Patents

Literature

204 results about "Particle packing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

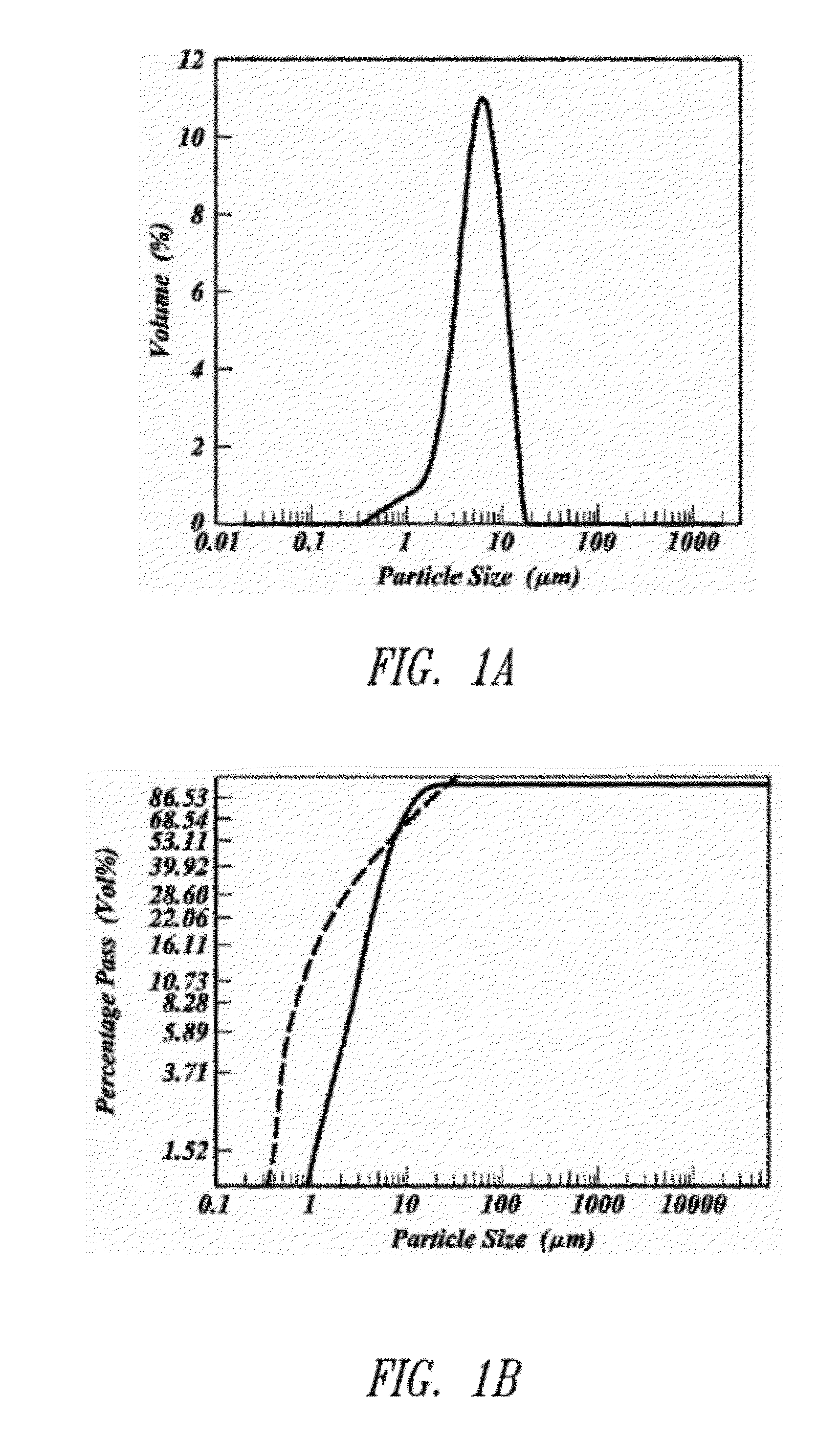

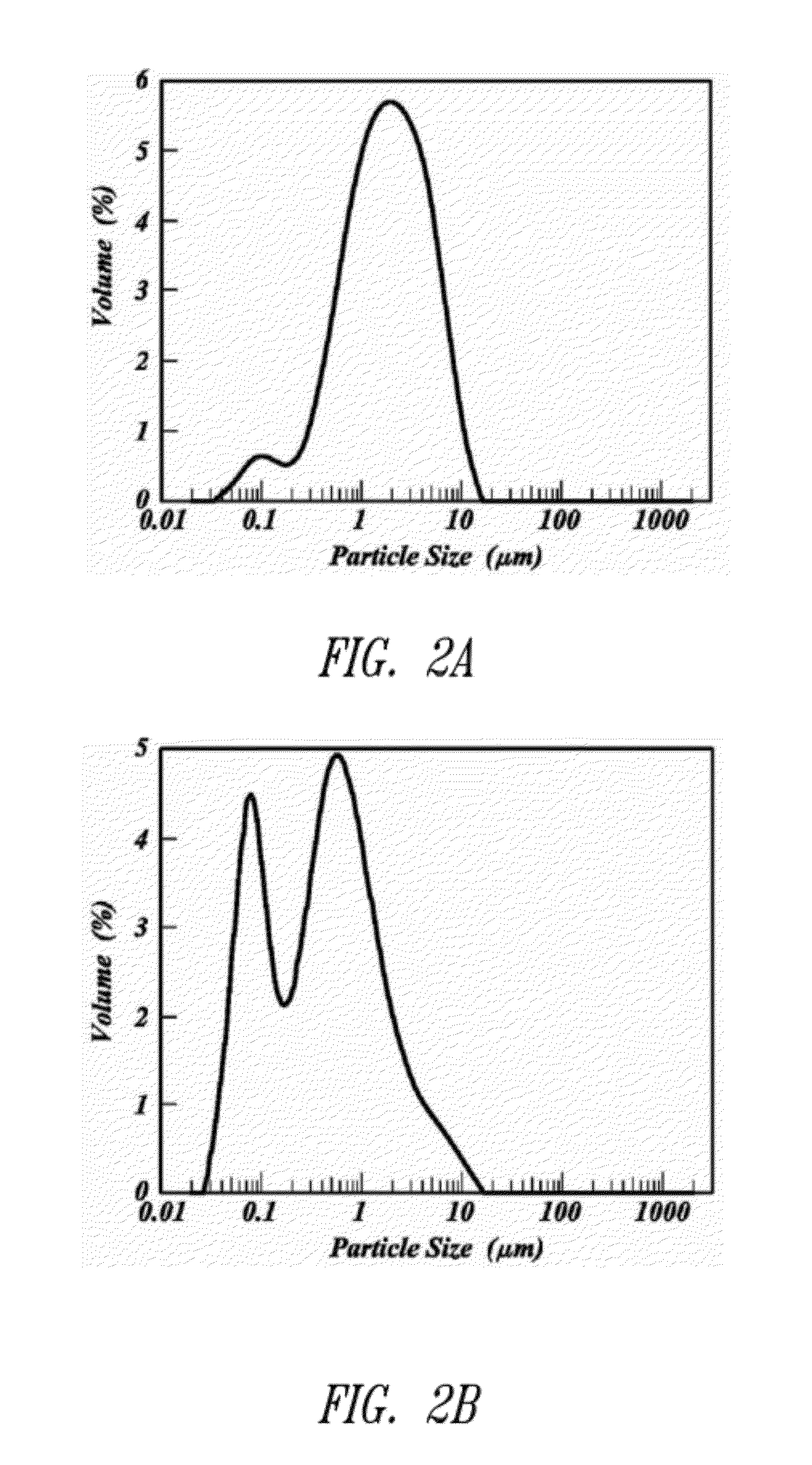

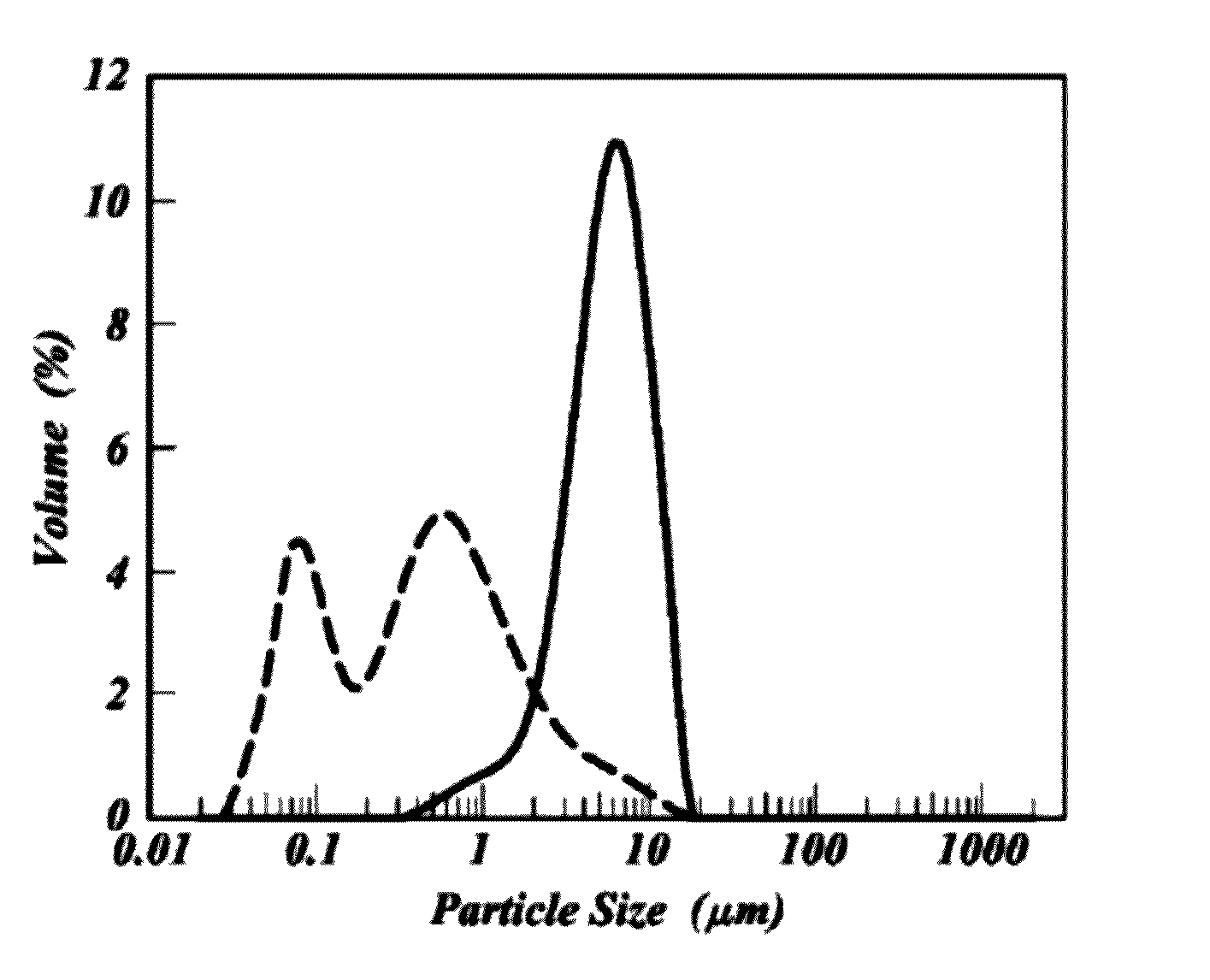

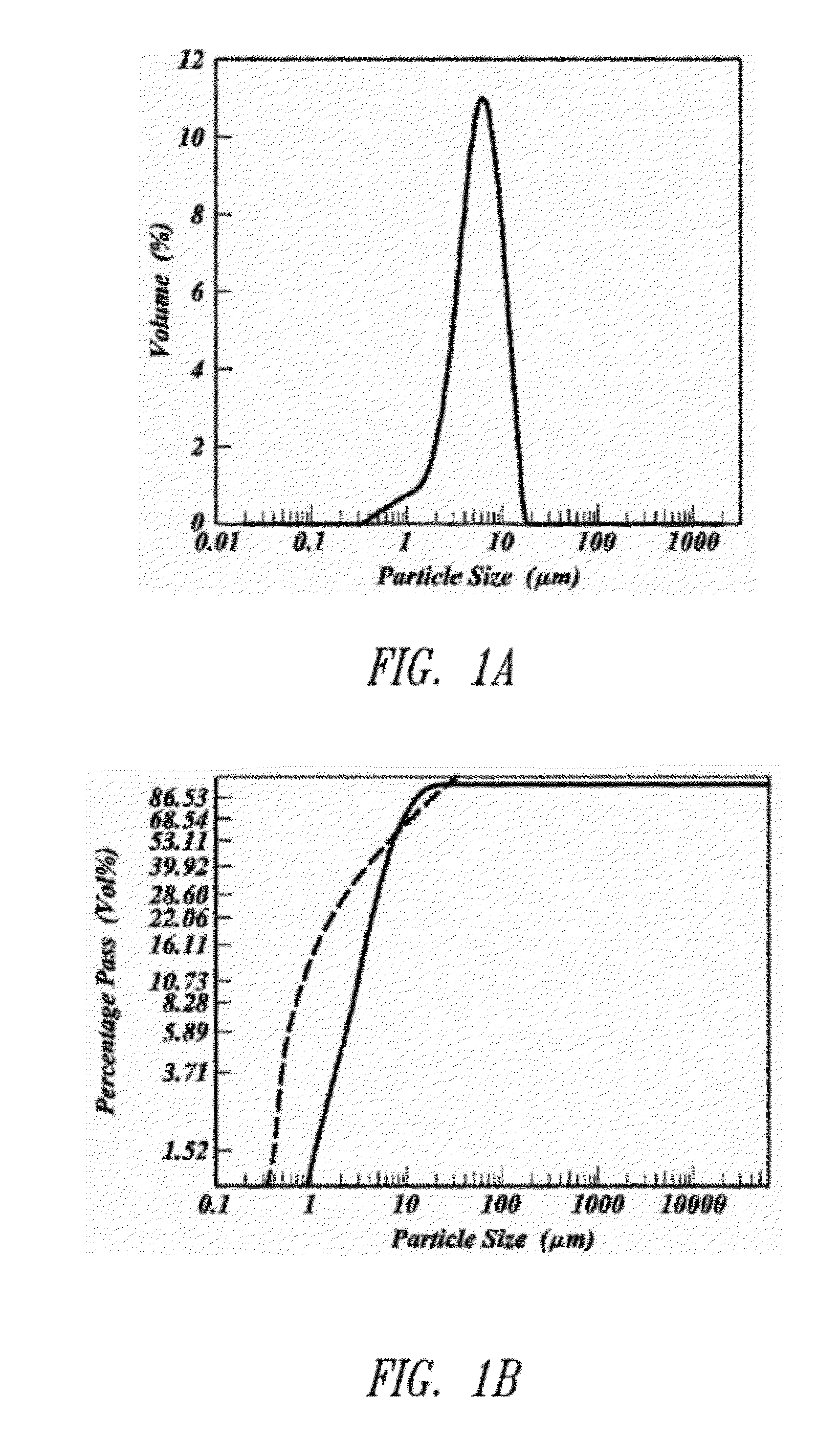

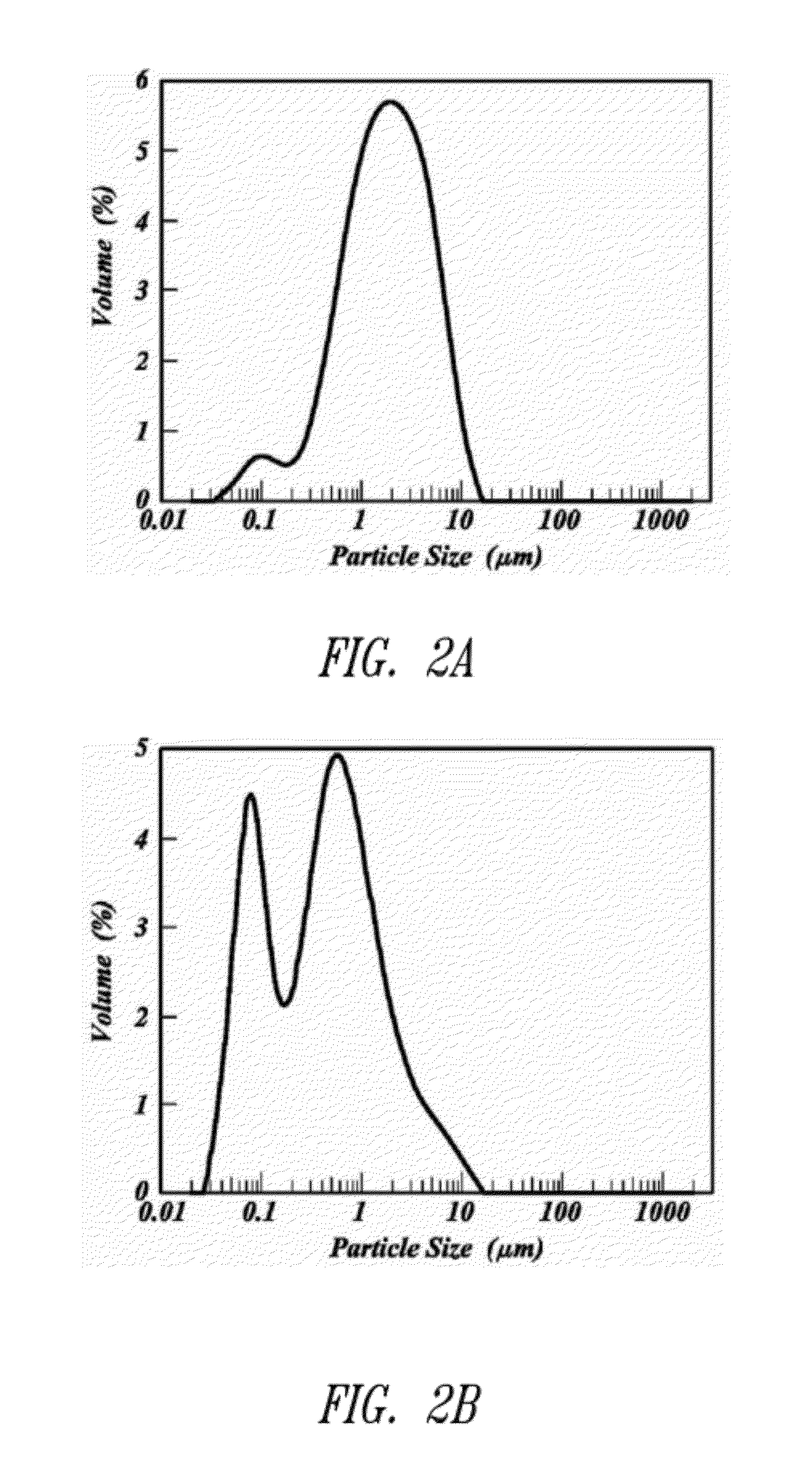

Enhanced packing of energy storage particles

InactiveUS20120081838A1Increasing performance of volumeLiquid electrolytic capacitorsCell electrodesCapacitanceActivated carbon

The present application is generally directed to energy storage materials such as activated carbon comprising enhanced particle packing properties and devices containing the same. The energy storage materials find utility in any number of devices, for example, in electric double layer capacitance devices and batteries. Methods for making the energy storage materials are also disclosed.

Owner:BASF AG

Enhanced packing of energy storage particles

The present application is generally directed to energy storage materials such as activated carbon comprising enhanced particle packing properties and devices containing the same. The energy storage materials find utility in any number of devices, for example, in electric double layer capacitance devices and batteries. Methods for making the energy storage materials are also disclosed.

Owner:BASF AG

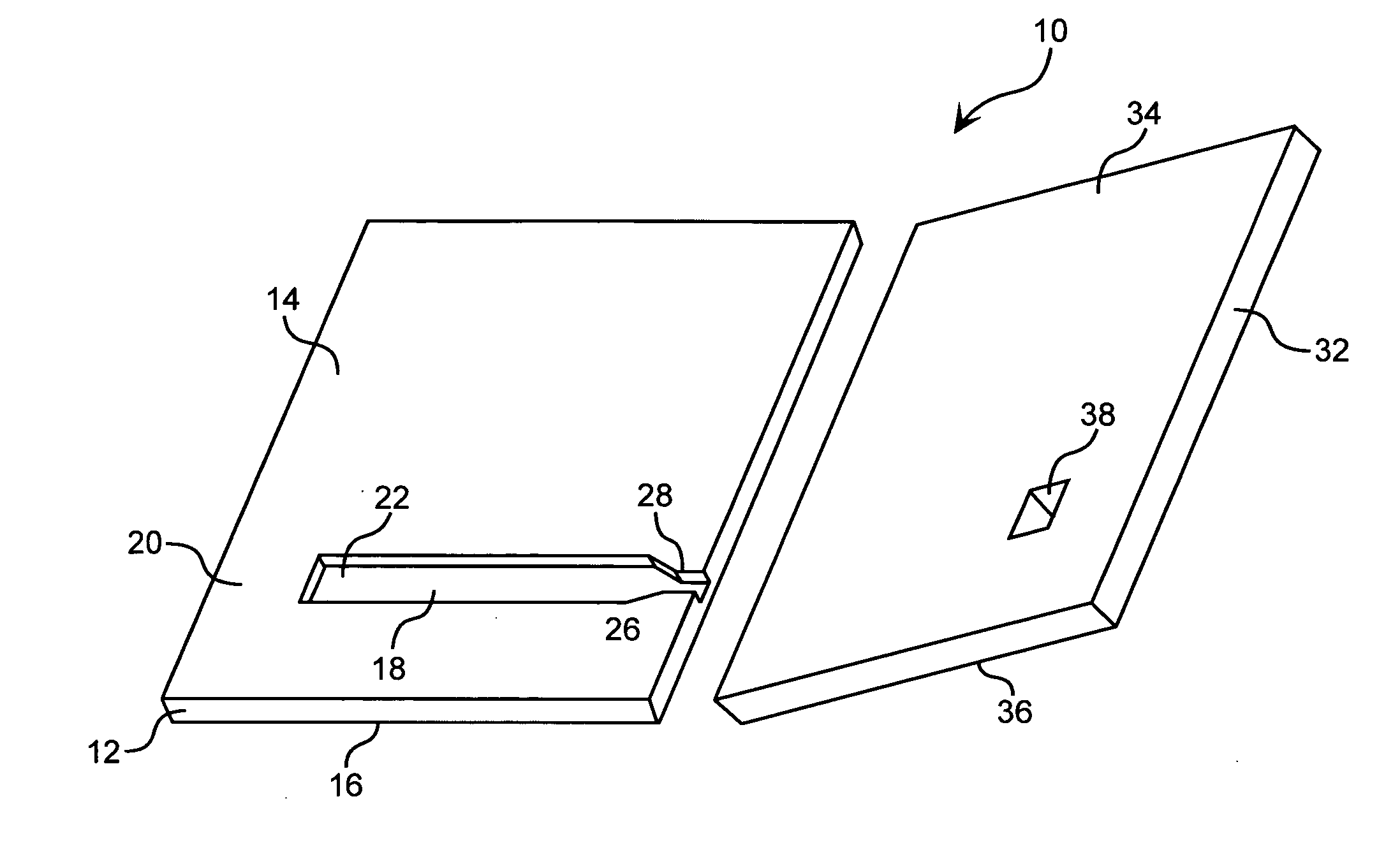

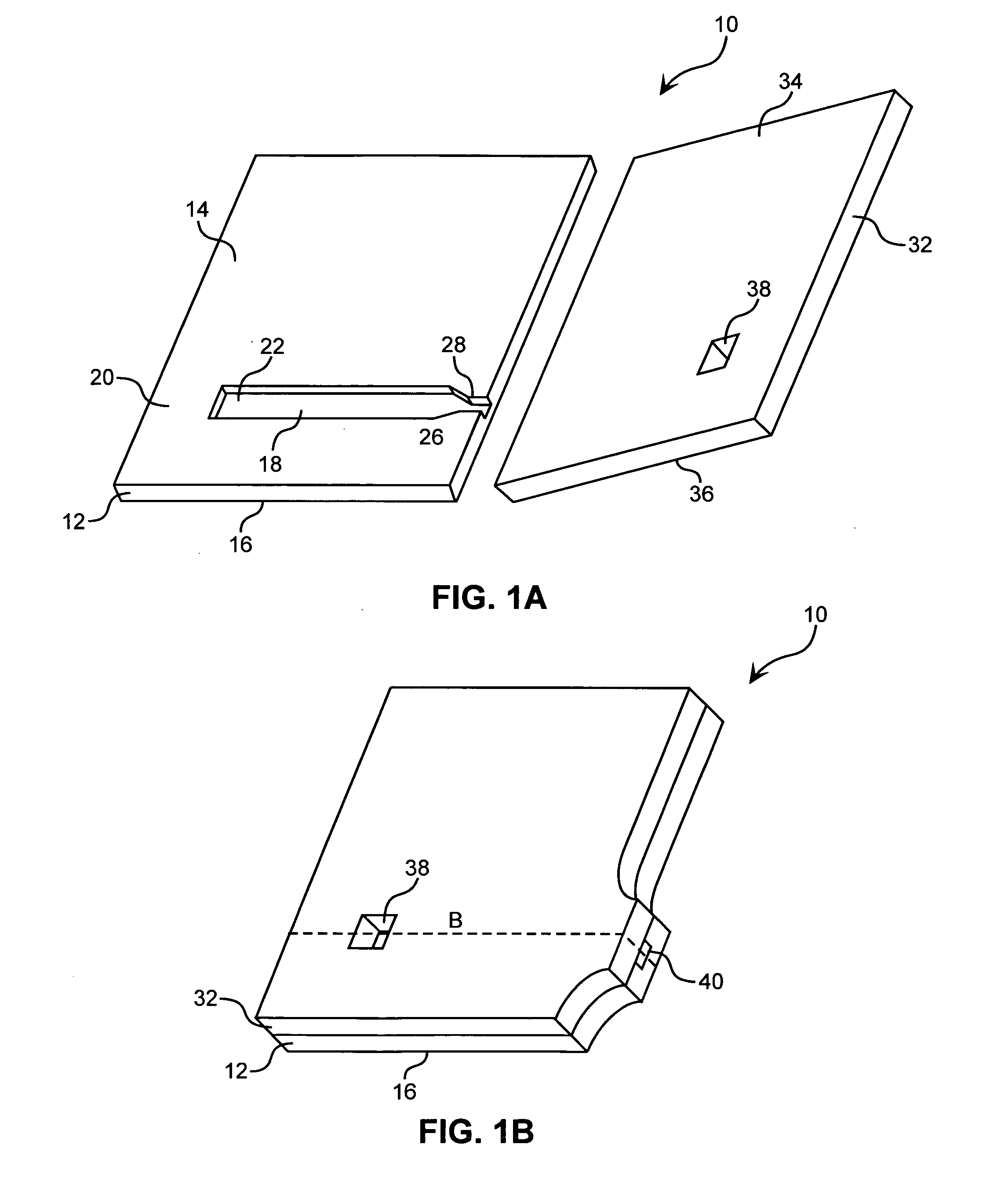

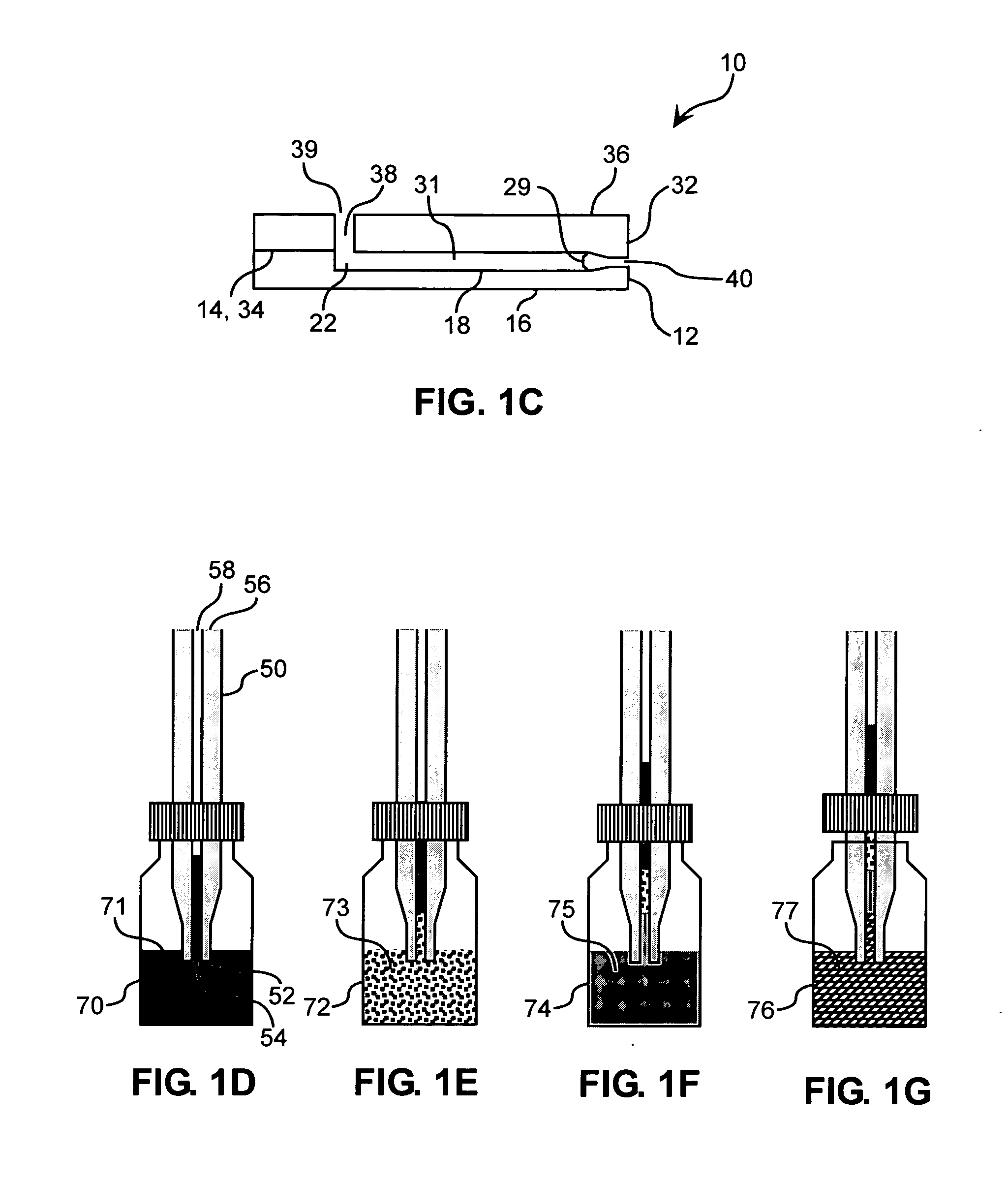

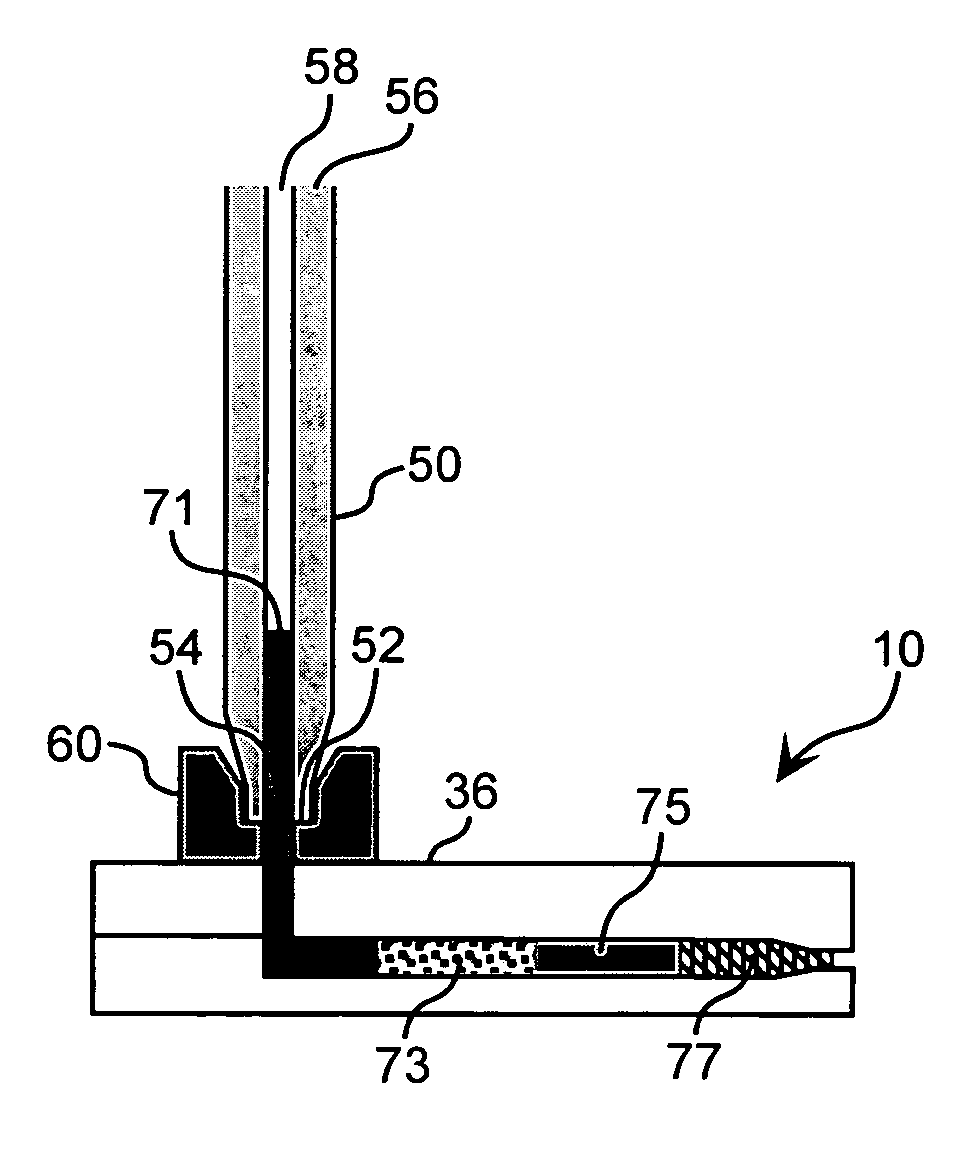

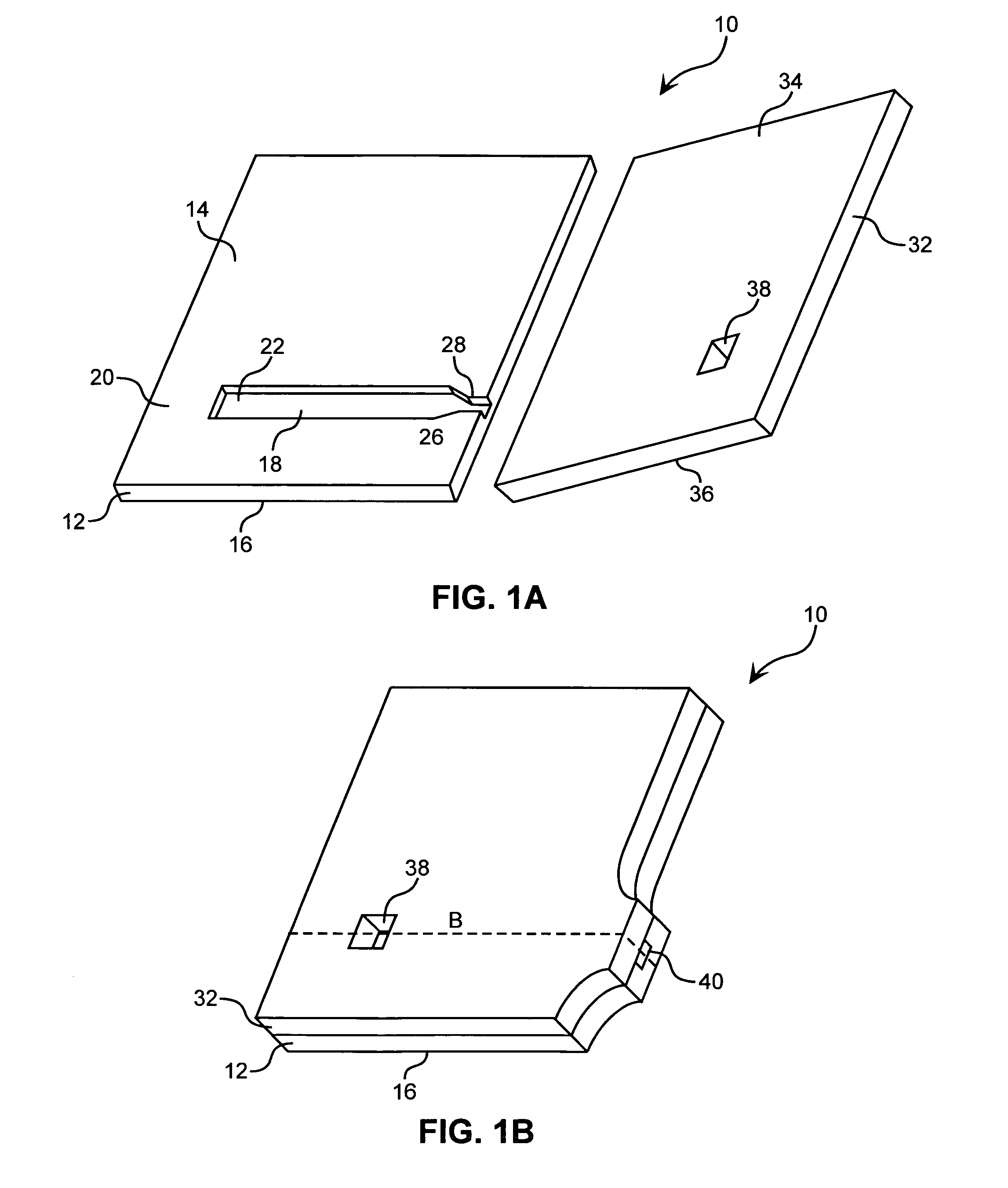

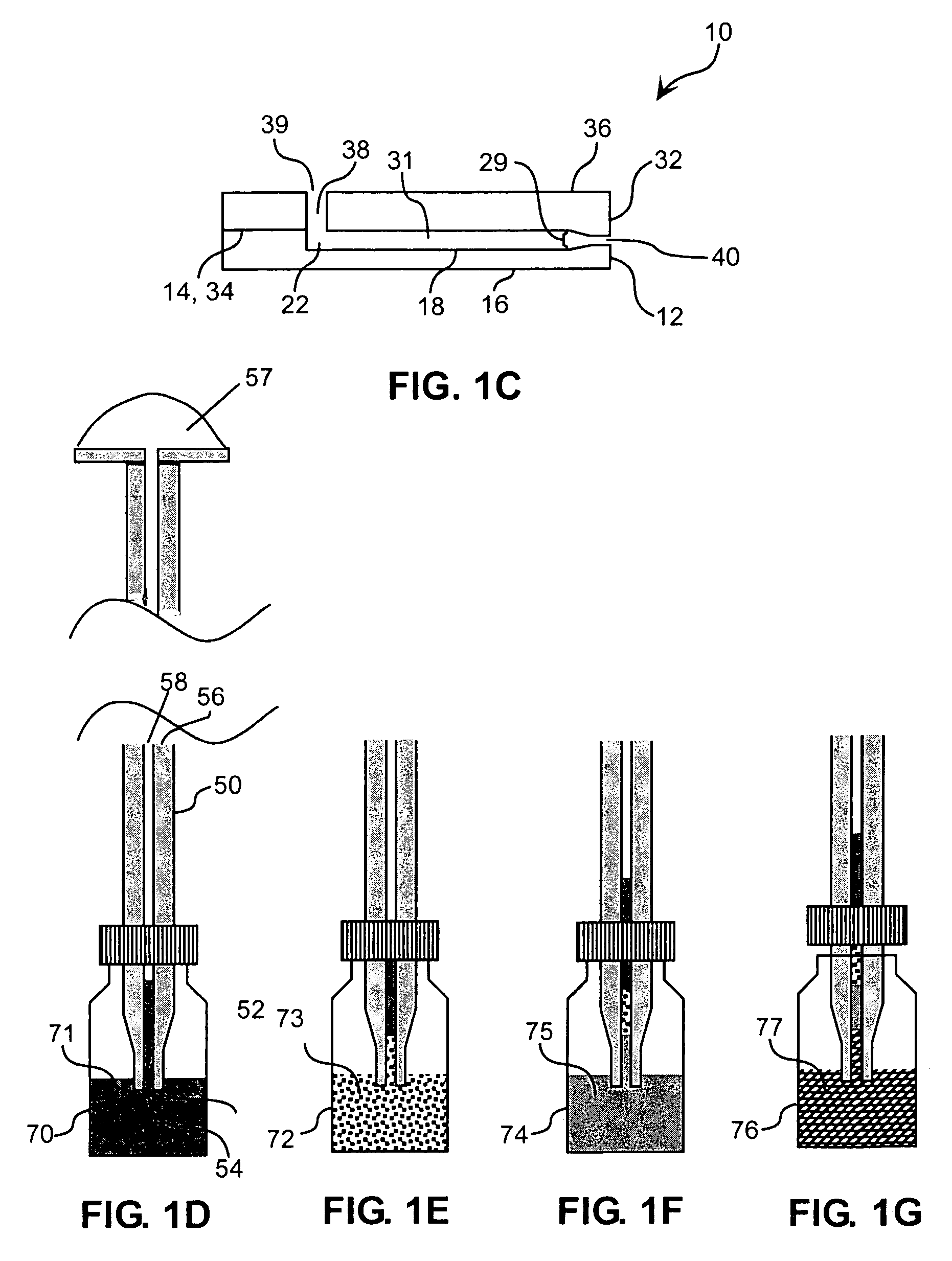

Particle packing of microdevice

ActiveUS20050224134A1Overcome disadvantagesLiquid fillingComponent separationParticle packingCatheter

Provided are apparatuses and methods for introducing particles into a microdevice conduit. Also provided are microdevices containing a plurality of particles that occupy at least about 25 volume percent of a microconduit. In some instances, particles may controllably form a particle bridge in a bridging zone within a microdevice.

Owner:AGILENT TECH INC

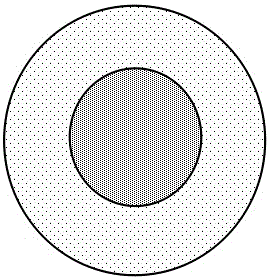

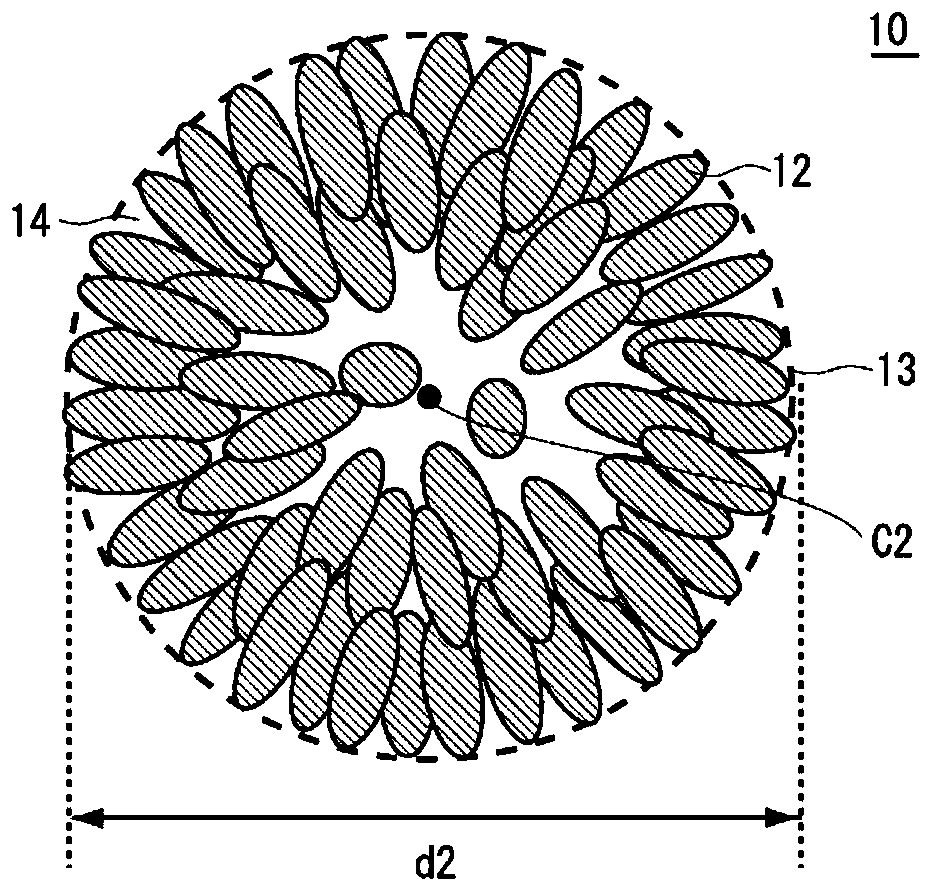

Ternary precursor material with internally dense and externally loose structure primary particle bulk density, anode material and preparation method thereof

ActiveCN104993122AIncrease concentrationReduce concentrationCell electrodesSecondary cellsMetallurgyParticle packing

The invention discloses a ternary precursor material with an internally dense and externally loose structure primary particle bulk density, an anode material and a preparation method thereof. The particle of the ternary precursor material has an internally dense and externally loose structure bulk density. The ternary precursor material is NixCoyMn2M1-x-y-z(OH)2 or NixCoyMnzM1-x-y-zCO3, x is greater than 0 and smaller than 1, y is greater than 0 and smaller than 1, z is greater than 0 and smaller than 1, x+y+z is smaller than or equal to 1, M is one or more of Zr, Fe, Sm, Pr, Nb, Ga, Zn, Y, Mg, Al, Cr, Ca, Na, Ti, Cu, K, Sr, Mo, Ba, Ce, Sn, Sb, La and Bi. According to the invention, based on comprehensive consideration of the tap density and rate performance changing situation, the introduction position and concentration of a surfactant are designed, and the accumulation compactness of particles from the inside to the outside at all parts is regulated, thus finally realizing development of the optimal overall performance of the material. The materials prepared by the method provided by the invention have the characteristics of excellent post-sintering rate and cycle performance, and high tap density.

Owner:HARBIN INST OF TECH

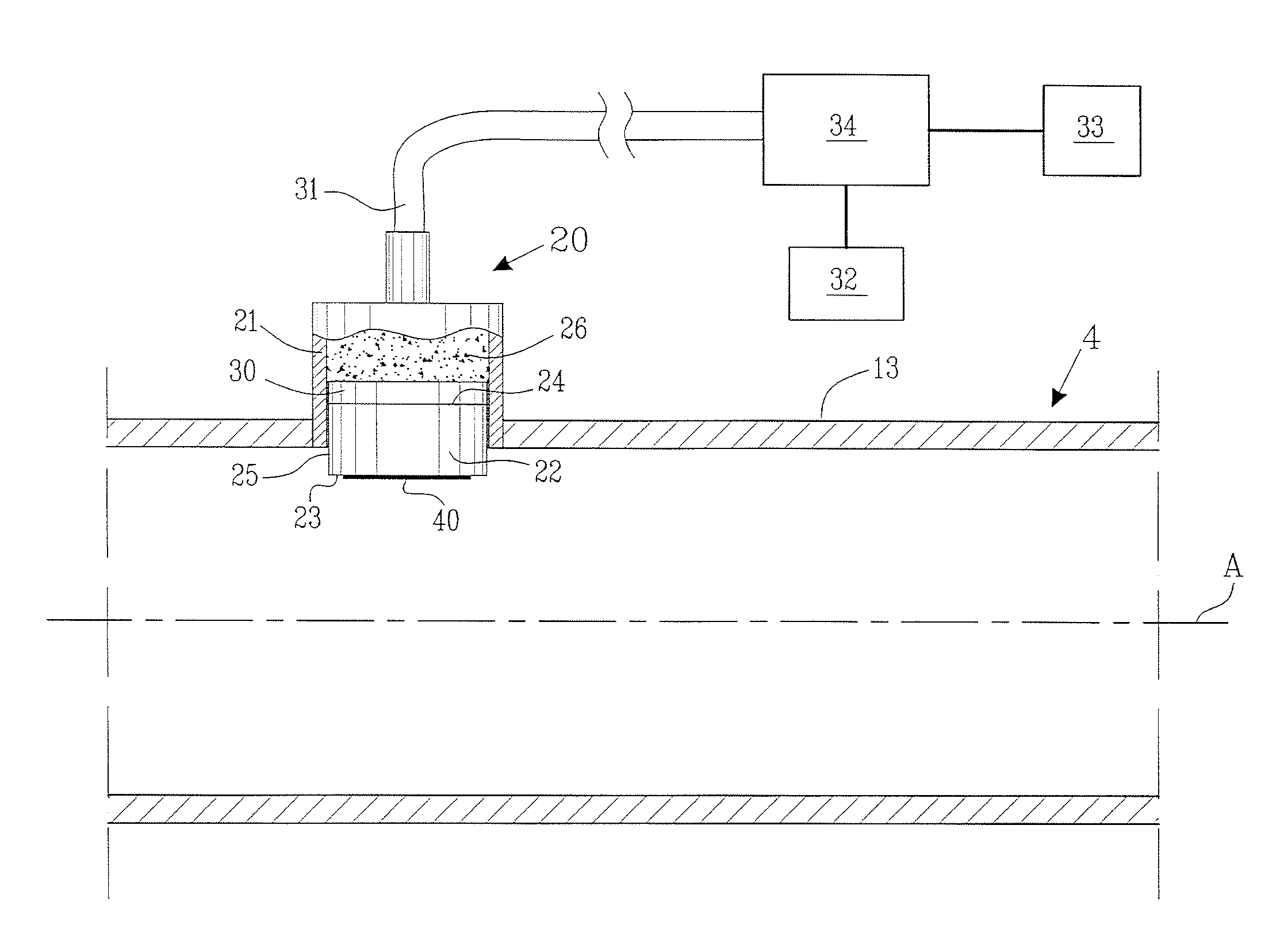

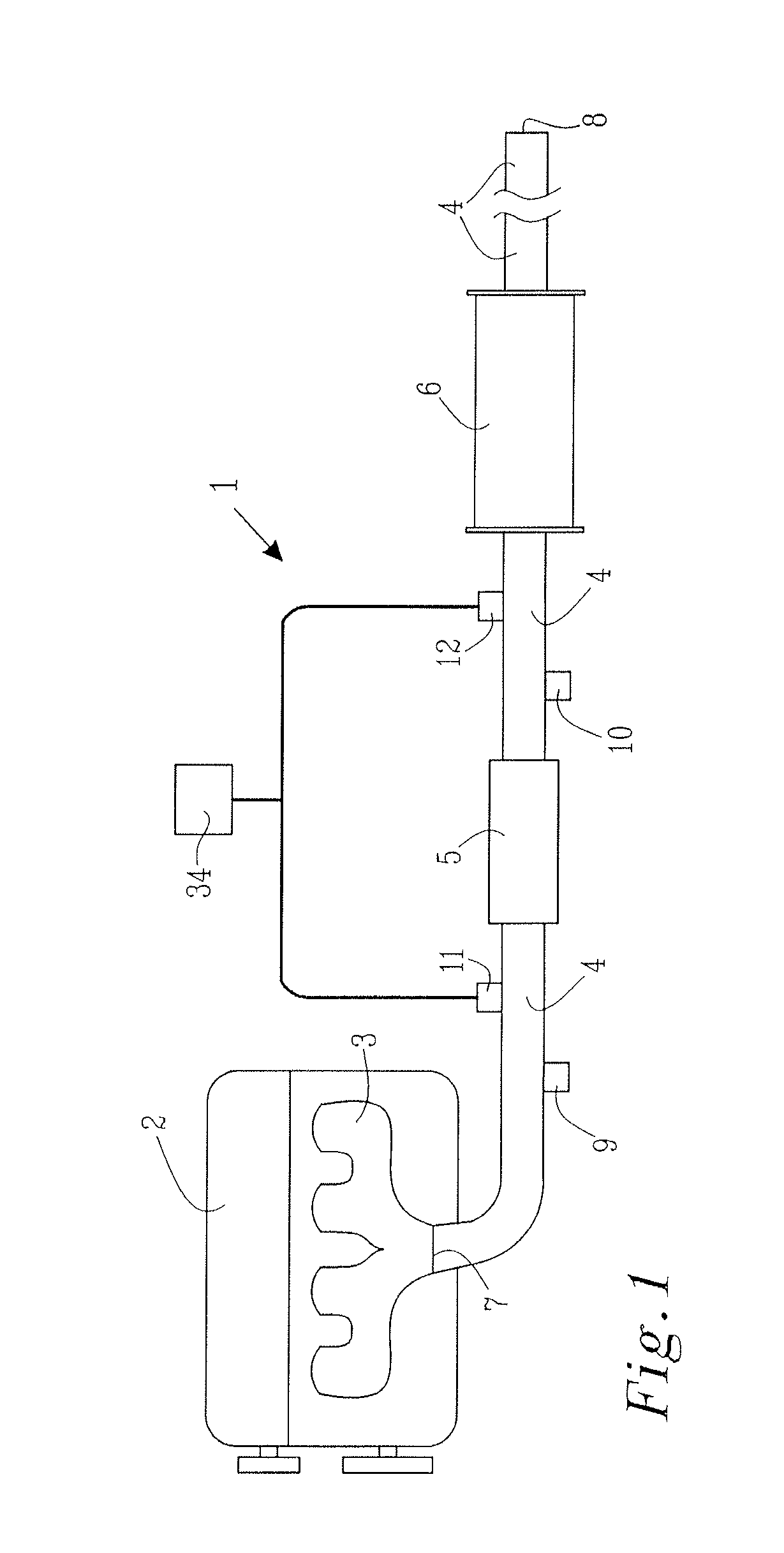

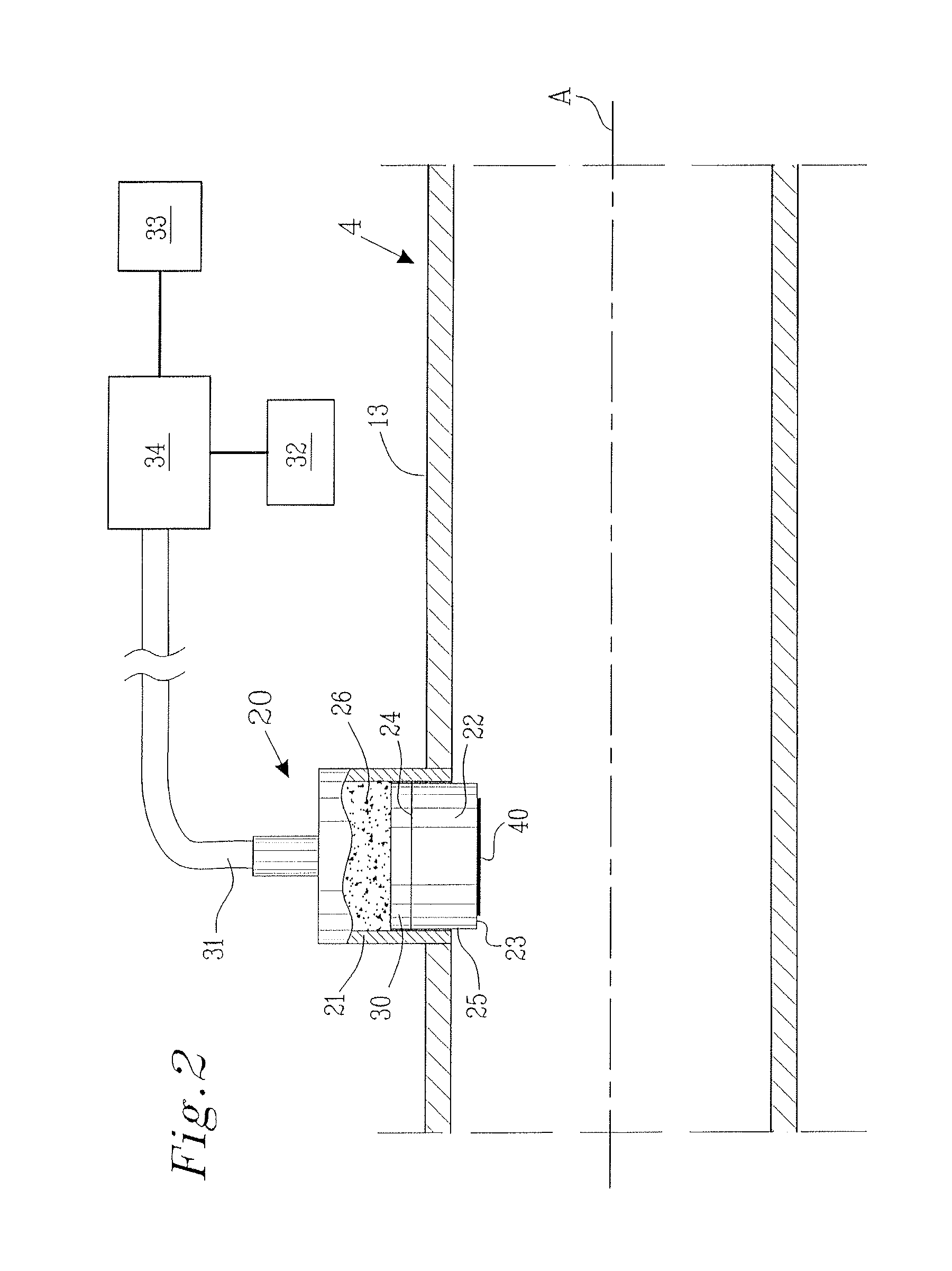

Method and arrangement for detecting particles

InactiveUS20110197571A1Improve Sensing PerformanceImprove conductivityInternal-combustion engine testingExhaust apparatusDiesel combustionEngineering

The present invention relates to a method for detecting particles and a particle sensor arrangement. More specifically, the present invention relates to a method and arrangement for detecting particles in a gas flow, e.g. from a diesel combustion engine. The method comprises the steps of; forcing a particle build up on a sensor element of a particle sensor arrangement by regulating the sensor element to a second temperature; wherein the second temperature is lower than a first temperature, the first temperature being the gas flow temperature. Additionally is the particle build up detected at the sensor element by means of a detector. The present invention provides for an accurate method and arrangement to detect and thereby measure particles present in a gas flow, e.g. from a combustion engine.

Owner:VOLVO TECH +1

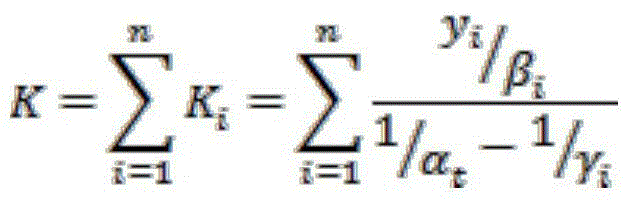

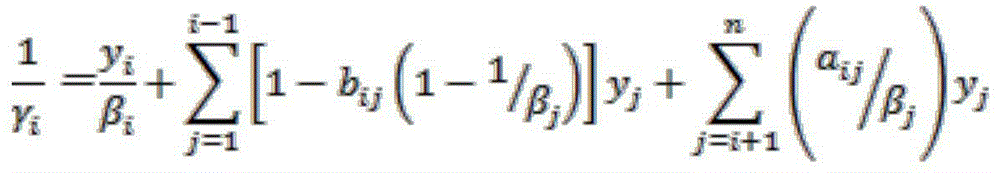

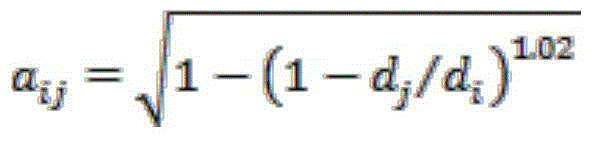

Green concrete mix proportion optimization method

The invention discloses a green concrete mix proportion optimization method. The method includes the following steps of firstly, determining the concrete mix proportion meeting the performance requirement according to the design requirement and existing standard and engineering experience; secondly, measuring raw material parameters and establishing a concrete performance prediction model; thirdly, conducting loop optimization design on the existing concrete mix proportion, and obtaining the final result. According to the method, the method which can rapidly and accurately predict the work performance and compressive strength of concrete is established through the advanced particle packing theory and the rigorous mathematical derivation and through the combination with the actual test situations of site materials; by means of the concrete mix proportion optimization method established on this basis, the minimum cement utilization amount obtained on the premise of ensuring the work performance and strength of the existing design can be calculated only through a computer under the situation of no follow-up tests.

Owner:SHENZHEN UNIV

Particle packing of microdevice

ActiveUS7077175B2Overcome disadvantagesLiquid fillingComponent separationParticle packingParticle physics

Provided are apparatuses and methods for introducing particles into a microdevice conduit. Also provided are microdevices containing a plurality of particles that occupy at least about 25 volume percent of a microconduit. In some instances, particles may controllably form a particle bridge in a bridging zone within a microdevice.

Owner:AGILENT TECH INC

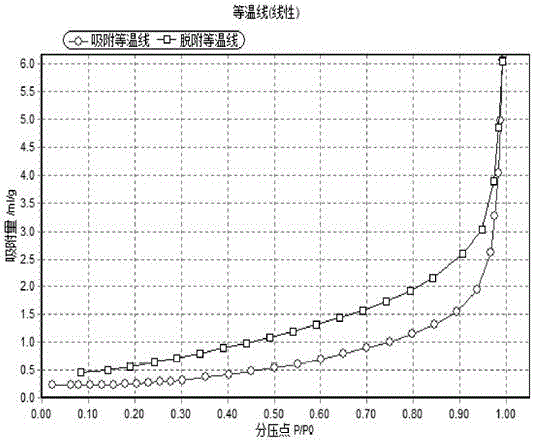

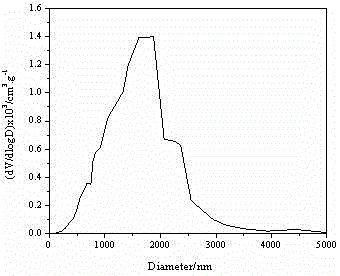

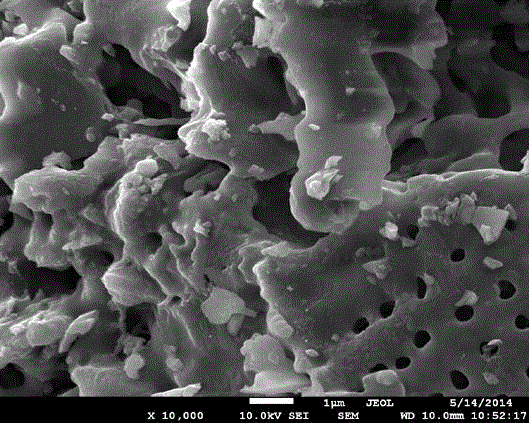

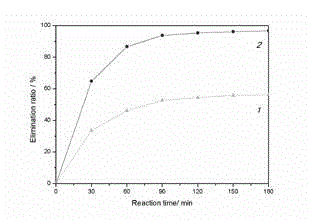

Kieselguhr-based particle adsorbent and preparation and modification method thereof

InactiveCN104437350AImprove adsorption capacitySmall apertureOther chemical processesWater contaminantsParticle packingSorbent

The invention belongs to the technical field of kieselguhr inorganic materials, and relates to kieselguhr-based particle adsorbent and a preparation method of the kieselguhr-based particle adsorbent. The kieselguhr-based particle adsorbent is made of the following raw materials: kieselguhr, kaolin, sintering aids, pore-forming agents, dispersing agents and water with the weight ratio of 72-90:2-12:1-16:1-18:0.01-2:12-45. The prepared kieselguhr-based particle adsorbent has the advantages that the bore diameter is small, high porosity is achieved, and cost is low (the original pore structure of the kieselguhr and pores formed after particle accumulation and pore-forming agent calcination are organically combined). After FeCl3 modification of the kieselguhr-based particle adsorbent, the good effect of removing phosphorus waste water is achieved, and the kieselguhr-based particle adsorbent is a natural environment-friendly product large in adsorption capacity and relatively high in strength.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

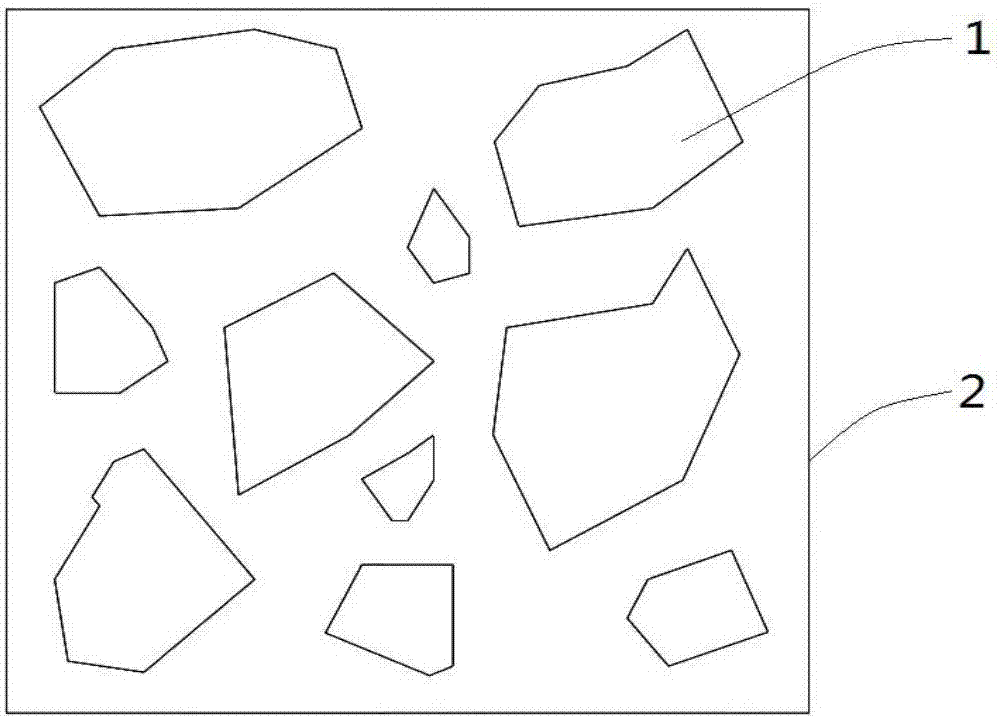

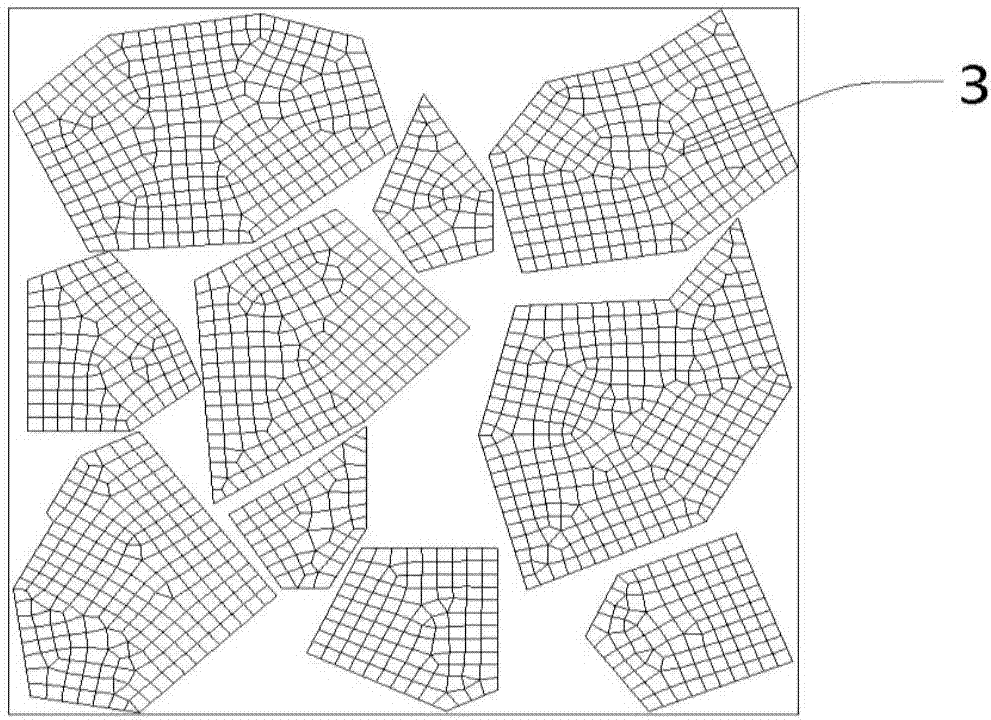

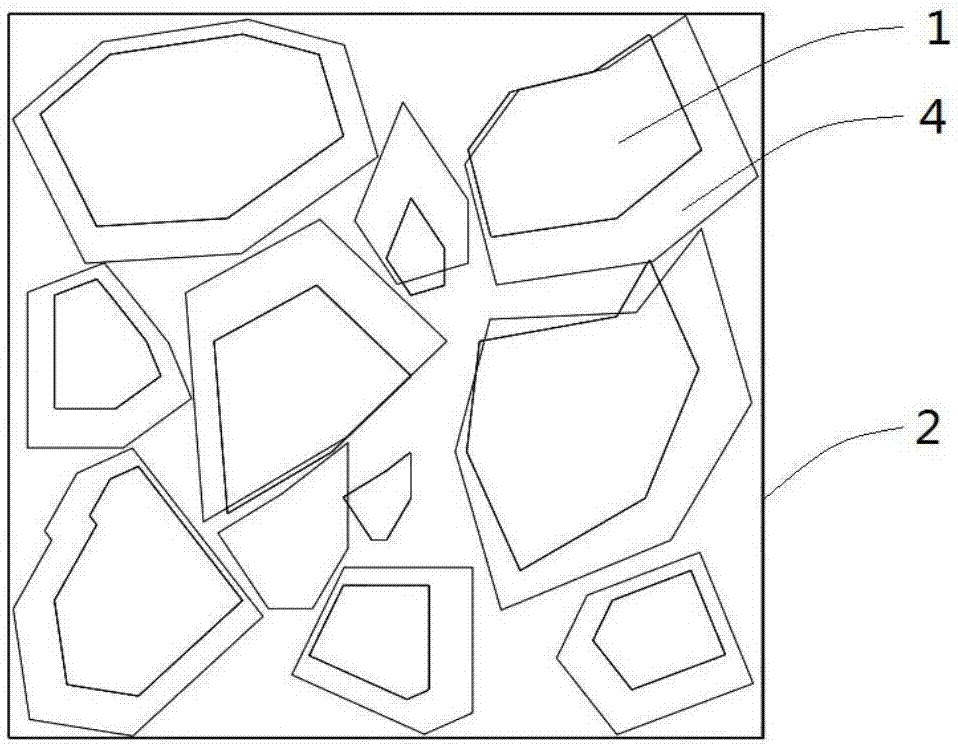

Modeling method for high-compactness discrete particle heterogeneous system

ActiveCN107423498AGuaranteed uniformitySolve modeling problemsDesign optimisation/simulationSpecial data processing applicationsParticle packingComputational physics

The invention discloses a modeling method for a high-compactness discrete particle heterogeneous system. The method comprises the following steps that: determining a model boundary; drawing up the volume sum of particle phases in each dimension range in the model; generating the compression models of the particle models in all dimension ranges; carrying out expansion on each particle in the compression model; and obtaining a high-compactness particle accumulation model. The method can be used for enhancing the modeling of microstructures including particle reinforced composite materials, soft substance particle materials, particle accumulation materials and the like, and can be expanded and applied to short fiber enhanced composite materials. By use of the method, a modeling problem generated when particles and the model boundary are cross is solved, and the modeling method can be applied to the modeling and the analysis of a composite material specimen of which the edge is subjected to machining.

Owner:SHANDONG UNIV

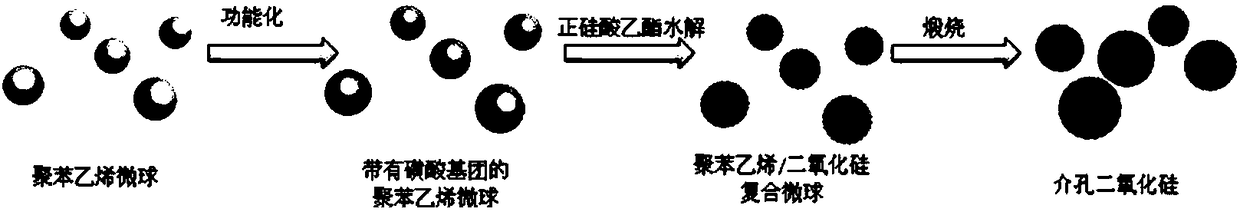

Preparation method of mesoporous silica microsphere

InactiveCN108579705ASmall sizeAdjustable sizeOther chemical processesDispersed particle separationMicrosphereMesoporous silica

The invention relates to a preparation method of a mesoporous silica microsphere. The method comprises the following steps that 1, a polystyrene microsphere is prepared; 2, the polystyrene microsphereis subjected to sulfonation; 3, a polystyrene / silicon dioxide composite microsphere is prepared; 4, polystyrene in the polystyrene / silicon dioxide composite microsphere is removed, and finally the mesoporous silica microsphere is obtained. According to the prepared mesoporous silica microsphere, by adjusting the cross-linking degree of a polystyrene template, the particle size of generated nano silicon dioxide can be controlled, therefore, the mesoporous size generated after particles are stacked is controlled, and pore diameter adjustable excellent performance is achieved. No expensive pore-forming agent is needed, and then the mesoporous silica microsphere which is uniform in pore diameter and high in specific surface area can be obtained.

Owner:HEBEI UNIV OF TECH

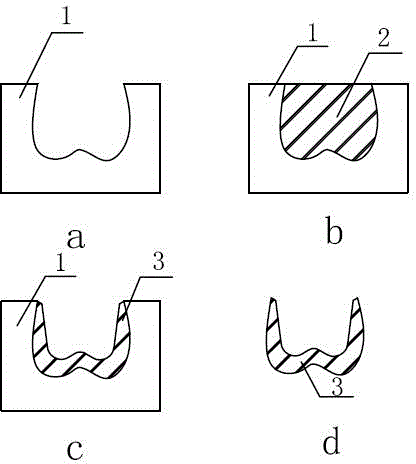

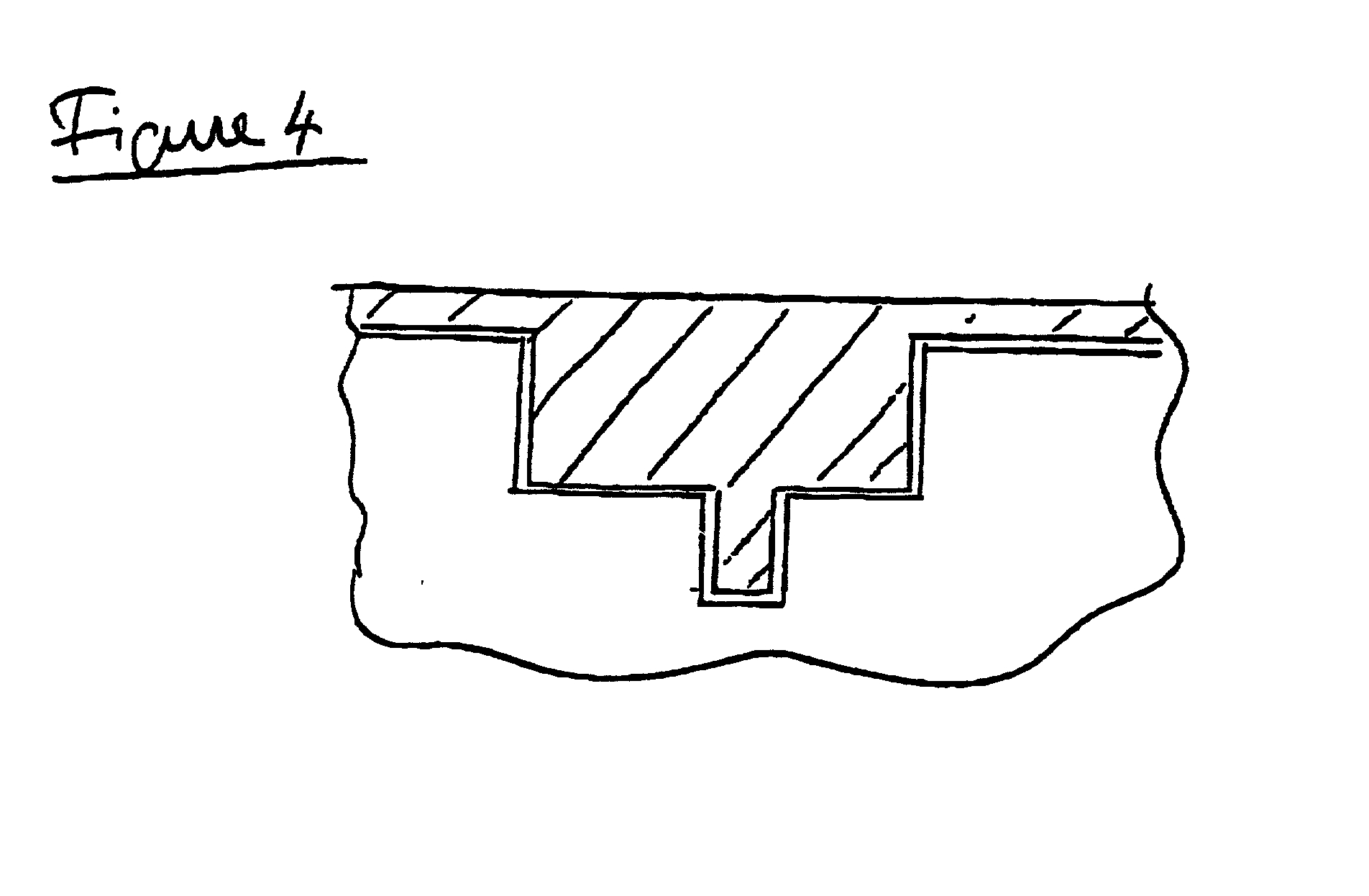

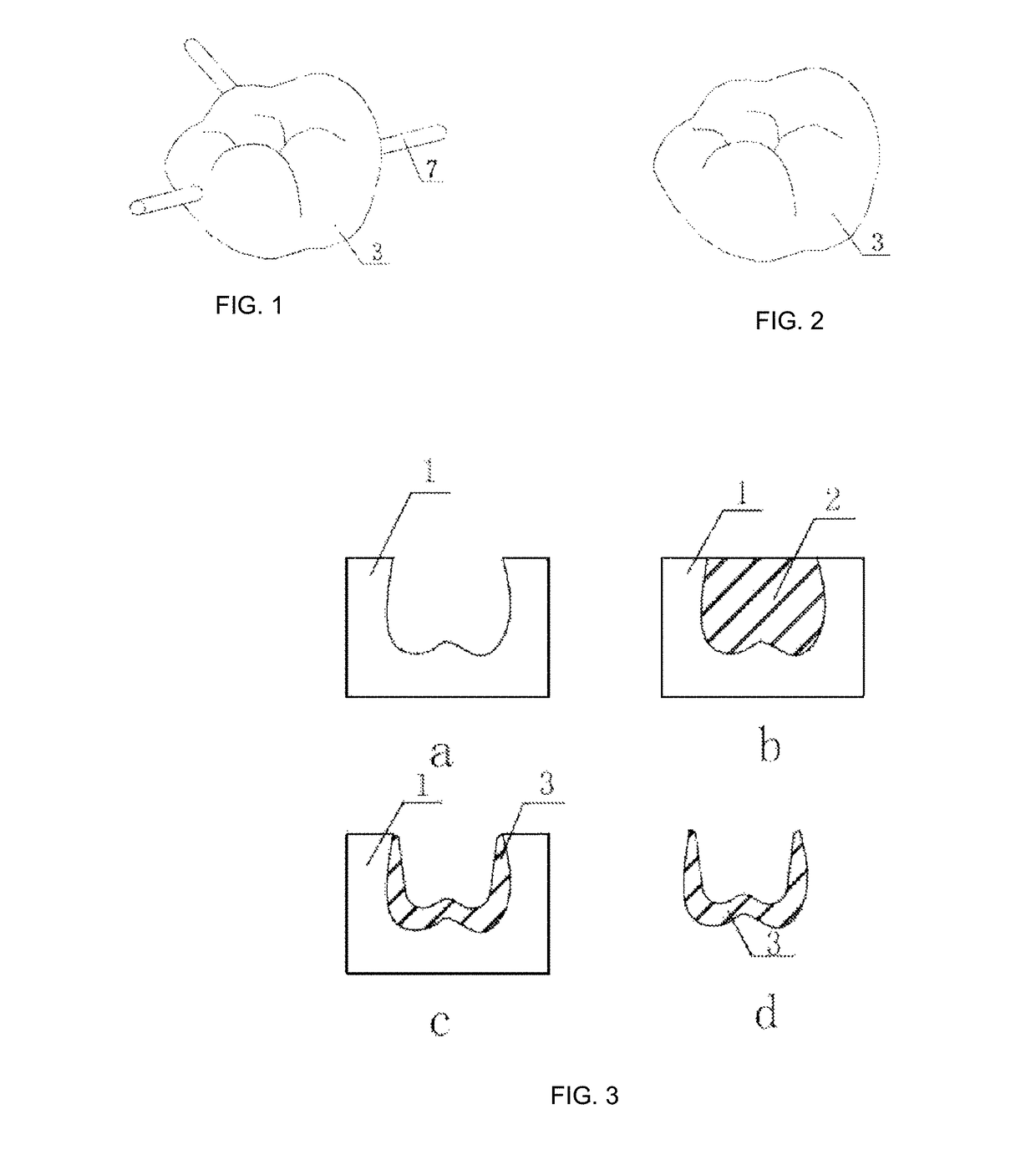

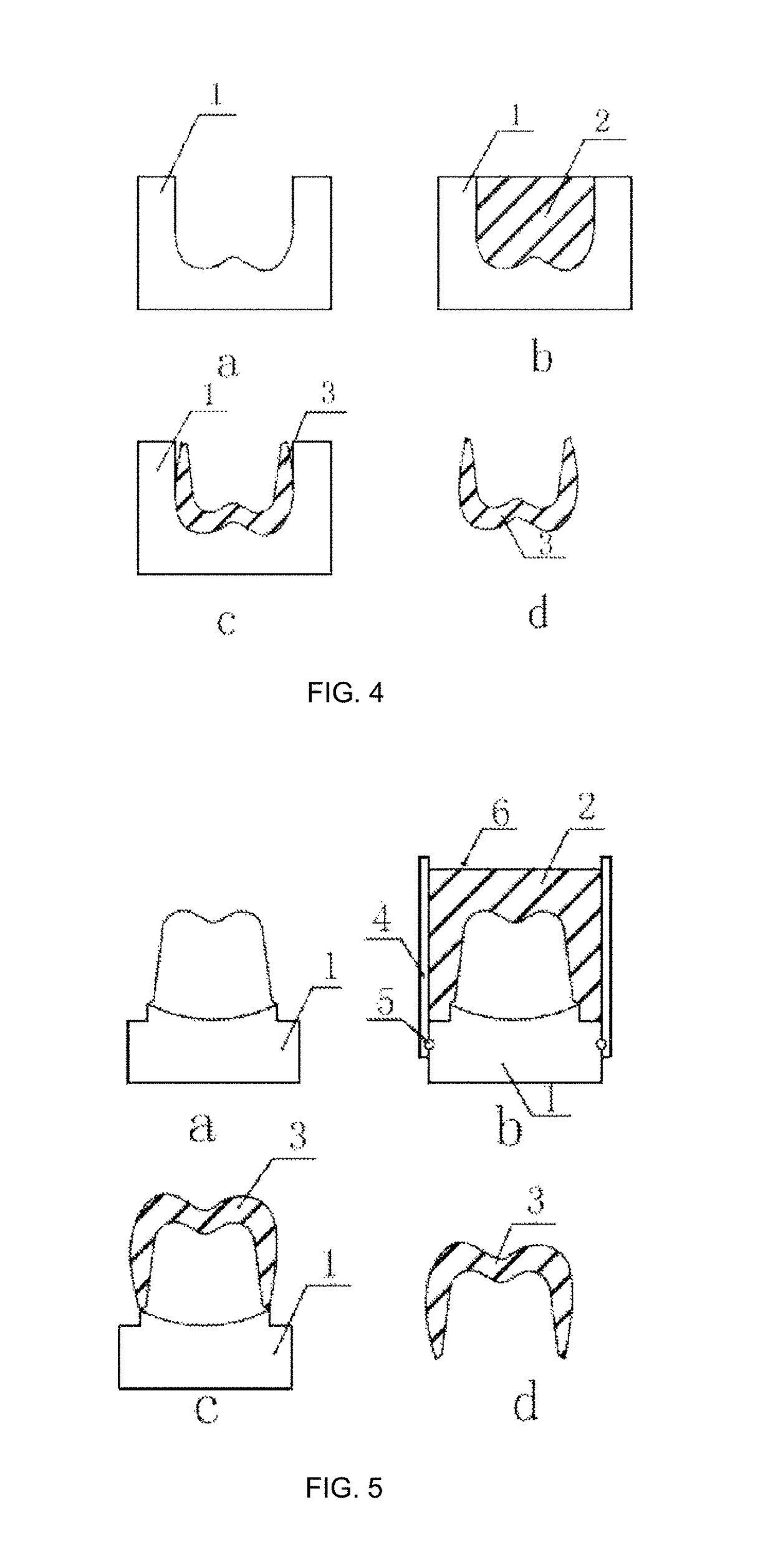

Wet forming production method of dental all-ceramic restoration

The invention discloses a wet forming production method of a dental all-ceramic restoration. According to the method, a prefabricated ceramic block is not used for processing, and in production processes, a support column is not required for fixing the ceramic block and the restoration, so that the process steps of manually removing the support column by milling to separate the formed restoration and the surrounding ceramic block and burnishing and polishing the excessively rough outer surface of the restoration caused by removing the support column by milling are avoided, and the risks of disintegration of the restoration and premature fracture failure are further reduced. A ceramic hard biscuit for milling processing is produced by adopting a wet forming technology, and compared with the ceramic block which is formed by dry pressing and partially sintered, the microscopic structure is more uniform and contains fewer particle packing defects. Through milling processing of the ceramic hard biscuit which is not sintered, the surface finish which is higher than that obtained by processing the ceramic block which is partially sintered can be obtained. The dental all-ceramic restoration produced by adopting the technical scheme of the invention has the advantages of no connection points for the support column on the outer surface, no partial milling marks and ceramic cracks, bright and clean surface, uniform and consistent structure and high reliability.

Owner:HANGZHOU ERRAN TECH

Granule for a thermoplastic end product comprising a mineral and/or a colorant pigment system

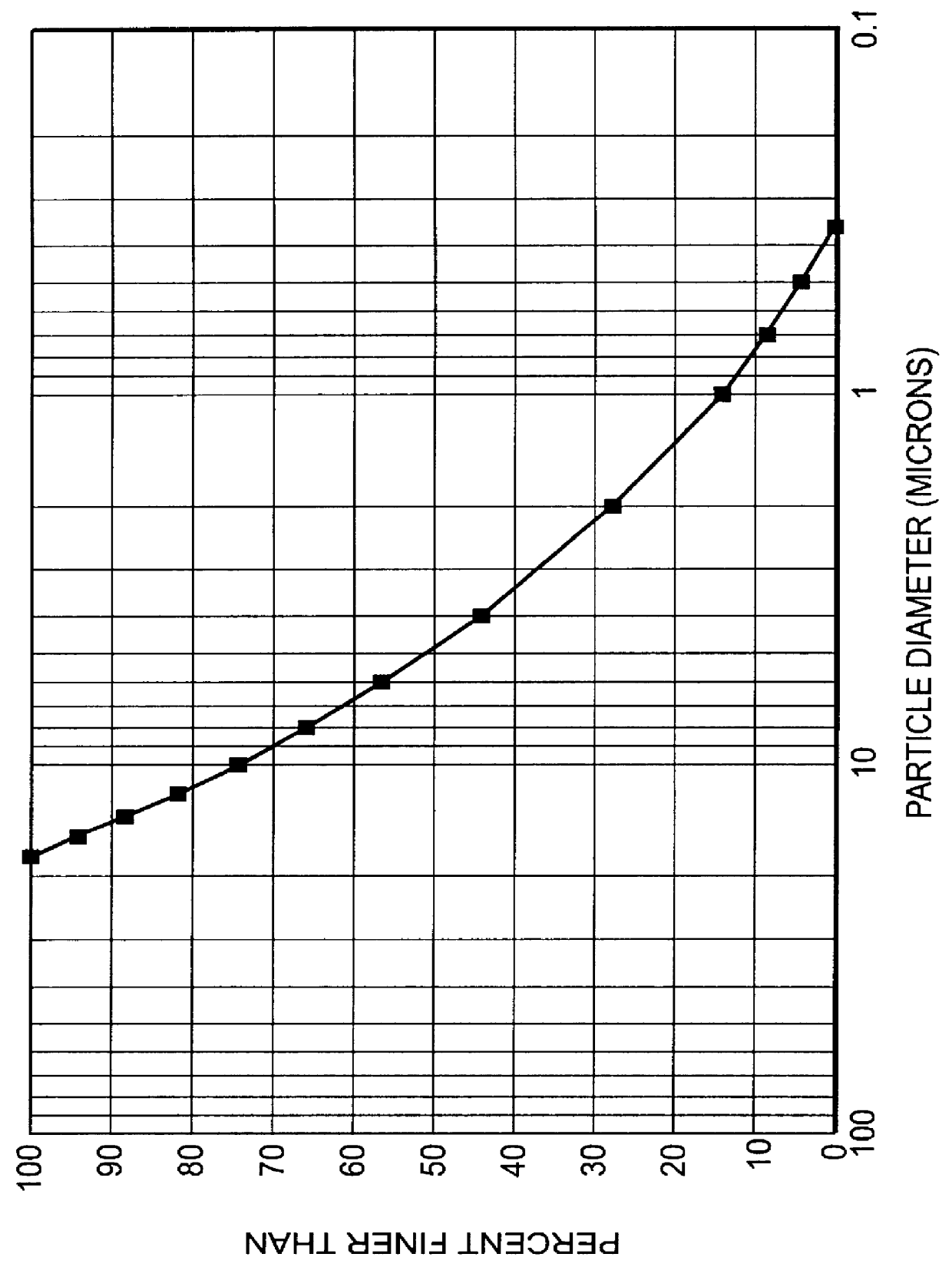

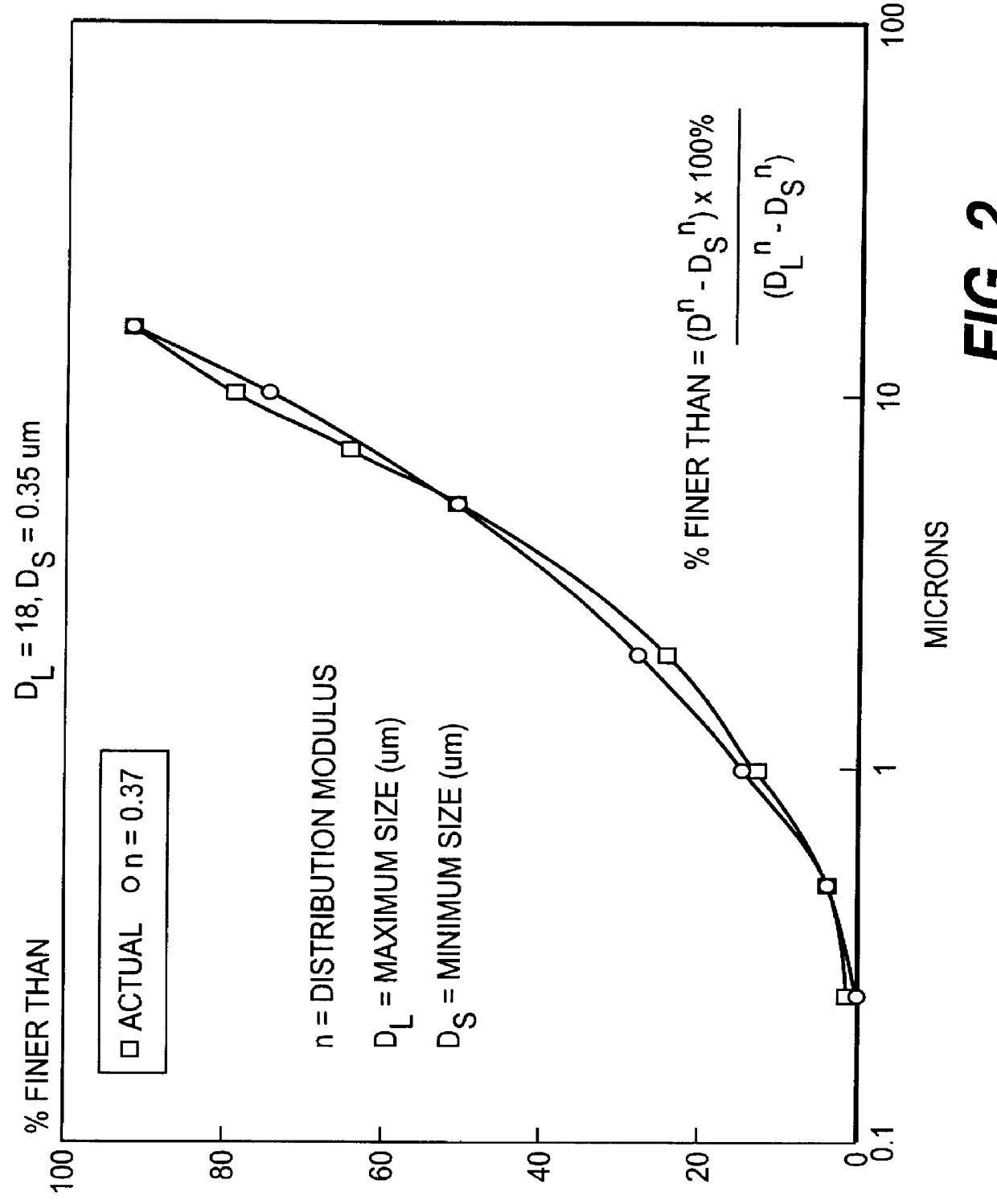

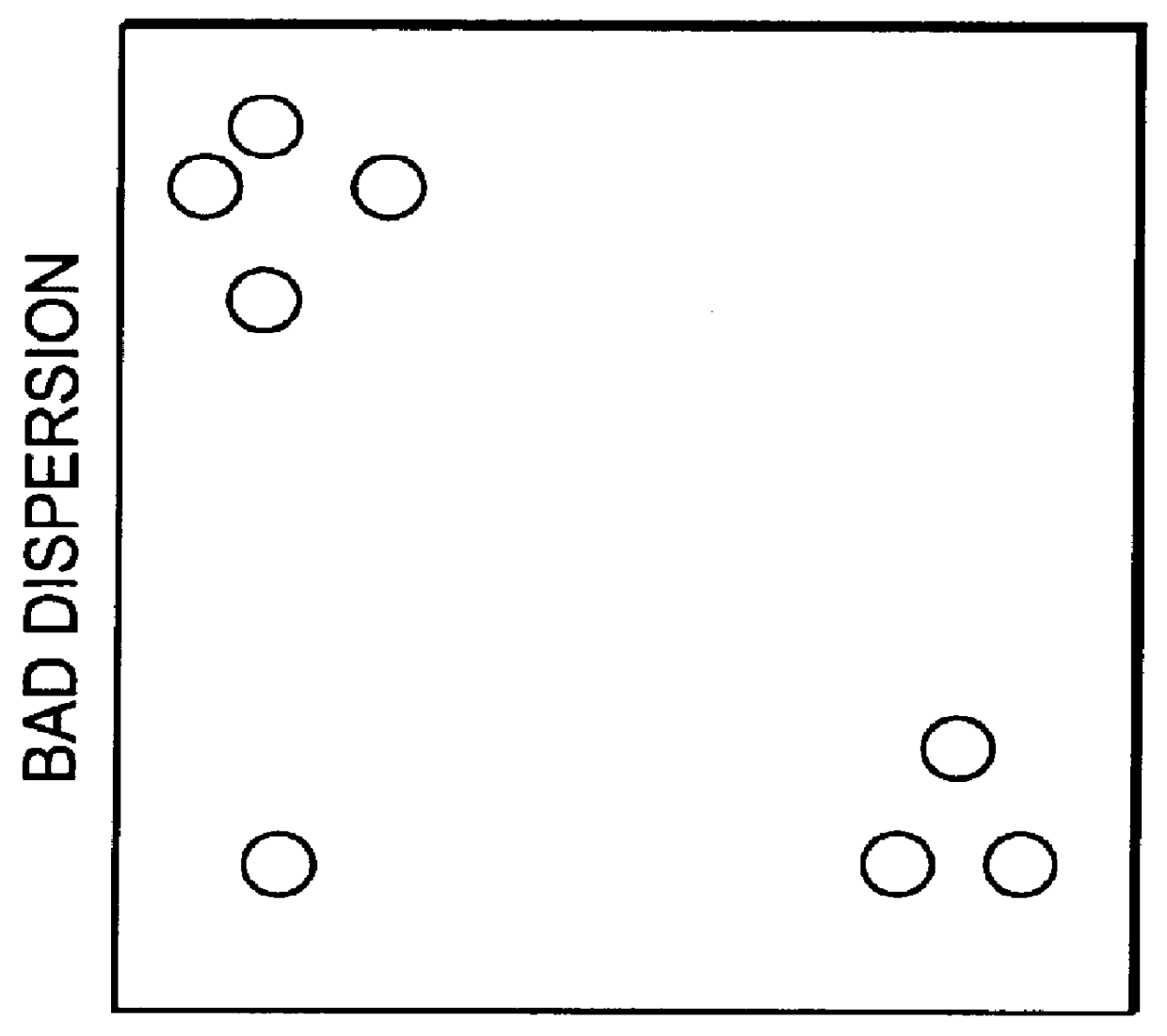

A granule containing a high proportion of a mineral filler and a colorant pigment system in a thermoplastic binder, for blending with an end product thermoplastic in which the mineral filler and the colorant pigment is to be dispersed. The granule comprises 85% to 92% by weight of the granule of mineral particles, which is coated with one or more fatty acids having a carbon chain length of from 12 to 20 carbon atoms and the colorant pigment. The colorant pigment may be inorganic or organic or a mixture thereof. The balance of the granule by weight comprises a thermoplastic polymeric binder. The particle size distribution of both the mineral and the colorant particles is in accordance with the optimum particle packing equation to optimize packing of the particles in the granule. The ratio of mineral to colorant pigment to binder may be about 75:15:10 or about 0.1:89.9:10. The invention includes a granule with only a colorant pigment system.

Owner:IMERYS PIGMENTS INC

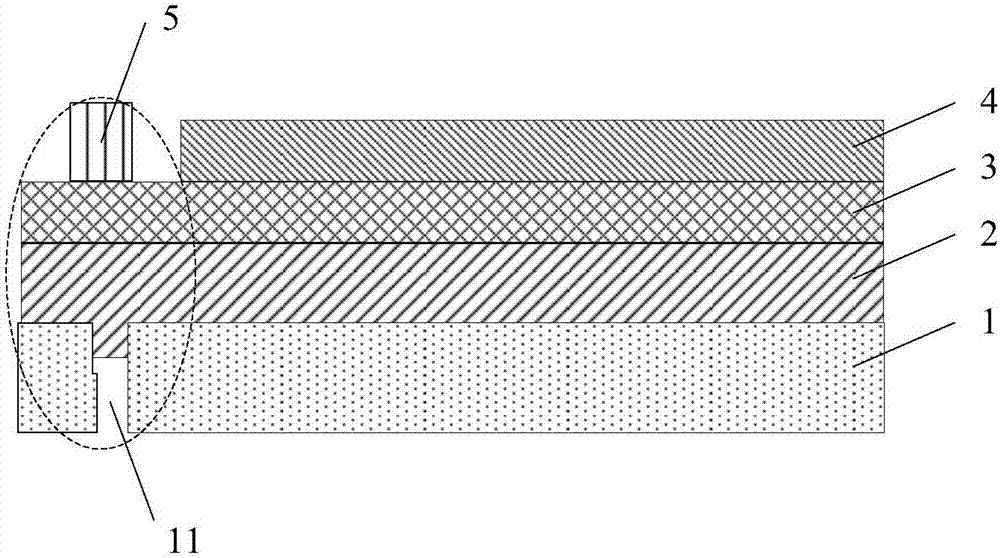

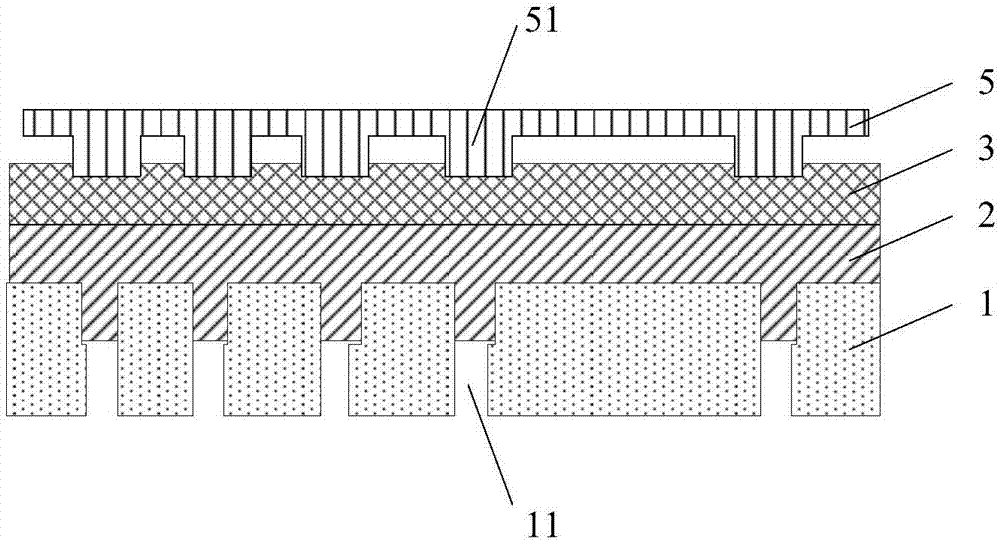

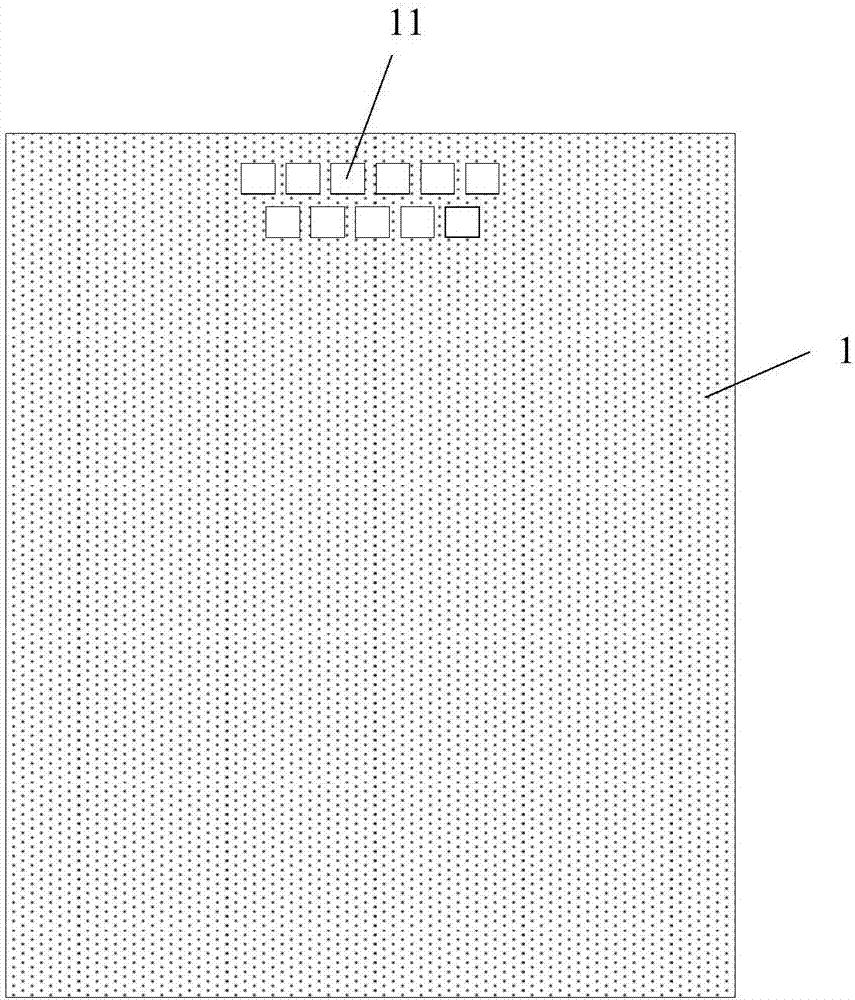

Display substrate and preparing method thereof and display device

The invention belongs to the technical field of display, and particularly relates to a display substrate, a preparing method of the display substrate and a display device. The display substrate comprises a display structure, electronic devices arranged on the two sides of the display structure and a basement film, wherein the display structure is connected with the basement film through a binding agent, and dredging holes are formed in the areas, corresponding to the electronic devices, of the basement film and used for dredging deformation of the binding agent. In the display substrate, a basement film in a back film is imaged relative to an IC bonding area, through holes are formed in the basement film of the IC bonding area, so that when hot-pressing bonding is carried out, pressure-sensitive adhesive in the back film can be deformed and overflowed from the dredging holes, it is avoided that as the pressure-sensitive adhesive flows and is sunk and warped to lateral corresponding places without bumps, a display screen is sunk and warped, ACF particle packing of a display-screen warping area and lateral contact of the adjacent IC bumps are avoided, and the IC short-circuit phenomenon and the circuit breaking phenomenon caused when the display screen is sunk and deformed are avoided.

Owner:BOE TECH GRP CO LTD

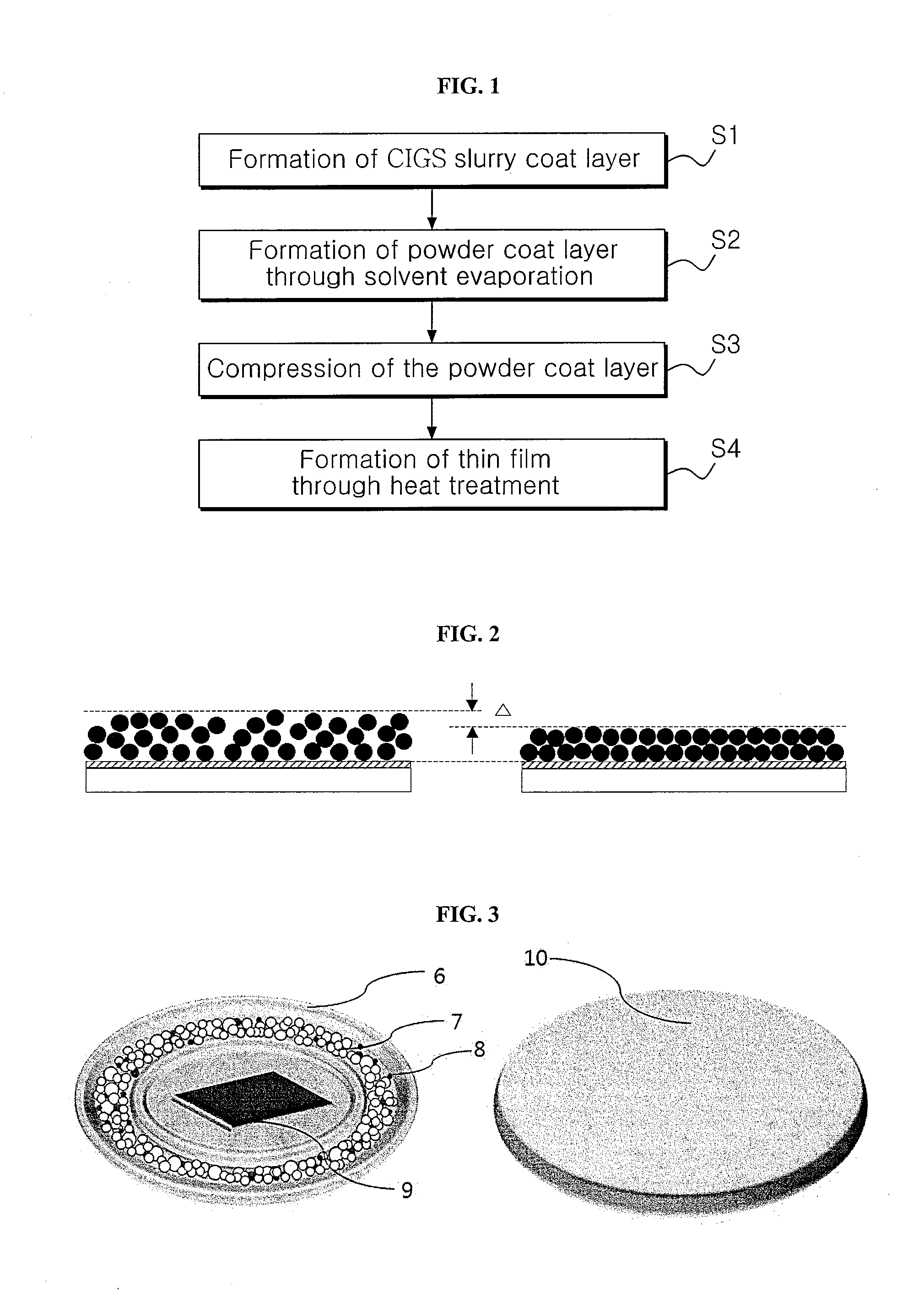

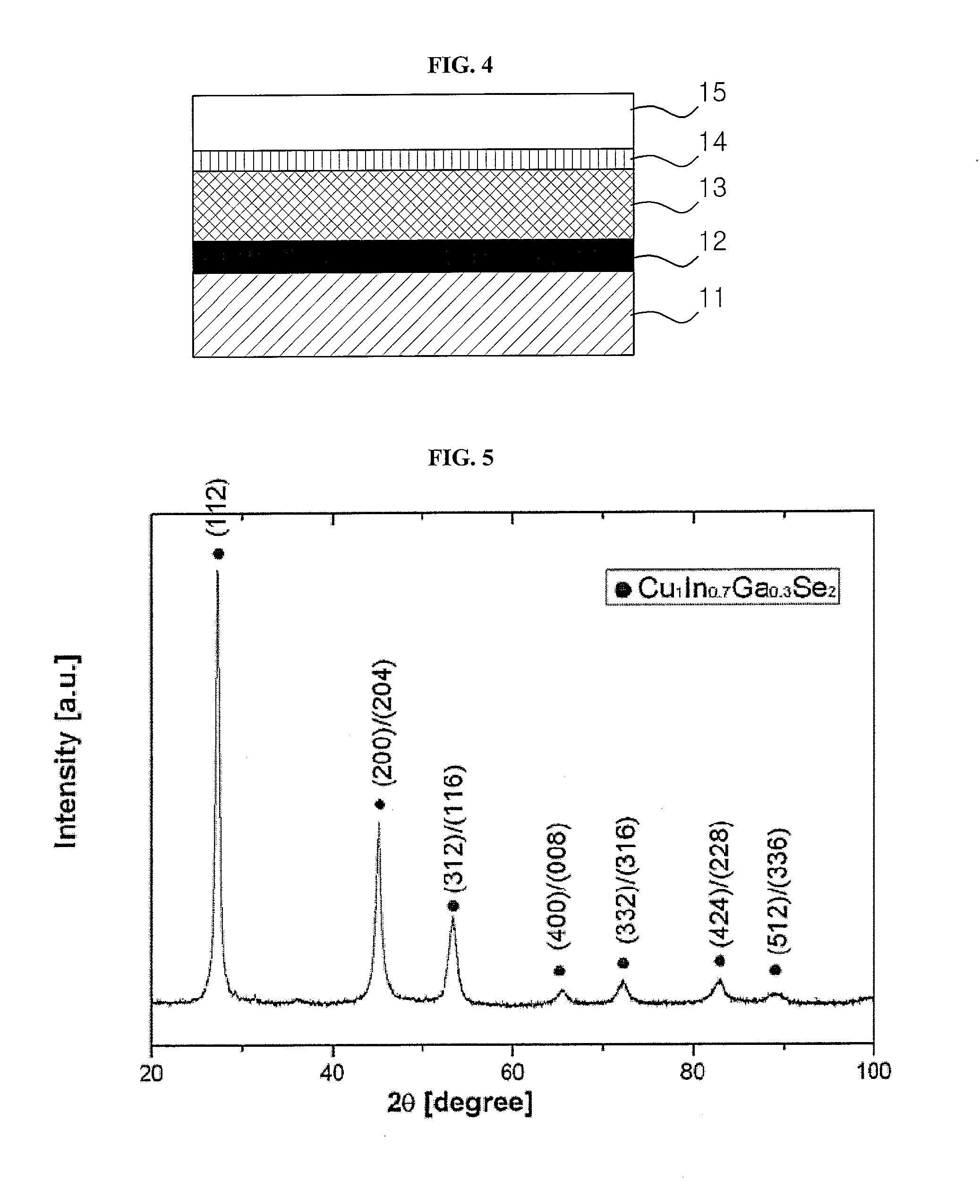

Method for producing thin-film light-absorbing layer and method for manufacturing thin-film solar cell including the same

ActiveUS20130048074A1Simple and highly and economicalImprove particle packing densityFinal product manufacturePretreated surfacesIndiumParticle packing

Disclosed is a method for producing a copper indium selenium (CIS) or copper indium gallium selenium (CIGS) thin-film light-absorbing layer. The method includes forming a coating layer of CIGS slurry, removing a solvent, a dispersant and a binder from the coating layer to form a powder coat layer, pressing the powder coat layer to improve its particle packing density, and heating the powder layer to form a dense thin film. The method uses a powder process as a non-vacuum process to produce a CIS or CIGS thin film in high yield at low cost. Further disclosed is a method for manufacturing a thin-film solar cell including the production method.

Owner:KOREA INST OF SCI & TECH

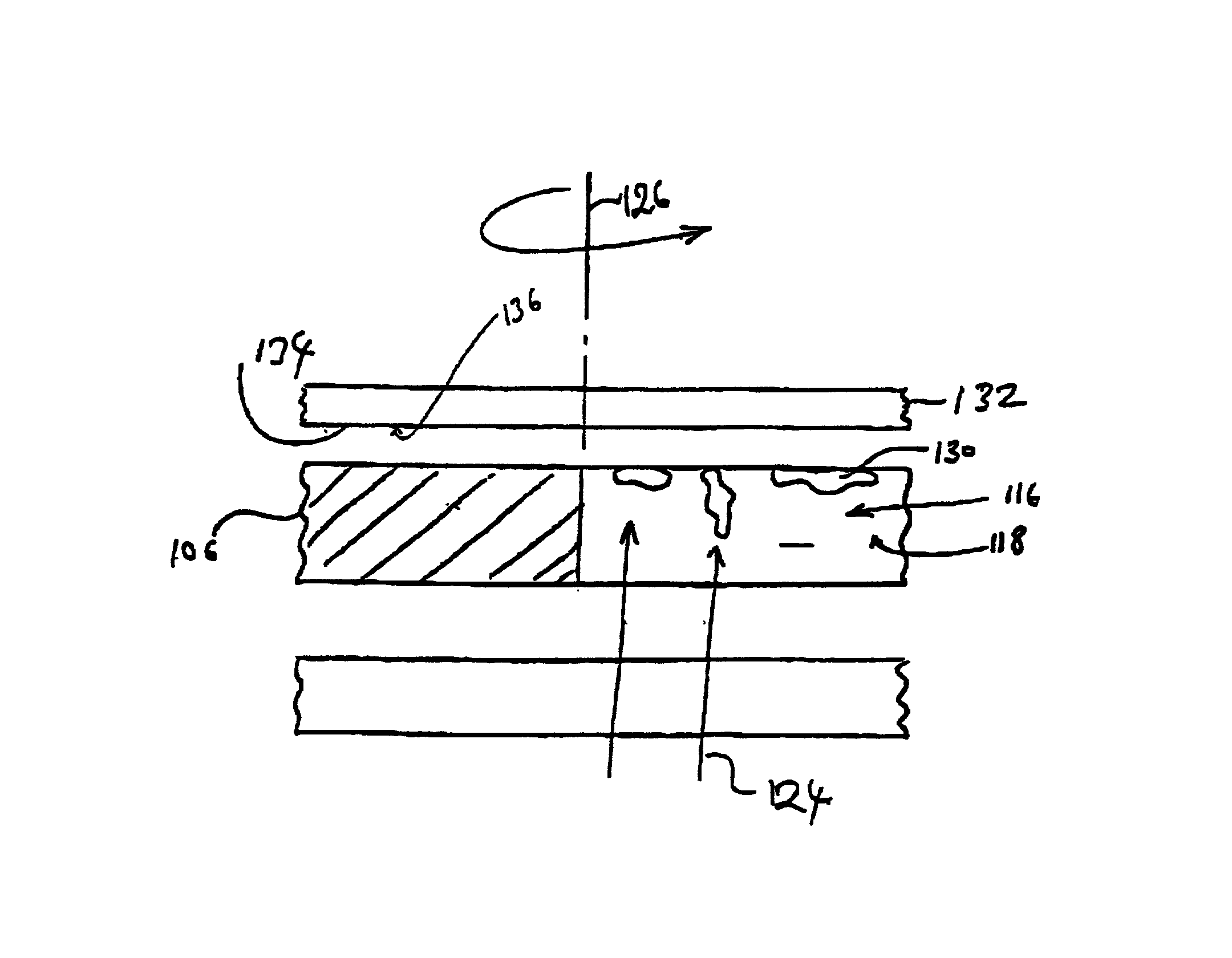

Method and apparatus for avoiding particle accumulation in electrodeposition

InactiveUS20020139682A1Reduce defectsEdge grinding machinesElectrolysis componentsMetal particleMaterials science

Systems and methods to remove or lessen the size of metal particles that have formed on, and to limit the rate at which metal particles form or grow on, workpiece surface influencing devices used during electrodeposition are presented. According to an exemplary method, the workpiece surface influencing device is occasionally placed in contact with a conditioning substrate coated with an inert material, and the bias applied to the electrodeposition system is reversed. According to another exemplary method, the workpiece surface influencing device is conditioned using mechanical contact members, such as brushes, and conditioning of the workpiece surface influencing device occurs, for example, through physical brushing of the workpiece surface influencing device with the brushes. According to a further exemplary method, the workpiece surface influencing device is rotated in different direction during electrodeposition.

Owner:NOVELLUS SYSTEMS

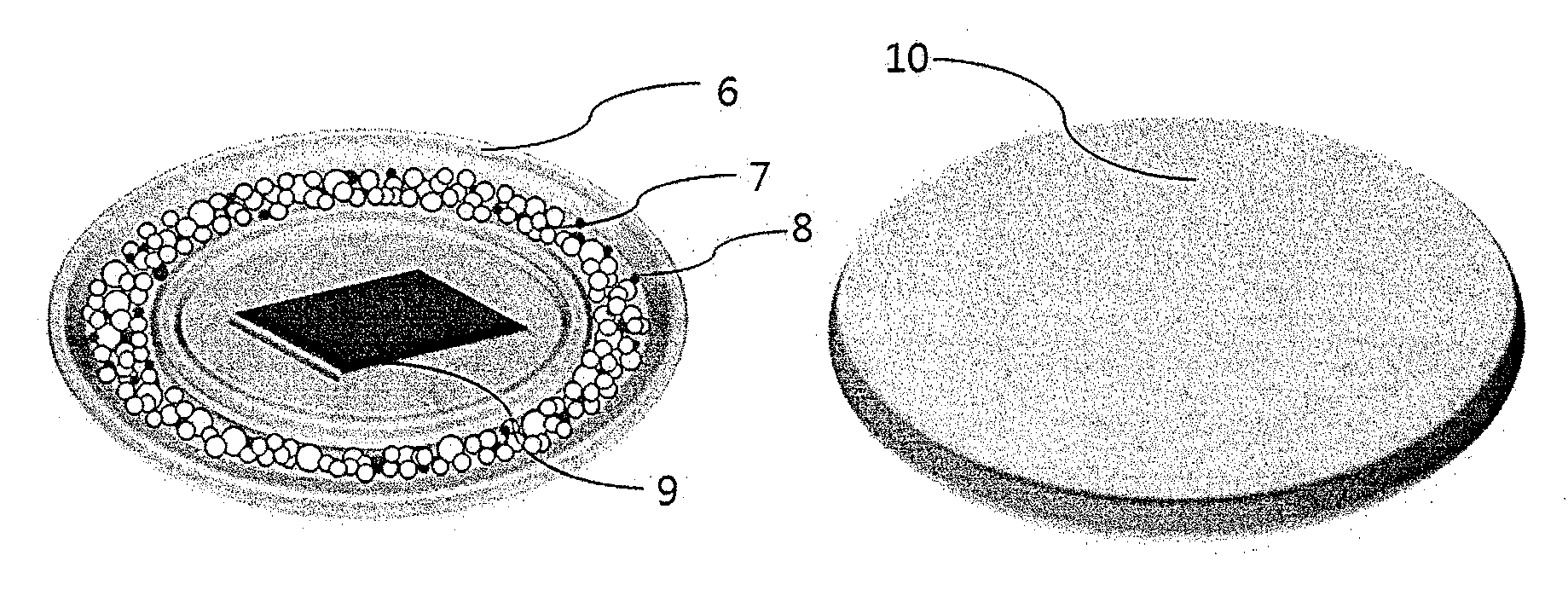

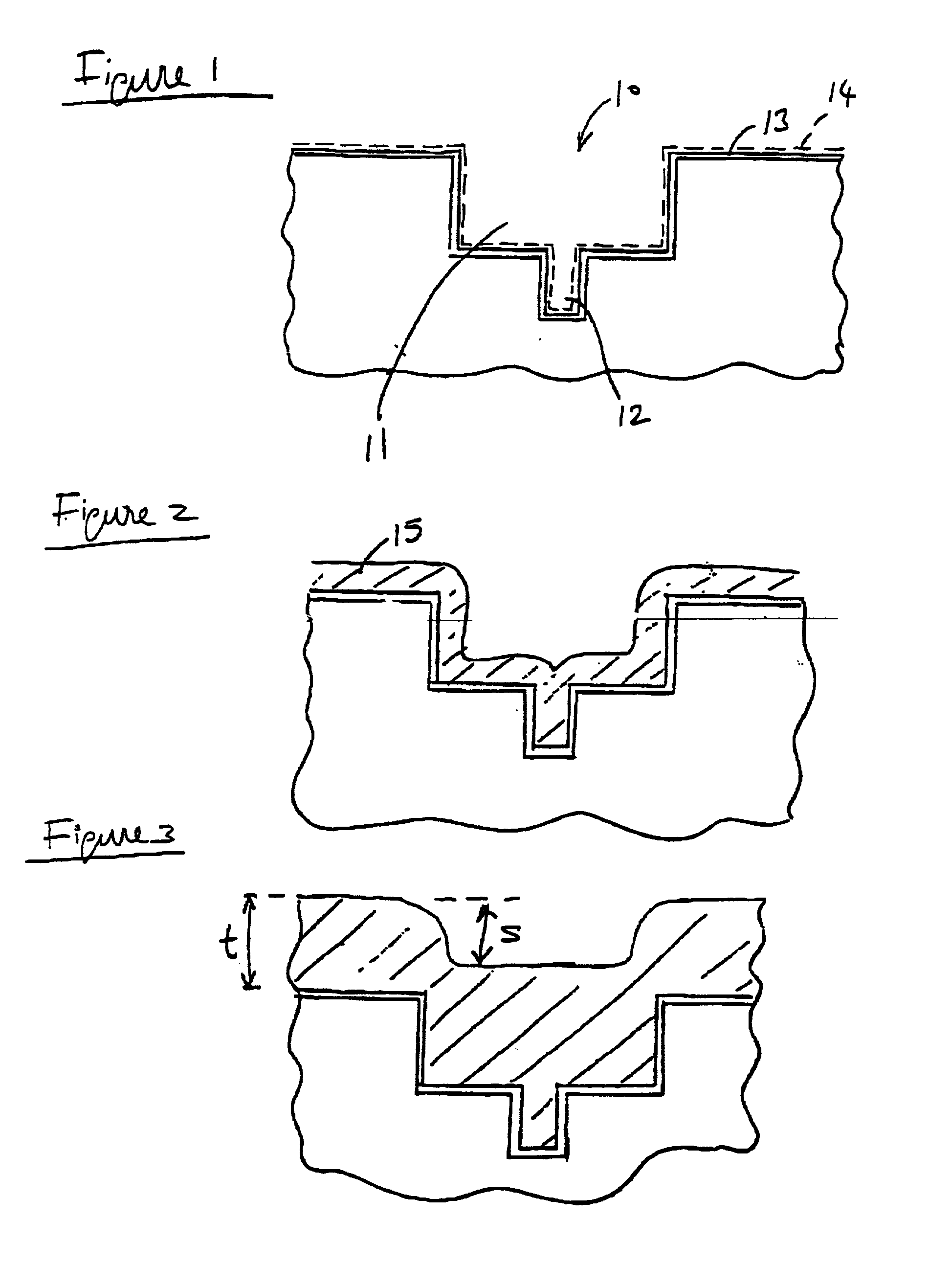

Dental all-ceramic restoration and manufacturing method thereof

ActiveUS20170231730A1Improve surface smoothnessIncrease success rateDental implantsImpression capsSurface finishParticle packing

A dental all-ceramic restoration and manufacturing method thereof; the outer surface of the dental all-ceramic restoration has neither visible marks remaining from the removal of the connecting bars (7) nor local grinding traces and chipping, and is smooth with uniform structure. The manufacturing method thereof is wet-forming or milling. No connecting bars are needed to connect the dental restoration bodies (3) with a surrounding mould blank or ceramic blank. This eliminates the need for manually cutting off the connecting bars (7) to separate the forming body from the surrounding ceramic blank, further grinding and polishing process to treat the excessively rough outer surface, and thereby reducing the risk of chipping and premature failure. In the manufacturing processes thereof, the hardened ceramic green body (2) made by wet-forming technique has more homogenous microstructure and less particle packing defects than the dry-pressed blanks and partially sintered blanks. Furthermore, higher surface smoothness can be obtained by milling unsintered hardened ceramic green body than by milling partially sintered blanks. The dental all-ceramic restoration has a high degree of surface finish, and can be directly used without polishing, veneering or glazing.

Owner:HANGZHOU ERRAN TECH

Pore character statistics method of microscopic pore model on basis of improved maximum ball method

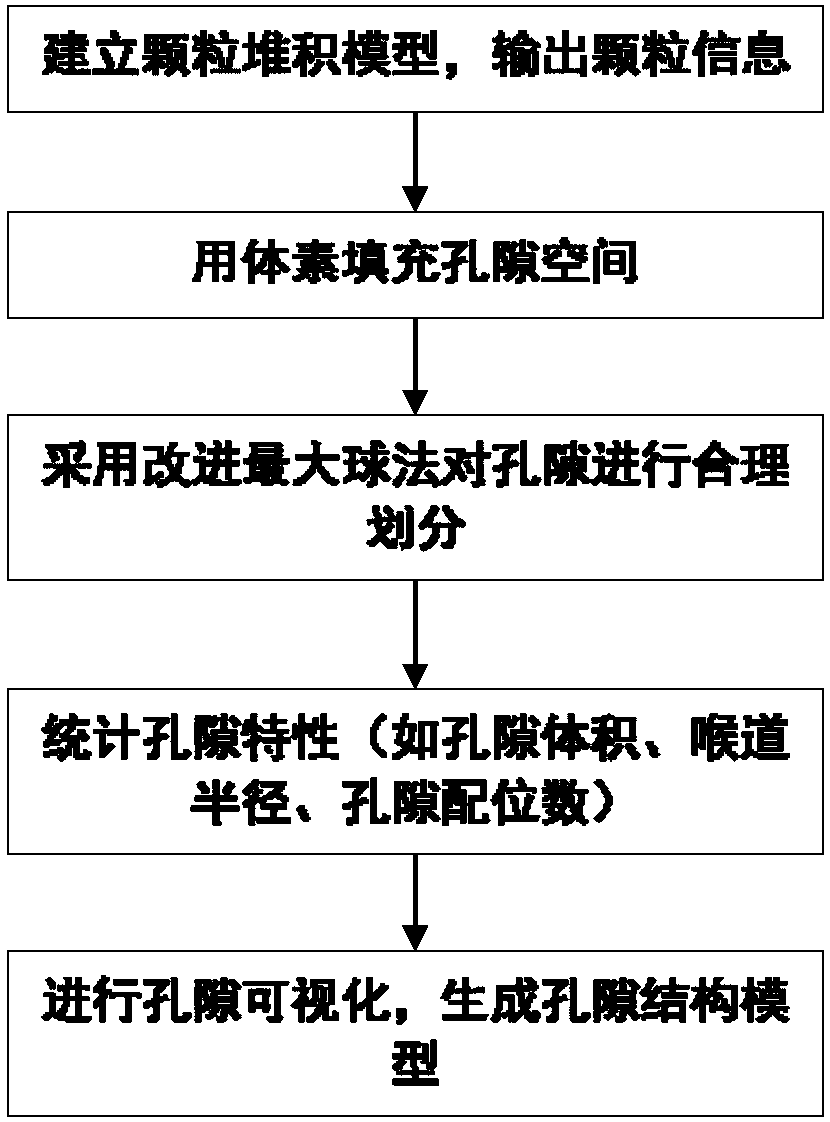

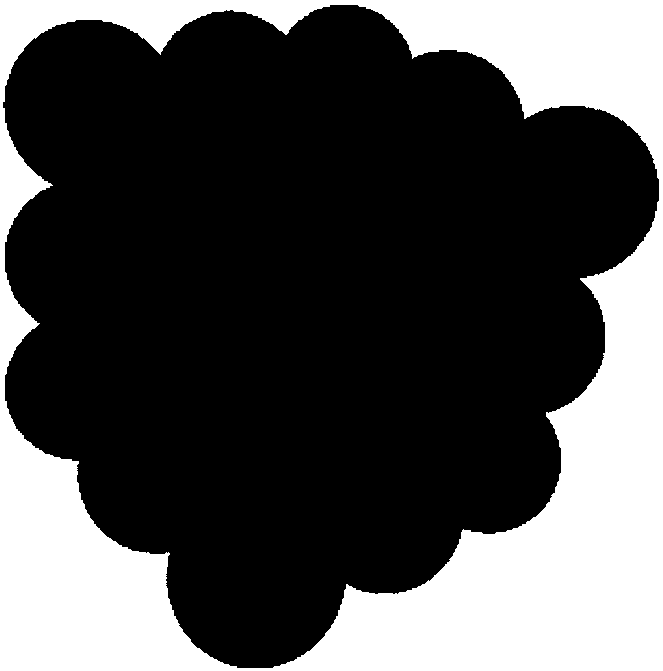

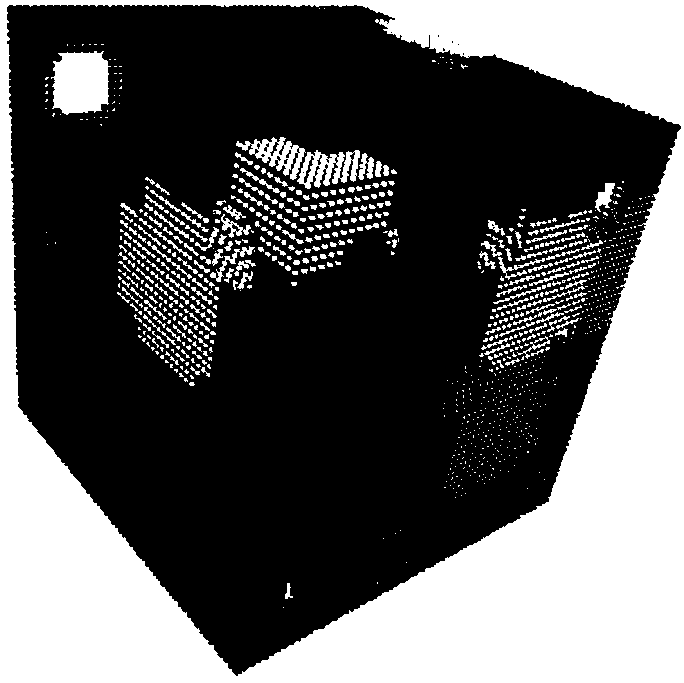

InactiveCN108491677AHigh degree of visualizationEasy to operateDesign optimisation/simulationSpecial data processing applicationsThroatVoxel

The invention discloses a pore character statistics method of a microscopic pore model on the basis of an improved maximum ball method, and belongs to the technical field of geotechnical engineering.The method comprises the following steps that S01, a particle accumulation module is built, and accumulated particle information is output; S02, a pore space of the particle accumulation module is filled with voxel particles; S03, the improved maximum ball method is adopted, a pore of the pore space is reasonably divided; S04, pore characters are counted, wherein the pore characters comprise the pore size, the throat radius and the pore coordination number; S05, pore visualization is conducted, and the pore structure model is generated. According to the pore character statistics method of themicroscopic pore model on the basis of the improved maximum ball method, compared with a test method, numerical simulation has the advantages of being high in repeatability, unlimited to instrument size, low in cost and capable of comprehensively counting various pore characters.

Owner:HOHAI UNIV

Animal particle packing as well as production method and application of animal particle packing

The invention belongs to the technical field of experimental animal feeding and particularly relates to an animal particle packing as well as the production method and the application of the animal particle packing. The animal particle packing is prepared by mixing birch wood shavings or poplar shavings, rice bran and activated carbon according to the mass ratio of 80:15:5. The packing has the advantages of strong moisture absorption, small powder dust and strong deodorization ability, the feeding environment of an animal house is improved, and the birthing quality of animals is improved.

Owner:江苏省协同医药生物工程有限责任公司

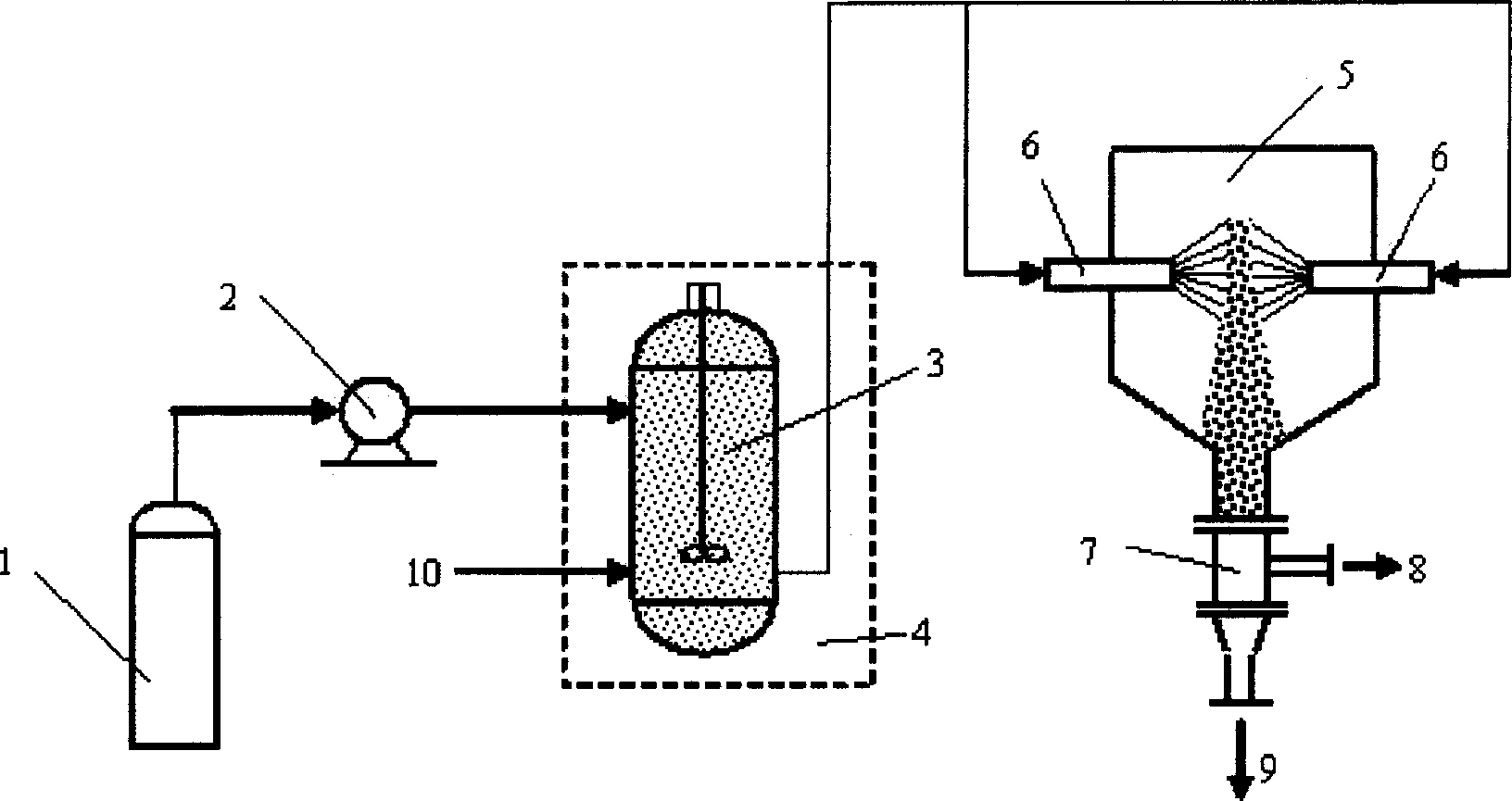

Supercritical impact flow method for wrapping micro granule

InactiveCN1879957AIncrease resistanceReduce resistanceMicroballoon preparationMicrocapsule preparationParticle packingPaper production

The invention relates to a ultra-critical impact flow particle packing method, which is characterized in that: adding the wall material into the mixer to be dissolved into solution; mixing and dispersing the particle uniformly, to form suspension; using a couple of coaxial nozzles to output the wall material to be deposited on the surface of packed particle to form the coat, and separated by the separator to obtain the micro capsule product. The invention can combine the advantages of present packing fluid bed packing method and impact flow method, to be used in food industry, paper production, etc.

Owner:DALIAN UNIV OF TECH

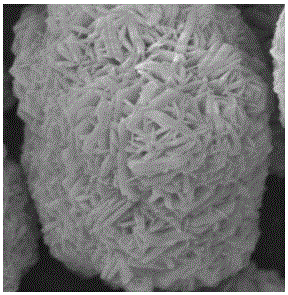

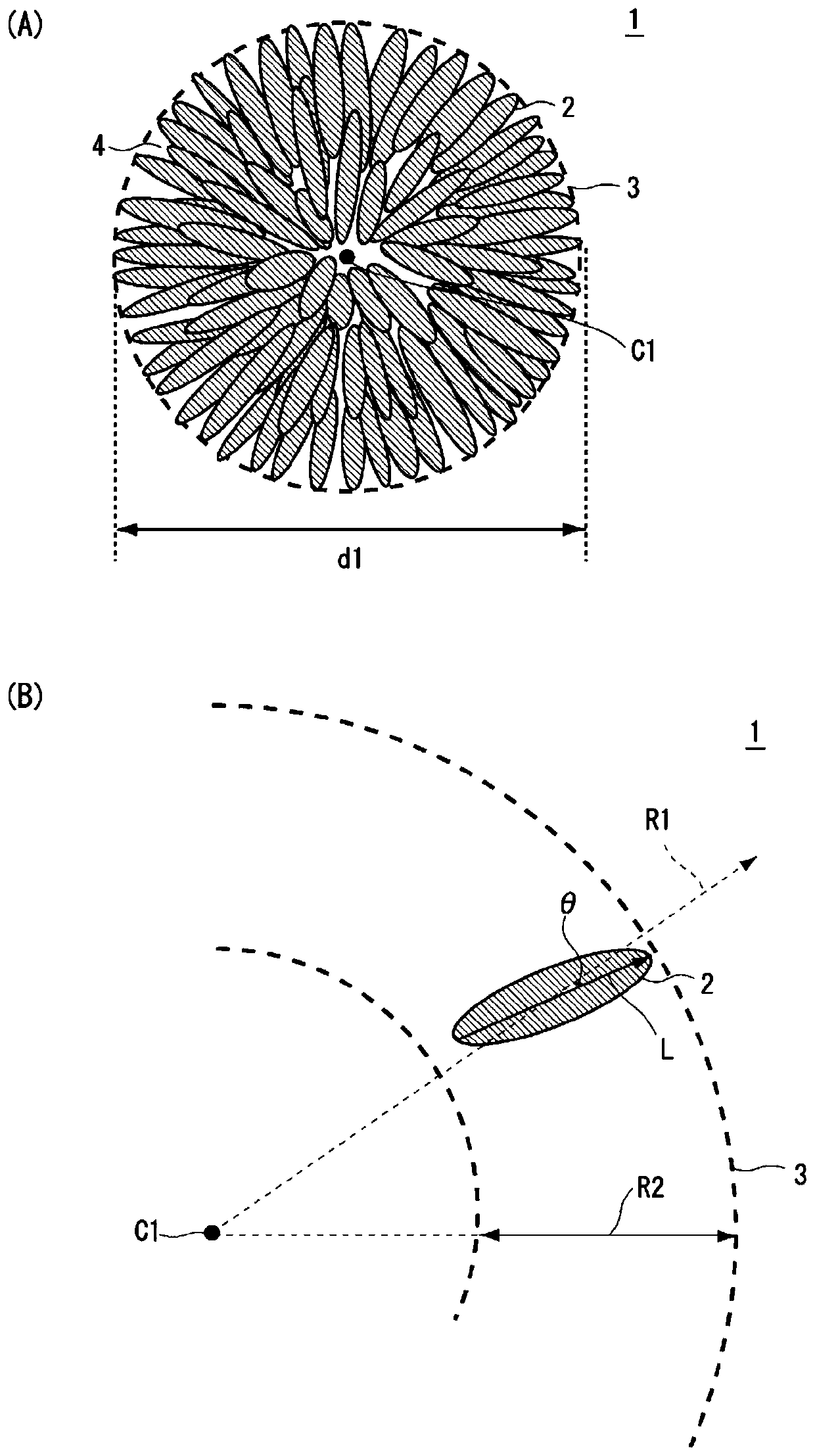

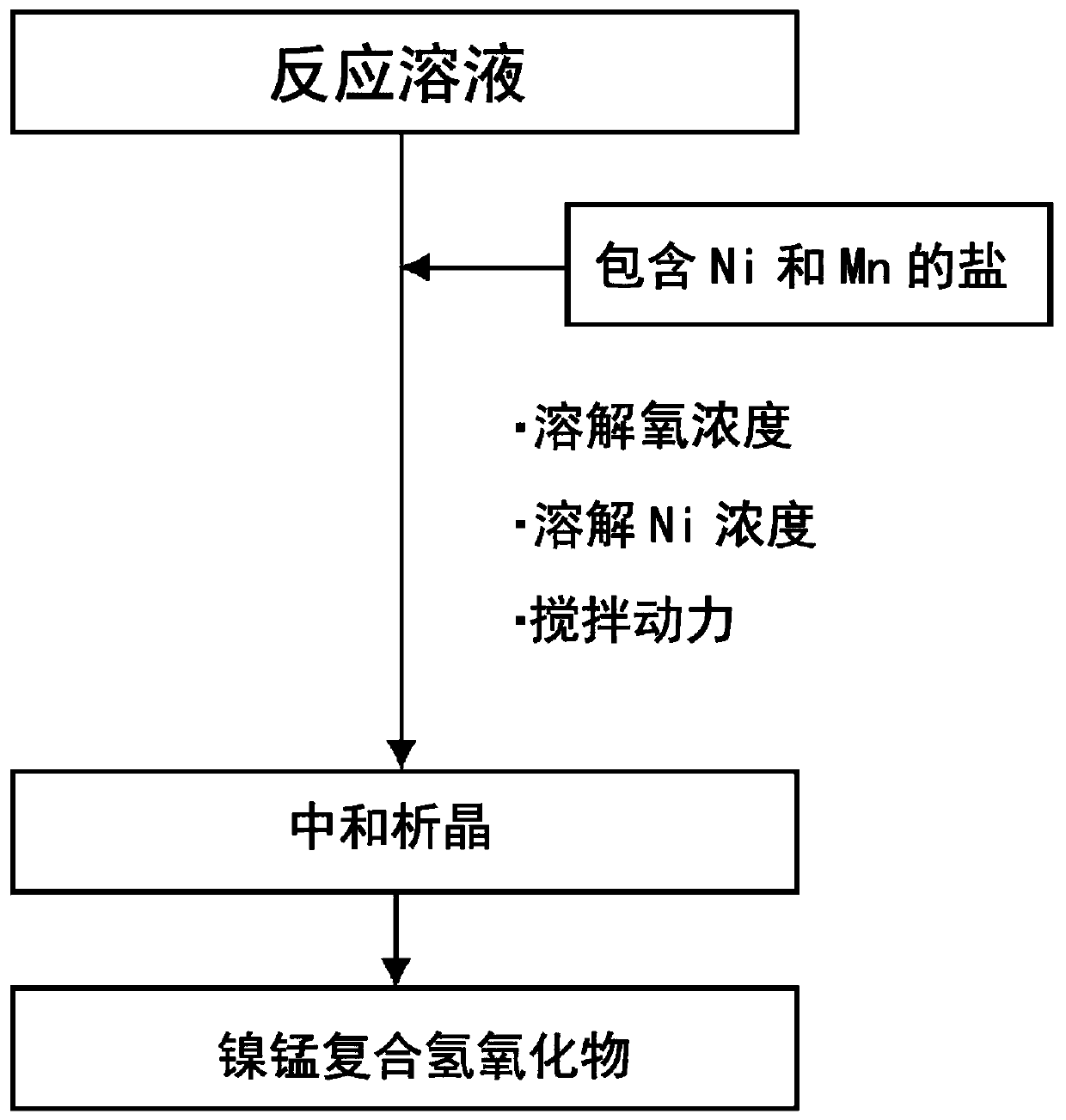

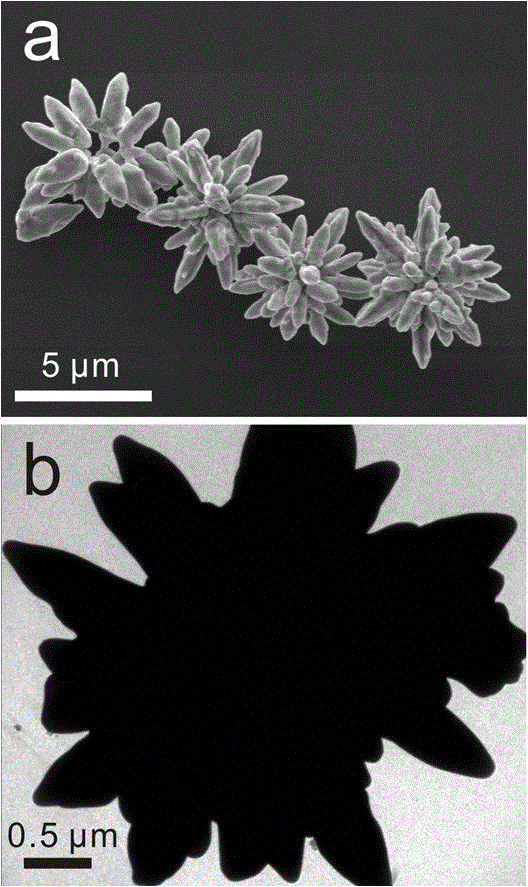

Nickel manganese composite hydroxide and method for producing same, positive electrode active material for nonaqueous electrolyte secondary battery and method for producing same, and nonaqueous electrolyte secondary battery

ActiveCN109803927AIncrease capacityImprove output characteristicsSecondary cellsPositive electrodesElectrical batteryParticle packing

The purpose of the present invention is to provide a nickel manganese composite hydroxide and method for producing the same, etc., which when used as a precursor for a positive electrode active material, allows a secondary battery to be obtained that has a high particle packing capability and excellent battery characteristics. The present invention provides a nickel manganese composite hydroxide and method for producing the same, the nickel manganese composite hydroxide being represented by the general formula, Ni<x>Mn<y>M<z>(OH)<2>+[alpha], and including secondary particles in each of which aplurality of primary particles are aggregated, wherein the primary particles have an aspect ratio of 3 or more, at least a portion of the primary particles are radially arranged in a direction from the center toward the circumference of the secondary particle, and the secondary particles are such that the ratio I(101) / I(001) of the diffraction peak intensity I(101) of the 101 plane to the peak intensity I(001) of the 001 plane by X-ray diffraction measurement is 0.15 or less.

Owner:SUMITOMO METAL MINING CO LTD

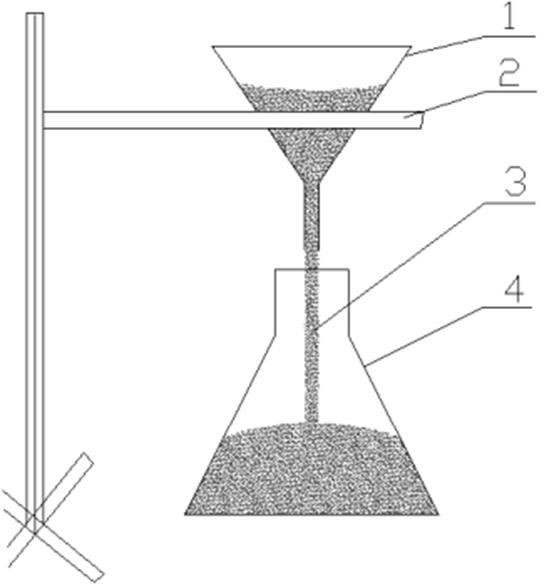

Method for testing particle packing density of concrete used powder

The invention provides a method for testing the particle packing density of concrete used powder, and the tight particle packing density degree of the concrete used powder can be tested through the ratio of the absolute volume of the mixing powder and the packing volume of powder in slurry. The method provided by the invention is simple to operate, scientific, and closer to the practical application condition, and can provide better guidance for the mix design of concrete.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

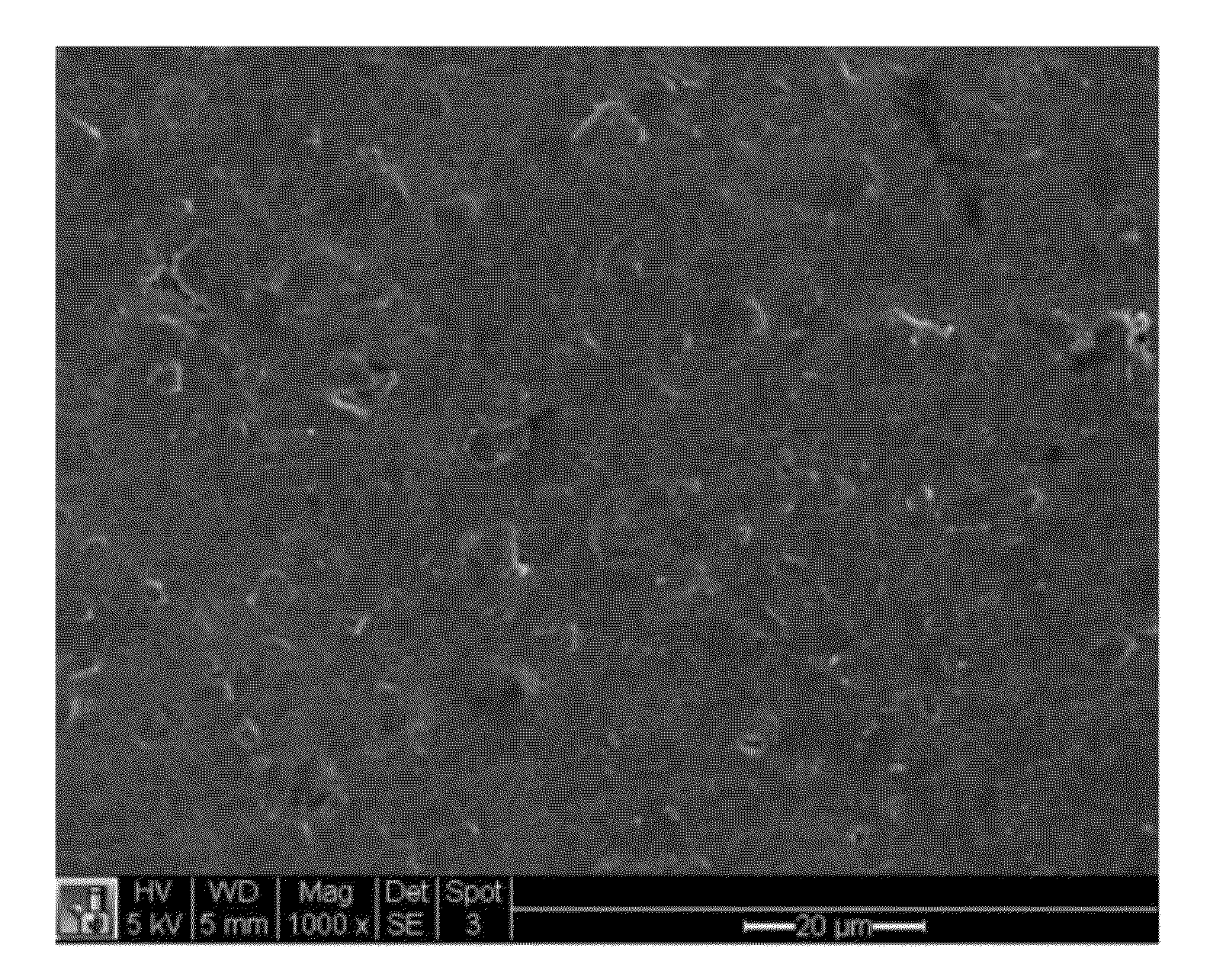

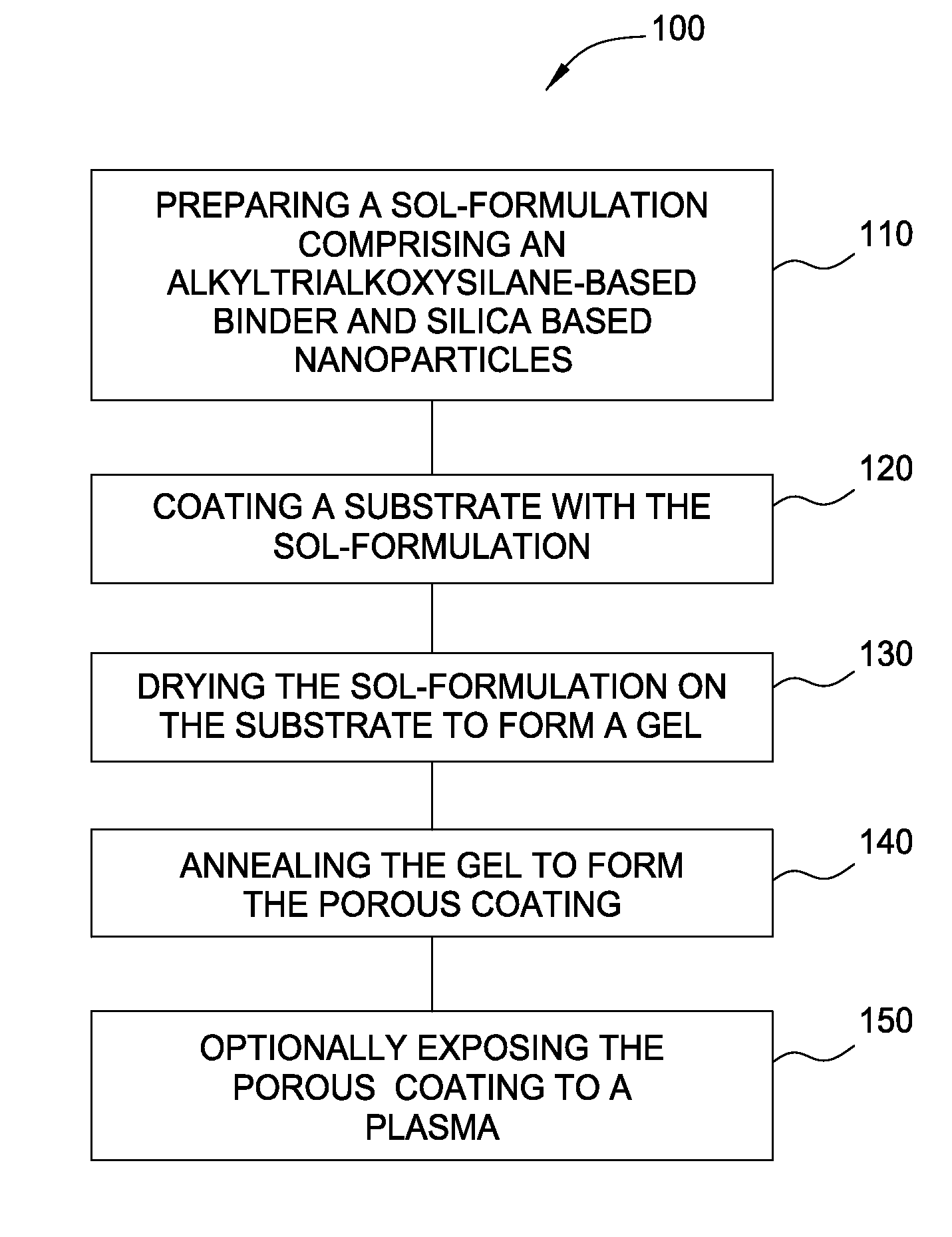

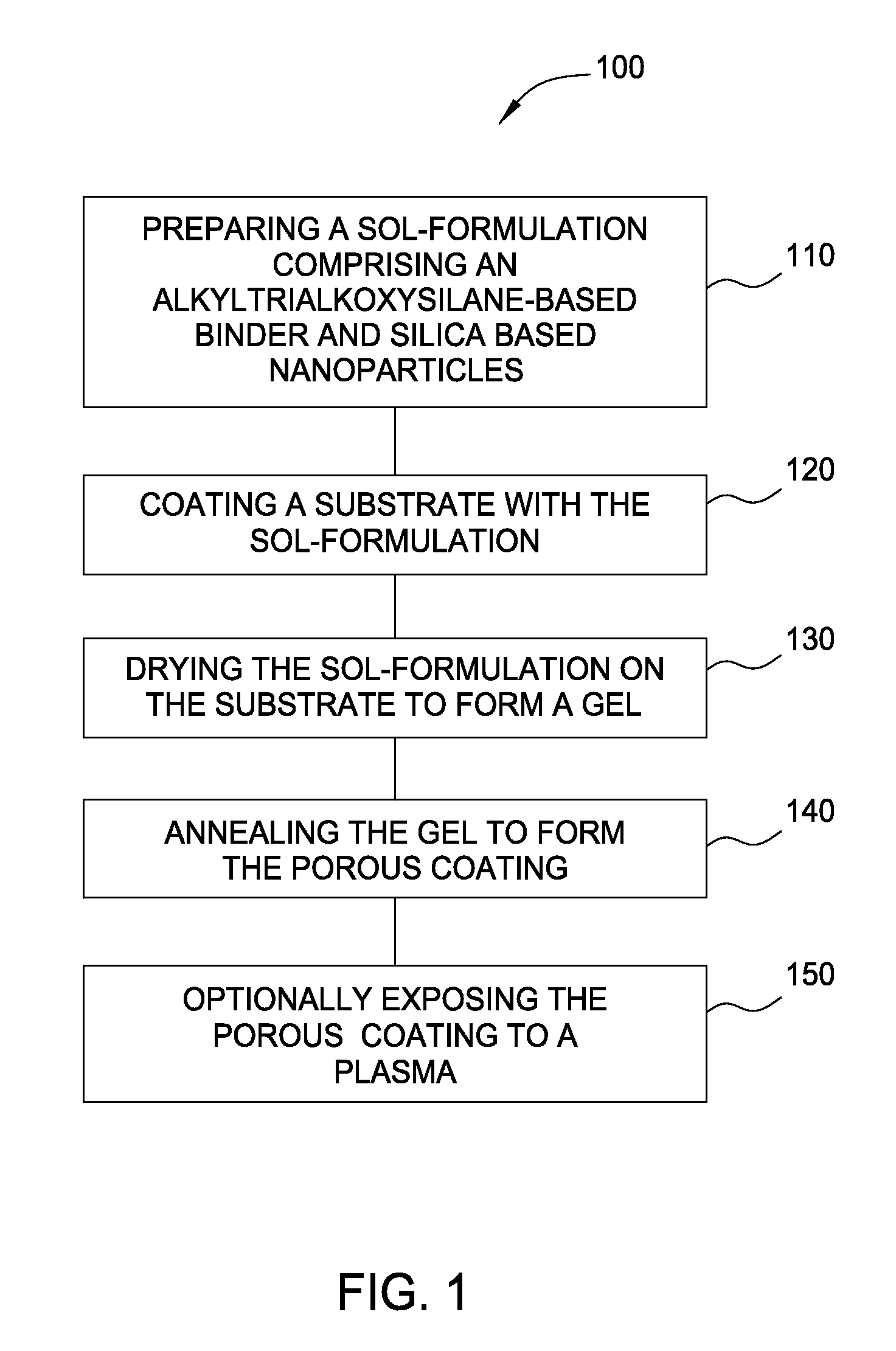

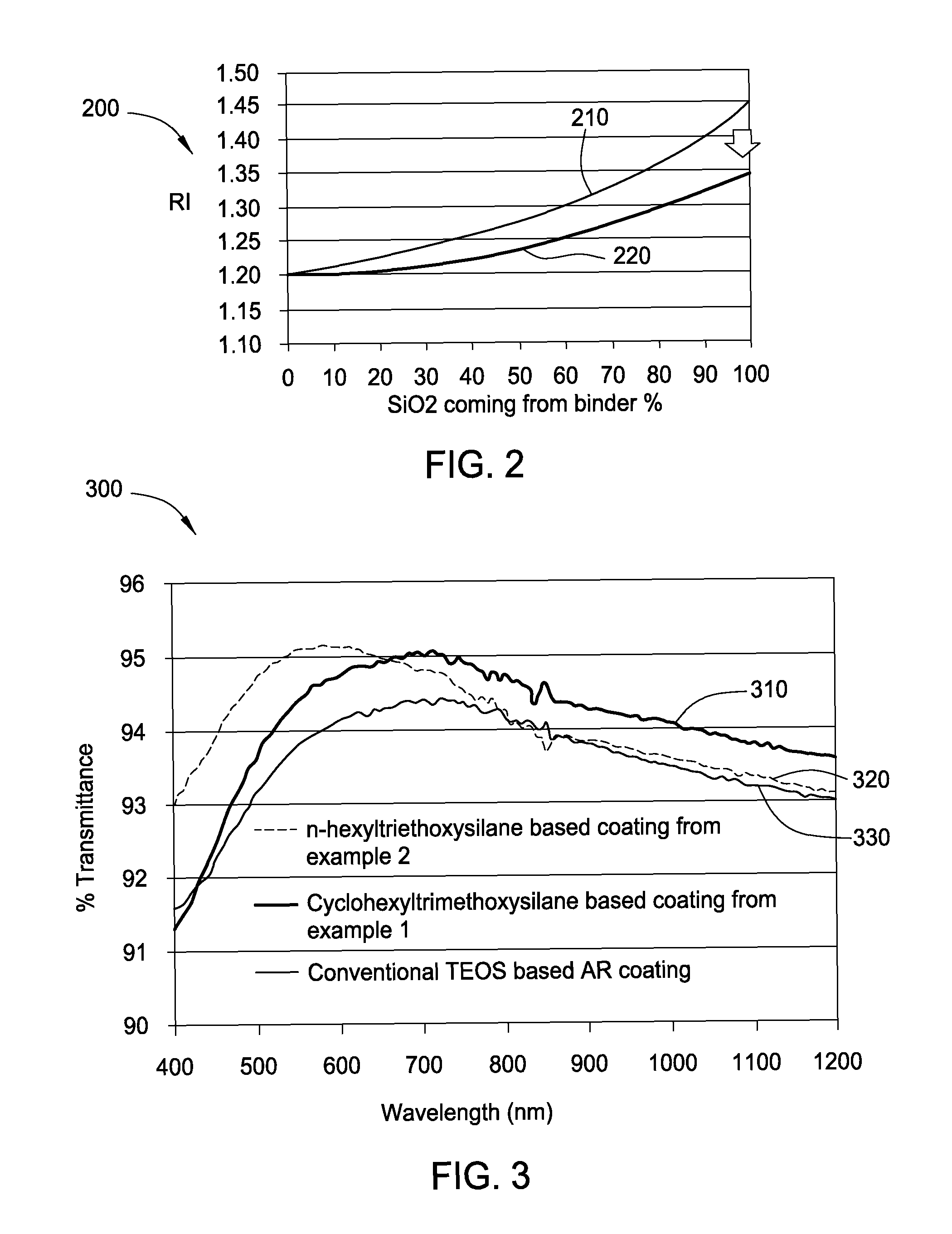

Sol-gel based antireflective coatings using alkyltrialkoxysilane binders having low refractive index and high durability

ActiveUS9109121B2Anti-reflective coatingsElectrostatic spraying apparatusAnti-reflective coatingPore distribution

Owner:GUARDIAN GLASS LLC

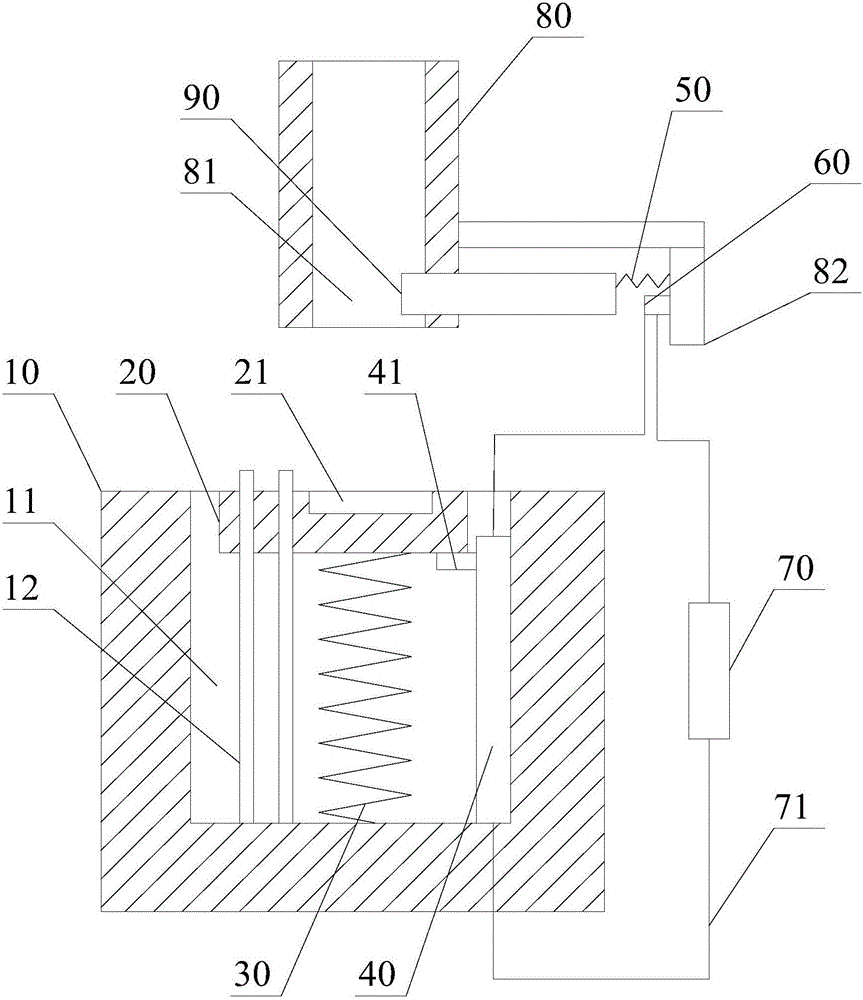

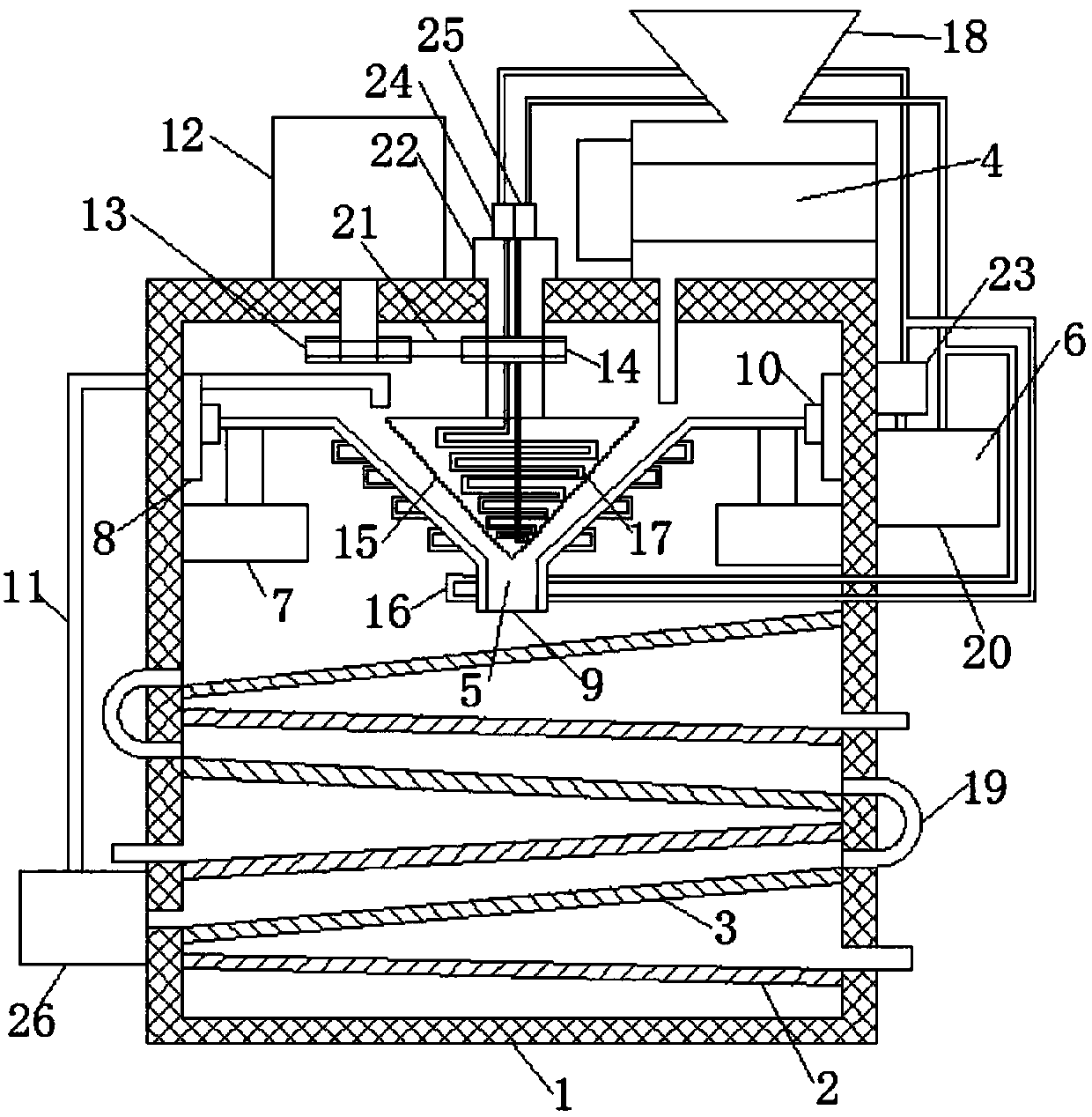

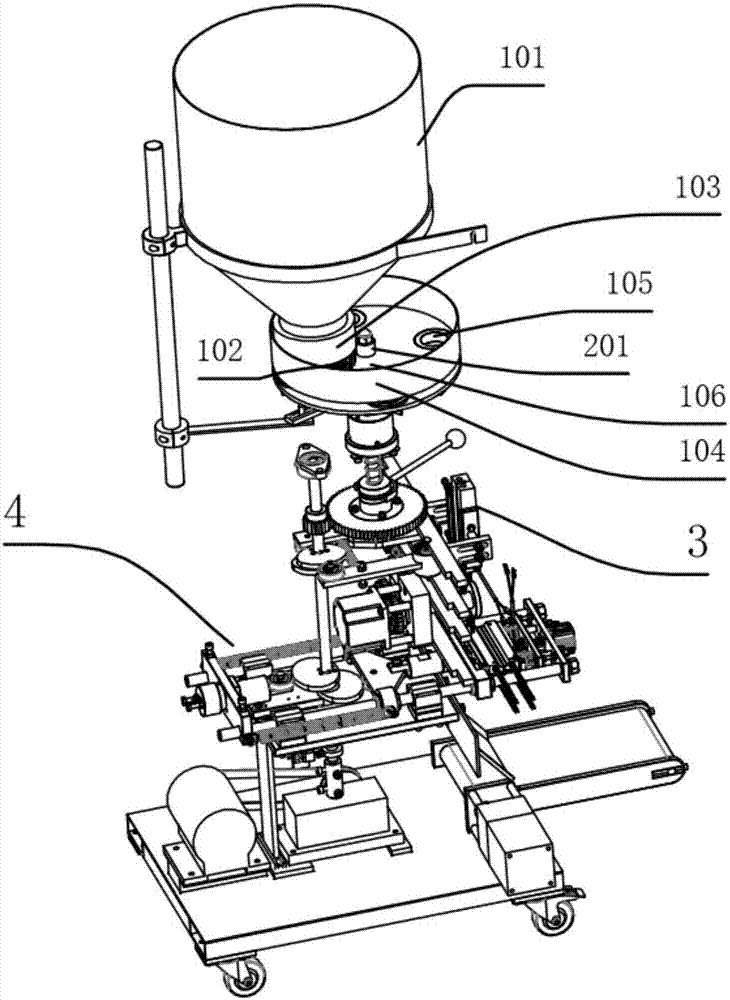

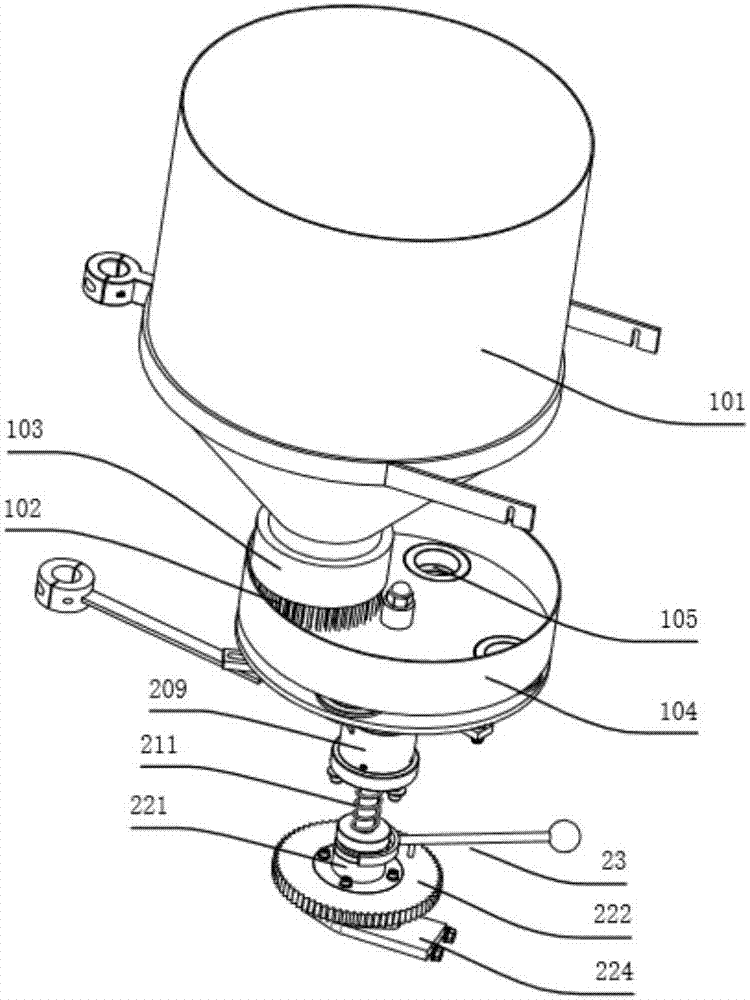

Plastic particle packing device

InactiveCN106516187ASlide up and down smoothlyHigh working reliabilityPackaging automatic controlSolid materialParticle packingMechanical engineering

The invention discloses a plastic particle packing device. A containing groove is formed in the upper surface of a base. A supporting plate is arranged in the containing groove in an up-down sliding mode. A supporting spring is arranged in the containing groove. One end of the supporting spring is connected with the supporting plate, and the other end of the supporting spring is connected with the bottom face of the containing groove. A feeding barrel is arranged over the supporting plate, and an opening of the end of the feeding barrel is right opposite to the supporting plate. A baffle is made of magnetic metal and arranged on the opening of the end of the feeding barrel in a sliding mode. A fixing plate is fixedly arranged on the periphery face of the feeding barrel. A driving spring is arranged between the fixing plate and the baffle, so that the baffle is away from the fixing plate, and seals the opening of the end of the feeding barrel. An electromagnet is arranged on the side, close to the baffle, of the fixing plate and right opposite to the baffle. A power supply device is connected with the electromagnet through a cable. A slide rheostat is connected to the cable and located in the containing groove, and the sliding part of the slide rheostat makes contact with the bottom face of the supporting plate. According to the plastic particle packing device, overweight of plastic particles in a container can be avoided.

Owner:重庆明杰塑胶有限公司

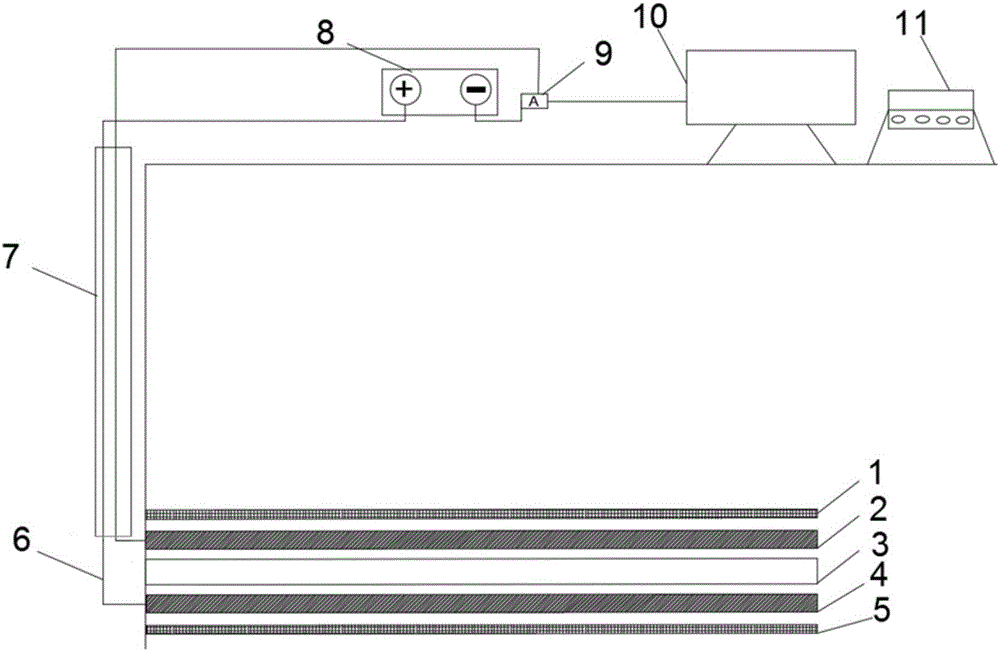

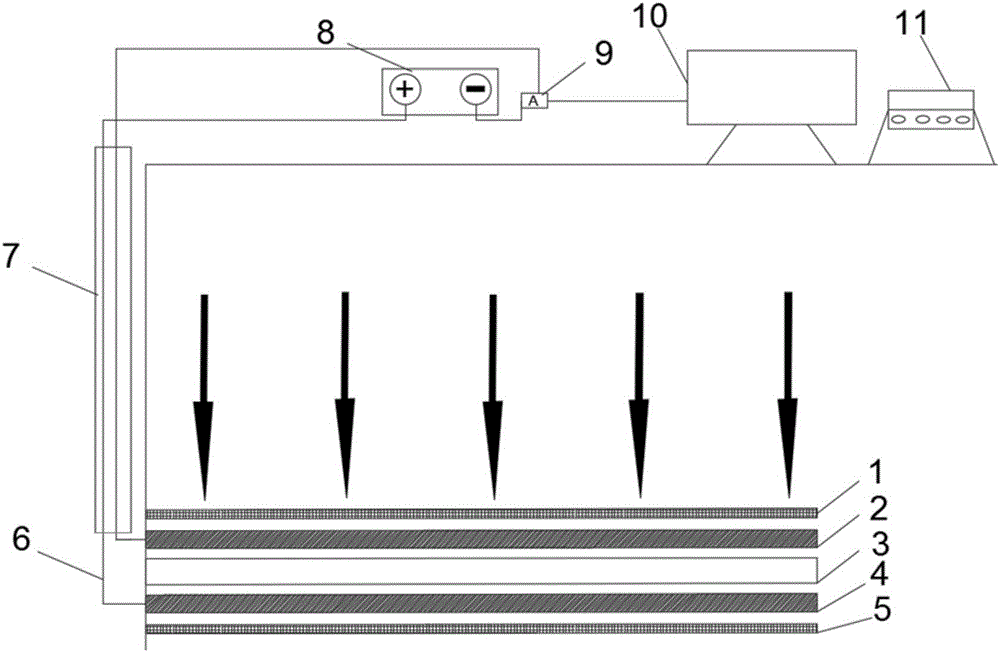

Landfill seepage-proof system for prolonging breakdown time of heavy metal irons and breakdown monitoring method

ActiveCN106759527ANo conductive failureControl impact migrationProtective foundationPermeability/surface area analysisEngineeringPollution

The invention discloses a landfill seepage-proof system for prolonging breakdown time of heavy metal irons and a breakdown method. The system comprises a seepage-proof cushion layer, a number direct current power supply, an electric current sensor, a computer and an alarming device. The seepage-proof cushion layer comprises a lower outer layer high-density polyethylene geomembrane, a lower conductive geotextile, a middle swelling clay layer, an upper conductive geotextile and an upper outer layer high-density polyethylene geomembrane. The upper conductive geotextile is connected with a negative pole of the number direct current power supply to serve as a cathode. The lower conductive geotextile is connected with a positive pole of the number direct current power supply to serve as an anode. Electric field force is applied to the middle seepage-proof cushion layer through the upper conductive geotextile and the lower conductive geotextile, so that the pollution irons of heavy metal and the like move reversely, and accordingly, the service life of the seepage-proof cushion layer is greatly prolonged. A microstructure of the middle swelling clay layer changes into a particle packing structure from an original flocculent structure under the effect of the electric field force, so that the transportation and diffusion of pollutants are better prevented.

Owner:ZHEJIANG UNIV

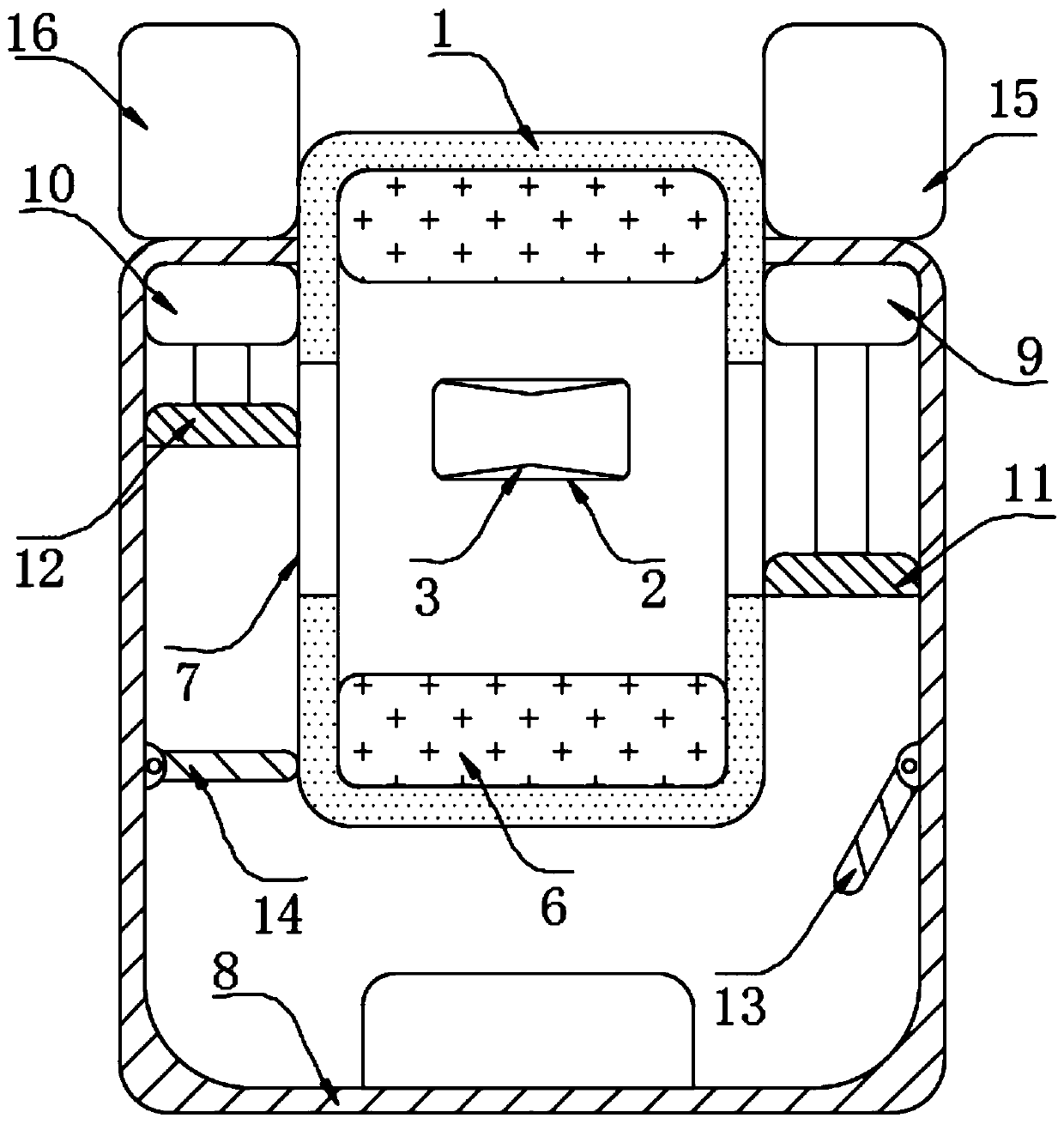

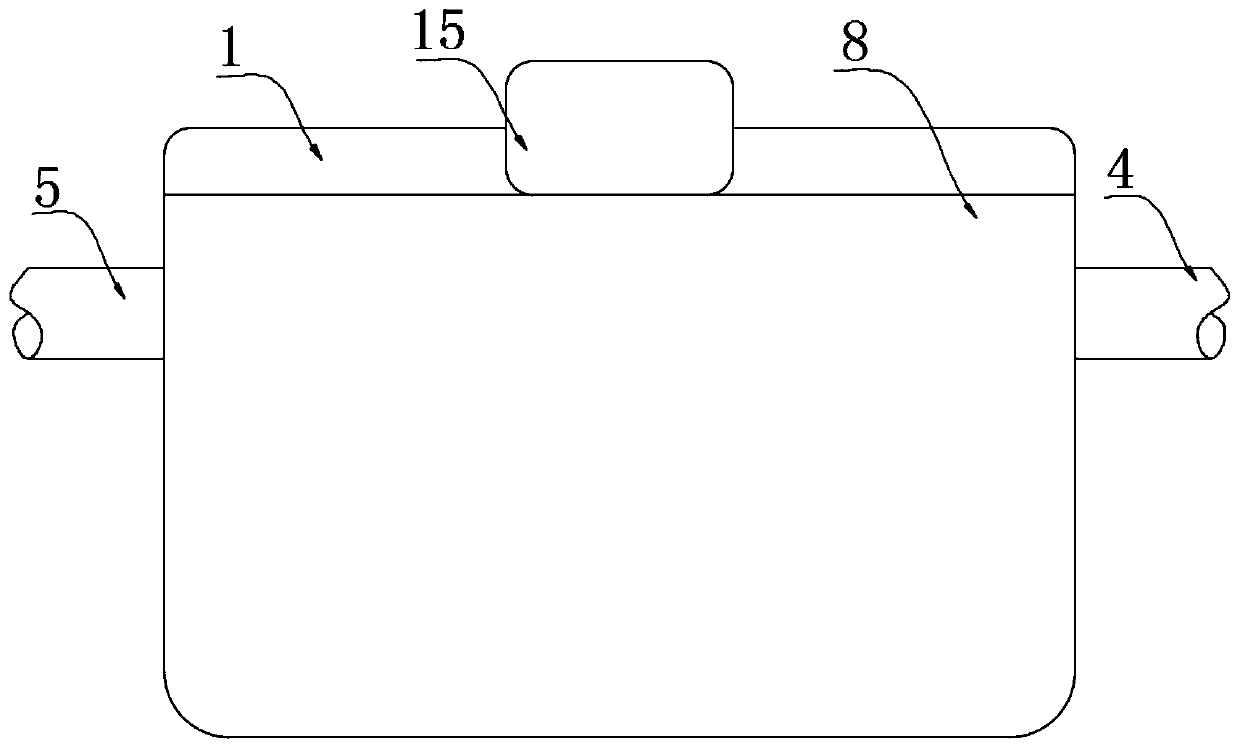

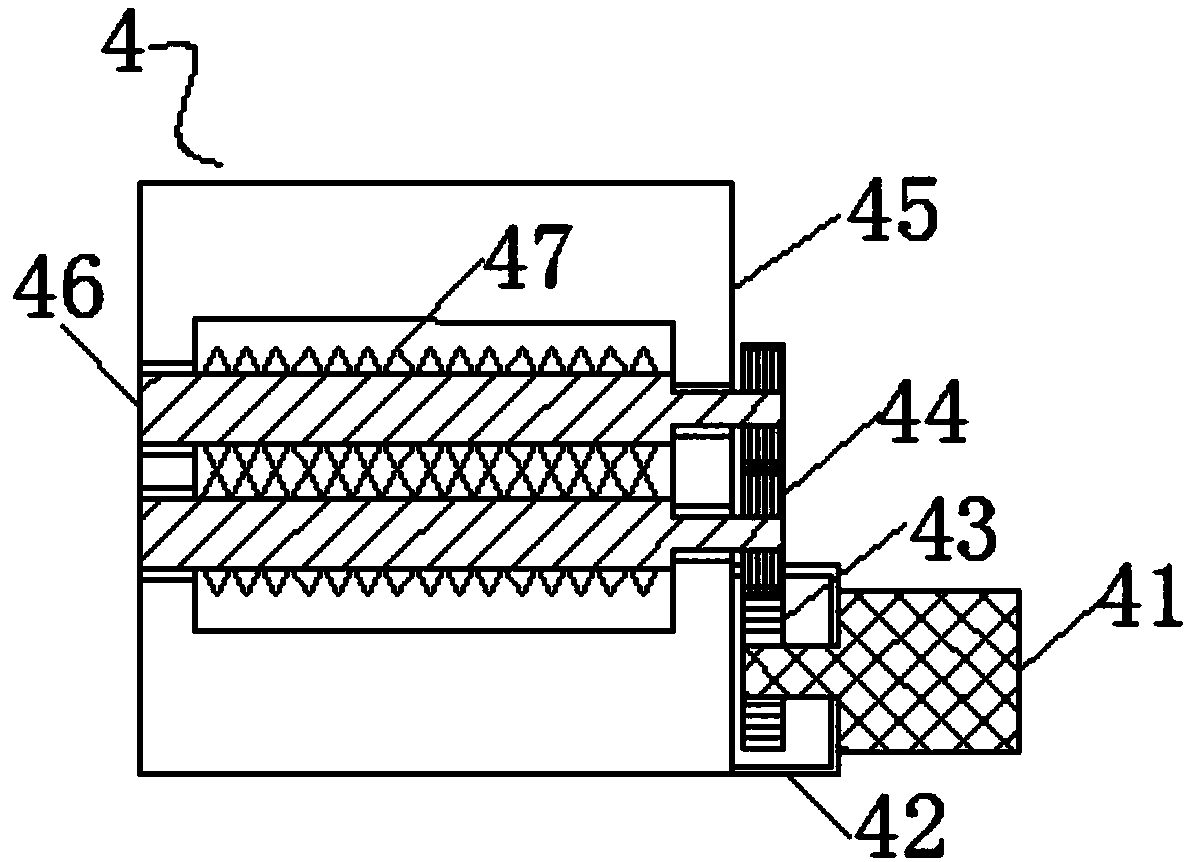

Electromagnetic dust collector

InactiveCN111468294AEasy to separateEasy to separate and collectExternal electric electrostatic seperatorElectric supply techniquesElectric machineParticle packing

The invention discloses an electromagnetic dust collector which comprises a treatment box and an electrostatic generator; an air inlet is formed in the side wall of the treatment box in a penetratingmanner; a discharge sheet is fixed on the inner wall of the air inlet; an air inlet pipe and an air outlet pipe are fixed on the two symmetrical side walls of the treatment box in a penetrating mode correspondingly; two electromagnets are symmetrically fixed on the inner wall of the upper end and the inner wall of the lower end of the treatment box; deflection grooves are formed in the inner wallsof the two sides of the treatment box in a penetrating mode correspondingly; a collecting box is fixed on the exterior of the treatment box, and a collecting and separating mechanism is arranged in the collecting box. The electromagnetic dust collector has the advantages that along with the rotation of a motor in the control box, a positive electricity partition plate and a negative electricity partition plate alternately move; and impurity particles in the air flow also deflect towards the two sides alternately, so that when the particles deflect towards one side, the particles collected atthe other side can stably fall to the inner bottom of the collecting box without being influenced by wind pressure, and the collecting process of the particles is not influenced by particle accumulation.

Owner:卢兰

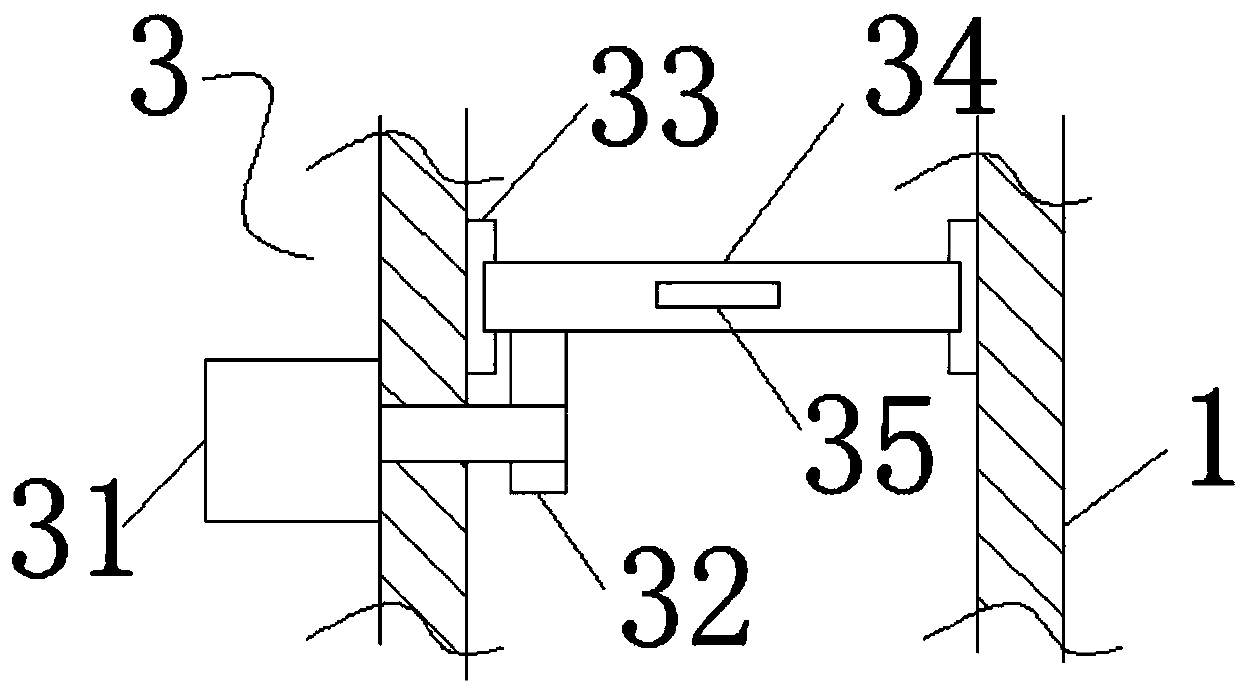

Energy-saving and environment-friendly plastic grinding equipment

InactiveCN111347593AAdjustable sizePrevent burning and deteriorationSievingScreeningParticle packingEngineering

The invention discloses energy-saving and environment-friendly plastic grinding equipment in the field of grinding equipment. The energy-saving and environment-friendly plastic grinding equipment comprises a box and a cooling device. A rotating shaft and a crushing device are arranged at the top of the box. A feeding funnel is arranged at the top of the crushing device. The lower end of the crushing device penetrates through the top wall of the box. The lower end of the rotating shaft penetrates through the top wall of the box to be provided with a grinding roller. A lower grinding device is arranged in an inner cavity of the box and is located below the grinding roller. Screening devices are arranged in the inner cavity of the box, the number of the screening devices is three sets, the screening devices are located below the lower grinding device, and guide plates are arranged below the three sets of screening devices. A lifter is arranged on the left side wall of the box. By means ofthe energy-saving and environment-friendly plastic grinding equipment, the grinding time is reduced, the sizes of grinding particles are adjusted, the situation that particles are scorched and go badis avoided through device cooling, plastic particles in limited intervals are screened out, and the situation that screens are blocked by particle accumulation is avoided through screen vibration.

Owner:张欣欣

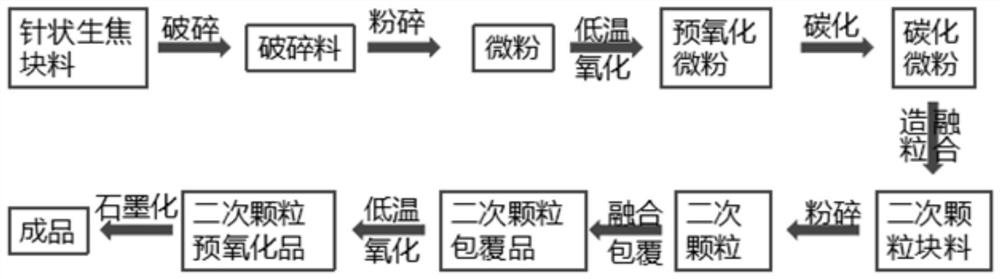

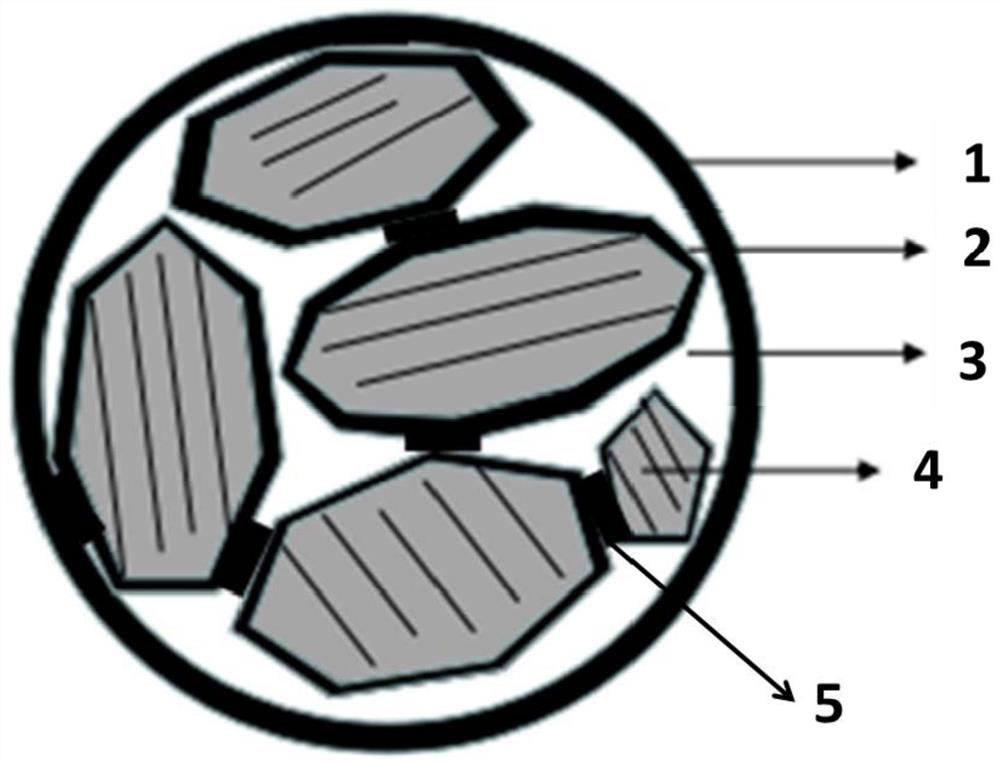

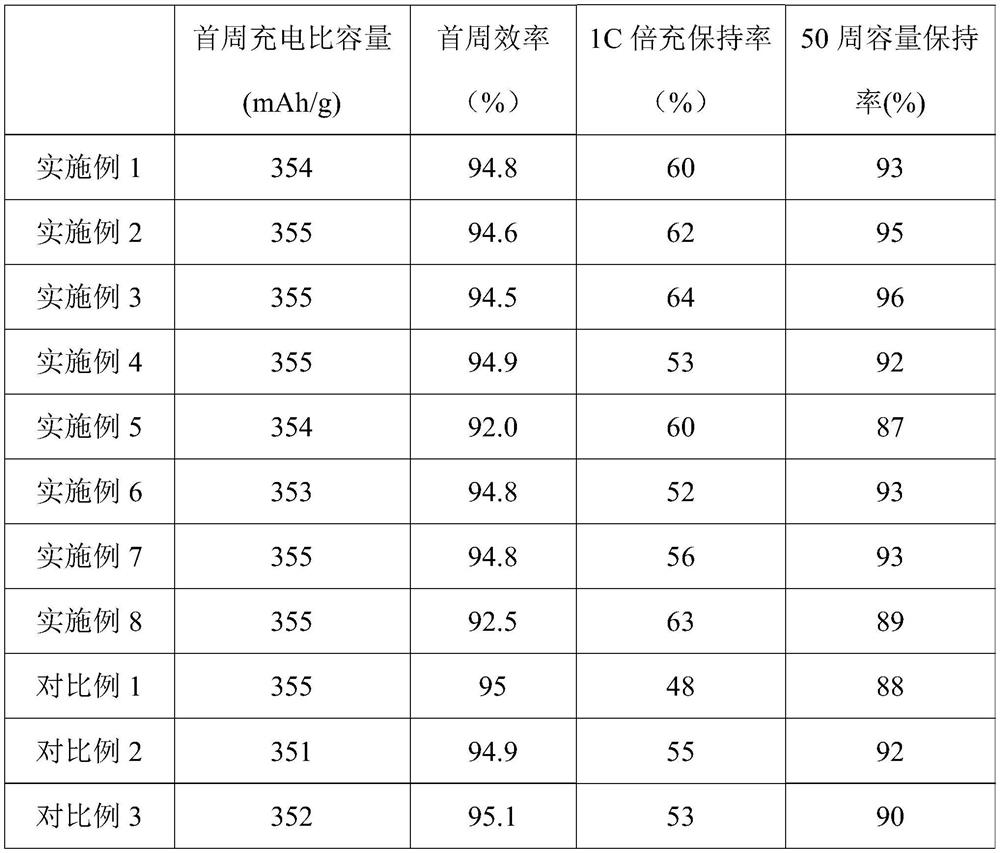

Graphite composite material as well as preparation method and application thereof

ActiveCN111682177AExcellent long cycle performanceHigh thickness consistencyNon-aqueous electrolyte accumulatorsNegative electrodesCarbon coatingParticle packing

The invention relates to a graphite composite material as well as a preparation method and application thereof. The graphite composite material is of a core-shell structure and comprises a secondary particle inner core and a second hard carbon coating layer on the surface of the secondary particle, wherein the secondary particles comprise a plurality of primary particles, and each primary particlecomprises a first hard carbon coating layer. In the graphite composite material provided by the invention, the hard carbon coating layer formed on the surface layer of the primary particle is tightlybonded with the inner core of the particle, no gap exists between the coating layer and the inner core, and the thickness consistency of the coating layer is high; the hard carbon coating layer of the secondary particle shell is beneficial to stabilizing the primary particle accumulation structure, and is beneficial to the long cycle performance of the material; the first hard carbon coating layer formed on the surface layer of the primary particle and the second hard carbon coating layer formed on the surface layer of the secondary particle can accelerate the desolvation process of lithium ions, so that lithium ions can be inserted into graphite more quickly; and according to the graphite composite material, the capacity can be ensured, and meanwhile, the quick charge and cycle performance can be greatly improved.

Owner:BTR NEW MATERIAL GRP CO LTD

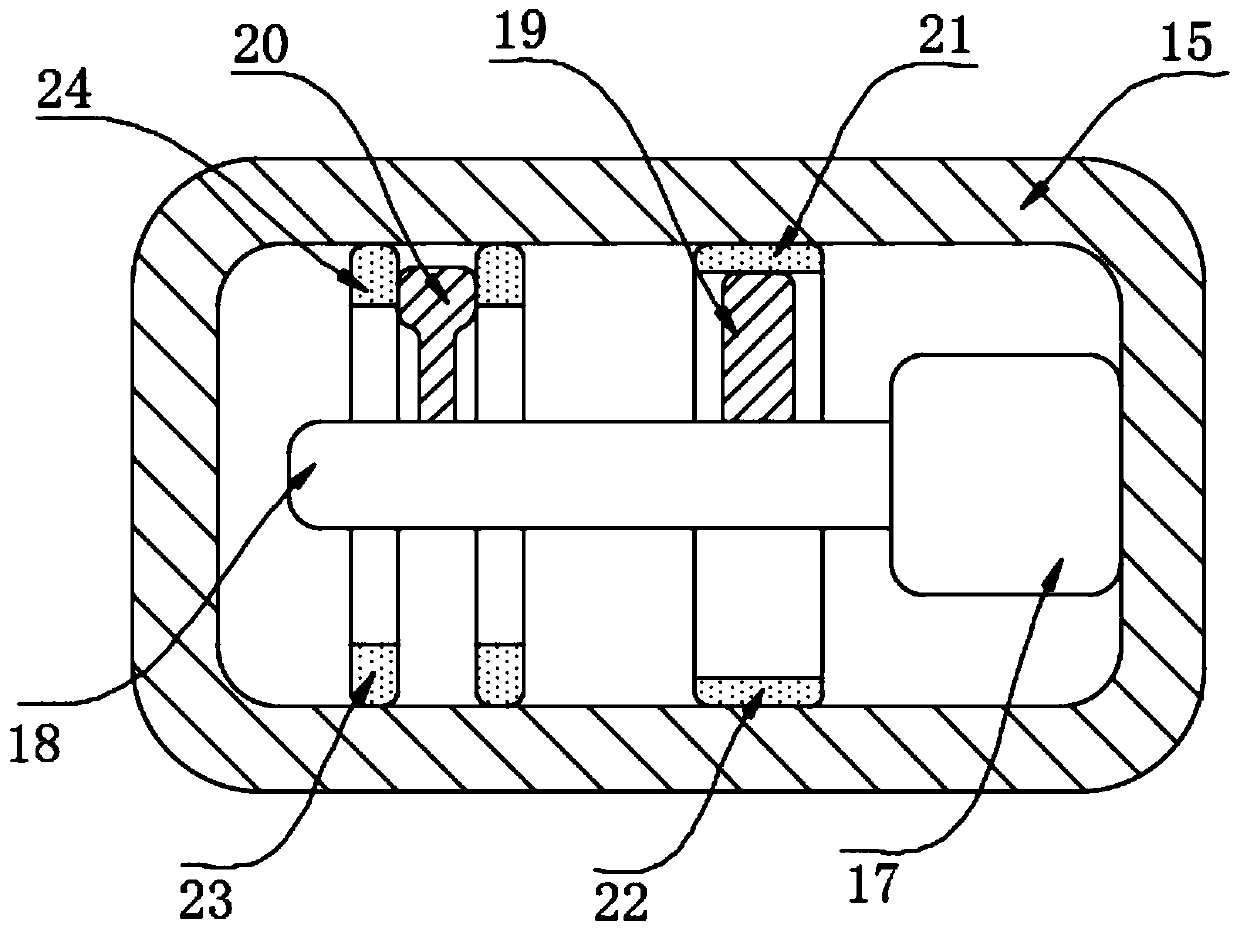

Sealing mechanism applied to particle packer

InactiveCN107323758AImprove work performanceEfficient and orderly automationWrapper twisting/gatheringSolid materialParticulatesParticle packing

The invention provides a packaging mechanism applied to a granule packaging machine, which includes a vertical vertical sealing station and a horizontal packaging station that is carried out simultaneously with the vertical vertical sealing station. Relatively arranged, the first power arm and the second power arm are horizontally arranged side by side, and a longitudinal hot-melt tension spring is connected between the rear end of the first power arm and the rear end of the second power arm; the first power The arm is movably connected with the first central axis of the thermal fusion force arm through a linear bearing. Adopting a packaging mechanism applied to a granular packaging machine of the present invention can efficiently and orderly automatically load the granular into the packaging bag and at the same time complete the packaging of the packaging bag filled with the granular; greatly improving the efficiency of packaging the granular into a bag The working effect also reduces the labor cost; at the same time, the particle quantitative loop of the corresponding specification and size can be replaced according to the required packaging dosage, so as to realize the control of the dosage of the particulate matter in the packaging bag.

Owner:柏跃龙

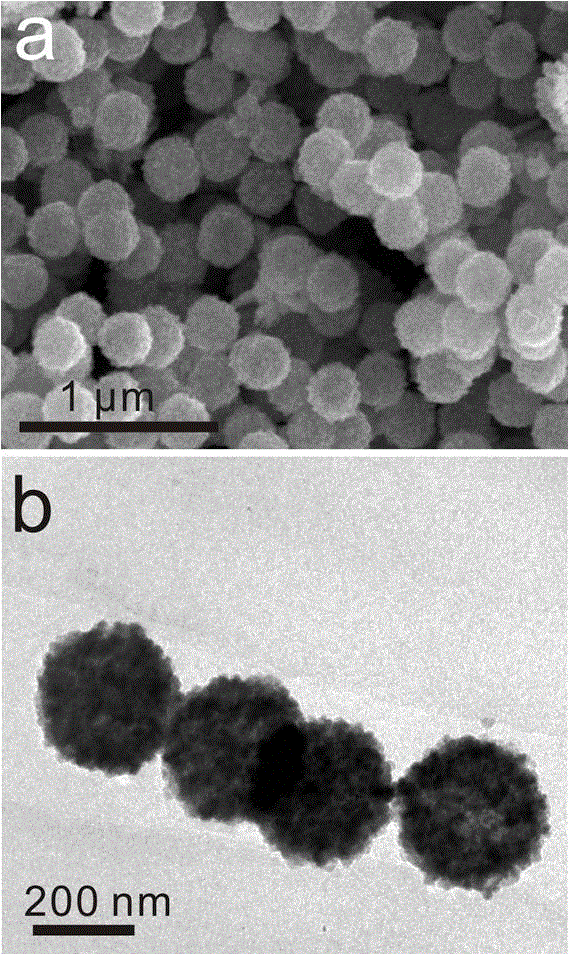

A magnetic surface-enhanced Raman spectroscopy substrate and a preparing method thereof

InactiveCN104034715AEnhancement effect is goodGood dispersionRaman scatteringSurface-enhanced Raman spectroscopyMicrosphere

A magnetic surface-enhanced Raman spectroscopy substrate is disclosed. The substrate is formed by stacking Fe3O4 / Ag particles having a shell-core structure that adopts Fe3O4 as a core and Ag as a shell. The preparing method includes: dispersing Fe3O4 microspheres into water, performing ultrasonic dispersion to obtain a dispersion liquid, adding ascorbic acid into the dispersion liquid, adding AgNO3 into the dispersion liquid, and reacting at 0-65 DEG c for 20-120 min to obtain the surface-enhanced Raman spectroscopy substrate formed by stacking the Fe3O4 / Ag particles. SERS enhancing effects of the Ag of the substrate are better by usually 1-2 order of magnitudes than that of gold. The method allows convenient collection with magnets, thus avoiding centrifugation, filtration, and other tedious and time-consuming manners.

Owner:HENAN INST OF ENG

Preparation method for slurry pump impeller

ActiveCN108637166AEnsure corrosionEnsuring impact strengthPump componentsFoundry mouldsMicron scaleQuenching

The invention belongs to the technical field of slurry pumps, and particularly relates to a preparation method for a slurry pump impeller. The preparation method comprises the steps that (1) burdeningand smelting are conducted; (2) sand mold making through resin; (3) casting is conducted; (4) a quenching and tempering treatment technique is adopted; (5) slurry for forming an anti-corrosion layeris brushed on the surface of the impeller after the impeller is formed, and drying treatment is conducted; and (6) the surface of the impeller is subjected to calcining treatment through mixed gas ofhydrogen and methane, calcining time is 10-15 s, and the slurry pump impeller is obtained. The surface of the slurry pump impeller is brushed in a micron-scale aluminum oxide and nano-scale aluminum oxide composite mode, and the compactness of particle packing in the anti-corrosion layer surface is ensured through the large-particle and small-particle aluminum oxide; and through high-temperature calcining of the mixed gas of hydrogen and methane, the combination state of a packing particle interface of the anti-corrosion layer surface is improved, the corrosion resistance and impact strength of the slurry pump impeller is ensured, and the service life of the slurry pump impeller is prolonged.

Owner:ANHUI SANHUAN PUMP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com