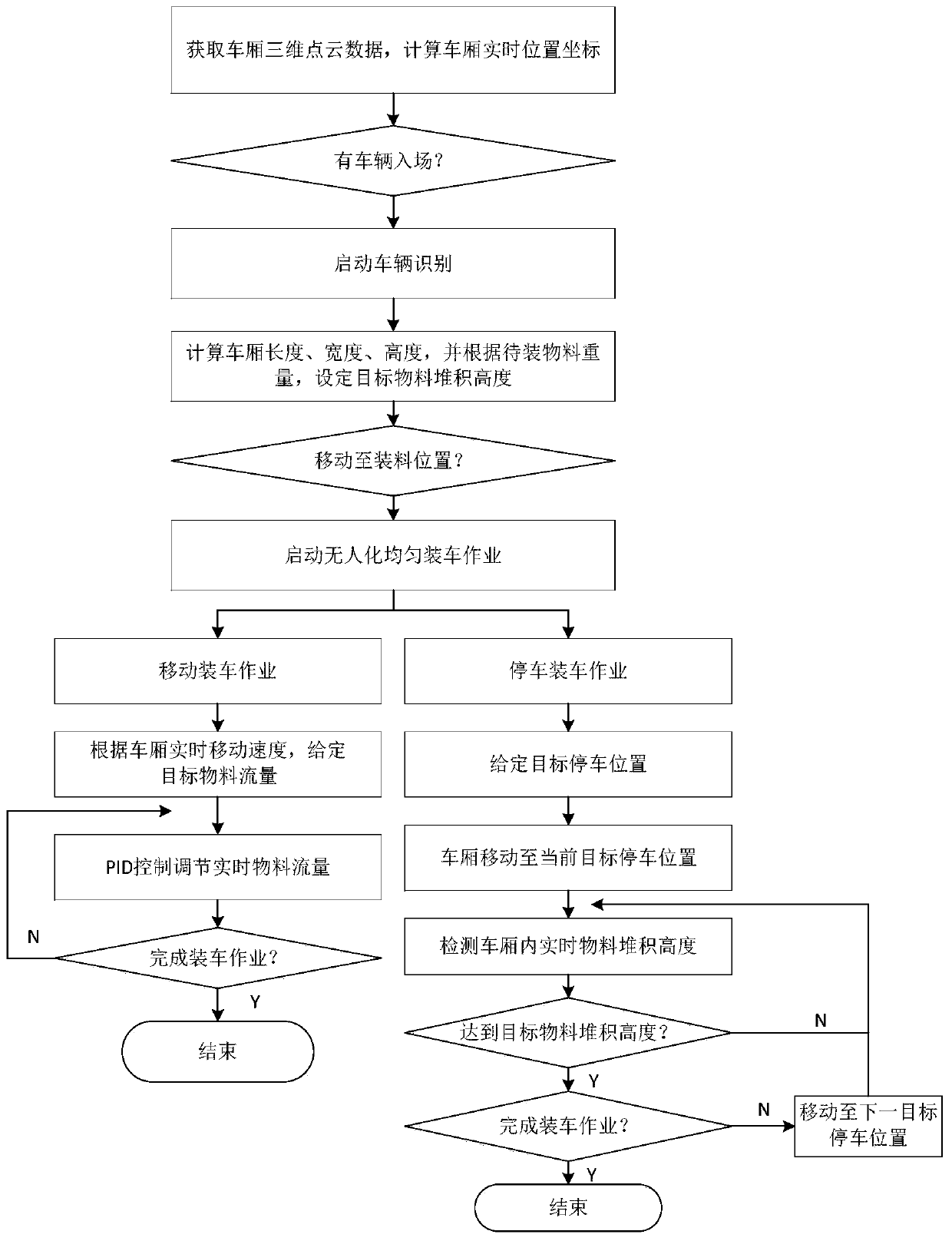

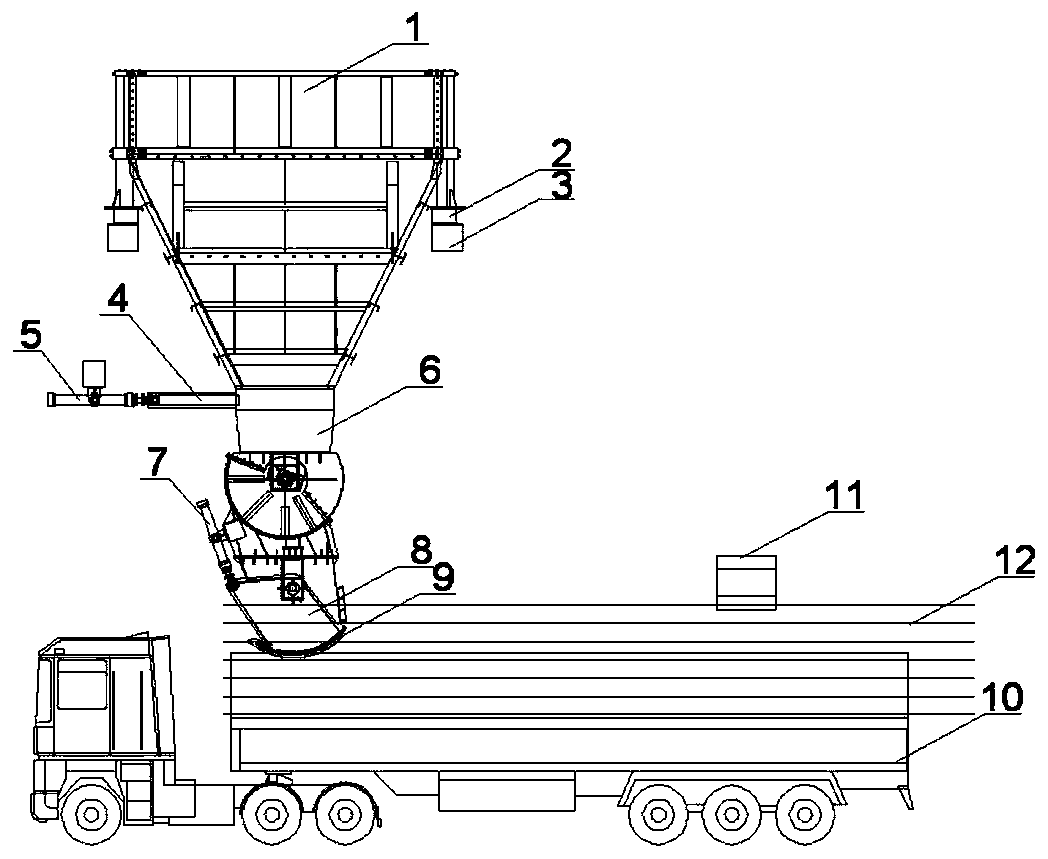

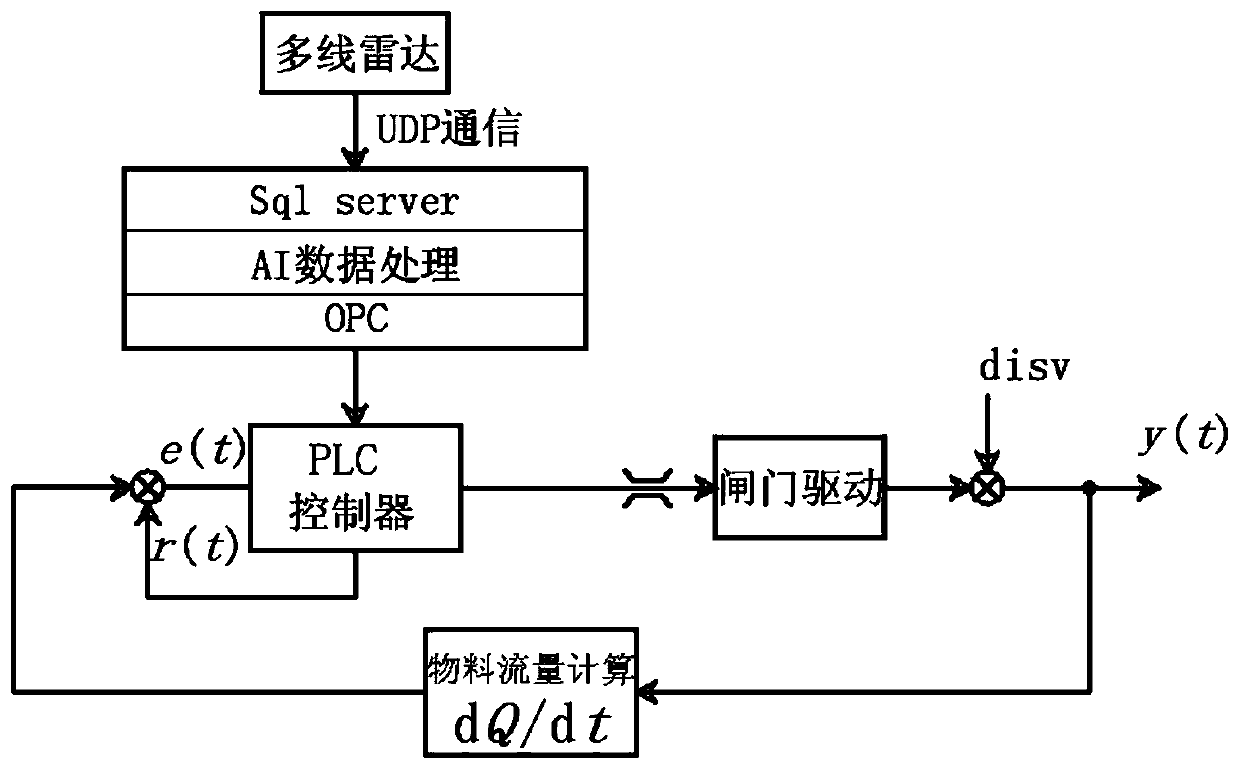

Bulk material unmanned loading control method, system and device based on multi-line laser radar

ActiveCN111487918ABreak through the bottleneck of intelligent loading technologyLower loading costsMeasurement devicesFlow control using electric meansRadarControl engineering

The invention relates to a bulk material unmanned loading control method, system and device based on a multi-line laser radar. The method comprises the steps: collecting three-dimensional point clouddata of a carriage through the multi-line laser radar; recognizing the size of the carriage, a real-time movement position of the carriage and a real-time movement speed; dynamically adjusting a loading process; and achieving unmanned automatic loading control. Different control parameters can be adopted for loading according to different carriage types, a technical bottleneck of loading intelligence is broken through, loading cost is reduced, and loading efficiency is improved. Problems that in the prior art, due to a fact that a manual loading mode is adopted, labor cost is increased, loading quality stability cannot be effectively guaranteed, conditions such as reciprocating loading or loading unbalance loading and the like often occur, and the loading efficiency is not high are solved.

Owner:TIANDI SCI & TECH CO LTD

Earthworm bioreactor and organic waste treatment method

InactiveCN102239822AUniform clothEarthworm production and multiplication efficiency is highSolid waste disposalClimate change adaptationWaste treatmentBioreactor

The invention provides an earthworm bioreactor and an organic waste treatment method. The earthworm bioreactor comprises a reactor box body, an organic waste distributing device, an earthworm dung output device, a forced ventilation system, an expansion bracket, an illuminator and an external central regulation and control system, wherein the expansion bracket is connected above the reactor box body; the illuminator is arranged above the reactor box body; distributing wheel tracks which are connected with the organic waste distributing device in a sliding manner are connected to upper edges on both sides of the reactor box body; the earthworm dung output wheel track which is connected with the earthworm dung output device in a sliding manner is arranged inside the reactor box body, and isfixed on the reactor box body; the forced ventilation system is connected on the outer side wall of the reactor box body; a heating interlayer is arranged below the bottom of the reactor box body; and the organic waste distributing device, the earthworm dung output device, the forced ventilation system, the illuminator and a radiating device are connected with the external central regulation and control system. By the earthworm bioreactor, earthworms can be propagated quickly while organic wastes are treated to a great limit.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Colored glaze ceramic tile, production method of colored glaze ceramic tile, and forming device using production method

ActiveCN103538141AReduce weightImprove viewing effectRoof covering using tiles/slatesFeeding arrangmentsWeather resistanceCeramic tiles

The invention relates to a colored glaze ceramic tile, a production method of the colored glaze ceramic tile, and a forming device using the production method and belongs to the field of building roof materials. The colored glaze ceramic tile comprises a tile body and a surface colored glaze layer. The surface colored glaze layer is attached to the tile body and faces out when in use. The tile body is made with, by weight, 25-40% of clay, 10-20% of quartz sand, 5-15% of auxiliary material, 30-45% of flux, and 0.15-0.5% of additive. The colored glaze ceramic tile, the production method and the forming device have the advantages that materials are selected and matched reasonably, the weight of the obtained colored glaze ceramic tile is evidently lower than that of clay or cement tiles, storage and transportation cost can be saved, and the tile is good in strength and weather resistance and water resistance; energy can be saved, and the requirements for industrial enlarged production are met; the surface colored glaze layer can be reliably attached to the tile body, and the appearance of the colored glaze tile can be improved; the finally obtained colored glaze ceramic tile can be even in thickness and density.

Owner:常熟大象建陶有限公司

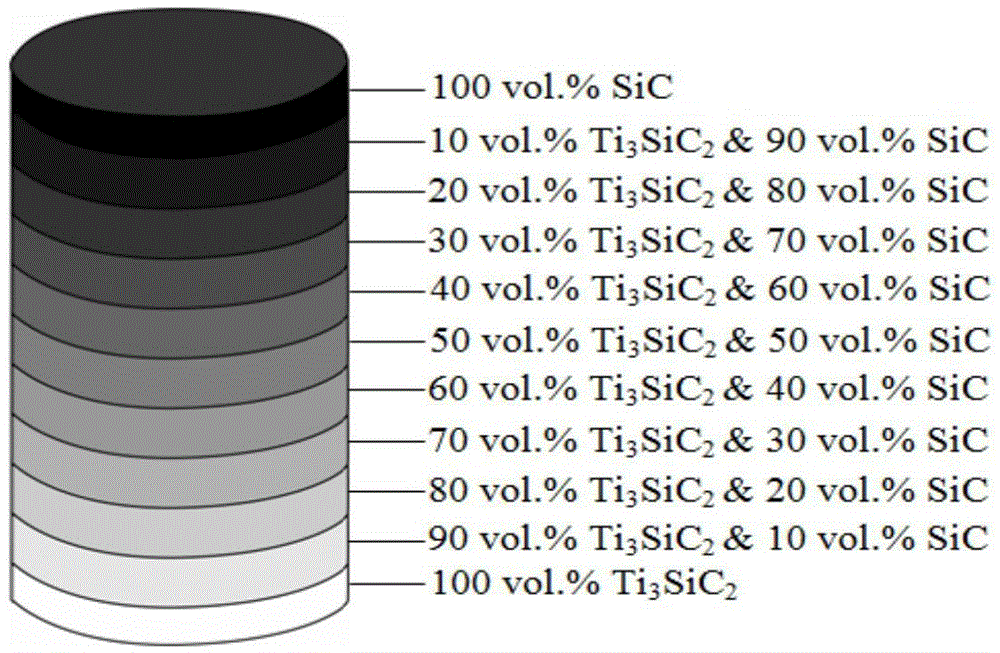

Preparation method of Ti3SiC2/SiC functionally gradient material

ActiveCN105541331AUniform and dense structureModerate combinationOxidation resistantFunctionally gradient material

The invention discloses a preparation method of a Ti3SiC2 / SiC functionally gradient material, comprising the steps of mixing Ti3SiC2 powder and SiC powder in a die layer by layer in a gradient way, then preparing a blank, performing vacuum hot-pressing sintering on the blank to obtain a green body, and sequentially performing dipping densification and pyrolysis treatment on the green body; the SiC powder comprises micron beta-SiC powder and nanometer beta-SiC powder; the vacuum hot-pressing sintering temperature is 1600-1700 DEG C, and is kept for 3-5h, and the maximum pressure is 25MPa; the dipping densification comprises performing dipping densification on gradient layers containing 60-100 vol. percent of SiC in the green body subjected to the hot-pressing sintering in polycarbosilane liquid. The Ti3SiC2 / SiC functionally gradient material prepared by the method is high in compactness, contains multiple gradient layers along the thickness direction from Ti3SiC2 to SiC (designing can be performed as required), the structure is uniform and compact in each gradient layer, interfaces among the gradient layers are moderately combined, the mechanical strength is high, the breaking tenacity is good, under high temperature, the oxidation resistance and the thermal shock resistance are good, and the Ti3SiC2 / SiC functionally gradient material having 11 gradient layers and the thickness of 8-15mm can be prepared.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

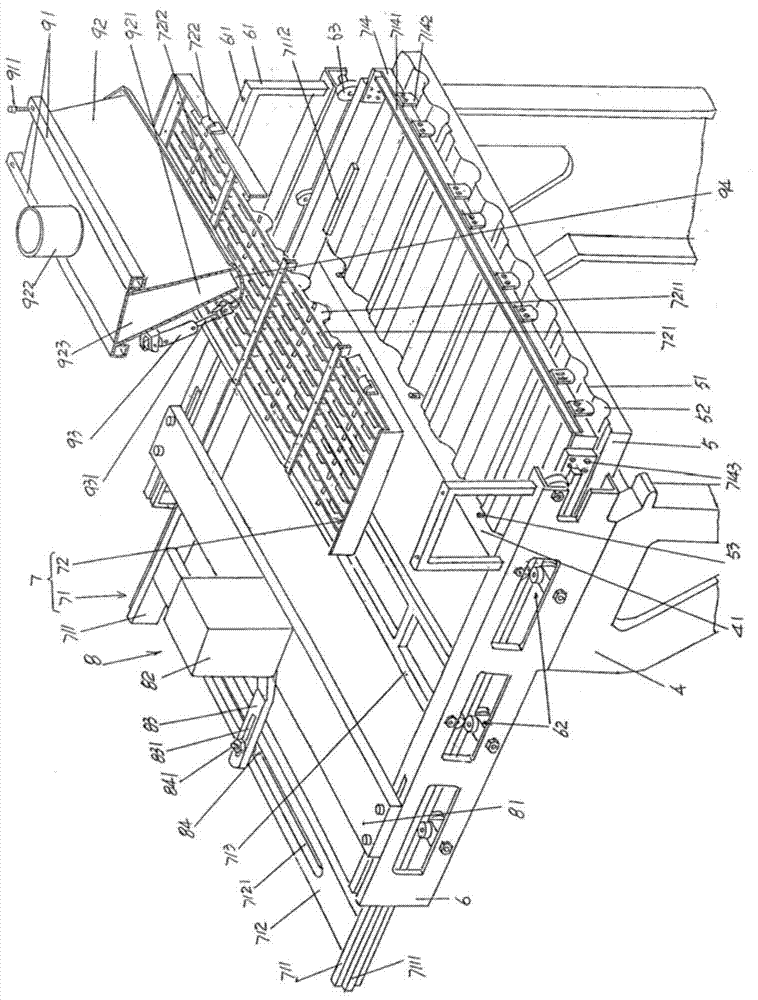

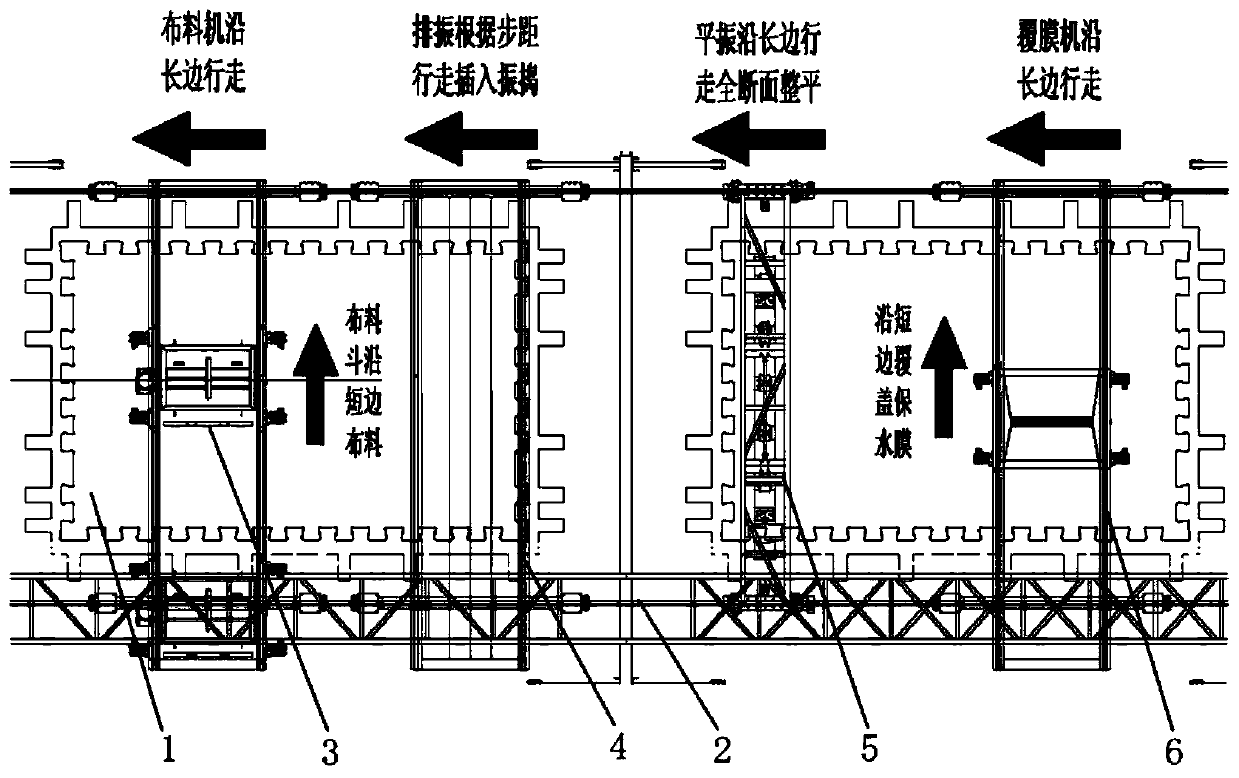

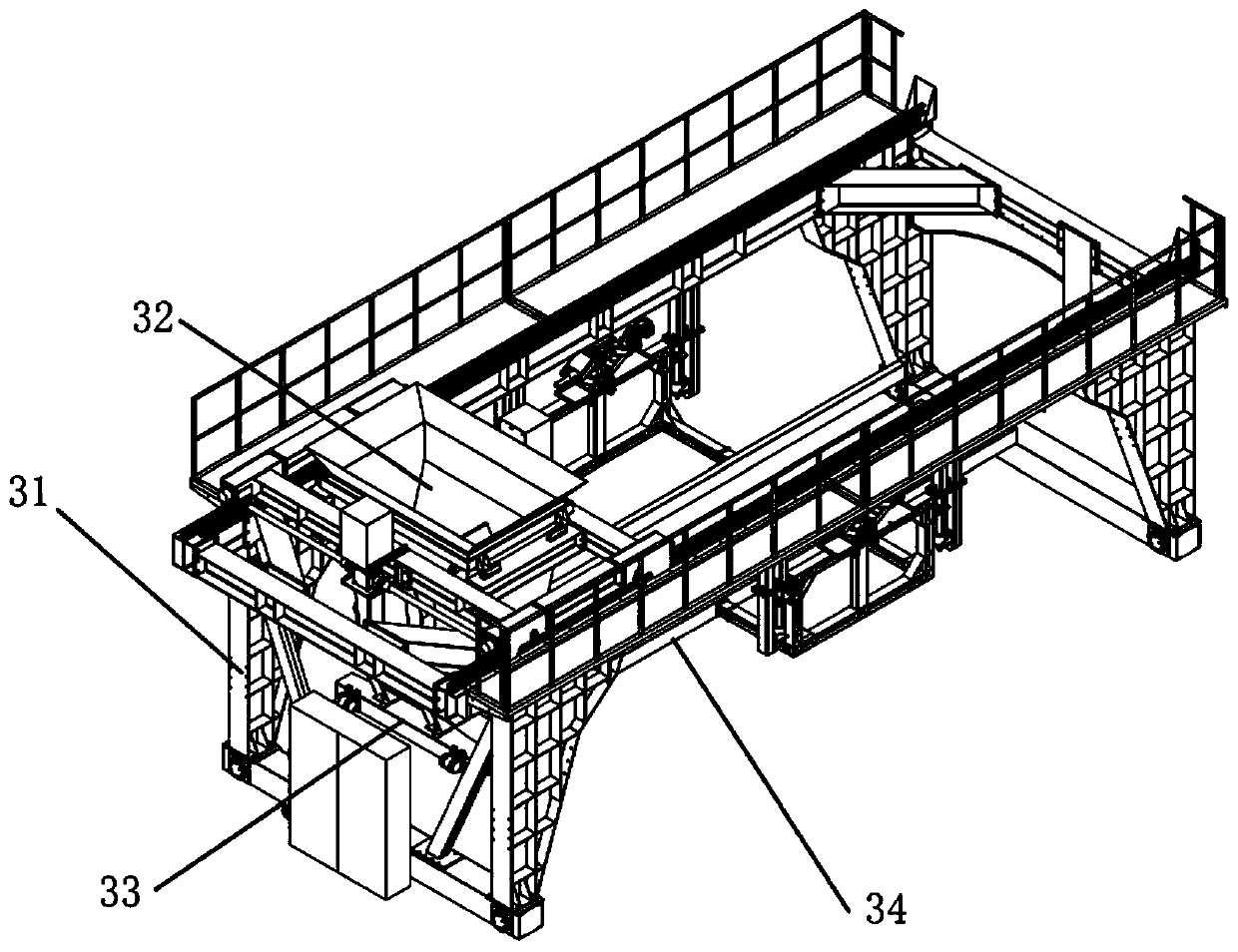

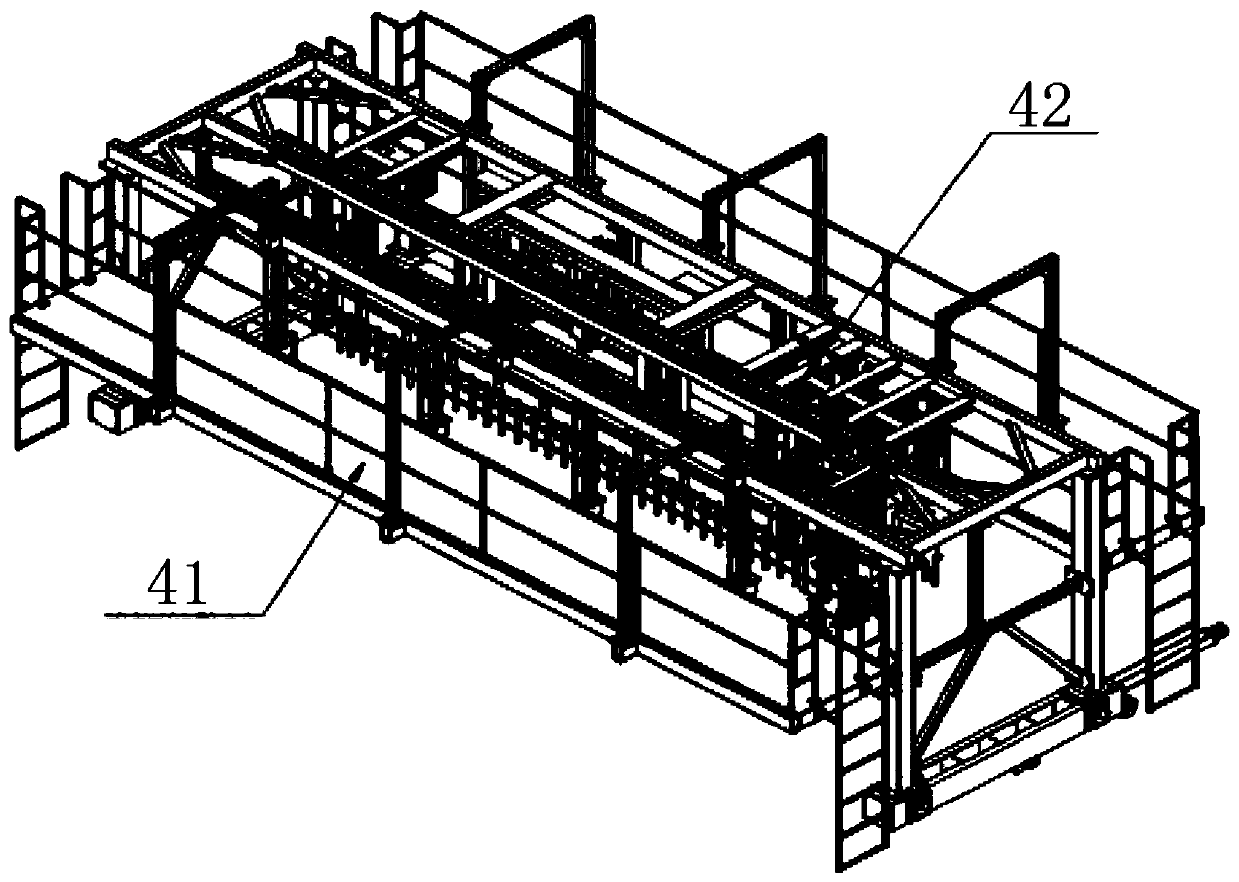

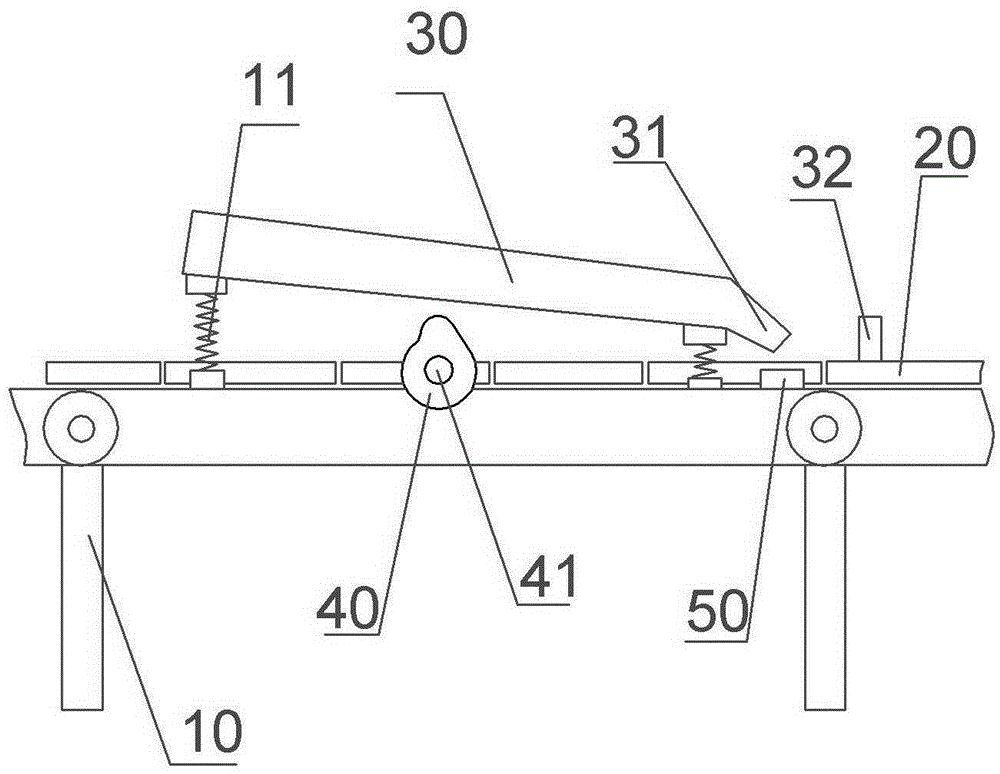

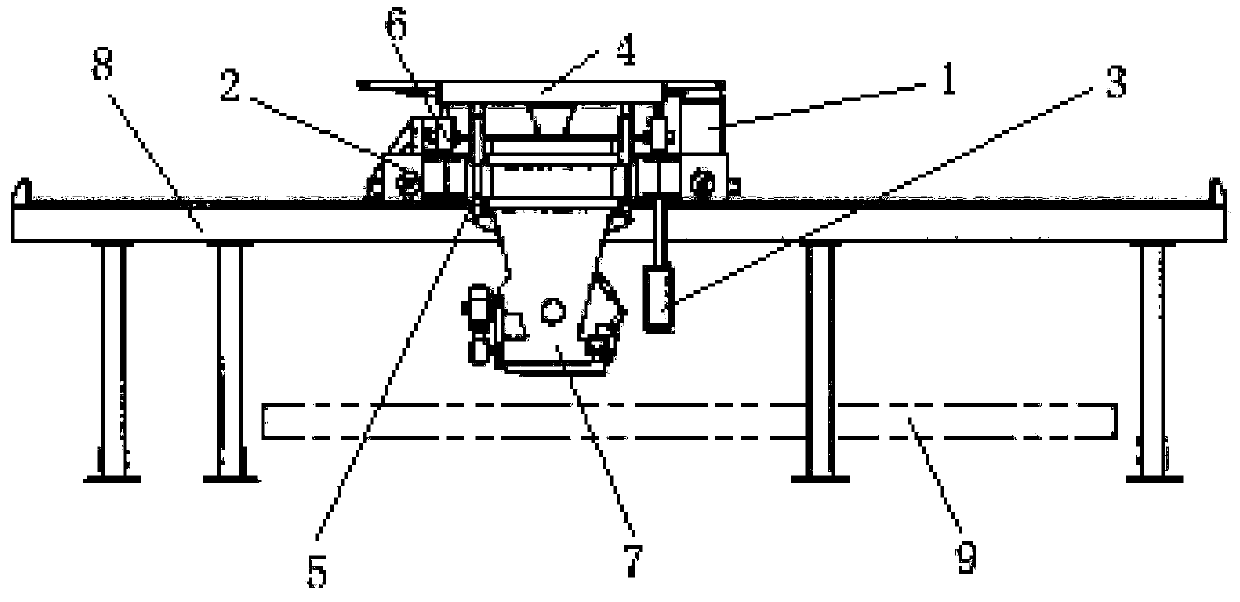

Automatic material distributing and vibrating system for concrete bridge deck slab and control method thereof

InactiveCN110777657AReduce construction waiting timeOvercoming problems that cannot be implemented quicklyBridge erection/assemblyProgramme control in sequence/logic controllersControl systemBridge deck

The invention discloses an automatic material distributing and vibrating system for a concrete bridge deck slab and a control method thereof. The automatic material distributing and vibrating system comprises a track, a material distributing machine, an array type vibrating machine, a flat plate vibrating and leveling machine, a rolling film laminating machine and a control system, wherein the material distributing machine comprises a walking frame moving along the track and a material distributing hopper mounted below the walking frame; the material distributing hopper moves along a frame cross beam; the frame cross beam is parallel to the short edge of a mold; the array type vibrating machine comprises a first walking cart moving along the track and an array device mounted below a crossbeam of the first walking cart; a plurality of rows of vibrating rods are arranged below the array device in the advancing direction of the array device; the first row of vibrating rods are special dovetail joint vibrating rods arranged at intervals according to the designed dovetail joint positions; and the other rows of vibrating rods are arranged in a full-section mode and correspond to steel bar meshes. The requirement of coarse aggregate reactive powder concrete for distribution uniformity can be met, and the influence of environment changes on the bridge deck slab is reduced.

Owner:CCCC SHEC FOURTH ENG

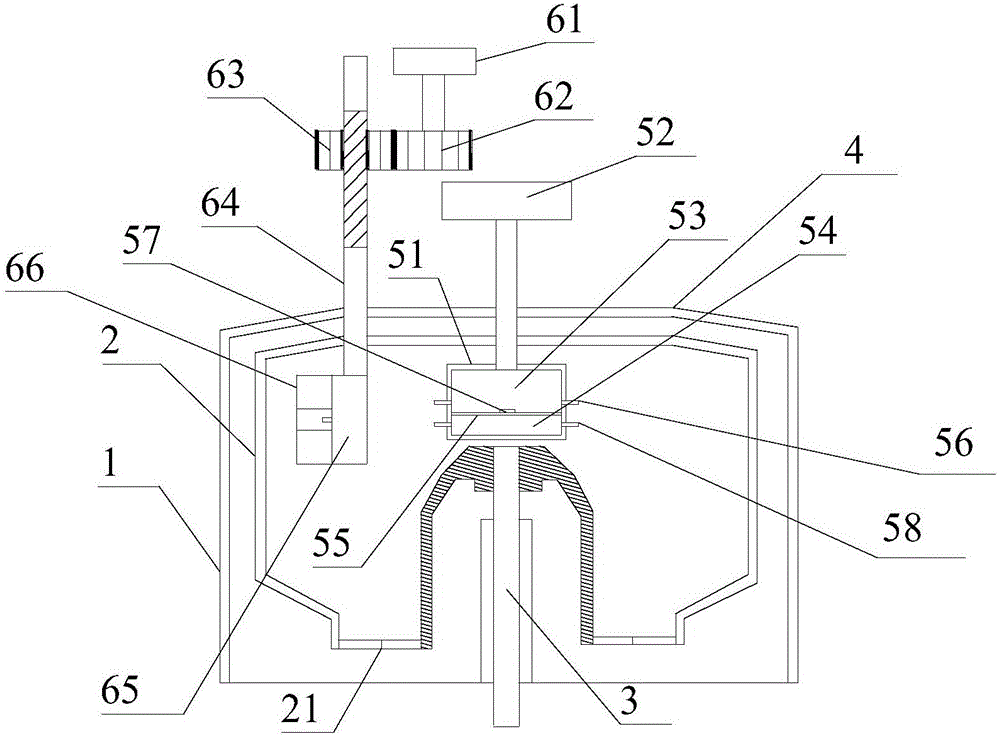

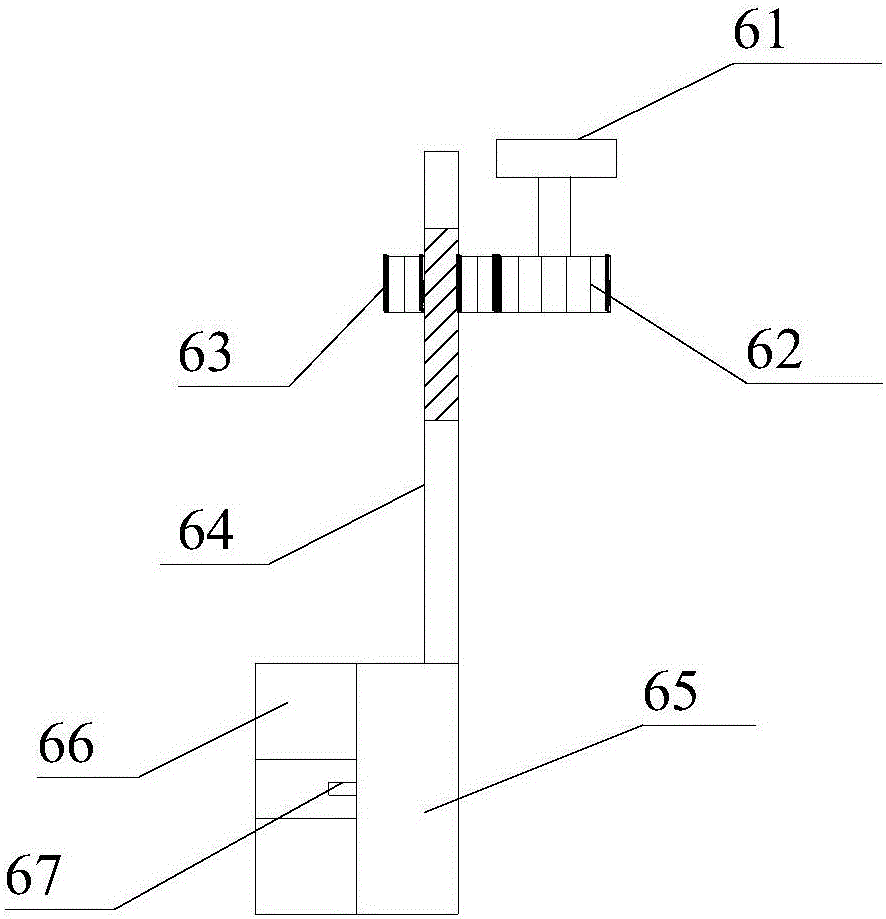

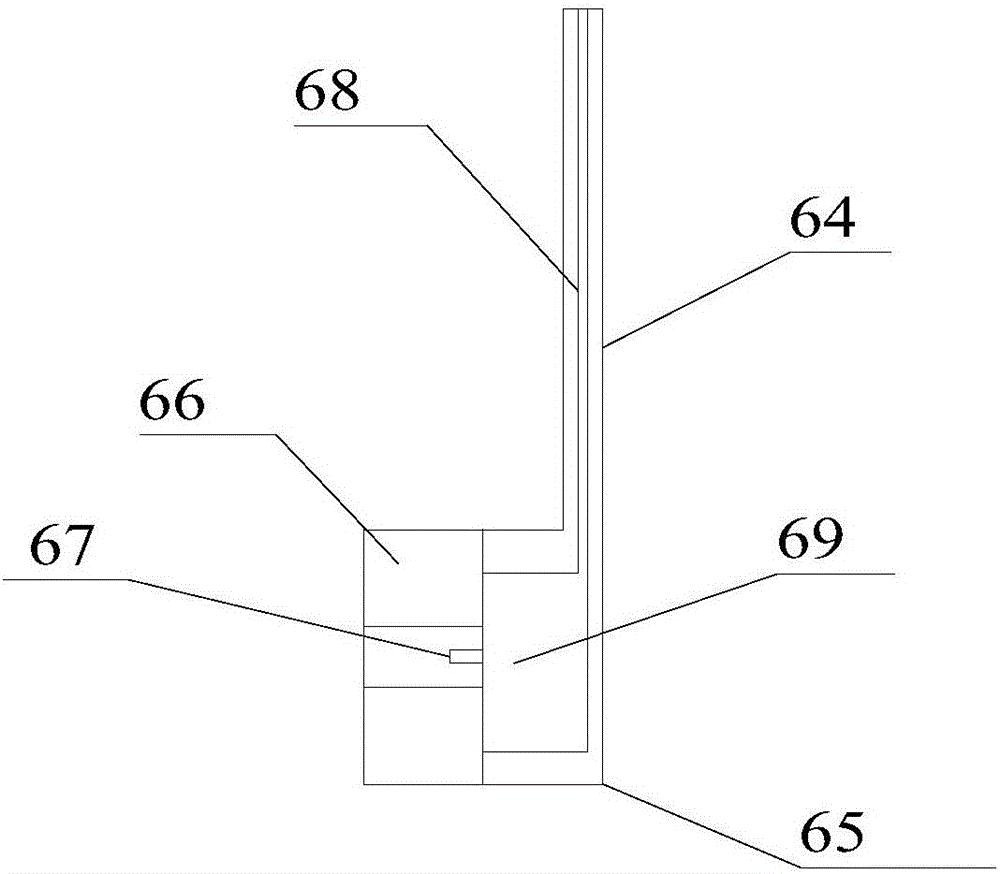

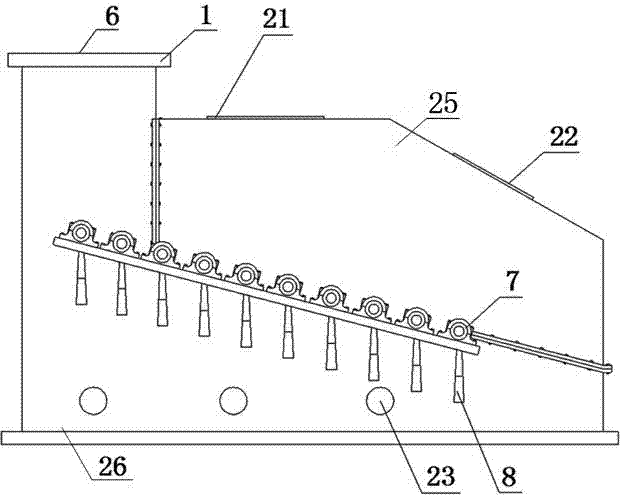

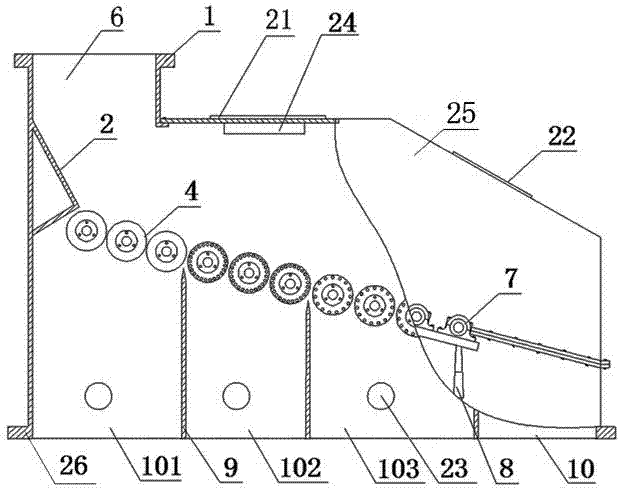

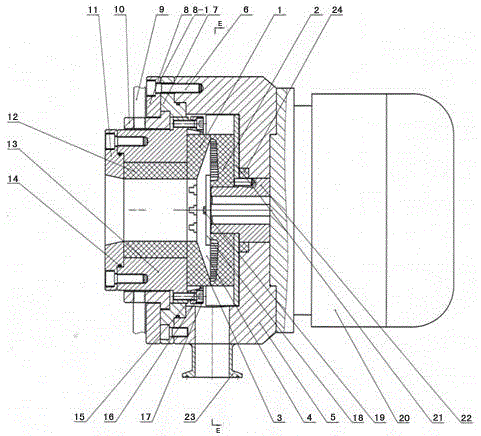

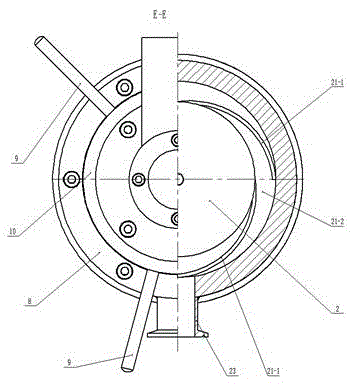

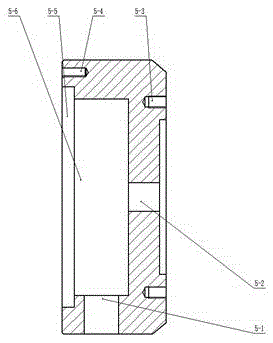

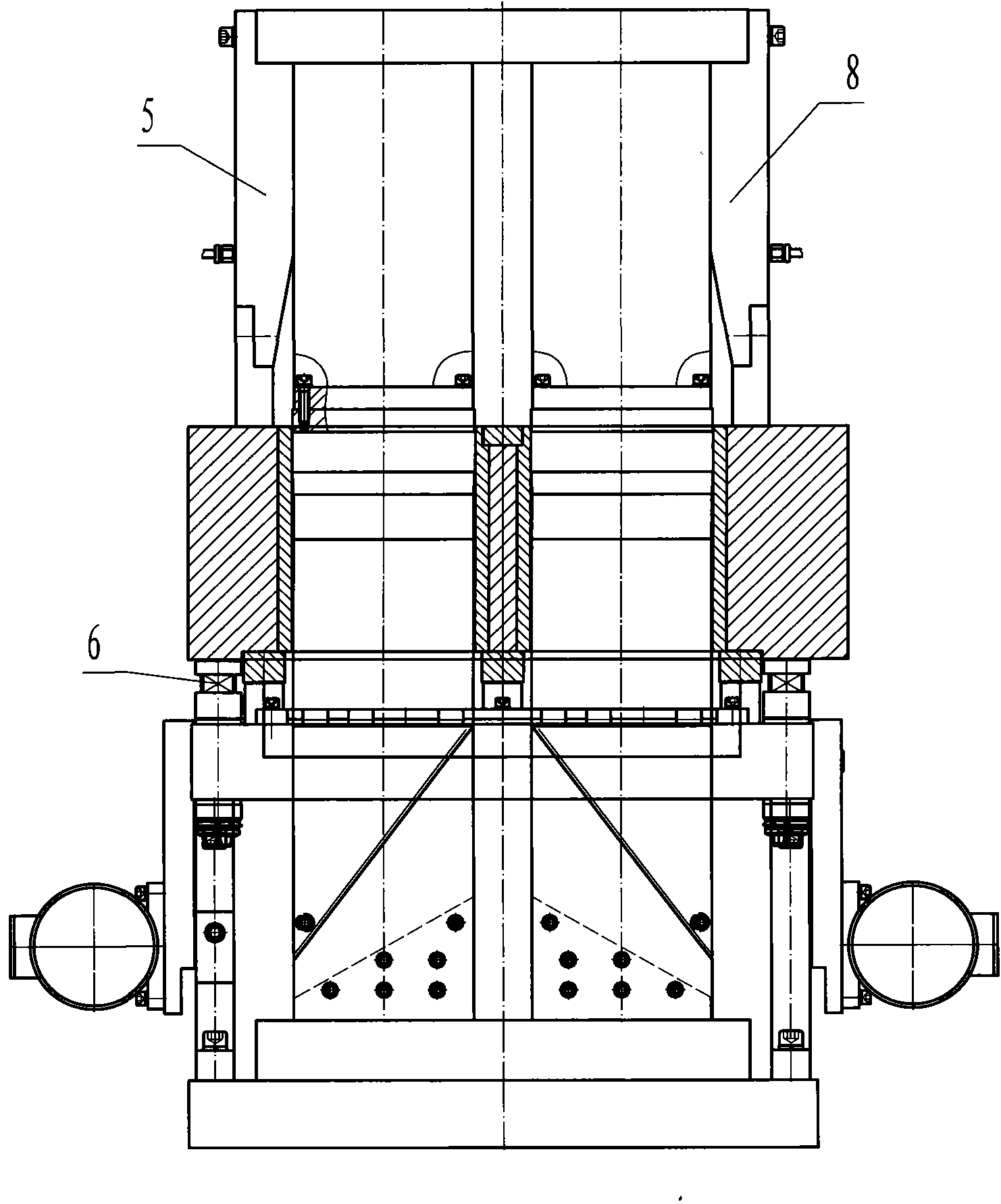

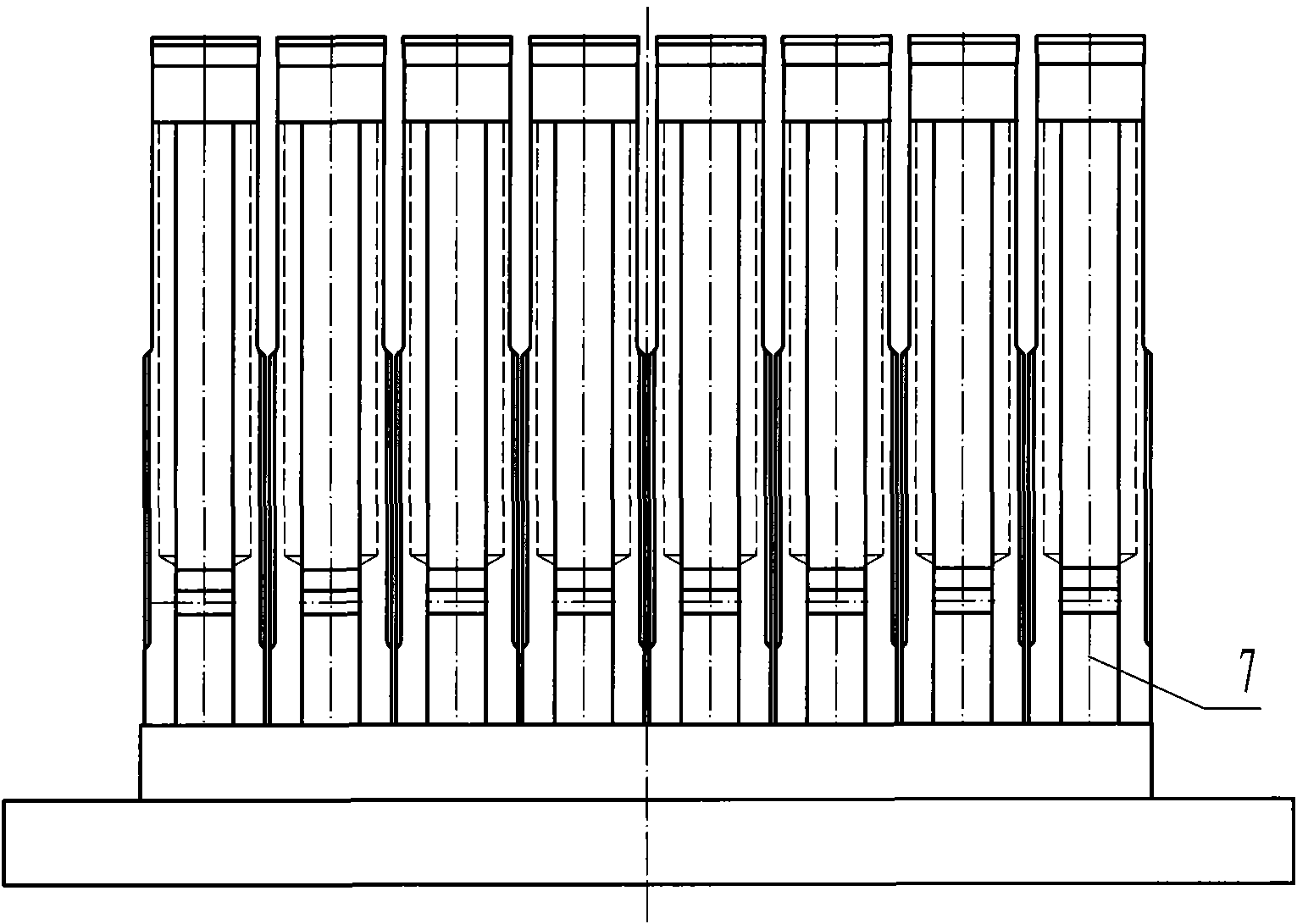

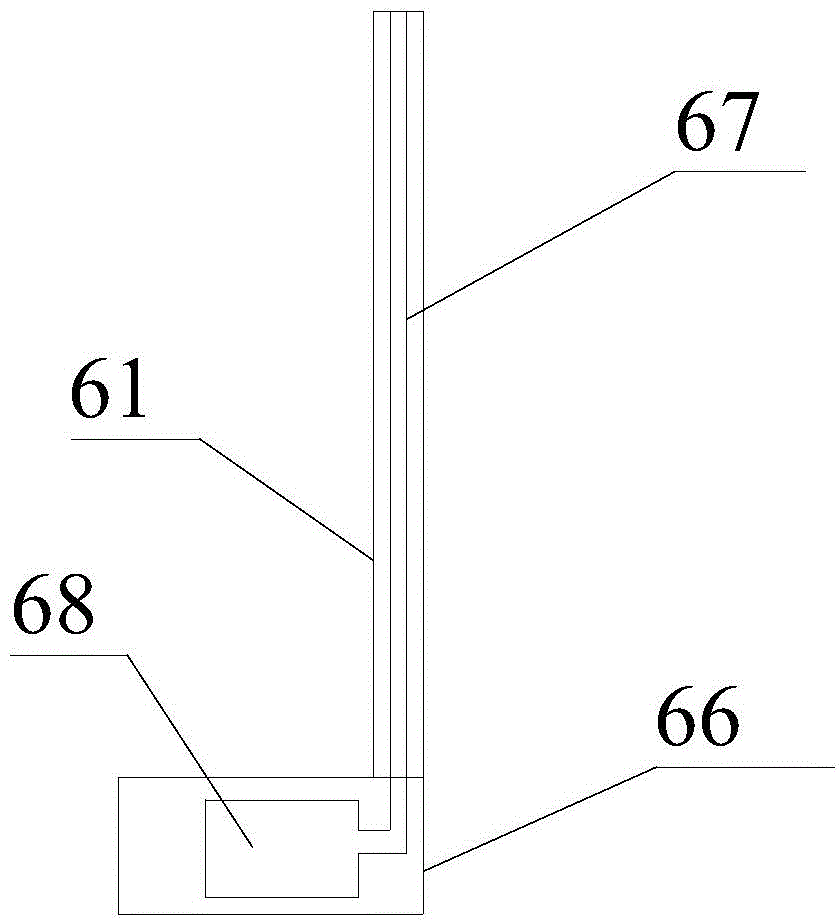

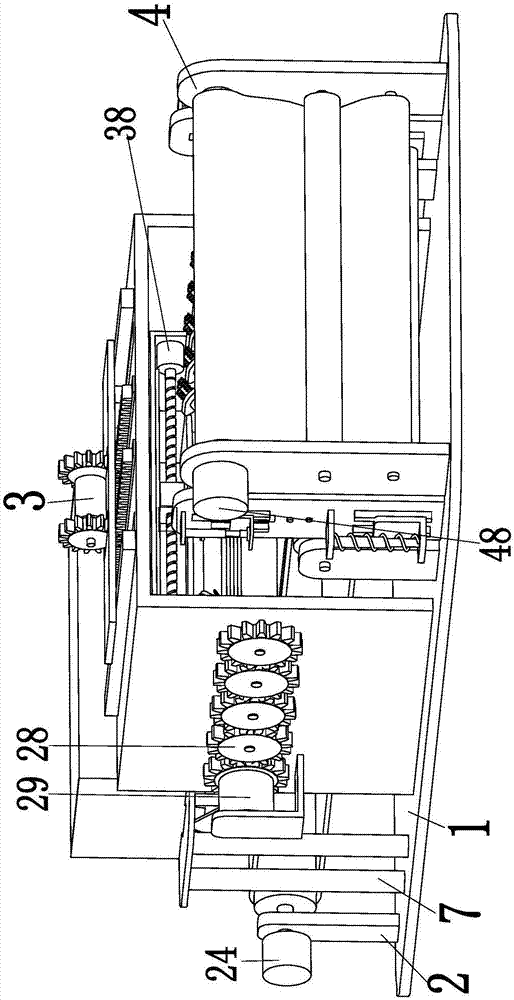

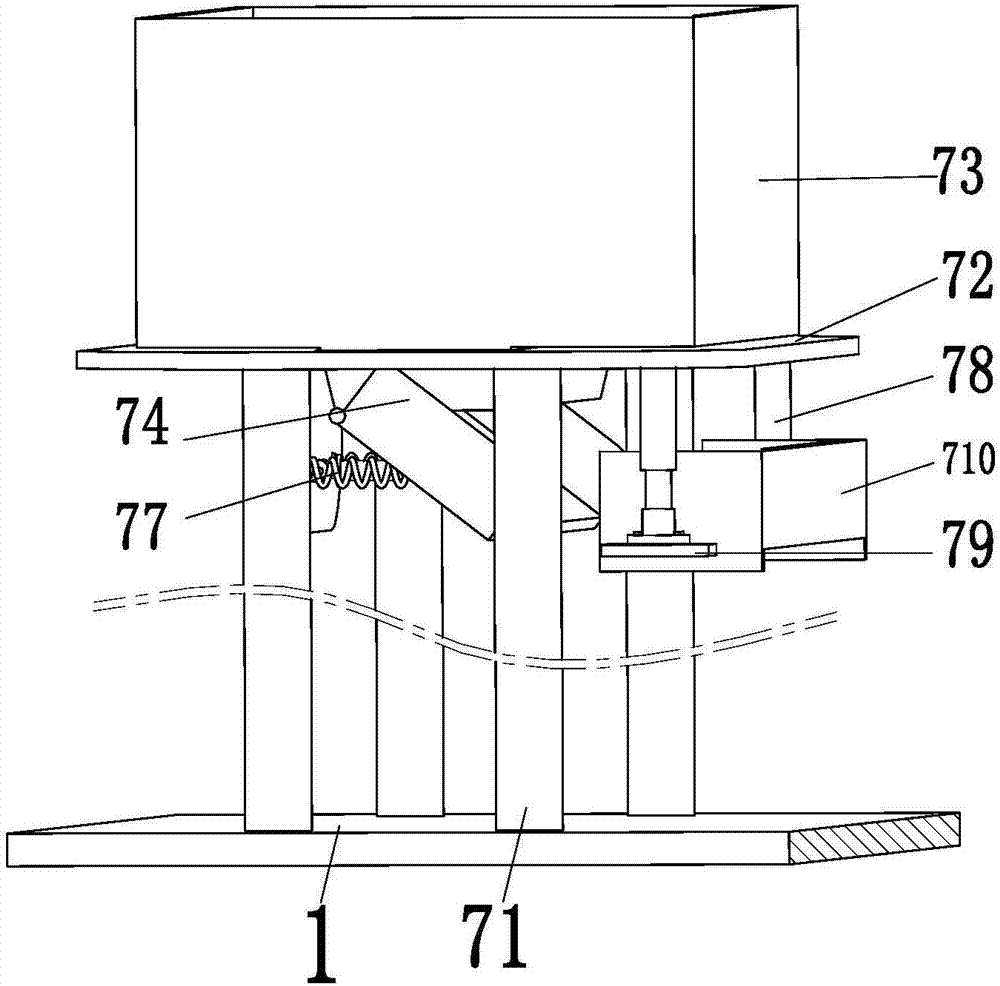

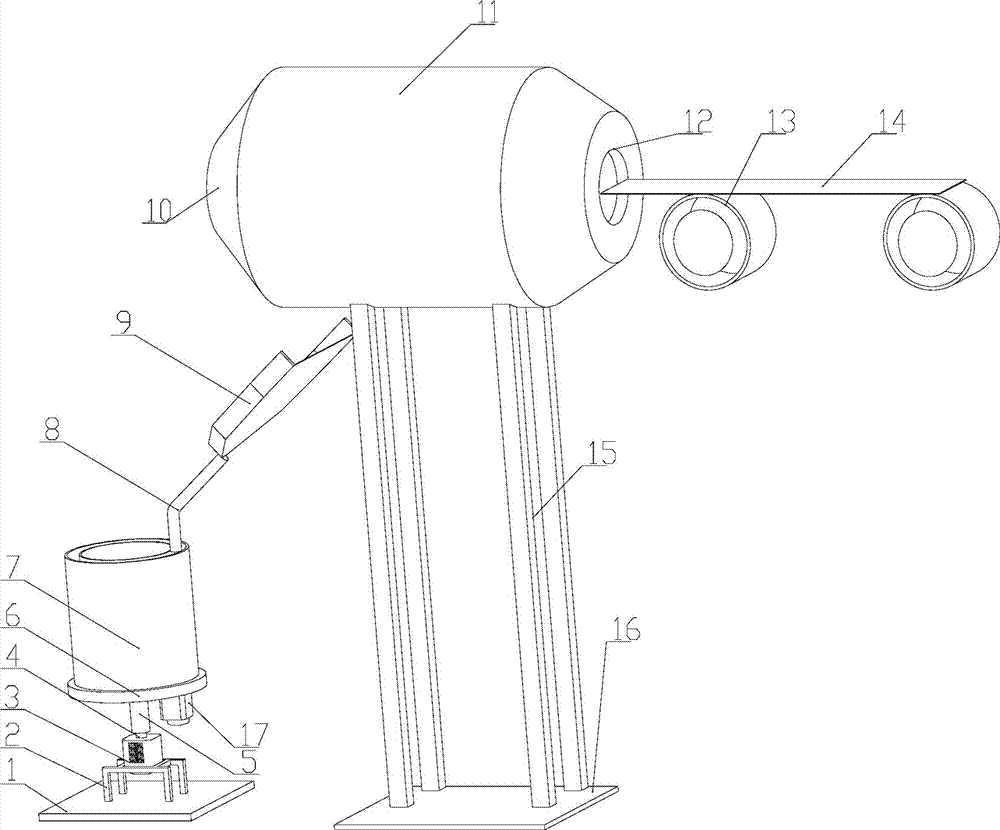

Distribution-uniform vertical centrifuge

InactiveCN105032624AEvenly dispersedUniform clothRotary centrifugesEngineeringMechanical engineering

The invention proposes a distribution-uniform vertical centrifuge. A feeding device comprises a first driving device, and a feeding box arranged in a drum; the feeding box is coaxially arranged with a main shaft, and rotates with the main shaft in opposite directions; a first bin body is arranged in the feeding box; a spraying ring formed by multiple first nozzles is arranged on the side wall of the first bin body in the peripheral direction; first valves are arranged in the first nozzles, and are connected with a controller; and a weight sensor is arranged at the bottom in the first bin body, and is connected with the controller. The distribution-uniform vertical centrifuge feeds raw materials with a preset quantity into the first bin body; the controller controls the opening of the first valves; when the feeding box rotates, the first nozzles spray the raw materials outside the first bin body; the feeding box and the drum relatively rotate; the materials are uniformly dispersed on the inner wall of the drum; the weight sensor detects the weight of the raw materials in the first bin body in real time, and sends the detection result to the controller; and when the detected weight value is equal to the preset weight in the controller, the controller controls the closing of the first valves.

Owner:SHUYANG YUZHAN IND CO LTD

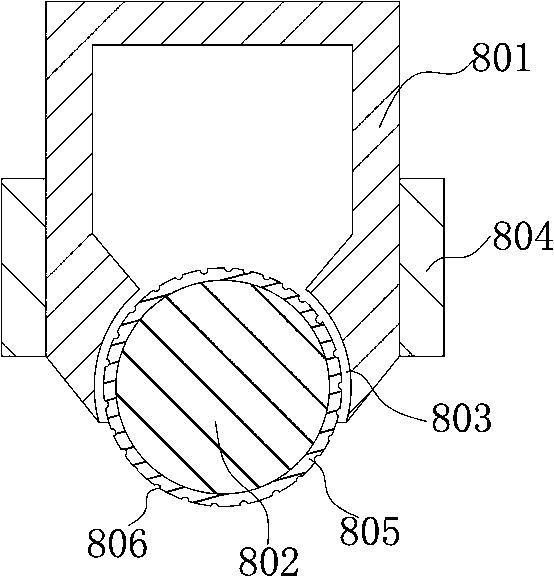

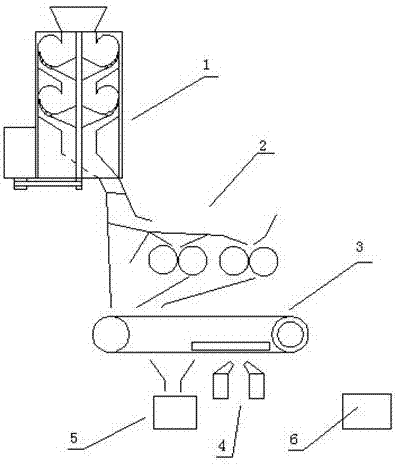

Mine magnetic separator

The invention relates to the field of mine magnetic separation, in particular to a mine magnetic separator. The mine magnetic separator comprises a crushing mechanism, a feeding mechanism, a conveying mechanism and a magnetic separation mechanism. The conveying mechanism is used for conveying magnetic ore output by the crushing mechanism into the feeding mechanism. An output port of the feeding mechanism is opposite to an inlet of the magnetic separation mechanism. The structure is suitable for magnetic ore screening of mines, in-situ magnetic separation is facilitated, and the magnetic separation cost of the ore is reduced. In addition, magnetic separation of the magnetic ore crushed by the crushing mechanism is more facilitated, the magnetic ore is evenly distributed conveniently through the feeding mechanism, production and application of the equipment are convenient, and the magnetic separation efficiency and the recovery rate of the magnetic ore are improved. Crushing is conducted by sufficiently utilizing the characteristics of ore grains, the crushing precision is higher, and safety and effectiveness of equipment application can be guaranteed through the structure. More specific collision is conducted on the magnetic ore through characteristics of the magnetic ore and non-magnetic ore, the service life of the equipment is prolonged, and the feeding mechanism has re-screening and crushing functions.

Owner:浙江国正安全技术有限公司

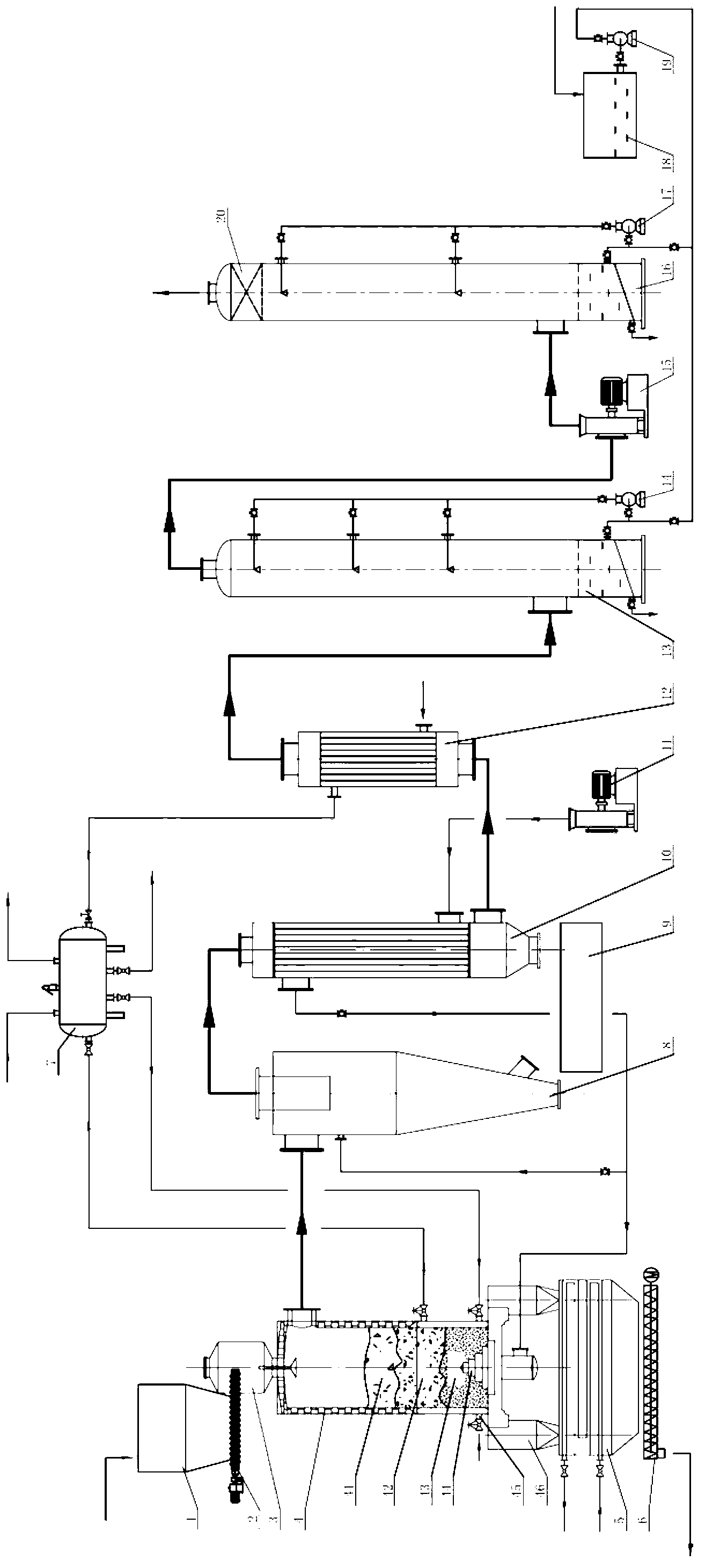

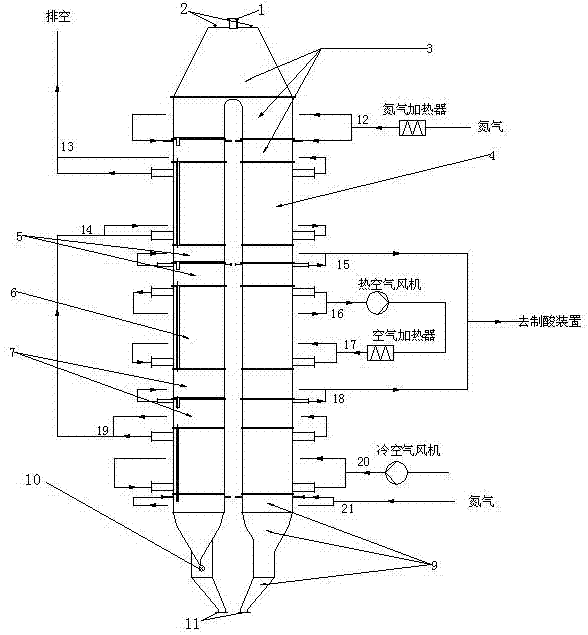

Three-section type carbon-based catalyst regeneration tower system

PendingCN107537591ARealize comprehensive utilizationAvoid corrosionCatalyst regeneration/reactivationThermodynamicsPtru catalyst

The invention provides a three-section type carbon-based catalyst regeneration tower system which can improve an energy utilization rate in a carbon-based catalyst regeneration process and enhance matching and flexibility between a carbon-base catalyst regeneration tower and a desulfurization and denitrification adsorption tower. A tower body of the three-section type carbon-based catalyst regeneration tower system disclosed by the invention is sequentially divided into a preparing section, a preheating section, a first transition section, a heating section, a second transition section, a cooling section and an outlet section from top to bottom; the three sections of the preheating section, the heating section and the cooling section are all of tube-shell type heat exchange structures; thetower body of the regeneration tower serves as a tube pass, a carbon-based catalyst passes through the tube pass, and a heat exchange medium passes through a shell pass; the carbon-based catalyst enters to the tower top and reaches the bottom of the regeneration tower through the tube pass; the first transition section is arranged between the preheating section and the heating section, the secondtransition section is arranged between the heating section and the cooling section, the two transition sections are used for exhausting enrichment SO2 gas in the tower, and the exhausted SO2 gas is introduced into an acid making device.

Owner:GUODIAN SCI & TECH RES INST

Material distributing screening machine

The invention discloses a material distributing screening machine, comprising a machine case (1), a forced fabric plate (2), a driving device (3), a filtering roller (4), a reducer motor (5) and an iron removing device (24), wherein the machine case (1) is provided with a feeding hole (6) and a plurality of discharging holes (10), the filtering roller (4) comprises a flange disk type roller (11) and a filtering rope type roller (12), the filtering roller (4) is provided with the driving device (3), the reducer motor (5) drives the filtering roller (4) to rotate by virtue of the driving device (3), and material enters from the feeding hole (6), is screened by the filtering roller (4) and is discharged by the discharging hole (10). The invention has the beneficial effects that: more than two materials in different grain sizes can be screened by setting different interstitial screen cuts, the working condition requirement for screening more than two materials can be met, screening efficiency is high, bulk material impact resistance is high, material is distributed more uniformly, no blockage is caused, and an iron piece contained in the material can be removed.

Owner:SICHUAN ZHONGMENG ELECTRIC POWER EQUIP MFG CO LTD

Ceramic pipe grinder for food grinding processing

A ceramic pipe grinder for food grinding processing solves the problems that in the prior art, the idle grinding area is large, the material discharge resistance is large, the grinding efficiency is low, the processing capacity is small, the processing effect is poor, the wear-resisting property of grinding discs is poor, the service life is short, and the application range is narrow. The ceramic pipe grinder is characterized in that a movable grinding disc and a semi-open type vane wheel are installed at the shaft end of a motor shaft extending into a shell, a fixed grinding disc is installed in a fixed grinding disc installation clip clutch, the joint surfaces of the fixed grinding disc and the movable grinding disc inwards form an internally-concave cone-shaped grinding cavity, a fixed grinding disc adjusting seat is connected with an adjusting nut in a threaded mode, the internally-concave conical surface of the fixed grinding disc is provided with symmetrical step-shaped oblique teeth, and the internally-concave plane of the movable grinding disc is provided with material guide grooves and trapezoid teeth. The ceramic pipe grinder for food grinding processing has the advantages that the fixed grinding disc and the movable grinding disc have the synergistic action of extruding, smashing, shearing and grinding on foodstuffs, the wear-resisting property is good, the manufacturing cost is low, the service life is long, the whole machine production efficiency is high, the production capacity is large, and the requirements for ultra-fine processing, dry material slurrying and industrialized continuous production can be met.

Owner:LIAONING YINGGUAN HIGH TECH CERAMIC CO LTD

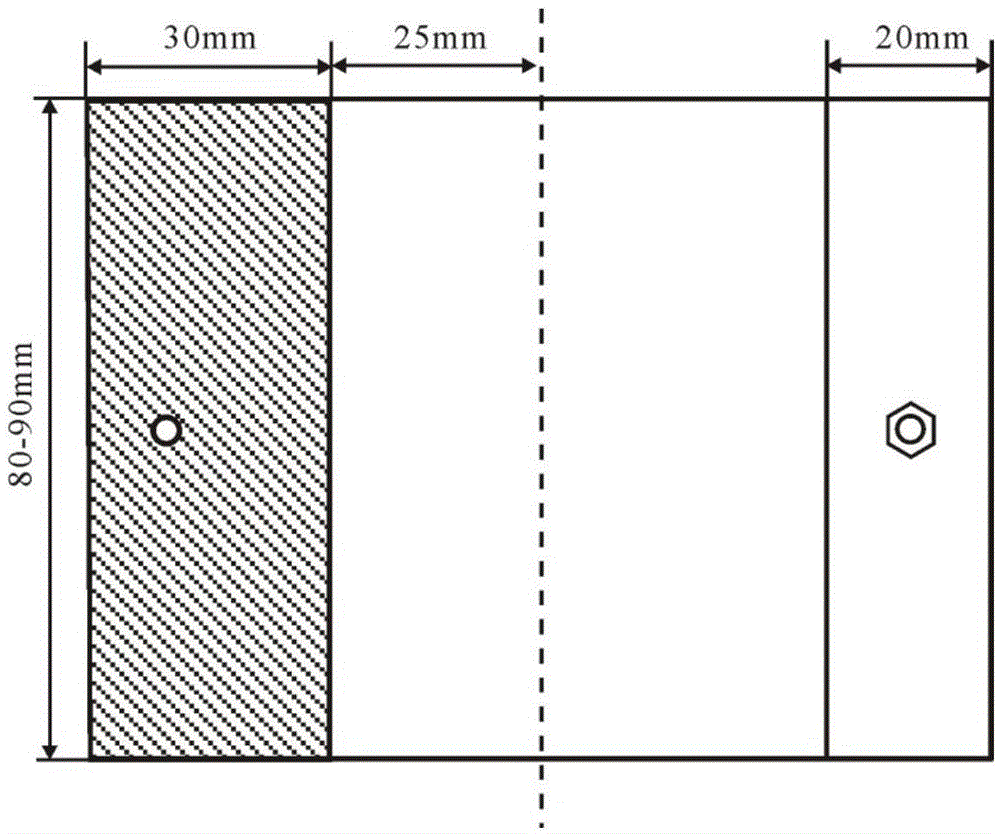

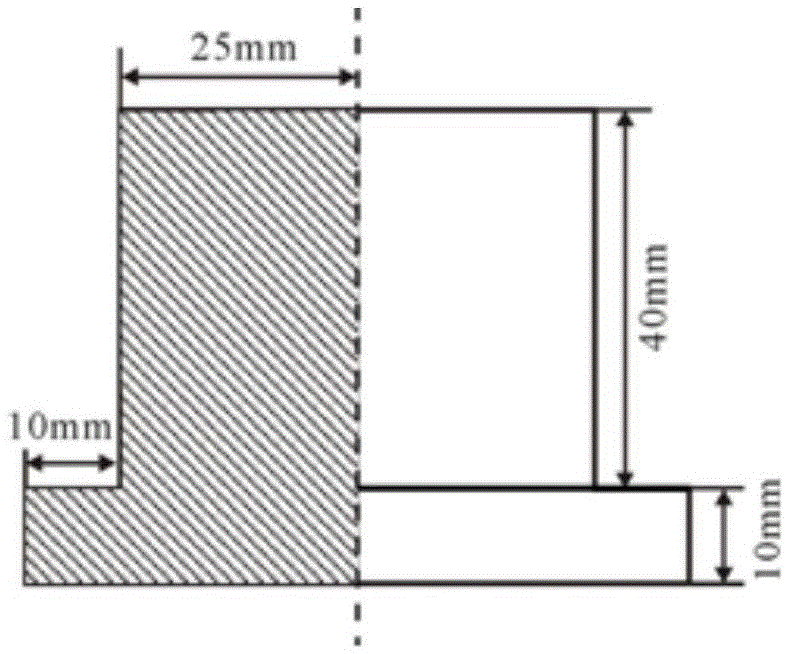

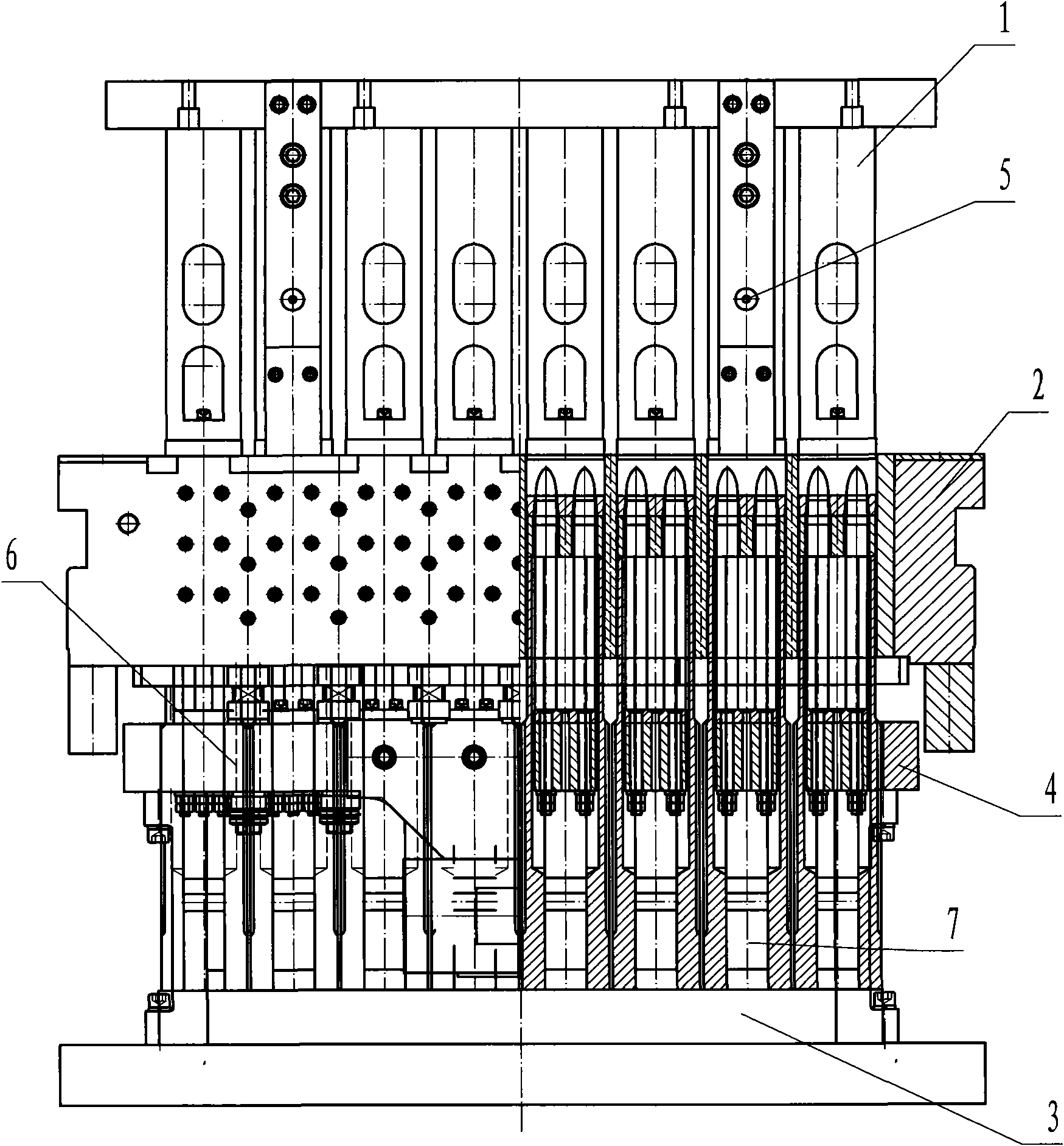

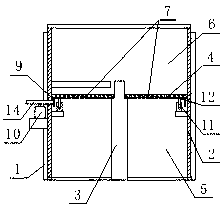

Method for pressing porous brick by using porous brick mould and porous brick mould

The invention discloses a method for pressing a porous brick by using a porous brick mould and the porous brick mould. The porous brick mould comprises an upper die, a middle frame, a lower die and a core rod member, wherein the core rod member comprises a core rod and a cantilever beam, and the middle frame and the core rod member are connected through a connecting rod. The invention provides a porous brick pressing method with high yield and efficiency and the porous brick mould, by utilizing the porous brick mould and the pressing method, the service life of the mould can be greatly prolonged; the material coating in a die cavity can be more uniform, and a brick blank has high density, thereby improving the quality of the brick blank; and the mould has smooth ash removal.

Owner:福建省海源智能装备有限公司

Vertical sedimentation centrifuge

The invention puts forward a vertical sedimentation centrifuge which comprises a shell, a main shaft, a drum sleeving the main shaft, and a machine cover firmly disposed on the top of the shell, wherein a discharge hole is disposed in the bottom of the drum. The vertical sedimentation centrifuge is characterized by comprising a controller and a feeding device, wherein the feeding device comprises a feeding tube and a feeding box disposed inside the drum, the feeding box and the main shaft are rotated in the same direction, and a material jet ring formed by a plurality of spray nozzles is disposed on circumference of the side wall of the feeding box; a feeding hole is disposed in one end of the feeding box near to the machine cover, the feeding tube passes through the machine cover and is stretched into the drum and communicated with the feeding hole, a quantitative feeding valve is disposed on the feeding tube, and the quantitative feeding valve is connected to the controller; and a weight sensor is disposed on one end inside the feeding box remote from the feeding hole, and the weight sensor is connected to the controller. The vertical sedimentation centrifuge provided by the invention can control the feeding tube to add raw materials of a pre-set total quantity into the centrifuge by multiple times, wherein the quantity of the raw materials added each time is equal, the feeding box and the drum are rotated coaxially, and the materials are dispersed uniformly on the inner wall of the drum. The vertical sedimentation centrifuge has low energy consumption, low cost and a simple structure and realizes a uniform material layout.

Owner:大庆博瑞特石油机械设备有限公司

Uniform feeding device for candy ovenware

InactiveCN105398790AAvoid falling at the same timeEvenly distributedJigging conveyorsConveyor partsEngineeringMaterial distribution

The invention discloses a uniform feeding device for candy ovenware. The uniform feeding device comprises a bracket, a vibration disc, a conveyor belt, a controller, a conveying motor and the ovenware, wherein the conveying motor is connected with the conveyor belt; the conveyor belt is driven by the conveying motor and arranged on the bracket; a vibration motor is arranged on the bracket; the output end of the vibration motor is connected with a cam; the cam is connected with the vibration disc; a discharge hole supplied for only one candy to pass through is formed in the vibration disc and matched with the ovenware; a baffle is also arranged at the discharge hole; the height of the baffle is equal to that of the candy; the ovenware is arranged on the conveyor belt, and a weight sensor for detecting the weight of the ovenware is also arranged on the bracket; and the weight sensor and the conveying motor are both electrically connected with the controller. The uniform feeding device for the candy ovenware can ensure uniform material distribution on the candy ovenware during feeding.

Owner:CHONGQING YU NIU FOOD CO LTD

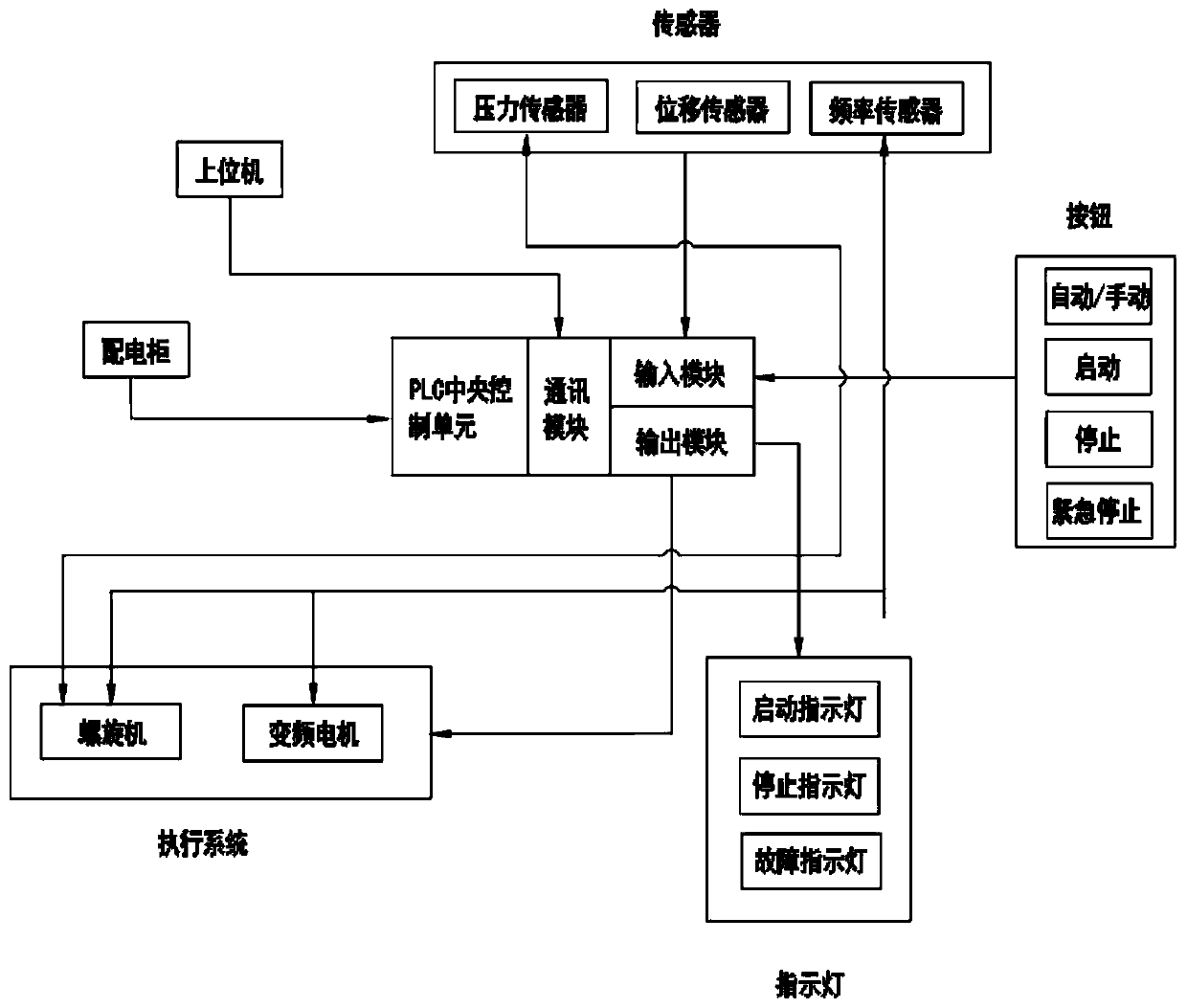

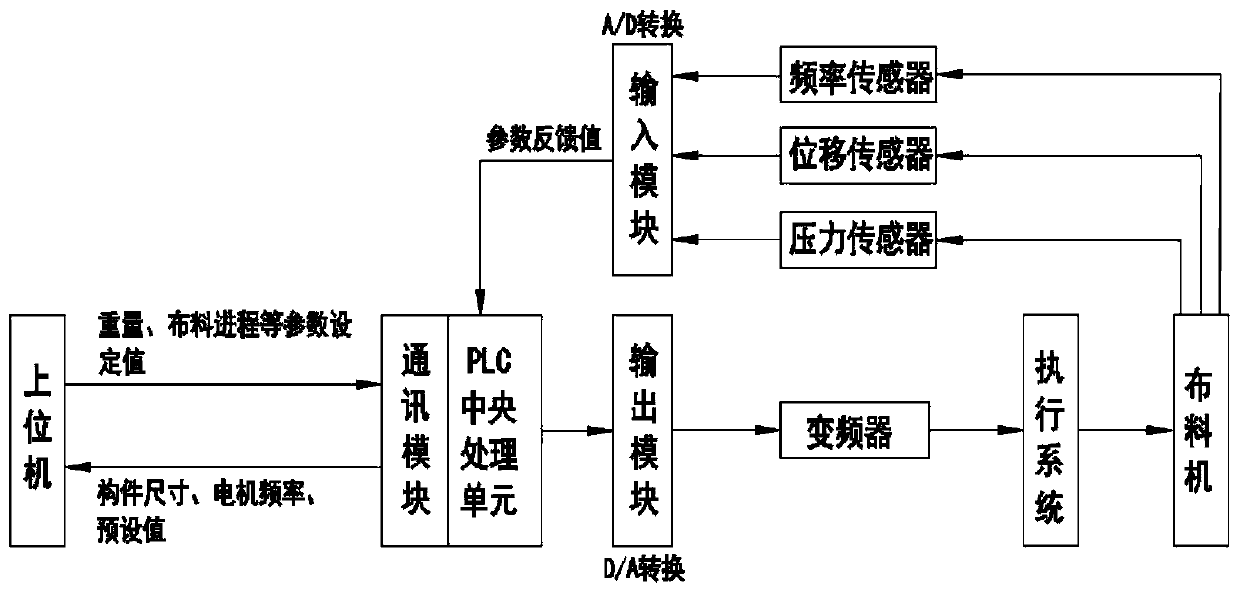

Automatic material distribution machine

PendingCN111347543AEasy to operateImprove consistencyFeeding arrangmentsAuxillary shaping apparatusControl systemControl engineering

The invention discloses an automatic material distribution machine. An executing system and a control system are included. The executing system comprises a foundation supporting beam arranged above aconcrete prefabricated component pouring die, a walking system, a material distribution bin, a lifting system, a metering system and a hydraulic system. The walking system is composed of an X-direction walking system and a Y-direction walking system which achieve all-plane movement on the foundation supporting beam. The walking system carries the material distribution bin, the lifting system, themetering system and the hydraulic system, and the control system is used for controlling the material distribution bin to finish fixed-position quantitative concrete pouring. The automatic material distribution machine is simple in operation, only the length, the width and the thickness of a needed prefabricated component need to be input, the material distribution machine automatically runs, material distribution is uniform, component consistency is enhanced, the component appearance quality is improved, concrete pouring forming of prefabricated components different in shape can be achieved,the automatic material distribution machine is widely applied to multiple different pouring scenes, the device is not limited by the field during usage and is not influenced by the component height, and operation is flexible and convenient.

Owner:中电建成都建筑工业化有限责任公司

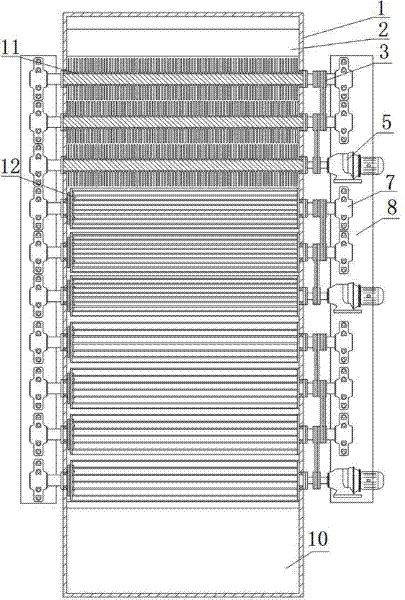

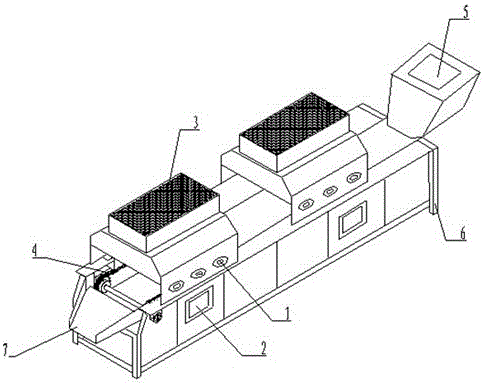

Belt type drier

InactiveCN105115271AImprove drying efficiencySmooth transmissionDrying machines with progressive movementsAgricultural engineeringMaterial distribution

The invention discloses a belt type drier. The belt type drier comprises a drier shell, a drier cavity, a transmission device and a heating drying system. The drier shell is a support of the whole belt type drier. The lower end of the drier shell is provided with a plurality of sets of drier legs. The drier shell is provided with a feeding hopper. An air inlet fan opening, a circulation fan opening, an exhaust fan opening and a humidity elimination fan opening are formed in the drier cavity. The belt type drier is stable in transmission, capable of conducting continuous drying, simple in structure, free of material blocking and even in material distribution, and the drying efficiency of materials is improved.

Owner:太仓市友联干燥粉碎设备有限公司

Special integrated and automatic processing robot for technology for preparing rice noodles from rice

InactiveCN107173684ARealize integrated automatic processingRealize the function of integrated automatic processingDrying gas arrangementsFood shapingUltimate tensile strengthAutomatic processing

The invention relates to an integrated automatic processing robot dedicated to the process of making rice noodles from rice, which includes a bottom plate, a material distributing device is installed at the rear end of the bottom plate, a conveying and rolling device is installed in the middle of the bottom plate, an air-drying device is installed on the conveying and rolling device, and a front end of the bottom plate is installed. The rolling and winding device, the conveying and rolling device, the air-drying device and the rolling and winding device cooperate with each other to complete the integrated automatic processing of rice noodles. The present invention can solve the problems existing in the existing small-scale processing and production of rice noodles in the traditional way, the need to manually use tools to control the thickness of the rice noodle raw material, the need to manually transport and extrude the rice noodle raw material, and the need to manually cool down the extruded rice noodle. Rice flour extrusion processing and cooling treatment cannot be carried out at the same time. The cooled rice noodles are manually wound and stretched. The traditional method of processing rice noodles has problems such as uniform distribution of raw materials, complex operations, high labor intensity and low work efficiency.

Owner:安庆米锐智能科技有限公司

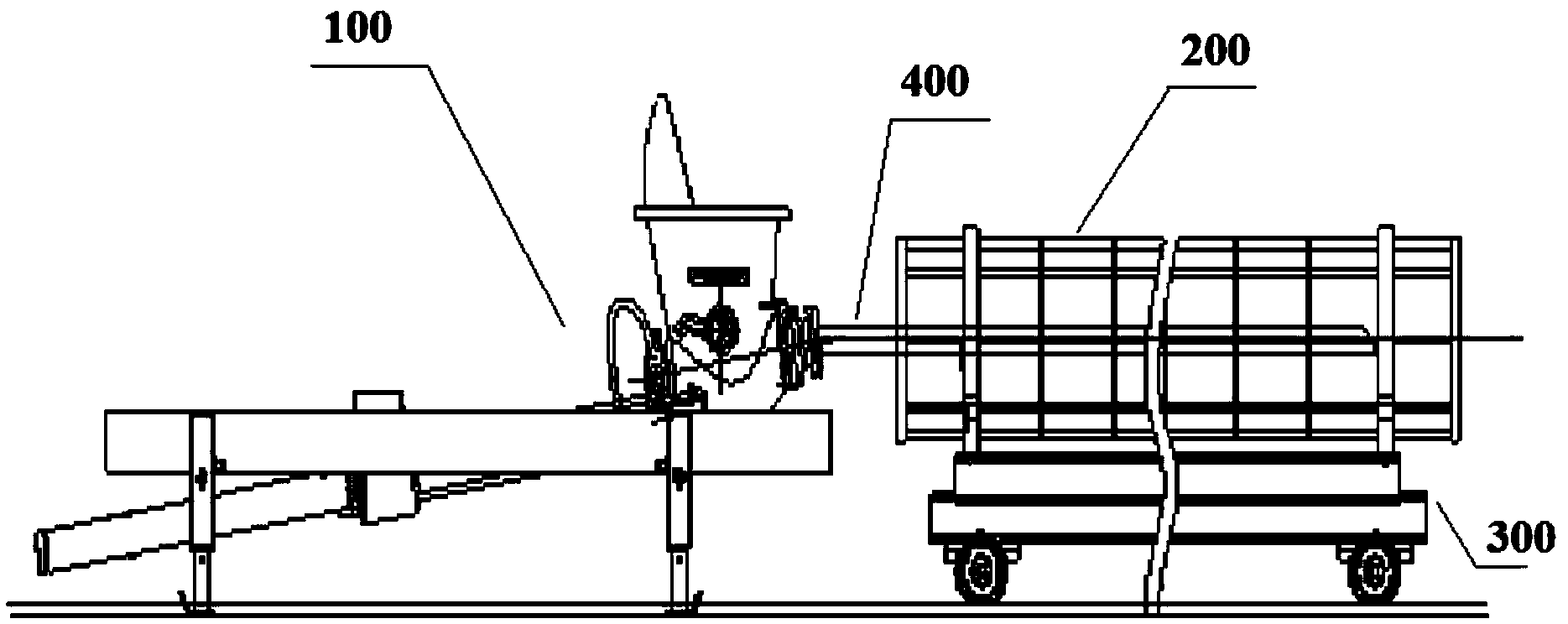

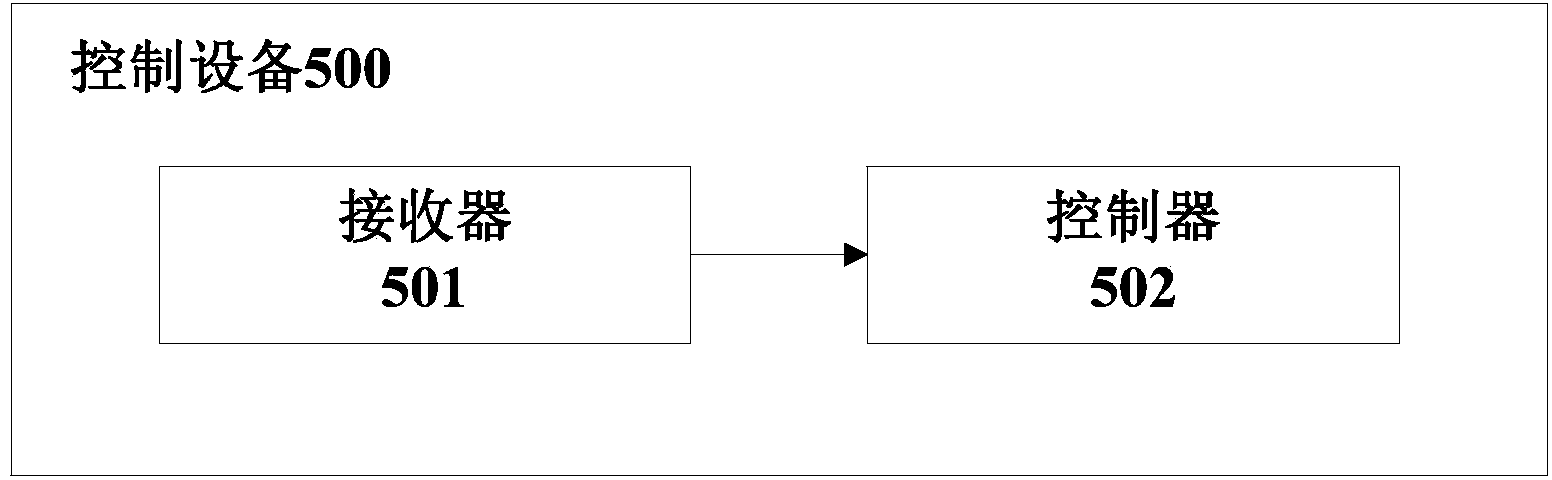

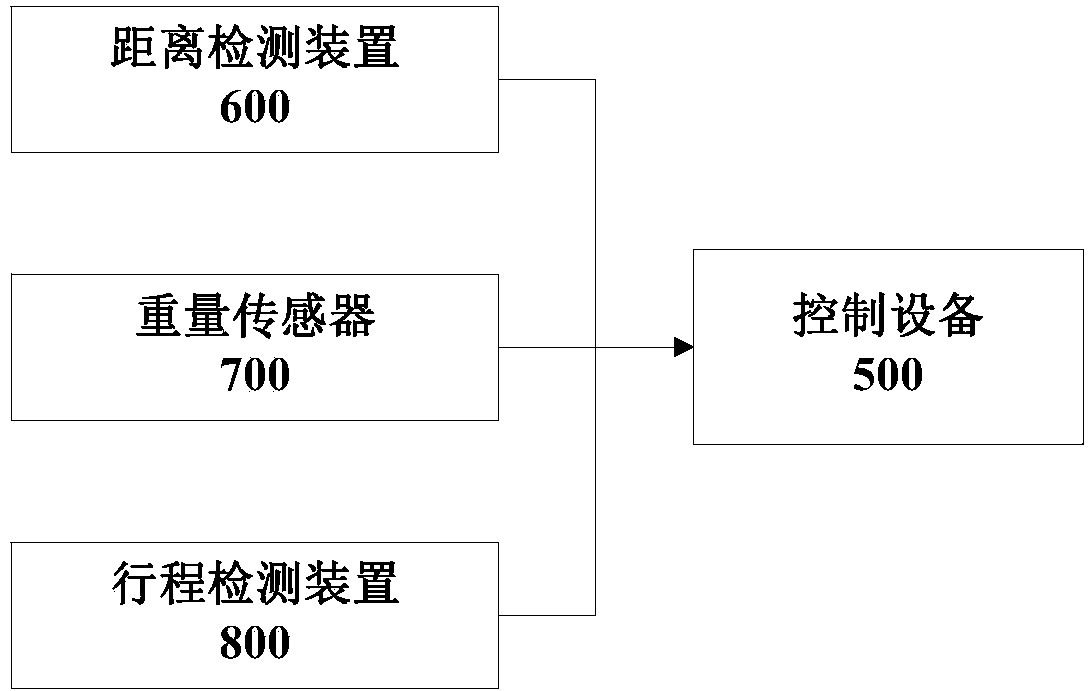

Control device, control system, control method and engineering machinery for tubular pile pumping and distributing system

Disclosed are a control device, a control system, a control method and engineering machinery for a tubular pile pumping and distributing system. The tubular pile pumping and distributing system comprises a concrete pumping device, a tubular pile formwork and a tubular pile formwork conveying device. The control device comprises a receiver and a controller. The receiver is used for receiving data of actual weight of concrete in the tubular pile formwork after one stroke of the concrete pumping device is ended and actual driving distance of the tubular pile formwork conveying device within the stroke. The controller is used for calculating increased actual weight of concrete in the tubular pile formwork within one stroke according to actual weight of the concrete and actual weight of the concrete in the tubular pile formwork at the end of the previous stroke, calculating actual weight of concrete per unit length in the tubular pile formwork according to the increased actual weight of concrete and the actual driving distance, and then regulating the driving speed of the tubular pile formwork conveying device within the next stroke according to the actual weight of the concrete per unit length, the theoretical weight of concrete per unit length and the increased actual weight of concrete. Therefore, weight metering is more accurate, and distributing uniformity is high by means of driving speed control.

Owner:ZOOMLION HEAVY IND CO LTD

Disc type moldy bran preparing machine

InactiveCN103013760AIncrease outputSmall footprintAlcoholic beverage preparationAgricultural engineeringSmall footprint

The invention discloses a disc type moldy bran preparing machine. The disc type moldy bran preparing machine comprises a frame, wherein a yeast preparing chamber of which the bottom and the top are airtight is connected to the frame; a main shaft is arranged in the middle of the yeast preparing chamber; a yeast preparing tray of which the periphery is in seal fit with the inner wall of the yeast preparing chamber is rotatablely connected to the main shaft and is driven to rotate by a power device; the inner space of the yeast preparing chamber is dived into a steam inlet cavity and a yeast preparing cavity from bottom to top by the yeast preparing tray; a plurality of air holes are densely distributed on the yeast preparing tray; a screw feeder and a pneumatic discharger which extend into the upper part of the yeast preparing tray are connected to the upper side wall of the yeast preparing chamber; a steam inlet pipe which is communicated with the steam inlet cavity is connected to the lower side wall of the yeast preparing chamber; and a steam discharge pipe which is communicated with the yeast preparing cavity is connected to the upper side wall of the yeast preparing chamber. By adopting the disc type moldy bran preparing machine, moldy bran can be prepared continuously. The disc type moldy bran preparing machine has the beneficial effects of small floor area, high production efficiency and high yeast preparing quality.

Owner:SHANDONG JINGZHI WINE

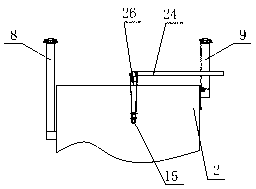

Low moisture coke quenching device and coke quenching method adopting same

The invention provides a low moisture coke quenching device. A low moisture coke quenching method adopting the device is characterized in that firstly primary coke quenching is carried out on high temperature coke formed after carbonization by spraying cold water, then secondary coke quenching is carried out on coke by utilizing massive water vapour produced during water spraying, and low moisture coke is formed after coke quenching is completed. Compared with the coke quenching method in the prior art, which has the problems that accurate control on temperature of semi coke after coke quenching is finished can not be realized, moisture content of the semi coke after the coke quenching is finished is still high and quality of the coke is poor, the low moisture coke quenching method adopting the low moisture coke quenching device can realize the effects that the temperature of the coke after the coke quenching is finished is accurately controlled to be 70-80 DEG C, water consumption in a coke quenching process can be effectively reduced, the moisture content of the coke after the coke quenching is finished is low and is about 1-2%, secondary drying is avoided, and no coal gas consumption is needed; besides, the produced water vapour as well as dust and toxic gas which are carried can be returned to a furnace and utilized again, excessive water vapour is led out through a pipeline for centralized treatment, and secondary pollution is eliminated.

Owner:HUADIAN HEAVY IND CO LTD

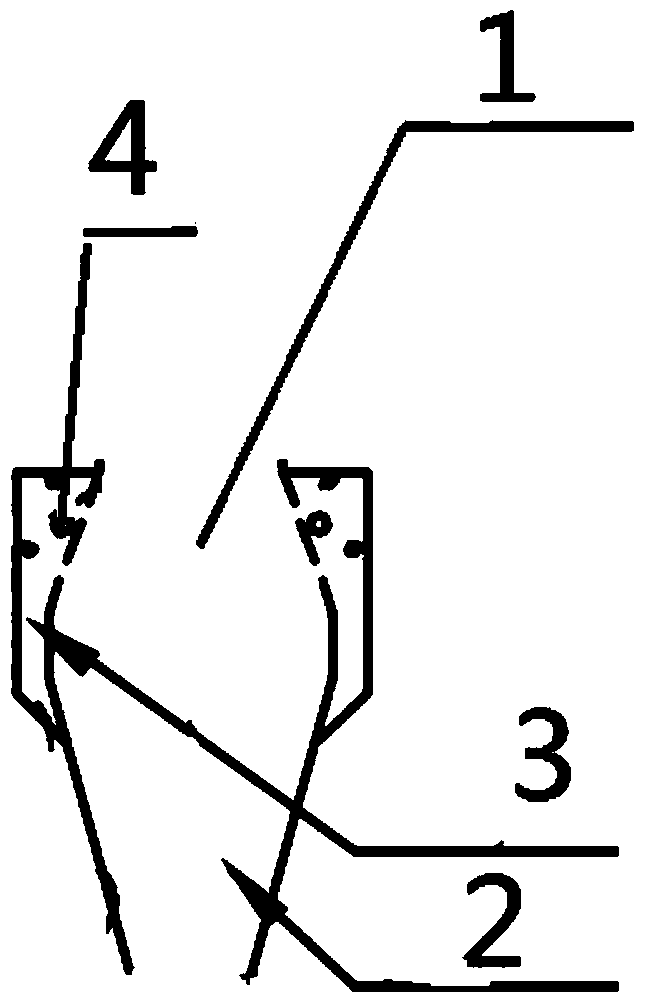

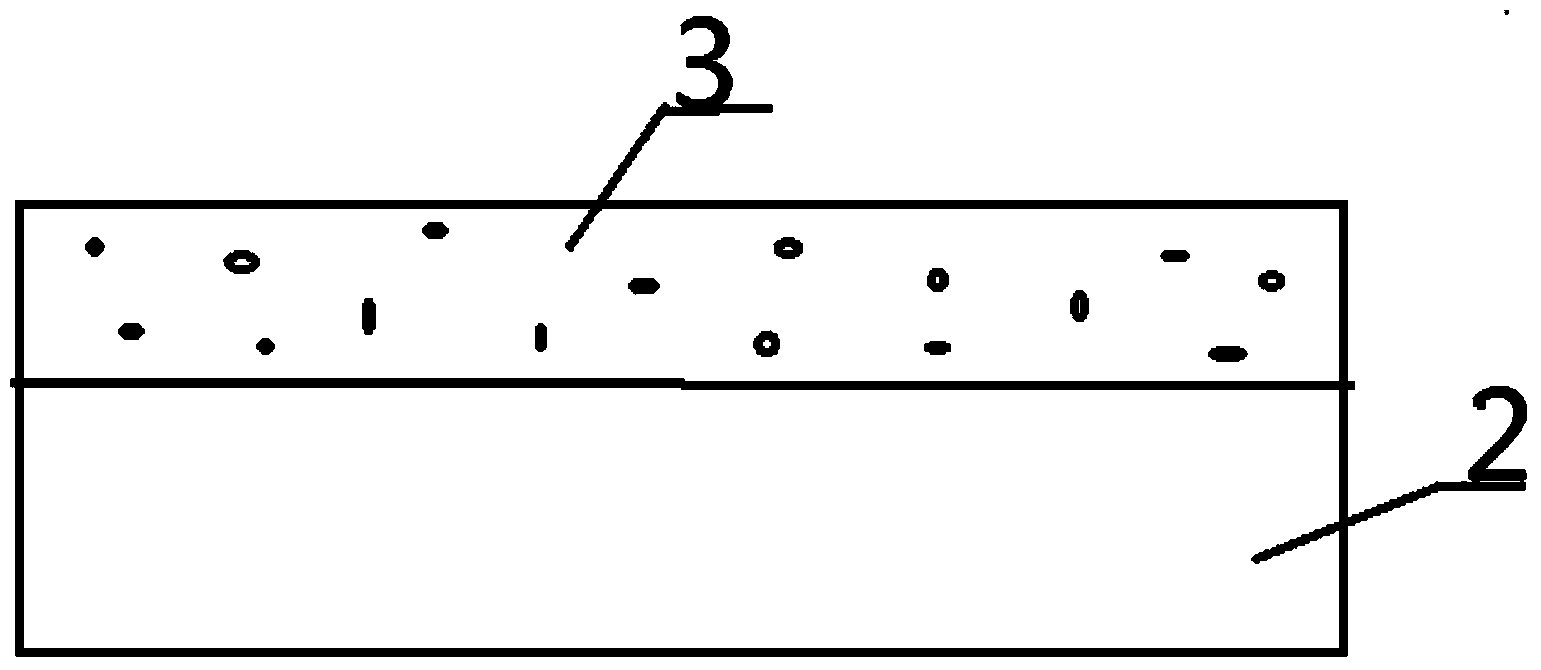

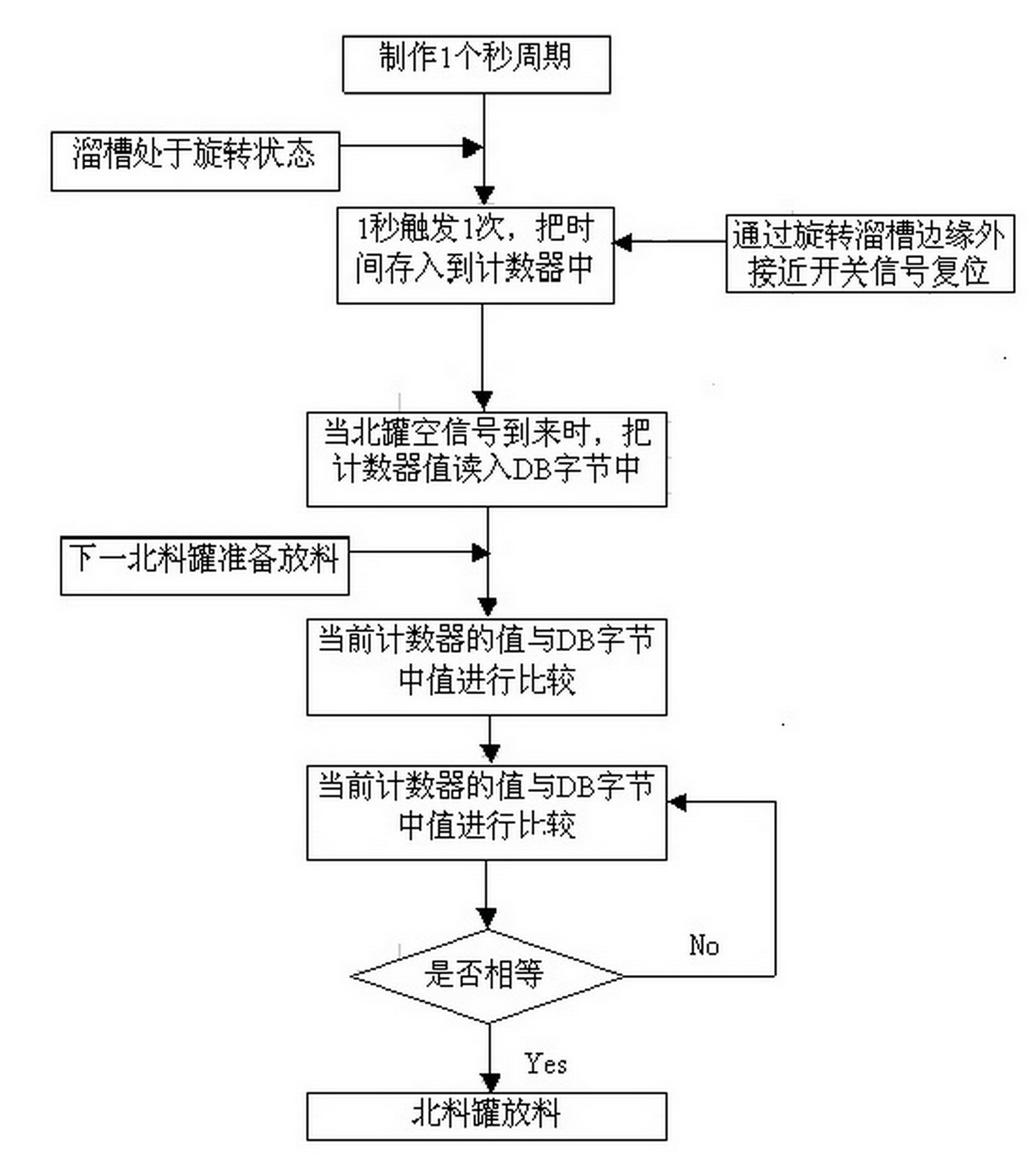

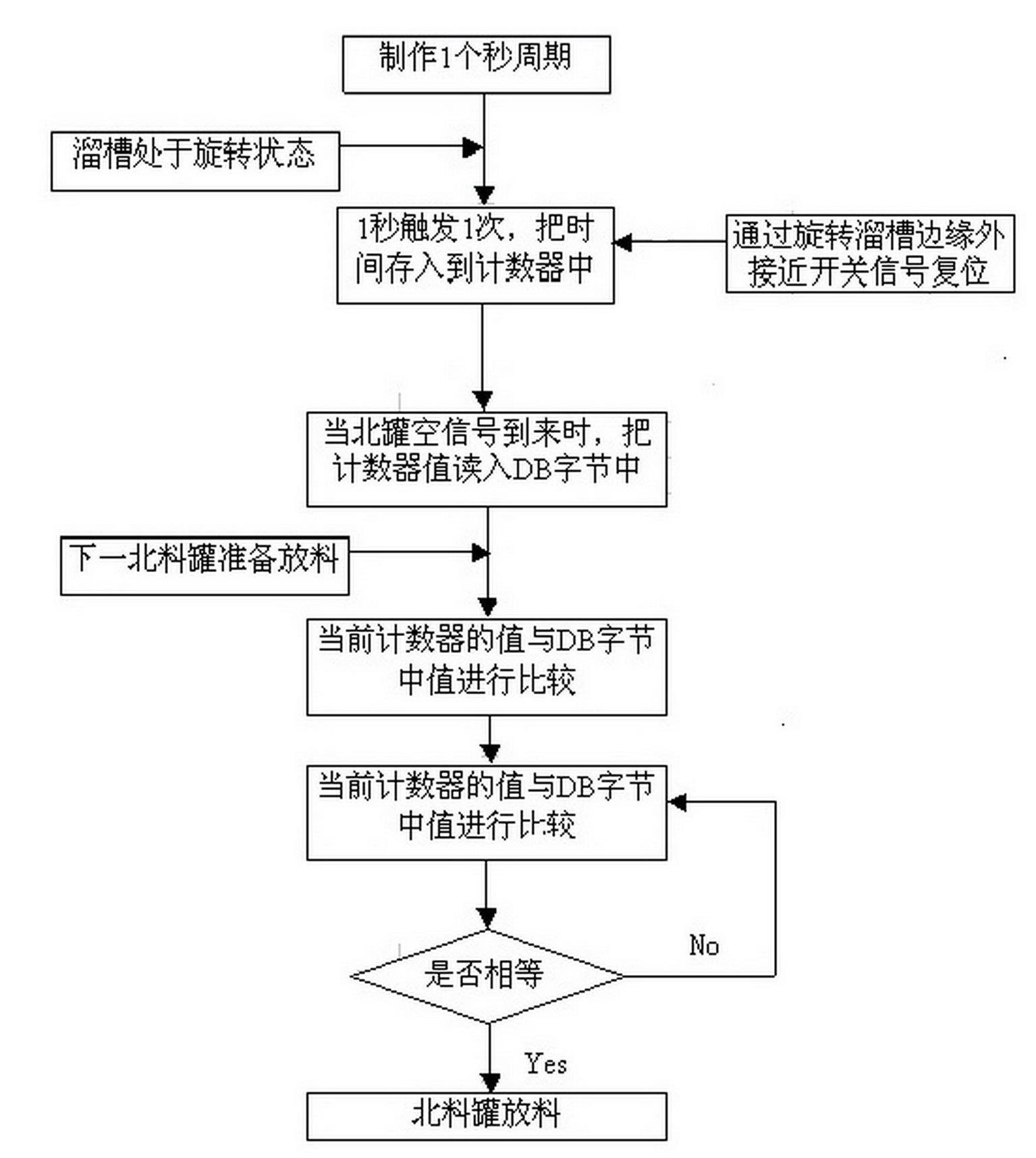

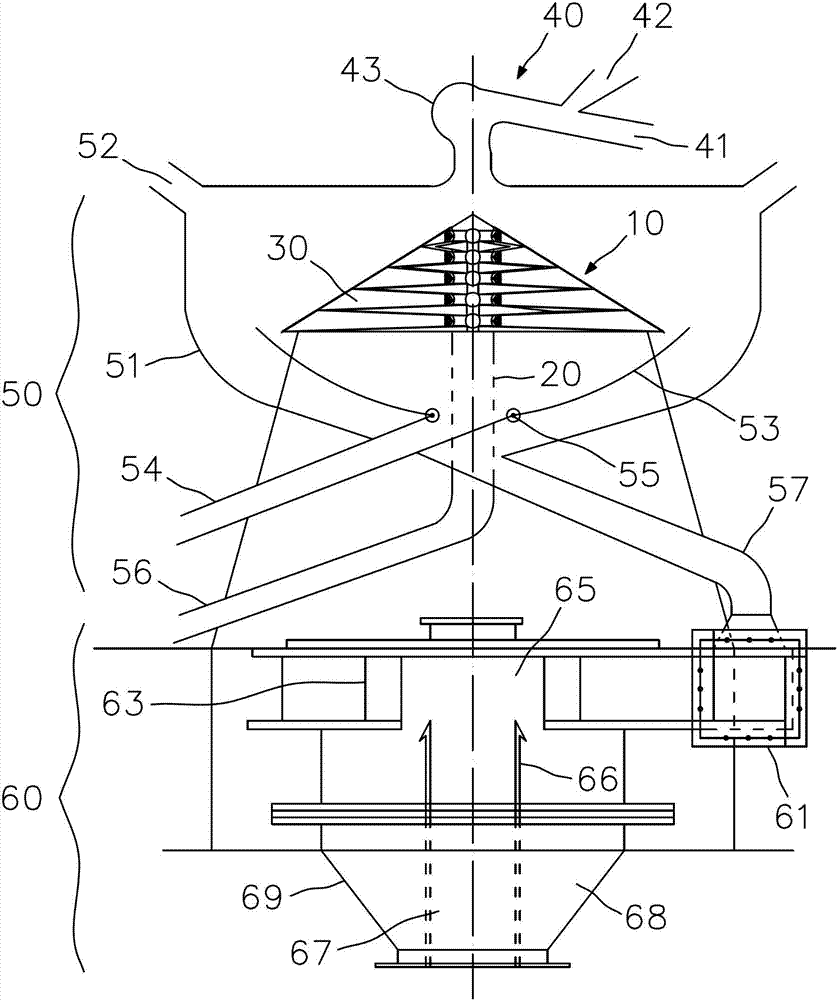

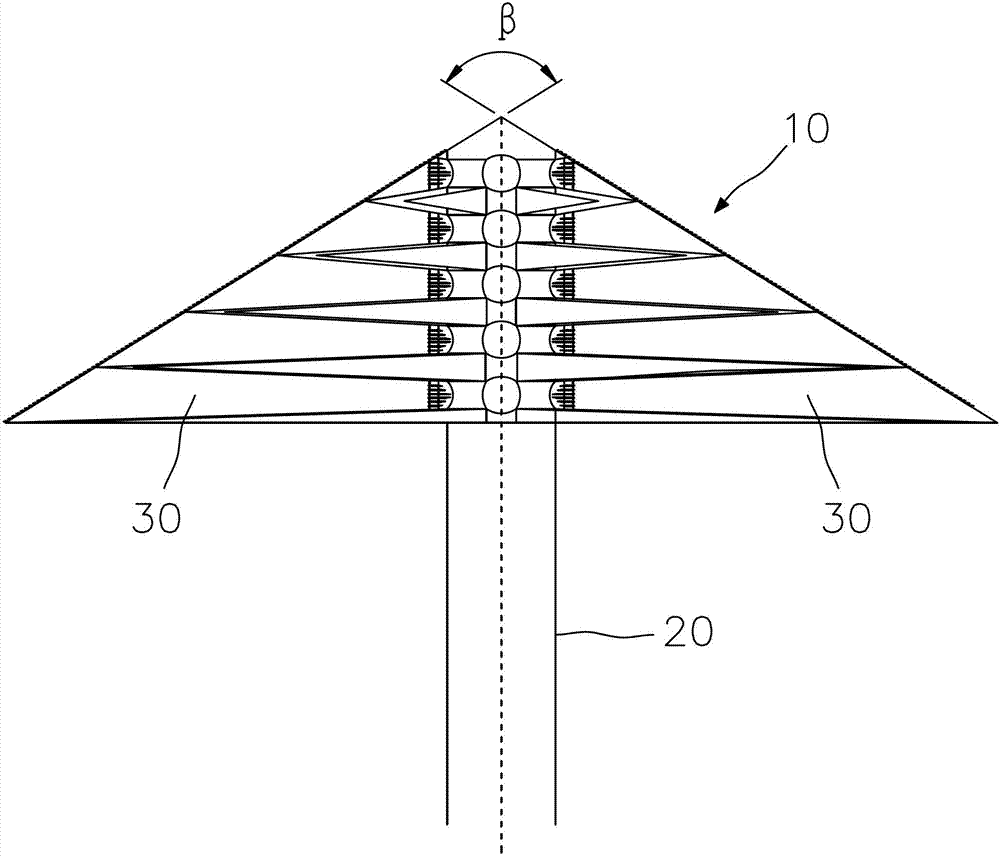

Uniform charging method of bell-less blast furnace

InactiveCN102010923AImprove standardizationMeet the production process requirementsBell-and-hopper arrangementProgram segmentBeta angle

The invention discloses a uniform charging method of a bell-less blast furnace. The method comprises the following steps: 1) an iron block is welded on the beta angle signaling device of a planetary gear reducer, the iron block is matched with a fixed approach switch to act; 2) a second period program segment is added in the blast furnace charging control program; 3) the running time of a rotary chute is continuously stored in the specified counter through second period counting in the production process, then the signals of the approach switch outside the edge of the beta angle signaling device are detected to perform zero clearing operation; and the counting and zero clearing operations are executed in cycles; 4) when a level gage detects the arrival of the empty signals of a stocking tank, the value of the counter is read in the define byte (DB); and 5) when the other charging conditions of the stocking tank for the next batch of material are provided, the step 3) is executed, the current value of the counter is compared with the value in the last recorded DB, if the two values are not equal, the comparison is performed repeatedly; and if the two values are equal, the charging operation of the stocking tank is performed.

Owner:BAOSTEEL GROUP XINJIANG BAYI IRON & STEEL

Self-vibrating even-distributing equipment for molding thick-wall cement pipe

The invention relates to a self-vibrating and uniform distribution equipment for forming thick-walled cement pipes, which comprises a No. 1 workbench, a motor support is fixed on the No. The coupling is connected with the self-vibrating pouring device. The self-vibrating pouring device is provided with a pouring mold. The top of the pouring mold is provided with a slurry conveying device for conveying the pouring slurry. The slurry is provided above the slurry conveying device. A stirring device, the other end of the slurry stirring device is connected with the raw material conveying device. The equipment is capable of pouring thick-walled cement pipes, ensuring the uniformity of pouring during the pouring process, and at the same time, it has the function of self-vibration, which improves the pouring quality and pouring efficiency, and has a high degree of automation.

Owner:枝江市鄂西水泥制品有限责任公司

Efficient airflow classification fine-coal remover for power coal before selecting

InactiveCN102784757AEvenly dispersedSmooth dischargeGas current separationMaterial classificationGranularity

The invention belongs to the technical field of fine-coal removal and classification before washing and selecting of coal and particularly relates to an efficient airflow classification fine-coal remover for power coal before selecting. The fine-coal remover comprises the following components such as a material dispersion area, a primary classification area and a secondary classification area; in the material dispersion area, materials are collided under the impact of airflow and are dispersed mutually; in the primary classification area, the materials after dispersion are divided into primary fine particle materials and primary coarse particle materials through a 360-degree full-annular air-distribution and material-distribution mechanism; and in the secondary classification area, the primary fine particle materials are divided into secondary fine particle materials and secondary coarse particle materials through a wind power rotary driving classification mechanism, and the secondary fine particle materials and the secondary coarse particle materials are discharged out of the secondary classification area so as to finish the eventual classification. According to the invention, the material classification process includes two dispersions and two classifications, so as to solve the problem of screen blinding as well as improve classification efficiency at the same time, realize that classification granularity can be adjusted and controlled within 0-13 mm as required, meet the requirements of classification and section of whole particle dry process, and ensures that a circulating fluidized bed furnace of a mine -mouth power plant has coal to use for generating power.

Owner:ANHUI UNIV OF SCI & TECH

Belt drier for traditional Chinese medicine decoction pieces

InactiveCN106123544ACompact designSmooth transmissionDrying solid materials with heatDrying gas arrangementsHorizontal transmissionEngineering

The invention discloses a belt drier for traditional Chinese medicine decoction pieces. The belt drier comprises a base, wherein machine frame legs are arranged at the lower end of the base; foot pads are arranged on the machine frame legs; cavities are arranged in the middle of the base; the cavities are drier cavities; a horizontal transmission plate is arranged on the drier cavities and connected with a conveying belt; one end of the conveying belt is connected with a discharge opening; and the other end of the belt is connected with a feed opening. The belt drier for the traditional Chinese medicine decoction pieces is compact in design structure, free of material blockage, stable in transmission and uniform in material distribution.

Owner:太仓市友联干燥粉碎设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com