Preparation method of inorganic substance coating oil-water separation mesh

An oil-water separation net, inorganic technology, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of strict preparation requirements, complex processes, labor, material and financial resources, etc., and achieves low cost and operation. Simple, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

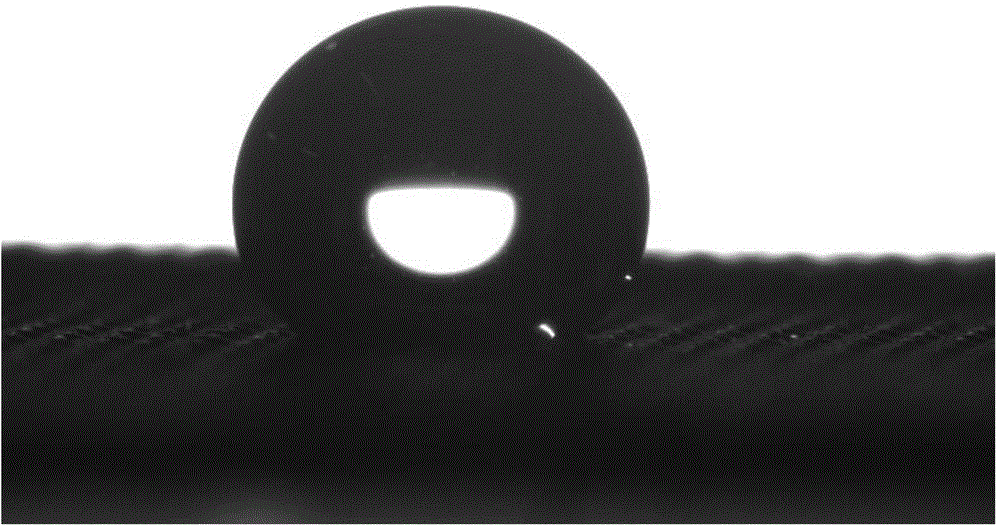

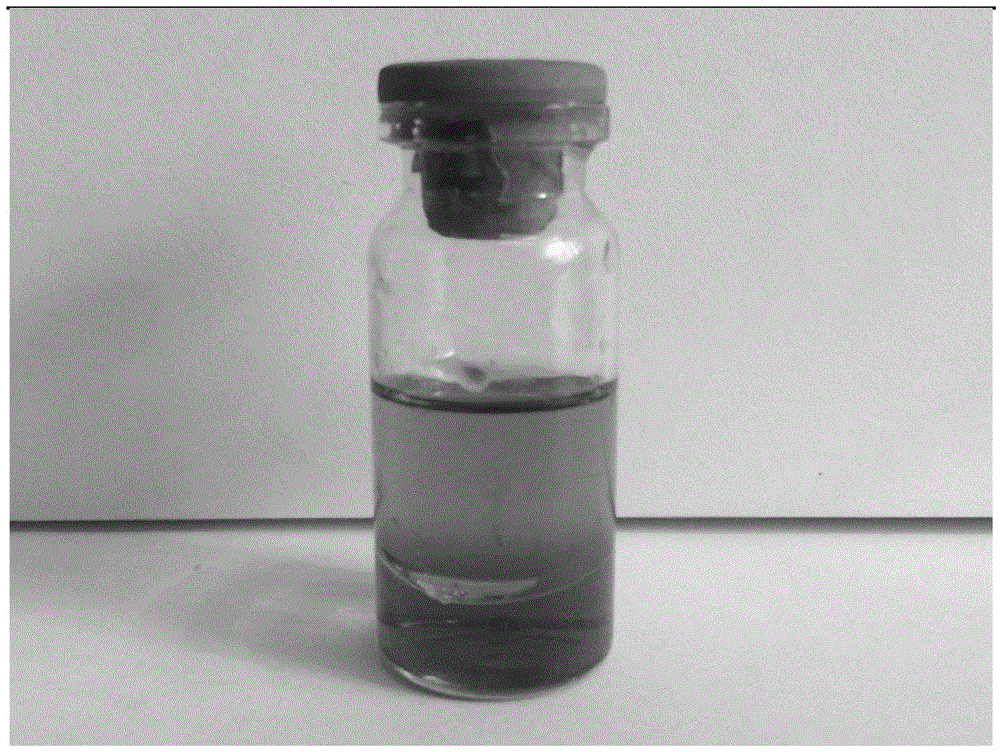

[0045] (1) Preparation of micro-nano composite polyhedron

[0046] Silica sol was injected into a reactor equipped with 80nm polystyrene (PS) nanospheres prepared according to Method 3 under negative pressure, and the template was immersed for 2h, and then the reactor was sealed and placed in a thermostat for 12h at 60°C. Remove the template by temperature program at 570℃ to obtain the solid block micro-nano composite polyhedron. The obtained block micro-nano composite polyhedron is fully ground to a powder. The particle size distribution range of the powder is 100nm-5000nm (Malvern Corporation, UK). Nano-ZS90 test, the following steps and implementation cases are the same), take 0.1g of the micro-nano composite polyhedron powder into the reactor, then add 10.0mL (7.88g) dispersion acetone, when the system temperature reaches 50 ℃, add 20.6μL (0.30 g) Perfluorooctyltrimethoxysilane, the modification reaction is carried out for 12 hours, and after the reaction is completed, a susp...

Embodiment 2

[0054] (1) Preparation of micro-nano composite polyhedron

[0055] Silica sol was injected into a reactor equipped with 200nm polystyrene (PS) nanospheres prepared according to Method 3 under negative pressure, the template was immersed for 2h, and then the reactor was sealed and placed in a thermostat for 12h at 60℃. The template was removed by temperature program at 570℃ to obtain a solid block micro-nano composite polyhedron. The obtained block micro-nano composite polyhedron was fully ground to powder, and 0.1g of the micro-nano composite polyhedron powder was added to the reactor, and then 10.0mL (7.88g) ) Dispersion acetone, add 36.9μL (0.57g) perfluorodecyltrimethoxysilane when the system temperature reaches 25℃, and the modification reaction is carried out for 12h. After the reaction, the mass fraction of the micro-nano composite polyhedron is controlled to 2.7% by volatilization. Suspension

[0056] The preparation of silica sol is the same as in Example 1;

[0057] (2) Co...

Embodiment 3

[0061] (1) Preparation of micro-nano composite polyhedron

[0062] Silica sol was injected into a reactor equipped with 300nm polyacrylamide (PAM) nanospheres prepared according to method one under negative pressure, and the template was immersed for 2h, then the reactor was sealed and placed in a thermostat, and reacted at 60℃ for 12h. Soak in water to remove the template to obtain a solid block micro-nano composite polyhedron. The obtained block micro-nano composite polyhedron is fully ground to powder, and 0.1g of the micro-nano composite polyhedron powder is added to the reactor, and then 10.0mL (7.88g) is added for dispersion Liquid acetone, add 19.1μL (0.22g) trifluoropropane trimethoxysilane when the system temperature reaches 25℃, and the modification reaction is carried out for 12 hours. After the reaction is completed, the mass fraction of the micro-nano composite polyhedron is controlled to a 5.0% suspension ;

[0063] The preparation of silica sol is the same as in Exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com