Patents

Literature

53results about How to "Low construction site requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for installing blast furnace single-tube downcomer

InactiveCN102851421AEasy to controlGuaranteed installation qualityBlast furnace componentsBlast furnace detailsHigh energyEngineering

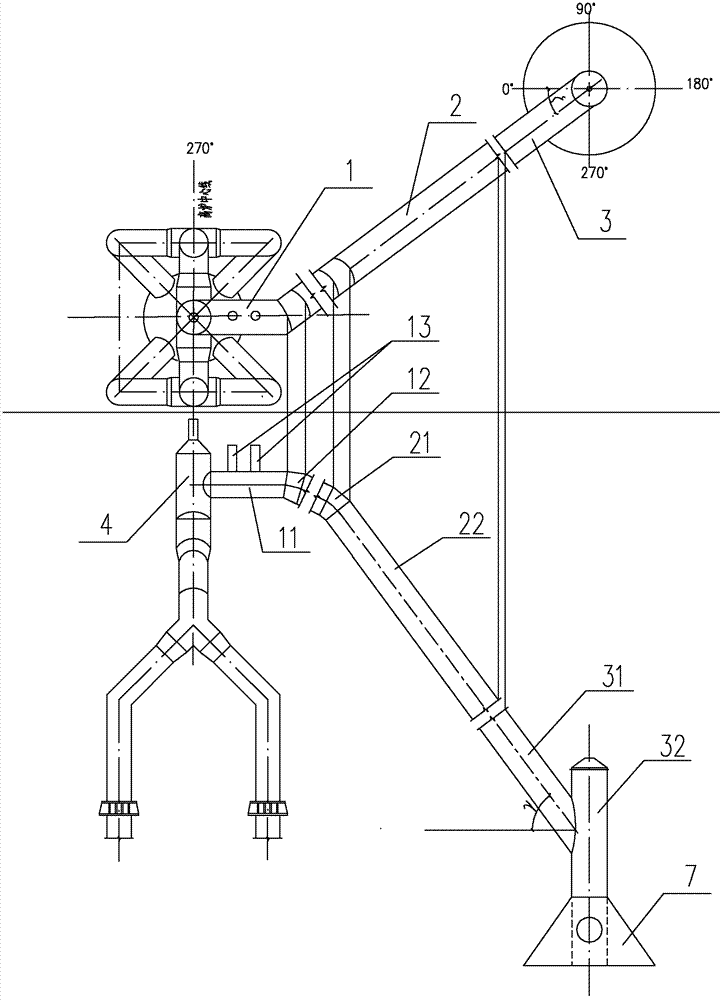

The invention discloses a method for installing a blast furnace single-tube downcomer, characterized by using single machine and double shackles to lift each lifting unit. The method comprises the following steps: 1, conducting lifting preparation: 1) dividing lifting units; 2) determining the barycenter of each lifting unit; 3) determining the lifting point and shackle position of each lifting unit and completing the welding of the shackles; 4) determining the position lines of a riser tube and an upper shaking head, and determining the position lines of a gravity deduster shell and a lower T-joint; and 5) building a joint temporary operation platform the inner side and the outer side of the joint of each lifting unit; and 2, conducting lifting operation. According to the invention, by using single machine to lift, the amount of large-scale machines is reduced, the limitation of narrow and small construction place can be overcome, the construction cost and energy consumption can be reduced, the construction safety is raised, the target of realizing safety, high quality, high efficiency, energy saving, and low carbon is realized, and the situation of high energy consumption, high cost and high pollution existing in traditional double-machine lifting is thoroughly changed.

Owner:TIANJIN 20 CONSTR

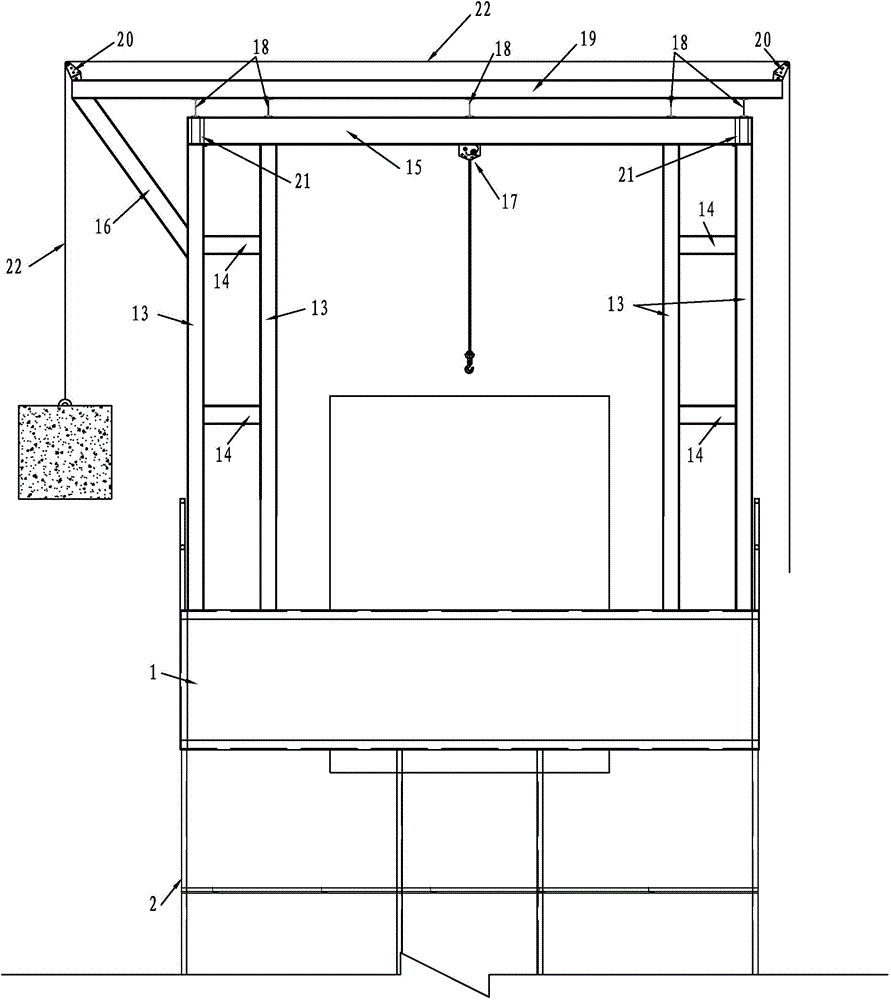

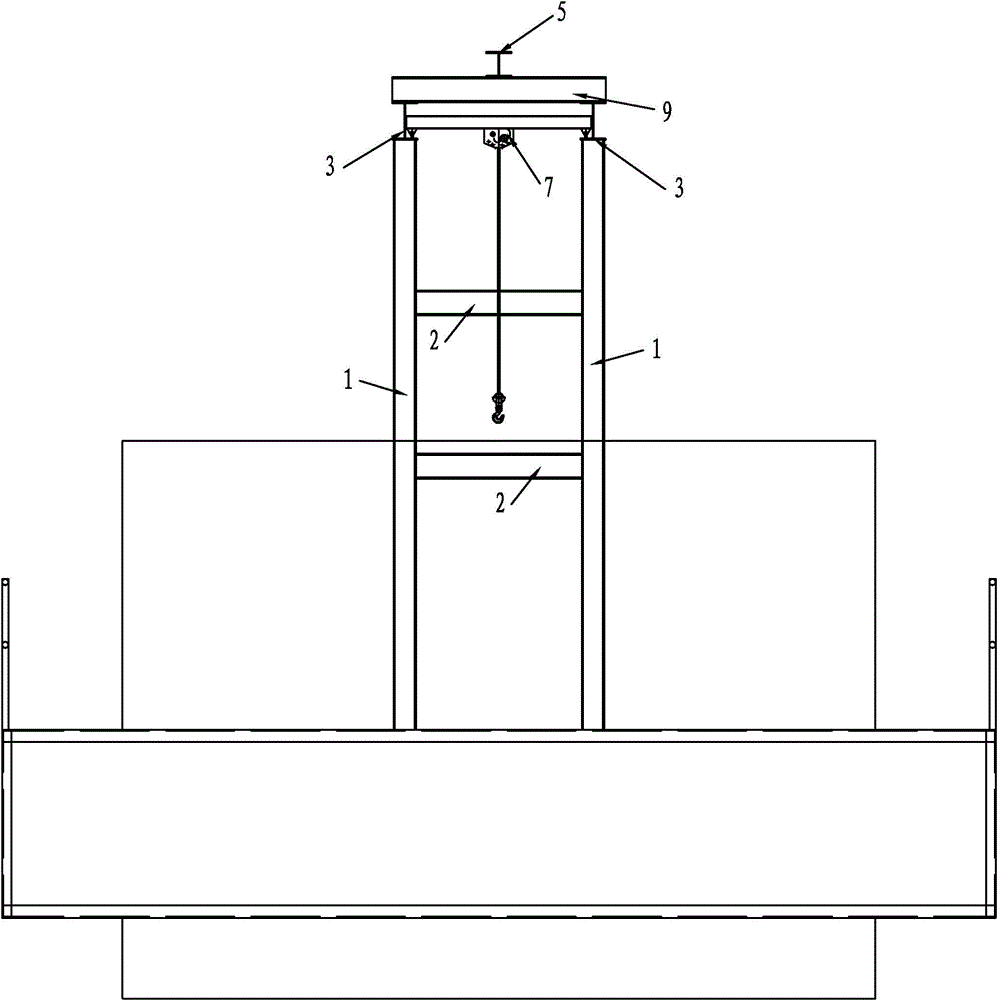

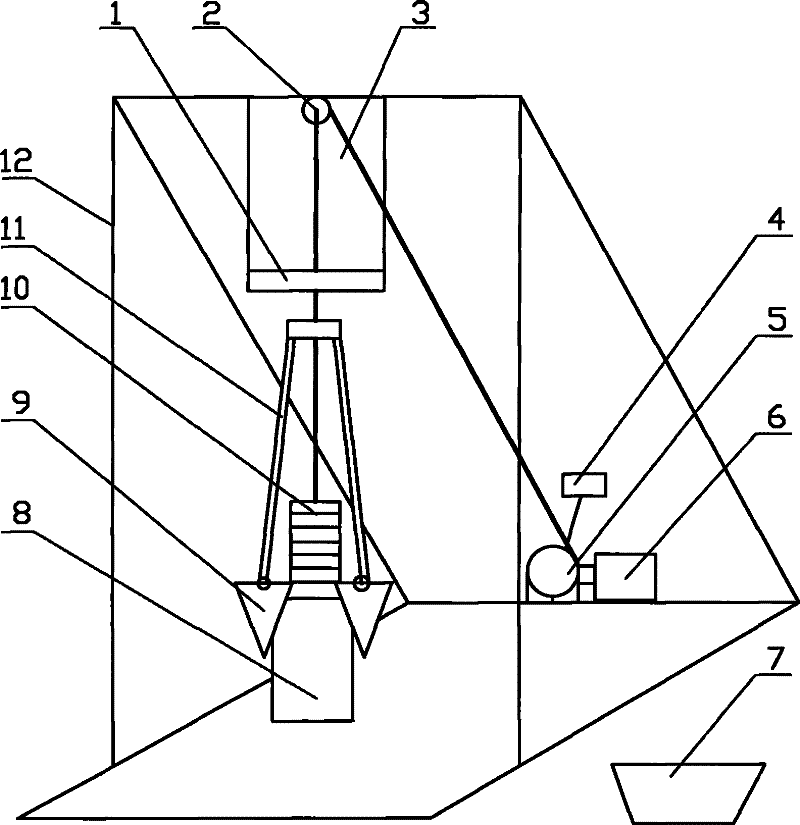

Self-lifting sliding and turnover construction system and construction method

ActiveCN104695337AReduce manual labor intensityReduce the risk of manual overmoldingBridge erection/assemblyTruckRebar

The invention discloses a self-lifting sliding and turnover construction system and a construction method. The system comprises a framework type combination crown block hanging bracket device and a semi-automatic turnover device. The construction method comprises steps as follows: construction of reinforcing steel bars of a pier body, large-area formwork bracket splicing, sliding formwork bracket splicing, self-lifting hanging bracket splicing, concrete pouring, sliding formwork bracket sliding rising, large-area formwork turnover and next stage of reinforcing steel bar construction. A self-lifting technique can be adopted, auxiliary construction by mechanical equipment such as a tower crane, a truck crane and the like can be omitted, high-pier construction is realized with the self-lifting technique, and the method guarantees the construction speed of a sliding formwork and the appearance quality of a turnover formwork without relying on external machines.

Owner:CCCC FIRST HIGHWAY XIAMEN ENG +1

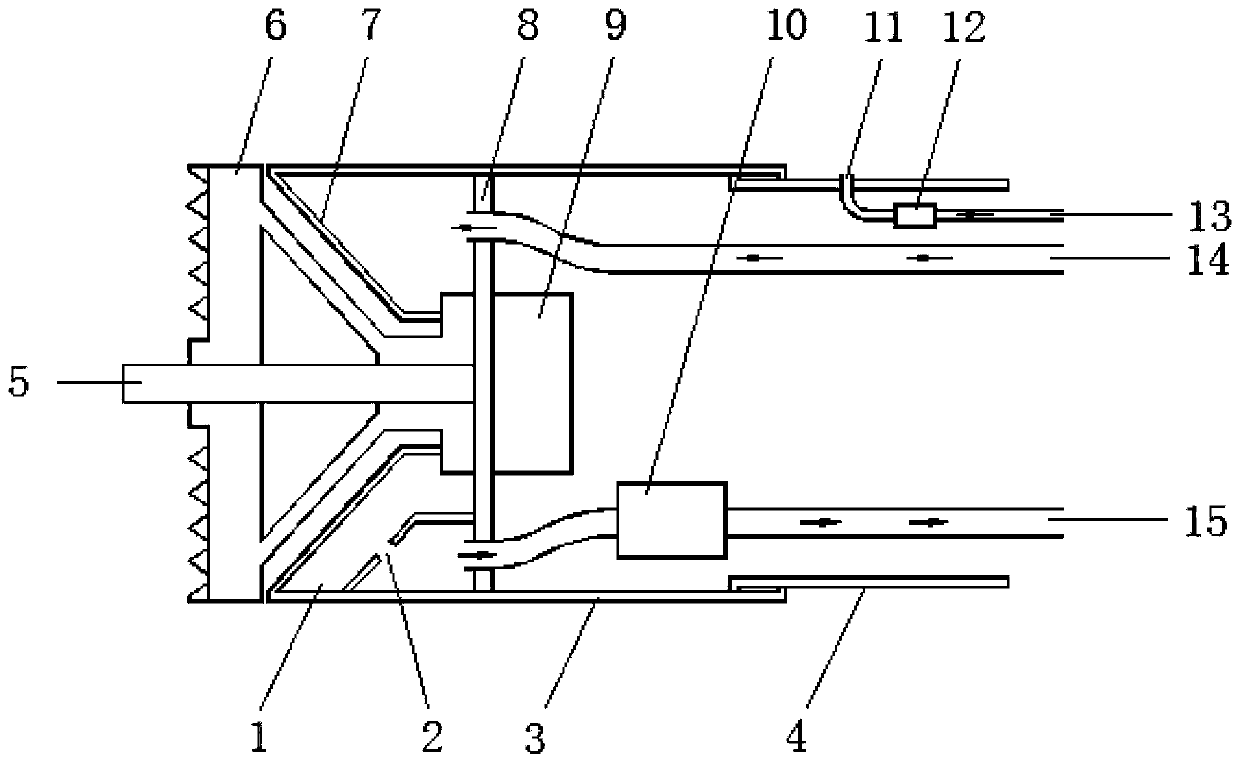

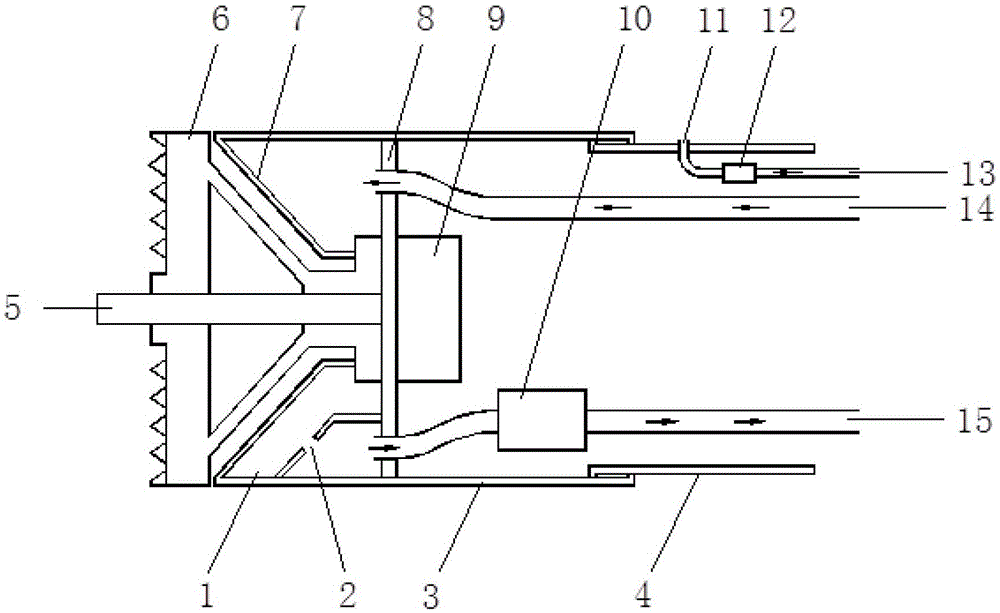

Horizontal directional drilling crossing construction method and horizontal directional drilling crossing drilling device

ActiveCN104213833AReduced displacement requirementsReduce dosageDirectional drillingFlushingWater dischargeDirectional drilling

The invention discloses a horizontal directional drilling crossing construction method and a horizontal directional drilling crossing drilling device, wherein the method and the device are designed for improving stability of the hole wall of the drilled hole and reducing the crossing construction risk. The front portion of the cabin wall in a drilling device body is connected with a main shaft, a conical breaking mechanism, a cutterhead and a horizontal directional drilling machine traction drill stem, and the rear portion of the cabin wall is connected with a cutterhead driving mechanism, a water supply pipe and a water discharge pipe. The rear end of the body is connected with and provided with an injected hole and internally provided with a dragging pipe short section of an injection pipe. The rear end of the dragging pipe short section is connected with a crossing pipeline. The method and the device are used for horizontal directional drilling crossing of pipelines with the diameter of 400 mm or larger, and can expand the drilled hole to the size of a finished hole at a time, and directly drag the pipeline back into the drilled hole so that pavement can be completed; meanwhile, a gap between the inner wall of the drilled hole and the crossing pipeline is filled, and drilling chips are discharged to the soil outlet end. By means of the method and the device, stability of the hole wall of the drilled hole can be improved, the construction risk caused by hole collapsing is reduced, construction cost is reduced, the environment is protected, the large-diameter and long-distance pipeline crossing under the loose stratum conditions and the hard rock stratum conditions can be achieved, and the application range of the horizontal directional drilling method is enlarged.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

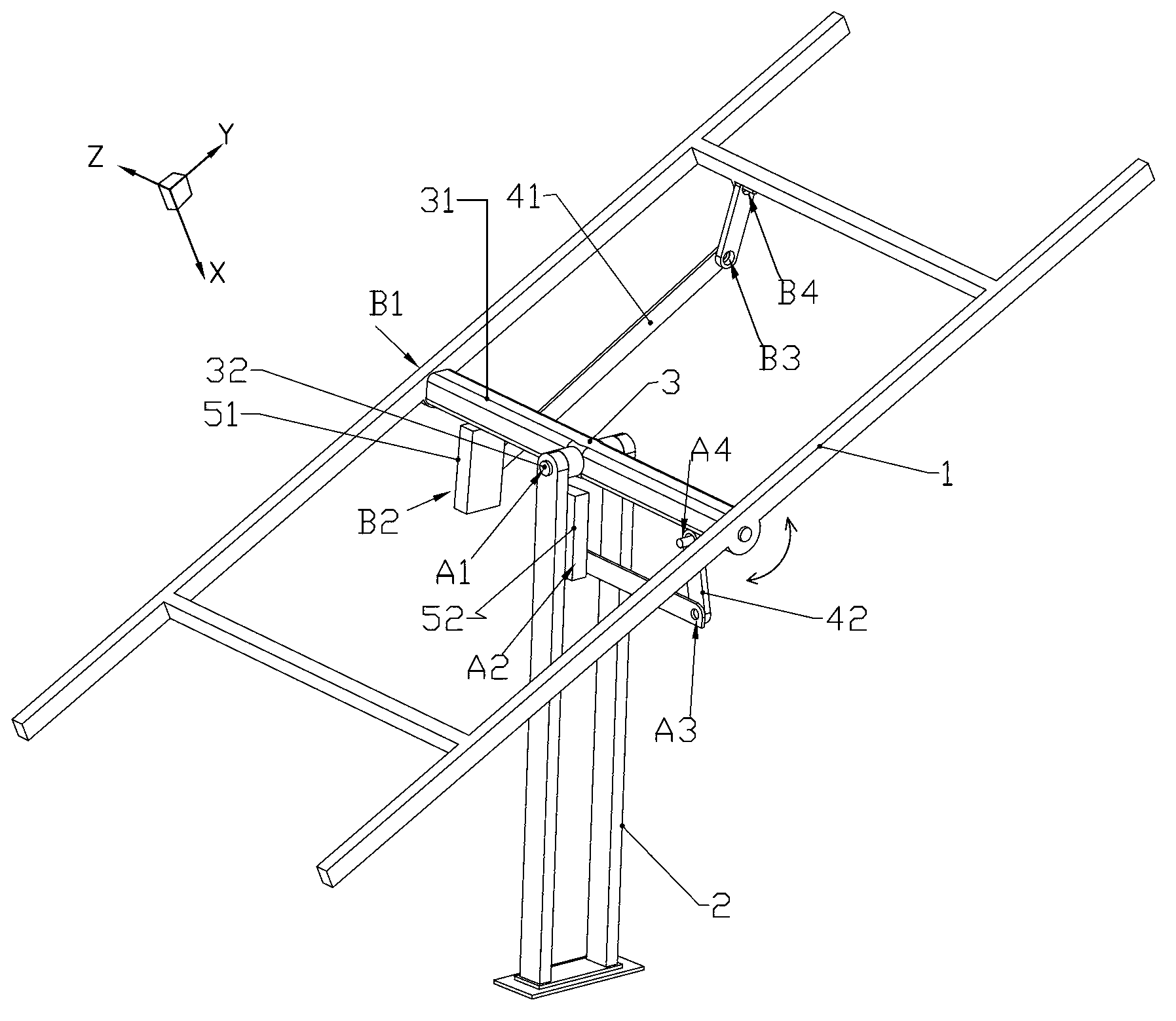

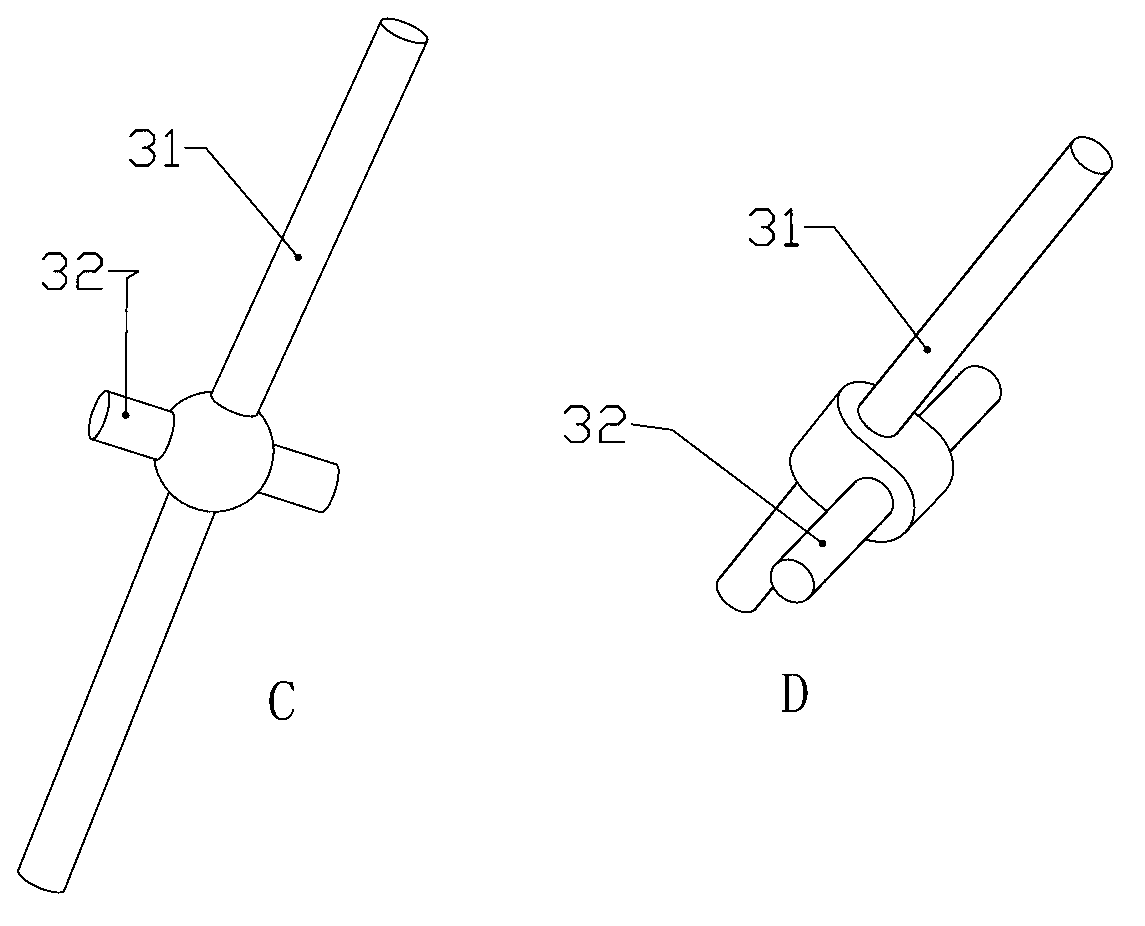

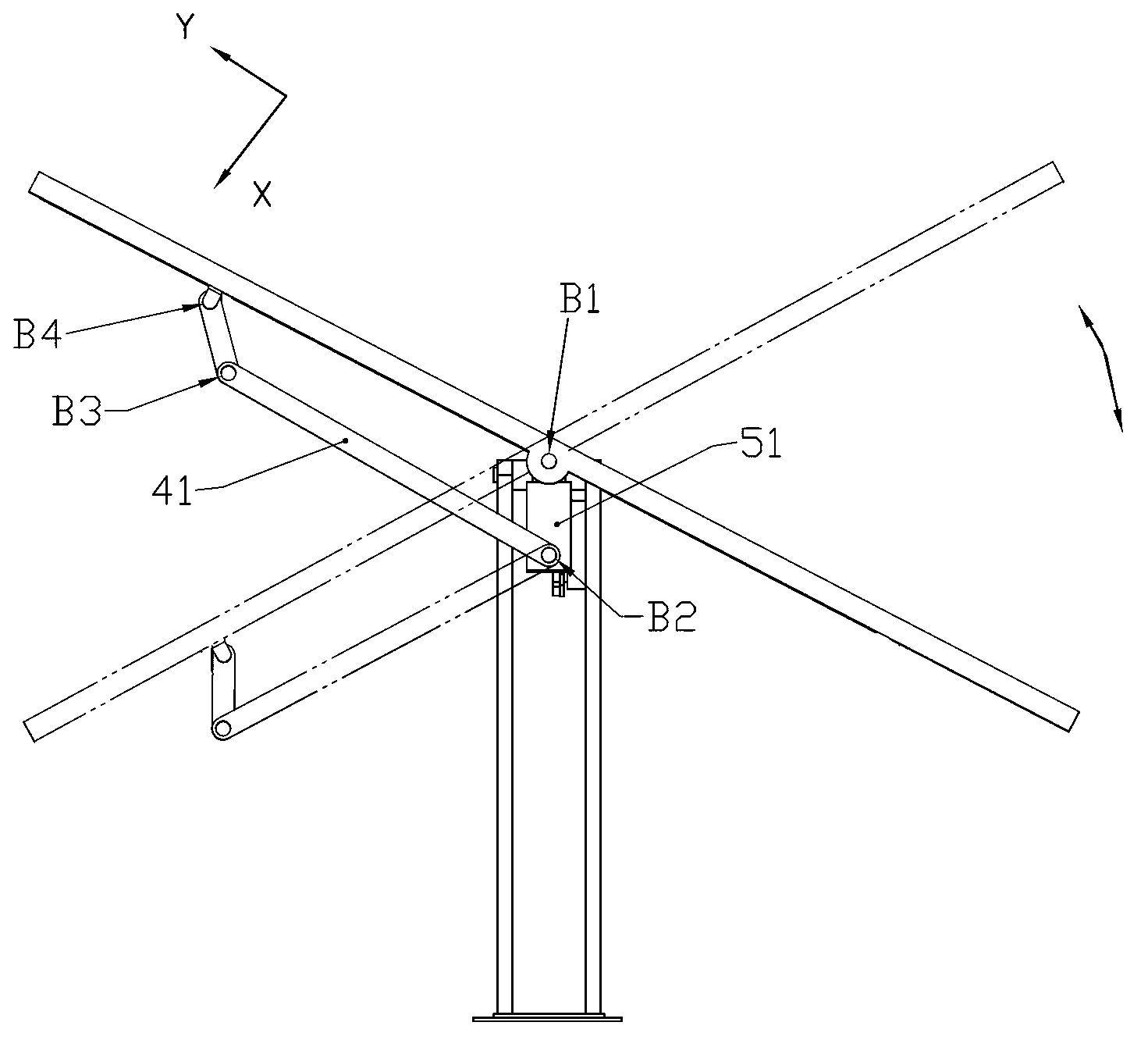

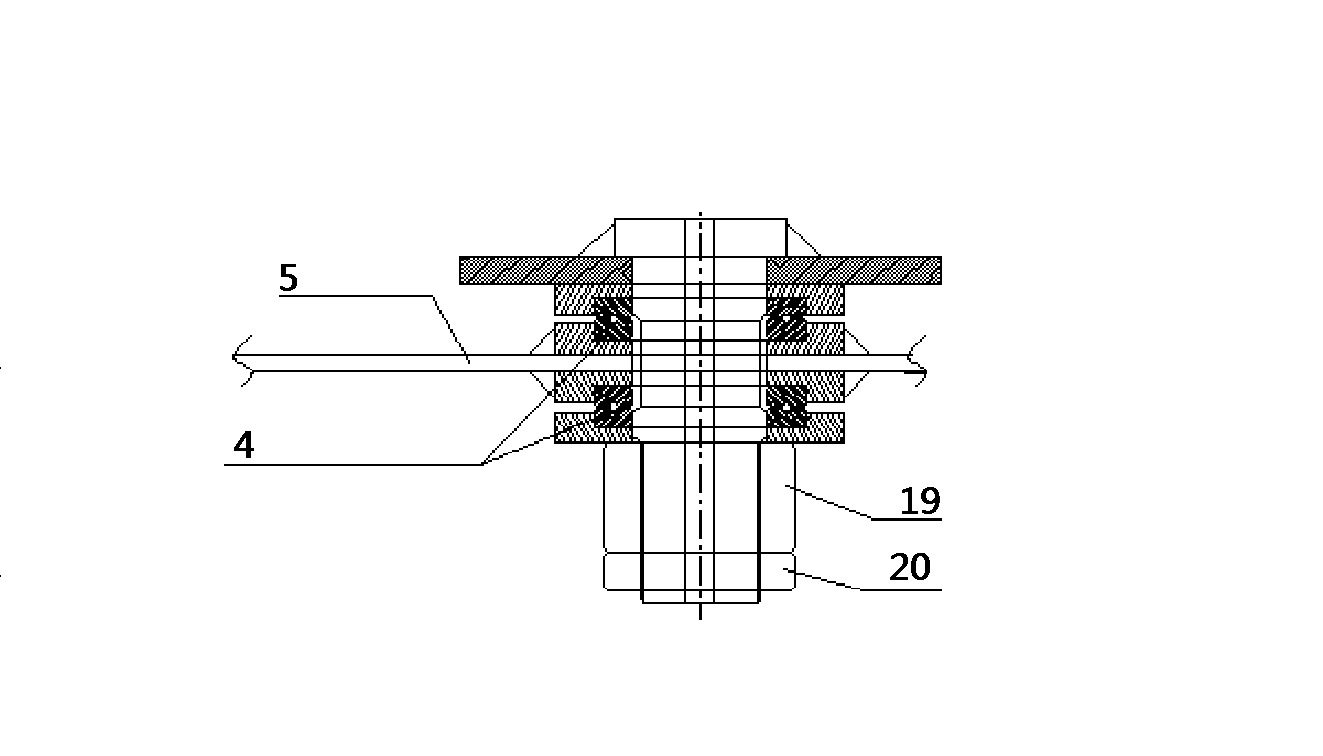

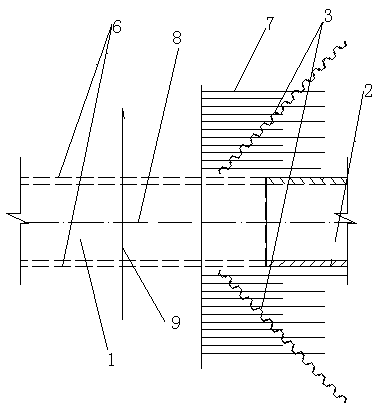

Double-shaft tracking support

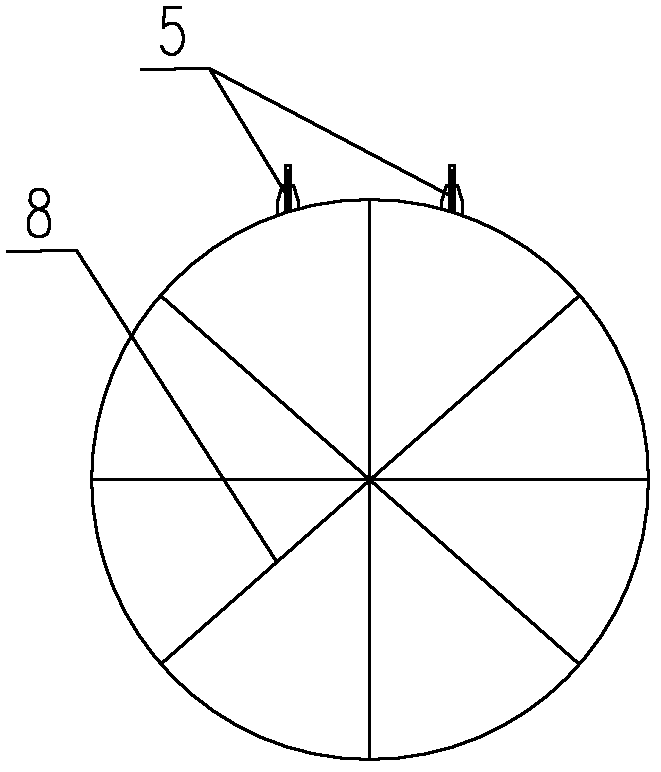

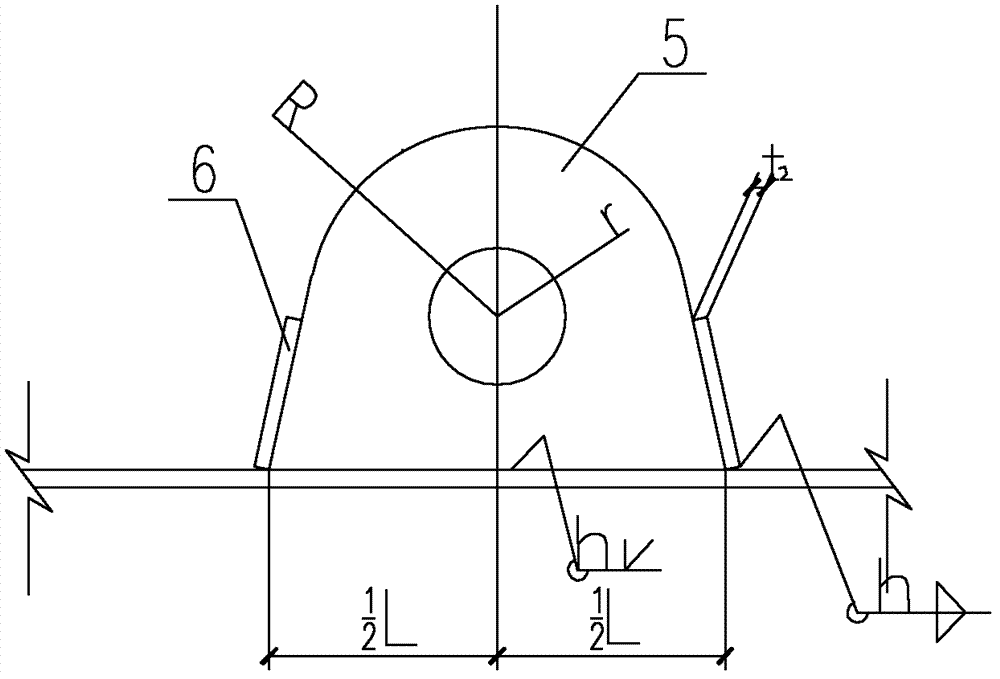

ActiveCN103324204AReduce the burden onReal-time changePhotovoltaic supportsSolar heating energyTurn angleElevation angle

The invention discloses a double-shaft tracking support. The double-shaft tracking support comprises a bracket, a stand column, a center pivotal shaft, a turn angle adjusting device and an elevation angle adjusting device which are all used for bearing a solar component. The bracket is connected with the stand column through the center pivotal shaft, a turn angle pivotal shaft of the center pivotal shaft is hinged to the bracket so that the bracket can rotate in the turn angle direction, and an elevation angle pivotal shaft of the center pivotal shaft is hinged to the stand column so that the bracket can rotate in the elevation angle direction. The turn angle adjusting device comprises a first transmission part and a first driving part, wherein the first transmission part is connected to the bracket, and the first driving part is mounted on the turn angle pivotal shaft and is matched with the first transmission part. The elevation angle adjusting device comprises a second transmission part and a second driving part, wherein the second transmission part is connected to the elevation angle pivotal shaft or the bracket, and the second driving part is mounted on the stand column and is matched with the second transmission part. The double-shaft tracking support has the advantages of being firm in structure, low in cost, low in power consumption, stable in operation, convenient to install, transport and maintain daily and the like.

Owner:刘建中

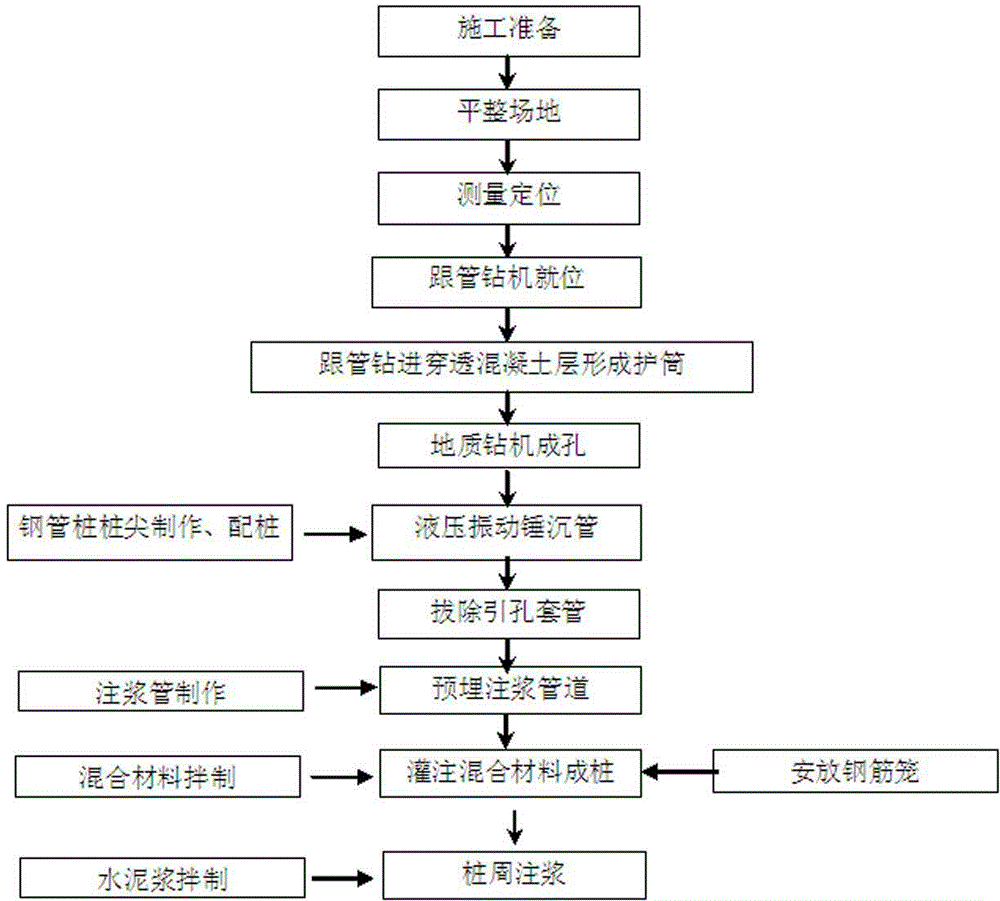

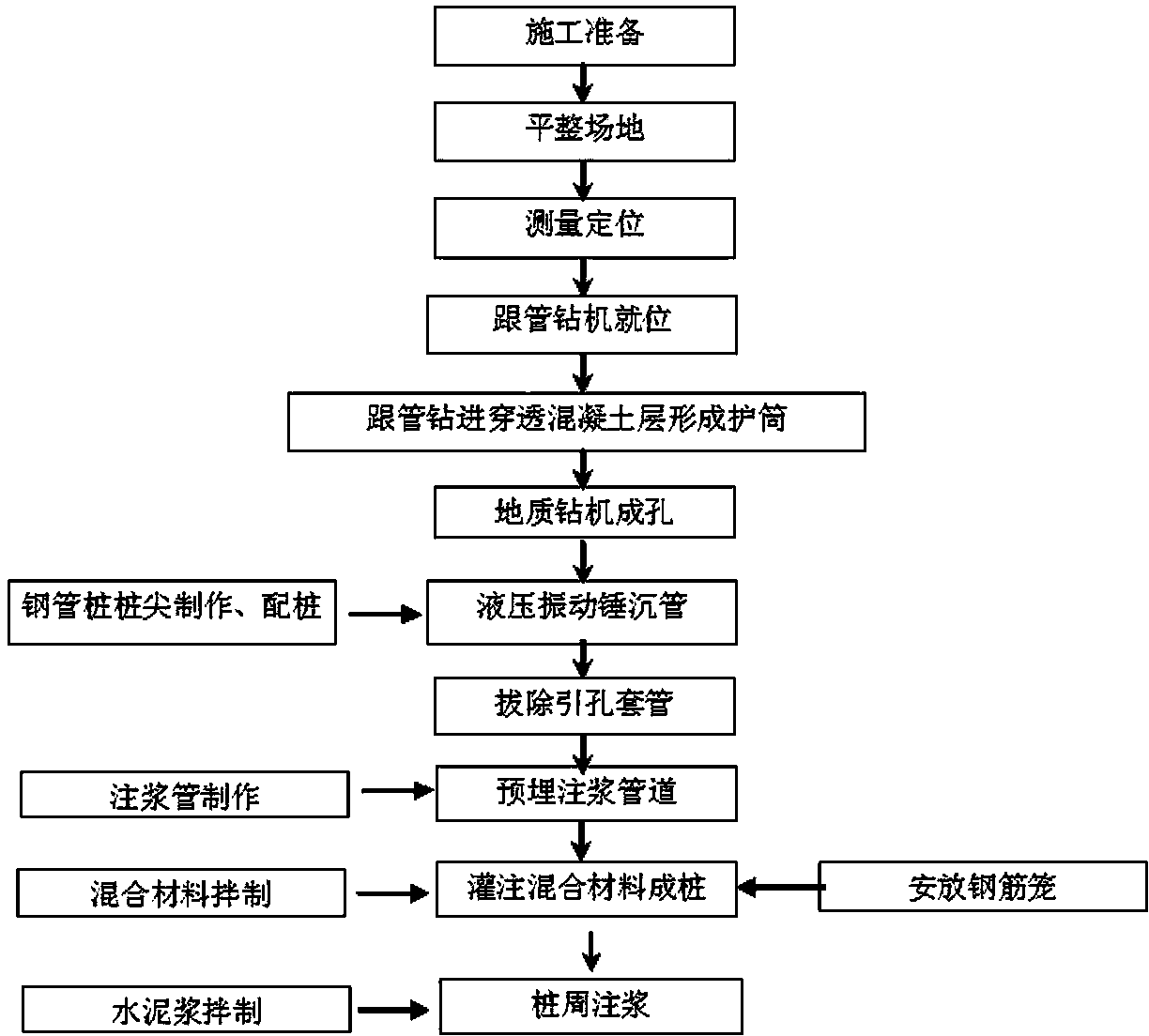

Construction method for miniature steel pipe concrete pile to penetrate through roadbed layer for reinforcing soft foundation construction

ActiveCN102943466AThe construction method is simple to operateEasy to masterBorehole drivesBulkheads/pilesMixed materialsHigh intensity

The invention discloses a construction method for a miniature steel pipe concrete pile to penetrate through a roadbed layer for reinforcing the soft foundation construction and belongs to the technical field of engineering construction. The construction method solves the problems that the traditional soft foundation treatment mode cannot meet the requirements of the engineering construction on the foundation intensity, and the construction cannot be carried out. The construction method comprises the following steps of carrying out pipe following operation by a down-hole hammer eccentric drilling rig; forming holes by a geological drilling rig; sinking pipes by a hydraulic vibration hammer; pulling out tube protecting sleeves; pre-burying grouting pipelines; placing a steel reinforcement cage; filling high-intensity mixed materials for forming piles; and grouting around the piles for forming a compound foundation. The construction method has the advantages that the construction is convenient, the equipment is small and flexible, the construction field requirements are low, safety and reliability are realized, the penetrating capability is high, and the construction period is short.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

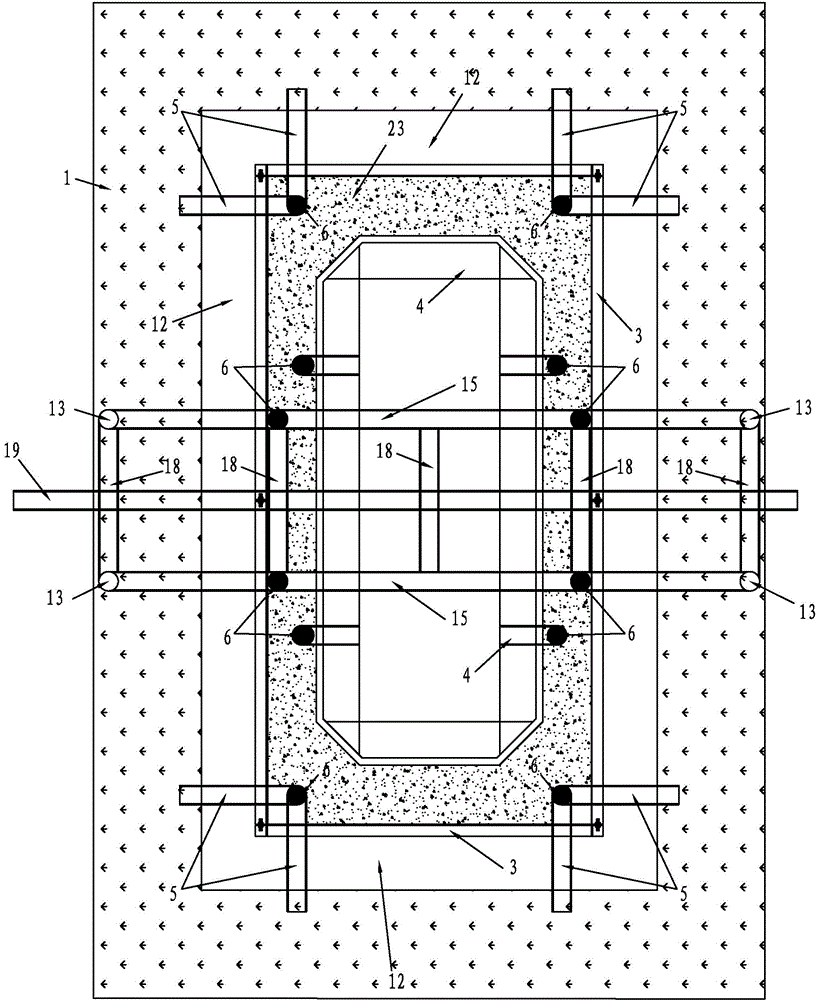

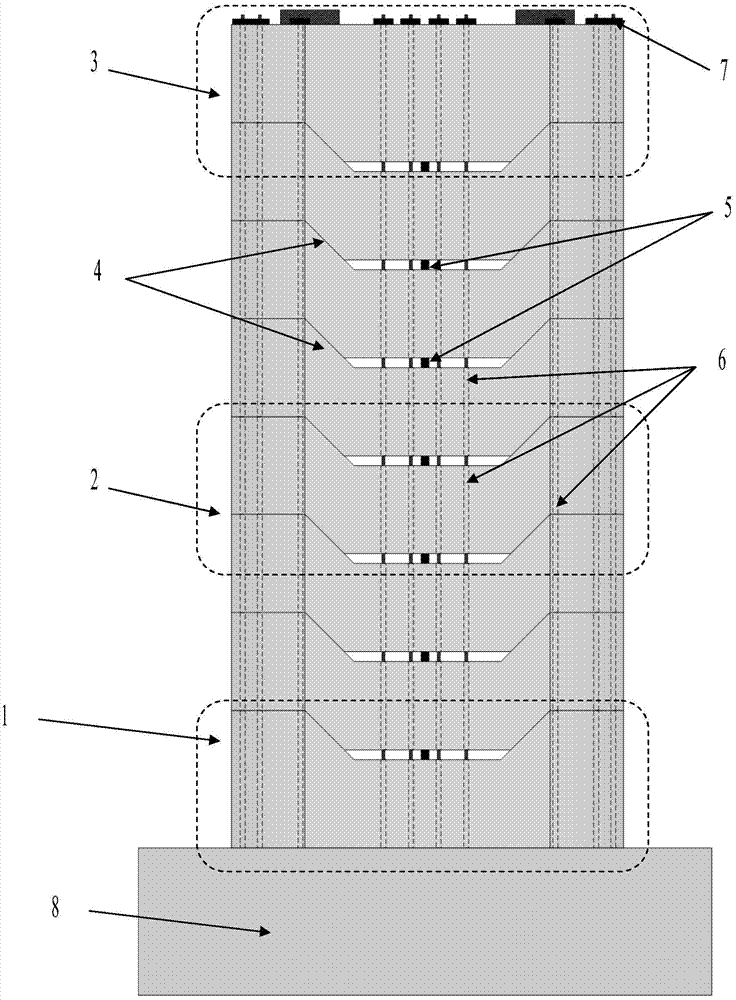

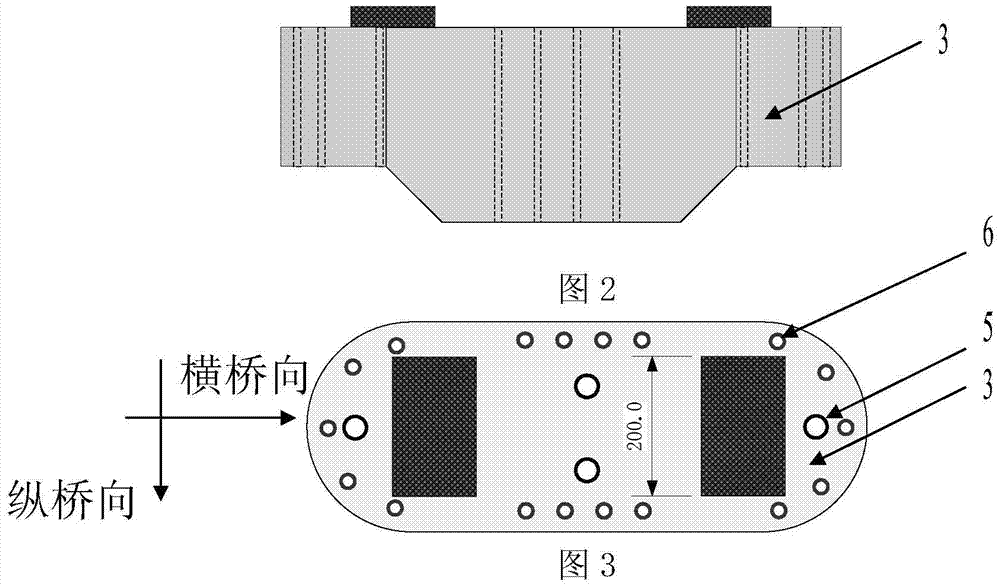

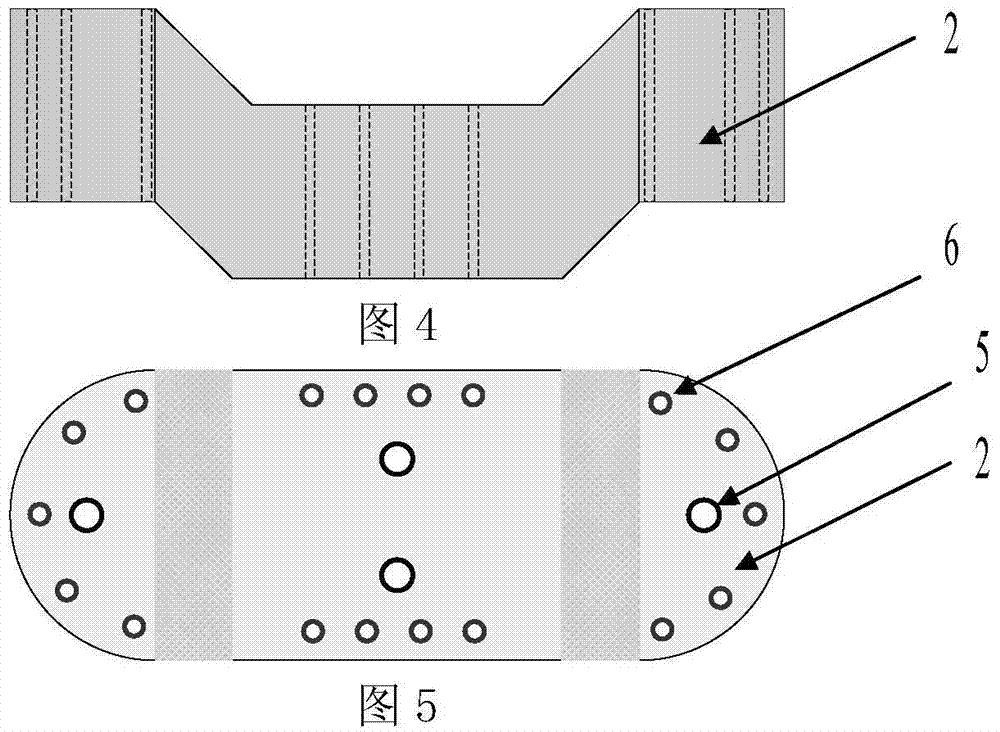

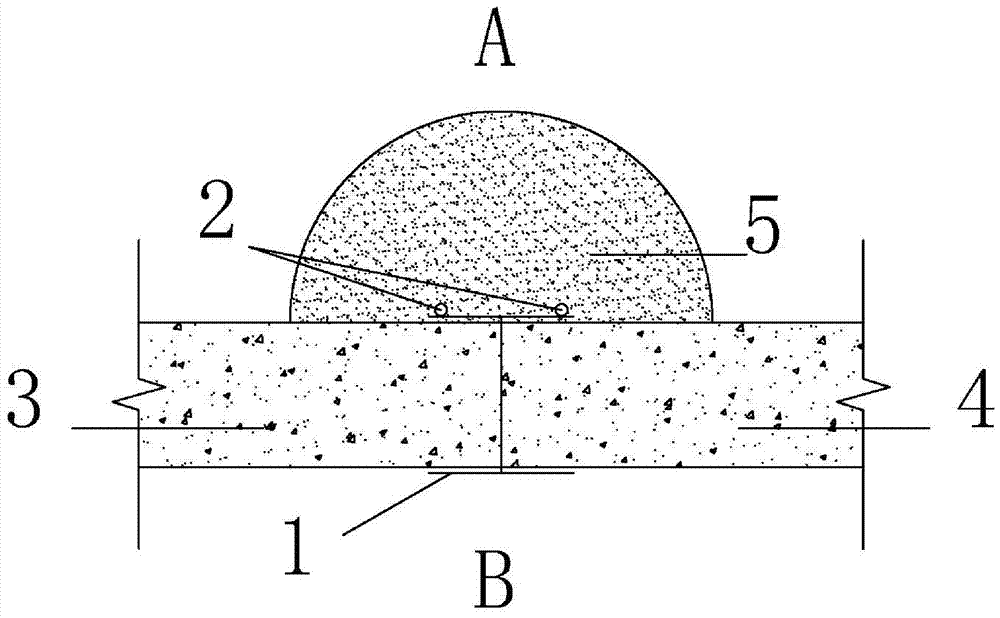

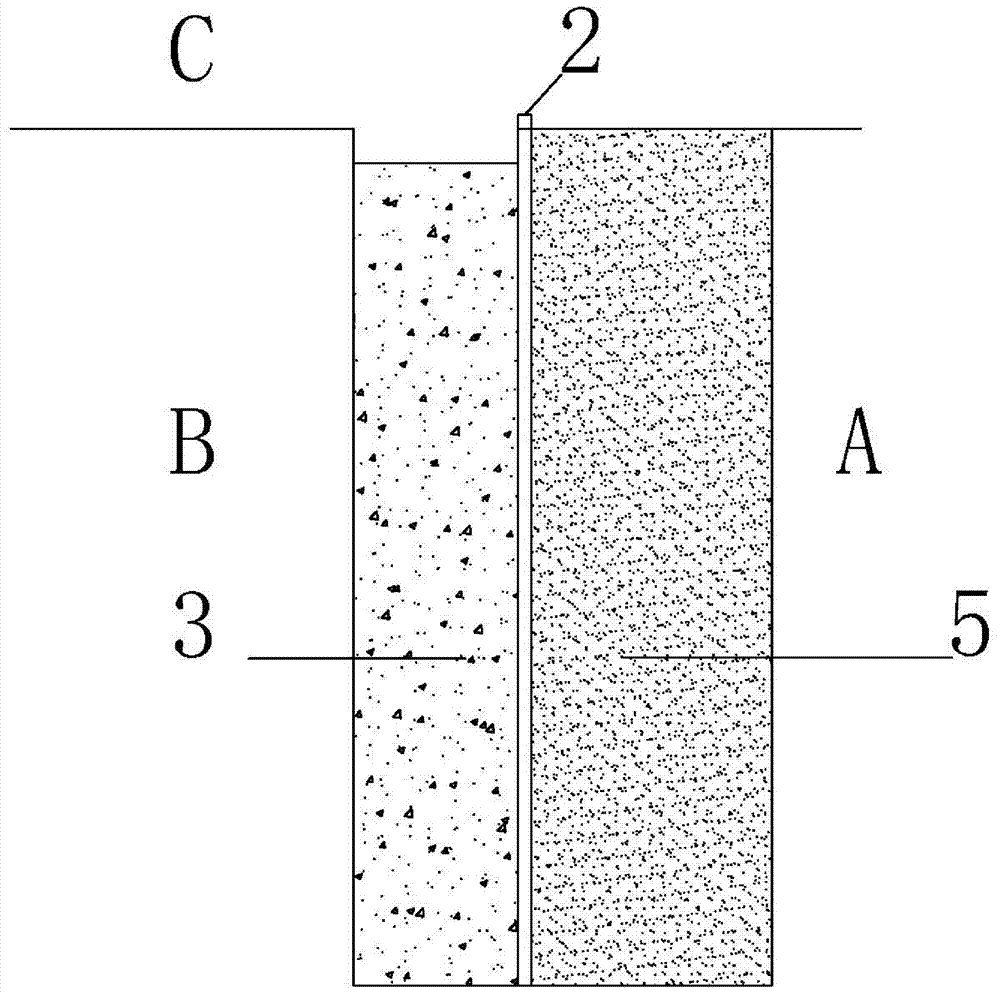

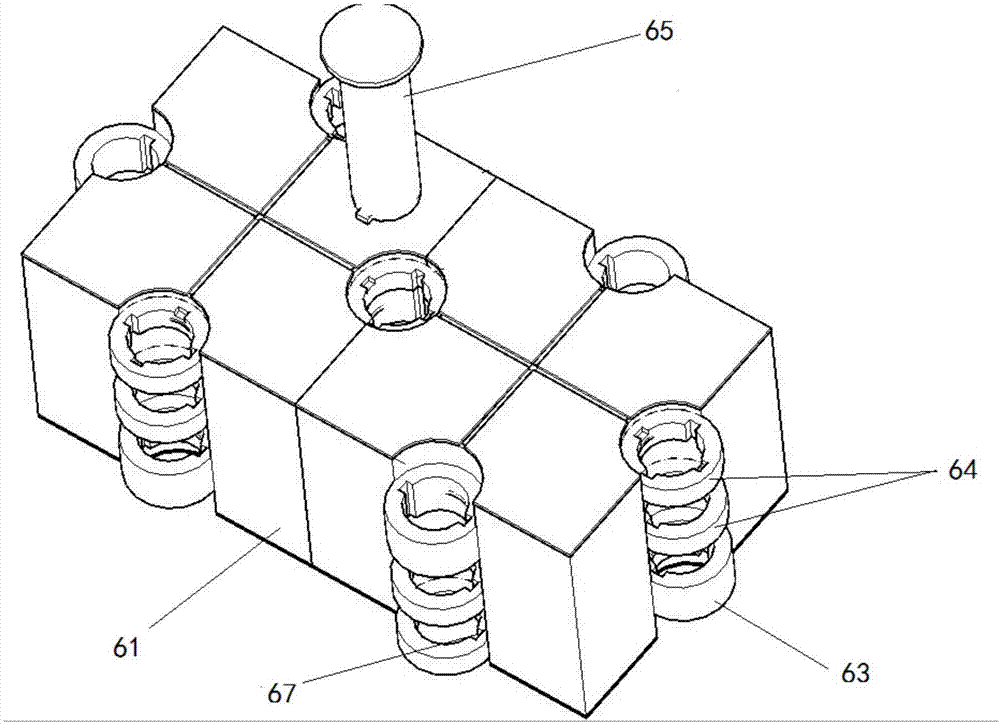

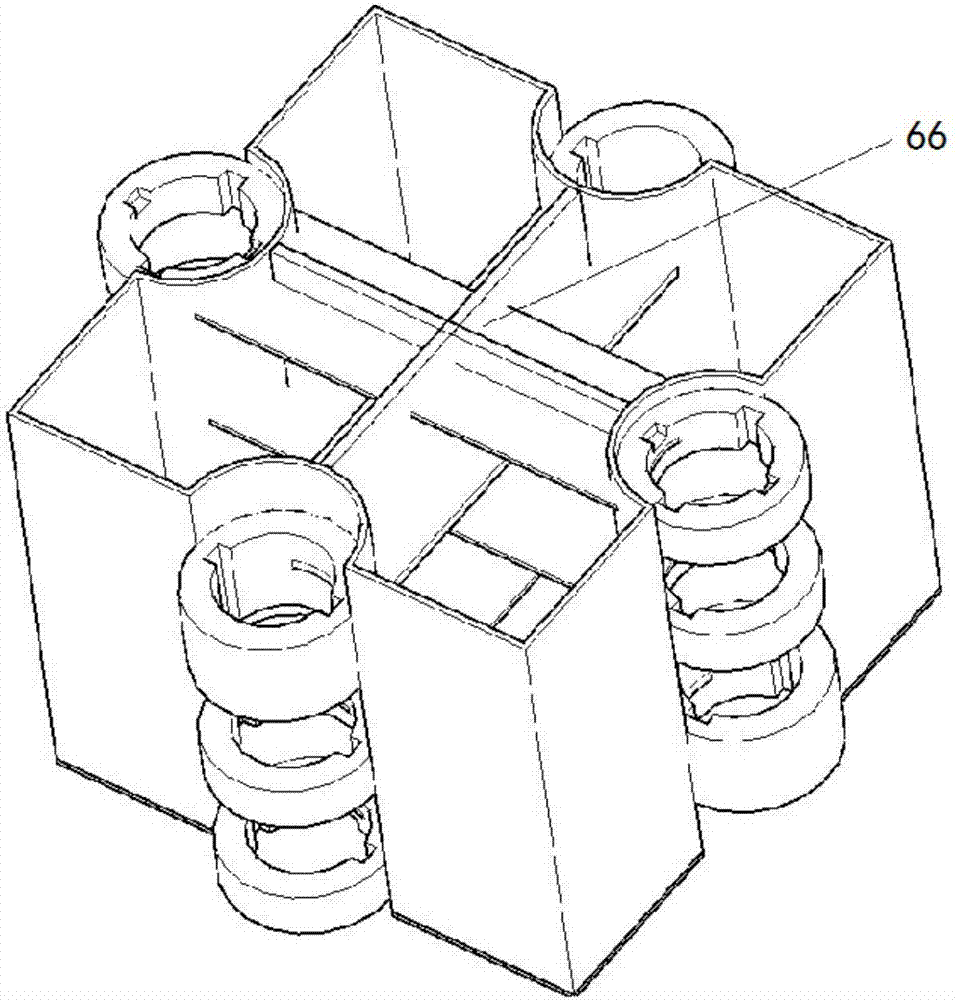

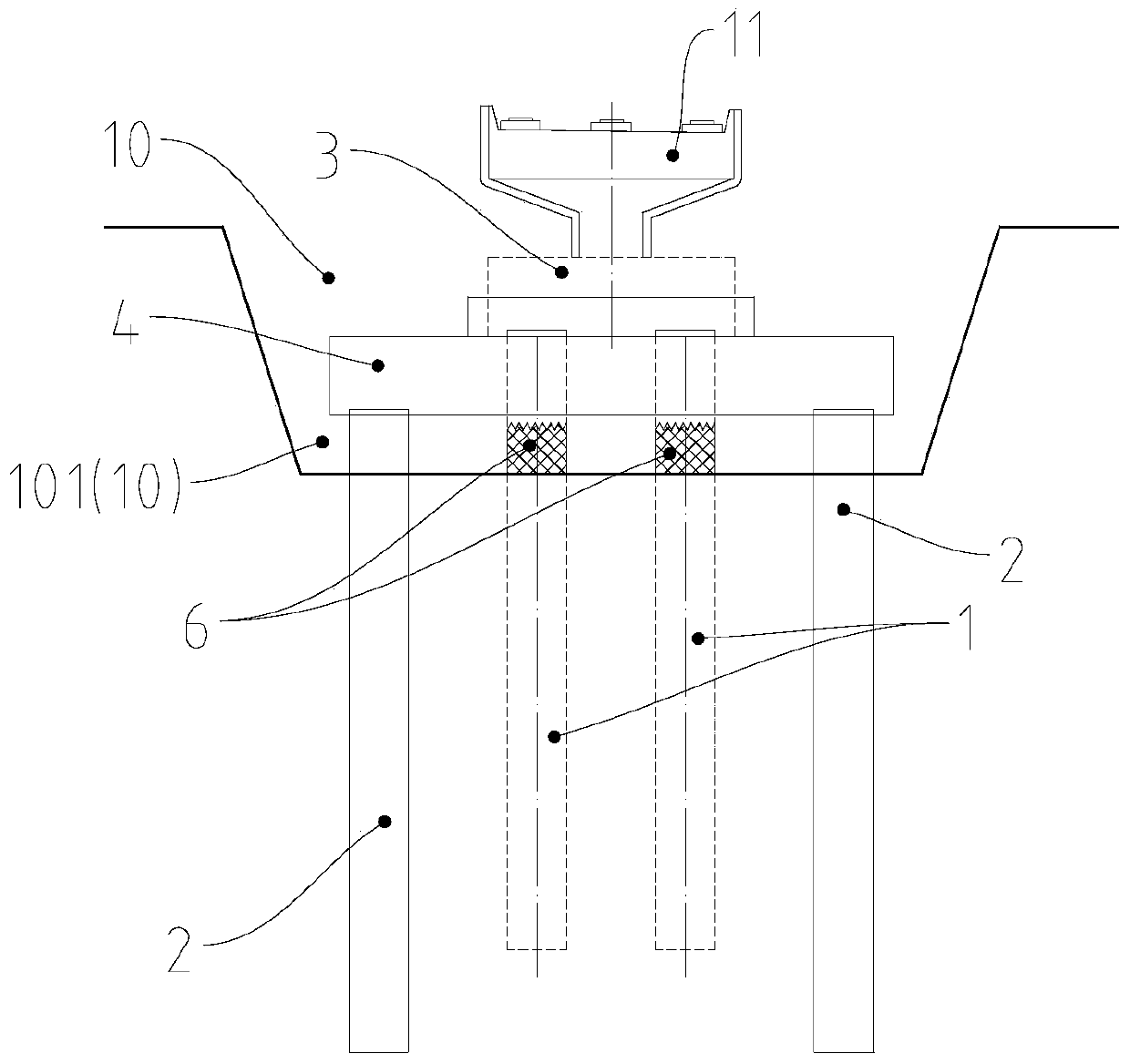

Transverse shear resisting section type self-resetting pier and construction method thereof

ActiveCN103590324ALow construction site requirementsReduce construction difficultyBridge structural detailsBridge erection/assemblyTransverse shearStructural engineering

The invention relates to a transverse shear resisting section type self-resetting pier and a construction method thereof. The pier comprises a transverse shear resisting pier bottom section, a plurality of transverse shear resisting pier body sections and a transverse shear resisting pier top section. The transverse shear resisting pier bottom section, the transverse shear resisting pier body sections and the transverse shear resisting pier top section are connected through meshing connecting faces and shear resisting bolts. The pier further comprises a plurality of self-resetting components. The self-resetting components penetrates and are anchored to the transverse shear resisting pier bottom section, the transverse shear resisting pier body sections and the transverse shear resisting pier top section through reserved holes. The invention further provides a mounting method of the pier. The self-resetting pier is simple in structure and convenient in material taking. The mounting method is simple, practical, safe and reliable, and the actual application difficult of section type concrete piers is solved.

Owner:TSINGHUA UNIV

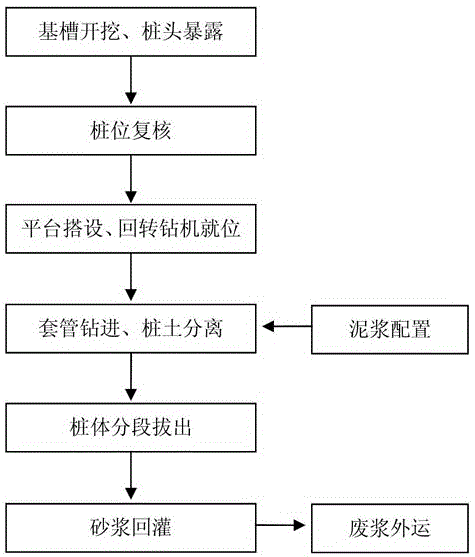

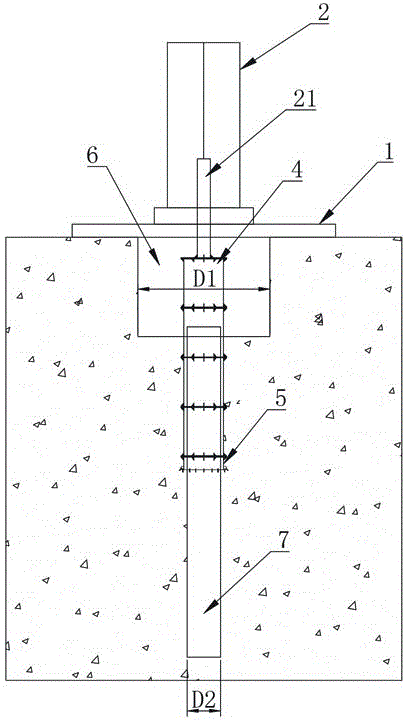

Construction device and construction method for pulling out piles through cooperation of rotating drilling machine and sleeve drill bit

The invention provides a construction device for pulling out piles through cooperation of a rotating drilling machine and a sleeve drill bit. The construction device comprises the rotating drilling machine, the sleeve drill bit and a sleeve set composed of a plurality of sleeves; at least one sleeve in the sleeve set is detachably connected to the rotary drilling machine; and the sleeve drill bit is detachably connected to the sleeve at the bottommost end of the sleeve set. The invention further provides a construction method of the construction device. The construction method comprises the steps that S1, a foundation trench is excavated, and the pile position is rechecked; S2, a platform is set up, and the rotary drilling machine is put in place; S3, the sleeve drill bit drills, and a pile body and soil are separated; S4, the pile body is lifted and is sectionally pulled out; and S5, backfilling of mortar is carried out, and slurry is transported outwards. The construction device and the construction method for pulling out the piles through the cooperation of the rotating drilling machine and the sleeve drill bit have the characteristics of being low in construction cost, low in risk, simple and convenient to operate, wide in application range and the like.

Owner:CHINA RAILWAY 12TH BUREAU GROUP 7TH CORPORATION LIMITED

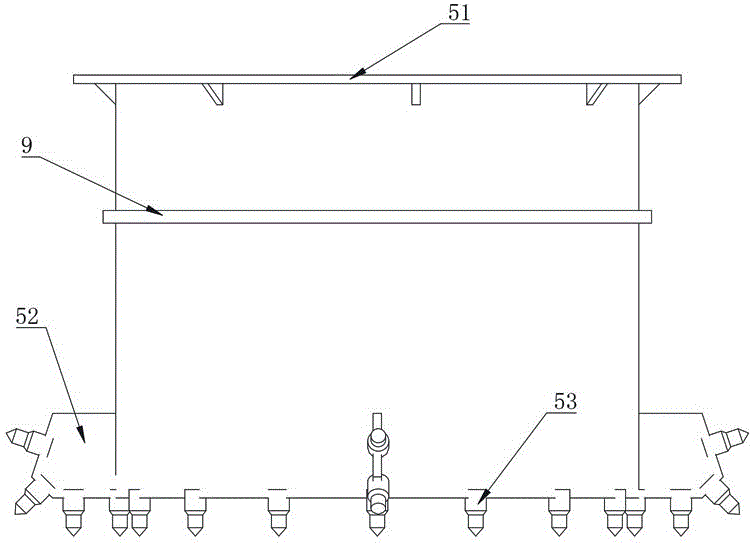

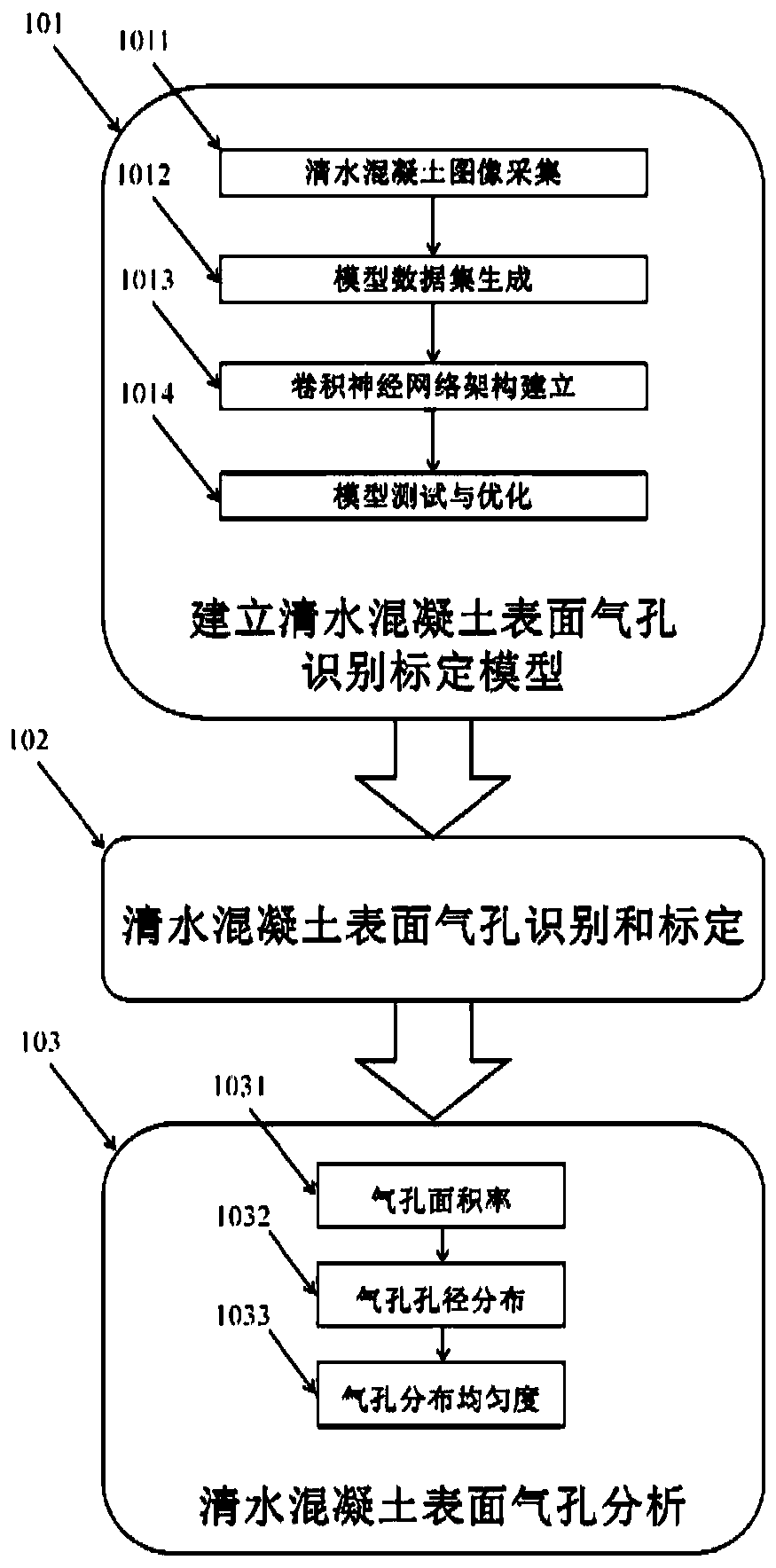

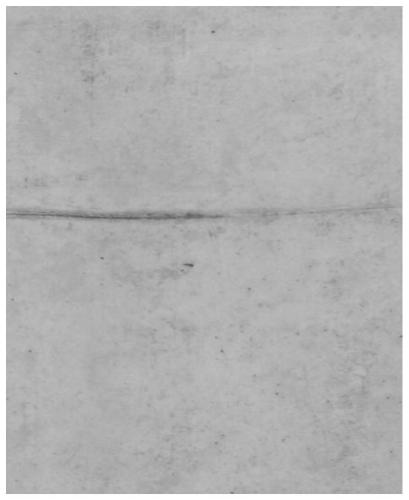

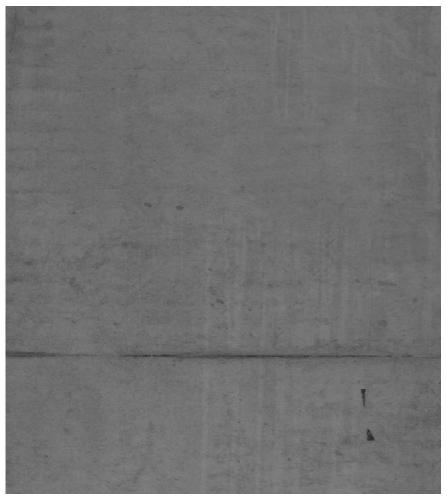

Fair-faced concrete surface pore analysis method based on convolutional neural network

PendingCN111311668AEasy to operateLow requirements on the construction siteImage enhancementImage analysisPore distributionEngineering

The invention discloses a fair-faced concrete surface pore analysis method based on a convolutional neural network, and the method comprises the steps: firstly collecting an appearance image of a fair-faced concrete material, and generating a data set needed by machine learning for training; then performing deep learning on the data set by adopting a convolutional neural network algorithm, and establishing a model capable of automatically identifying and calibrating surface pores of bare concrete; and finally, for a to-be-identified image, carrying out pore identification and calibration by utilizing the model, and analyzing from three aspects of pore area ratio, pore diameter distribution and pore distribution uniformity on the basis of a result. According to the invention, automatic identification is carried out on bare concrete surface pores based on machine learning and a convolutional neural network; objective quantitative indexes and digital analysis are provided for evaluation and acceptance of fair-faced concrete in building construction, and the problems that traditional fair-faced concrete appearance quality acceptance consumes manpower resources and is large in personalerror and low in efficiency are solved.

Owner:SOUTHEAST UNIV

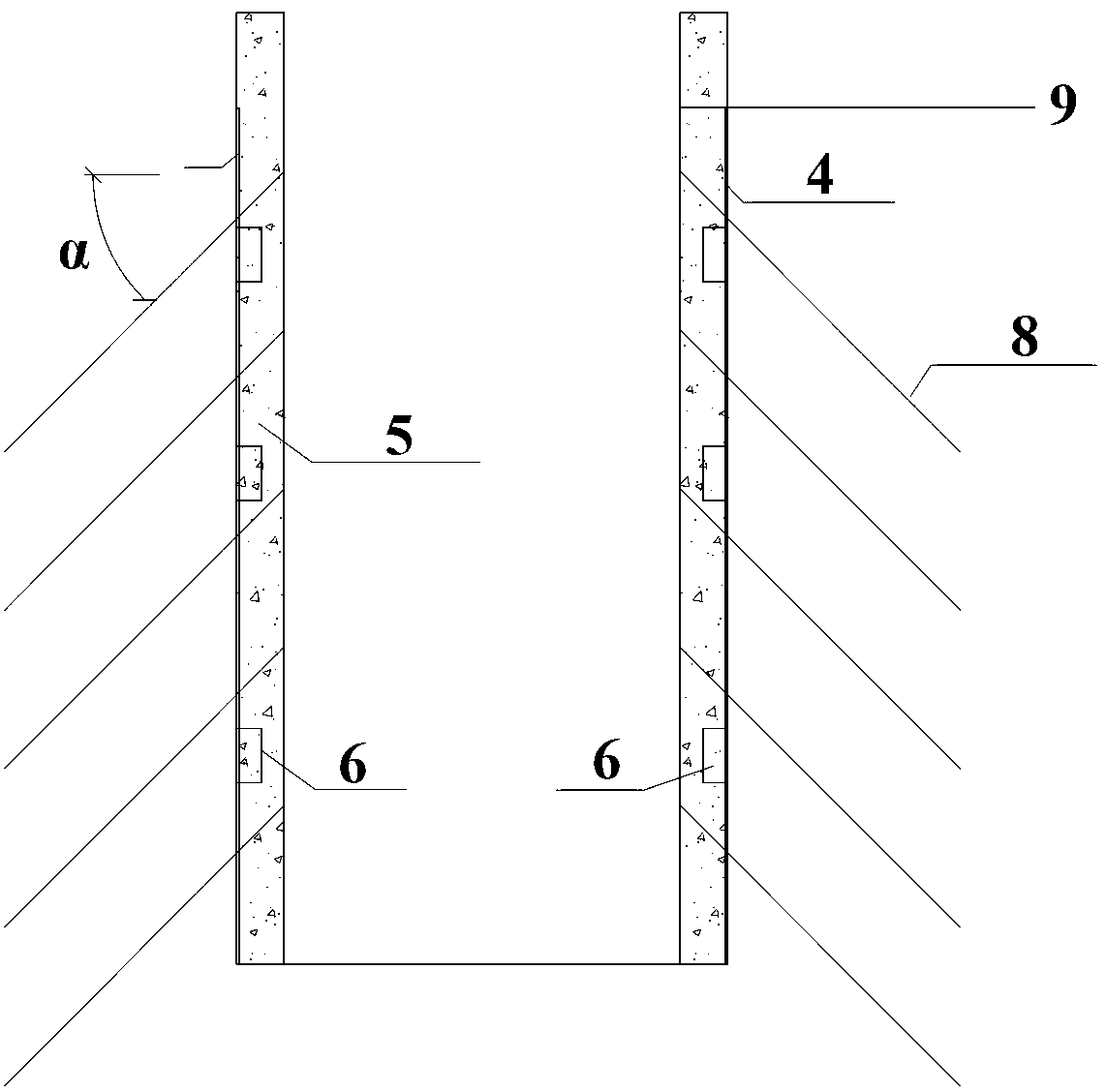

Retaining and protecting structure of reinforcing existing line of steel-structure self-drilling type hollow anchor rod

ActiveCN103615012AAvoid damageNo major demolition worksExcavationsBulkheads/pilesRetaining wallGround layer

The invention discloses a retaining and protecting structure of a reinforcing existing line of steel-structure self-drilling type hollow anchor rod. Protecting structures are arranged on side slopes of the two sides of a roadbed. Angle iron nets are horizontally and vertically arranged on the surfaces of side slope protecting walls from the bottoms of the side slopes and the tops of the side slopes in a crossed mode in the roadbed direction, and cushion plates are arranged on nodes of the angle iron nets. Hollow anchor rods which penetrate through the cushion plates and the nodes and go deep into the ground layers of the side slopes are vertically arranged on the protecting walls of the side slopes, and hollow cavities are formed in the hollow anchor rods. Anchoring force is generated on reinforcing bodies in the ground layers behind retaining walls and the protecting walls through self-drilling type hollow anchor rods, the anchoring force is evenly exerted on the wall faces of the reinforcing bodies by means of the cushion plates and angle iron, and a formed reinforcing system is good in integrity and high in stability.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

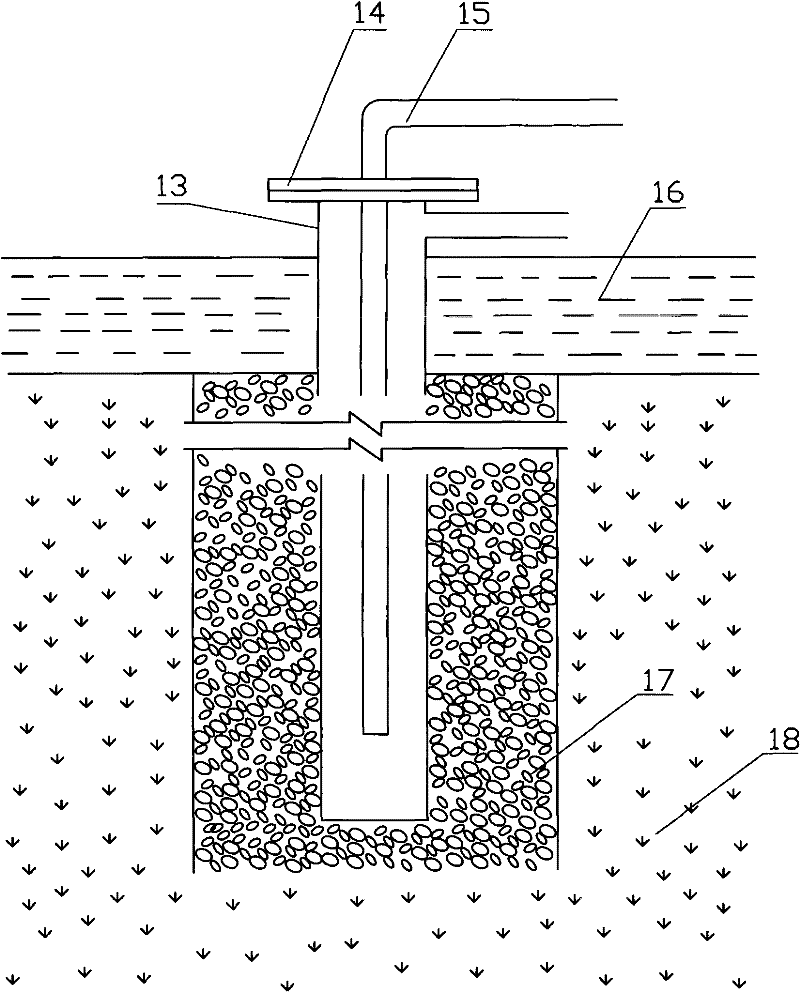

Landfill gas gas-collecting shaft construction method

ActiveCN101748751AImprove permeabilityImprove gas collection efficiencyArtificial islandsUnderwater structuresControl mannerPebble

The invention discloses a landfill gas gas-collecting shaft construction method, which adopts grabbing-bucket digging well method to dig the gas-collecting shaft, and the completed gas-collecting shaft has good permeability, and high gas-collecting efficiency. The grabbing-bucket is controlled through a steel rope, the length can be controlled; and the gas-collecting shaft with deep depth can be constructed according to needs, meanwhile, the control method can simplify the structure. Pebbles or gravels are poured into a gas-collecting vertical hole at the outside of a gas-collecting pipe to the top of the garbage layer, and the periphery of the gas-collecting shaft on the garbage layer is provided with bentonite, and the bentonite is tamped to form a sealing structure, accordingly, the efficiency can be further increased.

Owner:山高十方环保能源集团有限公司

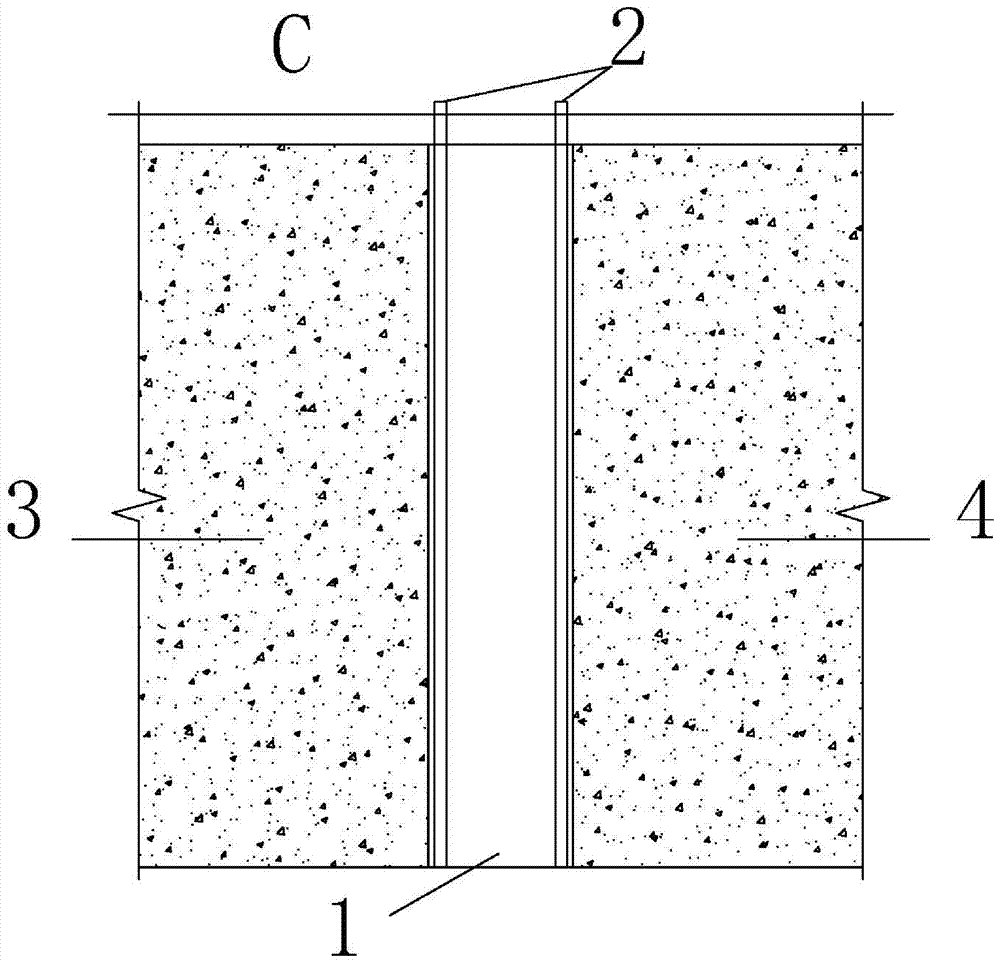

Construction method for strengthening and water-retaining for I-shaped steel joint of underground diaphragm wall

ActiveCN107268688AImprove waterproof performanceSimple and fast operationArtificial islandsUnderwater structuresSlurry wallWater leakage

The invention discloses a construction method for strengthening and water-retaining for an I-shaped steel joint of an underground diaphragm wall. The construction method comprises the following steps: firstly, welding a steel reinforcement cage in a first-stage construction groove section of the underground diaphragm wall with the I-shaped steel joint, pre-embedding two grouting steel pipes in a near-soil side of a flange plate of the I-shaped steel joint, and locating the two grouting steel pipes at the two ends of the flange plate of the I-shaped steel joint separately; secondly, arranging the first-stage steel reinforcement cage in the first-stage construction groove section, and carrying out pouring working in the first-stage construction groove section; thirdly, arranging a second-stage steel reinforcement cage in a second-stage construction groove section, and carrying out pouring working in the second-stage construction groove section; and finally, after pouring working in the first-stage construction groove section and pouring working in the second-stage construction groove section are completed, connecting the grouting steel pipes with a grouting machine and carrying out grouting, and after the grouting working is completed, forming a semicircular strengthening area taking the I-shaped steel joint as the circle center and having a radius of 1.0-1.8m on the near-soil side of the I-shaped steel joint. The construction method disclosed by the invention is capable of improving the waterproofness of the I-shaped steel joint during construction for the underground diaphragm wall, so as to achieve a purpose of effectively controlling water leakage at the I-shaped steel joint.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

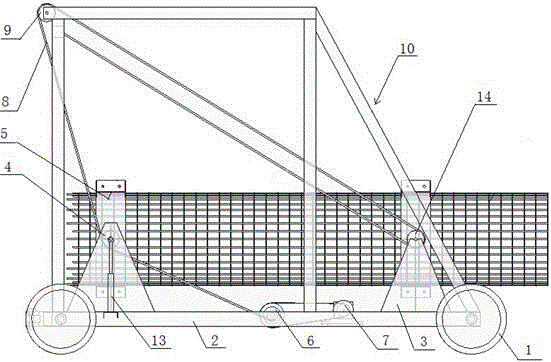

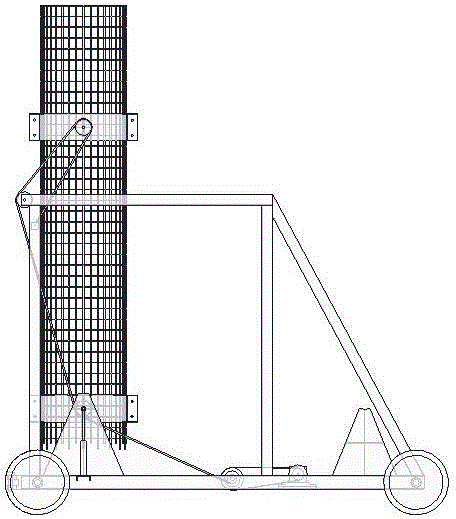

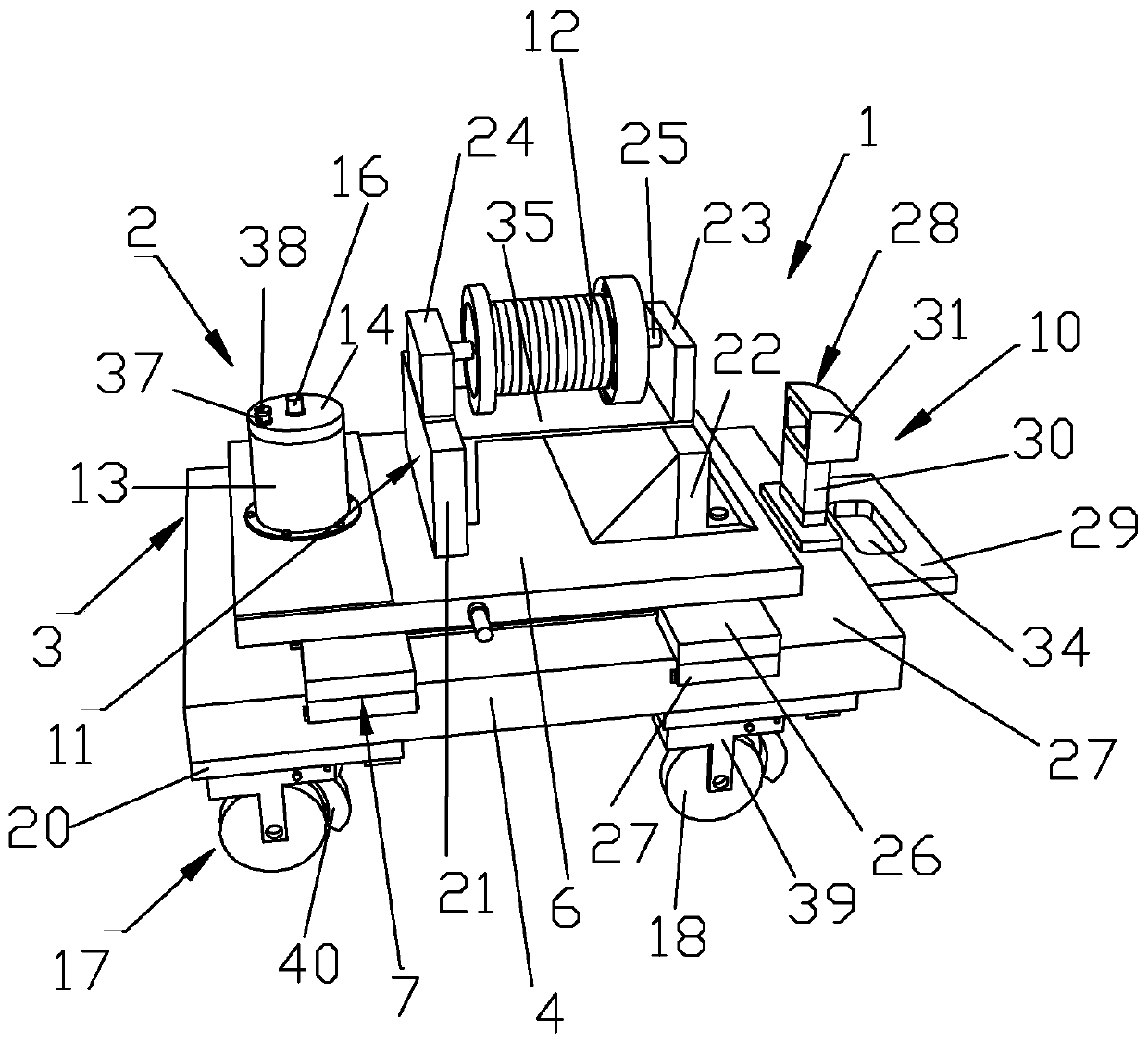

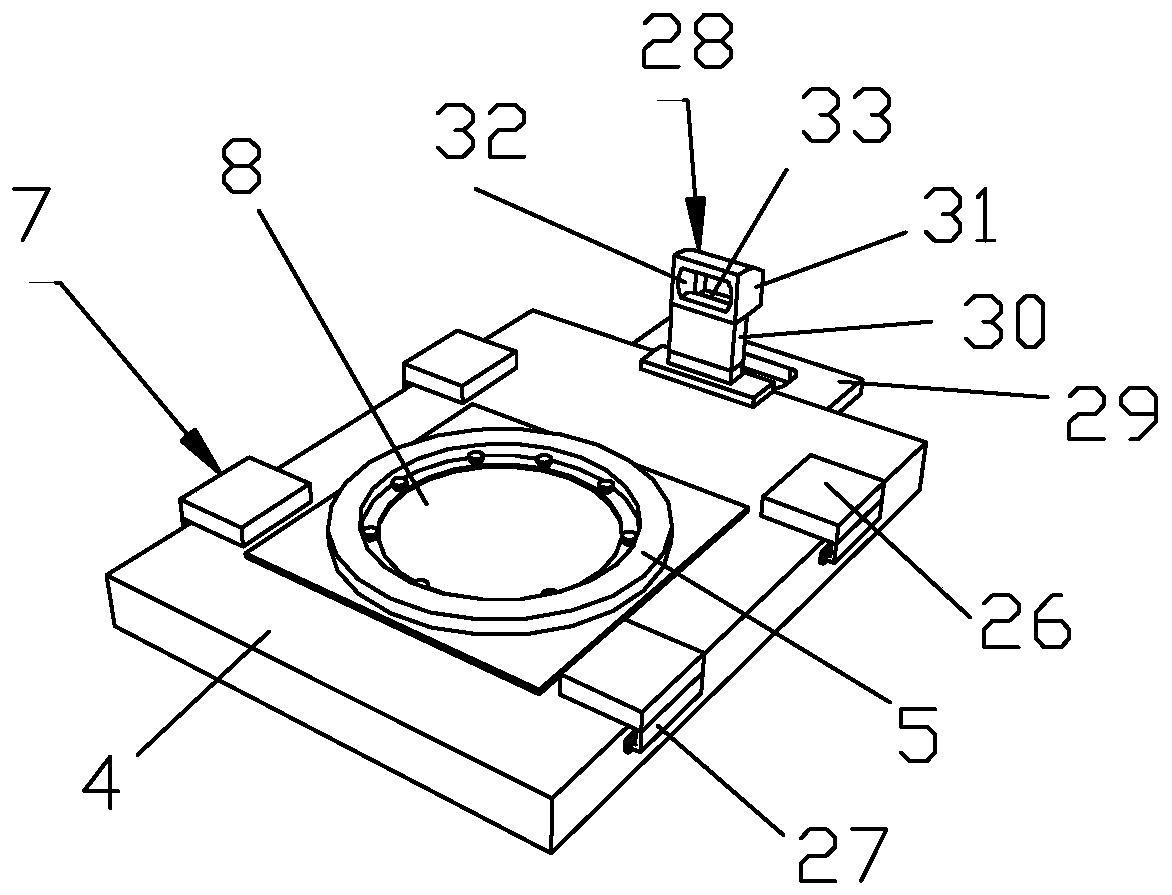

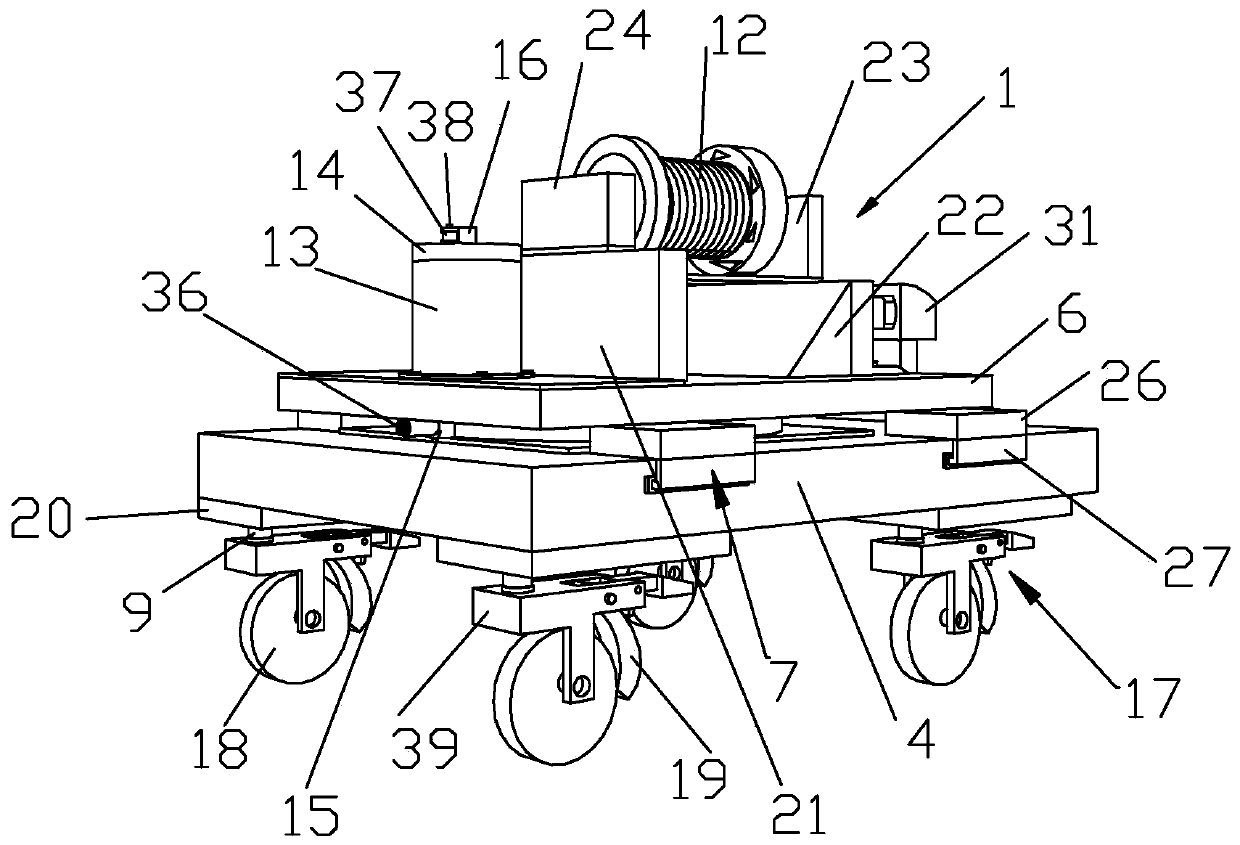

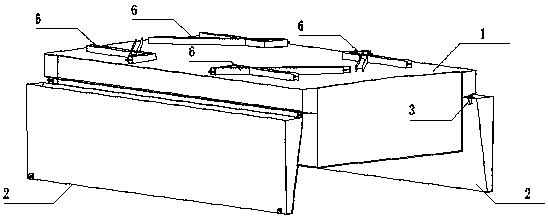

Movable type reinforcement cage mounting device

ActiveCN106087990AAddress too many requestsLow construction site requirementsBulkheads/pilesVehicle frameMovable type

The invention discloses a movable type reinforcement cage mounting device, and belongs to the field of building devices. The movable type reinforcement cage mounting device comprises a vehicle frame with rollers at the lower end, and a supporting mechanism used for bearing a horizontally-placed reinforcement cage, a turnover mechanism turning over the horizontal reinforcement cage to be in the vertical state and a discharging mechanism putting the reinforcement cage into a pile foundation hole are arranged on the vehicle frame; the supporting mechanism comprises a supporting base and a hinge base which are arranged in a front-and-back manner in the length direction of the vehicle frame, steel hoop rings surrounding and locking the reinforcement cage are arranged on the bearing base and he hinge base, symmetric shafts are arranged on the two sides of each steel hoop ring, the steel hoop rings on the bearing base are movably arranged on the bearing base in a lap joint manner through the symmetric shafts, and the steel hoop rings on the hinge base are hinged into the hinge base through the symmetric shafts; and the movable type reinforcement cage mounting device is simple in structure and flexible in work, and meanwhile mounting of the reinforcement cage is more precise and is in place.

Owner:STATE GRID CORP OF CHINA +2

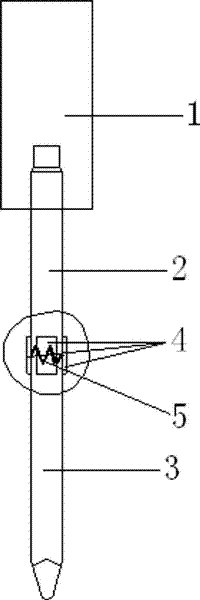

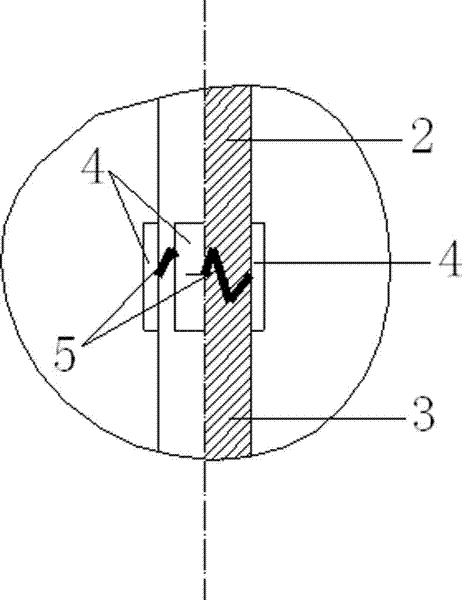

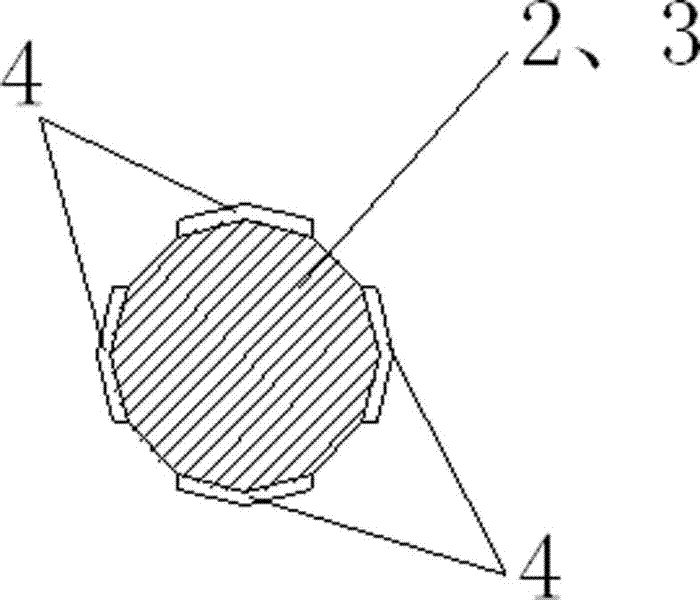

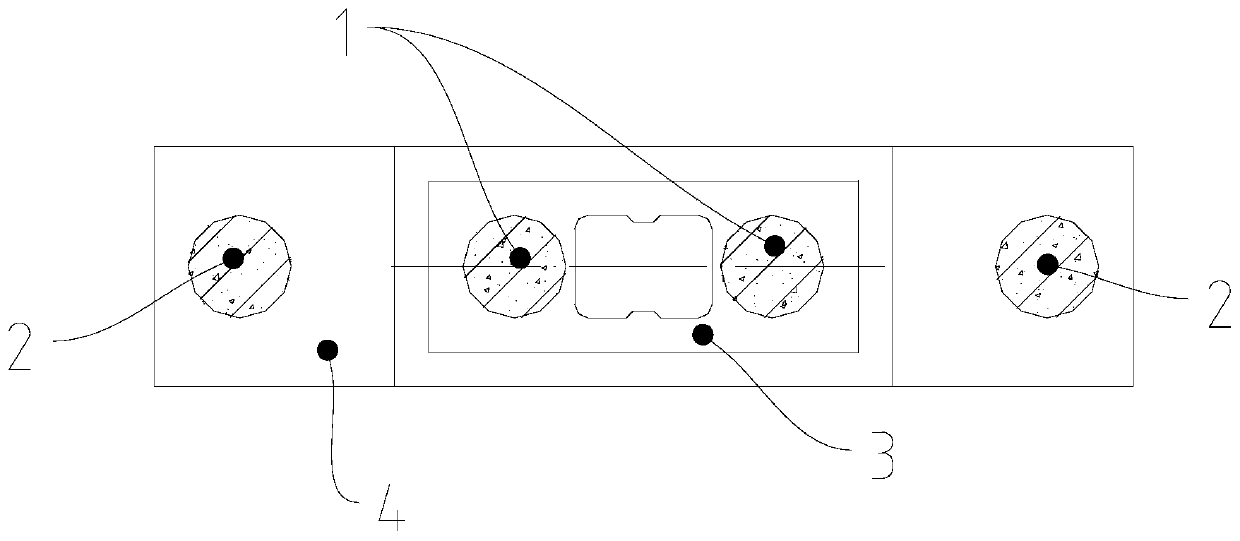

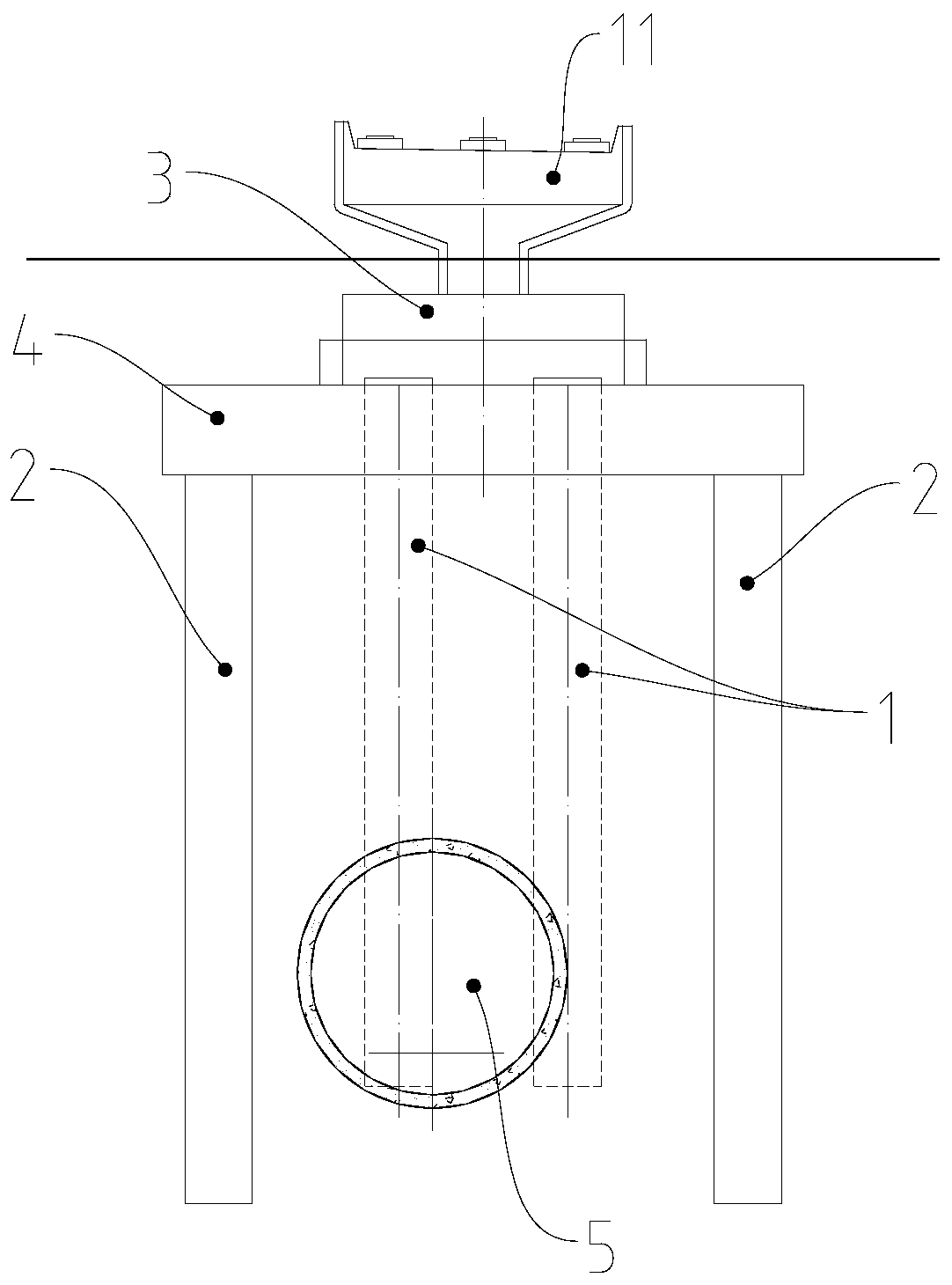

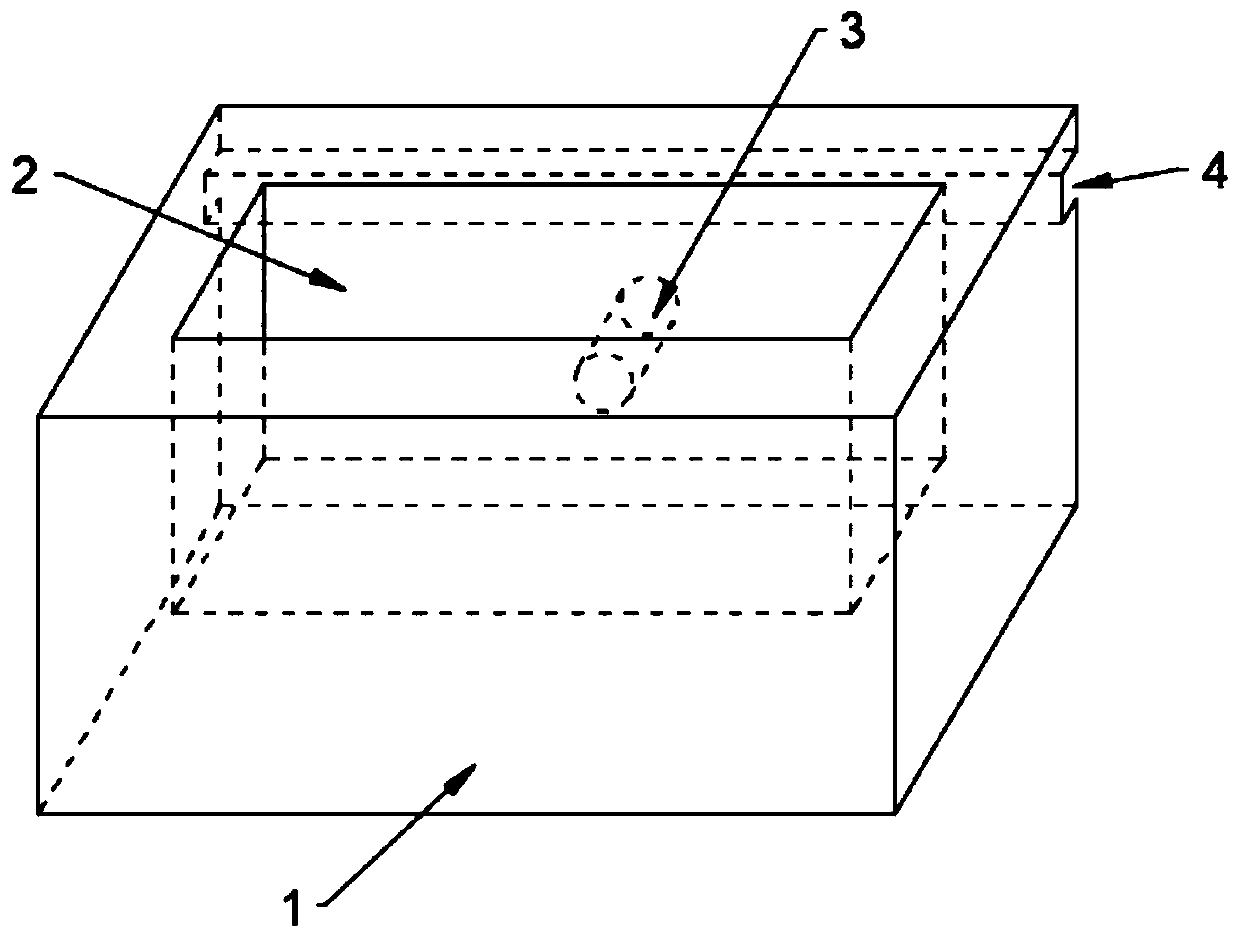

Hole guiding device and hole guiding method for bad ground

ActiveCN102505724AMove fastLow construction site requirementsReciprocating drilling machinesSoil-shifting machines/dredgersEngineeringHigh pressure

The invention relates to a hole guiding device and a hole guiding method for a bad ground. The hole guiding device comprises a breaking hammer main body (1), a first drilling rod (2), a second drilling rod (3) and a stiffening plate (4), wherein the breaking hammer main body (1) is connected with the first drilling rod (2); and the first drilling rod (2) is connected with the second drilling rod (3) by using the stiffening plate (4), a high-strength bolt or a welding joint (5). The hole guiding device has the advantages that: by adoption of a caterpillar excavator, the running speed is high, the requirement on a construction site is low, and construction can be performed under a bad ground condition, wherein the caterpillar excavator is common equipment and has adjustable power; fully-mechanized construction is performed, the hole forming time is short, the efficiency is high, and in practice, only 2 minutes is required to perform hole guiding on 5-meter-thick block stone earth-filling layer; and the hole guiding is performed in a vibrating compaction mode, and hole falling and hole collapsing phenomena cannot happen, so the hole guiding device is most suitable for injected holes with large areas, a plurality of holes and small intervals, high-pressure jet grouting drilled holes and guided holes of anchor rod jacked piles, and is also suitable for reconnaissance drilled holes with large hole pitches.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

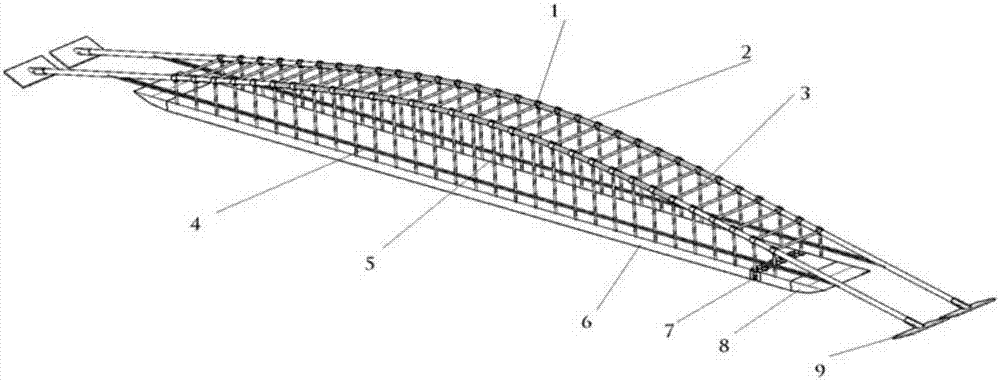

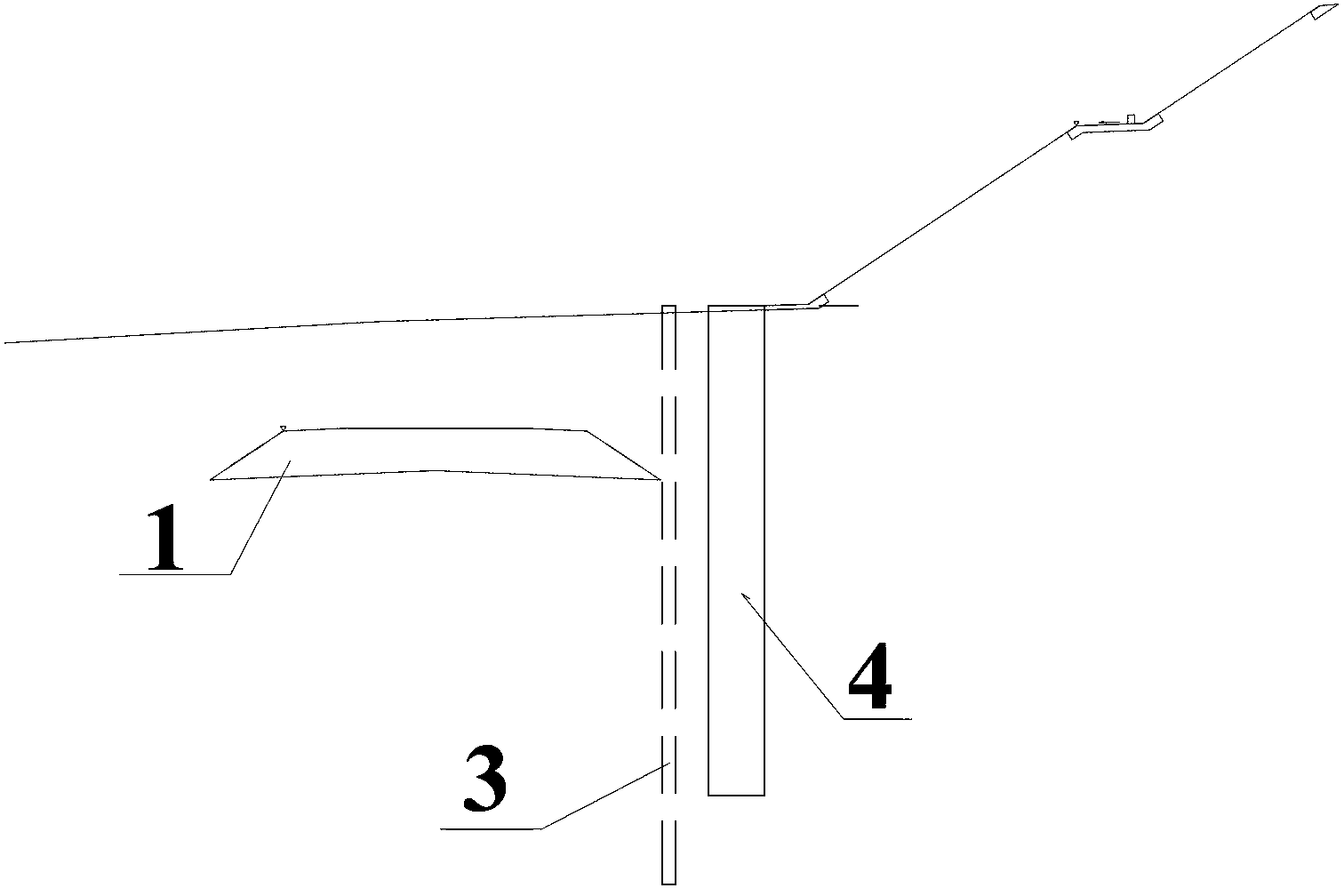

Tied-arch floating bridge and tied-arch floating bridge erecting method

ActiveCN107386095AImprove carrying capacitySimple structureBridge erection/assemblyFloating bridgesPontoon bridgeAbutment

The invention provides a tied-arch floating bridge and a tied-arch floating bridge erecting method, and relates to the technical field of civil engineering. The tied-arch floating bridge comprises a floating body structure, a hoisting structure and arch abutment support seats, the hoisting structure is arranged above the floating body structure and capable of hoisting the floating body structure, the hoisting structure comprises at least two main arch bodies, a plurality of cross supports, a plurality of perpendicular hoisting rods and a plurality of tie rods, two ends of main arch bodies are fixedly connected with the arch abutment support seats respectively, every two main arch bodies are connected with each other through the transverse supports, top portions of the perpendicular hoisting rods are connected with the main arch bodies, bottom portions of the perpendicular hoisting rods are connected with the floating structure, rod bodies of the tie rods are connected with the perpendicular hoisting rods which are mounted on the corresponding main arch bodies, and rod ends of the tie rods are fixedly connected with the corresponding main arch bodies. The tied-arch floating bridge is simple in structure and convenient to disassemble and assemble.

Owner:PLA UNIV OF SCI & TECH

Method for breaking underground obstacle pile

InactiveCN111335315AImprove securityDoes not affect tunnelingFoundation repairBulkheads/pilesArchitectural engineeringShield tunneling

The invention provides a method for breaking an underground obstacle pile. The method comprises the following steps that a foundation pit is dug, and the foundation pit is dug around the upper end ofthe obstacle pile; a pile head is chiseled away, and the pile head of the obstacle pile is chiseled away; a pile core is broken, the pile core of the obstacle pile is broken, and the pile side wall ofthe obstacle pile is reserved; the pile side wall is broken, and the pile side wall is broken; pile backfilling is carried out, and the pile core is filled; and the foundation pit is backfilled, andthe foundation pit is filled. The method is suitable for tunnel obstacle piles, other pile foundation engineering, municipal engineering and the like. The method has the advantages of an existing manual hole digging pile breaking technology, the defect that a supporting structure is newly added in an existing manual hole digging breaking scheme is overcome, and the breaking engineering amount is reduced; the construction procedures in the prior art are optimized, transverse channel horse head breaking construction is avoided, and the construction risk is reduced; and when the method is appliedto breaking the tunnel obstacle pile, shield tunneling is not affected by breaking the obstacle pile before shield construction, and the requirement for a construction site is low.

Owner:GUANGZHOU METRO DESIGN & RES INST

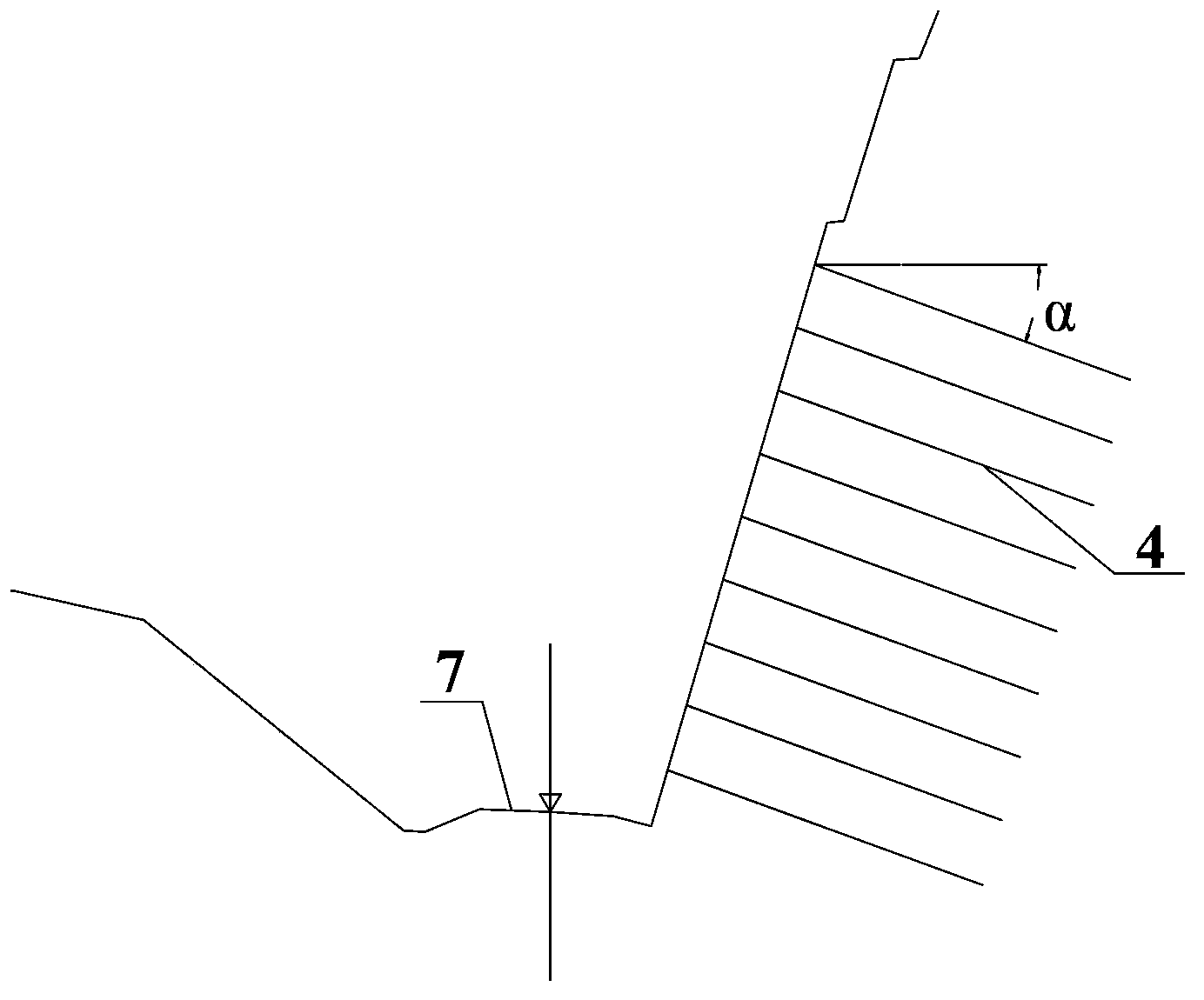

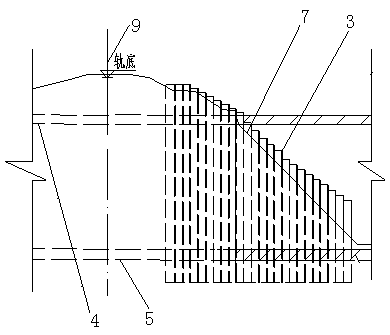

Water-rich stratum slide-resistant pile dado reinforced structure

The invention discloses a water-rich stratum slide-resistant pile dado reinforced structure which is arranged on the outer side of a rainfall water pumping and discharging pipe system on one side of a railroad bed. A row of water-rich stratum slide-resistant pile dado reinforced structures are arranged along the railroad bed. The water-rich stratum slide-resistant pile dado reinforced structure is matched with the rainfall water pumping and discharging pipe system. Rainfall well points are further arranged on the rainfall water pumping and discharging pipe system. The water-rich stratum slide-resistant pile dado reinforced structure comprises an outer-layer rebar mesh sheet and an inner-layer concrete dado. A plurality of rows of annular I-beams are arranged on the inner side of the rebar mesh sheet and arranged inside the concrete dado from top to bottom. A plurality of parallel slip casting sprayed molten steel tubes are arranged on the periphery of the reinforced structure in an inclined drilling mode from the concrete dado to a water-rich stratum. The water-rich stratum slide-resistant pile dado reinforced structure is combined with well point rainfall measures, the set of water-rich stratum slide-resistant pile excavation technology integrating reinforcing, rainfall, excavation, casting forming and the like is formed, the quantity of underground water inside a foundation trench is reduced, and the excavation working efficiency is improved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Horizontal directional drilling crossing construction method and drilling equipment

ActiveCN104213833BReduced displacement requirementsReduce dosageDirectional drillingFlushingEngineeringCrusher

The invention discloses a horizontal directional drilling crossing construction method and drilling equipment thereof, which are designed for improving the stability of the borehole wall and reducing the crossing construction risk. The main body of the drilling equipment body is connected to the main shaft, cone crushing mechanism, cutter head and horizontal directional drilling rig in front of the cabin wall, and the cutter head drive mechanism, water supply pipe and drainage pipe are connected to the back of the cabin wall. The rear end of the body is connected with grouting There is a pipe nipple for the grouting pipe inside the hole, and the rear end of the pipe nipple is connected to the crossing pipeline. The invention is used for horizontal directional drilling of pipelines with a diameter of more than 400mm. It can expand the borehole to the size of the hole at one time and directly drag the pipeline back into the borehole to complete the laying, and at the same time fill the gap between the inner wall of the borehole and the crossing pipeline. , to discharge the cuttings to the excavation end. The invention can improve the stability of the borehole wall, reduce the construction risk caused by the collapse of the hole, reduce the construction cost, protect the environment, realize the large-diameter and long-distance pipeline crossing under the condition of loose stratum and hard rock stratum, and expand the level The scope of application of directional drilling method.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Construction method for miniature steel pipe concrete pile to penetrate through roadbed layer for reinforcing soft foundation construction

ActiveCN102943466BEasy constructionLow construction site requirementsBorehole drivesBulkheads/pilesHigh intensityMixed materials

The invention discloses a construction method for a miniature steel pipe concrete pile to penetrate through a roadbed layer for reinforcing the soft foundation construction and belongs to the technical field of engineering construction. The construction method solves the problems that the traditional soft foundation treatment mode cannot meet the requirements of the engineering construction on the foundation intensity, and the construction cannot be carried out. The construction method comprises the following steps of carrying out pipe following operation by a down-hole hammer eccentric drilling rig; forming holes by a geological drilling rig; sinking pipes by a hydraulic vibration hammer; pulling out tube protecting sleeves; pre-burying grouting pipelines; placing a steel reinforcement cage; filling high-intensity mixed materials for forming piles; and grouting around the piles for forming a compound foundation. The construction method has the advantages that the construction is convenient, the equipment is small and flexible, the construction field requirements are low, safety and reliability are realized, the penetrating capability is high, and the construction period is short.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Spiral winding pipeline repairing device

The invention discloses a spiral winding pipeline repairing device. The device comprises a winding machine assembly, and further comprises a grouting assembly and a connecting assembly, wherein the connecting assembly comprises an operation table, a rotating disc, a total backing plate and a supporting assembly, an installation groove is formed in the operation table, the installation groove is internally provided with the rotating disc, the top of the rotating disc is fixedly connected with the total backing plate, and the total backing plate is arranged on the supporting assembly. Accordingto the spiral winding pipeline repairing device, a grouting function is additionally arranged on the basis of an existing spiral winding machine, so that grouting can be carried out between two new and old pipelines after pipe manufacturing is finished through a method of fixing pipe diameter; and in addition, positions of the winding machine assembly and the grouting assembly can be shifted through rotation, so that grouting can be immediately carried out after pipe winding is finished without assembling equipment in a construction site, in this way, timely construction is truly achieved, andconstruction efficiency and repairing speed are both accelerated.

Owner:福建全立建设发展有限公司

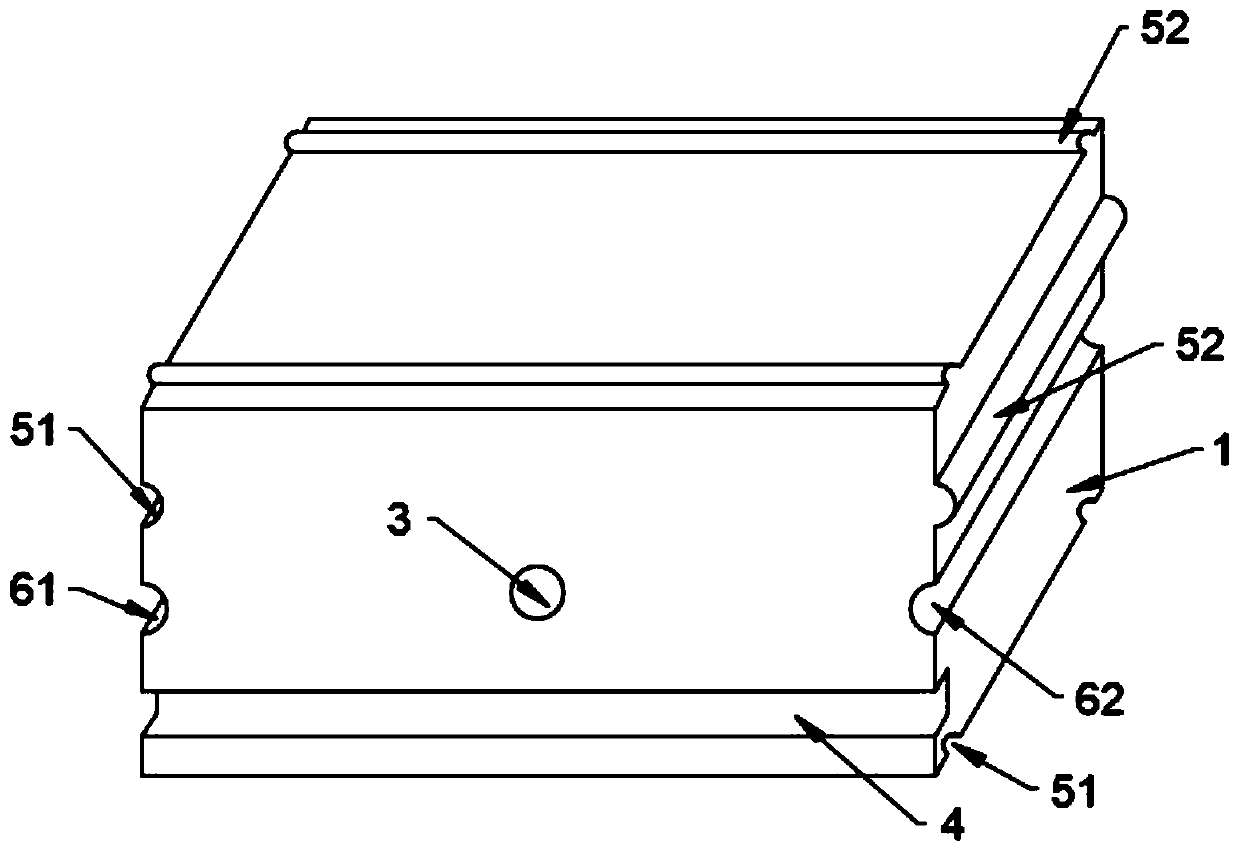

A simulated ice brick and an ice slideway

InactiveCN109706818AReduce maintenance costsReduce manufacturing costSki bindingsPaving detailsBrickEngineering

A simulated ice brick is provided with an ice brick body; the ice brick body is of a hollow structure, and an opening communicated with the outside is formed in the bottom of the ice brick body. A spray hole communicated with the hollow structure is formed in one side of the ice brick body; a bayonet is arranged at the bottom of the side surface of the ice brick body where the spray hole is located. The defect that traditional artificial ice can only be used in a subzero environment is overcome, and the simulated ice brick is not limited by any air temperature. The simulated ice brick is lightin weight, low in requirement on a construction site and rapid to build.

Owner:江苏驰童游乐设备有限公司

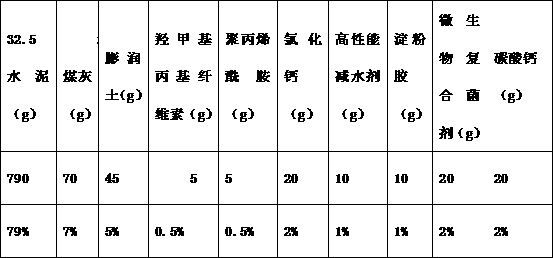

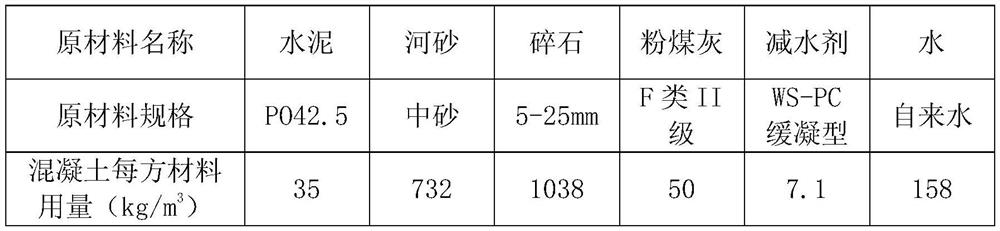

Material and construction method for ocean engineering rubble throwing foundation grouting solidification

InactiveCN110759671AImprove dispersion resistanceShort mixing timeFoundation engineeringCelluloseWater flow

The invention discloses a material and a construction method for the ocean engineering rubble throwing foundation grouting consolidation. The grouting material comprises a gel material, cellulose, a high-performance water reducing agent, a flocculating agent, an inert powder, calcium chloride, starch glue, seaweed gel, a microbial composite inoculant, and calcium carbonate. The grouting construction method comprises the following steps: current situation investigation, field formula test, measurement and positioning, drilling, hole-cleaning, slurry preparation, upward grouting from the bottomof a hole to a designed position, and hole-sealing. The grouting material provided by the invention can effectively solve the problem of underwater grouting, can work with water, and avoids the problem that the common slurry is dispersed when meeting water or is washed away by water flow, and the like.

Owner:烟台坭客环境科技有限公司

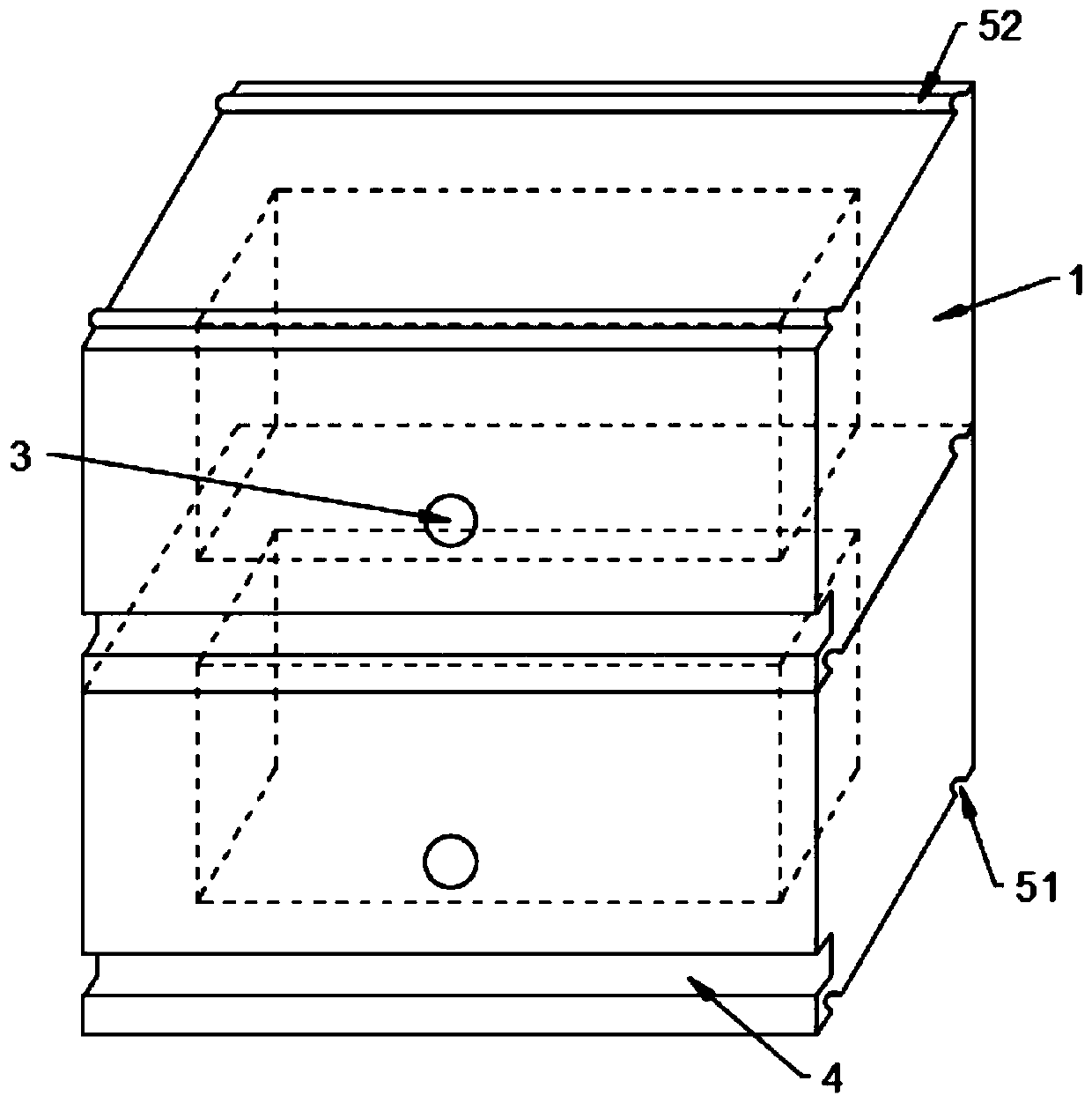

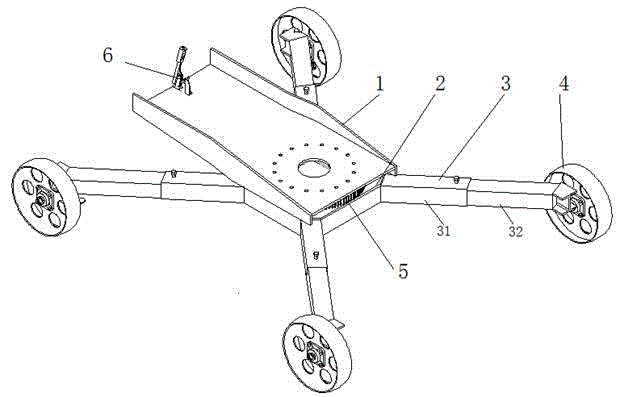

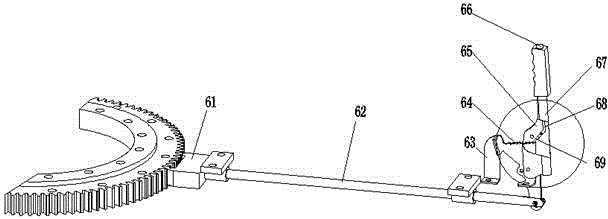

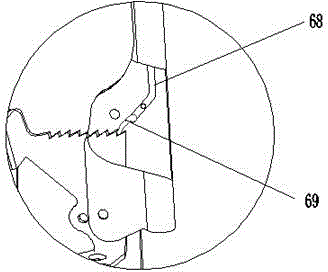

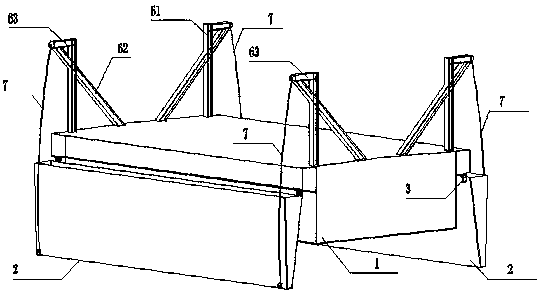

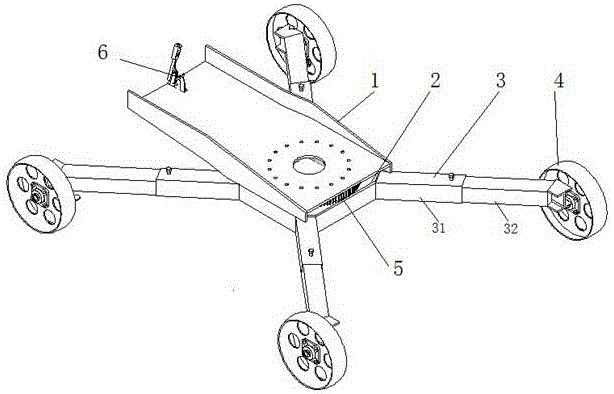

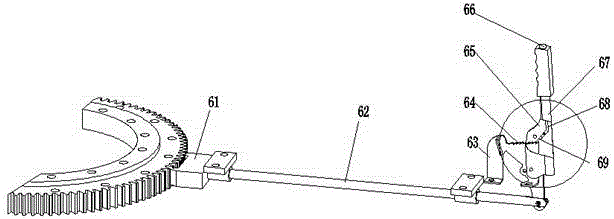

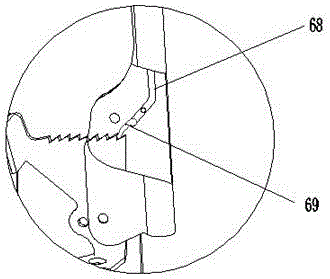

Crane underframe

The invention discloses a crane underframe which comprises a revolving platform, a base, a revolving support which is arranged between the revolving platform and the base, supporting legs which are fixed on the base, and traveling wheels which are arranged on the end parts of the supporting legs, wherein the outer ring of the revolving support is provided with teeth; a revolving locking mechanism of the underframe comprises a U-shaped fork, a pull rod, a locking handle and a limiting blocking block; the revolving locking mechanism and the revolving platform can form a four-rod mechanism comprising a moving pair; the limiting blocking block is provided with ratchets; the locking handle is internally provided with a pressing rod, and pawls matched with the ratchets; each supporting leg is composed of a crossed beam and a stretching leg which are made from rectangular-section-type square pipes; the crossed beams are fixedly connected with the base; the stretching legs are connected with the crossed beams in an inserting manner and then are fixed by tightening bolts. The crane underframe is simple in structure, safe, reliable, high in environment adaptability and convenient to dismount, mount and transport.

Owner:SHANDONG JIANZHU UNIV

Two-axis grating positioning lifting device for sewage factory and work principle thereof

InactiveCN106873637AIngenious designCompact structureControl using feedbackEngineeringSmall footprint

The invention discloses a two-axis grating positioning lifting device for a sewage factory and a work principle thereof. The two-axis grating positioning lifting device includes a chassis seat, side plates, a Z-axis rotating rack, a rotating plate, an X-axis rotating rack, and a controller, the Z-axis rotating rack is arranged on the chassis seat and is in driving connection with the Z-axis rotating rack, the two side plates are arranged at the two sides of the Z-axis rotating rack, the X-axis rotating rack is arranged on the side plates and is fixedly connected with the side plates, the top end of the X-axis rotating rack is provided with the rotating plate, the rotating plate is in driving connection with the X-axis rotating rack, and the controller is arranged between the Z-axis rotating rack and one of the side plates. The two-axis grating positioning lifting device for the sewage factory is simple and compact in design, reasonable in integral structure, and easy to install and maintain. The device is high in tracking precision, low in cost, low in energy consumption, safe and stable in operation, less in land occupation, easy to transport, and wide in adaptability.

Owner:XUZHOU UNIV OF TECH

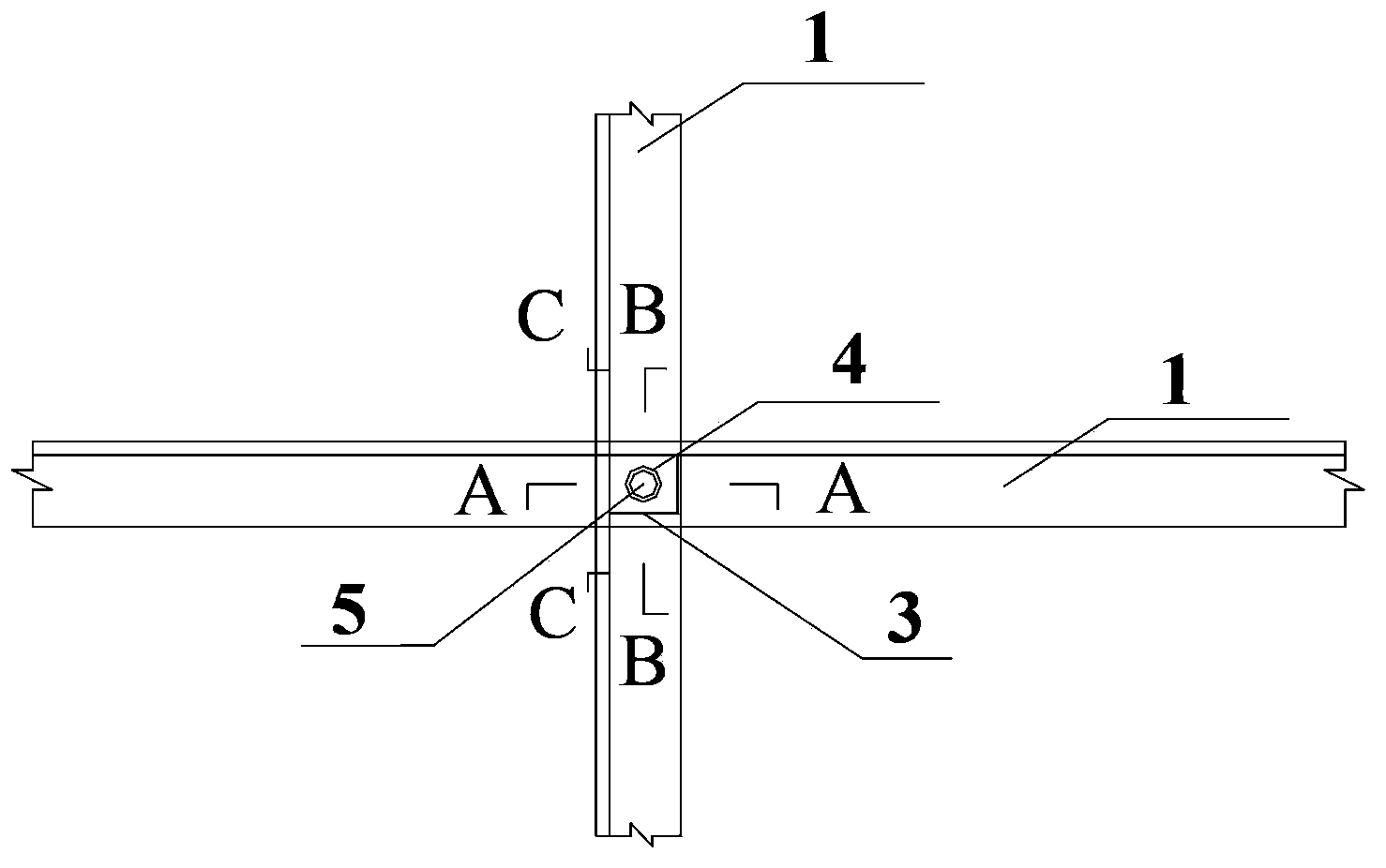

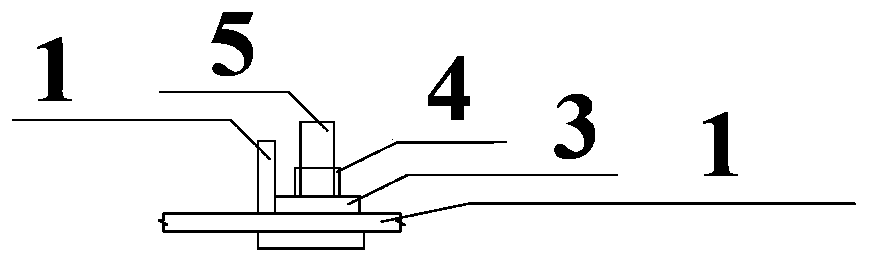

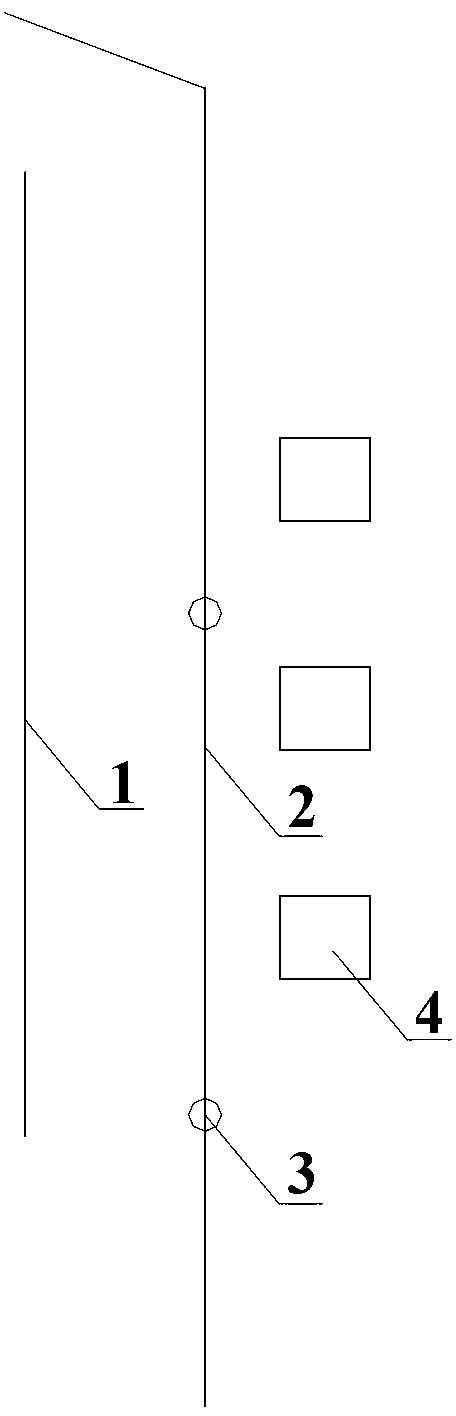

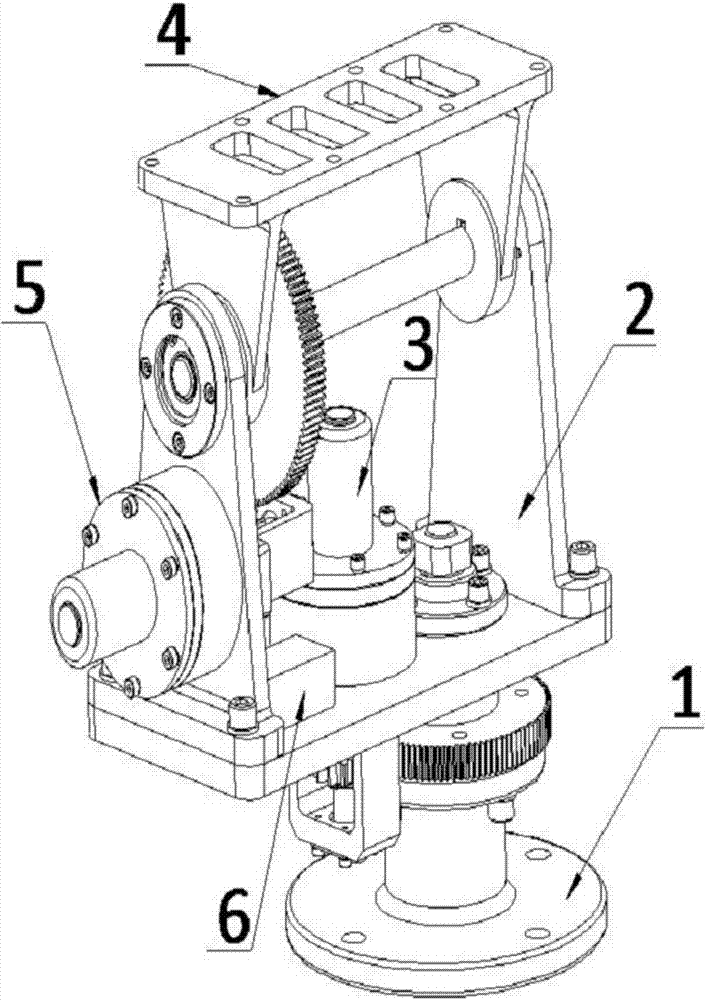

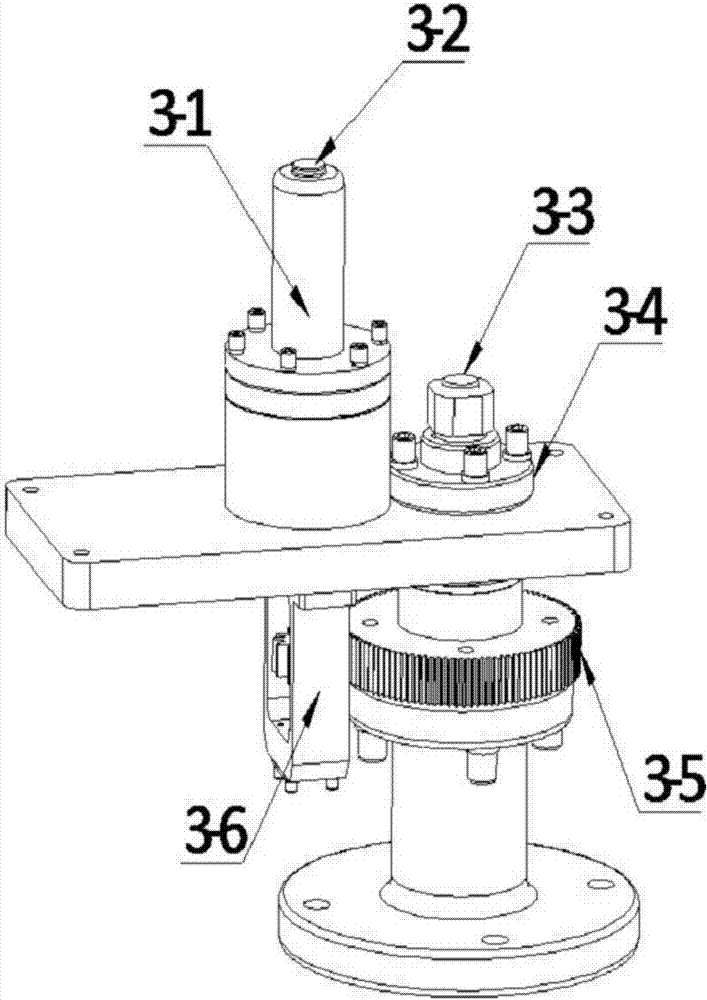

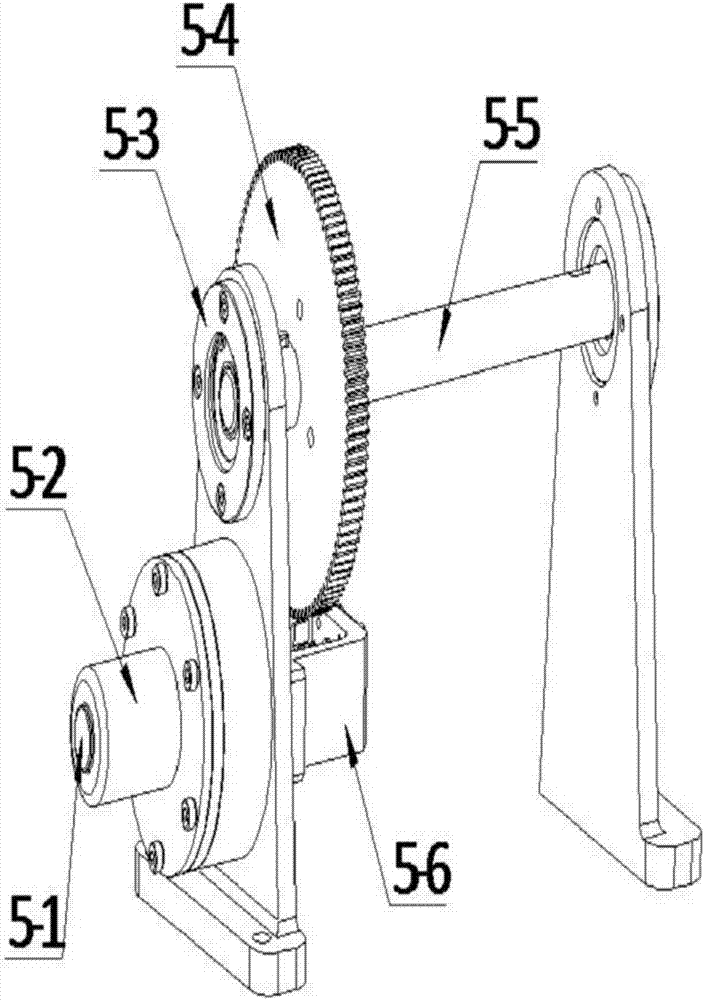

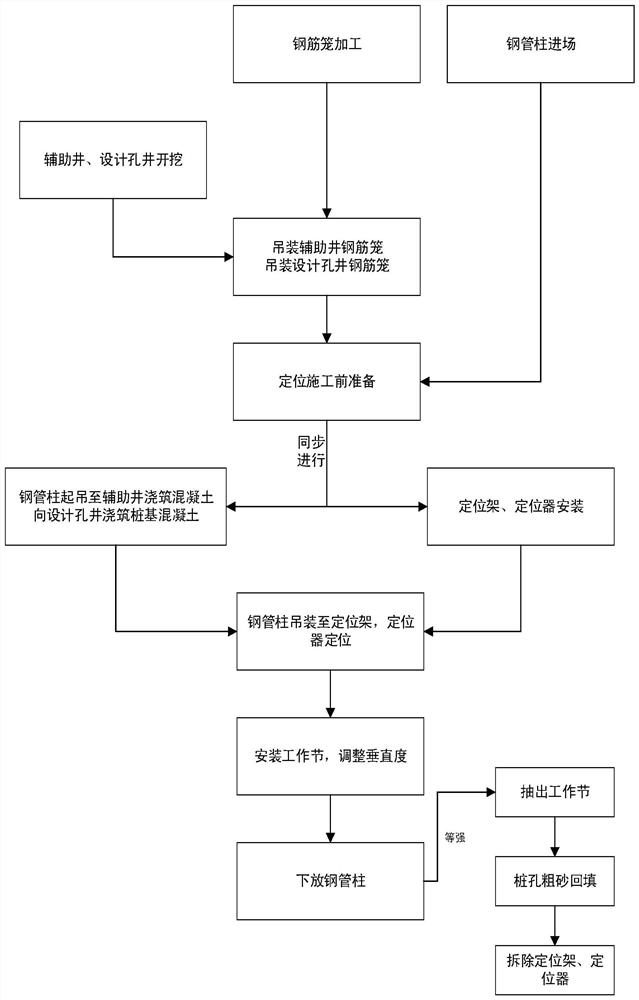

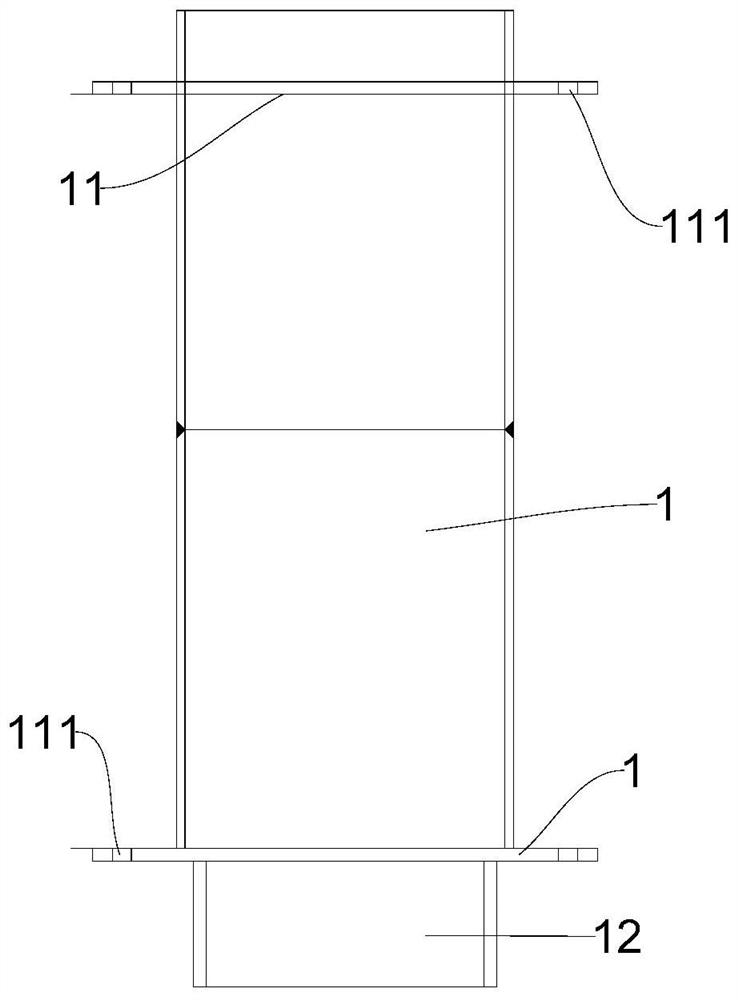

Steel pipe stand column positioning device and positioning construction method thereof

InactiveCN111676963ALow construction site requirementsEasy constructionBulkheads/pilesSteel tubePipe

The invention discloses a steel pipe stand column positioning device and a positioning construction method thereof. The steel pipe stand column positioning device comprises a positioning frame and a working section, wherein a steel pipe column penetrates through a stand column hole of the positioning frame to enter a designed hole well, the working section is connected with the steel pipe column,an adjusting device on the positioning frame adjusts the perpendicularity of the steel pipe column through the working section, the steel pipe column is positioned by using the positioning frame and apositioner, and the perpendicularity of the steel pipe column is adjusted by the working section and a telescopic oil cylinder. According to the steel pipe stand column positioning device and the positioning construction method thereof, accurate positioning of the steel pipe column in a narrow construction site is realized, the positioning precision is high, stable and controllable, deviation iseasy to correct, the operation method is simple and convenient, the technical difficulty is low, tool equipment can be recycled, the cost is low, the economic benefit is obvious, super concrete capable of keeping plasticity for a long time is newly arranged, the problems that the steel pipe column is inserted into a pile foundation to be resisted, and pile pulling is difficult are solved, the steel pipe column construction method is changed into a positioning frame rear-inserting method, concrete pouring is carried out on the interior of the steel pipe column in advance, the positioning frameis subjected to line production, the construction efficiency is improved, and the construction progress is accelerated.

Owner:CHINA POWER CONSTR SOUTHERN CONSTR INVESTMENT CO LTD +2

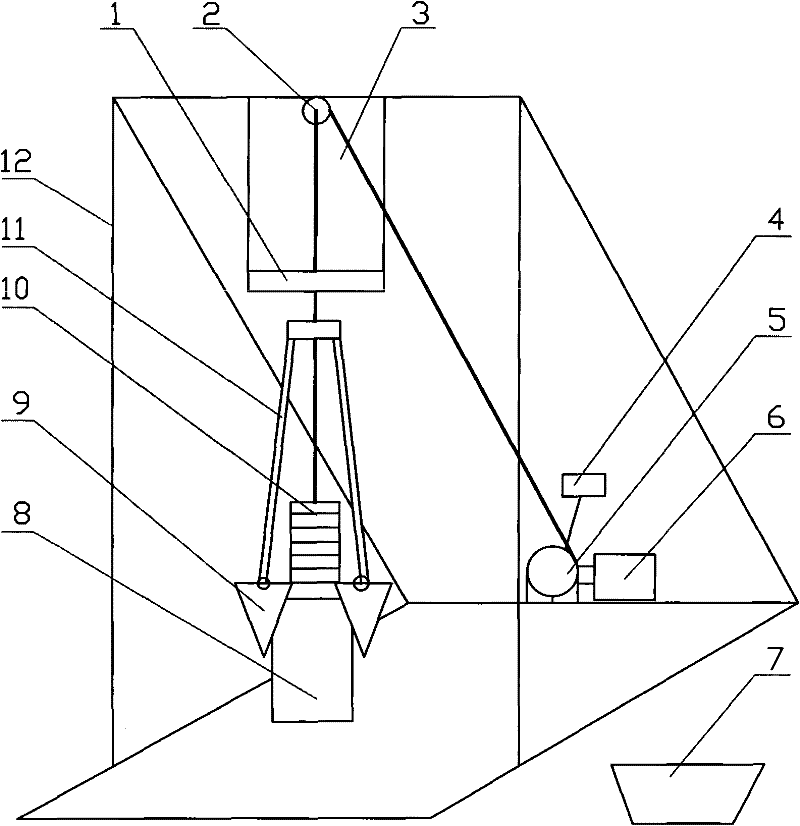

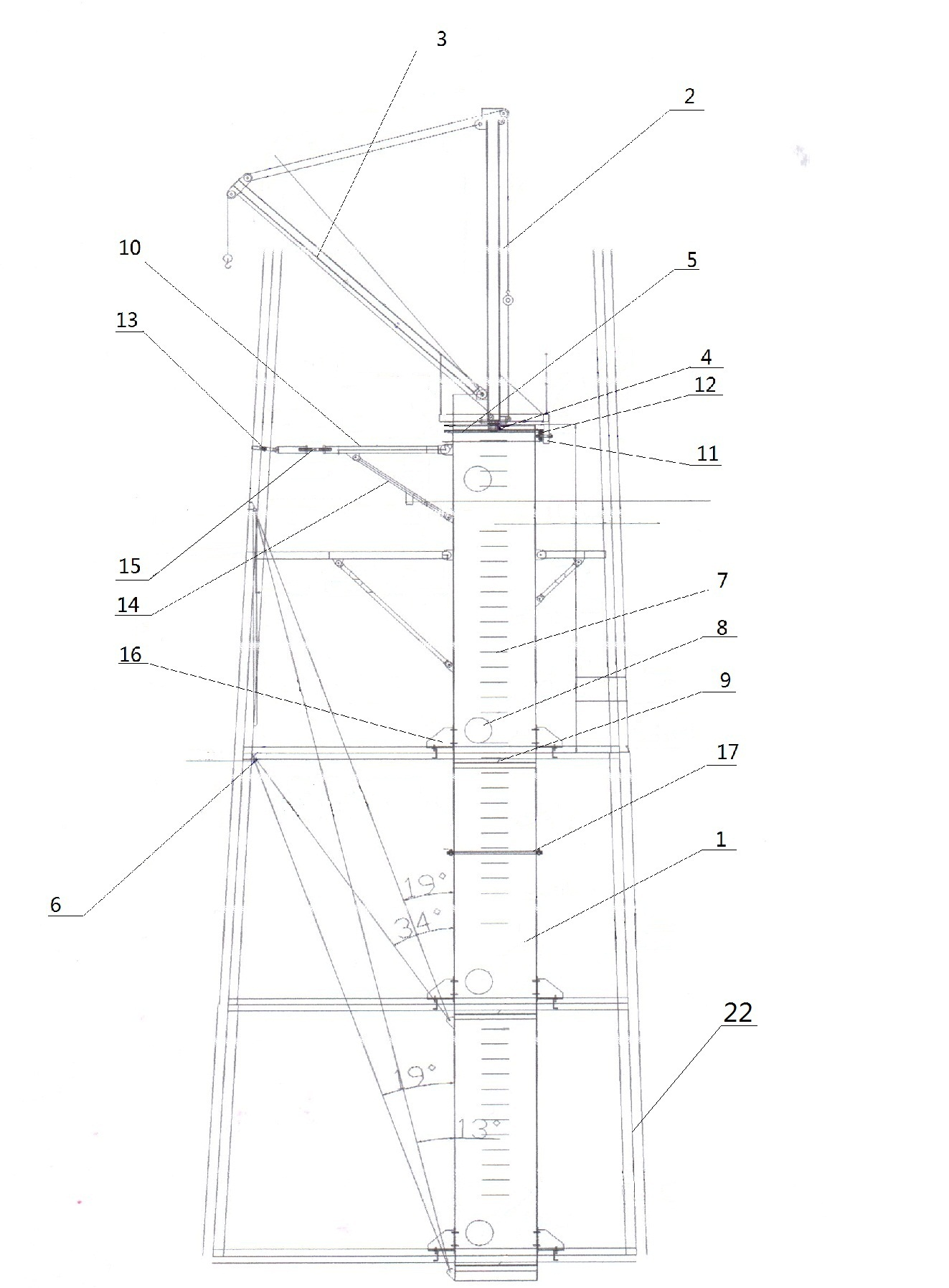

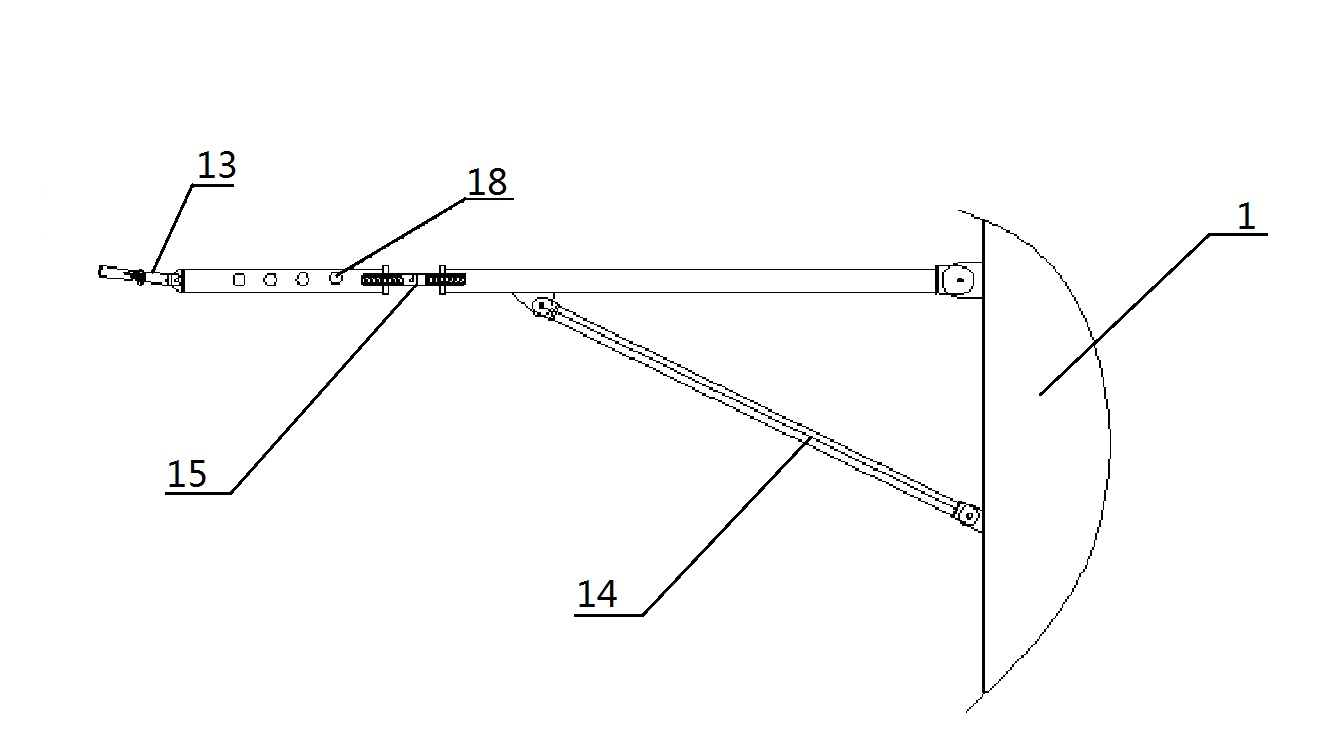

Self-elevating rotating crane installation device for tall towers

ActiveCN102642781AInstallation quality control technology is reasonableImprove installation qualityCranesChemical industryBall bearing

Disclosed is a self-elevating rotating crane installation device for tall towers which relates to an installation device of tower cranes. The device mainly comprises a center cylinder, a primary mast and a secondary mast, wherein the primary mast is arranged on the top of the center cylinder, a plane thrust ball bearing is arranged at the connection portion of the primary mast and the center cylinder, the primary mast and the plane thrust ball bearing are fixed on a top plate of the center cylinder through a nut, the primary mast is connected with the secondary mast, the center cylinder is connected with a cross beam of a tower frame, a ladder stand is arranged on the center cylinder, an operation hole is arranged on a center cylinder body, a platform is arranged on the inner portion of the center cylinder, the arrangement of the platform is matched with the operation hole, and an operation platform is arranged on the periphery of the top of the center cylinder. The device is suitable for all tall tower structures which are required to be assembled and installed on site in new-built, technically-improved and renovation items in smelting and chemical industries. Particularly, the device can be used for installing tall towers without large cranes on narrow construction sites and can effectively improve quality and accuracy of on-site assembly and installation of towers.

Owner:YUNNAN CONSTR & INSTALLATION JOINT STOCK +1

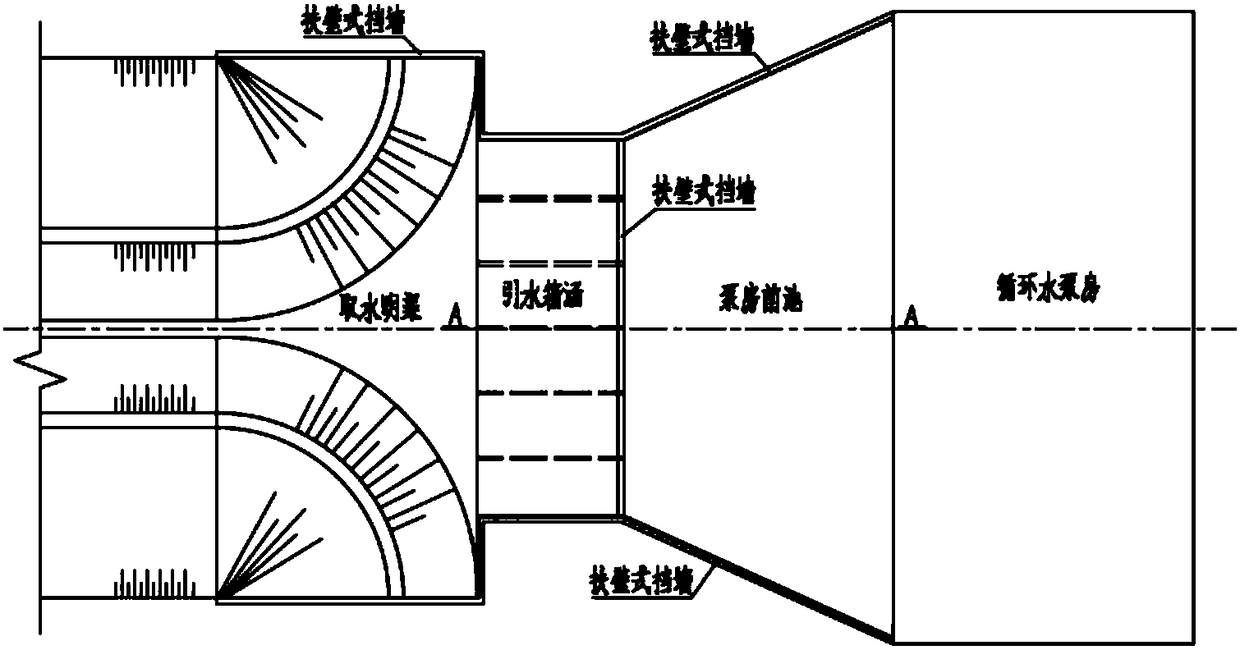

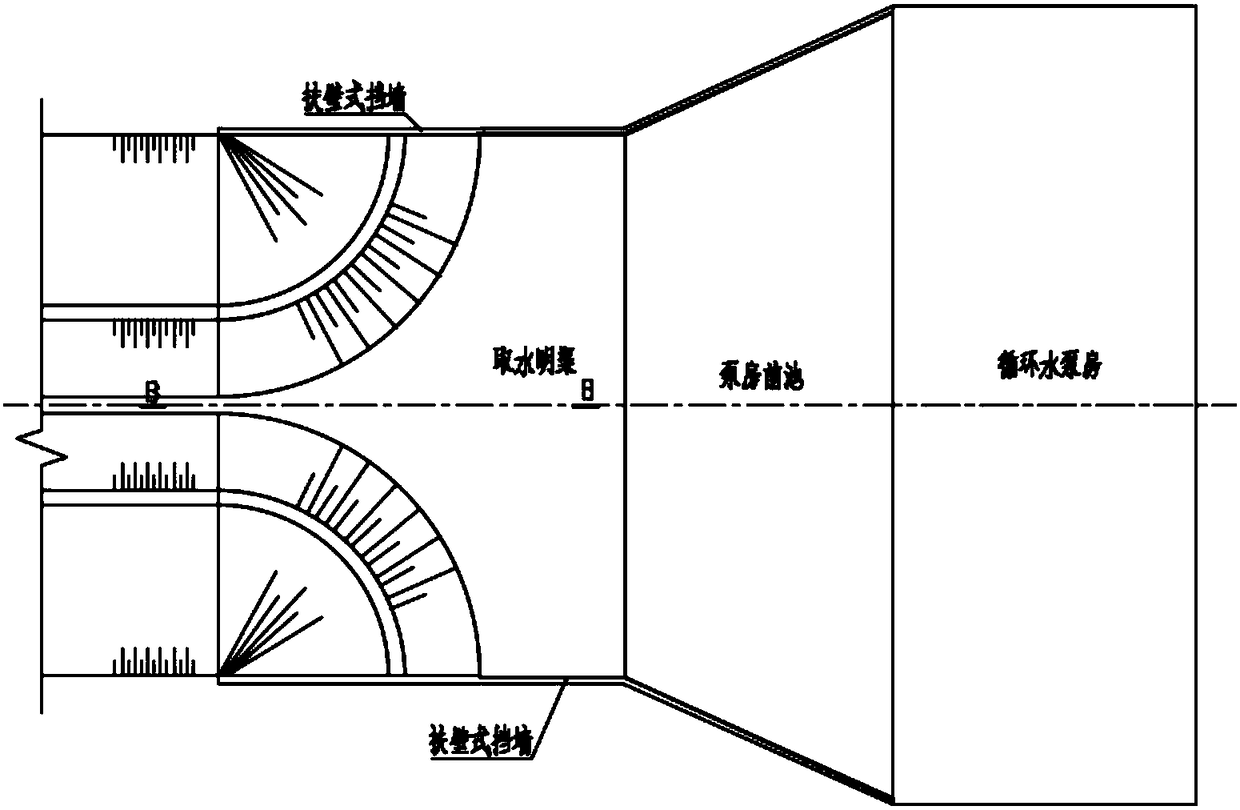

Water intake structure

ActiveCN109306720ASimple structureLow construction site requirementsDrinking water installationEngineeringWater intake

The invention relates to a water intake structure of coastal thermal power plants. The water intake structure comprises a water intake open channel, a pump house fore bay and transition sections; thewater intake open channel comprises two slopes oppositely arranged, and the two slopes are defined to form a water intake channel; the pump house fore bay comprises two side walls oppositely arranged,and the two side walls are defined to form a water inlet of the pump house fore bay; the two transition sections are connected between the two slopes and the two side walls respectively, and the twotransition sections are defined to form a transition channel communicated between the water intake channel and the water inlet; each transition section comprises a first connecting end connected withthe corresponding side wall, a second connecting end connected with the corresponding slope and a transition surface, and the transition surface is connected between the first connecting and the second connecting end, and is a hook face facing the transition channel. The water intake structure is low in cost, and can be applied to construction plants with a small space.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

Jumping type movable lifting and installing method of wavy roof steel structure trusses

InactiveCN110886493AReduce construction costsFast constructionExtraordinary structuresBuilding material handlingArchitectural engineeringRoad surface

The invention provides a jumping type movable lifting and installing method of wavy roof steel structure trusses. The jumping type movable lifting and installing method includes the following steps ofS1, making a preparation and paving at least two pavements on a construction field; S2, assembling the trusses to prepare a plurality of space frame bodies; and S3, hoisting the space frame bodies, wherein one space frame body is hoisted by small truck-mounted cranes onto concrete columns at one end of the construction field, the space frame bodies are carried to the adjacent concrete columns, the space frame bodies are carried onto the concrete columns at the other end of the construction field step by step, and in this way, the next space frame bodies are hoisted until all the space frame bodies are hoisted. By means of the installing method, no high-tonnage cranes need to be adopted, only two small-and-medium-sized cranes need to be used for lifting and hoisting, the construction speedis high, the requirements for the construction field are not high, and the method can also be implemented in a project with a narrow field; and no supporting beg-jigs need to be erected, and the construction cost is effectively saved.

Owner:HUNAN JINHAI STEEL STRUCTURE

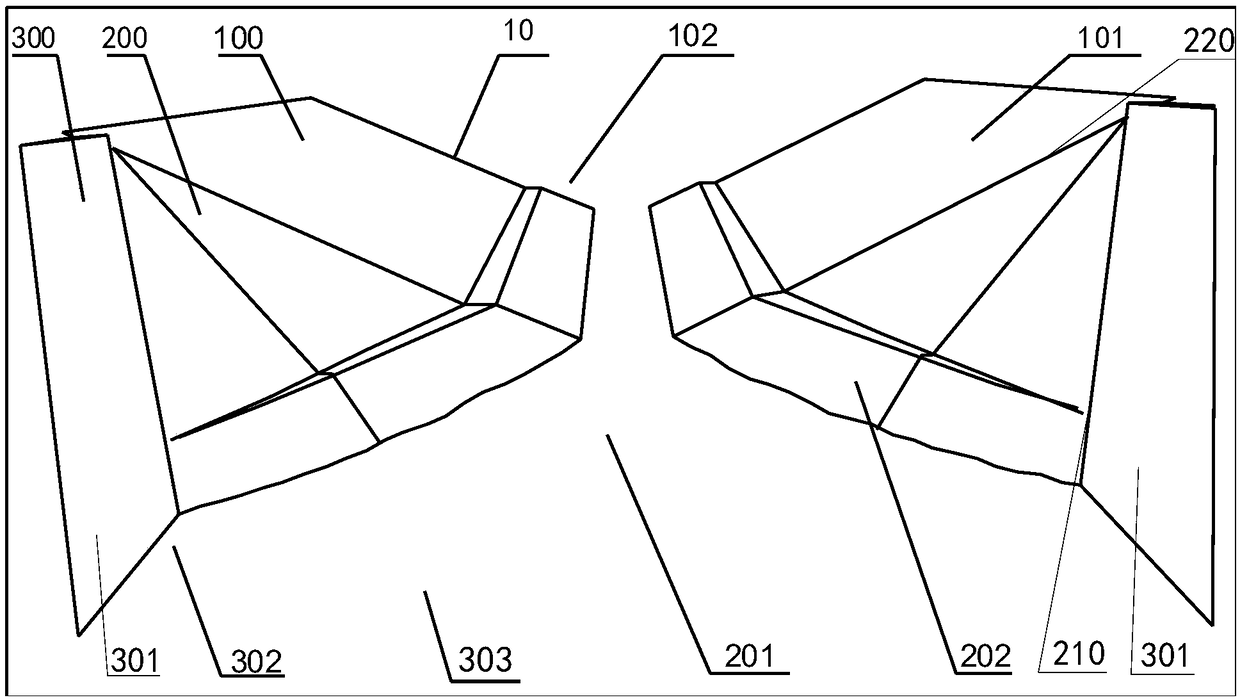

Ultra-wide steel box girder component of a bridge and a water splicing method thereof

InactiveCN109137711ASolve ultra-wideReduce usageBridge structural detailsBridge erection/assemblyEngineeringSteel box girder

The invention relates to an ultra-wide steel box girder component of a bridge. The ultra-wide steel box girder component of the bridge includes a main body unit and a flank unit pivotally connected with that main body unit, and the flank unit naturally drops and is located on both sides of the main body unit under the action of its gravity. The invention relates to a water splicing method of ultra-wide steel box girder component of the bridge includes 1. the ship transports the oversized members of the wing unit down to the area to be installed; 2, that support is erect and welded on the top surface of the main body unit of the box gird component; 3, the inverted chain is passed through the upper hanging lug and the lower hanging lug; 4, the side wing unit is rotated to the splice positionby the inverted chain, and then locking the inverted chain to weld the side wing unit and the main body unit; Step 5, the brackets are detached, and the transportation of the ultra-wide components and the assembly on the water are completed. The invention solves the problems of the ultra-wide box girder component passing through the sluice gate and assembling on the water, hereby reducing the useof large-scale machinery, reducing the construction site requirements; guaranteeing construction quality, and speeding up construction speed and saving cost.

Owner:CHINA MCC20 GRP CORP +1

Protective structure and a protective construction method of an existing roadbed in culvert extension construction

PendingCN108951440AReduce engineering investmentImprove the protective effectGround-workRailway tracksSheet pileCulvert

The invention discloses a protective structure of an existing roadbed in culvert extension construction, which comprises an existing culvert body, The two sides of the entrance and exit are the existing roadbed slopes, and Larsen steel sheet piles are continuously driven into the roadbed slopes. The plane formed by the Larsen steel sheet piles is at an angle of 45 degrees to the central axis of the existing culvert. The starting end of the continuous Larsen steel sheet piles is 3.5 m away from the centerline of the existing line, and the end is located at the foot of the roadbed slopes. The protective structure disclosed by the invention has strong adaptability and good protective safety performance, has low construction cost and short construction period.

Owner:中铁株洲桥梁有限公司

A crane chassis

The invention discloses a crane underframe which comprises a revolving platform, a base, a revolving support which is arranged between the revolving platform and the base, supporting legs which are fixed on the base, and traveling wheels which are arranged on the end parts of the supporting legs, wherein the outer ring of the revolving support is provided with teeth; a revolving locking mechanism of the underframe comprises a U-shaped fork, a pull rod, a locking handle and a limiting blocking block; the revolving locking mechanism and the revolving platform can form a four-rod mechanism comprising a moving pair; the limiting blocking block is provided with ratchets; the locking handle is internally provided with a pressing rod, and pawls matched with the ratchets; each supporting leg is composed of a crossed beam and a stretching leg which are made from rectangular-section-type square pipes; the crossed beams are fixedly connected with the base; the stretching legs are connected with the crossed beams in an inserting manner and then are fixed by tightening bolts. The crane underframe is simple in structure, safe, reliable, high in environment adaptability and convenient to dismount, mount and transport.

Owner:SHANDONG JIANZHU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com