Reactive flame retardant and method for durable flame-proof treatment on protein fibers by using reactive flame retardant

A protein fiber, durable flame-retardant technology, applied in the direction of flame-retardant fiber, fiber treatment, animal fiber, etc., can solve the problems of poor washability and safety, and achieve good washability, excellent flame retardancy, Solve the effect of poor washability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

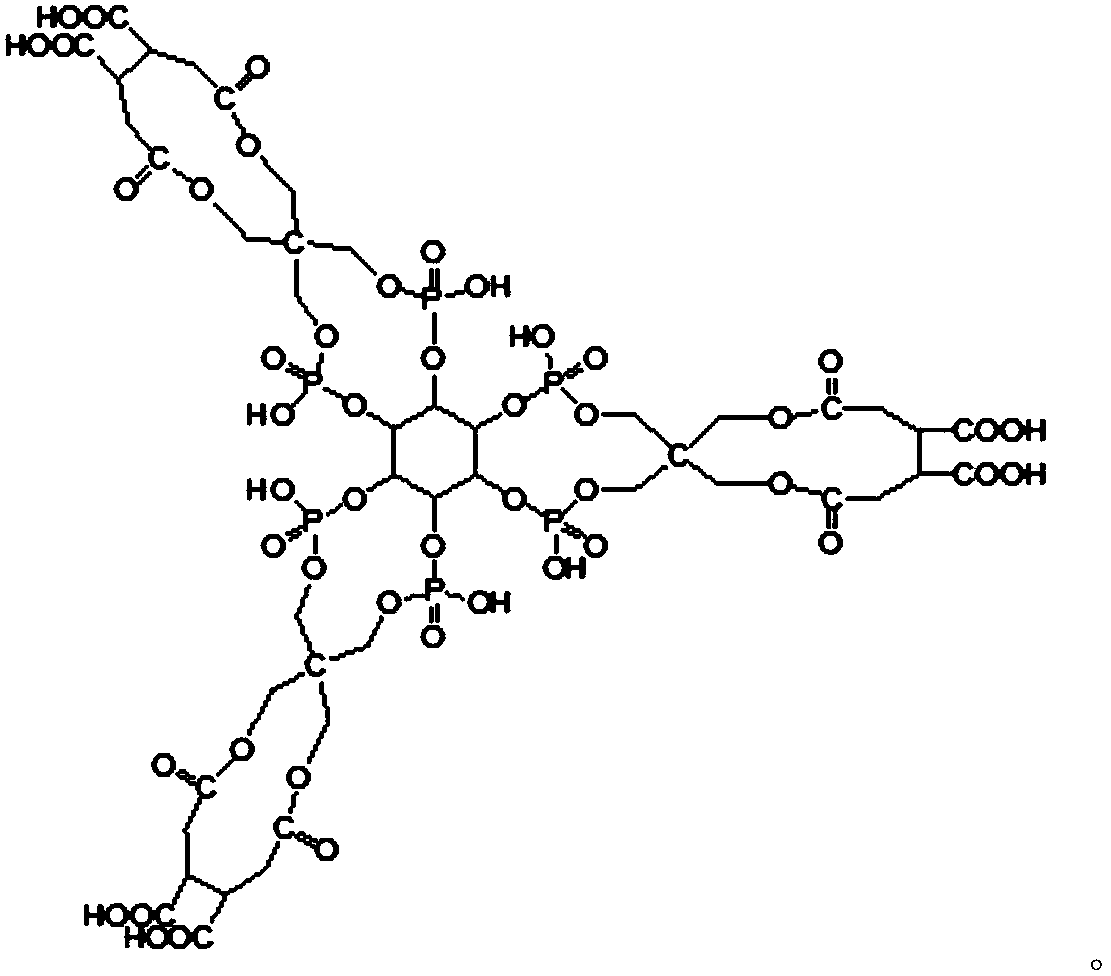

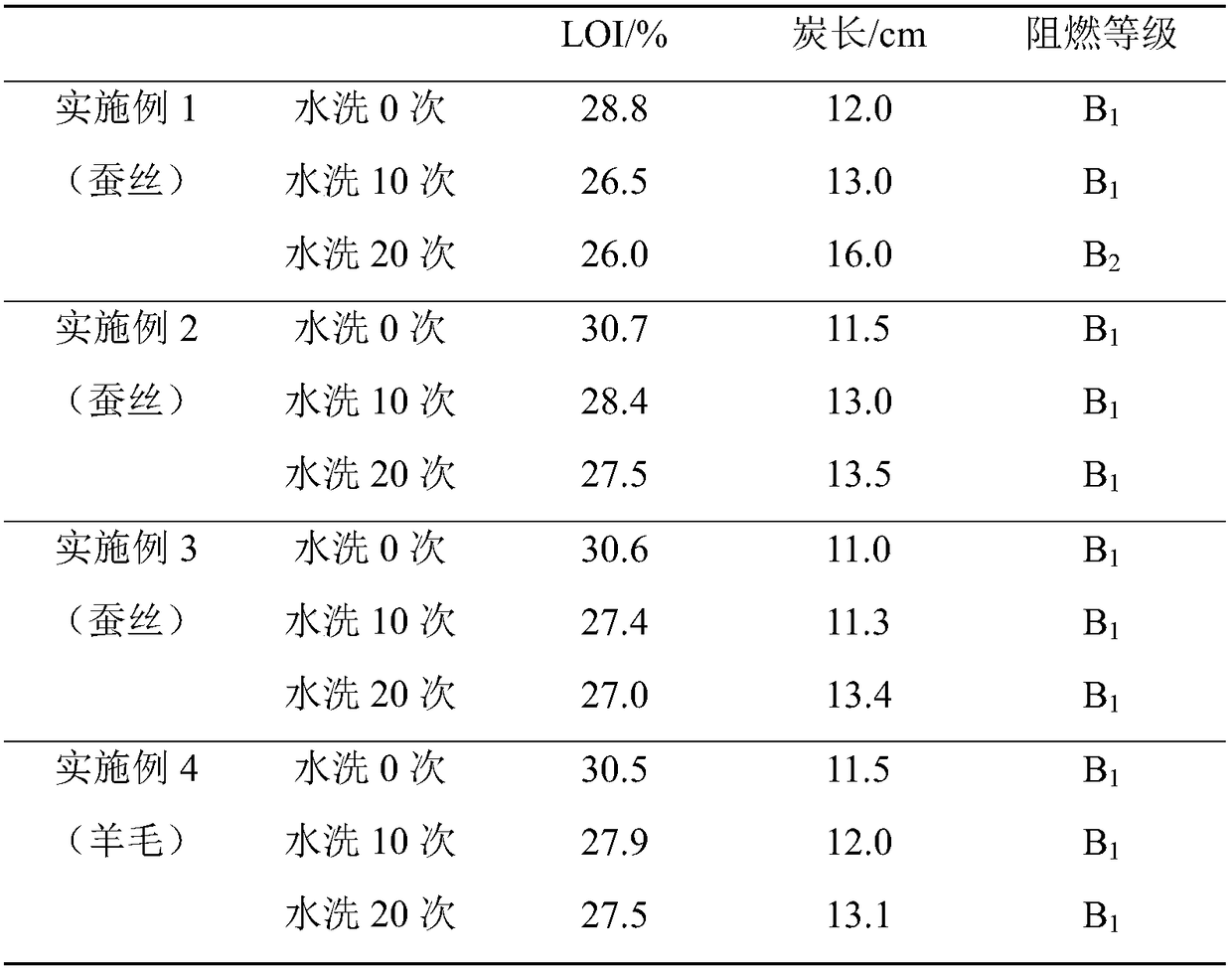

[0029] (1) Preparation of reactive flame retardant based on phytic acid: mix 6.6g phytic acid (70% aqueous solution, 0.007mol) and 2.72g (0.02mol) pentaerythritol in a 250mL Erlenmeyer flask and react at 120°C for 3h A light yellow viscous liquid pentaerythritol phytate was obtained. Add 4.68 g (0.02 mol) of butane tetracarboxylic acid to the mixture, and continue the reaction for 45 minutes to obtain the reactive flame retardant pentaerythritol phytate butane tetracarboxylate.

[0030] (2) Preparation of flame retardant silk fabric: the above flame retardant was dissolved in 100 mL of distilled water to prepare a finishing solution with a flame retardant concentration of 0.07 mol / L. Soak the silk fabric in the finishing solution for 10 minutes, then dip and roll twice, and the excess rate is 90%, then dry the silk fabric at 60°C for 8 minutes, then bake it at 150°C for 4 minutes, wash it with water and dry it.

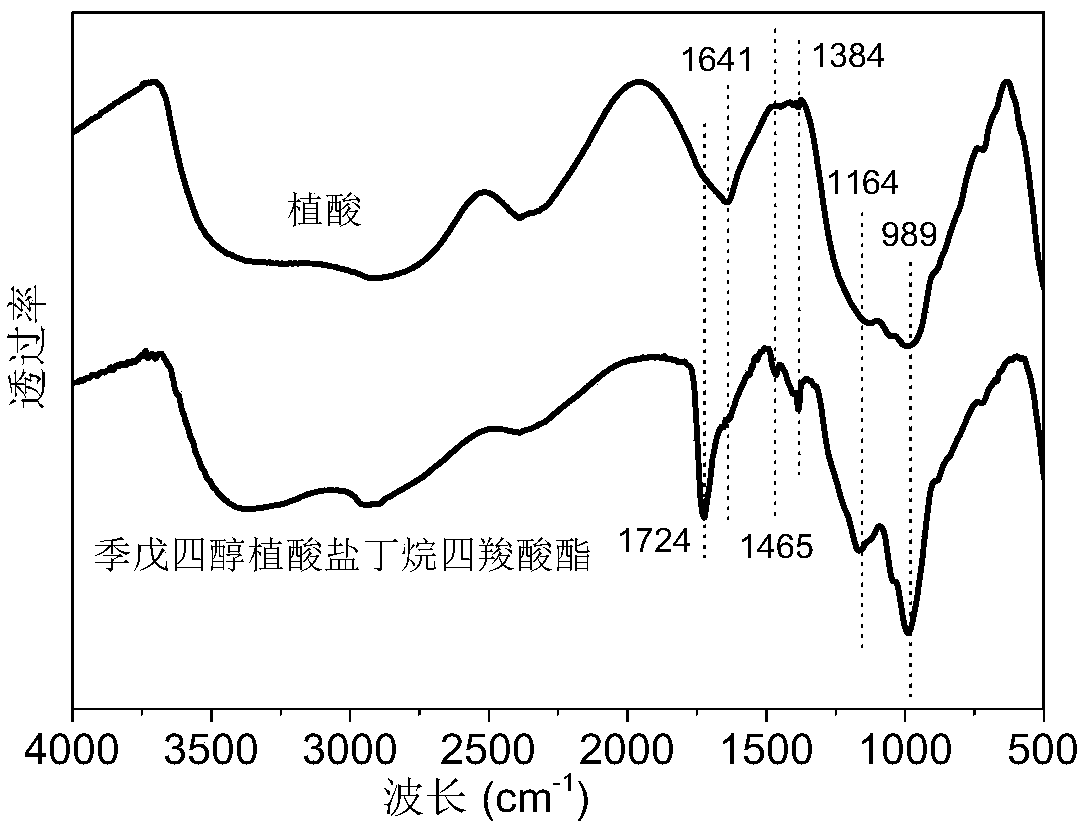

[0031] The infrared spectrum of the reactive flame retardant pe...

Embodiment 2

[0033] (1) Preparation of reactive flame retardant based on phytic acid: Mix 6.6g phytic acid (70% aqueous solution, 0.007mol) and 2.72g (0.02mol) pentaerythritol in a 250mL Erlenmeyer flask and react at 130°C for 2h A light yellow viscous liquid pentaerythritol phytate was obtained. Add 4.68 g (0.02 mol) of butane tetracarboxylic acid to the mixture, and continue the reaction for 30 minutes to obtain the reactive flame retardant pentaerythritol phytate butane tetracarboxylate.

[0034] (2) Preparation of flame retardant silk fabric: the above flame retardant was dissolved in 50 mL of distilled water to prepare a finishing solution with a flame retardant concentration of 0.14 mol / L. Immerse the silk fabric in the finishing solution for 10 minutes, then dip and roll twice, the excess rate is 100%, then dry the silk fabric at 80°C for 4 minutes, then bake at 160°C for 2 minutes, wash with water and dry.

Embodiment 3

[0036] (1) Preparation of reactive flame retardant based on phytic acid: mix 6.6g phytic acid (70% aqueous solution, 0.007mol) and 2.72g (0.02mol) pentaerythritol in a 250mL Erlenmeyer flask and react at 120°C for 3h A light yellow viscous liquid pentaerythritol phytate was obtained. 4.80 g (0.025 mol) of citric acid was added to the mixture, and the reaction was continued for 45 min to obtain the reactive flame retardant pentaerythritol phytate citrate.

[0037](2) Preparation of flame retardant silk fabric: the above flame retardant was dissolved in 50 mL of distilled water to prepare a finishing solution with a flame retardant concentration of 0.14 mol / L. Soak the silk fabric in the finishing solution for 10 minutes, then dip and roll twice, and the excess rate is 100%, then dry the silk fabric at 80°C for 5 minutes, then bake it at 160°C for 2 minutes, wash with water and dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com