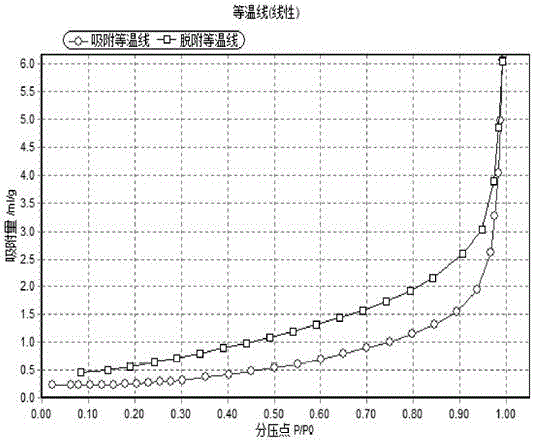

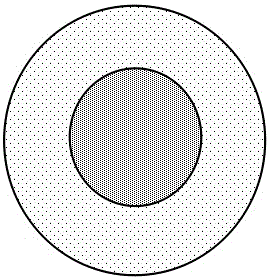

Ternary precursor material with internally dense and externally loose structure primary particle bulk density, anode material and preparation method thereof

A particle packing density and positive electrode material technology, applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems of high initial capacity, harsh conditions, and large irreversible capacity of layered lithium manganate, and achieve high rate and cycle performance Excellent, simple preparation process, and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

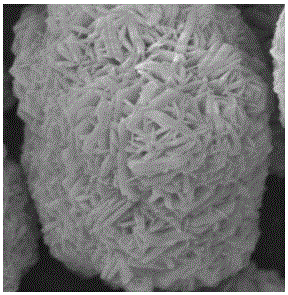

Embodiment 1

[0053] The preparation molar ratio is Ni:Co:Mn=8:1:1 and the nickel sulfate, manganese sulfate, cobalt sulfate metal salt solution that total concentration is 2mol / L, the complexing agent ammonia solution of 2.8mol / L, the 2mol / L Precipitating agent Sodium hydroxide solution, 1mol / L sodium dodecylsulfonate hot water solution. Add complexing agent solution, deionized water, and surfactant aqueous solution into the reaction kettle in a total of 800ml according to the molar ratio of 1:6:1, as the reaction bottom liquid at zero time; metal salt solution, 2.8mol / L complexing agent Mixture ammonia solution and 2mol / L precipitant sodium hydroxide solution are added into the high-speed stirring reaction kettle at a certain rate ratio (1:1:2), and the mixed solution of sodium dodecylsulfonate is introduced in the first 12 hours. Control the pH of the entire reaction system at 10±0.3, and control the temperature at 58°C. After 12 hours of reaction, suspend the feeding, and let the soluti...

Embodiment 2

[0061] The preparation molar ratio is Ni:Co:Mn=8:1:1 and the nickel sulfate, manganese sulfate, cobalt sulfate metal salt solution that total concentration is 2mol / L, the complexing agent ammonia solution of 2.8mol / L, the 2mol / L Precipitating agent Sodium carbonate solution, 1mol / L sodium dodecylsulfonate hot water solution. Add complexing agent solution, deionized water, and surfactant aqueous solution into the reaction kettle in a total of 800ml according to the molar ratio of 1:6:1, as the reaction bottom liquid at zero time; metal salt solution, 2.8mol / L complexing agent Mixture ammonia solution and 2mol / L precipitant sodium carbonate solution are added into the high-speed stirring reaction kettle at a certain rate ratio (1:1:1), and the mixed solution of sodium dodecylsulfonate is introduced in the first 12 hours, and the control The pH of the entire reaction system is 10±0.3, and the temperature is controlled at 58°C. After 12 hours of reaction, the feeding is suspended,...

Embodiment 3

[0063] The difference between this example and Example 1 is that the precipitation agent is a mixture of sodium hydroxide and potassium hydroxide, and the molar ratio of the two is 1:1; the lithium source is a mixture of lithium hydroxide, lithium nitrate and lithium sulfate, and hydrogen The molar ratio of lithium oxide, lithium nitrate and lithium sulfate is 1:1:2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com