Upper structure of large-sized aluminum cell

An aluminum electrolytic cell, large-scale technology, applied in the field of the superstructure of the electrolytic cell, can solve the problems of poor integrity of the superstructure, excessive air leakage area of the flue, poor smoke exhaust effect, etc., achieve uniform negative pressure, rational use of space, Material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

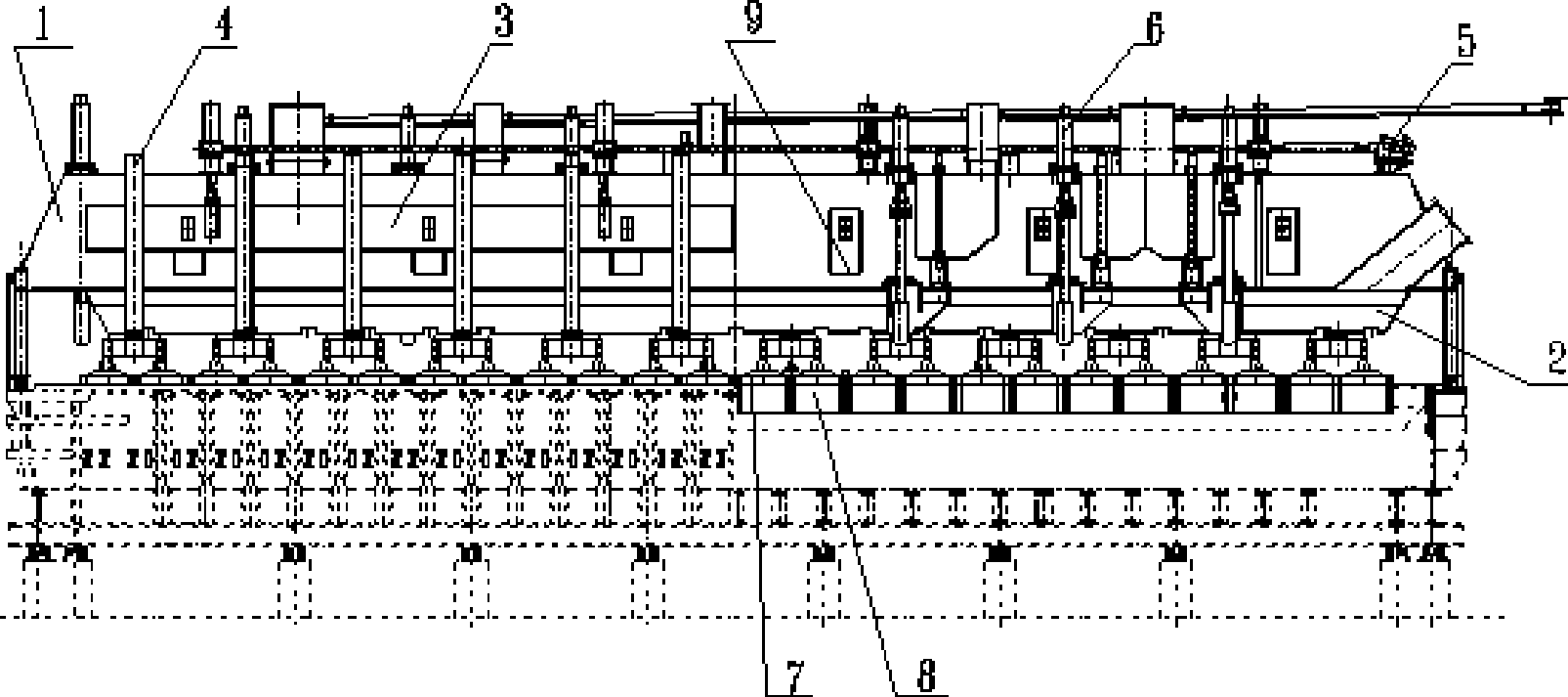

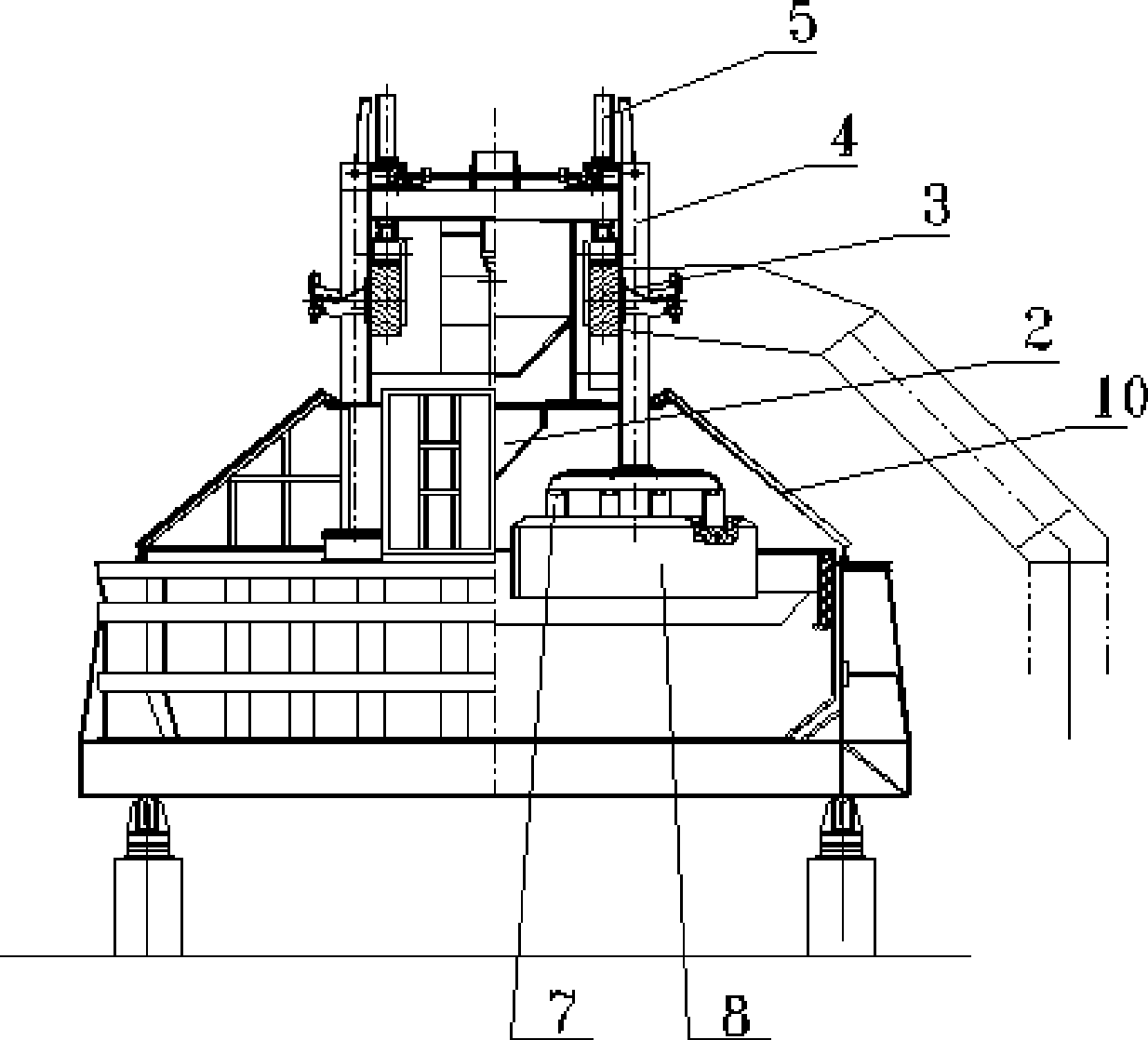

[0022] Embodiment of the present invention: the upper structure of the large aluminum electrolytic cell of the present invention includes girder 1, ventilation flue 2, anode bus bar 3, anode carbon block group 4, anode lifting mechanism 5, shelling and feeding device 7, steel claw 7, carbon Block 8, girder 1 web hole 9, gas collection cover 10, anode carbon block group 4 adopts double anode structure, anode steel claws have 8 claw heads, each carbon block is assigned 4 claw heads, and the eight claw heads are radial The anode guide rod is welded into one body, and a gap of 10-25mm is maintained between the two carbon blocks; the anode lifting mechanism 5 adopts the form of a screw jack driven by a single motor at the end, and multiple lifting points are designed for the whole slot; the main beam 1 adopts a web beam structure with good integrity; the ventilation flue 2 is arranged under the girder 1; the anode bus 3 adopts a split structure, and the middle is connected with a so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com