Patents

Literature

43results about How to "Improve gas collection efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing one-dipping two-baking anode carbon block

The invention discloses a method for producing one impregnating two calcining anode carbon blocks, which is on the basis of producing common anode carbon blocks and comprises following steps: selectively using calcined coke, adding a little antioxidant additive, preheating a common anode under the temperature of 280-330DEG C for 18-24 hours, then, hoisting in a high pressure impregnation tank, filling impregnating pitch whose temperature is 160-180DEG C under the vacuum pressure of 0.09-0.094MPa, pressurizing 1.55-1.6MPa, maintaining the pressure for 3-5 hours, hoisting out and cooling to normal temperature, then, calcining for 200-220 hours under the temperature condition that the maximum temperature is 800-900DEG C according to a heating curve, cooling, and then cleaning up to obtain a new one impregnating two calcining anode carbon block. Since the pitch is filled in an air vent of the anode, the mechanicalness and the physical and chemical properties of the anode carbon blocks are newly changed, the bulk density and the compressive strength are increased, the porosity is lowered, the resistivity is lowered, the activity of the binder coke and the activity of aggregate tend to be consistent, the speed of selective oxidation is lowered, the voltage drop of the anode carbon blocks is lowered, and the using period of the anode is prolonged.

Owner:WEN COUNTY DONGFANG CARBON

Reinforced smoke discharging mode in aluminum cell opening operation

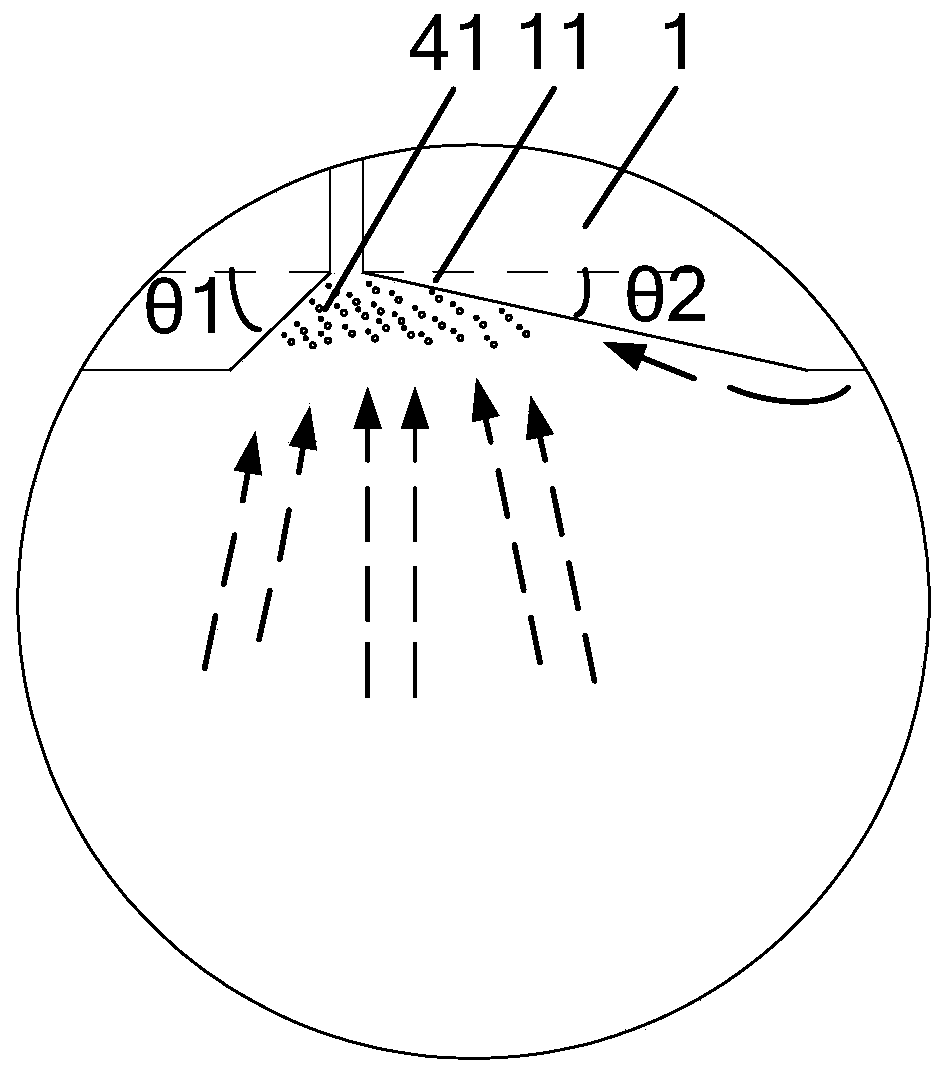

The invention discloses a smoke discharging method of aluminum cell, especially to an intensified smoke discharging method by hood-open processing. The invention accomplishes air-breathing by using air-proof space, which is formed by catelectrode, groove shell, horizontal cover plate of superstructure and seal closure, slot space on anode surface mulch as static pressure cabinet, ventilating structure and intensified ventilating path. The invention can ventilate efficiently, increase gas-collecting efficiency and inhibit contaminant emitting.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

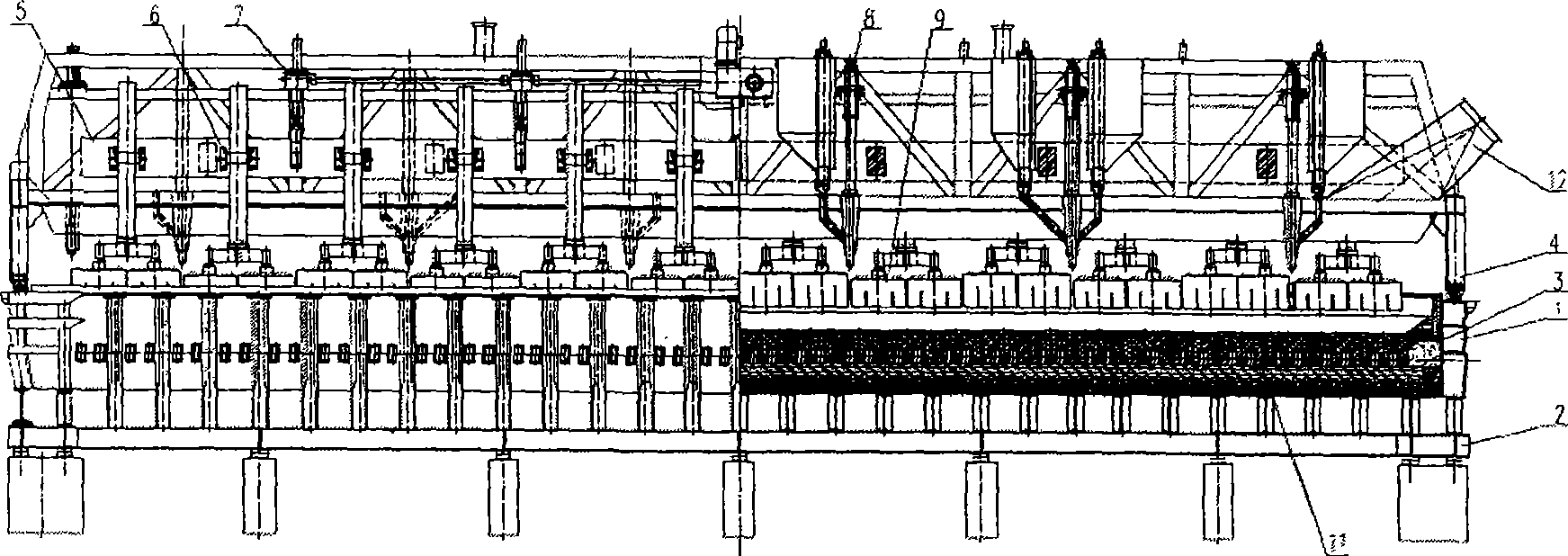

400kA energy-saving and emission-reducing pre-baked aluminum cell

Owner:NORTHEASTERN UNIV ENG & RES INST CO LTD

Pole changing method for prebaked-anode type cell

InactiveCN101319335AReduce power consumptionReduce negative impactNonferrous metalEnergy consumption

The invention belongs to the nonferrous metal aluminum electrolysis technical field, in particular relating to a method for changing anodes of a prebaked anode cell provided with 28 groups of anodes 200kA. The method is characterized in that: 4 groups of anodes in the corner of the first row and the second row adopt single-anode replacement during the anode replacement operation, and 24 groups of anodes in the middle adopt double-pole combined replacement. Due to adoption of the replacement means of double-pole combined replacement, the frequency of anode replacement operation is greatly reduced, thereby the negative influence on the electrolytic cell is reduced; and then the energy consumption per ton aluminum and the production cost per ton aluminum are reduced. Simultaneously, the work efficiency is also improved; the gas collecting efficiency of the electrolytic cell is improved; and the discharge of harmful gas is reduced.

Owner:FUSHUN ALUMINUM

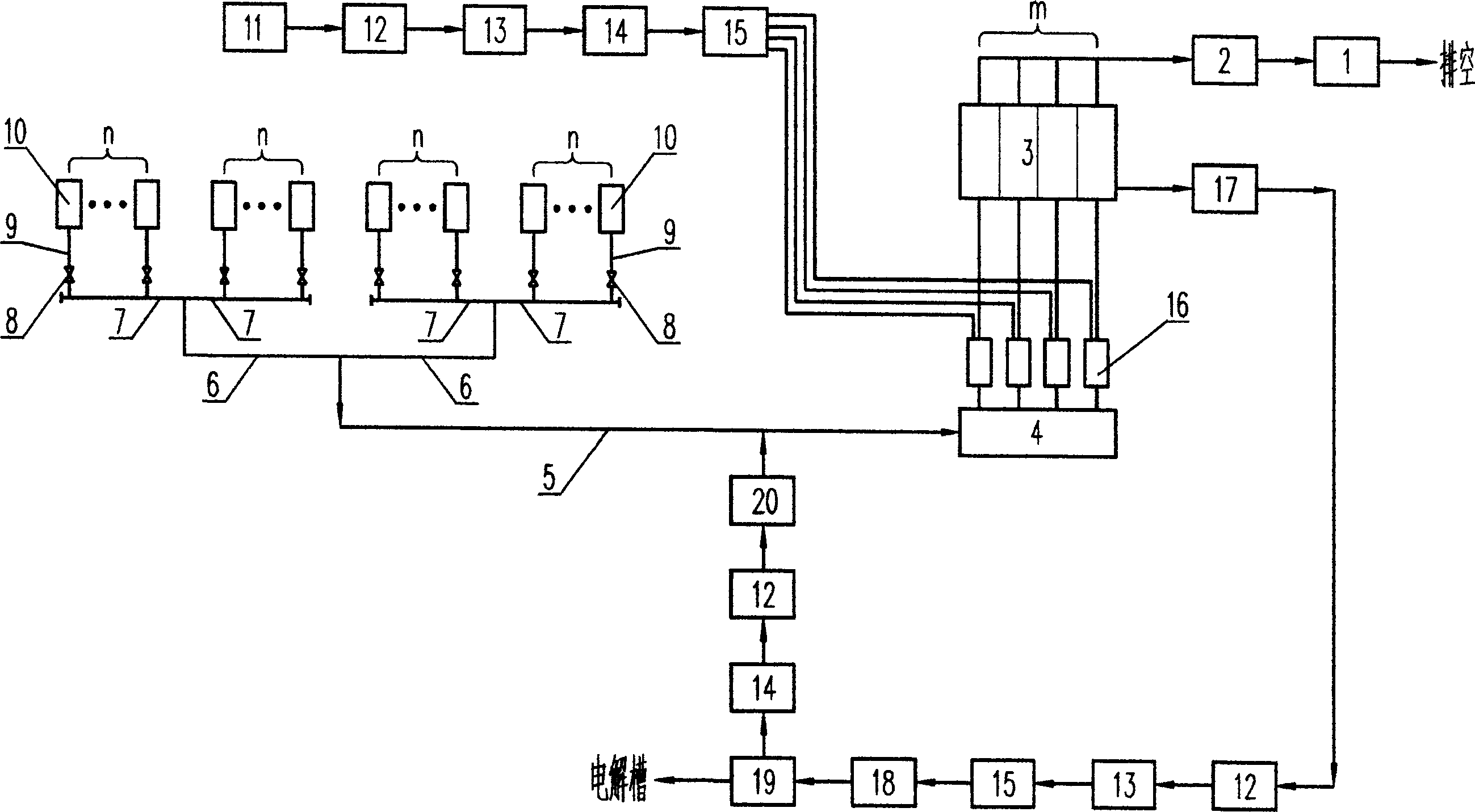

Process for purifying fluorine contg. flue-gas for aluminium electrolysis

ActiveCN1831201AUniform exhaustImprove mixing uniformityDispersed particle separationAluminium electrolysisEngineering

The invention discloses a purify technology of aluminum electrolyzing FI contained smoke that makes the smoke from electrolyzing FI passing through smoke evacuation branch pipe, smoke evacuation secondary main pipe, smoke evacuation main pipe and smoke evacuation total pipe spraying to impulse purifying filterer. Before coming into the filterer, the two steps material feeding would be taken and take adsorption reaction, and taking filtering and separating in the filterer. One section of the separated alumina containing FI could be used as the raw material to make electrolytic tank, and some would be return to the total pipe to mix with hydrogen fluoride. The purified smoke would be sent to air. The invention has short process, high efficiency, low power consumption, high reliable, no secondary pollution, etc.

Owner:GUIYANG AL-MG DESIGN & RES INST

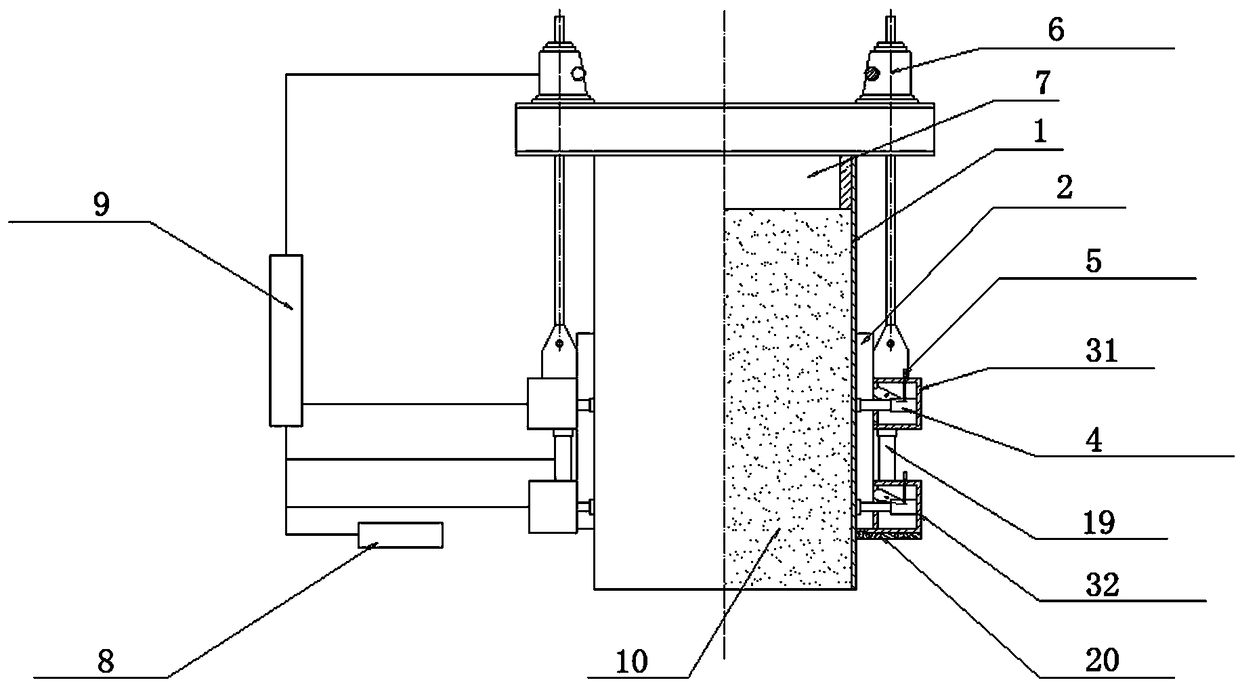

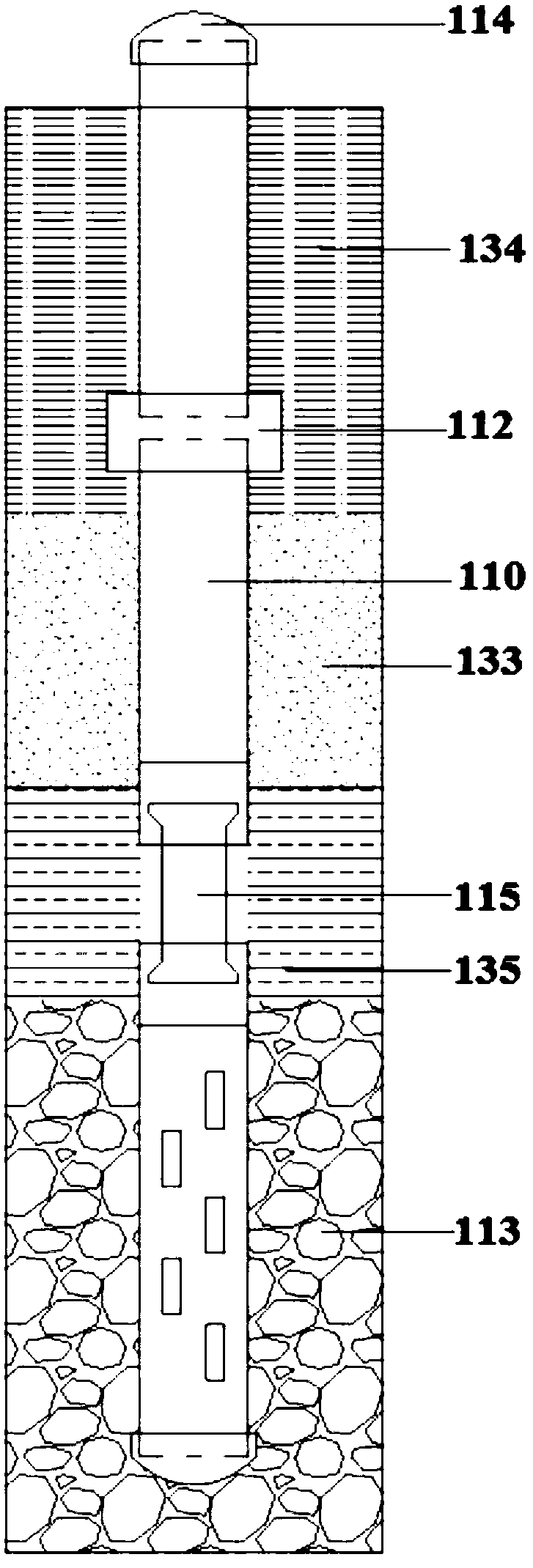

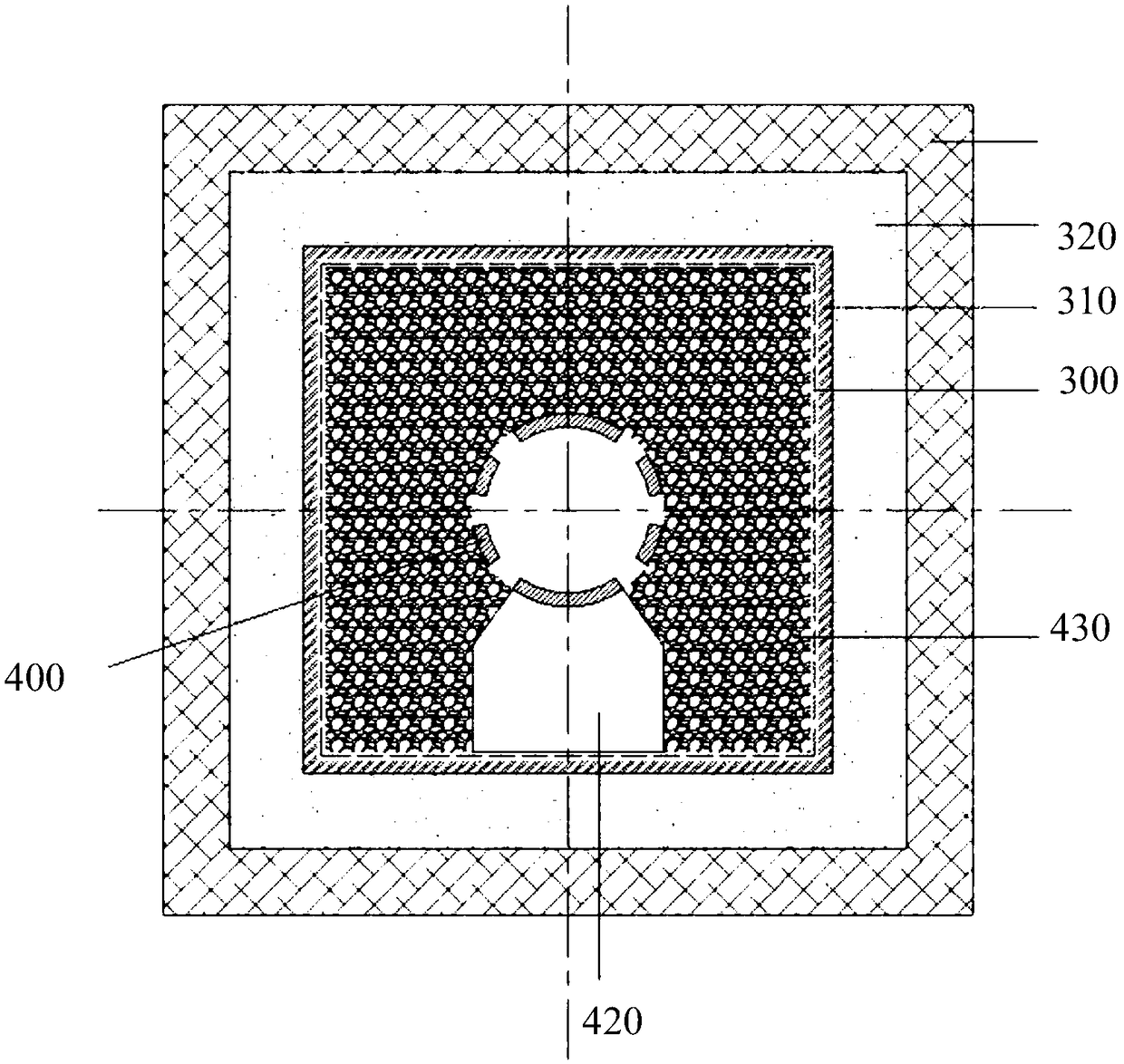

Aluminum electrolytic cell closed gas collecting device

The invention discloses an aluminum electrolytic cell closed gas collecting device. At least two electrolytic chambers are formed inside an aluminum electrolytic cell through an anode and a cathode; the anode is a self-baking anode, and an anode paste discharging system is arranged above the anode; three groups of flue gas gathering pipelines are arranged on the aluminum electrolytic cell, the first-stage flue gas gathering pipeline directly communicates with an inner space of a cell body, the second-stage flue gas gathering pipeline extends to the position, above the anode, inside the cell body, and the third-stage flue gas gathering pipeline extends into the cell body and is in butt joint with an anode paste feeding port in the top of the self-baking anode through the anode paste discharging system; and the aluminum electrolytic cell is provided with a two layers of sealing structures including the outer sealing structure and the inner sealing structure. By means of the aluminum electrolytic cell closed gas collecting device, the centralized treatment and recovery of the exhaust gas and the waste heat generated by the aluminum electrolytic cell adopting the multiple continuous operation chambers are realized, the ultra-low controllable discharge of air pollutant in the electrolytic cell is realized, the heat preservation state of the electrolytic cell is improved, the heat loss of the electrolytic cell is reduced, and the energy efficiency level of the electrolytic cell is effectively increased.

Owner:CENT SOUTH UNIV

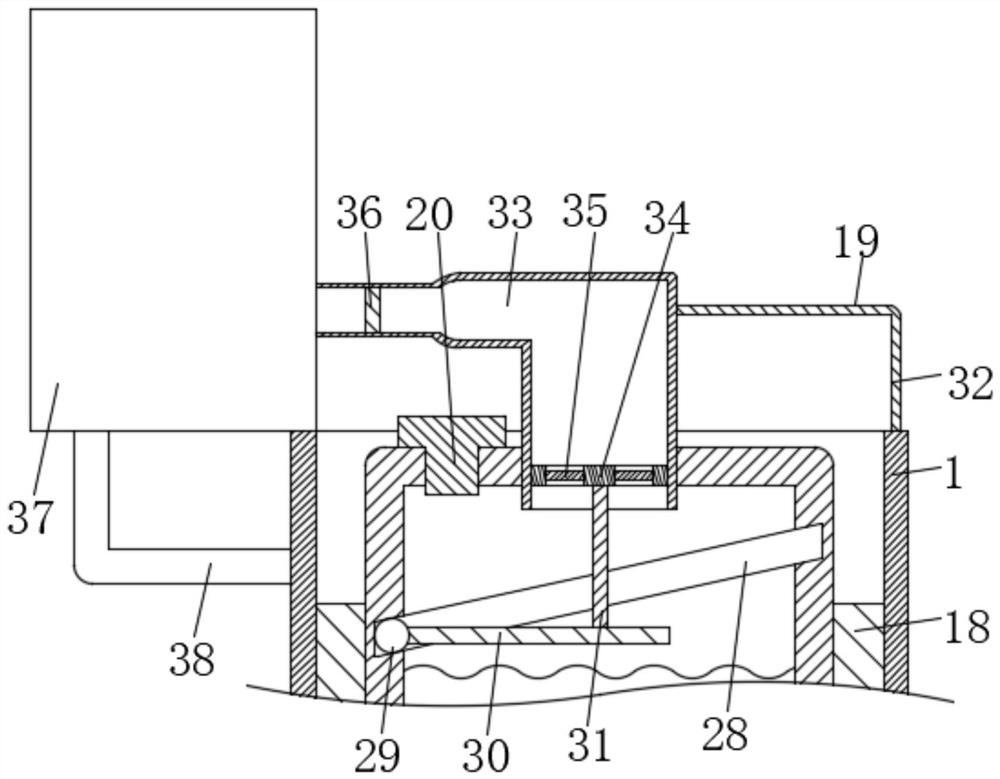

Method controlling cell voltage of electrolytic cell and clamping frame position

The invention relates to the technical field of aluminum electrolysis, in particular to a method controlling a cell voltage of an electrolytic cell and a clamping frame position. The technical problems that an existing cell voltage and clamping frame position control method is not reasonable, operation for lifting a clamping frame is complicated, and efficiency is low are solved. A device in use comprises a clamping frame and at least one aluminum tube anode arranged in the clamping frame and internally provided with a plurality of conductors; the aluminum tube anode comprises an aluminum tubein which the plurality of conductors in contact with the aluminum tube are arranged; at least one anode lifting mechanism connected with the clamping frame and used for adjusting the cell voltage isfurther included; the clamping frame is provided with a plurality of first pressing mechanisms in contact with the aluminum tube; at least one detecting unit is arranged around the clamping frame, andthe detecting unit, the first pressing mechanisms and the anode lifting mechanism are all connected with the control system; and a cell voltage signal of the electrolytic cell is acquired and input into the control system.

Owner:党星培

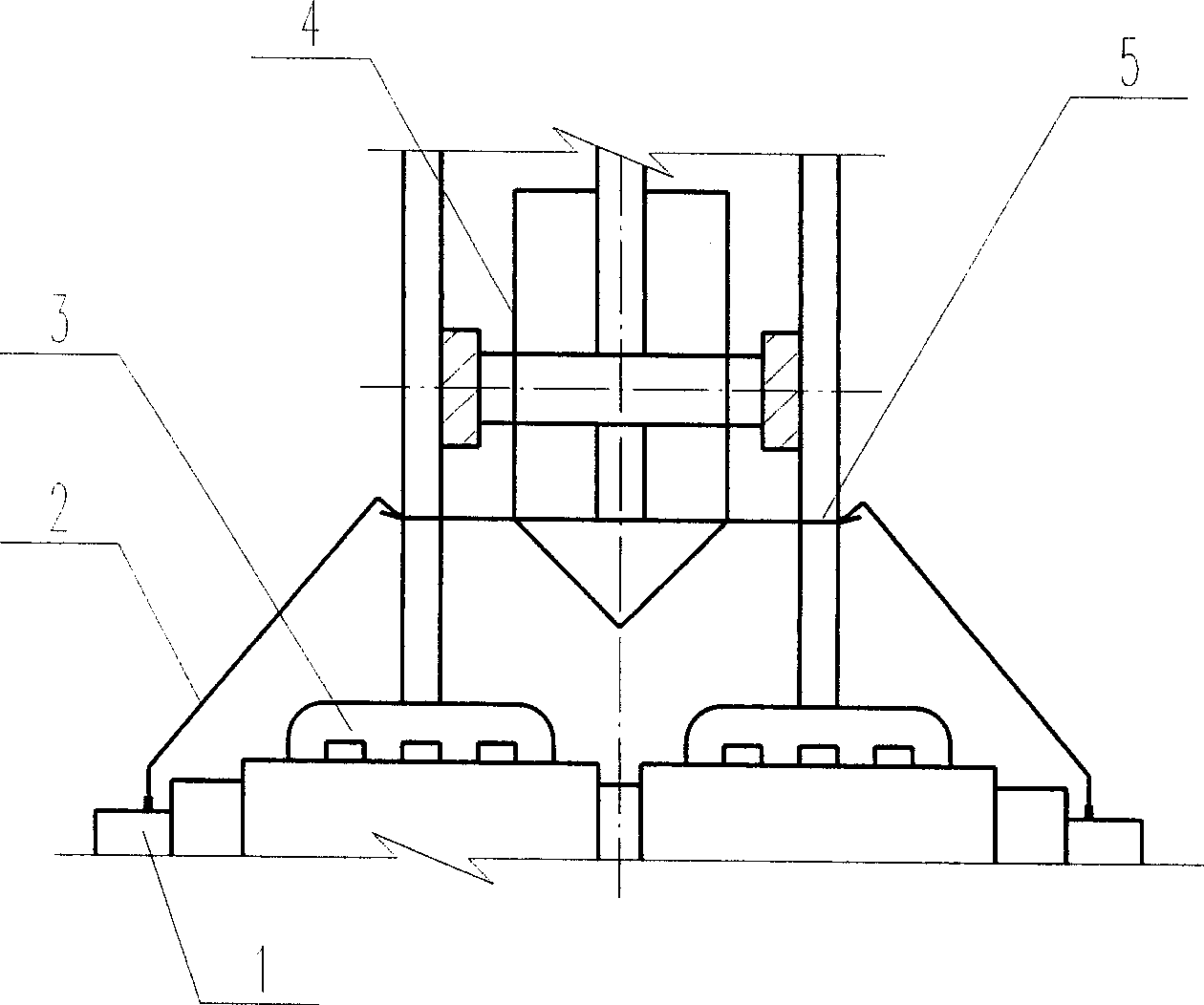

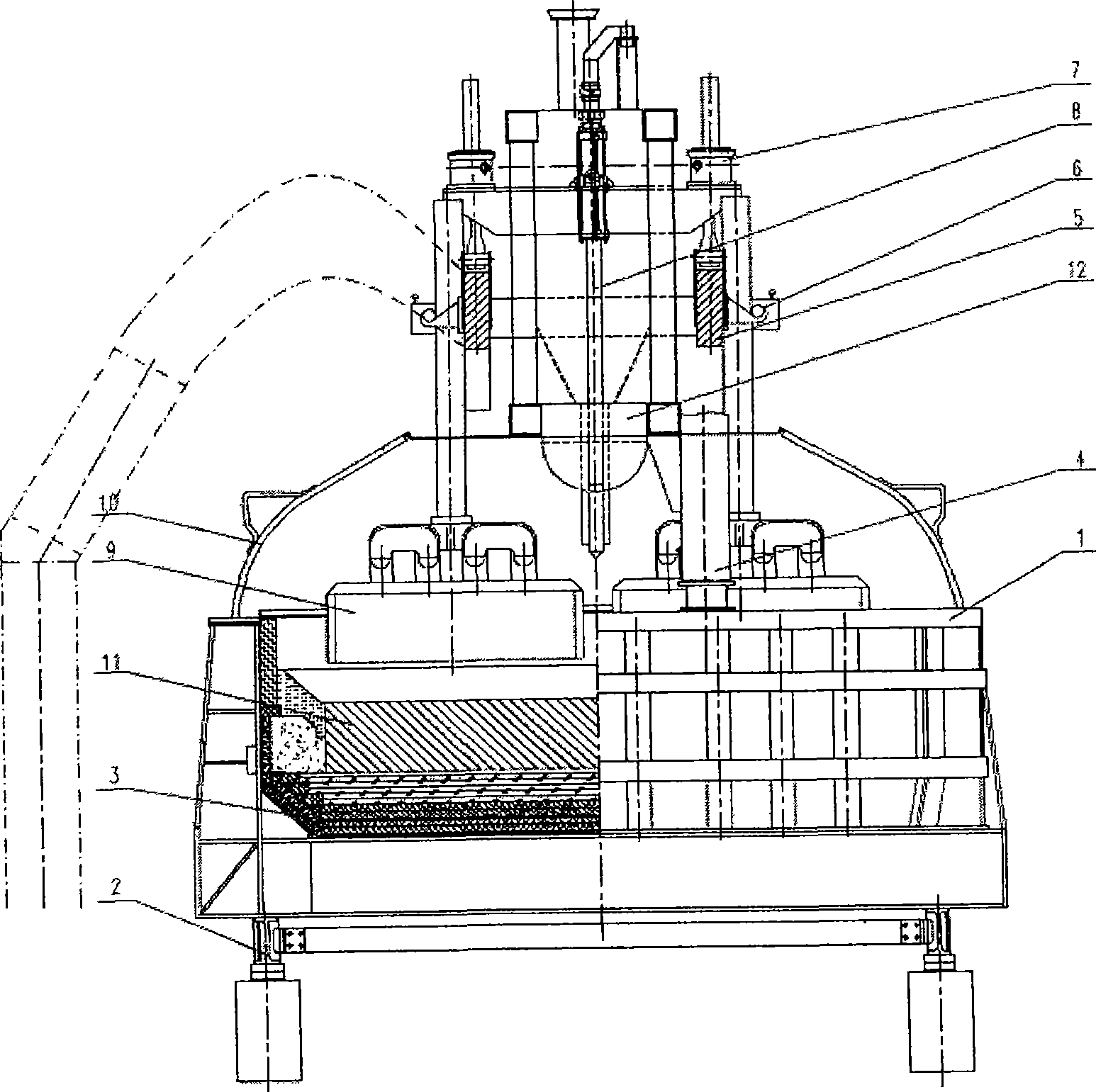

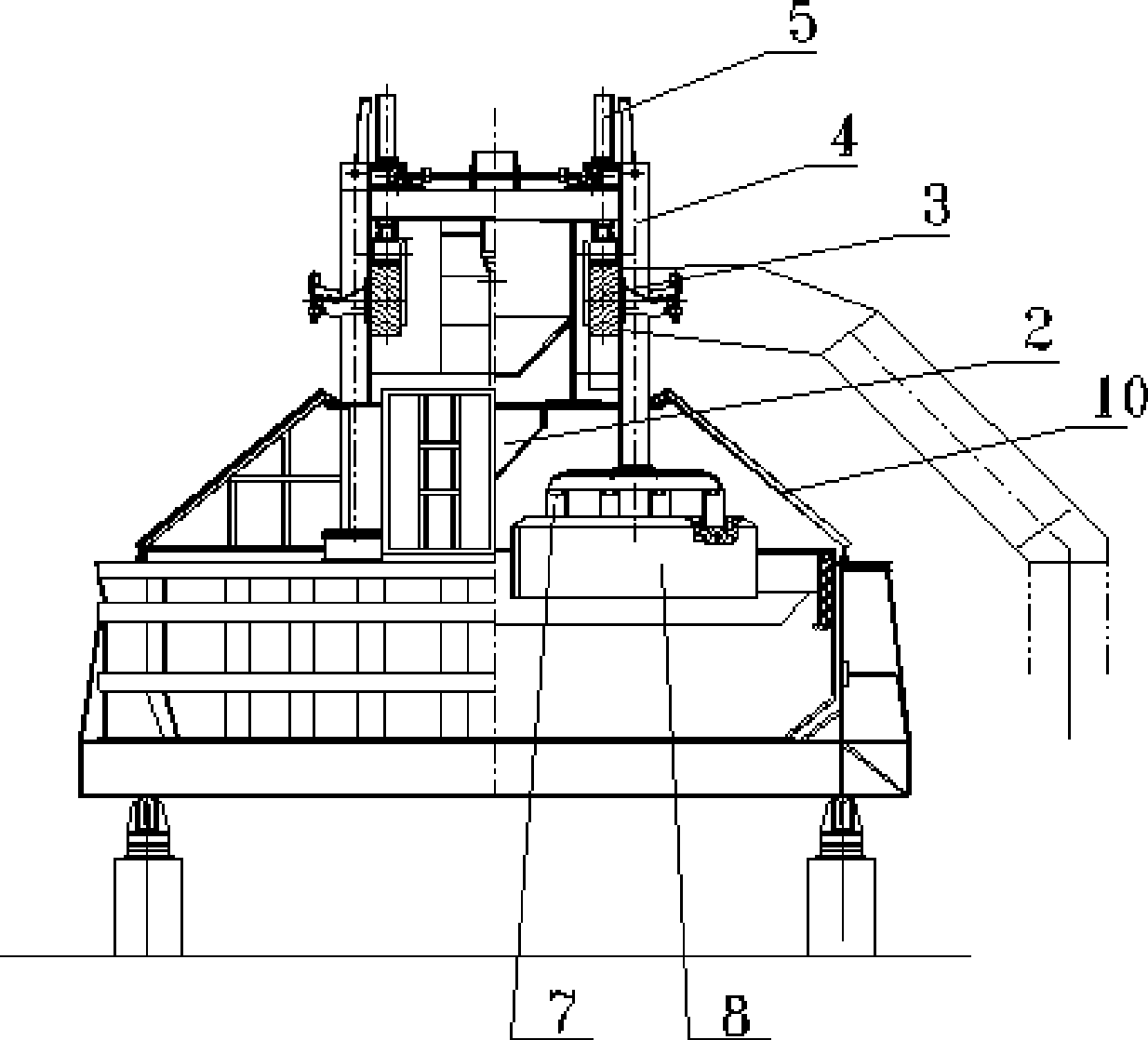

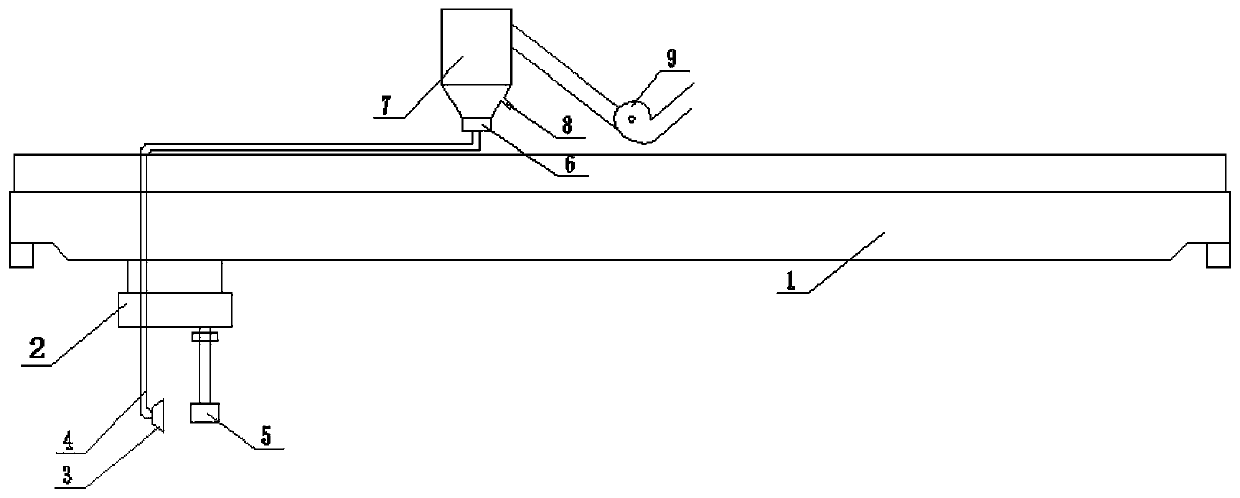

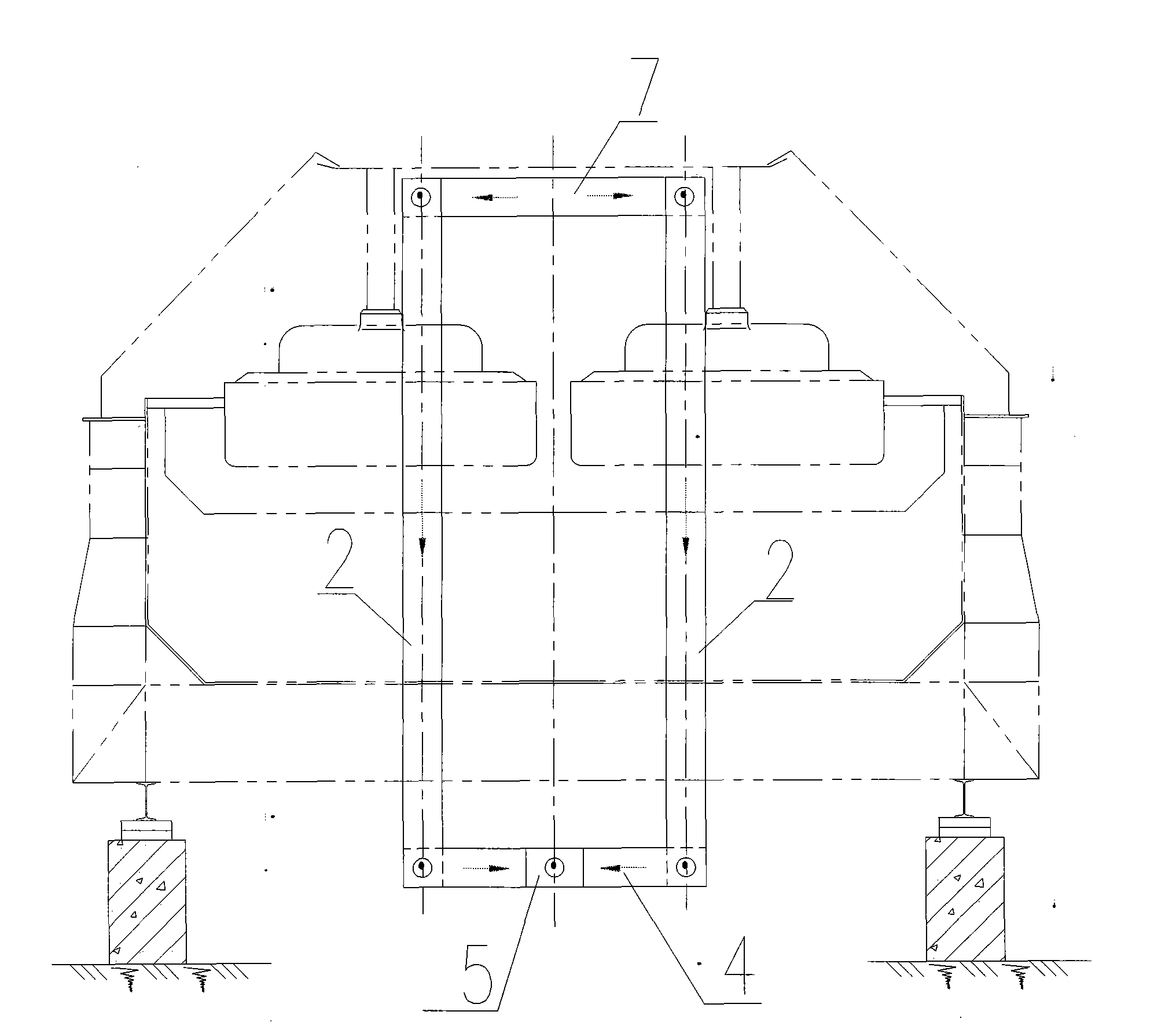

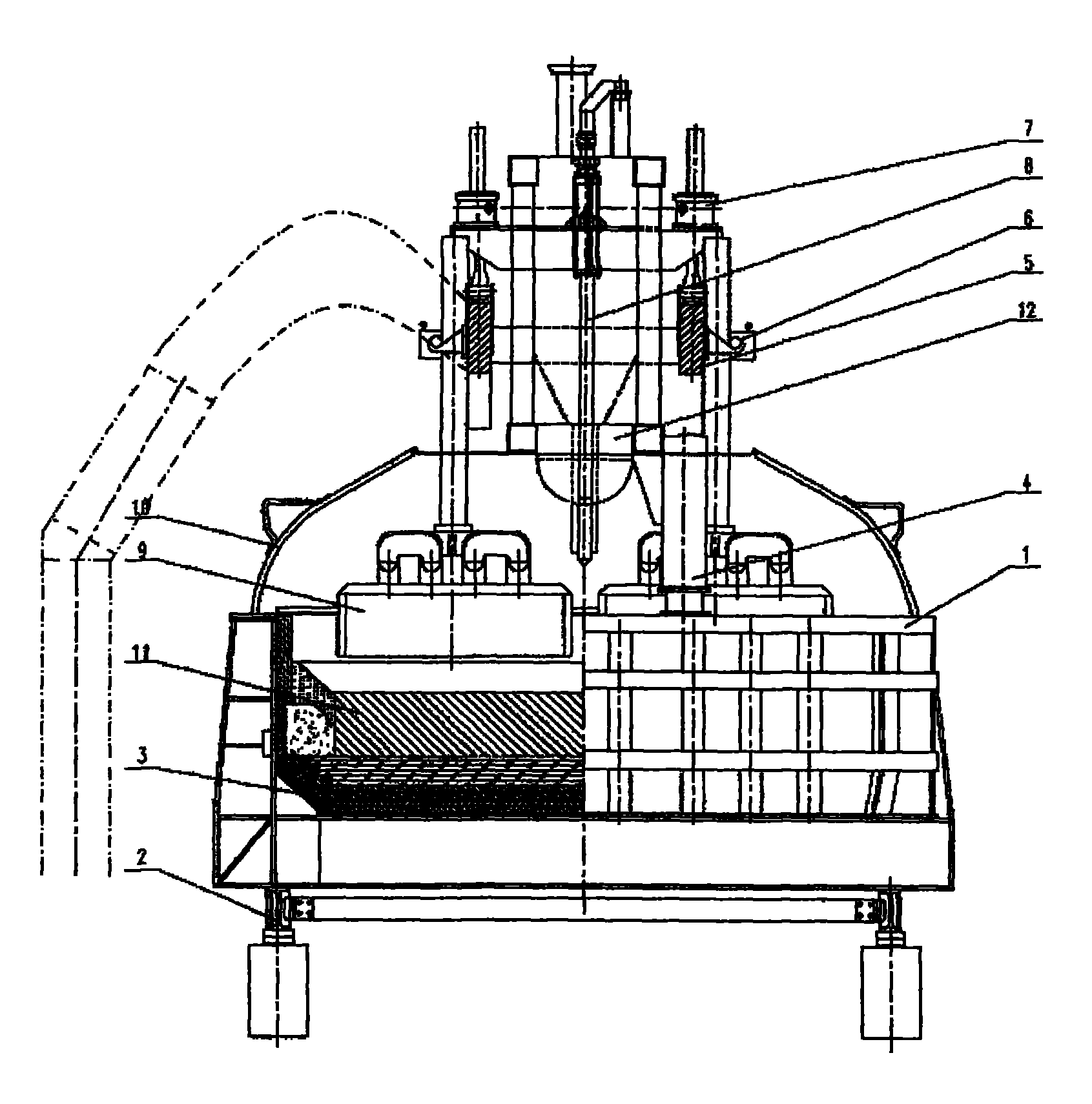

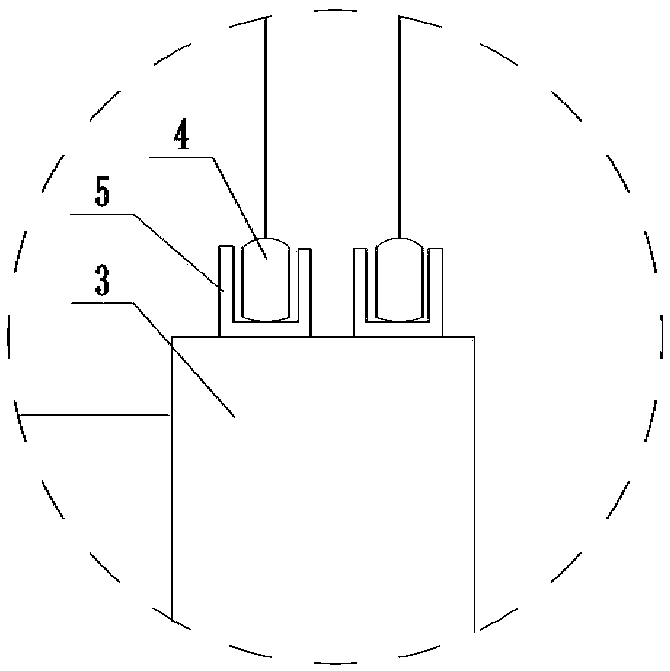

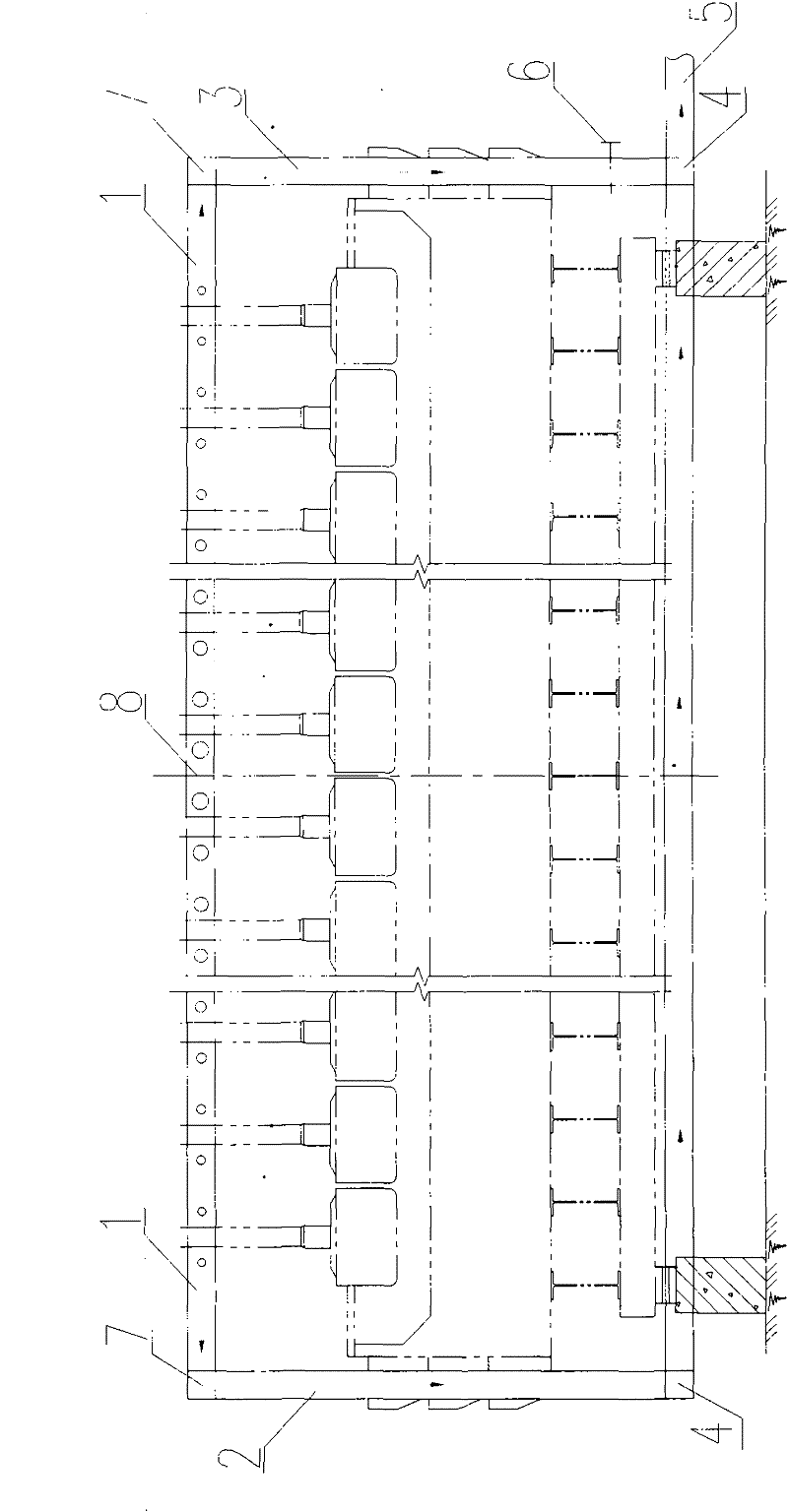

Upper structure of large-sized aluminum cell

The invention discloses an upper structure of a large scale aluminium cell, which comprises a cross beam (1), a vent stack (2), a positive bar (3), an anode carbon block group (4), an anode winding gear (5), a crust breaking charging device (6). The anode carbon block group (4) uses the binode structure; wherein, the binode structure of the anode carbon block group (4) is that an aluminum guide bar is connected with two carbon blocks (8) by eight steel claws (7); every four steel claws (7) are distributed to each carbon block (8). The eight steel claws (7) and one anode rod are welded into one whole. The anode winding gear (5) uses an end single motor for concentrating driving. The cross beam (1) uses the plate web girder structure. The vent stack is arranged below the cross beam (1). The positive bar (3) uses the split type structure. The web plate of the cross beam (1) is provided with a hole (9) which a balance busbar passes through. The anode has 40-56 pieces and is configured by the busbar with 5-7 dot large area incoming electricity.

Owner:GUIYANG AL-MG DESIGN & RES INST

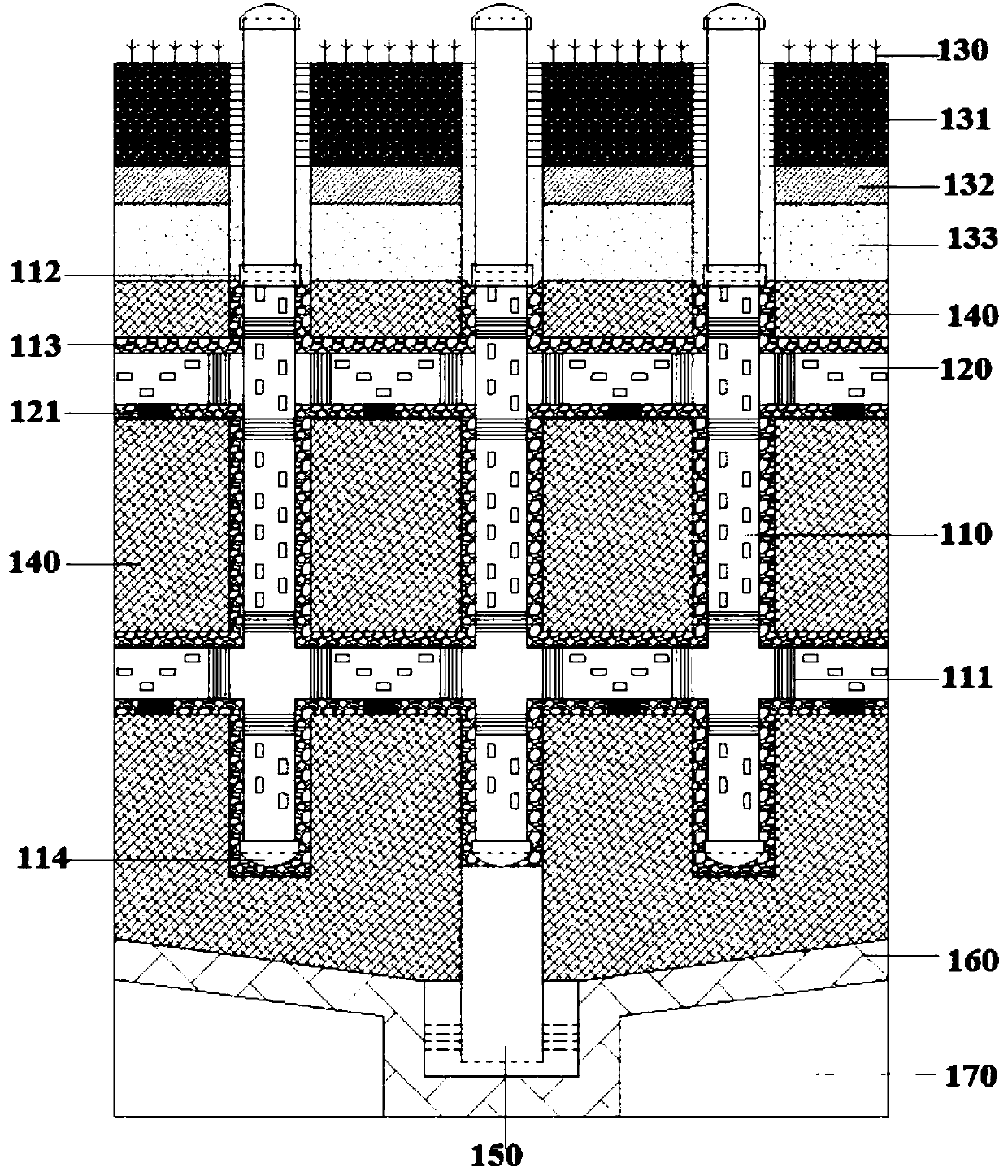

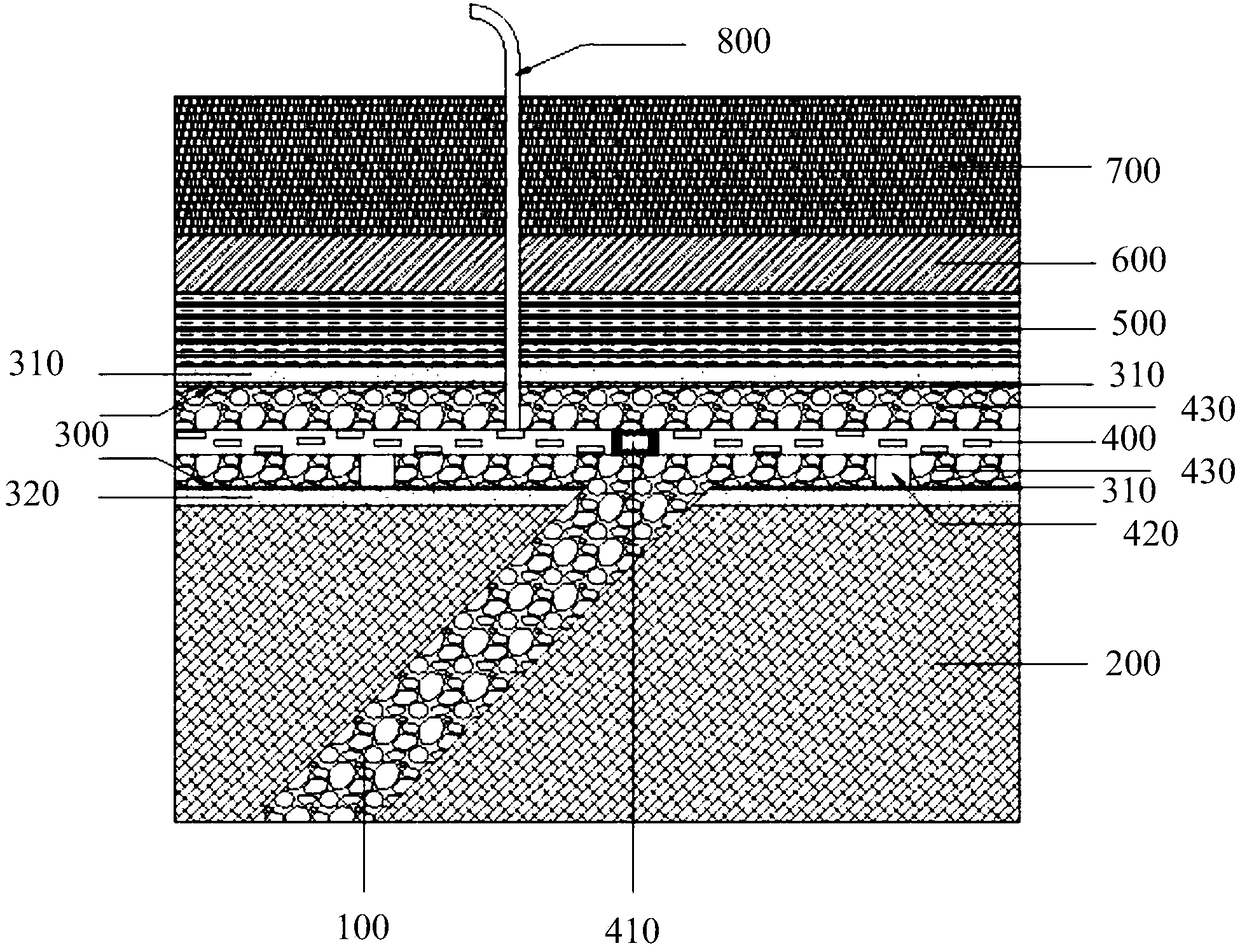

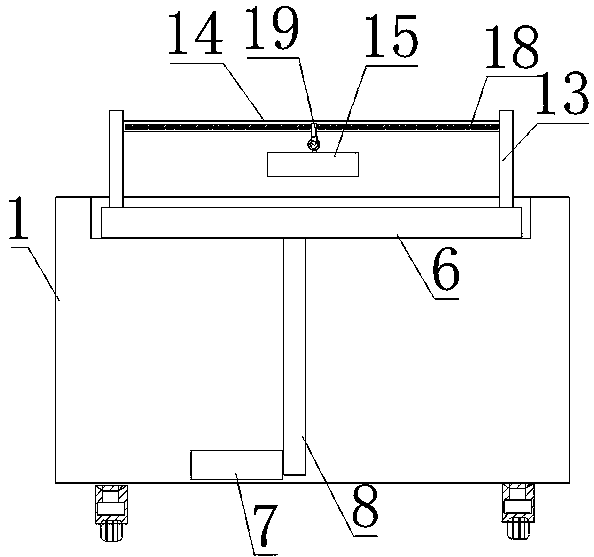

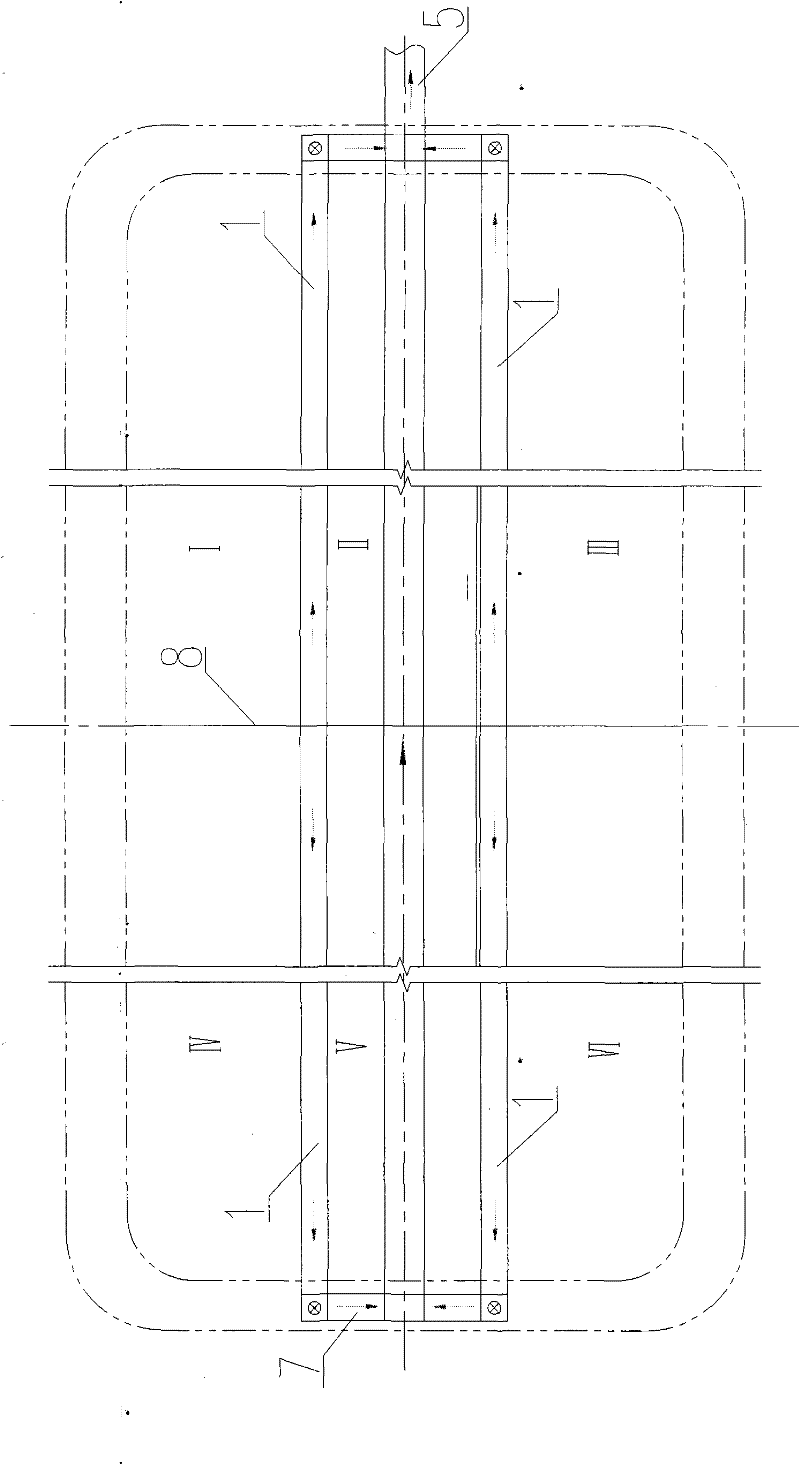

Urban landfill of bidirectional gas collecting system

InactiveCN106238435AEasy to useImprove gas collection efficiencySolid waste disposalLandfill technologiesEnvironmental engineeringLeachate

The invention discloses an urban landfill of a bidirectional gas collecting system. The urban landfill comprises a plurality of vertical gas collecting pipes, a plurality of horizontal gas collecting pipes and a leachate collection pond. A plurality of vent holes are formed in a pipe body of each vertical gas collecting pipe, and the vertical gas collecting pipes are arranged in the vertical direction of the landfill at equal distance and can collect gas. The horizontal gas collecting pipes communicate with the vertical gas collecting pipes through four-directional pipeline connectors, a plurality of vent holes are formed in a pipe body of each horizontal gas collecting pipe, and the multiple horizontal gas collecting pipes are arranged in the middle of the landfill and can collect gas when the vertical gas collecting pipes cannot collect gas conveniently. The leachate collection pond is arranged on the lower portion of the middle position of the landfill, slopes are arranged on the periphery of the leachate collection pond, and the leachate collection pond can collect leachate fast. The bidirectional gas collecting system is applied in the landfill for garbage collection and can collect gas in the horizontal direction and the vertical direction at the same time, and the gas collecting efficiency is improved; and the gas collecting pipes are stressed in a criss-cross manner so that uniformity can be achieved, the service life period of the gas collecting system is prolonged, and the gas collecting system is suitable for collecting gas in the large garbage landfill.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

Gas collecting method for crown block in electrolysis workshop

The invention discloses a gas collecting method for a crown block in an electrolysis workshop, which is mainly used for collecting flue gas generated during the pole changing operation of the electrolysis workshop. A gas collecting device is added to the crown block, and comprises a telescopic pipeline and a dust collecting hood; a flue gas purifying system is added to a crown block beam, and comprises a hydrogen fluoride adsorption device, a dust collector, an induced draft fan and a regular discharging device which are connected in sequence; when the crown block clamps the residual pole, leaves a electrolyzer and moves to a residual pole cooling system, the dust collecting hood is placed on the side of the residual pole and always moves with the residual pole to collect the flue gas emitted by the residual pole; the flue gas emitted by the residual pole enters the telescopic pipeline through the dust collecting hood to enter the flue gas purifying system; the flue gas first enters the hydrogen fluoride adsorption device and then the dust collector, and the induced draft fan is used for meeting the requirements of the entire system for the air volume and the negative pressure; the purified flue gas is discharged to the atmosphere through the induced draft fan. According to the invention, fluoride and dust can be can collected and treated, so that the amount of unorganized emissions during the transfer of the residual pole can be reduced.

Owner:沈阳铝镁科技有限公司 +1

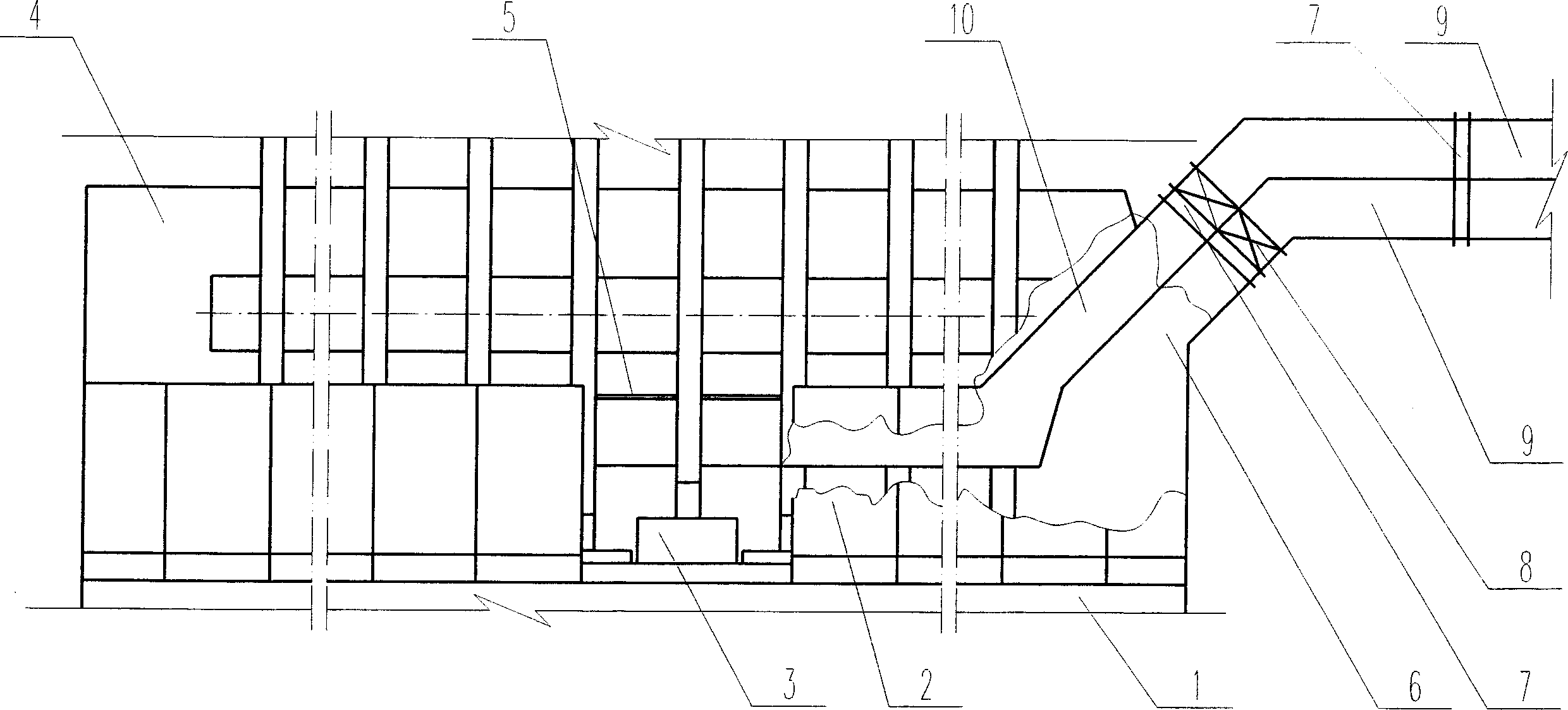

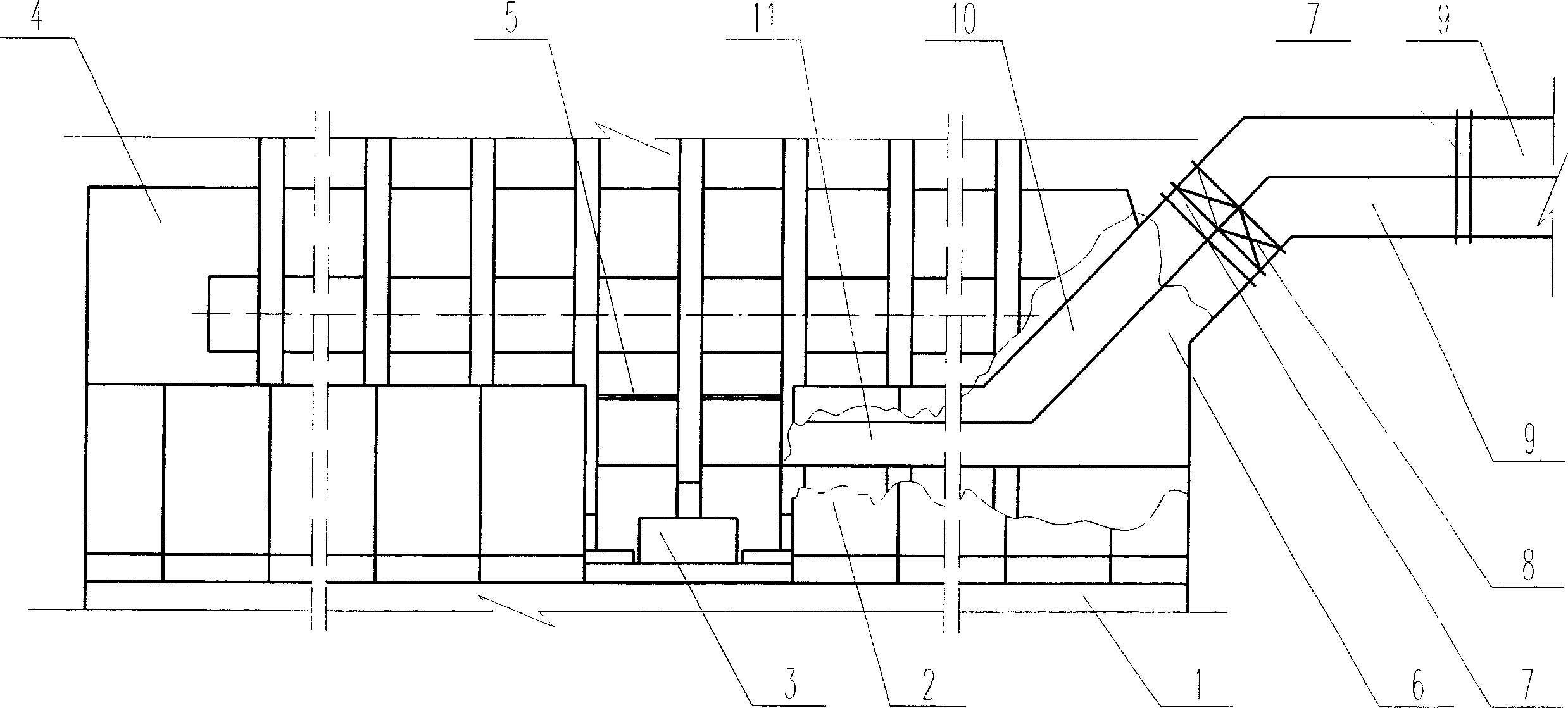

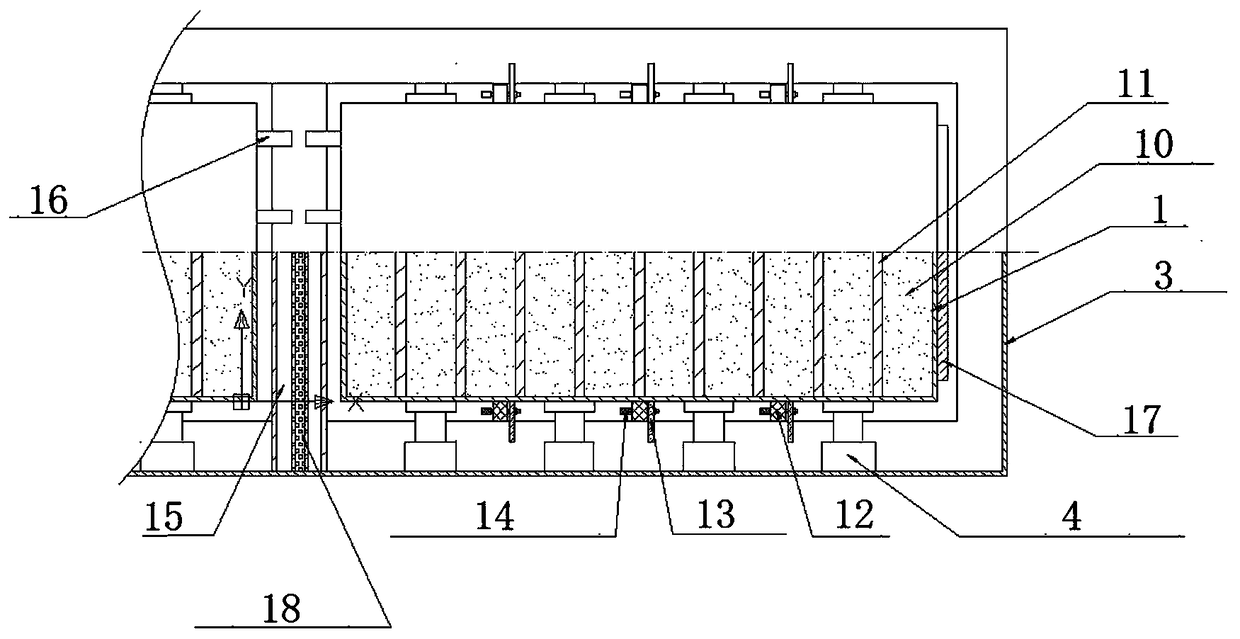

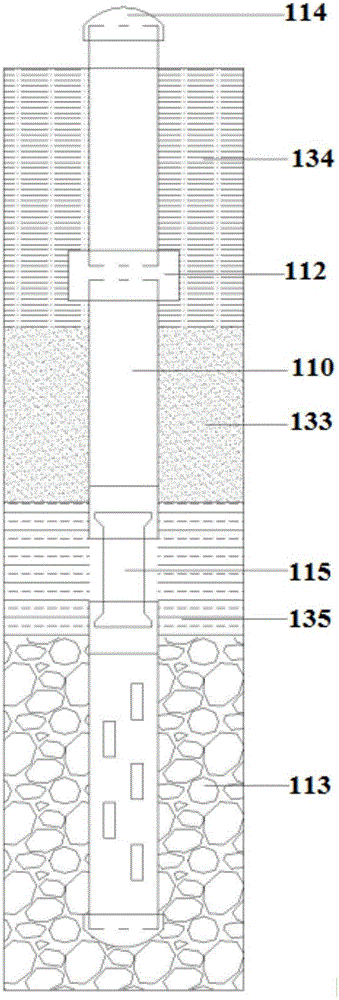

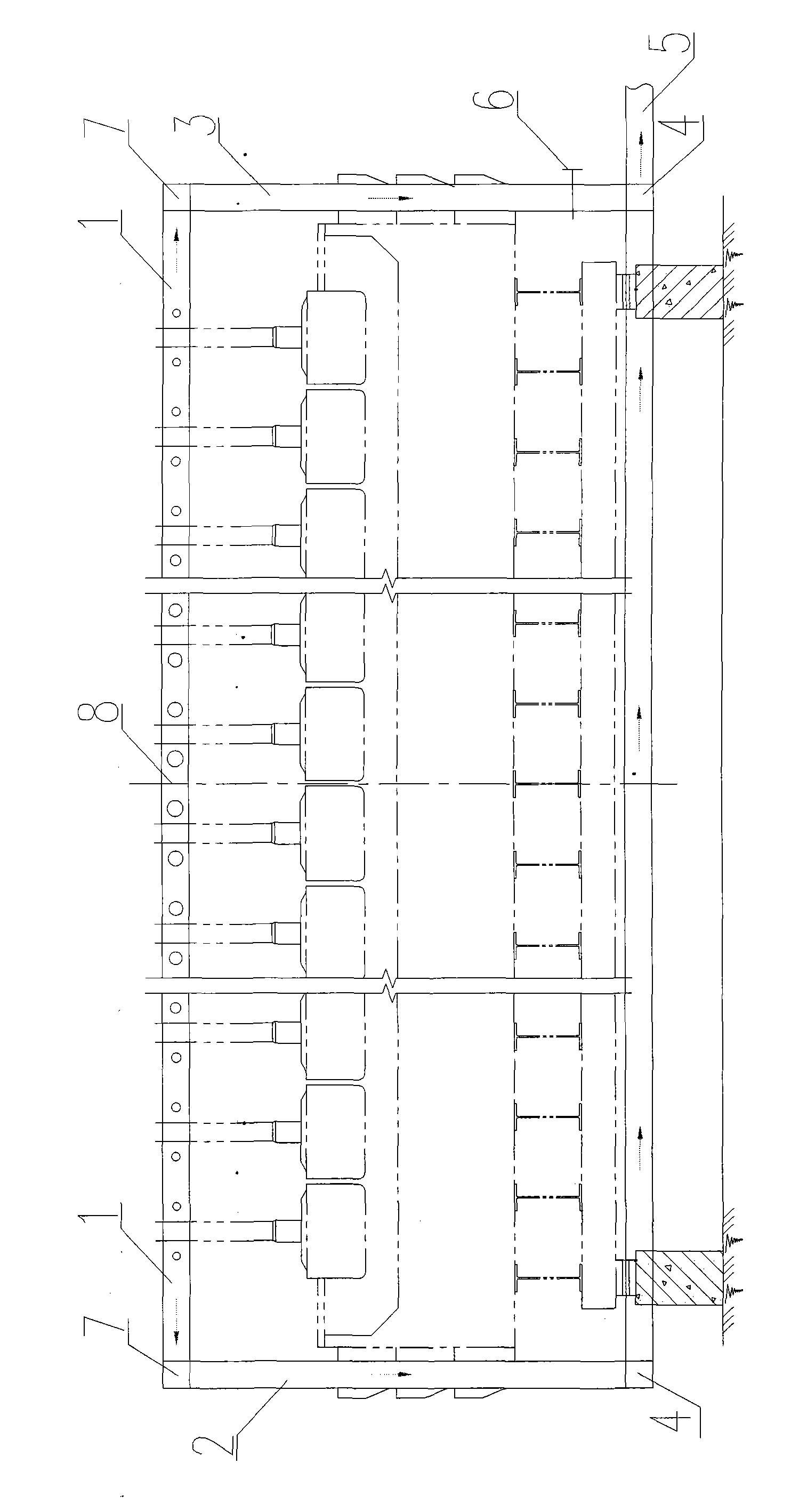

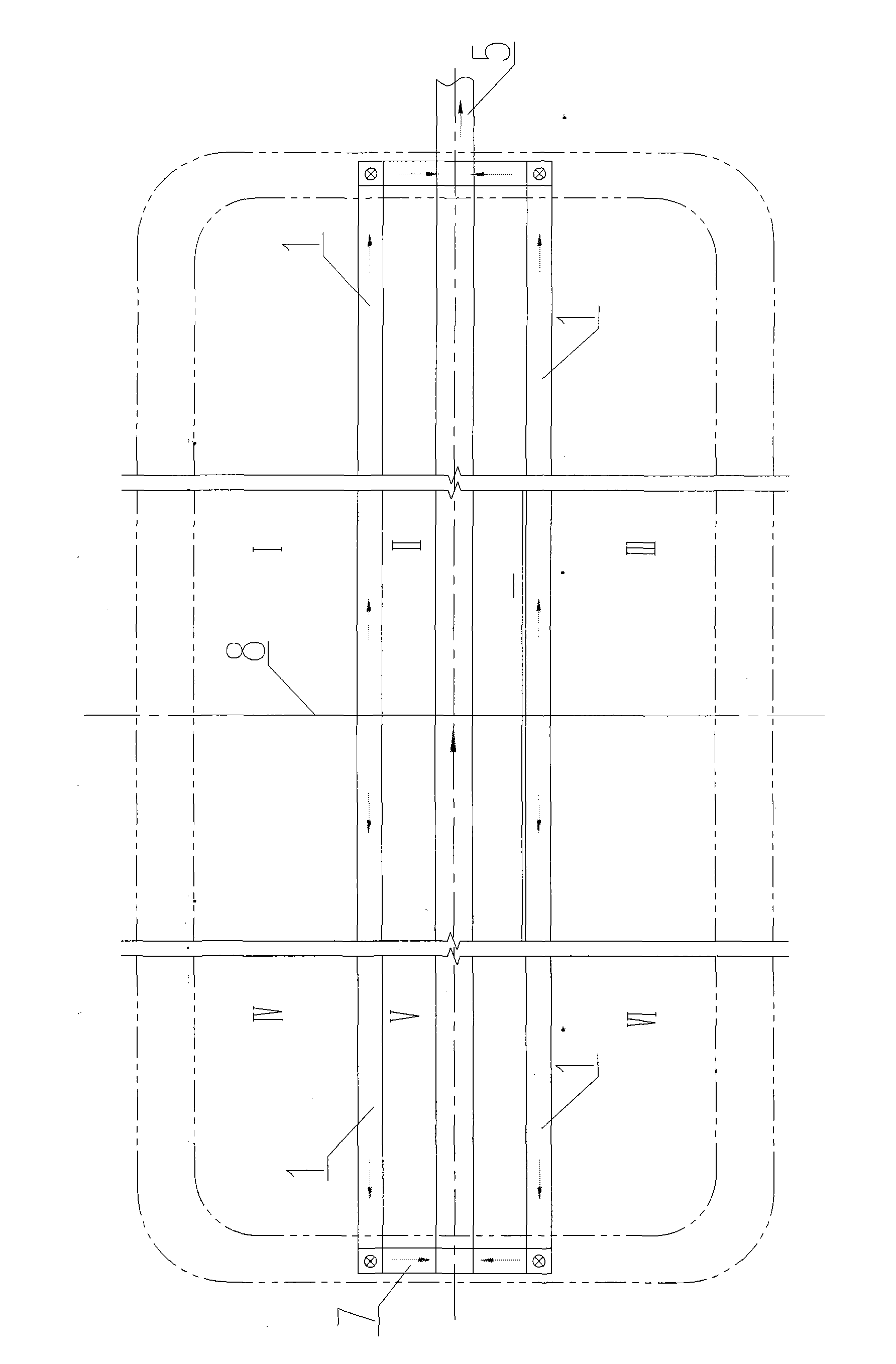

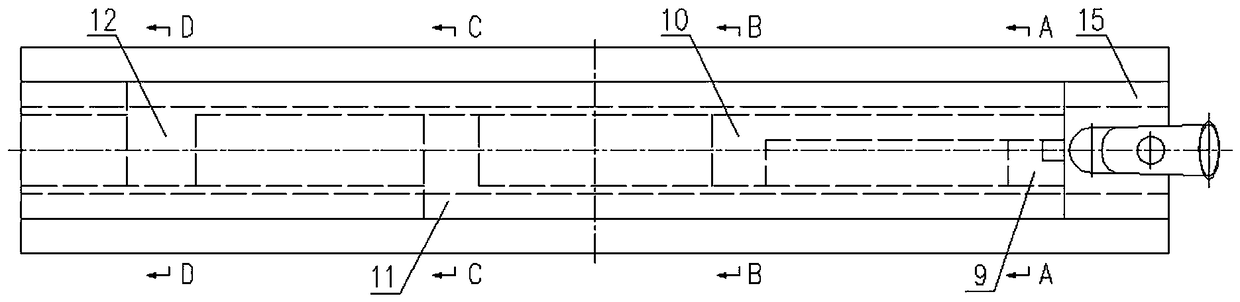

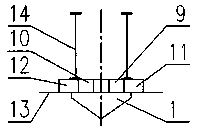

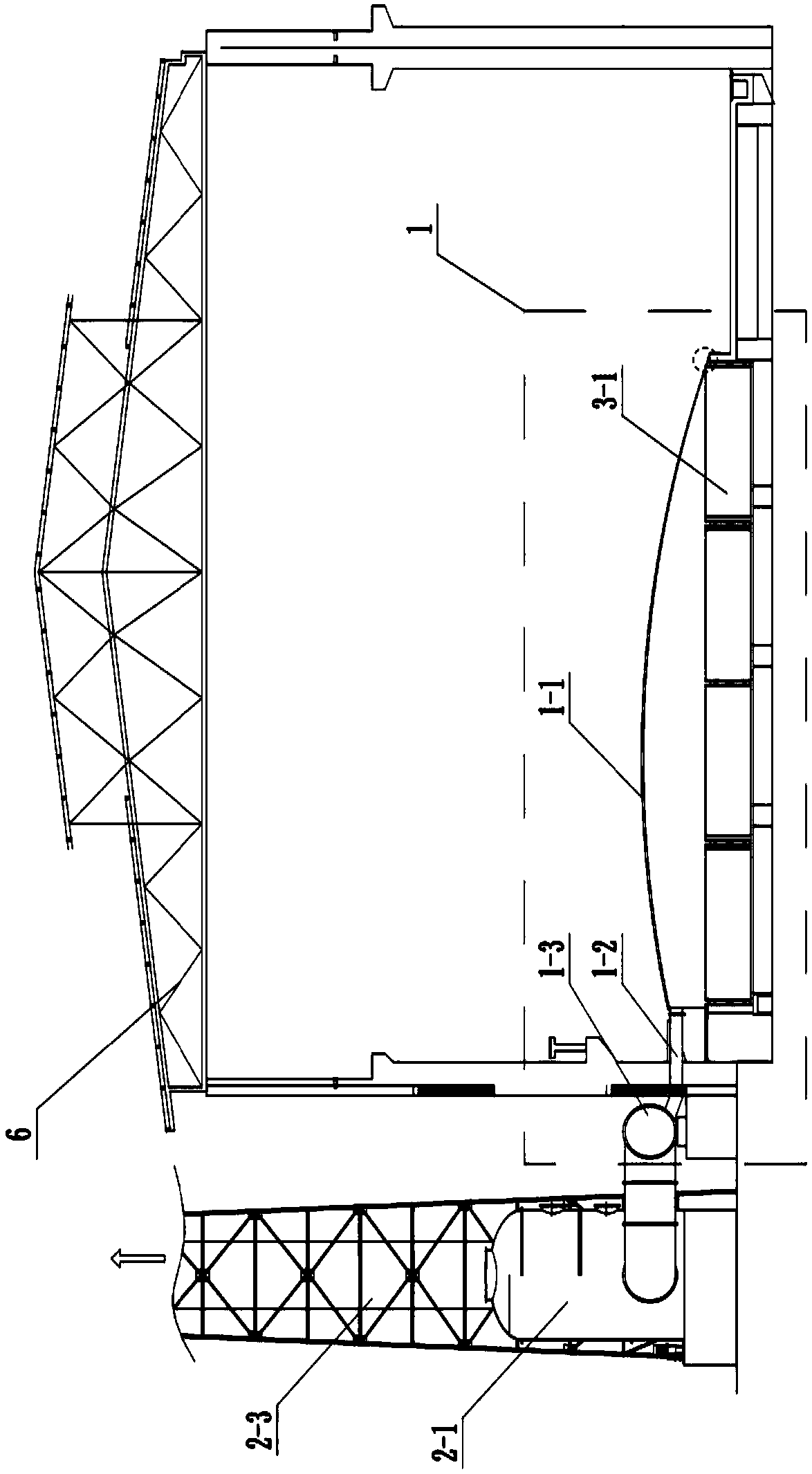

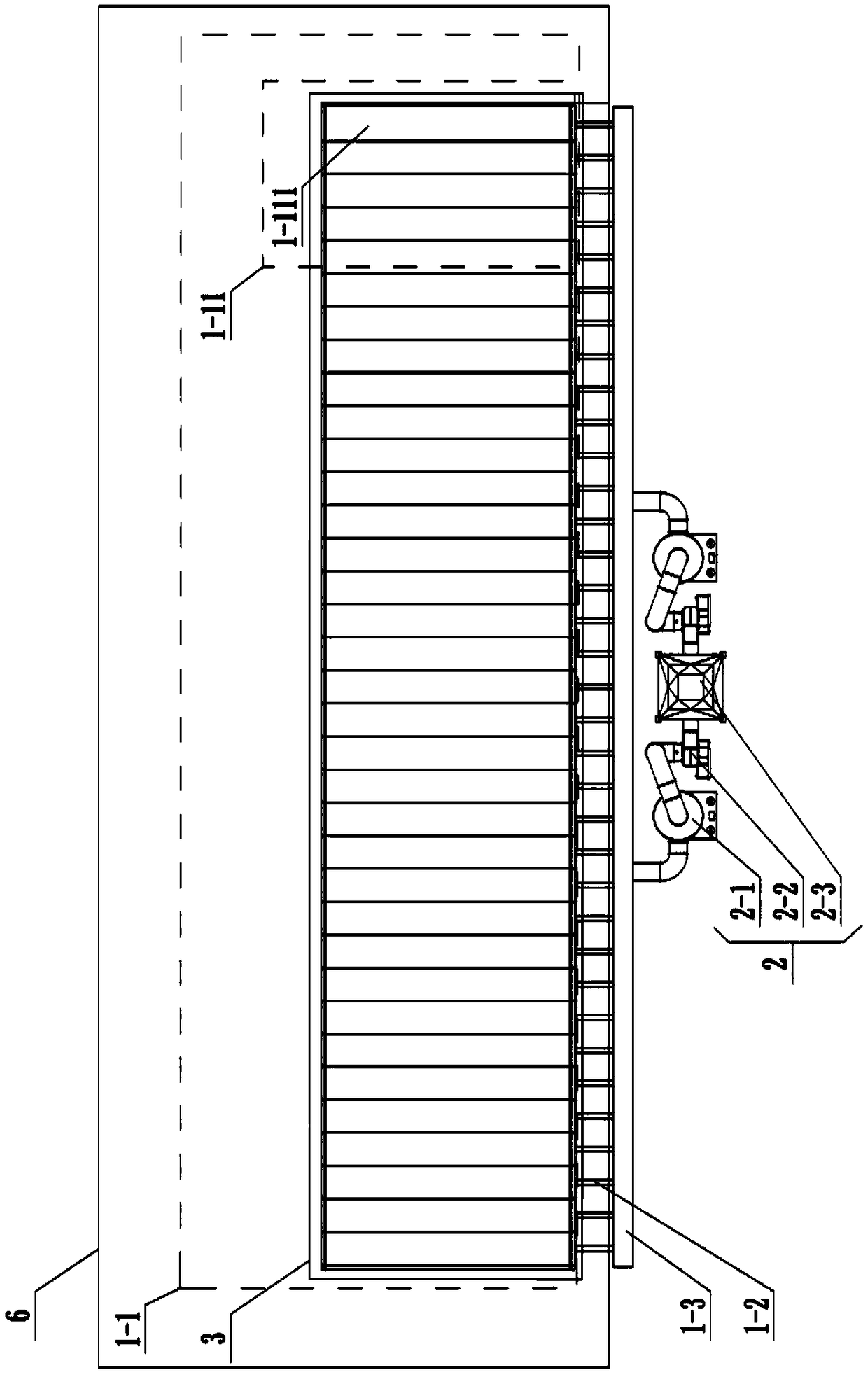

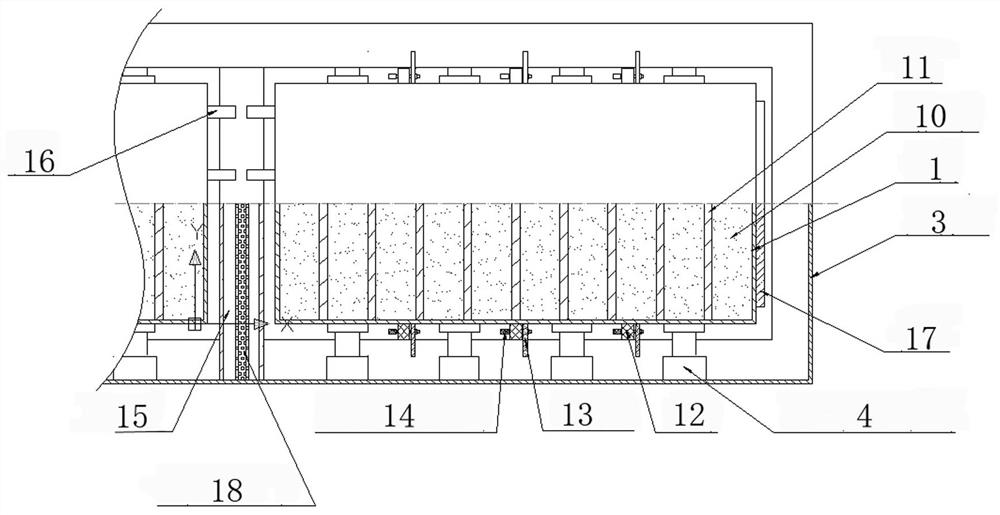

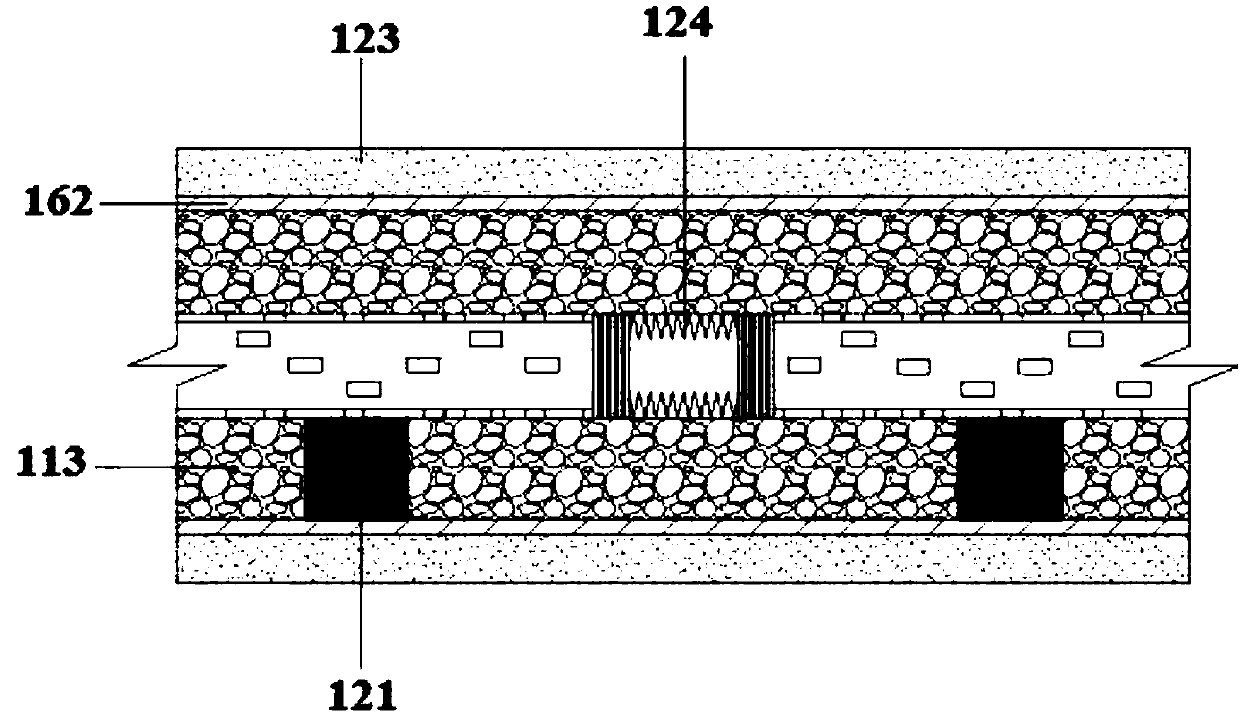

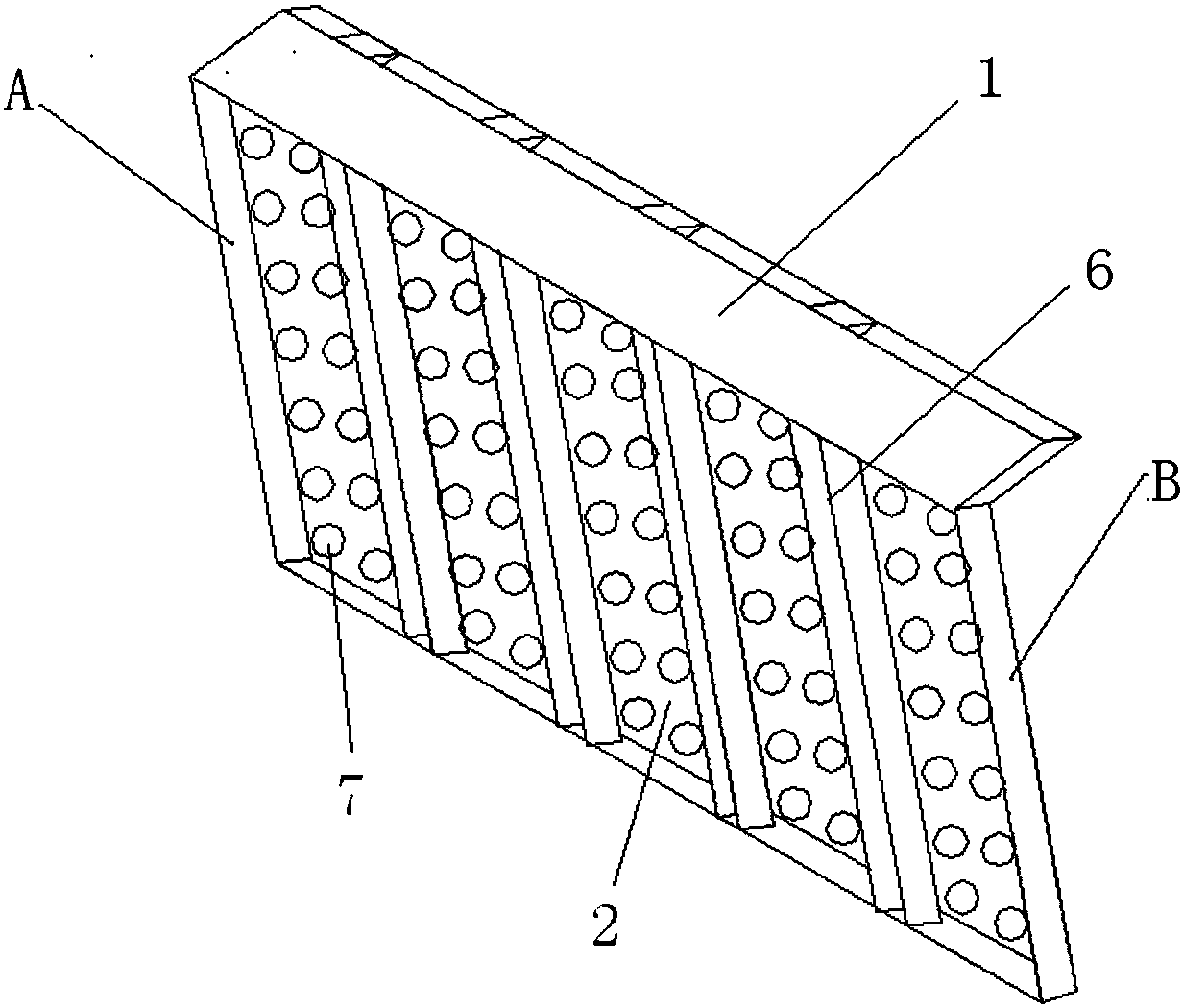

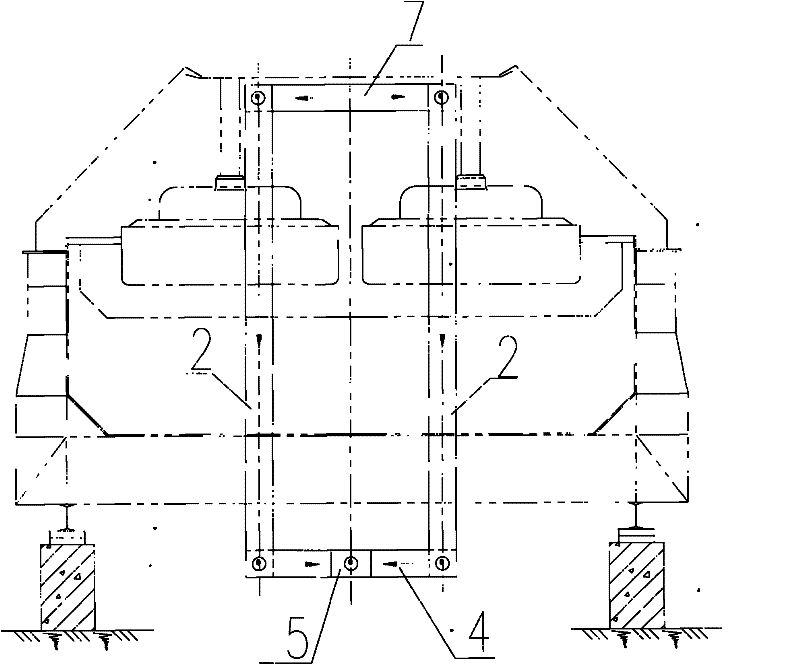

Gas gathering system of divisional gas-gathering type aluminum electrolytic bath

The invention relates to a gas gathering system of a divisional gas-gathering type aluminum electrolytic bath, which belongs to the technical field of electrolyzing aluminum. The gas gathering system of the electrolytic bath comprises in-bath horizontal flues, clapboards, vertical flues, upper convergence flues, bottom convergence flues and a main flue, wherein the number of the in-bath horizontal flues is between 2 and 5, the height range is between 100 and 400 millimeters; the clapboards are vertical to the length direction of the horizontal flues and equally divide the length of the horizontal flues; and the horizontal flues and the clapboards divide a horizontal gas-gathering area into a plurality of areas. The vertical flues are arranged at one end or two ends of the electrolytic bath, have a same structure with a door-type upright post or are positioned on the outside of the door-type upright column, and are communicated with the main flue though the bottom convergence flues. By applying the system, a two-end or single-end gas-gathering mode can be adopted, and no matter which gas-gathering mode is adopted, a plurality of the in-bath horizontal flues are arranged to divide the in-bath space into a plurality of areas to perform divisional gas gathering, and the distribution evenness of positive pressure in the bath is improved, thus the gas gathering efficiency is improved.

Owner:NORTHEASTERN UNIV ENG & RES INST CO LTD

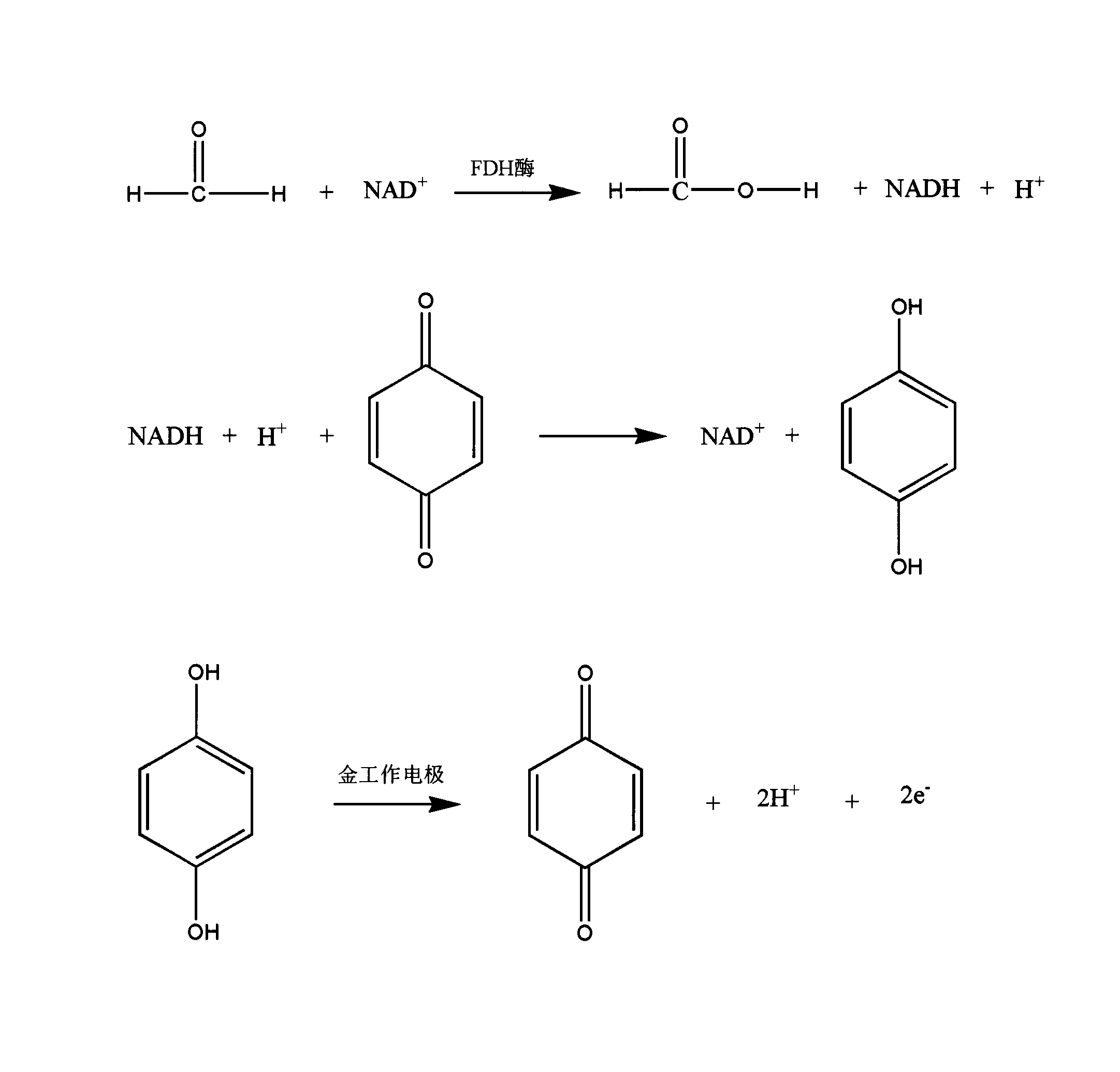

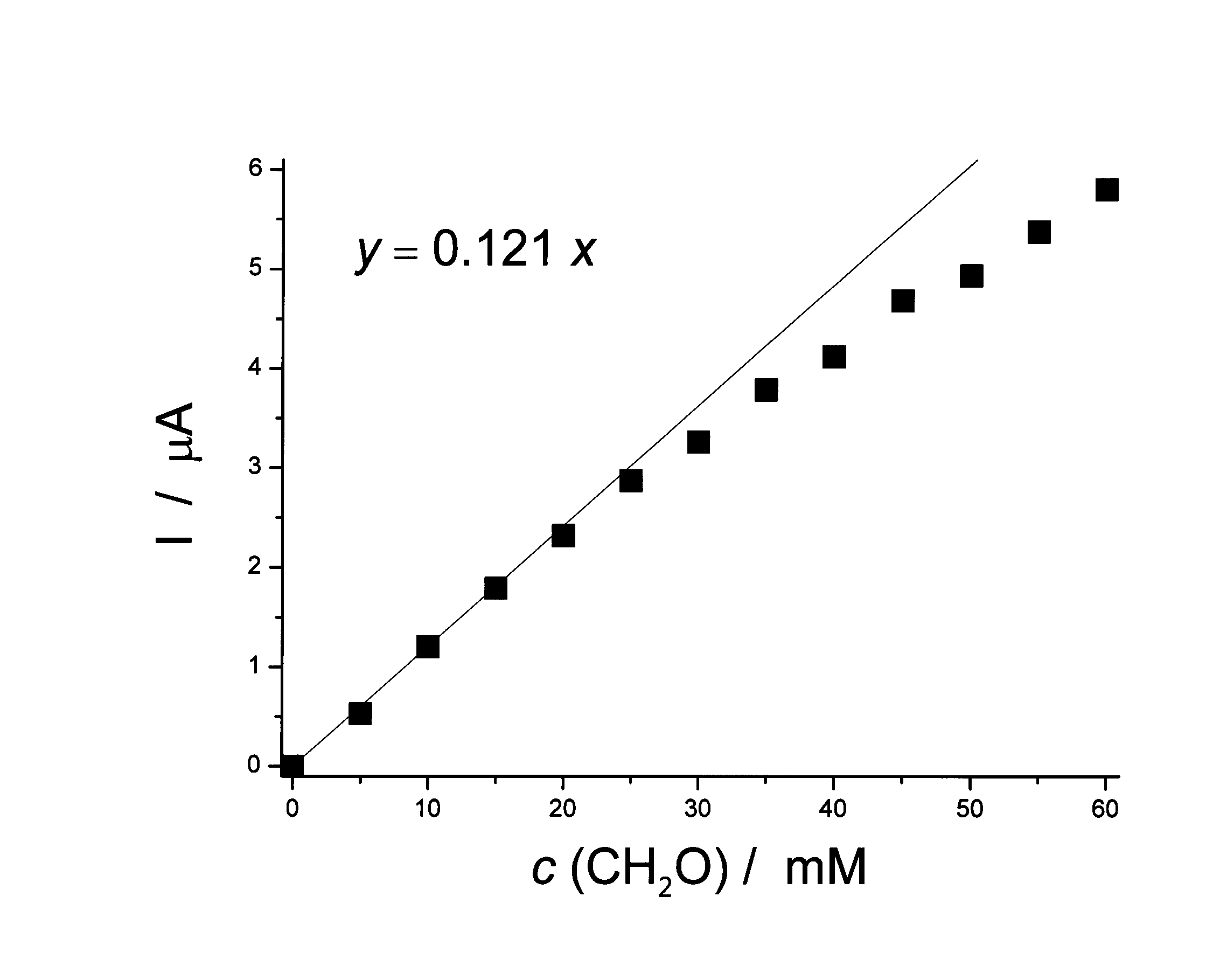

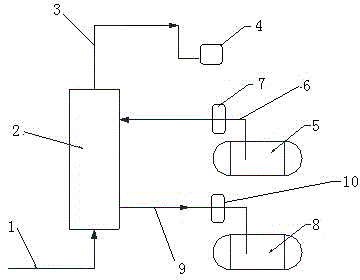

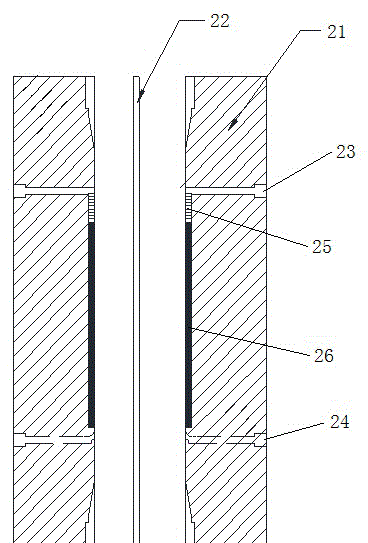

Preparation method of enzyme biosensor for detecting formaldehyde gas

InactiveCN102435652AIncreased sensitivityStrong specificityMaterial analysis by electric/magnetic meansMedical testingBenzoquinone

The invention relates to an enzyme biosensor for detecting a formaldehyde gas. The enzyme biosensor which adopts the high catalytic activity and the high specificity of an enzyme and a microporous polytetrafluoroethylene membrane to acquire is used to detect and monitor the concentration of the trace formaldehyde gas. The formaldehyde gas which permeates the microporous membrane and foamed carbon to enter a sensor reaction chamber transmits electrons in the foamed carbon electrode through NAD<+> and benzoquinone under the catalysis of a formaldehyde dehydrogenase, so the concentration of the formaldehyde gas can be measured through the current detection. The sensor of the invention, which has the characteristics of simple structure, high sensitivity and difficult influence by other gases, is suitable for the medical examination and the continuous monitoring of indoor formaldehyde pollution.

Owner:NANKAI UNIV

Rare earth modified nano coating glass plate self-cleaning gas collecting device

ActiveCN104697823ACatalyticQuick collectionWithdrawing sample devicesDispersed particle separationPeristaltic pumpAtmospheric air

The invention discloses a rare earth modified nano coating glass plate self-cleaning gas collecting device, and belongs to the fields of atmospheric sciences and environmental sciences. The gas collecting device comprises a gas inlet pipe, a gas collector, a gas outlet pipe, a peristaltic pump, a gathered liquid tank, a feeding pipe, a liquid inlet peristaltic pump, a collected liquid tank, a discharging pipe and a liquid outlet peristaltic pump, wherein the gas inlet pipe is connected with a gas inlet of the gas collector; the gas outlet pipe is connected with a gas outlet of the gas collector; the peristaltic pump is connected with the gas outlet pipe; the gathered liquid tank is connected with a gathered liquid pipeline on the gas collector by virtue of the feeding pipe; and the collected liquid tank is connected with a collected liquid pipeline on the gas collector by virtue of the discharging pipe. The rare earth modified nano coating glass plate self-cleaning gas collecting device disclosed by the invention has the characteristics of being easy to operate, high in gas collection efficiency and the like, and the gas colleting device can be widely applied to the fields of monitoring and research of gaseous pollutants in weather and environment industries as well as occasions in which gaseous pollutants are required to be effectively and rapidly separated from particle components.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

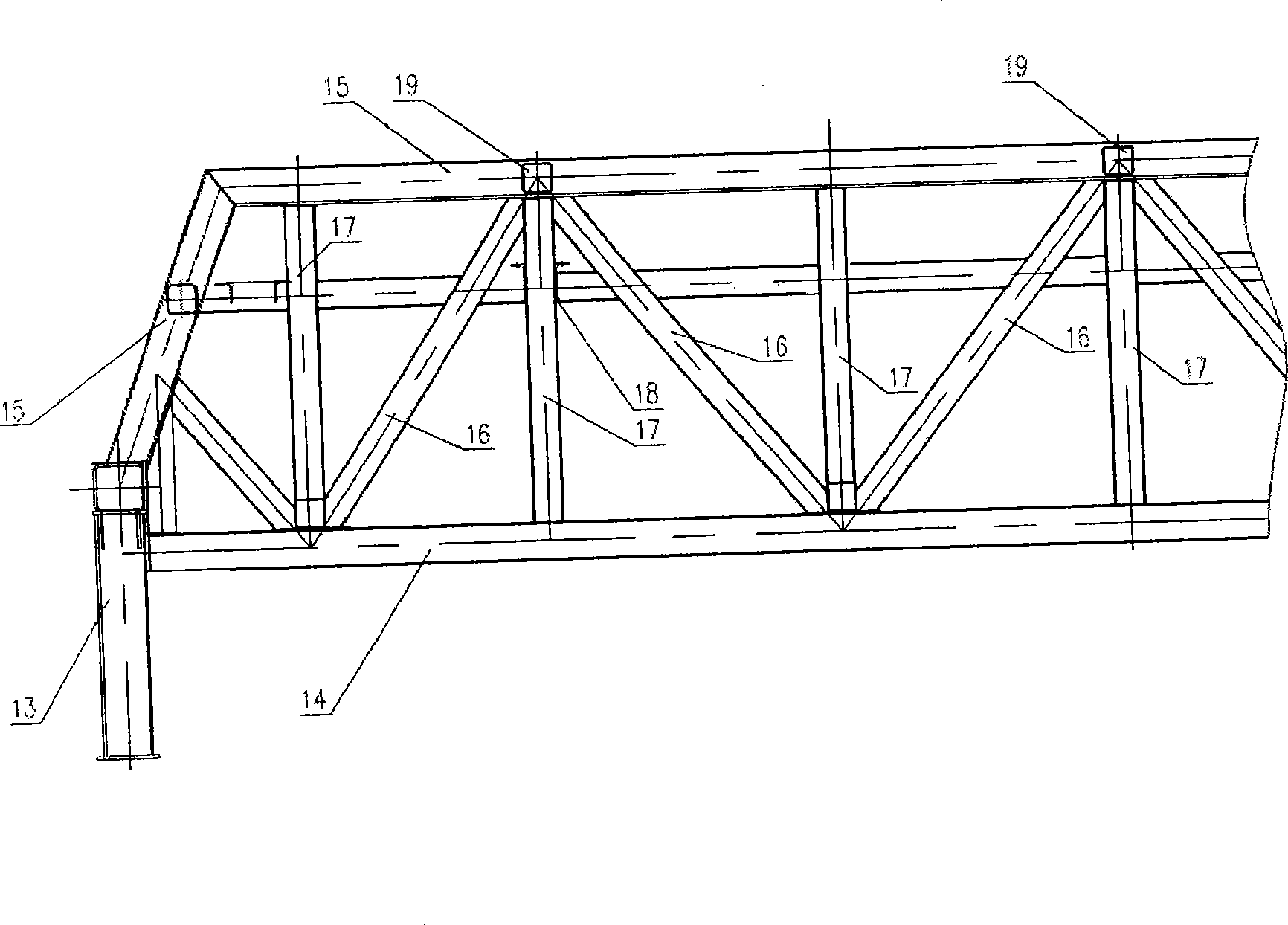

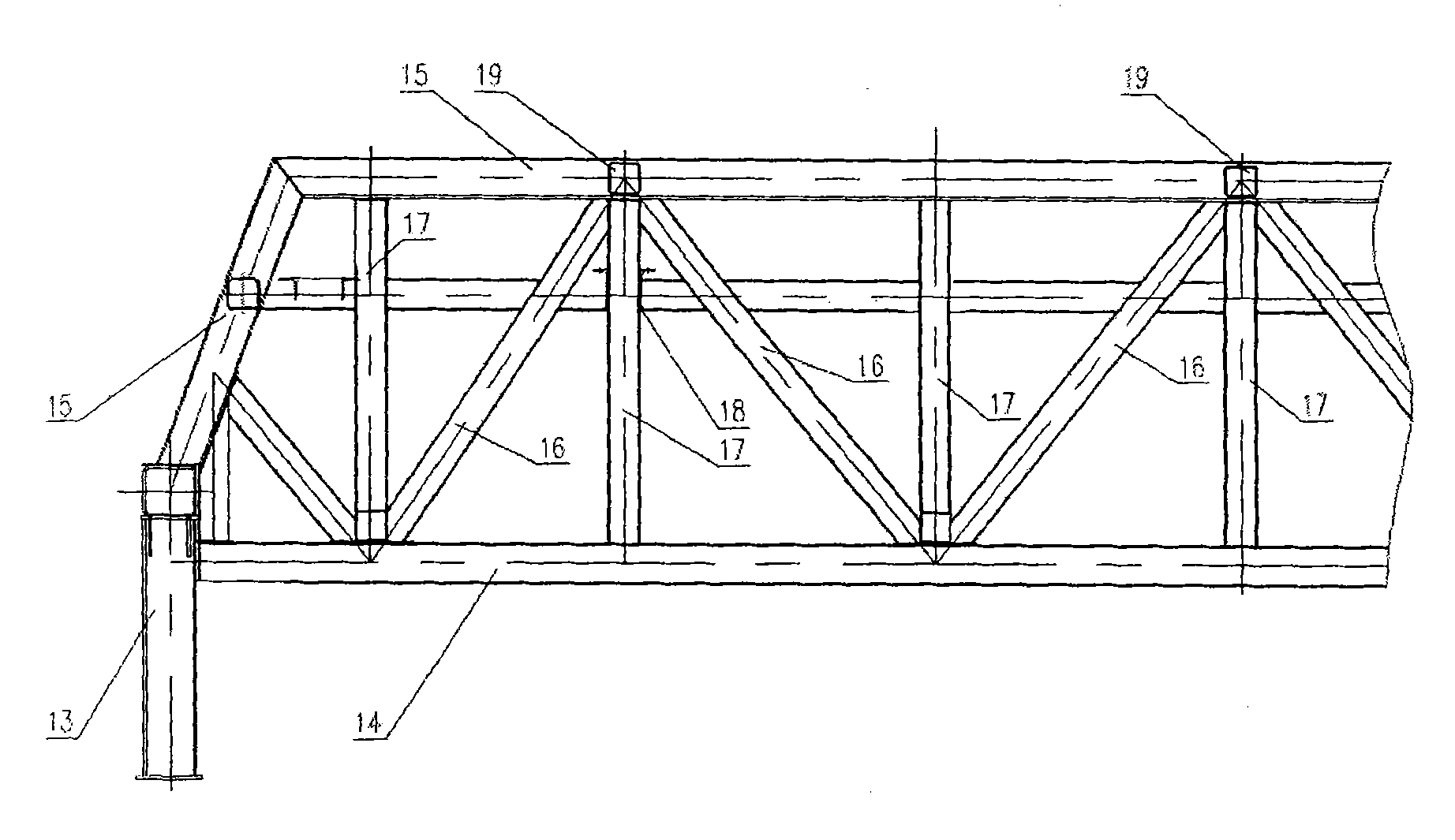

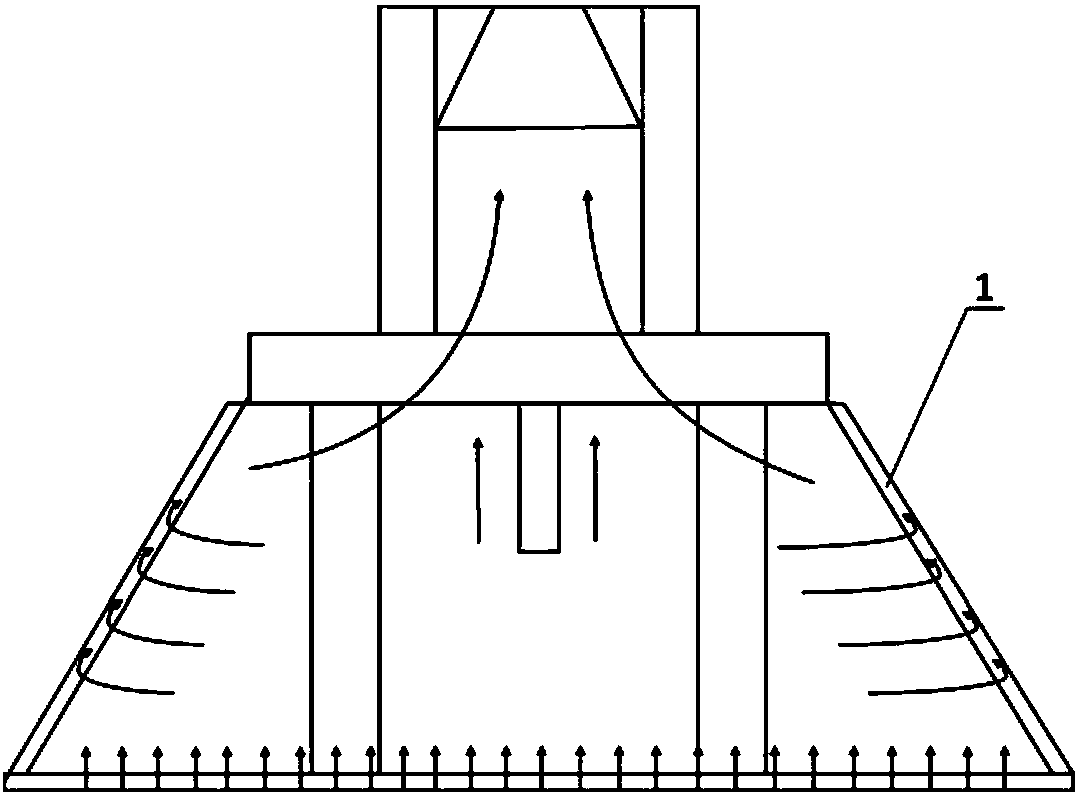

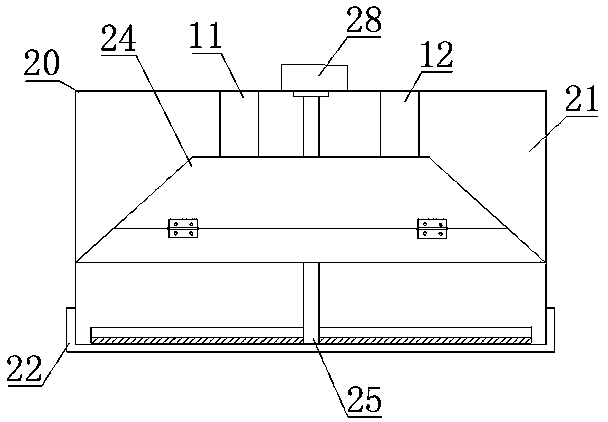

Large space frame type gas collection lower flue structure

The invention relates to a flue structure, in particular to a large space frame type gas collection lower flue structure. The large space frame type gas collection flue structure divides a gas collection lower flue into 2-10 segments, each segment of the flue is provided with separate branch smoke pipes for collecting gas separately, the gas is gathered into a main smoke chamber, the main smoke chamber is communicated with a main smoke exhaust pipe, the gas collection lower flue is arranged at the bottom of a horizontal cover plate, each branch smoke pipe is welded to the upper portion of thehorizontal cover plate, and the bottoms of girders are welded to the tops of the branch smoke pipes. According to the structure, a gas collection effect of the flue is improved, the contact area between the girders and the horizontal cover plate is increased, the strength of the girders is improved, the height of the girders can be effectively decreased, the height of an electrolysis plant is decreased at the same time, and the civil construction investment is saved.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

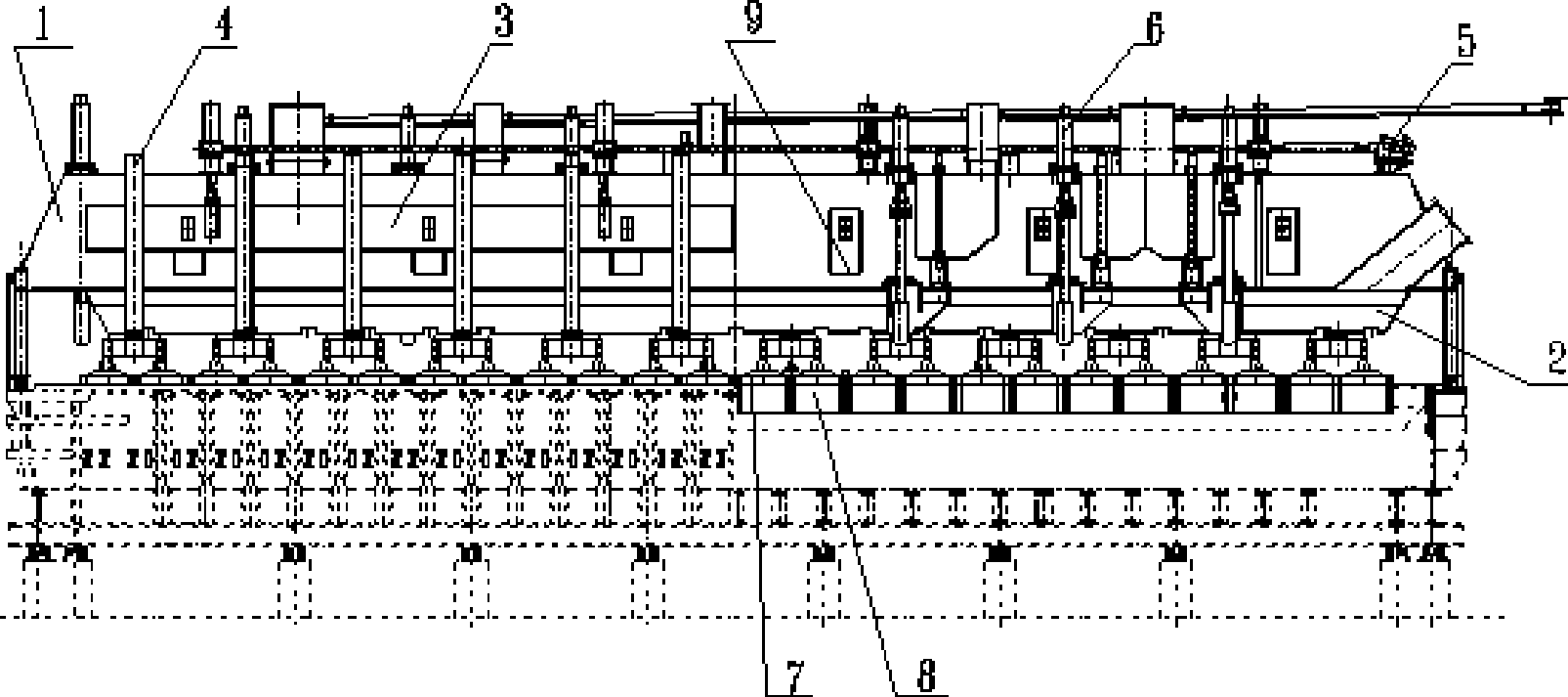

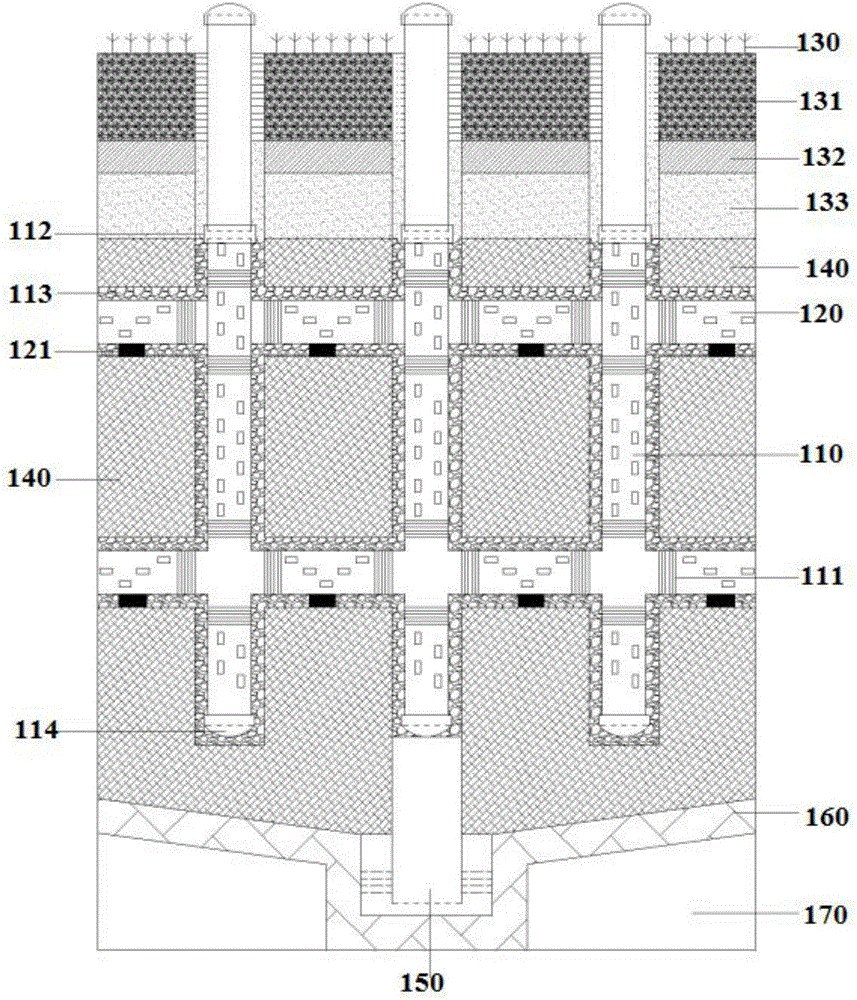

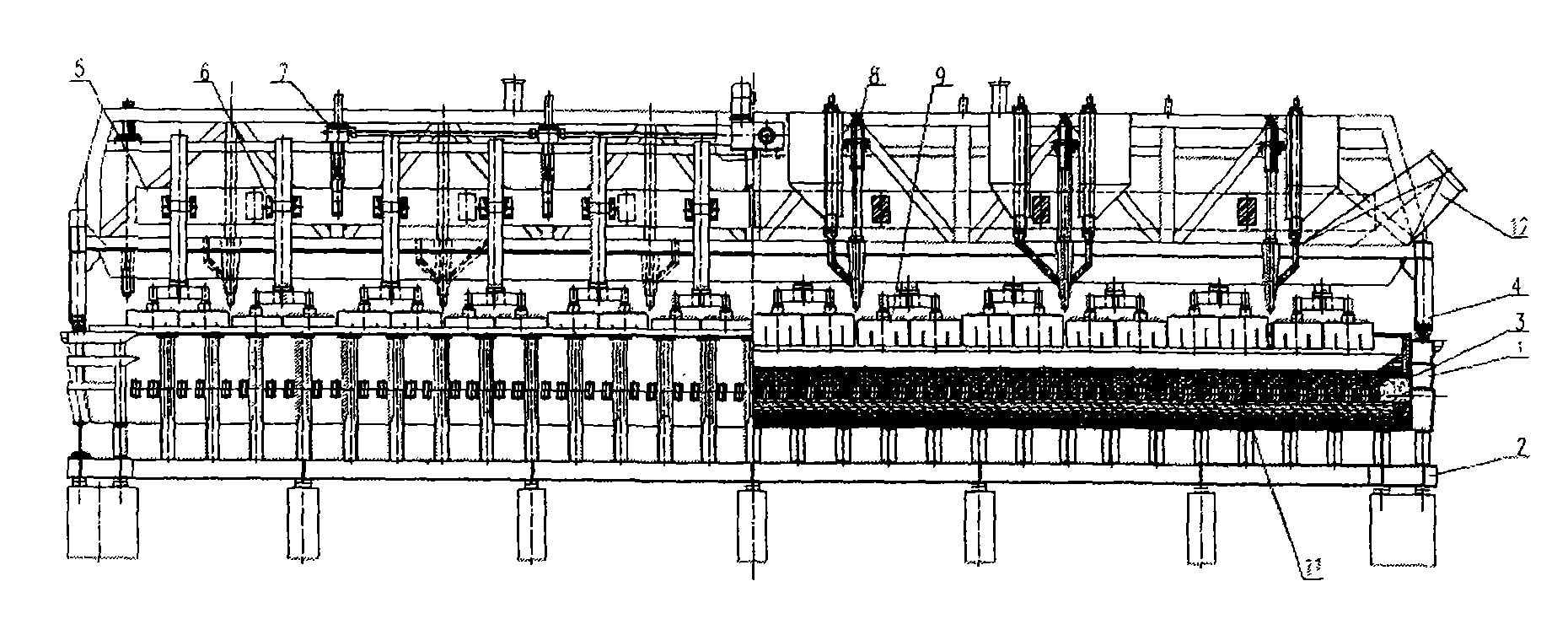

400kA energy-saving and emission-reducing pre-baked aluminum cell

A 400kA grade energy-saving and emission-reduction prebaking aluminum electrolytic cell comprises an anode carbon block group, an anode bus, a crust breaking and blanking device, an anode lifting mechanism, a crossbeam and a column, a cell sealing exhaust gas system, a cathode carbon block group, a lining structure and a cell shell structure. The 400kA grade energy-saving and emission-reduction prebaking aluminum electrolytic cell is characterized in that: (1) a top crossbeam and a portal column are supported by a tubular truss beam support structure; (2) steel claws of the anode carbon blockgroup are arranged in an eight-claw symmetrical structure; (3) a new anode configuration scheme is adopted and six aluminum oxide blanking points and two fluoride salt blanking points are designed; (4) a ventilation system for stepwise gas collection is arranged between a horizontal housing plate and a bin; (5) a device is employed to seal an anode rod by utilizing negative pressure suction; (6) a new lining structure is designed according to simulation of a thermo-electric field; (7) the cathode bus is configured in a symmetric manner and arranged in an extensive six-point feeding structure;and (8) a rectangular truss pipe is taken as an air supply pipeline on the cell and a tail gas muffler device of a crust breaking and blanking cylinder. The 400kA grade energy-saving and emission-reduction prebaking aluminum electrolytic cell can help achieve a significant energy-saving and emission-reduction purpose.

Owner:NORTHEASTERN UNIV ENG & RES INST CO LTD

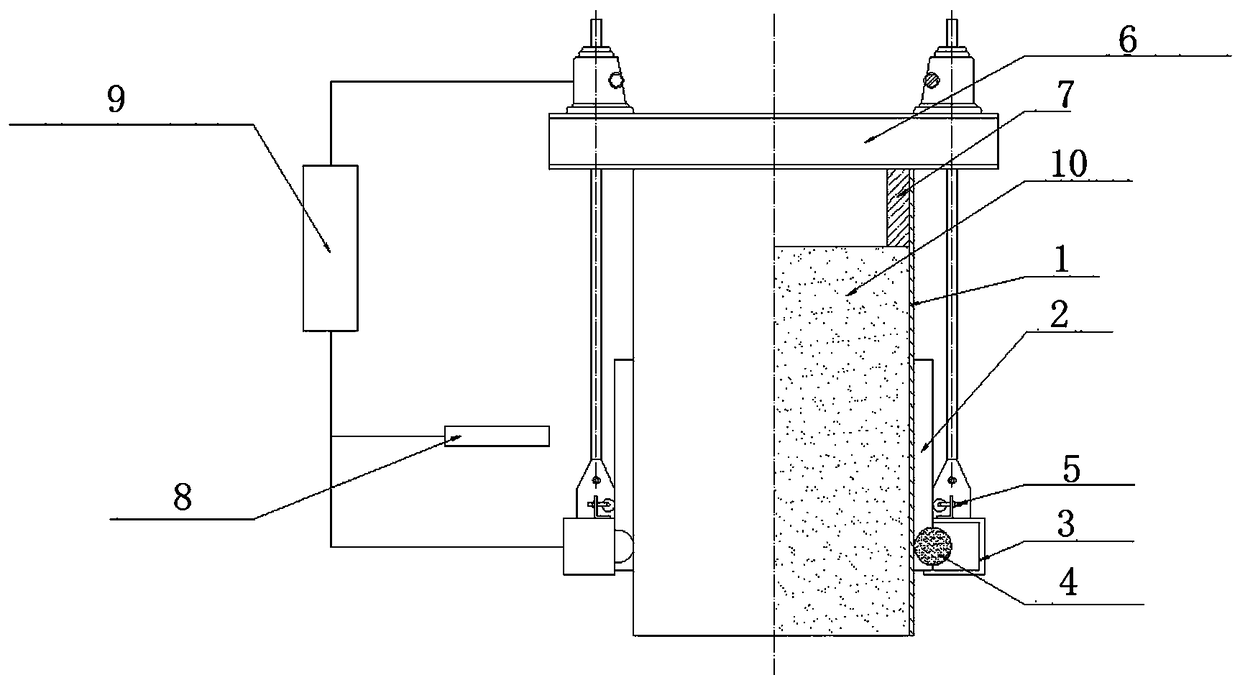

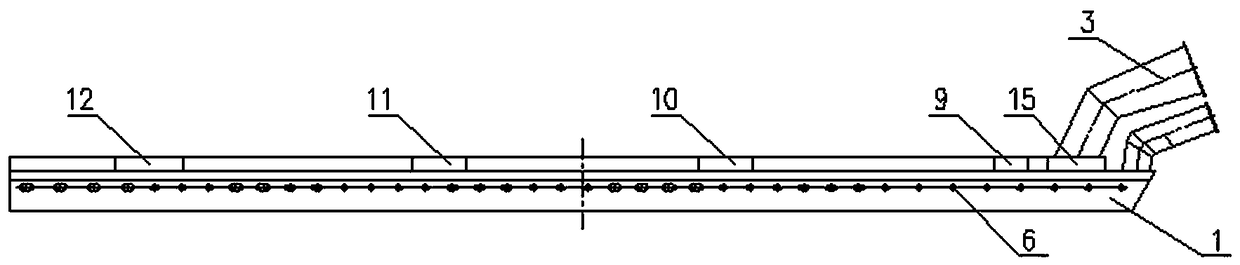

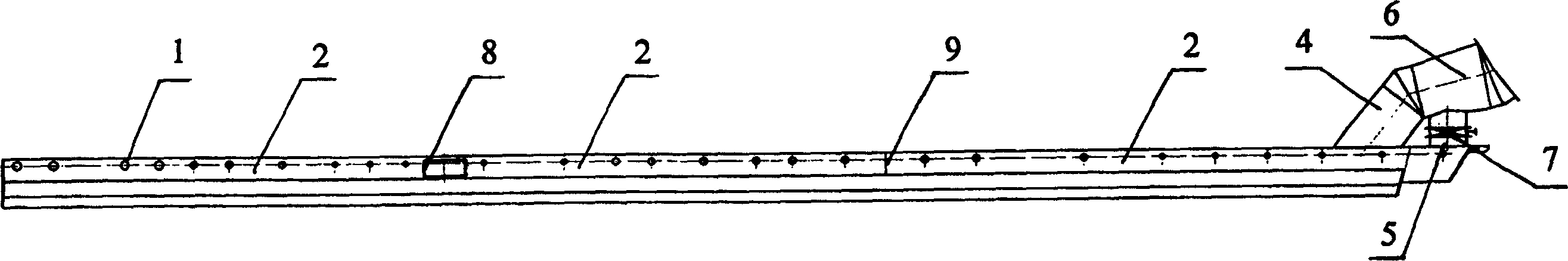

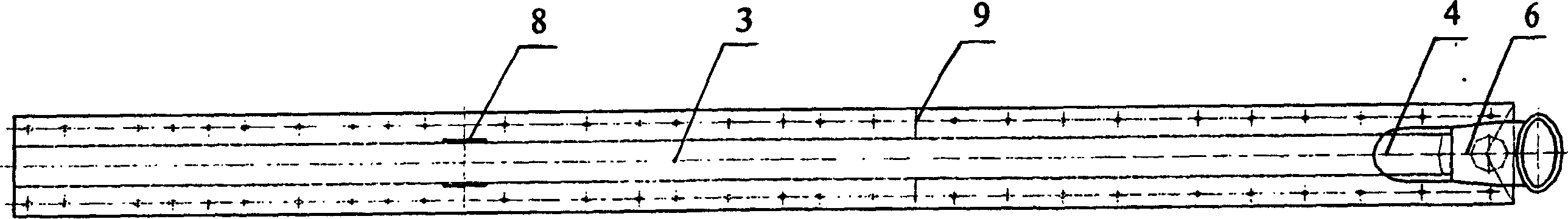

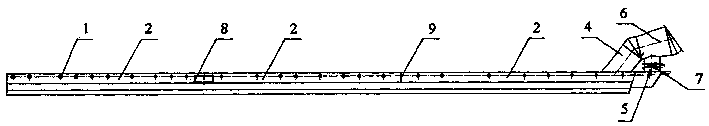

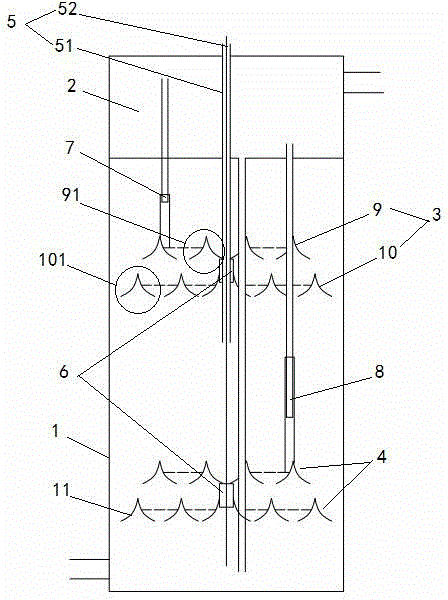

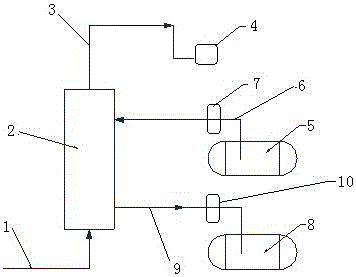

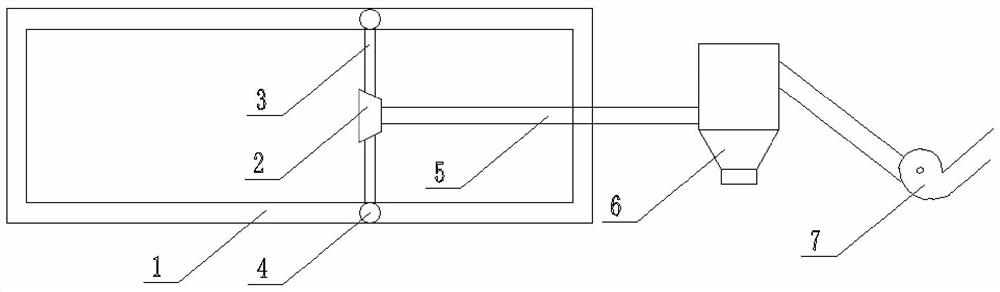

Electrolytic bath air gathering method

The invention discloses a gas collection method for an electrolytic cell, which solves the problem of low gas collection efficiency caused by the large negative pressure loss in the pipe along the direction of the gas collection pipe in the previous gas collection method. The invention adopts a segmented gas collection method, each section of flue gas enters the gas collection branch pipe (2) through the air inlet (1) or the gas collection cover, and each section of the gas collection branch pipe (2) is independent of each other, and is collected at the end of the electrolytic cell Afterwards, it is connected to the total air collecting pipe (6) of the electrolyzer. It ensures that the negative pressure of gas collection in each section is similar, and improves the gas collection efficiency of the flue gas in the electrolyzer.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Ammonia fog collection and treatment system for electrolysis workshop

PendingCN108837669AImprove collection efficiencyEasy to operateGas treatmentDispersed particle separationTherapeutic effectTreatment system

The invention belongs to the technical field of recovery of waste gases and relates to an ammonia fog collection and treatment system for an electrolysis workshop. The system comprises a cell face ammonia fog collection mechanism and an ammonia fog treatment mechanism, the cell face ammonia fog collection mechanism comprises a gas collection device, an exhaust branch, an exhaust main pipe, an electrolysis area, idler wheels and rails, the ammonia fog treatment mechanism comprises an ammonia washing tower, a centrifugal fan and a chimney, the gas collection device comprises a gas collection hood group, the gas collection hood group comprises 2-5 gas collection hoods, the gas collection hoods are installed in the rails in the electrolysis area through the idler wheels, and the adjacent gas collection hoods in the gas collection hood group have the height difference. By using the system, the gas collection hoods can be pushed and moved, and are mutually stacked and an electrolytic cell face is exposed, then a worker operates conveniently, or the gas collection hoods are pushed, moved and unfolded to cover the whole cell face, the waste gas produced in the electrolysis workshop is effectively collected, the gas collection efficiency is high, and the treatment effect is good.

Owner:NINGXIA TIANYUAN MANGANESE LIMITED

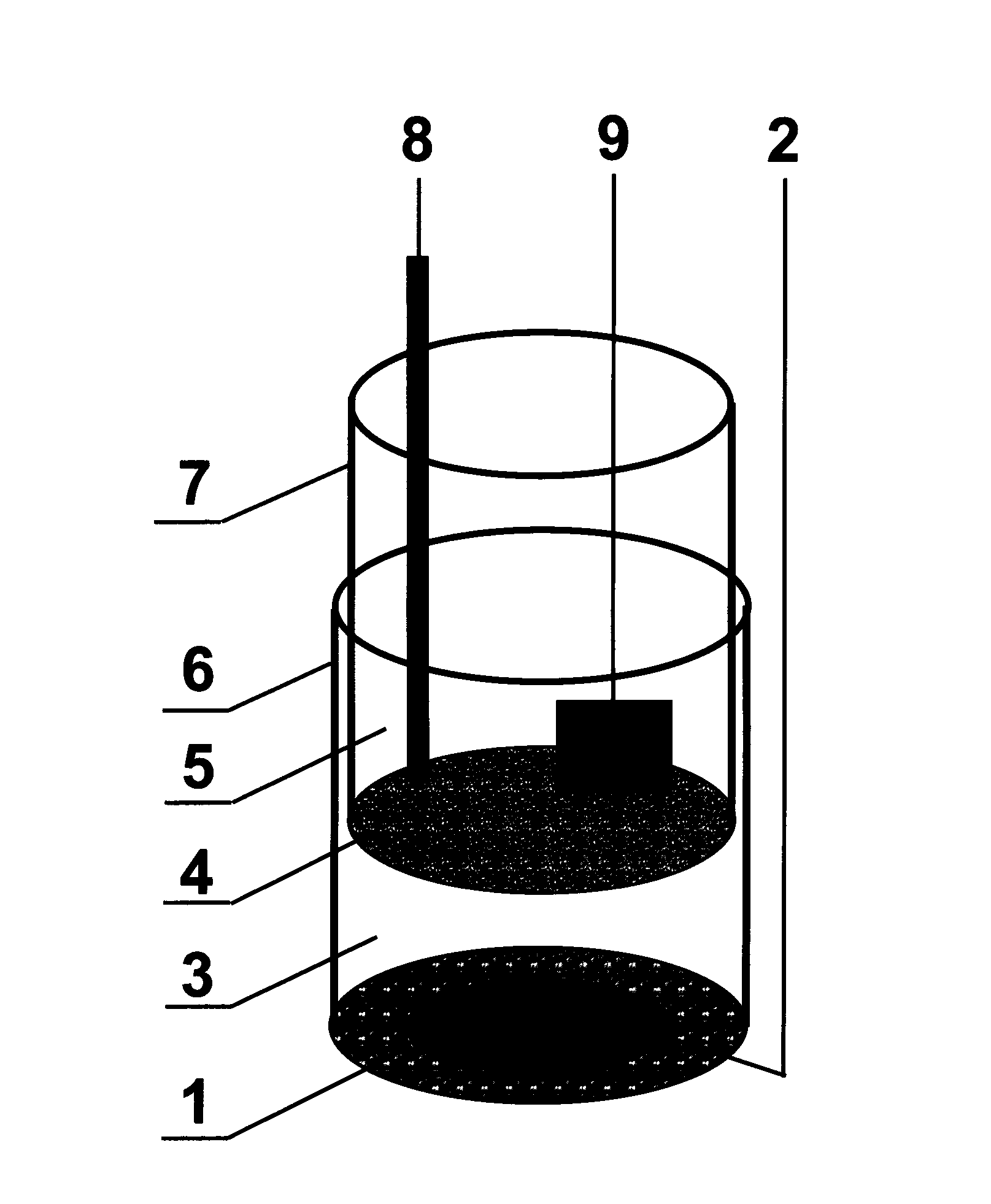

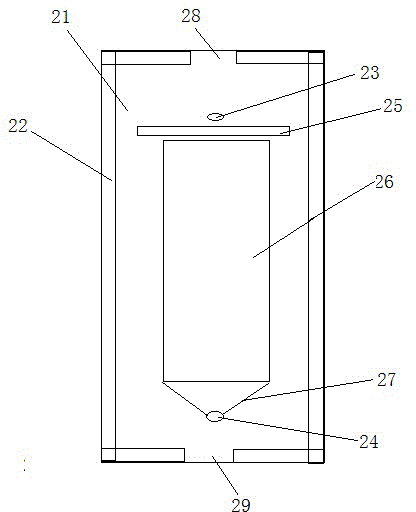

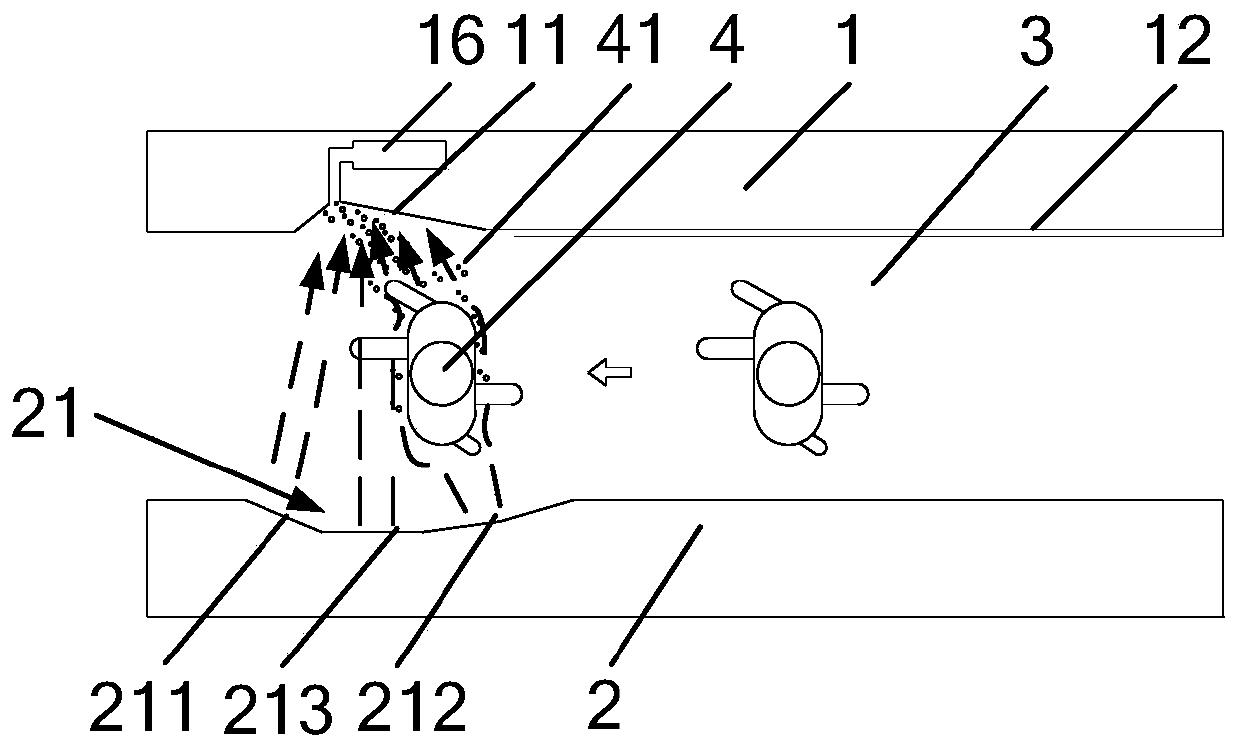

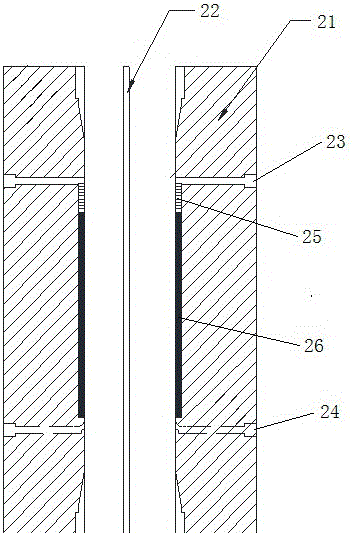

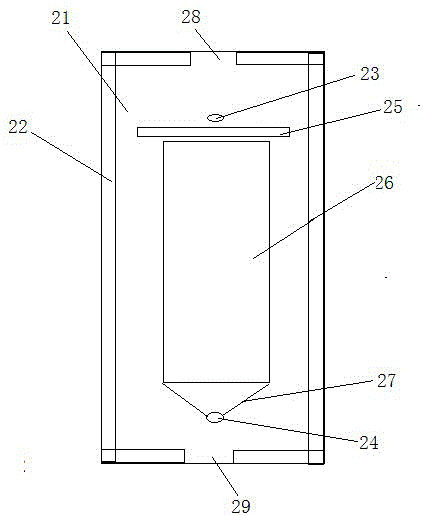

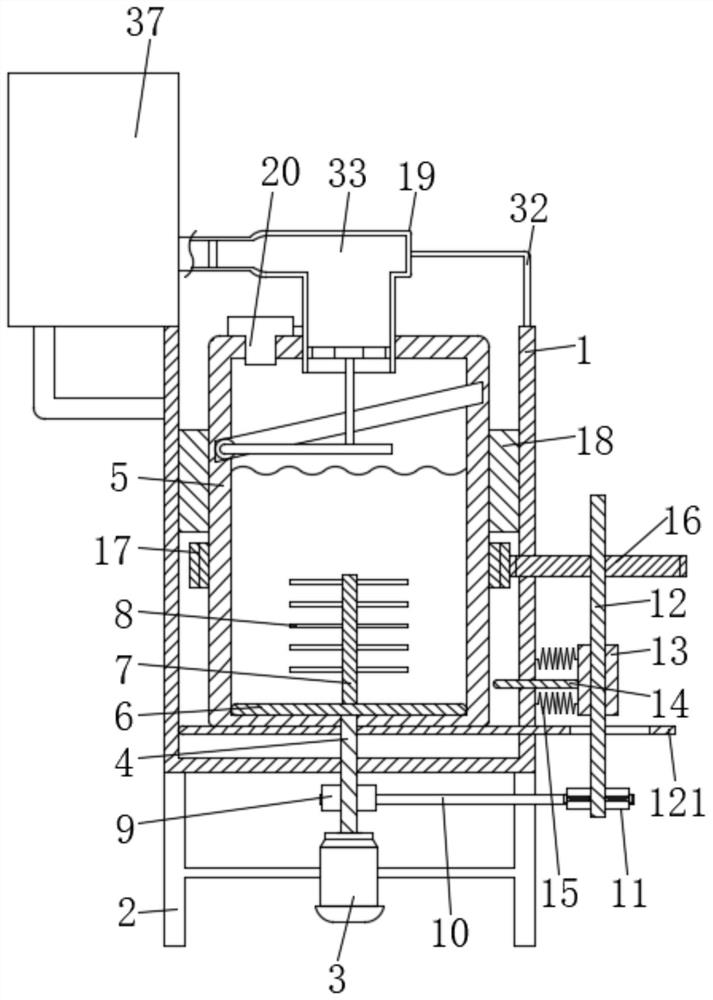

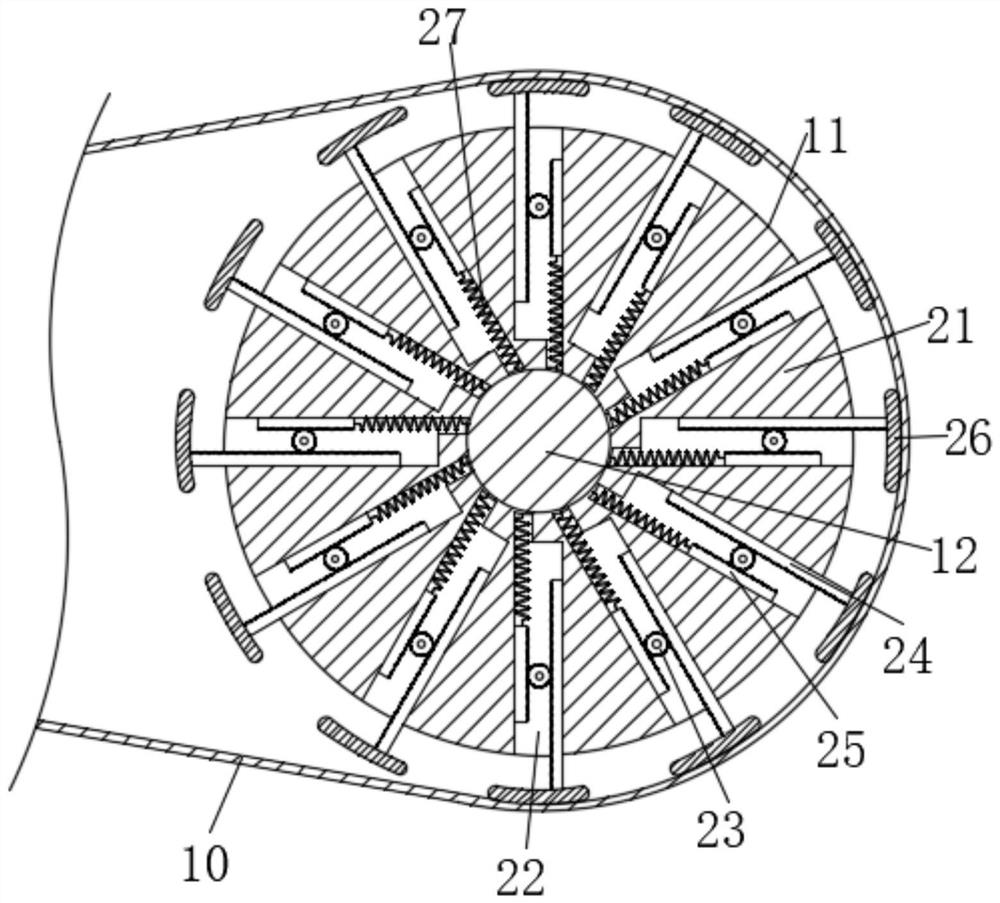

High-efficiency internal circulation anaerobic bioreactor

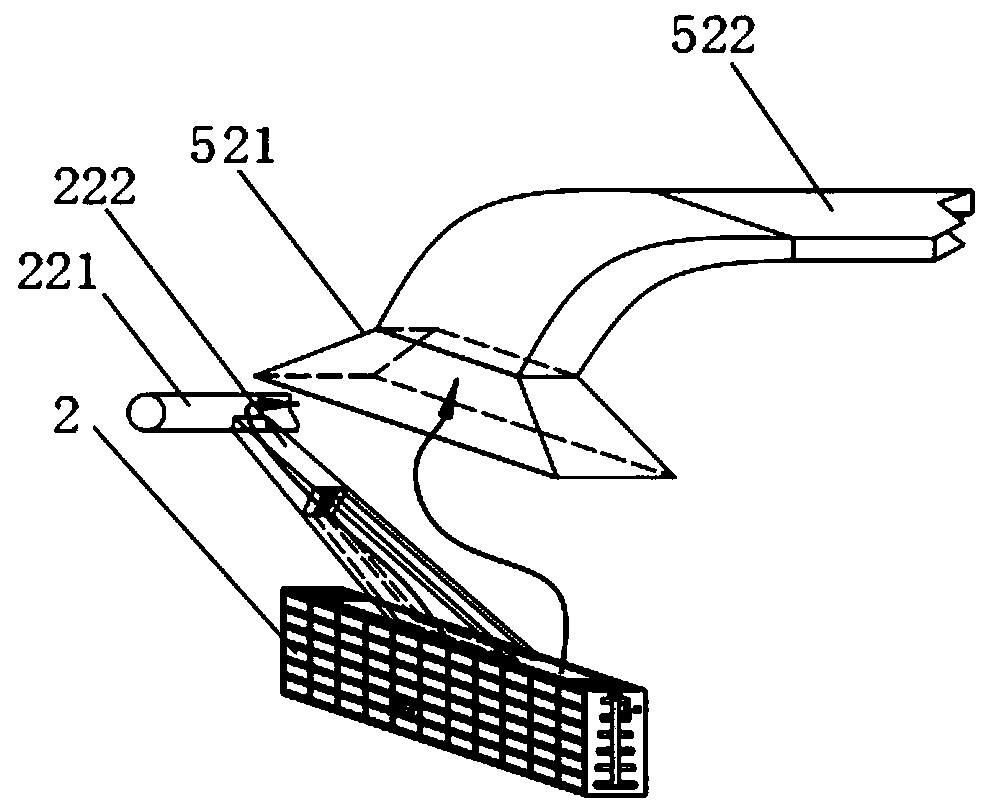

InactiveCN104909453AExpand the lower gas collection rangeIncrease gas gathering speedTreatment with anaerobic digestion processesVapor–liquid separatorThree-phase

The invention discloses a high-efficiency internal circulation anaerobic bioreactor. The anaerobic bioreactor comprises a tank body. The tank body is equipped with a gas-liquid separator, an upper layer three-phase separator and a lower layer three-phase separator. The heights of the upper layer three-phase separator and the lower layer three-phase separator can be changed in the tank body. The upper layer three-phase separator and the gas-liquid separator are connected through a telescoping gas collection pipe. The lower layer three-phase separator and the gas-liquid separator are connected through a telescoping riser pipe. The upper layer three-phase separator and the lower layer three-phase separator are equipped with an upper layer gas collection hood and a lower layer gas collection hood respectively. The upper layer gas collection hood is composed of a plurality of upper layer gas collection units through laying. The lower layer gas collection hood is composed of a plurality of lower layer gas collection units through laying. The upper layer gas collection units and the lower layer gas collection units have a structure with an openmouthed lower end and composed of two inclined side plates. The upper part gradient of the inclined side plate is more than the lower part gradient. The internal circulation anaerobic bioreactor can raise the single-layer three-phase separator gas collection efficiency, the internal circulation speed can be adjusted to meet condition requirements of different water inlet speeds and the like, and operation is stable.

Owner:JIANGSU XINHUANENG ENVIRONMENTAL ENG CO LTD

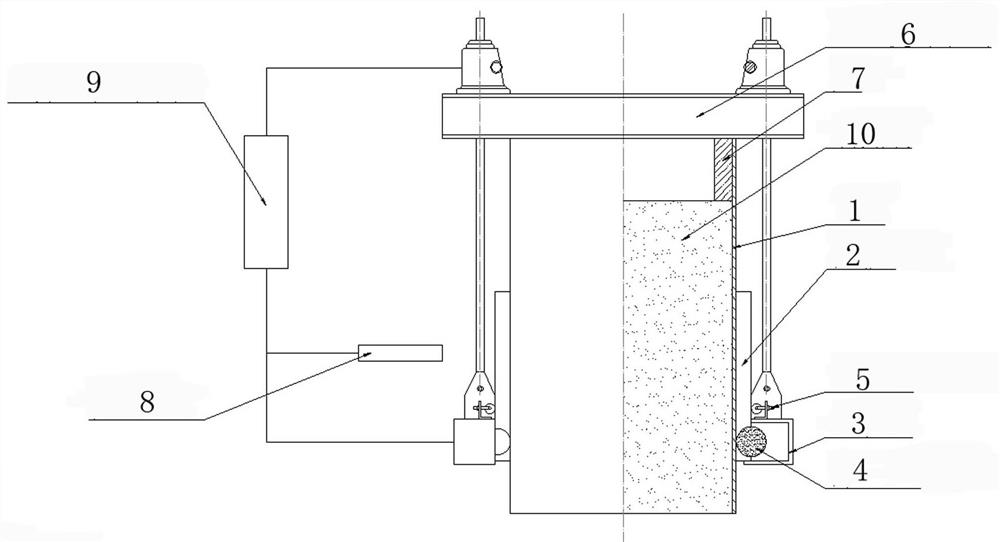

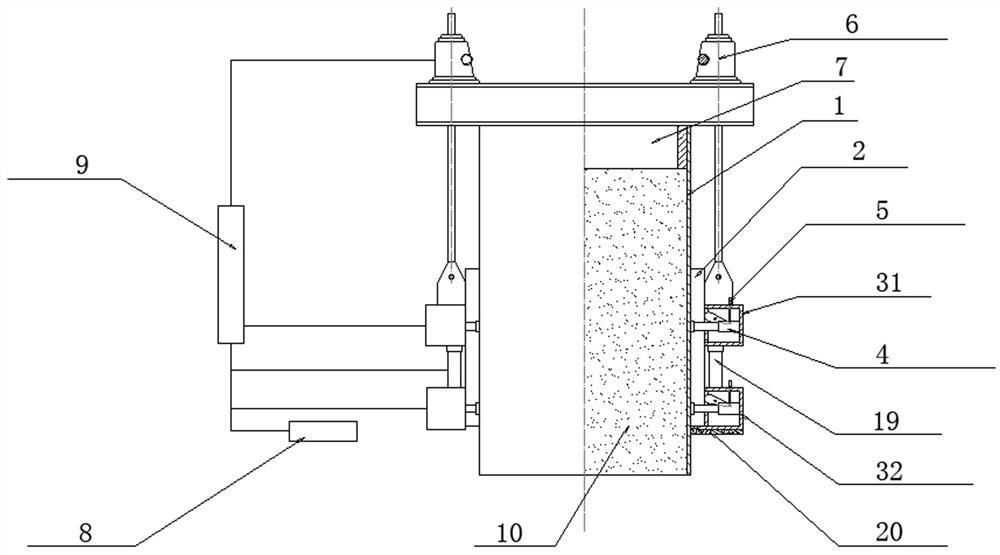

Gas collecting and measuring device

PendingCN111239343AImprove gas collection efficiencySimple structureWithdrawing sample devicesGas analyser construction detailsMeasurement deviceGas supply

The invention provides a gas collecting and measuring device which comprises a detector, a gas supply device and a shell, an enrichment groove is formed in the shell, the detector is arranged in the shell and connected with the enrichment groove, and the gas supply device is installed in the shell and used for sending gas to be measured into the enrichment groove. The gas collecting and measuringdevice provided by the embodiment of the invention is good in gas collection effect and high in measurement precision.

Owner:北京泰峰科仪技术有限公司

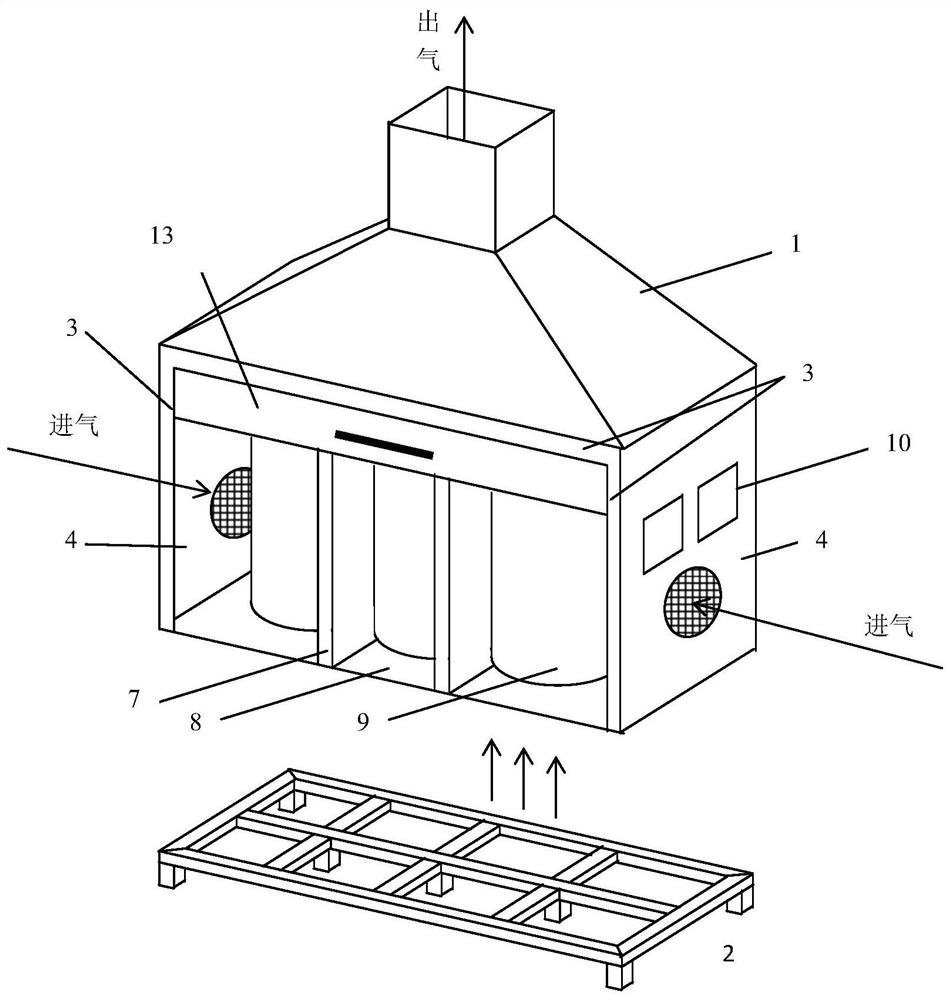

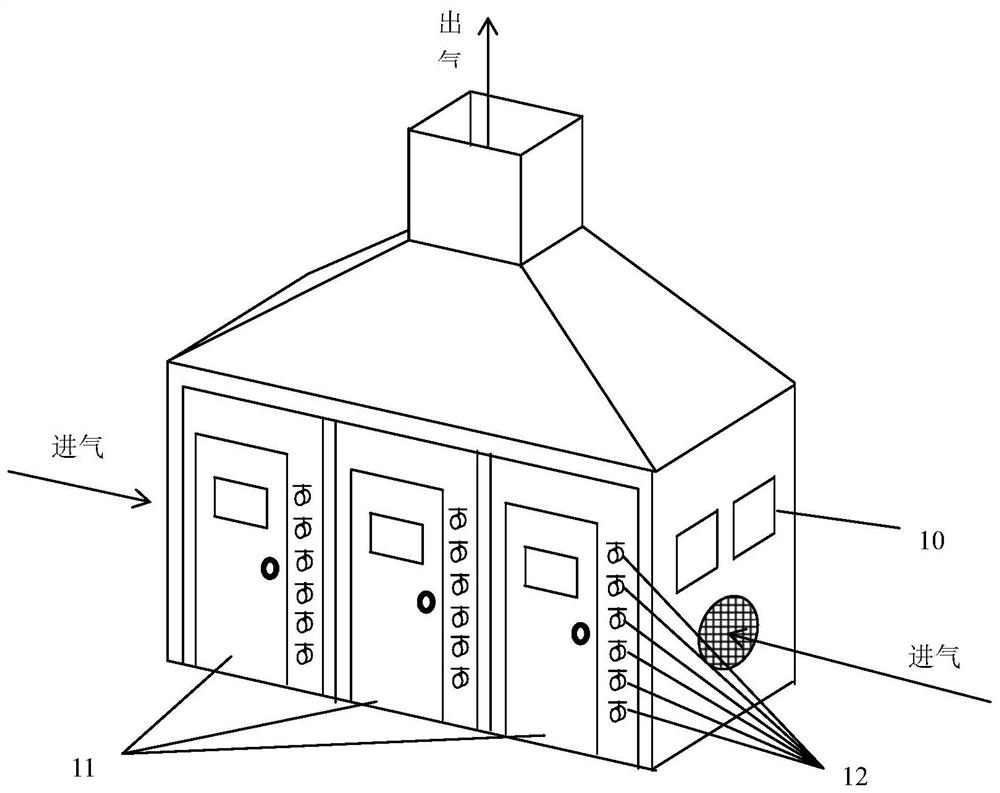

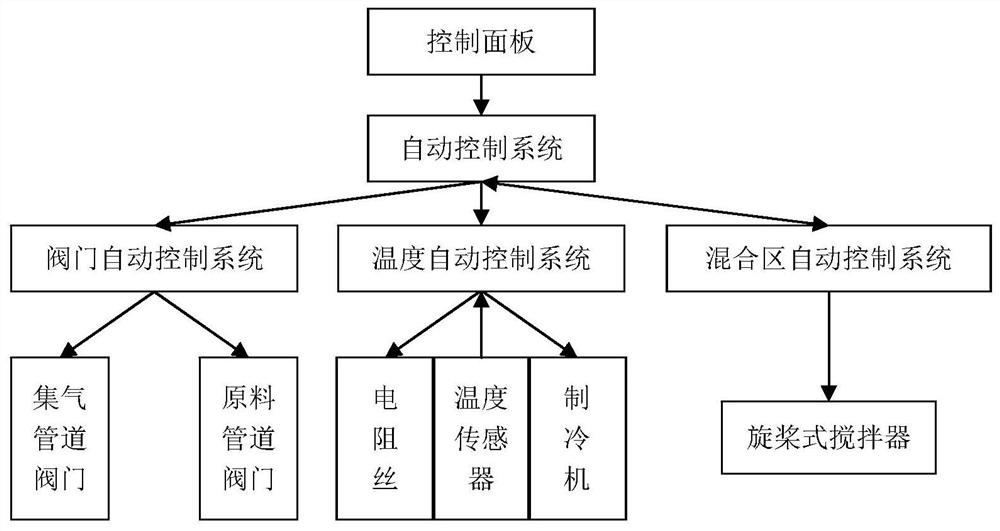

A gas collection device for liquid raw material feeding and mixing system

ActiveCN108499481BStable collectionAccurate collectionTransportation and packagingMixer accessoriesAutomatic controlAutomated control system

The invention discloses a gas collection device for liquid raw material feeding and mixing system, which includes a gas collection box, a top-suction gas collection hood arranged at the top opening of the gas collection box, and an automatic control system. There are air inlets on the left and right sides, and a number of raw material pipe joints used to connect the raw material barrels and raw material delivery pipelines are fixed and sealed on the back by surfacing welding. The automatic control system includes a valve automatic control system, a temperature automatic control system, a mixing zone gas system. The present invention makes the collection of unorganized exhaust gas in the feeding and mixing links more stable, more accurate and more thorough through the electrical connection of each control system; the unorganized exhaust exhaust gas in the mixing link is collected; the size of the raw material storage room is designed as The standard size of the forklift load plate enables standardized operation of loading and unloading of raw material barrels, improves the standardization, automation and integration of the device, is suitable for feeding and mixing of various liquid raw materials, and improves the gas collection efficiency of the gas collection device of the feeding system.

Owner:SOUTH CHINA UNIV OF TECH

A method of controlling the voltage of the electrolytic cell and the position of the clamping frame

Owner:党星培

A two-way gas collection system for urban landfills

InactiveCN106238435BEasy to useImprove gas collection efficiencyLandfill technologiesSolid waste disposalLitterCollection system

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

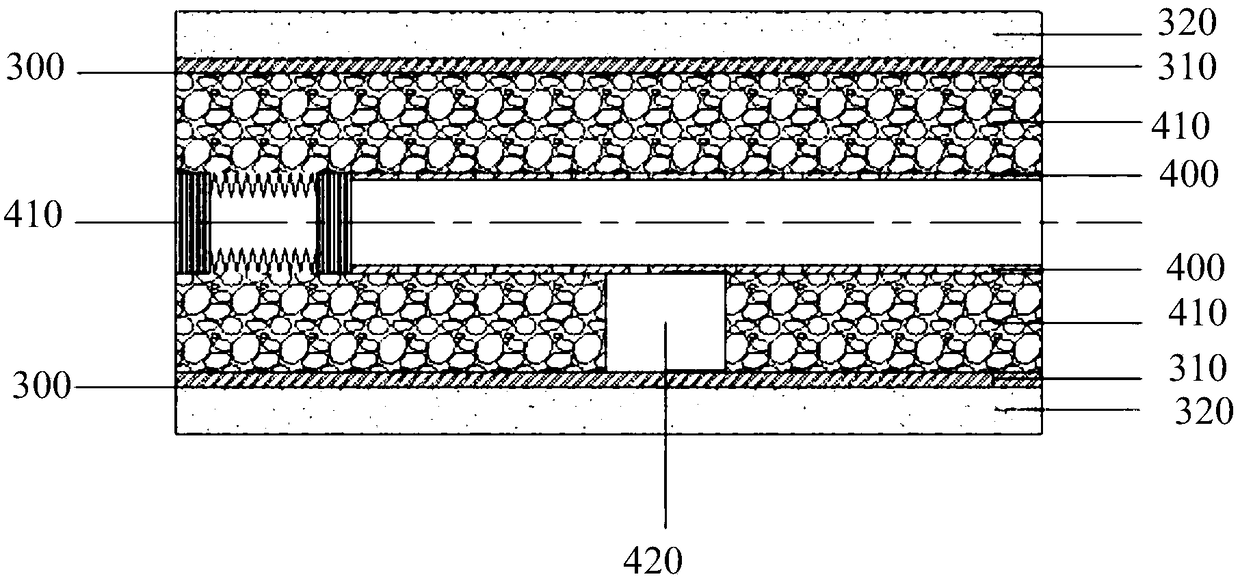

A pipe-through horizontal gas collection system for landfill

InactiveCN106077017BAvoid uniformityBreathability preventionLandfill technologiesSolid waste disposalCollection systemEngineering

The invention discloses a pipe-pipe horizontal gas collection system for a landfill, comprising: a plurality of gravel passages arranged obliquely inside the landfill; a plurality of blind ditches arranged horizontally on the top of the landfill, And communicate with the gravel channel; the metal mesh box, which is rectangular, is set inside the blind ditch; the horizontal gas collection pipe has a rectangular perforation, and is connected at the center of the metal mesh box; among them, the horizontal gas collection pipe It adopts a serrated interface connection that can be stretched and resisted damping, which can be freely stretched and twisted, which effectively improves the anti-unevenness ability and improves and improves the anti-seepage and drainage ability to improve the efficiency of gas collection.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

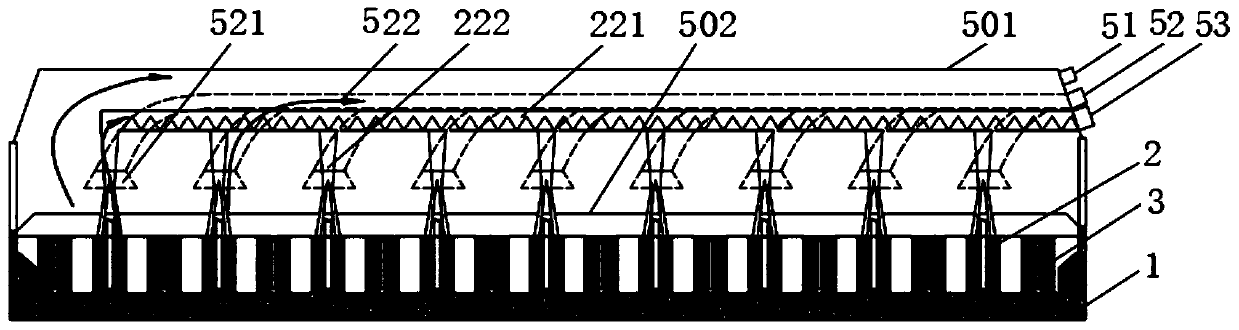

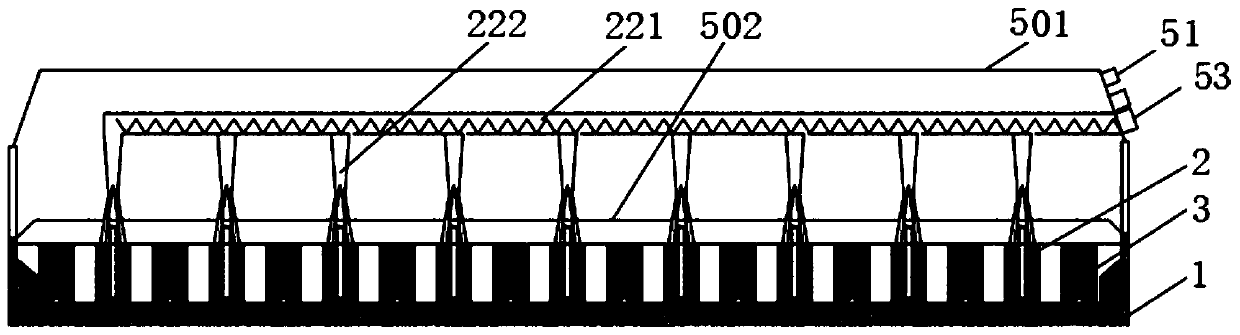

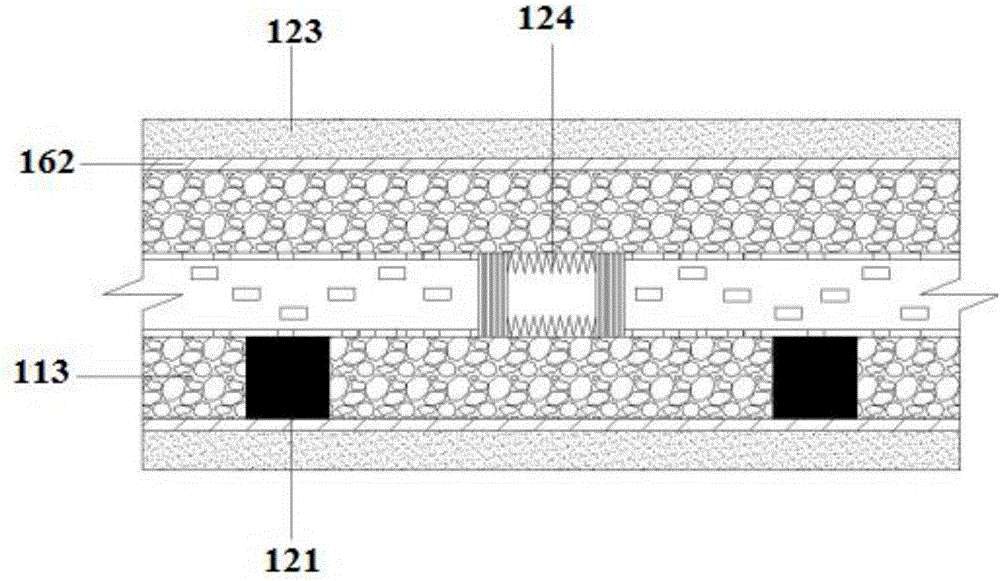

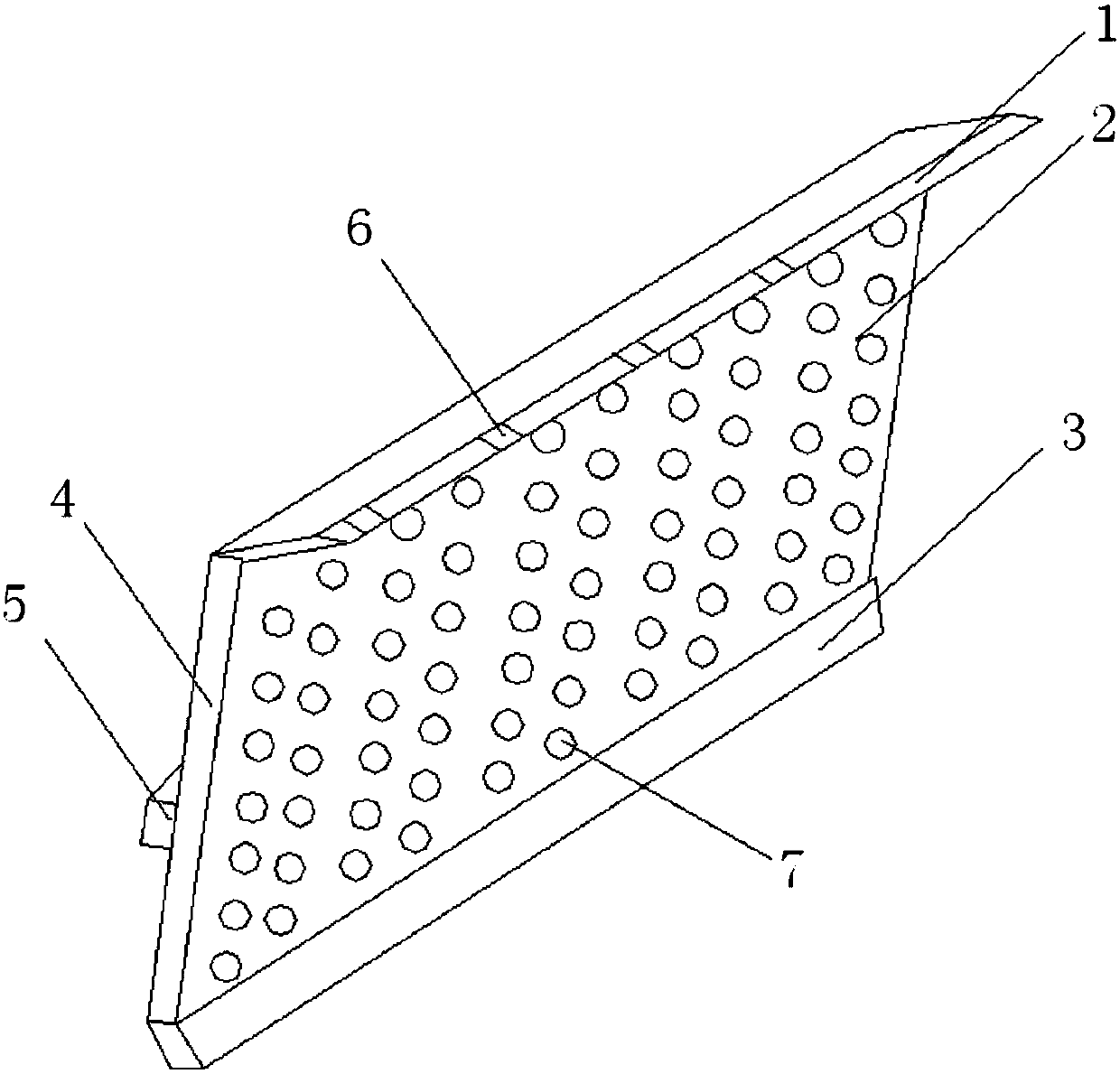

A double-layer aluminum electrolytic cell cover plate with side suction and enhanced heat preservation

InactiveCN105803485BAvoid stampedeImprove gas collection efficiencyThermal insulationAgricultural engineering

The invention discloses a double-layer aluminum electrolysis cell cover plate with side inspiration and enhanced thermal insulation. Ventilation holes (7) are drilled on an inner layer aluminum plate (2) with the ventilation holes; an upper hollow frame (1) is connected with the inner layer aluminum plate (2) with theventilation holes; an internal support framework (6) is fixedly arranged between the upper hollow frame (1) and the inner layer aluminum plate (2) with the ventilation holes; a lower solid frame (3) is connected with an outer side cell cover plate (5); and side surfaces of two ends of the inner layer aluminum plate (2) with the ventilation holes and side surfaces of two ends of the outer side cell cover plate (5) are respectively connected to form a hollow sandwich layer (4) of a two-layer aluminum plate. The thickness of the cell cover plate increases is increased, so that a thermal insulation effect can be effectively enhanced, the sealing insulation state of an electrolysis cell is improved, the thermal loss of the electrolysis cell is reduced, the energy is saved, and the consumption is reduced; the cell cover plate adopts the double-layer design to increase the hardness, so that the cell cover plate is not easy to deform after long-term use, and the service life is prolonged; and the design of the ventilation holes is matched with a gas collecting system, thus the gas collecting efficiency of the electrolysis cell can be effectively improved, thereby achieving the purpose of uniform and quick smoke absorption.

Owner:CENT SOUTH UNIV

A rare earth modified nano-coated glass plate self-cleaning gas collection device

ActiveCN104697823BCatalyticQuick collectionWithdrawing sample devicesDispersed particle separationPeristaltic pumpRare earth

The invention discloses a rare earth modified nano coating glass plate self-cleaning gas collecting device, and belongs to the fields of atmospheric sciences and environmental sciences. The gas collecting device comprises a gas inlet pipe, a gas collector, a gas outlet pipe, a peristaltic pump, a gathered liquid tank, a feeding pipe, a liquid inlet peristaltic pump, a collected liquid tank, a discharging pipe and a liquid outlet peristaltic pump, wherein the gas inlet pipe is connected with a gas inlet of the gas collector; the gas outlet pipe is connected with a gas outlet of the gas collector; the peristaltic pump is connected with the gas outlet pipe; the gathered liquid tank is connected with a gathered liquid pipeline on the gas collector by virtue of the feeding pipe; and the collected liquid tank is connected with a collected liquid pipeline on the gas collector by virtue of the discharging pipe. The rare earth modified nano coating glass plate self-cleaning gas collecting device disclosed by the invention has the characteristics of being easy to operate, high in gas collection efficiency and the like, and the gas colleting device can be widely applied to the fields of monitoring and research of gaseous pollutants in weather and environment industries as well as occasions in which gaseous pollutants are required to be effectively and rapidly separated from particle components.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

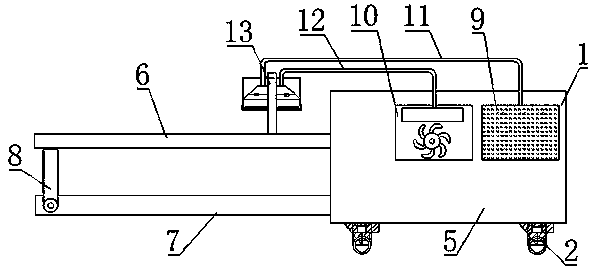

Ironing and pressing all-in-one machine with lint suction function for garment processing

ActiveCN110924111ASimple structureEasy to installIroning boardsIroning machinesEngineeringSteam engine

The invention relates to an ironing and pressing all-in-one machine with a lint suction function for garment processing. The ironing and pressing all-in-one machine with the lint suction function forgarment processing comprises a device box, a working plate, a telescopic plate, a support rod, a steam pipe, an extraction pipe, two moving plates, a connecting rod, an ironing and pressing device anda connecting piece. A storage bin with an opening facing the side end of the device box is arranged on the device box; a groove is formed in the top part of the device box; the ironing and pressing device comprises an ironing and pressing box, an ironing and pressing cover plate and an air collecting hood; an ironing and pressing bin with a downward opening is arranged on the ironing and pressingbox; a lint removing device for cleaning lint is arranged in the ironing and pressing bin, and comprises a rotary shaft and multiple cutters; a first power mechanism for driving the rotary shaft to rotate is arranged on the top part of the ironing and pressing box; a device bin is arranged in the device box; and a steam engine and an air extractor are arranged in the device bin. Through arrangingthe device box, the telescopic plate, the working plate, the ironing and pressing device and the lint removing device, the ironing and pressing all-in-one machine with the lint suction function for garment processing provided by the invention solves the problems that an ironing and pressing machine is large in volume so as to be inconvenient to store, cannot fix clothes and has no lint suction function; and the ironing and pressing all-in-one machine with the lint suction function for garment processing has higher practicability.

Owner:九江市冰能量服饰织造有限公司

Method for producing one-dipping two-baking anode carbon block

InactiveCN100580146CExcellent physical and chemical indicatorsLow resistivityPorosityVacuum pressure

The invention discloses a method for producing one impregnating two calcining anode carbon blocks, which is on the basis of producing common anode carbon blocks and comprises following steps: selectively using calcined coke, adding a little antioxidant additive, preheating a common anode under the temperature of 280-330DEG C for 18-24 hours, then, hoisting in a high pressure impregnation tank, filling impregnating pitch whose temperature is 160-180DEG C under the vacuum pressure of 0.09-0.094MPa, pressurizing 1.55-1.6MPa, maintaining the pressure for 3-5 hours, hoisting out and cooling to normal temperature, then, calcining for 200-220 hours under the temperature condition that the maximum temperature is 800-900DEG C according to a heating curve, cooling, and then cleaning up to obtain a new one impregnating two calcining anode carbon block. Since the pitch is filled in an air vent of the anode, the mechanicalness and the physical and chemical properties of the anode carbon blocks are newly changed, the bulk density and the compressive strength are increased, the porosity is lowered, the resistivity is lowered, the activity of the binder coke and the activity of aggregate tend to be consistent, the speed of selective oxidation is lowered, the voltage drop of the anode carbon blocks is lowered, and the using period of the anode is prolonged.

Owner:WEN COUNTY DONGFANG CARBON

A gas collection method for electrolyzer overhaul

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE +1

Automatic temperature control device

ActiveCN112430537AIncrease gas production rateActive growthBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlElectric machine

The invention discloses an automatic temperature control device which comprises a fixing frame, a support is fixedly connected to the bottom of the fixing frame, a motor is arranged on the support, afirst shaft is fixedly connected to the top of the output shaft on the motor, and the surface of the first shaft penetrates through the lower surface of the fixing frame and is rotationally connectedwith the fixing frame. A fermentation bin is rotationally connected in the fixing frame in a limited mode, the first shaft penetrates through the lower surface of the fermentation bin and is fixedly connected with a sealing rotary disc, the lower surface of the sealing rotary disc is rotationally connected with the bottom of the inner wall of the fermentation bin in a limited mode, and a second shaft is fixedly connected to the circle center of the upper surface of the sealing rotary disc. Through cooperative use of the structures, the defects that in the actual use process, due to the fact that a traditional biogas digester does not have heat preservation or constant-temperature control equipment or heat storage equipment and the like, annual continuous and stable production of biogas isdifficult to achieve, the production efficiency is reduced, and inconvenience is brought to use are overcome.

Owner:SICHUAN UNIV

Gas gathering system of divisional gas-gathering type aluminum electrolytic bath

The invention relates to a gas gathering system of a divisional gas-gathering type aluminum electrolytic bath, which belongs to the technical field of electrolyzing aluminum. The gas gathering system of the electrolytic bath comprises in-bath horizontal flues, clapboards, vertical flues, upper convergence flues, bottom convergence flues and a main flue, wherein the number of the in-bath horizontalflues is between 2 and 5, the height range is between 100 and 400 millimeters; the clapboards are vertical to the length direction of the horizontal flues and equally divide the length of the horizontal flues; and the horizontal flues and the clapboards divide a horizontal gas-gathering area into a plurality of areas. The vertical flues are arranged at one end or two ends of the electrolytic bath, have a same structure with a door-type upright post or are positioned on the outside of the door-type upright column, and are communicated with the main flue though the bottom convergence flues. Byapplying the system, a two-end or single-end gas-gathering mode can be adopted, and no matter which gas-gathering mode is adopted, a plurality of the in-bath horizontal flues are arranged to divide the in-bath space into a plurality of areas to perform divisional gas gathering, and the distribution evenness of positive pressure in the bath is improved, thus the gas gathering efficiency is improved.

Owner:NORTHEASTERN UNIV ENG & RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com