Self-vibrating even-distributing equipment for molding thick-wall cement pipe

A technology of uniform material distribution and cement pipes, which is applied in the direction of ceramic molding machines, supply devices, manufacturing tools, etc., can solve the problems of reduced service life, inconvenient use, and insufficient strength of cement pipe walls, so as to prevent accumulation, improve pouring quality, The effect of uniform cloth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

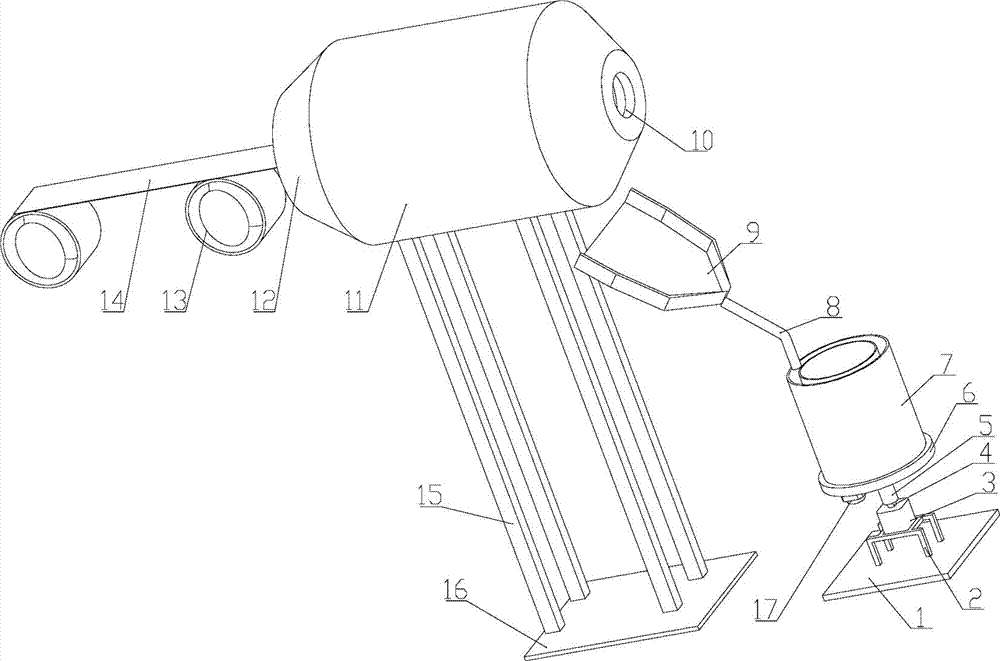

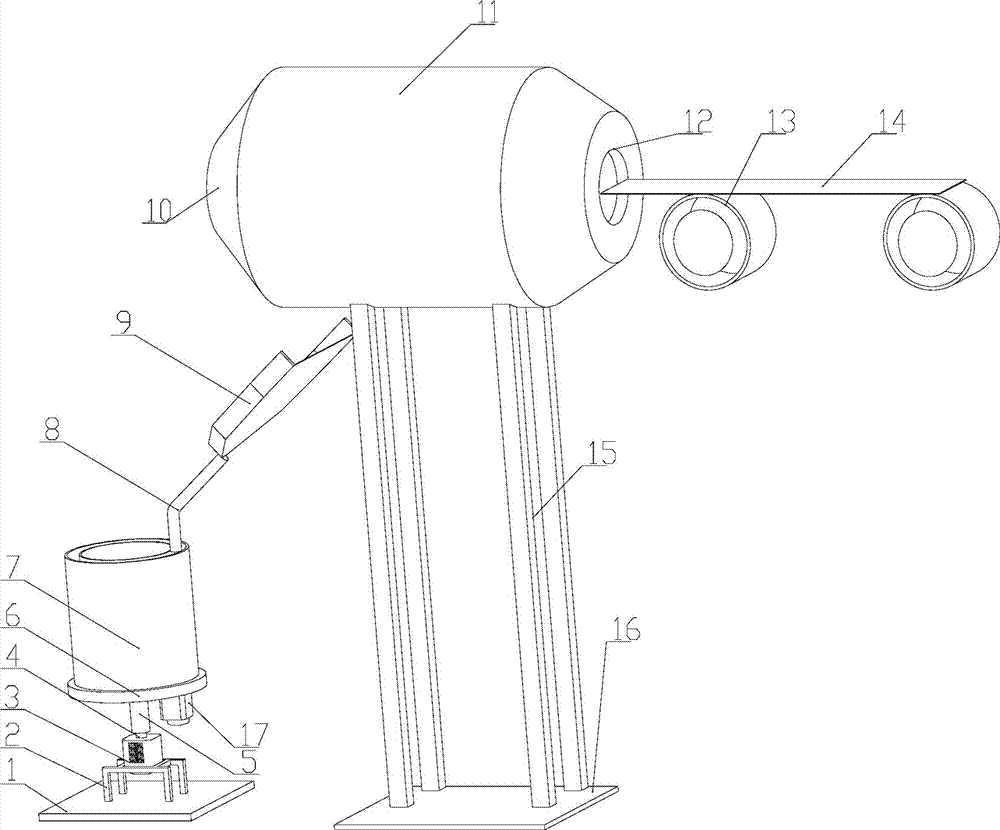

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0017] see Figure 1-2 , a self-vibrating uniform material distribution equipment for forming thick-walled cement pipes, it includes a No. 1 workbench 1, a motor bracket 2 is fixed on the No. 1 workbench 1, a motor 3 is fixedly installed on the motor bracket 2, and a motor 3 The output shaft 4 is connected to the self-vibrating pouring device through a coupling. The self-vibrating pouring device is provided with a pouring mold 7, and the top of the pouring mold 7 is provided with a slurry conveying device for conveying the pouring slurry. A slurry stirring device is arranged above the device, and the other end of the slurry stirring device is connected with the raw material conveying device. The cement pipe can be poured through the above structure, and the pouring efficiency can be effectively improved.

[0018] Further, the self-vibrating pouring dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com