Metallurgical pellet compound binding agent

A binder and pellet technology, which is applied in the fields of pellet binders and metallurgical materials, can solve the problems of reduced quality and strength of green pellets, reduced iron grade of pellets, and decreased quality of pellets, achieving reduction Steam pressure, economic benefits of energy saving and production increase, and the effect of reducing ore return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further describe the present invention, the metallurgical pellet composite binder of the present invention will be described in more detail below in conjunction with examples.

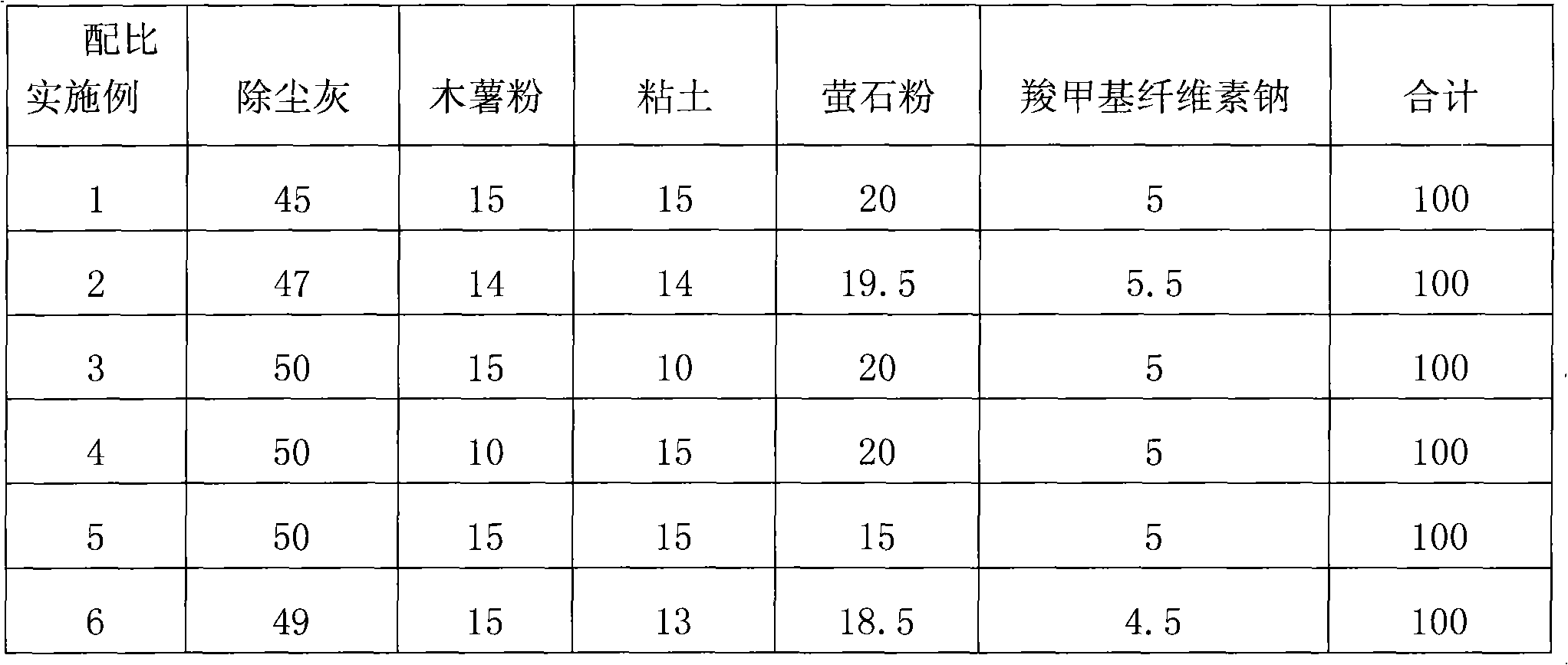

[0028] Table 1 lists the composition in weight percent used in the metallurgical pellet composite binder of the present invention.

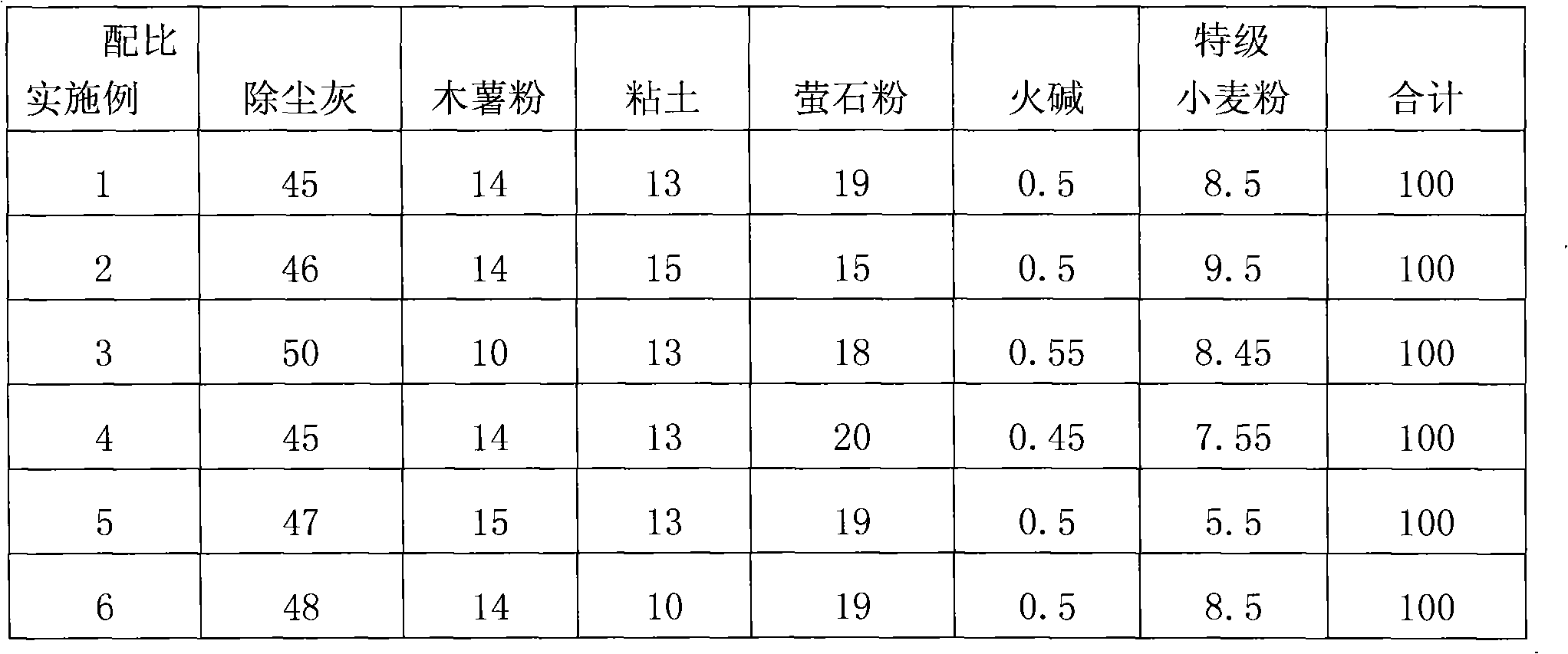

[0029] Table 2 lists the weight percent composition of another formulation of the metallurgical pellet composite binder of the present invention.

[0030] The weight percentage composition (%) of metallurgical pellet composite binder of table 1

[0031]

[0032] The weight percentage composition (%) of another kind of formulation of metallurgical pellet composite binder

[0033]

[0034] Among them: dust removal ash or iron powder, cassava flour, clay, fluorite powder, and sodium carboxymethyl cellulose in the process of blast furnace ironmaking and sintering production are ground to the required particle size and dried, blast furnace ironmaking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com