Patents

Literature

78results about How to "Excellent physical and chemical indicators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plant growth soil culture medium and preparation method thereof

ActiveCN101743793ASuitable for growthExcellent resistance to rain erosionSeed coating/dressingFertilizer mixturesSoil aggregateGrowth plant

The invention discloses a plant growth soil culture medium, which is composed of the following materials in percentage by weight: 30-32% of clay, 35-38% of organic matter, 19-25% of plant fiber, 3-6% of stabilizing agent, 0.035-0.085% of aggregate agent, 2% of fertilizer, 36-45% of clean water and 0.9-3.3% of seed. The invention also discloses a preparation method of the plant growth soil culture medium. The plant growth soil culture medium has the advantages of stable soil aggregate structure, water retention, fertilizer retention and good air permeability, and is suitable for plant growth. The preparation method is novel and convenient and has low consumption and operability.

Owner:青岛冠中生态股份有限公司

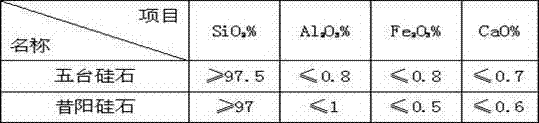

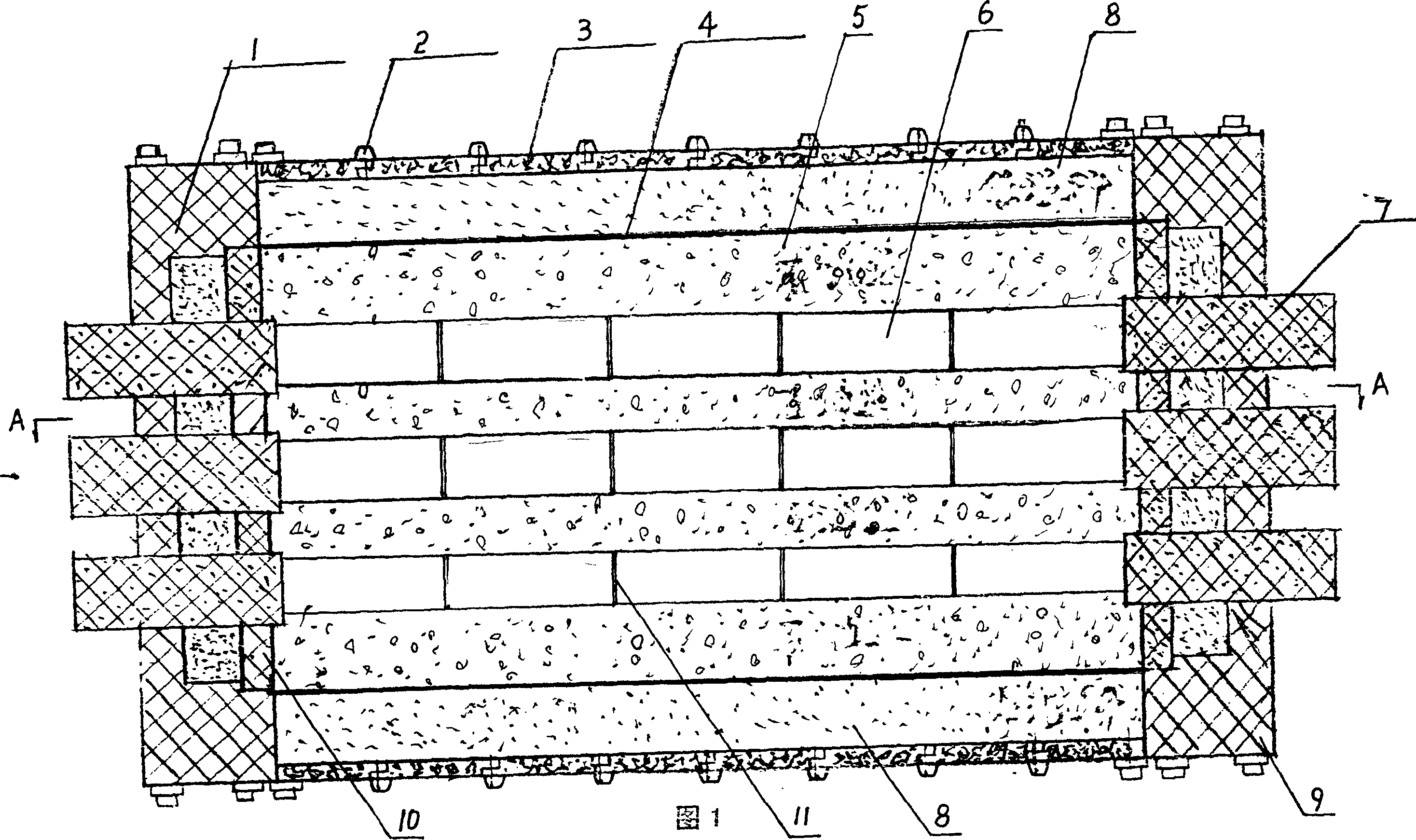

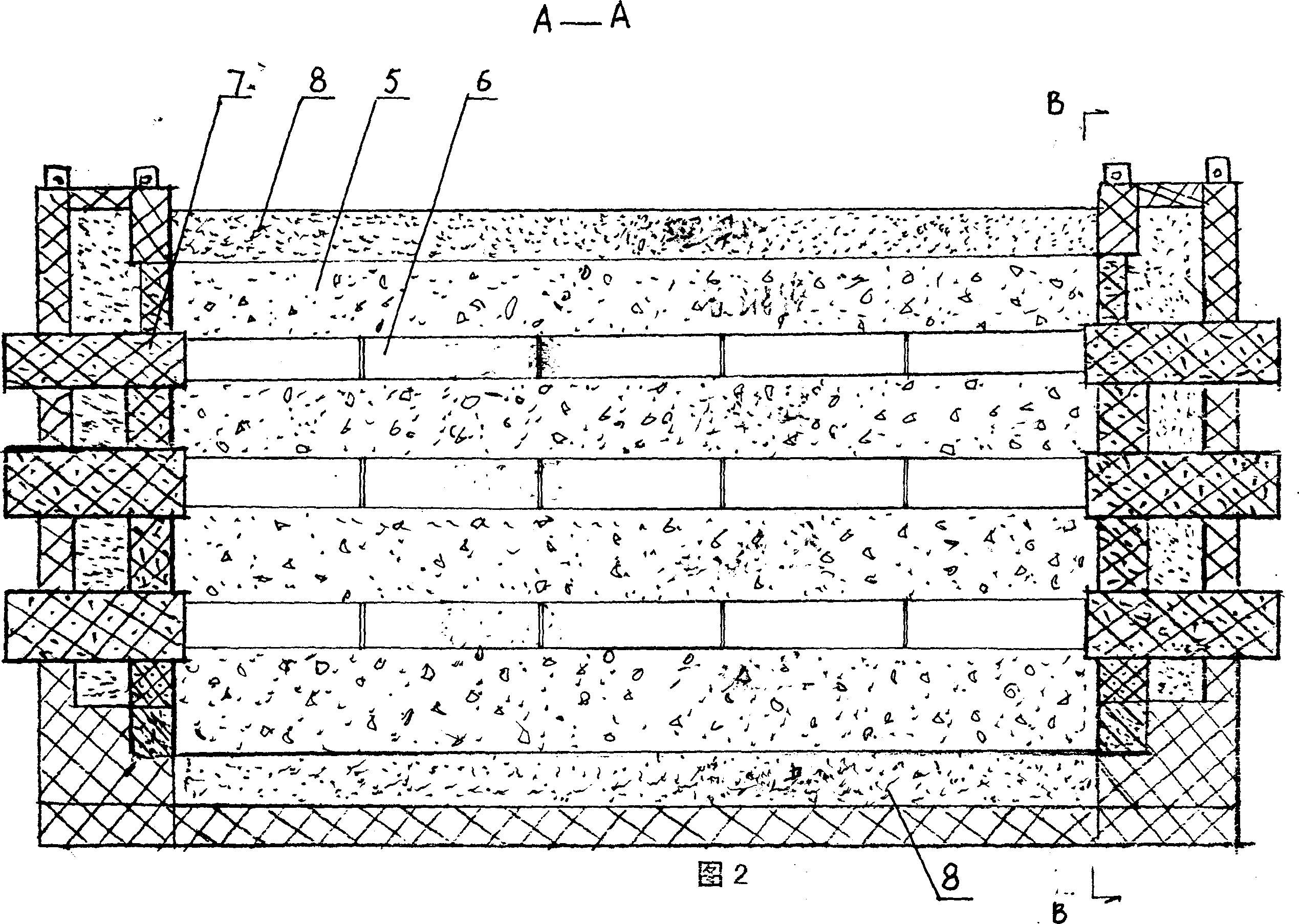

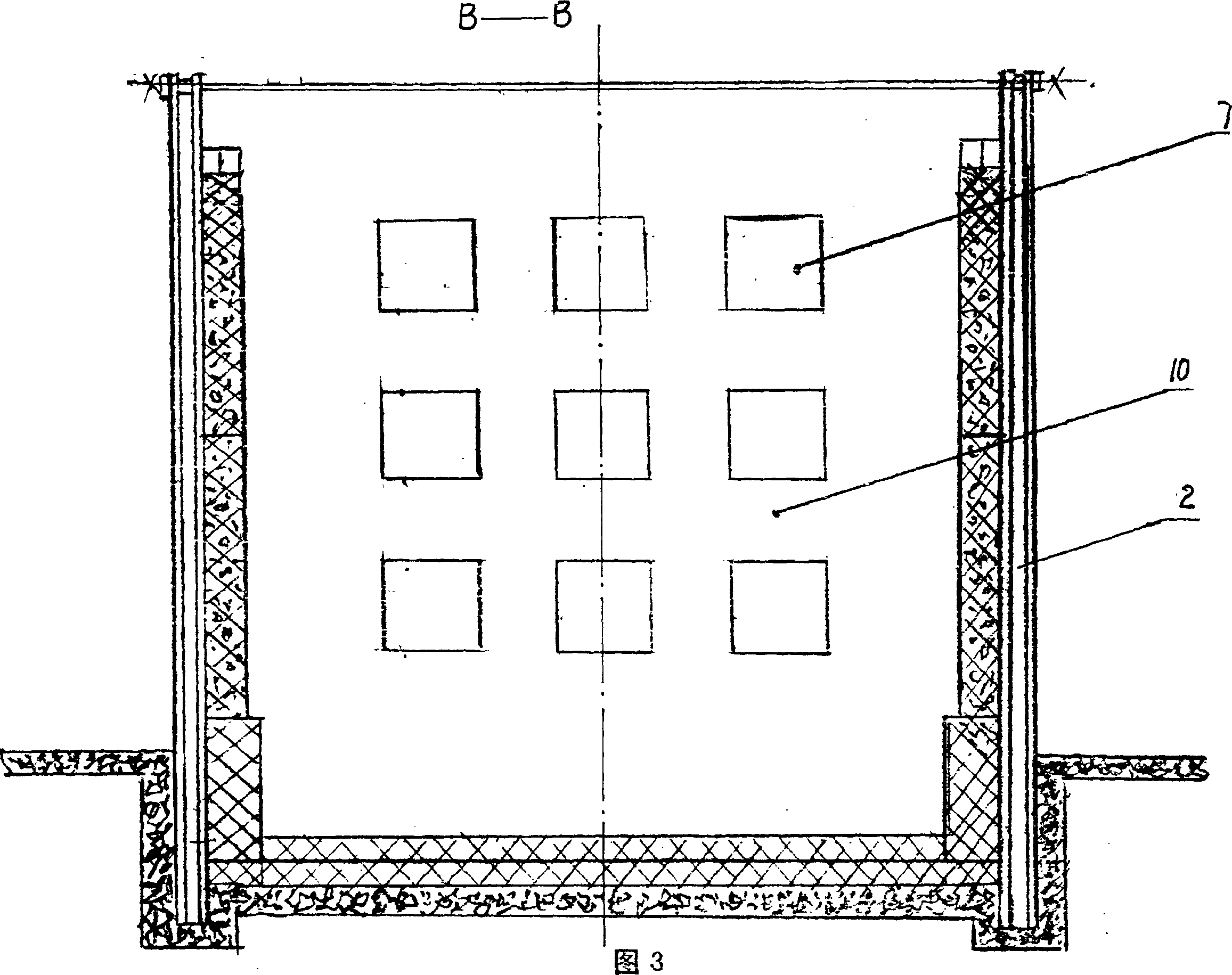

Silica heat-proof firebrick

ActiveCN101139210AExcellent physical and chemical indicatorsHigh temperature resistantSlurryRaw material

The present invention relates to the fireproof material technology field, in particular to a silicon heat insulation fireproof brick adaptable to be used in coke oven and carbon stove. The present invention can solve the shortcomings in the prior clay heat-insulation and fireproof brick that load distortion temperature is low; the material is easy to be shrunk in the high temperature; the heat conductivity ratio is much larger and the heat preservation effect is much worse and so on. The components and the relative weight ratio in the present invention are that: 81-85 percent of silica powder, 15-19 percent of perlite, and the following assistant materials, whose weight ratio occupied in the main raw materials is as follow: 045-0.55 percent of iron scale powder, 0.9-1.1 percent of cement, 6.5-7.5 percent of lime milk, 1.95-2.2 percent of paper slurry. The silica powder and the perlite with the stated matched ratio are added into a humid grinder and then the iron scale powder and the cement are added into to be grinded for 1-2 minutes; and then the water with the weight ratio occupied in the main raw material 1.8-2.2 percent is added, and then the lime milk is also added to be grinded and pressed for 10-15 minutes. Finally, the paper slurry is added to be grinded and pressed for 10-15 minutes. The mixture is taken out from the grinder to be molded. Each physical and chemical index of the silicon heat insulation fireproof brick in the present invention is better than the national standard; the present invention has the advantages of heat-resisting, low heat conductivity, low iron content, large compression strength and much better heat stability and so on. The present invention can be directly used as the inner bushing for the industrial stove.

Owner:山西盂县西小坪耐火材料有限公司

Silica brick for coke oven

The invention relates to a refractory material, in particular to a silica brick for a coke oven of 5.5 m. The silica brick comprises a raw material and an auxiliary material, wherein the raw material comprises the following components in part by weight: 200-250 parts of silica coarse powder, 330-380 parts of silica medium powder, 80-130 parts of silica fine powder and 80-120 parts of residual silica bricks as clinker powder; the auxiliary material comprises a mineralizing agent, lime milk and paper pulp which respectively occupy 1.2 percent, 8 percent and 1 percent of the total weight of the raw material; and the mineralizing agent is formed by mixing manganese powder of which the content of MnO2 is more than or equal to 25 percent and iron phosphate powder of which the content of FeO is more than or equal to 65 percent according to the proportion of 1:1. The preparation of the silica brick comprises the following steps: adding the silica coarse powder, the silica medium powder, the fine power and the residual silica bricks in a wet mill; adding the mineralizing agent for dry mixing for 4-5 minutes; adding the lime milk and compacting for 10-15 minutes; adding the paper pulp, mixing till pug is uniform, compacting and forming into a blank. The silica brick is improved from the aspects of raw material selection, raw material particle grain fineness, dimension distribution and the like, and the various physical and chemical indexes of the silica brick are superior to the national standard, so that the service life of the coke oven can be remarkably improved.

Owner:山西盂县西小坪耐火材料有限公司

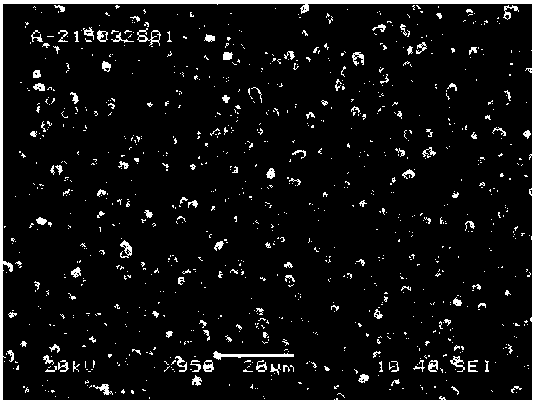

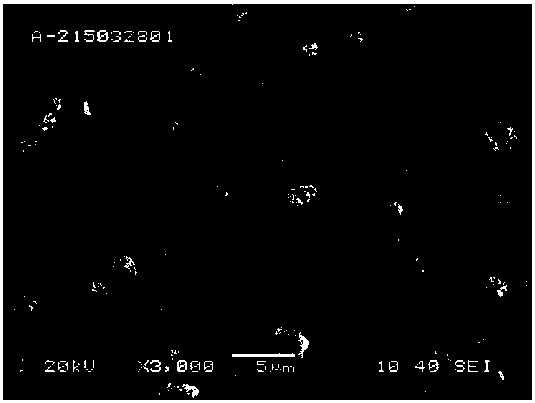

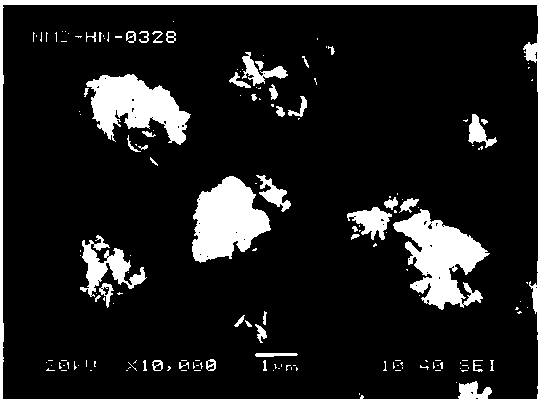

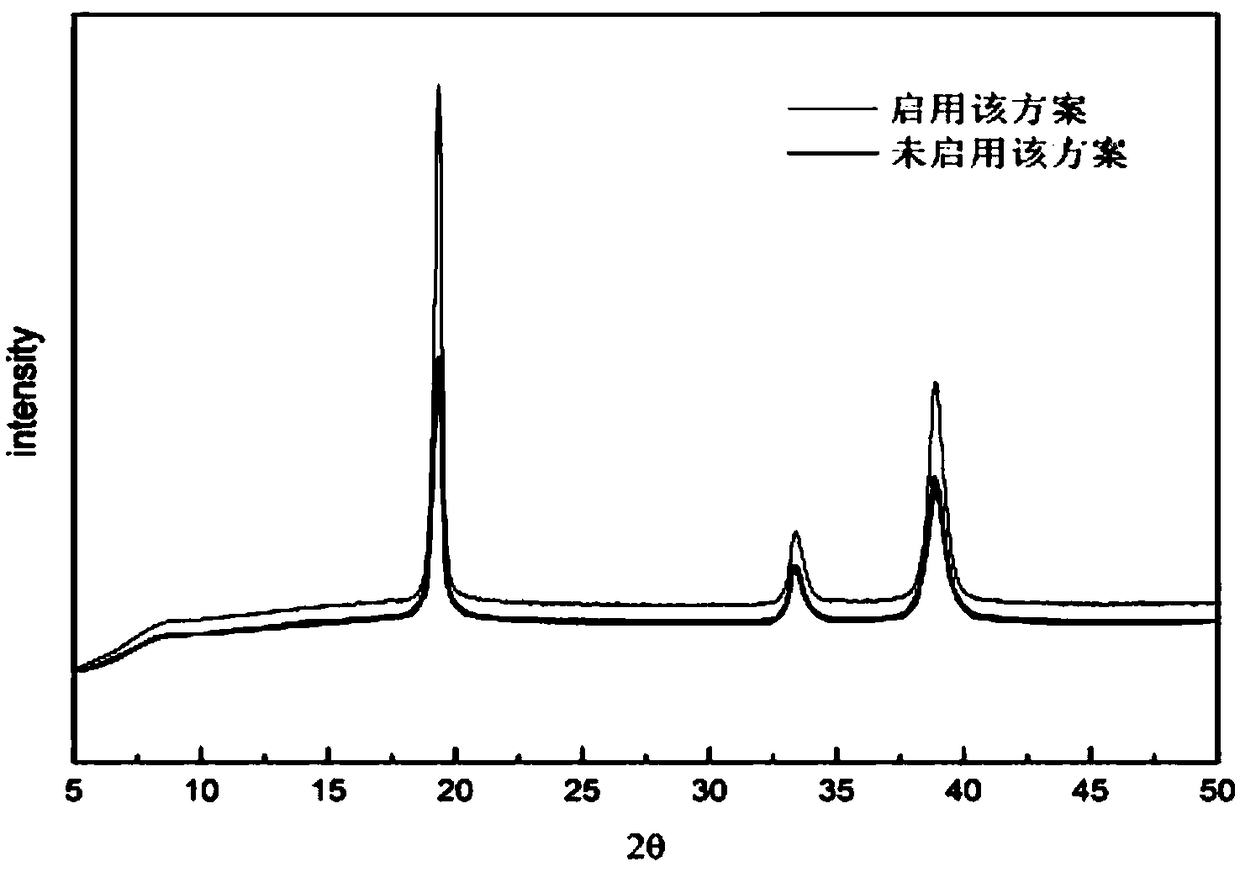

High-density and small-particle size nickel-cobalt-manganese hydroxide and preparation method thereof

InactiveCN107640792AHigh density and small tap densityLow tap densityCell electrodesSecondary cellsHigh densityManganese

The invention discloses a high-density and small-particle size nickel-cobalt-manganese hydroxide and a preparation method thereof. For the high-density and small-particle size nickel-cobalt-manganesehydroxide provided by the invention, a general chemical formula is NixCoyMnz(OH)2, wherein x+y+z=1, x is larger than or equal to 0.3 and smaller than or equal to 0.8, y is larger than or equal to 0.1and smaller than or equal to 0.4, and z is larger than or equal to 0.1 and smaller than or equal to 0.4; the particle sizes are d10 larger than or equal to 2 microns, d50 equal to 2.5-4 microns and d90 smaller than or equal to 6 microns, the tap density is larger than or equal to 1.4g / cm<3>, the specific surface area is 5-20m<2> / g, and the shape is spherical or spheroidal. The invention also discloses the preparation method of the high-density and small-particle size nickel-cobalt-manganese hydroxide. The preparation method is strong in controllability, can stably control the particle sizes ineach production batch without using a surfactant and is low in production cost, high in efficiency and good in physicochemical index of a final product.

Owner:ZHUJI PAWA NEW ENERGY

Method for producing one-dipping two-baking anode carbon block

The invention discloses a method for producing one impregnating two calcining anode carbon blocks, which is on the basis of producing common anode carbon blocks and comprises following steps: selectively using calcined coke, adding a little antioxidant additive, preheating a common anode under the temperature of 280-330DEG C for 18-24 hours, then, hoisting in a high pressure impregnation tank, filling impregnating pitch whose temperature is 160-180DEG C under the vacuum pressure of 0.09-0.094MPa, pressurizing 1.55-1.6MPa, maintaining the pressure for 3-5 hours, hoisting out and cooling to normal temperature, then, calcining for 200-220 hours under the temperature condition that the maximum temperature is 800-900DEG C according to a heating curve, cooling, and then cleaning up to obtain a new one impregnating two calcining anode carbon block. Since the pitch is filled in an air vent of the anode, the mechanicalness and the physical and chemical properties of the anode carbon blocks are newly changed, the bulk density and the compressive strength are increased, the porosity is lowered, the resistivity is lowered, the activity of the binder coke and the activity of aggregate tend to be consistent, the speed of selective oxidation is lowered, the voltage drop of the anode carbon blocks is lowered, and the using period of the anode is prolonged.

Owner:WEN COUNTY DONGFANG CARBON

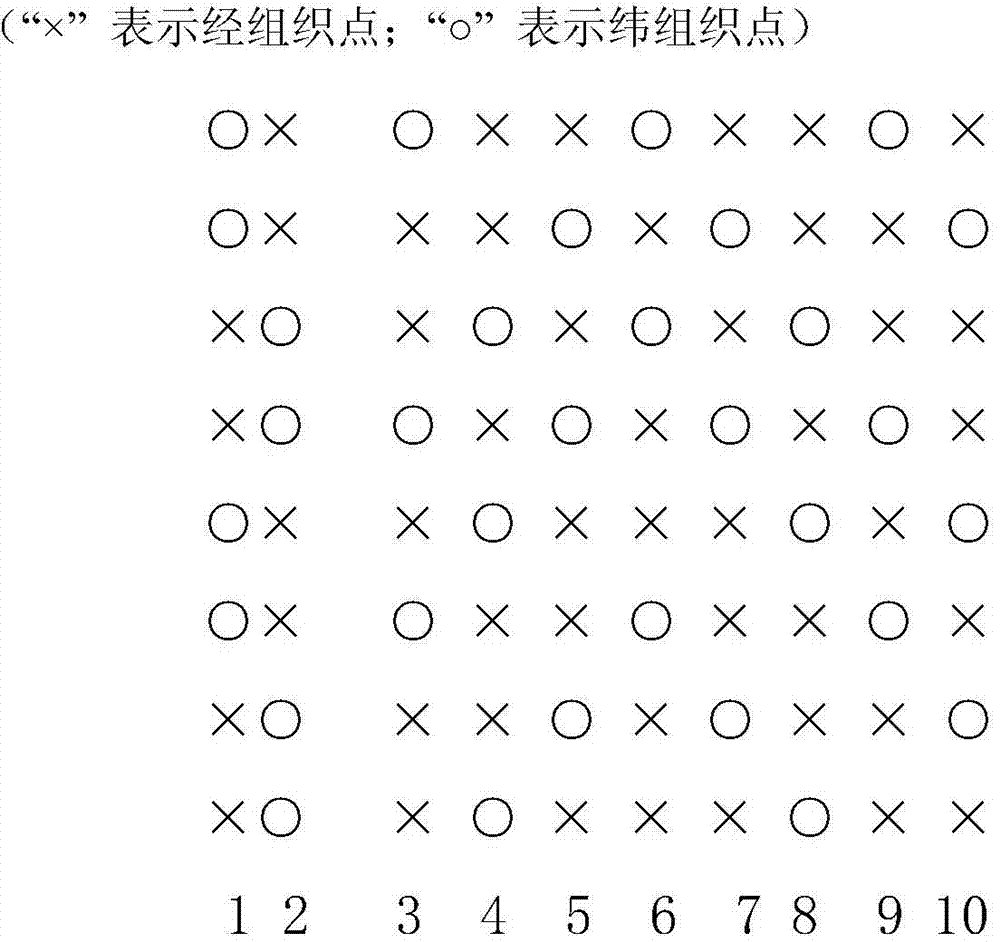

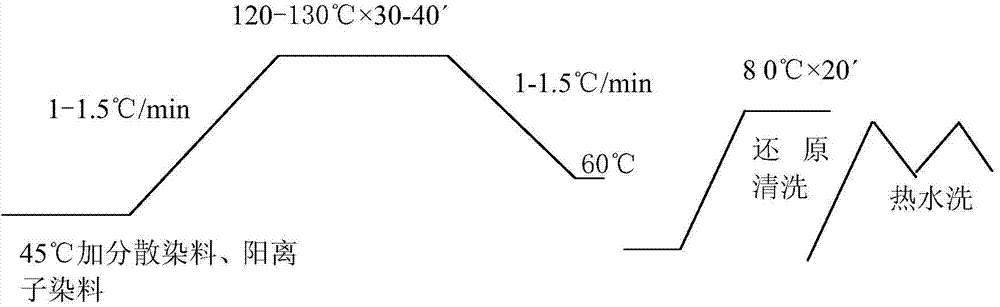

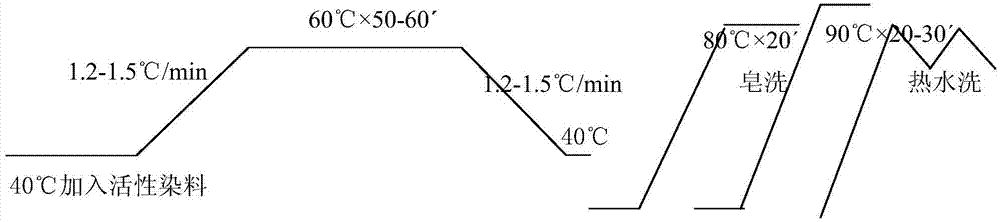

Coffee carbon multi-component fiber weaving fabric and preparation method thereof

The invention belongs to the field of spinning, dyeing and finishing, and particularly relates to coffee carbon multi-component fiber weaving fabric and a preparation method of the coffee carbon multi-component fiber weaving fabric. The coffee carbon multi-component fiber weaving fabric is made of the following raw materials of warp direction yarns and weft direction filaments, wherein the warp direction yarns are formed by blending the following raw materials, by weight, 25-45% of coffee carbon fibers, 25-40% of bamboo fibers, 20-30% of cationic modified polyester fibers and 0.5-0.8% of conductive fibers, and the weft direction filaments are formed by alternately ranking 150D-160D coffee carbon fiber filaments and 100D-120D PTP fiber filaments at the ratio of 1 to 1. The coffee carbon multi-component fiber weaving fabric has the advantages that different characteristics of the coffee carbon fibers and the other fibers are exerted, comfort of the apparel fabric and the uvioresistant function and other protection functions are integrated, physicochemical indexes are good, dyefastness is high, and cost performance of the fabric is high. The preparation method is provided, the process is reasonable, and a new path is opened up for improving high performance and comfort of the coffee carbon multi-component fiber weaving fabric.

Owner:SHANDONG WOYUAN NEWFASHIONED FABRIC

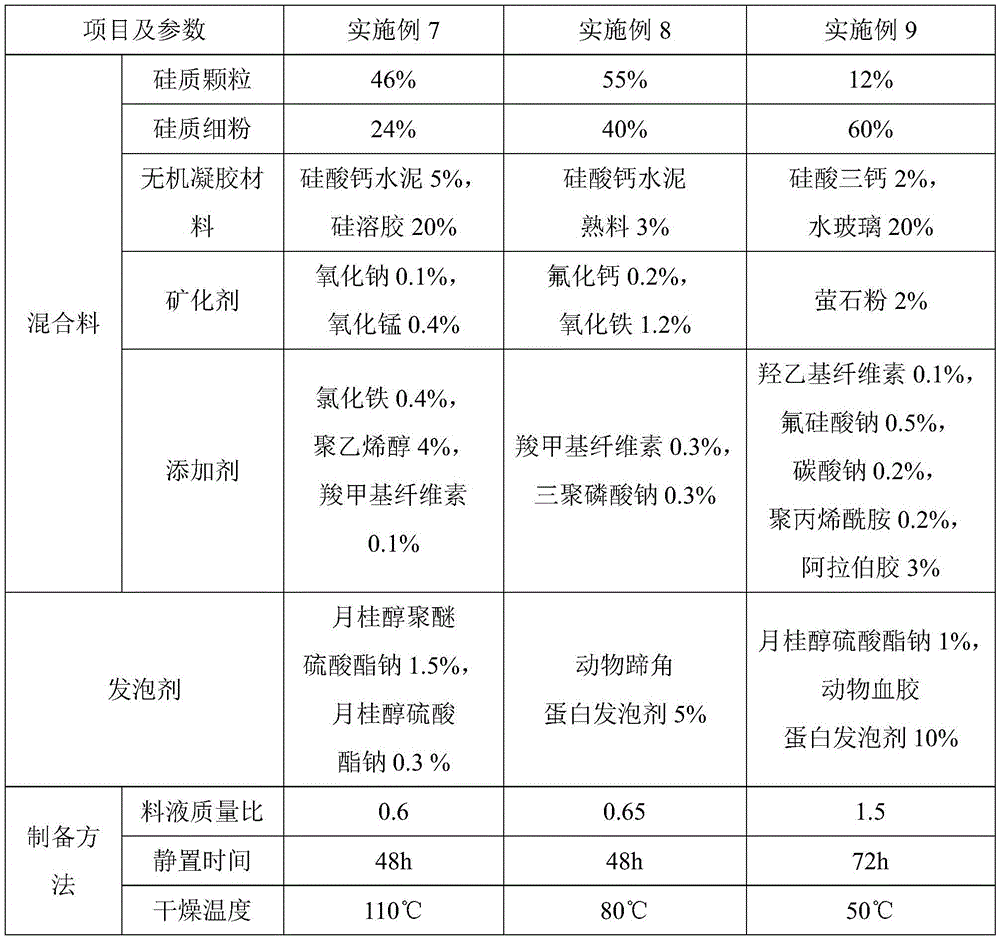

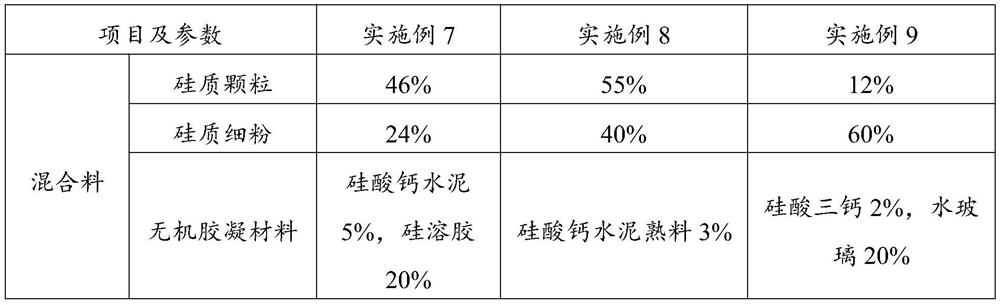

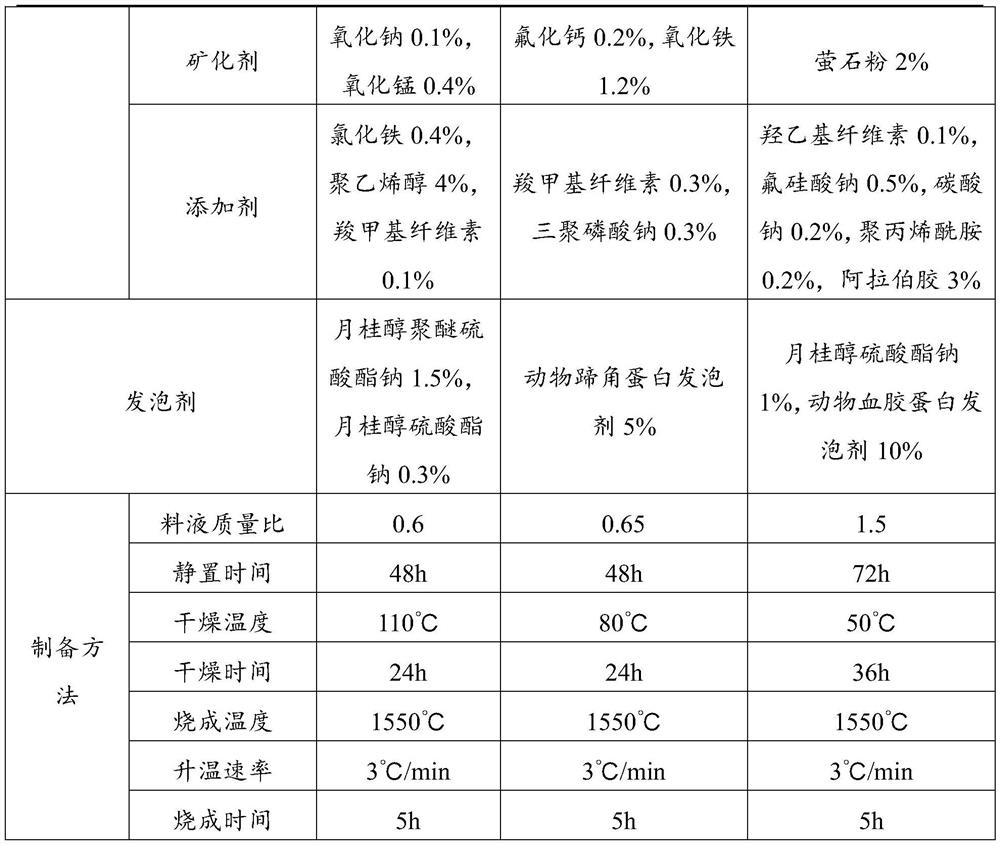

Micropore light weight silica brick and preparation method thereof

The invention discloses a micropore light weight silica brick and a preparation method thereof. The light weight silica brick is mainly prepared from a mixture and a foaming agent; a use quantity of the foaming agent is 0.1% to 10% of mass of the mixture; the mixture consists of the following components in percentage by mass: 70% to 95% of siliceous material, 1% to 25% of inorganic cementitious material, 0.1% to 15% of mineralizer, and 0.1% to 5% of additive, wherein the siliceous material consists of siliceous particles and siliceous fine powder, a particle size of the siliceous particles is 0.1 to 3mm, a particle size of the siliceous fine powder is smaller than or equal to 0.075mm, and a mass ratio of the siliceous particles to the siliceous fine powder is (1 to 65):(35 to 99). The obtained micropore light weight silica brick product has the advantages of fine aperture, small density, low thermal conductivity, high porosity, high mechanical intensity, high high-temperature volume stability, high resistance to the acid atmosphere, high slagging resistance and the like, is low in preparation cost and good in heat insulation effect, meets the harsh requirements of thermal equipment for a high-temperature environment and heat insulation, and is suitable for popularization and application.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Process for producing graphitizing petrol coke by Acheson graphitizing furnace

InactiveCN1834205ARaise the gradeExcellent physical and chemical indicatorsCoke ovensElectricitySulfur

This invention relates to a technique for manufacturing graphitized petrol coke in an Acheson type graphitization furnace, which comprises: hierarchically distributing petrol coke in the graphitization furnace, placing carbon material baking product between the electrodes at both ends of the furnace as electrically conductive heating elements, and using insulating materials composed of coke powders and quartz sands to fill the surroundings of the furnace. The electrically conductive heating elements can heat the petrol coke using the direct electricity provided by the rectification switchgear so that the temperature of the petrol coke reaches 2200-2500 deg.C, and the petrol coke is thus graphitized into recarburizing agent, which has such advantages as high quality, low sulfur, nitrogen and ash content, and excellent physicochemical index.

Owner:元氏县槐阳锂能科技有限公司

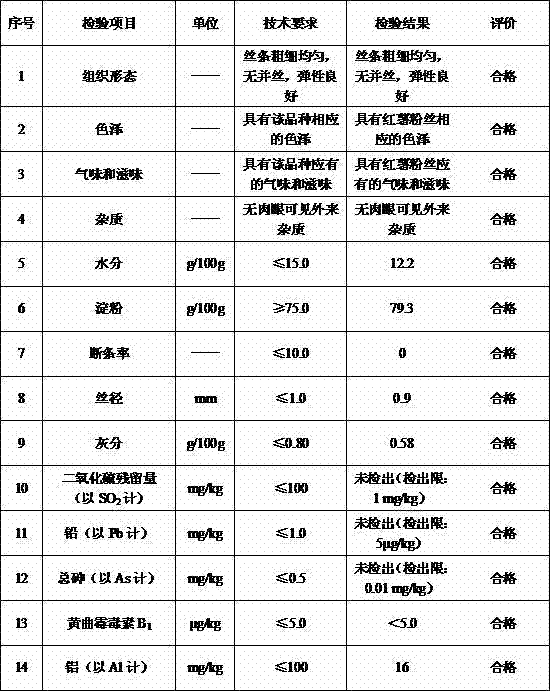

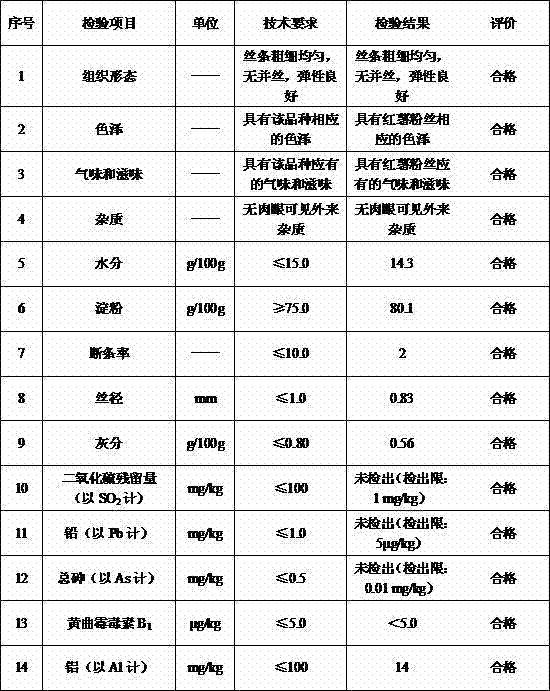

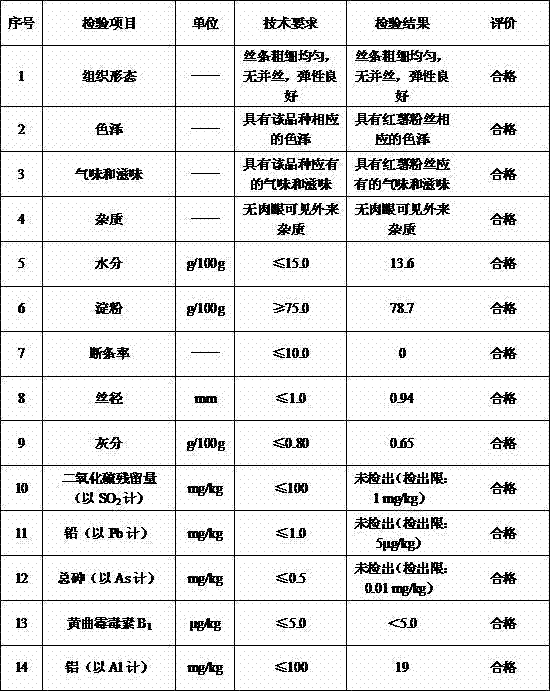

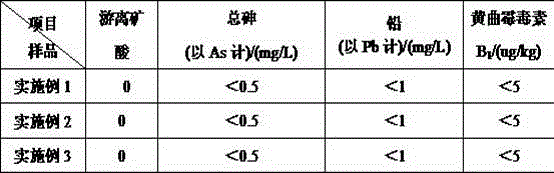

Alum-free vermicelli and preparation method thereof

The invention discloses alum-free vermicelli which is prepared from the following raw materials in parts by weight: 0.3-0.5 part of compound gluten fortifier, 0.3-0.5 part of compound phosphate, 2.5-5.0 parts of denaturized starch, 100 parts of starch and a proper amount of water through the steps of mixing, stewing, freezing and airing. The invention also discloses a preparation method of the alum-free vermicelli which is prepared from the raw materials in the weight ratio through the following steps of pulping, filtering, purifying, dewatering, pouring starchy sauce over the dish, curing, vacuumizing, forming, ageing, airing and the like. The vermicelli provided by the invention contains no sulfur dioxide, lead or total arsenic, the aflatoxin content accords with the national standard, the lead content is far lower than the national standard requirement not higher than 100mg / kg; fine sand and dust mixed in the starch can be sufficiently removed through the filtering and purifying processes, and the vermicelli is pure in color and luster and contains the dust content which is not higher than 0.7%; and due to the adoption of the periodical ageing process, the inside and the outside of the vermicelli are frozen uniformly, no barring and white tip phenomena are caused, the broken bar rate is not higher than 3% after rehydration, vermicelli is straight in bar shape, smooth in taste and free of foreign smell.

Owner:淮安甜心欣食品有限公司

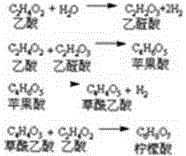

Multifunctional enzyme vinegar

InactiveCN106119055AHigh in nutrientsHigh in acetic acidMicroorganism based processesVinegar preparationRed yeast riceAspergillus niger

The invention relates to the technical field of food, and particularly relates to multifunctional enzyme vinegar. The multifunctional enzyme vinegar comprises the following raw materials in parts by weight: 10-50 parts of starch raw material, 20-60 parts of fruits, 20-60 parts of vegetable, 1-3 parts of aspergillus niger, 1-2 parts of aspergillus oryzae, 10-20 parts of Daqu, 5-10 parts of Chinese koji, 5-10 parts of red yeast rice, 2-4 parts of yeast, 0.15-0.4 part of lactic acid bacteria, and 4-7 parts of acetic acid bacteria. In the enzyme vinegar, total acid is greater than 11g / 100 mL, citric acid is greater than 2g / 100 mL, malic acid is greater than g / 100 mL, and lactic acid is greater than 1 g / 100 mL. the invention further relates to a preparation method of the enzyme vinegar. The enzyme vinegar is rich in nutrients, and mellow in mounthfeeling, the proportion of total acid to non-volatile acid is proper, and the enzyme vinegar has multiple nutritional health-care efficacies of strengthening the stomach, moistening intestine, calming down and relieving thirsty, reducing blood pressure and blood lipid, being anti-oxidant and anti-aging, and the like.

Owner:TIANJIN TIDAI MEDICINE SCI & TECH

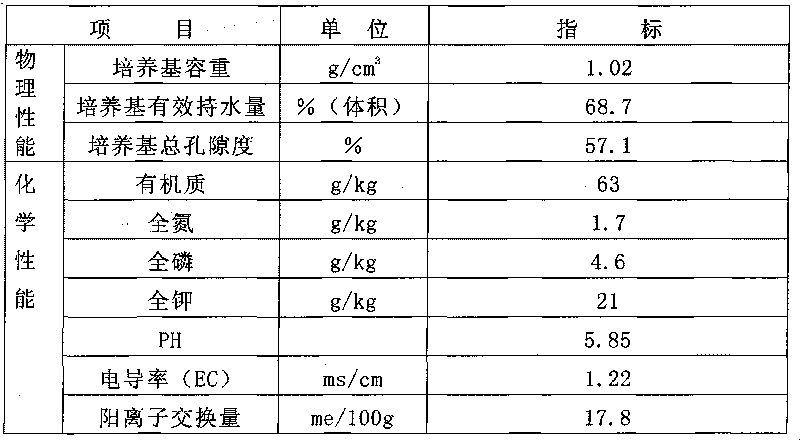

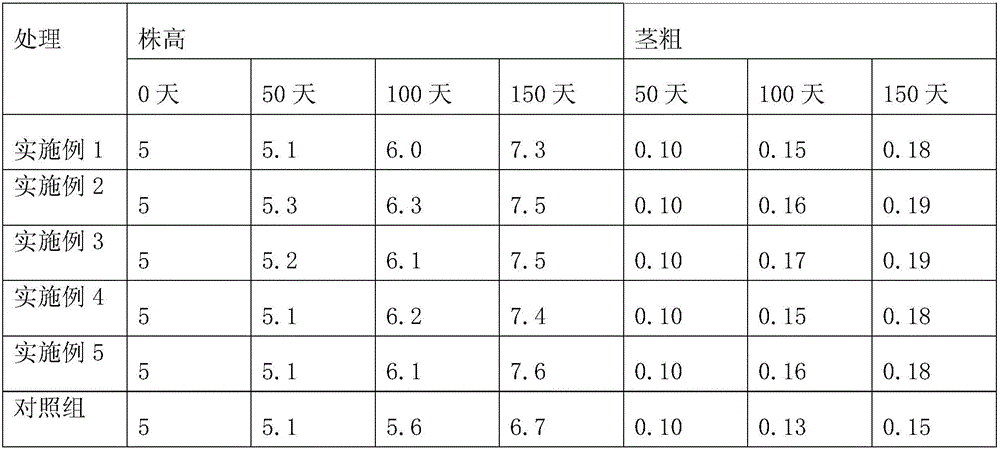

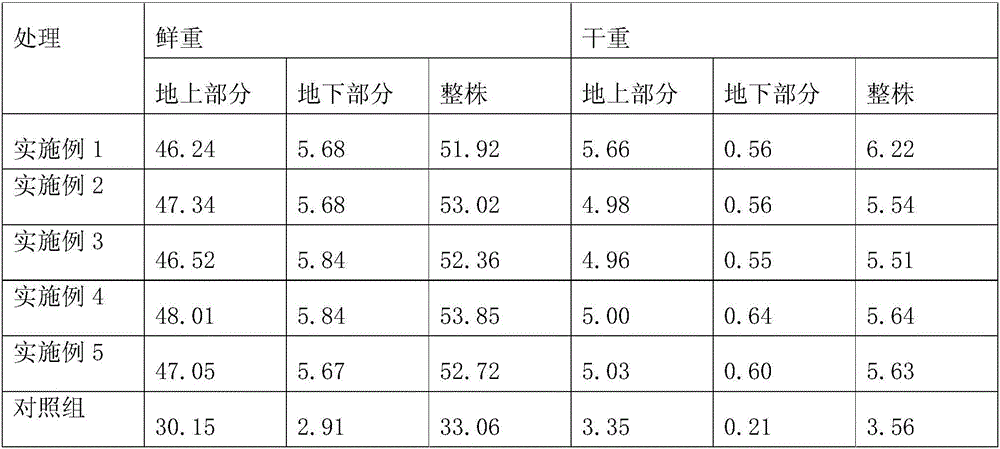

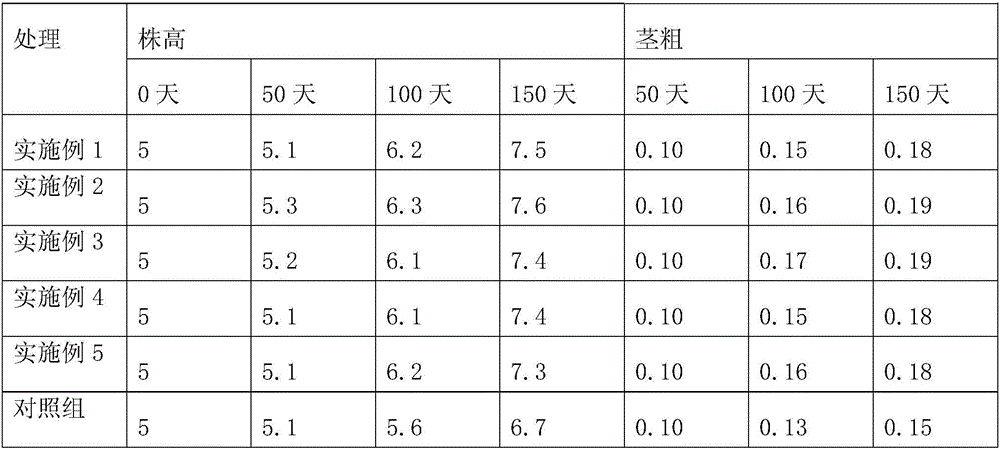

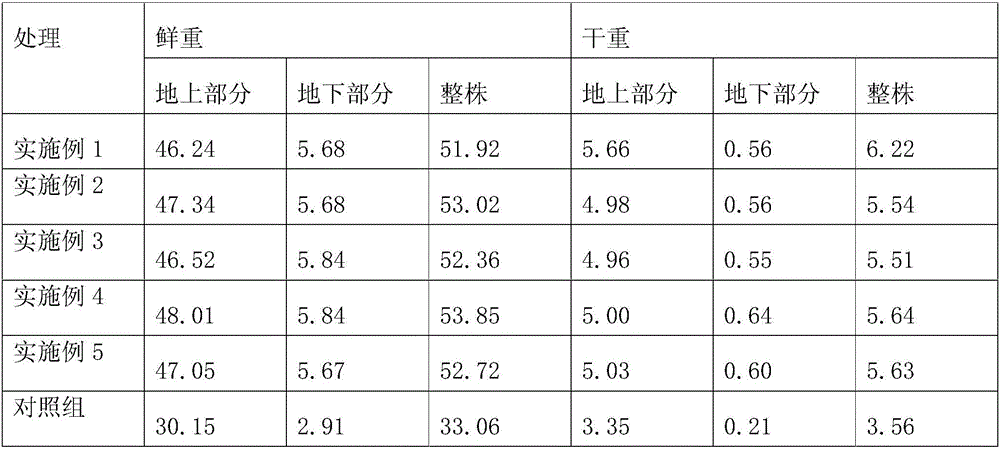

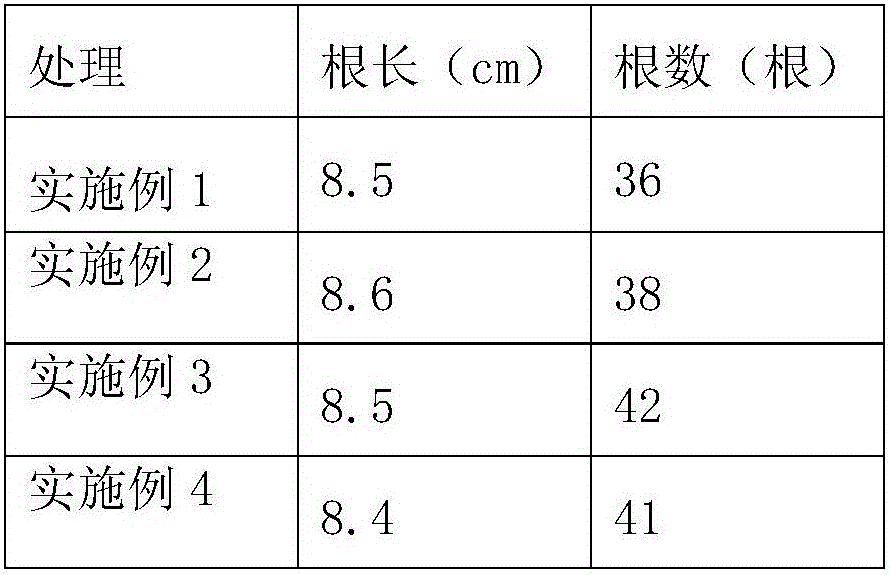

Special cultivation substrate for dendrobium officinale and preparation method of special cultivation substrate

InactiveCN105850682APromote absorptionSimple methodBioloigcal waste fertilisersGrowth substratesBrickAlcohol

The invention discloses a special cultivation substrate for dendrobium officinale. The special cultivation substrate comprises a bottom-layer substrate, a middle-layer substrate and an upper-layer substrate stacked sequentially from bottom to top, wherein the bottom-layer substrate is prepared from 10-20 parts of bean stalk or 15-25 parts of dry sugarcane leaves; the middle-layer substrate is a mixture of 5-15 parts of red brick powder, 15-30 parts of composted alcohol biogas residues and the like; the upper-layer substrate is a mixture of 15-35 parts of modified biological carbon, 15-45 parts of deadwood, 5-15 parts of expanded perlite and the like. The preparation method of the planting substrate comprises steps as follows: preparation of the modified biological carbon, preparation of the bottom-layer substrate, the middle-layer substrate and the upper-layer substrate and stacking of the bottom-layer substrate, the middle-layer substrate and the upper-layer substrate. The preparation method is simple and easy, the prepared planting substrate overcomes the defects that conventional substrates are rotten and air-impermeable and cannot hold water after being used for a long time, is low in cost, has rich nutrition and facilitates growth of dendrobium officinale, stems of dendrobium officinale grow more strongly, and root systems of dendrobium officinale are well developed.

Owner:GUANGXI ZHIBAO TECH CO LTD

Process of producing fermented wolfberry fruit yellow wine

InactiveCN101020879AIncrease profitHigh nutritional valueAlcoholic beverage preparationVitamin CLycium barbarum fruit

The process of producing fermented wolfberry fruit yellow wine belongs to the field of fermentation brewing technology. Before fermentation and during fermentation, wolfberry fruit slurry with citric acid and vitamin C in certain amount is added for fermentation in common. The fermented wolfberry fruit yellow wine has color of wolfberry fruit, rich nutrients, and high physical and chemical indexes.

Owner:JIANGNAN UNIV

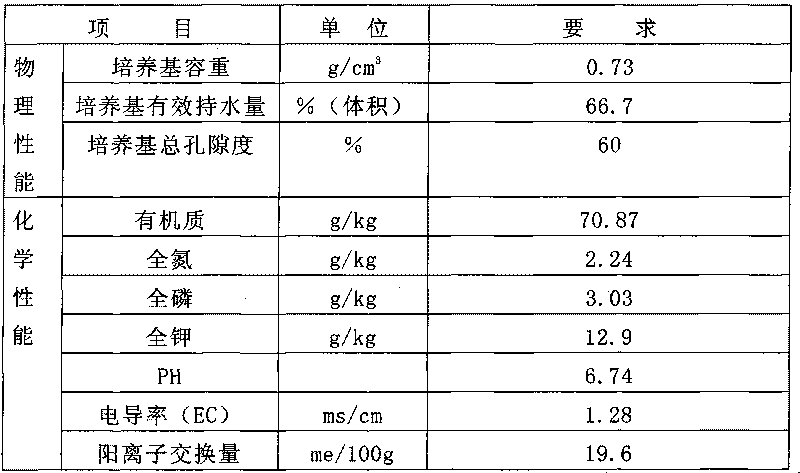

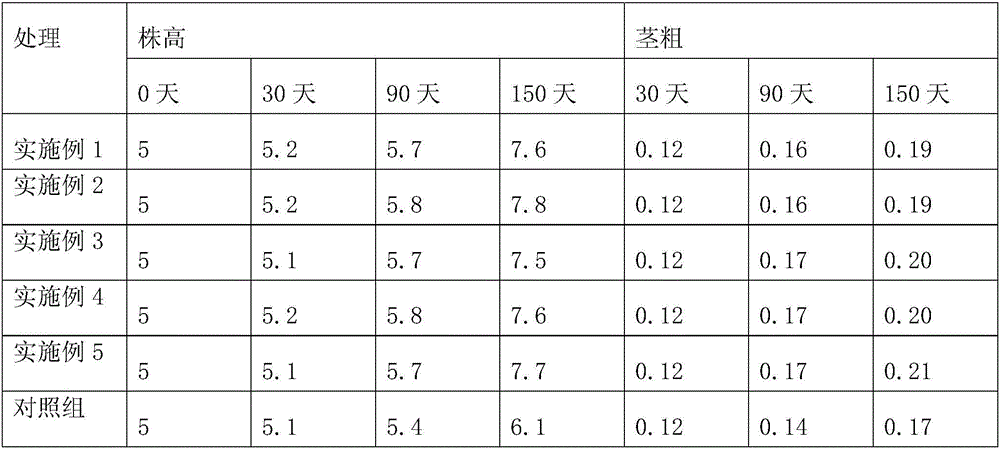

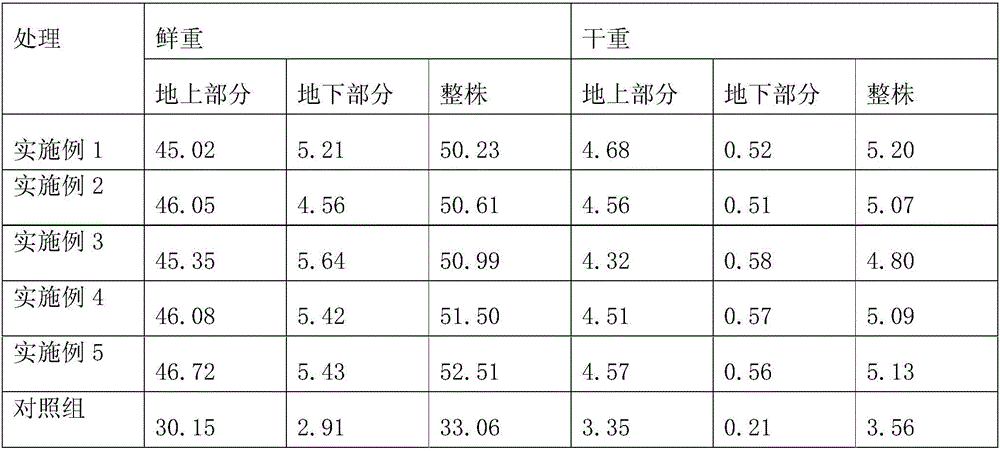

Dendrobium candidum planting substrate containing modified biochar and preparation method of Dendrobium candidum planting substrate

InactiveCN105850684ALarge specific surface areaModerate pore sizeGrowth substratesCulture mediaDendrobium candidumPaulownia

The invention discloses a dendrobium officinale planting substrate containing modified biochar, which comprises substrate A, substrate B and substrate C arranged sequentially from bottom to top; according to the ratio of parts by weight, substrate A is 10-20 parts of dry rice straw Or 10-20 parts of dry sugarcane leaves; substrate B is 5-20 parts of silkworm excrement, 10-30 parts of rice bran, etc.; 45 copies etc. The preparation method of the planting substrate is the preparation of modified biochar, the preparation of substrates A, B and C, and then superposition. The preparation method of the present invention is simple and easy to understand, and the planting substrate prepared by the present invention overcomes the long-term use of the substrate, rots and airtight, does not retain water, and has low cost and complete nutrition, which is more conducive to the growth of Dendrobium candidum, and promotes the growth of Dendrobium candidum Stronger and more developed root system.

Owner:LINGYUN LONGEVITY IMMORTAL GRASS BIOTECH SCI DEV

Wild-imitating planting substrate for dendrobium huoshanense and preparation method for wild-imitating planting substrate

InactiveCN105918084AQuality improvementImprove fertilityGrowth substratesCulture mediaBiologyMoisture

The invention discloses a wild-imitating planting substrate for dendrobium huoshanense. The wild-imitating planting substrate comprises a bottom-layer substrate, a middle-layer substrate and an upper-layer substrate which are arranged in a manner of being superposed sequentially from bottom to top, wherein the bottom-layer substrate is prepared from 10-20 parts (by weight) of dried corn stalks or dried sugarcane leaves; the middle-layer substrate is prepared from a mixture of 5-15 parts (by weight) of vermiculite and the like; and the upper-layer substrate is prepared from a mixture of 15-35 parts (by weight) of modified biocarbon, 15-45 parts (by weight) of rotten wood and the like. A preparation method for the planting substrate comprises the steps of preparing the modified biocarbon, preparing the bottom-layer substrate, the middle-layer substrate and the upper-layer substrate and then carrying out superposition. The preparation method for the planting substrate is simple and easy to understand; and the planting substrate prepared by the preparation method has the advantages that the condition that the substrate is rotted, is air-proof and does not hold moisture in long-term use is overcome, the cost is low, the nutrition is complete, the growth of the dendrobium huoshanense is better facilitated, dendrobium huoshanense stems are promoted to grow more sturdy, and dendrobium huoshanense root systems are promoted to be more developed.

Owner:GUANGXI ZHIBAO TECH CO LTD

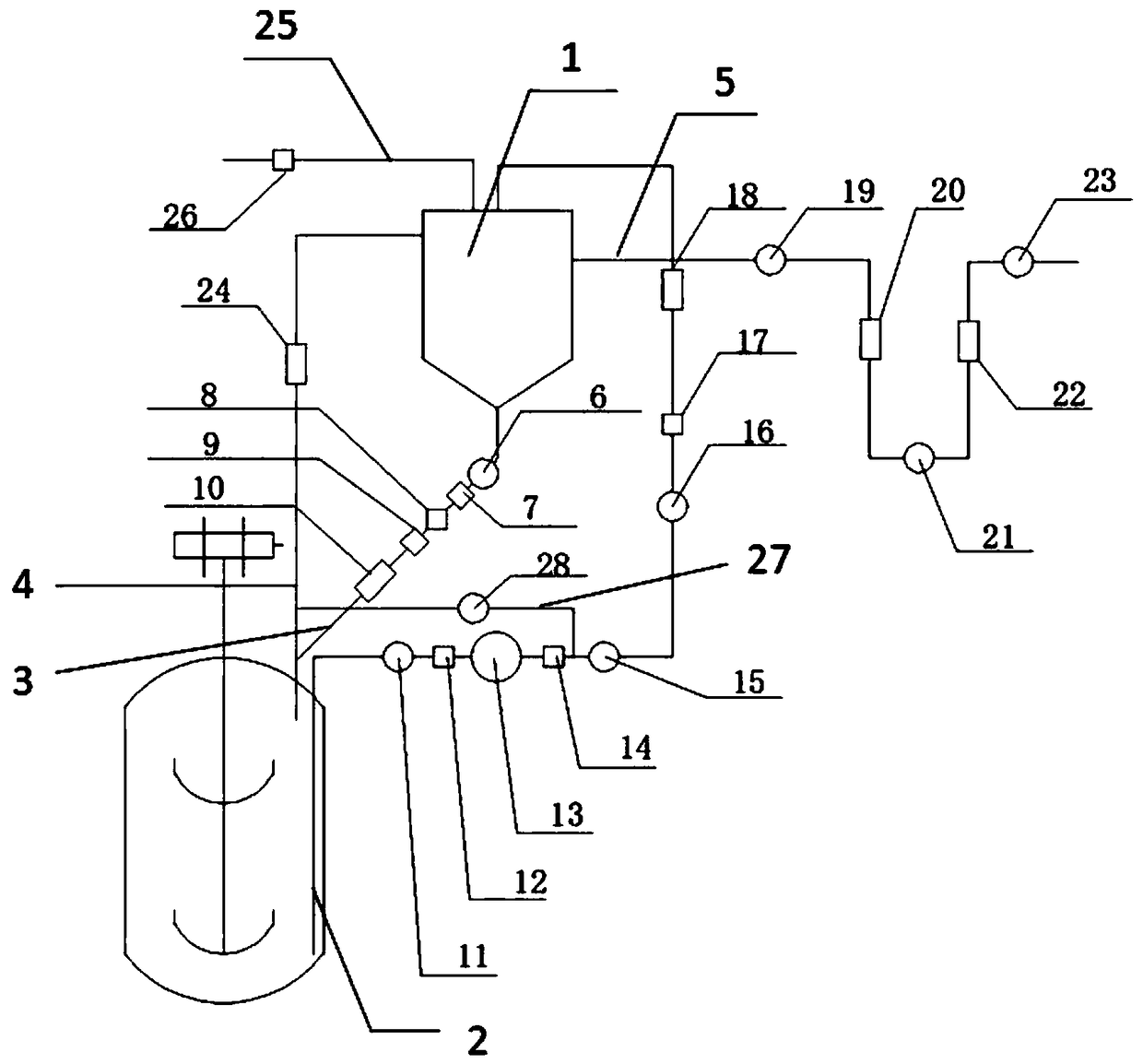

Thick hopper control system and method for synthesizing ternary precursor by utilizing same

PendingCN108786708AExtended stayExtended feeding timeProcess control/regulationChemical/physical/physico-chemical stationary reactorsManganeseEngineering

The invention relates to the technical field of preparation of a ternary positive electrode material for lithium ion batteries, in particular to a method for synthesizing a nickel-cobalt-manganese ternary precursor by utilizing a thick hopper control system. According to the invention, slurry at the bottom of a reaction kettle is pumped into a thick hopper through a pump on a material feeding pipeline, and no stirring is carried out in the thick hopper; gravity is utilized to carry out sedimentation and realize solid-liquid separation; then thick slurry is refluxed into the reaction kettle toincrease the solid content; at the same time, clear liquid is discharged to the outside through a clear liquid discharge pipeline; the system can be applied to continuous production and upgrading, canalso be used for intermittent production and upgrading, and can be opened in any process of production. When the system is in operation, the proportion of the clear liquid discharge can be increasedby increasing the material feeding flow rate, and the flow rate of the thick slurry can be changed by the opening degree of a thick slurry reflux pipeline valve. By adopting the method provided by theinvention, the production cost is effectively reduced, the operation difficulty is reduced, and the safety is improved; the precursor produced by the invention has more excellent physical and chemical indexes, and a sintered positive electrode material has more excellent performance.

Owner:HUAYOU NEW ENERGY TECH (QUZHOU) CO LTD +1

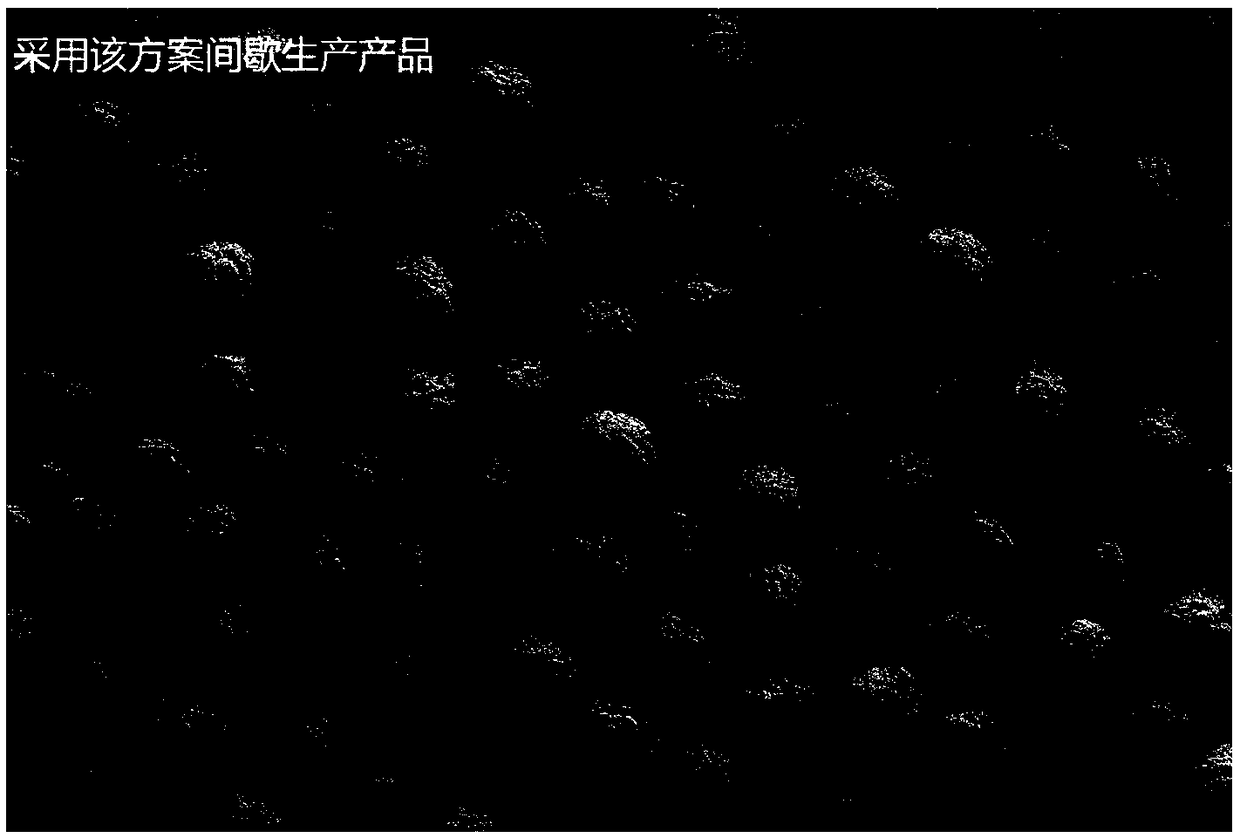

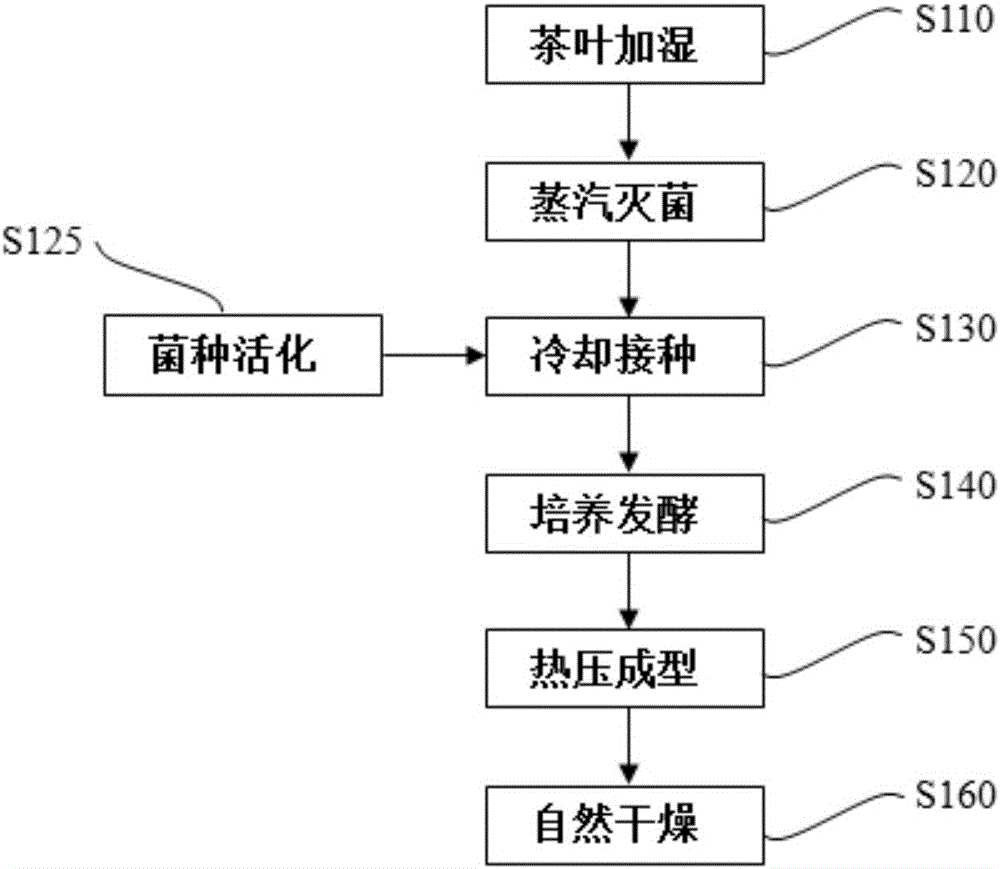

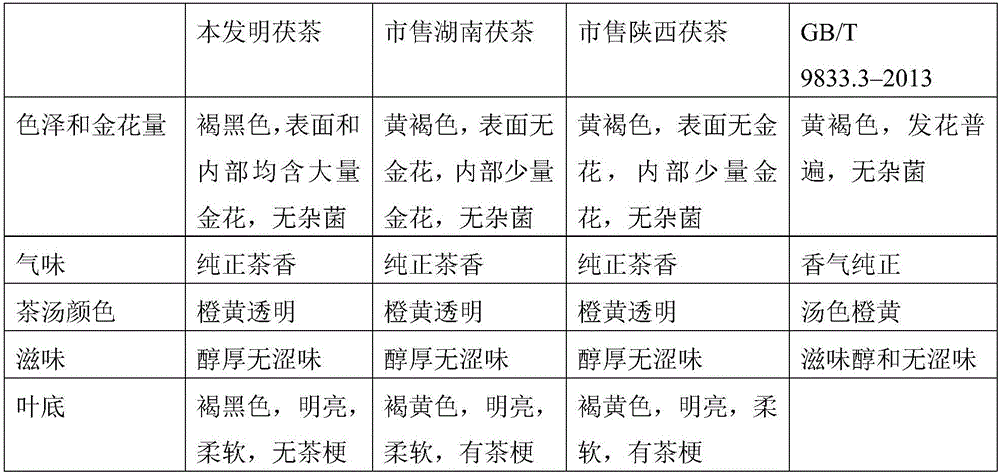

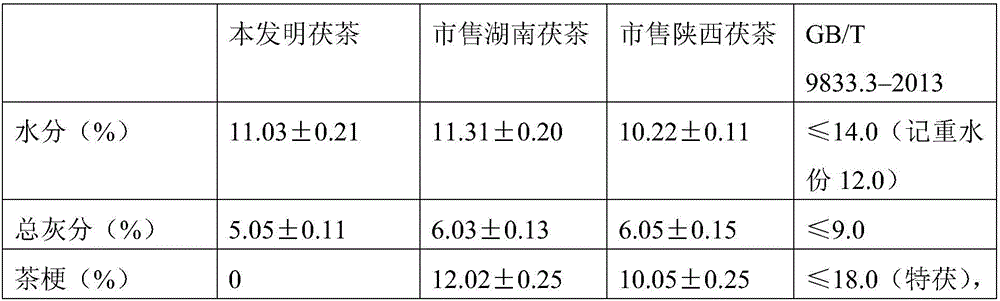

Method of producing Fu tea from artificial fermentation tea leaves and bacterial strain

InactiveCN105746756ASimple production technologyBreak the technical barriers of the industryFungiPre-extraction tea treatmentBacterial strainFermentation

The invention discloses a method of producing Fu tea by means of artificial fermentation. Themethod comprises the following steps in sequence: humidifying dry tea leaves to enable water content of the tea leaves to be 30-40%; sterilizing the humidified tea leaves at a temperature of 110-120 DEG C; cooling the sterilized tea leaves to a temperature below 40 DEG C, artificially inoculating activated eurotium cristatum under a sterile condition, and mixing uniformly; fermenting the tea leaves for 20-30 days in a sterile and air-permeable container at a temperature of 20-30 DEG C; hot-pressing and forming the tea leaves; drying the tea leaves naturally. The invention further discloses an eurotium cristatum bacterial strain with the preservation number of CGMCC No.3.15516. According to the invention, the method has the advantages of simplicity in operation, relatively low cost and no limitation from raw materials and geographical conditions. As a sterile culture technology is employed, sundry bacteria contamination is avoided, and high product quality and product safety are realized.

Owner:INST OF MICROBIOLOGY - CHINESE ACAD OF SCI

Silicon brick for 7-meter coke oven

ActiveCN101117294AExtensive sources of raw materialsAggregate fineness and particle size distribution are reasonablePotassium feldsparNational standard

The invention relates to the fire resistant material technical field, in particular to a silica brick of 7m for coke oven, which solves the problem of unreasonable distribution of the fineness and size of the particles of raw materials caused by the differences in quality and selection of the raw materials. The formulation of the raw materials comprises 25 to 35 percent of silex cribble powder, 41 to 47 percent of silex medium powder, 10 to 20 percent of fine powder consisting of 50 percent of silex and 50 percent of incomplete silex brick, 10 to 20 percent of incomplete silex brick, accessories which comprise 1.9 to 2.1 percent of mineralizer comprising manganese powder, iron phosphorus powder and potassium feldspar according to the proportion of 0.5 to 0.5 to1, 7.5 to 8.5 percent of line cream and 0.9 to 1.1 percent of pulp. The physics and chemistry index adopted by the formulation of the invention is higher than the national standard. The invention has the advantages of wide raw material source, reasonable distribution of fineness of aggregate and grain size. The produced silica brick is completely in accordance with requirements of design of brick shape, complexity and outside measurement of the coke oven brick and adaptability to the requirement of large-scale production of coke oven .

Owner:山西盂县西小坪耐火材料有限公司

Fine inorganic ceramic powder aggregate and preparing method thereof

InactiveCN101613491AIncrease hardness and steel strengthExcellent physical and chemical indicatorsPigment treatment with macromolecular organic compoundsPigment physical treatmentScrapPlasticizer

The invention belongs to the field of inorganic materials, in particular to fine inorganic ceramic powder aggregate and a preparing method thereof. The fine inorganic ceramic powder aggregate comprises the components of a plasticizer, an internal lubricant and an external lubricant, a crosslinking modifying agent, a filling agent, a flame retardant, paint and ceramic powder aggregate. In the technical scheme, the highly filled powder aggregate is prepared by adopting the mechanism of copolymerization and cladding of inorganic ceramic powder and other media, and the treatment problem of solid waste-ceramic scrap is effectively solved.

Owner:章建利 +1

Method for producing electro-fused zirconia-corundum ramming material by utilizing waste bricks of glass kiln

The invention discloses a method for producing an electro-fused zirconia-corundum ramming material by utilizing waste bricks of a glass kiln, which comprises the following steps: removing large impurities in the waste bricks detached from the glass kiln; grinding the selected waste bricks until the granularity is less than 50mm, removing small particles with the granularity less than 2mm, and maintaining the particle material with the granularity between 2 and 50mm for later use; feeding the particle material obtained in the second step into a furnace, smelting the particle material at the temperature of between 1,700 and 2,100 DEG C for 90 minutes, casting into a mould, and naturally cooling; grinding the cast and cooled solution block again, and screening aggregate with the granularity less than 5mm for later use; and taking 65 parts of the aggregate obtained in the fourth step, 20 parts of bauxite cement, 10 parts of zirconia-corundum powder and 5 parts of white mud, and fully mixing the materials uniformly in a blender mixer to obtain the finished product of the electro-fused zirconia-corundum ramming material. The electro-fused zirconia-corundum ramming material has the advantages of good stability, typical properties better than the traditionally used ramming material, production cost 30 to 40 percent lower, and simple production process.

Owner:ZHENGZHOU XINGUANGSE REFRACTORY

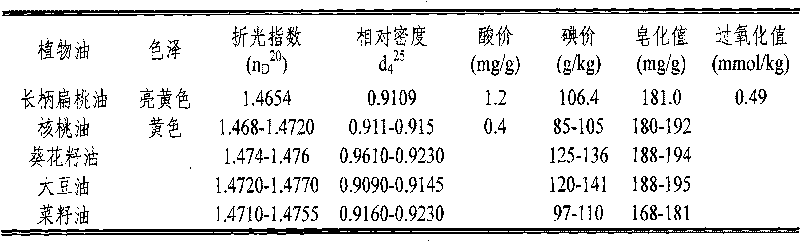

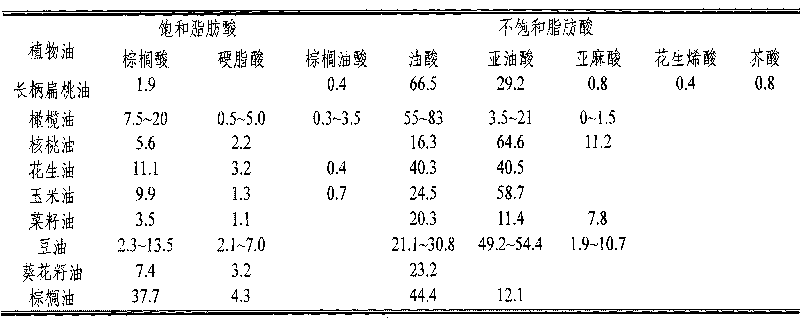

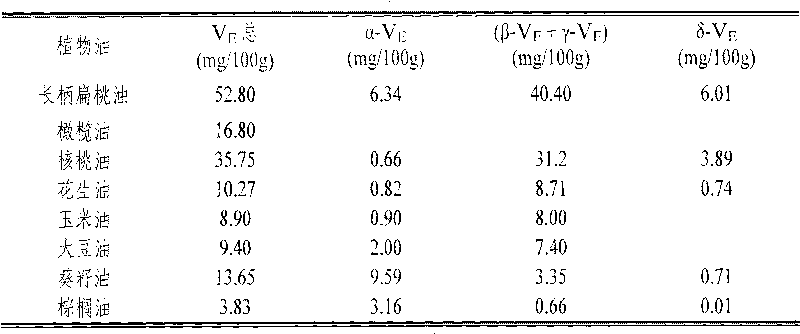

Application of amygdalus pedunculata pall oil as edible oil

InactiveCN101731367AExcellent physical and chemical indicatorsRich in nutrientsEdible oils/fatsAdditive ingredientColneleic acid

The invention discloses amygdalus pedunculata pall oil as well as an extracting preparation method thereof and application as edible oil. The amygdalus pedunculata pall oil comprises the following components according by weight percent: 1.9% of palmitic acid, 0.4% of palmitoleic acid, 66.5% of oleic acid, 29.2% of linoleic acid, 0.8% of linolenic acid, 0.4% of peanut olefine acid and 0.8% of erucic acid. The extracting method of the amygdalus pedunculata pall oil comprises the following steps of: (1) drying amygdalus pedunculata pall seeds to remove seed coats at 40-100 DEG C; (2) adding bran accounting for 1-3% of the mass of seeds after removing the seed coats, squeezing for several times (twice to four times) by a hydraulic oil mill at low temperature, combining and then filtering the oil squeezed for several times to obtain the amygdalus pedunculata pall oil. In the invention, the amygdalus pedunculata pall oil has excellent tupical properties and abundant nutrient elements and can be developed to be high-quality edible oil.

Owner:NORTHWEST UNIV(CN)

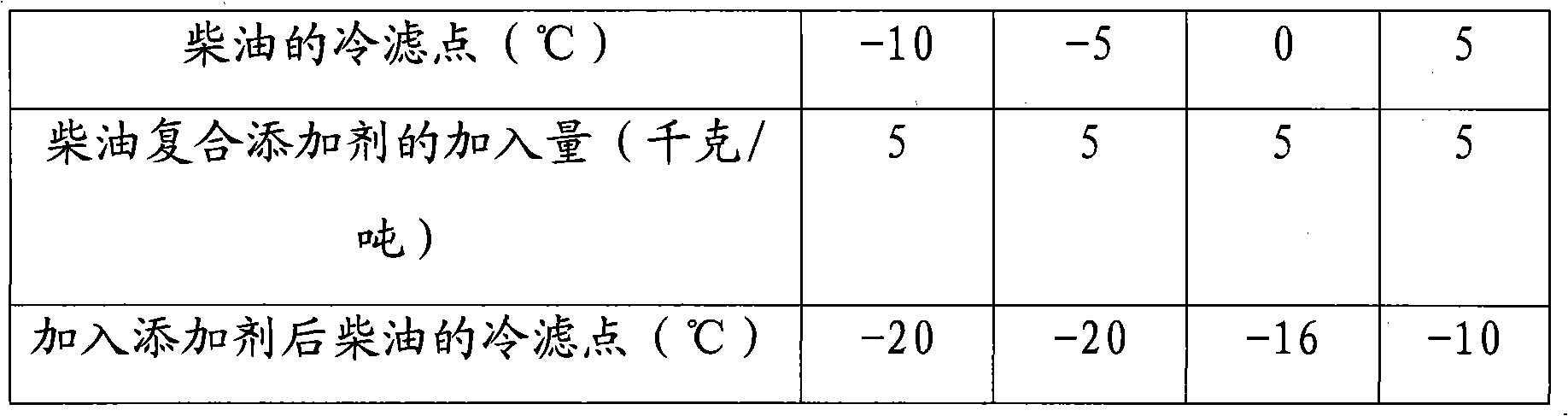

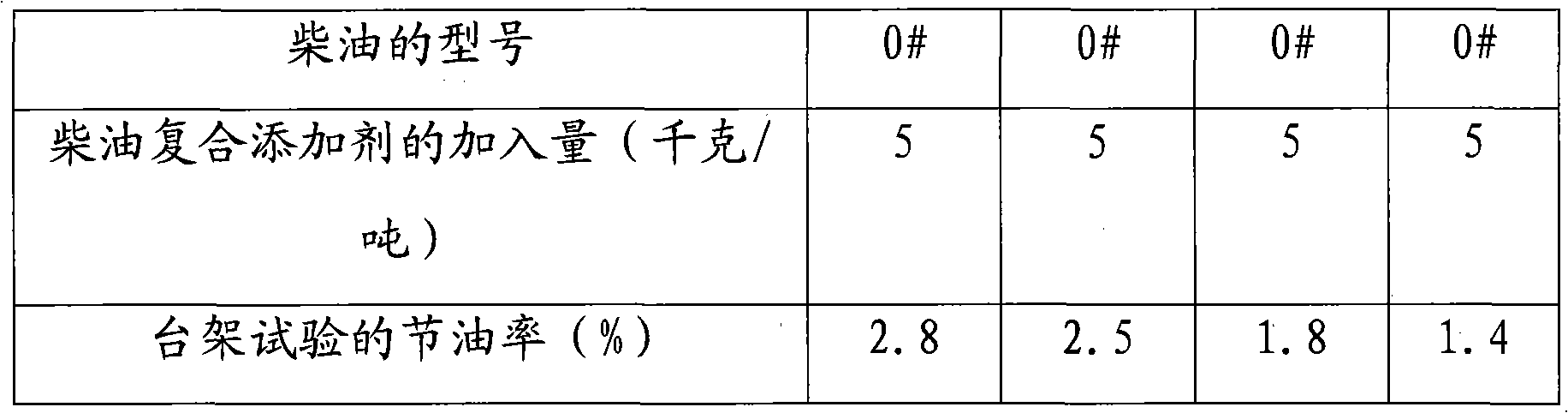

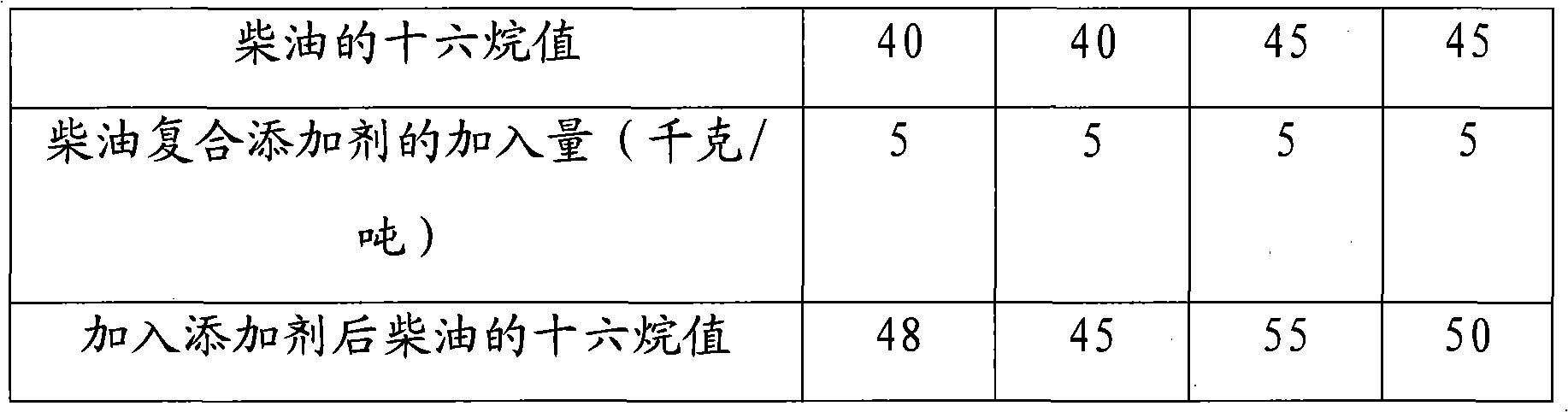

Novel diesel compound additive

ActiveCN102041110AImprove stabilityImprove performanceLiquid carbonaceous fuelsFuel additivesFrostFuel oil

The invention belongs to the technical field of petroleum additive products, and particularly relates to a novel diesel compound additive. The novel diesel compound additive is prepared from antioxidant, cetane number improver, and low-temperature flow improver. The diesel compound additive can obviously improve storage stability of fuel oil, has an obvious effect of improving combustibility, makes fuel oil completely combusted, and has excellent frost resisting capacity at a low temperature, is suitable for common diesel, and even has the very ideal effect of optimizing secondary processing diesel with harsh requirement, so that the utilization field and range of the diesel is widened.

Owner:SHANDONG TAIDE NEW ENERGY

Method for continuously producing high-quality rare-earth ferrosilicon alloy by adopting carbon-thermal method process

The invention discloses a method for continuously producing rare-earth ferrosilicon alloy by a carbon-thermal method. The method aims to overcome the defects of an existing method for preparing rare-earth iron alloy by a carbon-thermal reduction process in the aspect of continuous production and to solve the problem of the existing method for preparing the rare-earth iron alloy by the carbon-thermal reduction process in the aspect of improving the product quality. The core content of the scheme is a batching process method based on a core-shell multi-layer structure and a batching and smeltingprocess method, one-step smelting is carried out through a submerged arc furnace so that the furnace bottom rising situation can be effectively avoided, therefore, continuous operation is realized and a high-quality rare-earth ferrosilicon alloy product is obtained, meanwhile, the smelting operation condition is similar to that of the ferrosilicon alloy, the operation procedure of a working surface becomes simpler and more convenient, and the energy consumption level is obviously reduced.

Owner:乌拉特前旗三才第一铁合金有限公司

Sea-buckthorn vinegar preparing method

The invention provides a sea-buckthorn vinegar preparing method. The method comprises the steps of material selection, starter propagation, smashing, steaming, saccharification and alcoholic fermentation, acetic fermentation, vat fuming, red vinegar sprinkling, curing, finished vinegar sprinkling and ageing. According to the method, solid anaerobic airtight fermentation is conducted, and various microorganisms coexist; in the co-fermentation and fermentation process of various enzyme systems, mould, saccharomycetes and acetic bacteria coexist, various enzyme systems including liquefying amylase, saccharifying amylase, cellulose, pectinase, zymase and acetification enzyme are adopted for co-fermentation, the color, aroma, taste and appearance of vinegar are good, concentration is high, clarity is high, and main physicochemical indexes including total acid, non-volatile acid and revertose are excellent.

Owner:陕西永寿秦源有限公司

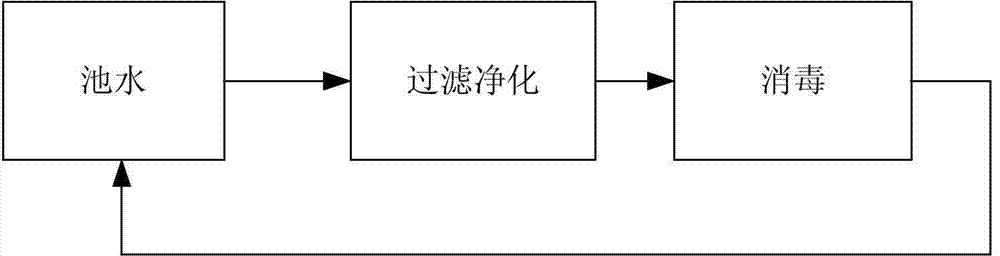

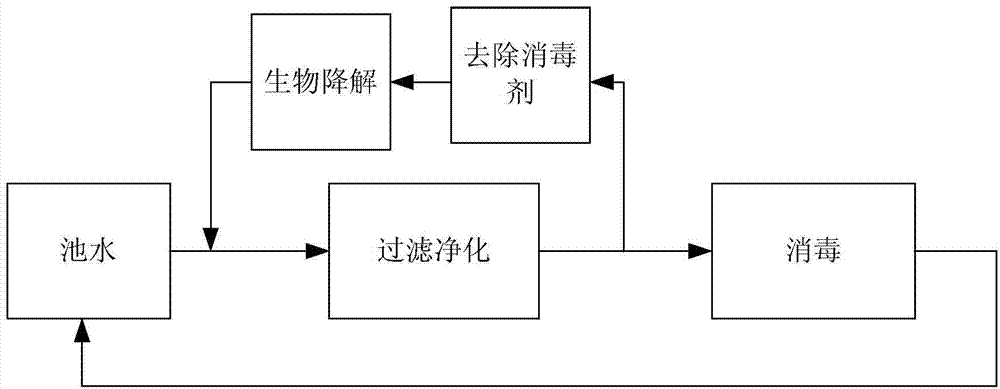

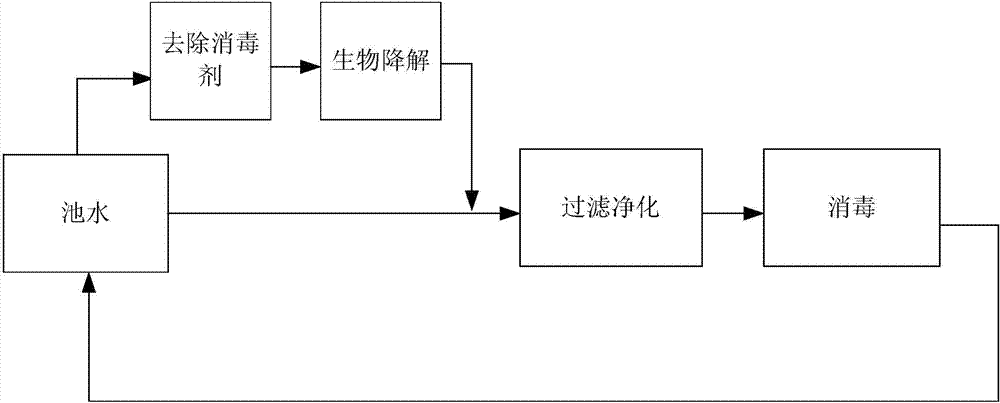

Water treatment method for swimming pool or hydrotherapy pool

ActiveCN103663878ALow running costImprove water qualityMultistage water/sewage treatmentBromineChemistry

The invention discloses a water treatment method for a swimming pool or a hydrotherapy pool. 2 percent to 10 percent of water in the swimming pool or the hydrotherapy pool is taken per hour to be sequentially treated by the following steps of: removing a disinfectant in the water, wherein the disinfectant comprises chlorine, bromine and ozone and in the process of removing the disinfectant in the water, the speed of water flow needs to be guaranteed to be below 20m / h; using activated carbon, quartz sand or ceramsite as a biological carrier for carrying out biodegradation on the water subjected to removal of the disinfectant so as to remove organisms in the water, wherein empty bed residence time of biodegradation is over 3 minutes; carrying out filtering purification and disinfection on the biodegraded water to remove suspended matter and microorganisms in the water. The method disclosed by the invention can effectively decompose urea, ammonia nitrogen and other organisms in the pool water, can greatly improve water quality and reduce the use amount of the disinfectant and the volume of changed water.

Owner:BEIJING HENGDONG ENVIRONMENT TECH

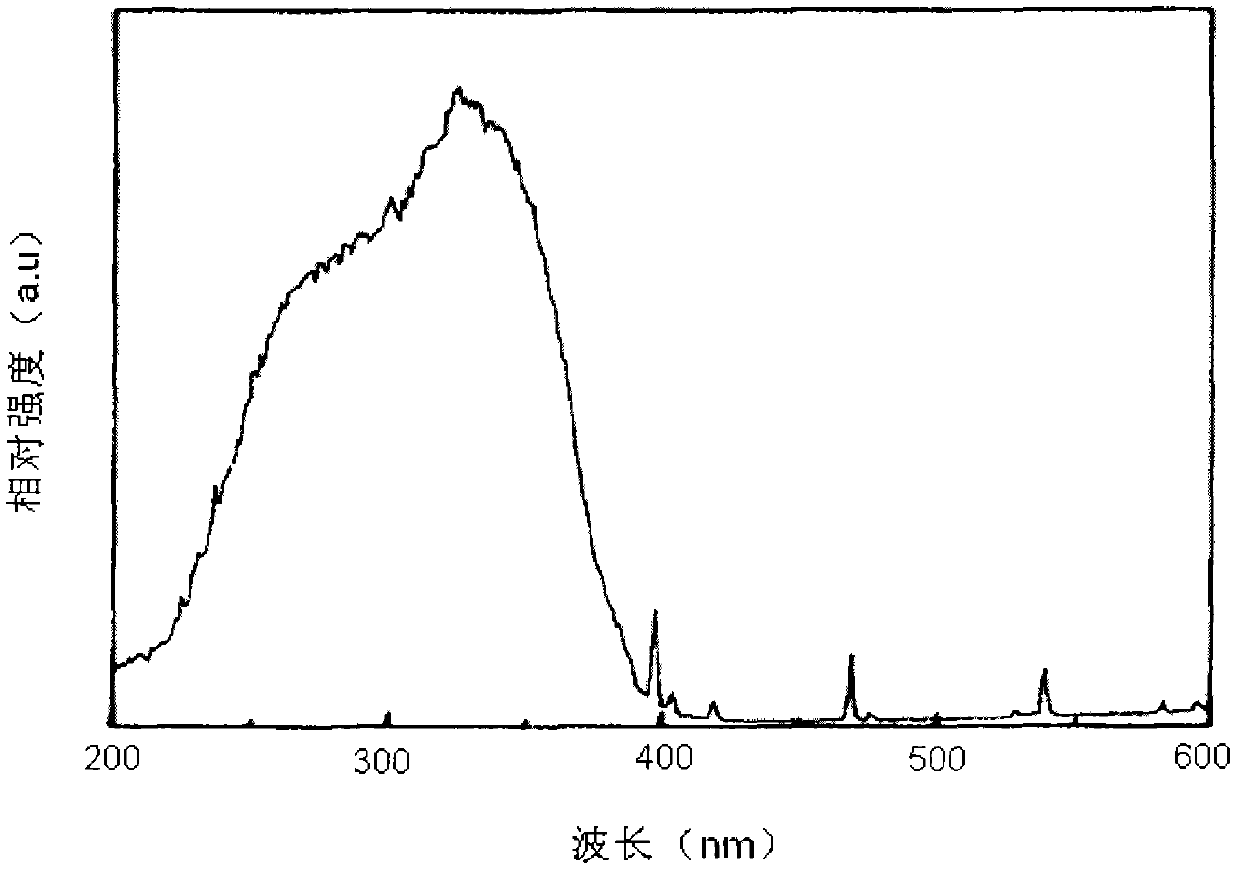

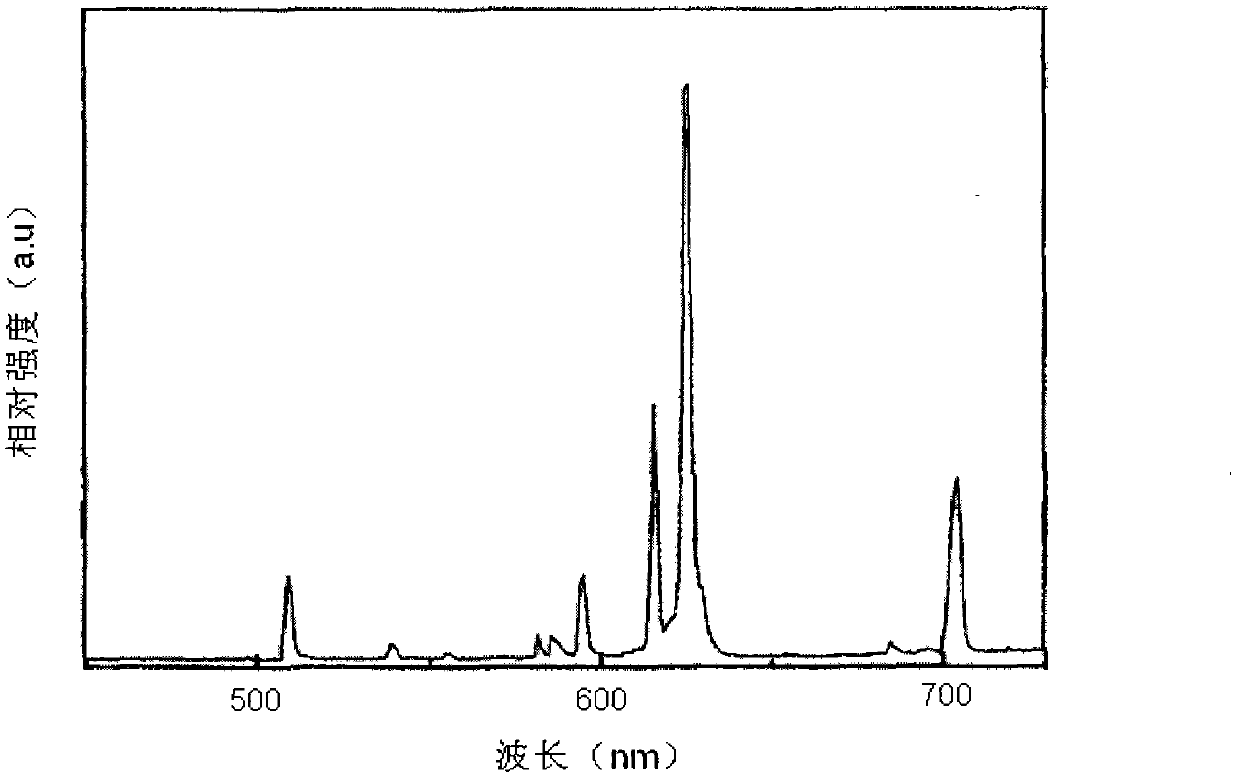

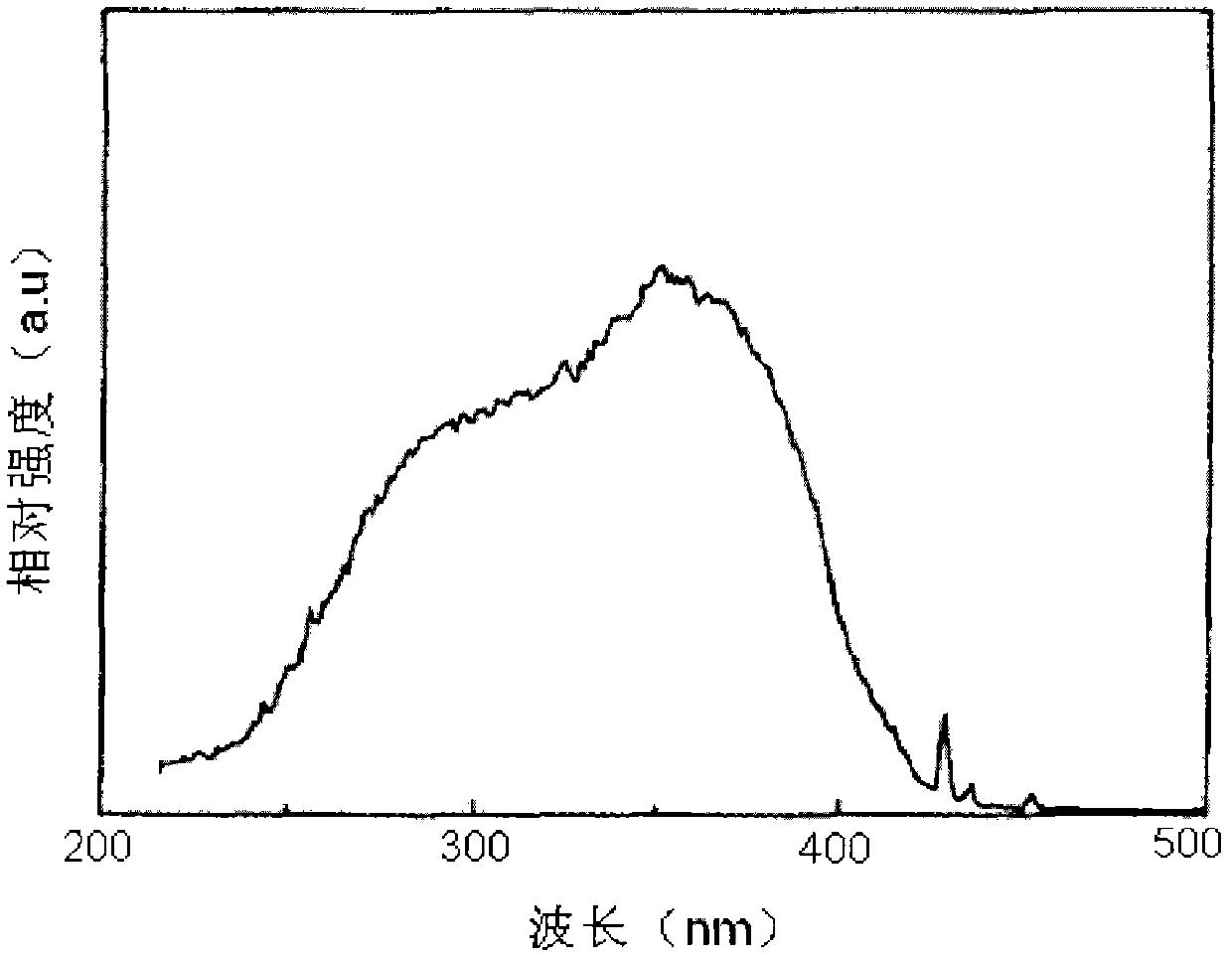

Ultrafine particle energy-storage type long-lasting phosphor material and preparation method thereof

The invention discloses an energy-storage type long-lasting phosphor material and a preparation method thereof. According to the preparation method, after multiple metal oxides are respectively doped with manganese element, multiple oxide superfine particle powder raw materials are prepared; and then the multiple oxide superfine particle powder raw materials are uniformly mixed, and the obtained mixture is roasted so as to obtain an energy-storage type long-lasting phosphor material. The preparation process is low in energy consumption, and the prepared phosphor material is non-toxic, non-radioactive, low in excitation conditions, high in optical storage speed, high in afterglow brightness, long in afterglow time, stable in luminescence property, and wide in application scope.

Owner:梁清源 +1

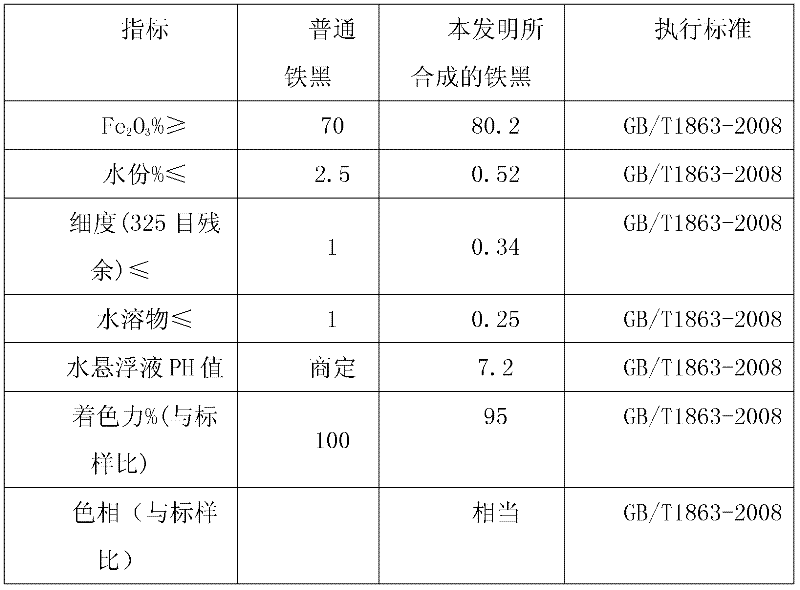

Method for synthersizing iron oxide black by taking lime as raw material

This invention relates to a method for synthersizing iron oxide black by taking lime as a raw material, comprising the following steps: digesting lime and water, adding water after finishing digesting the lime and the water, stirring, curing to form lime milk, and sieving to remove slide impurities; mixing the obtained milk slurry and ferrous sulfate solution, adding water to adjust unit the content of solid is 8-10% to obtain a mixed slurry, adjusting the pH value of the mixed slurry to 7.5-8.5 by using the lime milk, introducing steam to heat to 95-98 DEG C, introducing air to oxidize for 2.5-3.5 hours, comparing the mixed slurry with a standard sample repeatedly, stopping the reaction after the production index of the iron oxide black is achieved, and discharging to obtained the slurry of reaction; sieving the slurry of reaction to remove calcium sulfate impurities, filtering, washing, drying and crushing to obtain the product. The iron oxide black synthesized by adopting the method is superior to the common iron oxide black in physical and chemical indexes and is more superior to common iron oxide black in pigment performance.

Owner:ANHUI MINGZHU PIGMENT TECH

Method for preparing beer bottles from cullet

The invention provides a method for preparing beer bottles from cullet. A powder material is added into every 1000 kg of cullet. During the preparation of a white beer bottle, the powder material comprises, by weight, 55-57 kg of quartz sand, and soda 15 - 19 kg of soda ash, 15-19 kg of calcite, 3-6 kg of dolomite, 6-8 kg of feldspar, 3-5 kg of mirabilite, 5-7 kg of fluorspar, and 1-2 kg of sodium nitrate or 0.5-1.5 kg of cerium dioxide. During preparation of a green beer bottle, the powder material comprises, by weight, 53-57 kg of quartz sand, 17-21 kg of soda ash, 7-10 kg of calcite, 3-5kg of dolomite, 4-6 kg of feldspar, 4-6 kg of mirabilite, 5-7 kg of fluorspar and 0.5-1.5 kg of chrome ore powder. During preparation of a brown beer bottle, the powder material comprises, by weight, 52 -56 kg of quartz sand, 17-20 kg of soda ash, 12-15 kg of calcite, 3-5 kg of dolomite, 4-6 kg of feldspar, 5-7 kg of mirabilite, 5-7 kg of fluorspar and 0.3-1.0 kg of carbon powder. The method of invention can improve the utilization rate of cullet and guarantee glass quality and allows the prepared glass to be applicable to the manufacturing of beer bottles.

Owner:刘书刚

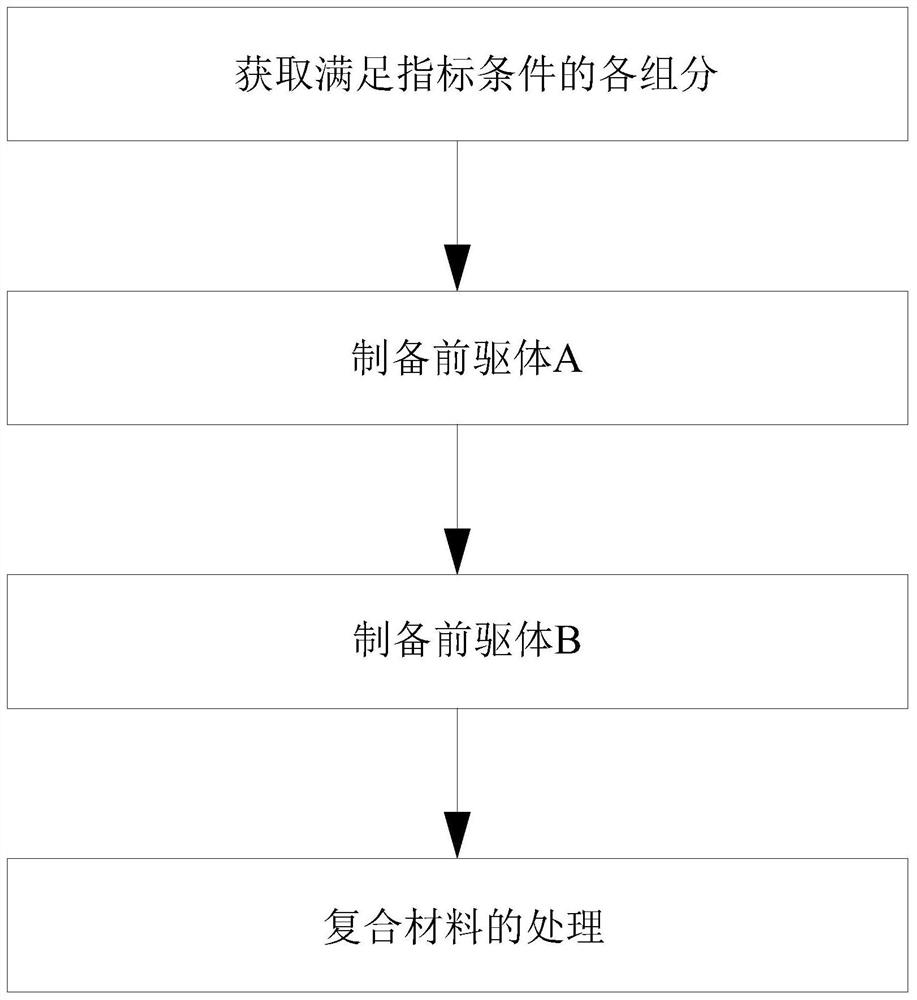

Graphene-carbon graphite composite isostatic pressing material and preparation method thereof

The invention relates to a preparation method of a graphene-carbon graphite composite isostatic pressing material, which specifically comprises the following steps: obtaining components meeting index conditions, preparing a precursor A, preparing a precursor B and treating a composite material, and preparing the graphene-carbon graphite composite isostatic pressing material based on the steps. The raw materials are reasonably selected, and the preparation process is scientific; through research and test, the inventor finally determines the components and the proportion of the components, due to the components and the proportion relation of the components, particles with different particle sizes can be tightly stacked, and the volume density, the porosity, the mechanical strength and the thermal expansion coefficient of the material can reach a very good balance; namely, the prepared material is large in volume density, small in porosity, small in thermal expansion coefficient and high in mechanical strength, and the physical and chemical indexes of graphite are excellent.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Method and device for processing sewage by virtue of multistage alternative microbial generator

InactiveCN103771590APrevention and control of secondary pollutionImprove removal effectBiological water/sewage treatmentSewage treatmentSewage

The invention discloses a method and device for processing sewage by virtue of a multistage alternative microbial generator. The method comprises the following steps: alternatively operating at least one-stage optimal three-stage microbial generation system, a biological generator group A and a biological generator group B, deriving step by step and logarithmically growing. The three-stage microbial generation system comprises an I-stage microbial generation system, a (img file='2014100613797100004dest-path-image001.TIF'wi='17'he='16' / )-stage microbial generation system and a (img file='559932dest-path-image002.TIF'wi=27'he='17' / )-stage microbial generation system. Each microbial generation system comprises a biological generator group A and a biological generator group B; the alternative operation of the biological generator group A and the biological generator group B comprises the processes of enabling the biological generator group B to have a rest for being needed again when the biological generator group A works normally; enabling the biological generator group A to have a rest for being needed again when the biological generator group B works normally. The step of deriving step by step comprises a process of taking a strain to simulate water temperature, climate, water quality and load in the I-stage microbial generation system, the (img file='2014100613797100004dest-path-image001.TIF'wi='17'he='16' / )-stage microbial generation system and the (img file='559932dest-path-image002.TIF'wi=27'he='17' / )-stage microbial generation system, then enabling microorganism to logarithmically grow in a special environment domestication and accelerating to generate microbial species. The method and the device for processing sewage through the multistage alternative microbial generator are good in processing effect and capable of greatly reducing sludge amount in the sewage treatment.

Owner:陈贤芳 +1

Microporous lightweight silica brick and preparation method thereof

The invention discloses a microporous lightweight silica brick and a preparation method thereof, the lightweight silica brick is mainly prepared from a mixture and a foaming agent, and the dosage of the foaming agent is 0.1-10% of the mass of the mixture; the mixture is prepared from the following components in percentage by mass: 70%-95% of a siliceous material, 1%-25% of an inorganic cementing material, 0.1%-15% of a mineralizing agent and 0.1%-5% of an additive; wherein the siliceous material is composed of siliceous particles and siliceous fine powder, the particle size of the siliceous particles is 0.1-3 mm, the particle size of the siliceous fine powder is smaller than or equal to 0.075 mm, and the mass ratio of the siliceous particles to the siliceous fine powder is (1-65): (35-99). The obtained microporous lightweight silica brick product has the advantages of fine aperture, small density, low thermal conductivity, high porosity, high mechanical strength, good high-temperature volume stability, strong acid atmosphere and slag erosion resistance and the like, is low in preparation cost and good in heat insulation effect, meets harsh high-temperature environment and heat insulation requirements of thermal equipment, and is suitable for popularization and application.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com