Preparation technology of ultraviolet-ageing-resisting PBO (Poly-p-phenylene Benzobisoxazole) fibers

A technology of anti-ultraviolet aging and preparation process, applied in the field of preparation technology of anti-ultraviolet aging PBO fiber, can solve the problems of mechanical properties decline, limitation, easy aging, etc., achieve excellent elastic properties and flexibility, improve flexibility and elasticity, and improve flexibility. The effect of degree and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

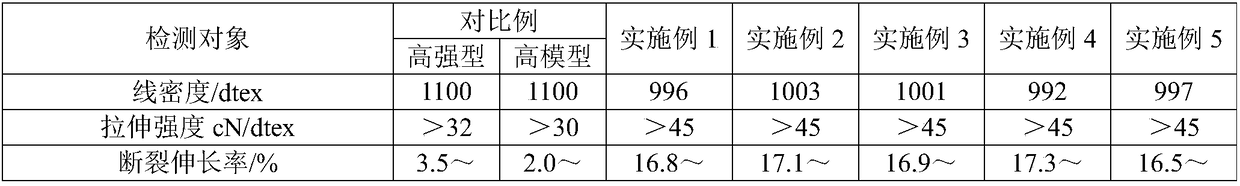

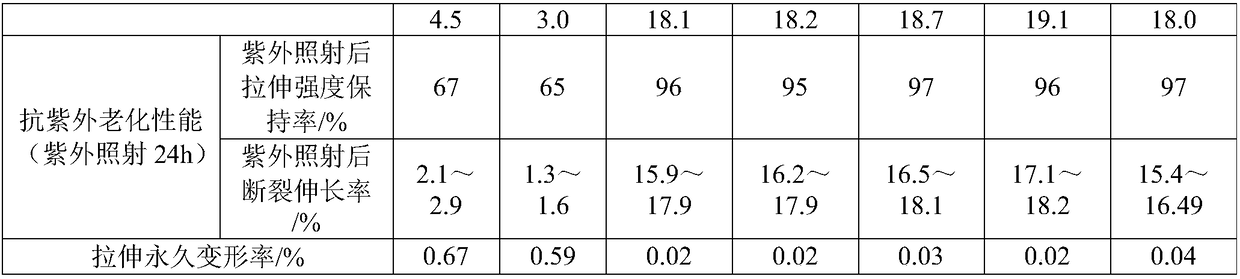

Examples

Embodiment 1

[0039] A kind of preparation technology of anti-ultraviolet aging PBO fiber, described preparation technology comprises following preparation steps:

[0040] 1) Surface etching modification of PBO fiber: Dissolve polyphosphoric acid in acetic acid solution, stir evenly to prepare acid etching modification solution, put the cleaned and dried PBO fiber in acid etching modification solution and soak in acid etching Treat for 15 minutes. After the treatment, add ammonia water dropwise until it becomes neutral and continue the immersion treatment for 20 minutes. After the immersion treatment, put it in water for ultrasonic rinsing and dry it under vacuum to obtain etched PBO fibers. The polymer in the acid etching modification solution The concentration of phosphoric acid is 15wt%;

[0041] 2) Preparation of carbon-based suspension: Sorting graphite waste to remove impurities, then pulverizing it into 60-mesh fine powder, oxidizing it into graphite oxide with dilute nitric acid, mi...

Embodiment 2

[0045] A kind of preparation technology of anti-ultraviolet aging PBO fiber, described preparation technology comprises following preparation steps:

[0046] 1) Surface etching modification of PBO fiber: Dissolve polyphosphoric acid in phenylacetic acid solution, stir evenly to prepare acid etching modification solution, and place the cleaned and dried PBO fiber in acid etching modification solution for acid etching Soaking treatment for 25 minutes, after the treatment, add sodium carbonate solution dropwise until it tends to neutrality, and continue the immersion treatment for 30 minutes. The concentration of polyphosphoric acid in the sex liquid is 18wt%;

[0047] 2) Preparation of carbon-based suspension: Sorting graphite waste to remove impurities, then pulverizing it into a fine powder of 300 mesh, oxidizing it into graphite oxide with potassium permanganate solution, mixing graphite oxide with water , to form a mixed solution, add 300 mesh fine aluminum powder to the mi...

Embodiment 3

[0051] A kind of preparation technology of anti-ultraviolet aging PBO fiber, described preparation technology comprises following preparation steps:

[0052] 1) Surface etching modification of PBO fiber: dissolve polyphosphoric acid in oxalic acid solution, stir well to prepare acid etching modification solution, put the cleaned and dried PBO fiber in acid etching modification solution After the treatment, sodium bicarbonate solution was added dropwise until it became neutral and the immersion treatment was continued for 25 minutes. After the immersion treatment, it was placed in water for ultrasonic rinsing and dried under an argon protective atmosphere to obtain etched PBO fibers. The concentration of polyphosphoric acid in the acid etching modification solution is 16wt%;

[0053] 2) Preparation of carbon-based suspension: sort graphite waste to remove impurities, then crush it to 180-mesh fine powder, oxidize it into graphite oxide with concentrated sulfuric acid, mix graph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com