Disc type moldy bran preparing machine

A kind of manufacturing machine, disc-type technology, applied in the field of disc-type bran koji manufacturing machine, can solve the problems of low production efficiency, large floor area, uneven mixing, etc., and achieve high production efficiency, small floor space, high production quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

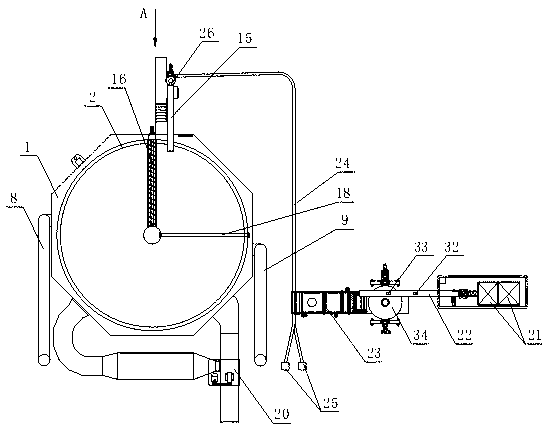

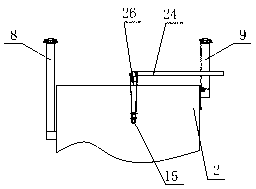

[0022] like figure 1 The shown disc type bran koji making machine includes a frame 1, the frame 1 is connected with a koji-making chamber 2 with a closed bottom and a top, and one side of the koji-making chamber 2 is provided with a feeding device and a feeding pipe 24 , according to the workshop space, a plurality of koji-making chambers 2 can be arranged, and one or two sets of feeding devices can be set up. connect.

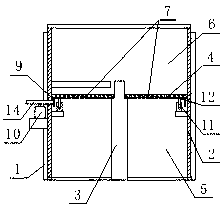

[0023] like figure 1 and figure 2 As shown in the figure, a main shaft 3 is arranged in the middle of the music-making chamber 2, and the main shaft 3 is rotatably connected with a music-making tray 4 whose periphery is sealed with the inner wall of the music-making chamber 2 and is driven and rotated by a power device. The camber motor 10 on the side wall, the lower surface of the camber tray 4 is surrounded by toggle columns 13 arranged at intervals, the power output shaft of the camber motor 10 is provided with a horizontal arrangement and cooperates wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com