Microchannel and manufacture method thereof

A technology of microchannel and plane expansion, applied in chemical instruments and methods, laboratory utensils, laboratory containers, etc., can solve the problem of inability to have the same surface modification in the cross section, inability to perform partial surface modification in the exposure section, and inability to realize microchannels. Surface modification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

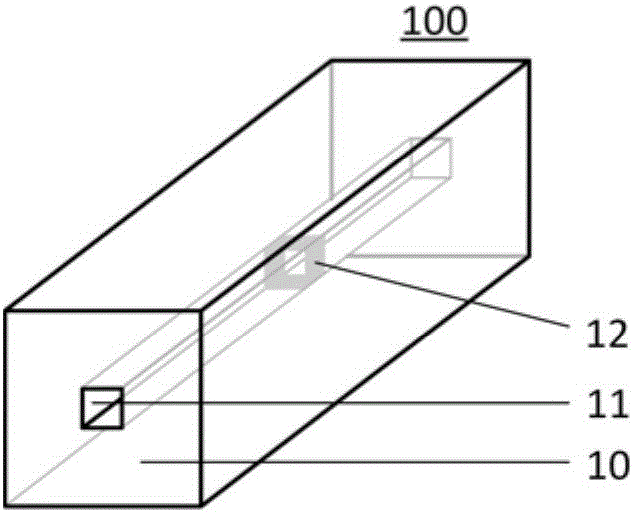

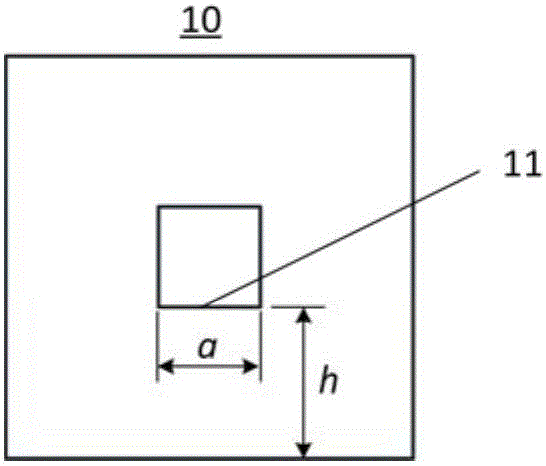

[0105] In this embodiment, a PDMS microchannel (100) with a square cross-section is fabricated using a planar folding technique. Among them, refer to Figure 2a , the microchannel is a square cross-section (10), and a hydrophilic coating (12) needs to be made locally on the inner wall surface (11); refer to Figure 2b , and the side length a of the microchannel is 1 mm, and the wall thickness h is 2 mm. The specific production process is as follows:

[0106] (1) Reference Figure 2c , the square section (10) of the microchannel (100) can be decomposed into an expanded figure (30) consisting of N=4 isosceles trapezoids (20); wherein, the upper base of the isosceles trapezoid a=1 mm, height For h=2 millimeters, base angle θ=(180°-360° / N) / 2=45°; the upper base of the isosceles trapezoid corresponds to the inner wall surface (11) of the microchannel, and the waist of the isosceles trapezoid corresponds to that of the folded microchannel Bonding surface (21).

[0107] (2) desi...

Embodiment 2

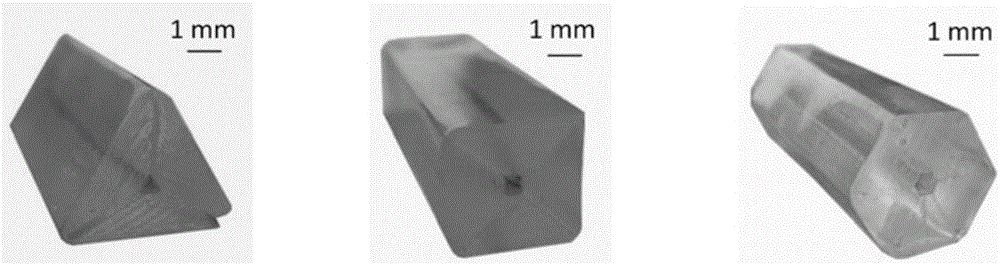

[0112] In this embodiment, a triangular section PDMS microchannel (200) is fabricated using planar folding technique. refer to Figure 3a , the microchannel is an equilateral triangle section (110), and the inner wall surface (111) is made with a metal film helical coil (112); the side length a of the microchannel is 1 millimeter, the wall thickness h is 2 millimeters, and the metal film substrate is 10 nanometers thick Chromium film, metal film surface layer is 50 nanometers thick gold film. The specific production process is as follows:

[0113] (1) Reference Figure 3b , the triangular section (110) is decomposed into a planar expansion figure (120) made of N=3 isosceles trapezoids (113), the upper base a=1 millimeter of the isosceles trapezoid (113), and the height is h=2 millimeters , base angle θ=(180–360 / N) / 2=30°.

[0114] (2) According to the planar expansion figure (120) design such as Figure 3c The mold (130) is cast as shown, and the mold (130) is made using 3...

Embodiment 3

[0120] In this embodiment, according to the method and conditions substantially the same as in Embodiment 2, a regular triangular cross-section (NOA) photosensitive resin microchannel was fabricated using planar folding technology. The difference is that in this example,

[0121] (a) Perform steps (1)-(2) of Example 2 to obtain a casting mold (130).

[0122] (b) Mix the NOA photosensitive resin prepolymer and the initiator evenly, pour the mixed solution into the mold (130) and degas it, then cure it under ultraviolet exposure, and cast to obtain the planar unfolded structure of the polymer.

[0123] (c) Coat the bonding surface with a resin adhesive, and fold and close the planar unfolded structure to obtain a microchannel with a regular triangular cross-section.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com