Spile device of spile machine

The technology of a working device and a plug-in machine, which is applied in basic structure engineering, soil protection, soil drainage, etc., can solve the problems of low moving speed, poor flexibility, and increase the amount of engineering construction, and achieves low requirements for construction sites and avoids The truss is shaken and the adjustment effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

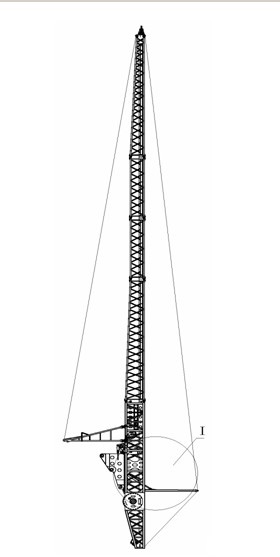

[0026] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

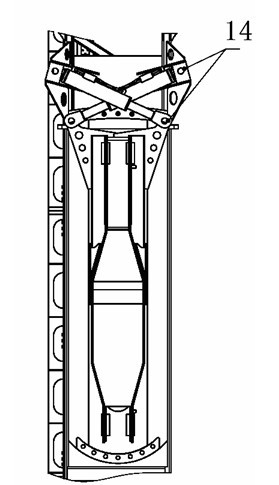

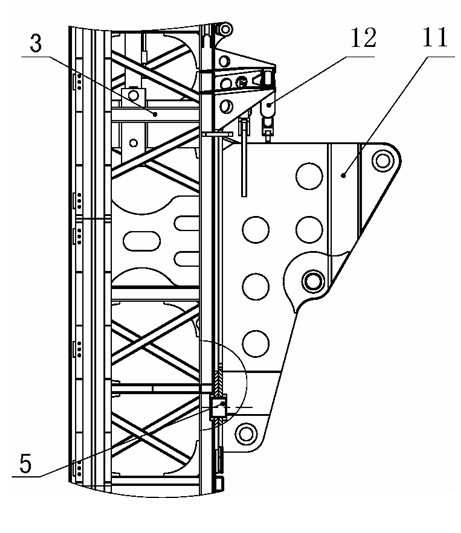

[0027] A plugging machine slotting working device, the transmission operating mechanism transmits power to the lifting mechanism through hydraulic control, the lifting mechanism drives the working device 3 to rotate, and the working device 3 is equipped with a steel casing 43 driven by hoisting. A drainage board 42 is arranged inside the steel casing 43; a left and right vertical adjustment mechanism, a retractable plate wire frame, and a detachable support device are respectively arranged on the working device 3 .

[0028] Such as figure 1 , figure 2 As shown, the left and right vertical adjustment mechanism of the present invention is to connect the first swing frame 11 on the working device 3, one end of the first swing frame 11 is connected to the oil cylinder 12 through the oil cylinder pin 14, and the other end of the oil cylinder 12 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com