Patents

Literature

122 results about "Functional Treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

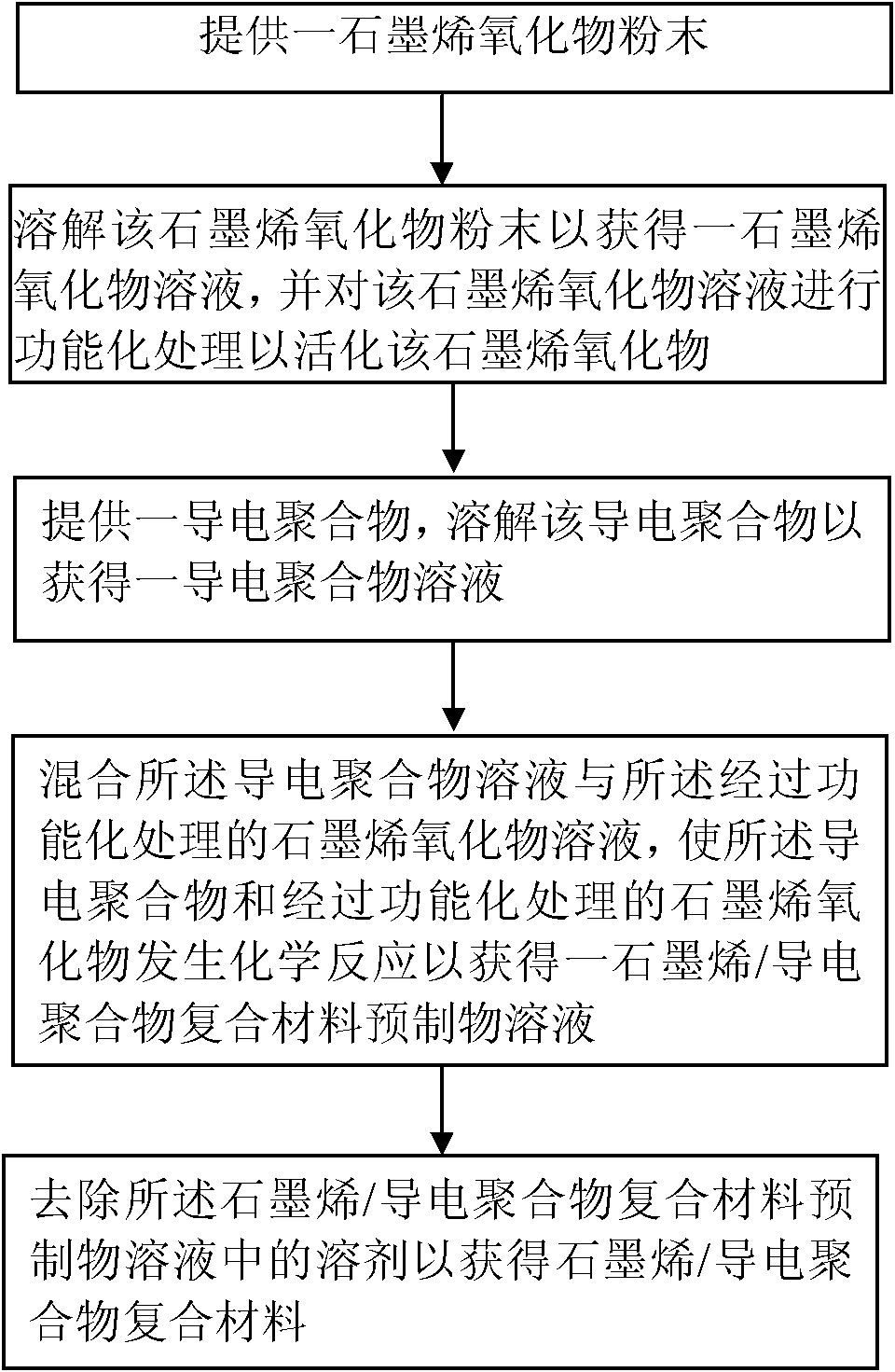

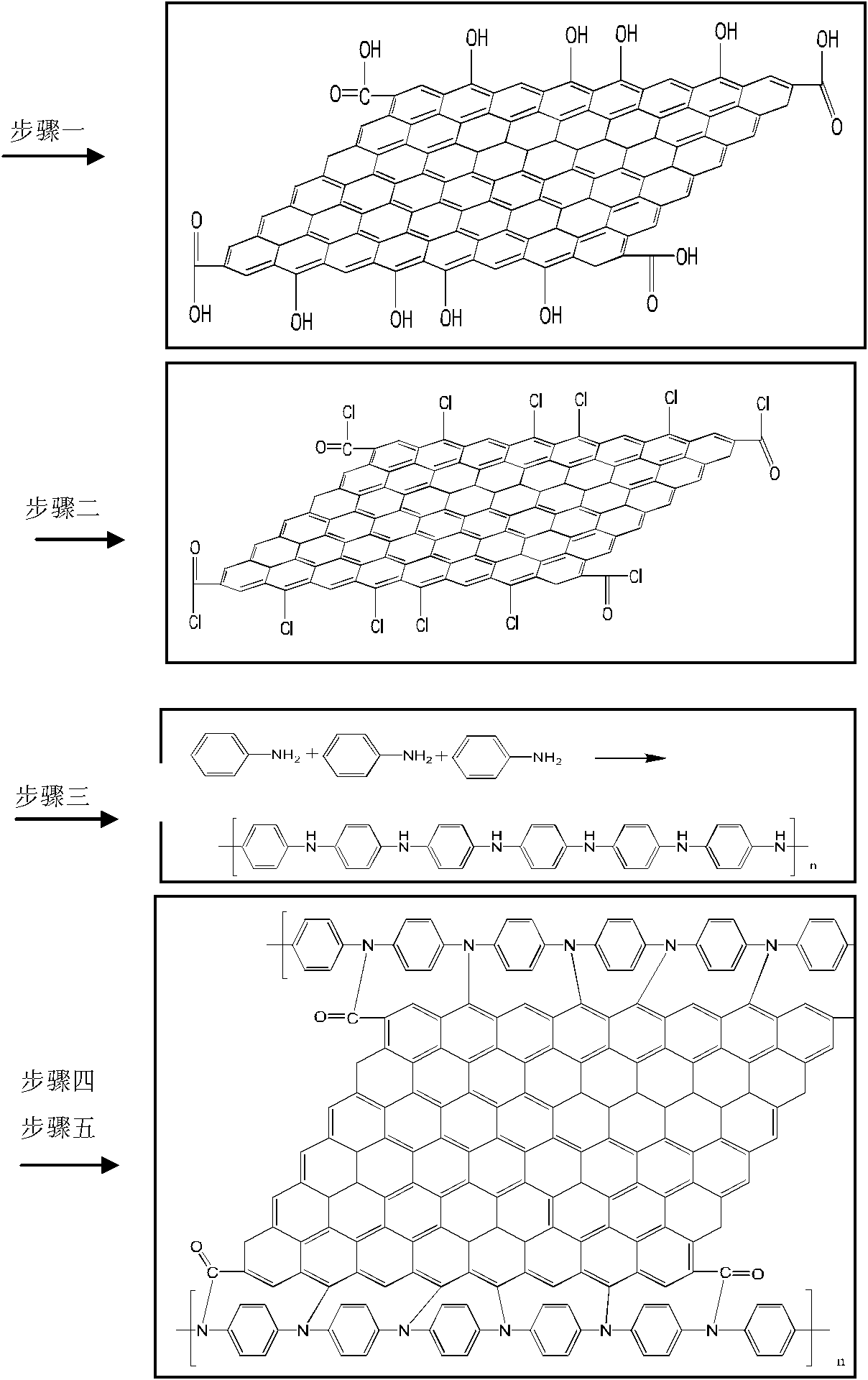

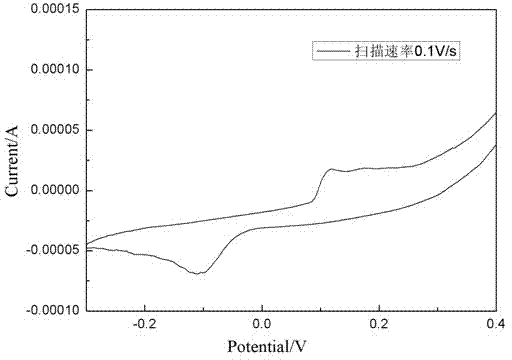

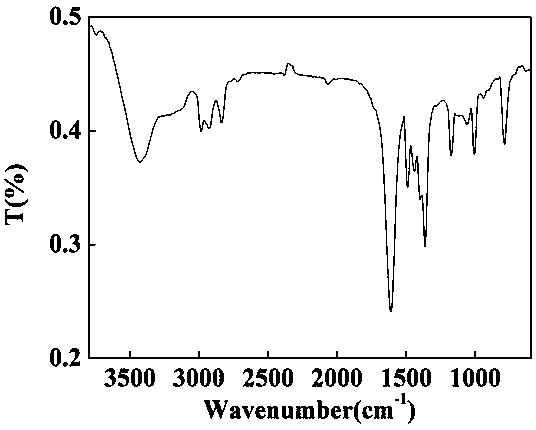

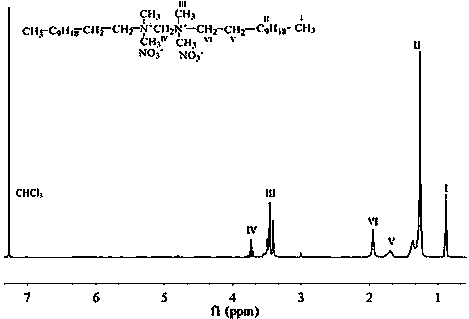

Grapheme/electroconductive polymer composite and preparation method thereof

The present invention relates to a graphene / electroconductive polymer composite and a preparation method thereof. The preparation method comprises the following steps: dissolving graphite oxide to obtain a graphene oxide solution; carrying out functional treatment on the grapheme oxide solution; dissolving an electroconductive polymer to obtain an electroconductive polymer solution; mixing the electroconductive polymer solution and the functionally treated graphene oxide solution for chemical reaction; and removing solvents to obtain the graphene / electroconductive polymer composite. The composite is obtained by carrying out chemical bonding on the functionally treated graphene oxide and the electroconductive polymer by an amido group. The graphene / electroconductive polymer composite is in a microscopic structure that the electroconductive polymer is wrapped by graphene and an overall network structure, and has the characteristic of structural stability.

Owner:BEIHANG UNIV

Wearable OLED device

PendingCN108783778APromote healingEasy to shapeSolid-state devicesSemiconductor/solid-state device manufacturingChange colorBiomedical engineering

The invention discloses a wearable OLED device. The wearable OLED device comprises one or more flexible OLED light-emitting panel, a housing fixing device, a connecting device and a light-emitting side, wherein the wearable OLED device is worn on a human body, and the light-emitting side emits light towards the human body in a wearing area basically. The wearable OLED device is capable of realizing large-scale treatment, wearable near the body, light in weight, thin in thickness, and capable of performing the multi-functional treatment or the local treatment through changing colors.

Owner:BEIJING SUMMER SPROUT TECH CO LTD

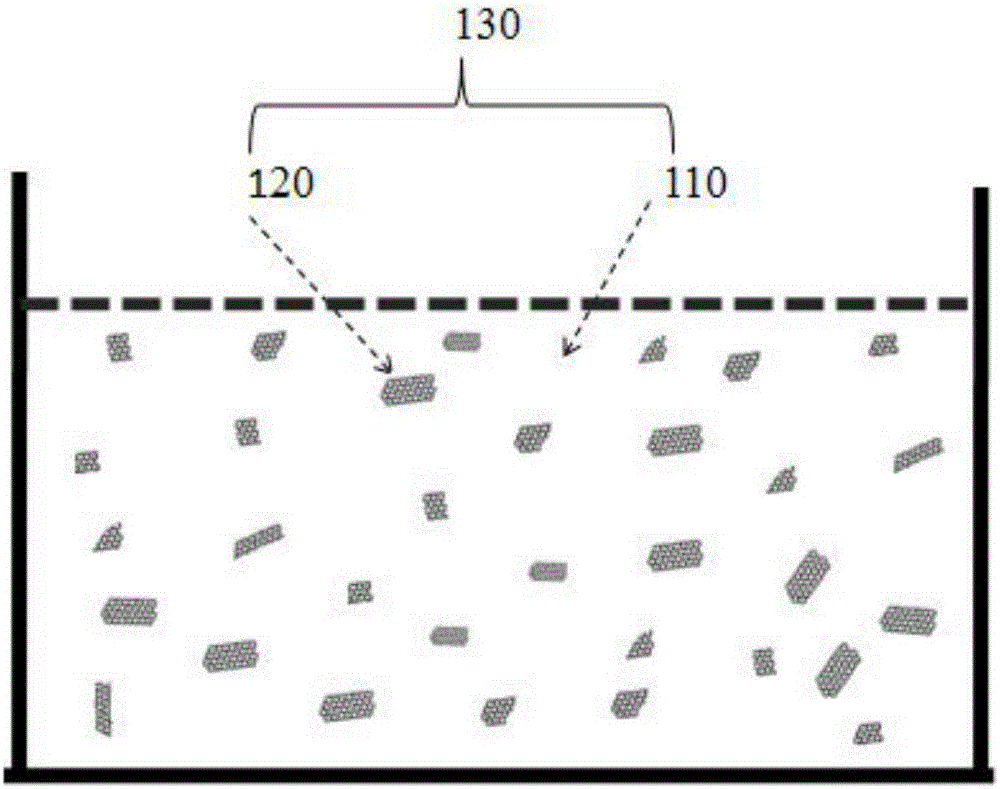

Solid-liquid two-phase mixed working medium suitable for electric discharge surface treatment

The invention discloses a solid-liquid two-phase mixed working medium suitable for electric discharge surface treatment. The solid-liquid two-phase mixed working medium comprises kerosene and a solid additive. The solid additive is one or more of graphene, two-dimensional boron nitride or a two-dimensional titanium carbide nanosheet subjected to alkyl functional treatment. The solid additive has good self-dispersion and dispersion stability in kerosene. The working medium disclosed by the invention has the advantages such as low breakdown strength, electric good discharge uniformity, less inter-electrode stray capacitance and refined electric discharge energy, can effectively improve uniformity of components and thickness of a strengthened layer, and can reduce defects such as holes and cracks of the strengthened layer, so that wear resistance and corrosion resistance of the strengthened layer are improved; and the solid-liquid two-phase mixed working medium is expected to be widely applied in the surface modifying field of tools, moulds and various mechanical parts.

Owner:GUANGDONG UNIV OF TECH

Application of chemical foam finishing in weave dyeing and finishing technique

InactiveCN101168924AHigh water consumptionReduce water consumptionFibre treatmentEngineeringSewage treatment

The invention discloses an application of chemical foam finishing in textile dyeing and finishing process, and relates to an application of a functional chemical being made into foam state and then applied in the textile dyeing and finishing process. Any treatment process of the prior dyeing and finishing process takes water as a carrier. Thus a great amount of water is required, and the sewage treatment of the textile industry is also a most important issue, thereby reducing the drainage concentration, a great amount of water is added into for dilution, and thus the waste of water is caused. The invention adopts a treating liquid operating various functional treatments to the textile, such as: softening, waterproofing and fire preventing, etc., and is smashed into petty foams through the conventional lashing method such as egg breaking, so as to be uniformly and semi fluidly coated on a specified surface or a specified position of the textile by controlling. The invention is used on the site having the requirements of energy conservation, water conservation, raw material conservation and work efficiency improvement in the process, more particularly used for the requirement of excellently completing the single side coating and finishing.

Owner:张志军

Reactive flame retardant and method for durable flame-proof treatment on protein fibers by using reactive flame retardant

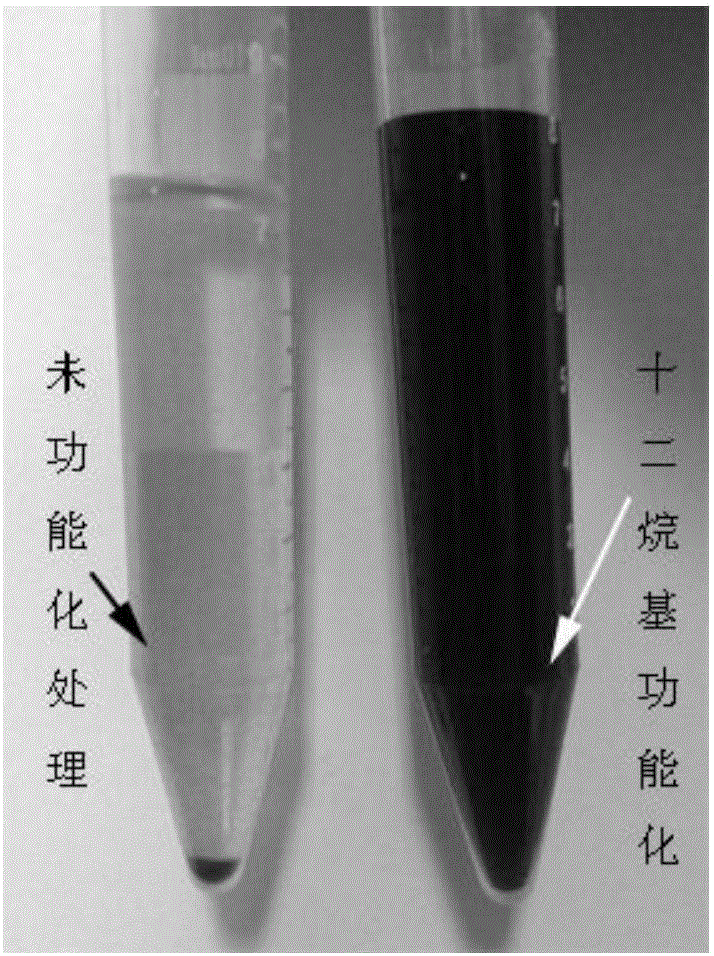

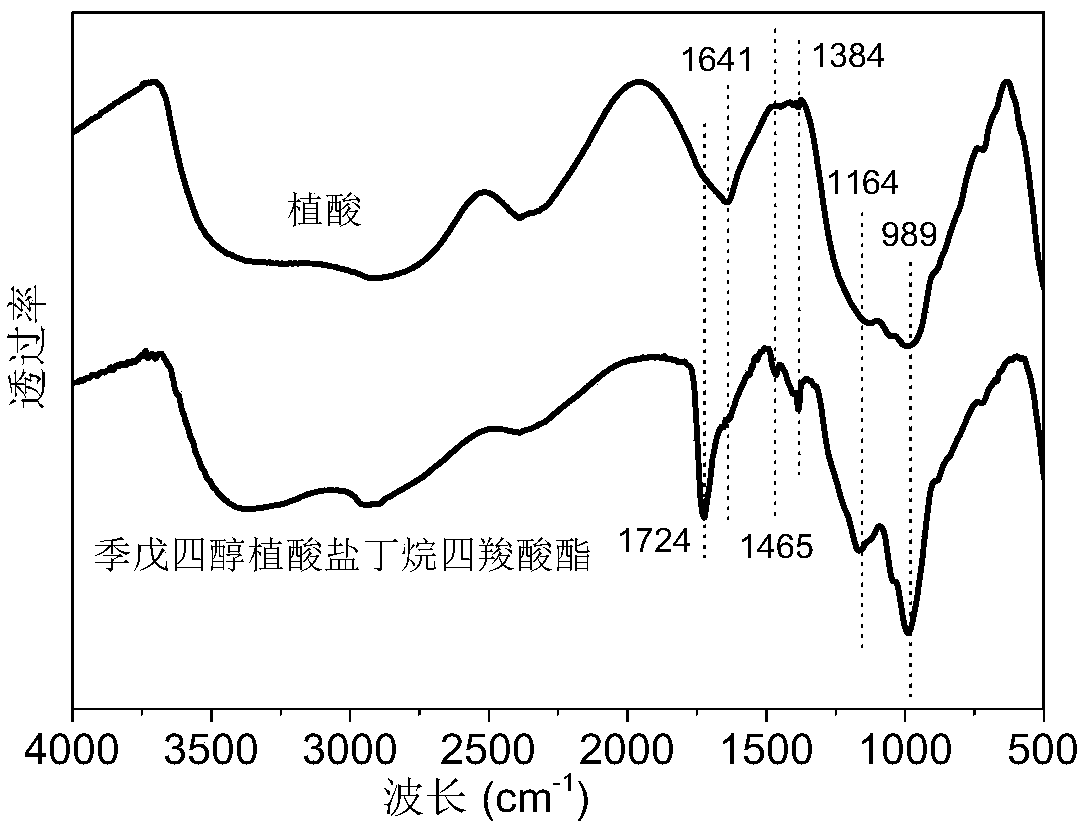

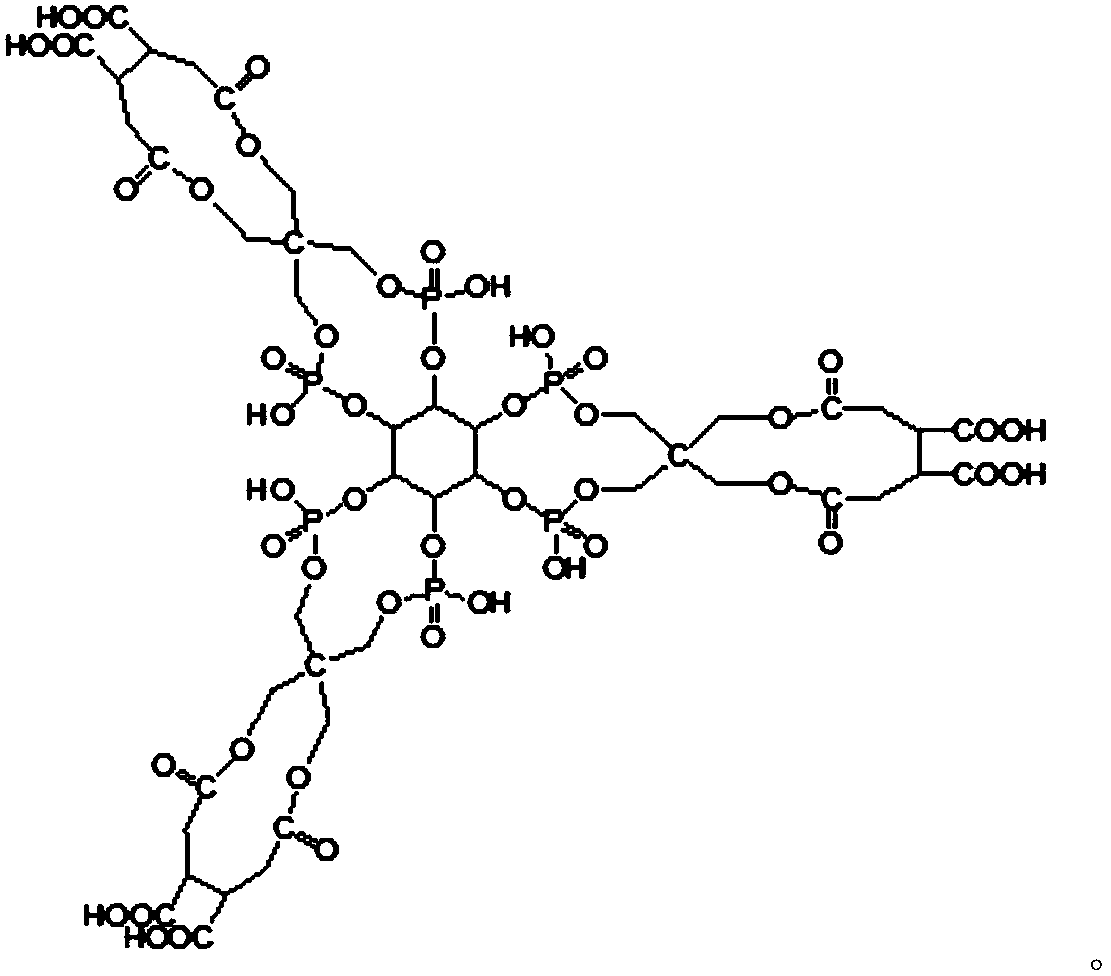

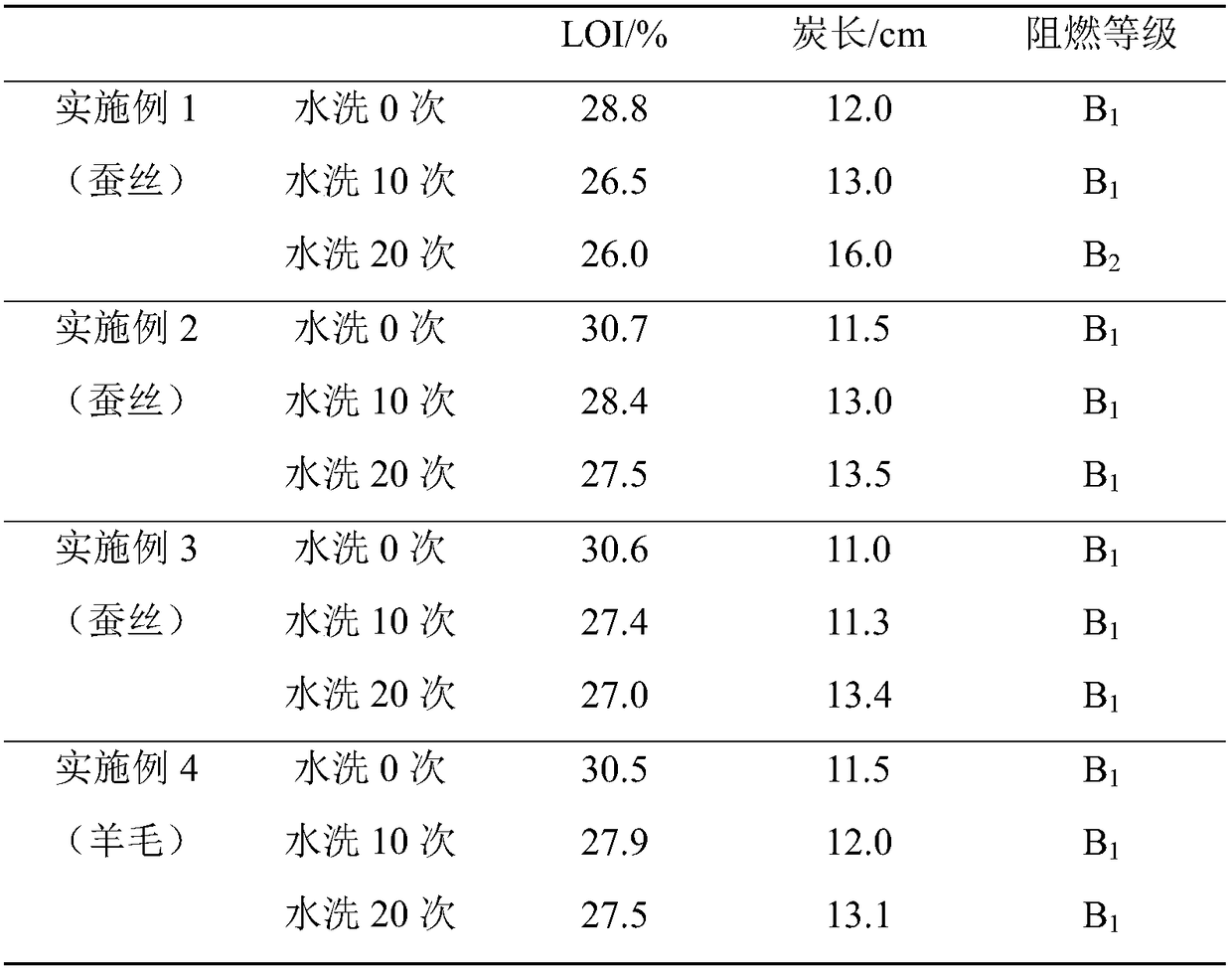

ActiveCN109355902AHigh phosphorus contentHigh reactivityHeat resistant fibresAnimal fibresCooking & bakingPhytic acid

The invention discloses a reactive flame retardant and a method for durable flame-proof treatment on protein fibers by using the reactive flame retardant, and belongs to the technical field of functional treatment of textile. The reactive phosphorus-containing flame retardant is prepared from phytic acid, polyhydric alcohols such as pentaerythritol and polybasic carboxylic acids such as 1,2,3,4-butane tetracarboxylic acid through esterification reaction. The phosphorus content of the flame retardant is high, molecules contain a plurality of reactive groups, the reaction activity is high, the reactive flame retardant can be crosslinked with the protein fibers during baking at a high temperature, and an additional crosslinking agent is not required. The phytic acid for synthesis of the flameretardant is a plant extract, and the obtained flame retardant is environmentally friendly. The protein fibers treated by the flame retardant not only has excellent flame-retardance performance, butalso has good washability, and the problem that protein fibers which are treated by the phytic acid only is poor in washability is solved.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST +1

Highly dispersed carbon nanotube carried catalyst and preparation method of precursor thereof

InactiveCN101954298AGood dispersionImprove electrocatalytic activityCell electrodesCatalyst activation/preparationFuranHydrogen atmosphere

The invention discloses a simple and efficient method for preparing a highly dispersed carbon nanotube carried catalyst used in fuel cells, which belongs to the fuel cell technology and the nano-material preparation technology. The method is characterized by using a heterocyclic compound (furan, tetrahydrofuran, etc.) aprotic polar solvent to dissolve noble metal salt and transition metal salt and directly dispersing carbon nanotube carriers in the solution without carrying out functional treatment on carbon nanotubes, alternatively adding an ultrasonic dispersion solvent and a heating volatile solvent until obtaining mushy carbon mud, deoxidizing in an hydrogen atmosphere at a certain temperature after drying, and finally obtaining highly dispersed carbon nanotube noble metals and an alloy catalyst. The method of the invention is simple and easy, and the prepared carbon nanotube catalyst shows a high degree of dispersion, excellent electrocatalytic activity and good stability.

Owner:BEIHANG UNIV

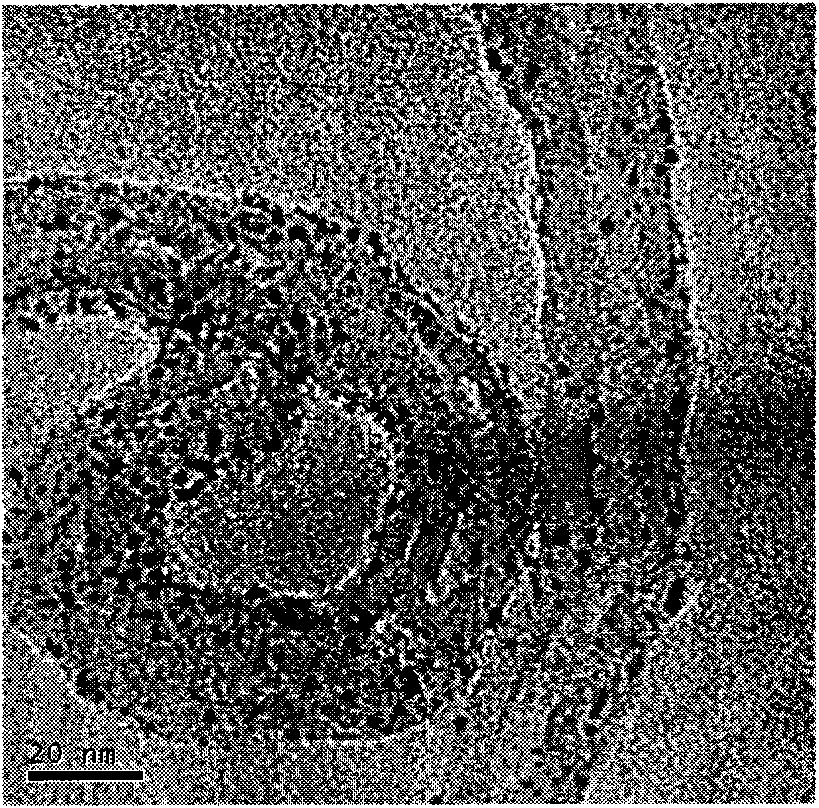

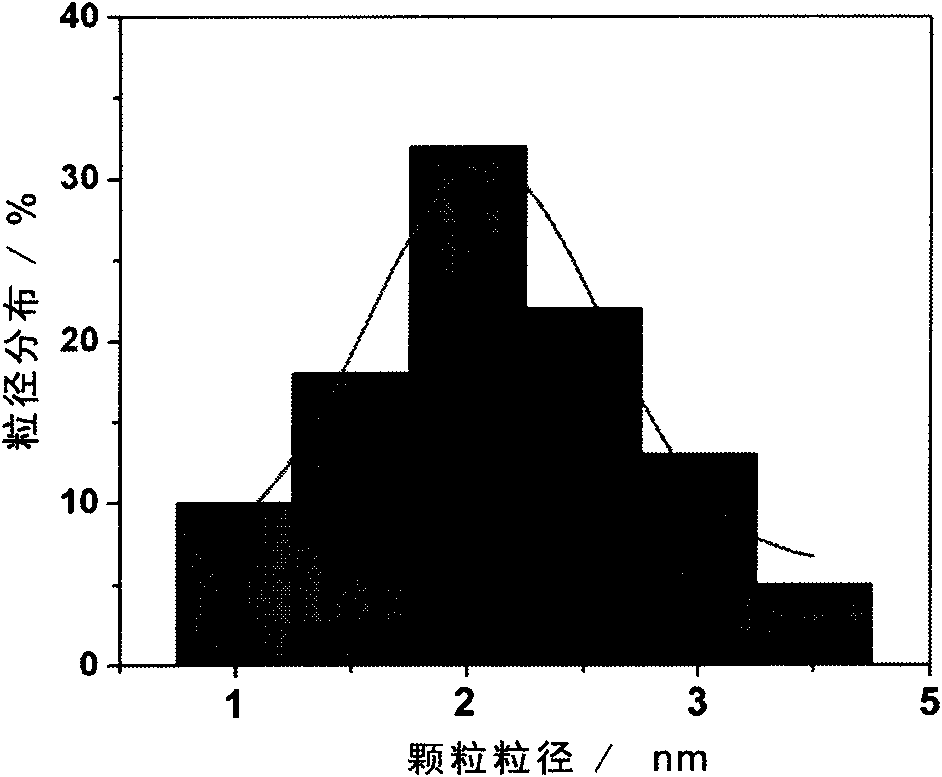

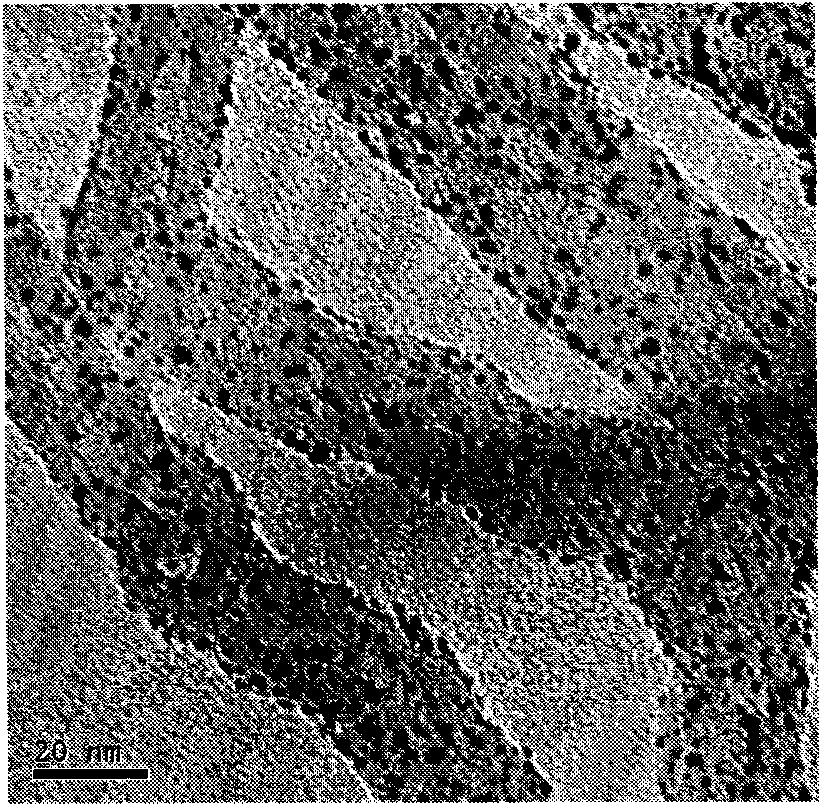

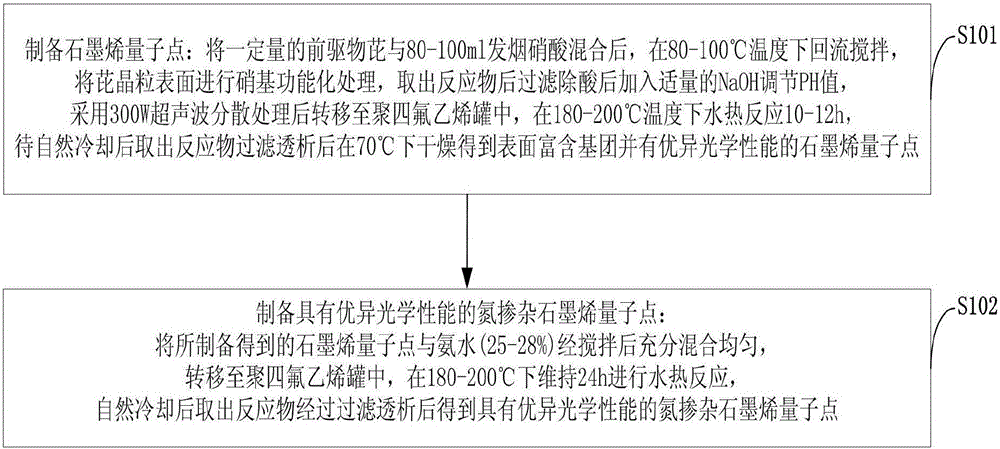

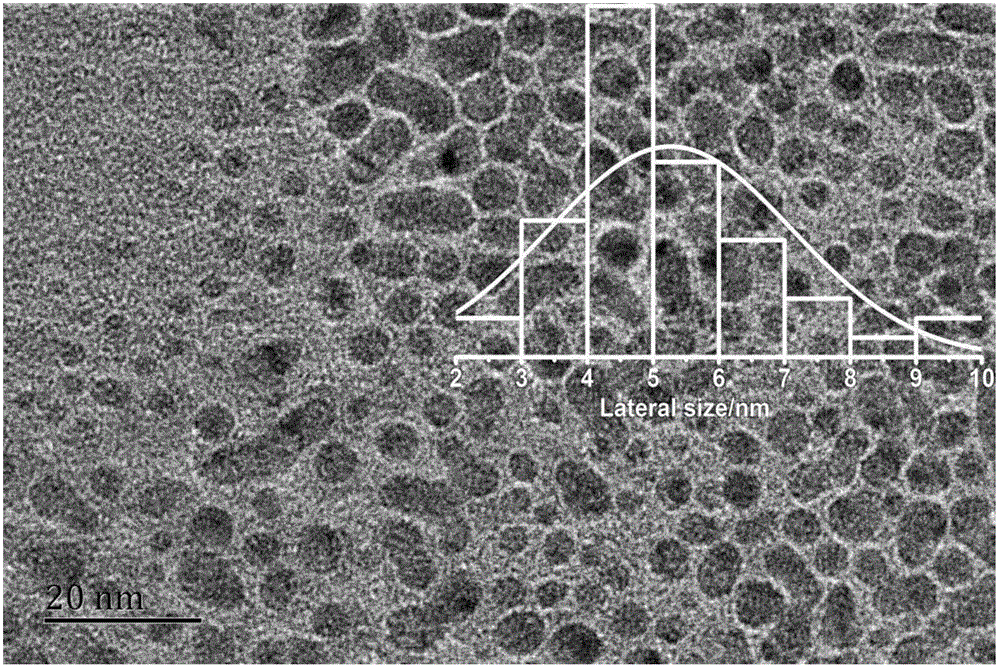

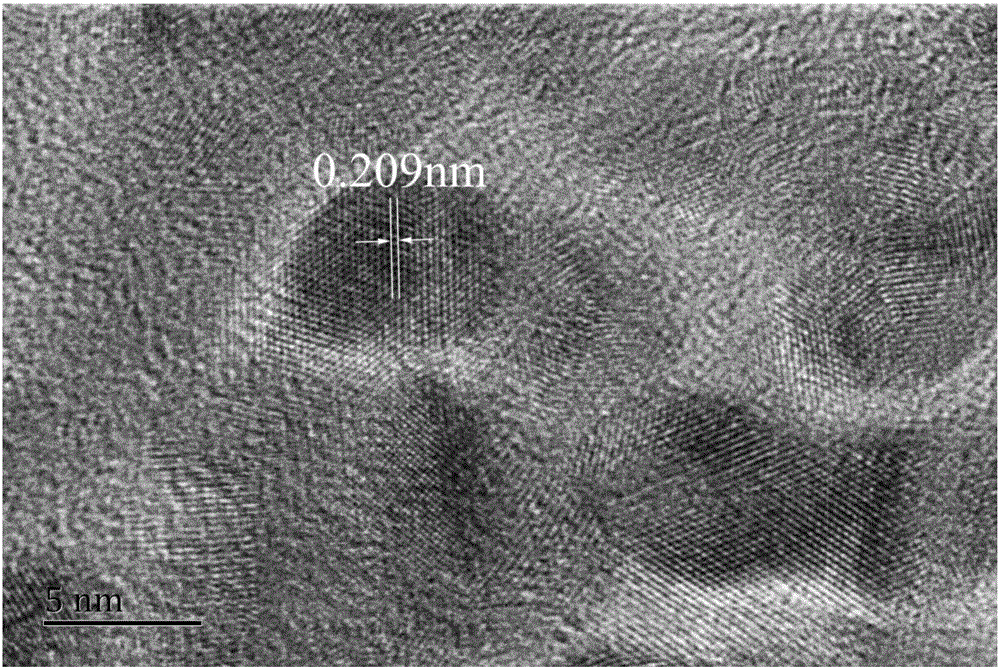

Nitrogen-doped graphene quantum dot and preparation method thereof

InactiveCN105800595AEasy accessThe production process is simple and easy to controlFiltrationNitrogen doped graphene

The invention discloses a nitrogen-doped graphene quantum dot and a preparation method thereof. The preparation method comprises the following steps: mixing a precursor pyrene with 80-100ml of fuming nitric acid, performing backflow stirring, performing nitro functional treatment on the surfaces of pyrene crystal grains, taking out the reactant, filtering to remove acid, adding a proper amount of NaOH, adjusting the pH value to 7, performing 300W ultrasonic dispersion treatment, transferring to a polytetrafluoroethylene tank, performing hydrothermal reaction, naturally cooling, taking out the reactant, filtering, dialyzing, and drying so as to obtain a graphene quantum dot; stirring the graphene quantum dot with ammonia water, sufficiently and uniformly mixing, transferring into a polytetrafluoroethylene tank, performing high-temperature high-pressure hydrothermal reaction, naturally cooling, taking out the reactant, and performing filtration dialysis, thereby obtaining the nitrogen-doped graphene quantum dot with excellent optical properties. The nitrogen-doped graphene quantum dot is simple in synthesis process step, high in yield, high in finished product rate and few in impurity. The nitrogen-doped graphene quantum dot disclosed by the invention can be stably dispersed in water, and is stable in structure, excellent in optical property and rich in group in surfaces.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Process for producing negative-ion far-infrared nano composite functional non-woven fabric

InactiveCN103147282APermanent negative ion releasePermanent functionNon-woven fabricsVegetal fibresFunctional TreatmentWoven fabric

The invention discloses a process for producing a negative-ion far-infrared nano composite functional non-woven fabric. The process comprises the following steps of: unpacking, clearing and outputting; carding into a net; carrying out multi-stage water treatment; carrying out functional treatment; drying; rolling up; slitting; and carrying out final detection and packaging. The gray cloth is finished by negative ions and a far infrared nano functional finishing agent, and the negative ions and far infrared nano particles are combined firmly with a non-woven fabric through bonding the negative ions and the far infrared nano particles with the fiber molecules of the non-woven fabric by adopting the technology of compounding a variety of powders of a nano material, the technology of compounding a variety of functions and the technology of assembling molecules, thus the non-woven fabric has long-lasting functions of releasing negative ions and emitting far-infrared biological waves, integrates the negative ion releasing function, the far-infrared wave emitting function and the bacteria and mould resisting function, has preventive sanitation and healthcare effects, good moisture absorptivity and air permeability, is soft and comfortable and also has the effects of increasing the concentration of negative irons in air, improving the quality of air in a habitable room, promoting the blood circulation and improving the immunity of the human body and resisting bacteria and mould.

Owner:ZHEJIANG KEDEBANG NONWOVEN CLOTH

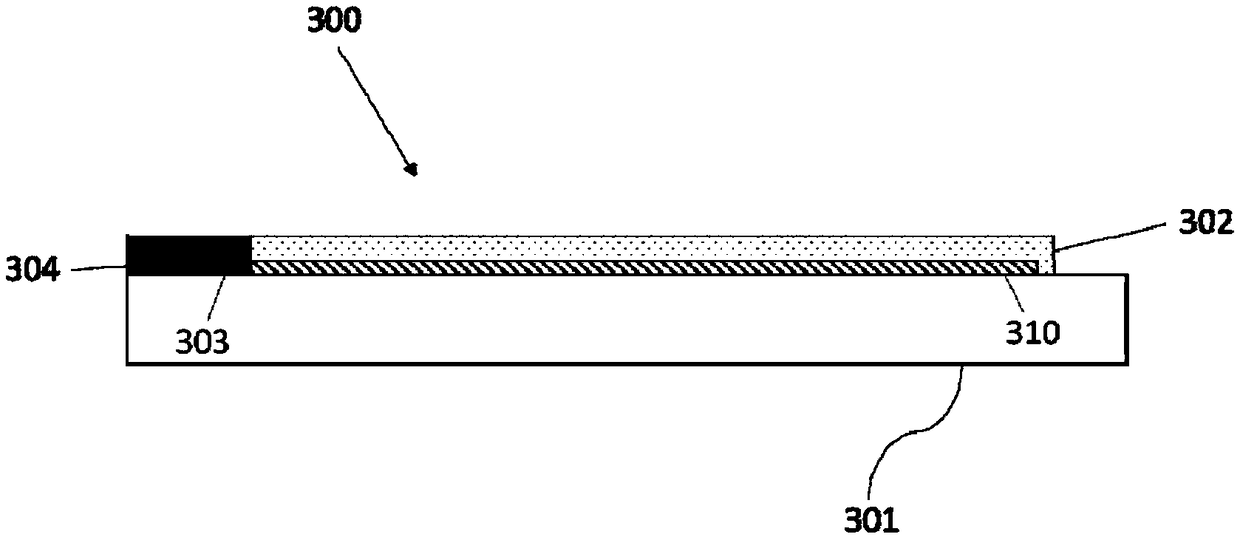

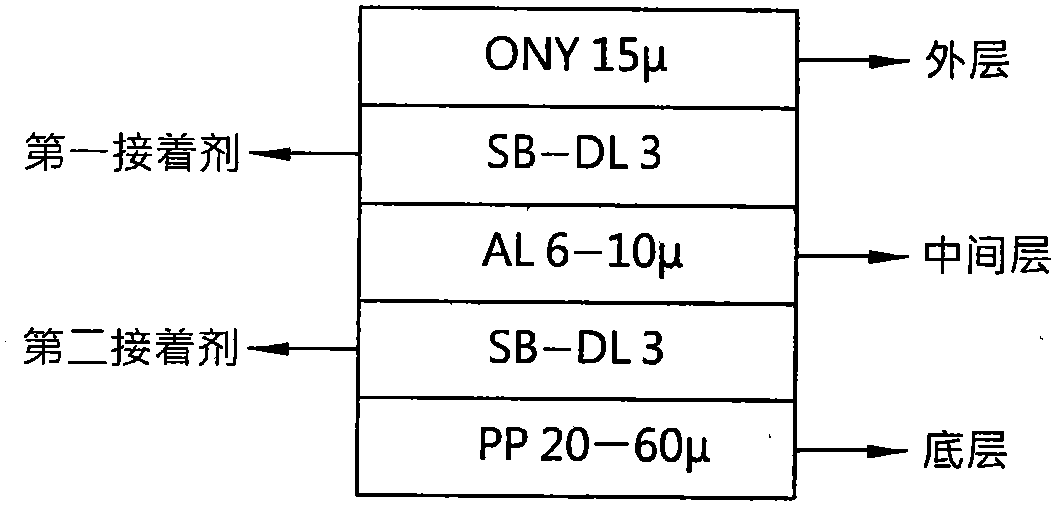

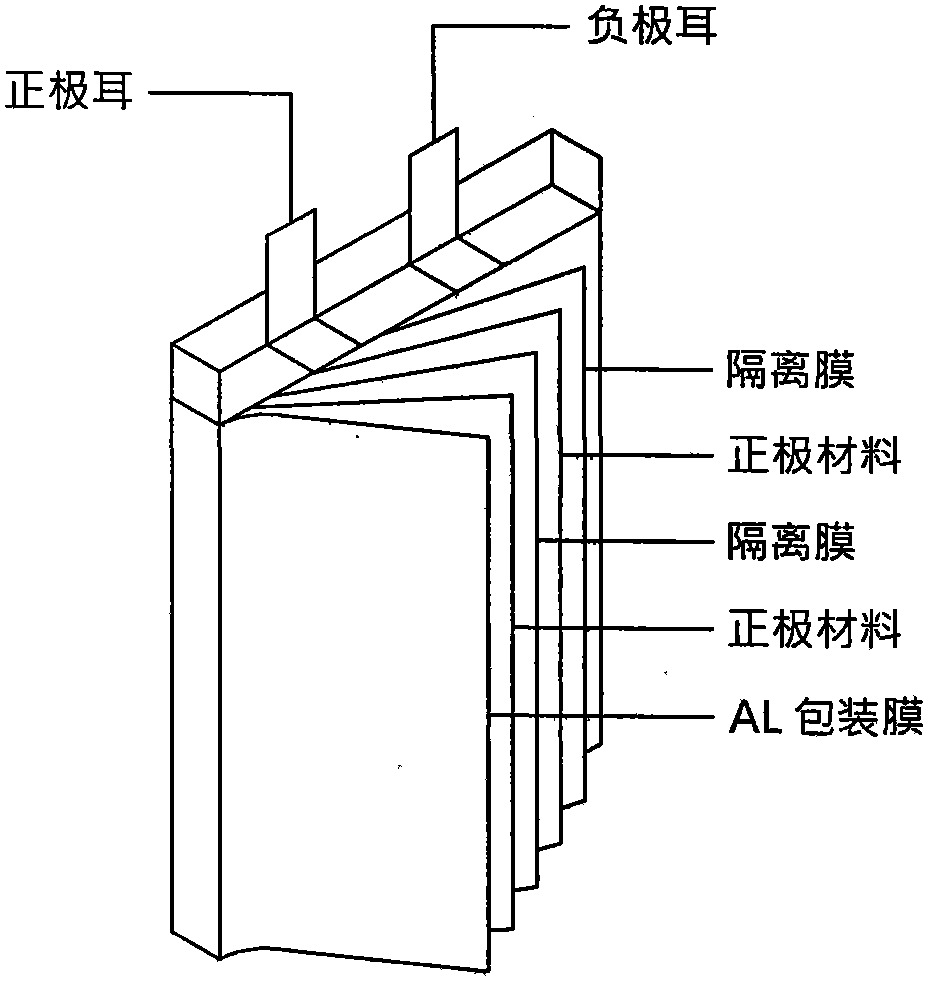

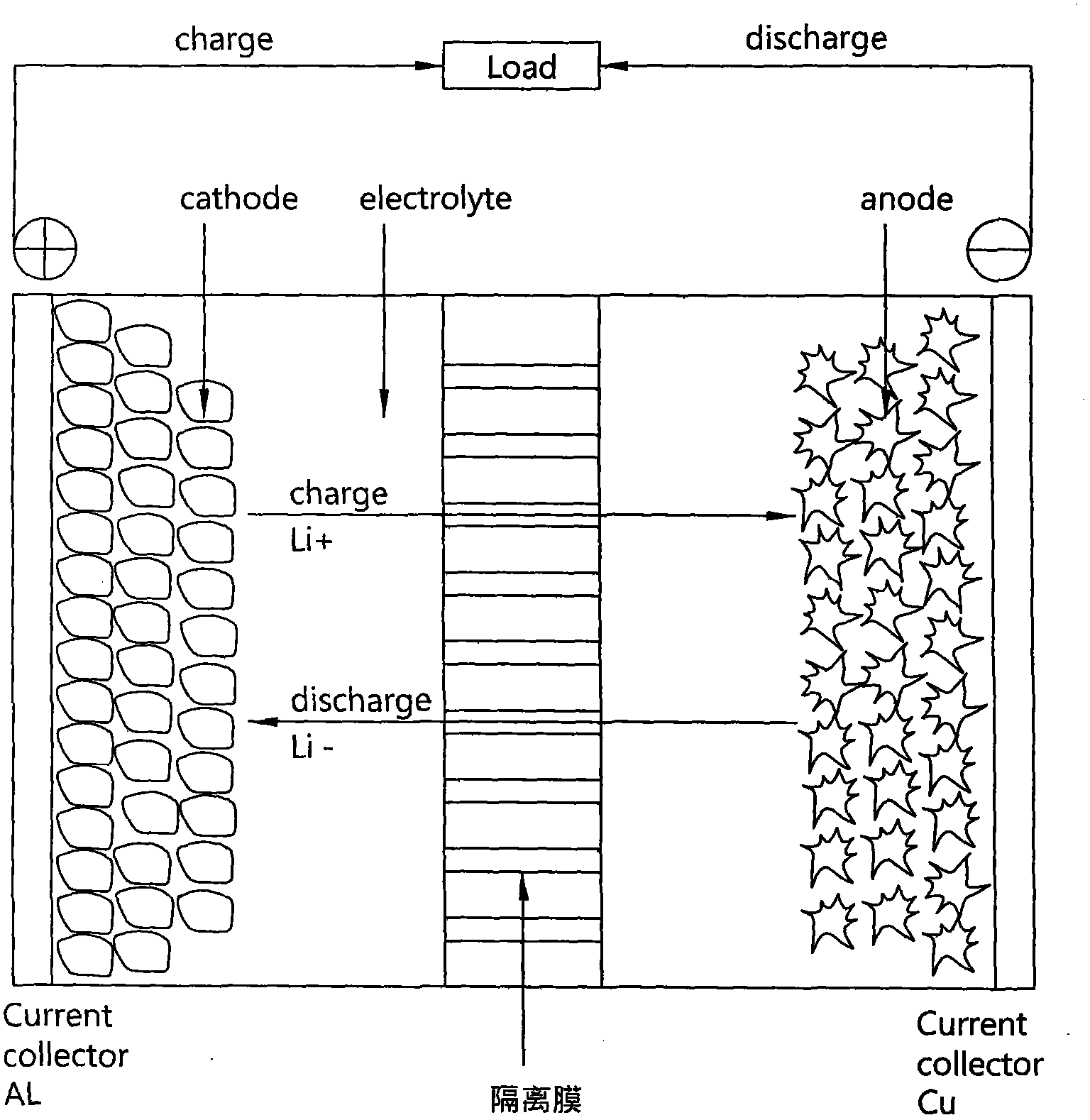

Aluminum plastic film

InactiveCN103507331AMaintain electrical performanceCell component detailsMetal layered productsHydrogen fluorideEngineering

The invention provides an aluminum plastic film and in particular relates to an aluminum plastic film (a lithium battery package material) specially used for a lithium battery. An outer layer, a first adhesive layer, a first priming coat layer, a middle layer, a second priming coat layer, a second adhesive layer and a bottom layer are sequentially arranged from top to bottom; the first adhesive layer is used for combining the inner surface of the outer layer and the middle layer; the bottom layer is positioned below the inner surface of the middle layer; the second adhesive layer is used for combining the inner surface of the middle layer and the bottom layer; the first priming coat layer and the second priming coat layer are functional treatment layers. Salts in organic electrolyte of the lithium battery can react with steam to generate hydrogen fluoride which is extremely corrosive, so that the treatment of the functional treatment layers at a preset position in the aluminum plastic film serves as protection for the middle layer and structural treatment of barriers; the overall structure is specially used for materials applied to package of the lithium battery.

Owner:刘德成

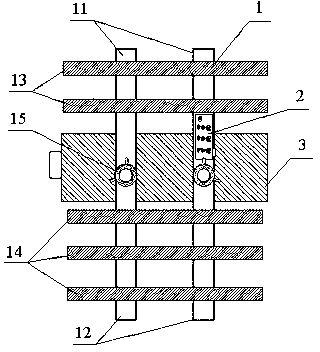

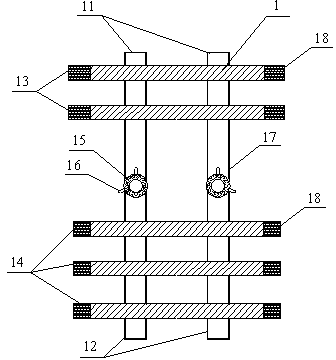

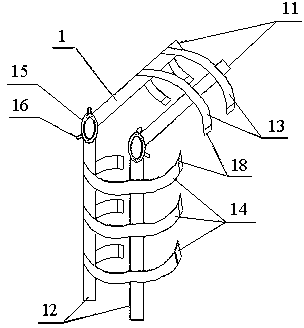

Novel multi-functional knee joint treatment unit with correctable gravity line

InactiveCN103263314AProper locationReasonable structureDevices for pressing relfex pointsFracturePhysical medicine and rehabilitationKnee Joint

The invention discloses a novel multi-functional knee joint treatment unit with a correctable gravity line. The novel multi-functional knee joint treatment unit comprises a knee joint corrector, a massage treatment apparatus and an insulation knee pad capable of fully wrapping the knee joint. The knee joint corrector comprises rigid fixing plates and soft elastic fixing straps, and each of the upper and lower fixing plates is connected through a chuck capable of adjusting angles of the same. The massage treatment apparatus is fixed on the fixing plate of the knee joint corrector, and the insulation knee pad is fixed in a position of the chucks of the knee joint corrector. The novel multi-functional knee joint treatment unit with the corrective gravity line comprises three main components of the knee joint corrector, the massage treatment apparatus and the insulation knee pad which are properly arranged, an integral structure is reasonable, and functions do not mutually interfere; and integrating functions of correction, treatment and health care of the knee joint into one, and the novel multi-functional knee joint treatment unit can provide simple, convenient, experimental and effective diagnosis and treatment services for patients and athletes with knee osteoarthritis, and other people with knee injuries and proneness to injuries.

Owner:YUEYANG INTEGRATED TRADITIONAL CHINESE & WESTERN MEDICINE HOSPITAL SHANGHAI UNIV OF CHINESE TRADITIONAL MEDICINE

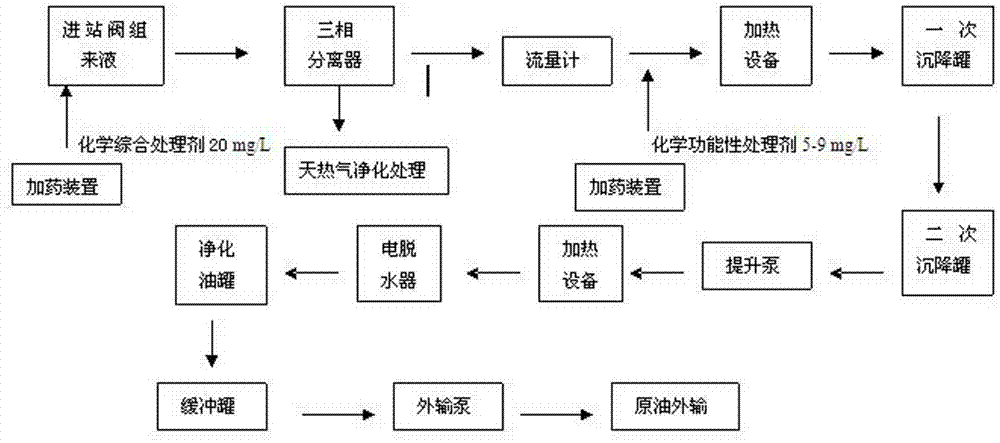

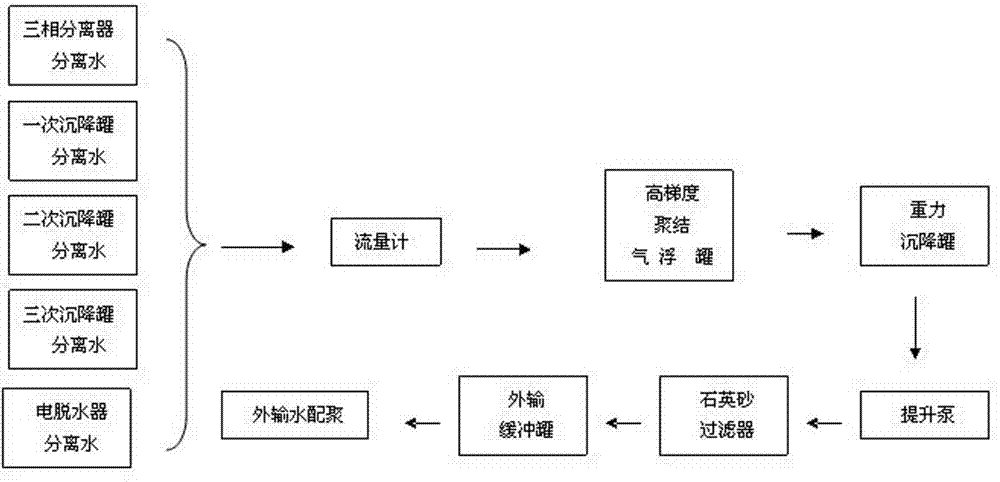

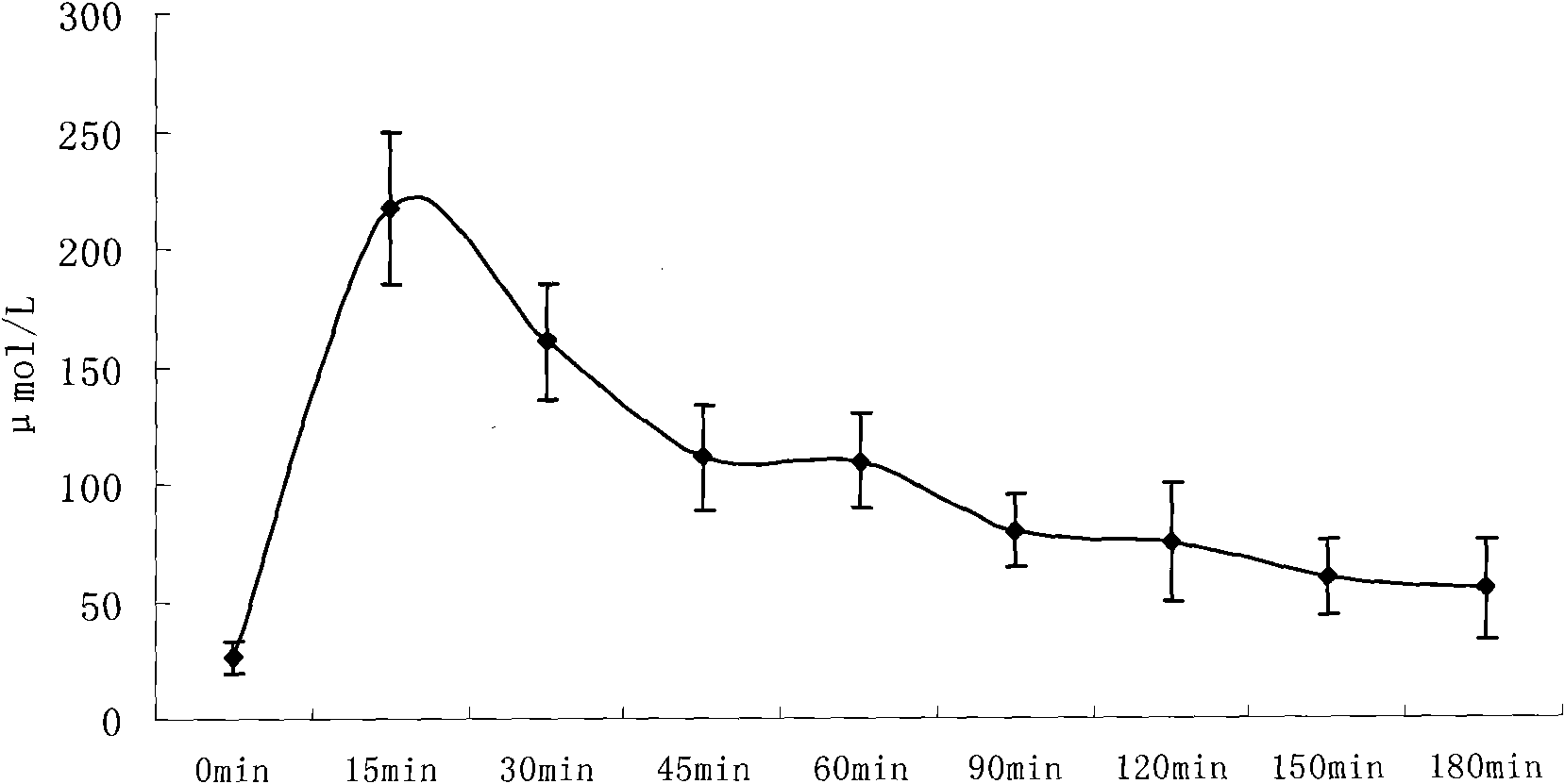

Integrated treatment method of chemical flooding produced emulsion

InactiveCN102899073AAvoid it happening againWaste water treatment from quariesTreatment with plural serial refining stagesOil sludgeWater content

The invention relates to an integrated treatment method of a chemical flooding produced emulsion. The crude oil treatment flow and the sewage treatment process are integrated to optimize oil and water treatment equipment, an adaptive comprehensive treatment agent and a functional treatment agent are selected, a dosing position is reasonably laid, and the chemical flooding emulsion is transferred and treated in the oil and water integrated treatment flow, so that the water content of transported crude oil reaches 0.6%, the oil content of transported sewage is 9.3mg / L, the suspended solid content is 8.0mg / L, the polymer content is 242mg / L, and the retention rate of polymer-bearing sewage polymer is more than 95%, and thereby avoiding the generation of aging oil and polymer-bearing sludge.

Owner:CHINA PETROLEUM & CHEM CORP +2

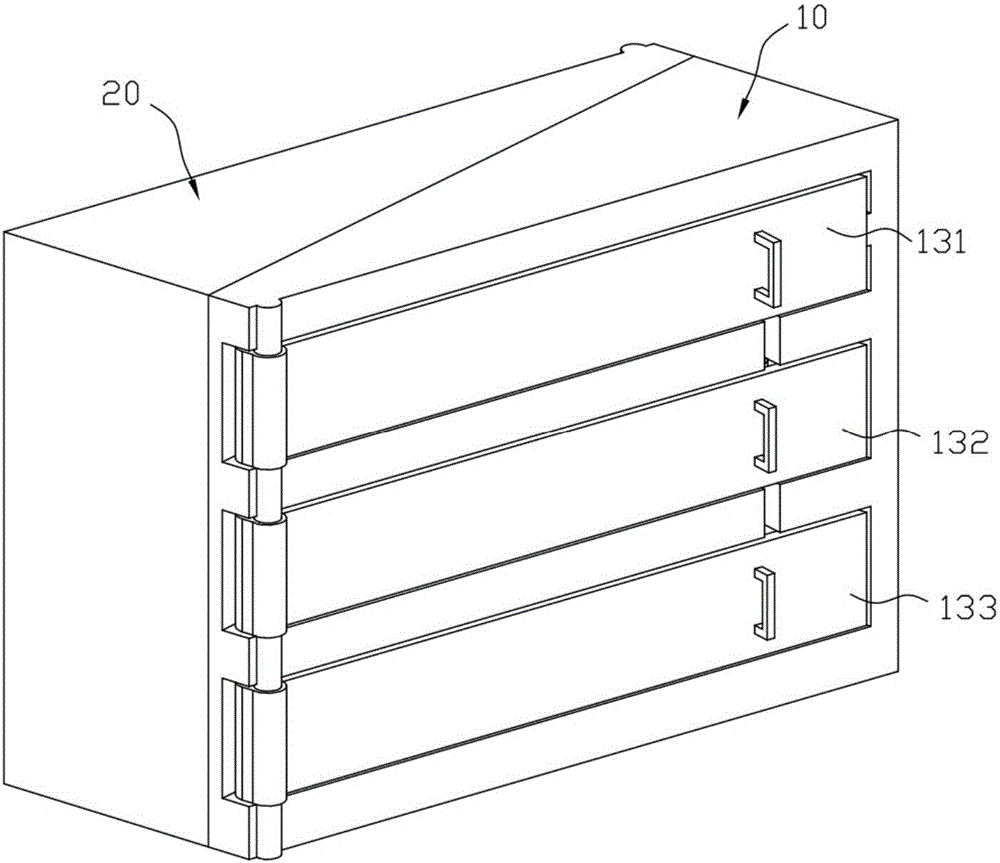

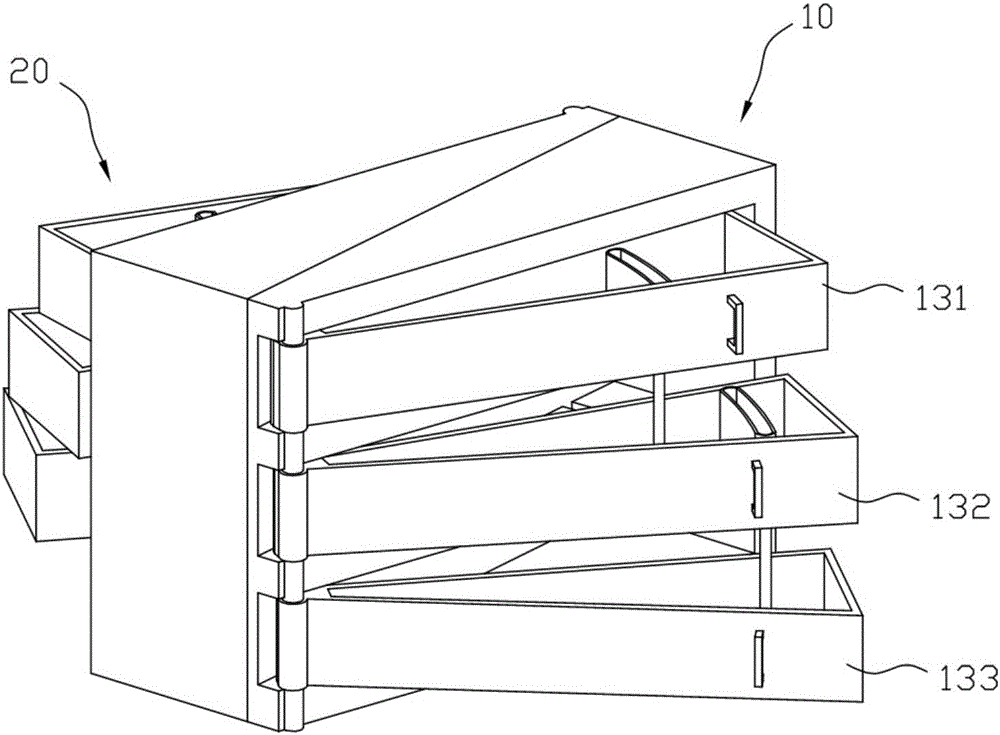

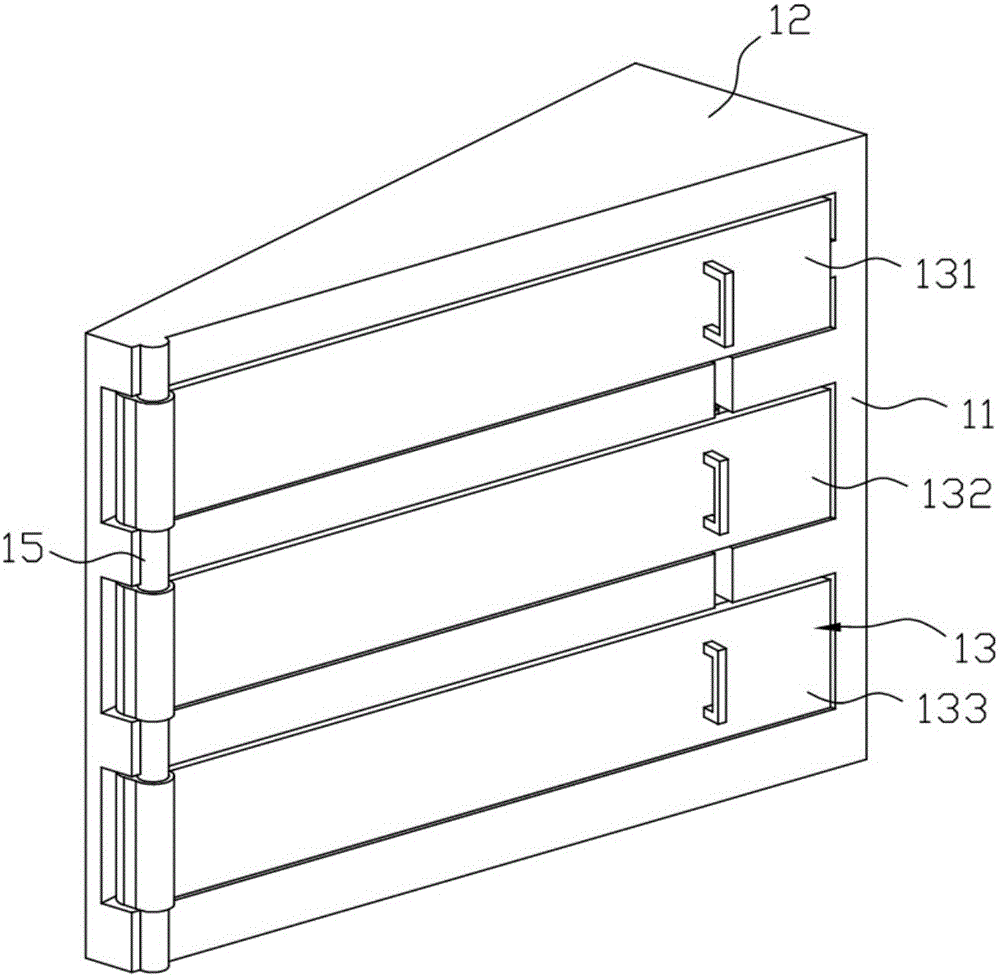

Multi-functional treatment table

The invention discloses a multi-functional treatment table. The multi-functional treatment table comprises a first branch body, wherein the first branch body comprises a rack, a treatment table surface, drawer groups and a fixing shaft; the rack is provided with drawer groove groups which are arranged in an upper-lower layering way; the drawer groups are arranged in the drawer groove groups; the fixing shaft is arranged at one side of the rack; one end of each drawer is hinged to the fixing shaft; the drawers are fan-shaped and can independently rotate around the fixing shaft. According to the technical scheme, a medical staff stands beside the fixing shaft to operate medicine on the treatment table surface, one drawer is enabled to rotate around the fixing shaft by pulling a handle of the drawer when the medical staff needs to take articles from the drawer, and the articles in the drawer appear in front of the medical staff after the drawer rotates by a certain angle, so that the medical staff only needs to stand or sit beside the fixing shaft to take articles from the drawers without moving positions, convenience is provided for the medical staff, the labor intensity of the medical staff is reduced, and the working efficiency of the medical staff can also be increased.

Owner:SUZHOU BAODI HAISI MEDICAL DEVICE TECH DEV CO LTD

Preparation method of microfiber leather

InactiveCN108642891AUniform thicknessGood hygroscopicityTextile/flexible product manufactureTextiles and paperProduction lineHigh density

The invention discloses a preparation method of microfiber leather. The production line of the preparation method comprises the following steps: production of a high-density spunlaced nonwoven fabricfrom sea island short fibers, ironing shrinkage, wet impregnation in PU resin, toluene reduction extraction, drying tentering, oiling softening, puffing , dry PU lamination, and functional treatment for producing the microfiber leather. The preparation method has the advantages of simple treatment process and environmentally-friendly production process, the microfiber leather contains no chromiumor other harmful substances, the raw material is a petroleum product, is environmentally friendly and nontoxic, and can be recycled, and the microfiber leather produced by the preparation method has the advantages of uniform thickness, excellent moisture absorption property, excellent air permeability, excellent mold resistance, excellent alkali resistance, excellent aging resistance and excellentwater repellency.

Owner:海宁裘仕制衣有限公司

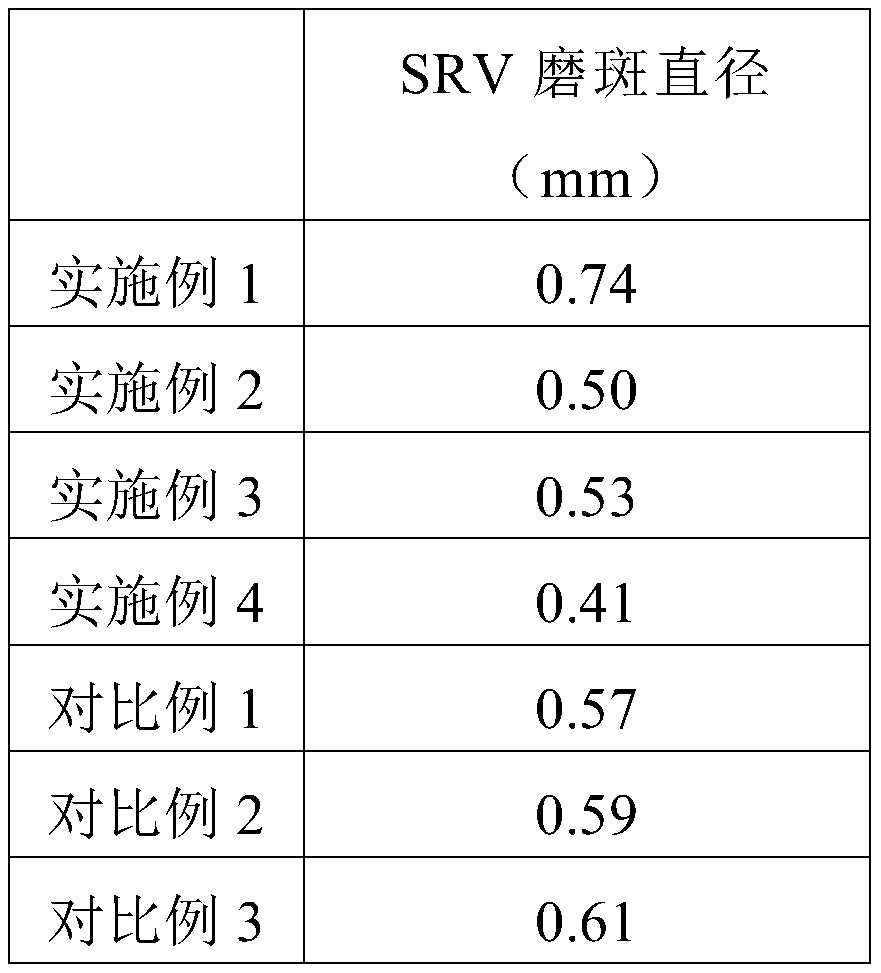

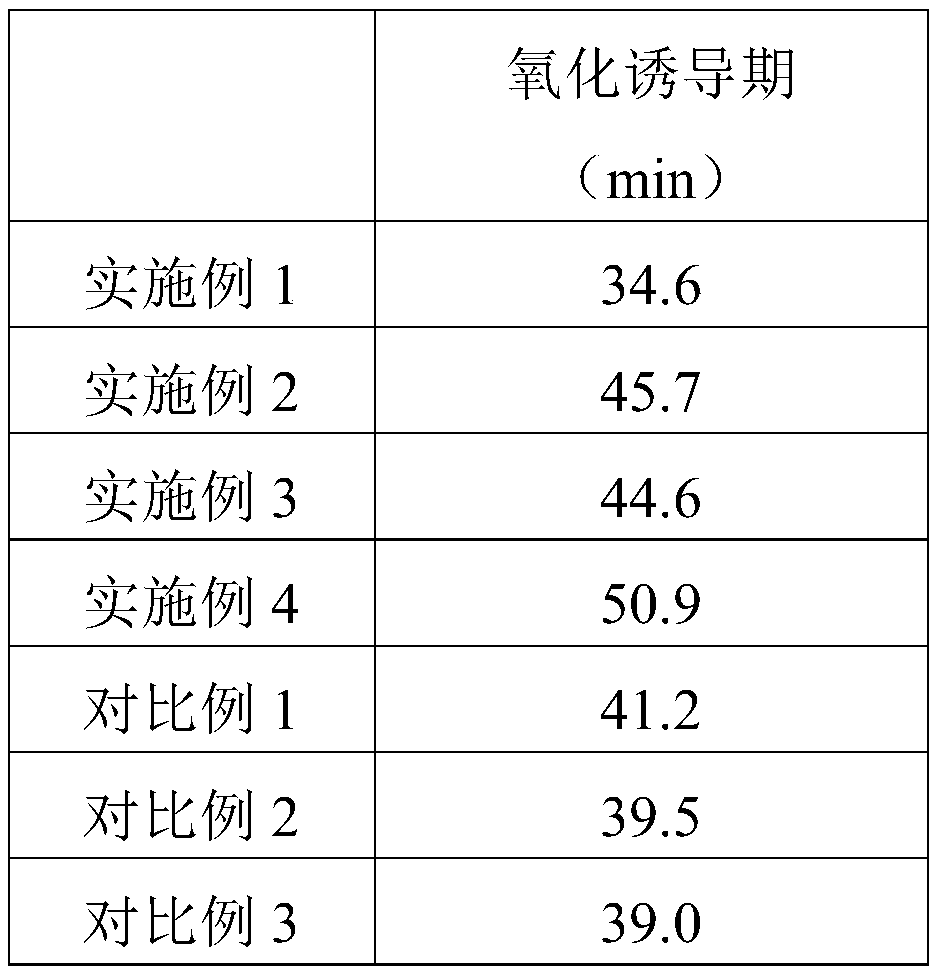

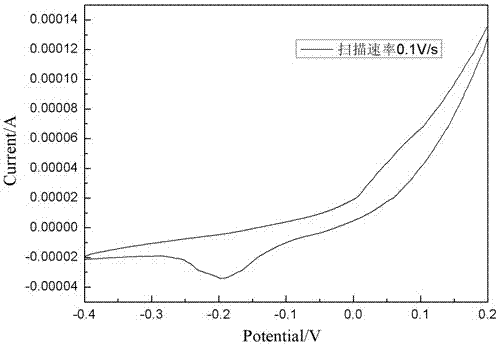

Biodegradable lubricating oil, and preparation method thereof

ActiveCN110157531AImprove the lubrication effectImprove anti-wear performanceBase-materialsPolymer scienceCottonseed oil

The invention discloses a biodegradable lubricating oil, and a preparation method thereof. The preparation method comprises following steps: 1, raw materials are prepared, wherein the raw materials comprise cotton seed oil, bis(2-ethylhexyl) sebacate, a dispersant, an extreme pressure antiwear agent, an antioxidant, potassium sorbate, dodecenyl succinic acid, a viscosity index improver, an a defoaming agent; 2, an obtained cotton seed oil mixture is introduced into a blending vessel for stirring, and is discharged through a 2-10<mu>m filter so as to obtain a finished product. The biodegradablelubricating oil is scientific and reasonable in formula, is friendly to the environment, is nontoxic, is prepared taking cotton seed oil as a base oil, is cheap, and is biodegradable; cotton seed oilis subjected to functional treatment, so that the lubricating performance and anti-wearing performance of the lubricating oil are improved greatly; the preparation method is simple and convenient, and is convenient for industrialized production. The biodegradable lubricating oil is excellent in wear resistance, lubricating performance, low temperature performance, high temperature performance, and heat oxidation stability, and the bio-degradability and the economical performance are better than those of fully synthetic oil.

Owner:深圳市超美化工科技有限公司

Method for preparing amino functional multiporous silica-based composite material for ion detection

InactiveCN102520041AEasy accessHigh sensitivityMaterial analysis by electric/magnetic meansPlatinumP type silicon

The invention provides a method for preparing an amino functional multiporous silica-based composite material for ion detection. The method comprises the following steps of: pretreating an N-type or P-type silicon slice, putting the silicon slice into an erosion solution, taking the silicon slice as a positive electrode and a platinum slice as a negative electrode by using a double-electrolytic-bath or single-electrolytic-bath electrochemical erosion method, and applying erosion current, namely eroding the silicon slice to obtain multiporous silicon; and then washing, performing thermal oxidization treatment on the surface of the multiporous silicon to introduce a silicon hydroxyl bond into the surface of the multiporous silicon, putting the multiporous silicon into a substance containing an amino ligand, stirring and performing amino functional treatment, and thus obtaining the amino functional multiporous silica-based composite material. The material has relatively high sensitivity and selectivity to trace silver ions and copper ions, and has extremely large specific surface area and high surface activity, so that the material is subjected to simple and high-efficiency surface modification. The method is simple, and is easy to operate; and the amino functional multiporous silica-based composite material can be obtained quickly.

Owner:KUNMING UNIV OF SCI & TECH

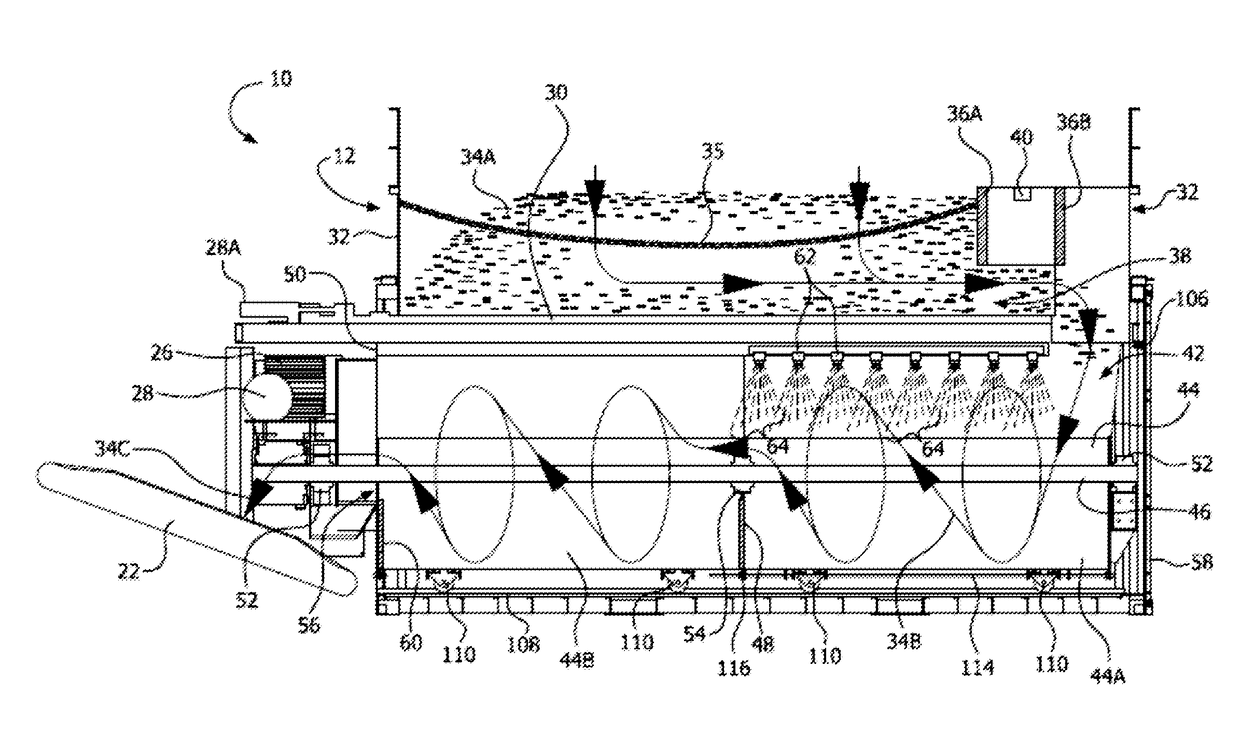

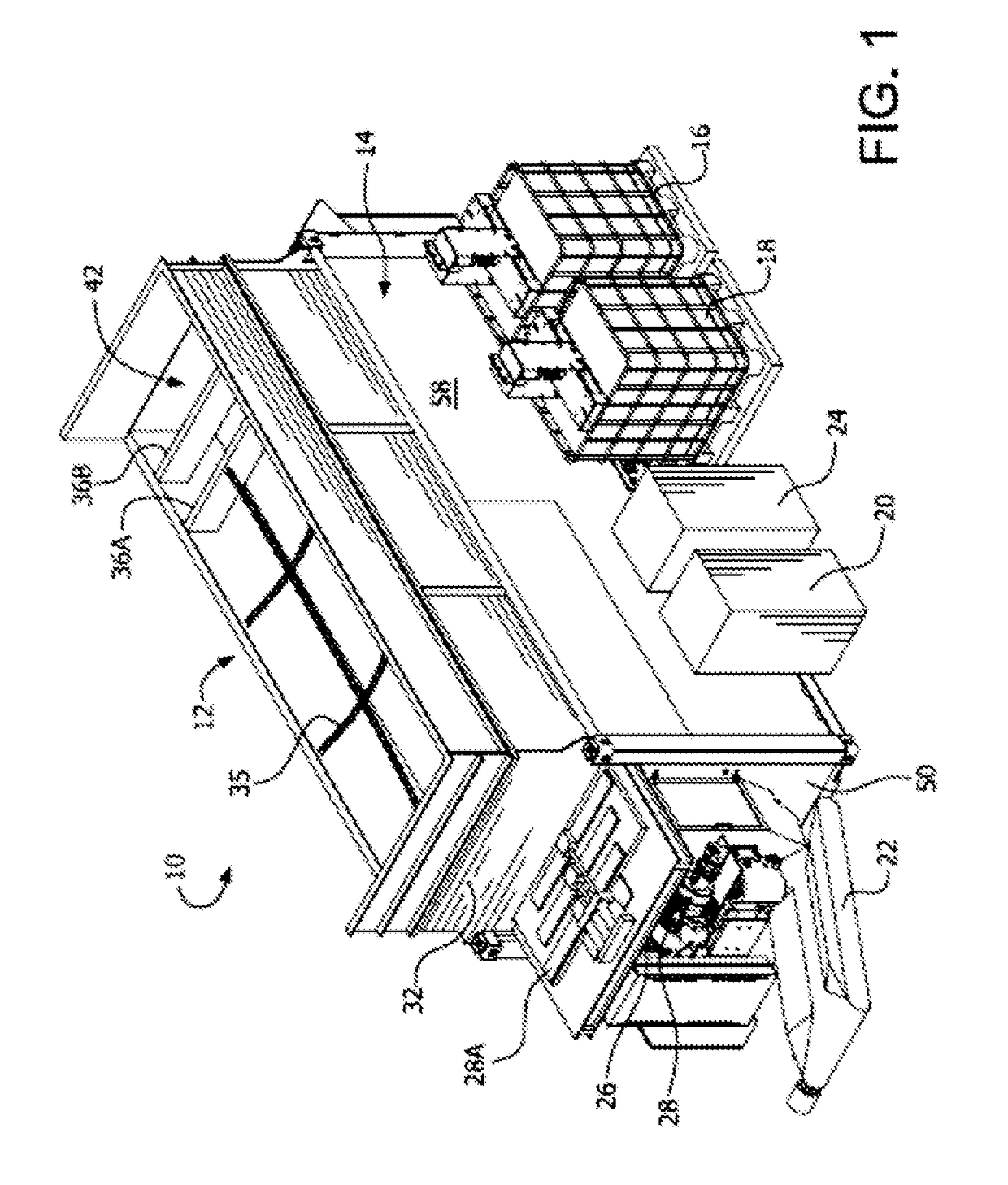

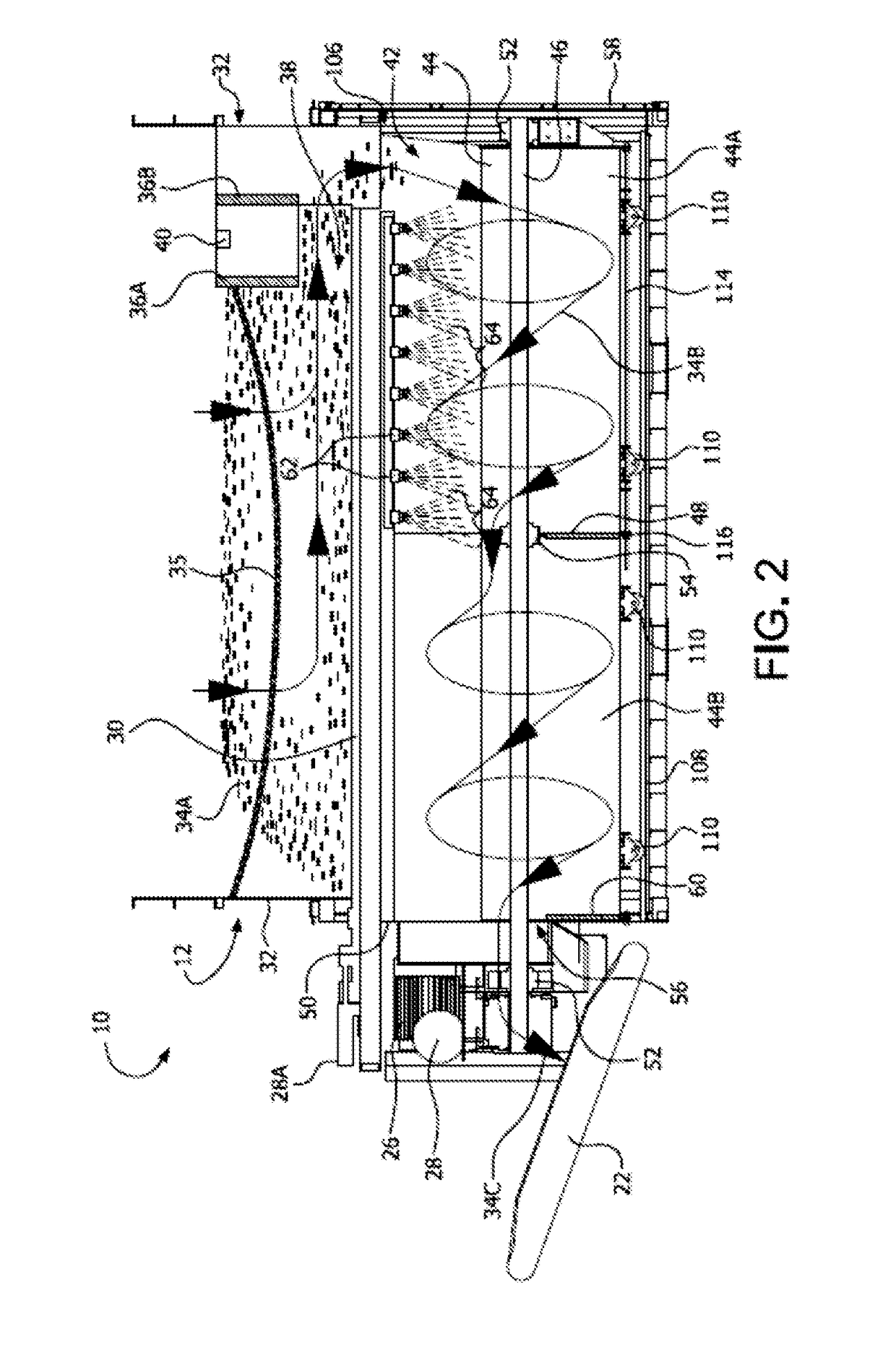

Functional treatment application to particulate materials such as mulch or potting soil

ActiveUS20170080446A1Improve fertilityGood for healthLiquid surface applicatorsGrowth substratesMaterials scienceMulch

In a method of coating a particulate material, a particulate material is fed into a mixing chamber. The particulate material is agitated within the mixing chamber and conveyed to a mixing chamber outlet. A coating is directed into the mixing chamber and the flow of the coating is controlled based on the volumetric flow rate of the particulate material into the mixing chamber. The coating includes at least one compound selected from herbicides, insecticides, nutrients, wetting agents, surfactants, fungicides, biologicals, inoculants, and mixtures thereof.

Owner:BASF CORP

Preparation method of novel Au/Fe2O3-TiO2 nanotube catalyst

InactiveCN103601236ASteps to avoid pre-functionalizationStrong complexing abilityMaterial nanotechnologyTitanium dioxideFerric hydroxideDispersity

The invention relates to a preparation method of a titanium-iron composite supporter nanotube supported gold catalyst with high gold dispersity and controllable particle size. The TiO2 nanotubes synthesized by a hydrothermal process are used as a supporter and impregnated in a ferric hydroxide colloid, a sol perfusion process is utilized to prepare the titanium-iron composite supporter nanotubes, and lysine is used as a protective agent for noble metal nanoparticles and a linking agent between the noble metal particles and supporter, so that the small-size noble metal nanoparticles are uniformly supported onto the supporter in the formation process, thereby avoiding the step of previous functional treatment on the supporter, further synthesizing the supported noble metal catalyst material by one step, and greatly simplifying the synthesis steps. The composite supporter supported high-gold-dispersity catalyst can overcome the defects of low catalytic activity, small specific area, low dispersity of the active component gold, high accumulation tendency, high tendency to activity loss and the like, and has important practical application value. By reasonably selecting the composite supporter, regulating the structure and reasonably supporting the gold particles, the supported gold catalyst with smaller size and higher gold dispersity has higher catalytic activity.

Owner:TIANJIN POLYTECHNIC UNIV

Surface modified titanium implant and functional treatment method thereof

ActiveCN110241451AImprove biological activityHigh crystallinitySurgerySurface reaction electrolytic coatingMicro arc oxidationPlasma electrolytic oxidation

The invention belongs to the field of surface treatment, and discloses a surface modified implant and a functional treatment method thereof. The functional treatment method for the titanium implant surface comprises the step (1) of placing a titanium implant in mixed solutions containing sodium salt, potassium salt and ammonium salt for micro-arc oxidation treatment, and obtaining a surface titanium oxide implant; the step (2) of cleaning the surface titanium oxide implant through picosecond or femtosecond laser for removing a loose oxide layer in a crystalline titanium oxide film, and obtaining a dense titanium oxide implant; and the step (3) of performing spray deposition treatment to the dense titanium oxide implant through nano-hydroxyapatite suspension, and performing drying, sintering and short-wave irradiation upon completion of spray deposition treatment in sequence. By adopting the method, the bonding strength between a hydroxyapatite layer and the crystalline titanium oxide film can be improved, and the obtained implant is high in hydrophilicity and biological activity, and benefits promotion of osseointegration.

Owner:DABO MEDICAL TECH CO LTD +1

Method for in-situ detection of nano noble metal catalyst

InactiveCN101995382ASimple methodLow costPreparing sample for investigationColor/spectral properties measurementsCatalytic effectUltimate tensile strength

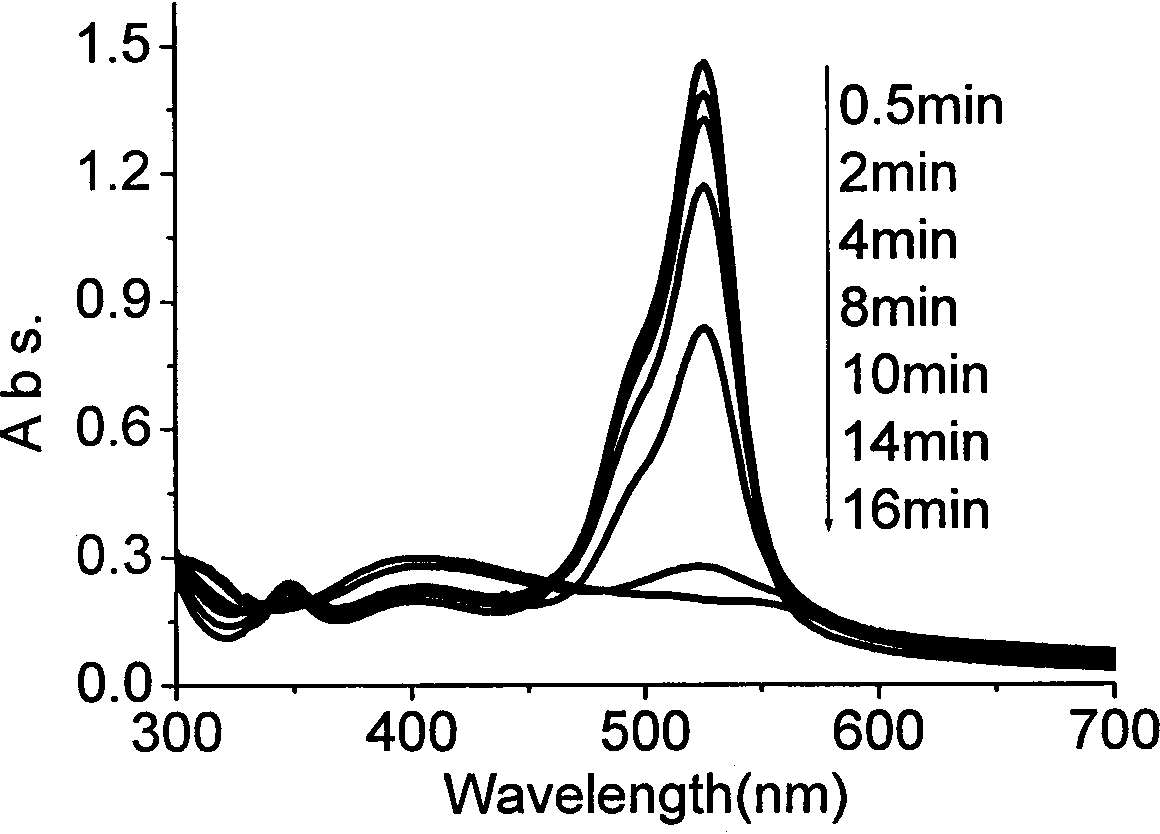

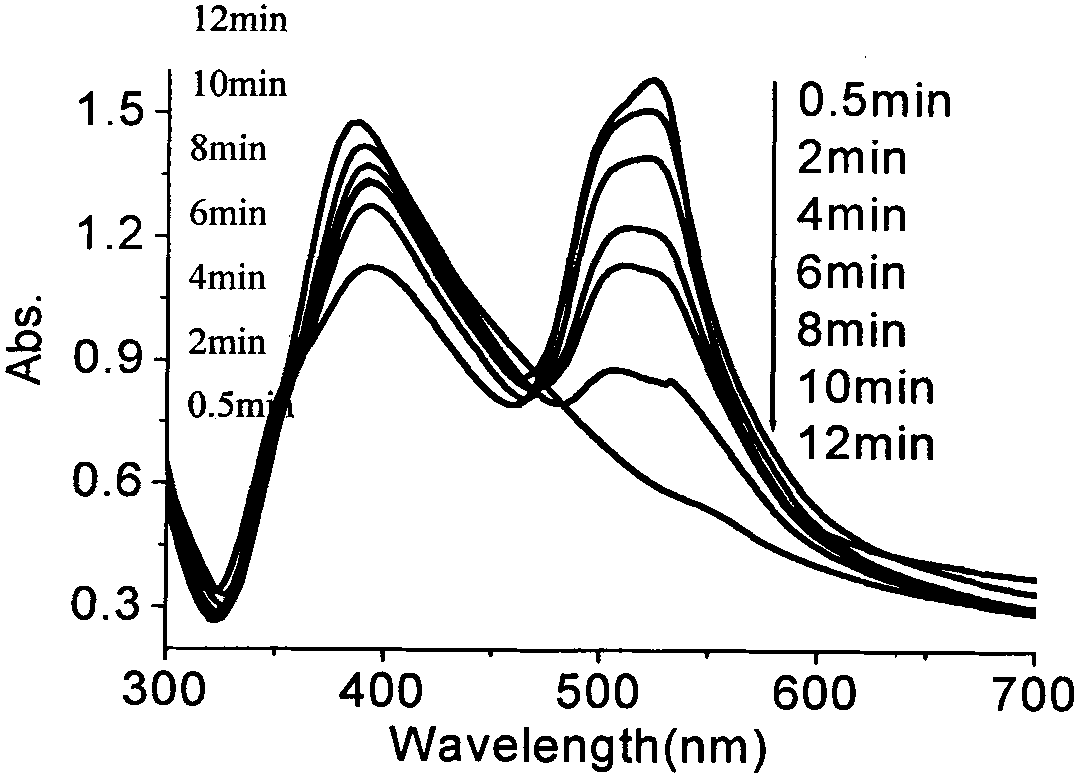

The invention belongs to the technical field of nano material detection and in particularly relates to a method for in-situ detection of a nano noble metal catalyst, especially a gold / silver catalyst. In the method, SiO2 subjected to amino functional treatment and 4nm Ag sol or 2-4nm Au sol are used as raw materials and are compounded to form a SiO2-Ag or SiO2-Au composite material which has a core-shell structure and used as a catalyst, the SiO2-Ag composite material catalyst has an obvious catalytic action on the reduction reaction of a NaBH4 catalytic dye, and the SiO2-Au composite material catalyst has an obvious catalytic effect on catalyzing CO to be oxidized into CO2; and an in-situ detection is carried out on SiO2-Ag and SiO2-Au through an ultraviolet visible spectrum, the changes of SPR (Surface Plasmon Resonance) peak position and strength before and after catalyst reaction are compared so as to determine whether the nano silver / gold catalyst is inactivated after reaction or not and ensure the recycling of the nano silver / gold catalyst.

Owner:JILIN NORMAL UNIV

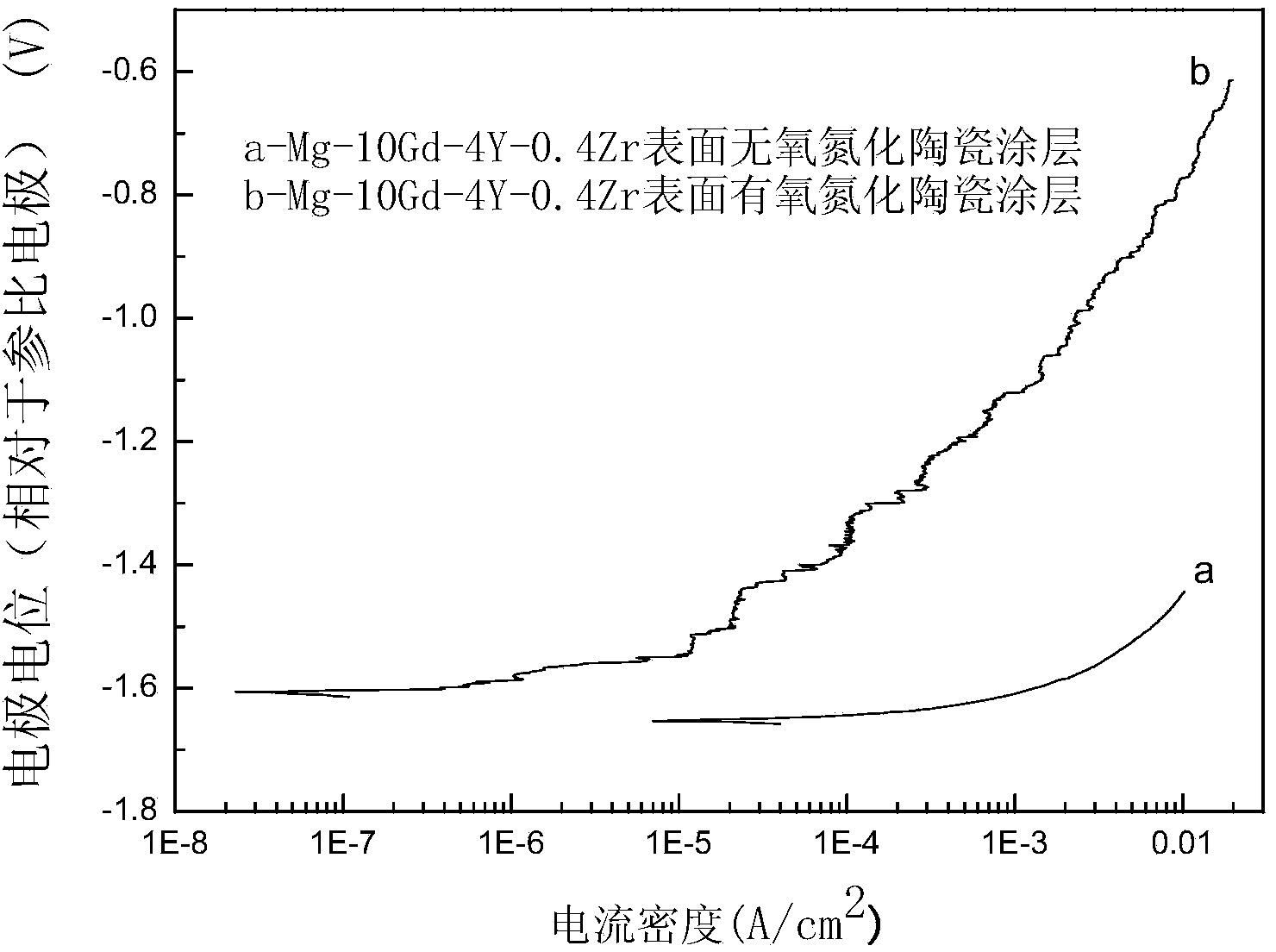

Fused salt oxygen, carbon and sulfur co-cementation type corrosion-resistant ceramic coating of magnesium alloy surface as well asand preparation and application

InactiveCN103451595AImprove corrosion resistanceHigh hardnessSolid state diffusion coatingCeramic coatingRaw material

The invention relates to a processing technology of a magnesium alloy surface, and in particular relates to a fused salt oxygen, carbon and sulfur co-cementation type corrosion-resistant ceramic coating of the magnesium alloy surface and preparation and application thereof, aiming at solving the problem due to the corrosion resistance of a part manufactured from a magnesium alloy and overcoming the shortcoming that the inner hole of a deep hole in an irregular complex magnesium alloy part cannot be protected with a corrosion-resistant layer. The preparation comprises the following steps of: taking the magnesium alloy as a substrate material; and immersing a magnesium alloy part into a liquid oxygen, carbon and sulfur co-cementation solution to perform liquid oxygen, carbon and sulfur co-cementation treatment on the magnesium alloy surface, thus obtaining an oxidized ceramic coating with high corrosion resistance; the ceramic coating is uniform and dense in thickness, ranging from 10 to 60 microns. By adopting the fused salt oxygen, carbon and sulfur co-cementation type corrosion-resistant ceramic coating, the hardness as well as abrasion resistance of the magnetism alloy surface can be improved; the corrosion resistance of the magnesium alloy can be obviously improved; the fused salt oxygen, carbon and sulfur co-cementation type corrosion-resistant ceramic coating can be applied to functional treatment of the surfaces of a hub, a radiating fin and other parts manufactured from the magnesium alloy; in addition, the liquid oxygen, carbon and sulfur co-cementation solution isare simple in components, the raw materials are easy to getcarry out, and the industrial production can be performed.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

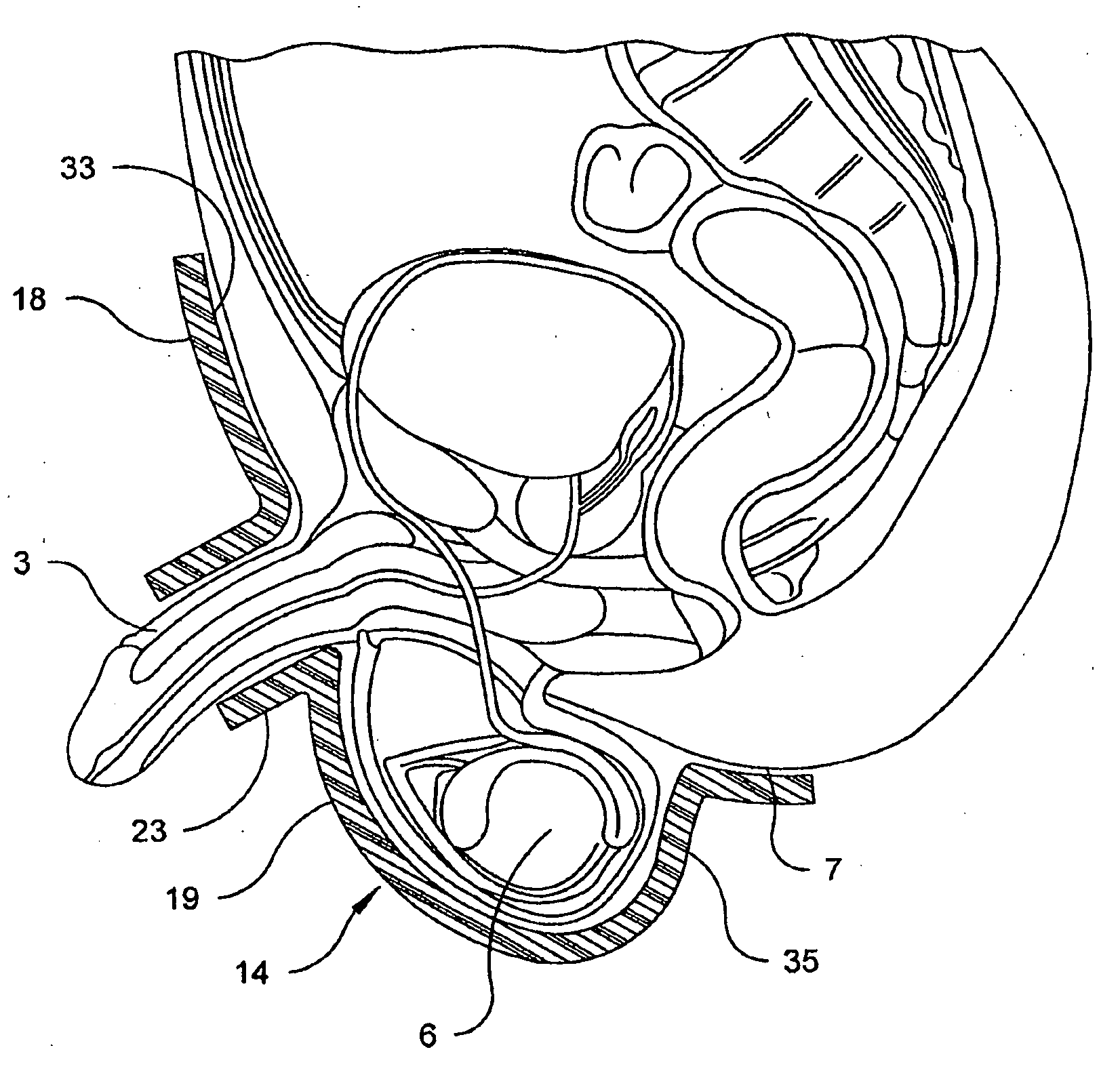

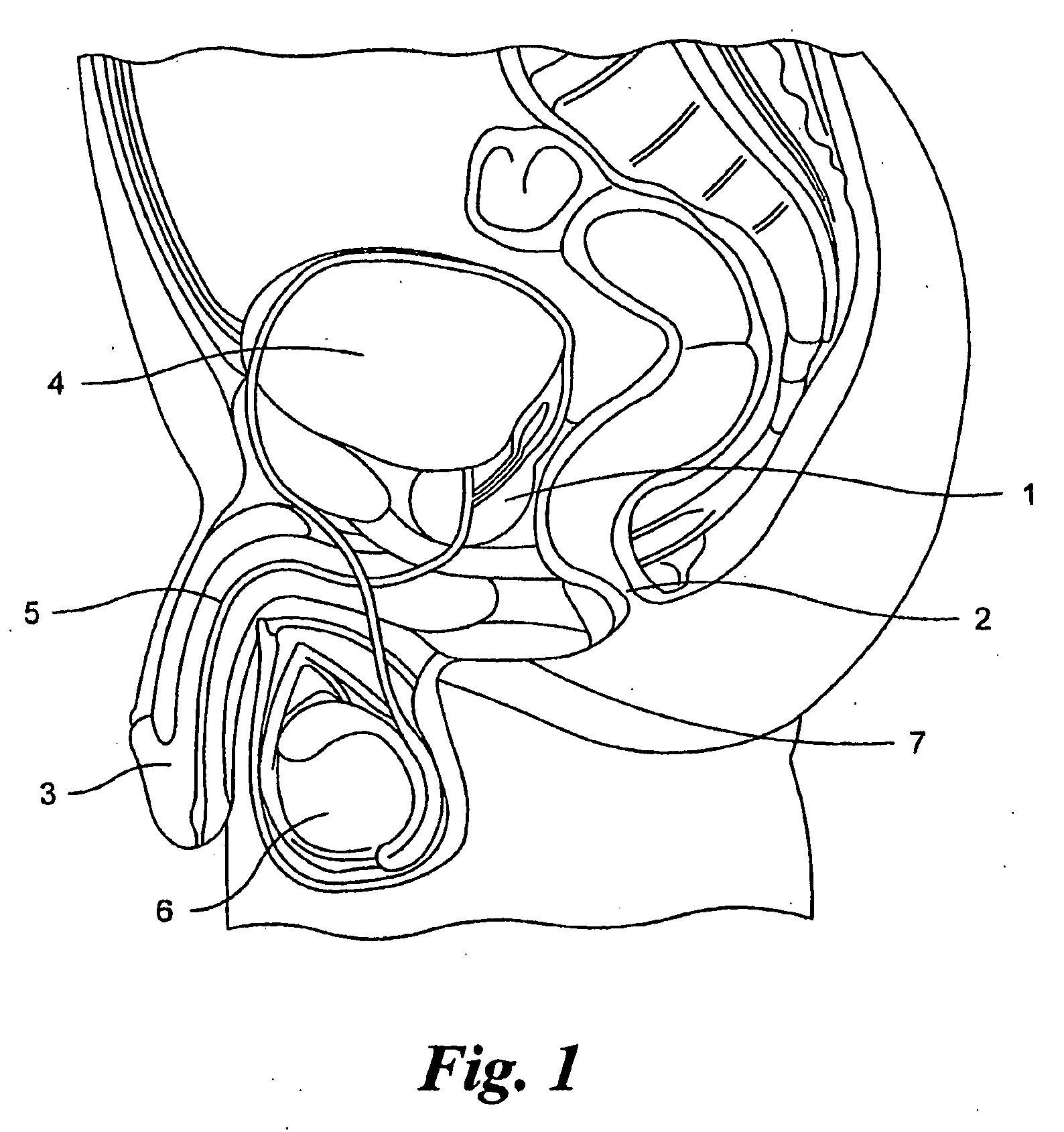

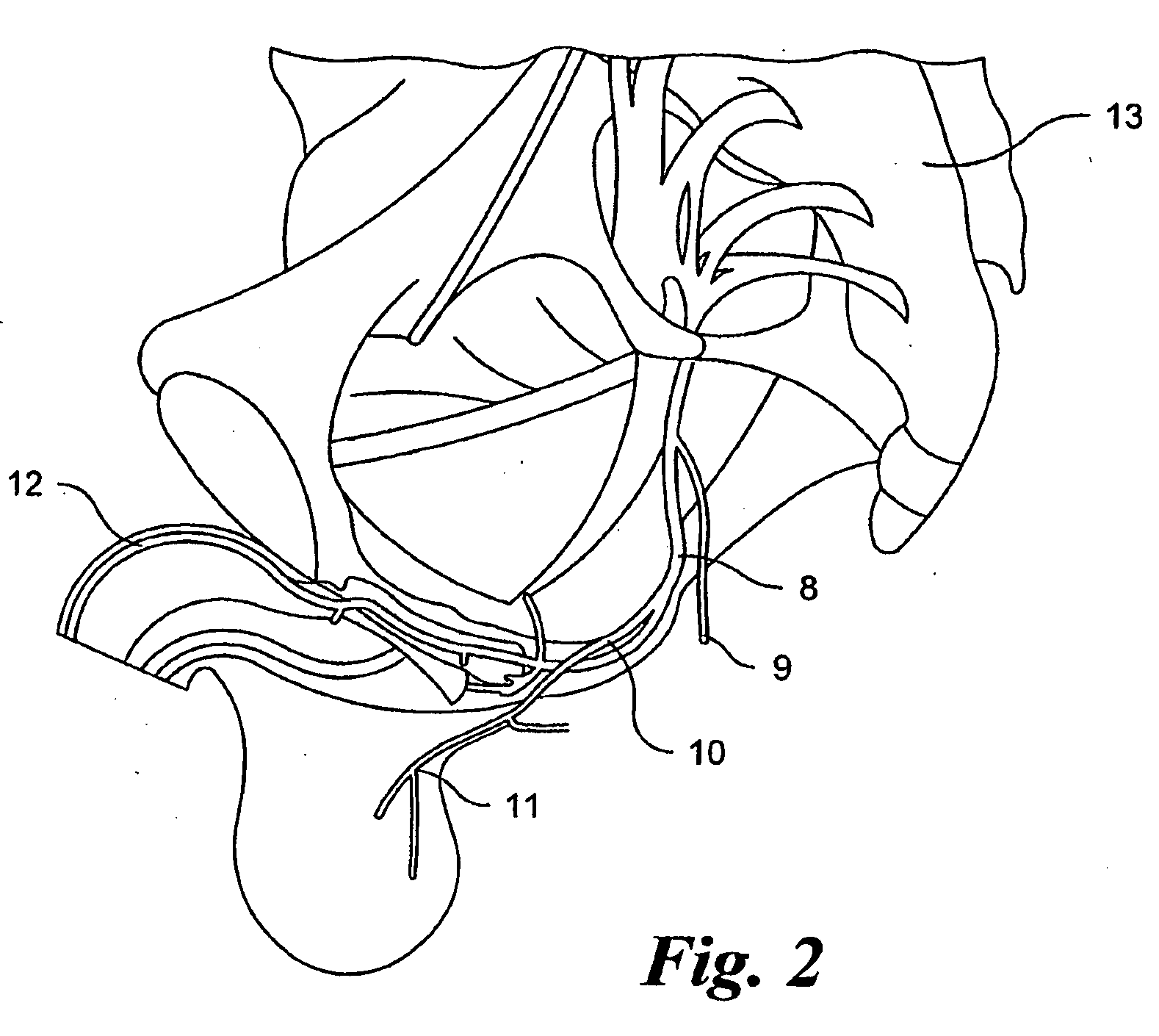

Therapeutic device for thermally assisted urinary function

ActiveUS20090105793A1Avoid side effectsAvoid complicationsElectrotherapyTherapeutic coolingStored energyPenis

A therapeutic device for thermally assisted urinary function is presented. The therapeutic pad (14) is composed of an upper thermal element (18) and a lower thermal element (19) having a portal (15), both elements substantially cup-shaped to cover and contact the groin. The therapeutic pad (14) is composed of a material sufficiently capable of storing energy from either an external or internal source. The therapeutic pad (14) communicates stored energy as heat to tissues comprising the groin and regions adjacent thereto. The portal (15) allows for the unimpeded flow of urine from the urinary tract into a receptacle. A variety of alternate embodiments are provided, including lift tabs (17a, 17b), an extension element (35) for heating the perineum, a portal sleeve (23) for heating the penis, a slit (34) which bisects the therapeutic pad (14) and portal sleeve (23), a pair of rings (26, 27) to open and close the slit (34), an interior cover (30) about the therapeutic pad (14) for applying moist heat, and support elements (31) along the therapeutic pad (14).

Owner:BROWN MARK

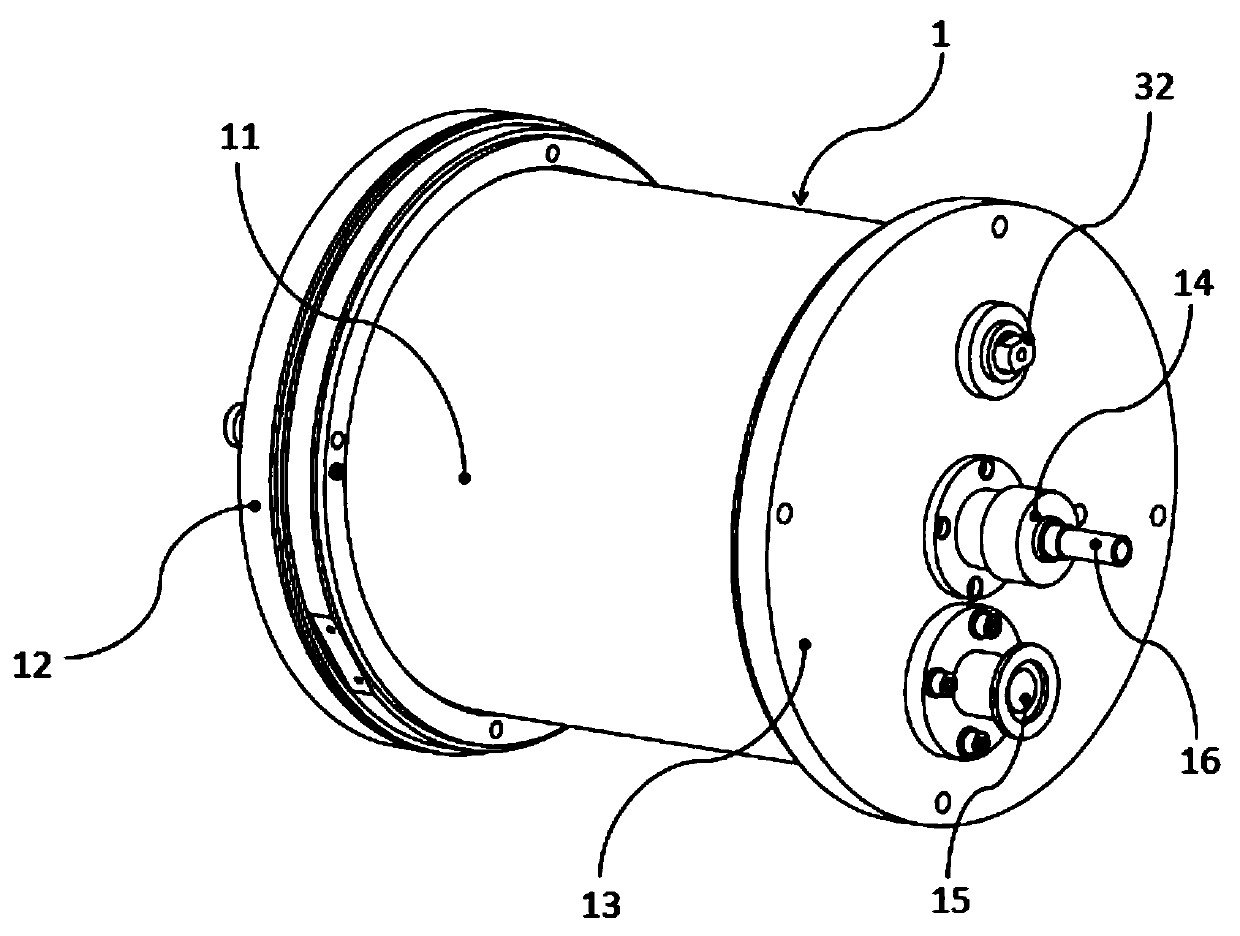

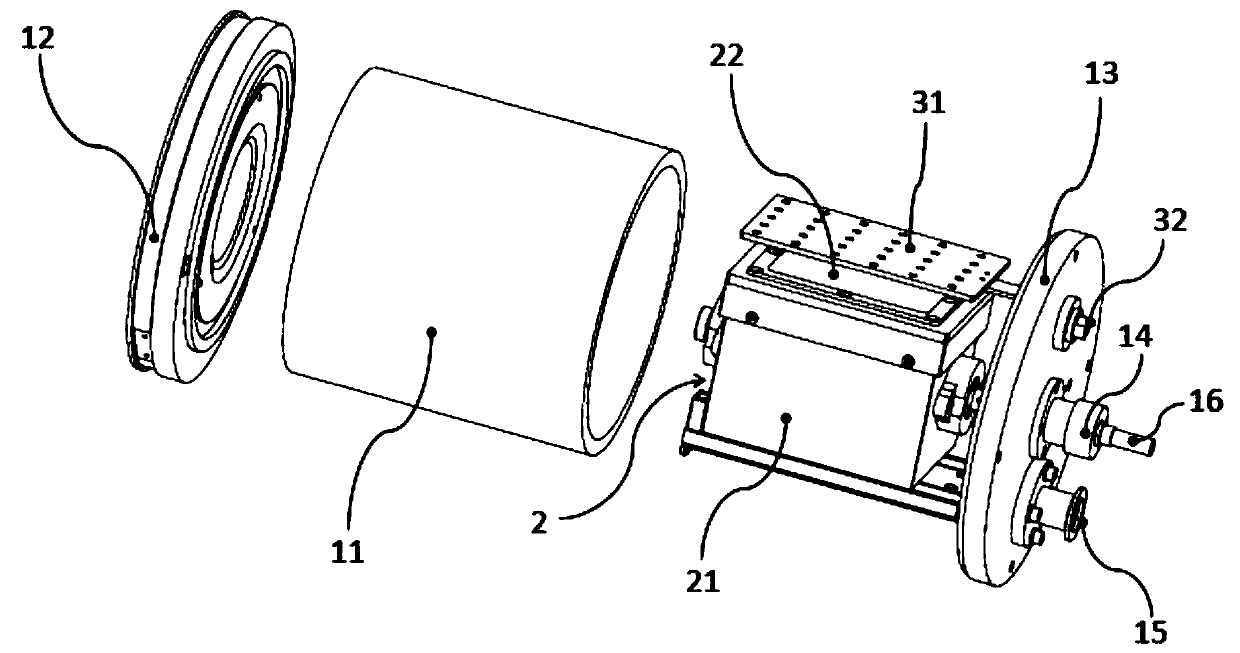

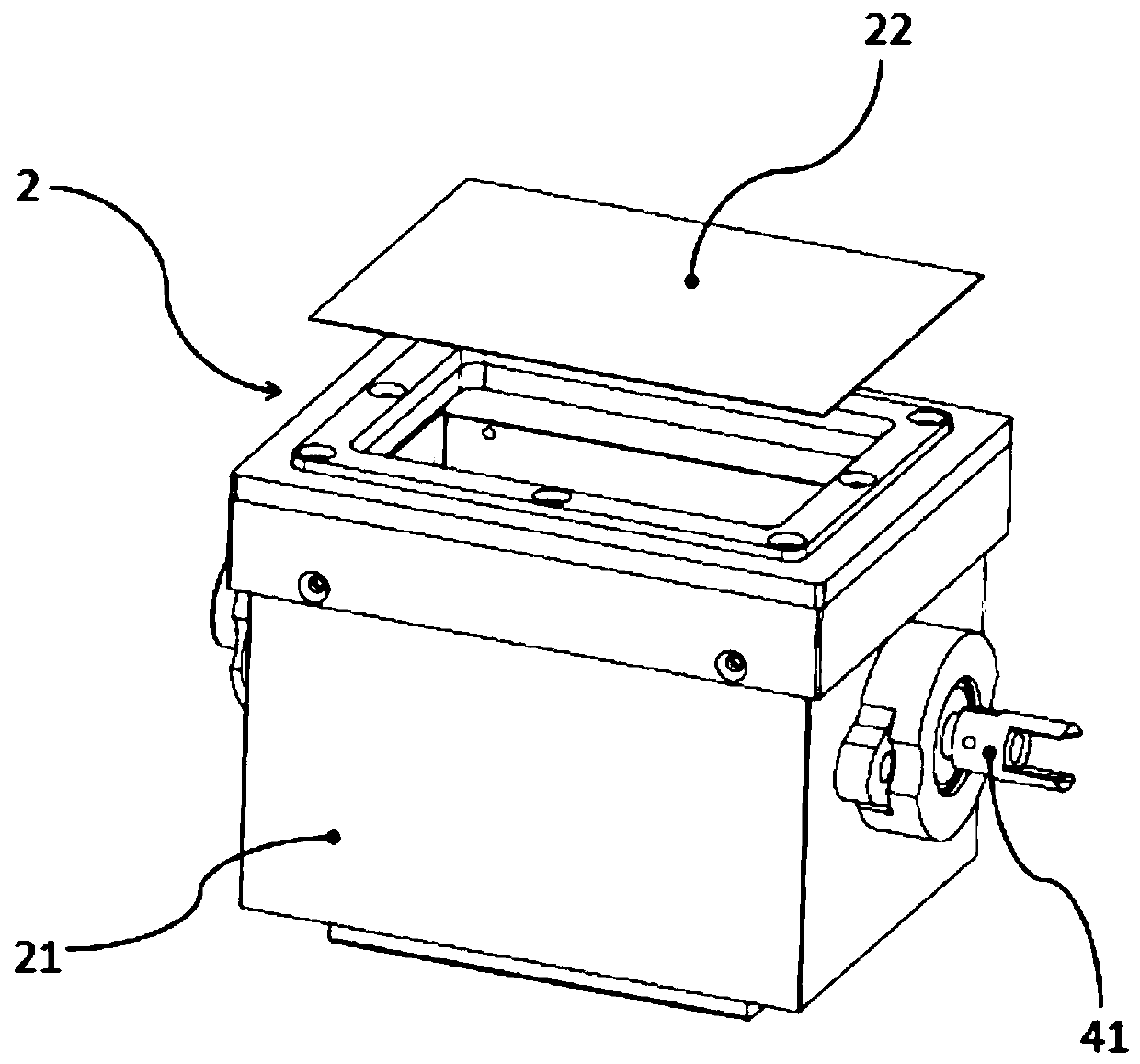

Plasma surface treatment equipment for granular and powdery materials

PendingCN109865484AUniform treatmentHandle a wide range of particle sizesEnergy based chemical/physical/physico-chemical processesPressure/vacuum vesselsVacuum pumpingPlasma generator

The invention discloses plasma surface treatment equipment for granular and powdery materials, comprising a vacuum outer cavity, a vacuum inner cavity, a particle stirring mechanism and a plasma generator, wherein the vacuum inner cavity is disposed in the vacuum outer cavity, the particle stirring mechanism is disposed in the vacuum inner cavity; the right side of the vacuum outer cavity is provided with a vacuum suction port and an air inlet, the vacuum inner cavity includes a reaction chamber and a filter mesh plate, and the air inlet port communicates with the right side of the vacuum inner cavity; and the plasma generator includes an electrode group and a plasma generating power source. The particle stirring mechanism stirs particles, and the treatment is uniform; at the same time, the vacuum outer cavity and the vacuum inner cavity are arranged, the sealing is good, and the treated particles are prevented from overflowing; the filter mesh plate is arranged in the vacuum inner cavity, and the particle size of treatable particles and powder is wide; functional treatment, such as hydrophilic treatment, hydrophobic treatment and coating wrapping, is carried out on the surfaces ofparticles by exciting different types of plasma.

Owner:深圳市奥普斯等离子体科技有限公司

Male moth yang-strengthening compound preparation formula and preparation technique thereof

InactiveCN101642502AAvoid drug resistanceAvoid side effectsAnthropod material medical ingredientsSexual disorderHealthy dietWestern medicine

The invention discloses a male moth yang-strengthening compound preparation formula and a preparation technique thereof. The male moth yang-strengthening compound preparation formula comprises the following components, by weight percent: 25-35% of male moth, 20-25% of herba epimedii, 10-20% of prepared rehmannia root, 8-12% of cinnamon, 2-5% of Chinese dodder, 2-5% of eucommia bark, 2-5% of aweto,2-5% of angelica and 2-5% of licorice; the preparation technique comprises the following steps: putting the male moth into a baking oven for drying, adding alcohol after removing impurities and proportioning with other materials, then extracting by ultrasonic waves, removing the alcohol from extracting liquid, obtaining raw material powder and pressing into tablets. The invention has the advantages that the invention utilizes traditional Chinese medicines with medicine and food isogeny as raw materials to carry out reasonable matching so as to prepare a health-care food, avoids drug resistance and toxic or side effect caused by western medicines and achieves the function of functional treatment on the basis of scientific and healthy diet.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Cationic dyeable polyester fabric dyeing and finishing process with composite functions of resisting ultraviolet light, having cool touch and repelling mosquitoes

The invention discloses a cationic dyeable polyester fabric dyeing and finishing process with composite functions of resisting ultraviolet light, having cool touch and repelling mosquitoes. The cationic dyeable polyester fabric dyeing and finishing process comprises the following steps: (1), soaking the cationic dyeable polyester fabric into a dyeing solution, adding acid to regulate the pH valueto 4.0-5.0, and performing dyeing treatment for 20-60 minutes at a temperature of 110-135 DEG C; (2), performing thermal washing, reduction washing and acid neutralizing on the fabric in sequence; and(3) dehydrating and drying the fabric, and padding after-finishing liquor, and finally roasting and shaping. The process selects a special ultraviolet-light absorber for cationic dyeable polyester fabric, simultaneously performs anti-ultraviolet functionalization and dyeing, only performs mosquito repelling and cooling functionalization for finishing link, can obtain relatively good ultraviolet light resistance through a special functional treatment way, and finally enables the cationic dyeable polyester fabric to have three functions of relatively good ultraviolet light resistance, cool touch and mosquito repelling.

Owner:CHANGZHOU NEW WIDE KNITTING & DYEING

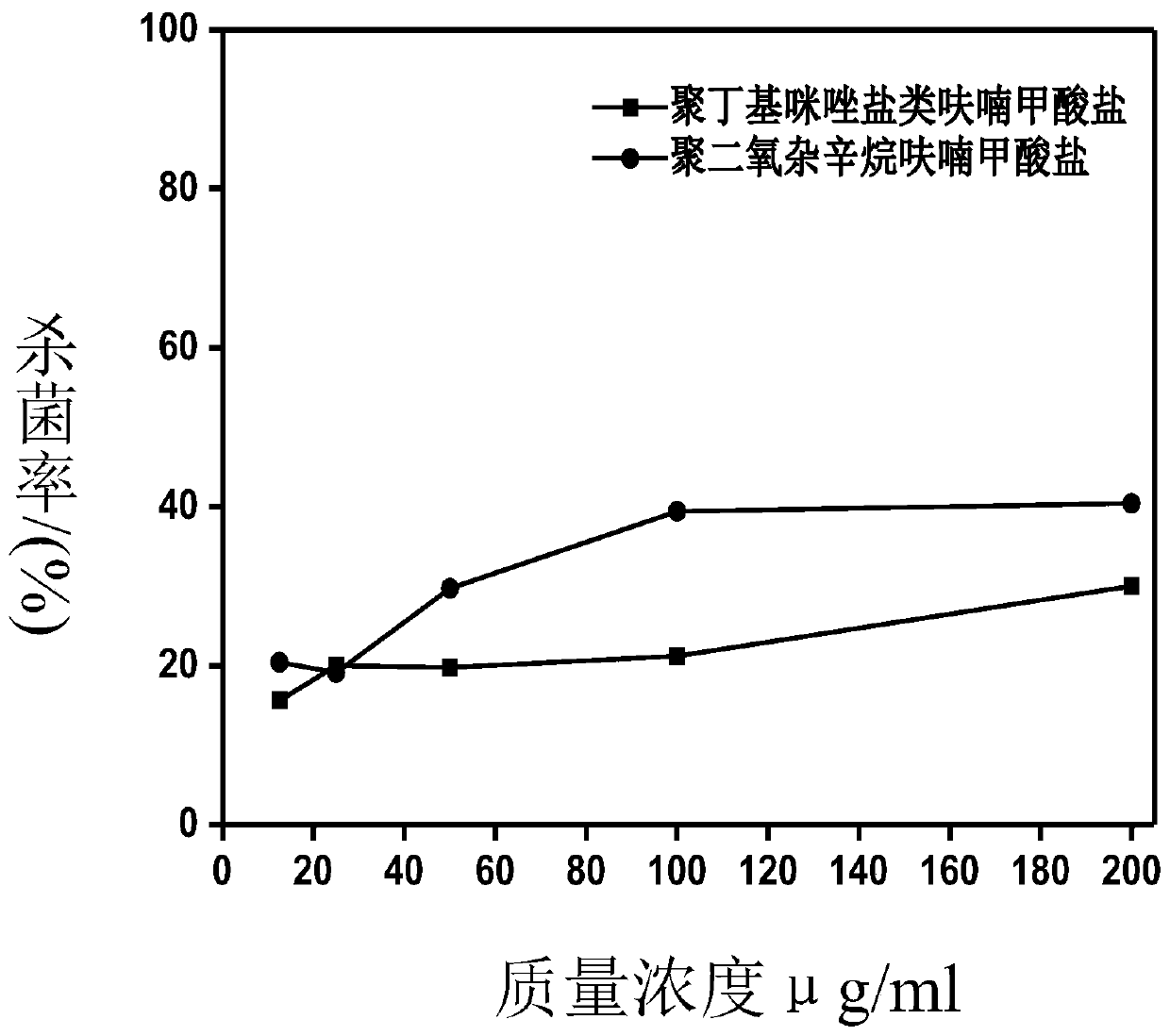

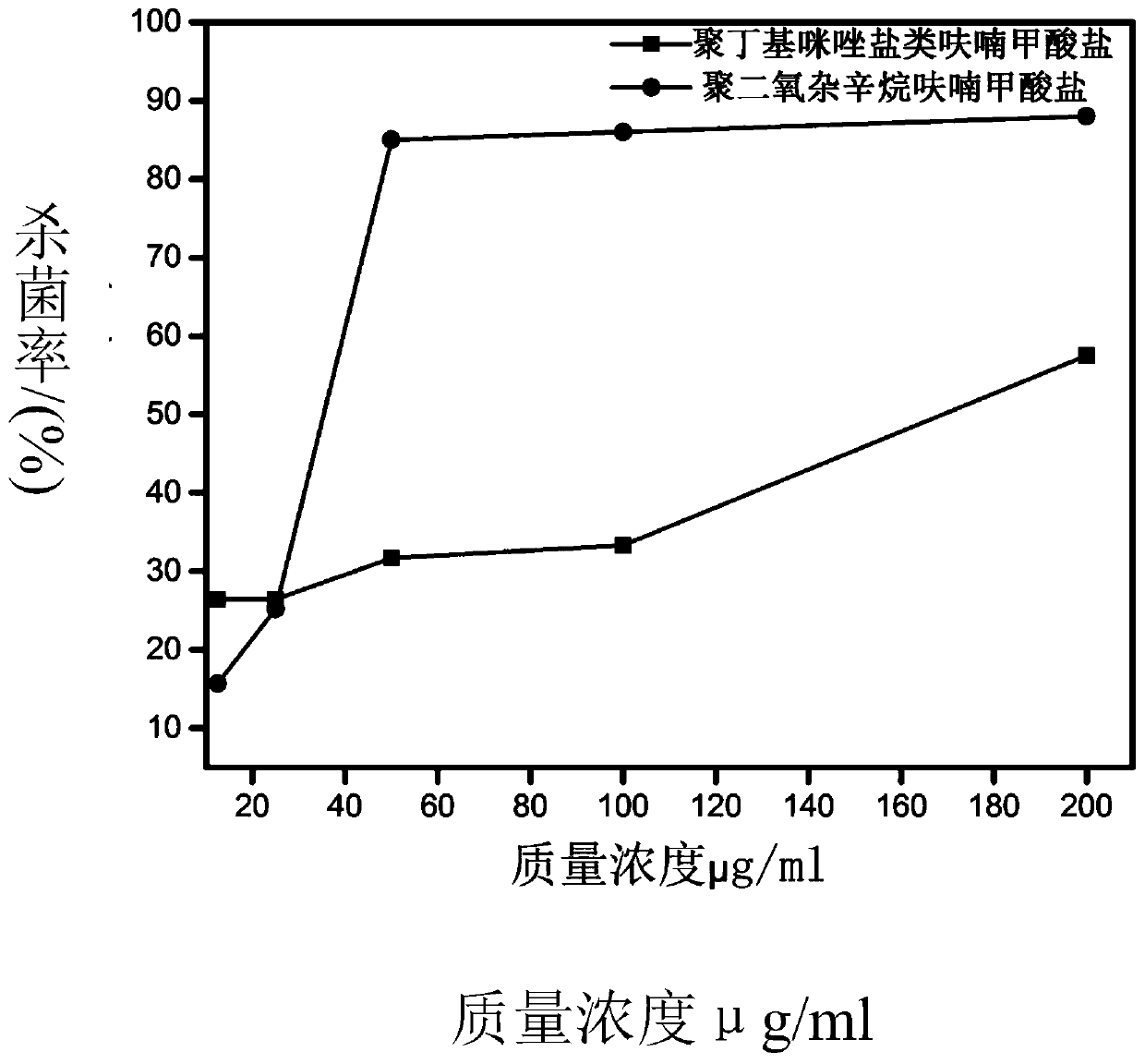

Preparation method of imidazolium salt antibacterial polymer

InactiveCN110591090ASimple preparation processGood repeatabilityBiocideAbsorbent padsEscherichia coliFreeze-drying

The invention relates to the field of pharmacy and in particular relates to a preparation method and application of an imidazolium salt antibacterial polymer. The preparation method comprises the following steps: dissolving an amido-containing polymer into a solution of formaldehyde and glyoxal, adding an organic carboxylic acid to regulate the pH value, and carrying out an oil bath reaction; andafter the reaction is finished, transferring the solution to a dialysis bag, and performing dialyzing and freeze-drying. The antibacterial polymer which is provided by the invention and contains the main chain imidazolium salt is synthesized by a one-pot method, the preparation process is simple and convenient, and the yield is high. In addition, staphylococcus aureus and escherichia coli are usedfor carrying out antibacterial performance testing on the polymer. Results show that the antibacterial polymer has a rapid sterilization function and can also maintain good biocompatibility. The prepared imidazolium salt antibacterial polymer has the potential of being applied to functional treatment of antibacterial dressings in biomedical materials.

Owner:CHANGZHOU UNIV

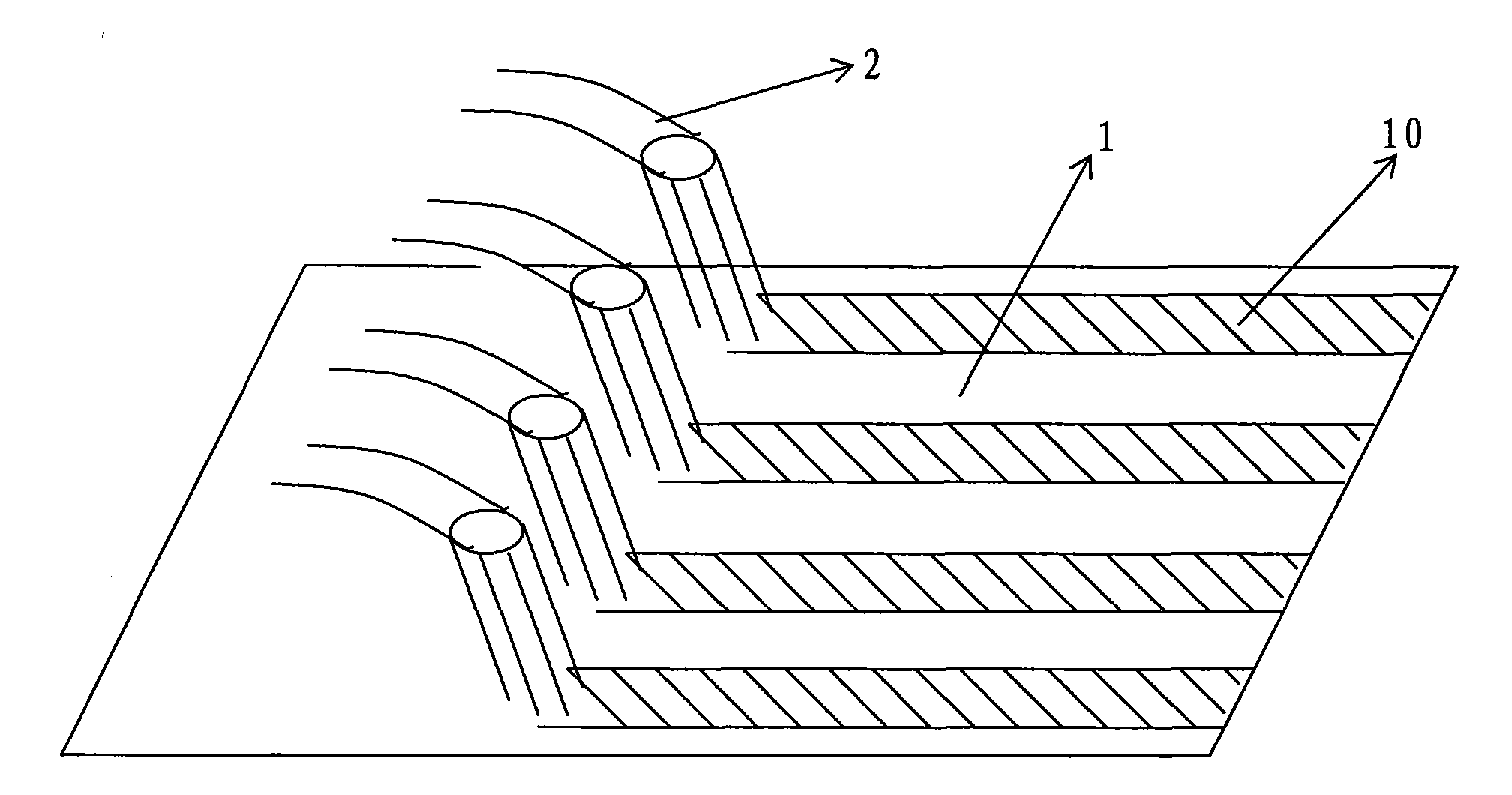

Nonwoven material prepared through discontinuous type functional treatment and preparation method thereof

ActiveCN101812778AEasy to transformReduce investmentFibre treatmentNon-woven fabricsHuman bodyMedicine

The invention discloses a nonwoven material prepared through discontinuous type functional treatment and a preparation method thereof. The nonwoven material basement is processed through discontinuous type functional treatment to form functional areas which are arranged discontinuously. The preparation method of the invention can be used to perform various functional treatments to nonwoven material basement, the equipment modification is easy, the investment is low, the preparation method can not conflict with the production technology of the common nonwoven fabric, the existing equipment and process can also be used; and therefore, the method is easy to realize and the production cost is low. The nonwoven material prepared through discontinuous type functional treatment of the invention can have different functions; the material can be freely cut into multiple pieces with small breadth along the transverse breadth direction, for example the nonwoven material with small breadth in the arrangement manner of 'non-treatment + functional treatment + non-treatment' can be prepared; and the amount of raw material used in functional treatment can be reduced, the cost is saved, and the bad effects of some raw materials to human body can be lowered.

Owner:SHANDONG JUNFU NONWOVEN MATERIALS

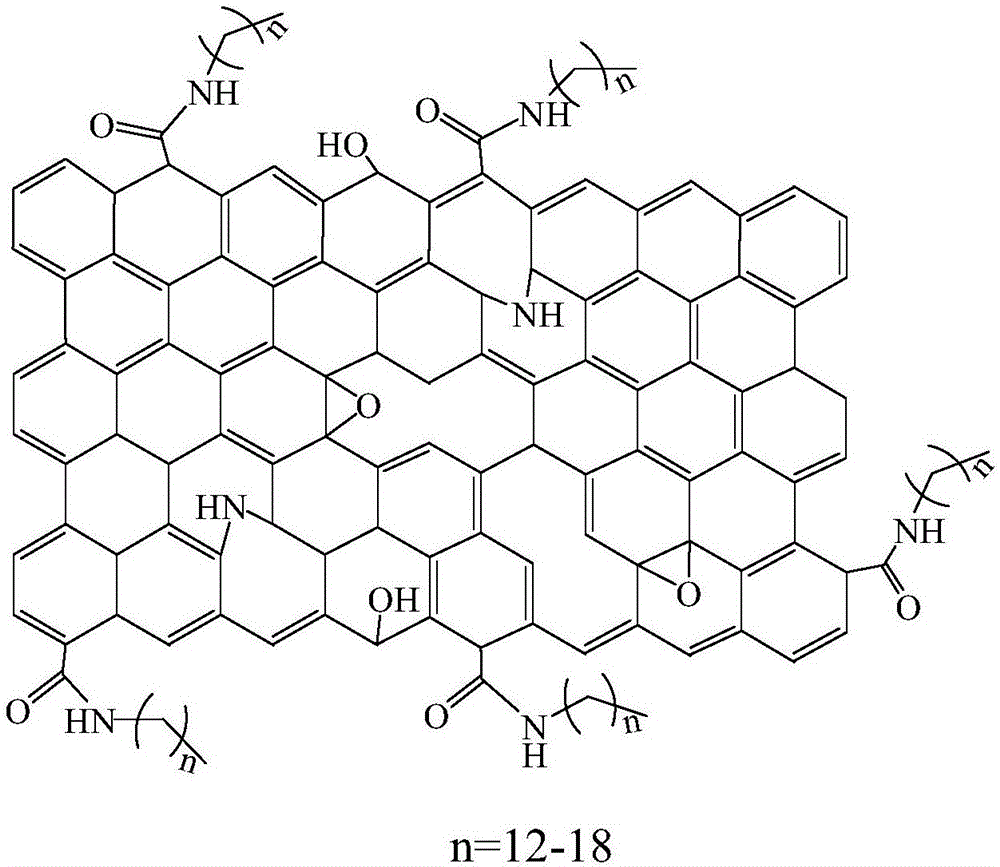

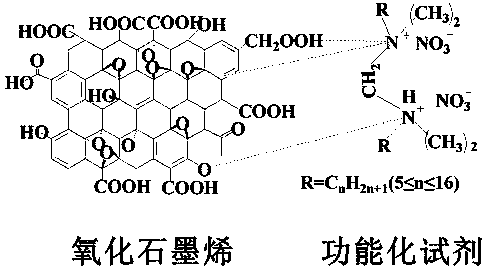

Adsorbent for treating hexavalent chromium in neutral wastewater and preparation method of adsorbent

ActiveCN109107537ALow costSimple structureOther chemical processesWater contaminantsSorbentReaction temperature

The invention discloses an adsorbent for treating hexavalent chromium in neutral wastewater and a preparation method of the adsorbent, which belong to the field of sewage treatment and environmental protection. A structural formula of the adsorbent for treating hexavalent chromium in neutral wastewater is N4O6CXH2X+1-GO, wherein X is greater than or equal to 15, and smaller than or equal to 37, and X is a positive integer. Graphene oxide (GO) is firstly synthesized, and is further subjected to functional treatment, so that a functional graphene oxide adsorbent is obtained. The prepared adsorbent is great in specific surface area, is good in selectivity, and is high in adsorption efficiency; and adsorption rate for Cr (VI) is greater than 96% when the pH value is within the range of 2-9. The preparation method of the adsorbent for treating hexavalent chromium in neutral wastewater has the advantages of low reaction temperature, short time, simple purifying and high operability.

Owner:UNIV OF JINAN

Interval type hydrophilic nonwoven material and preparation method thereof

ActiveCN101812777AEasy to transformReduce investmentFibre treatmentNon-woven fabricsMaterials scienceWater treatment

The invention discloses an interval type hydrophilic nonwoven material and a preparation method thereof. The nonwoven material basement is arranged in an interval way and processed through hydrophilic treatment form hydrophilic areas which are arranged at intervals. The preparation method of the interval type hydrophilic nonwoven material can be used to perform various on-line functional treatments to the nonwoven material, the equipment modification is easy, the investment is low, the preparation method can not conflict with the production technology of the common nonwoven material, the existing equipment and process can also be used; and therefore, the method is easy to realize and the production cost is low. The interval type hydrophilic nonwoven material can have different functions; the interval type hydrophilic nonwoven material can be freely cut into multiple pieces with small breadth along the transverse breadth direction, and for example the nonwoven material with small breadth in the arrangement manner of 'non-treatment + hydrophilic treatment + non-treatment' can be prepared; and the amount of raw material used in hydrophilic treatment can be reduced, the cost is saved, and the bad effects of some raw materials to human body can be lowered.

Owner:SHANDONG JUNFU NONWOVEN MATERIALS

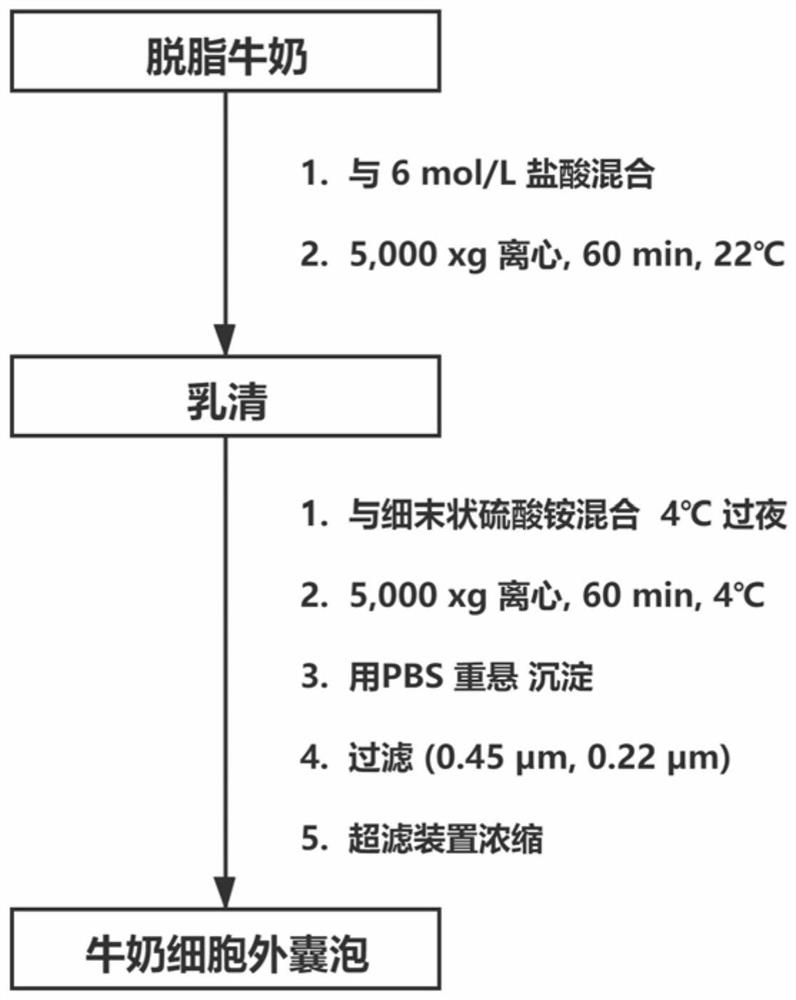

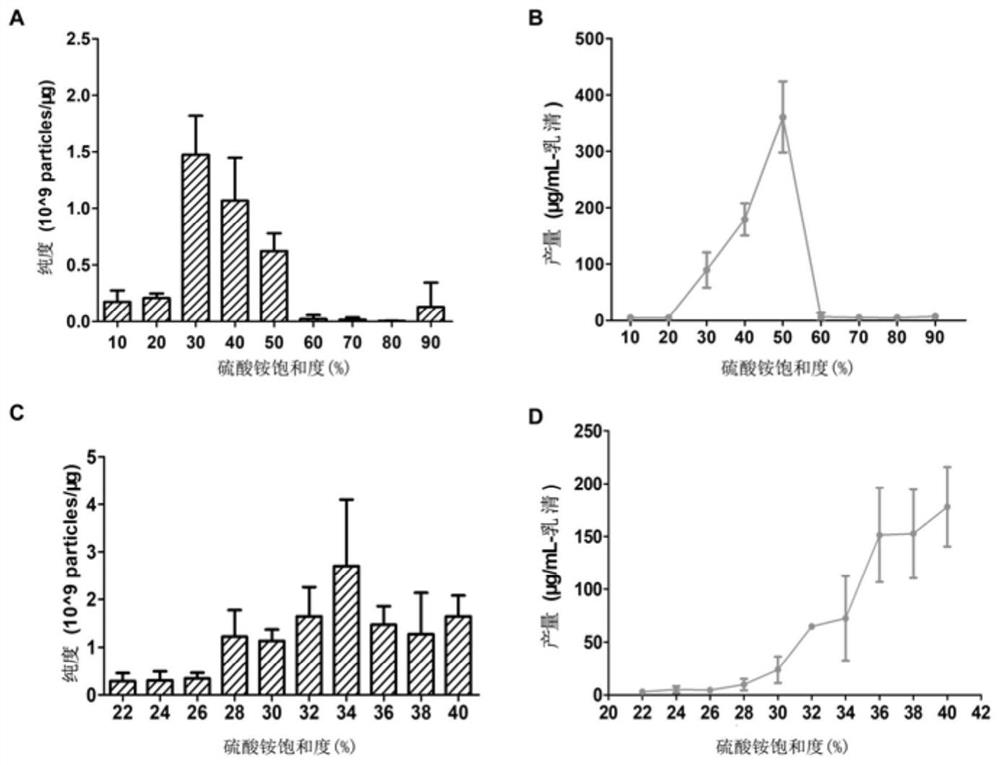

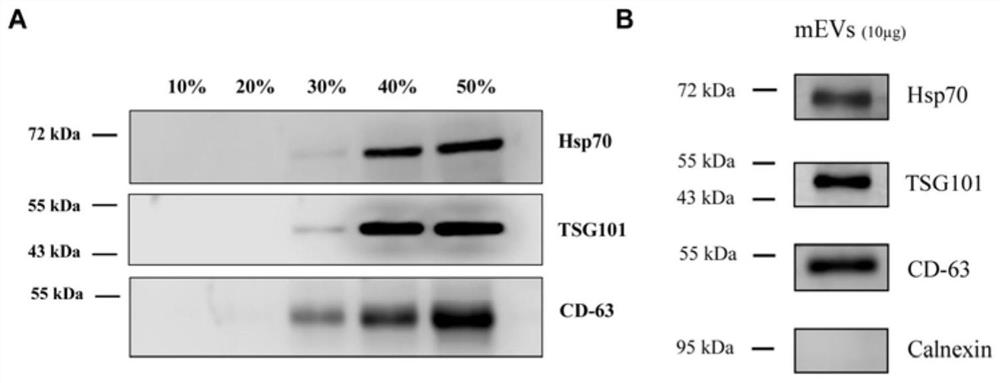

Method for extracting extracellular vesicles from milk

ActiveCN113215079AActiveIncrease productionCell dissociation methodsEpidermal cells/skin cellsAmmonium sulfateProtein

The invention relates to the technical field of biology, in particular to a method for extracting extracellular vesicles from milk. The invention provides a method for extracting extracellular vesicles from milk. The method comprises the step of adding ammonium sulfate into whey. The method for extracting the extracellular vesicles from the milk has the following advantages that it is verified for the first time that the ammonium sulfate can be used for precipitation of mEVs, and the mEVs still have activity after redissolution; the method can increase the yield of the mEVs, can achieve the equivalent purity, is lower in cost, and can be used for large-scale production of the mEVs; and in the future, the mEVs can be used as natural nano-carriers to deliver bioactive molecules such as proteins, medicines and functional RNA, can regulate the functions of cells and treat diseases, and has a great clinical transformation prospect.

Owner:PEKING UNIV FIRST HOSPITAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com