Landfill gas gas-collecting shaft construction method

A technology of landfill gas and construction method, applied in the field of landfill gas collection and utilization, can solve the problems of low construction efficiency, high cost, low efficiency, etc., and achieve cost reduction, gas collection efficiency improvement, and good permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

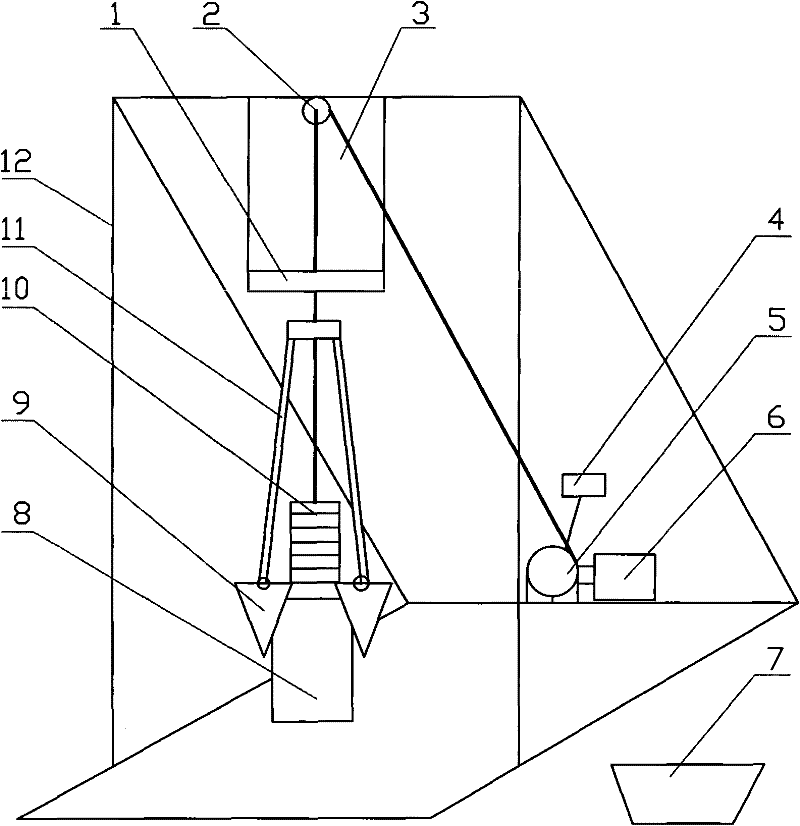

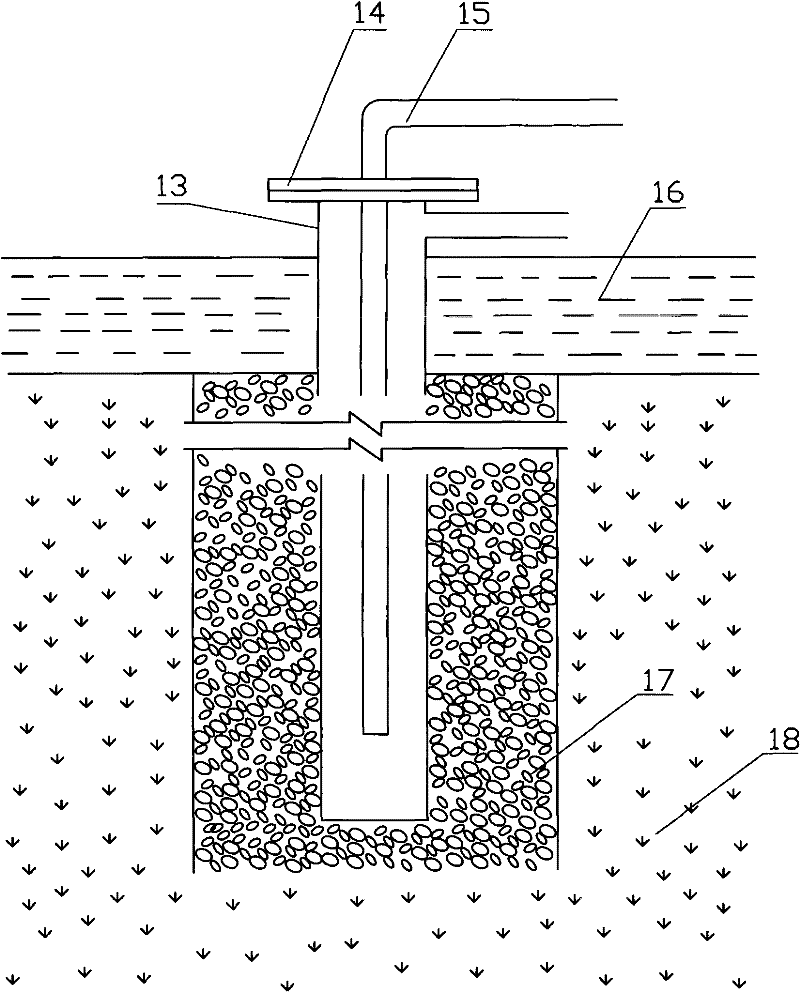

[0033] Refer to the attached figure 1 and 2 , a construction method for a landfill gas collection shaft, comprising the following steps:

[0034] a) erect the bracket 12 of the drilling equipment at the predetermined construction position, and the upper part of the bracket is provided with a fixed pulley 2;

[0035] b) a steel wire rope 3 passing through the fixed pulley is set, and a winch 5, a diesel engine 6 and a control cabinet 4 matching the steel wire rope are arranged to control the winding of the steel wire rope;

[0036] c) hang a grab bucket 9 with a connecting part preset at the bottom under the wire rope, and set a control device for controlling the opening and closing of the grab bucket; perform the following steps after completing the installation of the hole-forming equipment;

[0037] d) controlling the grab to open and release, causing it to drive into the predetermined hole-forming position;

[0038] e) After closing the grab to grab the material, lift th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com