High-abrasion-resistance ceramic glazed brick and manufacturing method thereof

A high-wear-resistant, glazed tile technology, applied in the field of architectural ceramics, can solve the problems of poor wear-resistant performance of polished glazes, and achieve the effects of low cost, small workload, and improved transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

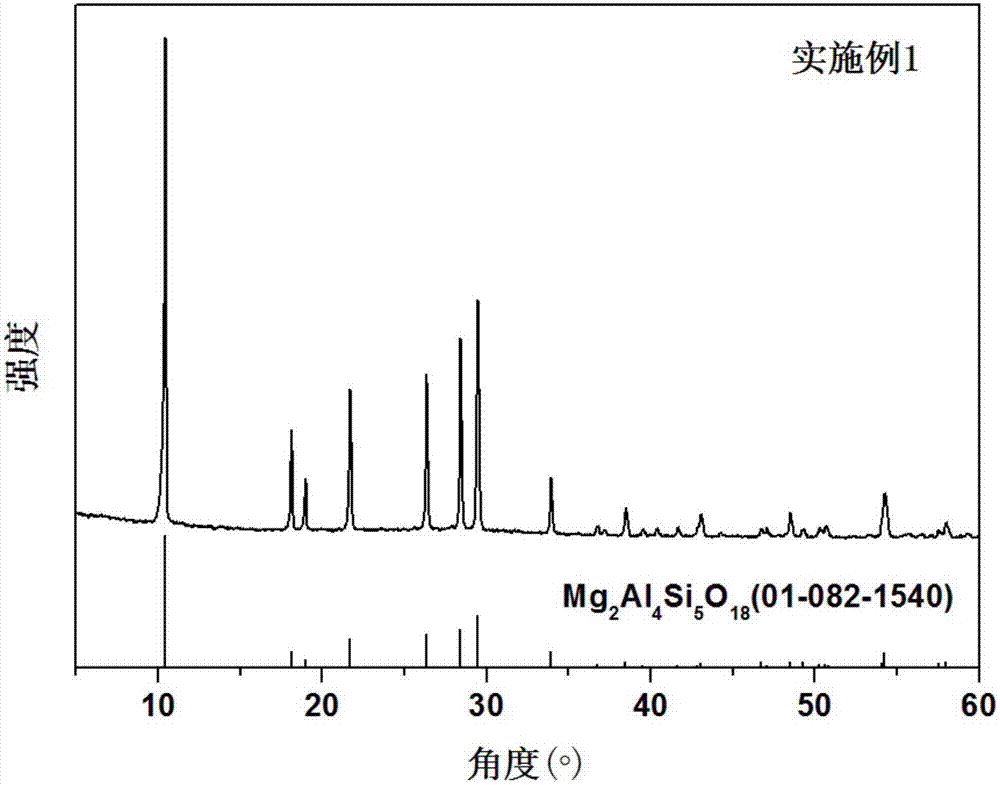

Embodiment 1

[0032] A preparation method for high wear-resistant ceramic glazed tiles, comprising the steps of:

[0033] 1) In parts by mass, 70 parts of cordierite, 5 parts of kaolin, 5 parts of feldspar, 8 parts of talc, 4 parts of calcite, 6 parts of spodumene, 0.5 part of zinc oxide, 0.5 part of barium carbonate and 1 part of boric acid Mix and grind to make a glaze slurry.

[0034] 2) Apply the glaze slurry prepared in step 1) to the green body printed with the pattern through a glaze pouring machine. The green body of this embodiment is a conventional ceramic tile green body, and the ceramic brick has a certain decorative function by printing patterns on the green body.

[0035] 3) After drying the green body with glaze slurry applied in step 2, it is fired in a roller kiln to obtain high wear-resistant ceramic glazed tiles. The maximum firing temperature is 1230° C., and the firing cycle is 90 minutes.

[0036] 4) The ceramic glazed tile fired in step 3) is mechanically ground and...

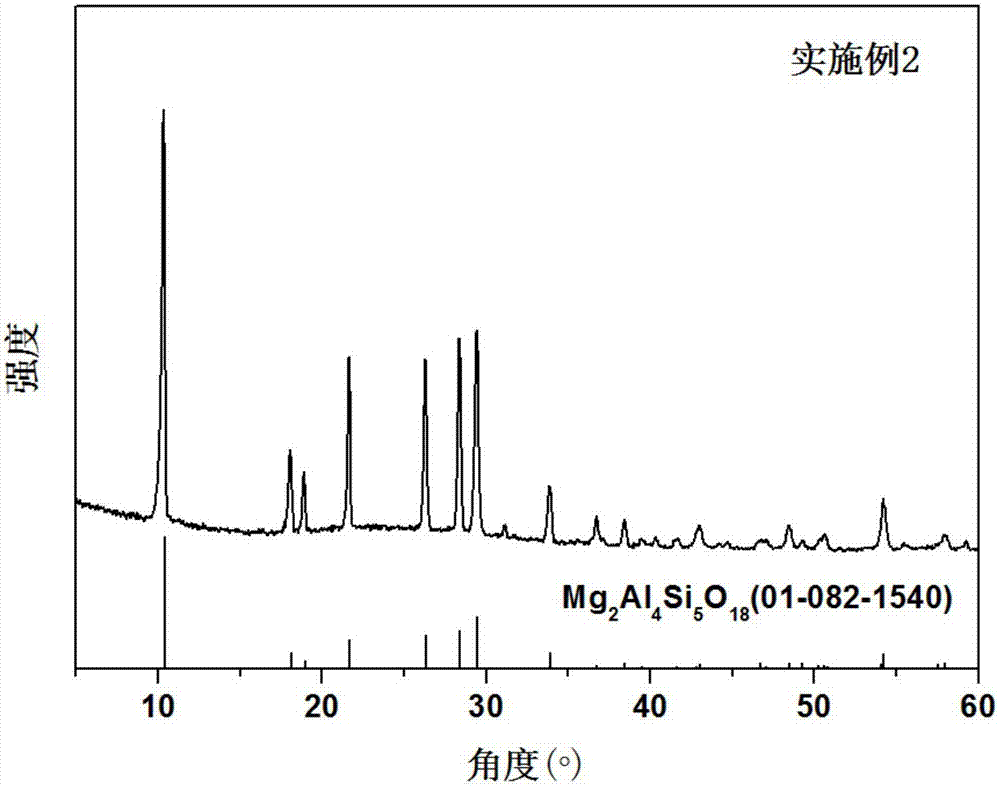

Embodiment 2

[0044] A preparation method for high wear-resistant ceramic glazed tiles, comprising the steps of:

[0045] 1) In terms of parts by mass, 40 parts of cordierite, 5 parts of kaolin, 5 parts of quartz, 20 parts of feldspar, 8 parts of talc, 10 parts of dolomite, 5 parts of wollastonite, 2 parts of lithium carbonate, 2 parts of oxide Zinc, 2 parts of strontium carbonate and 1 part of titanium dioxide are mixed and ground to prepare glaze slurry.

[0046] 2) Apply the glaze slurry prepared in step 1) to the green body printed with the pattern through a glaze pouring machine.

[0047] 3) After drying the glazed body in step 2), it is fired in a roller kiln to obtain high wear-resistant ceramic glazed tiles. The maximum firing temperature is 1270° C., and the firing cycle is 60 minutes.

[0048] It can be easily judged by naked eyes that the glaze layer of the ceramic glazed tile prepared in this embodiment has good transparency, and the decorative pattern of the prepared ceramic g...

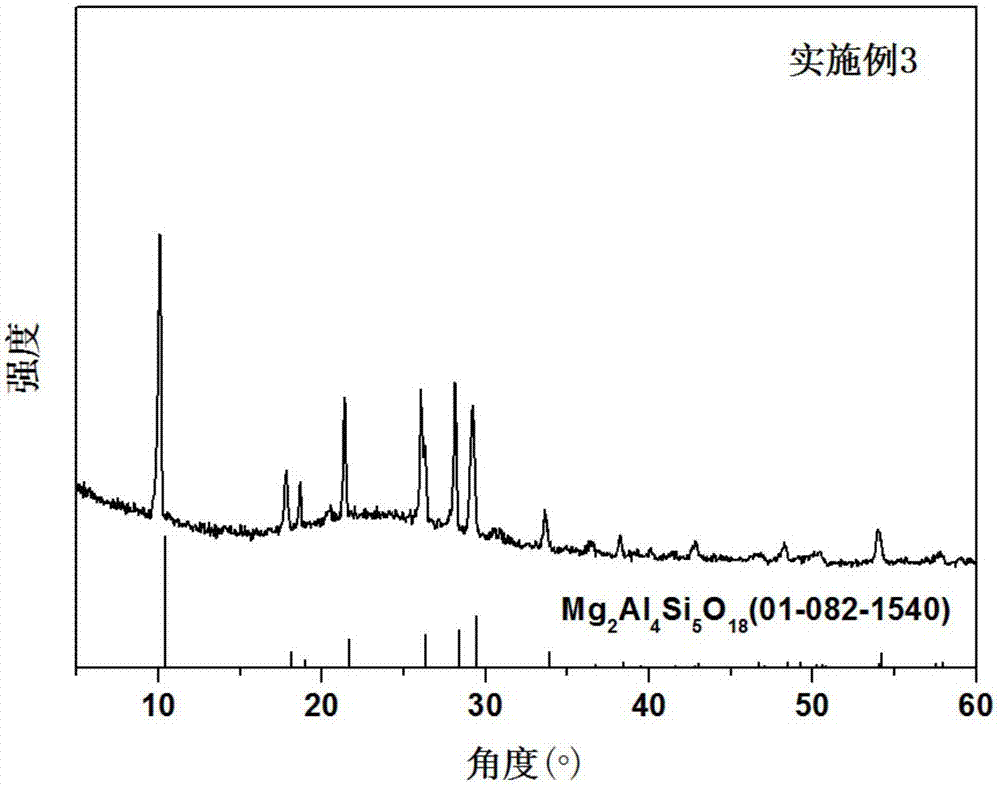

Embodiment 3

[0052] A preparation method for high wear-resistant ceramic glazed tiles, comprising the steps of:

[0053] 1) In terms of parts by mass, mix and grind 15 parts of cordierite, 5 parts of kaolin, 12 parts of quartz, 2 parts of alumina, 26 parts of feldspar, 10 parts of talc, 20 parts of calcite and 10 parts of frit to prepare a glaze slurry .

[0054] 2) Apply the glaze slurry prepared in step 1) to the green body printed with the pattern through a glaze sprayer.

[0055] 3) After drying the glazed body in step 2), it is fired in a roller kiln to obtain high wear-resistant ceramic glazed tiles. The maximum firing temperature is 1150° C., and the firing cycle is 30 minutes.

[0056] 4) The ceramic glazed tile fired in step 3) is mechanically ground and polished, and the glossiness of the obtained surface is 20°.

[0057] It can be easily judged by naked eyes that the glaze layer of the ceramic glazed tile prepared in this embodiment has good transparency, and the decorative pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com