Patents

Literature

38results about How to "Increase insertion depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

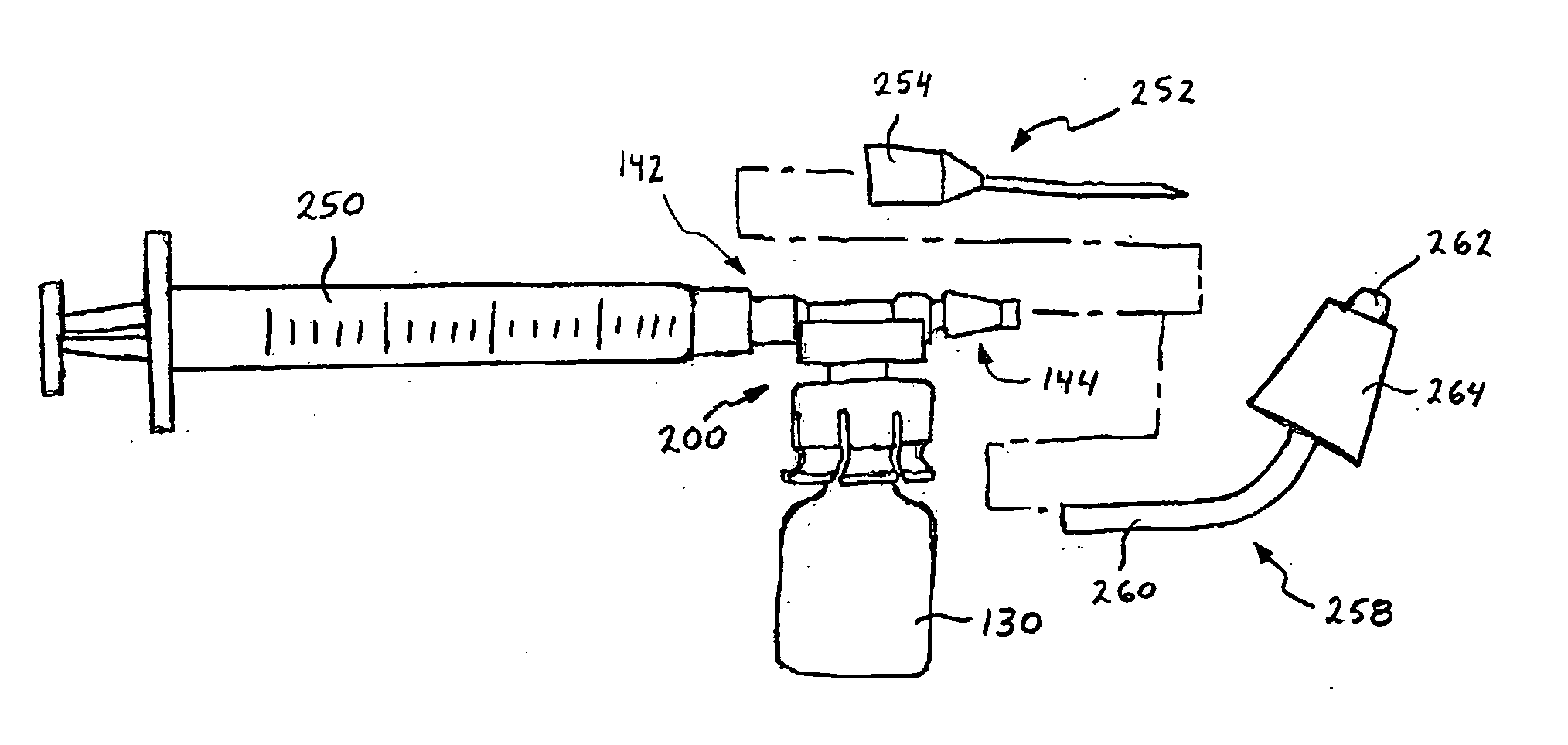

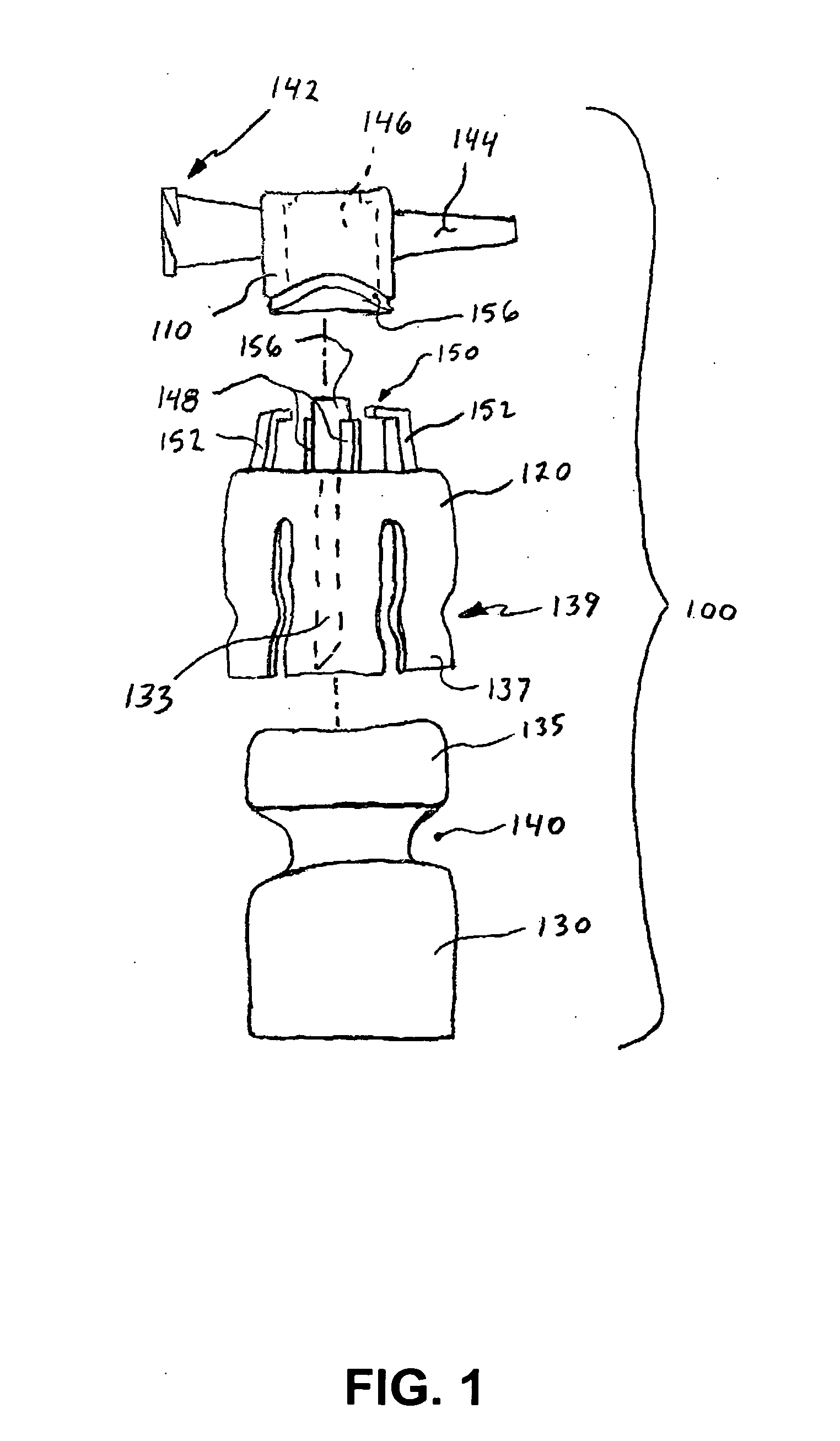

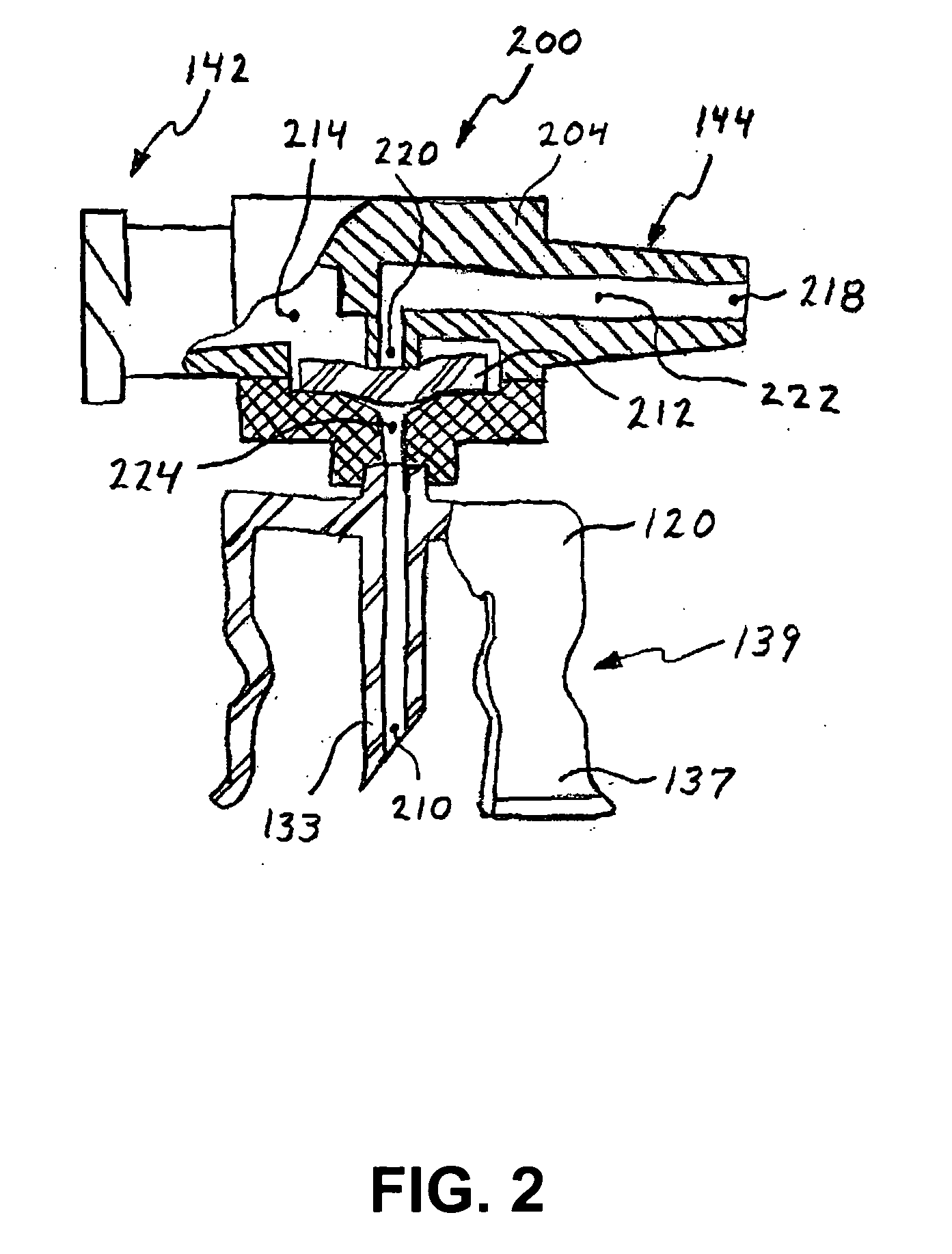

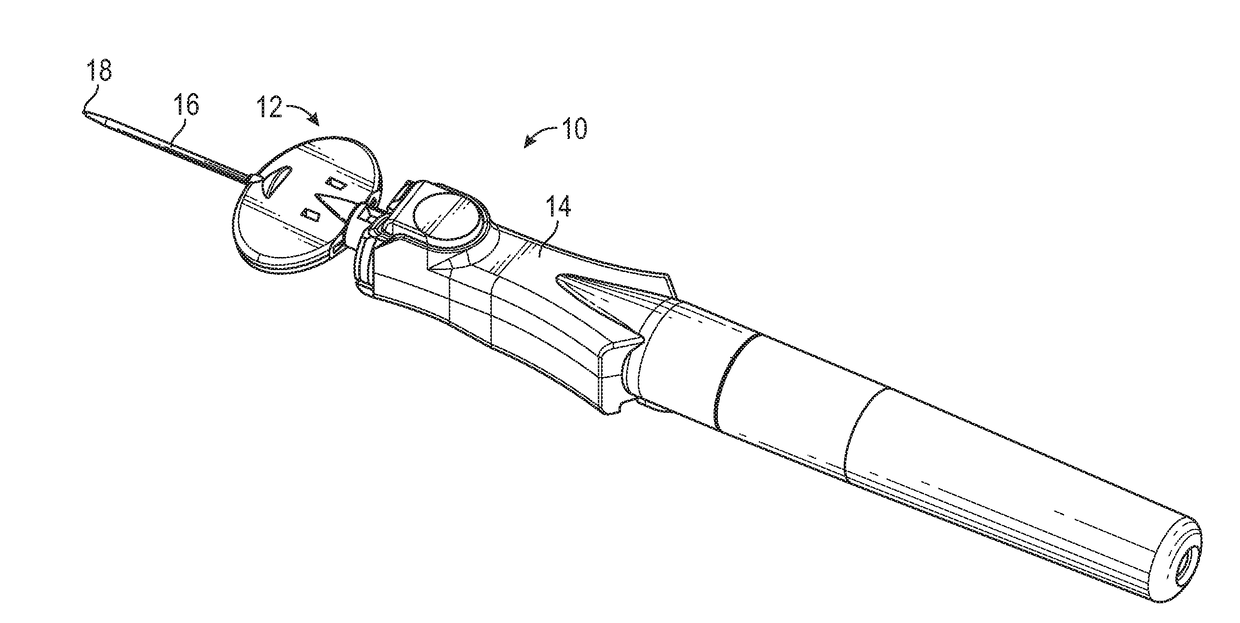

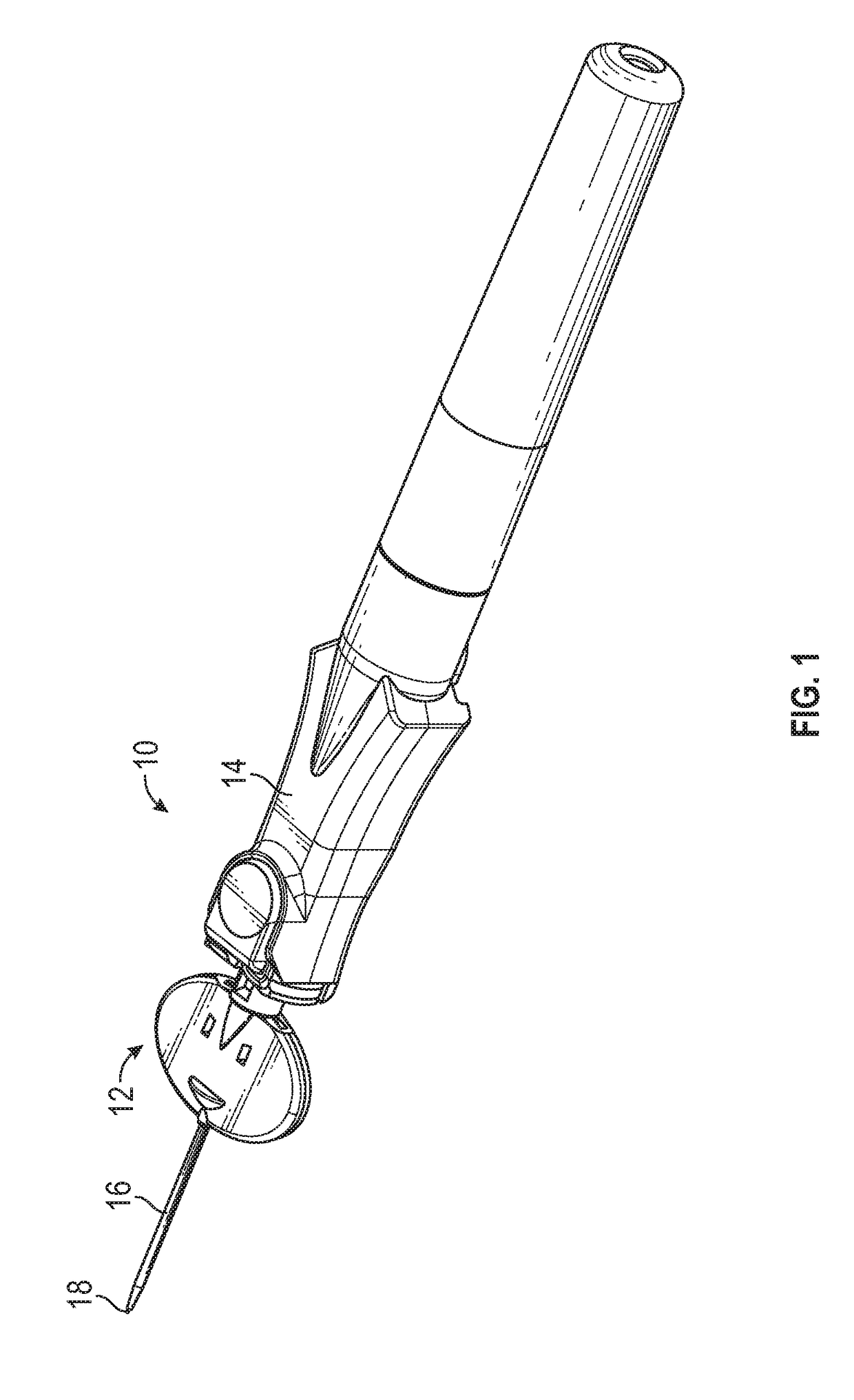

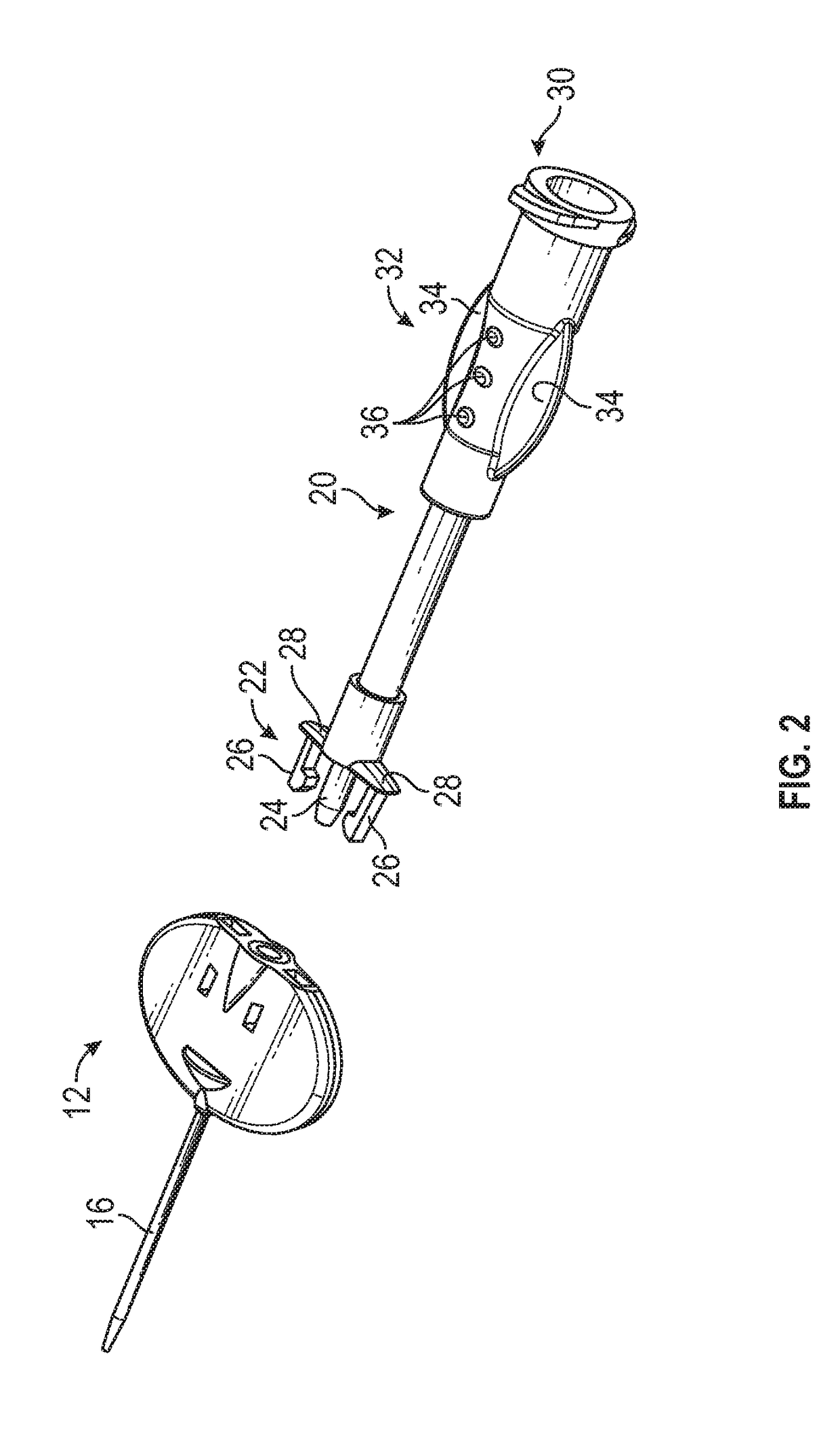

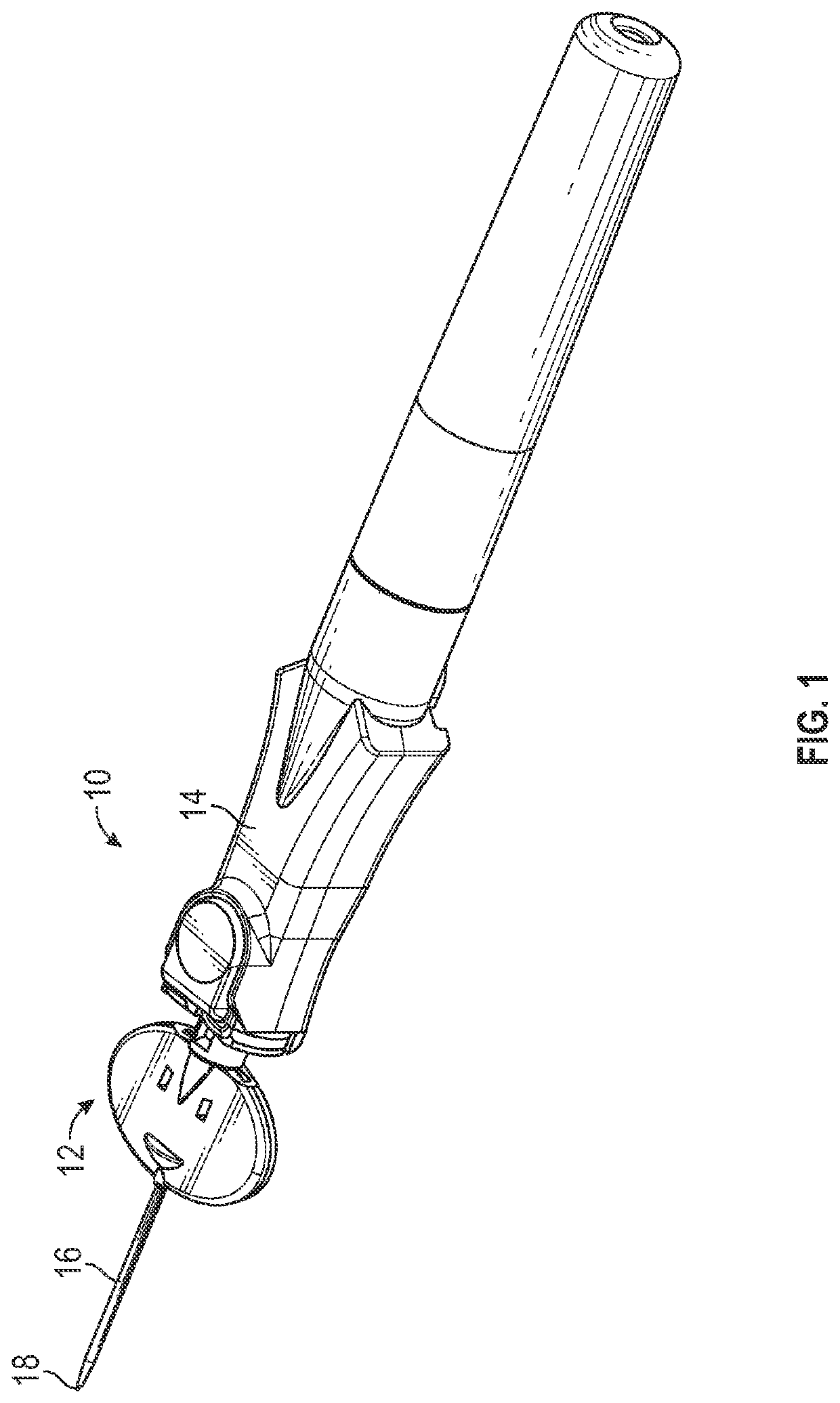

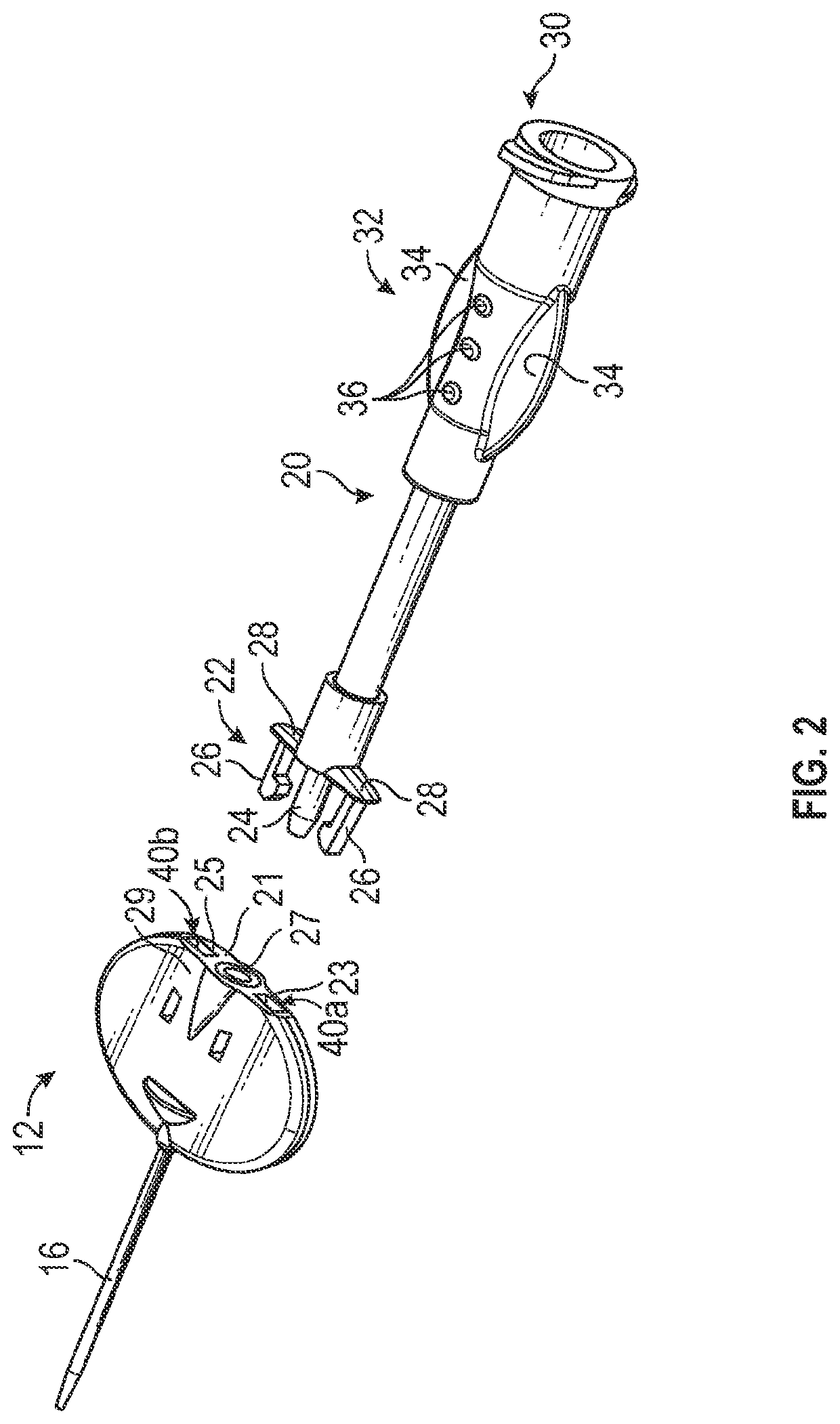

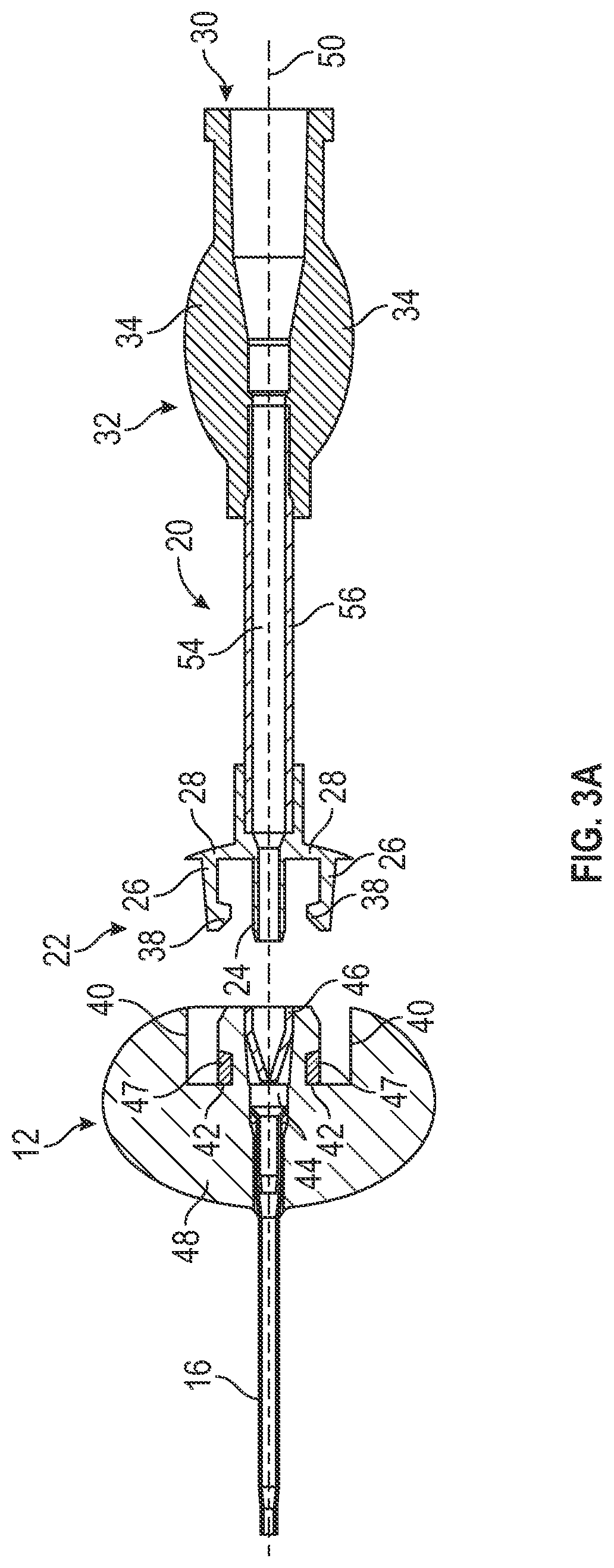

Vial multi-access adapter

InactiveUS20110083665A1Increase insertion depthInfusion devicesPharmaceutical containersNostrilGynecology

A multi-access adapter operable to dispense doses of a medicament in succession from a bulk container, such as a vial. A preferred adapter may be used alone, or in combination with various discharge devices. A first preferred combination includes the adapter paired with a needle for injection of the medicament into one or more patients. A second preferred combination includes an atomizing nozzle affixed to the adapter and arranged for discharge of the medicament therethrough. Sometimes the atomizing nozzle carries a nostril guide structure that can be absorbent and may operate as a splash guard.

Owner:WOLFE TORY MEDICAL

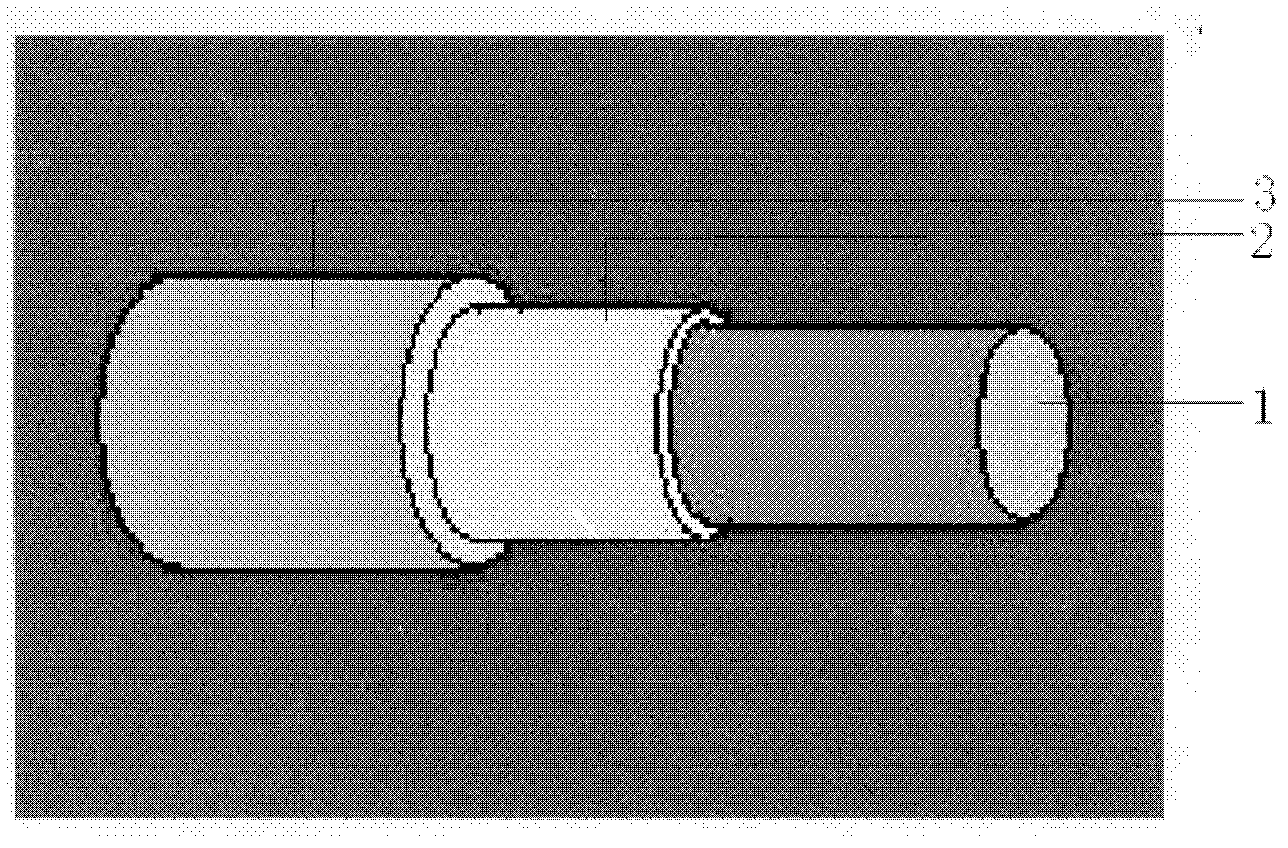

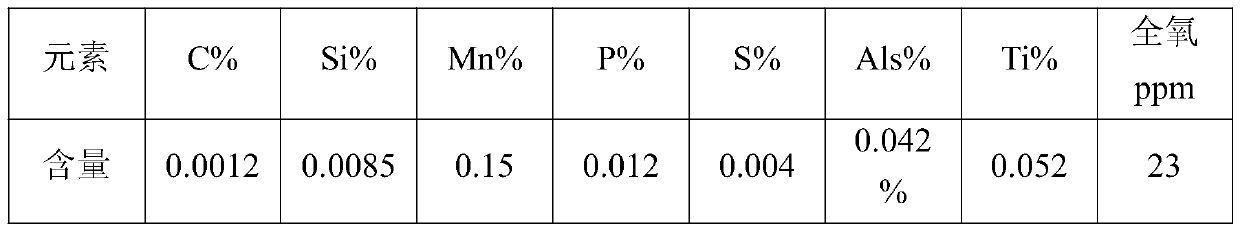

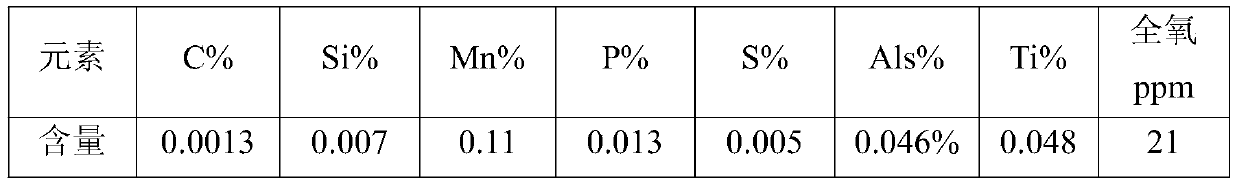

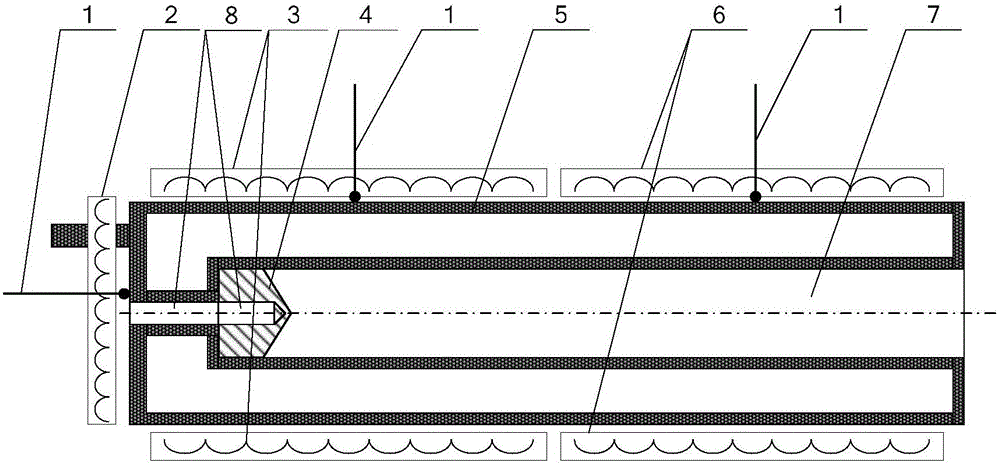

Seamless solid metal calcium cored wire for steelmaking and deoxidation and preparation method thereof

The invention discloses a seamless solid metal calcium cored wire for steelmaking and deoxidation and a preparation method thereof. The seamless solid metal calcium cored wire consists of an outer-layer steel tube, a middle coating layer and an inner core, wherein the inner core is a solid metal calcium (pure calcium) wire. The seamless solid metal calcium cored wire disclosed by the utility model has the beneficial effects that vapor pressure and the gasification rate of metal calcium can be reduced, the depth of the seamless solid metal calcium cored wire inserted in molten steel is increased, the boiling of the molten steel is reduced, the time that the metal calcium is adsorbed by metal is reduced, the boiling phenomenon of the existing seamed solid calcium cored wire inserted in the molten steel is overcome, the phenomenon that the wire feeding is affected due to hollow powder calcium cored wire and non-uniform core powder weigh is reduced, and the bring-in of harmful elements (S, P, C and Si) in the powder calcium cored wire is avoided, so that the yield and the stability of metal calcium are greatly improved.

Owner:周海涛 +1

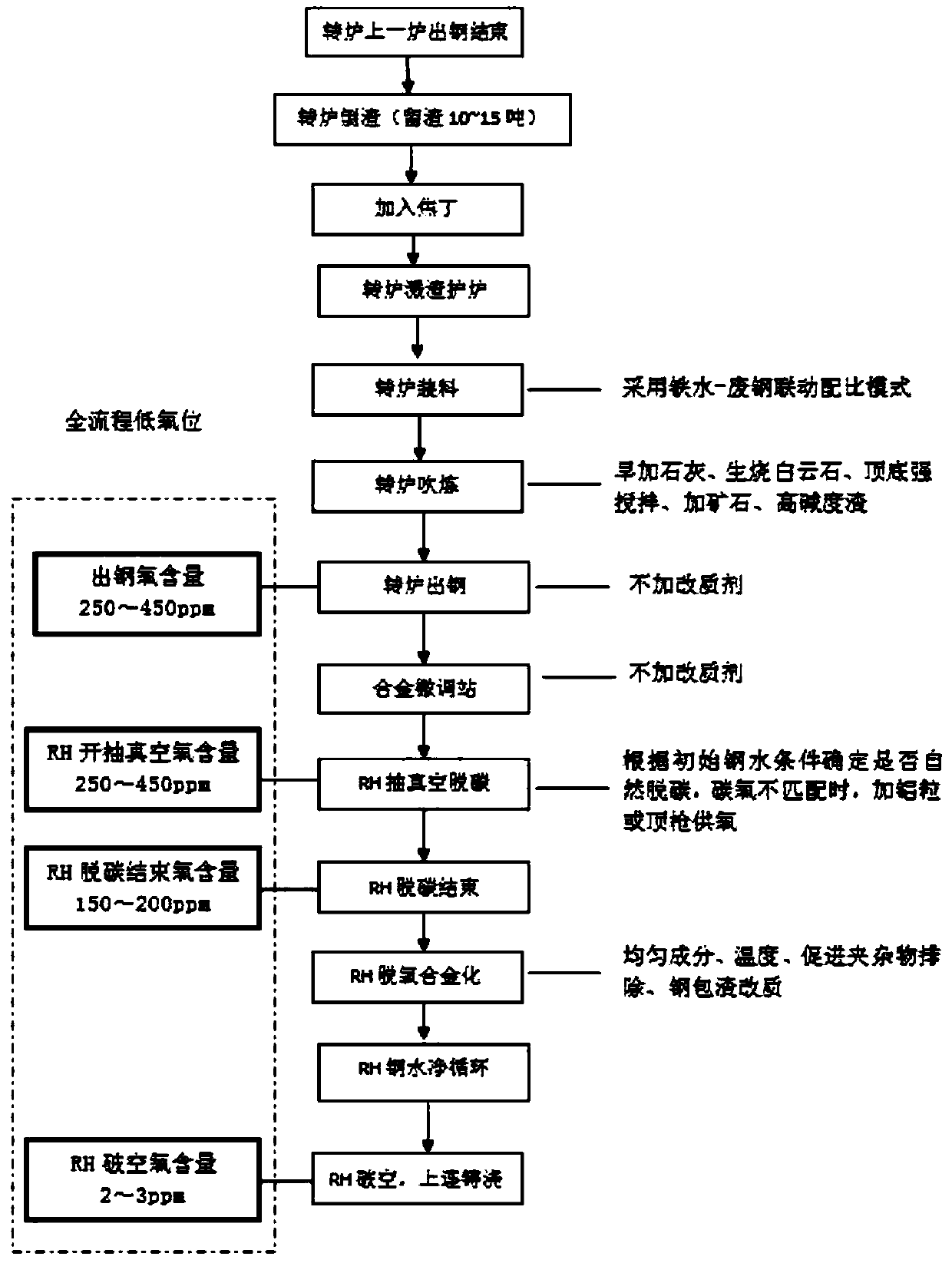

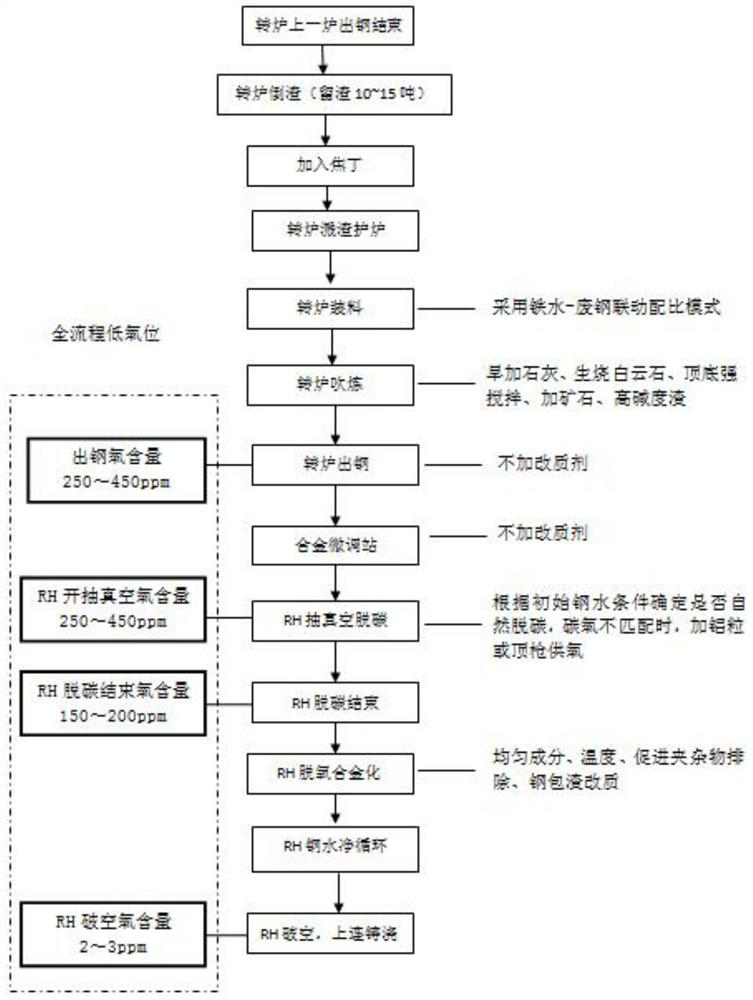

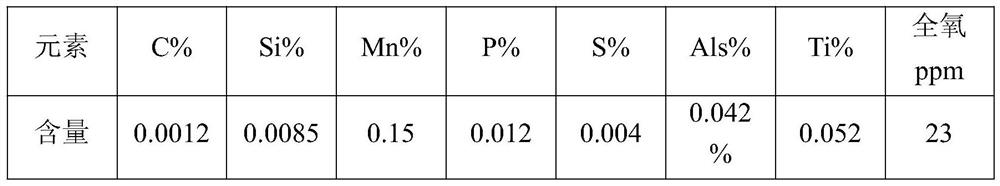

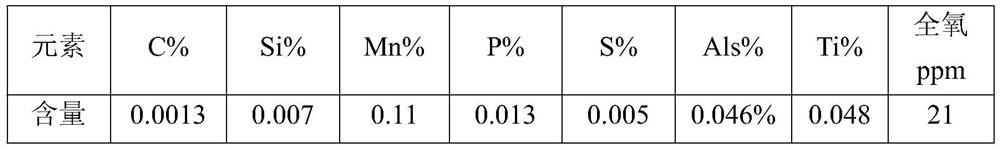

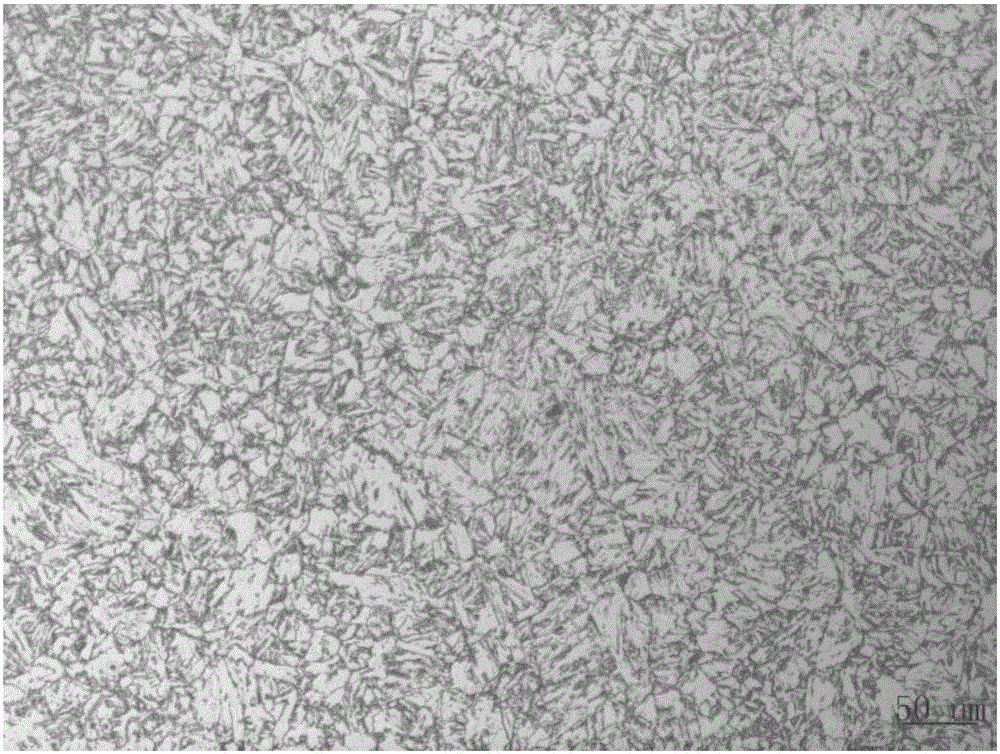

Smelting method for complete-flow low-oxygen-level producing of IF steel

ActiveCN110205436AReduce peroxidationReduce oxidationManufacturing convertersProcess efficiency improvementVacuum pumpingSlag

The invention discloses a smelting method for complete-flow low-oxygen-level producing of IF steel, and belongs to the technical field of steel smelting. The method comprises the steps that firstly, after converter steel smelting is finished, deslagging is carried out, 10 to 15 tons of slag is left in a converter, 50 to 100 kg of coke powder is added for removing oxygen in the slag, and the slag-splashing furnace protection operation is carried out; secondly, converter charging is carried out; thirdly, converter main blowing is carried out; fourthly, after converter main blowing is finished, through an auxiliary gun, the molten steel temperature and the carton content are measured, and according to the measuring value, auxiliary oxygen blowing amount is controlled; fifthly, after auxiliaryblowing is finished, before tapping, strong bottom blowing is carried out for 30 seconds; sixthly, converter tapping is carried out; seventhly, molten steel enters in the RH procedure; and eighthly,after a steel ladle is jacked, a vacuum pump is started for vacuum pumping decarburization. The converter tapping molten steel peroxidation degree is reduced, the steel ladle slag oxidation is reduced, the generation amount of deoxidation type inclusions Al2O3 can be reduced, the molten steel cleanliness level is improved, the cost is reduced, and the obvious economic benefits are achieved.

Owner:MAANSHAN IRON & STEEL CO LTD

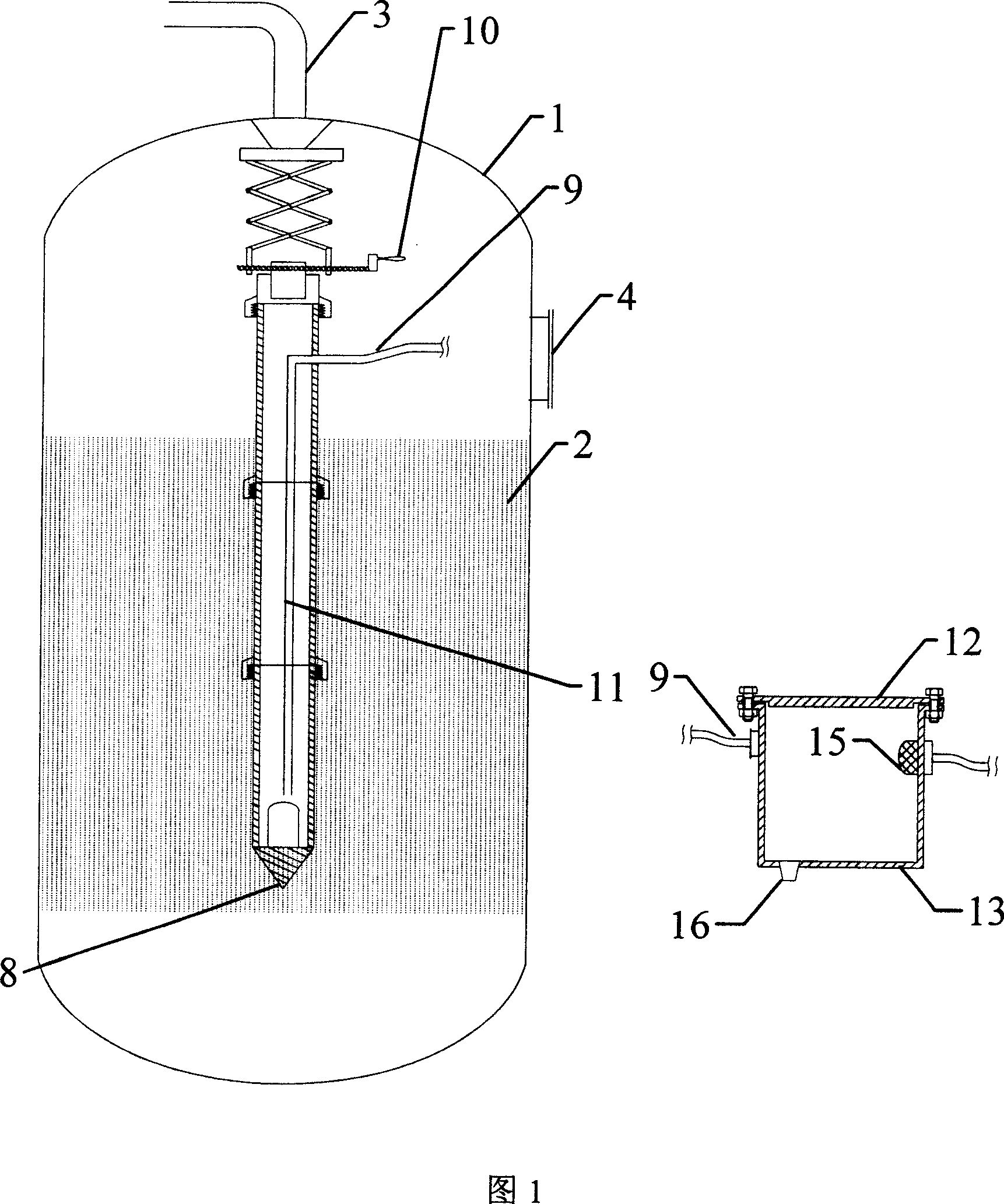

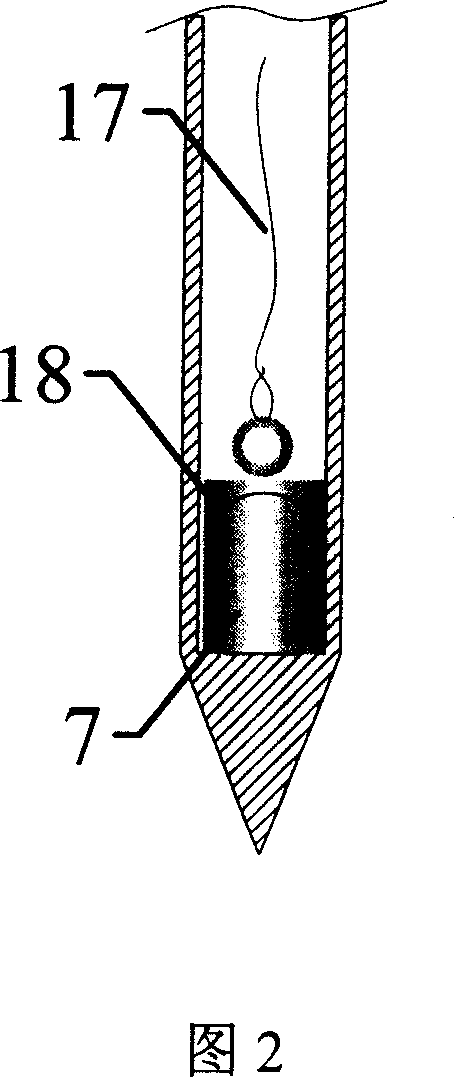

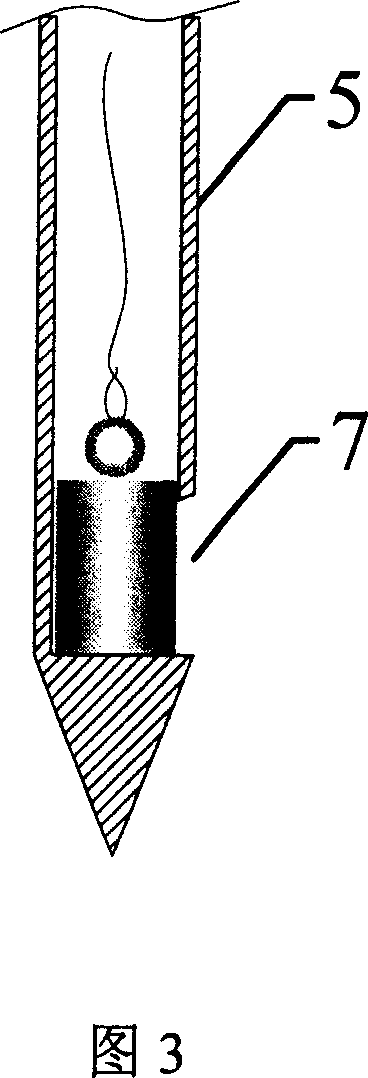

Catalyst sampler

ActiveCN101074906AReduce resistanceIncrease insertion depthWithdrawing sample devicesPropellerEngineering

A catalyst sampler is prepared as erecting propeller at top end of sampling tube, setting conical head at bottom end, arranging a sampling hole at bottom portion of sampling tube, setting a ring tube being able to move up and down in said bottom portion, setting bottom end of sample guide tube to be near to top of sampling hole, connecting top end of sample guide tube to flexible tube then connecting top end of sample guide tube to collector of sample vacuum system.

Owner:CHINA PETROLEUM & CHEM CORP +1

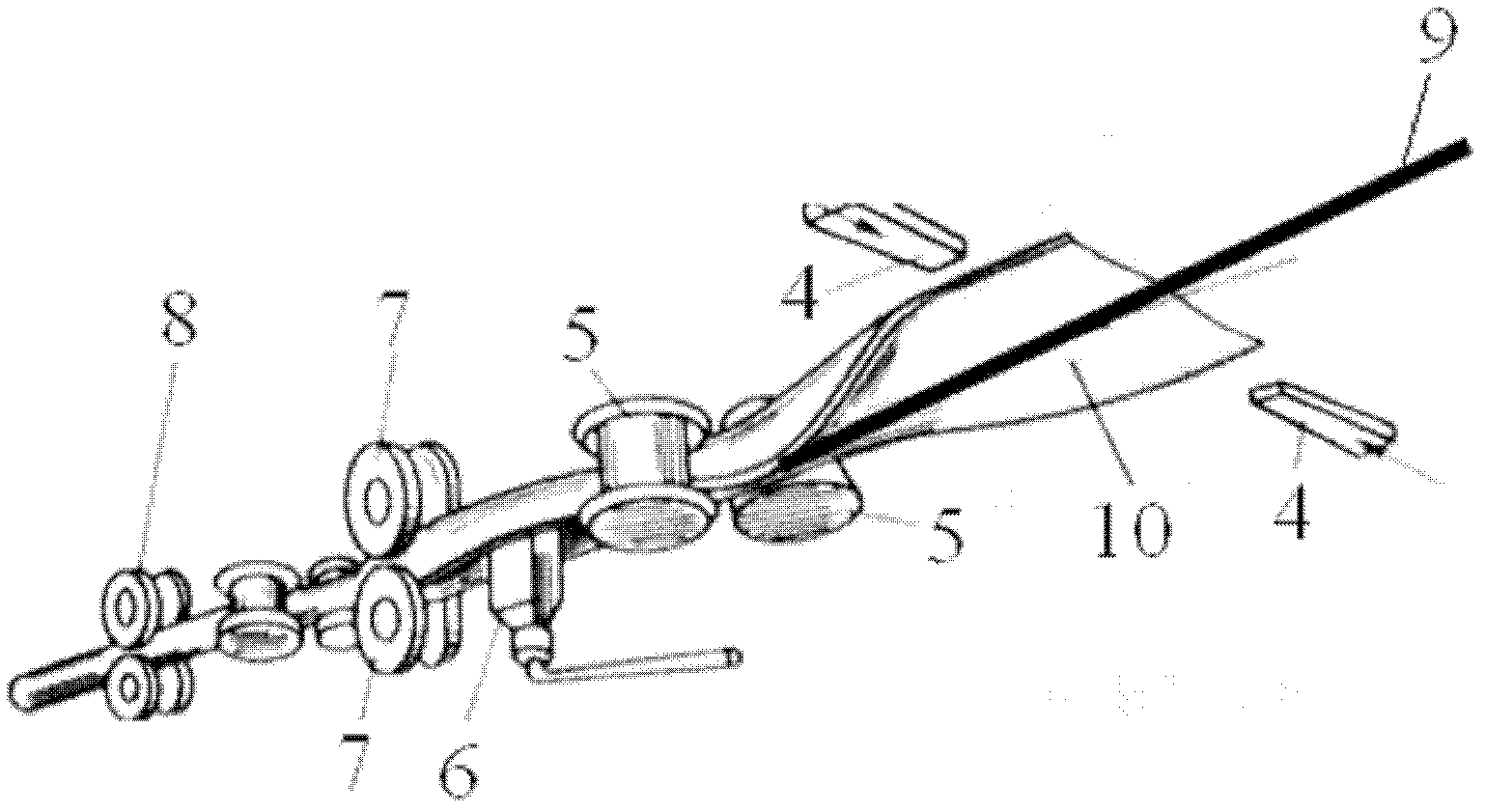

Mechanical agitation desulphurization method for molten iron desulphurization pretreatment

The invention discloses a mechanical agitation desulphurization method for molten iron desulphurization pretreatment. The desulphurization method includes five steps including prior sample taking for temperature measurement, prior slag scrabbling, desulfurizing agent adding and agitation, later slag scrabbling and later sample taking for temperature measurement. In the steps of desulfurizing agent adding and agitation, an agitation device is inserted into a molten iron tank containing molten iron, and is composed of an agitator and a guide plate, and the guide plate and the agitator are both vertically instead into the molten iron; and the vertical distance between the bottom of the guide plate and the top of a blade of the agitator is H. Compared with the rotating speed of a conversional KR method, the rotating speed of the agitator is decreased by 10% to 20%; and the insertion depth of the agitator is increased by 10% to 30% compared with the insertion depth of the conversional KR method.

Owner:武汉钢铁有限公司

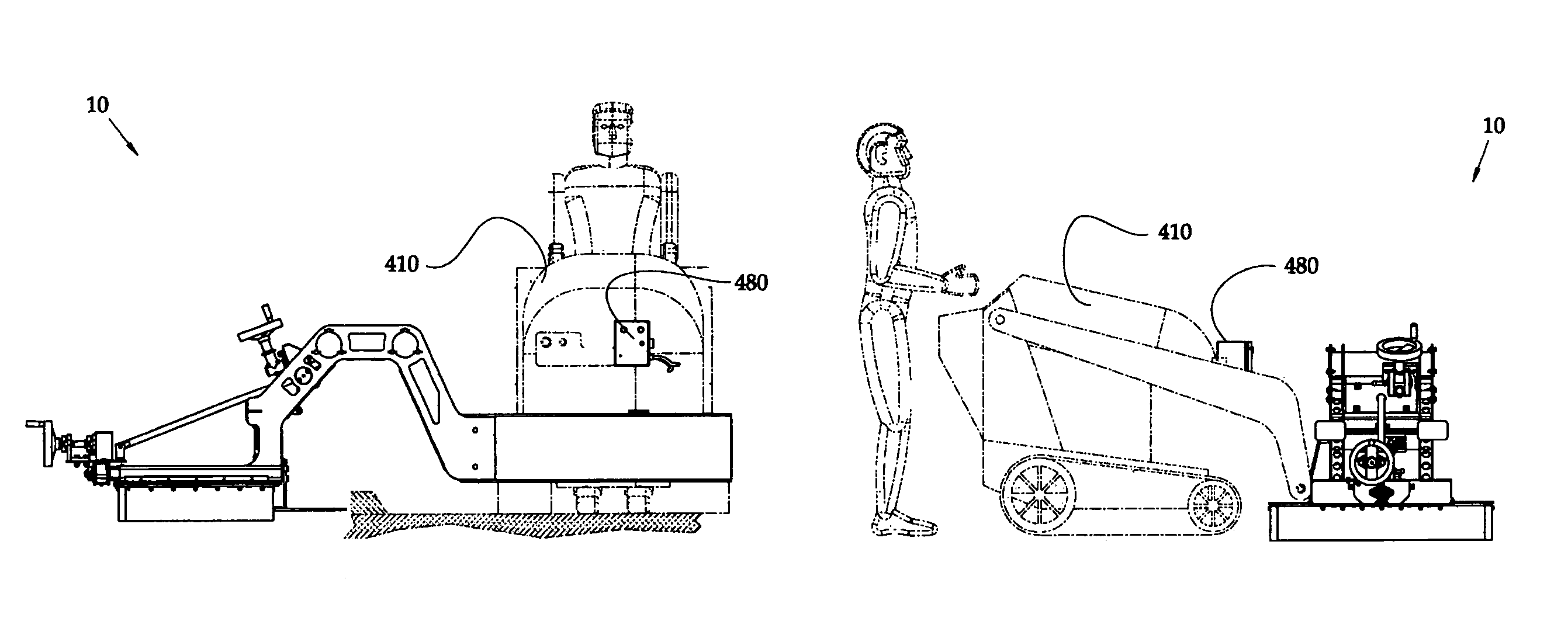

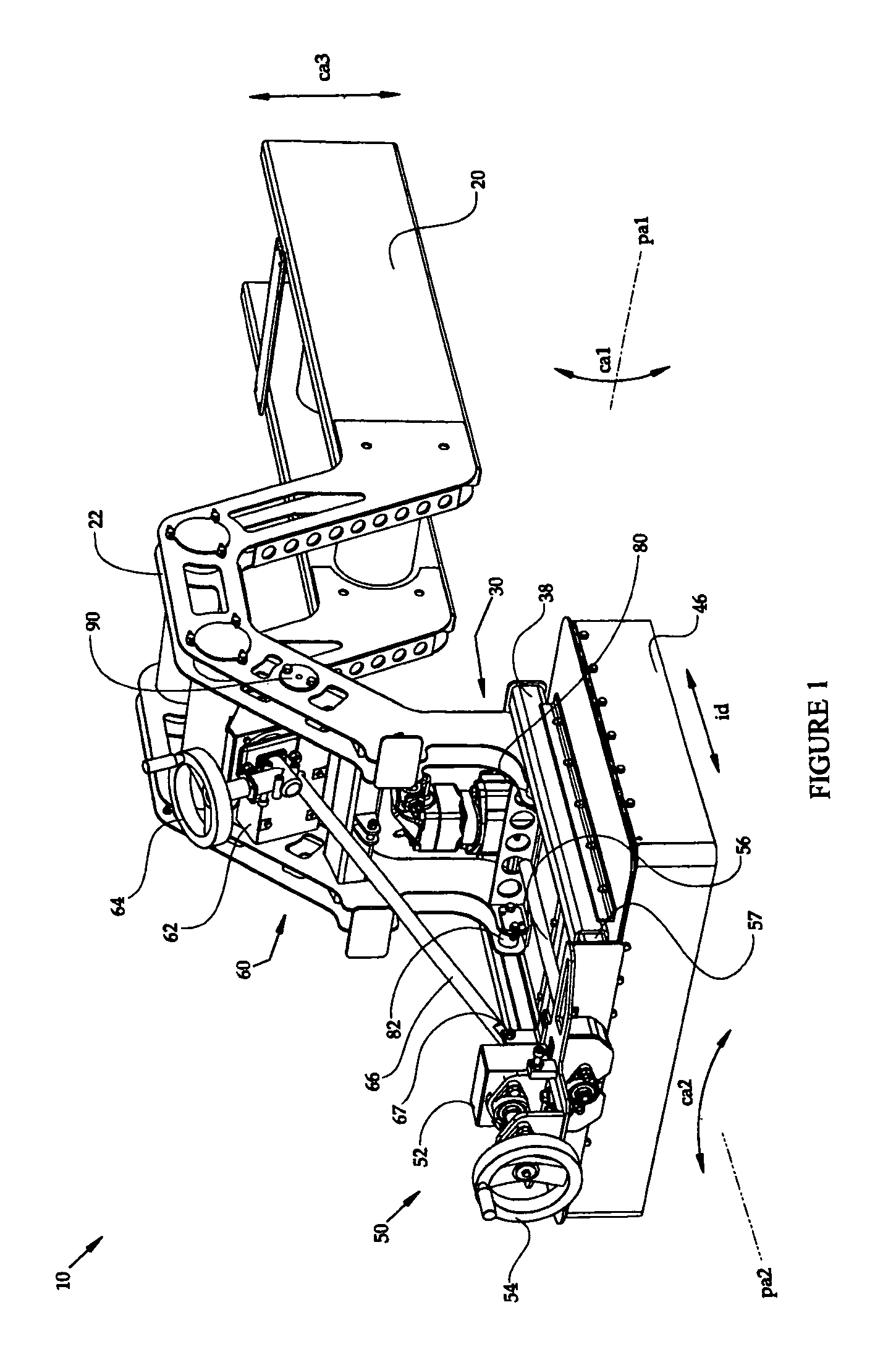

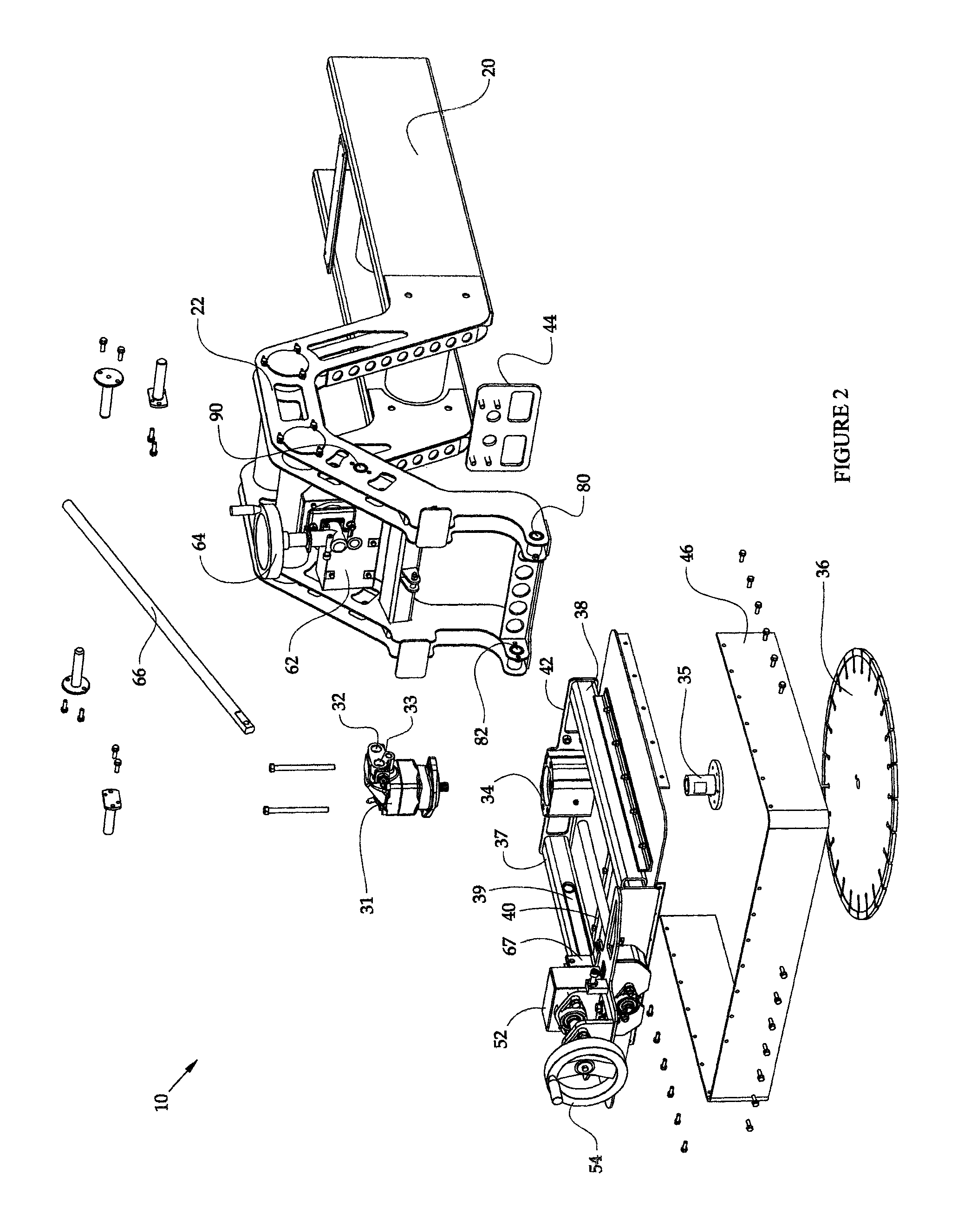

Cutting attachment apparatus and method

ActiveUS9422678B1Increase insertion depthReduce insertion depthMetal sawing devicesRoads maintainenceInsertion depthEngineering

A cutting attachment apparatus and method comprise an attachment frame, and a host machine interface coupled with the attachment frame for coupling the attachment with a host machine. A cutting assembly is coupled with the attachment frame. A cut insertion depth assembly is coupled with the attachment frame and the cutting assembly for altering the insertion depth of a cut of the cutting assembly, and a cut angle assembly is coupled with the attachment frame and the cutting assembly for altering an angle of the cut of the cutting assembly.

Owner:JS INNOVATIONS LLC

Low-profile extension for a catheter assembly

ActiveUS20180289920A1Prevent skin irritationReduce riskGuide needlesTube connectorsCantileverCATHETER ADAPTER

An extension for a catheter assembly may include a distal end and a proximal end. The distal end may include one or more cantilever arms and an insertion feature spaced apart from the cantilever arms. The insertion feature may be configured to insert into a lumen of a catheter adapter to provide a fluid connection between the catheter adapter and the extension. The one or more cantilever arms may be configured to engage in a snap-fit with the catheter adapter. The proximal end of the extension may include a female luer fitting.

Owner:BECTON DICKINSON & CO

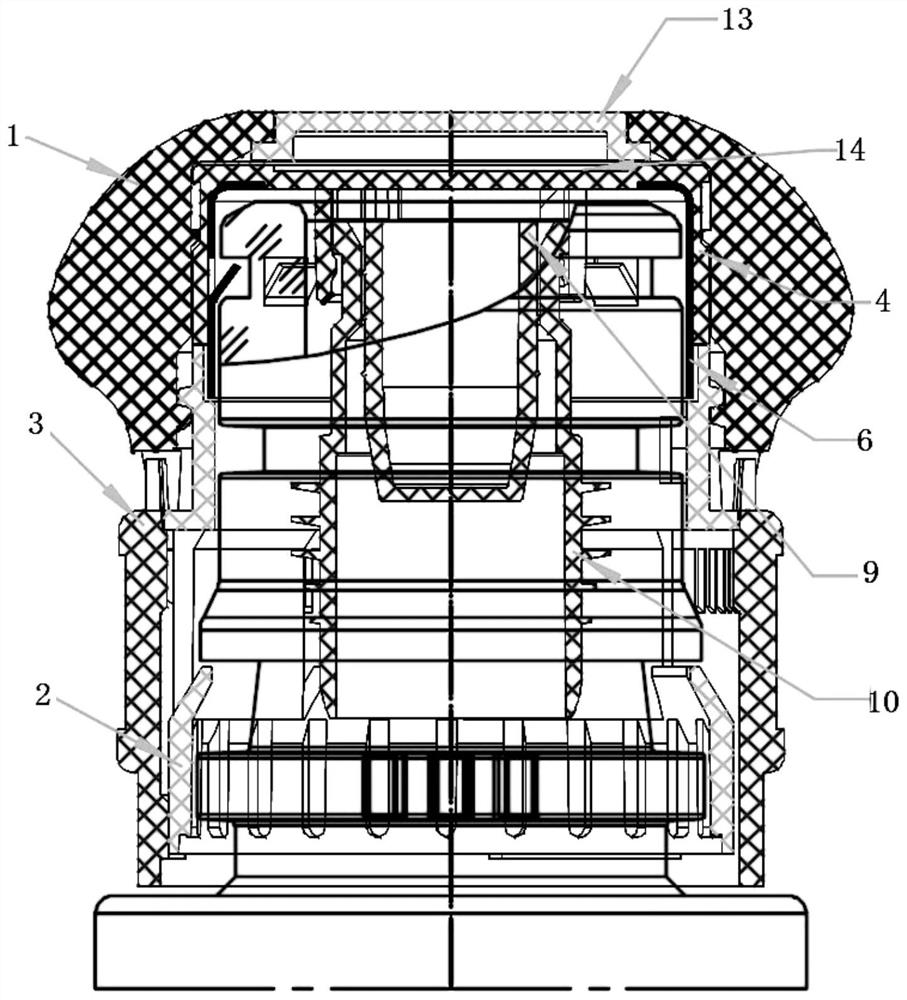

Inner cone type temperature equalizing target heat pipe blackbody

ActiveCN106052884AReduce heat lossImprove heating efficiencyPyrometry using electric radation detectorsElectrical resistance and conductanceBlackbody cavity

The present invention relates to an inner cone type temperature equalizing target heat pipe blackbody and belongs to the radiation temperature measurement technical field. According to the device, a blackbody cavity (7) and a heat pipe (5) are designed integrally, so that heat conduction loss between the heat pipe and the blackbody cavity can be decreased, and therefore, heating efficiency and a temperature rise rate can be improved; an inner cone type temperature equalizing target (4) is arranged at the bottom of the blackbody cavity (7), and a distance between a standard thermocouple and the surface of the target is made as small as possible, so that the accuracy of the temperature of the surface of the target can be ensured; the inner cone type temperature equalizing target can assist in increasing the insertion depth of the standard thermocouple or a platinum resistor, so that heat conduction error can be decreased; and the heat pipe (5) adopts three-section heating, and the temperature sensor (1) of each section of the heat pipe (5) is installed on the external wall surface of the heat pipe, and two sections of the heat pipe wrap the exterior of the cylinder of the heat pipe, and the third section is a heating disc and is arranged at the bottom of the heat pipe, and the temperature of the three sections is adjusted respectively, so that the uniformity of the axial temperature field of the blackbody cavity can be guaranteed. Compared with the prior art, the inner cone type temperature equalizing target heat pipe blackbody of the invention has the advantages of high temperature uniformity and high accuracy.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

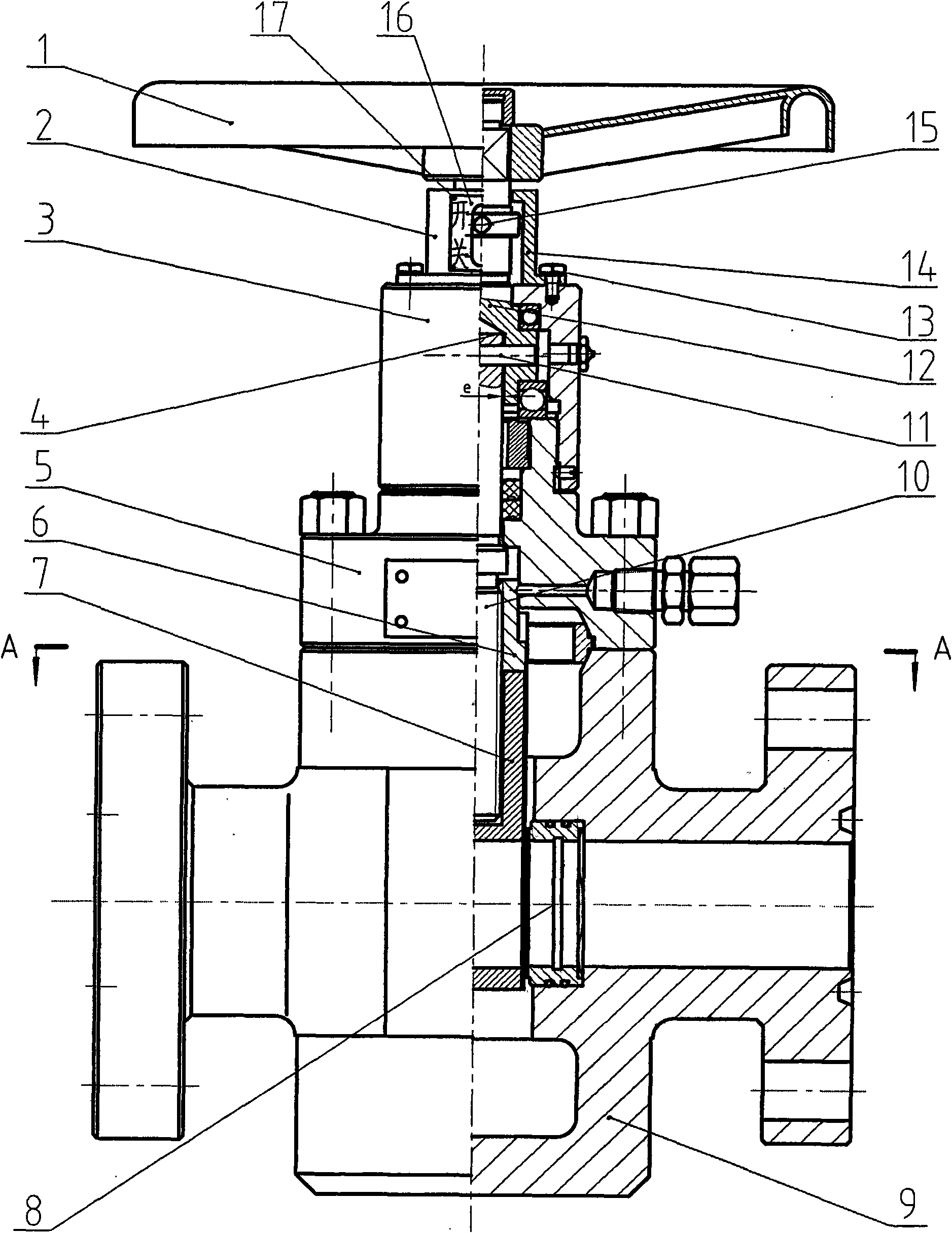

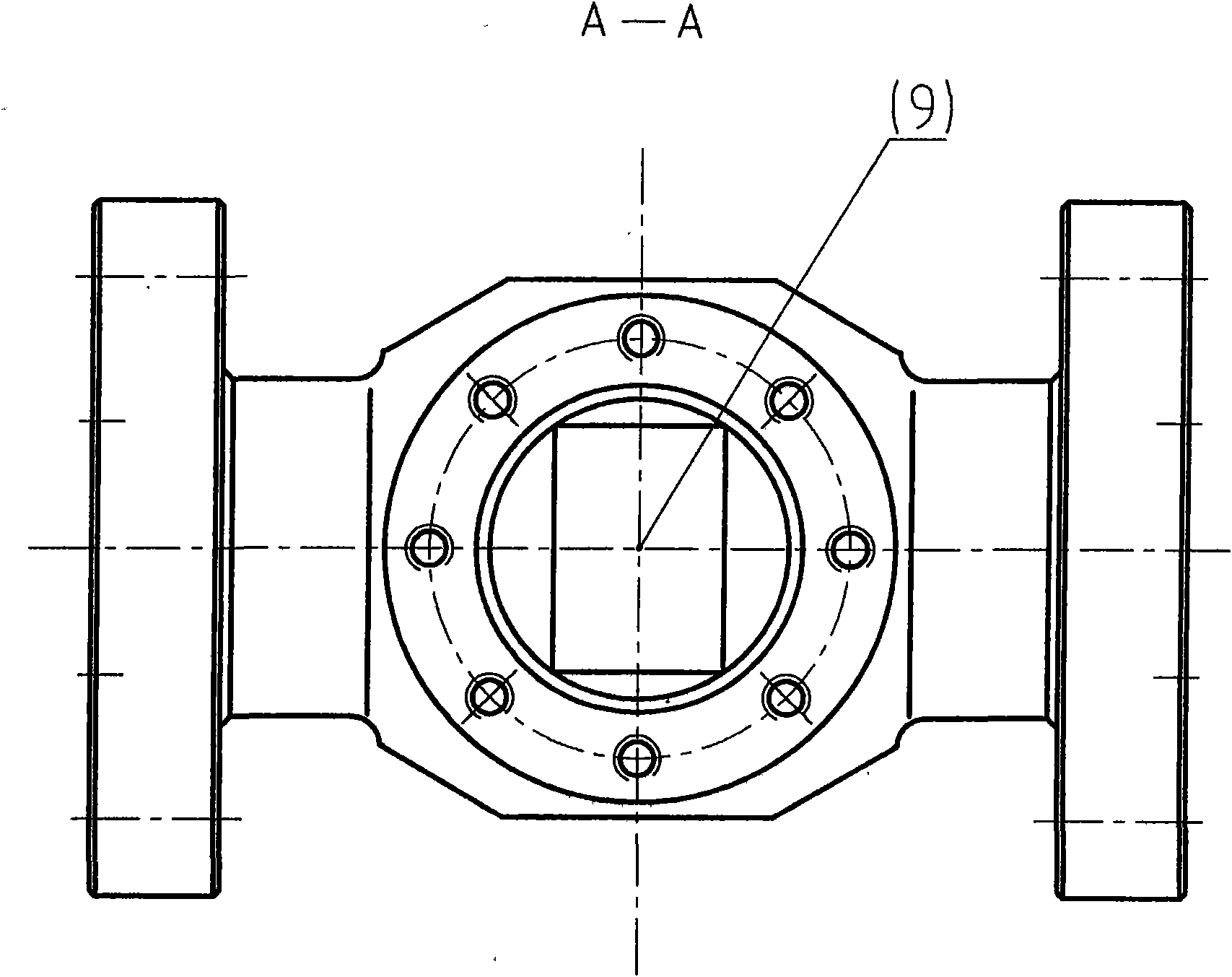

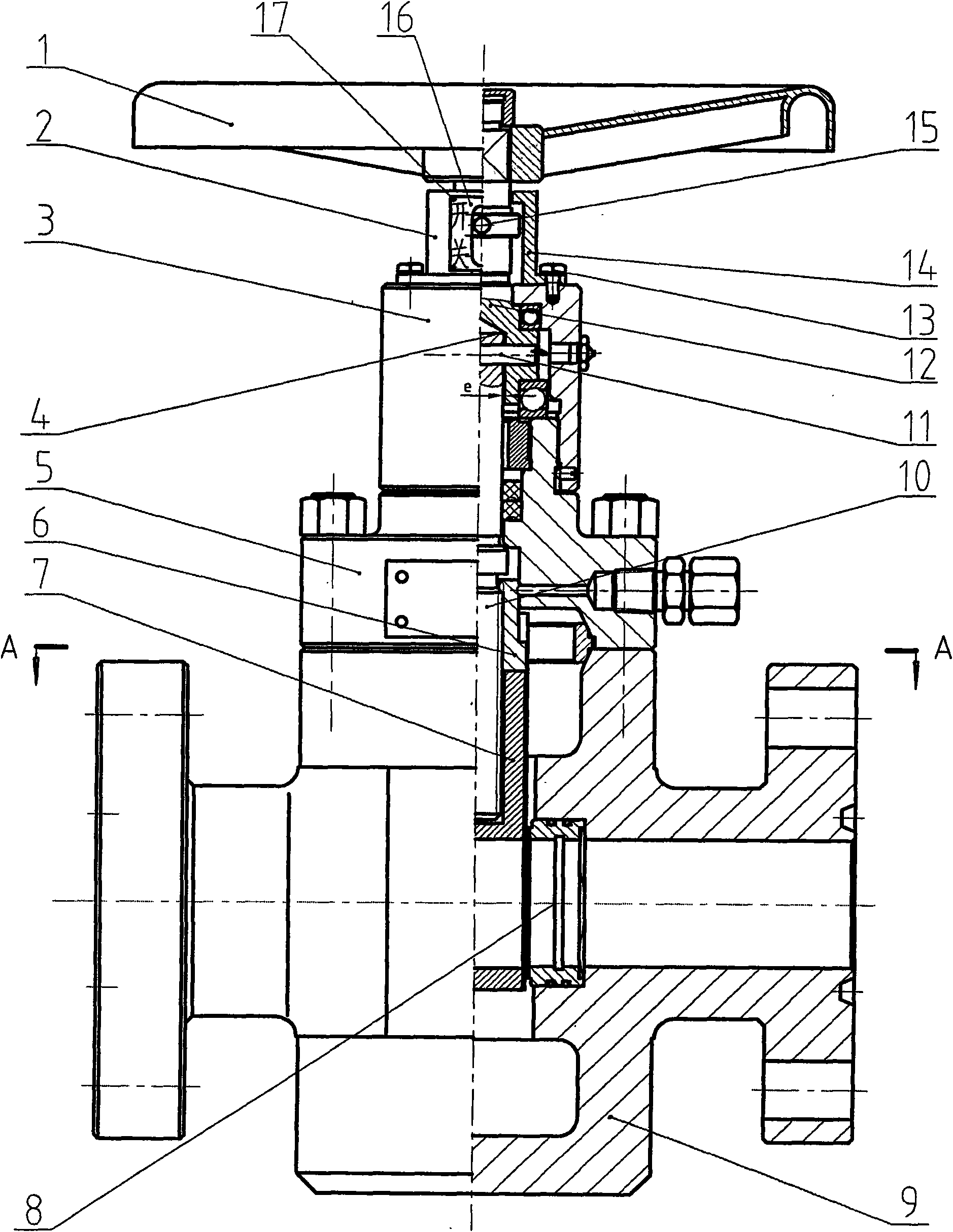

Two-section nonrising stem flat valve with switch indicator

InactiveCN102031944AMitigates the effects of one-way extrusion forcesExtended service lifeValve arrangementsWell/borehole valve arrangementsInsertion depthEngineering

The invention discloses a two-section non-rising stem flat valve with a switch indicator. The two-section non-rising stem flat valve with the switch indicator consists of a handwheel assembly, a switch indicating part, a support rotating part, valve rod parts, a seal lubrication part, a nut, a wedge disc, a valve seat assembly and a valve body. Two sections of valve rod parts connected by a cylindrical pin are particularly adopted; the switch indicating part is arranged between the handwheel assembly and the support rotating part; and the middle of the valve body is processed into a cavity in which two rounds clamp a cuboid, namely the cavity has hollow cylinders on upper and lower parts, and a hollow cuboid in the middle. The technical means can reduce the moment of resistance generated by different axialities among parts and pressure difference on the wedge disc, and is convenient for an operator to observe the opening or the closing of the valve; and two opposite nearest sides of the hollow cuboid in the valve cavity increase the wall thickness of the valve body and increase the insertion depth of the valve seat into an inner wall hole so as to improve the stability of the valve seat, reduce the abrasion of the parts, prolong the service life of the valve and make the valve opened or closed easily and quickly.

Owner:JIANGSU HONGTAI PETROCHEM MACHINERY

Deep-layer fertilization equipment

InactiveCN106416552AReduce wasteFully absorb and utilizeFertiliser distributersAgricultural engineeringRoot system

The invention discloses deep-layer fertilization equipment. The deep-layer fertilization equipment comprises a fertilizer storage barrel, a roller and a manipulation handle, wherein a fertilizer inlet is formed in the fertilizer storage barrel; the fertilizer storage barrel is fixedly connected with the manipulation handle; the fertilizer storage barrel and the roller are transversely arranged; the fertilizer storage barrel is arranged in a filling cavity of the roller; the fertilizer storage barrel is tightly fitted with the roller; a rotary central shaft of the roller is the fertilizer storage barrel; a first through hole is formed in the lower part of the fertilizer storage barrel; a fertilization inserting column is arranged on a rotary surface of the roller; a third through hole is formed in the fertilization inserting column; one end of the third through hole is communicated with a second through hole in the rotary surface of the roller; the other end of the third through hole is located at the tail end of the fertilization inserting column; the second through hole is discontinuously communicated with the first through hole when the roller rotates. The deep-layer fertilization equipment provided by the invention is convenient to operate and time and labor are saved; the deep-layer fertilization equipment can be effectively used for applying fertilizers into a deep part of soil, so that wastes of the fertilizers can be reduced; crops can sufficiently absorb and utilize the fertilizers, and root systems of the crops are accelerated to grow toward deep layers, so that the root systems are enhanced and lodging is prevented from occurring.

Owner:渠县金穗农业科技有限公司

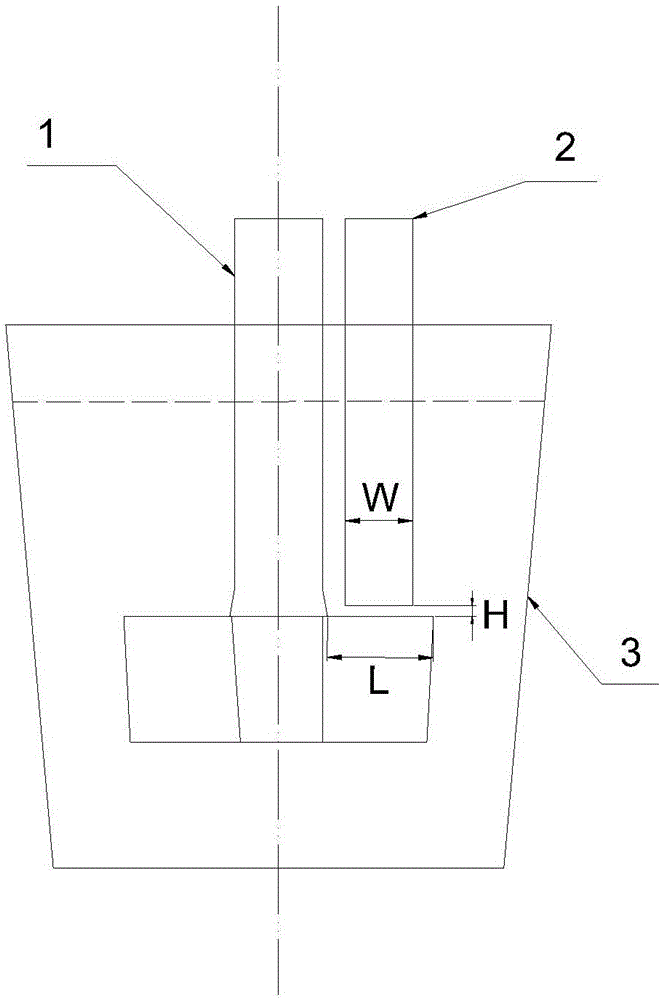

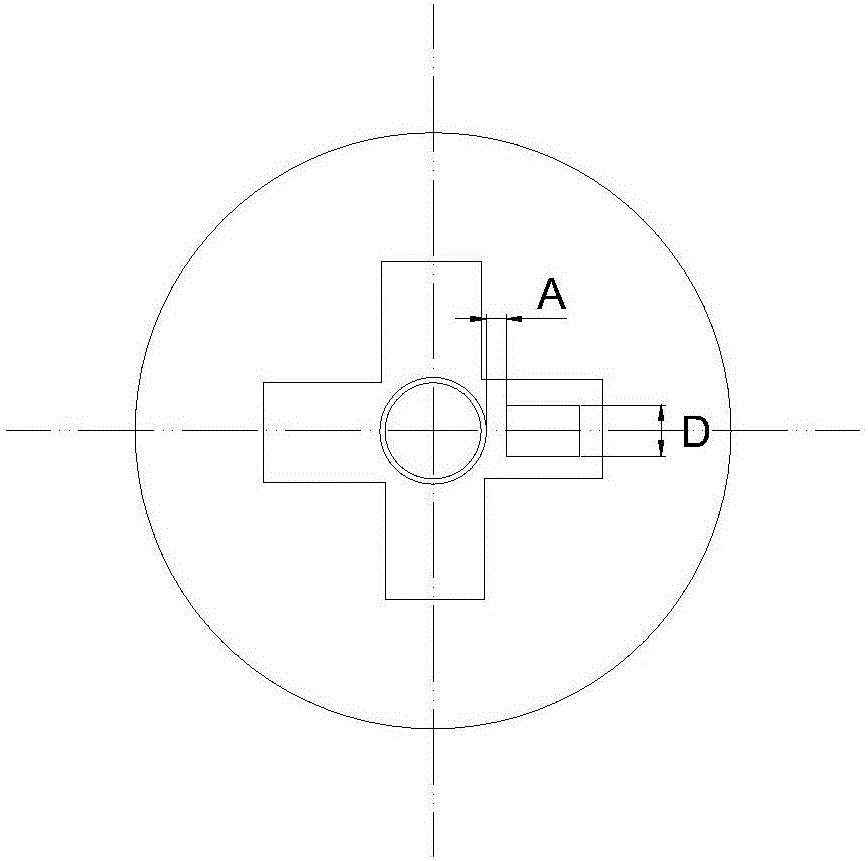

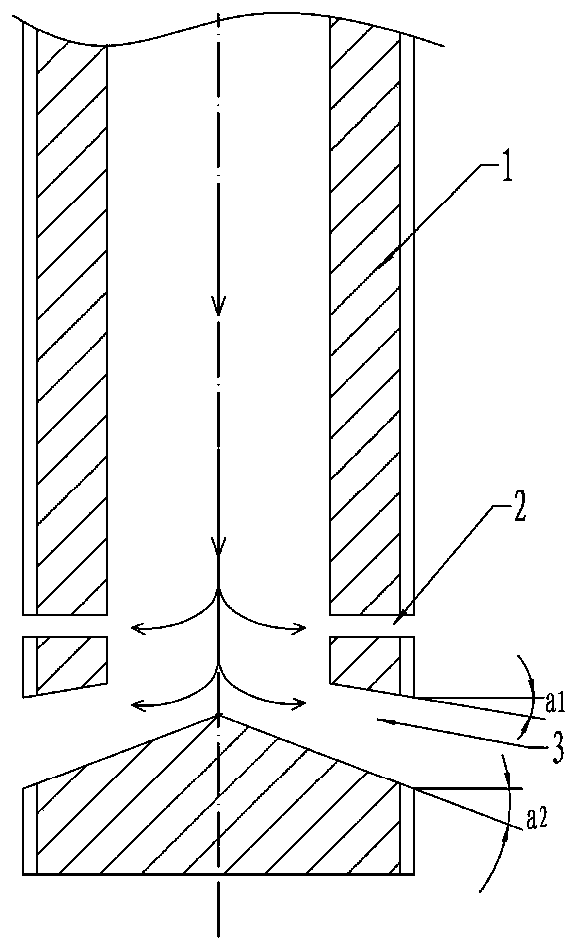

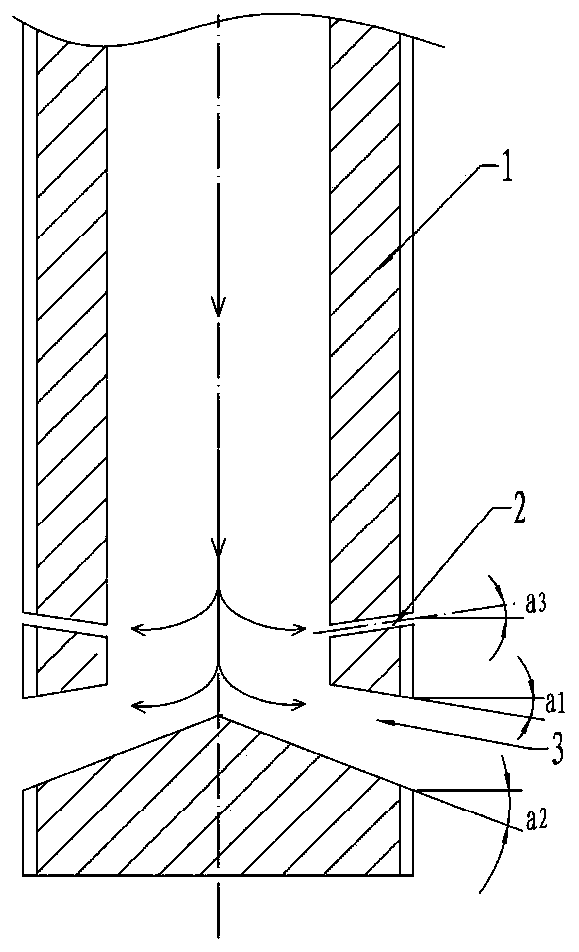

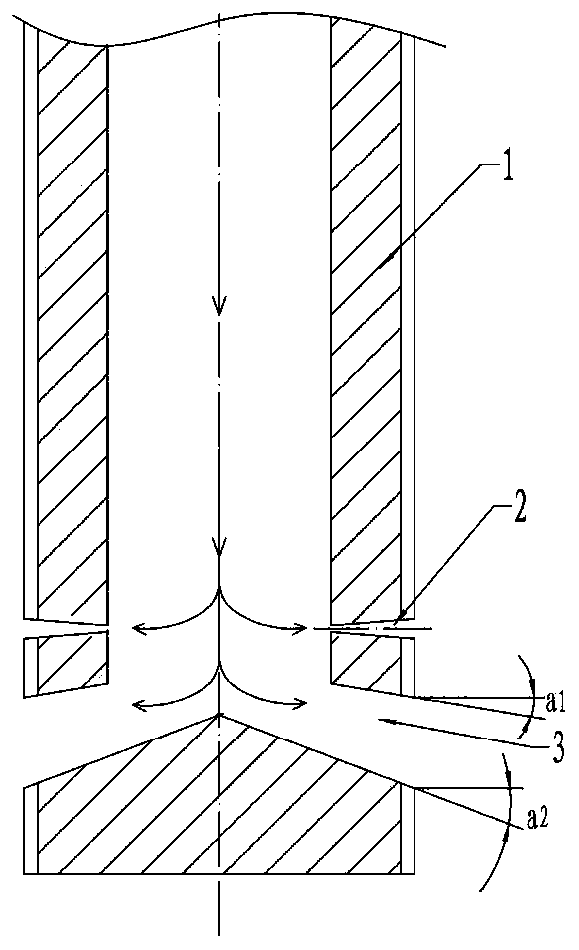

Immersion type side water injection nozzle capable of improving crystallizer flow field for continuous casting

PendingCN110773731AImprove upper backflow heat transferImprove heat transfer performanceMelt-holding vesselsHeat flowMolten steel

The invention discloses an immersion type side water injection nozzle capable of improving a crystallizer flow field for continuous casting. The immersion type side water injection nozzle is arrangedinside a crystallizer and comprises symmetrically-formed main side holes. The cross sections of the main side holes are in a rectangular or square shape, the upper surfaces of the main side holes areprovided with upper dip angles a1, the lower surfaces of the main side holes are provided with lower dip angles a2, the degrees of the upper dip angles are smaller than the degrees of the lower dip angles, and the difference between the upper dip angles and the lower dip angles is 3-5 degrees. Auxiliary side holes are formed in the upper portions of the main side holes, and the flow area of the auxiliary side holes is 1 / 40-1 / 10 that of the main side holes. The immersion type side water injection nozzle has the beneficial effects that the auxiliary side holes are formed, some molten steel flowsout from the auxiliary side holes, upper heat output is improved, upper backflow heat transfer of the molten steel is improved, and the good foundation is supplied to increase of the insertion depthof the immersion type water nozzle; and due to the fact that the upper dip angles and the lower dip angles of the main side holes adopt different degrees, and the upper dip angles are smaller than thelower dip angles, molten steel streams flow back upwards to be reinforced, upper backflow molten steel heat transfer is further improved, and a heat flow field is optimized.

Owner:德龙钢铁有限公司 +1

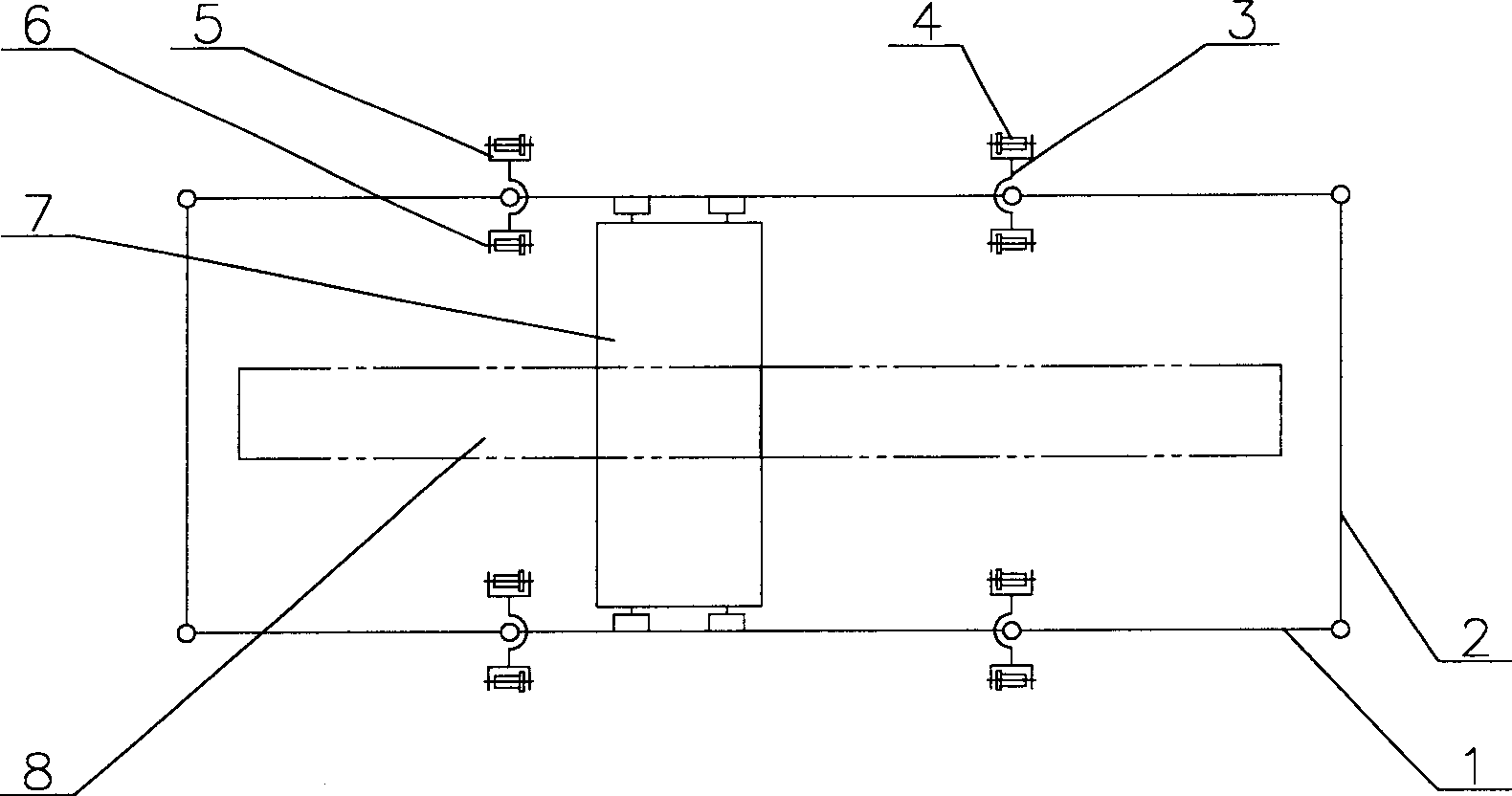

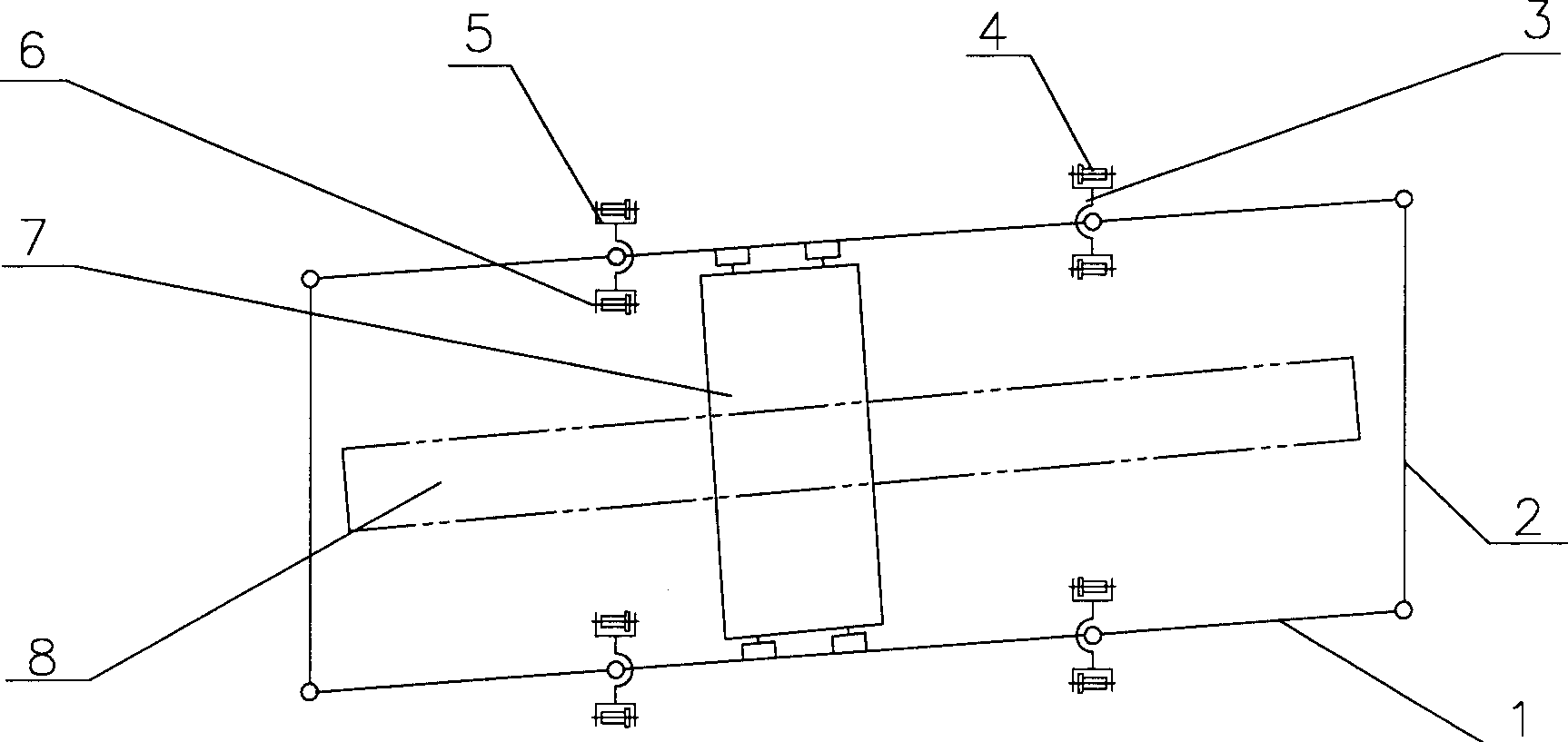

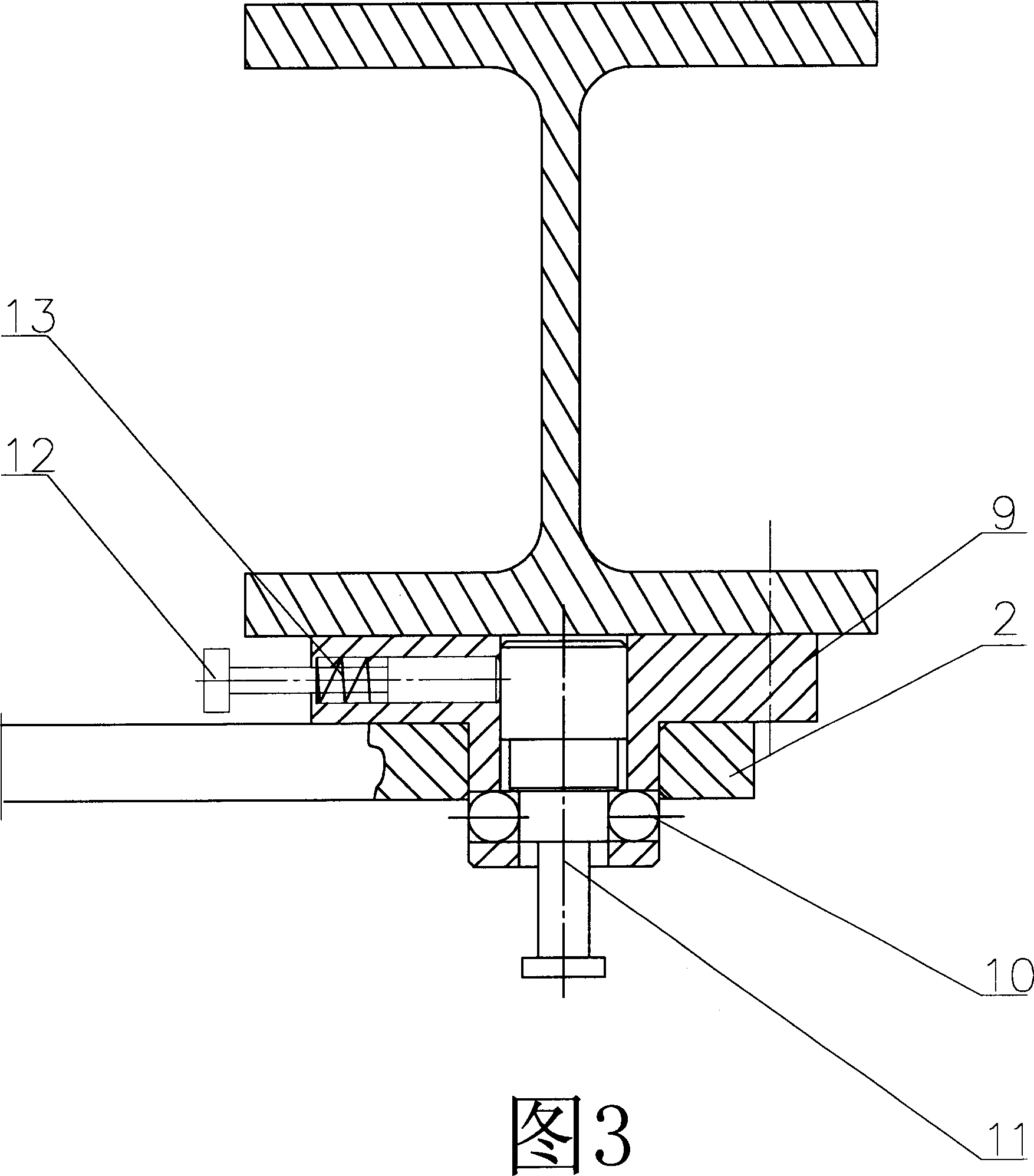

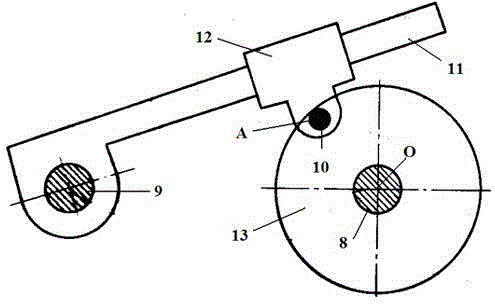

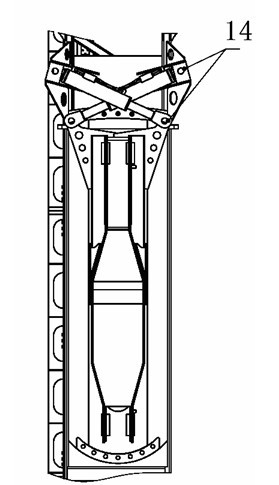

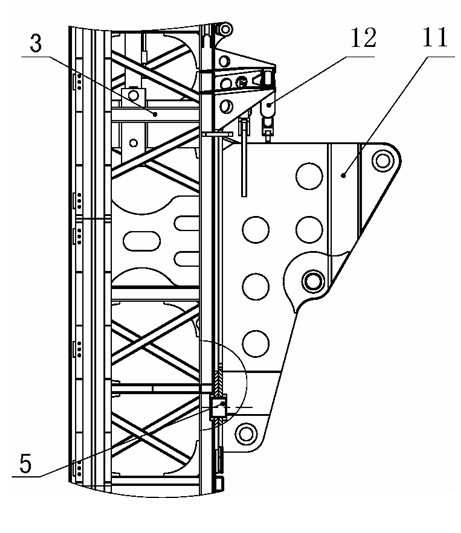

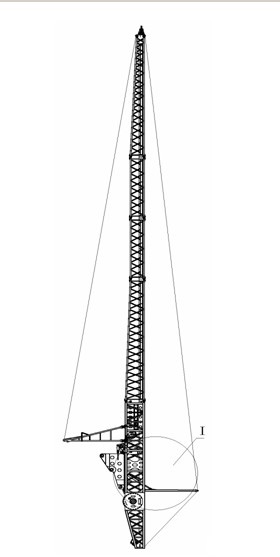

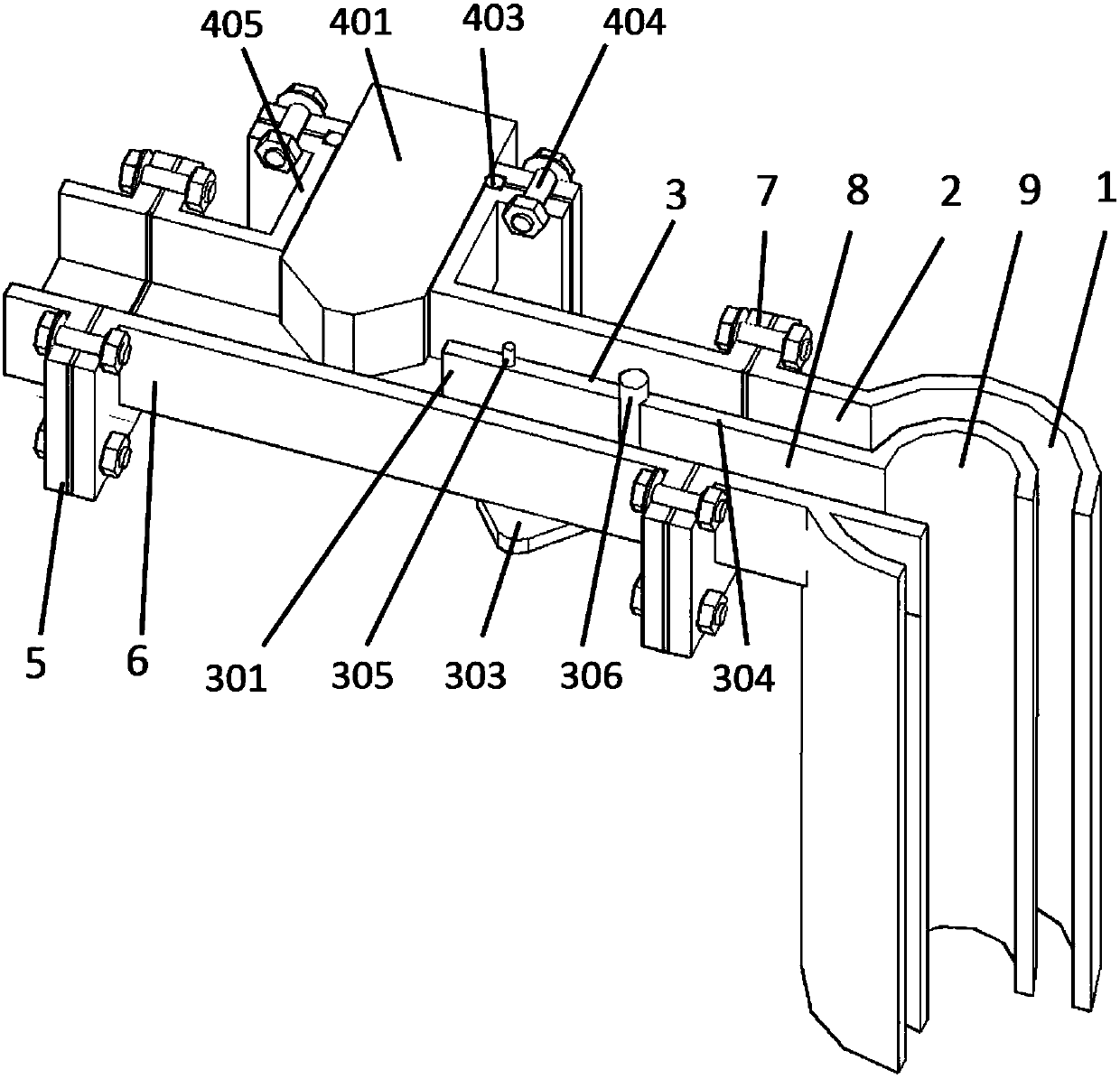

Quickly-dismantled horizontal swinging type slide frame of turnout tamper

Owner:SHENYANG LUBANG MACHINERY CO LTD

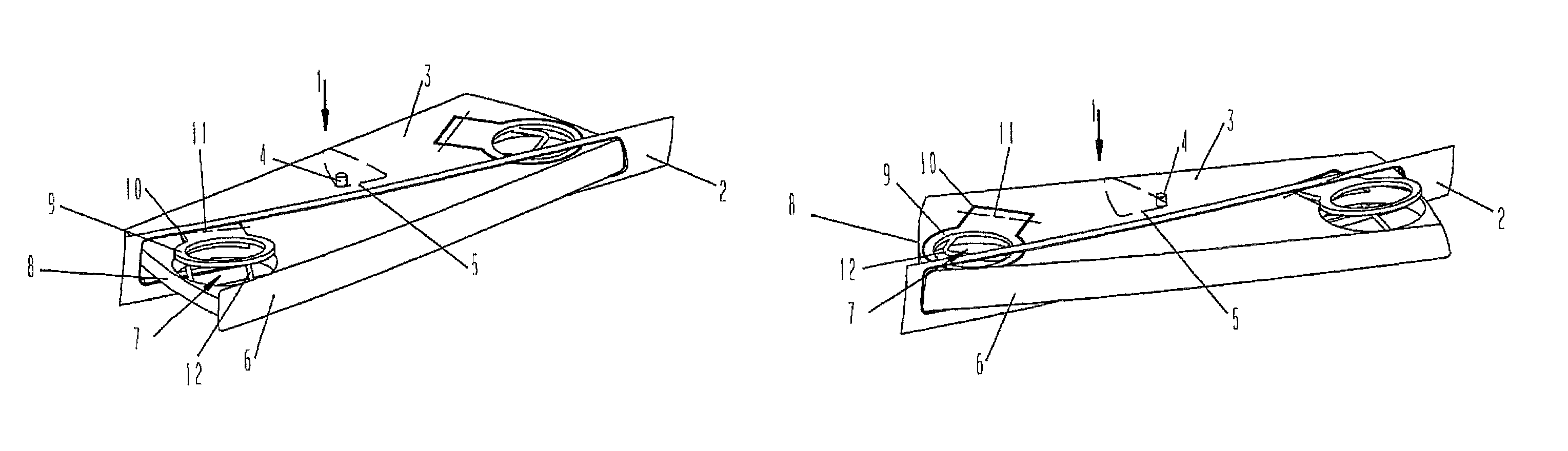

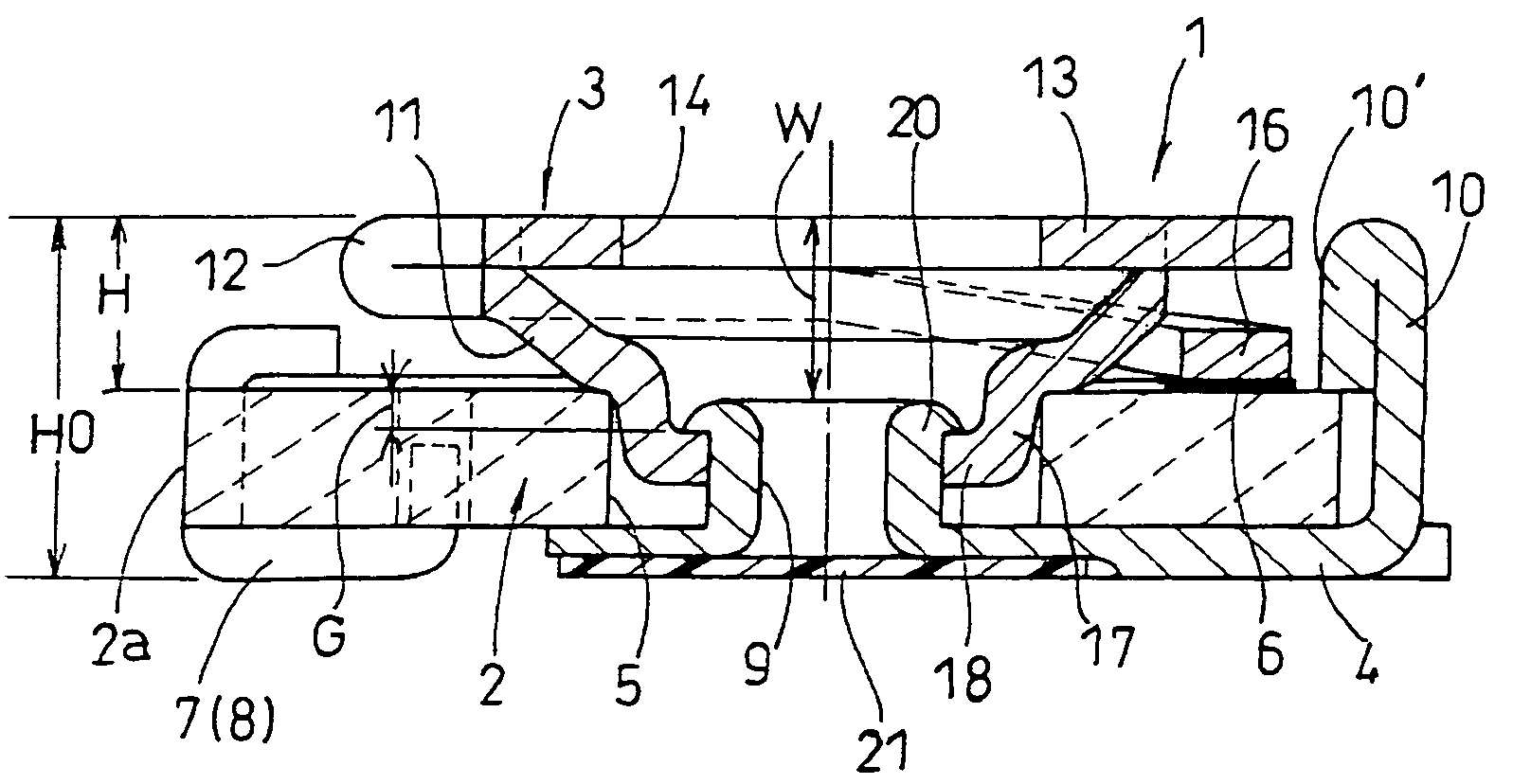

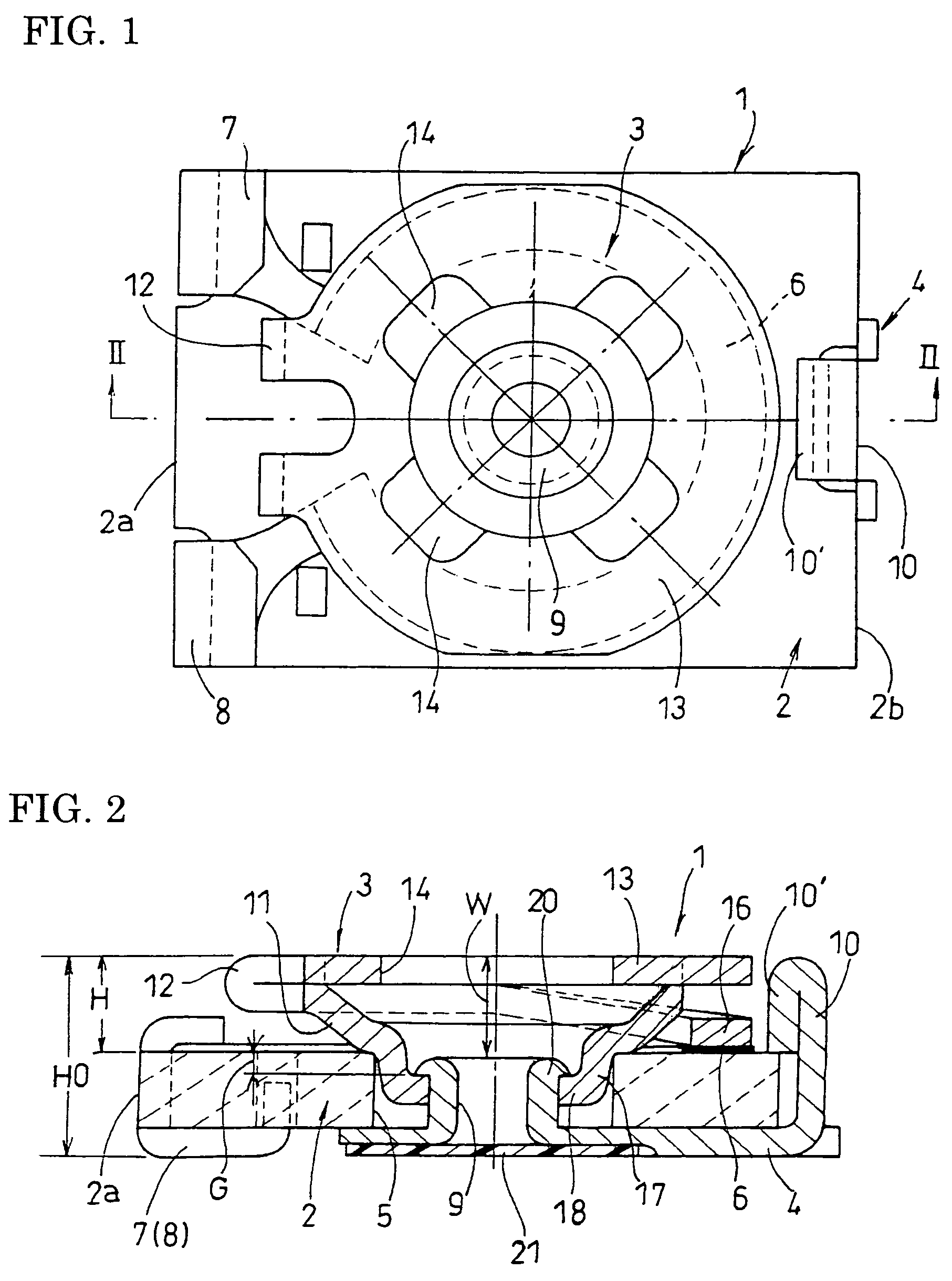

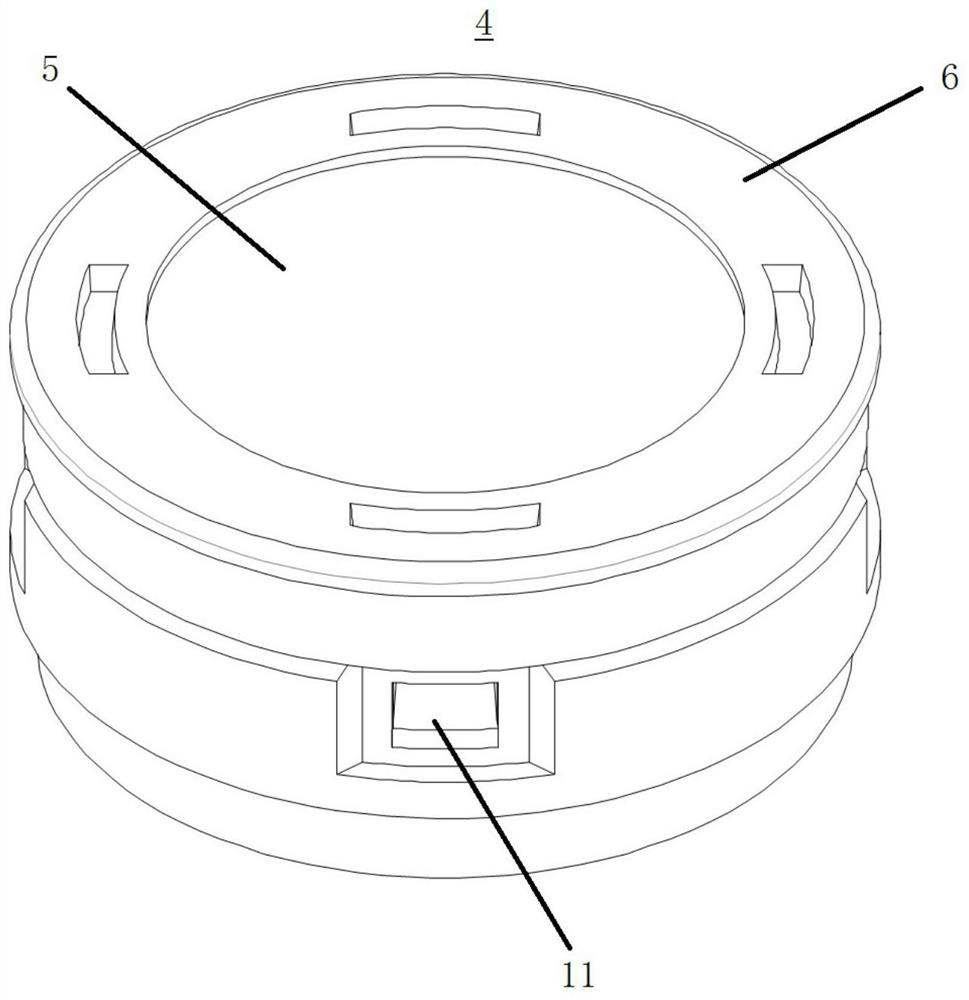

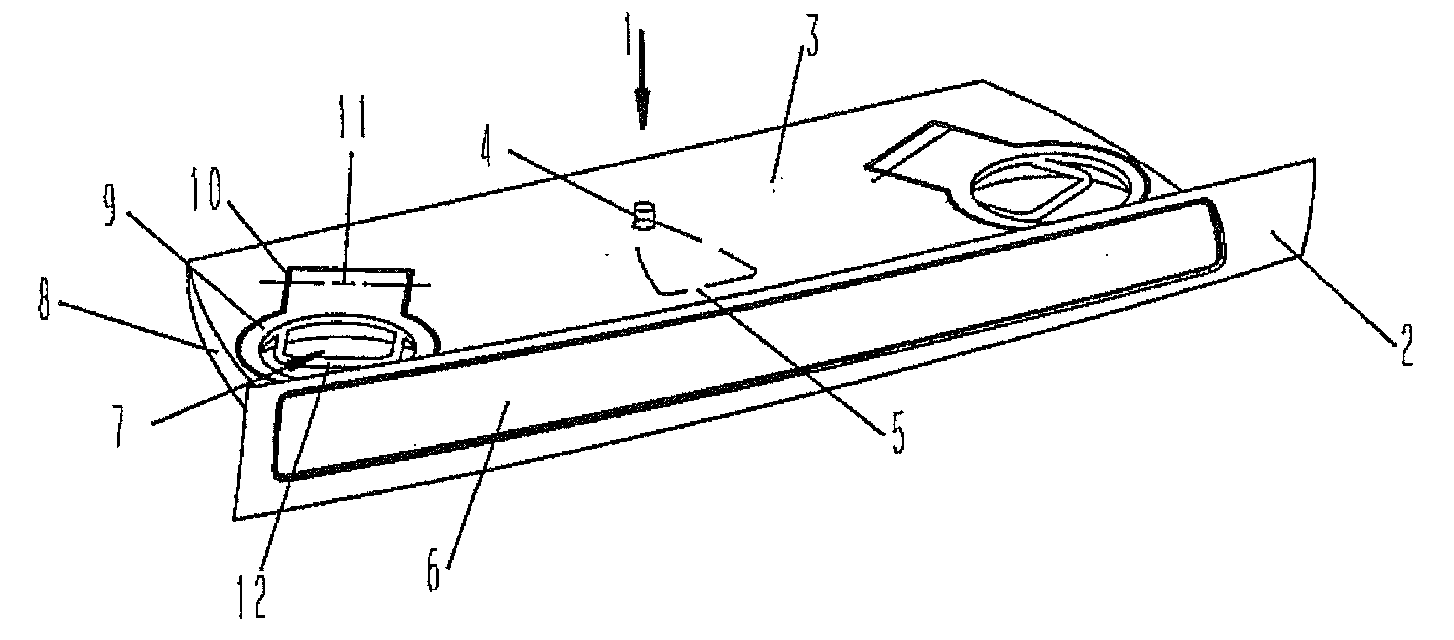

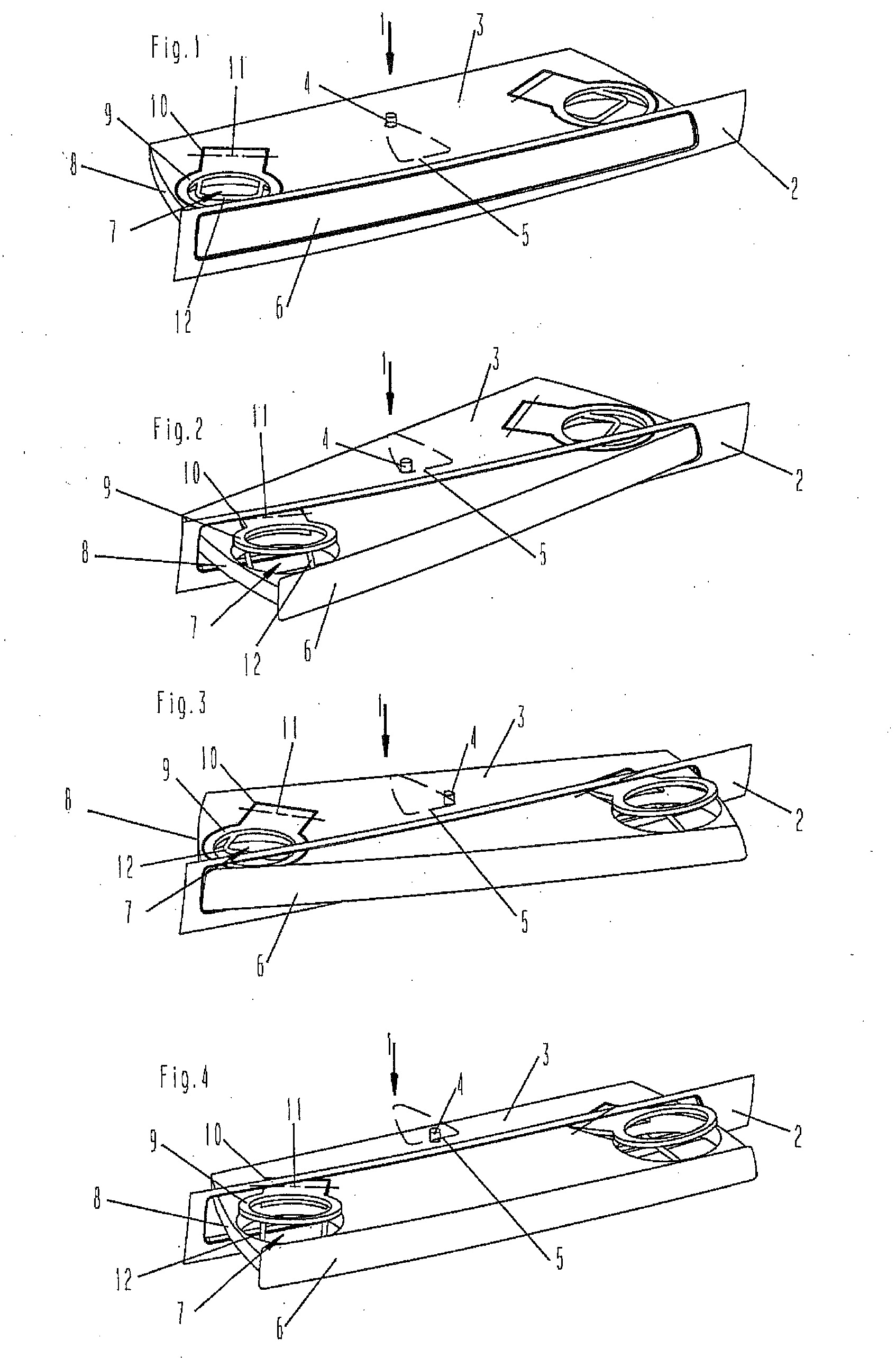

Holder for a beverage container

InactiveUS7740217B2Increase insertion depthVehicle arrangementsWash-standsMobile vehicleReady to use

A holder for two beverage containers is provided for installation in a motor vehicle. The holder has a pull-out element having insertion openings for the beverage containers. The pull-out element is guided not only displaceably but also is mounted pivotally, so that, as desired, one insertion opening instead of both insertion openings is accessible and available for use.

Owner:FISCHER AUTOMOTIVE SYST

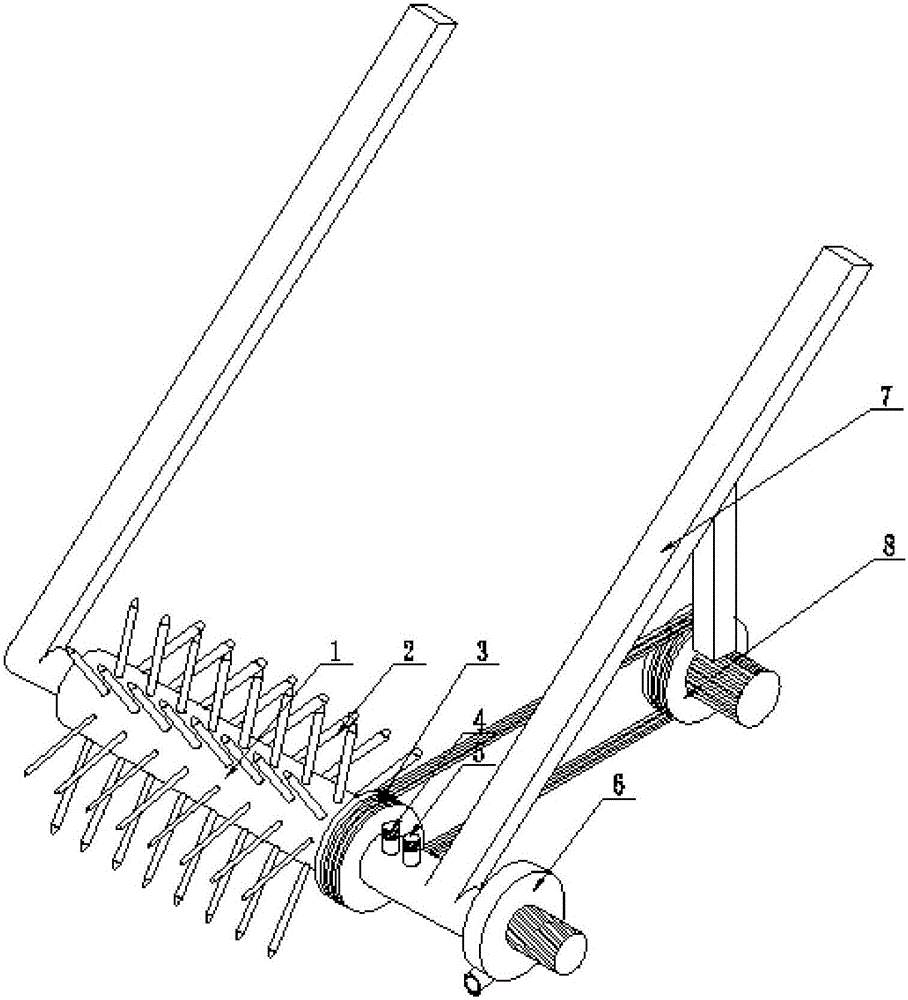

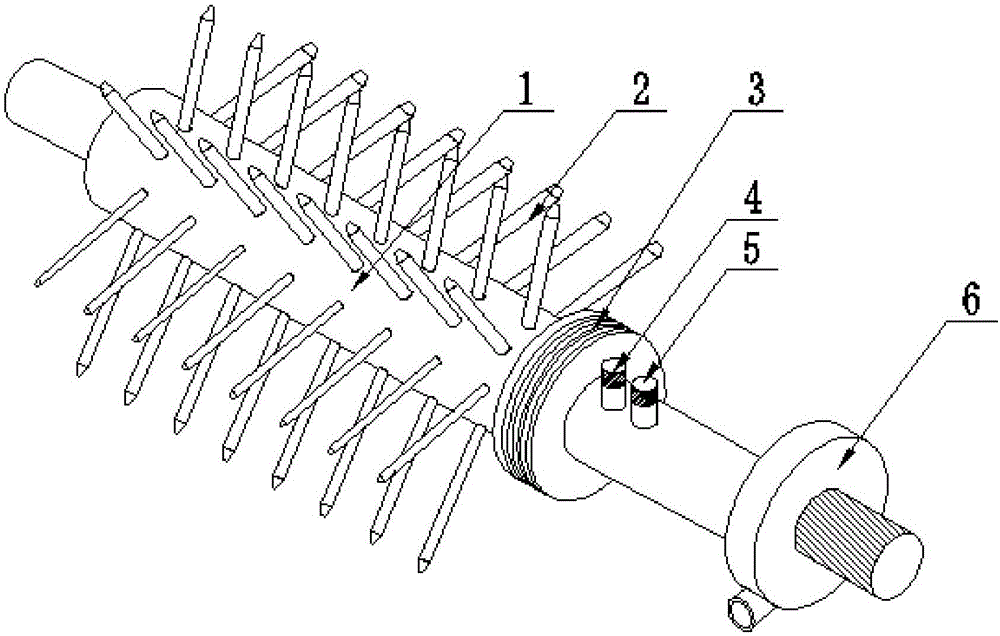

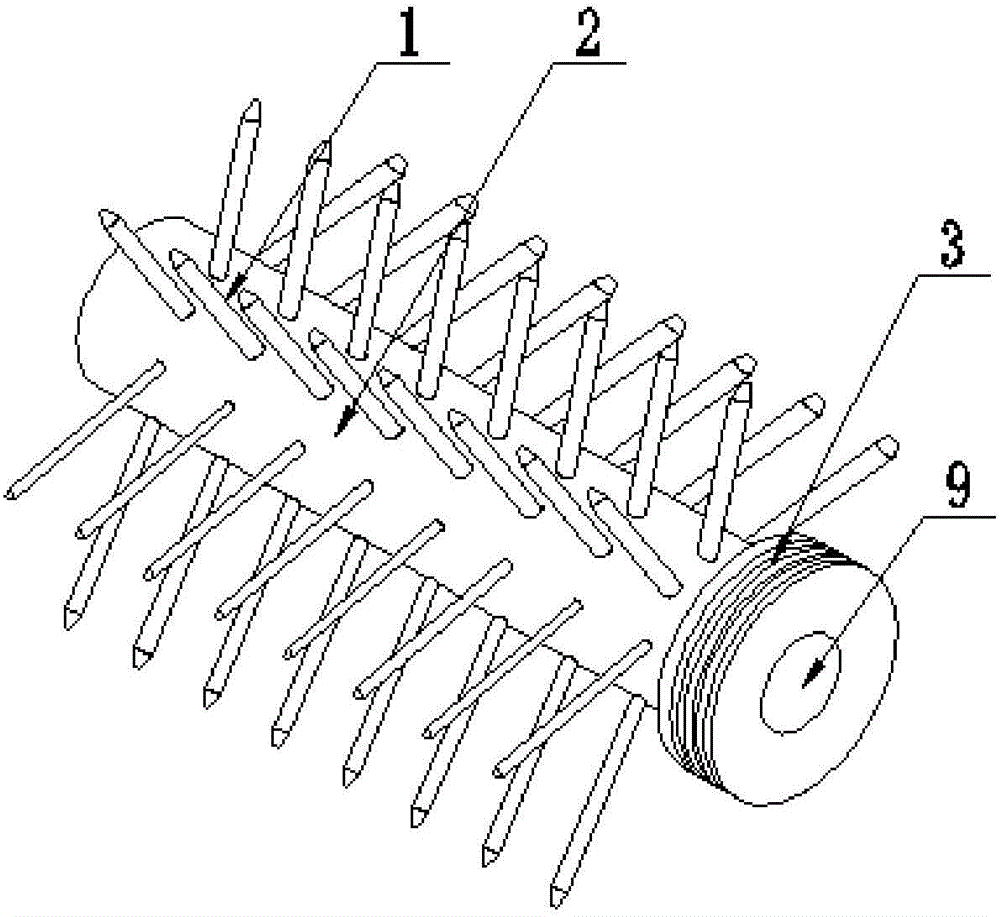

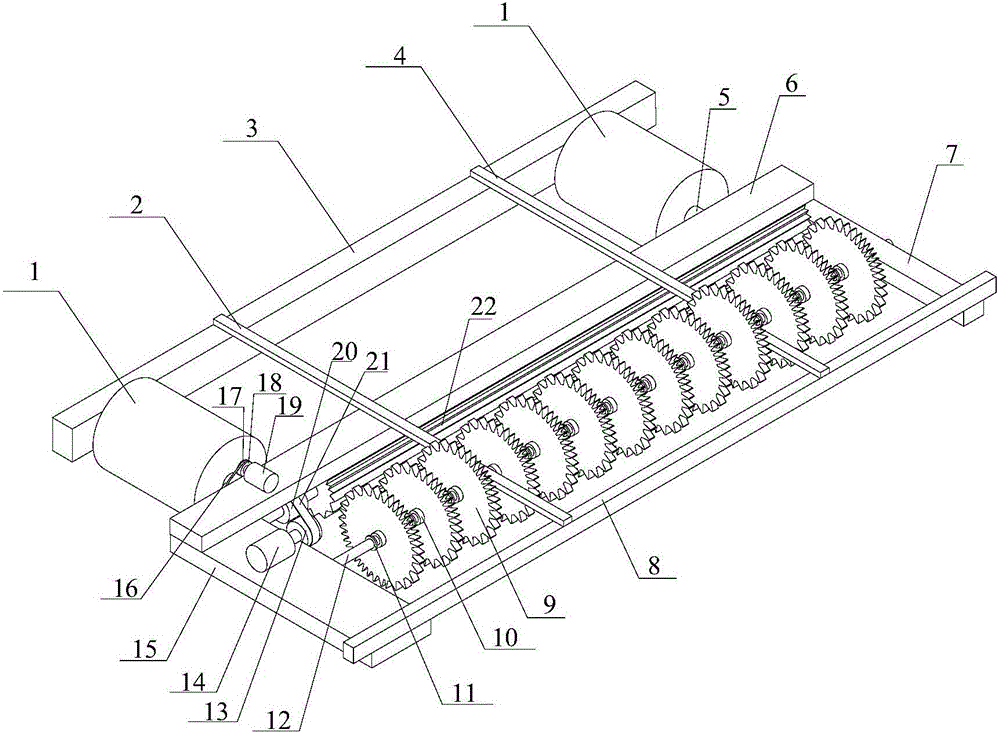

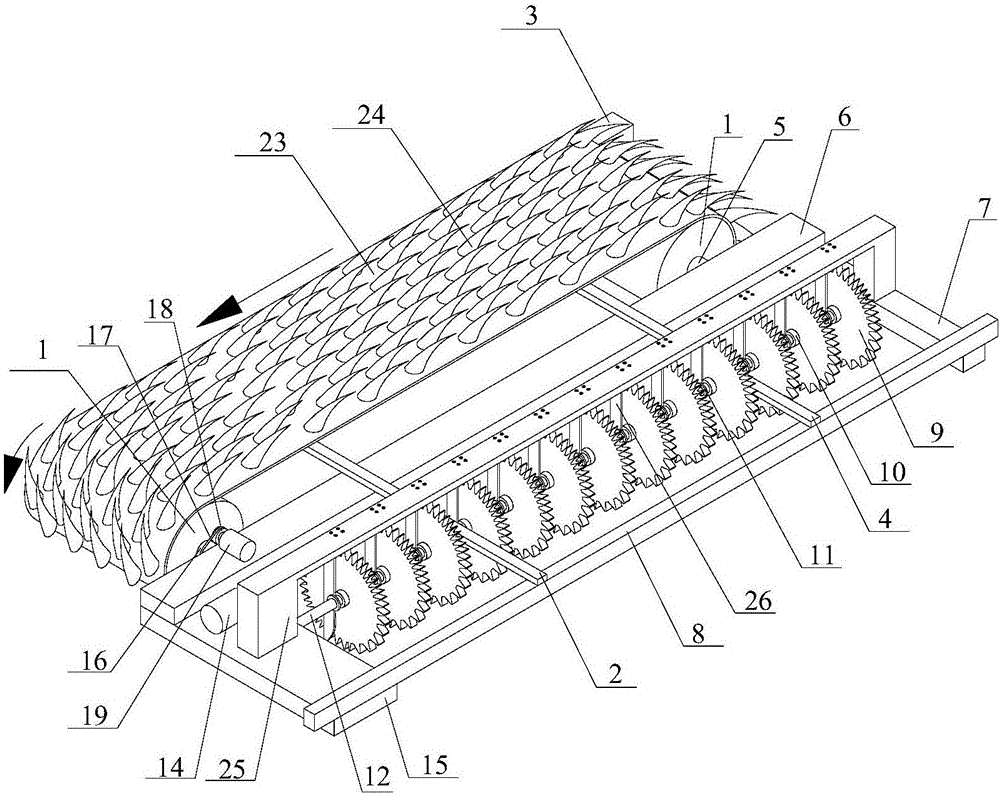

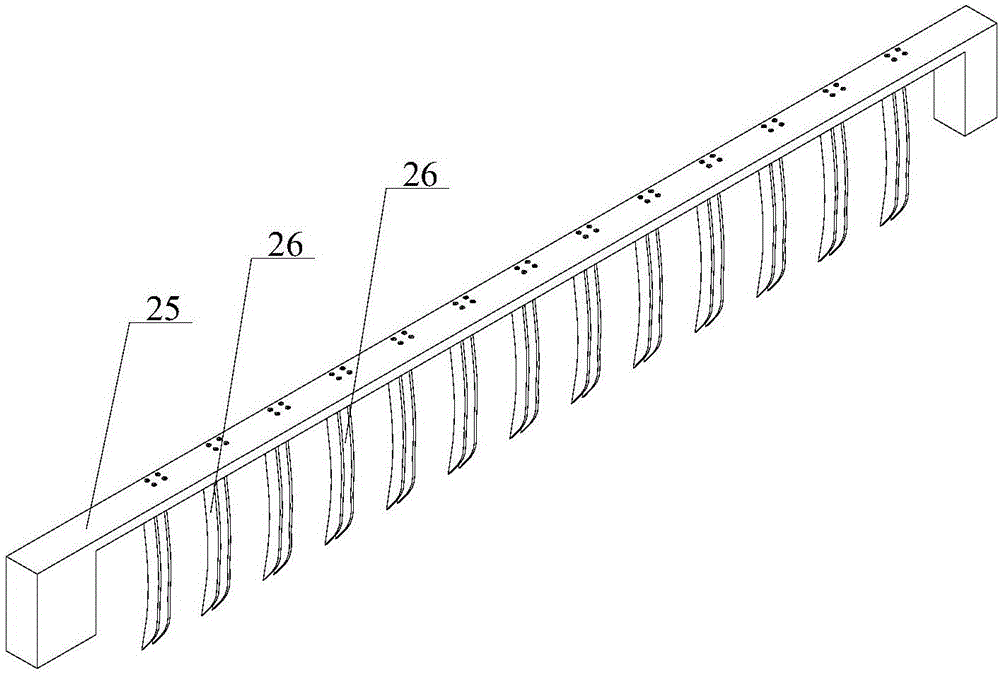

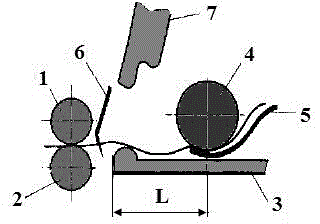

Rice transplanter assisted straw turnover device

The invention discloses a rice transplanter assisted straw turnover device which comprises a bracket, a straw pressing track and a plurality of straw pressing fluted discs, wherein the straw pressing track is arranged on two rollers in a sleeving manner; a plurality of rake teeth are distributed on the straw pressing track; the rollers are fixed on a roller shaft; two ends of the roller shaft are respectively fixed on the bracket through bearings; the straw pressing fluted discs are arranged on a connecting shaft in a sleeving manner; two ends of the connecting shaft are respectively fixed on the bracket; a gear shaft is fixed on the bracket and meshed with the straw pressing fluted discs; and two power mechanisms are fixed on the bracket, wherein one power mechanism is used for driving the straw pressing track to work, pressing straws or weeds on the ground into a shallow underground layer and carding the straws or weeds into a transverse direction, and the other power mechanism is used for driving the straw pressing fluted discs to rotate and further pressing the straws or weeds in the shallow underground layer into a deeper underground position. The device disclosed by the invention is matched with a rice transplanter, so that the straw turnover operation can be completed during rice transplanting. Moreover, soil between two adjacent straw pressing fluted discs is extruded and arched into ridges, rice seedlings can be inserted into the ridges by the rice transplanter, and the condition that rice seedling floating and lodging occur can be avoided.

Owner:于光成

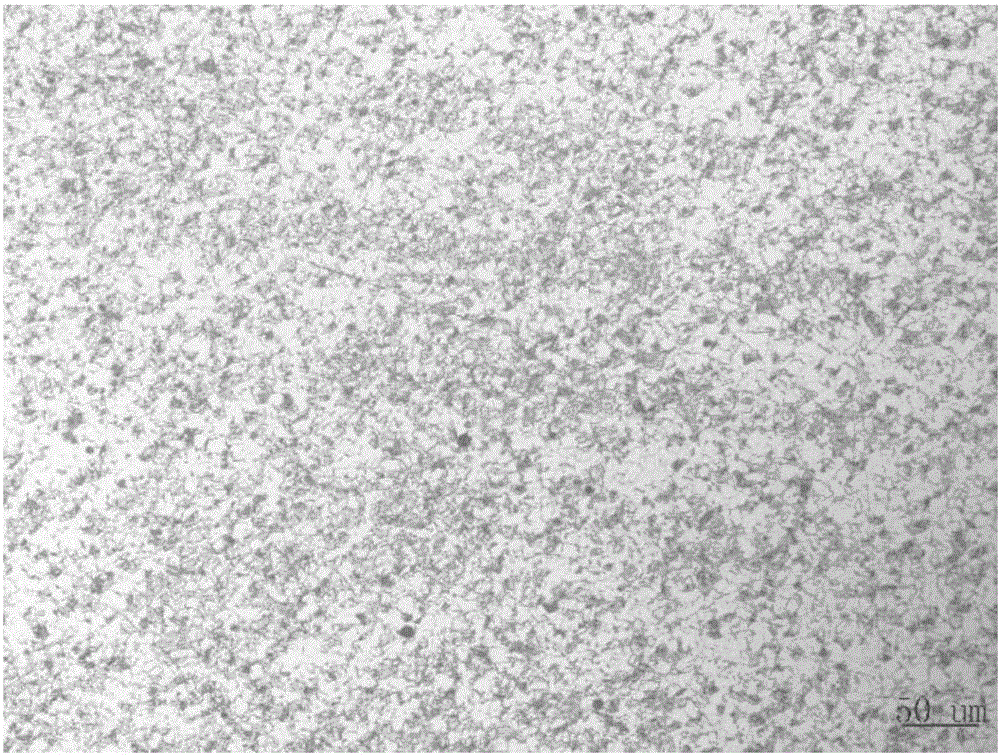

Fluorite-magnesium grain cored wire, application of fluorite-magnesium grain cored wire and production process for high heat input welding steel

The invention discloses a fluorite-magnesium grain cored wire, application of the fluorite-magnesium grain cored wire and a production process for high heat input welding steel. The cored wire comprises an outer layer and a clad core. Low-carbon steel serves as the outer layer, and the thickness ranges from 0.5 mm to 1.0mm; sustained-release passivated magnesium grains serve as the clad core, and the clad core comprises a sustained-release agent and passivated magnesium grain bodies; and fluorite serves as the sustained-release agent, the sustained-release agent accounts for 5%-90% of the clad core, and the passivated magnesium grain bodies account for 10%-95% of the clad core. The application refers to application of the cored wire in manufacturing of the high heat input welding steel. According to the production process, the sustained-release passivated magnesium grain cored wire with the fluorite serving as the sustained-release agent is fed into molten steel, the absorption rate of Mg is stable, the effect and the utilization rate of Mg are high, slag inclusions are dispersed and abundant, and the slag inclusions containing Mg reach over 80%. By the adoption of the fluorite-magnesium grain cored wire, application and the production process, control is easy, production cost is low, and industrialized mass production of the high heat input welding steel can be achieved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

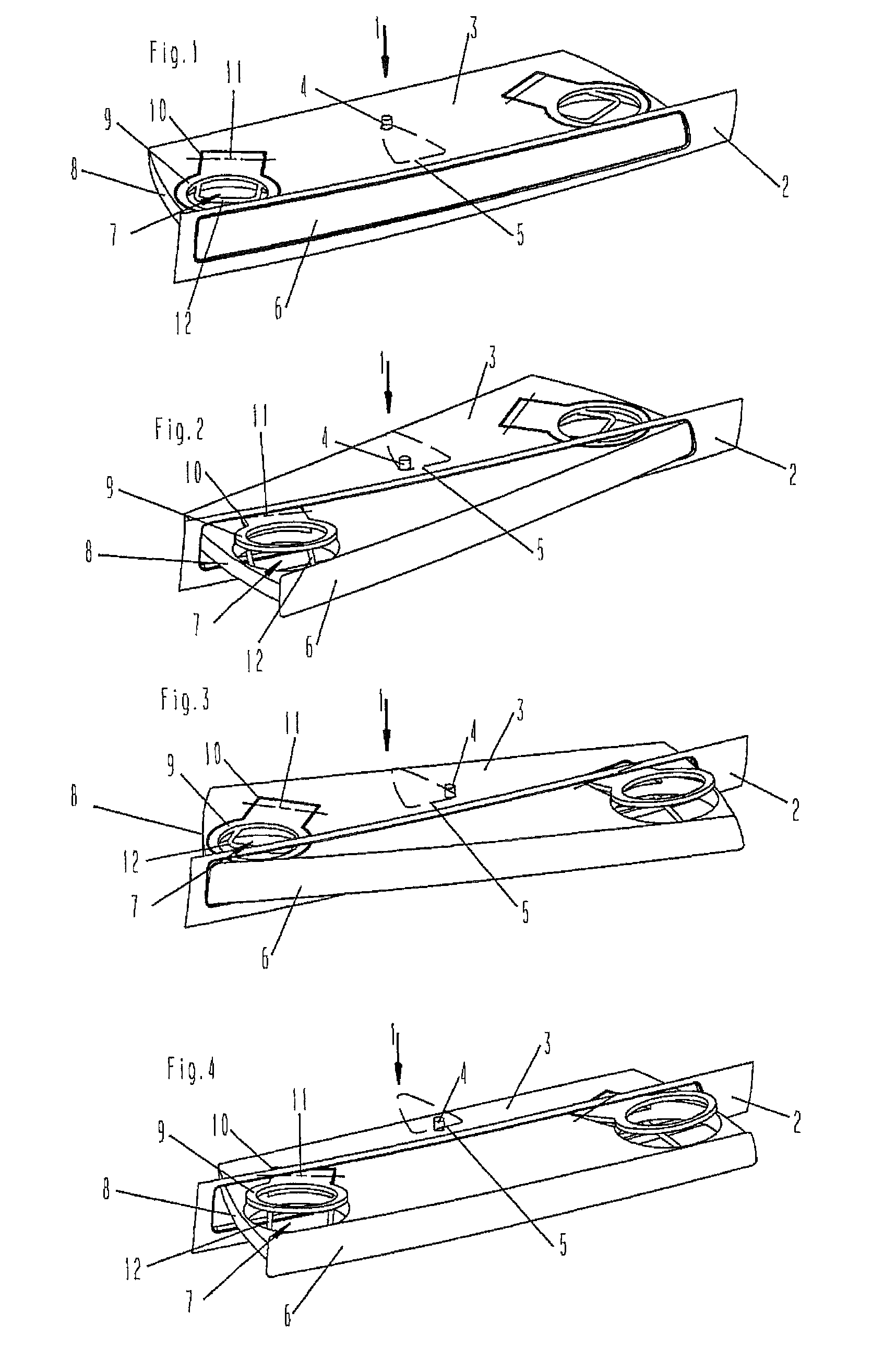

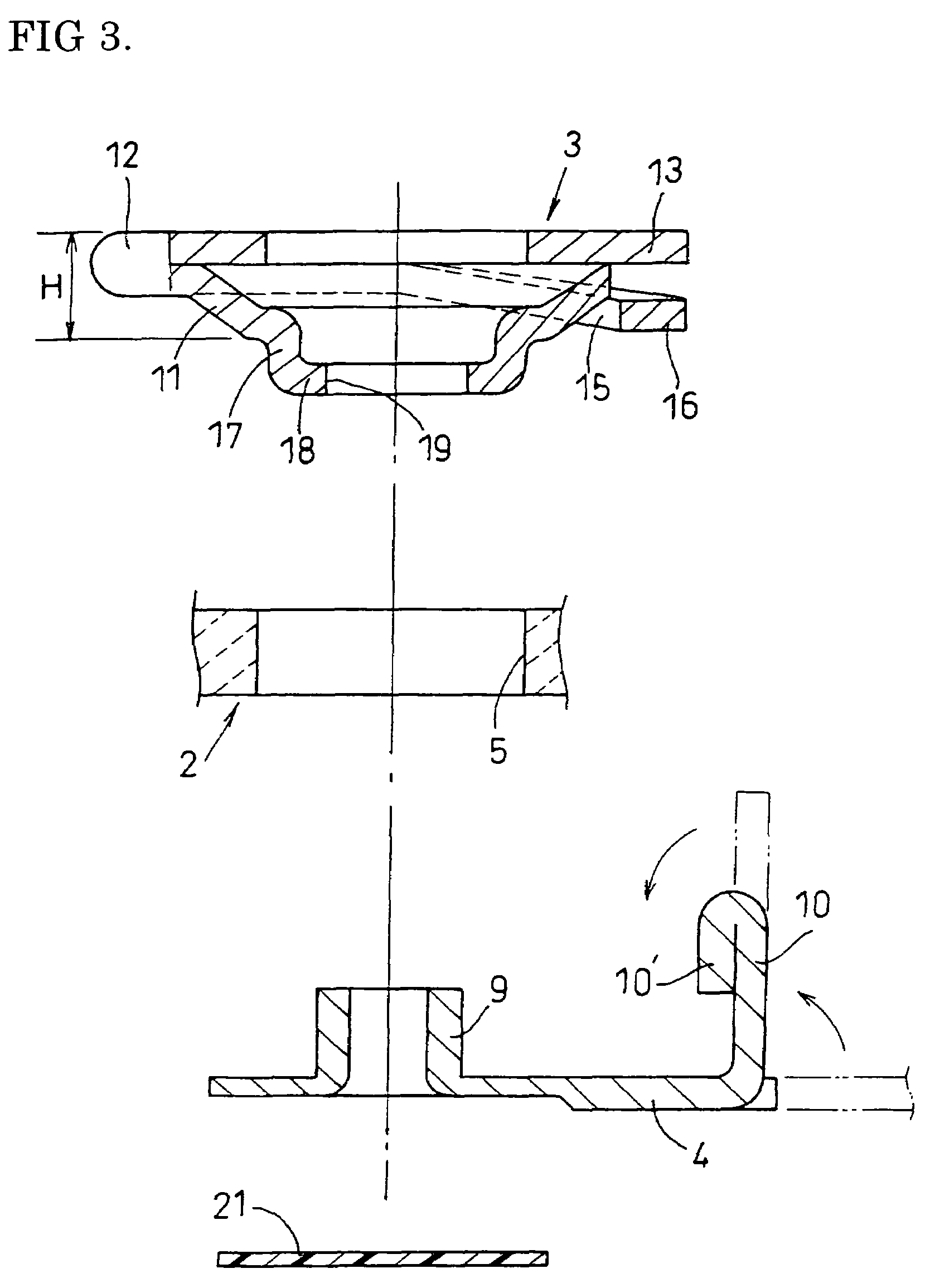

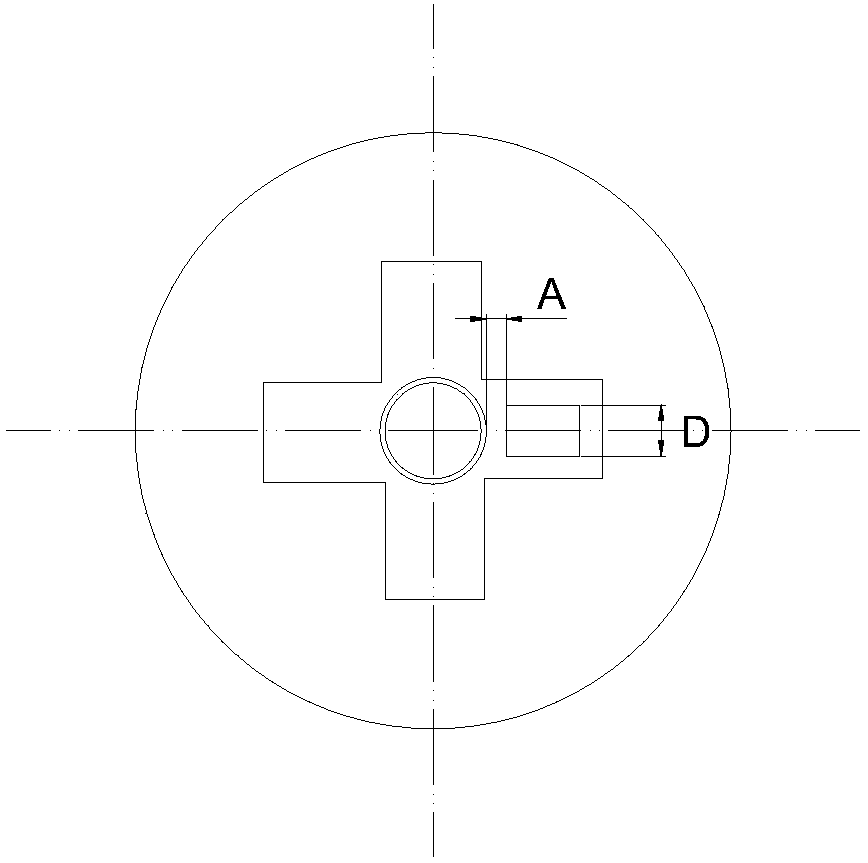

Chip type variable electronic part and chip type variable resistor

InactiveUS7633372B2Increase insertion depthGood effectResisitors with sliding contactInsertion depthMetal

A chip type variable electronic part includes an insulating substrate with a through hole, an adjustment rotor formed of a metal plate in a bowl shape to receive a screwdriver and disposed on the upper surface of the insulating substrate, an internal terminal electrode plate made of a metal plate disposed in close contact with a lower surface of the insulating substrate, and a shaft portion integrally formed with the internal terminal electrode plate to be fitted in the through hole. A bottom plate of the adjustment rotor is rotatably fitted to the upper end portion of the shaft portion, and the upper end portion of the shaft portion is crimped to outwardly extend over the upper surface of the bottom plate. A portion of the bottom plate of the adjustment rotor, fitted over the shaft portion, is located at a lower level than the uppermost edge of an inner portion of the through hole on the upper surface of the insulating substrate. Thus, the overall height of the chip type variable electronic-part is reduced with an increased insertion depth of a screwdriver into the rotor.

Owner:ROHM CO LTD

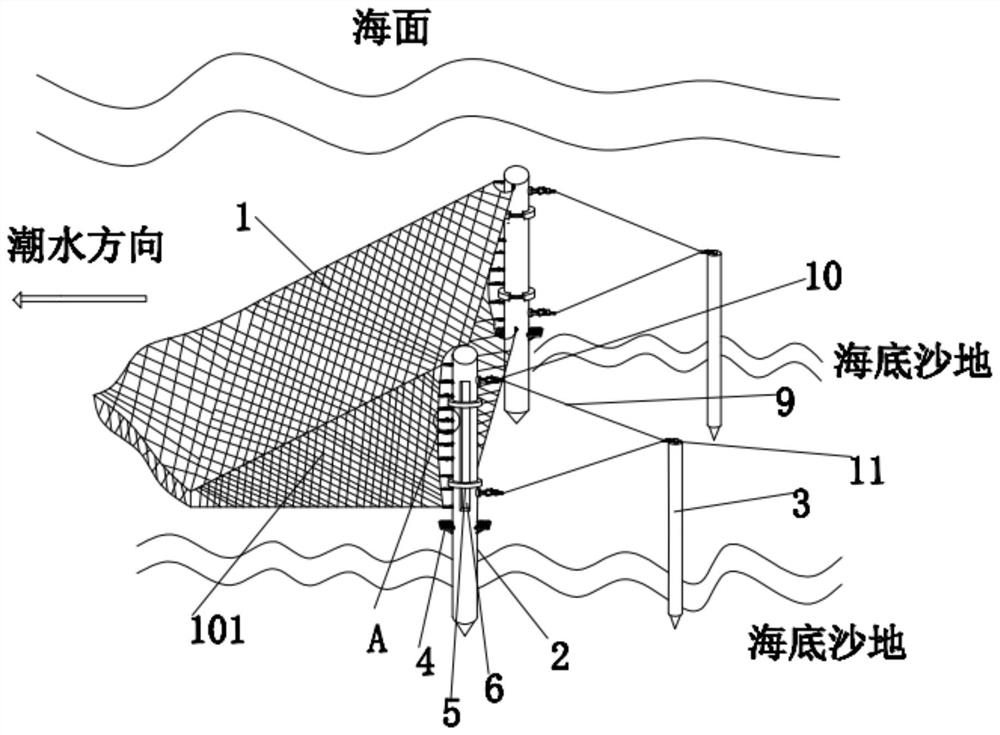

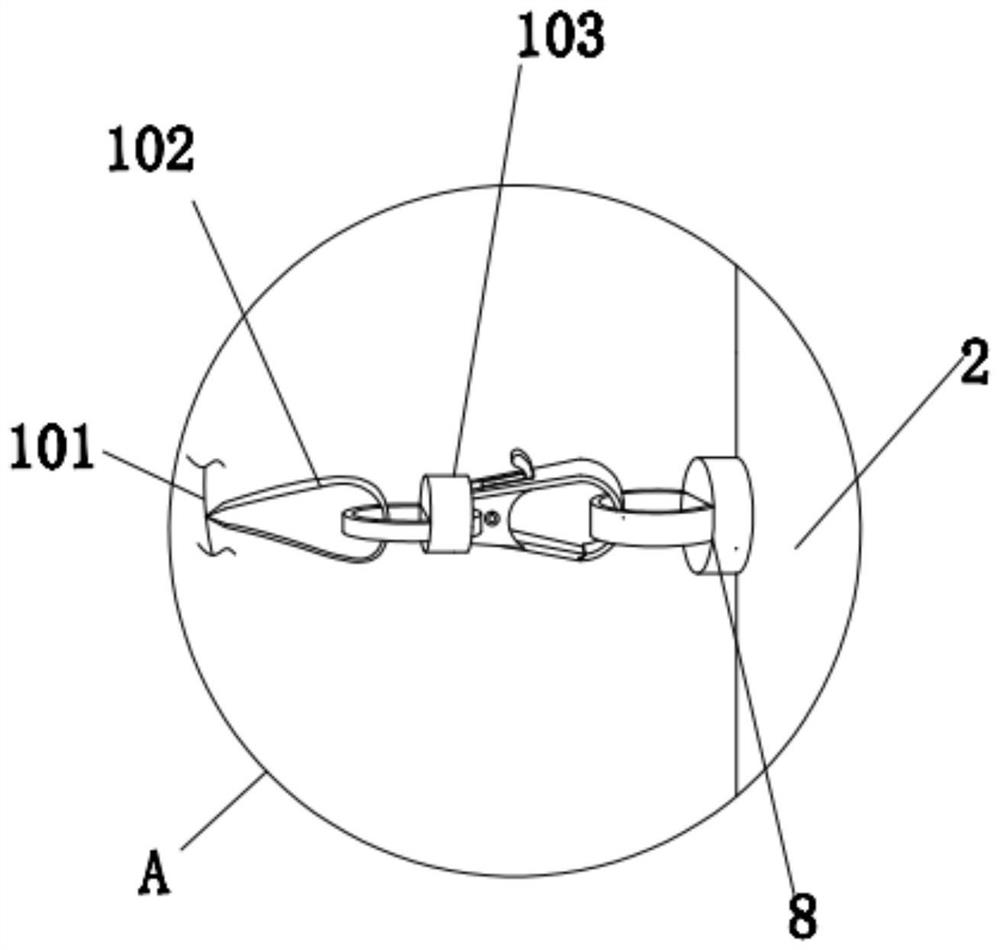

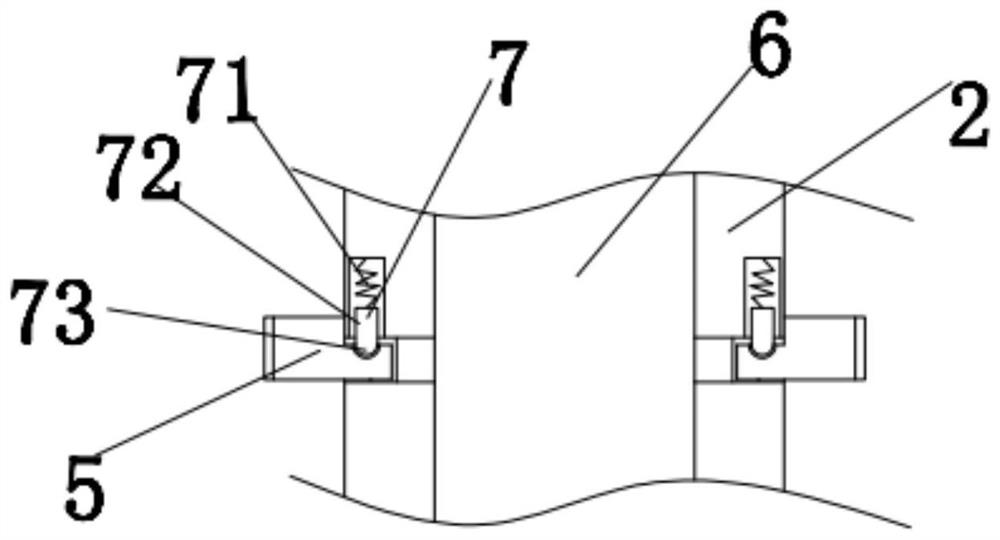

Fishing farming customized net

The invention discloses a fishing farming customized net. The fishing farming customized net comprises two sets of fixed columns; the two sets of fixed columns are symmetrically arranged front and back; buckling rings are arranged on the two sets of fixed columns; a fishing net mechanism is arranged on the left sides of the fixed columns; the fishing net mechanism and the fixed columns are fixed together through the buckling rings; rotating blocks are rotationally clamped to the fixed columns in an up-down symmetrical mode; downward pressing mechanisms are symmetrically arranged on the lower side of the lower rotating block in a left-right mode; first key padlocks are clamped to the buckling rings symmetrically arranged at the right ends of the fixed columns in an up-down mode; and the right ends of the two first key padlocks are connected with two ends of a pull rope correspondingly. According to the fishing farming customized net, third key padlocks are matched with the buckling rings on a fixed columns, the fishing net can be rapidly fixed to the fixed columns, a broken fishing net can be rapidly replaced, and time is saved; the downward pressing mechanisms are arranged, the insertion depth of the fixed columns can be conveniently increased, and the stability of the fixed columns is improved; and a containing cavity is formed, and therefore, equipment is convenient to carry.

Owner:祖常亮

Low-cotton-droppings processing technology for cotton spinning combing machine

ActiveCN104562312AReduce the chance of being snatchedIncrease insertion depthCombing machinesYarnFiber

The invention discloses a low-cotton-droppings processing technology for a cotton spinning combing machine. The technology comprises the steps: on a pre-drawing frame of a combing preparation procedure, increasing the number of cotton slivers fed, and increasing total draft multiple and rear area draft multiple; on a ribbon lap machine of the combing preparation procedure, increasing the number of cotton slivers combined, and increasing the total draft multiple; on the combing machine of a combing procedure, determining the cotton roll fixed quantity and cotton feeding length of the combing machine; adopting a forward cotton feeding manner, and forwards moving a cotton feeding roller; improving a clamping plate transmission system of the combing machine; reducing cotton droppings spacing; reducing the total tooth number of a cylinder and increasing carding spacing; reducing the carding strength and insertion depth of a top comb. According to the technology, the probability that fibers are grabbed by pin teeth of the cylinder during carding is lowered, and the aim of low cotton droppings during combing is realized, so that the cotton droppings ratio of combing is lowered to 4-8%, the requirements of semi-combed yarn, of which the combed yarn is relatively thick and the quality requirements are relatively low, on low cotton droppings are met, and the aims of reducing cotton consumption cost and increasing spinning economic benefit are achieved.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Spile device of spile machine

ActiveCN102587350ASimple structureGood adjustment effectSoil drainageSoil preservationEngineeringTransmitted power

A spile device of a spile machine relates to the technical field of spile machines. A transmission operating mechanism transmits power to a lifting mechanism under hydraulic control, the lifting mechanism drives the spile device to rotate, and a drain board is disposed in a steel casing which is disposed inside the spile device and driven by a winch. A left verticality adjusting mechanism, a right verticality adjusting mechanism, a pay-off and take-up type line puller and a detachable support device. The spile device has the advantages that movement is fast, action is flexible, driving depth is large, ground adaptability is high, operation is convenient, power is high and driving speed is high.

Owner:JIANGSUSNGQI GROUP

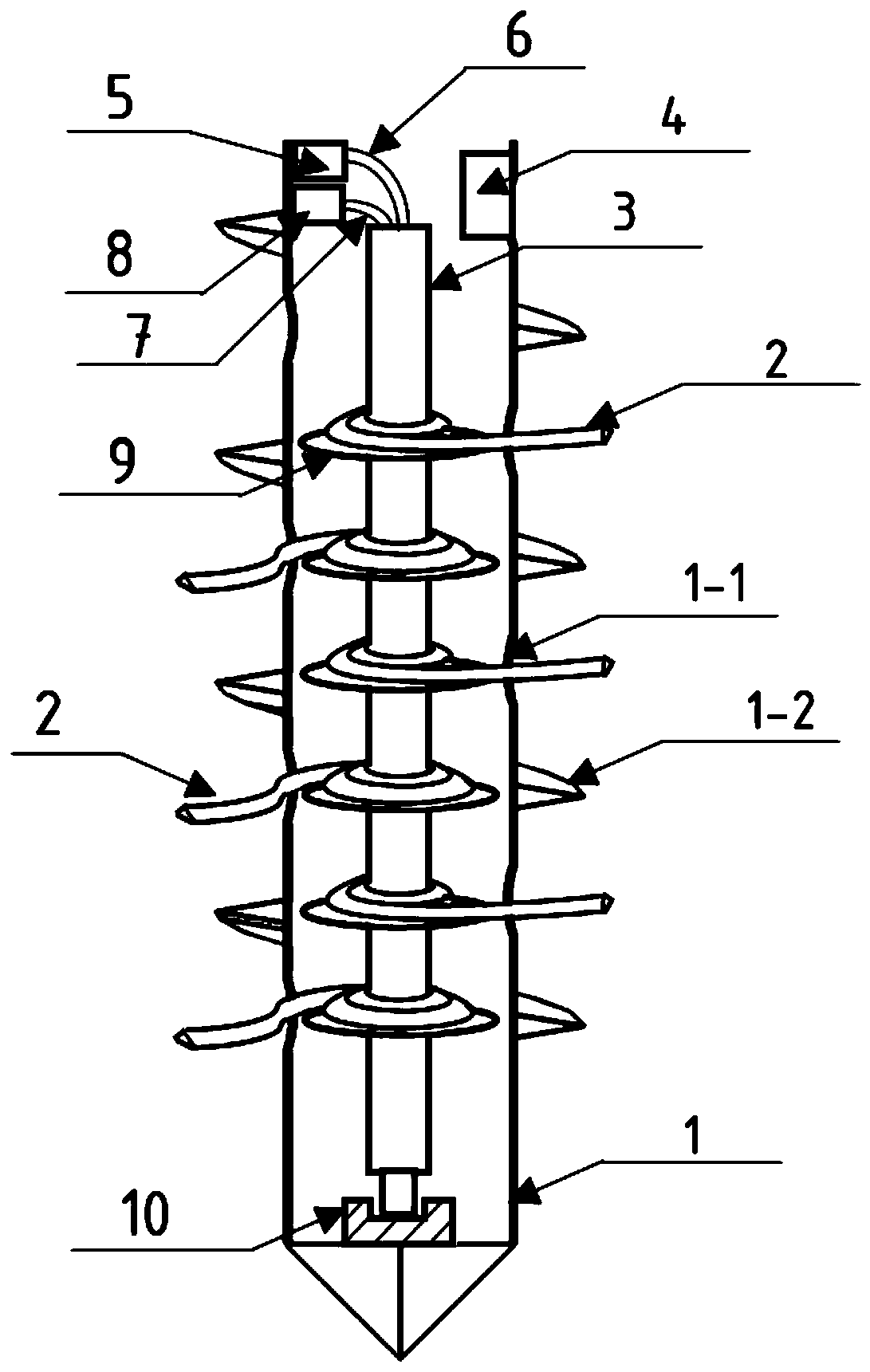

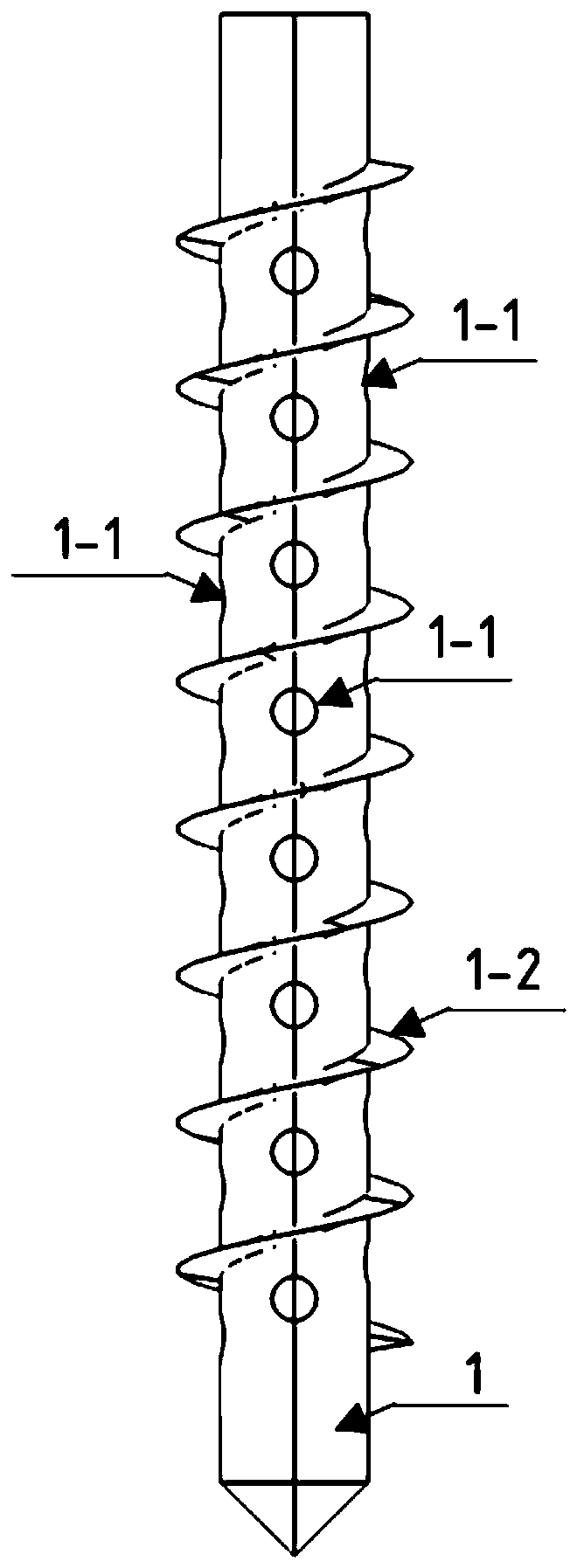

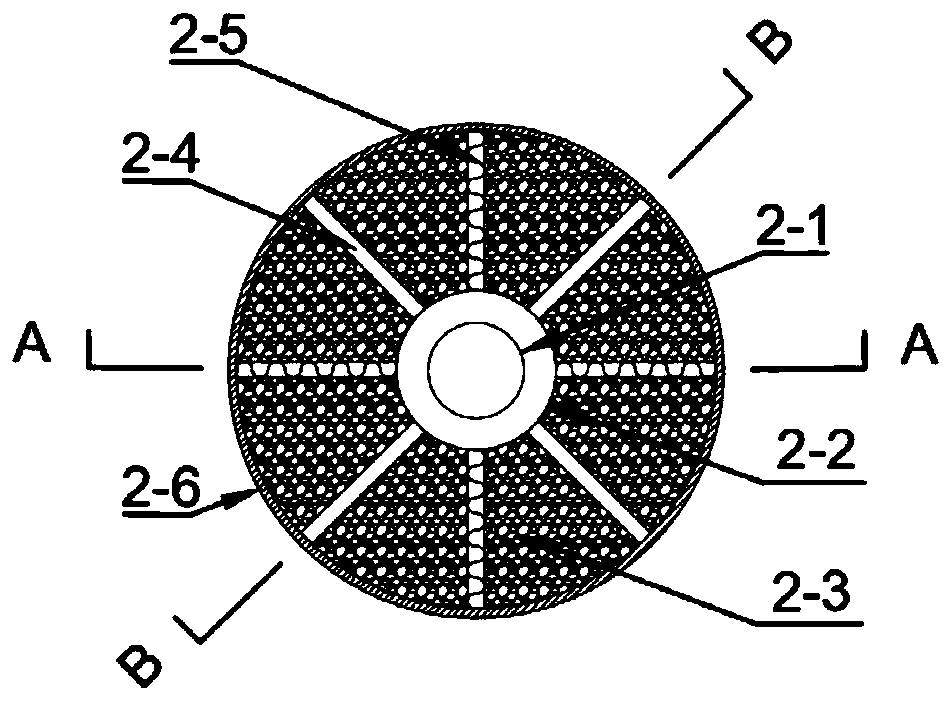

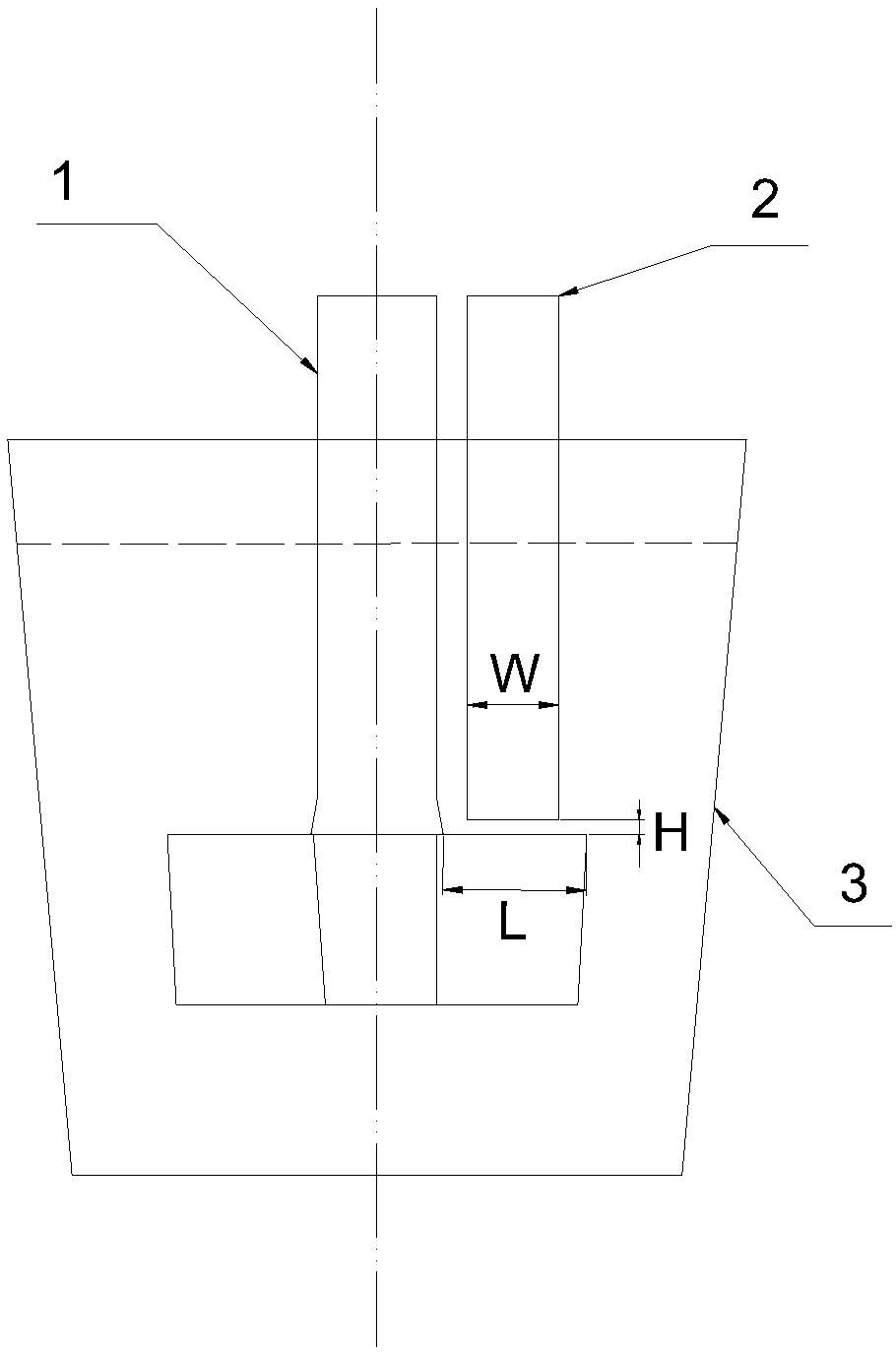

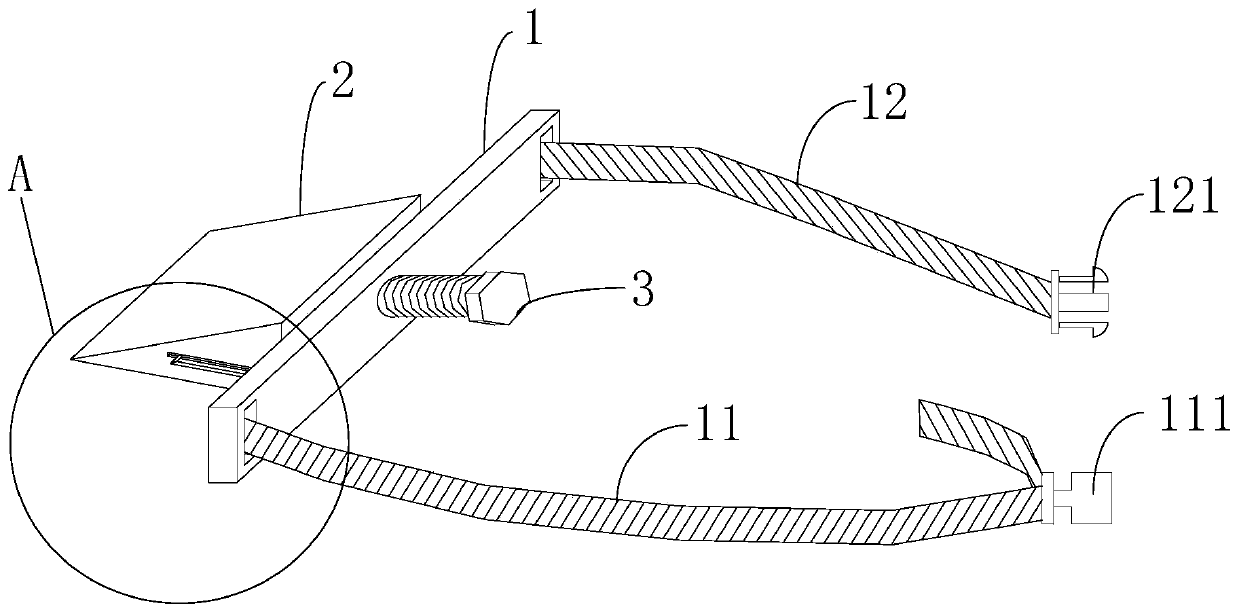

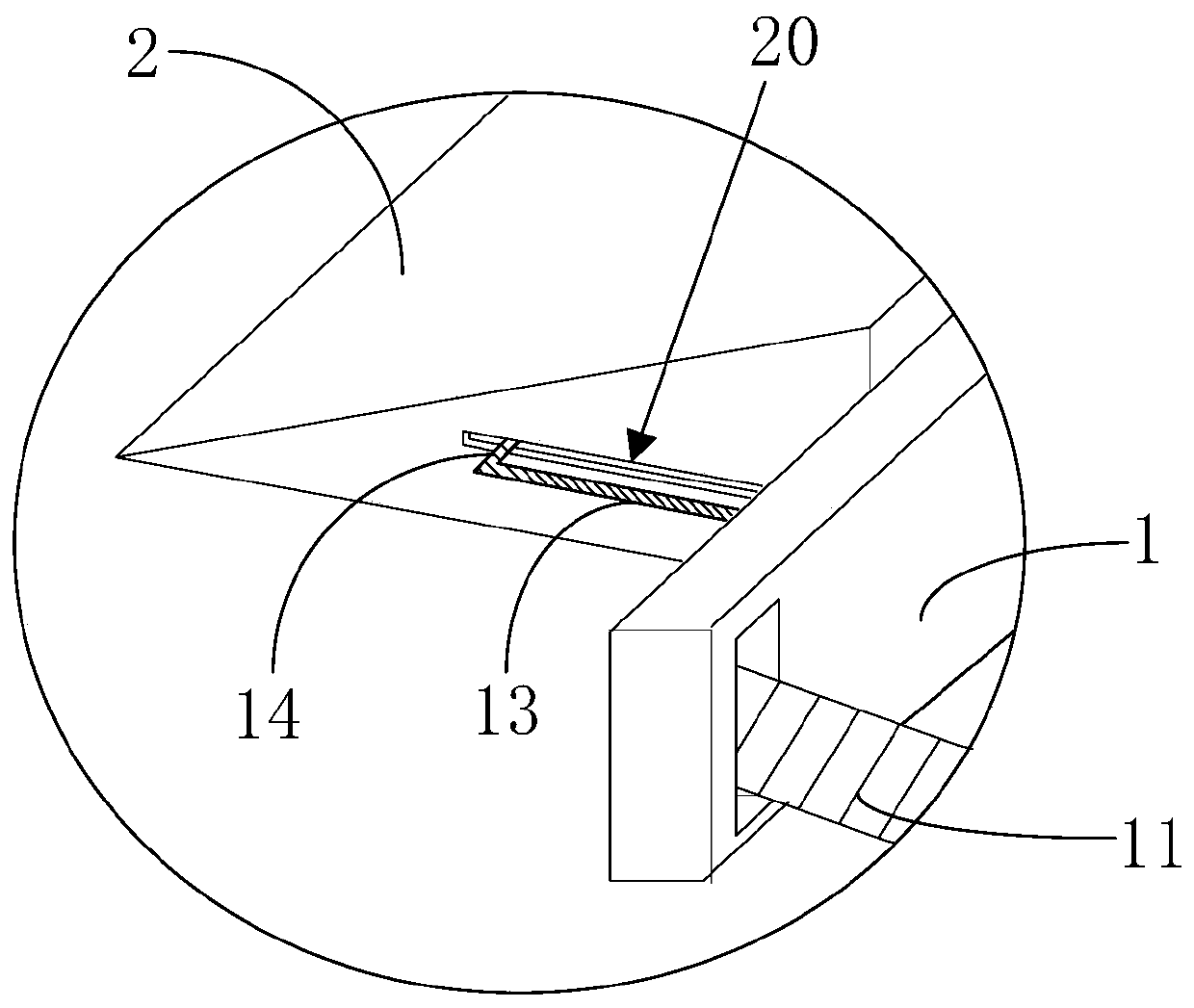

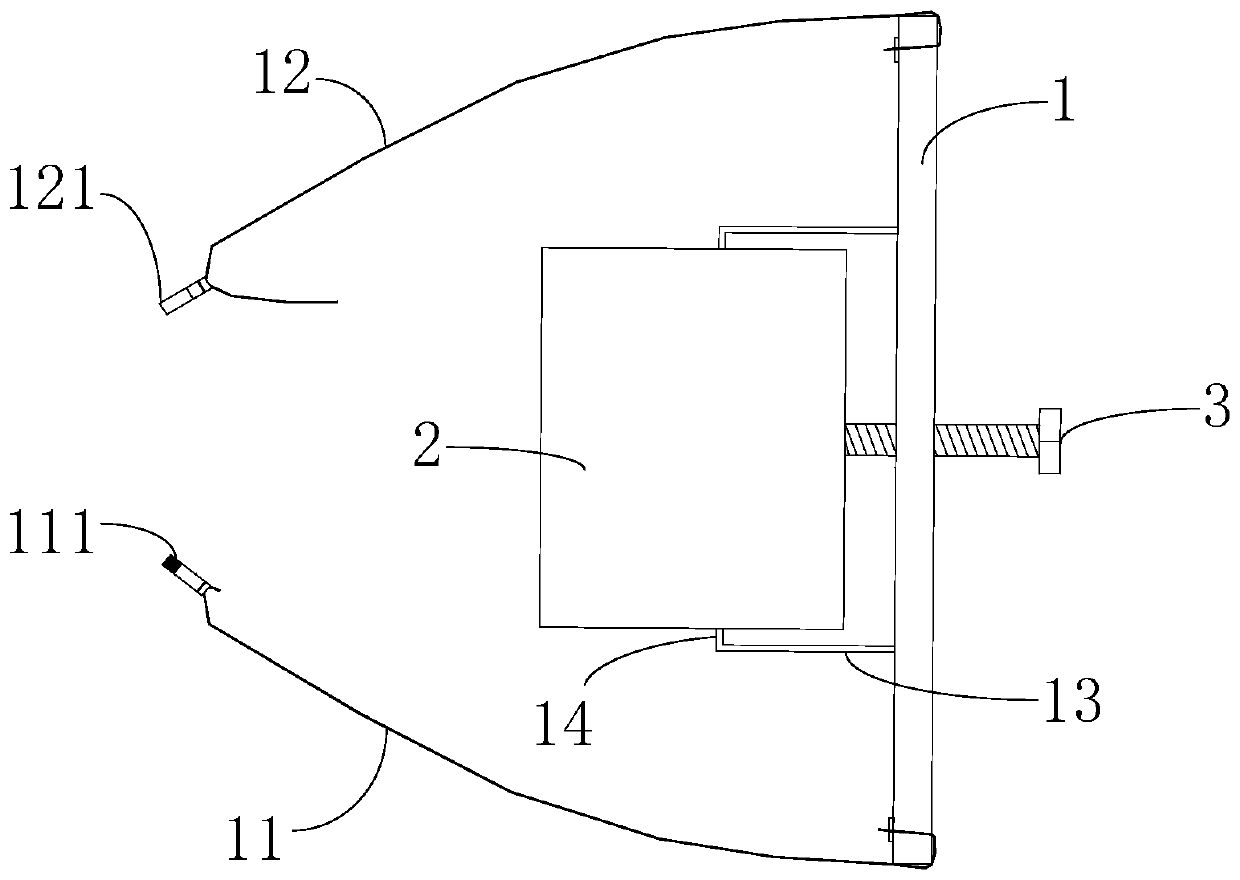

Soft-soil consolidation drainage device

PendingCN109944230AIncrease insertion depthShort installation periodSoil preservationEngineeringHydraulic pump

Owner:TIANJIN RES INST FOR WATER TRANSPORT ENG M O T

Mechanical stirring desulfurization method for desulfurization pretreatment of molten iron

The invention discloses a mechanical agitation desulphurization method for molten iron desulphurization pretreatment. The desulphurization method includes five steps including prior sample taking for temperature measurement, prior slag scrabbling, desulfurizing agent adding and agitation, later slag scrabbling and later sample taking for temperature measurement. In the steps of desulfurizing agent adding and agitation, an agitation device is inserted into a molten iron tank containing molten iron, and is composed of an agitator and a guide plate, and the guide plate and the agitator are both vertically instead into the molten iron; and the vertical distance between the bottom of the guide plate and the top of a blade of the agitator is H. Compared with the rotating speed of a conversional KR method, the rotating speed of the agitator is decreased by 10% to 20%; and the insertion depth of the agitator is increased by 10% to 30% compared with the insertion depth of the conversional KR method.

Owner:武汉钢铁有限公司

Low-profile extension for a catheter assembly

ActiveUS11116936B2Avoid skin irritationReduce riskGuide needlesTube connectorsCATHETER ADAPTERCatheterise

An extension for a catheter assembly may include a distal end and a proximal end. The distal end may include one or more cantilever arms and an insertion feature spaced apart from the cantilever arms. The insertion feature may be configured to insert into a lumen of a catheter adapter to provide a fluid connection between the catheter adapter and the extension. The one or more cantilever arms may be configured to engage in a snap-fit with the catheter adapter. The proximal end of the extension may include a female luer fitting.

Owner:BECTON DICKINSON & CO

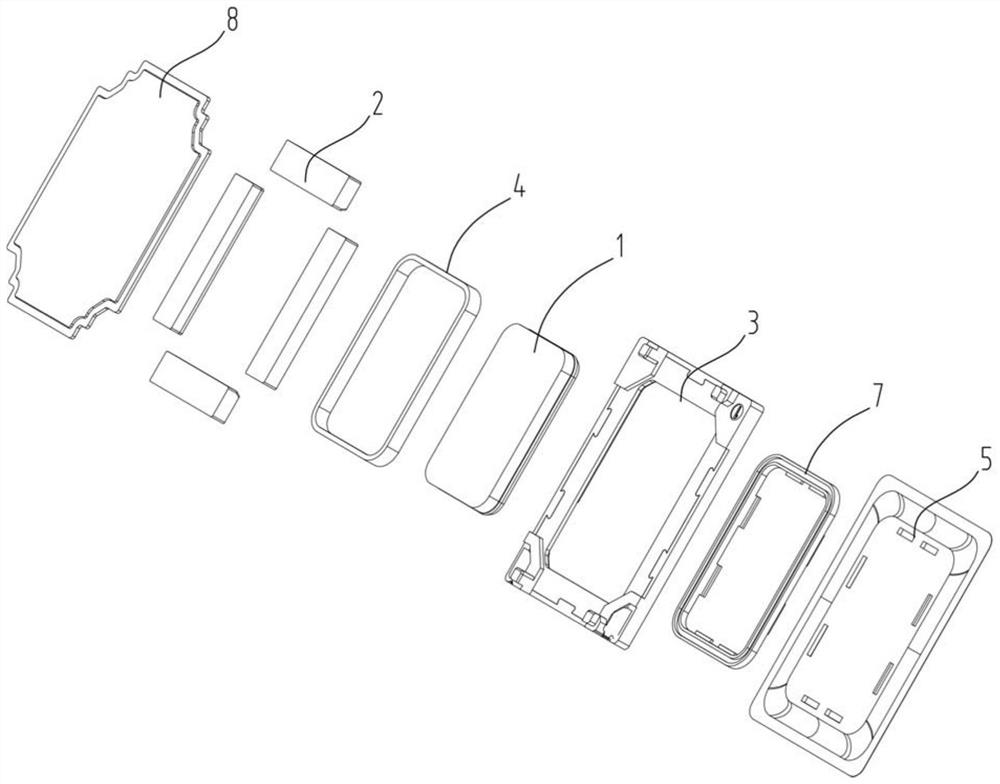

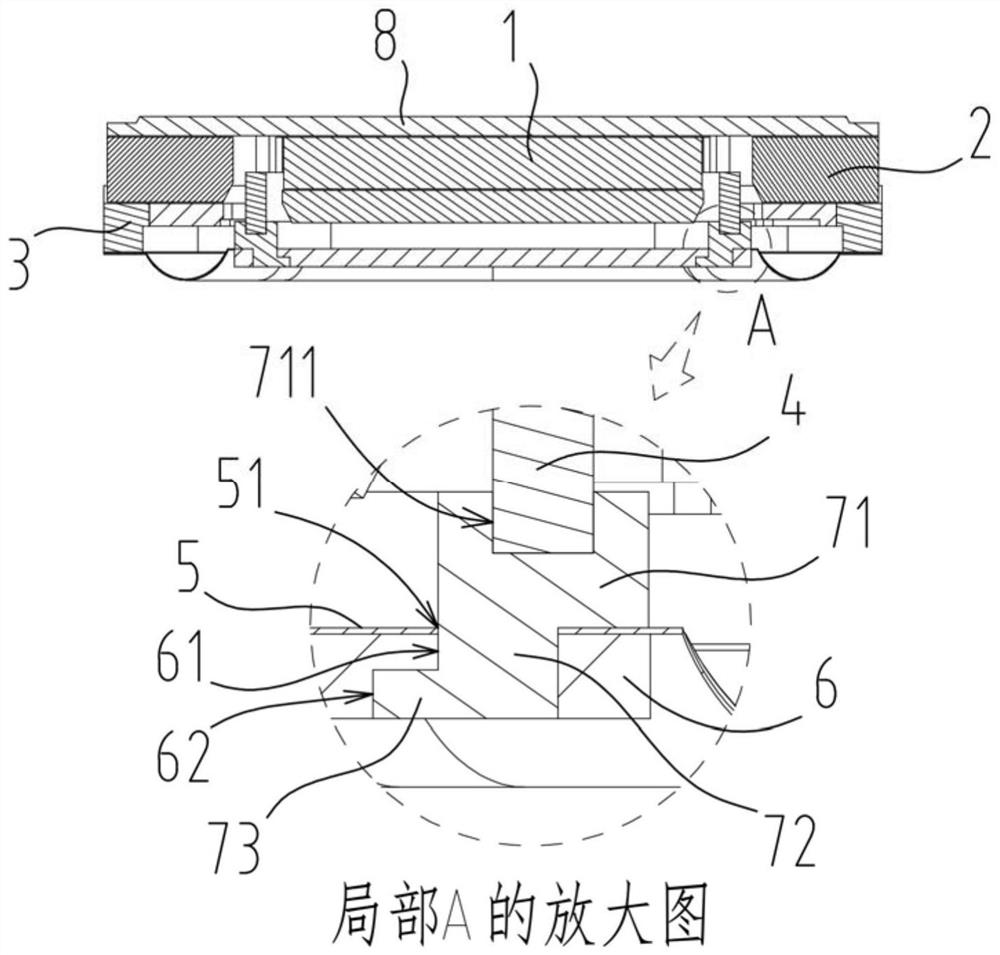

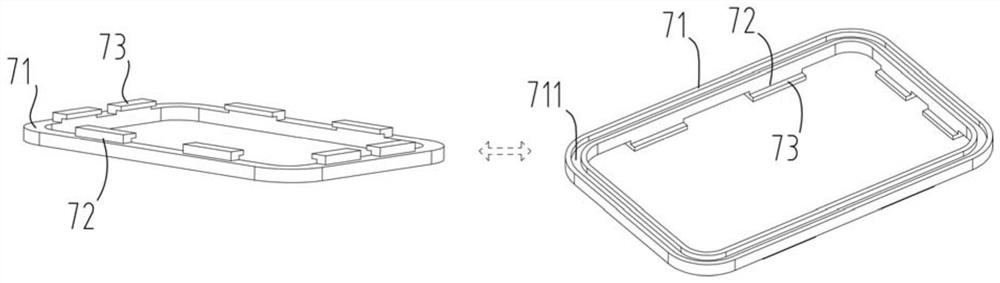

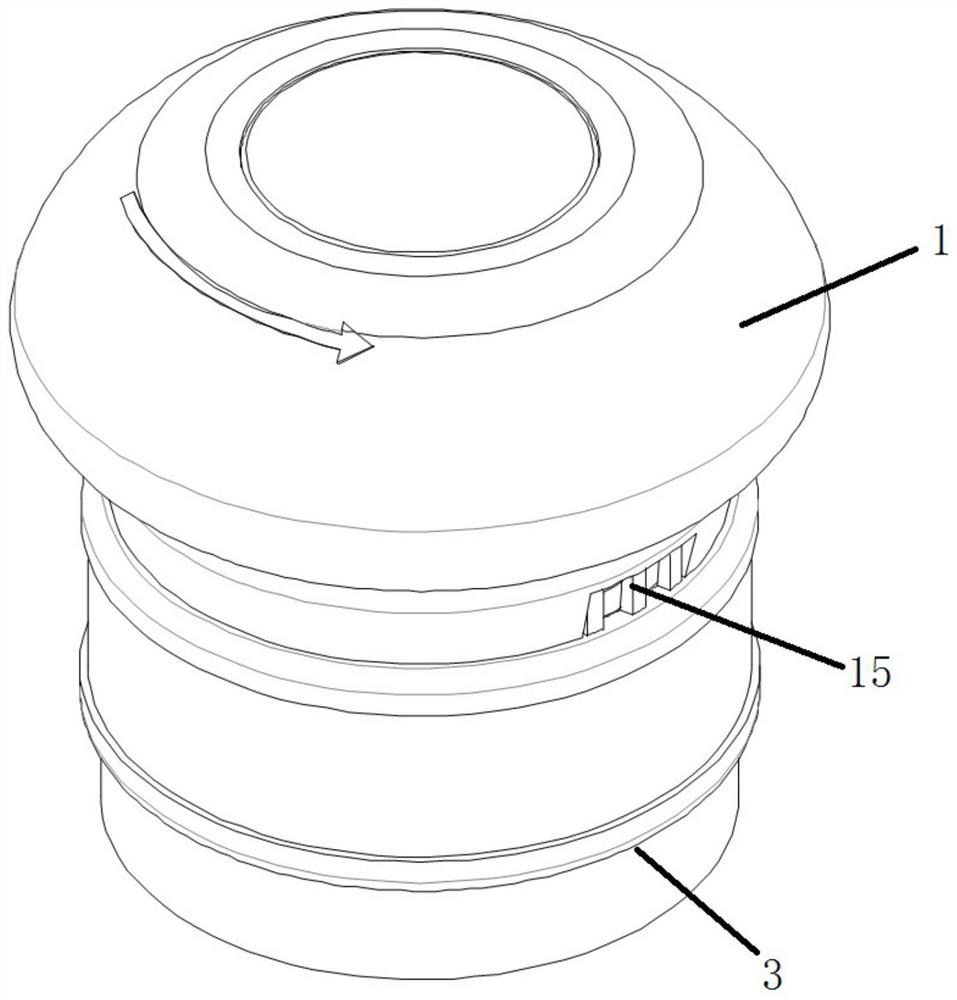

A loudspeaker with a positioning part and its assembly method

ActiveCN111163407BIncrease insertion depthIncrease the effective heightElectrical transducersLoudspeakersEngineeringLoudspeaker

The invention relates to the field of loudspeakers, and provides a loudspeaker with a positioning piece and an assembling method of the loudspeaker. The assembling method of the loudspeaker with the positioning piece comprises the following steps: S1, adhering a dome with a second through hole and a third through hole to the outer side of a vibrating part of a vibrating diaphragm with a first through hole; s2, putting the vibrating diaphragm bonded with the dome into an injection mold, and putting a voice coil into the injection mold; s3, starting an injection molding procedure, premeating injection molding molten liquid into the first through hole, the second through hole and the third through hole, bonding the voice coil, the vibrating diaphragm and the dome into a whole, and forming a solid positioning piece after the injection molding molten liquid is cooled; and S4, bonding a base frame bonded with the magnetic circuit system on the vibrating diaphragm, and completing assembly. According to the loudspeaker, the positioning piece is arranged between the vibrating diaphragm and the voice coil, the voice coil, the vibrating diaphragm and the dome are fixed into a whole by the positioning piece, and the insertion depth of the voice coil in the magnetic field is increased, so that the effective height of the voice coil for cutting the magnetic field is increased, and the electroacoustic performance of the loudspeaker is improved.

Owner:厦门东声电子有限公司

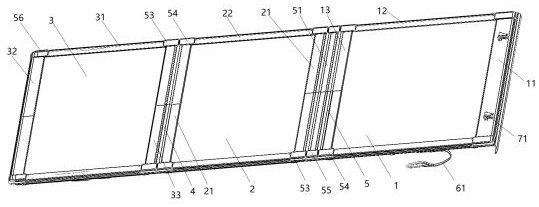

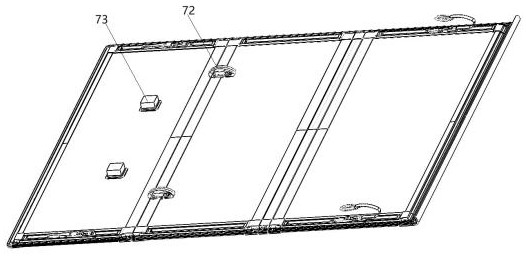

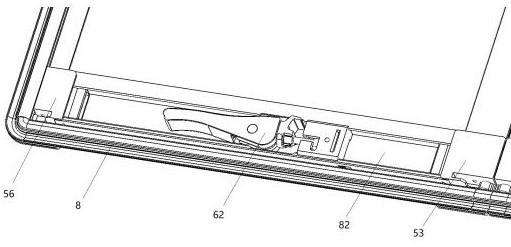

Hard board three-folding vehicle hood

PendingCN112977244AAvoid scratchesIncrease insertion depthLoad coveringStructural engineeringMechanical engineering

The invention discloses a hard board three-fold vehicle hood. Three boards can be freely bent through a single hinge and double hinges. Omnibearing enhanced sealing is achieved through the design of the 6-shaped sealing piece and the plug. The sliding grooves are formed in the side frames, the hood fixing pieces are arranged in the sliding grooves, the hidden design is achieved, the hood fixing pieces are closer to a hopper guardrail, and fixing is more convenient; through combination of the h-shaped frame and the three-layer plate, semi-embedded installation, flat visual thinning design and the like are realized.

Owner:贝昂机电实业(南京)有限公司

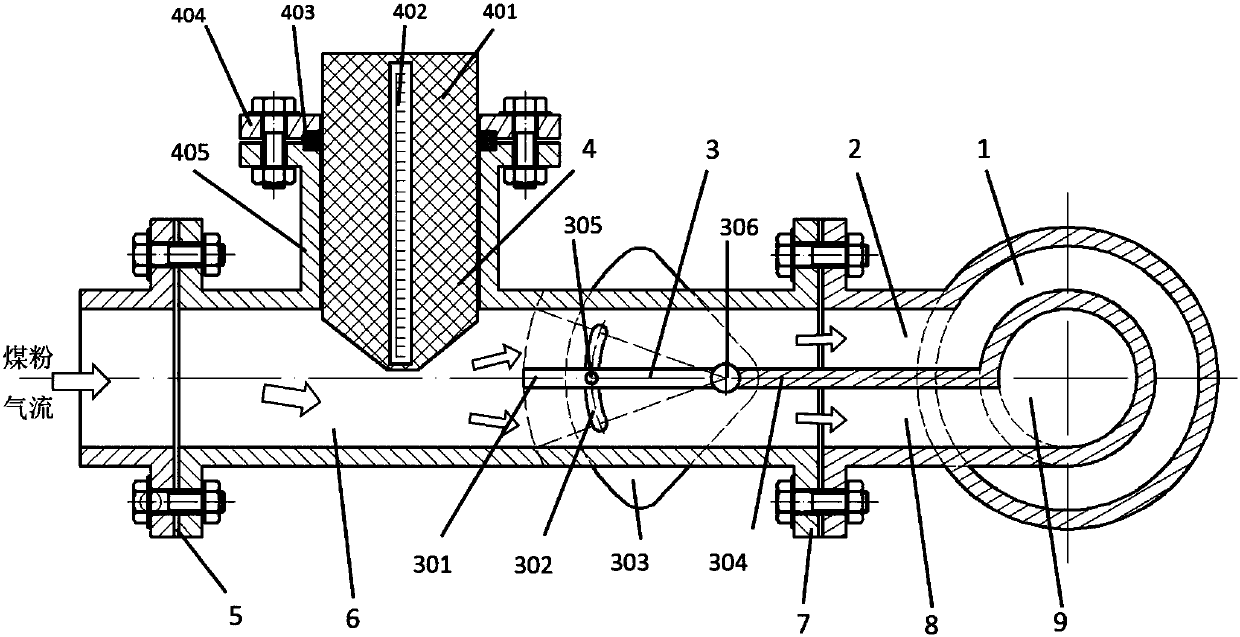

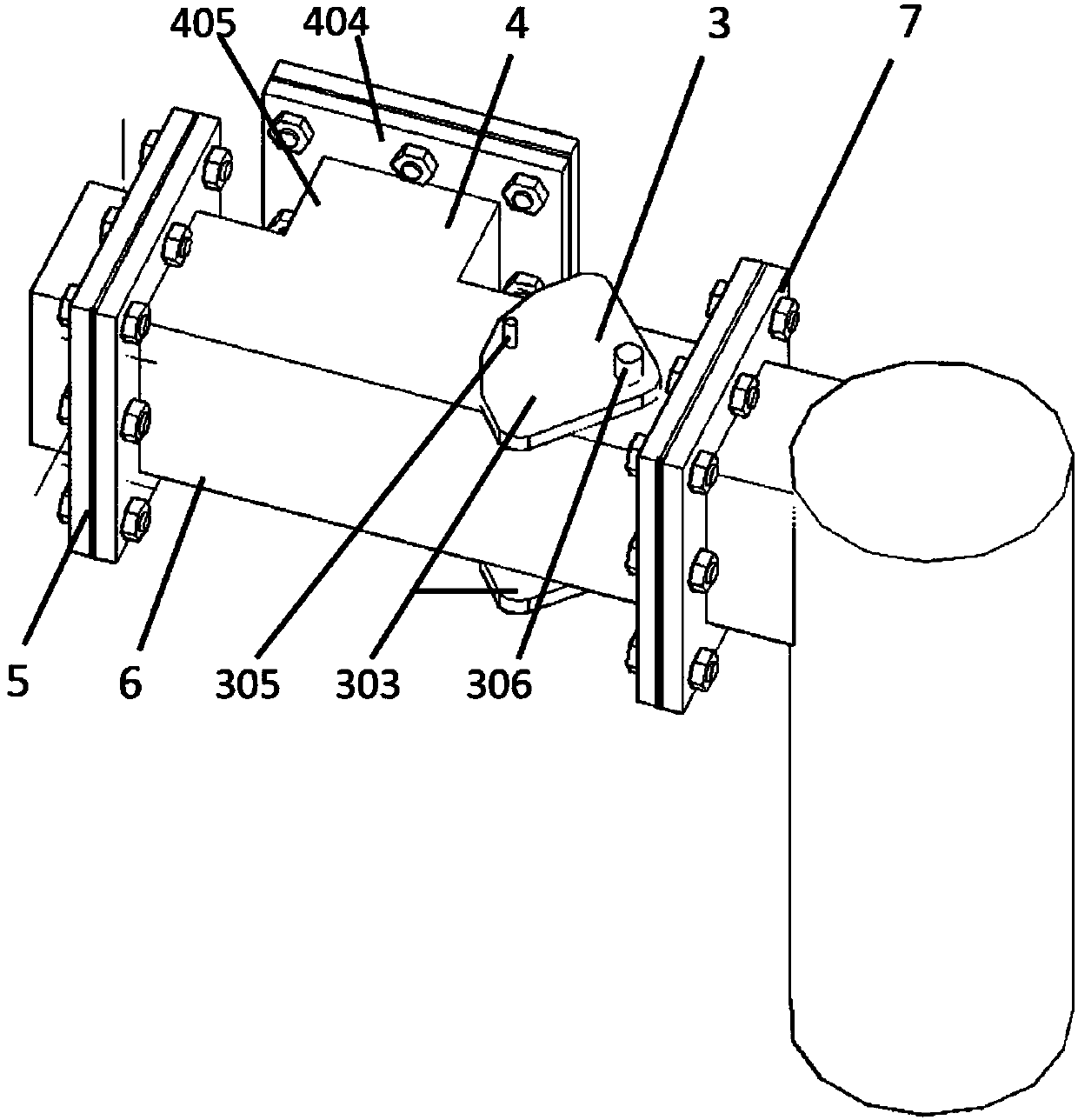

An online adjustable pulverized coal concentrator

ActiveCN105953223BImprove concentrationSupport thick and thin combustion technologyFuel supply regulationPulverulent fuel combustion burnersHigh concentrationInsertion depth

An online adjustable pulverized coal concentrator, including a pulverized coal flow channel, an adjustable stop mechanism, an adjustable pulverized coal flow distribution mechanism, a light / concentrated side pulverized coal channel, and an external / internal primary air; in the adjustable stop mechanism, The wear-resistant block is inserted into the pulverized coal channel through the block channel, the block scale is fixed on the side surface of the wear-resistant block, and the block sealing flange cooperates with the sealing ring to fix and seal the wear-resistant block; in the adjustable pulverized coal flow mechanism, The adjustable splitter plate is connected to the fixed splitter plate through a hinge, and the sealed dial records the position of the adjustable splitter plate; the pulverized coal airflow collides with the wear-resistant block to change the direction of movement, and then separated by the adjustable splitter baffle, it is divided into low / high Concentration Two streams of pulverized coal flow through the light / concentrated side coal pulverized channel and enter the outer / inner primary air channel to form a pulverized coal concentration effect of inner thicker and outer light; adjust the insertion depth of the wear-resistant stopper and the position of the adjustable splitter plate to realize On-line adjustment of pulverized coal concentration effect under variable coal type wide working conditions.

Owner:XI AN JIAOTONG UNIV

Column leveling device and column leveling method

PendingCN110345914AIncrease insertion depthMeet the design requirementsTowersTheodolitesPush and pullEngineering

The invention provides a column leveling device and a column leveling method. The device comprises: a support beam, the support beam being provided with a connecting structure; a leveling wedge, the leveling wedge having relatively wide and narrow sides, the wide side being disposed toward the support beam, the leveling wedge being formed with two opposite chutes, and the chutes being formed fromthe wide side to the narrow side; and a regulating assembly comprising two connecting rods and a distance adjusting rod for pushing and pulling the wide side of the leveling wedge, the connecting rodsbeing connected to the support beam and disposed in the chutes in a sliding manner, and the distance adjusting rod being mounted to the support beam. The device and the method solve the problem of low conventional leveling efficiency of supporting columns in municipal road construction projects.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

A smelting method for producing IF steel with low oxygen level in the whole process

ActiveCN110205436BImprove cleanliness levelIncrease insertion depthManufacturing convertersProcess efficiency improvementSlagCoke

The invention discloses a smelting method for producing IF steel with low oxygen level in the whole process, and belongs to the technical field of iron and steel smelting. The steps of the present invention are as follows: step 1: slag dumping at the end of converter steel smelting, leaving 10-15 tons of slag in the converter, adding 50-100 kg of coke powder to remove oxygen in the slag, and then performing slag splashing to protect the furnace; step 2: charging the converter ;Step 3: Converter main blowing; Step 4: After the converter main blowing, measure the molten steel temperature and carbon content through the sub-lance, and control the auxiliary blowing oxygen amount according to the measured value; Step 5: After the auxiliary blowing, before tapping Bottom blowing for 30 seconds; Step 6: Converter tapping; Step 7: Molten steel enters the RH process; Step 8: After the ladle is lifted, turn on the vacuum pump to vacuum and decarburize. The invention can reduce the degree of peroxidation of molten steel in converter tapping, reduce the oxidizability of ladle top slag, and reduce deoxidized inclusions Al 2 o 3 The amount of production is increased, the cleanliness level of molten steel is improved, and the cost is reduced, which has significant economic benefits.

Owner:MAANSHAN IRON & STEEL CO LTD

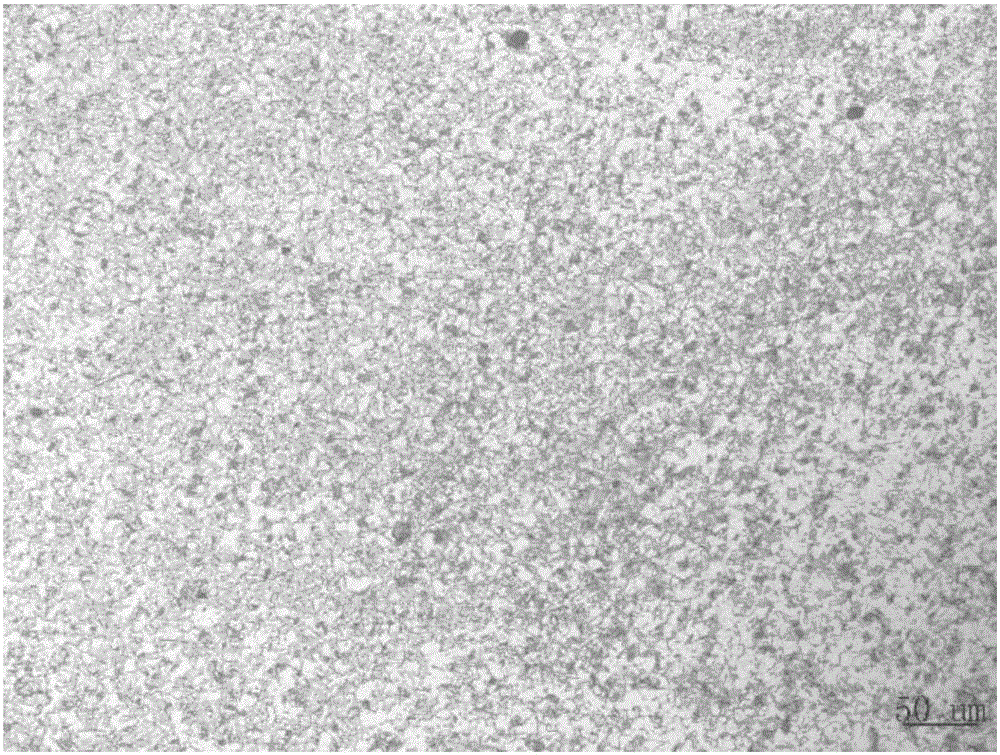

Cement clinker magnesium granule cored wire, application and production technology of steel for large heat input welding

InactiveCN106011375AIncrease feed speedIncrease insertion depthManufacturing convertersCarbon steelAbsorption rate

The invention discloses a cement clinker-magnesium particle cored wire and its application and production process of steel for large heat input welding. The cored wire includes an outer layer and a cored core; the outer layer is low-carbon steel with a thickness of 0.5-1.0 mm; The core is slow-release passivated magnesium particles, the core includes slow-release agent and passivated magnesium particles, the slow-release agent is cement clinker, the slow-release agent accounts for 5-90% of the content of the core, and the passivated magnesium particles account for the content of the core 10-95% of that. Application of the cored wire of the present invention in preparing steel for high heat input welding. The invention feeds the slow-release passivated magnesium grain cored wire with cement clinker as the slow-release agent to the molten steel, the absorption rate of Mg is stable, the effect and utilization rate of Mg are high, the inclusions are dispersed and abundant, and the inclusions containing Mg up to 80% or more. Adopting the present invention has the advantages of simple control, low production cost, and industrialized large-scale production of steel for welding with large heat input.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Prying-off type bottle cap and prying-off type bottle

InactiveCN112478432AImprove anti-counterfeiting performanceSolve the technical problem of poor anti-counterfeiting effectClosure using stoppersClosures to prevent refillingEngineeringStructural engineering

The invention discloses a prying-off type bottle cap and a prying-off type bottle. The bottle cap comprises an outer cap, an inner sleeve, an outer sleeve, an inner cap assembly and an inner plug assembly, wherein the inner sleeve is detachably connected with the outer cap, the outer cap is sleeved at the top end of the inner cap, and a prying hole is formed in the side wall of the top end of theinner sleeve; the inner cap assembly comprises an upper cap body, a lower connecting sleeve and a limiting structure; the upper cap body and the lower connecting sleeve are fixedly connected and are arranged in the outer cap together; the lower connecting sleeve is inserted into the inner sleeve and is coaxial with the inner sleeve; the limiting structure is fixed on the bottom surface of the upper cap body and is positioned in the lower connecting sleeve; a plurality of fixing structures fixed to the bottle opening are arranged on the inner wall of the lower connecting sleeve; the inner plugassembly comprises an upper inner plug and a lower inner plug; and the top end of the upper inner plug is clamped in the limiting structure, and the lower inner plug is plugged in a bottle neck and forms a sealing structure of the bottle neck with the upper inner plug. The whole bottle is damaged in the prying process, lawbreakers cannot use the bottle again, fake wine is avoided from the source,and therefore the anti-counterfeiting effect of the bottle cap is improved.

Owner:桐城市申达包装有限公司

Holder for a beverage container

InactiveUS20080073227A1Increase insertion depthVehicle arrangementsWash-standsMobile vehicleMotorized vehicle

A holder for two beverage containers is provided for installation in a motor vehicle. The holder has a pull-out element having insertion openings for the beverage containers. The pull-out element is guided not only displaceably but also is mounted pivotally, so that, as desired, one insertion opening instead of both insertion openings is accessible and available for use.

Owner:FISCHER AUTOMOTIVE SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com