Green concrete mix proportion optimization method

An optimization method and concrete technology, which is applied in the field of concrete for building pouring, can solve problems such as environmental pollution, harmful dust emissions, and design methods that do not have universal applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

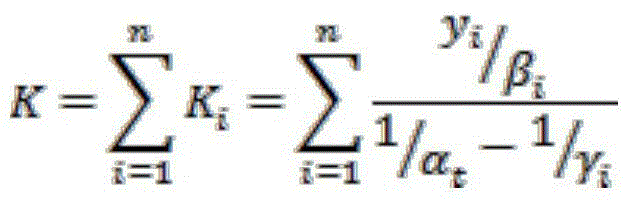

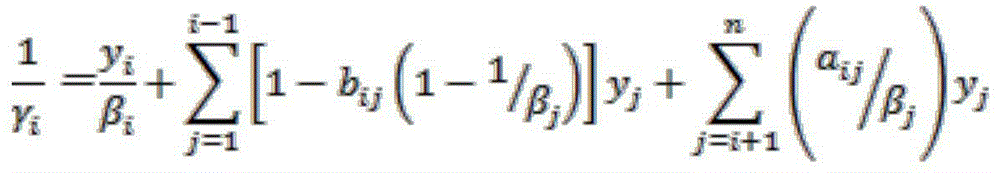

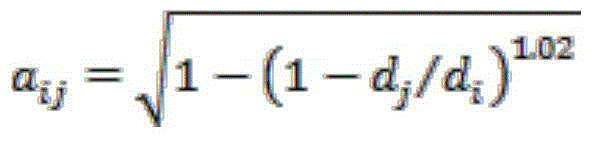

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0117] 1. Material testing

[0118] Material parameter determination:

[0119] The particle size distribution test of the gelled material was measured by a laser particle size analyzer, and the results are shown in Table 1 and Table 2.

[0120] Table 1 Granularity distribution of arbitrary grades of cement C

[0121]

[0122] Table 2 Particle size distribution of class Ⅱ fly ash FA in random classification

[0123]

[0124]

[0125] See Table 3 for raw material densities.

[0126] Table 3 Measured density of raw materials

[0127]

[0128] The remaining packing density of the cementitious material was measured by the minimum water demand method, and the results are shown in Table 4.

[0129] Table 4 The measured packing density and residual packing density of powder materials

[0130]

[0131] The remaining packing density of each particle size of sand and gravel is determined after the actual packing density is measured by the drainage method. The results ...

Embodiment 2

[0150] 1. Material testing

[0151] The materials used are consistent with Example 1.

[0152] 2. Mixing ratio cycle optimization process

[0153] As shown in Table 7

[0154] Table 7 Mixing ratio cycle optimization process 2

[0155]

[0156] Process 1:

[0157] The predicted slump of the reference group is 131mm, and the compressive strength is f 28d =56.6MPa, firstly adjust the gradation of sand and gravel, so that the packing density of the mixture is further increased to 0.8275, through calculation, the workability influence coefficient W drops from 0.9928 to 0.9728, and the predicted value of work performance is 158mm, which decreases at this time Water consumption up to 178L / m 3 , make W=0.9928, which is consistent with the original work performance, that is, slump=131mm, and then calculate the equivalent cement particle gap index S=0.7833, and the predicted value of the 28d compressive strength is f 28d =62.4MPa;

[0158] Process 2:

[0159] Due to the optim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com