Gas collecting method for crown block in electrolysis workshop

An electrolysis workshop and crane technology, applied in the field of gas collection in electrolysis workshops, can solve problems such as harm to people's lives in agricultural and animal husbandry production, affecting the health of production workers, and deteriorating working conditions, and achieve easy control, easy operation, and simple methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the schematic diagrams.

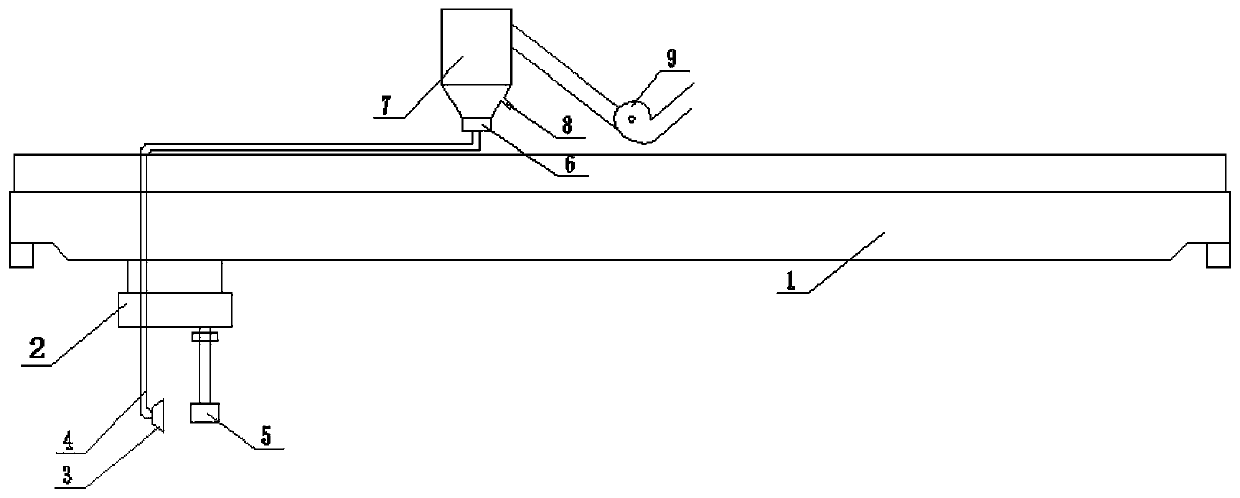

[0025] Such as figure 1 As shown, a gas collecting device is added on the crane tool trolley 2, including a telescopic pipe 4 and a dust collection cover 3, and a flue gas purification system is added on the crane girder 1. The flue gas purification system includes a hydrogen fluoride adsorption device 6, a dust collector 7 , Induced fan 9, regular discharge device 8, etc. When the tool trolley 2 of the skycar clamps the residual pole 5 and leaves the electrolytic cell, the dust collection cover 3 is placed on the side of the residual pole through the telescopic pipe 4. During the transfer of the residual pole 5 to the cooling system of the residual pole, the dust collection cover 4 moves with the residual pole 5 all the time, collects the flue gas that residual pole 5 distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com