Patents

Literature

416results about How to "Meet the production process requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

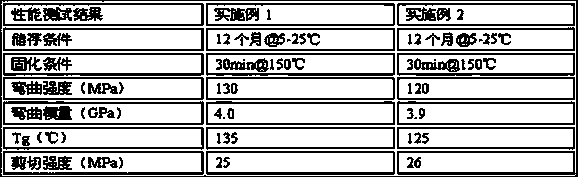

Thermosetting resin composition for integrated circuit as well as prepreg and laminated board both fabricated by using composition

ActiveCN103265791AImprove heat resistanceHigh Tg characteristicSynthetic resin layered productsHigh densityPrepolymer

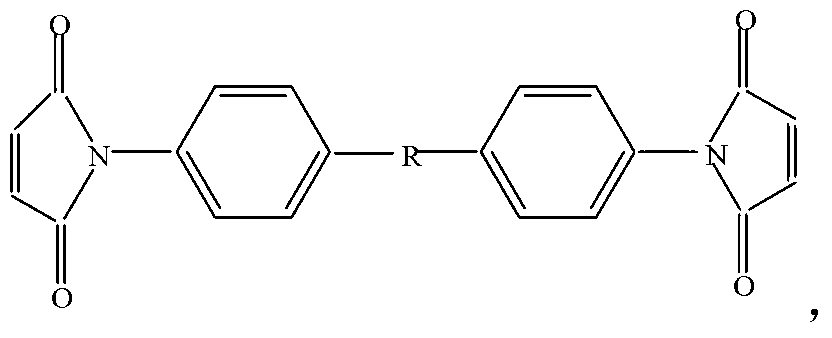

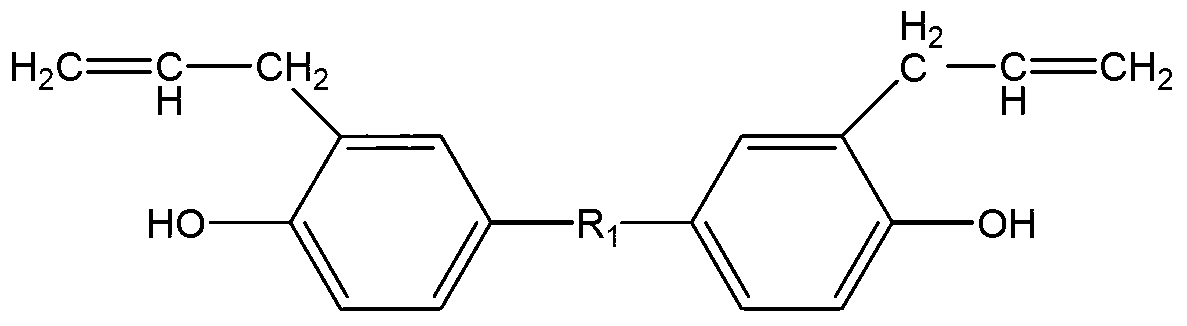

The invention discloses a thermosetting resin composition for an integrated circuit. The thermosetting resin composition comprises (a) 10-60 parts of an allyl modified bismaleimide resin prepolymer, (b) 10-40 parts of an anhydride compound, (c) 10-50 parts of benzoxazine resin, (d) 5-50 parts of epoxy resin, (e) 5-50 parts of a fire retardant, (f) 0-5 parts of a curing accelerator and (g) 0-35 parts of inorganic stuffing, wherein the number-average molecular weight of the allyl modified bismaleimide resin prepolymer is 1500-8000 g / mol. The resin composition provided by the invention keeps high heat resistance and high Tg characteristic of the allyl modified bismaleimide resin prepolymer, and achieves UL94V-0 level in halogen-free flame retardant aspect on the basis of low phosphorus content, and simultaneously, has low dielectric constant of the anhydride; and therefore, the resin composition is capable of meeting the requirements of the production process of high-performance printed circuit boards such as a high-density interconnected integrated circuit package.

Owner:SHENGYI TECH SUZHOU

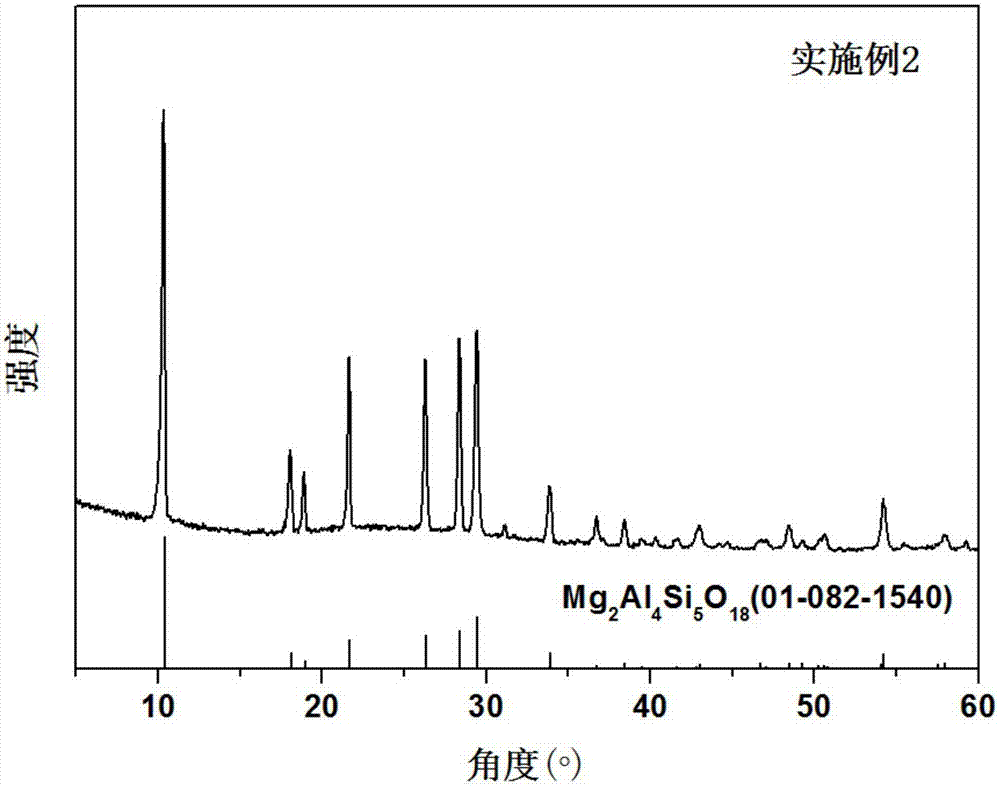

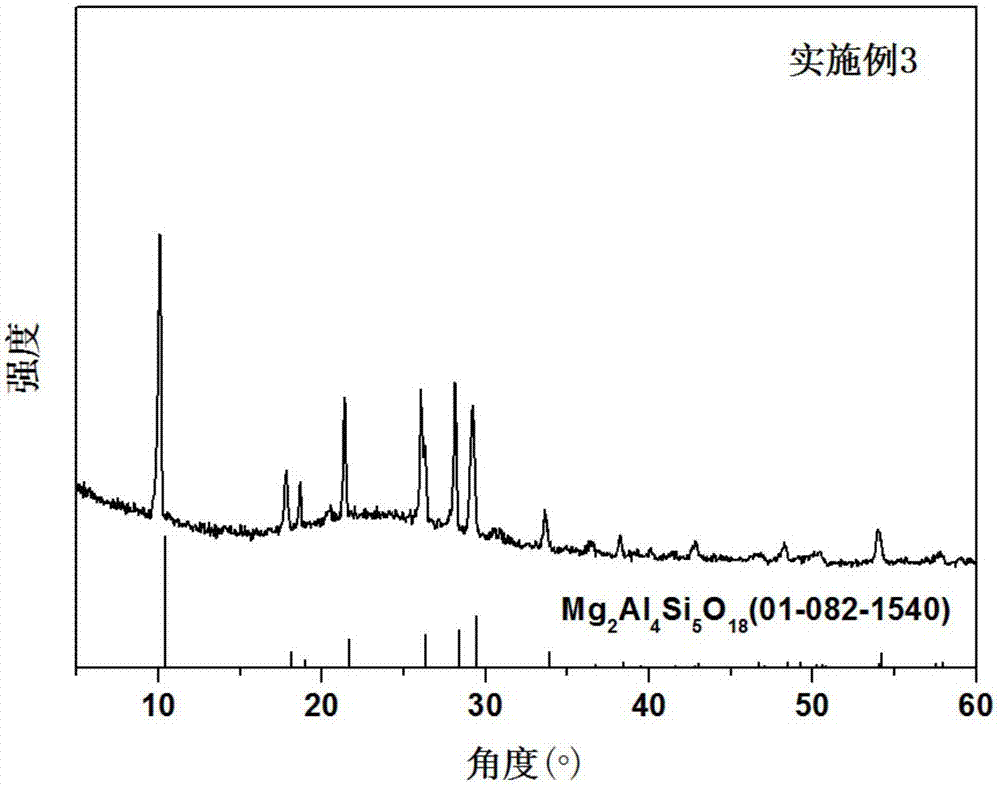

High-abrasion-resistance ceramic glazed brick and manufacturing method thereof

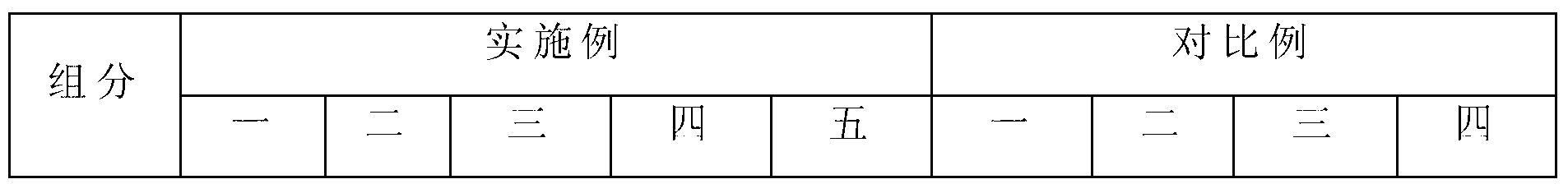

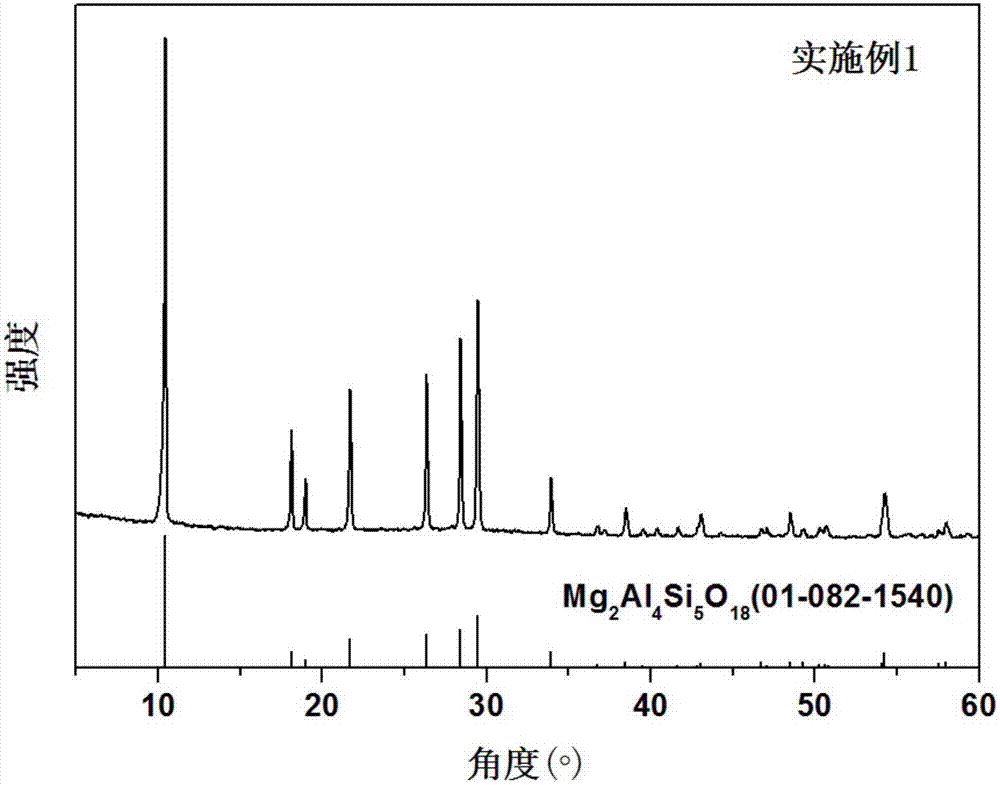

The invention discloses a high-abrasion-resistance ceramic glazed brick and a manufacturing method thereof. The ceramic brick surface is provided with a glaze layer; the glaze layer of the high-abrasion-resistance ceramic glazed brick is characterized in that a cordierite crystal is taken as a main crystal phase; the glaze layer contains 10 to 60 percent of the cordierite crystal; the glaze layer is mainly prepared from the following chemical components in percent by weight: 50 to 65 percent of SiO2, 10 to 25 percent of Al2O3, 6 to 15 percent of MgO, 2 to 10 percent of CaO, 0 to 2 percent of Li2O, 0 to 4 percent of Na2O, 0 to 4 percent of K2O, 0 to 3 percent of ZnO, 0 to 3 percent of BaO, 0 to 2 percent of SrO, 0 to 2 percent of B2O3 and 0 to 2 percent of TiO2. The prepared glazed layer containing the cordierite crystal has the advantages of remarkably improving the hardness and abrasion resistance of a glaze surface, and enlarging the application range of the glazed brick under the condition of keeping the transparency of the glaze layer.

Owner:佛山市大千色釉料有限公司

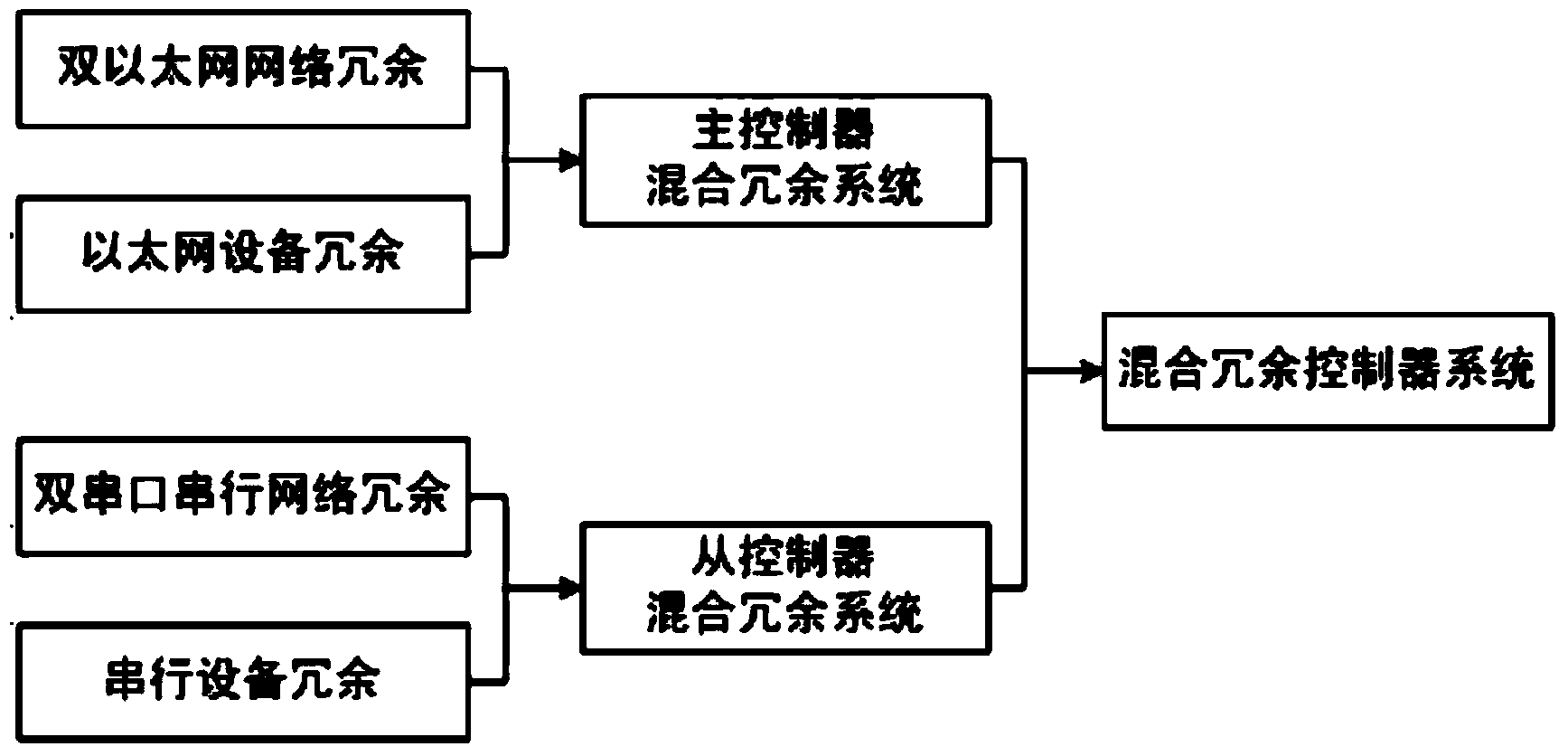

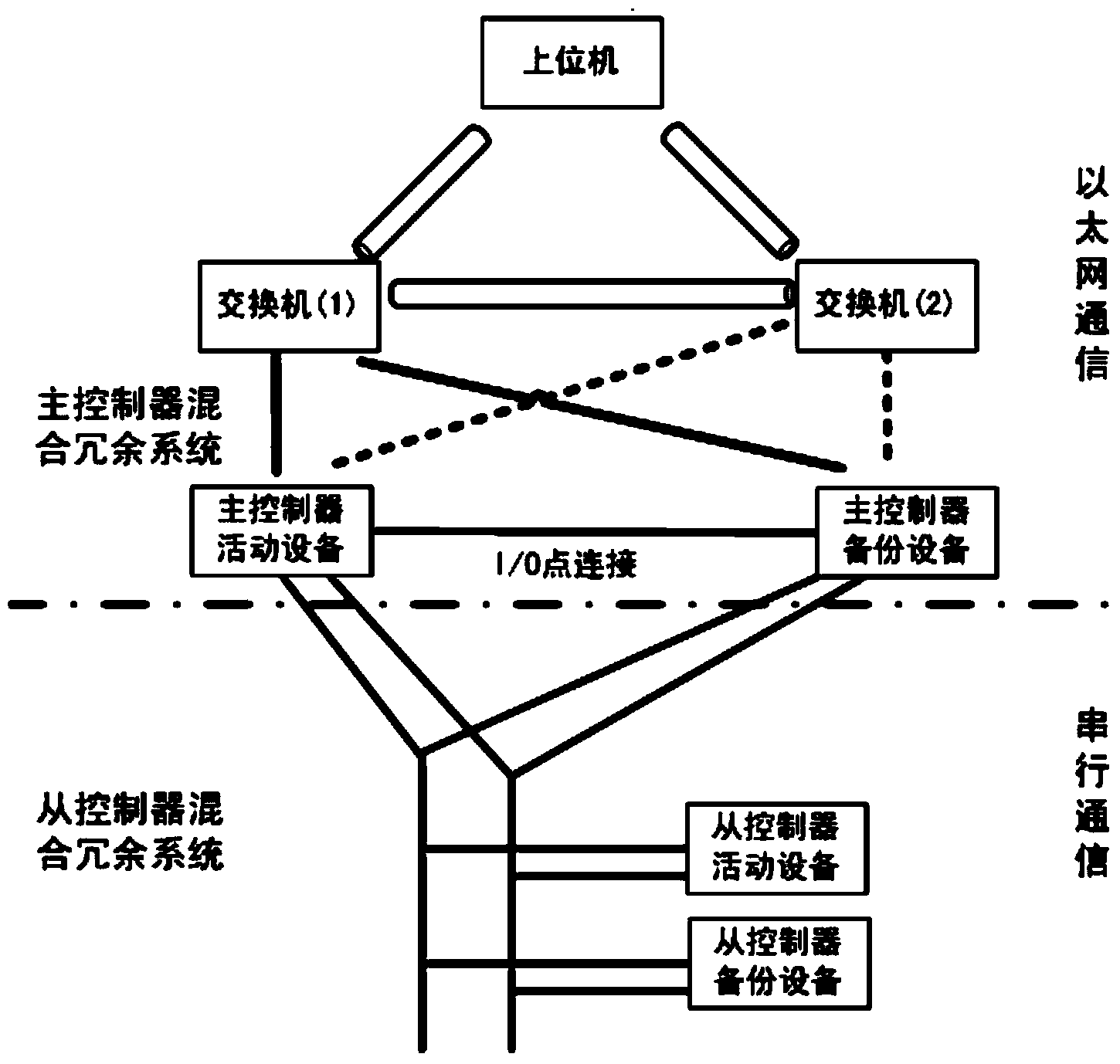

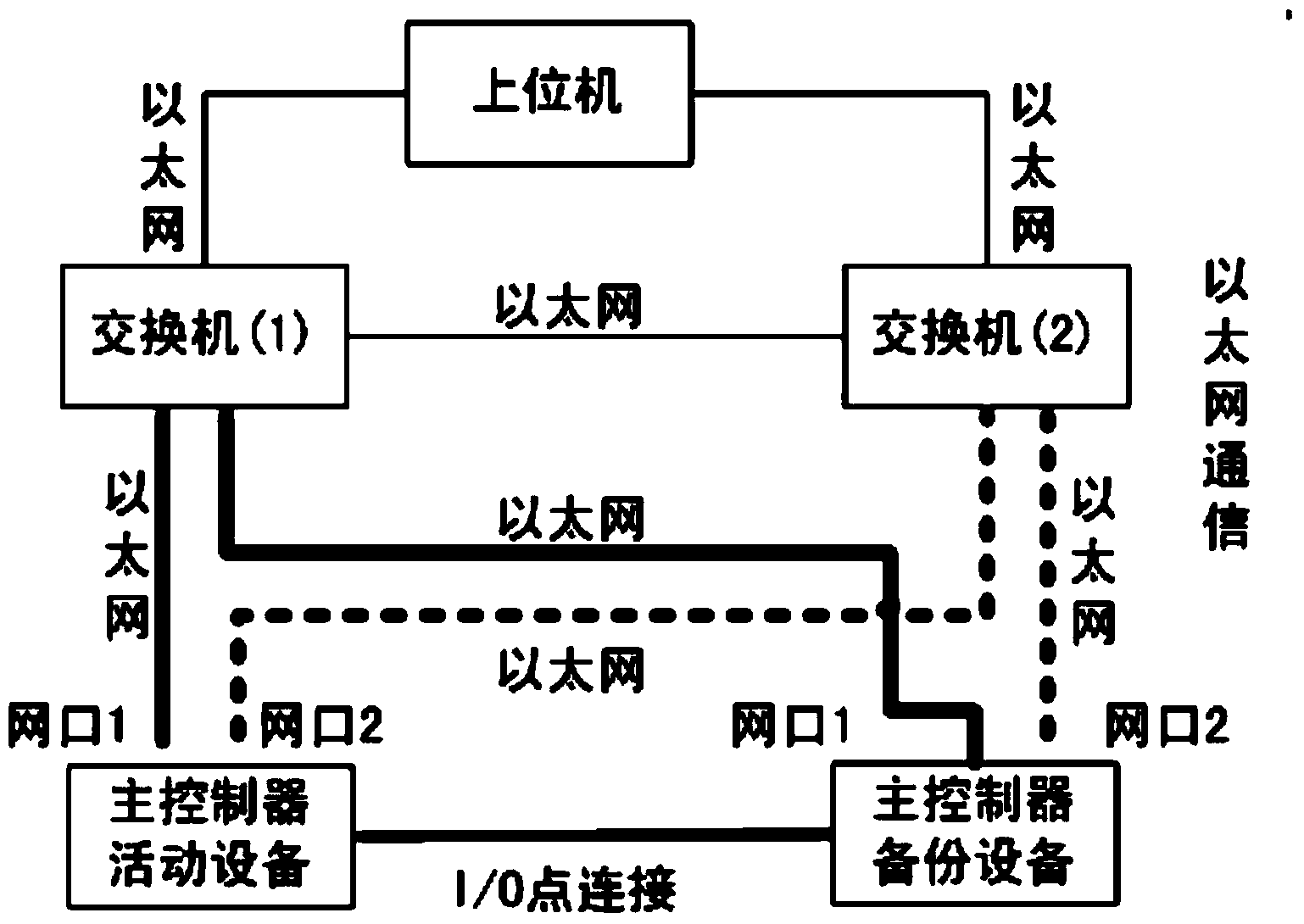

Mixed redundancy programmable control system based on equipment redundancy and network redundancy

ActiveCN103647781AImprove reliabilityFast switching speedNetworks interconnectionControl systemNormal mode

The invention relates to the industrial automation control technology field and relates to a mixed redundancy programmable control system based on equipment redundancy and network redundancy. The mixed redundancy programmable control system comprises a main controller mixed redundancy system and a secondary controller mixed redundancy system, and four levels of redundancy, such as double-Ethernet-equipment redundancy, Ethernet equipment redundancy, double-serial-port serial network redundancy and serial equipment redundancy are included. A main controller is a controller of a double-Ethernet port, four-line mechanism realizes mixed redundancy of the main controller, two switching modes of a normal mode and a rapid mode are provided through matching of an Ethernet mode and an I / O mode, and resource synchronization realizes smooothness of role switching. A secondary controller is a double-serial-port controller, according to a mapping relation between main and secondary equipment, one block of redundancy equipment is added to the secondary equipment, so dual redundancy of a serial communication network and equipment is realized. The mixed redundancy programmable control system is advantaged in that cost is low, four-line mechanism and four levels of redundancy are employed to realize mixed redundancy, reliability is high, and different switching modes satisfy different production technology requirements.

Owner:大连爱智控制系统有限公司

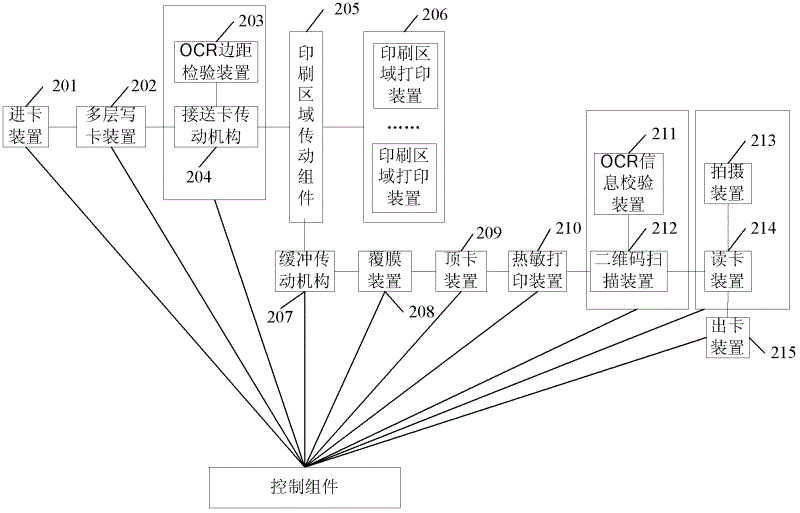

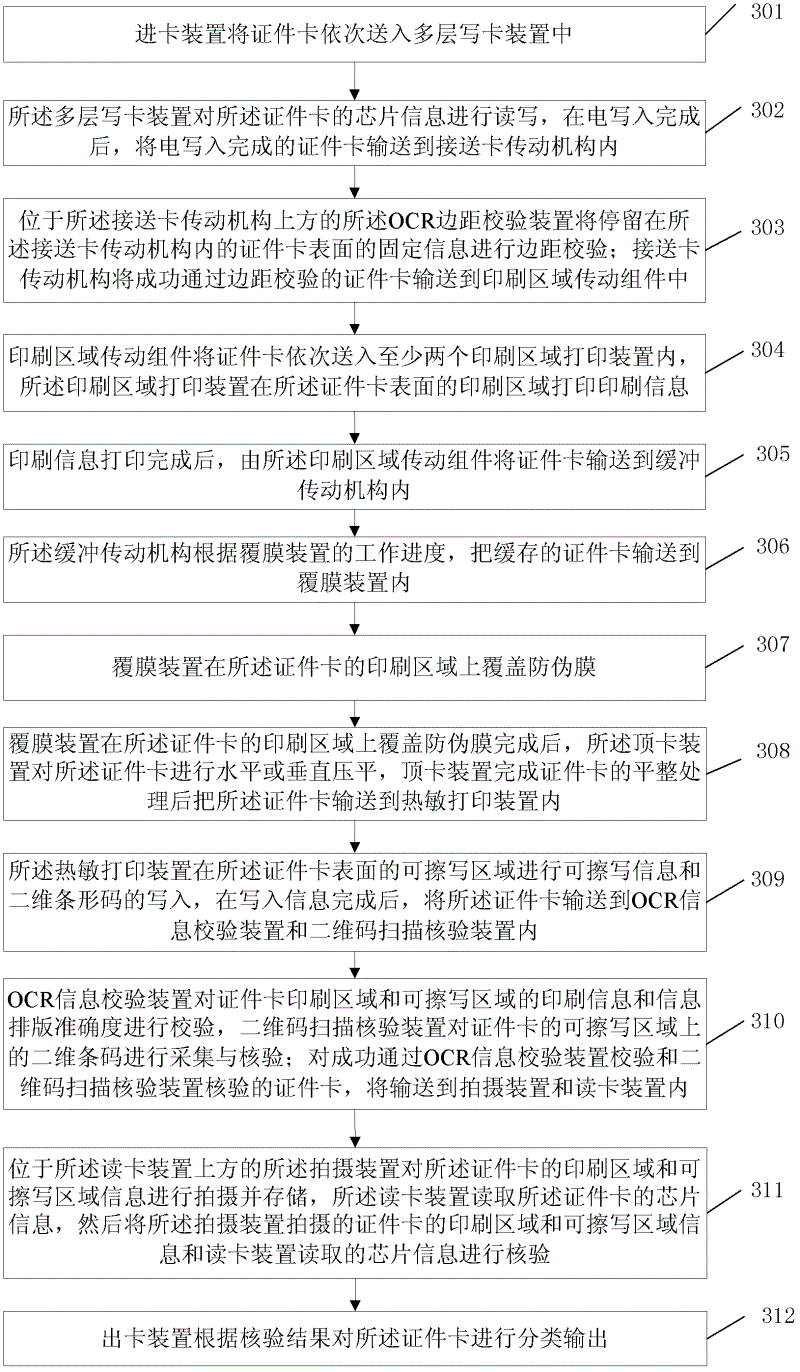

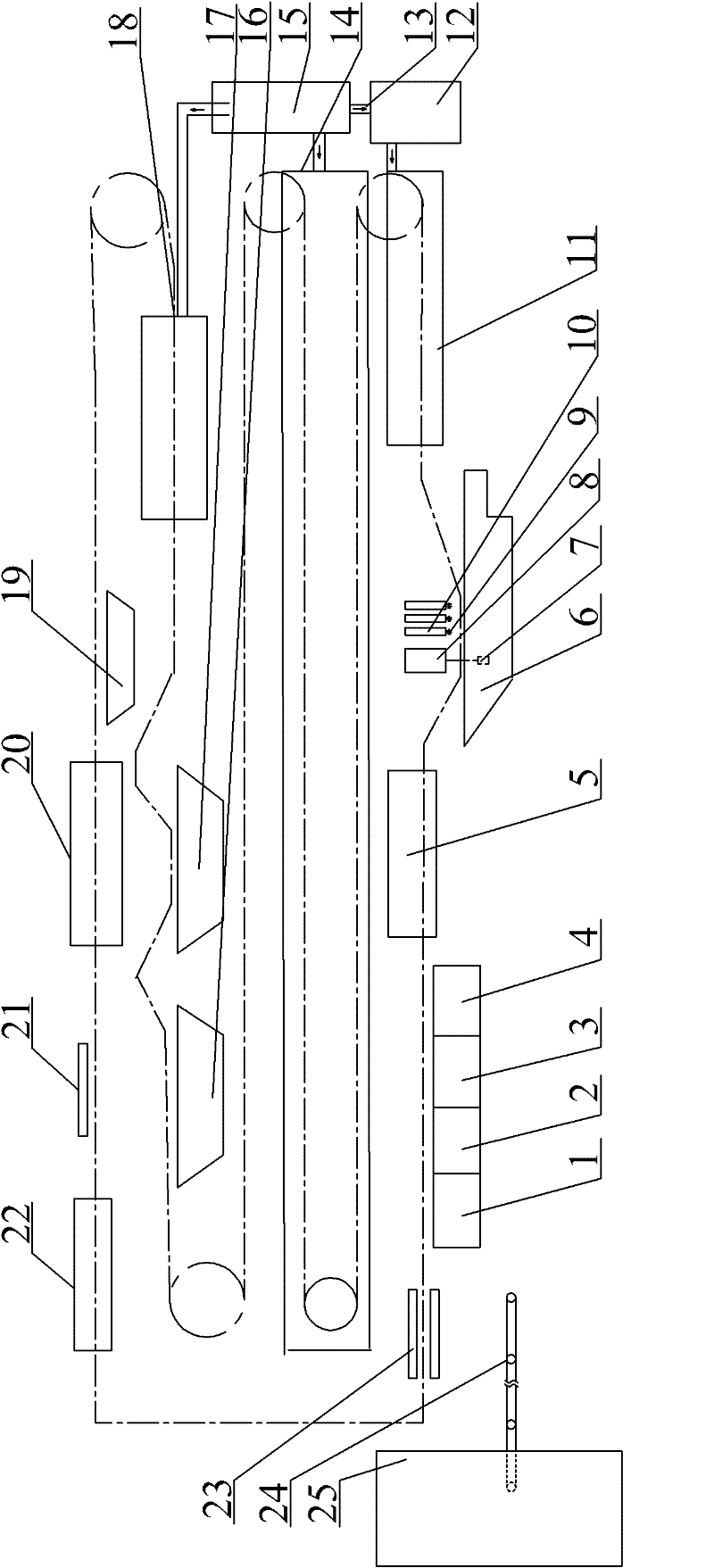

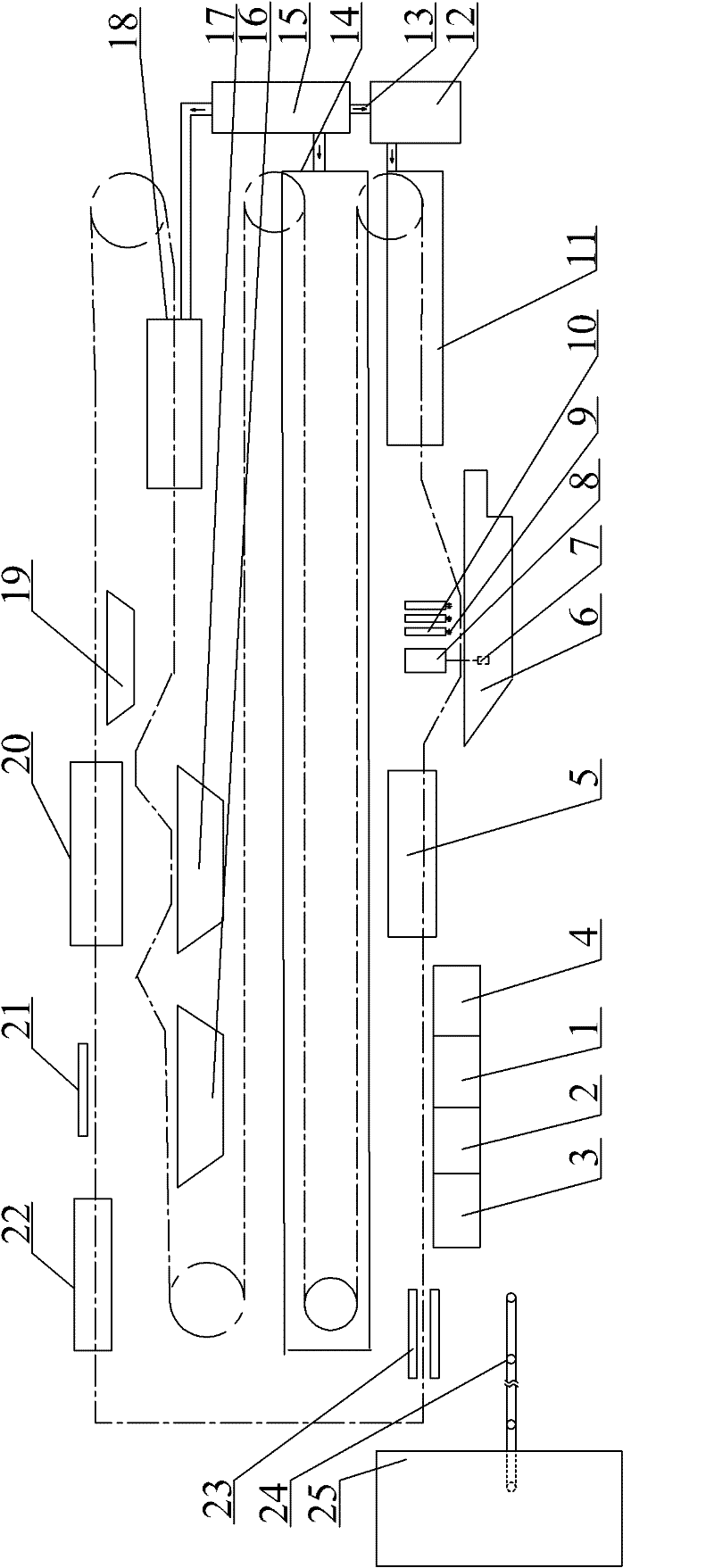

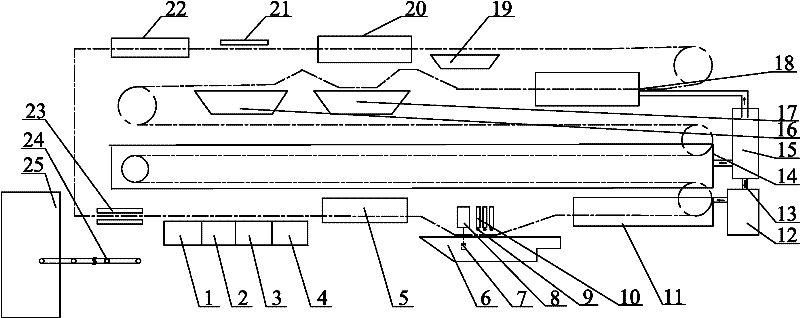

Multifunctional certificate card manufacturing equipment and method

ActiveCN102622622AEasy to operateThe certification process is simpleCo-operative working arrangementsEngineeringOptical character recognition

The invention provides multifunctional certificate card manufacturing equipment and a method, which belong to the technical field of manufacture of certificate cards. The equipment comprises a card feeding device, a multilayered card writing device, a card receiving and conveying transmission mechanism, an OCR (optical character recognition) edge distance checking device, a printing region transmission component, a printing region printing device, a buffer transmission, a film coating device, a card jacking device, a thermosensitive printing device, an OCR information checking device, a two-dimensional code scanning and verifying device, a shooting device, a card reading device and a card discharging device and the like. In a certificate card manufacturing process, the equipment can realize functions of chip information writing and reading, OCR checking, printing region information printing, anti-counterfeiting film treatment, erasable region information repeated erasing, certificate card shooting filing, quality self checking, certificate card sorting and the like. The problem that certificate cards need to be manufactured by a large device or multiple devices in the prior art is avoided, operation is more intelligent, a technological process is convenient, certificate card manufacturing efficiency is higher, single certificate card manufacture and batch certificate card manufacture are combined, and the multifunctional certificate card manufacturing equipment and the method are widely applied to manufacturing various types of certificate cards, and innovate social management of certificate service.

Owner:GUANGZHOU HUABIAO SCIENCEAND TECH DEV CO LTD

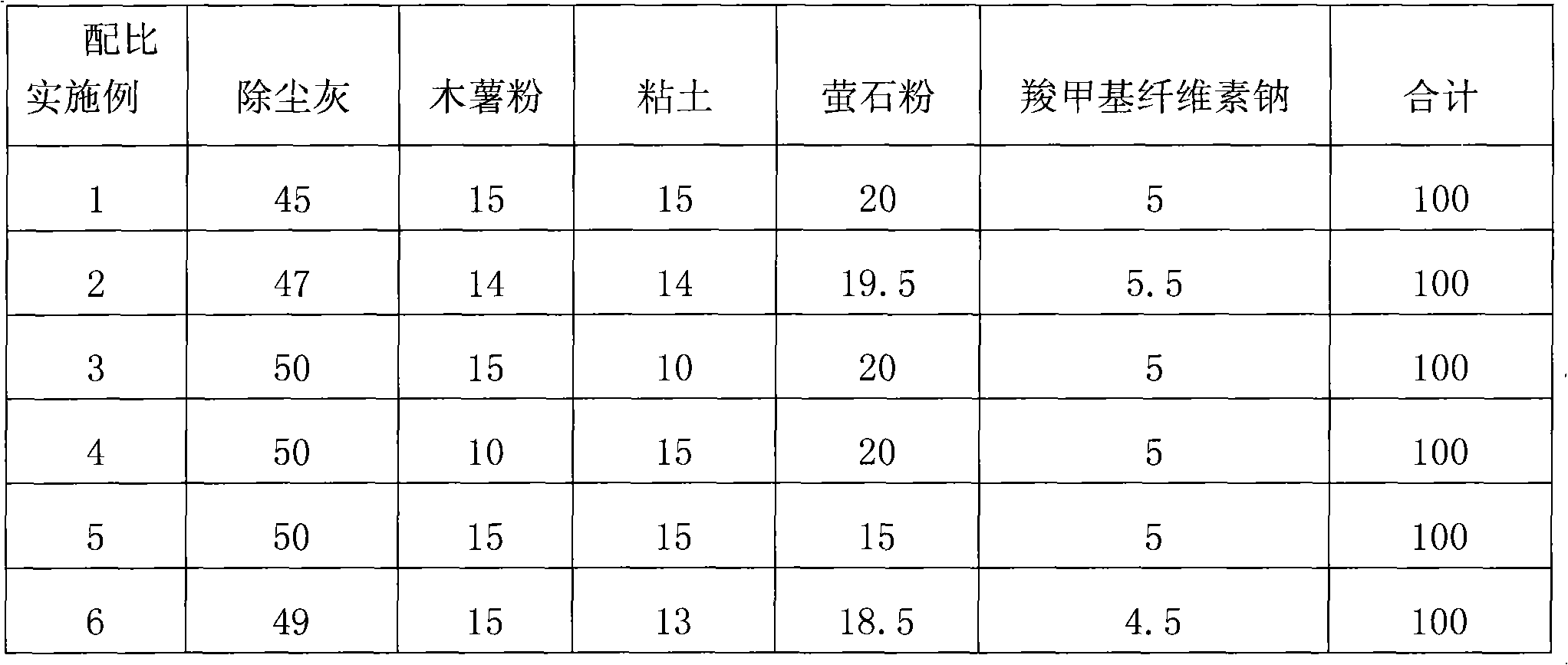

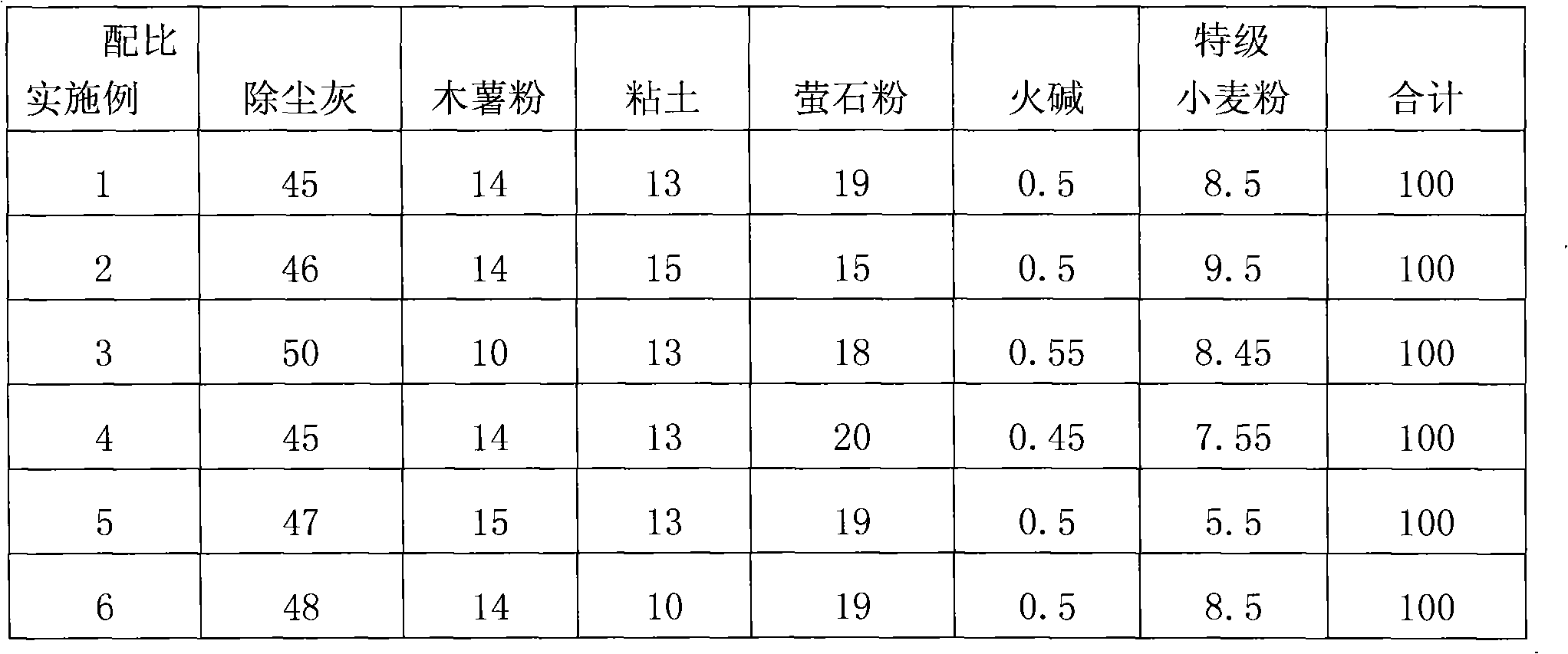

Metallurgical pellet compound binding agent

The invention discloses a metallurgical pellet compound binding agent. The compound binding agent comprises the following components in percentage by weight: 45 to 50 percent of dust generated in blast furnace ironmaking and sintering production processes, wherein the dust is grounded to ensure that more than or equal to 80 percent of the dust has the particle size of 0.043 mm, the TFe in the dust is more than or equal to 60 percent, and montmorillonite in the dust is more than or equal to 20 percent; 10 to 15 percent of cassava meal of which more than or equal to 80 percent has the particle size of 0.043 mm; 10 to 15 percent of clay of which more than or equal to 80 percent has the particle size of 0.043 mm; 15 to 20 percent of fluorspar powder of which more than or equal to 80 percent has the particle size of 0.043 mm; and 4.5 to 5.5 percent of carboxymethylcellulose sodium of which more than or equal to 80 percent has the particle size of 0.043 mm. The carboxymethylcellulose sodium of the compound binding agent can be replaced by caustic soda and special-grade wheat flour. The components are uniformly stirred according to the percentage by weight to prepare the pellet compound binding agent; and during the production of pellets, 0.8 to 1.2 percent of 0.5 percent replaceable bentonite is added, and not only a requirement on pellet production can be meet, but also the used amount of the bentonite is reduced, thereby fulfilling the aims of improving the grade of pellet iron ores and simultaneously improving blast furnace coefficients.

Owner:马鞍山市金鑫建材有限公司

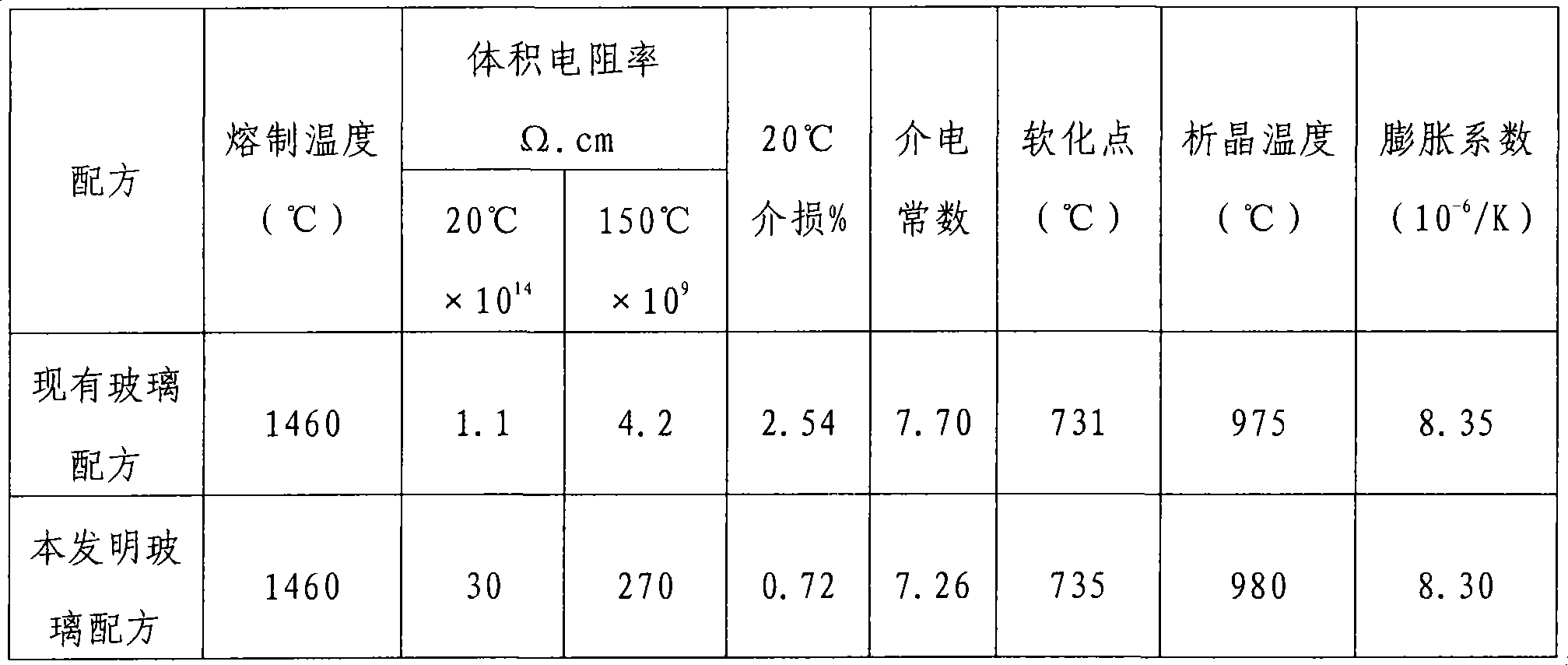

Glass formula for producing direct current glass insulator

The invention discloses a formulation of glass for producing a direct current glass insulator. The formulation is characterized in that the glass comprises the following compositions in percentage by weight: 65 to 72 percent of SiO2, 1.5 to 3.5 percent of Al2O3, 0.05 to 0.4 percent of Fe2O3, 5 to 8 percent of CaO, 2 to 4 percent of MgO, 5 to 9 percent of K2O, 0.1 to 3 percent of BaO and 6 to 9 percent of Na2O; and simultaneously, the glass also comprises 0.1 to 1 percent of Li2O and 0.1 to 2 percent of SrO. The formulation can effectively reduce the transfer of sodions, improve volume resistivity of the glass, reduce dielectric loss and improve electrical performance of the glass insulator.

Owner:南京电气绝缘子有限公司

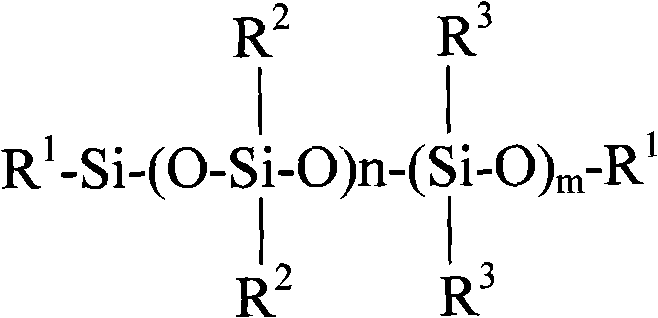

Light-coloured high temperature resistant organic silicone adhesive/sealant

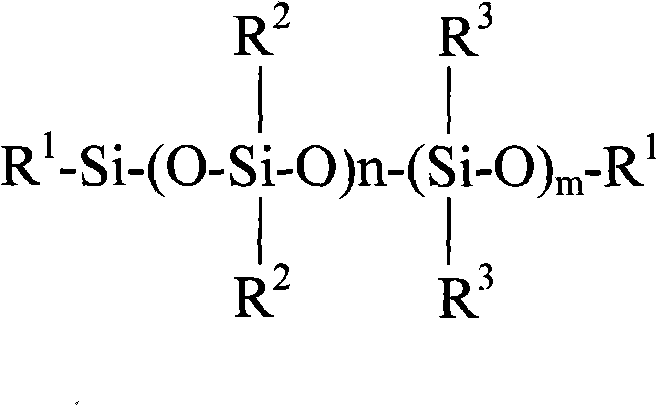

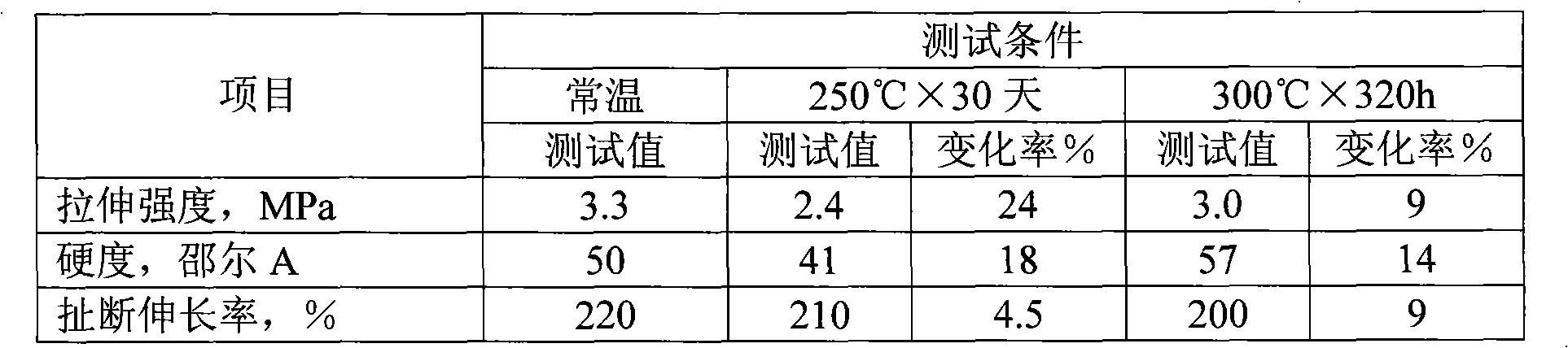

InactiveCN101311238AImprove agingImprove temperature resistanceOther chemical processesAdhesivesHeat conductingCross linker

The invention relates to a tint high-temperature resistant organic silicon adhesive / sealant, which takes the polysiloxane with the end capped by active functional groups as the foundation, the white carbon soot with the surface going through hydrophobic treatment as reinforcing stuffing, the vapor phase titanium dioxide as a free oxygen consumption agent and the silane coupling agent containing phenyl as a cross linker and combines with proper heat conducting stuffing and catalyst. The silicon adhesive / agent can be solidified at room temperature or rapidly solidified through heating. The product is French grey paste, which allows diversified color matching. The solidified product of the silicon adhesive / agent can endure the temperature as high as 300 DEG C.

Owner:上海橡胶制品研究所有限公司

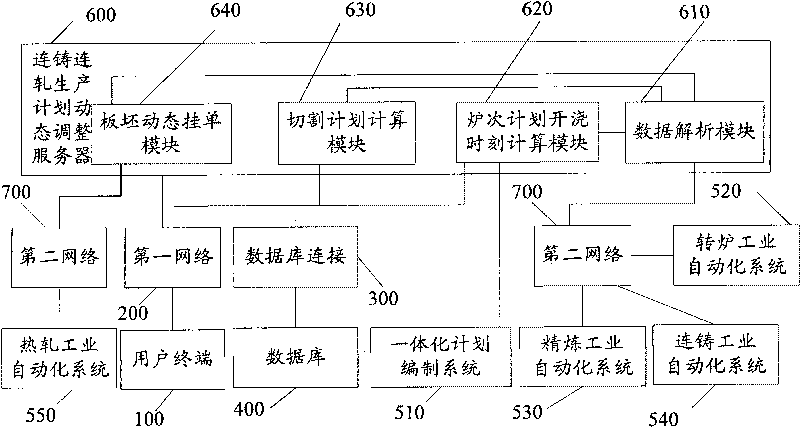

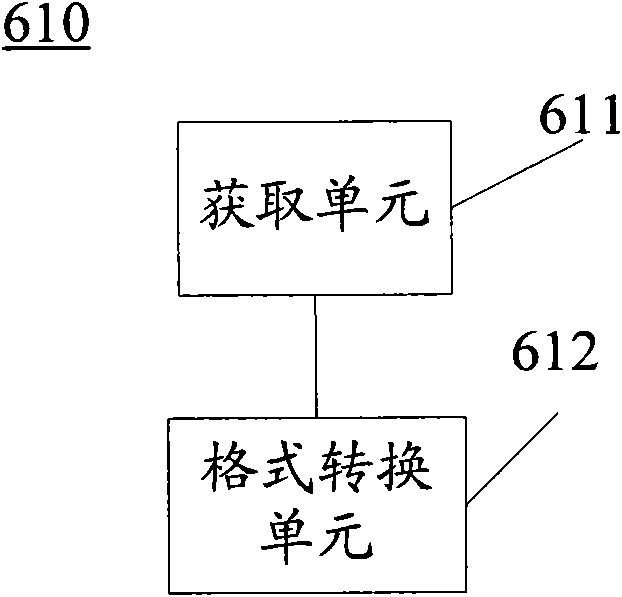

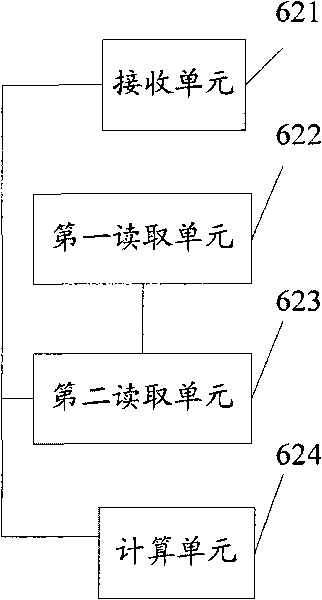

Dynamic adjustment system for metallurgical continuous casting and continuous rolling production plan

InactiveCN101727103AMeet the production process requirementsMaximize steel production capacityTotal factory controlProgramme total factory controlSteelmakingContinuous rolling

The invention discloses a dynamic adjustment system for a metallurgical continuous casting and continuous rolling production plan. The system comprises a dynamic adjustment server for the continuous casting and continuous rolling production plan, database connection and a database, a network, a converter industrial automation system, a refining industrial automation system, a continuous casting industrial automation system, a hot-rolling industrial automation system, and an integral planning system. The dynamic adjustment server for the continuous casting and rolling production plan can acquire the moment data of the converter industrial automation system, the refining industrial automation system and the continuous casting industrial automation system, calculate the cast-on moment of a heat plan in real time and dynamically generate a casting machine cutting plan according to the moment data and a rolling plan stored in the database by the integral planning system, and produce an order according to actual distributed slabs so as to guide the production. Therefore, the dynamic adjustment system for the metallurgical continuous casting and continuous rolling production plan can adapt to the order-oriented production mode, accord with the requirement on production technology, and realize maximized productivity of the steelmaking production and the optimized rolling process.

Owner:武钢集团有限公司

Formaldehyde-free artificial board adhesive and preparation method thereof

InactiveCN108329889ALow costWide variety of sourcesStarch adhesivesLignocellulosic adhesivesPolyamidePVA - Polyvinyl alcohol

The invention relates to wood adhesive, in particular to novel formaldehyde-free artificial board adhesive and a preparation method thereof. In order to solve the problem that waterborne polyisocyanate (EPI) adhesive and soybean protein adhesive have short opening time and are unable to meet the needs of the artificial board production process, PAE (polyamide-polyamine-epichlorohydrin) or modifiedPAE is used as a main adhesion material that is subjected to compounding and modification with polyvinyl alcohol solution, polymer emulsion, wheat flour, soybean protein powder, wood powder and the like so as to obtain the formaldehyde-free artificial board adhesive having long opening time.

Owner:东营市盛基环保工程有限公司

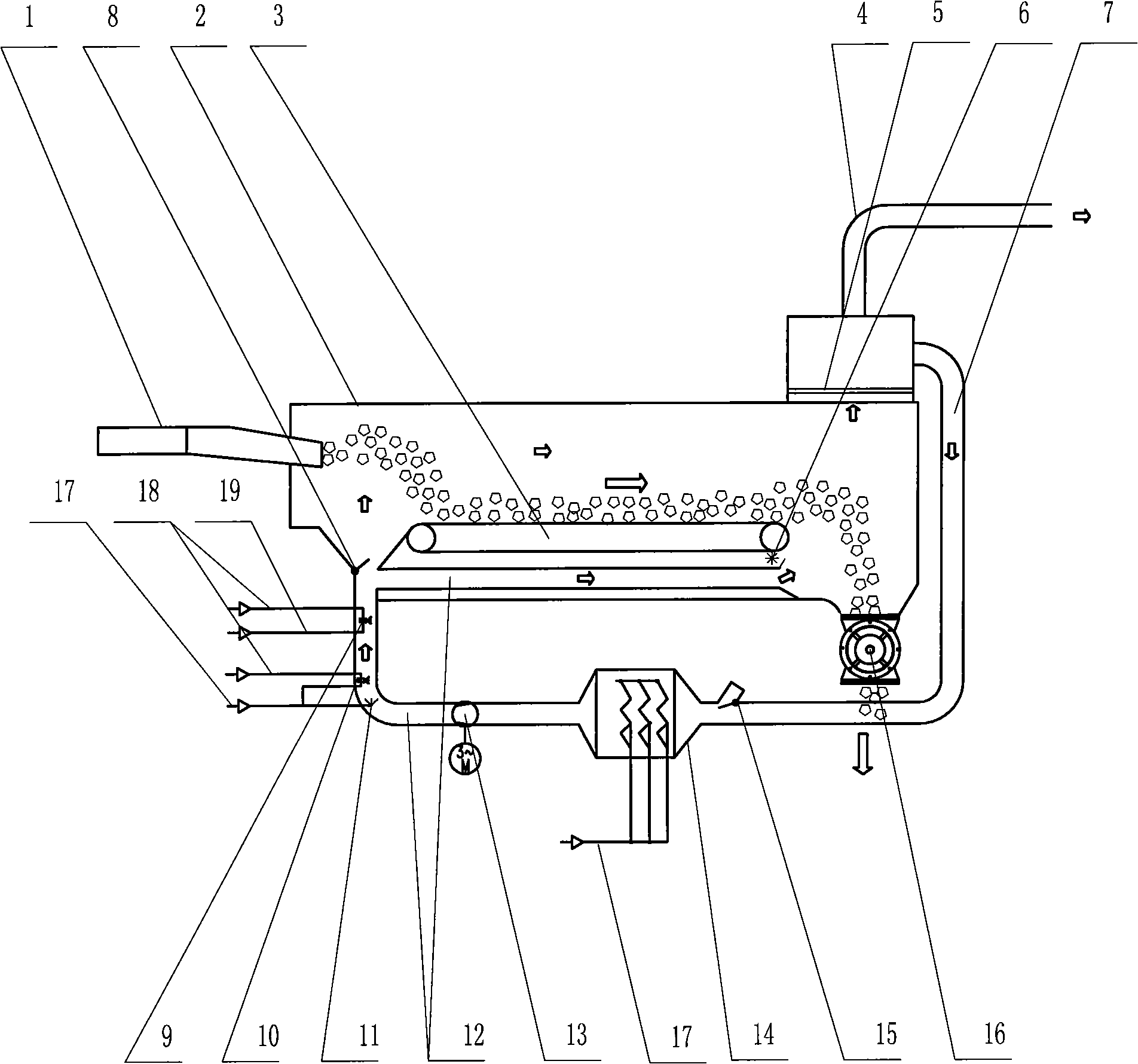

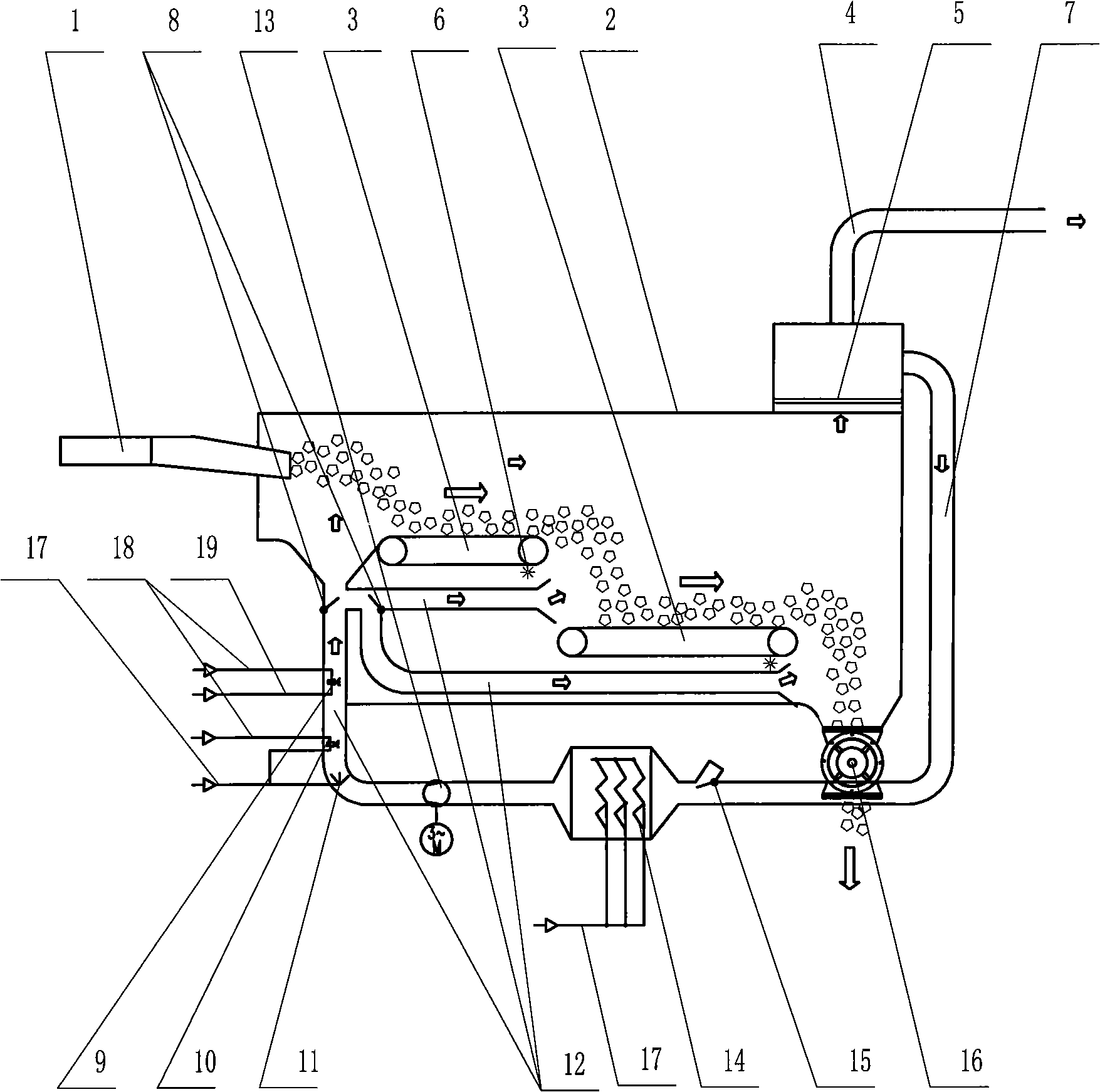

Moisture regaining method and apparatus for tobacco, Chinese herbal medicine and its products

InactiveCN101313776ANo color changeIntrinsic mass changeTobacco preparationEngineeringMoisture regain

The invention discloses a moisture-regaining method for tobacco, Chinese herbal medicines and products thereof and a moisture-regaining device thereof, and relates to a material moisture-regaining method and a moisture-regaining device thereof in tobacco industry. The moisture-regaining method comprises the following steps that: materials are delivered forward at a certain speed and blown by moist-hot wind coming from low part or side lower part to be in a suspended state in falling space to fully contact the moist-heat wind and absorb moist and heat to regain moisture. An entrance of a chamber of the device is provided with a conveyer, and the front lower part of the conveyer is at least provided with a common conveyer belt or a mesh belt; and a circular fan and a heat exchanger, or a circular hot-air pipeline which is arranged outside a moisture-regaining chamber are communicated with the moisture-regaining chamber through a moist-heat air pipe. The moisture-regaining method has the advantages that: 1. the method is suitable for high-grade materials; 2. the method is particularly suitable for small-batch single material; 3. the method produces less crumbs to the materials; and 4. the method can achieve balance in shorter time. The device has the advantages of special and reasonable design, simple structure, easy implementation and convenient operation.

Owner:WUHAN TOBACCO GROUP

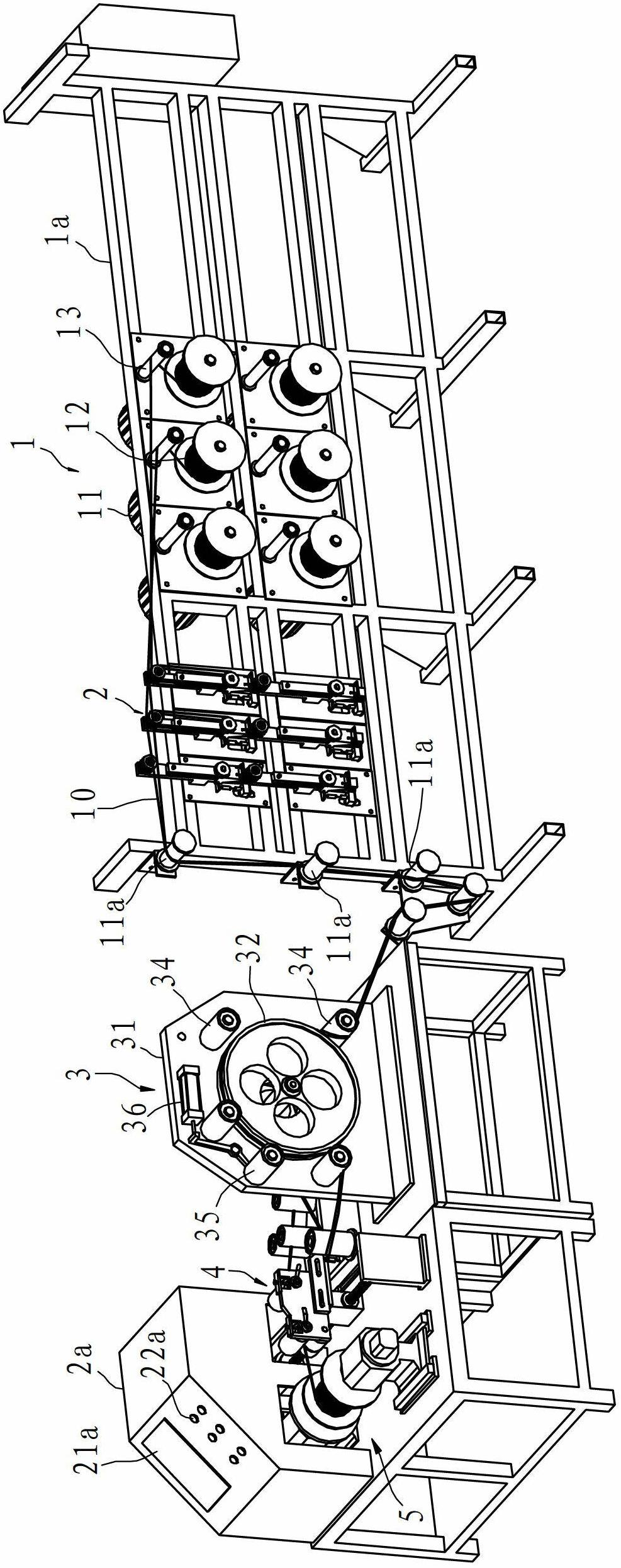

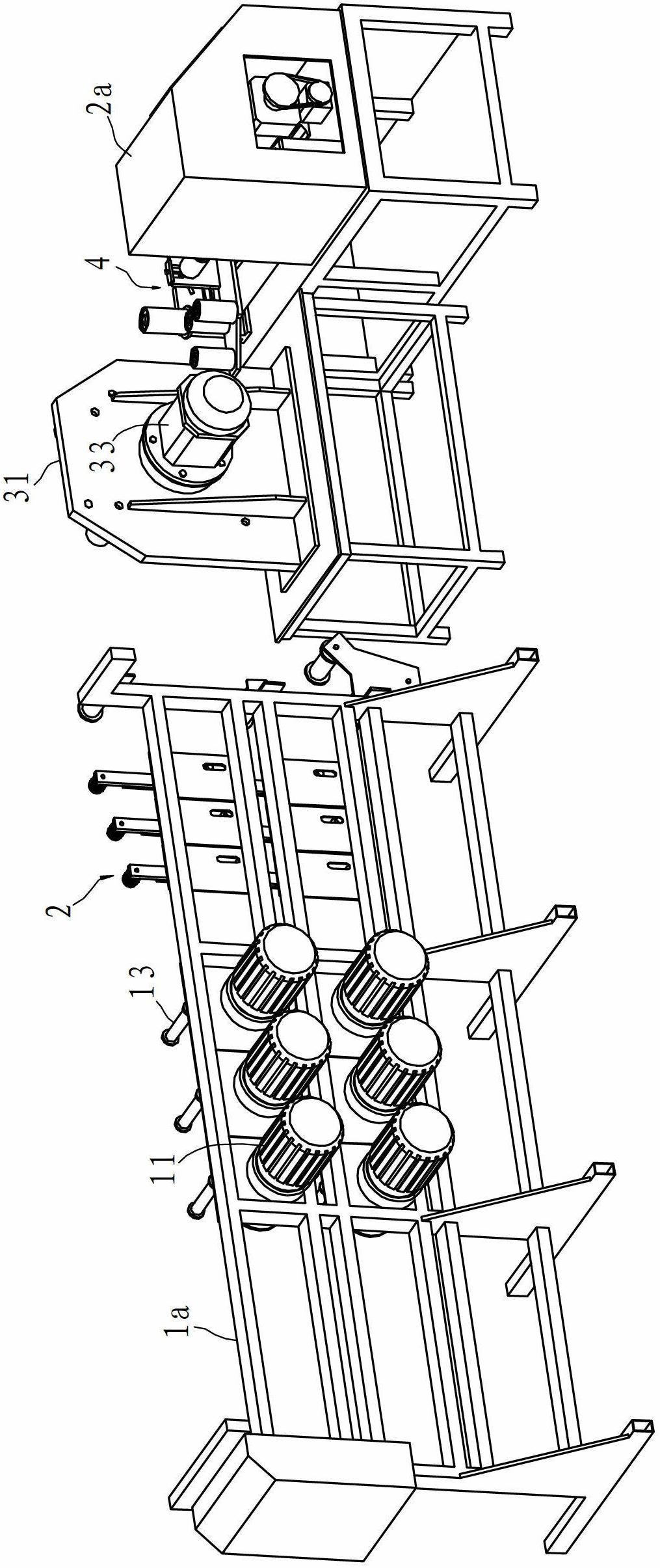

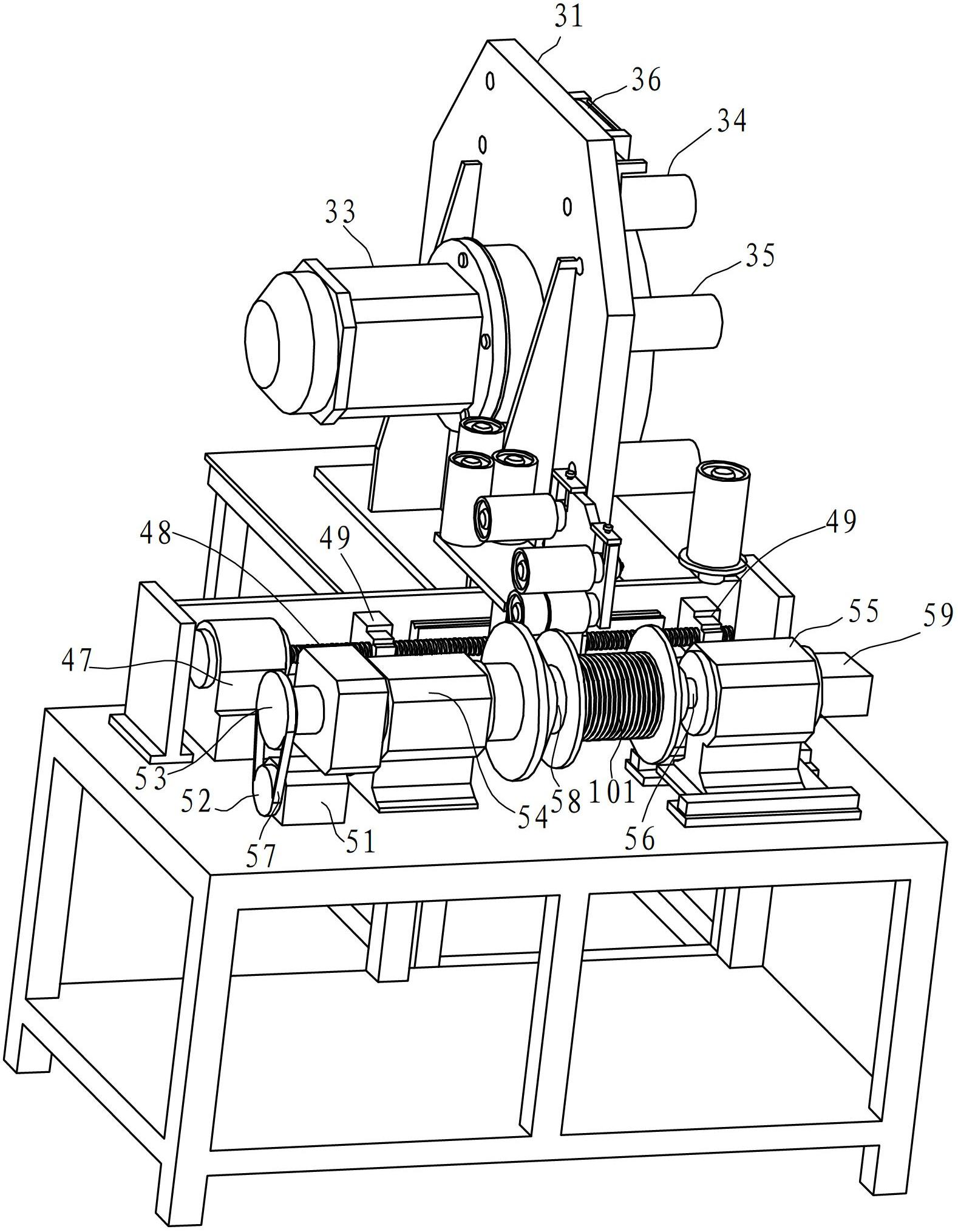

Stranding machine

InactiveCN102677493AImprove work efficiencyHigh degree of automationRope making machinesElectric machineStructural engineering

The invention discloses a stranding machine, comprising an unwinding mechanism, a tension adjusting device, a traction mechanism, a wire-arranging mechanism, a rolling mechanism and a controller, wherein the unwinding mechanism comprises a bracket, a plurality of unwinding rolls and unwinding motors arranged on the bracket; the power output end of each unwinding motor is connected with the respective and corresponding unwinding roll; the traction mechanism comprises a support, a traction disc and a traction motor; and the self speed of the unwinding motors can be adjusted by the controller according to the rotating speed of the traction motor. Compared with the prior art, the stranding machine disclosed by the invention has the advantages that active unwinding is carried out by the unwinding motors, the real-time speed adjustment is carried out on the unwinding motors by combination with the traction motor through the controller, so that the tensions of the front sections and the rear sections of metal wires are constant, certain speed for the stranding and the wire arrangement is maintained, the stranding speed is maintained to be 600-700m / min, and the working efficiency is greatly improved.

Owner:宁波市鄞州文辉机械设备制造有限公司

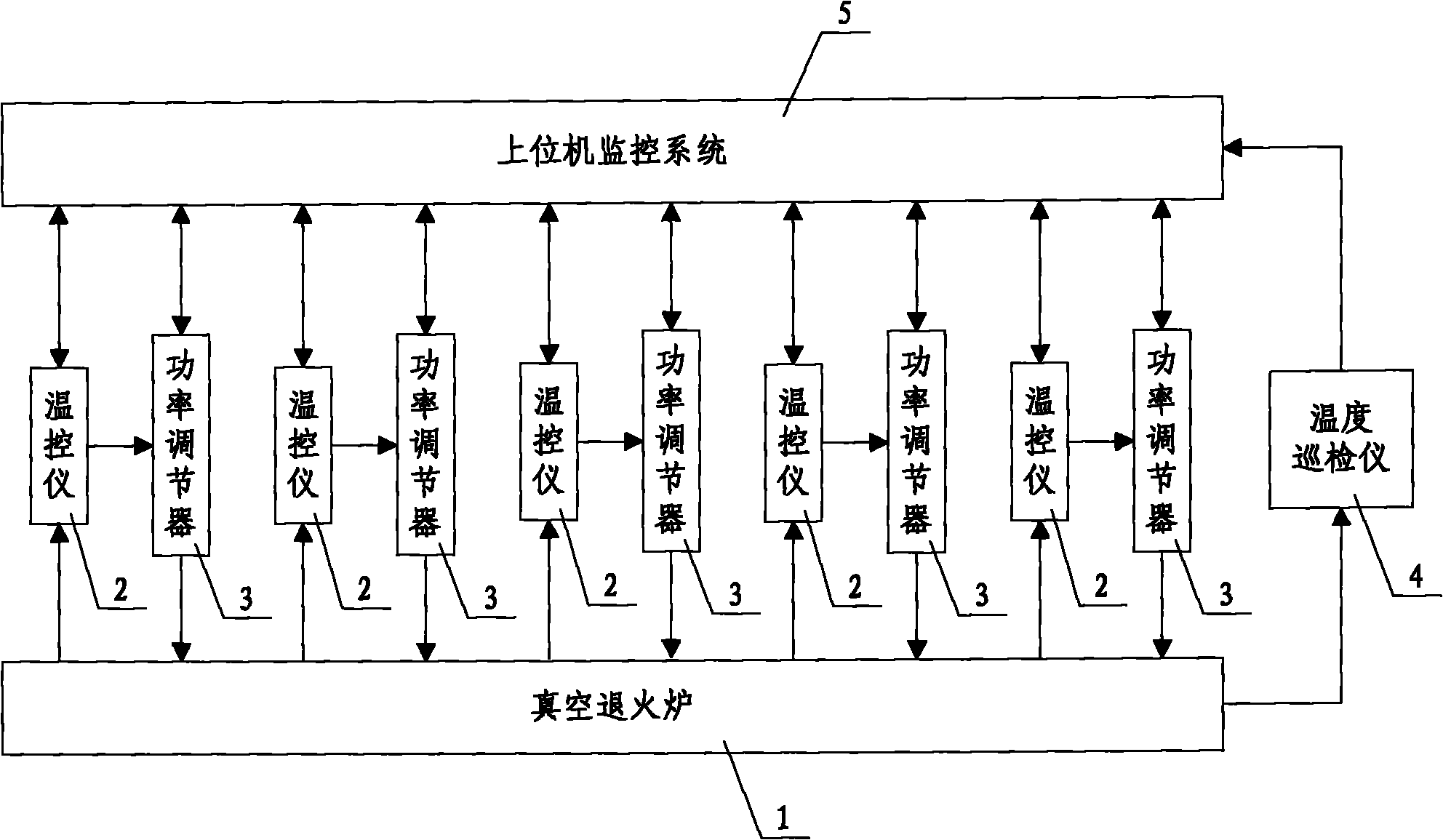

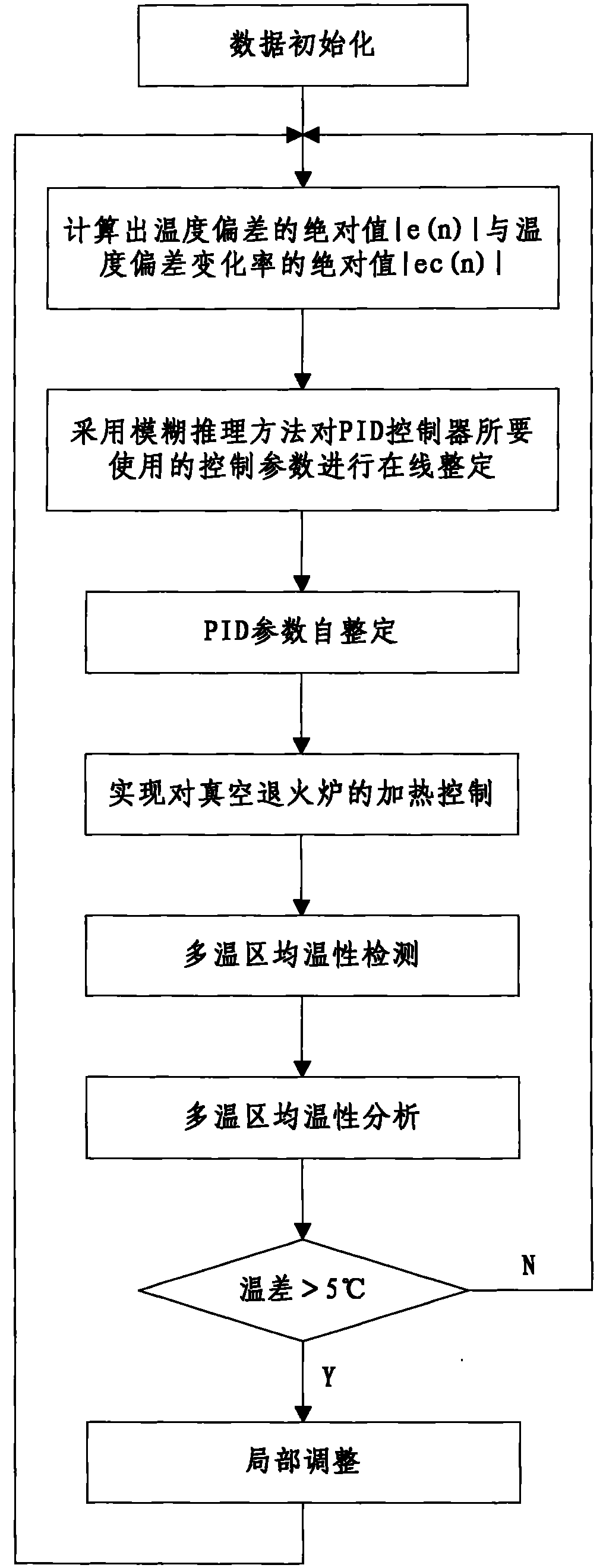

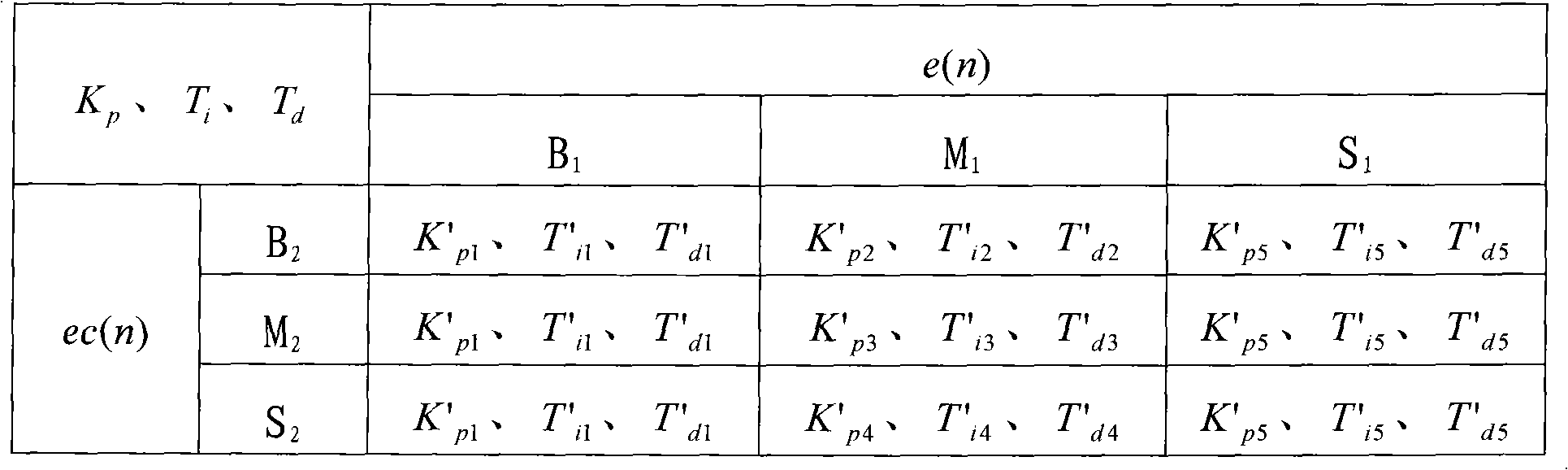

Temperature uniformity control system for multi-temperature zone of large plate vacuum annealing furnace and control method thereof

InactiveCN101962708AHigh degree of intelligenceEasy to useFurnace typesHeat treatment process controlTemperature controlProportion integration differentiation

The invention discloses a temperature uniformity control system for a multi-temperature zone of a large-plate vacuum annealing furnace and a control method thereof. The control system comprises a plurality of temperature controllers, a plurality of power regulators, a uniform temperature data logging device and an upper computer monitoring system, wherein the upper computer monitoring system is used for analyzing detection signals of the uniform temperature data logging device and monitoring the working process of each temperature controller and each power regulator. The control method comprises the following steps of: (1) initiating data; (2) working out the absolute value of the temperature difference e(n) and the absolute value of the temperature difference change rate ec(n); (3) setting control parameters required to be used by a PID (Proportion Integration Differentiation) controller on line by using a fuzzy reasoning method; (4) automatically setting the PID parameters; (5) controlling the heating of the vacuum annealing furnace; (6) detecting the temperature uniformity of the multi-temperature zone; and (7) analyzing and locally adjusting the temperature uniformity of the multi-temperature zone. The control system has the advantages of high temperature control accuracy, good temperature uniformity, high reliability and good adaptivity and robustness, the production process requirements of the rare metal vacuum annealing furnace can be well satisfied, and the control system is convenient for popularization and application.

Owner:XI'AN PETROLEUM UNIVERSITY

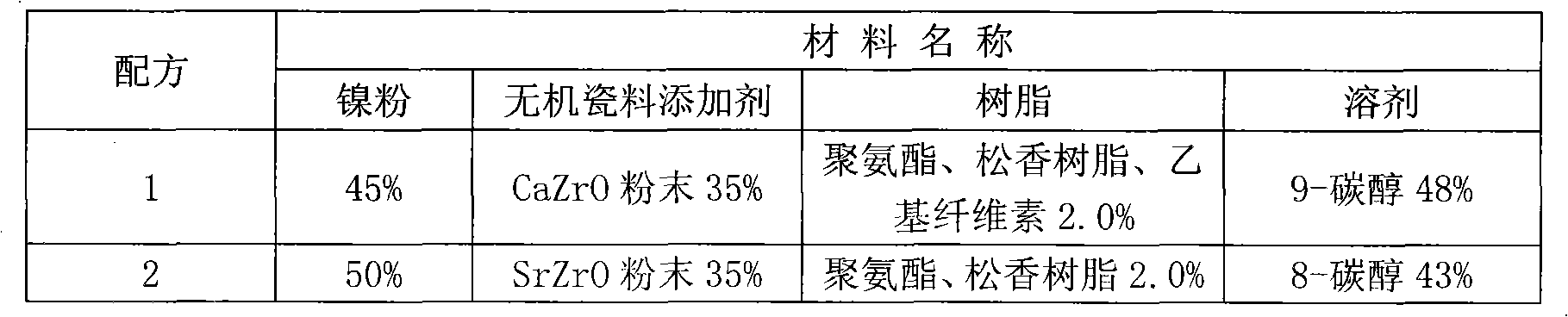

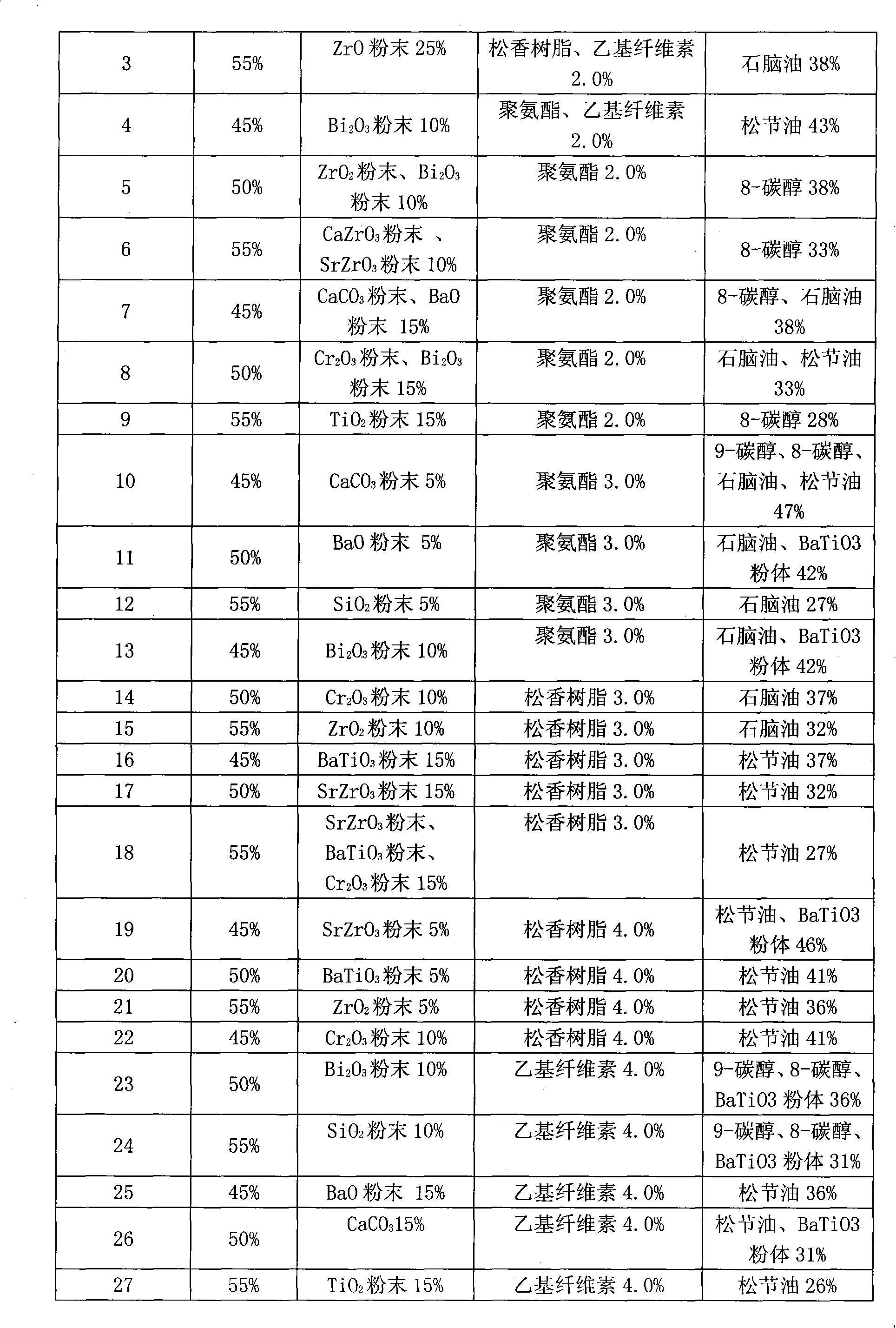

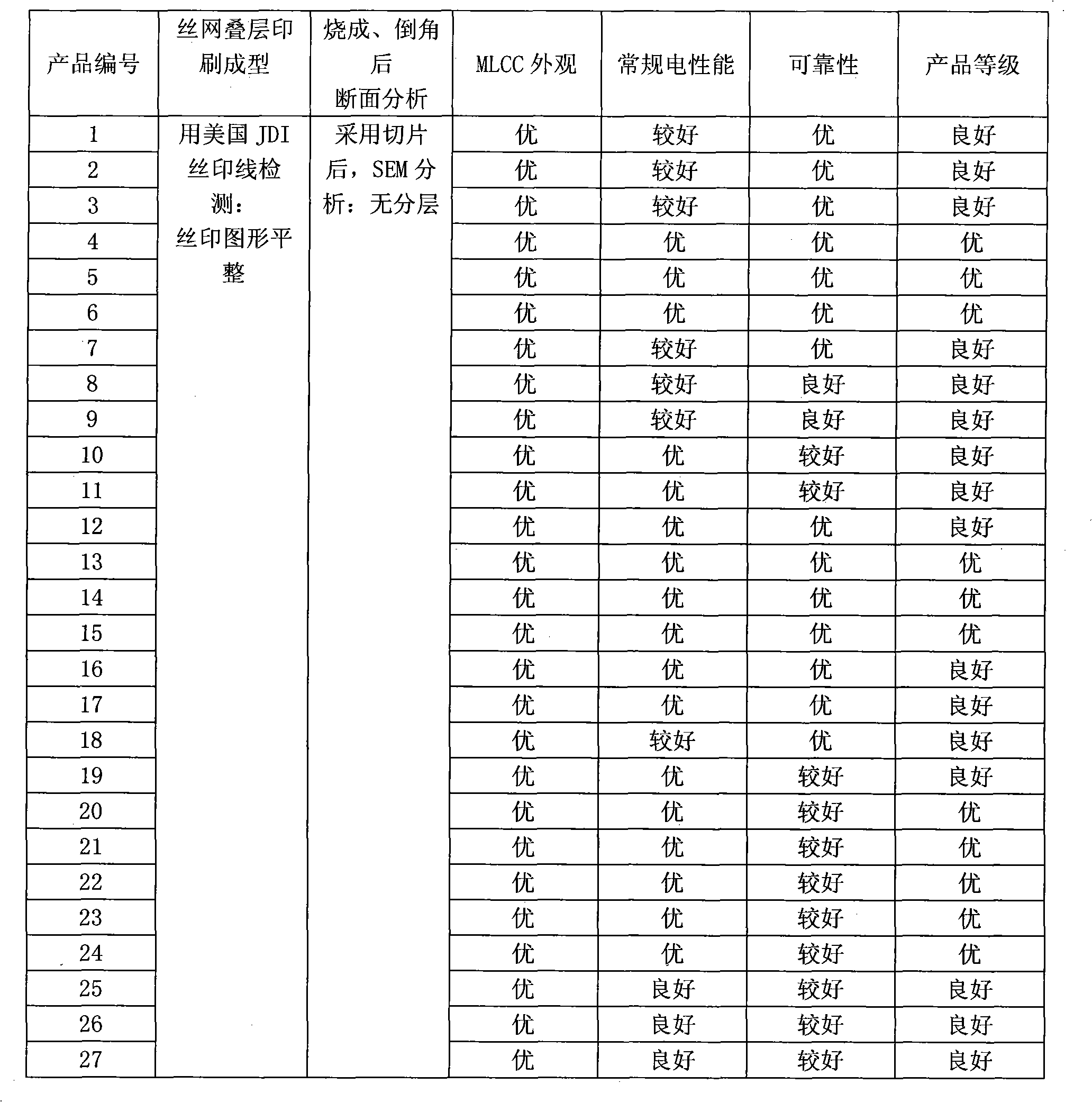

Nickel inner electrode slurry

ActiveCN101872679AGood dispersionPromote environmental protectionFixed capacitor electrodesStacked capacitorsOrganic solventCeramic capacitor

The invention discloses nickel inner electrode slurry. The slurry comprises the following components in percentage by weight: 45 to 55 percent of superfine nickel powder, 5 to 15 percent of inorganic ceramic additive, 2 to 4 percent of high molecular resin and 26 to 48 percent of organic solvent. The particle size of the superfine nickel powder is less than 1 mu m. The obtained nickel inner electrode slurry has the advantages of high dispersibility, high performance and high environmental friendliness. When the slurry is taken as an inner electrode of multilayer ceramic capacitor (MLCC), the matching performance of an inner electrode layer and a dielectric layer is high and the cracking problem is not caused.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Enamel prepared from waste ceramic and its preparation method

The invention provides a ceramic glaze and preparation method from waste ceramic. Wherein, the product comprises: 18~25% waste ceramic powder, 20~30% quartz, 10~20% feldsparú¼8~12% China clayú¼0~5% zinc oxide, 0~10% dolomiteú¼7~15% calciteú¼and 0.2~0.5% methylcellulose. The preparation method comprises: cleaning and dedusting the ceramic powder, drying, breaking, and screening; putting said materials into ball grinder with proper water; screening, adding prepared ceramic powder; grinding and screening to prepare glaze slurry; adding methylcellulose into slurry to mix and obtain the product. This invention reduces cost and pollution.

Owner:林伟河

Process for preparing granular type threonine product

ActiveCN104757273AReduce pollutionAvoid pollutionAnimal feeding stuffFertilizer mixturesEnvironmental resistanceMycoprotein

The invention belongs to the technical field of production of amino acids and in particular relates to a process for preparing a granular type threonine product. The process comprises the following steps: (1) preparing threonine fermentation liquor; (2) preparing powdery threonine; (3) preparing threonine granules; (4) refining a mycoprotein; (5) preparing the feed; and (6) preparing an organic fertilizer. According to the process disclosed by the invention, the threonine granules are prepared, moisture absorption and agglomeration can be avoided, the components of the waste mother solution are effectively utilized, wastes are not produced in the whole process, the process is environmentally friendly and pollution-free, and energy conservation and emission reduction are realized.

Owner:齐齐哈尔龙江阜丰生物科技有限公司

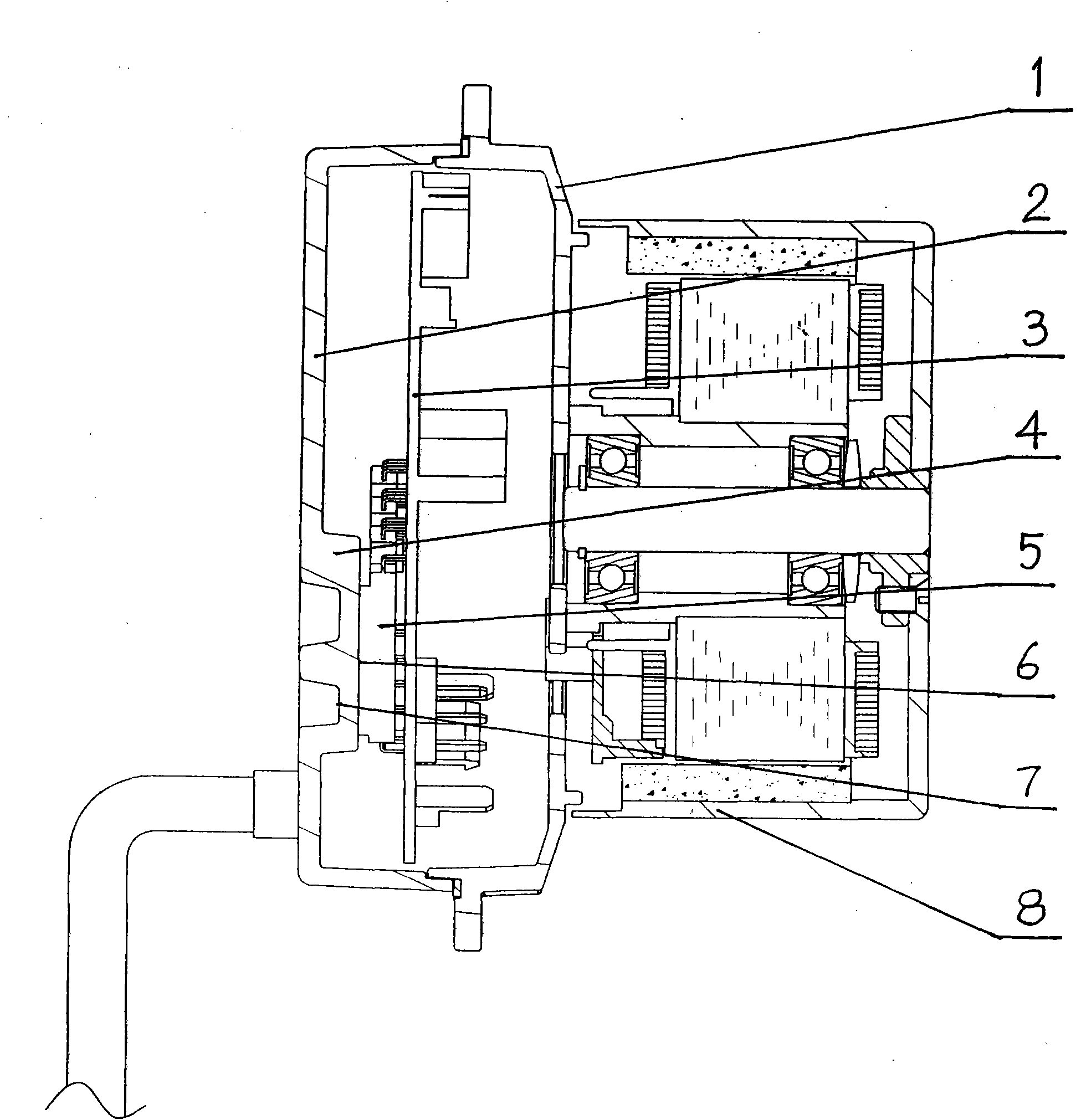

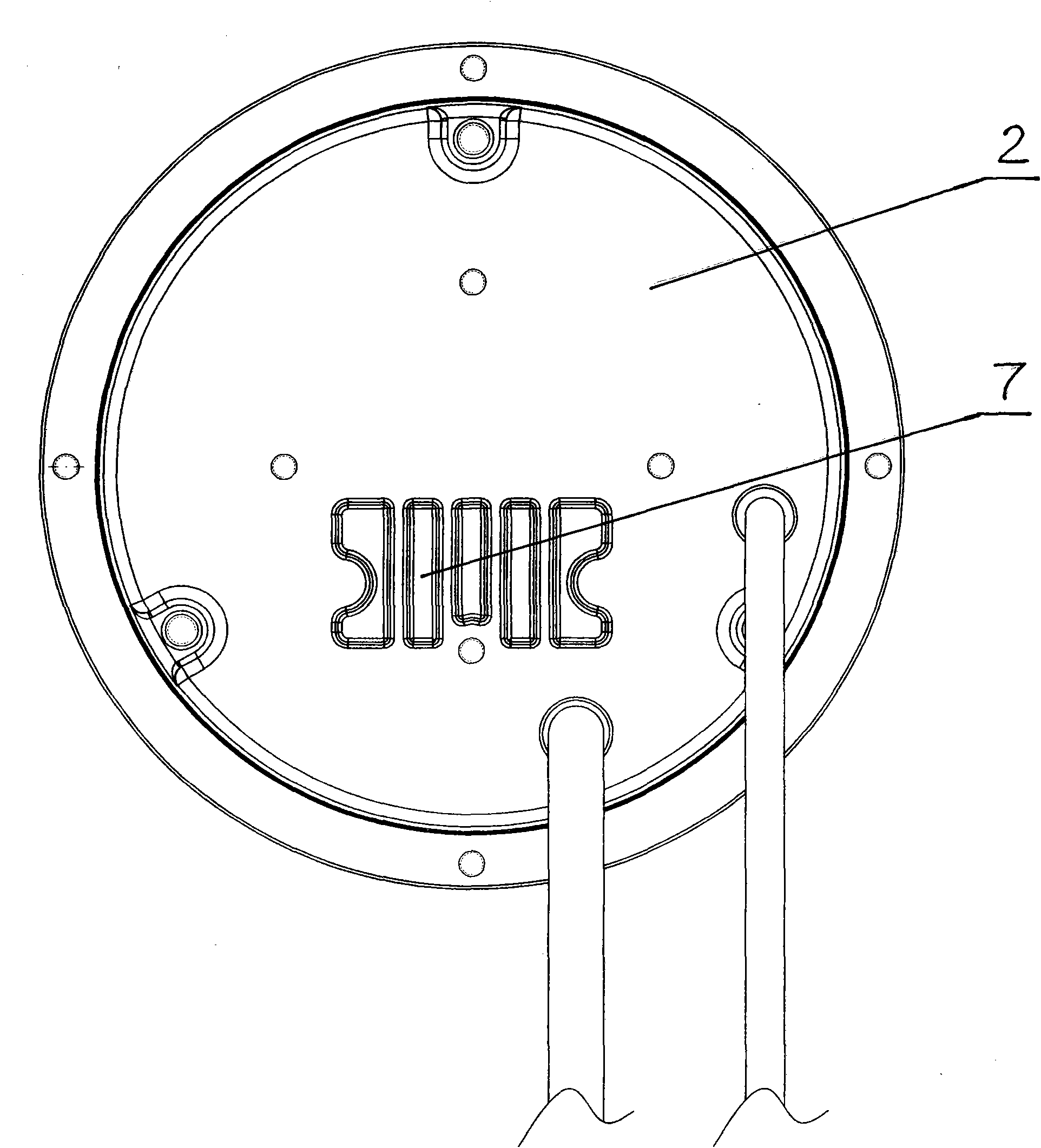

Radiating structure for outer-rotor direct-current brushless motor

InactiveCN102104296AImprove cooling effectIncrease cooling areaCooling/ventillation arrangementSupports/enclosures/casingsPhysicsConductor Coil

Owner:FOSHAN NANHAI DISTRICT DONGTANG ELECTRICAL MACHINERY FACTORY

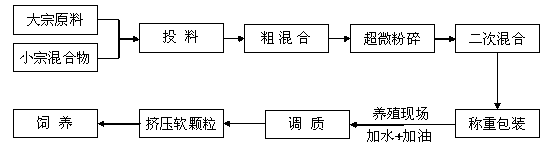

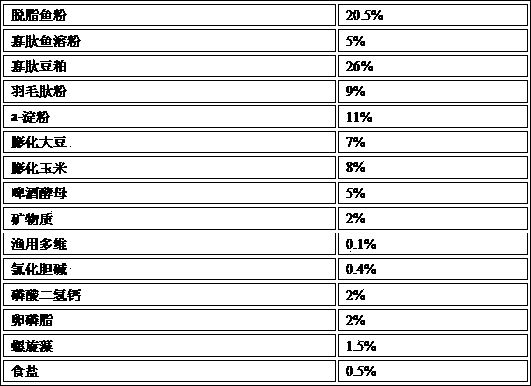

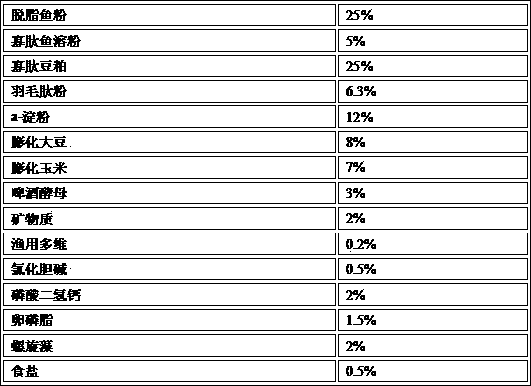

Compound feed for female parent fishes of sturgeons

InactiveCN103349157AHigh viscoelasticityHigh in proteinAnimal feeding stuffFish oilMonocalcium phosphate

The invention discloses a compound feed for female parent fishes of sturgeons. The compound feed is prepared in the following craft processes of: preparing raw material components into a mixture according to a processing method of a powdered feed, adjusting water and fish oil, and carrying out extrusion and pelleting. The powdered mixture comprises the following raw material components: degreased fish meal, alpha-starch, extruded soybeans, extruded corns, oligopeptide bean pulp, oligopeptide soluble fish meal, feather peptide powder, beer yeast, mineral substances, multivitamins for the fish, choline chloride, monocalcium phosphate and the like. Compared with the other sturgeon feeds, the compound feed disclosed by the invention has the advantages that the content of oligopeptide protein is remarkably increased, the use level of the fish meal is obviously reduced, not only is the culturing cost lowered, and the baiting performance and the nutrition characteristic can be improved as well. With the adoption of the compound feed for the female parent fishes of the sturgeons, the nutrition state of a female parent fish population of the sturgeons can be greatly improved, the maturing of sexual glands of the female parent fishes are promoted, and the reproductive performances such as the egg laying amount and the quality of ova are improved.

Owner:CENT LAB FUJIAN ACADEMY OF AGRI SCI +1

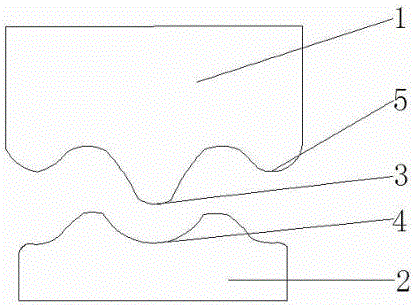

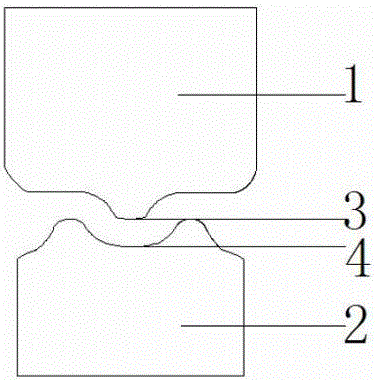

Corrugated board creasing wheel and creasing wheel device

InactiveCN105922652AAdapt to production requirementsSimple and fast operationMechanical working/deformationCardboardEngineering

The invention discloses a corrugated board creasing wheel which comprises an upper creasing wheel body and a lower creasing wheel body. The upper creasing wheel body and the lower creasing wheel body can be engaged correspondingly during rotation. The upper creasing wheel body is in a three-convex type or a single-convex type. The height of a middle protrusion of the upper creasing wheel body is half the thickness of a corrugated board. The height difference between the middle protrusion and auxiliary protrusions on the two sides is larger than or equal to 2 mm. A groove is formed in the middle of the top of the lower creasing wheel body. The width of the groove surface of the groove is twice the thickness of the corrugated board. The invention further discloses a creasing wheel device for the corrugated board. The creasing wheel device is connected with the creasing wheel through a detachable device. The corrugated board creasing wheel and the creasing wheel device can adapt to requirements of corrugated boards of various specifications, the quality of the corrugated boards in the crease production process is guaranteed, and the defects that seam breaking is caused when creases are too shallow or too deep, or seam breaking is caused by poor bending resistance in the using process, and a non-straight creasing trace is generated when a swing cover is folded are effectively overcome.

Owner:云南省弥勒市红阳有限责任公司

Aqueous coating agent for aluminum foil and preparation method of aqueous coating agent

ActiveCN103045068AHigh bonding strengthLow viscosityPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsPolyurethane dispersionAluminum foil

The invention relates to an aqueous coating agent for aluminum foil and a preparation method of the aqueous coating agent. The aqueous coating agent for the aluminum foil comprises the following components in percentage by weight: 90-99% of a single-component aqueous polyurethane dispersion liquid, 0.05-0.3% of a wetting agent, 0.05-0.3% of a defoaming agent, 0.05-0.3% of a flatting agent and 1-10% of an antisticking agent. The aqueous coating agent provided by the invention has the advantages of high bonding strength, good coating effect, low viscosity and the like, and is antisticking in rolling after coating. Provided by the invention is the aqueous coating agent for the coating production of the aluminum foil; and according to the aqueous coating agent, the harm to human bodies caused by environment pollution is avoided, the production cost is saved, and the development needs of low carbon and environment protection are satisfied.

Owner:JIANGSU ZHONGJIN MATAI MEDICINAL PACKAGING

Epoxy adhesive for electron component integrated molding technology and preparation method of epoxy adhesive

InactiveCN103555246AMeet the requirements of one-piece molding processAdapt to different needsNon-macromolecular adhesive additivesEpoxynovolac adhesivesSolventUltimate tensile strength

The invention discloses an epoxy adhesive for an electron component integrated molding technology and a preparation method of the epoxy adhesive. The epoxy adhesive comprises the following components in parts by weight: 30-70 parts of epoxy resin, 1-10 parts of curing agent, 1-10 parts of accelerator, 20-40 parts of solvent, and 0.1-5.0 parts of additive. Compared with the prior art, the epoxy adhesive is capable of satisfying the demand of an integrated molding process, and well adapting to different requirements of a new process in comparison with the traditional adhesive; the adhesive has high body strength, high modulus, high Tg, and high bonding strength, and is high in reliability. The epoxy adhesive is capable of satisfying the production process demand of the integrated molding process of the electron element and has higher reliability.

Owner:TONSAN ADHESIVES INC

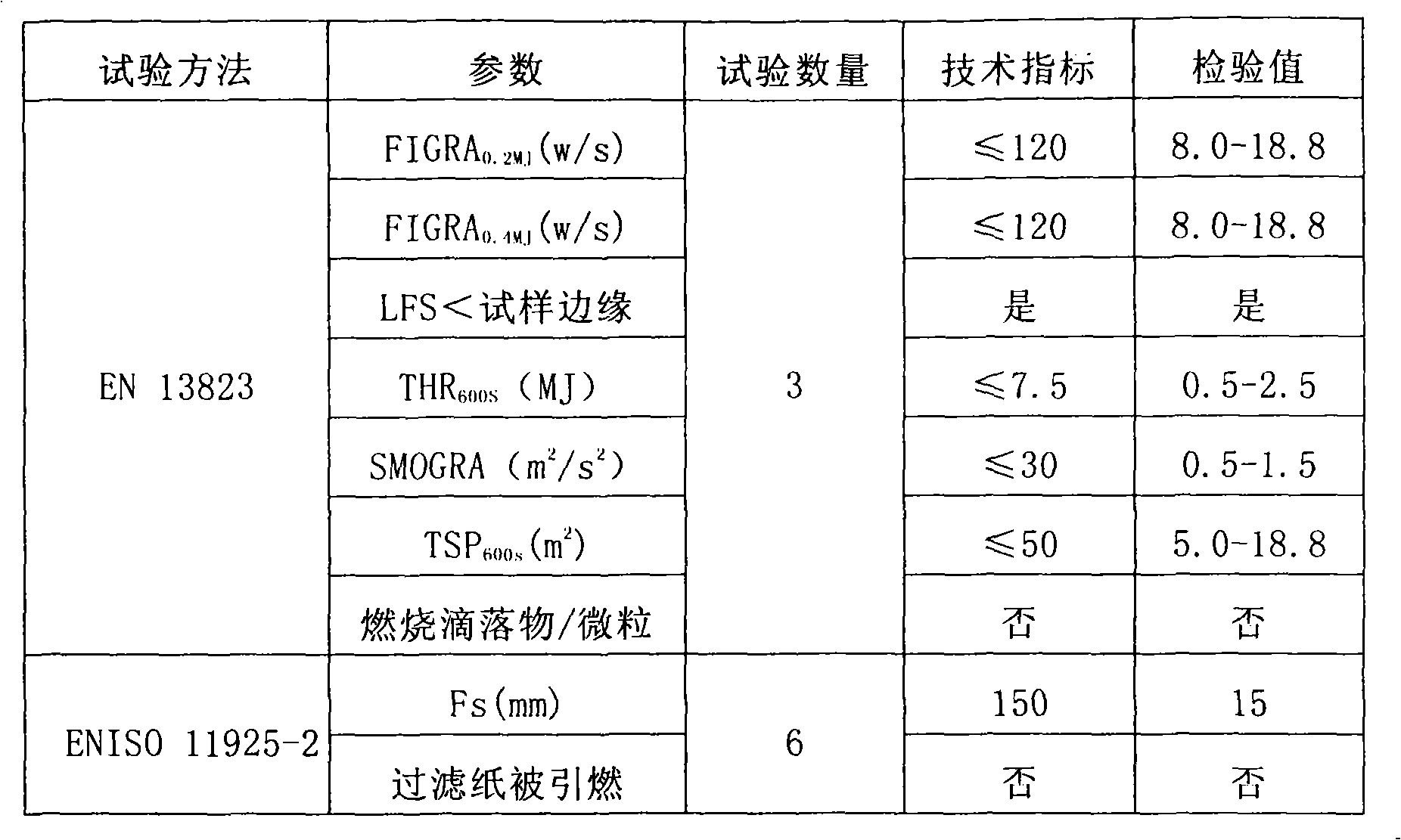

Halogen-free flame-retardant polyethylene functional material for aluminum-plastic composite board and preparation thereof

InactiveCN101280083AComply with the requirements of the directiveMeet the production process requirementsAntioxidantVolumetric Mass Density

The invention discloses a halogen-free flame-retardant polyethylene functional material for APCP and the preparation method of the material. The material has the following components and contents (based on weight proportion): 25-40% of polyethylene, 2.5-25% of modified polyethylene, 32-50% of brucite powders, 0.1-10.0% of silicone flame retardants, 0.5-3.5% of coupling agent, 0.5-8.5% of synergist, and 0.25-1.5% of antioxidant. The technical performance indicators of the material of the invention are as follows: 12.5 to19.5MPa for tensile yield strength, 30 to 230% for ultimate elongation, 15.5 to24.5 MPa for bending strength, 19.0 to 25.0KJ / m2 for notch impact strength, 85 to 95 DEG C for Vicat softening temperature, 1.25 to 1.37 g / cm3 for density, 32 to 36% for oxygen index, and 0.25 to 1.50g / 10min for melt flow rate; besides, the environmental protection index of the material meets the International Safety Standards IEC62321, in line with the requirements of ROHS Directive. The preparation method of the invention is to use vacuum exhaust-type parallel twin-screw extruding hot-cutting and granulating technology to prepare the material. The raw materials of the invention can be easily obtained and the technology is easy to control; besides, the material of the invention has the advantages of excellent comprehensive performance and cost ratio, as well as good flame-retardant properties and thermal stability, which can be extruded and molded through injection and can realize large-scale continuous production.

Owner:HUNAN KEOCT MATERIALS +1

Continuous graphitizing ultra-high temperature tube furnace

ActiveCN102797075ASmall sizeMeet the production process requirementsFibre chemical featuresFurnace temperatureCarbon composites

The invention discloses a continuous graphitizing ultra-high temperature tube furnace, whose heating working temperature falls within a range of 2200-2800 DEG C. A structure of the continuous graphitizing ultra-high temperature tube furnace comprises a muffle furnace hearth, a protective tube, a heat insulation refractory layer and a furnace shell. A graphite muffle furnace hearth is tubular, is divided into three temperature areas and is an unique heating body. Water cooling copper electrodes are mounted at two ends of the muffle furnace hearth; the protective tube with an adjusting device is arranged outside the muffle furnace hearth; the protective tube is positioned between the muffle furnace hearth and the heat insulation refractory material; and the axis of the protective tube can be adjusted by the adjusting device. A heat insulation system, which is formed by a soft graphite felt, a soft felt, a carbon / carbon composite material and other materials, is arranged in a furnace body; the airtight furnace shell with a water cooling steel structure is arranged outside the heat insulation system; the water cooling furnace shell comprises a plurality of independent water cooling chambers; and the chambers are respectively used for cooling different areas of the furnace body. The continuous graphitizing ultra-high temperature tube furnace disclosed by the invention has the advantages of high working furnace temperature, uniform and stable temperature field, less muffle furnace hearth surface heat accumulation phenomenon, long muffle furnace hearth service life, simple structure, easiness for machining and so on.

Owner:ATA CARBON FIBER TECH GUANGZHOU

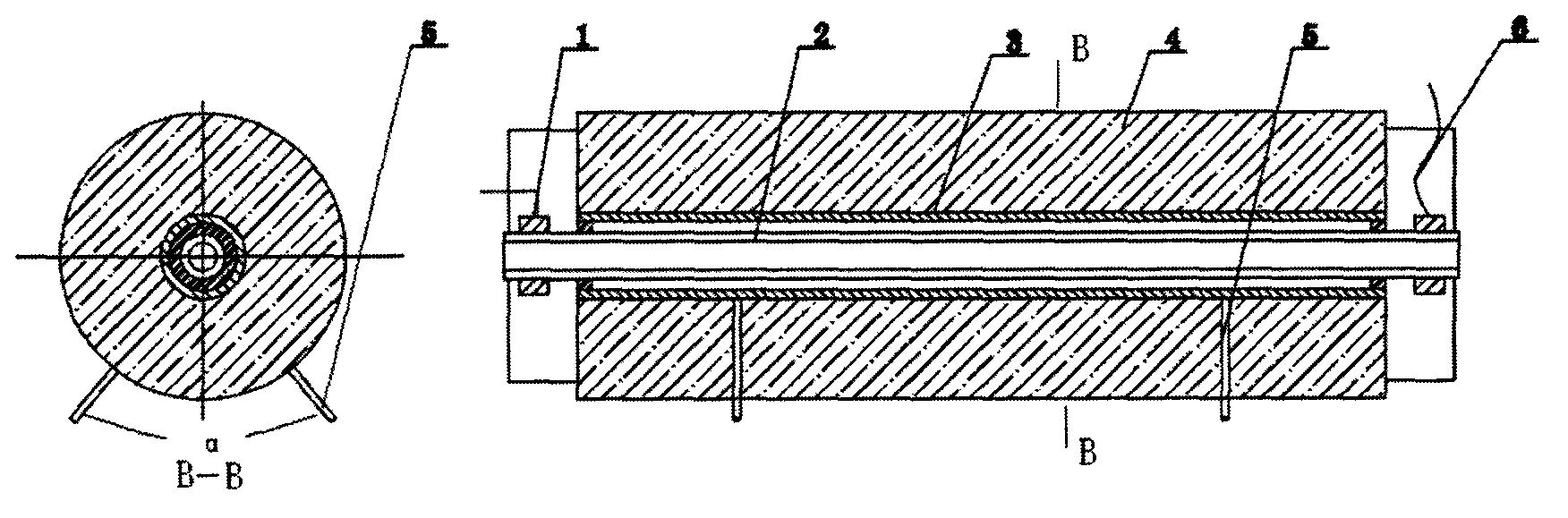

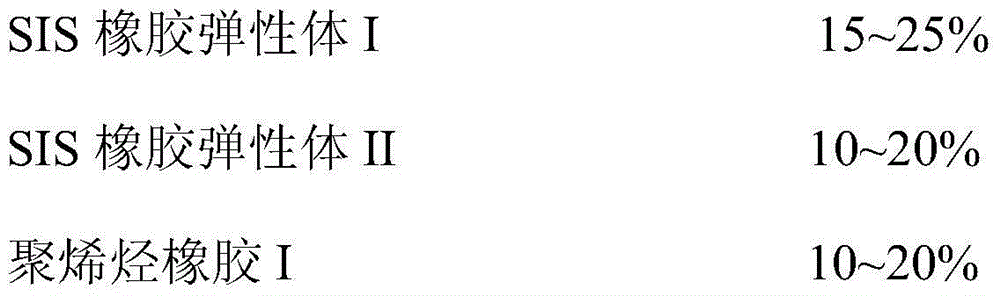

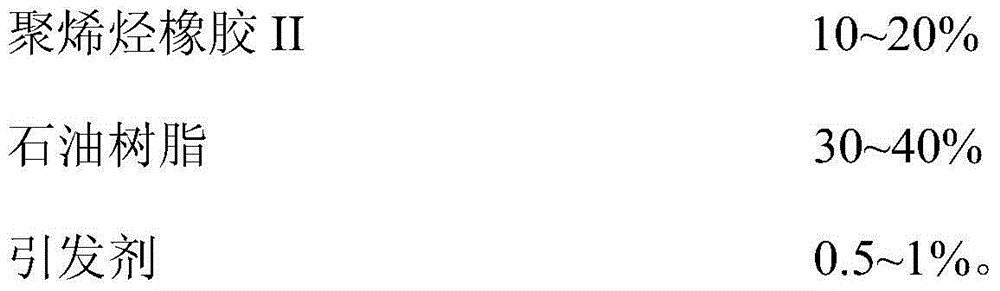

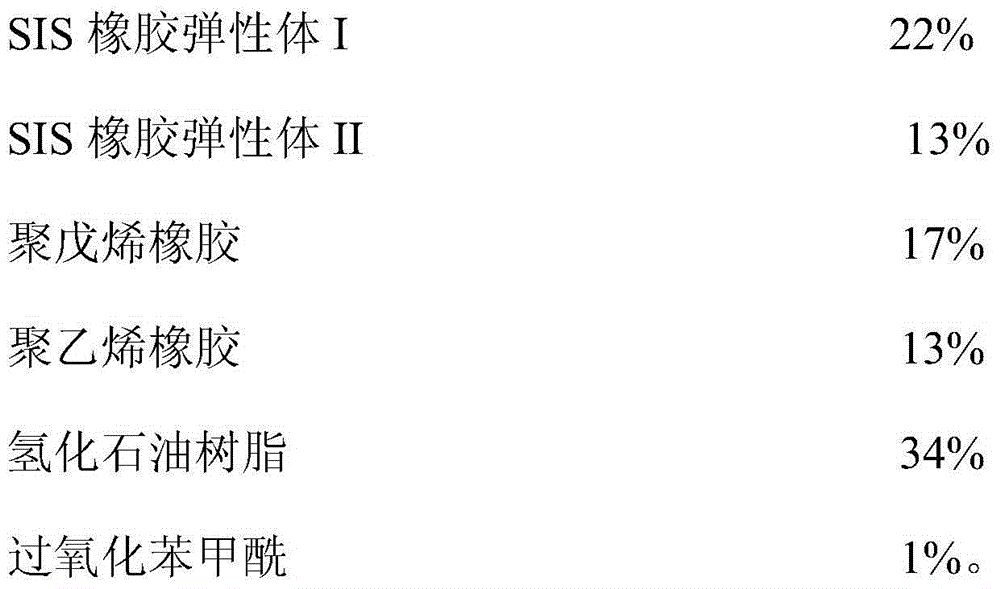

Single-surface adhesive tape for lithium battery and preparation method for single-surface adhesive tape

ActiveCN104559823AGuaranteed performanceQuality improvementMineral oil hydrocarbon copolymer adhesivesFilm/foil adhesivesRelative displacementChemical reaction

The invention relates to a single-surface adhesive tape for a lithium battery. The single-surface adhesive tape comprises a sealing hot-melt pressure-sensitive adhesive layer and a base film layer, wherein the sealing hot-melt pressure-sensitive adhesive layer and the base film layer are connected with each other. The single-surface adhesive tape is high in adhesiveness, can resist corrosion of electrolyte of the lithium battery without generating chemical reaction with the electrolyte in the lithium battery, and keeps the performance of the lithium battery and the quality of the lithium battery. When the single-surface adhesive tape is used, the adhesive surface is attached to a pole group, and the pole group is wrapped by an external packaging material; furthermore, the relative position between the pole group and the external packaging material is adjusted, and the lithium battery is heated and pressurized; glue can overflow out of the two side surfaces of the single-surface adhesive tape to adhere the pole group and the external packaging material, so that the single-surface adhesive tape is convenient to use and meets the requirement of the production technology of the lithium battery; the pole group of the lithium battery and the external packaging material can be fixed by the single-surface adhesive tape and are firmly adhered, so that no relative displacement is generated; the single-surface adhesive tape is high in anti-falling capacity, high in safety, long in service life and stale in quality.

Owner:DONGGUAN AOZON ELECTRONICS MATERIAL

Polyvinyl chloride (PVC) glove production device

ActiveCN102173017ARapid coolingGood release effectDomestic articlesCoatingsPolyvinyl chlorideEngineering

The invention belongs to the field of polyvinyl chloride (PVC) glove production and relates to a PVC glove production device. The device comprises a hand mold rail line and a glove production device, wherein the hand mold rail line is positioned above the glove production device; the glove production device comprises a PVC material groove, a PVC material dripping section, a PVC plasticizing forming device, a polyurethane (PU) material groove, a PU drying device, a PVC glove hemming device and a demolding device in turn; and the PVC plasticizing forming device and the PU drying device are connected with a heat supply boiler. The device is characterized in that: a hand mold cleaning device and a hand mold drying device are arranged in turn between the demolding device and the PVC material groove; the PVC material groove is provided with a viscosity detection adjusting device; and a PU washing device and a washing drying device are arranged in turn between the PU drying device and the PVC glove hemming device. The device has high automation degree and good effect of forming PVC gloves; moreover, the product is easy to demold, and stickness or damage hardly appears in the demolding process, so that the glove quality is ensured.

Owner:SHANDONG INTCO MEDICAL SUPPLY CO LTD

Double-side adhesive tape adhering apparatus and double-side adhesive tape adhering method

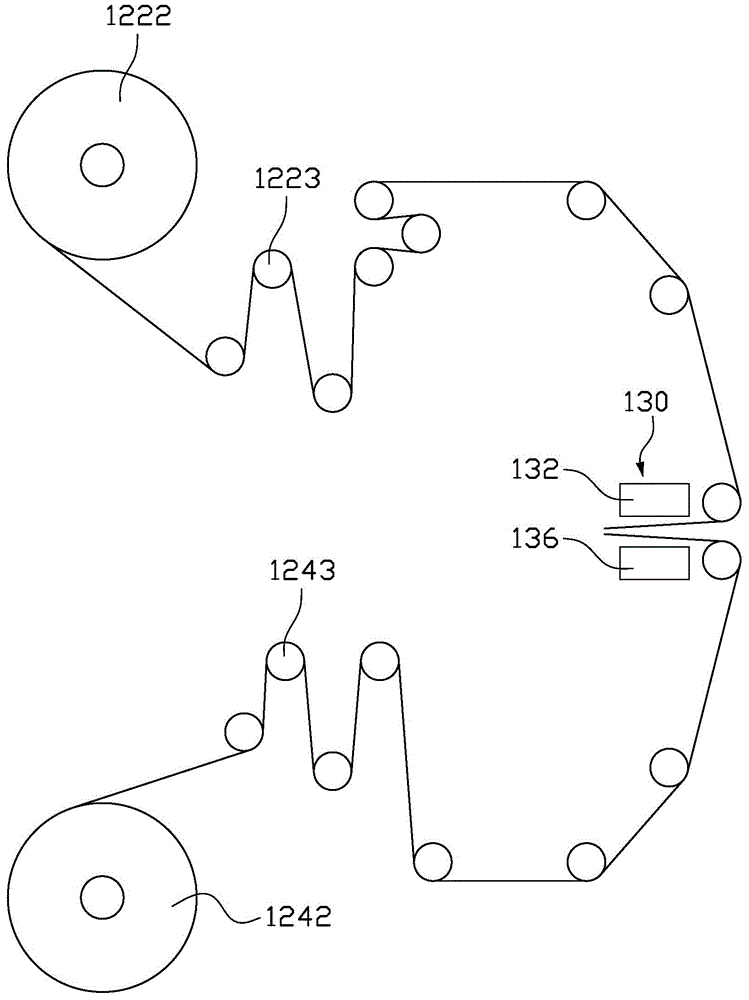

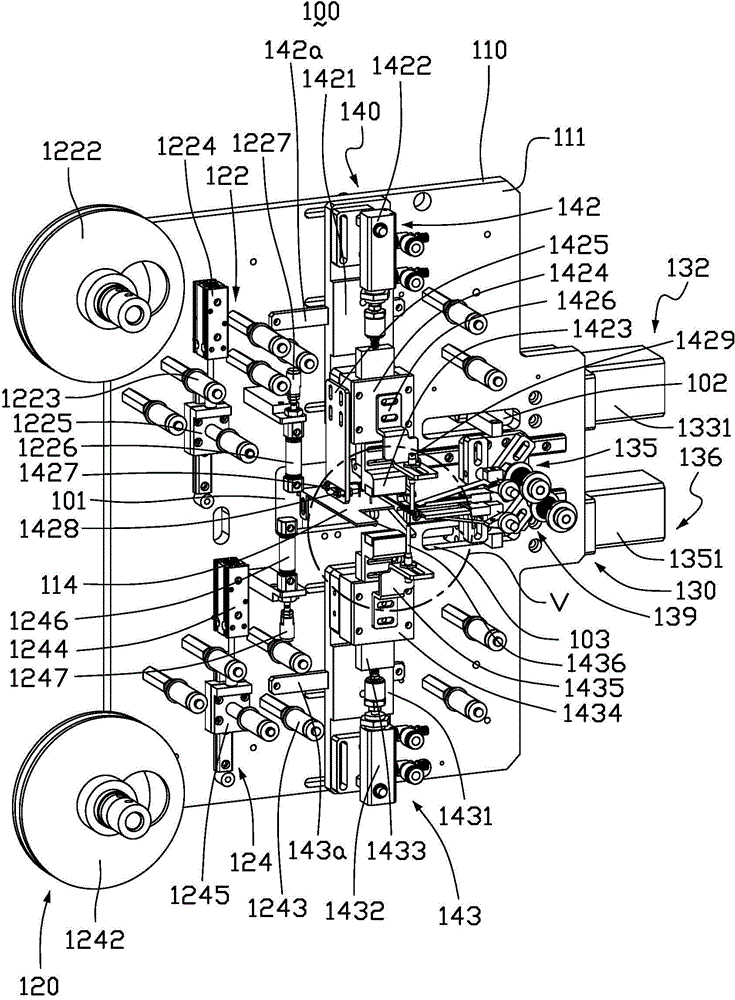

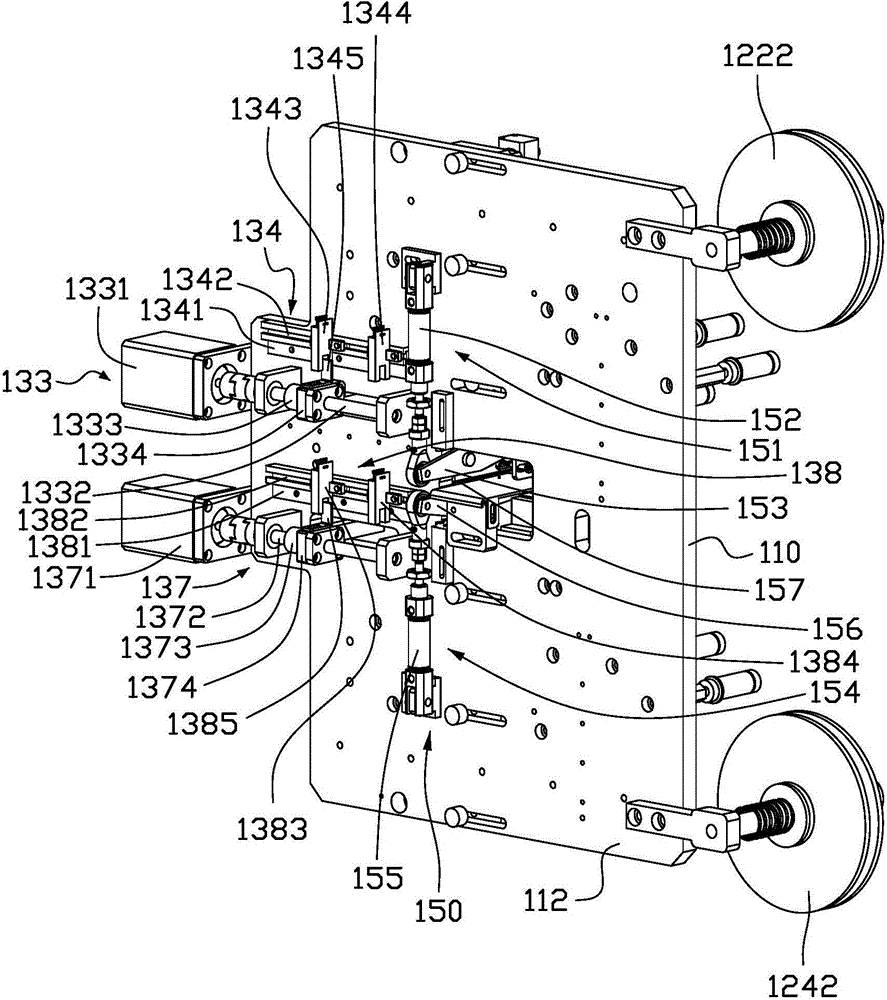

ActiveCN104916873AHigh transmission accuracyNo side-to-side offset movementFinal product manufactureCell component detailsAdhesiveEngineering

A double-side adhesive tape adhering apparatus comprises a supporting plate, an adhesive tape feeding mechanism set, an adhesive tape adhering mechanism set and a shearing mechanism set. The adhesive tape feeding mechanism set comprises a first adhesive tape feeding mechanism and a second adhesive tape feeding mechanism; the first adhesive tape feeding mechanism comprises a first adhesive tape feeding driving part and a first adhesive tape feeding part; the first adhesive tape feeding part is provided with a first adhesive tape feeding block and a first adhesive tape pressing spring plate; the second adhesive tape feeding mechanism comprises a second adhesive tape feeding driving part and a second adhesive tape feeding part; the second adhesive tape feeding part is provided with a second adhesive tape feeding block and a second adhesive tape pressing spring plate; the adhesive tape adhering mechanism set comprises a first adhesive tape adhering mechanism and a second adhesive tape adhering mechanism; the first adhesive tape adhering mechanism comprises a first adhesive tape adhering driver and a first adhesive tape adhering block; the second adhesive tape adhering mechanism comprises a second adhesive tape adhering driver and a second adhesive tape adhering block; and the adhesive tape feeding mechanism set drives the first adhesive tape feeding part and the second adhesive tape feeding part to enable an adhesive tape to be positioned at both sides of a pole piece, the adhesive tape adhering mechanism set drives the first adhesive tape adhering block and the second adhesive tape adhering block to enable the adhesive tape to press the pole piece and the shearing mechanism set shears the adhesive tape. By the double-side adhesive tape adhering apparatus, accuracy of the adhesive tape adhering position can be improved; and the double-side adhesive tape adhering apparatus can be suitable for the pole piece with a small width. The present invention relates to a double-side adhesive tape adhering method.

Owner:SHENZHEN CHENGJIE INTELLIGENT EQUIP CO LTD

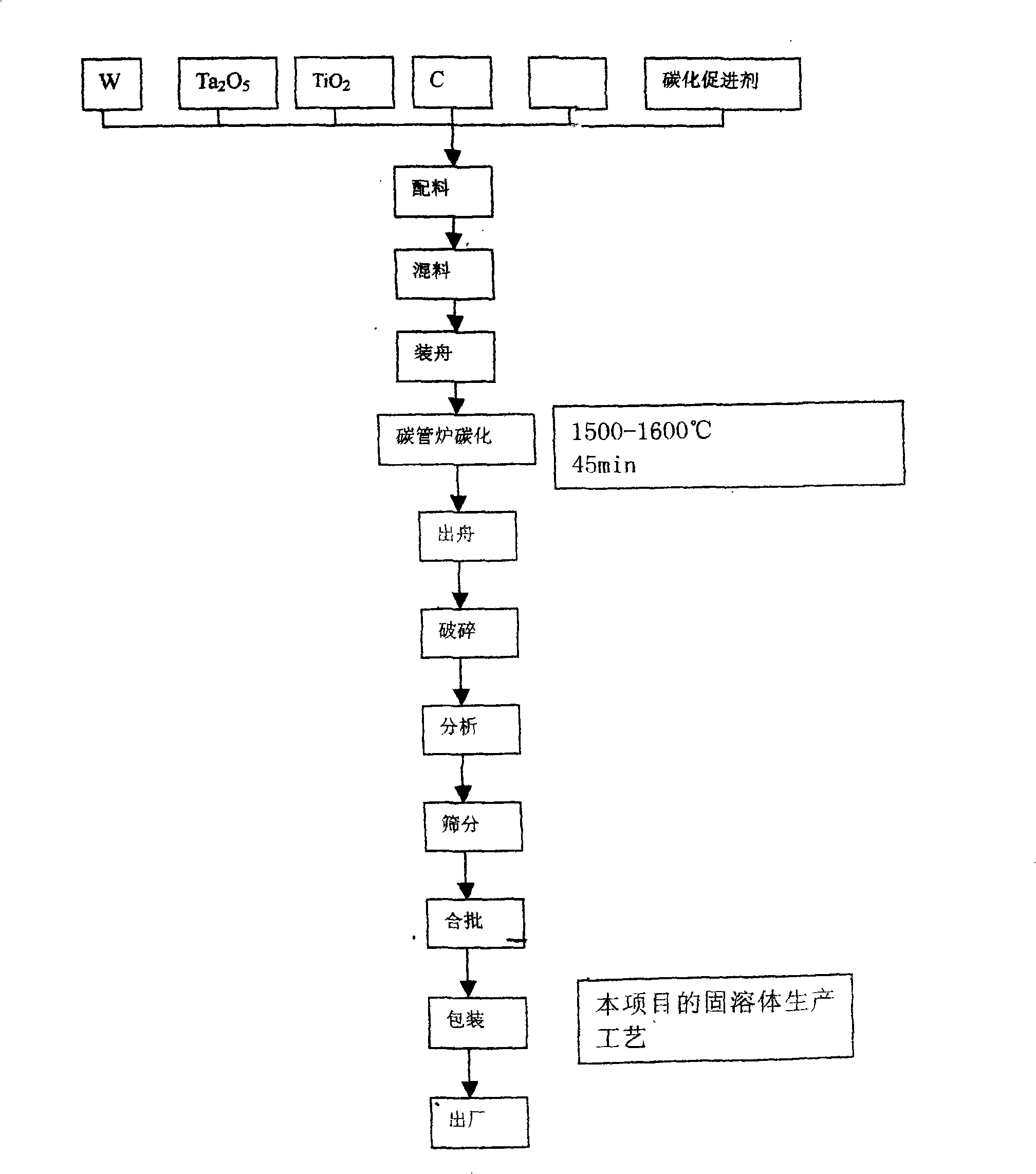

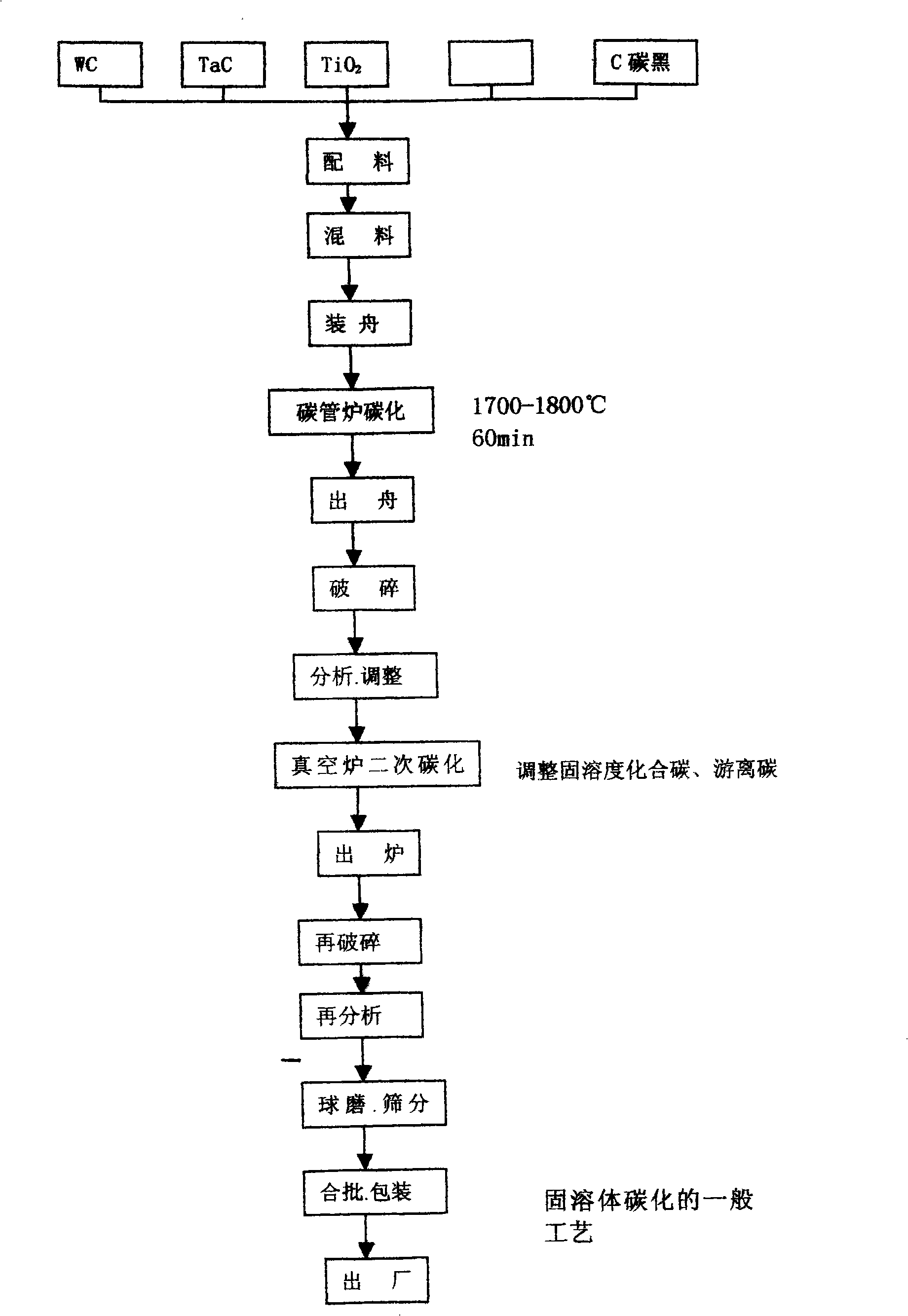

Tungsten carbide-titanium carbide-tantalum carbide solid solution powder

The invention relates to tungsten carbide-titanium carbide-tantalum carbide solid solution powder, namely addition of the tungsten carbide-titanium carbide-tantalum carbide solid solution powder TRC-33 during the process of producing cemented carbide materials can make the metallurgical structure of the alloy materials more uniform and the product performance more stable, and obviously improves the strength, the hardness and the toughness of the product. The TRC-33 is a first-rate solid solution, has a forward-looking promotion and application prospect and can further improve the performance of the cemented carbide material WC-TiC-TaC-Co of China.

Owner:长沙伟徽高科技新材料有限公司

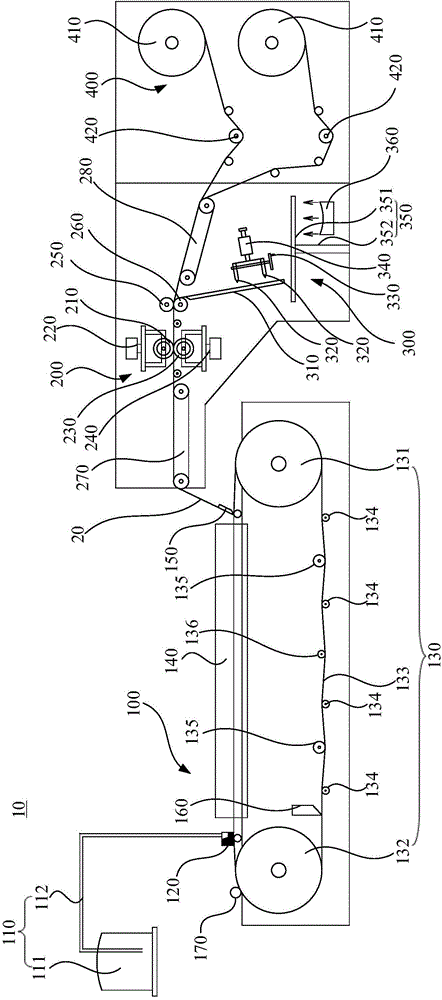

Casting machine

ActiveCN104552712AMeet the production process requirementsImprove cutting accuracyCoatingsArticle deliverySlurryMaterials science

The invention relates to a casting machine which comprises a casting mechanism and a splitting mechanism. The casting mechanism comprises a slurry feeding module, a casting box, a base band unfolding system and a releasing module, wherein the splitting mechanism which is located behind a work station of the releasing module comprises an upper slicer, a lower slicer, an upper dragging roller and a lower dragging roller. The slurry feeding module of the casting mechanism continuously feeds slurry to the casting box, the slurry is casted or coated by the casting box to a base band to form a membrane band, and a power source drives a driving roller to rotate so as to drive a driven roller to rotate, so that the base band further moves forward; the releasing module separates the base band from the membrane band; the membrane band under the action of interaction of the upper and lower dragging rollers is dragged to move forward, and the upper and lower slicers are matched to split the membrane band, and casting and splitting are organically combined, so that the mechanical casting and splitting are realized. Therefore, the cutting precision and the production efficiency are greatly improved, the requirements on the production process of different enterprises are satisfied, and the casting machine is compact and reasonable in structure.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

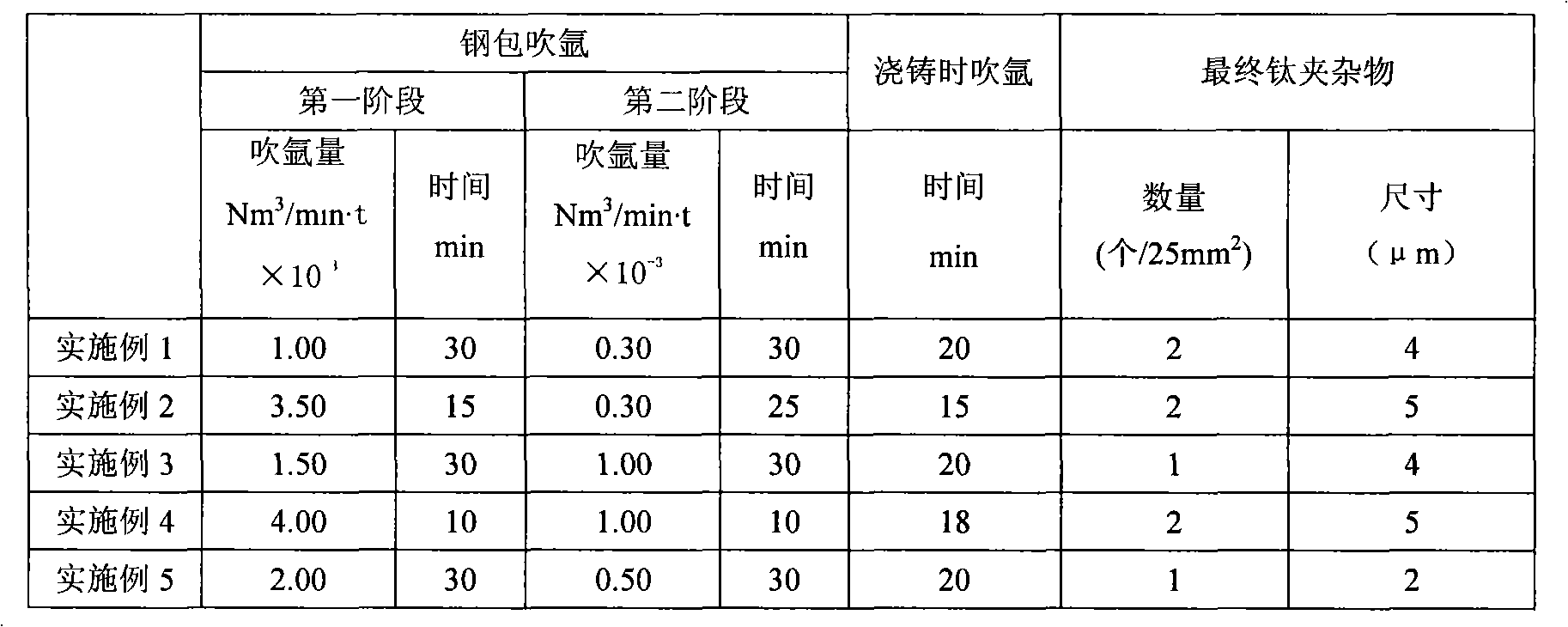

Method for reducing titanium inclusion of molten steel

The invention discloses a method for reducing titanium inclusion of molten steel, which is characterized in that: a ladle wait bit is subject to the bottom blowing argon after cord wire steel is refined and the blowing argon is performed during the steel casting of the ladle; a ladle is subject to the blowing argon by two states during the wait bit, the flow of argon is controlled within 0.3*10 to 4*10Nm / min. t; the blowing argon is performed during the steel casting of the ladle, the maximum flow of the argon is 1.5*10Nm / mim. t, and the flow change of the blowing argon is decreased according to the casting weight of the ladle through the formula Y being equal to (1.5*10 to 3*10.X)Nmmin. t. Because the ladle is subject to the bottom blowing argon by using the wait bit and the blowing argon is performed during the steel casting of the ladle, the invention further removes titanium and other inclusions of the molten steel, improves the purity of the molten steel, balances the ingredients and the temperature in steel, and reduces the granularity of the titanium inclusion and other friable oxide inclusions in the cord wire steel, thereby meeting the requirements of the production process of the cord wire steel and improving the drawing property and the fatigue resistance of the cord wire steel.

Owner:ANGANG STEEL CO LTD

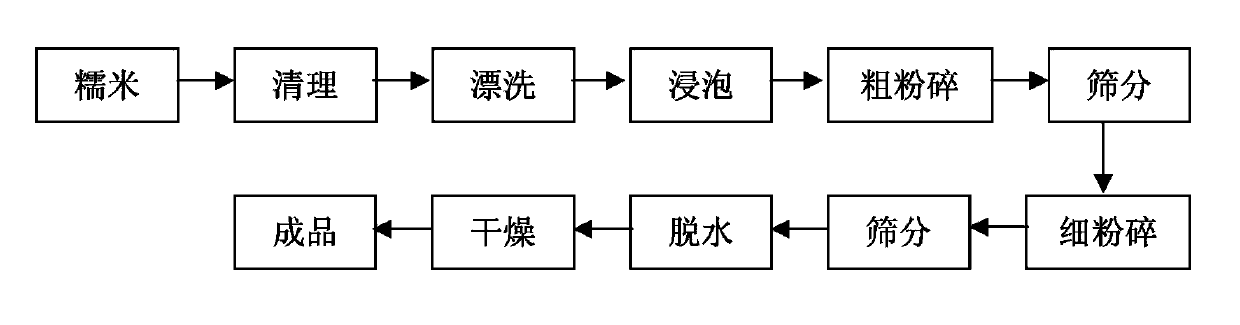

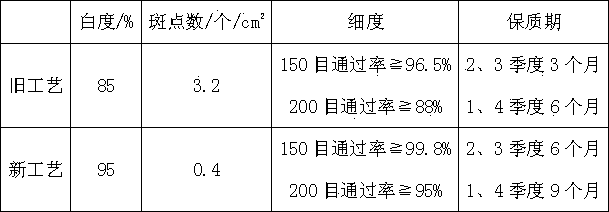

Method for producing water-grinding glutinous rice flour

The invention relates to a method for smashing glutinous rice, in particular to application of the smashing-screening coupling technology in the water-grinding glutinous rice flour production technology. The method for producing water-grinding glutinous rice flour comprises the steps that ash and impurities in rice are removed through a pretreatment process; coarse grinding is conducted on the soaked glutinous rice through a grinder and primary screening is conducted by a vibrating screen classifier; glutinous rice husks in glutinous rice milk are removed and 50-80-mesh milk is obtained; refined grinding is conducted through an ultra-fine grinder, secondary screening is conducted through the vibrating screen classifier, and ground glutinous rice milk particles are all over 100 meshes; the glutinous rice milk is dehydrated and dried and the finished product is obtained. The screening process is adopted for twice through the grinding technology and the method has the advantages that the technology is simple, cost is low, the prepared water-grinding glutinous rice flour is high in purity, low in impurity contents of fat, ash and the like, small in number of spots, high in whiteness and fineness and long in expiration date the mean grain size is in narrow distribution, the energy consumption is low, the production capacity is large and the like.

Owner:HENAN HUANGGUO GRAIN COMPANY

Toxin-reducing cigarette additive and preparation method and use thereof

InactiveCN102038286AReduce HCNWill not change the taste of cigarette smokingTobacco treatmentTobacco smoke filtersFlavorParticulates

The invention discloses a toxin-reducing cigarette additive, and a preparation method and use thereof. In the toxin-reducing cigarette additive, cores are made of an inorganic particulate matter such as silica gel and active carbon, shells are made of waste tobacco powder fibers, and granulation forming is performed under the action of an adhesive, and according to needs, an alkaline functional material can be added in the forming process for reducing HCN content in smoke. The preparation method of the cigarette tip particle additive is simple, the cost of the cigarette tip particle additive is low, and when the prepared additive is added into the tips, the HCN content in the smoke of cigarettes can be reduced effectively without influencing the smoke flavor of the cigarettes.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com