Automatic material distribution machine

A distributing machine and distributing technology, which is applied to ceramic forming machines, auxiliary forming equipment, supplying devices, etc., can solve the problems of extensive construction, complicated operation, and inability to ensure uniform distribution, and achieve improved appearance quality, enhanced consistency, and uniform distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

[0041] In conjunction with the accompanying drawings.

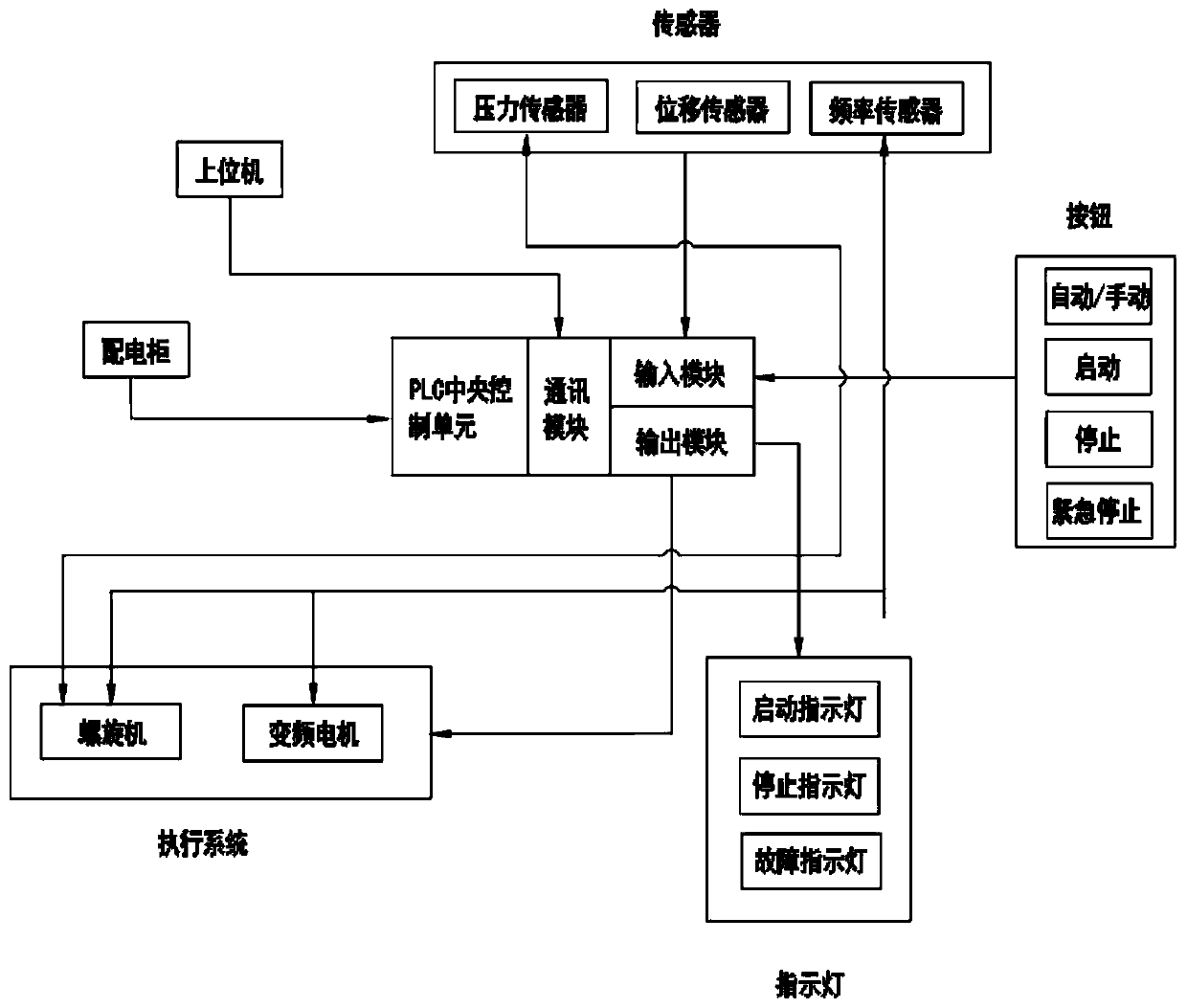

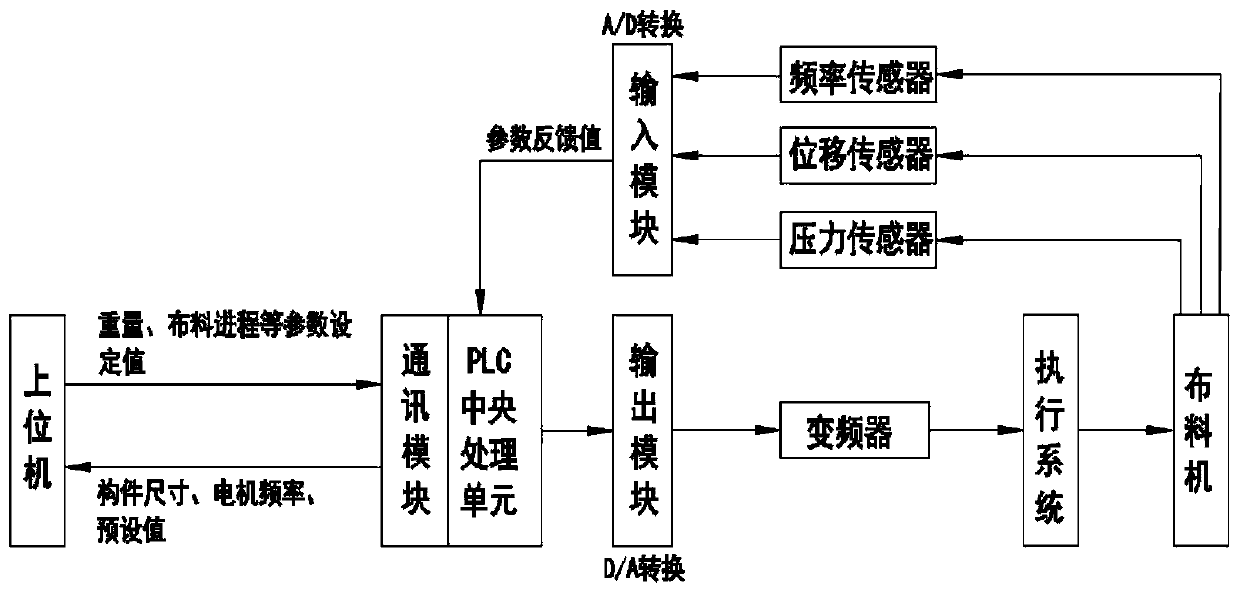

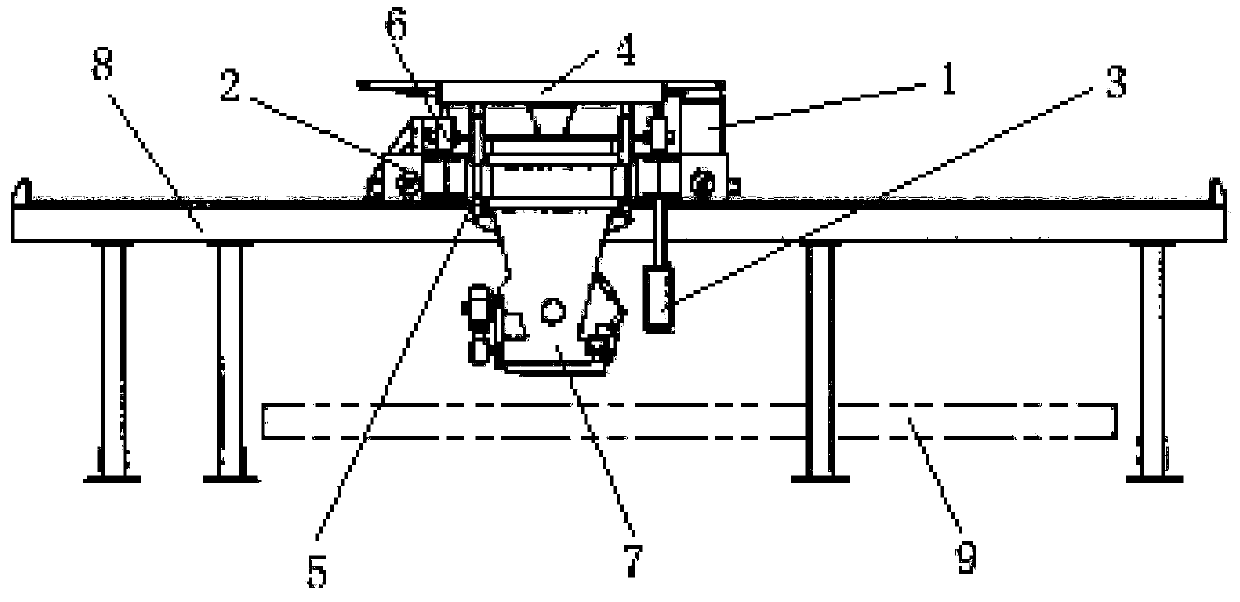

[0042] Figure 4 , Figure 5 As shown, the distribution machine consists of X-direction travel system 2 as the X-direction travel system, Y-direction travel system 6 as the trolley travel mechanism, and also includes a distribution warehouse 7, a lifting system 4, a metering system 3, a hydraulic system 5 and an electric control system 1.

[0043] Among them, the X-direction traveling system 2 and the Y-direction traveling system 6 are composed of frequency converters, variable frequency motors and corresponding rails, which can realize vertical and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com