Preparation method of mesoporous silica microsphere

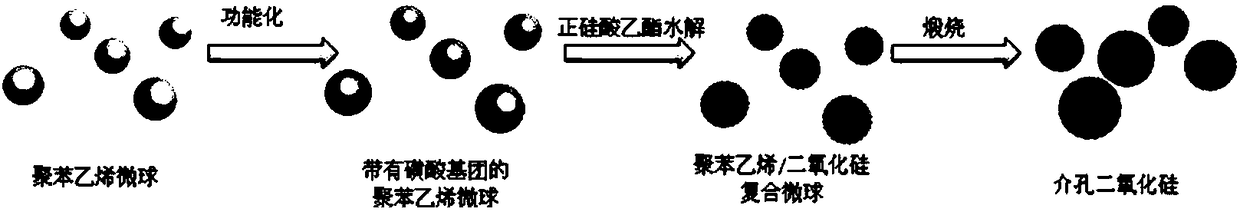

A technology of mesoporous silica and silica, applied in chemical instruments and methods, separation methods, alkali metal oxides/hydroxides, etc., can solve the problem of wide size distribution of mesoporous silica microspheres and synthesis parameters Difficult to control, uneven appearance and other problems, to achieve the effect of easy to realize industrial production, good physical and chemical properties, and good industrial development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) The preparation of polystyrene microspheres with a degree of crosslinking of 2%

[0047] Take 0.1g NaHCO 3 , 0.2g of sodium dodecylsulfonate (SDS) was dissolved in 120mL of distilled water, the solution was transferred to a reaction kettle, nitrogen gas was introduced, mechanically stirred, the temperature was raised to 70°C, and 20mL of monomers (19.6mL of styrene and 0.4 mL of a mixture of divinylbenzene) was added to the reaction system, and 0.32 g of potassium persulfate was weighed and dissolved in 30 mL of distilled water, and added to the reaction system, the stirring speed was controlled at 180 r / min, and the reaction was stopped after 13 hours of reaction, and the obtained emulsion was removed and left to stand. The solvent evaporates naturally at room temperature to obtain polystyrene microspheres with a crosslinking degree of 2%;

[0048] attached figure 2 It is obtained by scanning polystyrene microspheres with a cross-linking degree of 2% with a mode...

Embodiment 2

[0060] (1) preparation of polystyrene microspheres with a degree of crosslinking of 3%

[0061] In a 500mL four-necked bottle, add 0.1g NaHCO successively 3 , 0.3g sodium dodecylsulfonate (SDS) and 120mL water, heated to 70°C in a water bath, introduced argon, mechanically stirred, and then added mixed monomers (19.4mL styrene and 0.6mL diethylene benzene mixture), while dissolving 0.5g of potassium persulfate in 30mL of water and heating to 70°C, and then dropwise adding it to the previous reactor. The emulsion was left standing, and the solvent evaporated naturally at room temperature to obtain polystyrene microspheres with a crosslinking degree of 3%.

[0062] (2) Sulfonation of polystyrene microspheres

[0063] Submerge 1 g of dry cross-linked polystyrene microspheres in 30 mL of concentrated sulfuric acid, and react at a constant temperature of 40 ° C for 13 h. After the reaction, discard the liquid, wash with water until the pH value of the supernatant remains unchange...

Embodiment 3

[0068] (1) preparation of polystyrene microspheres with a degree of crosslinking of 20%

[0069] In a 250mL four-neck flask, add 1g of polyvinylpyrrolidone, 95mL of absolute ethanol and 10mL of water, control the stirring speed at 100r / min, put it in a water bath at 75°C after passing through argon, and add 16mL of benzene to the beaker. Ethylene, 4mL divinylbenzene, and 0.2g azobisisobutyronitrile were mixed evenly and added to a four-neck flask, protected by argon, and reacted at a constant temperature for 15 hours. Polystyrene microspheres with a joint degree of 20%;

[0070] (2) Sulfonation of polystyrene microspheres

[0071] Submerge 0.5 g of dry cross-linked polystyrene microspheres in 10 mL of concentrated sulfuric acid, and react at a constant temperature of 40 ° C for 20 h. After the reaction, discard the liquid, wash with water until the pH of the supernatant remains unchanged, and freeze-dry the obtained product , to obtain cross-linked polystyrene microspheres w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com