Seamless solid metal calcium cored wire for steelmaking and deoxidation and preparation method thereof

A technology of calcium metal and cored wire, which is applied in the field of seamless solid calcium metal cored wire and its preparation, can solve problems such as insufficient depth and boiling of molten steel, reduce process temperature drop, increase steel strip thickness, and reduce boiling The effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

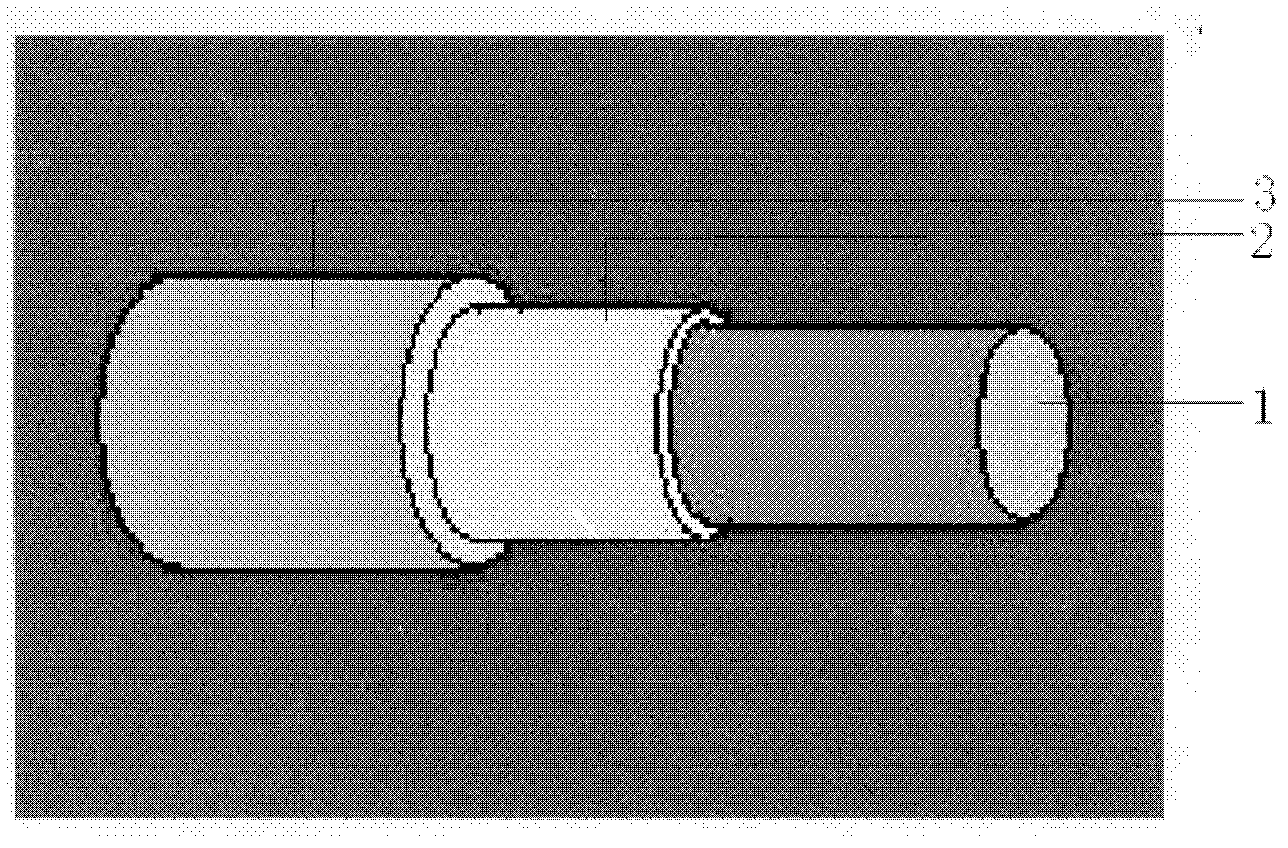

[0024] Step 1. Use the solid metal calcium wire with the sum of impurities not higher than 3% as the inner core 1, and prepare the calcium wire preparation method with reference to the application number 201010292333.8, but use industrially pure calcium ingots with the sum of impurities not higher than 3% as the raw material Then adopt the plasma spraying method to spray, coat one deck nano-scale silicon powder (particle diameter at 40nm) on the surface of the solid metal calcium wire as the intermediate layer 2,

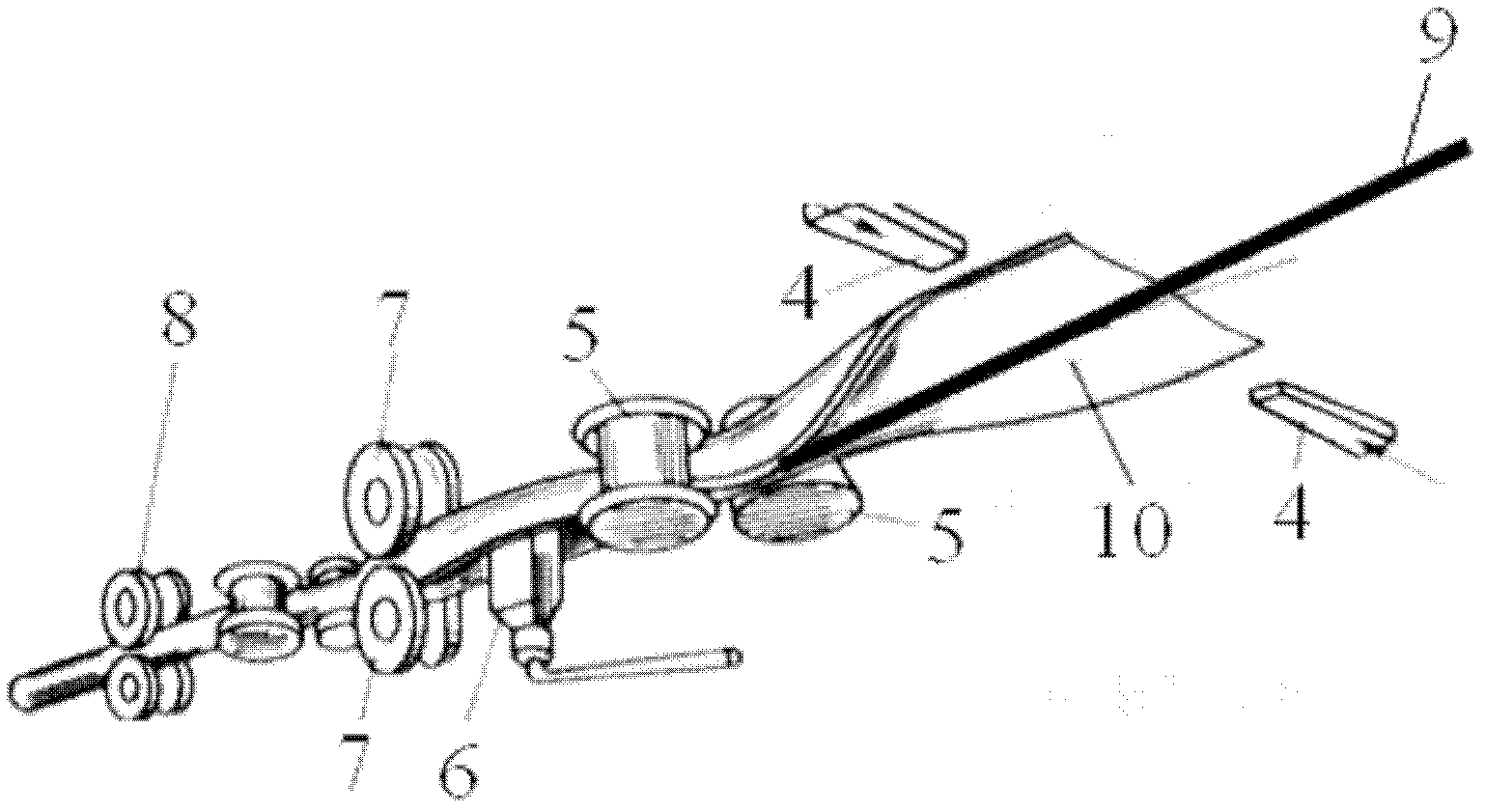

[0025] Step 2. Send the solid metal calcium wire coated with nano-scale silicon powder and the steel strip into the argon arc welding unit at the same time, and after compression, welding and drawing, the steel strip is made into a seamless steel pipe as the outer layer 3 and covered Outside solid calcium metal wires coated with nanoscale silicon powder.

[0026] The diameter of the solid calcium metal wire described in step 1 is 8.3 mm, and the thickness of the nan...

Embodiment 2

[0029] All the other steps are the same as in Example 1, except that the diameter of the solid calcium metal wire described in step 1 is 6.5mm, and the thickness of the nanoscale silicon powder (particle diameter at 30nm) as the middle layer 2 is 0.01mm. The steel strip described in step 2 is 08A steel strip or 08D steel strip or carbon steel strip, and the thickness of the steel strip is 0.8mm.

Embodiment 3

[0031] All the other steps are the same as in Example 1, except that the diameter of the solid calcium metal wire described in step 1 is 10mm, and the thickness of the nanoscale silicon powder (particle diameter at 50nm) as the intermediate layer 2 is 0.3mm. The steel strip described in step 2 is 08A steel strip or 08D steel strip or carbon steel strip, and the thickness of the steel strip is 1.5mm.

[0032] The specification parameters of the cored wire of the present invention are as follows:

[0033] 1. Core-spun wire diameter: 7.31-11.8mm

[0034] 2. Core-spun wire composition (mass%): steel pipe 82-70, solid metal calcium wire 18-30

[0035] 3. Chemical composition of solid calcium metal wire (%)

[0036] Ca

Fe Ni Mn Cu Mg Al Si N

≥97

≤3

98.59

0.01 0.005 0.03 0.003 0.8 0.5 0.01 0.05

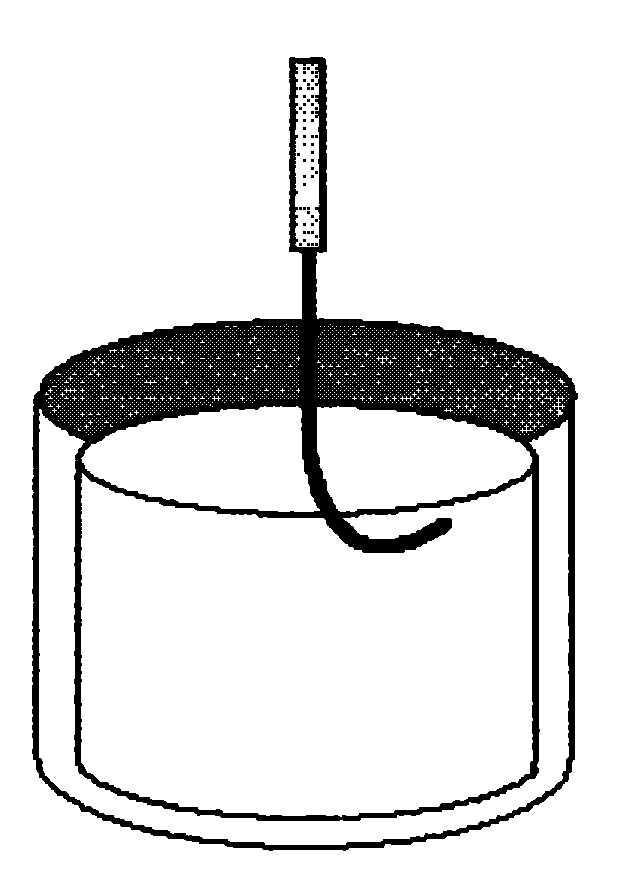

[0037]Feeding method: feed the seamless solid calcium cored wire prepared in Example 1 at the end of the electric furnace treatment, stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com