Construction device and construction method for pulling out piles through cooperation of rotating drilling machine and sleeve drill bit

A technology of rotary drilling rig and construction method, which is applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., and can solve the problem of restricting the application range of full rotary drilling rig for pulling out piles, the soil is prone to remnants of steel bars or concrete, pipe jacking, and shield tunneling To achieve the effect of light weight, simple construction method and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

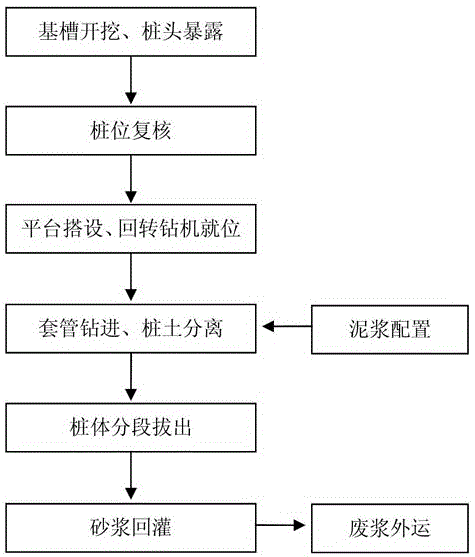

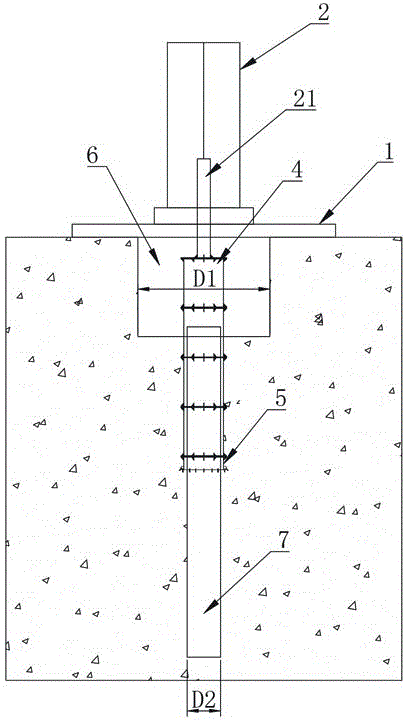

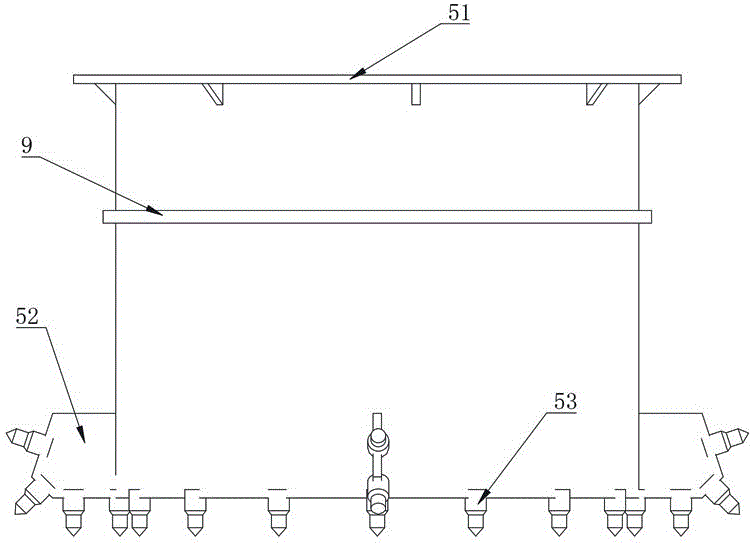

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0038] Such as Figures 1 to 9 As shown, the rotary drilling machine of the present invention cooperates with the casing bit pile pulling construction device, including the rotary drilling machine 2, the casing bit 5 and the casing group 4 composed of a plurality of casing pipes 41, at least one of the casing groups 4 The root casing 41 is detachably connected to the rotary drilling machine 2 , and the casing drill bit 5 is detachably connected to the bottommost casing 41 . The rotary drilling rig 2 in the device can walk on foot without a large tonnage crane for hoisting. The rotary drilling rig 2 is small in size, light in weight, simple and compact in equipment, simple in construction technology and low in construction cost. At least one casing 41 in the casing group 4 is detachably connected to the rotary drilling machine 2, and the casing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com