Patents

Literature

47results about How to "Good prospects for industrial development" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

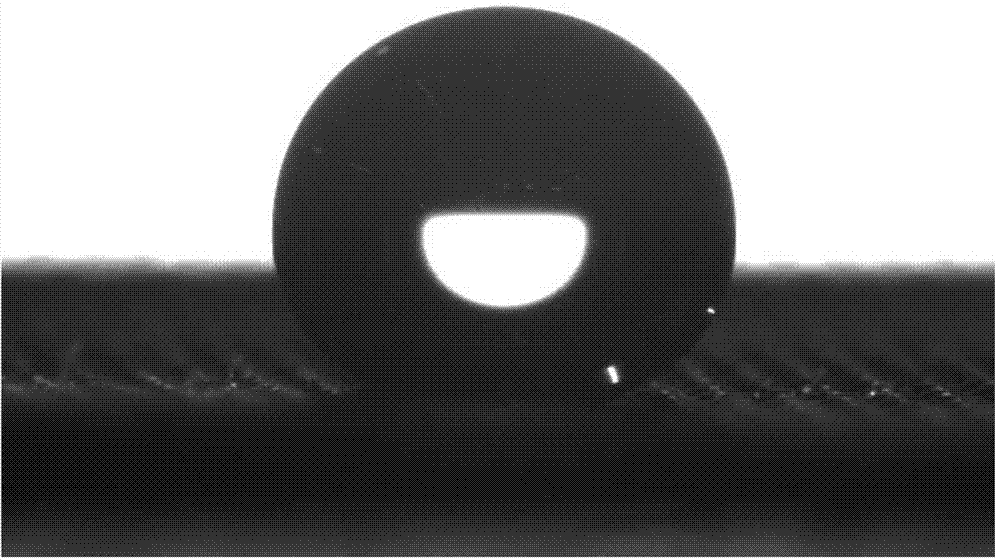

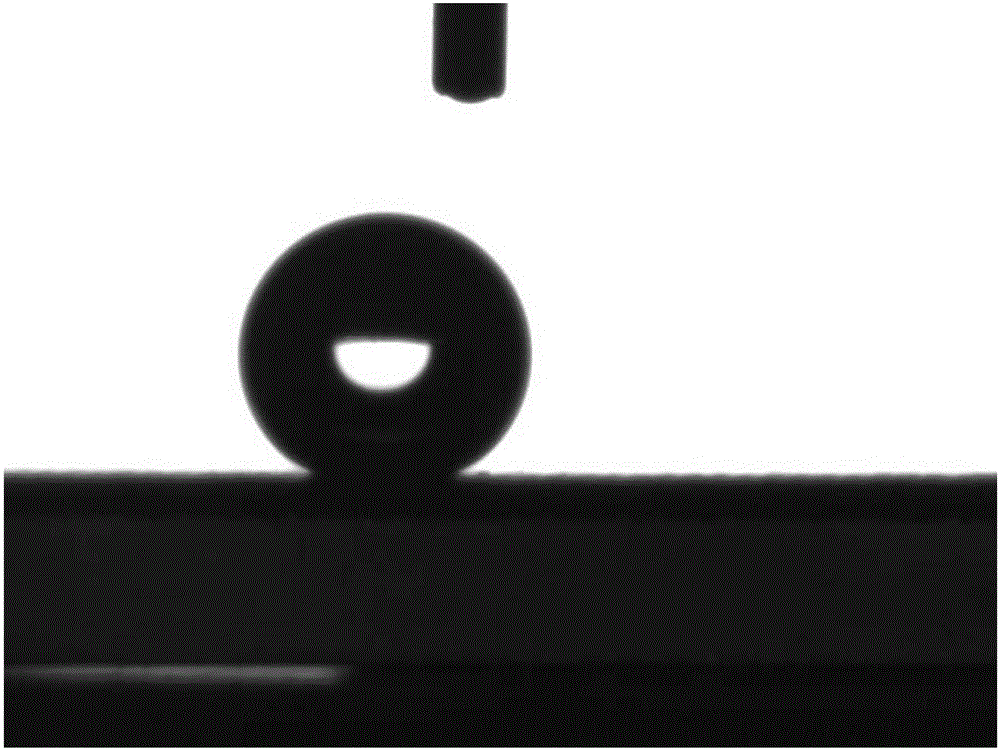

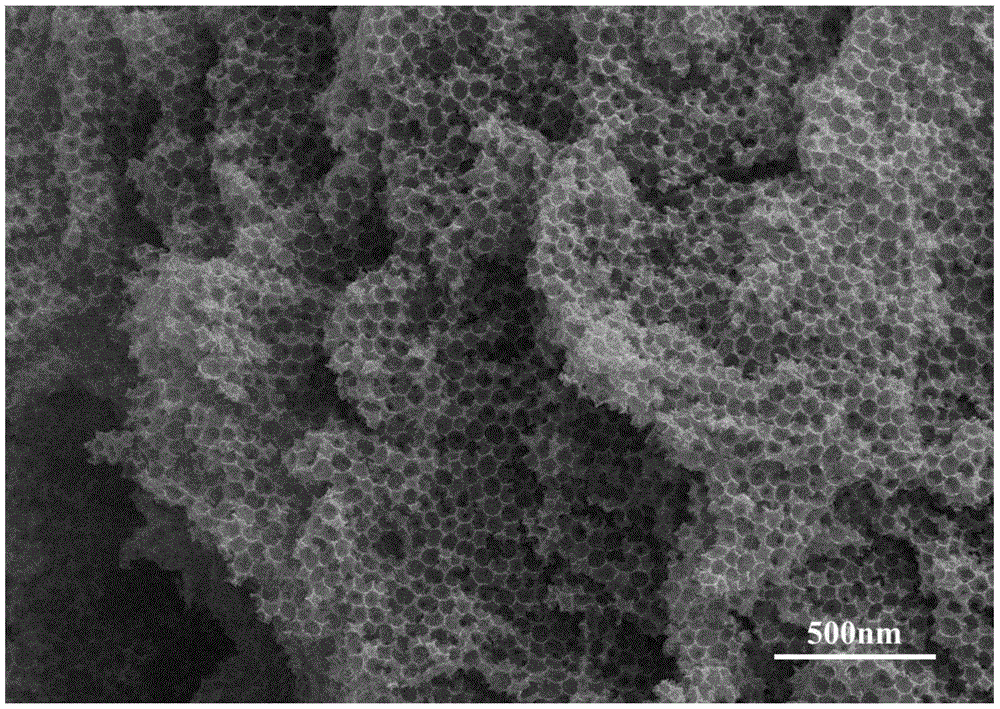

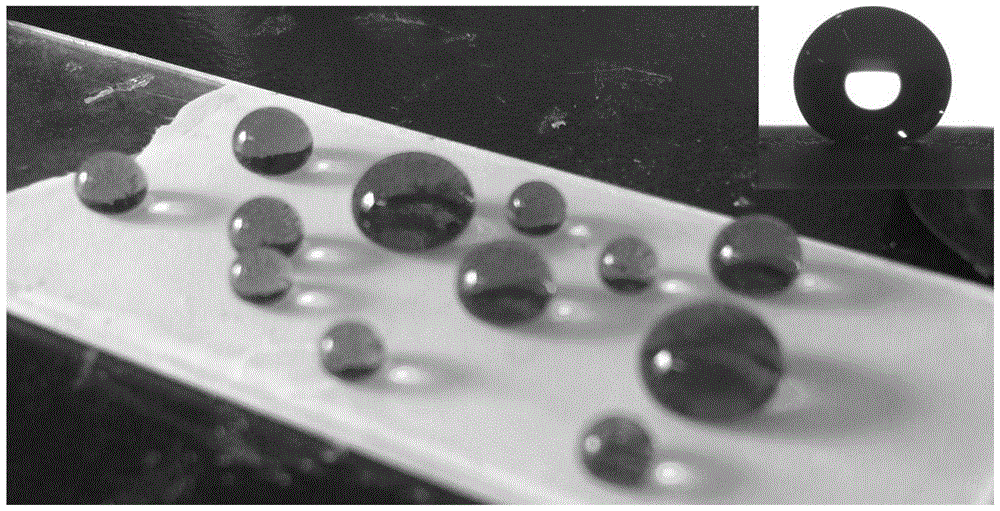

Inorganic substance super-hydrophobic paint and application thereof

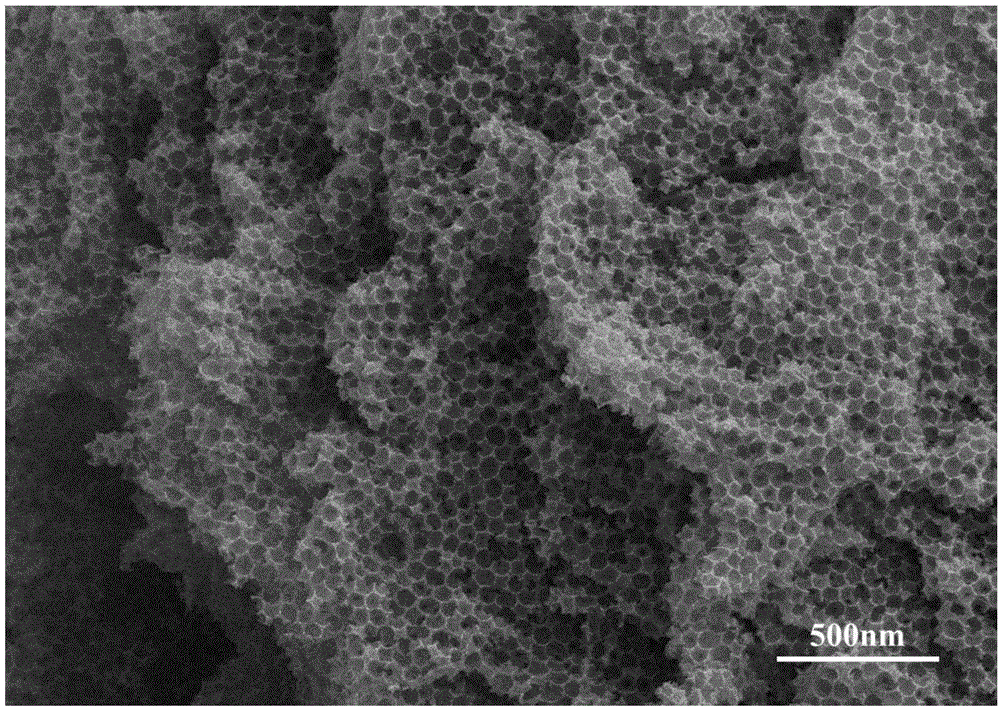

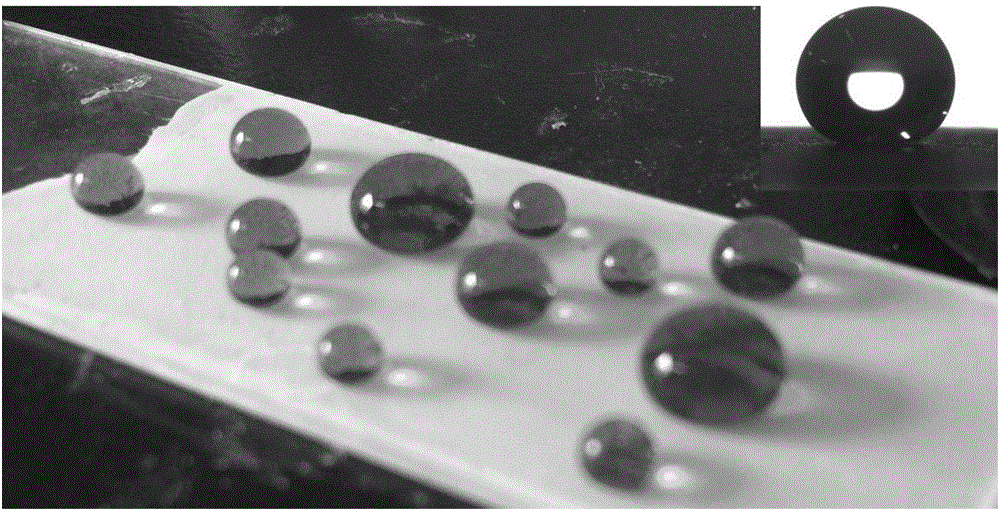

ActiveCN104672962ASimple manufacturing methodImprove stabilityAntifouling/underwater paintsLayered productsMicro nanoMicrosphere

The invention relates to inorganic substance super-hydrophobic paint and application thereof. The paint is prepared in the following method: silica sol is injected into a reactor with a nano microsphere template under a negative pressure condition, the template is immersed in the silica sol for 2h, then the reactor is sealed and stored in a thermostat, the silica sol and the template react at the temperature of 60 DEG C for 12h, the template is removed by virtue of heating or water immersion, a solid blocked micro-nano composite polygon is obtained, and after the blocked micro-nano composite polygon is dried, the blocked micro-nano composite polygon is ground into powder; the powder is poured into another reactor, dispersion liquid acetone is mixed with the powder, a low-surface-energy silane coupling agent is used for modifying the powder at a temperature of 25 to 50 DEG C, the powder reacts for 10h to 15h, the micro-nano composite polygon powder accounts for 0.5 to 20 percent of the mass of the paint, and the super-hydrophobic paint is prepared. The inorganic substance super-hydrophobic paint can be smeared on the surfaces of various conventional materials, the preparation method of the paint is simple, and the obtained super-hydrophobic surface is excellent in stability.

Owner:天津超疏水纳米科技有限公司

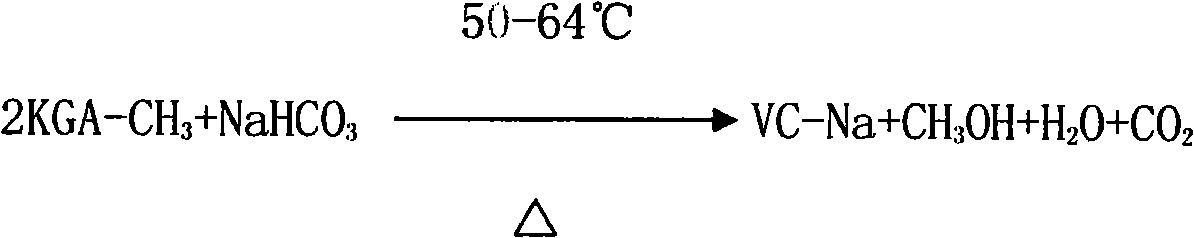

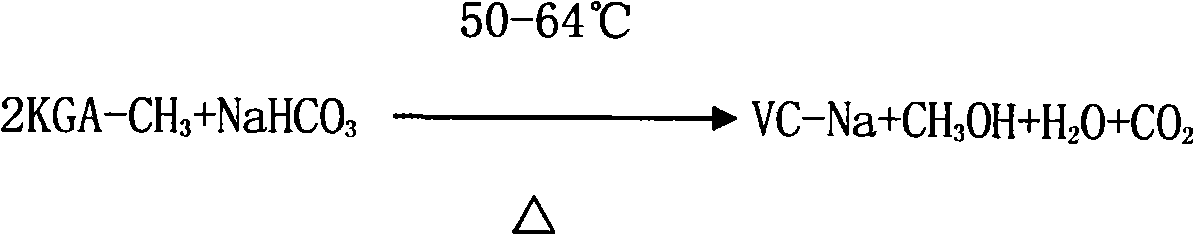

Method for directly preparing vitamin C with sodium gulonate

InactiveCN101298445ASignificant technological progressGood energy saving and emission reduction effectOrganic chemistryFermentationHigh concentrationVitamin C

The invention relates to a method for preparing ascorbic acid by using gulconic sodium to converse directly; the invention is importantly improved based on the existing two-step fermentation method for manufacturing VC: a 2KGA-Na crystal of high purity can be obtained by the techniques of hyperfiltration clarification, low temperature concentration and constant temperature crystallization, etc.; the completely novel method for separating the gulonic acid that are not converted into VC by the technique conditions of separating Na[2]SO[4] solid during the prophase of methyl reaction and optimizing and conversion reaction as well as by adopting an advanced chromatogram technology during the processes of acidification and refining leads to obtain the top-grade product from the crude VC by one-step crystallization, thereby leading the total yield for manufacturing VC by the two-step fermentation method to be improved to more than 86 percent; the waste water with high concentration is completely removed; and the energy consumption can be reduced by about 20 percent.

Owner:徐昌洪

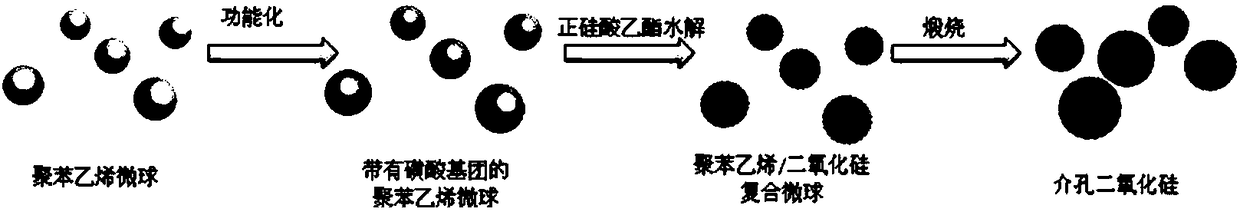

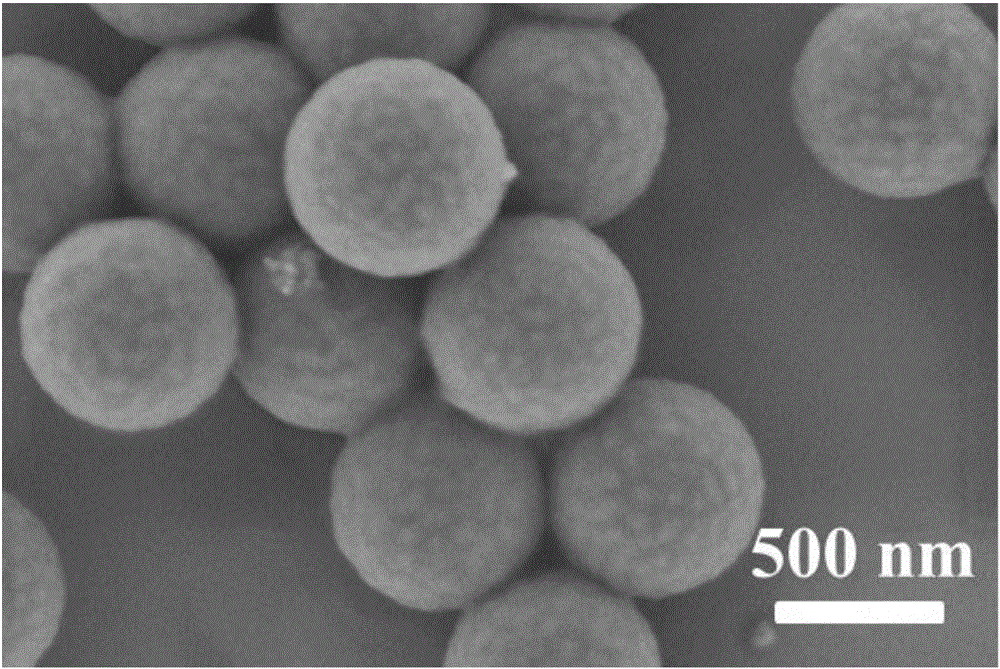

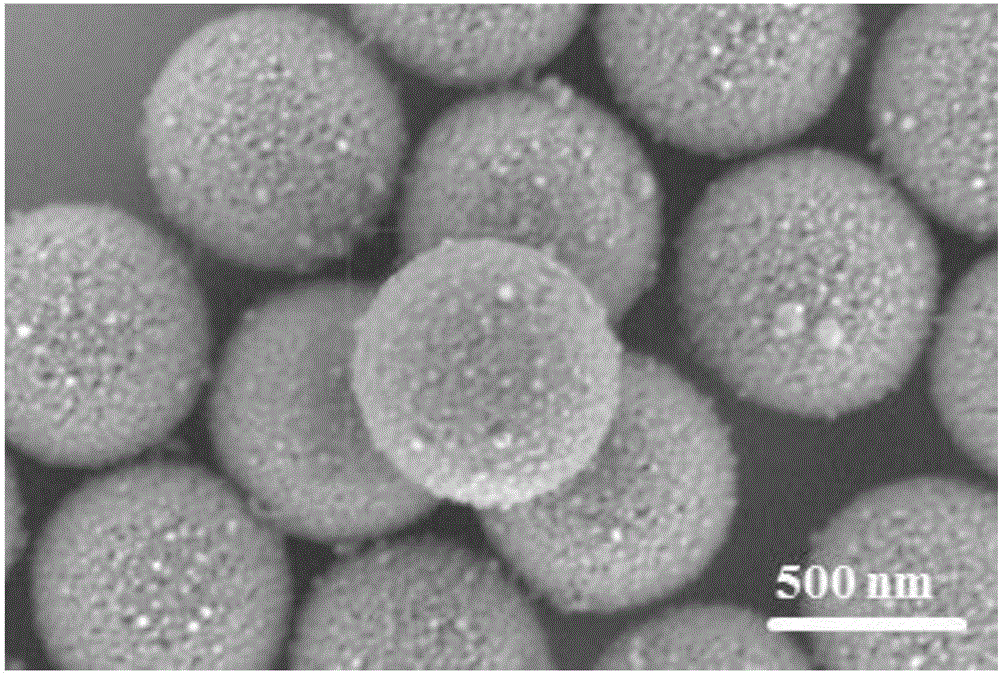

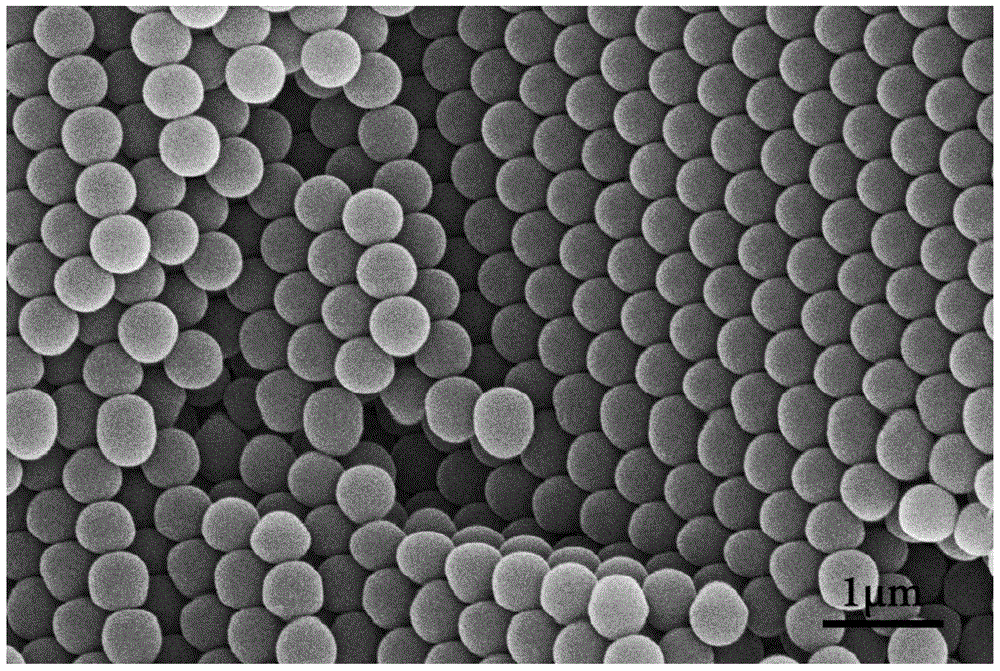

Preparation method of mesoporous silica microsphere

InactiveCN108579705ASmall sizeAdjustable sizeOther chemical processesDispersed particle separationMicrosphereMesoporous silica

The invention relates to a preparation method of a mesoporous silica microsphere. The method comprises the following steps that 1, a polystyrene microsphere is prepared; 2, the polystyrene microsphereis subjected to sulfonation; 3, a polystyrene / silicon dioxide composite microsphere is prepared; 4, polystyrene in the polystyrene / silicon dioxide composite microsphere is removed, and finally the mesoporous silica microsphere is obtained. According to the prepared mesoporous silica microsphere, by adjusting the cross-linking degree of a polystyrene template, the particle size of generated nano silicon dioxide can be controlled, therefore, the mesoporous size generated after particles are stacked is controlled, and pore diameter adjustable excellent performance is achieved. No expensive pore-forming agent is needed, and then the mesoporous silica microsphere which is uniform in pore diameter and high in specific surface area can be obtained.

Owner:HEBEI UNIV OF TECH

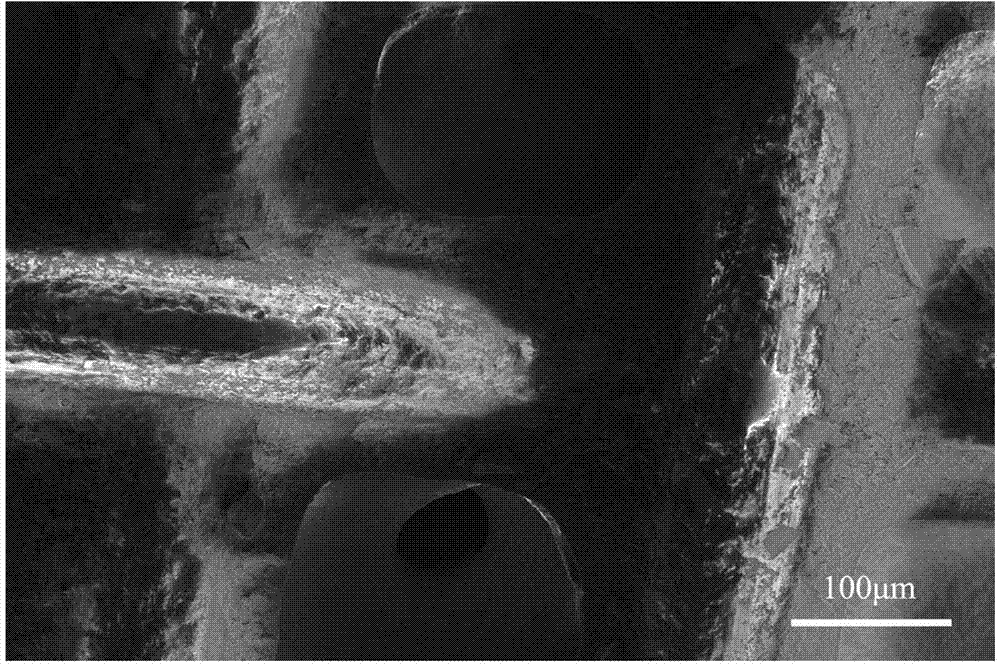

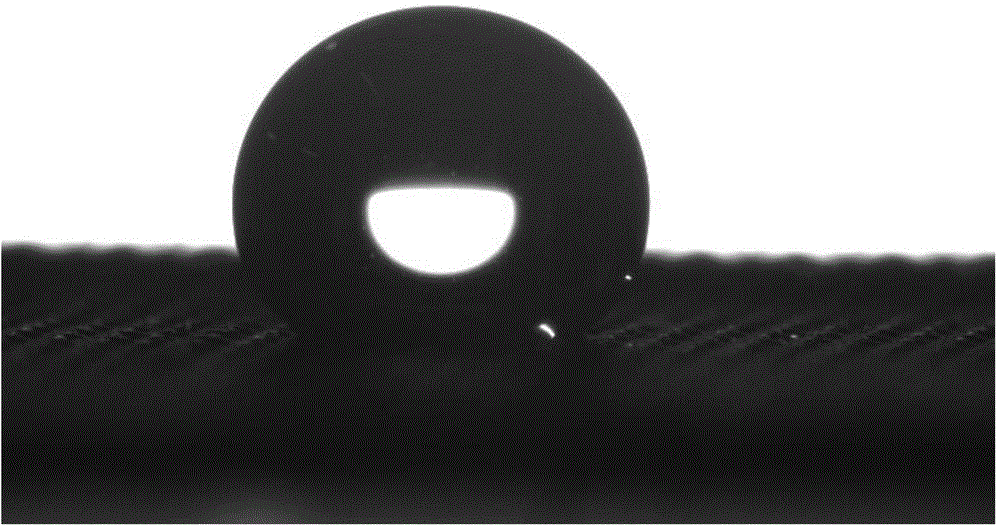

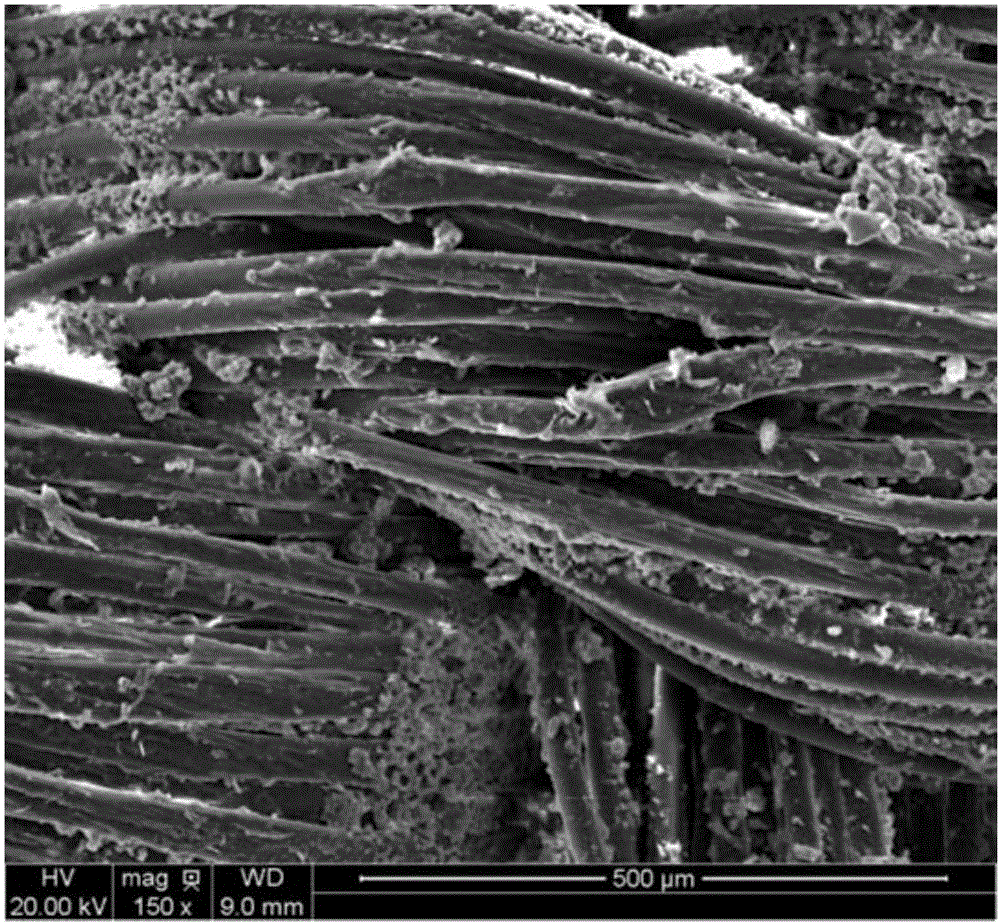

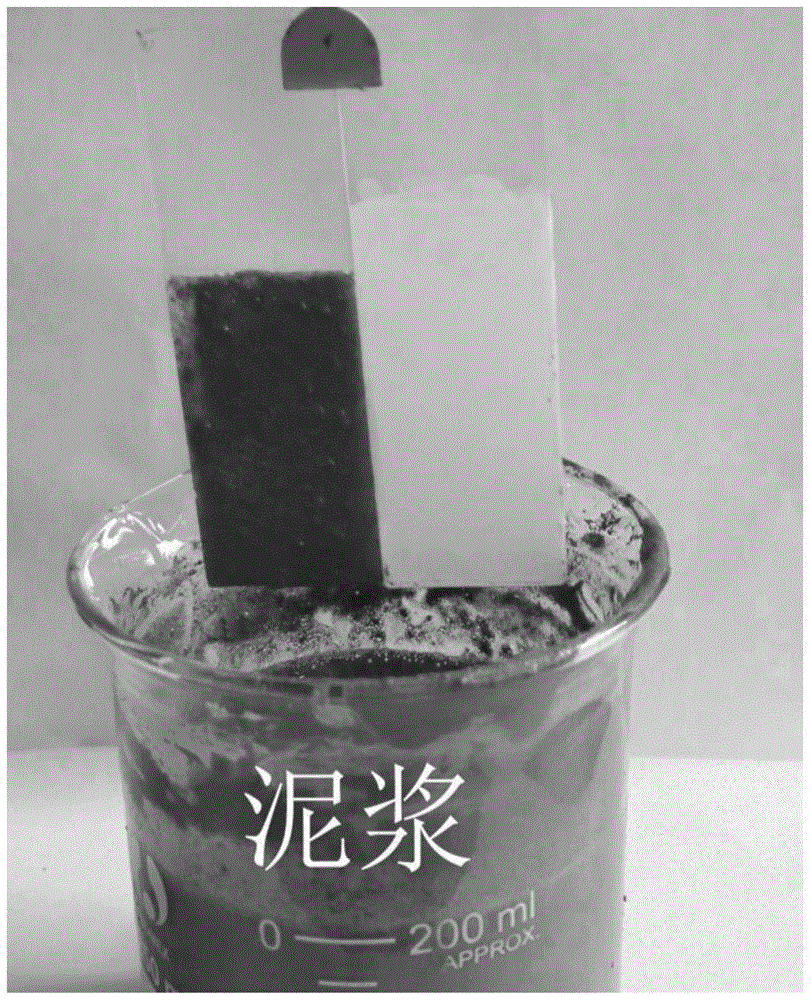

Preparation method of organic macromolecule polymer coating oil-water separating net

The invention relates to a preparation method of an organic macromolecule polymer coating oil-water separating net, which comprises the following steps: 1)mixing a polymerization monomer and an initiator in proportion and stirring, injecting a mixed liquor into a reactor equipped with a template under negative pressure condition, immersing the template for 1 hour, polymerizing for 24 hours at temperature of 80 DEG C, after a polymerization reaction is stopped, peeling a homopolymer on surface of the template, removing the template, fully grinding the blocked micro nano polyhedral compound to obtain the powder, adding into a dispersion liquid, wherein the solid masses concentration percentage is 0.5-20% of suspending liquid; 2)performing ultrasonic cleaning on the netted material and drying under air, immersing an adhesive solution and then taking out, after a part of the adhesive is solidified, and employing a spray process for coating the suspending liquid on the net so as to form the netted material capable of separating oil and water. The preparation method reduces usage restriction of the oil-water separating net membranes, and has rapid and stable oil-water separating effect.

Owner:天津超疏水纳米科技有限公司

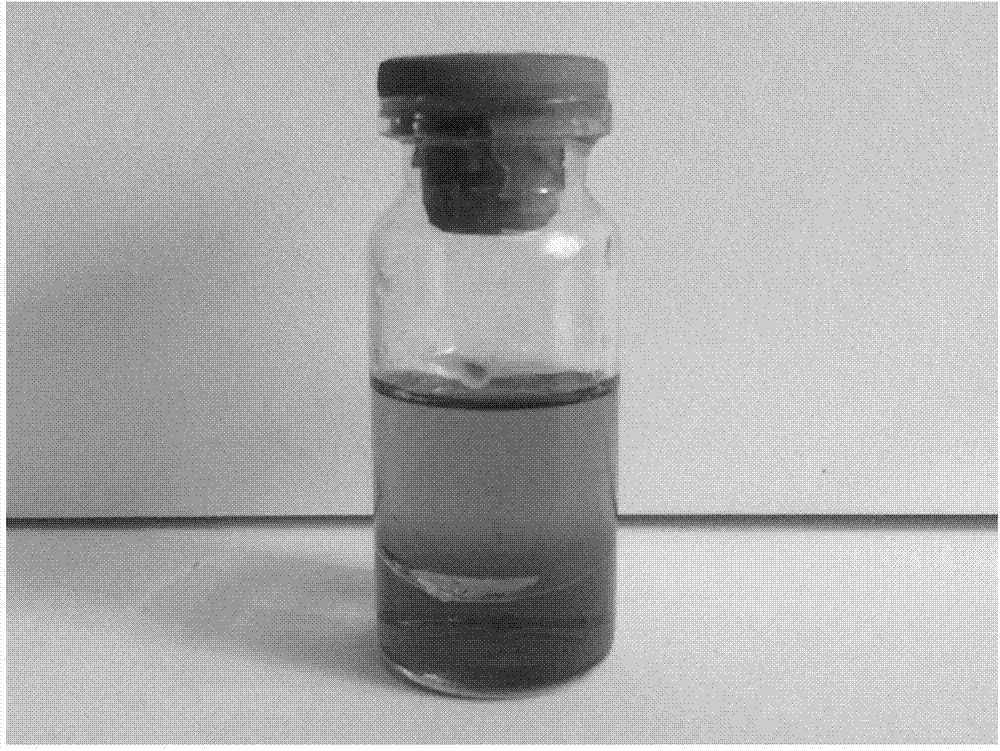

Preparation method of inorganic substance coating oil-water separation mesh

ActiveCN104689602ALower usage limitEasy to separateFibre treatmentNon-miscible liquid separationSolubilityMicro nano

The invention provides a preparation method of an inorganic substance coating oil-water separation mesh; the method comprises the steps: injecting a silica sol into a reactor with a mould plate under a negative pressure condition and soaking the mould plate for 2h; then sealing the reactor, placing the reactor into a thermostat, reacting for 12h at 60 DEG C and removing the mould plate to obtain a solid block-shaped micro-nano composite polyhedron; drying the block-shaped micro-nano composite polyhedron, sufficiently grinding the polyhedron into powder, pouring the powder into the reactor with dispersing acetone solution, adding a low-surface-energy silane coupling agent for modification, reacting for 12h and then obtaining modified micro-nano composite polyhedron turbid liquid; enabling the mass concentration percentage of the solid in the turbid liquid to be 0.5-20% by volatilizing acetone or adding acetone again. Not only crude oil, diesel oil, gasoline oil and water-insoluble oily liquid can be separated, but ester type organic oily solvents having certain solubility with water can be separated.

Owner:天津超疏水纳米科技有限公司

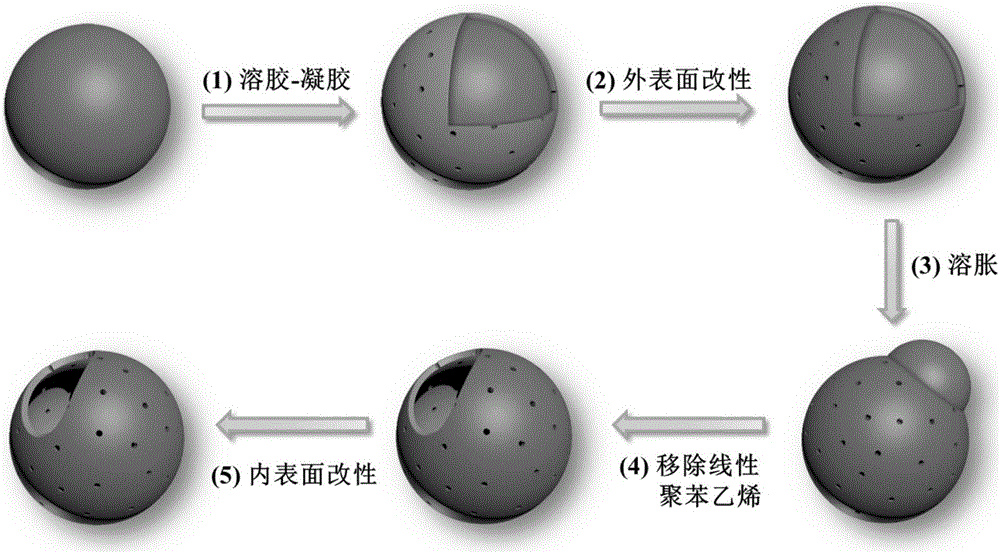

Preparation method of amphiphilic Janus hierarchical pore microcapsule with opening structure

ActiveCN106732221ASimple manufacturing processEasy to scaleMicroballoon preparationMicrocapsule preparationOrganic solventMicrometer

The invention relates to a preparation method of an amphiphilic Janus hierarchical pore microcapsule with an opening structure. The preparation method comprises the following steps of performing occupying modification on the outer surfaces of core / shell composite microspheres; then, swelling the core / shell composite microspheres to form the anisotropic composite microspheres with bulges, and dissolving by a good solvent to remove a template, so as to form a microcapsule with the opening structure; finally, performing different functionalizing on the inner surfaces of the microcapsules, so as to obtain the microcapsule material with the hydrophilic inner surface and the hydrophobic outer surface, or the hydrophobic inner surface and the hydrophilic outer surface. The prepared microcapsule material has excellent biological compatibility, good organic solvent-resistant property, chemical corrosion-resistant property and high mechanical stability, and has huge potential application value in the fields of micrometer-nanometer reactors, load catalyzing and the like.

Owner:HEBEI UNIV OF TECH

Wear-resistant, hydrophobic and lipophilic material, preparation method therefor and application of wear-resistant, hydrophobic and lipophilic material

ActiveCN106512480AAchieve hydrophobic and lipophilic effectOvercome the problem of easy sheddingNon-miscible liquid separationVegetable oilKerosene

The invention discloses a wear-resistant, hydrophobic and lipophilic material. According to the wear-resistant, hydrophobic and lipophilic material, a lipophilic substrate material is adopted, metal stearate is adhered to the surface of the substrate, and a wear-resistant and hydrophobic surface layer is formed on the surface of the substrate by using the hydrophobic characteristic of the metal stearate, so that wear-resistant, hydrophobic and lipophilic effects are achieved. The material is low in cost, has good hydrophobic characteristic and lipophilic characteristic and can be applied to oil-water separation technologies, and an oil-permeable and water-impermeable meshed membrane is achieved; and the material is applicable to the separation of water-insoluble organic solvents such as kerosene, gasoline, diesel, engine oil, toluene, dichloromethane, vegetable oil and petrol from water.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

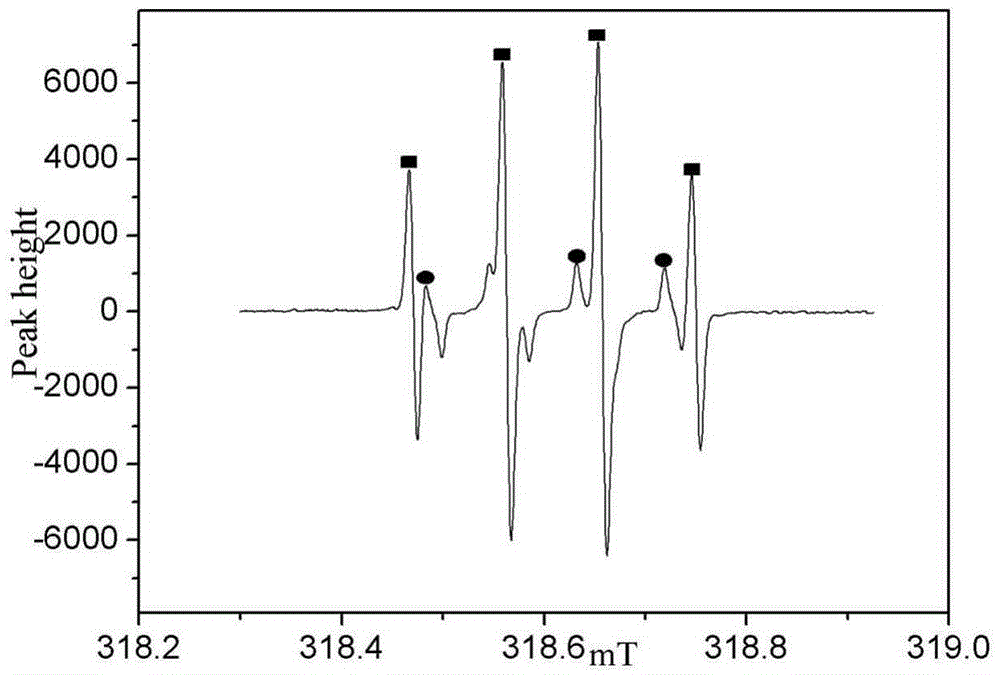

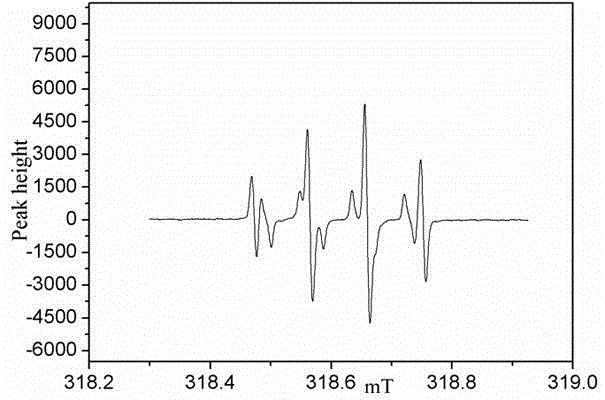

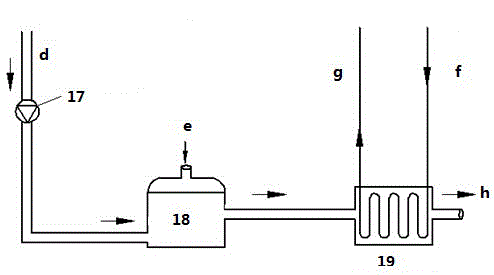

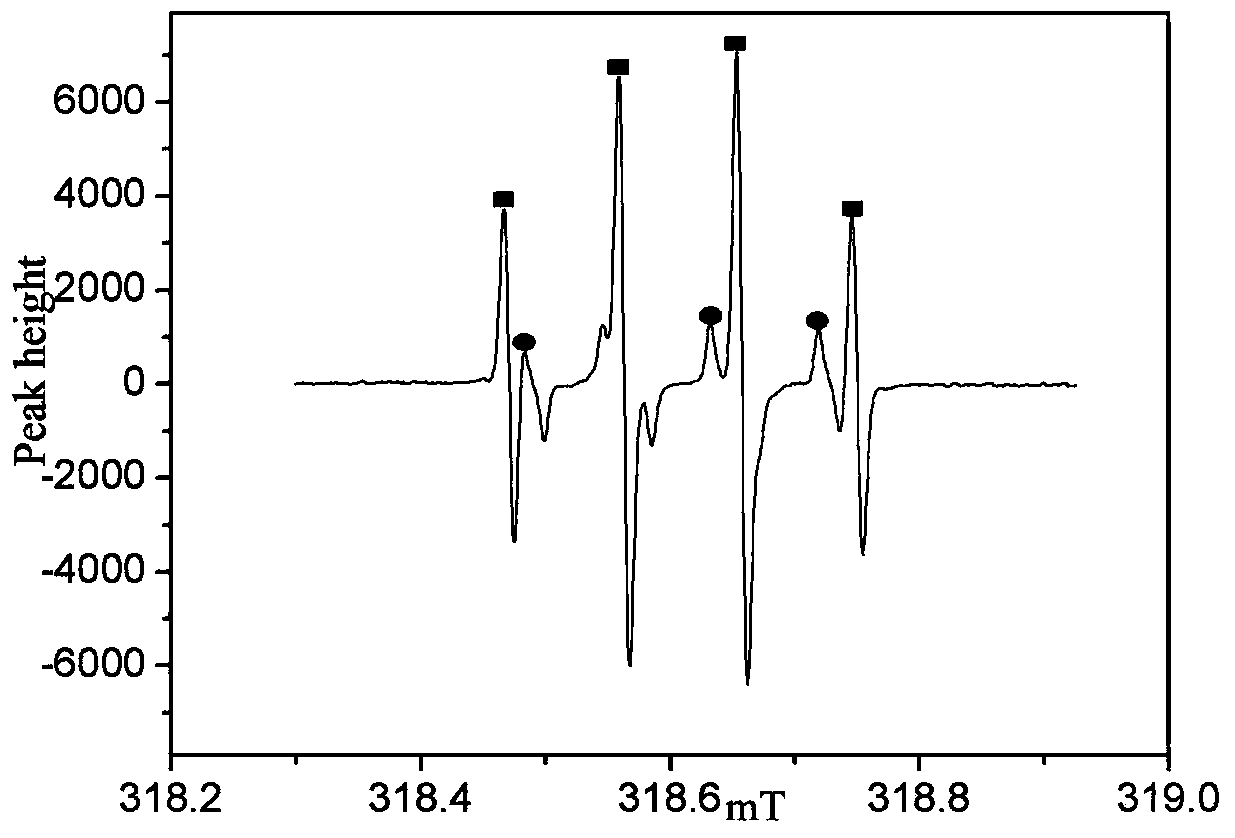

Method for removing VOCs (volatile organic chemicals) by ozone and photolytic peroxide

ActiveCN104815537ANo secondary pollutionEfficient removalDispersed particle separationAir quality improvementSulfate radicalsDecomposition

The invention relates to a method for removing VOCs (volatile organic chemicals) by ozone and photolytic peroxide. According to the method, the VOCs from a discharging source are firstly pre-oxidized into organic intermediate by the ozone in a flue, ultraviolet light excites the peroxide to generate sulfate radical and hydroxyl free radical, so that the VOCs and the organic intermediate generated by oxidization of the ozone are further oxidized, and final decomposition products are harmless CO2 and harmless H2O. The VOCs in flue gas can be efficiently removed, secondary pollution is avoided in the removing process, and a novel VOCs purification system has a wide application prospect.

Owner:CHANGSHU YONGXIN PRINTING & DYEING CO LTD

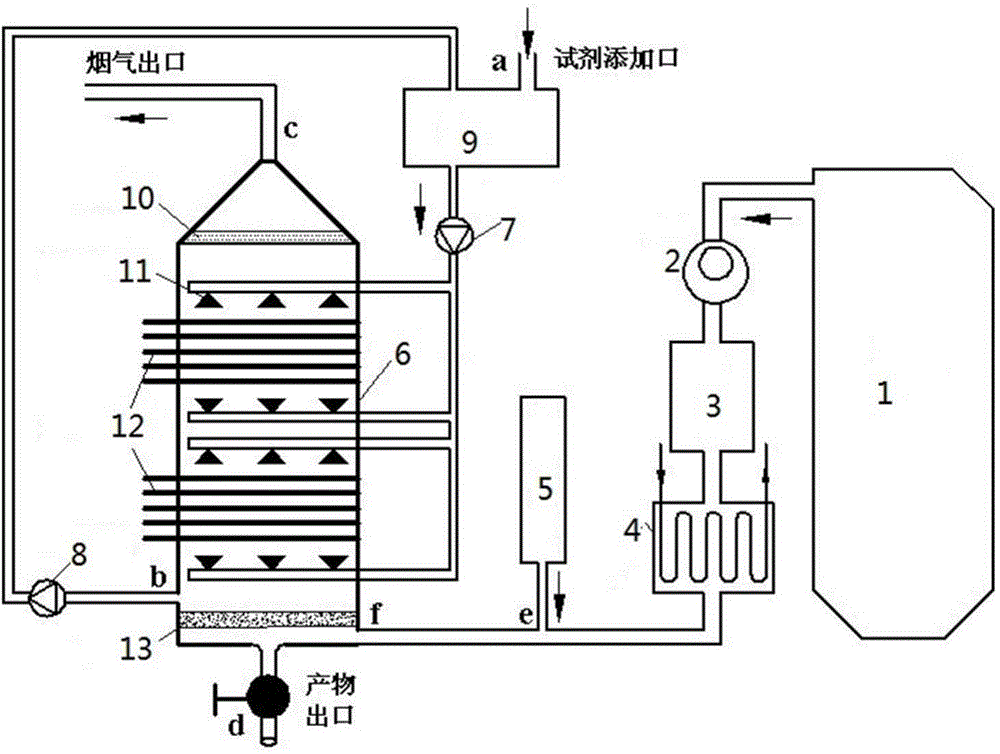

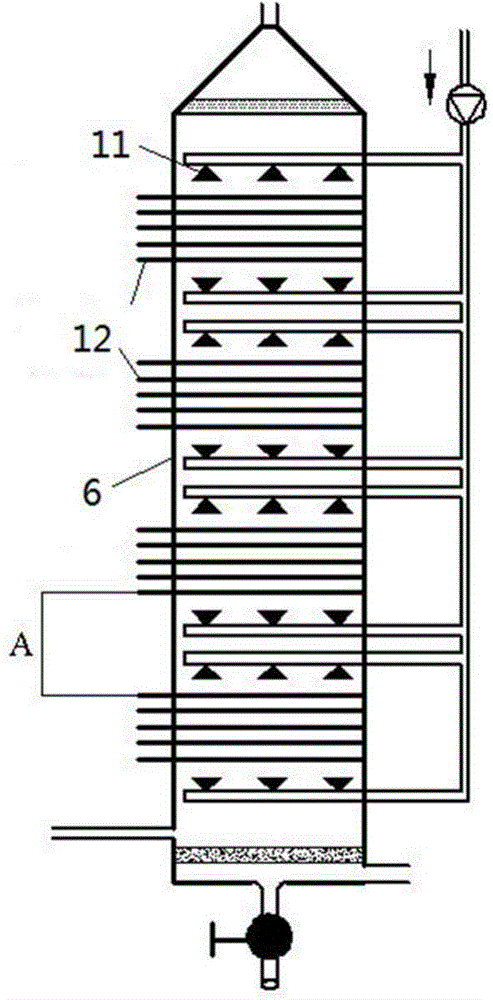

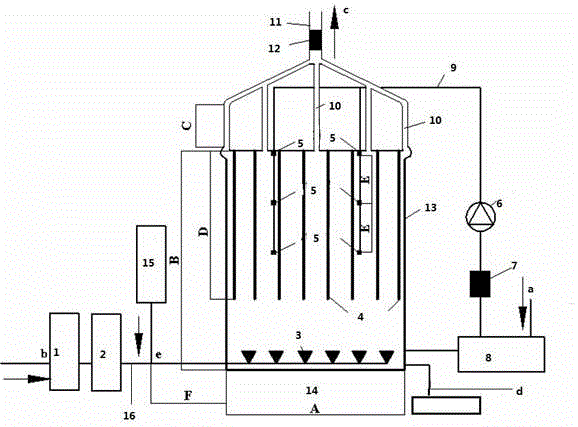

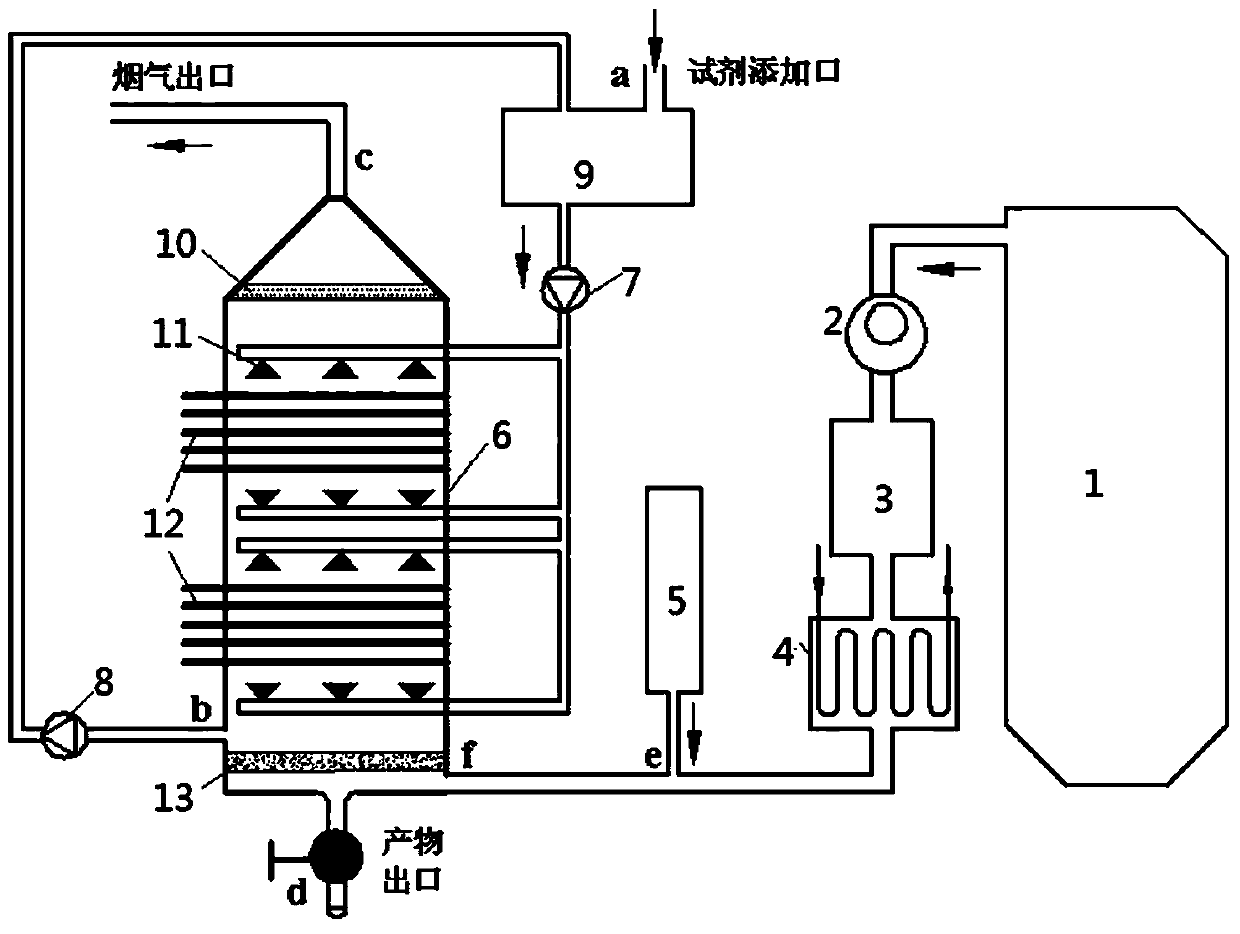

Ozone combined photo-excited peroxide VOCs (volatile organic chemicals) purification system and method

ActiveCN104815534ALow application costEasy to removeDispersed particle separationParticulatesSulfate radicals

The invention relates to an ozone combined photo-excited peroxide VOCs (volatile organic chemicals) purification system and method, and belongs to the field of atmospheric pollutant control. The purification system mainly comprises a dust collector, a cooler, a photochemical atomization bed reactor, a gas distribution nozzle, a circulating pump, a particulate matter filtering device, a charging tower, a spray pipeline, a main flue, a demister and a product post-processing system. VOCs from a discharging source are firstly pre-oxidized into organic intermediate by the ozone in a flue, ultraviolet light excites peroxide to generate sulfate radical and hydroxyl free radical, so that the VOCs and the organic intermediate generated by oxidization of the ozone are further oxidized, and final decomposition products are harmless CO2 and harmless H2O. The VOCs in flue gas can be efficiently removed, secondary pollution is avoided in the removing process, and the novel VOCs purification system has a wide application prospect.

Owner:JIANGSU UNIV

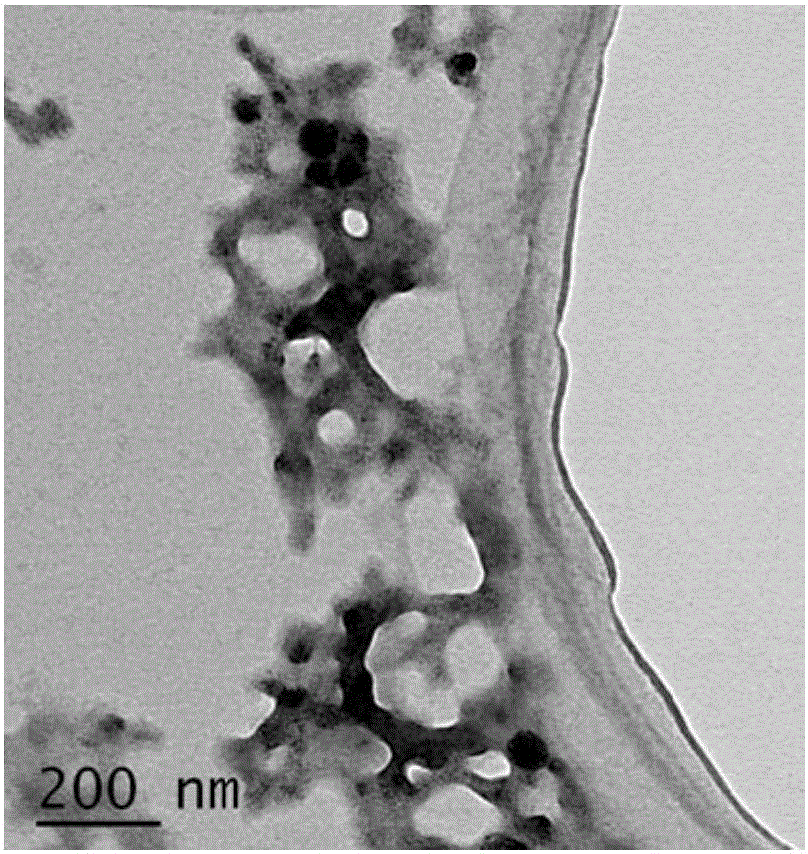

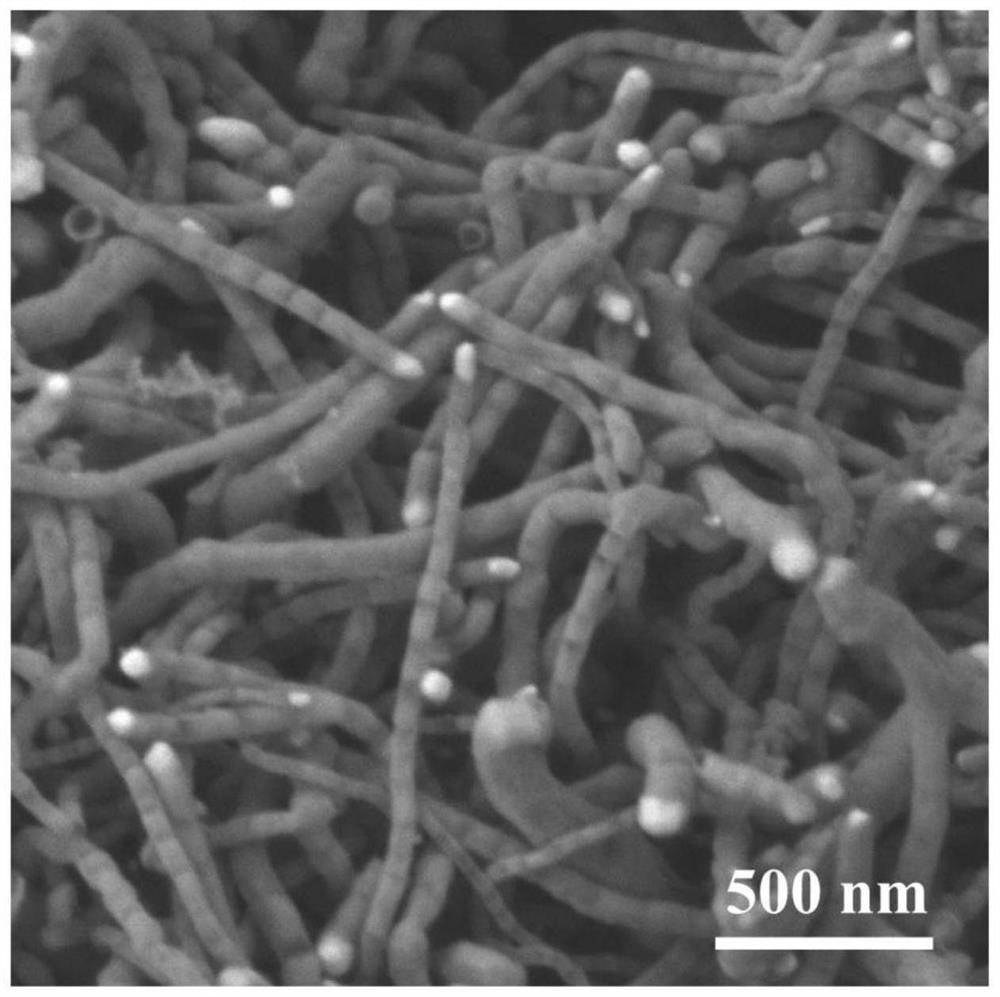

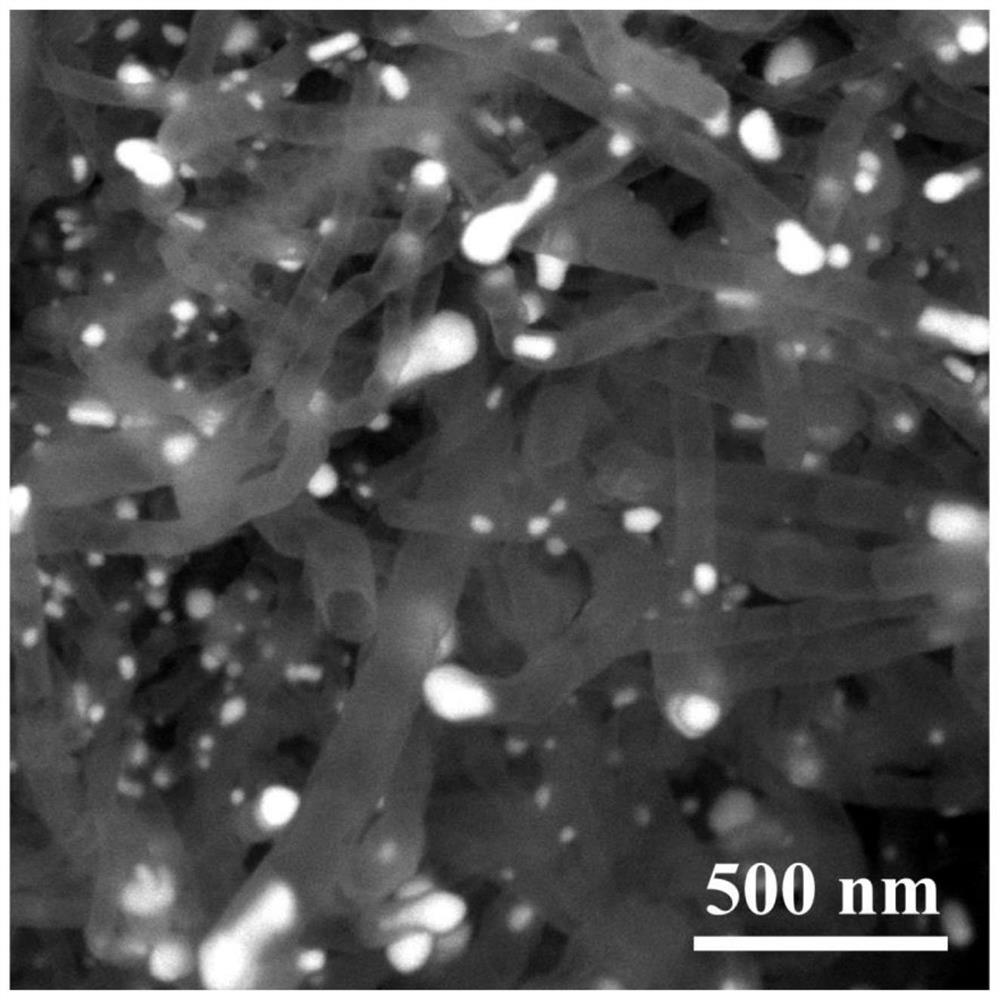

Preparation method of bamboo-like nitrogen-doped carbon nanotubes loaded with metal monoatoms and nanoparticles

ActiveCN113786856AEasily exposedImprove mass transfer efficiencyOrganic chemistryCatalyst activation/preparationZinc compoundsMeth-

The invention relates to a preparation method of bamboo-like nitrogen-doped carbon nanotubes loaded with metal monoatoms and nanoparticles. The method comprises the following steps of: adding 2-methylimidazole, metal salt, a zinc-containing compound and grinding balls into a ball milling tank, and carrying out ball milling for 2-8 hours to obtain a mixture containing ZIFs single crystals; and placing the mixture containing ZIFs single crystals in a quartz boat, heating the mixture to 800-1100 DEG C from room temperature at a speed of 2-5 DEG C min <-1 > in a tubular furnace, maintaining the temperature for 1-3 hours, and naturally cooling to room temperature to finally obtain bamboo-like nitrogen-doped carbon nanotubes loaded with metal monoatoms and nanoparticles. The steps of washing, separating and the like are not needed, the method has huge potential application value in the fields of photo-thermal catalysis, concerted catalysis and the like, and the application range of the method in the catalysis field is widened.

Owner:HEBEI UNIV OF TECH

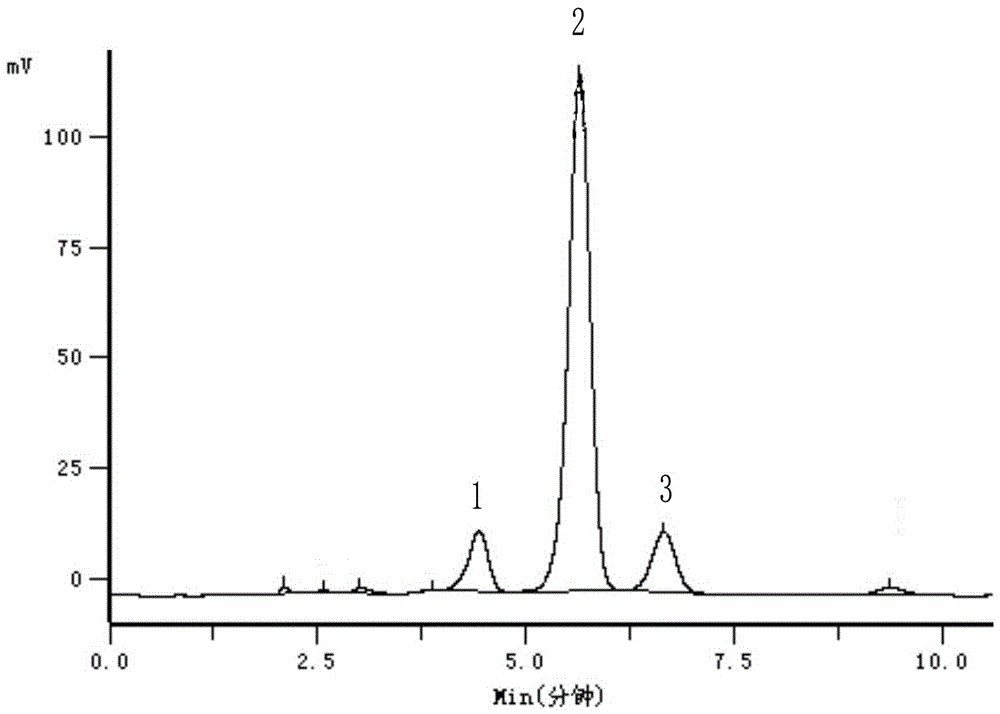

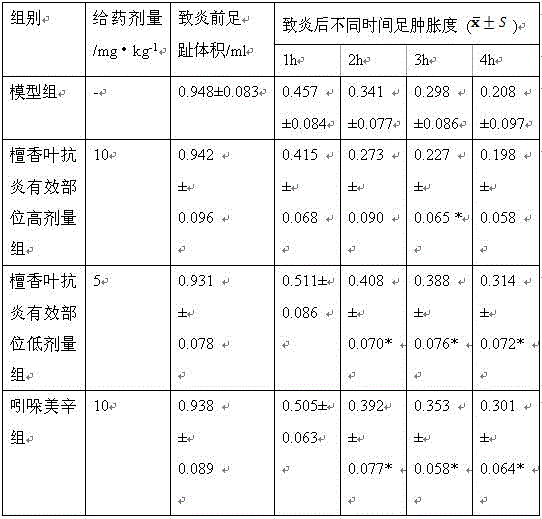

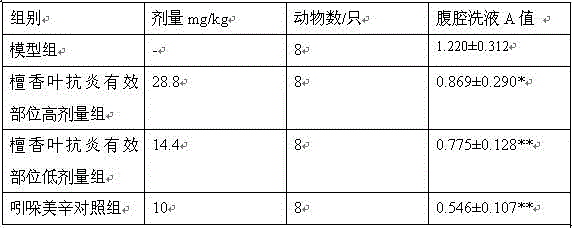

Anti-inflammatory effective part of leaf of Santalum album L. and preparation method and application of anti-inflammatory effective part of leaf of Santalum album L.

InactiveCN106265791AGood treatment effectThe chemical composition of the active part is clearOrganic active ingredientsAntipyreticOrientinIsovitexin

The invention relates to an anti-inflammatory effective part of a leaf of Santalum album L.. The anti-inflammatory effective part comprises vitexin, isovitexin and orientin, and the content of the vitexin, the isovitexin and the orientin in the effective part is not less than 80%. The invention further provides a preparation method and application of the anti-inflammatory effective part of the leaf of Santalum album L.. The anti-inflammatory effective part of the leaf of Santalum album L. is clear in chemical components and the content of the known components exceeds 80%; systematic anti-inflammatory experiments show that the effective part is effective in treatment of acute inflammation.

Owner:GUANGDONG MEDICAL UNIV

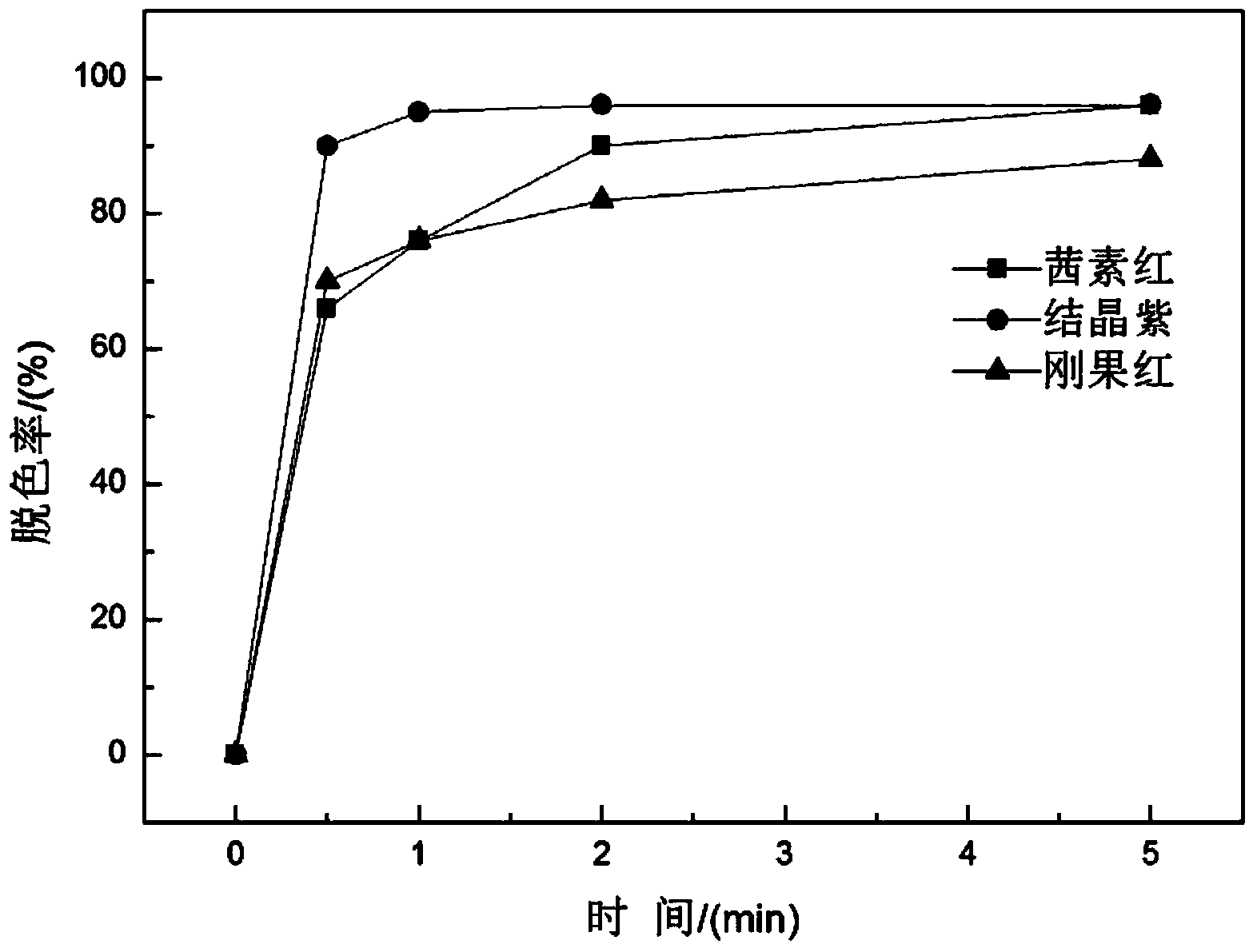

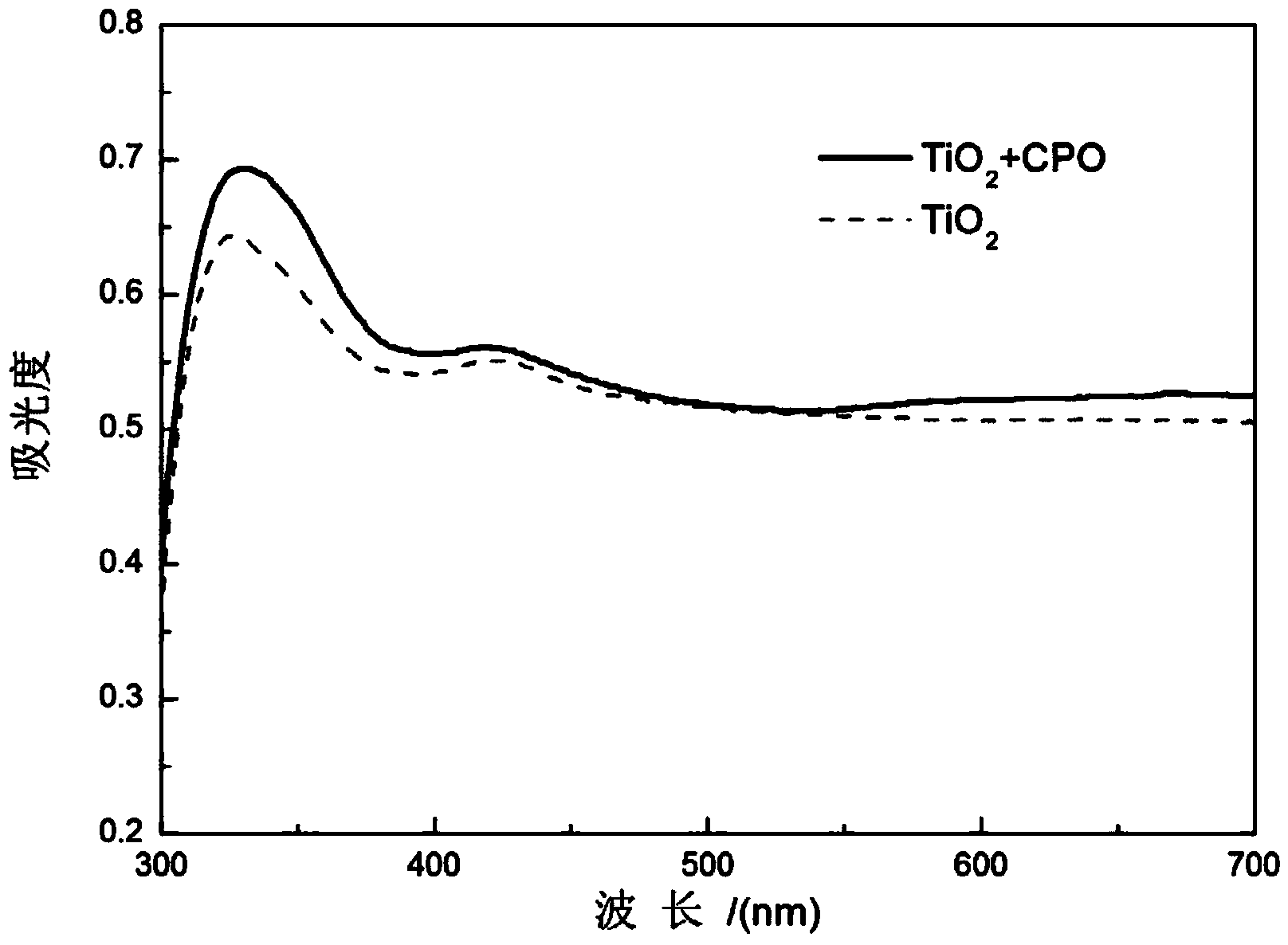

Bioreactor based on enzymatic-photocatalytic synergistic effect as well as preparation method and application of bioreactor in degradation of organic dye

InactiveCN104263643AImprove adaptabilityEasy to separateWater/sewage treatment by irradiationWater treatment compoundsOrganic dyeSunlight irradiation

The invention relates to a bioreactor based on enzymatic-photocatalytic synergistic effect as well as a preparation method and application of the bioreactor in degradation of an organic dye. The bioreactor is a TiO2 film loaded with chloroperoxidase, wherein the content of chloroperoxidase (CPO) is 5-30mg / cm<2>. According to the bioreactor, by selecting a semiconductor photocatalyst TiO2 as a carrier for immobilizing CPO, the effective immobilization of CPO is achieved, the adaptability of CPO to the reaction environment is improved, the loss is avoided and the waste is reduced; and meanwhile, the photocatalytic effect makes up the reduction in catalytic activity caused by the enzyme surface comformational change, the catalyst TiO2 is more suitable for working under sunlight irradiation conditions, the synergistic effect can be generated between the two catalysts and thus the catalytic efficiency is significantly improved and the decolorization rate can be significantly improved when the bioreactor is applied in degradation of organic dyes.

Owner:SHAANXI NORMAL UNIV

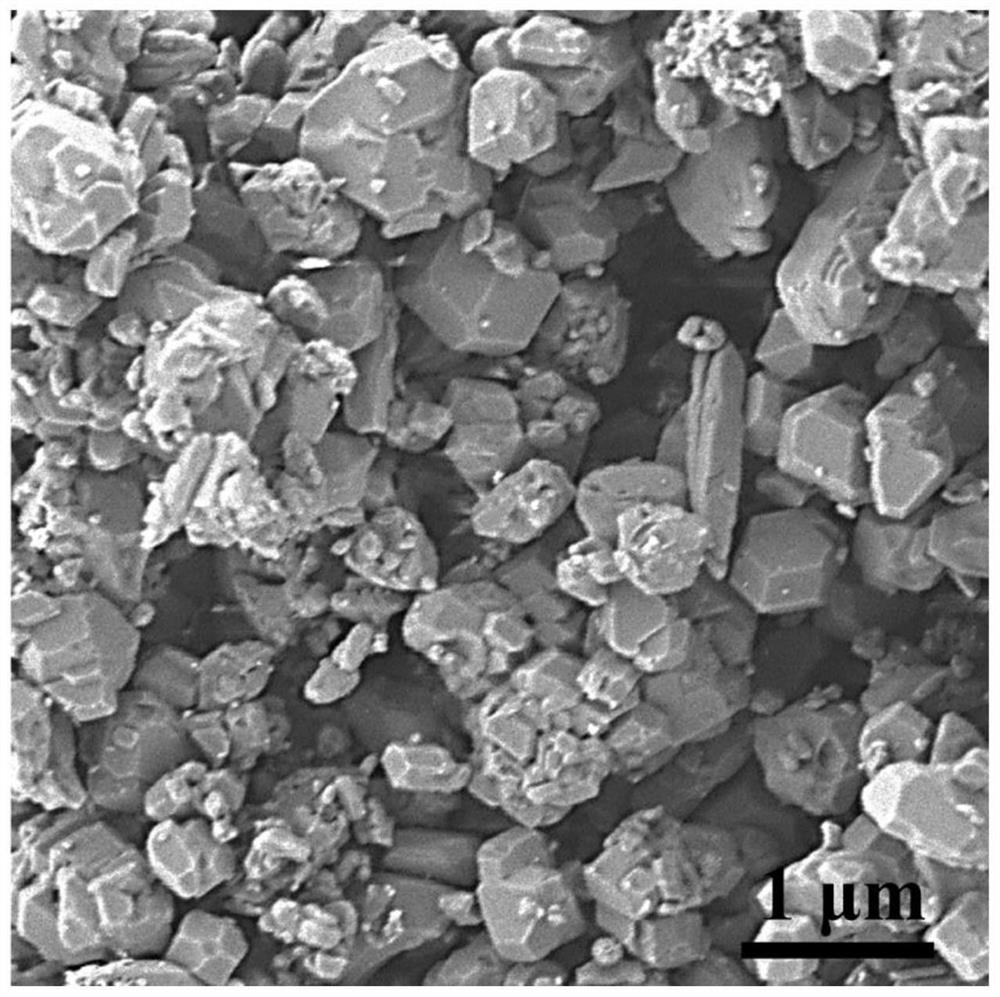

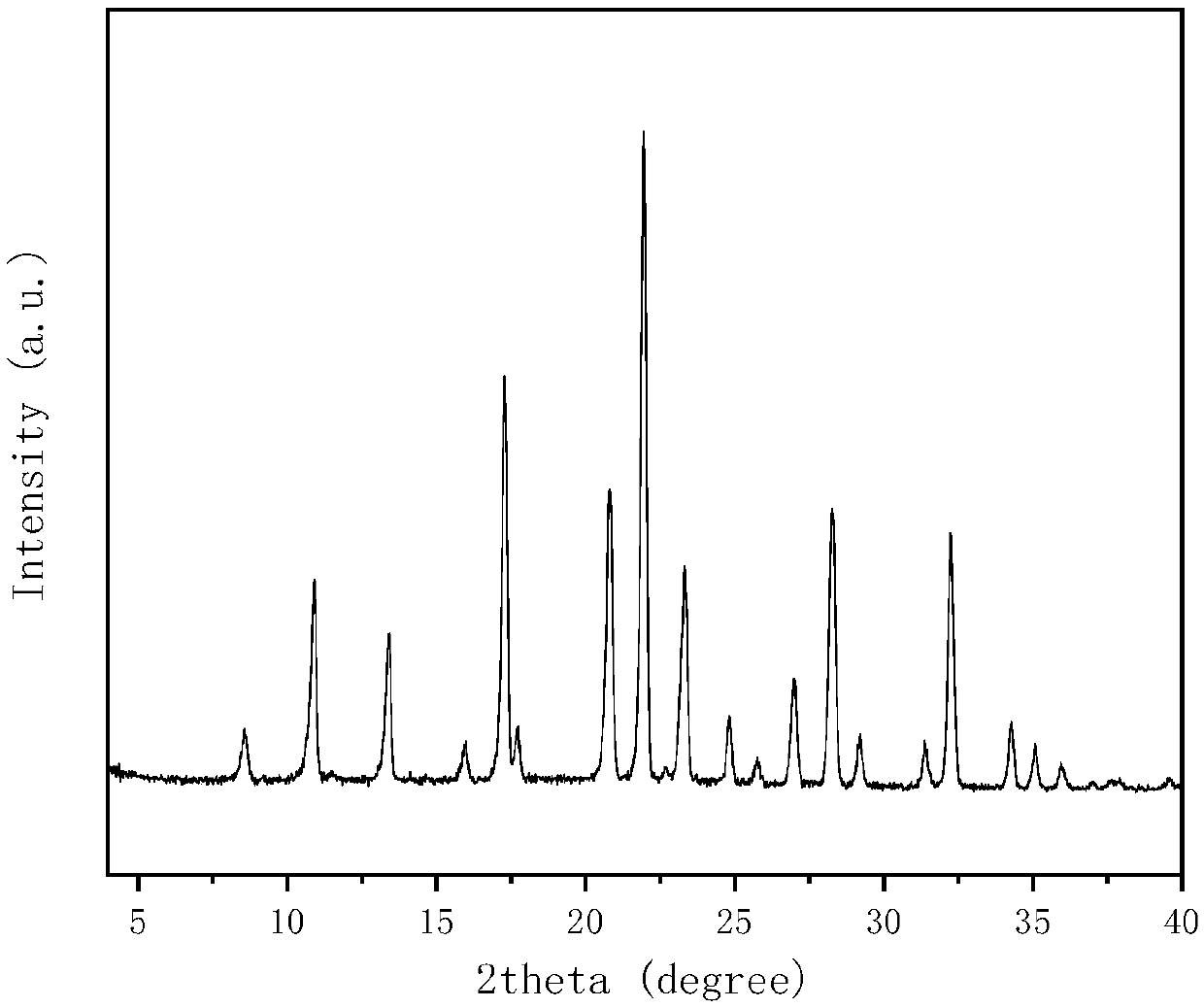

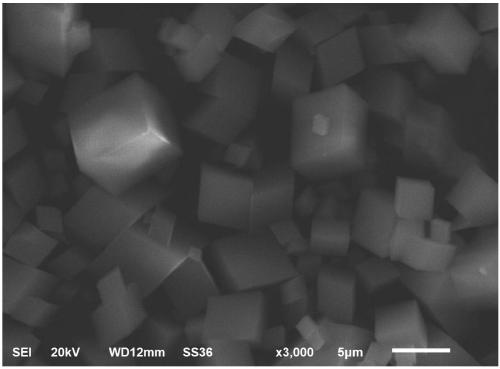

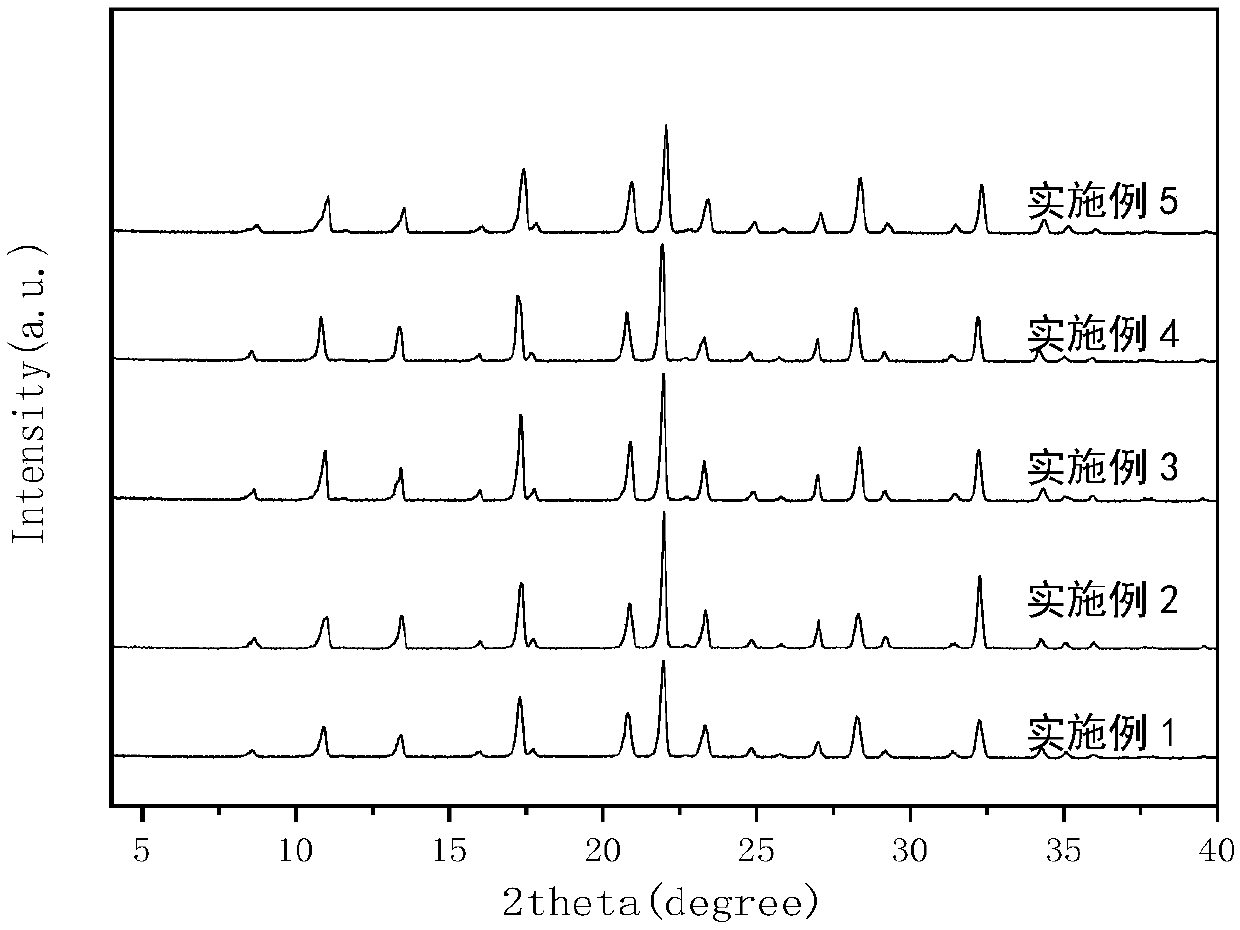

Method for preparing SAPO-35 molecular sieve with N-methyl piperidine being template agent

ActiveCN109626394AHigh crystallinityImprove thermal stabilityMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveThermal stability

The invention discloses a method for preparing an SAPO-35 molecular sieve with N-methyl piperidine being a template agent, and belongs to the technical field of SAPO molecular sieve preparation. A silicon source, an aluminum source, a phosphorus source and the N-methyl piperidine template agent are mixed and then stirred at the temperature of 10-40 DEG C uniformly to obtain initial synthesized gel; then the initial synthesized gel is subjected to hydrothermal crystallization for 1-5 days at the temperature of 160-200 DEG C and under a self-generated pressure condition; finally, hydrothermal crystallization products are collected, washed and separated and dried in a drying oven at the temperature of 50-100 DEG C to obtain the SAPO-35 molecular sieve. The prepared SAPO-35 molecular sieve isgood in crystallization degree, basically free of impurities and better in thermal stability and hydrothermal stability, and the adjustable range of the content of silicon is wide. The method is simple in step and convenient to operate, and the prepared SAPO-35 molecular sieve is suitable for a hydrocarbon conversion technology and others, suitable for an methanol-to-olefin process, and high in selectivity for ethylene, and has good prospects of industrial development.

Owner:JILIN UNIV

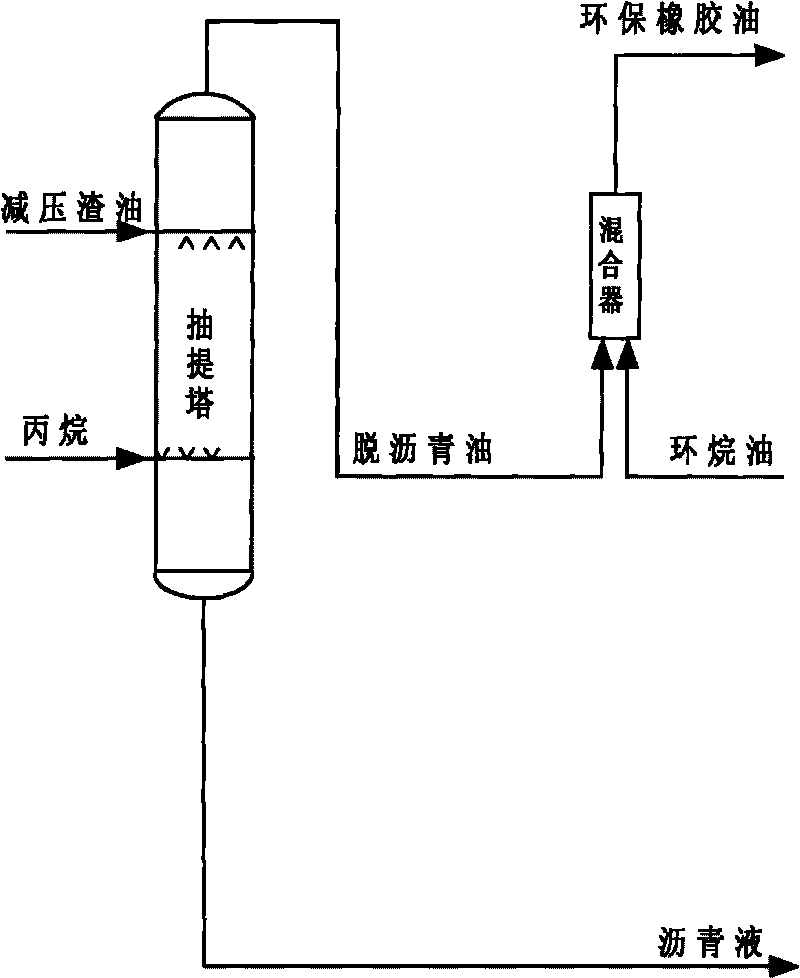

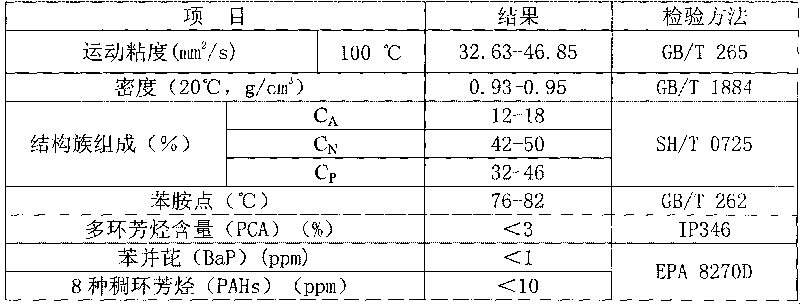

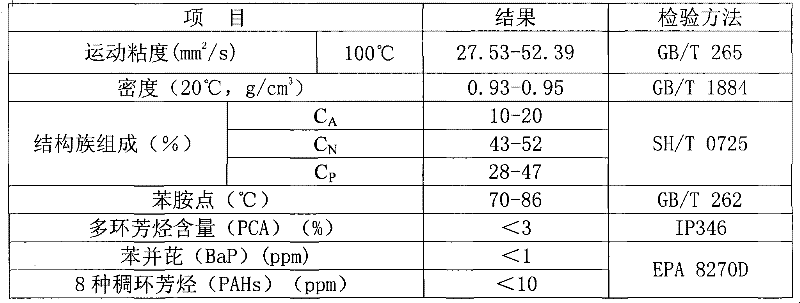

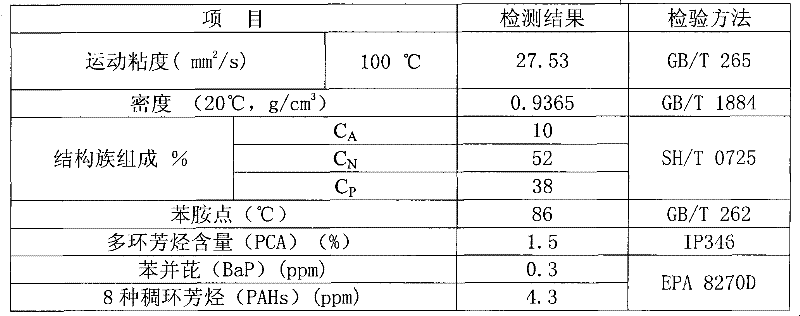

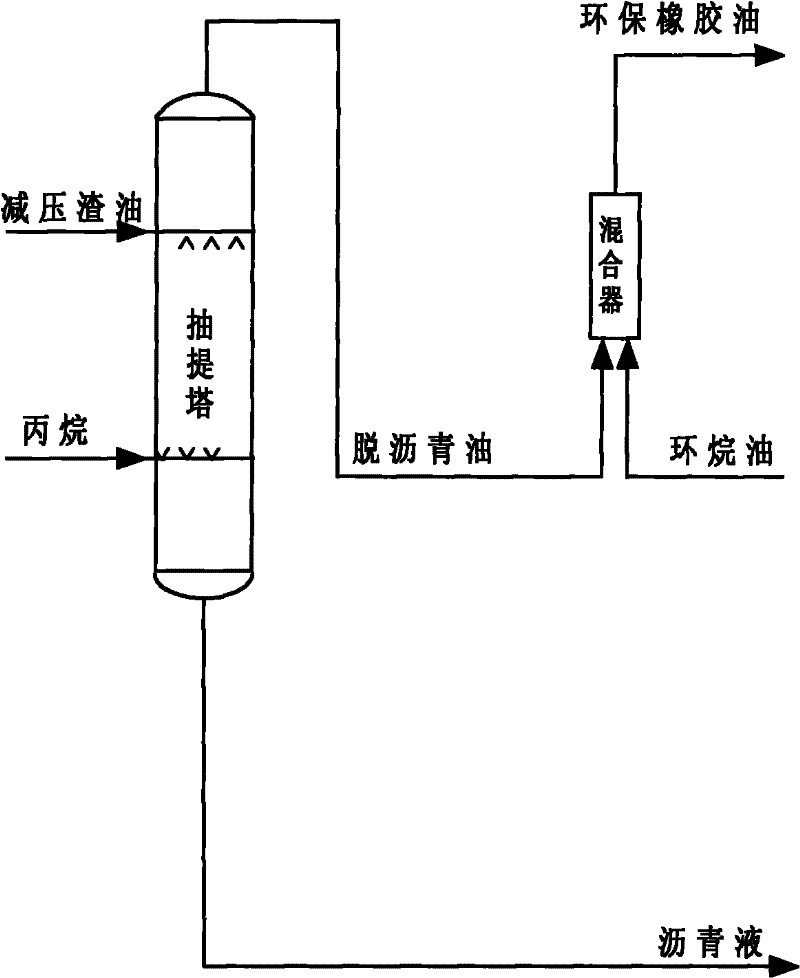

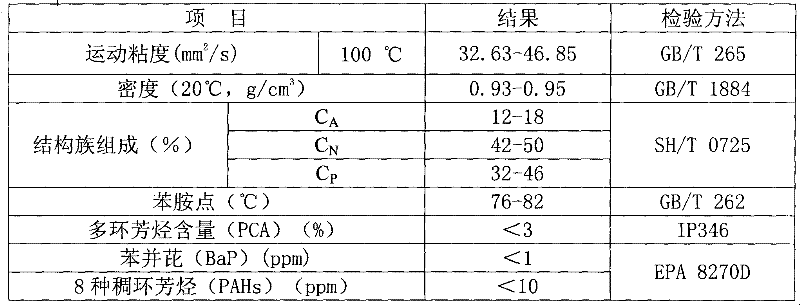

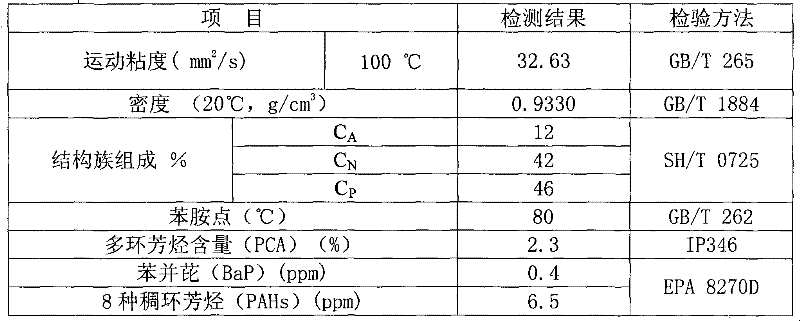

Method for producing environment-friendly rubber oil through blending method

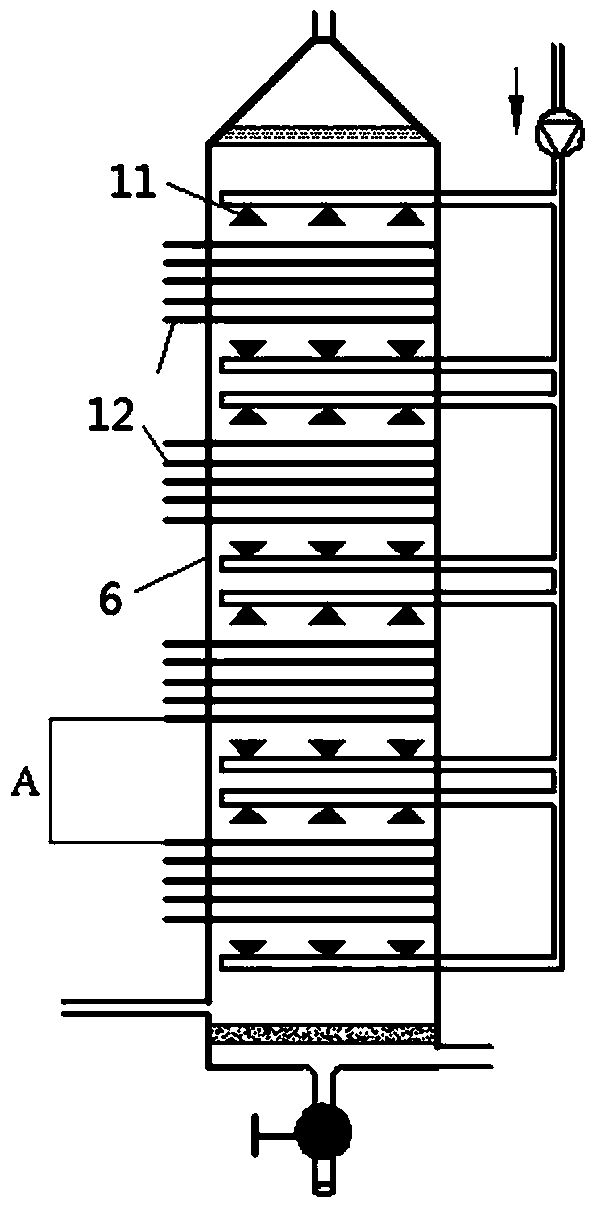

ActiveCN101693772AImprove wet skid resistanceHigh aromatic contentHydrocarbon oils refiningResidual oilTower

The invention discloses a method for producing environment-friendly rubber oil through blending method. The method provided by the invention comprises the following steps that firstly extracting decompressed residual oil with solvent to obtain deasphalted oil, wherein the solvent for extraction is propane, the ratio by volume of the solvent and the decompressed residual oil is (6-8):1, and the extraction conditions are that the temperature of a tower top is 60-95 DEG C, the temperature of a tower bottom is 50-80 DEG C, and the pressure is 2.8-7.0 MPa, secondly mixing deasphalted oil obtained in the first step with naphthenic oil for 30-120 min with 70-90 DEG C to obtain environment-friendly rubber oil, wherein the mass ratio of the deasphalted oil and the naphthenic oil is (0.2-0.6):(0.8-0.4). The environment-friendly rubber oil produced by the invention accords with the environment-friendly instruction requirement of EU 2005 / 69 / EC, wherein aromatic-carbon rate is 12%-18%, the content of PCA is smaller than 3%, the content of aromatic hydrocarbons is high, and the rubber oil is environment-friendly, nontoxic, and has no carcinogenic effect. The environment-friendly rubber oil can be used as succedaneum of existing aromatic oil, and has great economic values.

Owner:CHINA NAT OFFSHORE OIL CORP +2

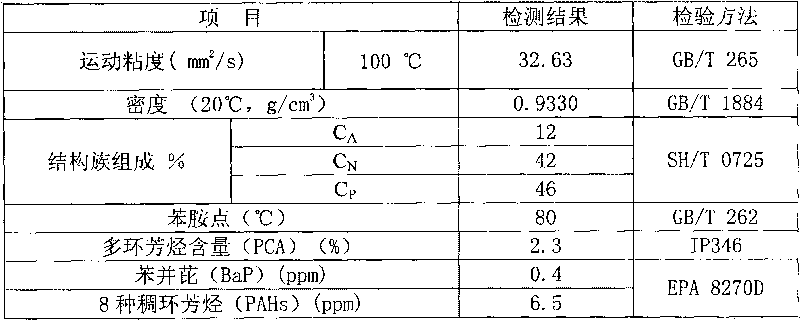

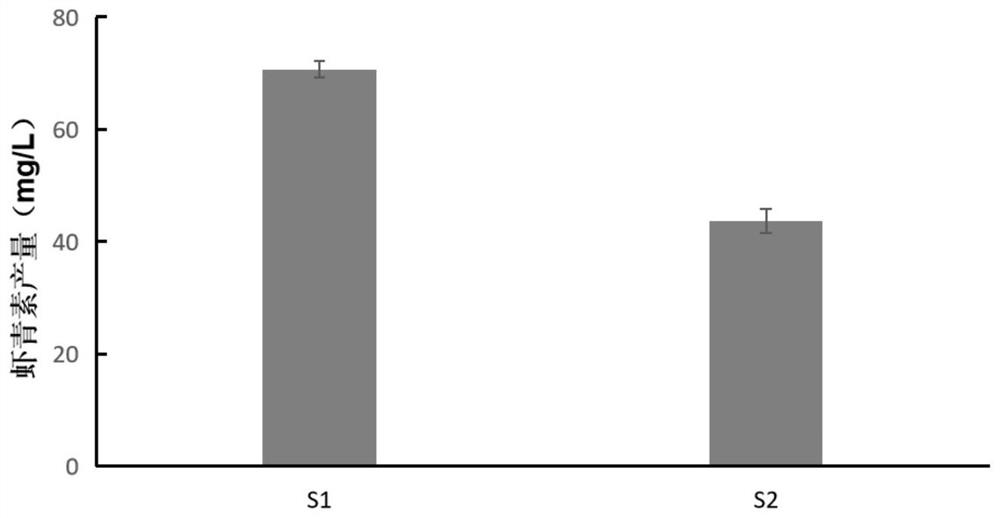

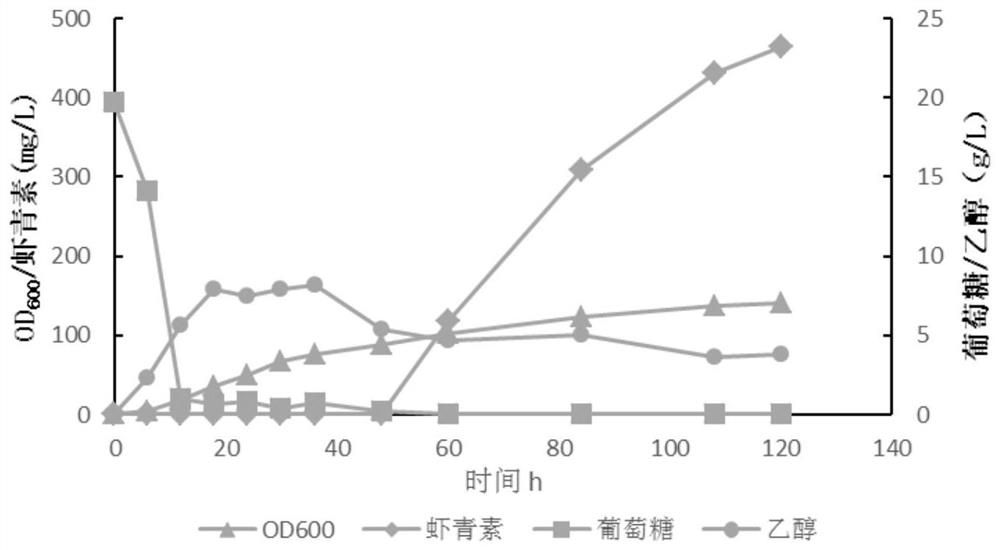

Recombinant saccharomyces cerevisiae for producing astaxanthin, and application of recombinant saccharomyces cerevisiae

ActiveCN113699053AHigh-yielding orderImprove metabolic fluxFungiMicroorganism based processesEnzyme GeneAstaxanthin

The invention discloses recombinant saccharomyces cerevisiae for producing astaxanthin, and application of the recombinant saccharomyces cerevisiae. According to the recombinant saccharomyces cerevisiae disclosed by the invention, a [beta]-carotene ketolase gene CrtW is subjected to constitutive expression, a [beta]-carotene hydroxylase gene CrtZ is subjected to inducible expression, and an intermediate product [beta]-carotene is synthesized into the astaxanthin. According to the recombinant saccharomyces cerevisiae, a constitutive promoter is used for regulating and controlling the CrtW gene to be firstly expressed, the inducible promoter is used for regulating and controlling the CrtZ gene to be expressed subsequently, so that the metabolic flux of the synthesis path of the astaxanthin of the saccharomyces cerevisiae is obviously improved, the yield of the astaxanthin reaches 464.90 mg / L, and the recombinant saccharomyces cerevisiae has a good industrial development prospect.

Owner:WANHUA CHEM (SICHUAN) CO LTD +1

A kind of vocs removal method of ozone combined with photolysis peroxide

ActiveCN104815537BImprove removal efficiencyTo improve the removal efficiency of pollutants, priority must be given to strengthening the removal efficiencyDispersed particle separationAir quality improvementSulfate radicalsDecomposition

The invention relates to a method for removing VOCs (volatile organic chemicals) by ozone and photolytic peroxide. According to the method, the VOCs from a discharging source are firstly pre-oxidized into organic intermediate by the ozone in a flue, ultraviolet light excites the peroxide to generate sulfate radical and hydroxyl free radical, so that the VOCs and the organic intermediate generated by oxidization of the ozone are further oxidized, and final decomposition products are harmless CO2 and harmless H2O. The VOCs in flue gas can be efficiently removed, secondary pollution is avoided in the removing process, and a novel VOCs purification system has a wide application prospect.

Owner:CHANGSHU YONGXIN PRINTING & DYEING CO LTD

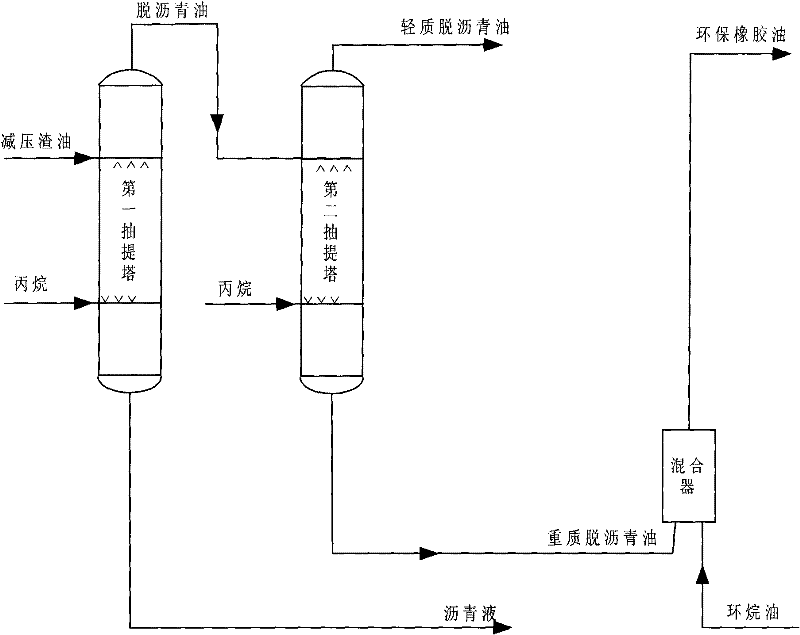

Blending-process method for producing environment-friendly rubber oil

ActiveCN101691427BImprove wet skid resistanceHigh aromatic contentTreatment with plural serial refining stagesResidual oilSolvent

The invention discloses a blending-process method for producing environment-friendly rubber oil. The method provided by the invention comprises the following steps: 1) performing solvent extraction on reduced-pressure residual oil to obtain deasphalted oil, wherein a solvent used for extraction is propane; the volume ratio of the solvent to the reduced-pressure residual oil is (6-8):1; and extraction conditions are tower-top temperature between 70 and 91 DEG C, tower-bottom temperature between 57 and 80 DEG C and pressure between 3.8 and 7.0 MPa; 2) performing solvent extraction on the deasphalted oil obtained in a step 1) to obtain heavy deasphalted oil, wherein the solvent used for extraction is propane; the volume ratio of the solvent to the deasphalted oil is (6-8):1; and the extraction conditions are tower-top temperature between 60and 80 DEG C, tower-bottom temperature between 50 and 70 DEG C and pressure between 2.8 and 3.9 MPa; and 3) mixing the heavy deasphalted oil obtained in a step 2) with naphthenic oil at a temperature between 70 and 90 DEG C for 30 to 120 minutes to obtain the environment-friendly rubber oil, wherein the mass ratio of the heavy deasphalted oil to the naphthenic oil is (0.3-0.7):(0.7-0.3). The environment-friendly rubber oil has the advantage of meeting the requirements of EU 2005 / 69 / EC environment-protecting directives, along with aromatic-carbon rate between 10 and 20 percent, PCA content of less than 3 percent, high aromatic hydrocarbon content, environment-protecting property, no toxicity and no carcinogenic effects. The environment-friendly rubber oil can be used as a substitute for the prior aromatic oil, and has significant economic value.

Owner:CHINA NAT OFFSHORE OIL CORP +2

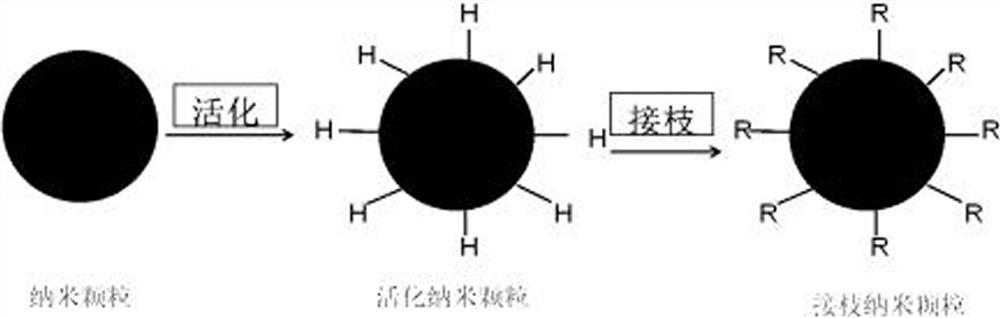

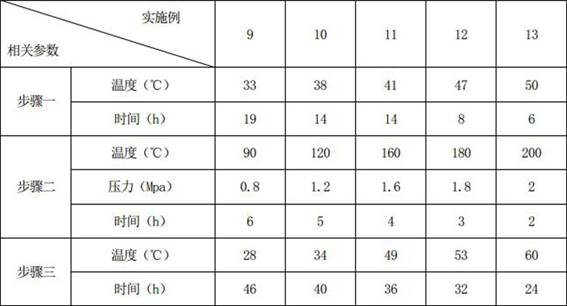

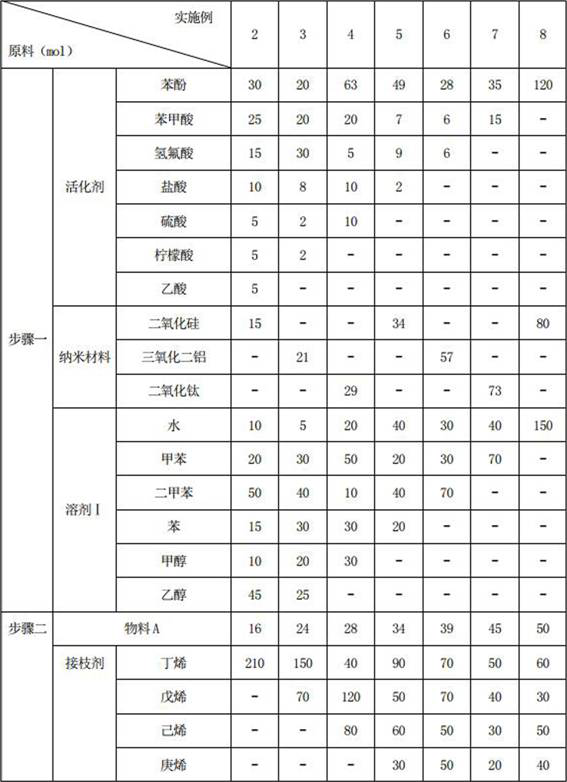

Modification method of nano material for high-viscosity coating, and preparation method and application of corona-resistant composite coating

InactiveCN111808528AEvenly dispersedGood dispersionInsulatorsCoatingsCoating systemCompatibilization

The invention discloses a modification method of a nano material for a high-viscosity coating, and a preparation method and application of a corona-resistant composite coating. The modification methodof the nano material for the high-viscosity coating comprises the steps of activation, grafting and silane coupling modification which are carried out in sequence. The preparation method of the corona-resistant composite coating comprises the step of mixing the modified nano material with a corona-resistant coating to obtain the corona-resistant composite coating which is applied to the coating of corona-resistant enameled wires. The nano material modified by the method is uniformly dispersed in a high-viscosity coating system, does not settle and has high stability. The invention belongs tothe field of high polymer materials. The nano material is suitable for the corona-resistant composite coating, and the corona-resistant composite coating is used for coating the corona-resistant enameled wires, and can prolong corona-resistant time by more than 80 hours. The modified nano material has good compatibility with the corona-resistant composite coating, and does not influence the performance of the main body polymer of the corona-resistant composite coating.

Owner:HUNAN UNIV OF SCI & TECH

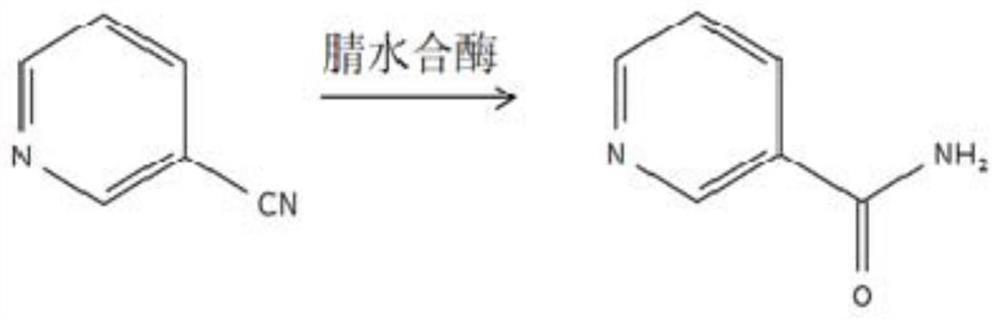

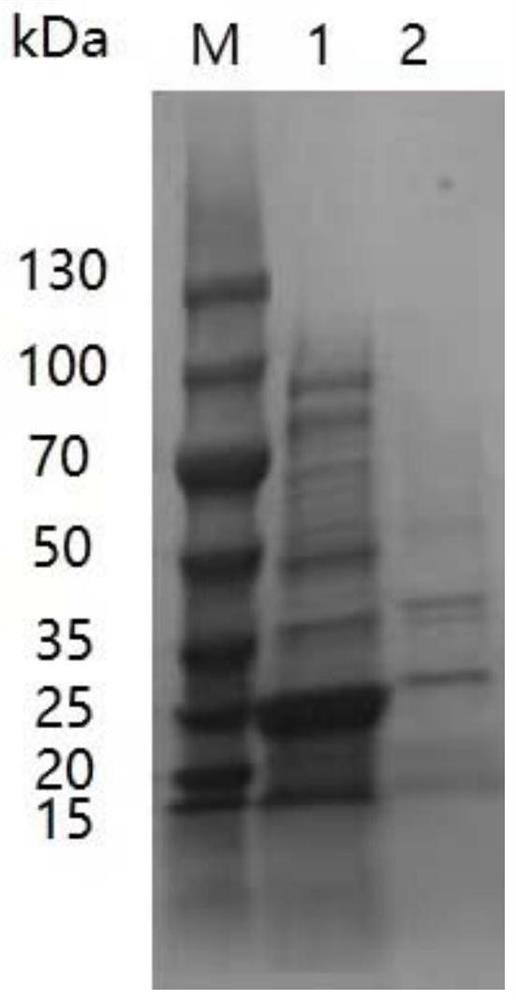

Recombinant expression vector, genetically engineered bacterium, and culture method and application of genetically engineered bacterium

PendingCN113943746AImprove efficiencyIncrease enzyme activityBacteriaMicroorganism based processesMicroorganismSpecific enzyme

The invention relates to a genetically engineered bacterium expressed by a nitrile hydratase gene, and particularly relates to a recombinant expression vector, a genetically engineered bacterium, and a culture method and application of the genetically engineered bacterium. The recombinant expression vector contains a section of nitrile hydratase gene, and the sequence of the nitrile hydratase gene is shown as SEQ ID NO. 1; the genetically engineered bacterium is a host microorganism carrying the recombinant expression vector; the culture method comprises the following steps of: culturing the host microorganism in an LB culture medium to obtain a seed solution, and then inoculating the seed solution into a fermentation culture medium for culturing to obtain the genetically engineered bacterium. Compared with the prior art, the nitrile hydratase gene can realize efficient expression in the engineered bacterium and has excellent enzymatic activity, and the specific enzyme activity can reach 50U / mg or above through determination and can reach 100U / mg under a preferred condition, so that the catalytic synthesis efficiency of nicotinamide is high, the conversion rate can reach 99% or above, and the production efficiency reaches 720g / (L.h).

Owner:SHANGHAI INST OF TECH

A kind of inorganic superhydrophobic coating and its application

ActiveCN104672962BSimple manufacturing methodImprove stabilityAntifouling/underwater paintsLayered productsMicro nanoMicrosphere

The invention relates to inorganic substance super-hydrophobic paint and application thereof. The paint is prepared in the following method: silica sol is injected into a reactor with a nano microsphere template under a negative pressure condition, the template is immersed in the silica sol for 2h, then the reactor is sealed and stored in a thermostat, the silica sol and the template react at the temperature of 60 DEG C for 12h, the template is removed by virtue of heating or water immersion, a solid blocked micro-nano composite polygon is obtained, and after the blocked micro-nano composite polygon is dried, the blocked micro-nano composite polygon is ground into powder; the powder is poured into another reactor, dispersion liquid acetone is mixed with the powder, a low-surface-energy silane coupling agent is used for modifying the powder at a temperature of 25 to 50 DEG C, the powder reacts for 10h to 15h, the micro-nano composite polygon powder accounts for 0.5 to 20 percent of the mass of the paint, and the super-hydrophobic paint is prepared. The inorganic substance super-hydrophobic paint can be smeared on the surfaces of various conventional materials, the preparation method of the paint is simple, and the obtained super-hydrophobic surface is excellent in stability.

Owner:天津超疏水纳米科技有限公司

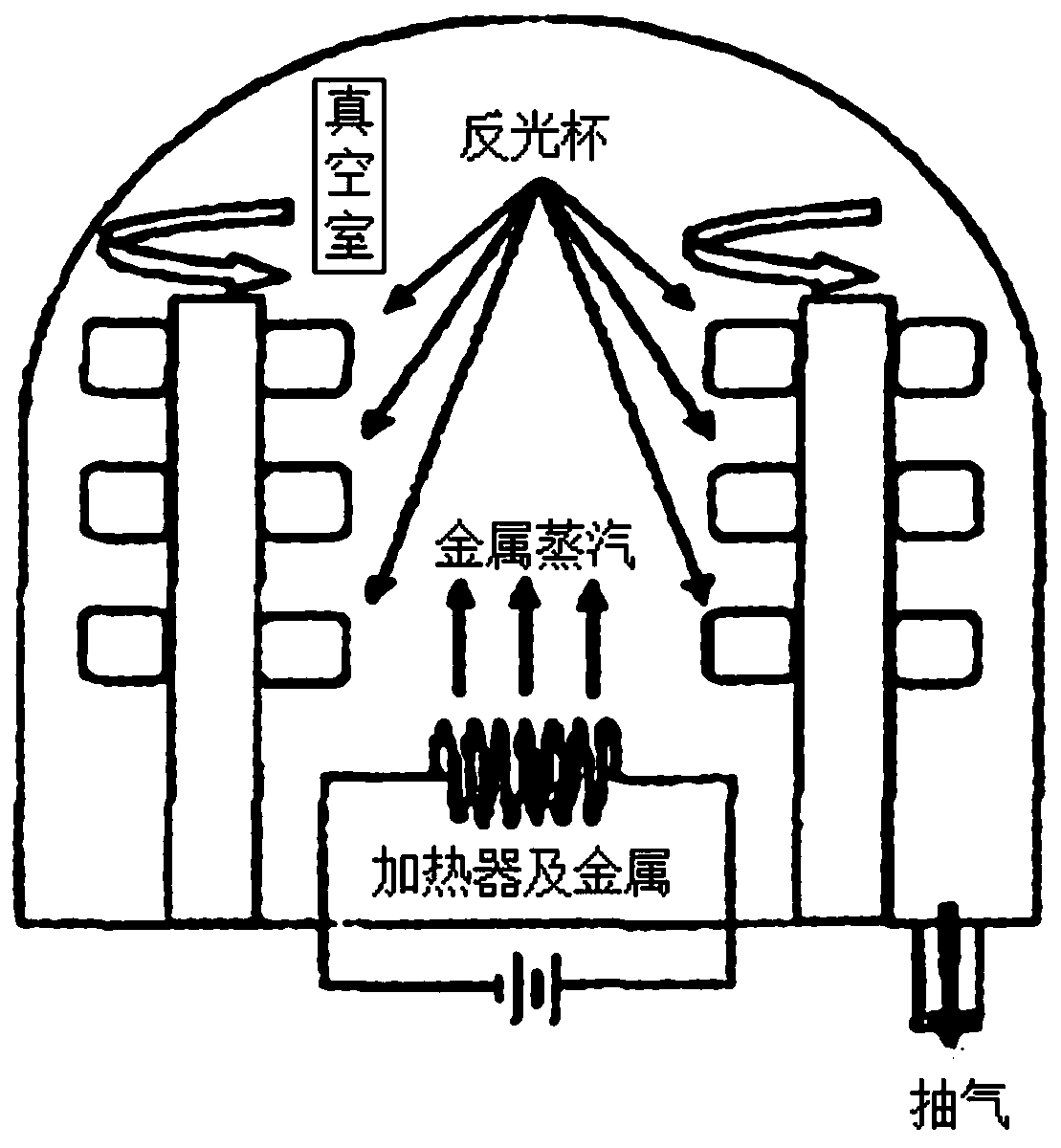

Method for nano vacuum coating of reflective cup

InactiveCN110565053APollution threatPhysical health threatVacuum evaporation coatingSputtering coatingEvaporationPre treatment

The invention discloses a method for nano vacuum coating of a reflective cup. The method comprises the following steps: (1) pre-treatment: cleaning oil stains and a release agent on the surface of thereflective cup and activating the surface of the reflective cup; (2) drying and electrostatic dust collection: after drying the pre-treated reflective cup, ionizing gas by means of an static electricfield to absorb dust particles to an electrode in an electrified manner; (3) first time evaporation of silicone oil: fixing the reflective cup treated in the step (2) to a clamp and mounting the reflective cup in a vacuum chamber of an evaporative coating machine for plating silicone oil, wherein the thickness of the silicone oil is 2.5-3.0 [mu]m; (4) evaporation: coating the reflective cup plated with the silicone oil, wherein the thickness of the coating is 50-60 [mu]m; (5) second time evaporation of silicone oil: plating silicone oil to the evaporated reflective cup, wherein the thicknessof the silicone oil is 2.5-3.0 [mu]m; and (6) inspection and packaging: inspecting the reflective cup treated in the step (5) and packaging and putting qualified products in storage.

Owner:韦立

A method of processing low-value fish antibacterial peptides

InactiveCN107099572AHigh yieldHigh purityFermentationAnimals/human peptidesEnzymatic hydrolysisMicrowave

A method of processing low-value fish antibacterial peptides is disclosed. The method includes steps of preparing, sterilizing, degreasing, performing microwave extraction for purification, performing centrifugal purification, performing enzymatic hydrolysis, performing centrifugal purification, and performing purification with ammonium sulfate to obtain a finished product. Swim bladders of low-value fish are degreased, impurities are removed by filtration, proteins in the swim bladders are purified, then the enzymatic hydrolysis is performed to hydrolyze the proteins into antibacterial peptides, and enzymatic-activity peptides are used to increase activity of compound protease, thus accelerating hydrolysis and increasing the processing efficiency. Beneficial effects of the method are that the swim bladders of low-value fish are utilized to produce the antibacterial peptides to achieve high-value utilization of the swim bladders, the antibacterial peptides prepared by the method have characteristics of capability of being natural, nontoxic, pollution-free, antibacterial, efficient, wide in antibacterial spectrum, and the like, and the finally obtained antibacterial peptides are high in yield and purity, can be applied in industrial production and have a good development prospect.

Owner:舟山达康科技有限公司

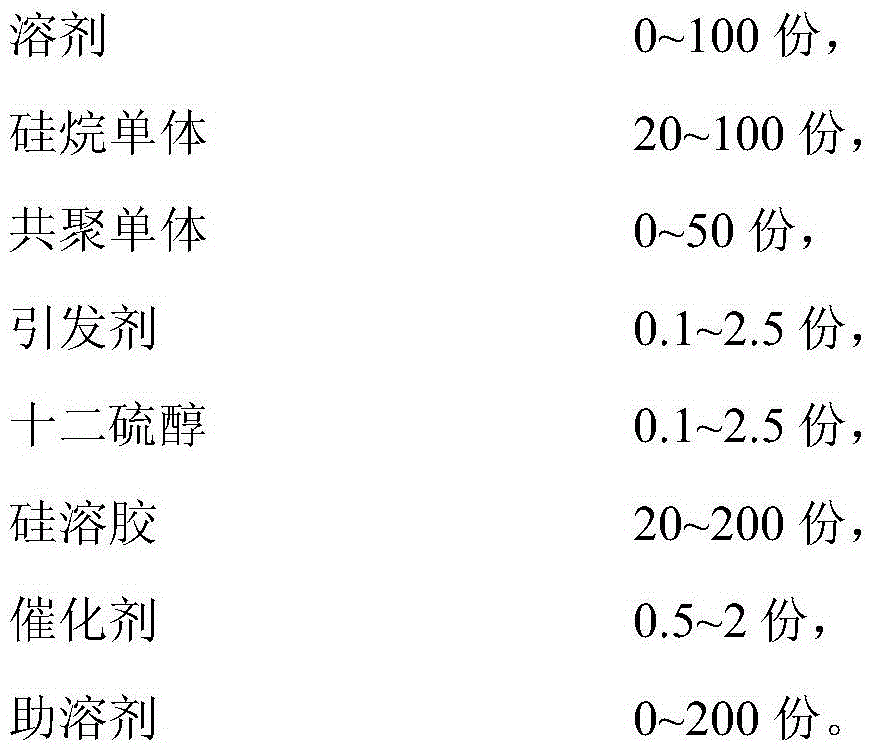

Preparation method and application of organic modified silica sol

ActiveCN105542515ASolve the problem of too fast self-condensationImprove stabilityCoatingsPigment treatment with macromolecular organic compoundsWater basedFlocculation

The invention belongs to the field of organic-inorganic composite materials. In order to solve the problem that silica sol is sensitive to the external complex environment so as to be easy to cause the phenomena such as flocculation and solidification, the invention provides a preparation method of an organic modified silica sol. The method comprises the following steps of preparing an organic modifier first, and then modifying the silica sol, so that the obtained silica sol is higher in grafting yield, good in storage stability and applied to water-based paint.

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

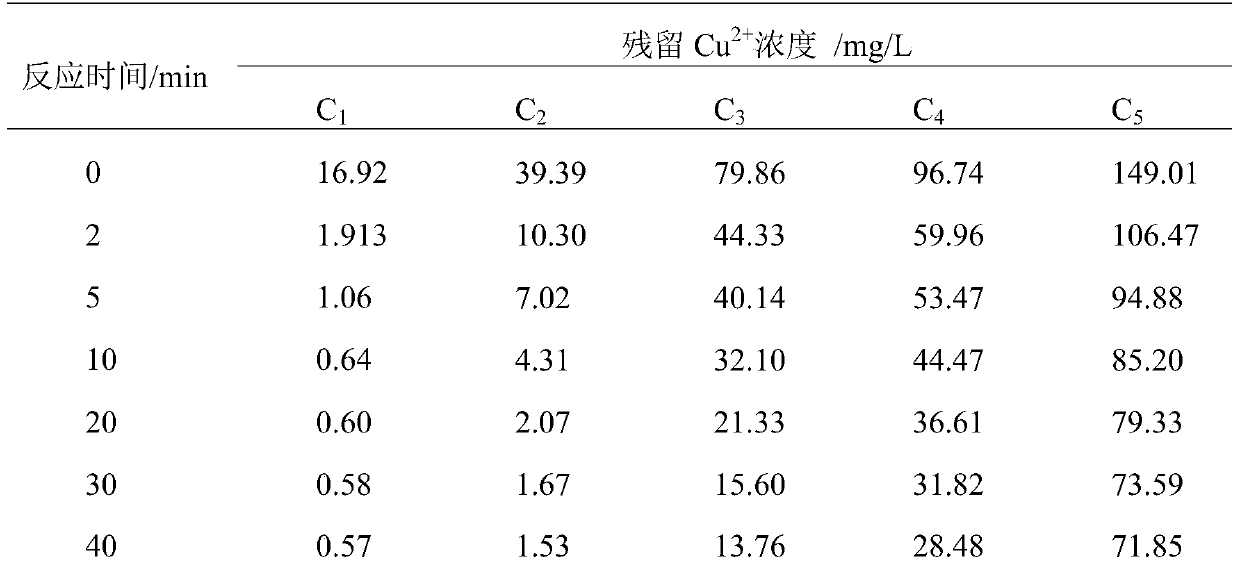

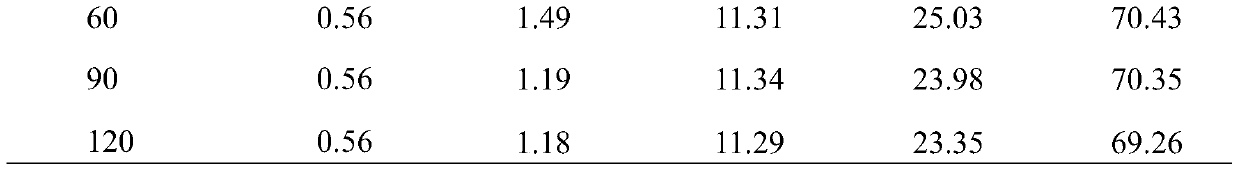

A kind of preparation method and application of potassium octatitanate whisker

InactiveCN105056874BReduce manufacturing costEase of industrial productionOther chemical processesTitanium compoundsPotassium octatitanatePhysical chemistry

The invention discloses a preparation method of potassium octatitanate whiskers and a method for absorbing heavy metal ions. The preparation method uses metatitanic acid and potassium carbonate as raw materials, adopts a sintering method to prepare potassium octatitanate whiskers, and uses It adsorbs Cu2+, Pb2+, Ni2+ or Cr3+ heavy metal ion solution. In the method, potassium octatitanate whiskers are prepared by using metatitanic acid, an intermediate product in the sulfuric acid process titanium dioxide production process, as a raw material, and the production cost is low and the preparation method is simple. The prepared potassium octatitanate whiskers have the advantages of good adsorption effect on heavy metal ions, easy separation, good reusability, low environmental pollution, etc., and have good industrial development prospects.

Owner:JIANGSU UNIV

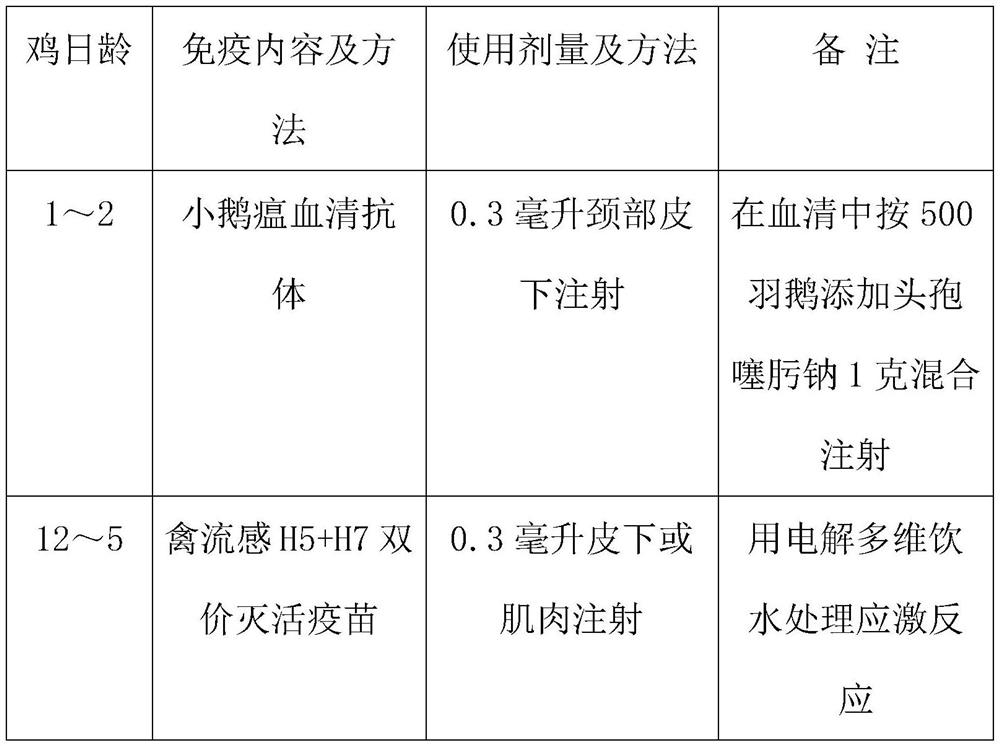

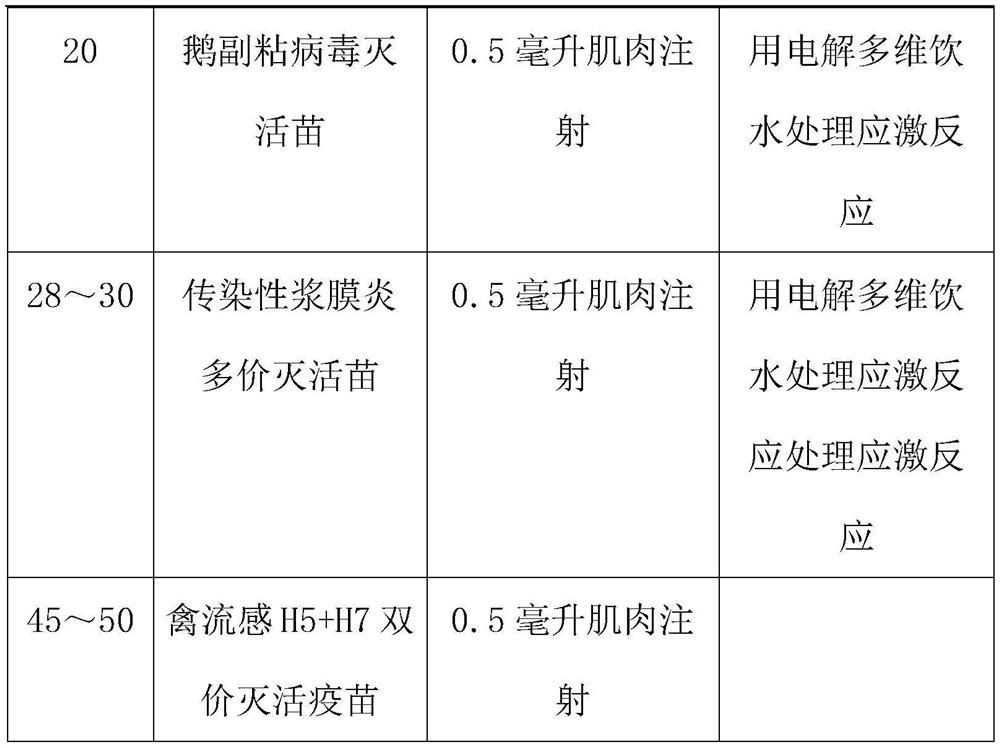

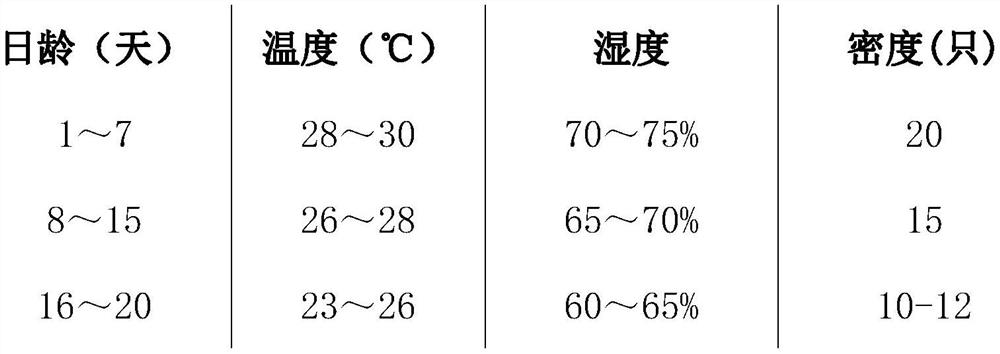

Under-forest ecological breeding method for geese

ActiveCN113598130AHigh utilization rate of forest and grassImprove lean meat percentageAnimal husbandryDiseaseLean meat

The invention discloses an under-forest ecological breeding method for geese. The under-forest ecological breeding method for geese comprises the following steps: step 1, selecting a breeding site; step 2, performing site planning and layout; step 3, building a breeding house and meeting requirements; step 4, constructing harmless treatment facilities for the feces and the geese died of illness; step 5, performing variety selection; step 6, carrying out epidemic disease immune prevention and control; step 7, performing feeding management technical key points; step 8, performing conventional disease diagnosis, prevention and treatment; step 9, performing harmless treatment on the feces and the geese died of illness; and step 10, establishing a healthy breeding file. The under-forest ecological breeding method for geese has the advantages of achieving high forest grass utilization rate, resistance to coarse feed, low feed cost, high lean meat percentage, low meat cholesterol content, high plush economic additional value and the like, and has good industrial development prospects. Through fine goose feeding management and short-term fattening technology application, the breeding economic benefit is remarkably improved.

Owner:GUIZHOU INST OF ANIMAL HUSBANDRY & VETERINARY

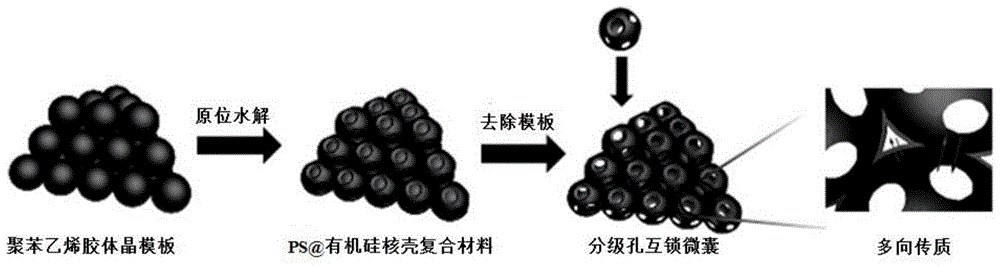

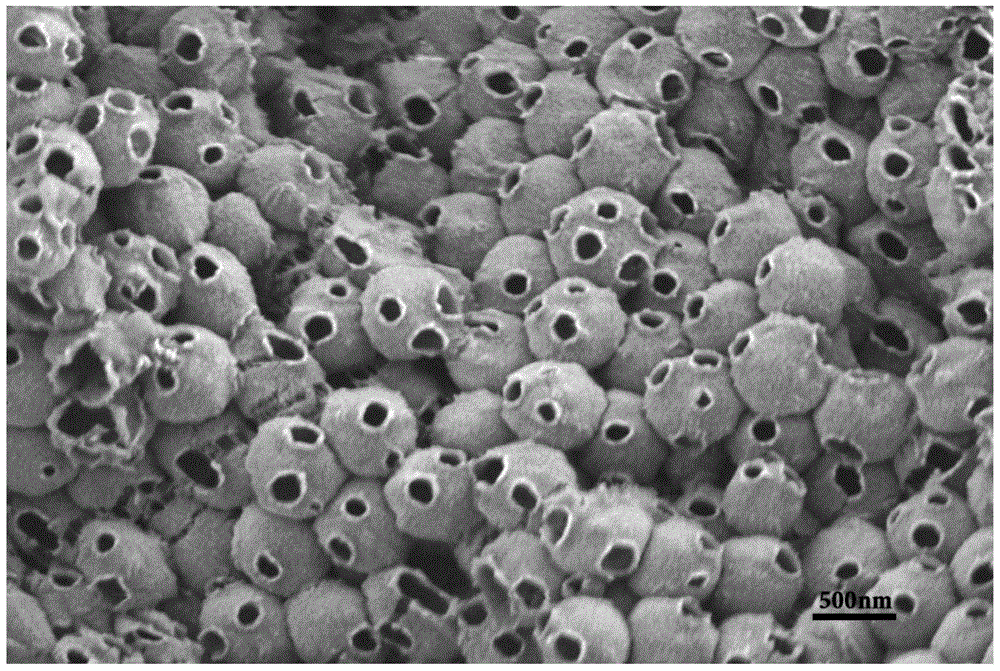

A kind of preparation method of organosilicon material graded pore structure interlocking microcapsules

InactiveCN104772087BSimple manufacturing processMild reaction conditionsMicroballoon preparationMicrocapsule preparationCross-linkPolystyrene

The invention discloses a preparation method of an organic silicon material hierarchical porous structure interlocking microcapsule. The preparation method comprises the following steps: (1) performing surface functionalization on a polystyrene colloidal crystal template; (2) preparing PS@ organic silicon core-shell composite material and (3) removing polystyrene in the PS@ organic silicon core-shell composite material. Compared with a polymer-based hierarchical porous structure interlocking microcapsule, the preparation method has the advantages that the preparation technique is simple in process and moderate in reaction conditions; no subsequent cross-linking pore-forming is needed; as the obtained product is rich in amidogen, the preparation method has a huge potential application value in the field of nano-gold loaded catalysis.

Owner:HEBEI UNIV OF TECH

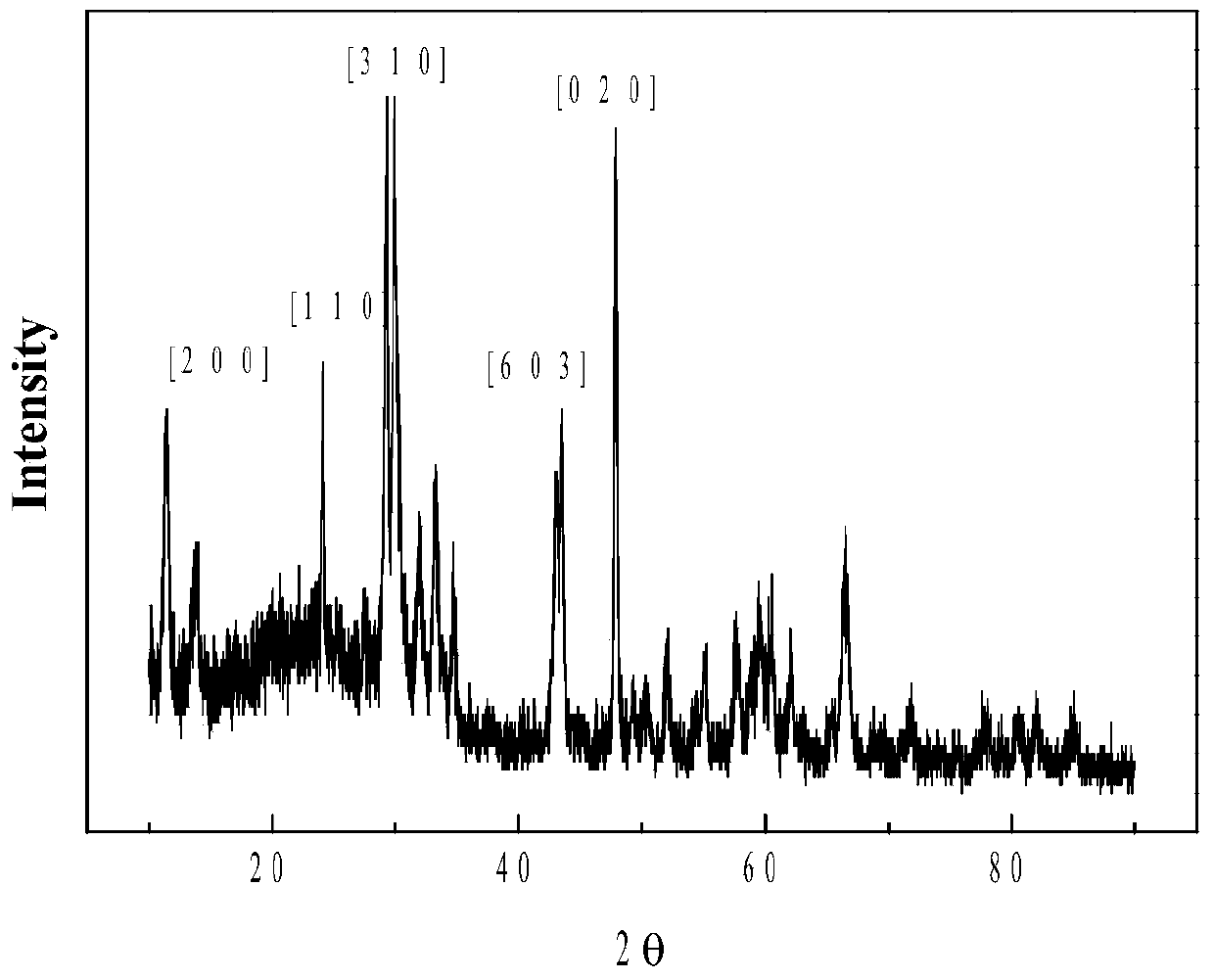

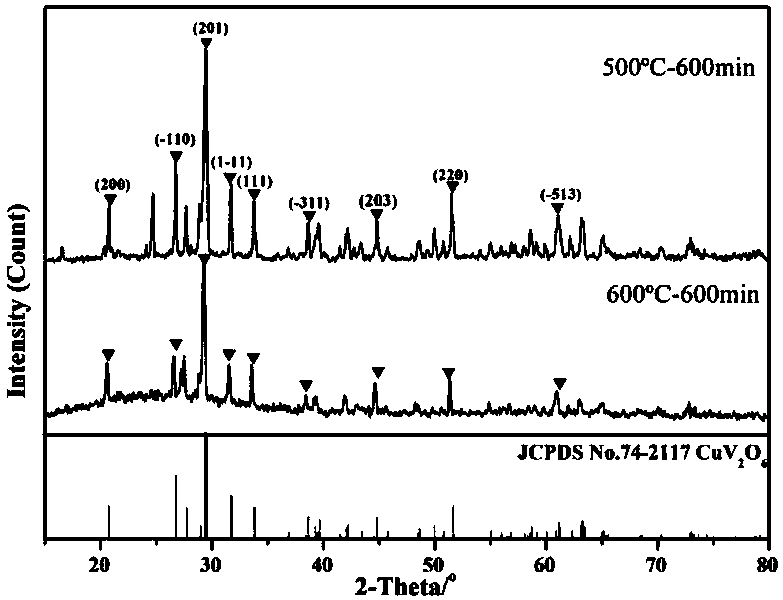

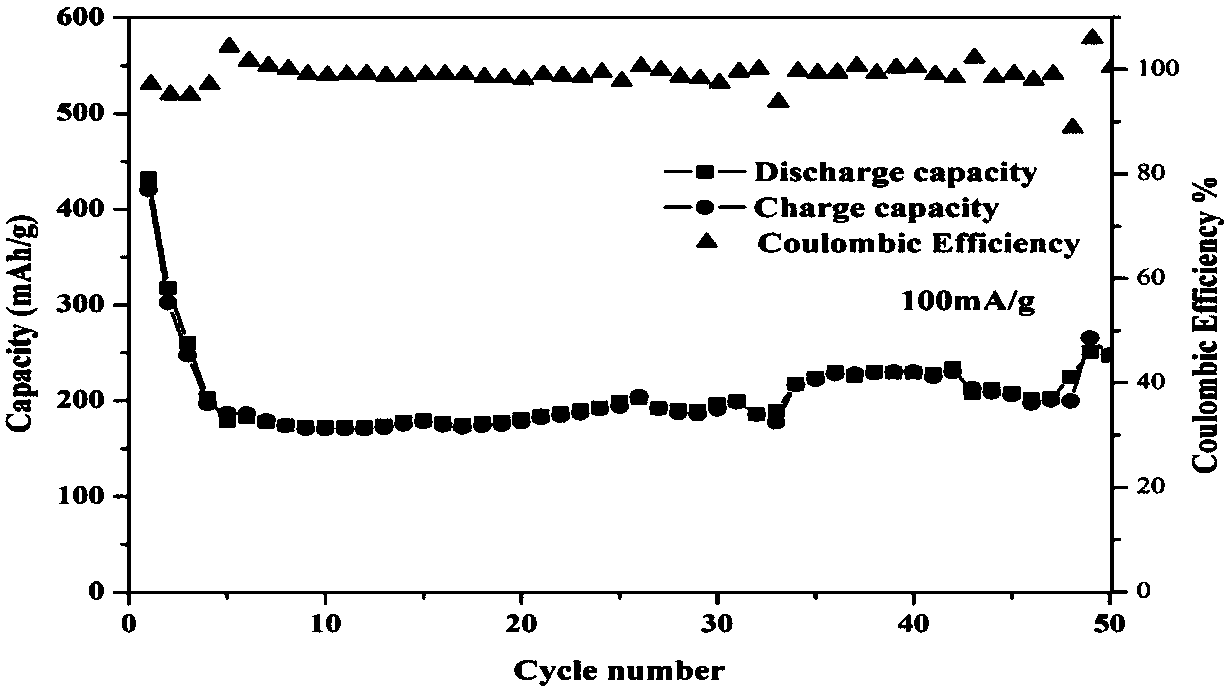

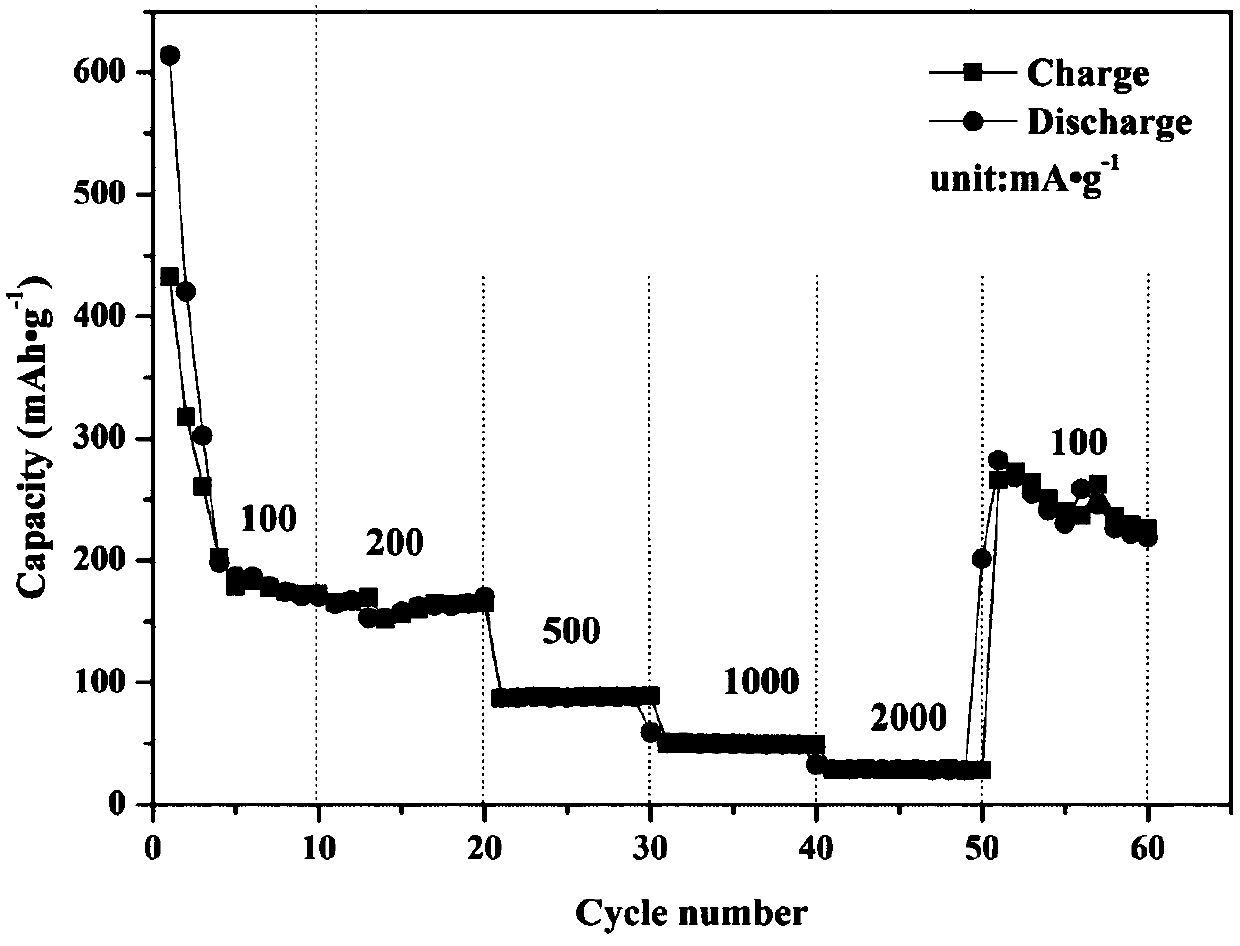

A kind of preparation method of copper vanadate coating for positive electrode of lithium ion battery

ActiveCN105789603BEnhance and improve performanceConditions are easy to controlSecondary cellsVanadium compoundsRadio frequency magnetron sputteringRadio frequency

A preparation method of a CuxVyOz coating for a positive electrode of a lithium ion battery comprises the following steps of placing a CuO-acetylene black target material and a V2O5 target material in two radio frequency target positions; fixing a single light aluminum foil on a film coating sample table; vacuumizing a film coating chamber and a sample chamber of a magnetron sputtering device; introducing Ar gas into the film coating chamber; setting a heating temperature of the aluminum foil to be 350-600 DEG C and the radio frequency sputtering power to be 50-400W; and starting to carry film coating on the aluminum foil, so that the mole ratio of Cu atom to V atom which are sputtered is 1:1, and the sputtering time is 10-100 minutes. A CuxVyOz thin film is synthesized on the aluminum foil at one step by radio frequency magnetron sputtering, and the prepared sample can be directly applied to the positive electrode of the lithium ion battery after stamped and cut. The method is high in reaction efficiency and high in film formation, the prepared coating is uniform in constituents, high in adhesive force and high in durability and stability, and the performance of the lithium battery is favorably enhanced and improved.

Owner:SHAANXI UNIV OF SCI & TECH

Five-color rice and breeding method of five-color rice

ActiveCN102715076BAchieve the same field plantingPlanting costs are the samePlant genotype modificationBiotechnologyPollination

Owner:FOOD CROPS RES INST YUNNAN ACAD OF AGRI SCI

Method for producing environment-friendly rubber oil through blending method

ActiveCN101693772BImprove wet skid resistanceHigh aromatic contentHydrocarbon oils refiningResidual oilTower

The invention discloses a method for producing environment-friendly rubber oil through blending method. The method provided by the invention comprises the following steps that firstly extracting decompressed residual oil with solvent to obtain deasphalted oil, wherein the solvent for extraction is propane, the ratio by volume of the solvent and the decompressed residual oil is (6-8):1, and the extraction conditions are that the temperature of a tower top is 60-95 DEG C, the temperature of a tower bottom is 50-80 DEG C, and the pressure is 2.8-7.0 MPa, secondly mixing deasphalted oil obtained in the first step with naphthenic oil for 30-120 min with 70-90 DEG C to obtain environment-friendly rubber oil, wherein the mass ratio of the deasphalted oil and the naphthenic oil is (0.2-0.6):(0.8-0.4). The environment-friendly rubber oil produced by the invention accords with the environment-friendly instruction requirement of EU 2005 / 69 / EC, wherein aromatic-carbon rate is 12%-18%, the contentof PCA is smaller than 3%, the content of aromatic hydrocarbons is high, and the rubber oil is environment-friendly, nontoxic, and has no carcinogenic effect. The environment-friendly rubber oil can be used as succedaneum of existing aromatic oil, and has great economic values.

Owner:CHINA NAT OFFSHORE OIL CORP +2

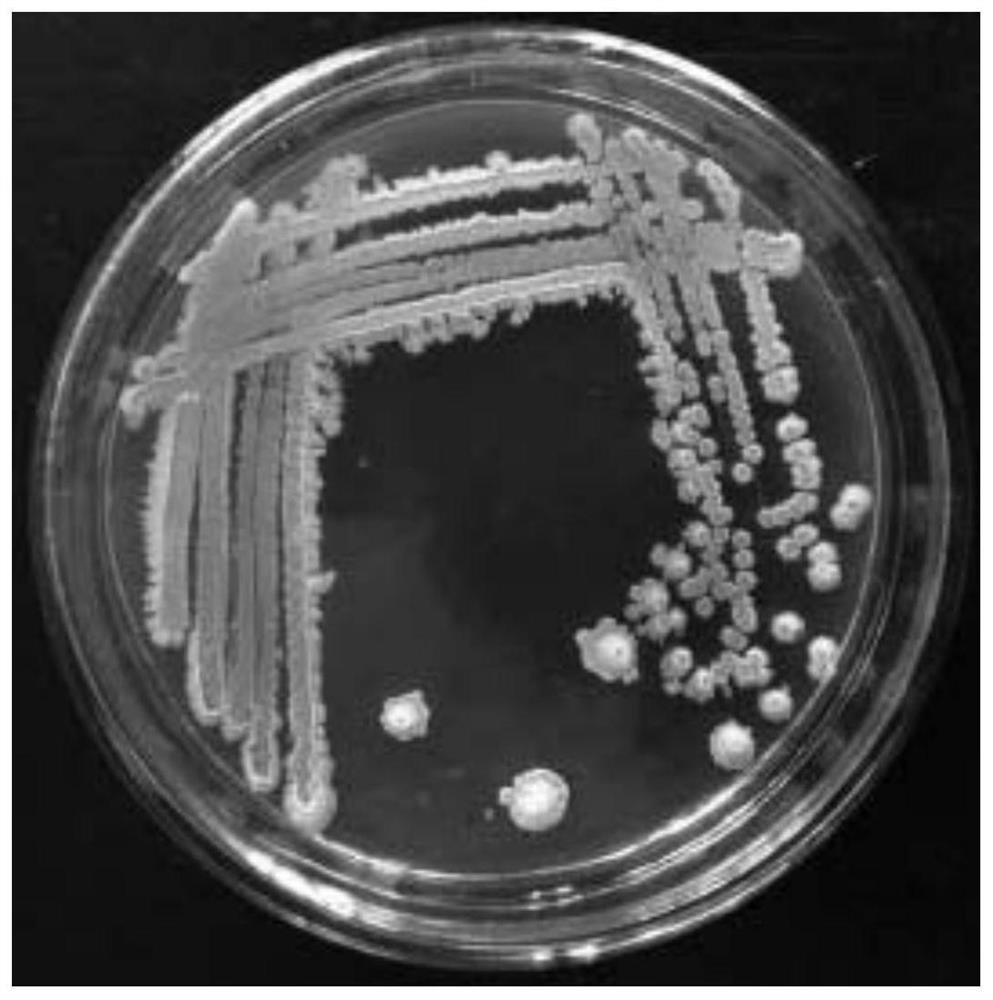

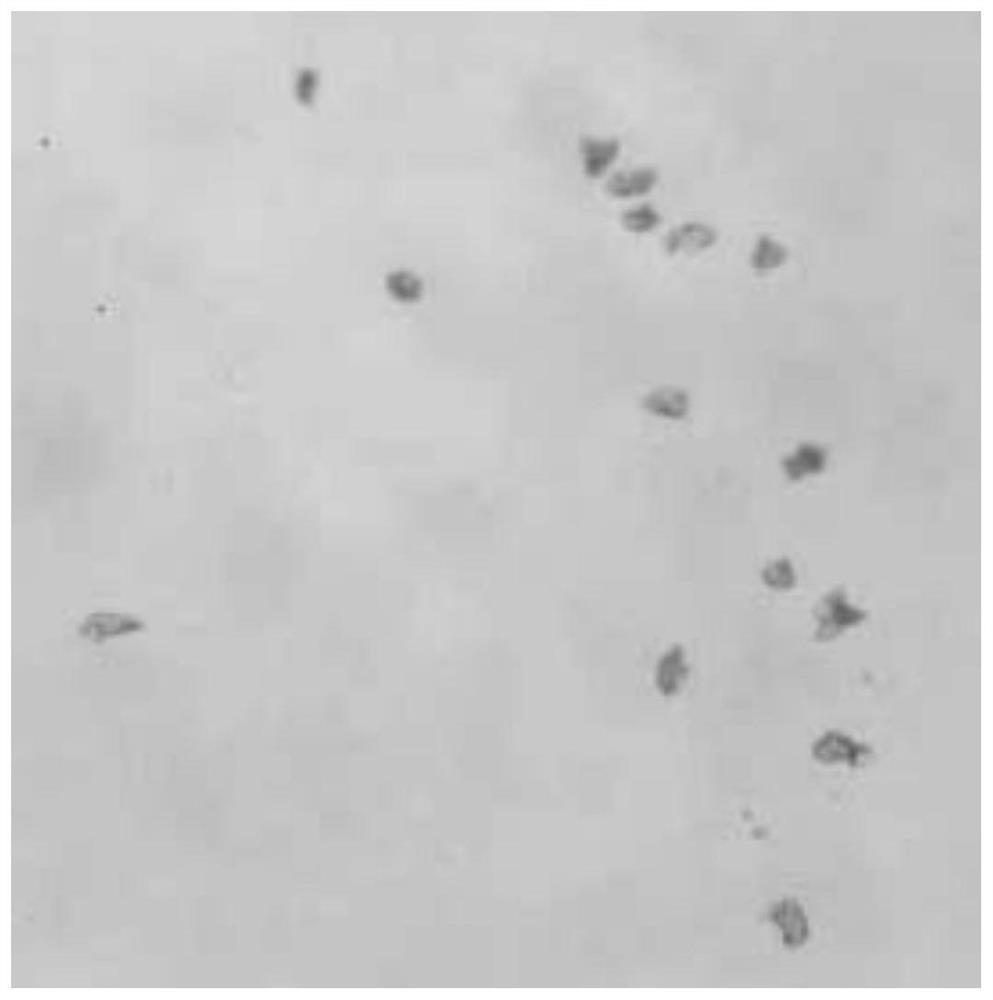

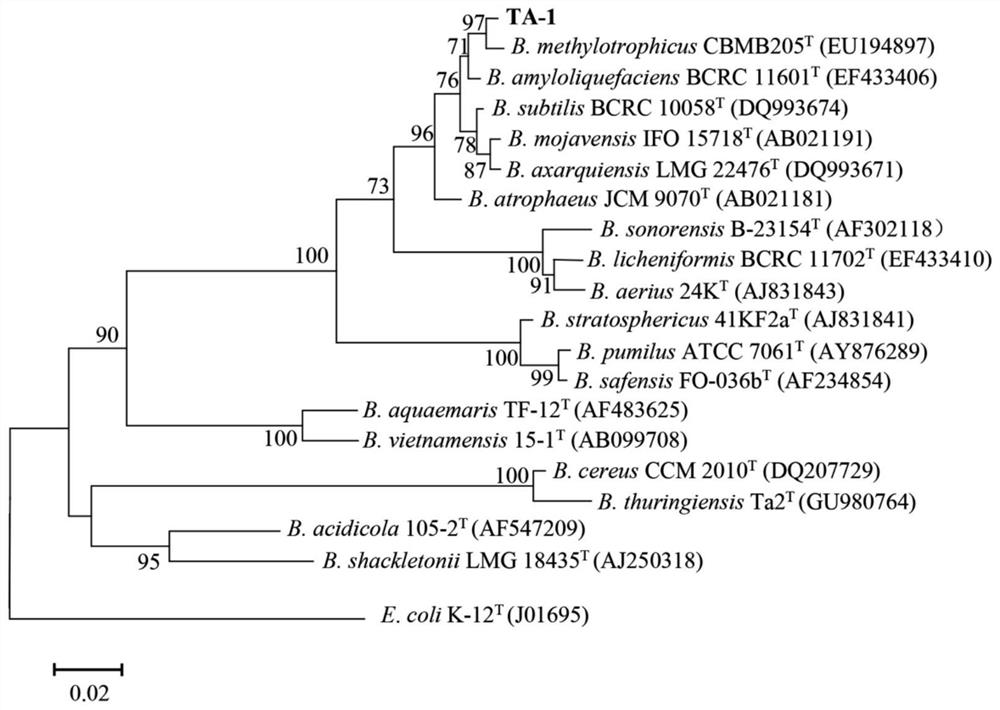

A methylotrophic Bacillus and its application

ActiveCN108641989BPromote growthGood prevention effectPlant growth regulatorsBiocideBiotechnologyNicotiana tabacum

The invention provides a strain of methylotrophic Bacillus TA-1, the preservation number of which is CCTCC No.M 2018362. The above-mentioned methylotrophic bacillus or / and fermentation product can be used for preventing and treating corn stalk rot, tomato cinerea, rice sheath blight, capsicum phytophthora, cotton fusarium wilt and tobacco black shank; growth; it has the application prospect of preparing microbial preparations and fertilizers.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com