Room-temperature curing epoxy resin adhesive and preparation method thereof

An epoxy resin glue, room temperature curing technology, used in epoxy resin glue, adhesives, adhesive additives and other directions, can solve the problem of high curing temperature, achieve strong solubility, high electrochemical stability, excellent mechanical properties and thermal stability. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

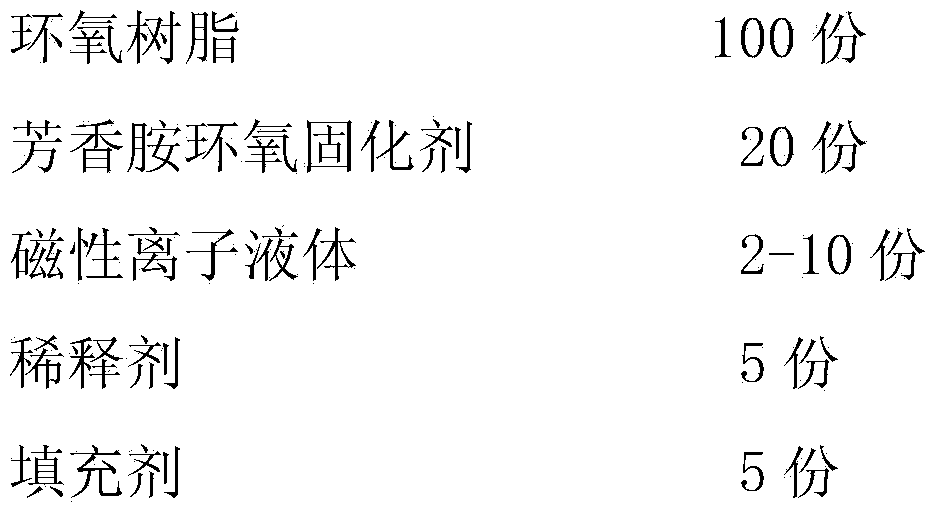

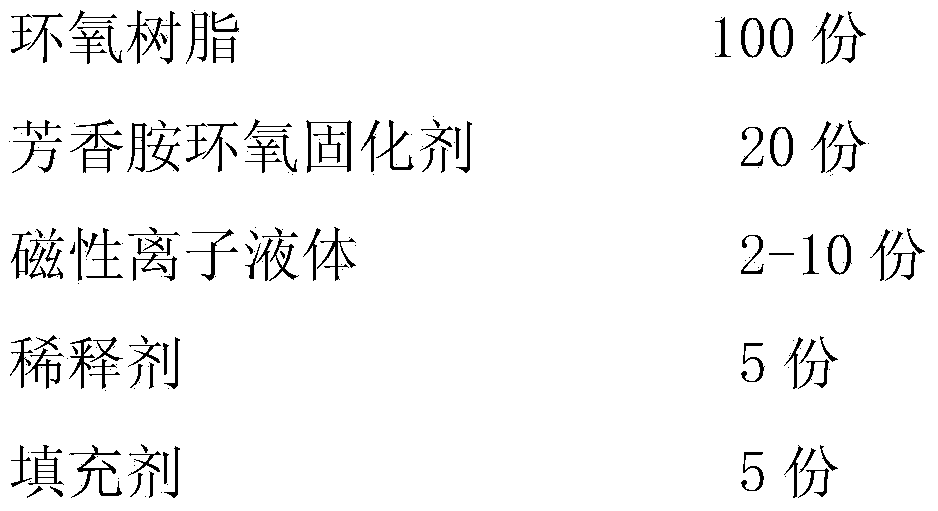

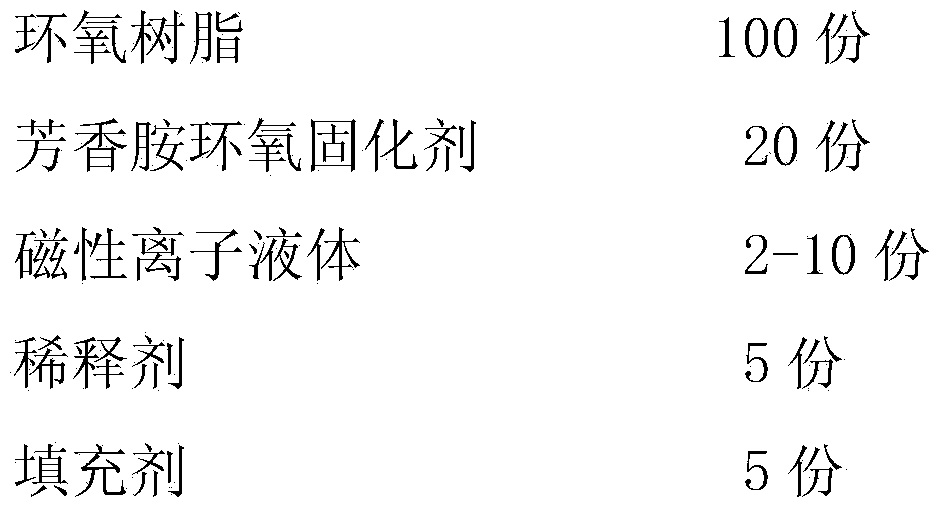

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of magnetic ionic liquid of the present invention preferably comprises:

[0033] Step 1: dissolving 1-hydroimidazole and an iodine-containing alkyl compound in a solvent, and then adding potassium hydroxide to react to obtain the first mixed solution;

[0034] Step 2: reacting the first mixed solution with methyl iodide to obtain a second product;

[0035] Step 3: reacting the second product with ferric trichloride hexahydrate or ferric tribromide hexahydrate to obtain a magnetic ionic liquid.

[0036] According to the present invention, the solvent in Step 1 is not particularly limited, as long as it can dissolve 1-hydroimidazole and an iodine-containing alkyl compound, preferably toluene, the reaction temperature in Step 1 is preferably 45-55°C, and the reaction time is preferably 3 to 5 hours. The general structural formula of the iodine-containing alkyl compound is CH 3 (CH 2 ) n CH 2 I, where n=1-15, the molar ratio of the 1-hydroimidaz...

Embodiment 1

[0044] Dissolve 1mol 1-hydroimidazole and 1mol methyl iodide in toluene, add 1mol KOH, stir at 45°C for 5 hours, add 1mol methyl iodide, heat up to 55°C and continue stirring for 3 hours, cool to room temperature, distill off the solvent under reduced pressure, and dry , to obtain the product, the product was stirred with 1mol ferric chloride hexahydrate at 25°C for 5 hours, after the reaction was completed, it was left to stand for 24 hours, vacuum-dried for 2 hours after vacuum distillation, and the magnetic ionic liquid 1,3-dimethyl Imidazolium tetrachloride salt.

Embodiment 2

[0046] Dissolve 1 mol of 1-hydroimidazole and 1 mol of iodobutane in toluene, add 1 mol of KOH and stir at 55°C for 3 hours, then add 1 mol of methyl iodide, heat up to 65°C and continue stirring for 1 hour, cool to room temperature, and distill off the solvent under reduced pressure. Dry to obtain the product. Stir the product with 1mol ferric chloride hexahydrate at 25°C for 7 hours. After the reaction is completed, let it stand for 24 hours, vacuum-dry it for 2 hours after vacuum distillation, and obtain the magnetic ionic liquid 1-butyl-3 - methylimidazolium tetrachloride ferric salt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com