Patents

Literature

406results about How to "High phosphorus content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

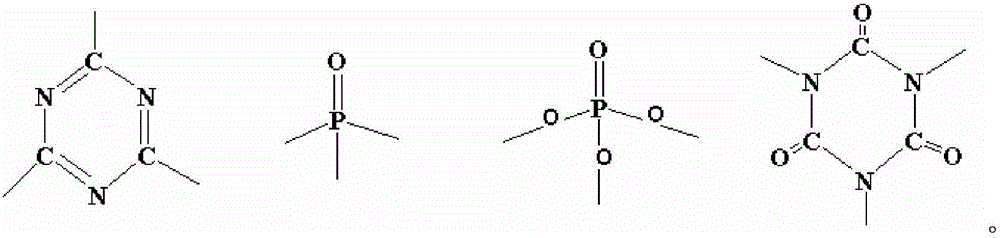

Phosphaphenanthrene flame-retardant compound containing s-triazine structure, and preparation and use thereof

ActiveCN101376665AReduce energy consumptionEasy to operateGroup 5/15 element organic compoundsEpoxyPolymer science

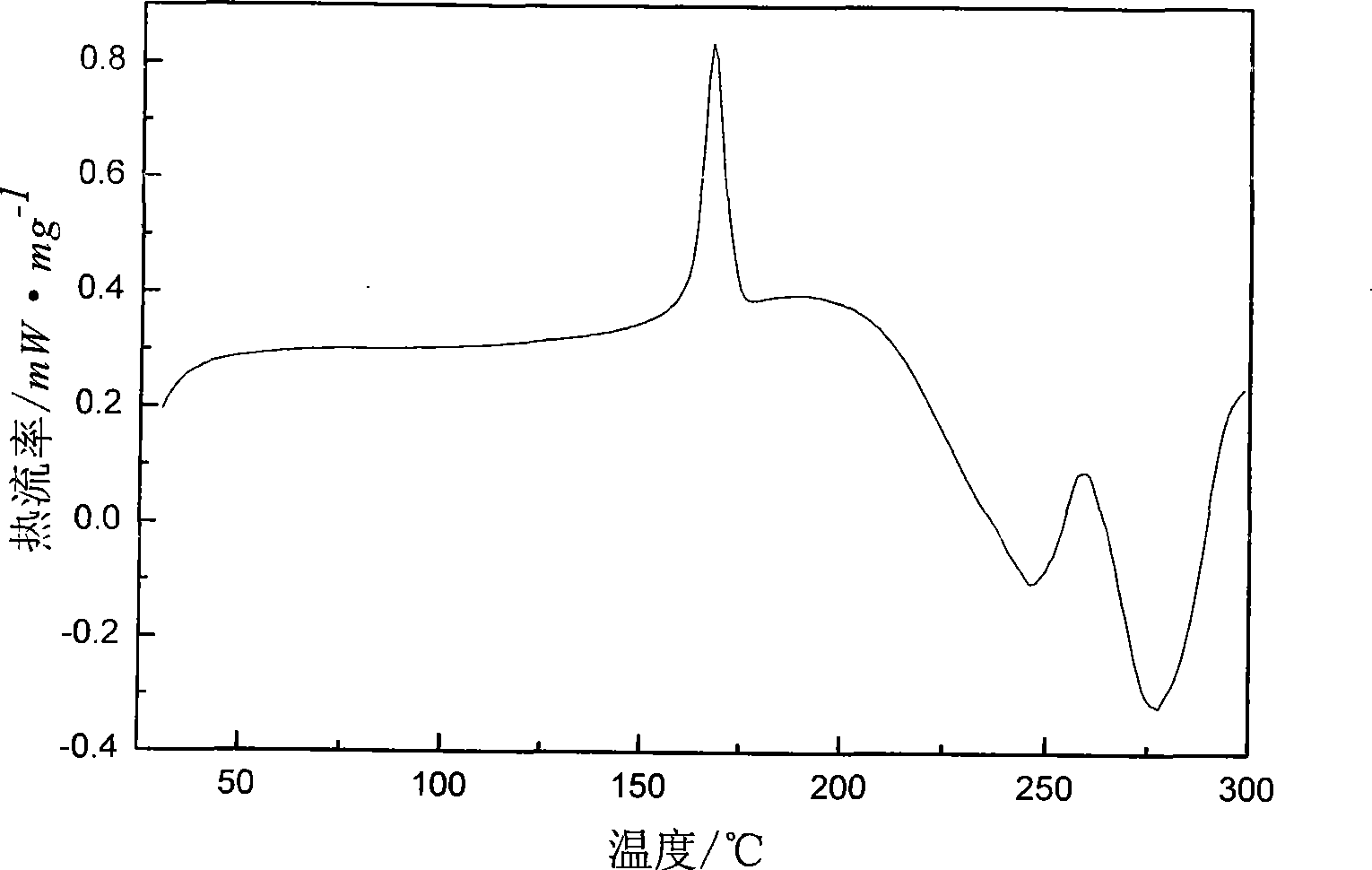

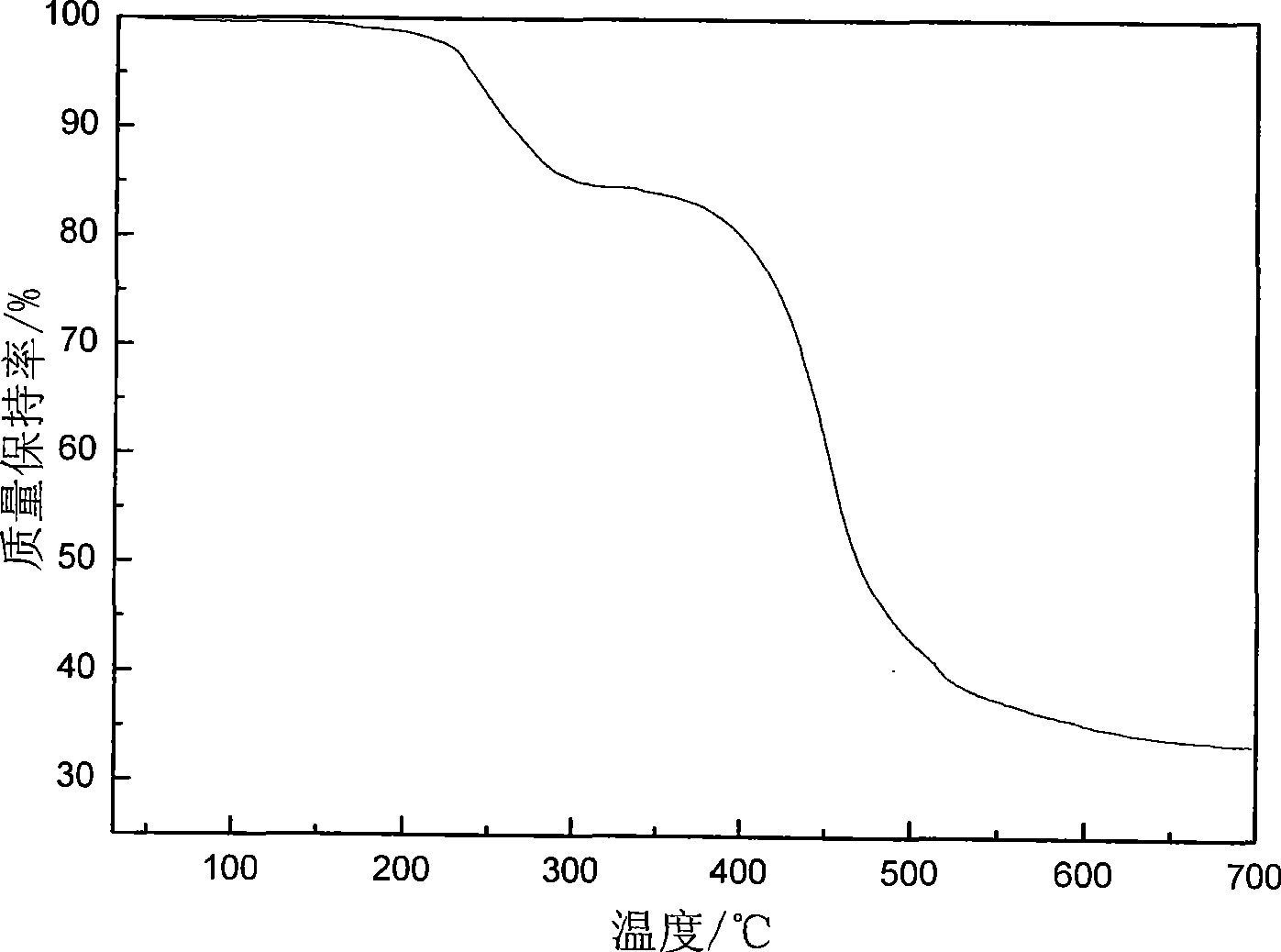

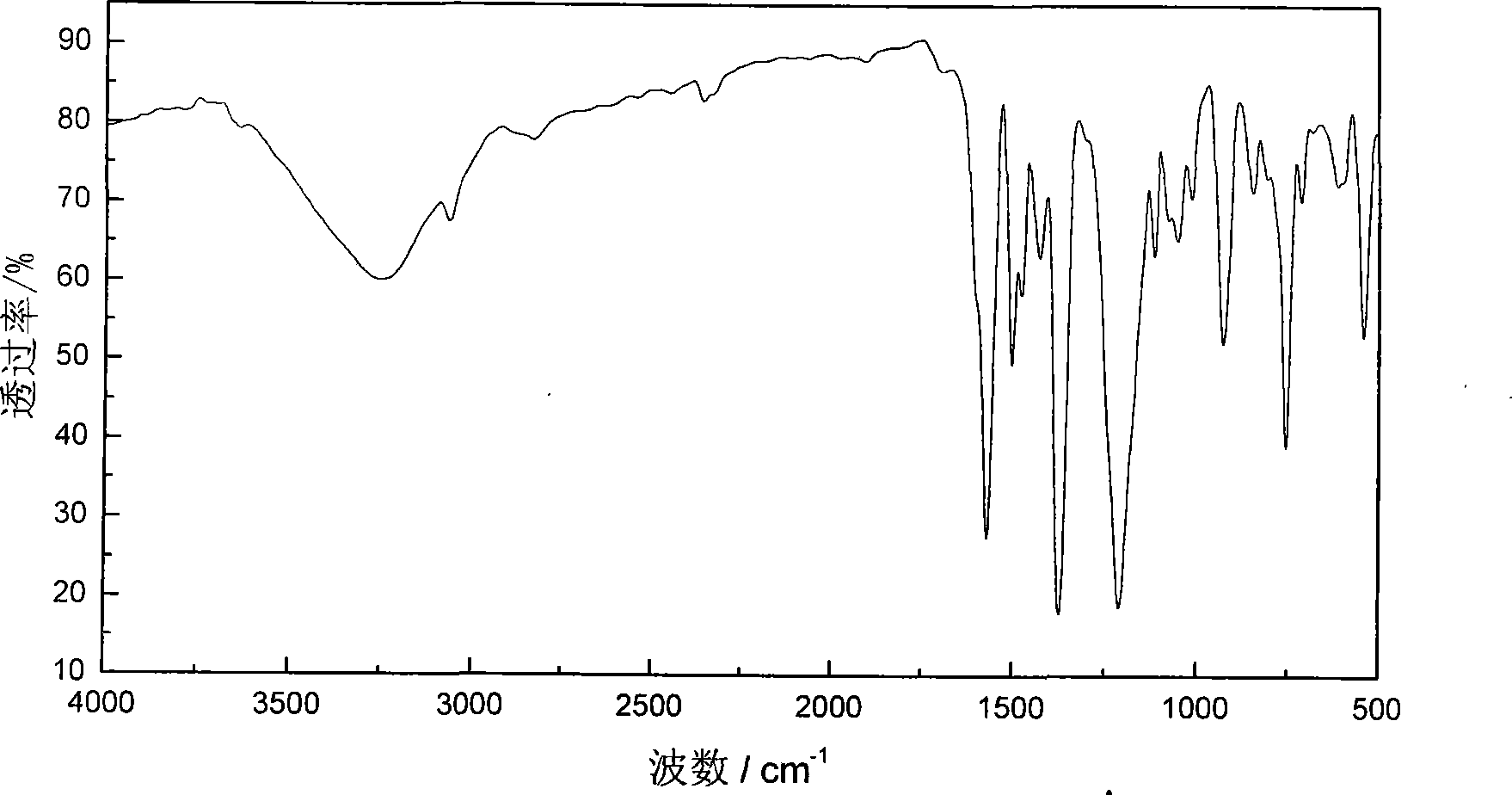

The invention discloses an oxa-phosphaphenanthrene flame retardant compound containing the sym-triazine structure and a preparation method thereof. The method is characterized in that an intermediate is synthesized from 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide(DOPO) and p-hydroxybenzaldehyde as raw material by the solution method, and then reacts with cyanuric chloride in the presence of phase transfer catalyst to obtain a 2,4,6-tri(4-(10-methenyl hydroxy-9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide)phenoxy)-1,3,5-triazine product. The compound is white crystal, and has a melting point of 166 to 169 DEG C, good thermal stability and high flame retardation efficiency, and can be adopted as a reactive flame retardant for the flame retardation of thermosetting resins such as epoxy resin, polyurethane and the like, and also as an additive flame retardant for the flame retardation of engineering plastics such as ABS, nylon and the like.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

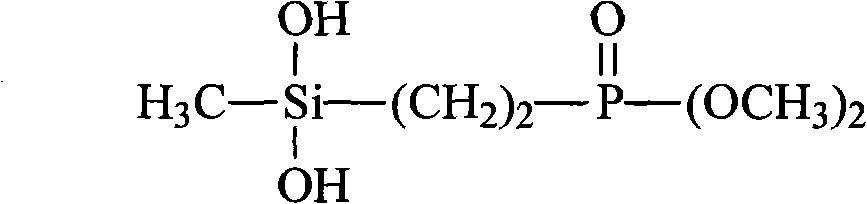

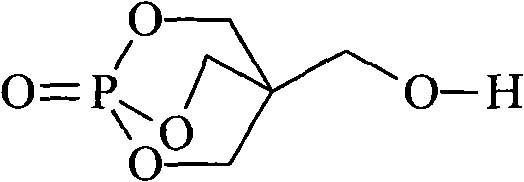

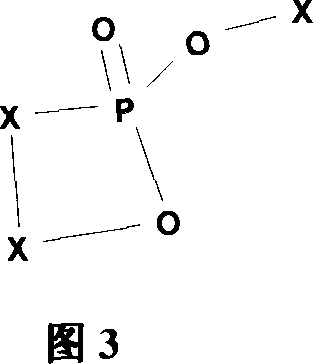

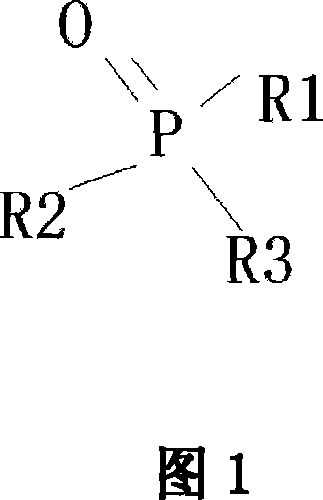

Caged bicyclic phosphate siloxane flame retardant and preparation method thereof

ActiveCN102153590AImprove thermal stabilityHigh molecular weightGroup 5/15 element organic compoundsCombustionSilanes

The invention discloses a caged bicyclic phosphate siloxane flame retardant and a preparation method thereof. A structural formula of the caged bicyclic phosphate siloxane flame retardant is shown in a general formula (I). During the preparation, the needed product can be obtained by reacting 1-oxophospha-4-hydroxymethyl-2,6,7-trioxabicyclo[2.2.2]octane and chlorosilane or alkoxy silane. A plurality of rigid caged bicyclic phosphate groups and silicon element which are contained in the compound play a role in synergistic flame retardancy; and the flame retardant has higher thermal stability and carbon-forming performance, and can effectively reduce the smoke produced in the combustion.

Owner:SOUTH CHINA UNIV OF TECH

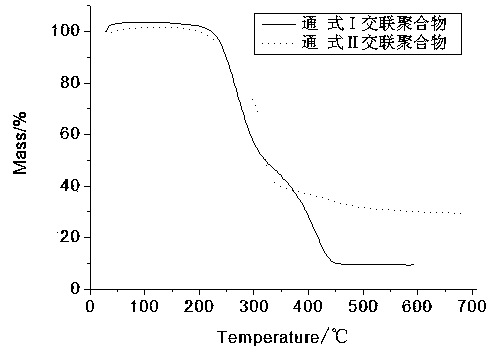

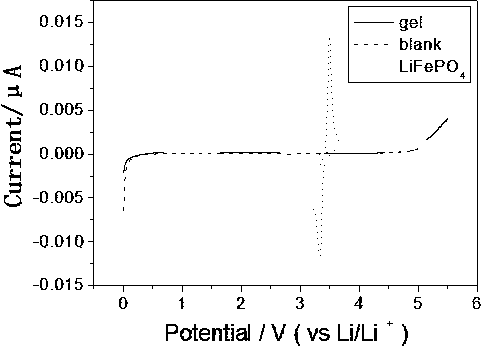

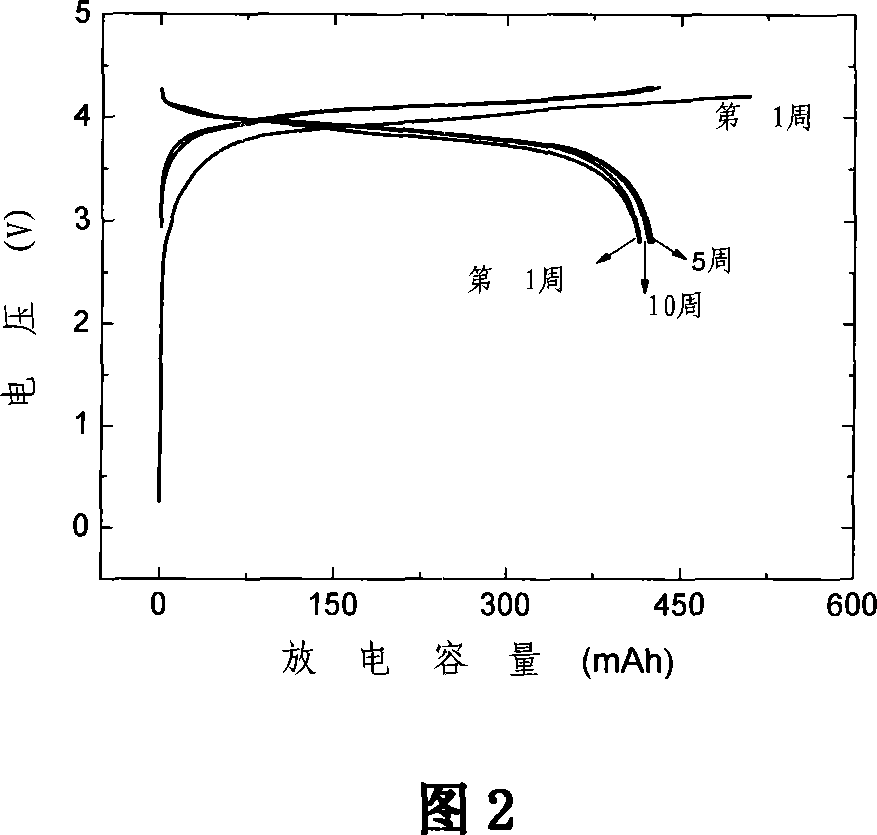

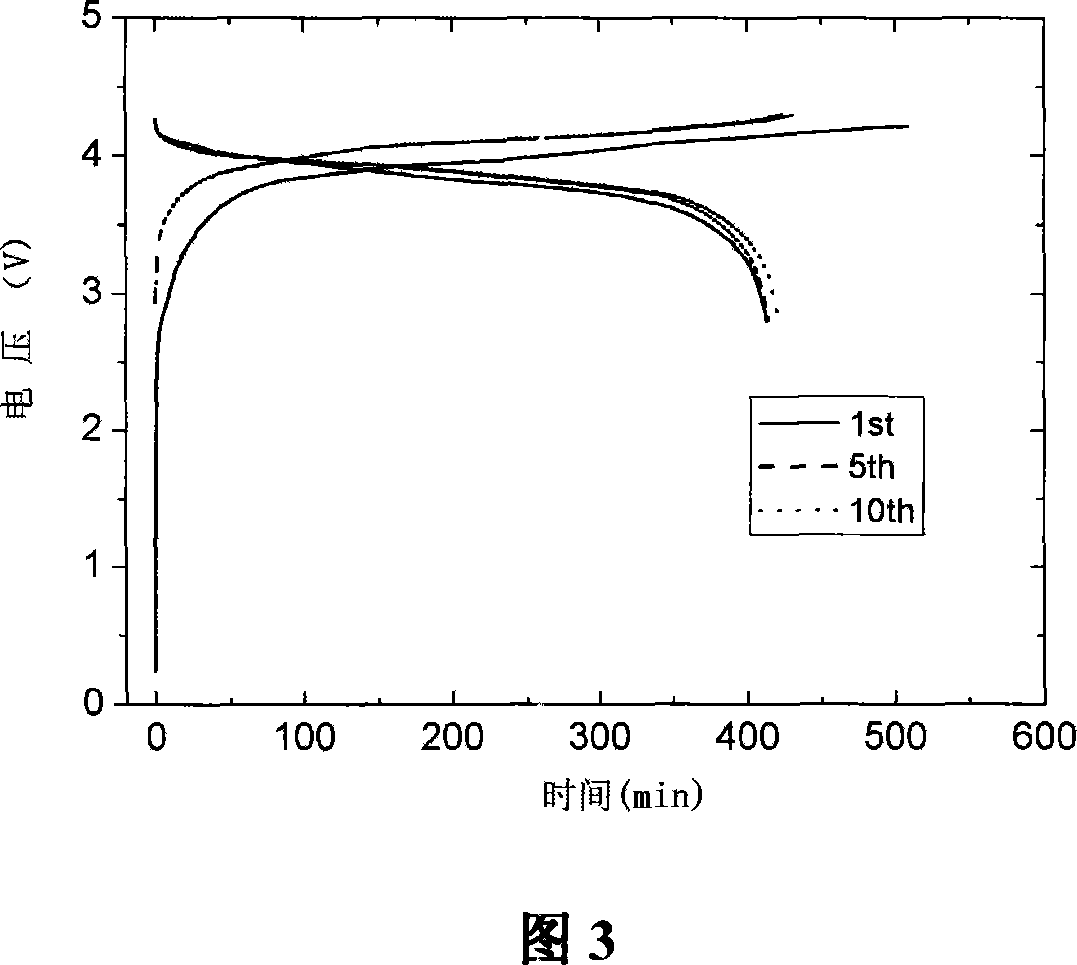

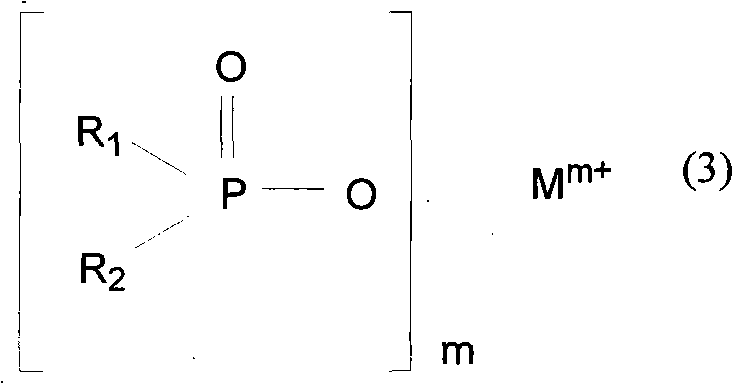

Phosphorus-containing crosslinked gel polymer electrolyte and on-site thermal-polymerization preparation method and application thereof

The invention belongs to the technical field of gel polymer electrolytes and particularly discloses a phosphorus-containing crosslinked gel polymer electrolyte and an on-site thermal-polymerization preparation method and application thereof. The preparation method comprises the steps of preparing the following raw materials, of which the total weight percent is 100%: 5-15% of polymerization monomers, 3-10% of crosslinker, 0.01-1.0% of thermal initiator and 75-90% of lithium-ion battery liquid electrolyte, uniformly mixing, and then, reacting for 20-100 minutes at the temperature of 75-150 DEG C under the protection of inert gas, thereby obtaining the phosphorus-containing crosslinked gel polymer electrolyte. The invention further discloses application of the phosphorus-containing crosslinked gel polymer electrolyte in the preparation of solid lithium-ion batteries. The invention provides novel phosphates and / or phosphonates, containing double bonds, which serve as monomers of the gel polymer electrolyte, and the phosphorus-containing crosslinked gel polymer electrolyte designed and synthesized from the monomers has the advantages of simple and convenient preparation method, high ionic conductivity, high thermal stability and good electrochemical stability, so that phosphorus-containing crosslinked gel polymer electrolytes with relatively good stability are provided for the practical application of the solid lithium-ion batteries and high-power lithium-ion batteries.

Owner:ZHENGZHOU UNIV

Method for preparing active fly ash phosphorus adsorbent

InactiveCN1669632AReduce dosageWide variety of sourcesOther chemical processesWater/sewage treatment by sorptionIndustrial wasteCoal

The invention relates to a method for preparing an active coal ash phosphoric adsorbent, which comprises the following steps: a) mixing the coal ash and the basic activating agent evenly in the high-speed batch mixer, b) roasting and activating them in the calcining furnace, c) putting them into the acidproof retort after cooling and adding acidic modifier into the retort, d) heating them to react, then drying and grinding the materials and getting the powdered phosphoric adsorbent with high active. Said invention uses the industrial waste coal ash as the raw material, and by means of the low-cost activating agent and modifier it can dissolve out the material with high absorptive in the coal ash, and the prepared absorbent has high dephosphorize effect.

Owner:SHANGHAI JIAO TONG UNIV

Non-halogen fire-retardant polypropylene and production thereof

Non-halogen fire-retardant polypropylene and its production are disclosed. The polypropylene consists of homopolymer polypropylene particle and fire-retardant agent. The fire-retardant agent consists of aluminum hydroxide, magnesium hydroxide and polyammonium phosphate. The process is treating aluminum hydroxide and magnesium hydroxide from coupling agent, coating polyammonium phosphate from cyanurotriamide -formaldehyde resin, dispersing treated nanometer particle on polypropylene matrix, premixing for polypropylene powder, nanometer aluminum hydroxide, magnesium hydroxide and polyammonium phosphate microcapsule proportionally in high-speed mixer from single-screw extrude and blend method, adding into single-screw extruder at normal feed rate, temperature and rotation speed, extruding, cooling and granulating. It achieves smokeless, non-toxic, good fire-retardant performance and less pollution.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Oxa-phosphaphenanthrene flame retardant containing cyclotriphosphonitrile structure, and preparation method and application thereof

ActiveCN102757579AEasy to operateAdvanced technologyGroup 5/15 element organic compoundsEpoxyEngineering plastic

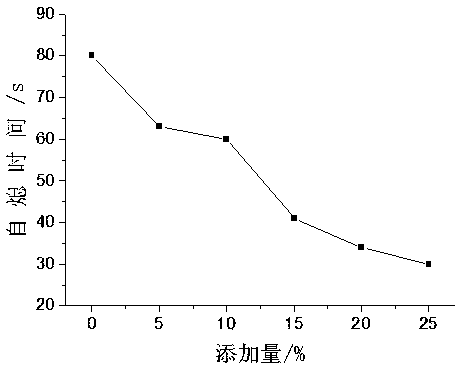

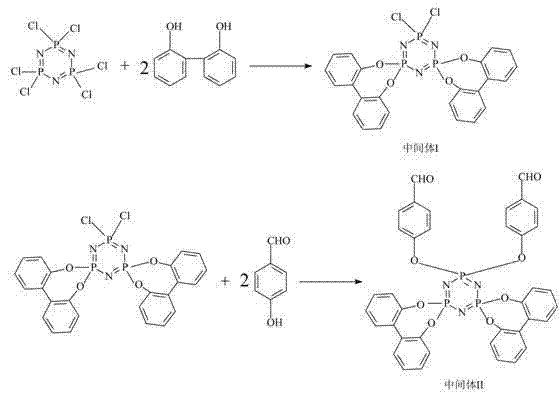

The invention relates to an oxa-phosphaphenanthrene flame retardant containing cyclotriphosphonitrile structure, and a preparation method and application thereof. The preparation method comprises the following steps: under the actions of K2CO3 and acetone, reacting hexachlorocyclotriphosphonitrile and 2,2'-diphenyldiphenol to obtain an intermediate I, reacting the intermediate I with p-hydroxybenzaldehyde to obtain an intermediate II, and reacting the intermediate II and DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide) to obtain the target compound. The appearance of the compound is white, and the melting point is 186-188 DEG C; and the product has the advantages of favorable thermal stability, high flame retardancy and high purity (up to 99%). The invention has the advantages ofaccessible raw materials and advanced technique, and can easily implement industrial production. The flame retardant can be used as a reactive flame retardant to be connected to epoxy resin, polyurethane and other thermosetting resins, and can also be used as an additive flame retardant for halogen-free flame retardancy of ABS (acrylonitrile-butadiene-styrene), nylon and other engineering plastics with high heat resistance requirements.

Owner:HUBEI YAOMEI FLEXIBLE CERAMICS

An electrolyte of efficient low-poison and combustion-resisting lithium cell and its lithium cell

InactiveCN101079504AReduce phosphorus contentHigh phosphorus contentOrganic electrolyte cellsSecondary cellsSolubilityCombustion

The invention discloses a high-effective low-toxic flameproof lithium battery electrolyte and lithium battery, which is characterized by the following: adopting one ore more phosphate (methyl phosphodimethylester, ethyl phosphodiethylester, ethyl phosphodimethylester) as pure solvent or solvent component; displaying incombustibility based on the electrolyte of phosphate; saving the cost; improving the conductivity and lithium salt solubility and safety with stable electrochemical property.

Owner:常熟紫金知识产权服务有限公司

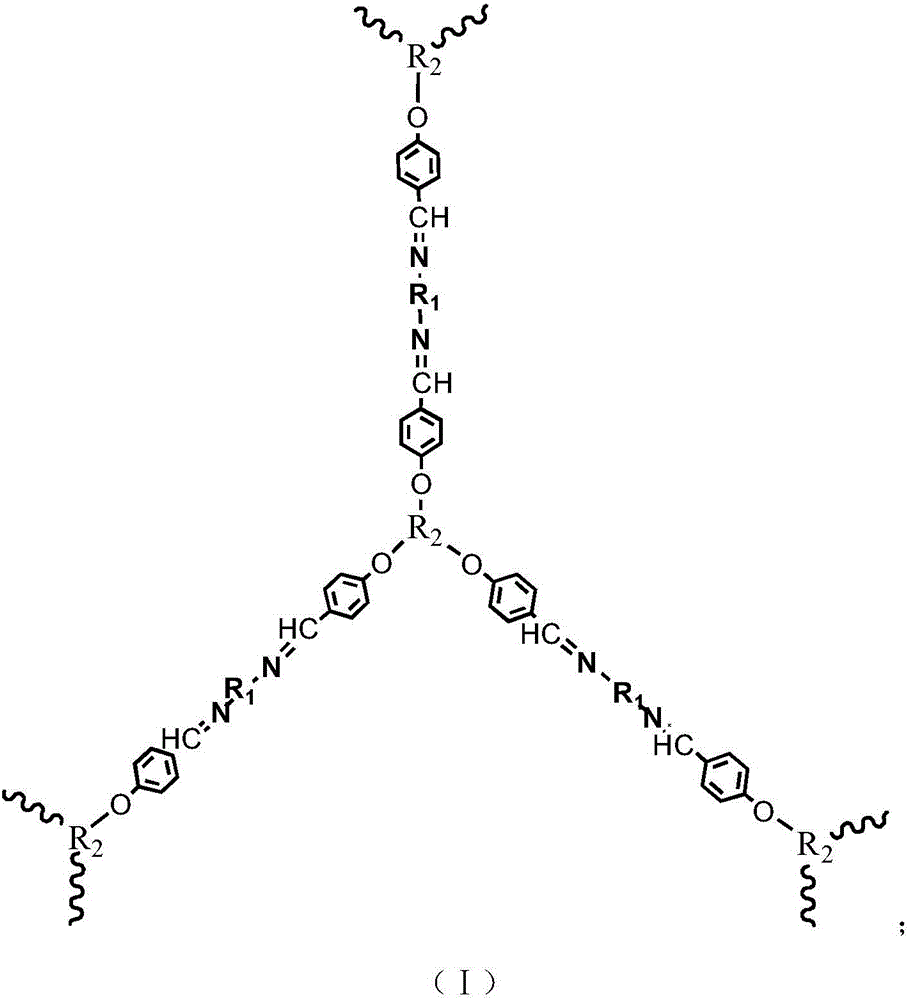

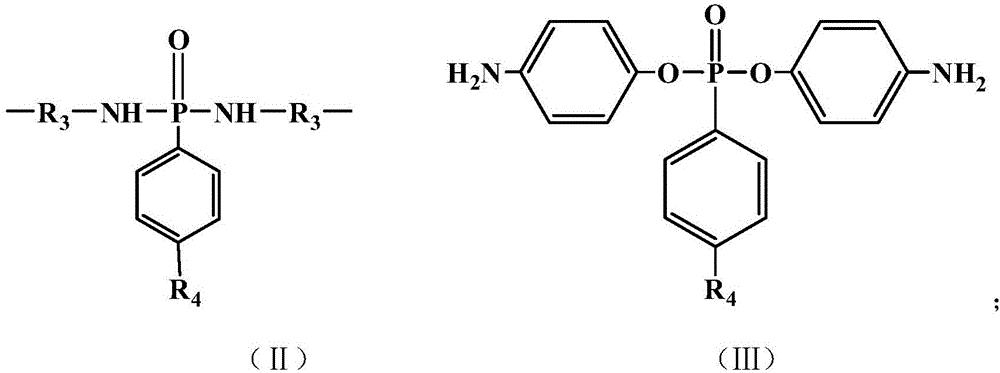

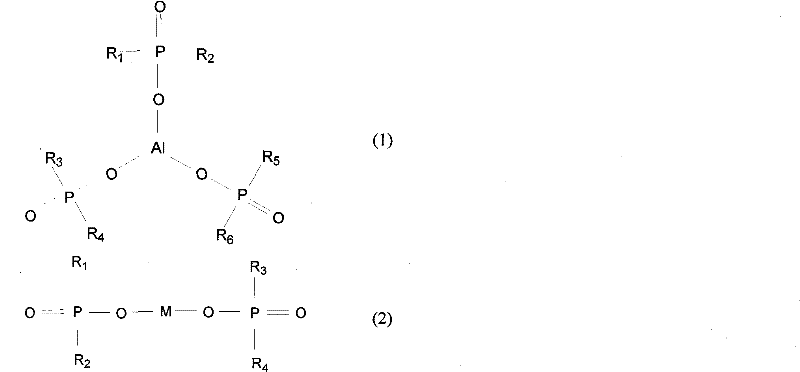

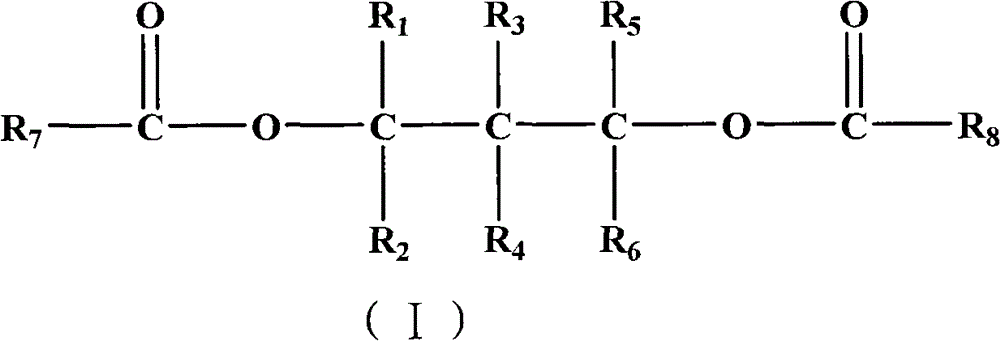

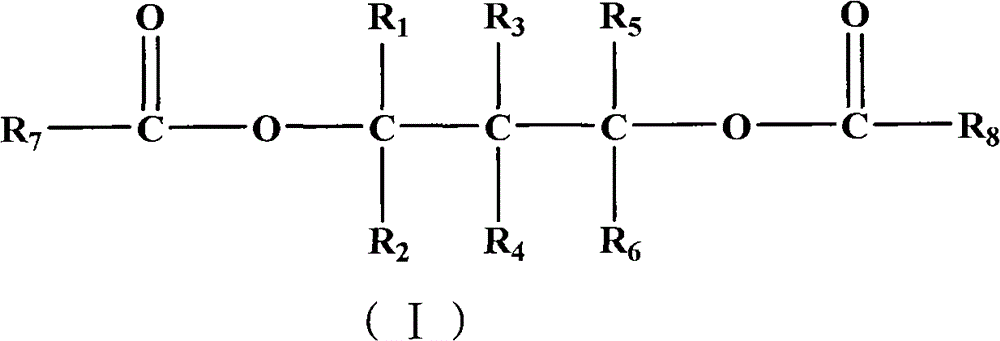

Phosphorus-containing Schiff base structured flame retardant and preparation method thereof

The invention discloses a phosphorus-containing Schiff base structured flame retardant and a preparation method thereof. The phosphorus-containing Schiff base structured flame retardant consists of hyperbranched macromolecules; a hyperbranched repeat unit is shown in the formula (I) as shown in the specification; in the formula, R1 is a phosphorus-containing structure, and R2 is a trifunctional structure; the molecular weight of the flame retardant is 500-100000. The flame retardant disclosed by the invention consists of hyperbranched macromolecules and is relatively large in molecular weight; when the flame retardant is used in polyurethane foams, the carbon residue amount of polyurethane can be greatly increased; the flame retardant disclosed by the invention is free of halogen and is a green and environment-friendly flame retardant; the flame retardant contains substances of a Schiff base structure, and due to existence of a C=N structure, very important chemical and biological significances can be achieved due to lone pair electrons on N atoms.

Owner:UNIV OF SCI & TECH OF CHINA

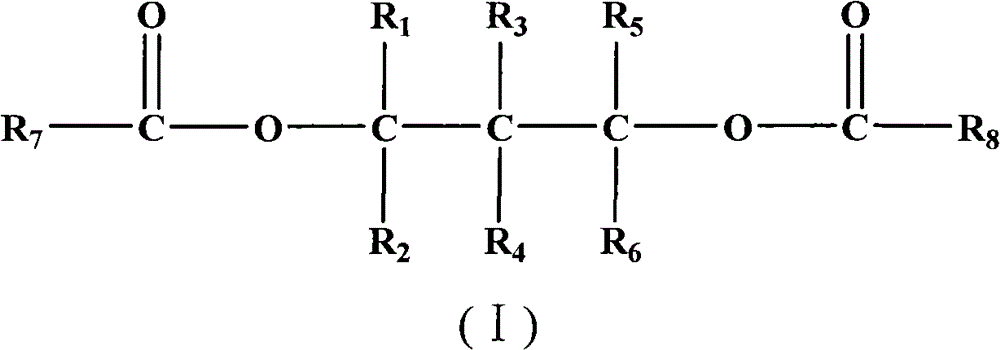

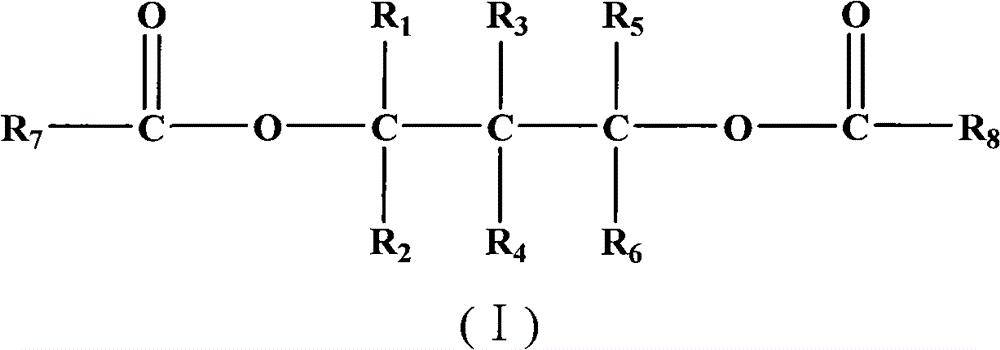

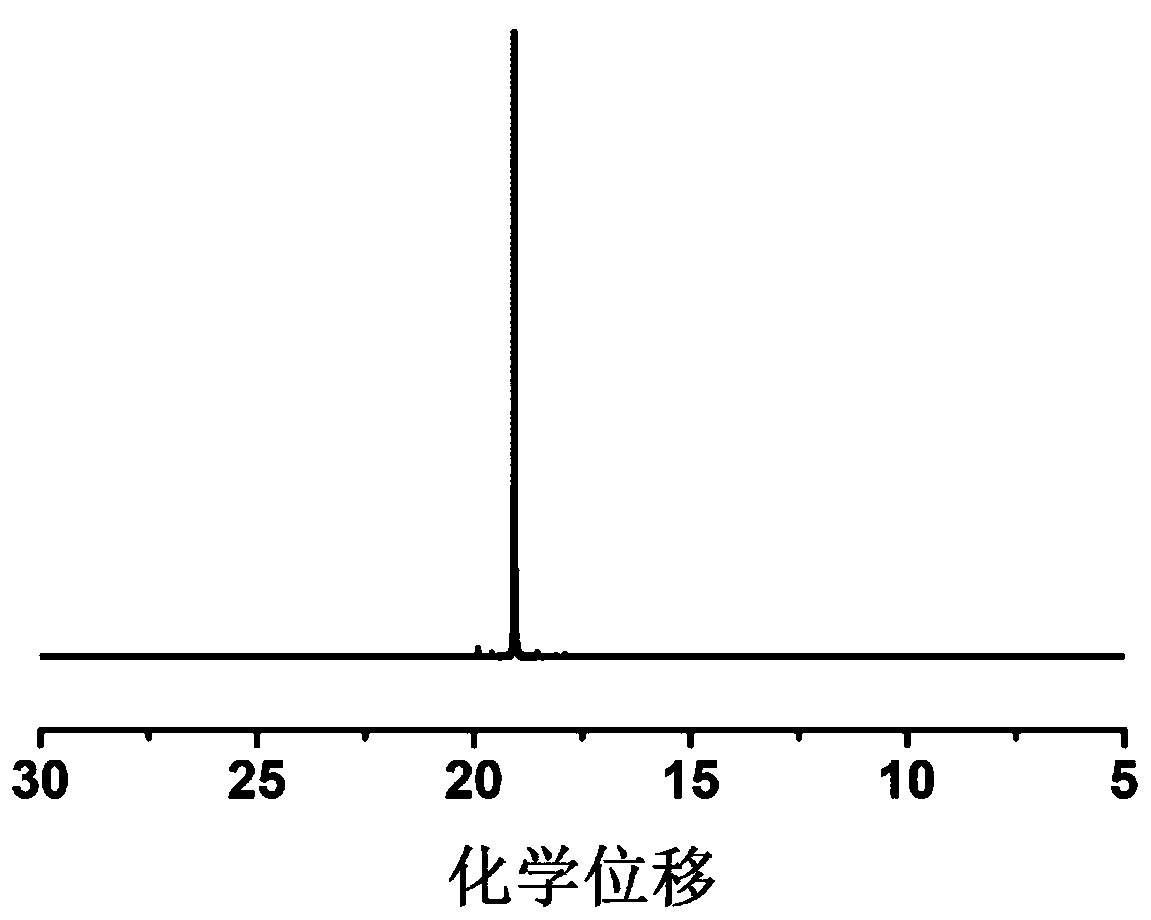

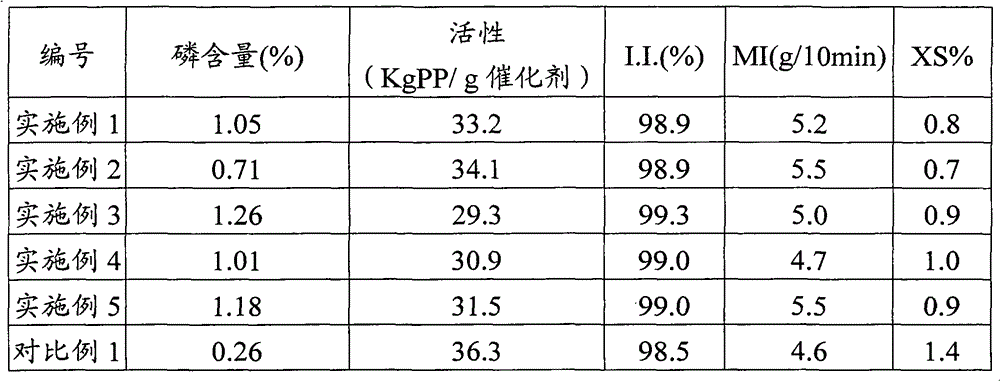

Catalyst component for olefin polymerization and catalyst thereof

The invention provides a catalyst component for olefin polymerization. The catalyst component is prepared by: dispersing an alcohol adduct melt of magnesium halide in a dispersing agent system of white oil and silicone oil to form an emulsion, discharging the emulsion into a cooling liquid to perform cooling shaping, thus forming a magnesium halide alcohol adduct microsphere, washing and drying the magnesium halide alcohol adduct microsphere to form a spherical carrier; and then treating the spherical carrier through a titanium compound, raising the temperature gradually, adding an internal electron donor during treatment, and after treatment, carrying out washing with an inert solvent, and performing drying, thus obtaining the spherical catalyst component. Specifically, a phosphorus-containing compound is added during the steps, and the phosphorus content in the catalyst component is 0.2-3.0wt%. The internal electron donor compound contains at least one diol ester compound selected from the following general formula (I). When the catalyst is used for olefin polymerization, especially propylene polymerization, a polymer with a high isotactic index and a high melt flow rate can be obtained. Particularly under a high hydrogen concentration, a polymer with a high melt flow rate and a high isotactic index can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ecoalimental macrobrachium rosenbergii feed and production method thereof

InactiveCN101444266ALower protein contentImprove stabilityFood processingClimate change adaptationMacrobrachiumCompounded preparations

The invention discloses an ecoalimental macrobrachium rosenbergii feed and a production method thereof, belonging to an animal feed production method. The macrobrachium rosenbergii feed comprises fish meal, bean pulp, fermented bean pulp, wheat middling, cuttlefish paste, oil bran, various mineral salt, lycine, fish oil, various vitamins, eclosion hormone, bond, antioxidant, mildew preventive, compound enzyme preparation, microecological preparation 'quick-healing hormone', a Chinese herb sophora flavescens alkaloid compound preparation, and the like. The yield of per mu is 310kg and can be improved by 44kg by using the ecoalimental the macrobrachium rosenbergii feed than common feeds. The effective utilization of the protein and amino acid in the feed by the macrobrachium rosenbergii is improved; the coefficient of the macrobrachium rosenbergii feed bait is 1.57 which is lower by 0.2 than the common feed. The ecoalimental macrobrachium feed reduces the pollution to a breeding environment. The produced matching feed of the macrobrachium rosenbergii can induce the macrobrachium rosenbergii to eat, the growing speed of the macrobrachium rosenbergii is quick, and feed coefficient is low.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES +1

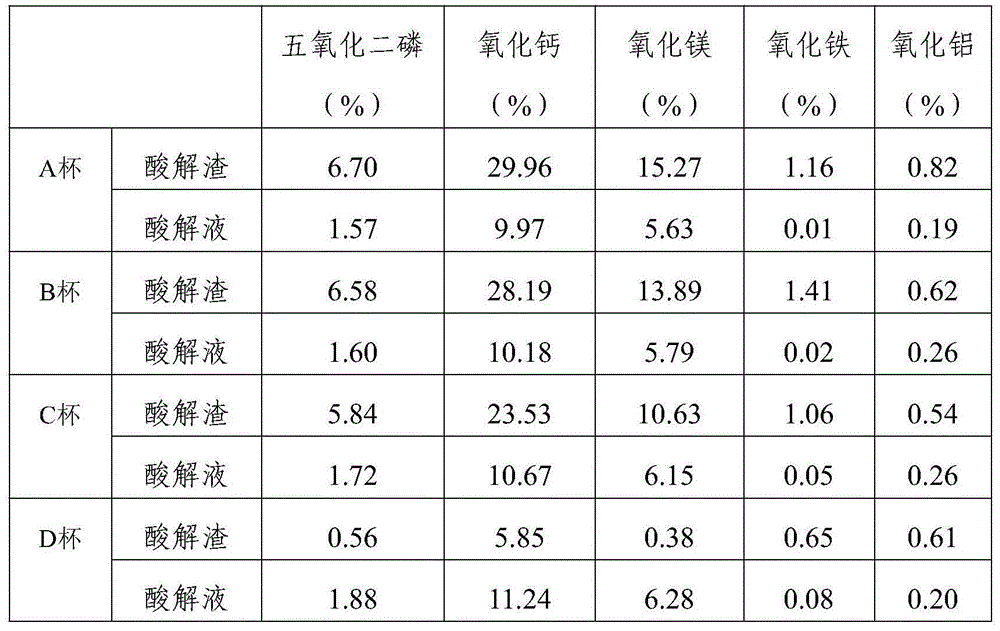

Method for preparing calcium magnesium ammonium phosphate and calcium magnesium ammonium nitrate from phosphor tailings

The invention discloses a method for preparing calcium magnesium ammonium phosphate and calcium magnesium ammonium nitrate from phosphor tailings. The method comprises the following steps: adding a nitric acid solution into a reaction tank, then adding phosphor tailings, carrying out reactions at a certain rotation speed and temperature, filtering and washing the reaction products to obtain residues and acid-leach liquor; adding ammonia water into the acid-leach liquor to adjust the pH value, carrying out reactions at a certain stirring speed and temperature, filtering the reaction products to obtain a neutralized solution and filter residues, drying the filter residues to obtain calcium magnesium ammonium phosphate, condensing the neutralized solution, and granulating to obtain calcium magnesium ammonium nitrate. The provided method can process phosphor tailings in a large amount, and the obtained calcium magnesium ammonium phosphate and calcium magnesium ammonium nitrate can be used to produce compound fertilizer.

Owner:GUIZHOU RES INST OF CHEM IND

Combustion-resisting electrolyte of lithium secondary cell and its lithium cell

InactiveCN101079505AImprove flame retardant performanceSafe storageSecondary cellsCombustionPhosphate

The invention discloses a flame-proof electrolyte and its lithium battery for secondary lithium battery, which is characterized by the following: adopting one or more phosphosubester (such as methyl acid phosphate dimethyl ester, ethyl phosphate diethyl ester and its derivant) as pure solvent or solvent component; reducing the price of electrolyte with incombustibility, low toxicity and high conductivity; improving the combusting safety effectively.

Owner:WUHAN UNIV

Balling method using medium- and low-grade phosphate rocks or ground phosphate rocks

ActiveCN103663396AHigh strengthHigh phosphorus contentPhosphorus compoundsPhosphoric acidCalciums magnesium

The invention relates to a balling method using medium- and low-grade phosphate rocks or ground phosphate rocks. The method comprises the following steps: S1, preparing materials, namely A, 85-100 parts of 60-120-mesh medium-grade and low-grade phosphate rocks or ground phosphate rocks, B, 1-10 parts of water or aqueous liquor of phosphoric acid, C, 2-8 parts of coke powder with the granularity of 60-120 meshes and D, 1-8 parts of one or more of phosphate fire clay, kaolin, sodium silicate, sodium carbonate, calcium carbonate and serpentine; S2, stirring, namely after uniformly mixing the raw materials, pressing the mixture into balls by use of a dry powder ball press machine, after pre-drying, delivering the mixture to a vertical calcining kiln, using purified yellow phosphorus tail gas, heating to 850-950 DEG C; starting roasting to obtain a finished product. The method is free from binders and low in cost, and the medium-grade and low-grade phosphate rocks are not hardened. The value of the medium-grade and low-grade phosphate rocks can be improved, and the ground phosphate rock of a mine can be fully utilized. The phosphate rock balls prepared are suitable for production of yellow phosphorus or calcium magnesium phosphate fertilizers.

Owner:刘静忠 +1

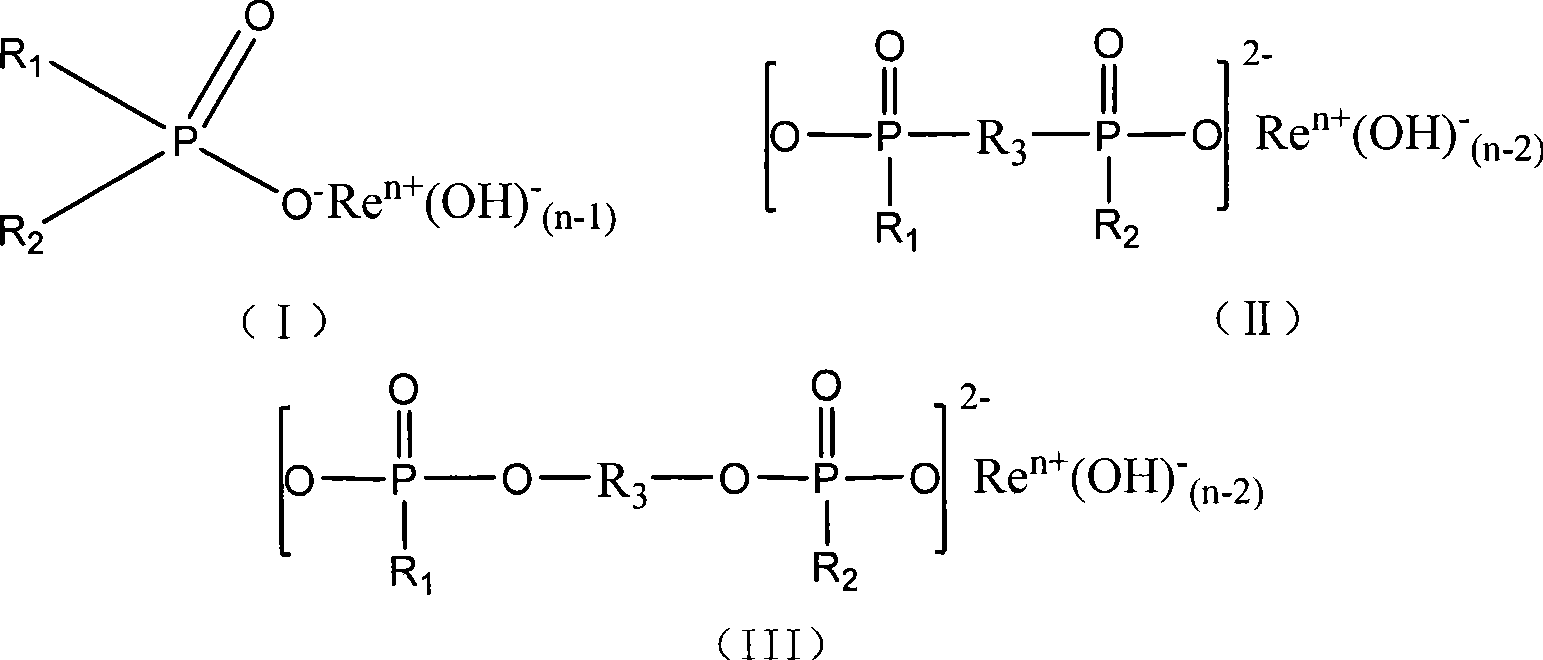

Partially alkylated phosphinic acid nonalkali metal salt and preparing method and application thereof

InactiveCN101747368AImprove flame retardant effectReduce pollutionGroup 5/15 element organic compoundsPhosphinic AcidsDouble bond

The invention provides a partially alkylated phosphinic acid nonalkali metal salt and a preparing method and application thereof. The preparing method comprises the following steps of: ensuring that radical addition occurs between a phosphinic acid nonalkali metal salt and compound containing double bonds in the presence of an initiator, and generating partially alkylated phosphinic acid nonalkali metal salt products. The application is as follows: a flame-retardant polymer comprises a thermoplastic polymer or thermosetting polymer, and more than one of the partially alkylated phosphinic acidnonalkali metal salt. The invention has the advantages of simple technical process, easy operation, less byproducts, low energy consumption and pollution and the like.

Owner:SOUTH CHINA UNIV OF TECH

Hydroxyl-containing liquid phosphor-nitrogen fire retardant and preparation method thereof

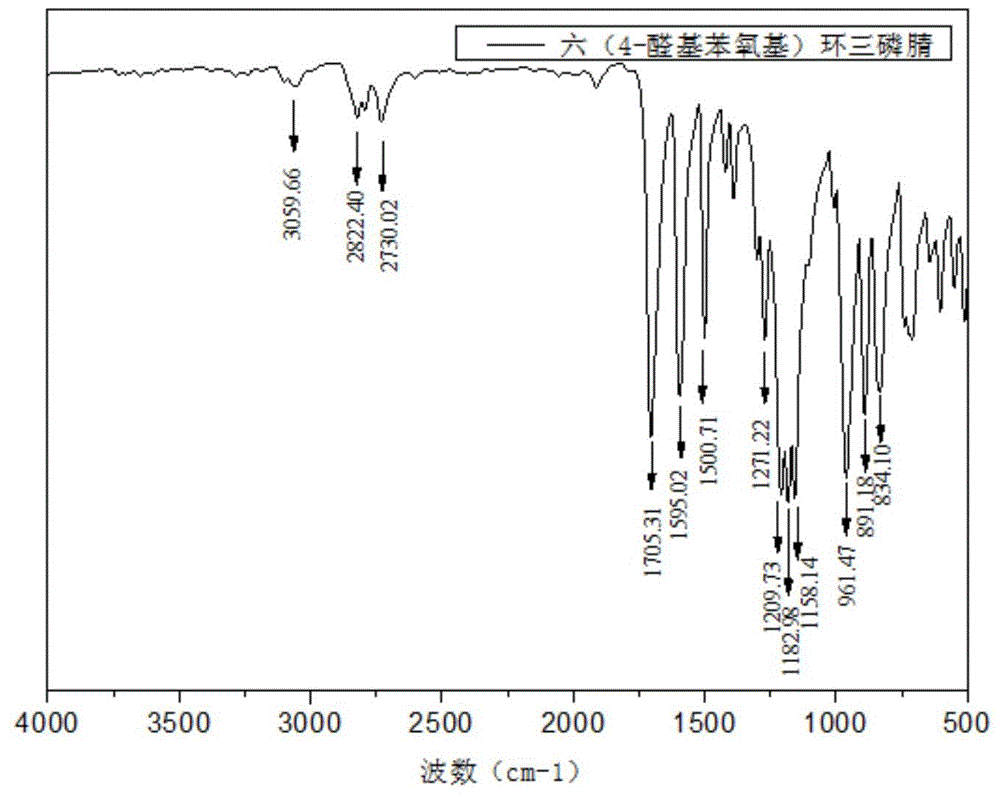

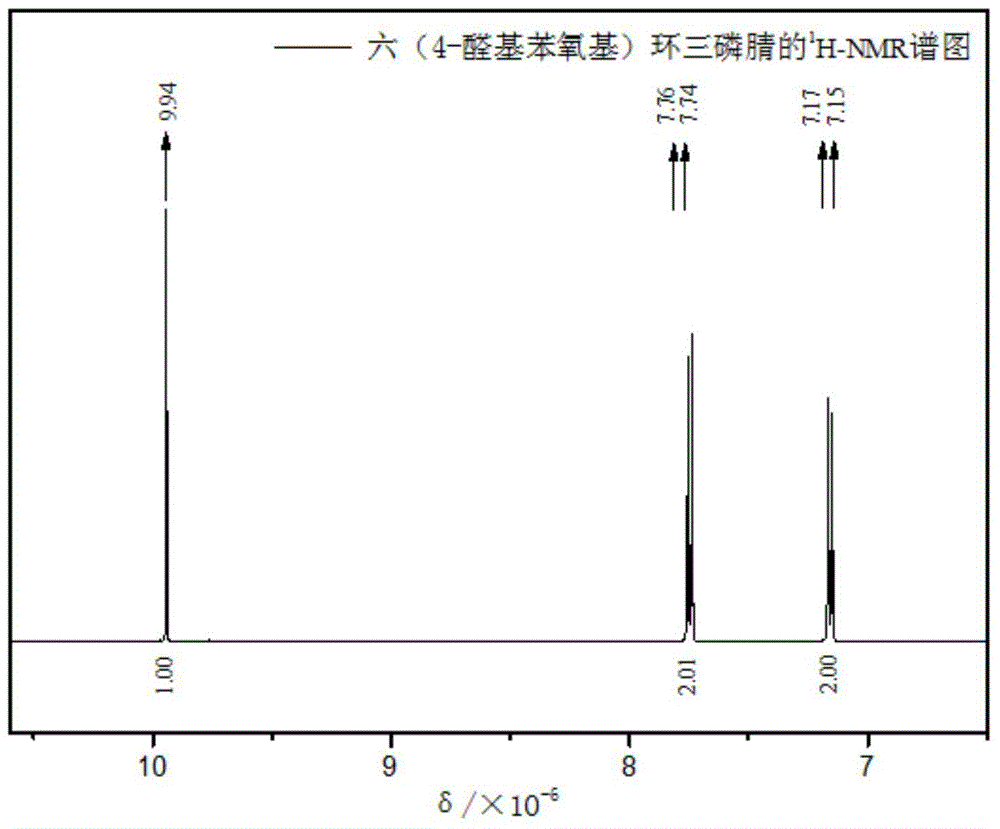

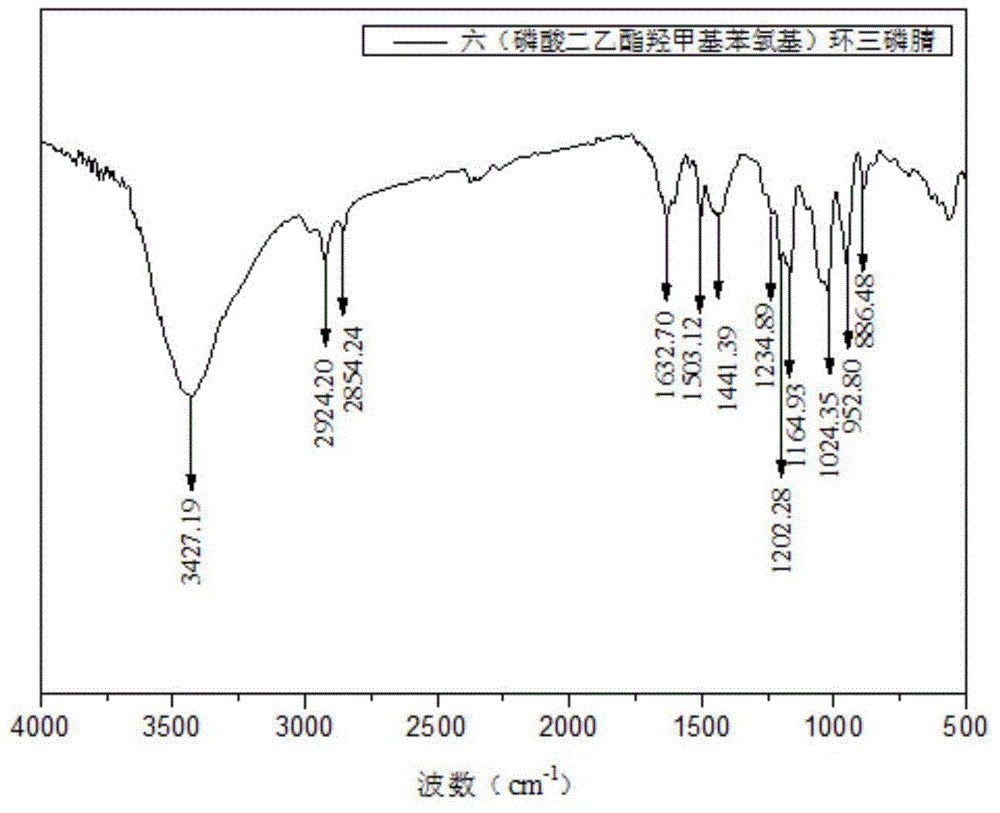

InactiveCN104877173AHigh in phosphorusImproved thermal stability and flame retardancyGroup 5/15 element organic compoundsChemistryDistillation

The invention relates to a hydroxyl-containing liquid phosphor-nitrogen fire retardant and a preparation method thereof, and belongs to the technical field of flame retardation. The preparation method comprises that hexachlorocyclotriphosphazene, p-hydroxybenzaldehyde and an acid binding agent are added into an organic solvent and undergo a heating reflux reaction, the reaction product is subjected to aftertreatment to form white solid powder hexa(4-formylphenoxy)cyclotriphosphazene, the hexa(4-formylphenoxy)cyclotriphosphazene, diethyl phosphite and triethylamine undergo a heating reflux reaction in an organic solvent, and the reaction product is subjected to reduced pressure distillation so that the organic solvent, diethyl phosphite and the catalyst are removed and a hexa(4-diethyl phosphate hydroxymethylphenoxy)cyclotriphosphazene fire retardant is obtained.

Owner:CHANGZHOU UNIV

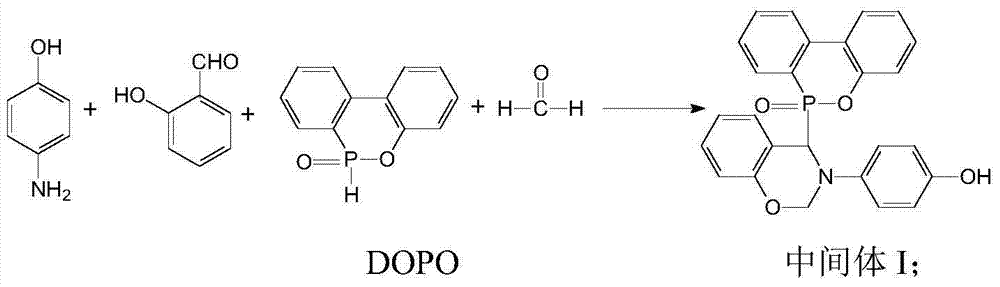

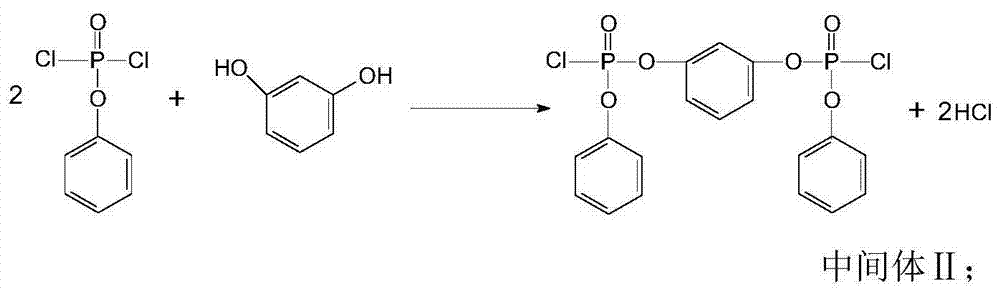

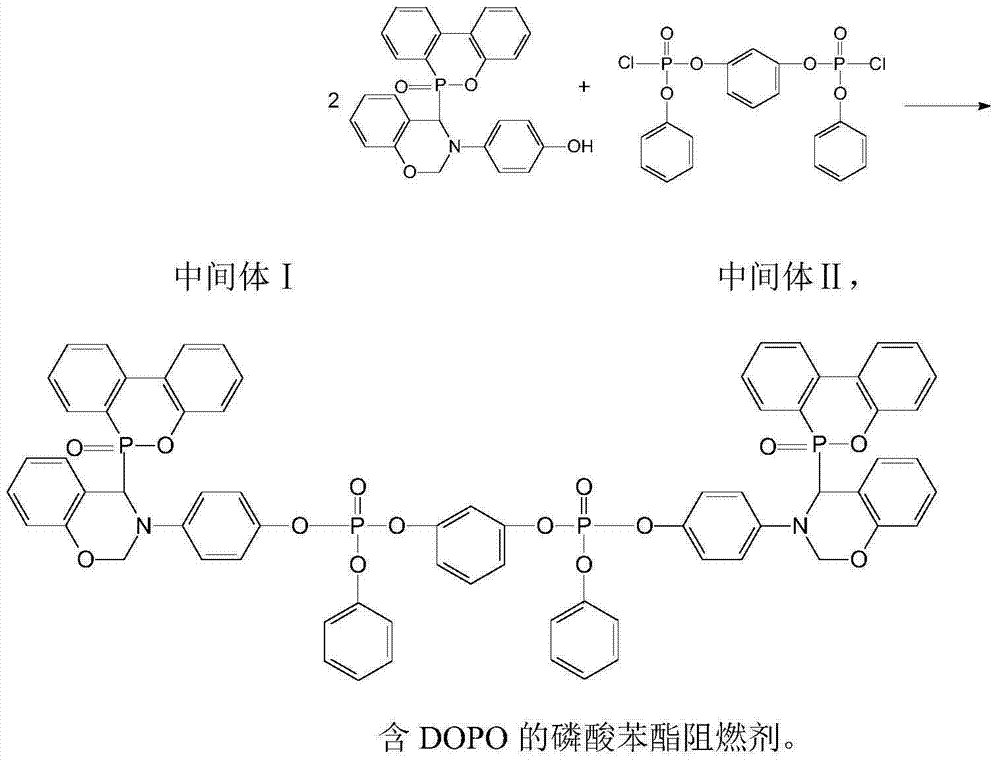

Phenyl phosphate flame retardant containing DOPO, and preparation method and application thereof

InactiveCN104774343AImprove heat resistanceHigh temperature char formation rateGroup 5/15 element organic compoundsDecompositionBenzaldehyde

Preparation method and application of a phenyl phosphate flame retardant containing DOPO. The method is as below: under the action of methanol, reacting 4-amino phenol, 2-hydroxy benzaldehyde, DOPO and formaldehyde in one pot to synthesize an intermediate I; reacting phenyl dichlorophosphate and resorcinol to synthesize an intermediate II (resorcinol bisphenoxyl phosphoryl chloride); and reacting the intermediate I and intermediate II to obtain a white solid which is the phenyl phosphate flame retardant containing DOPO. The initial decomposition temperature of the flame retardant was about 363, and the rate of residual carbon was 49% at 468, 800, and the flame retardant had good thermal stability, high residual carbon ratio and good flame retardant effect, which can be used for the non halogen flame retardant of polypropylene and ABS.

Owner:湖北万锦科技有限公司

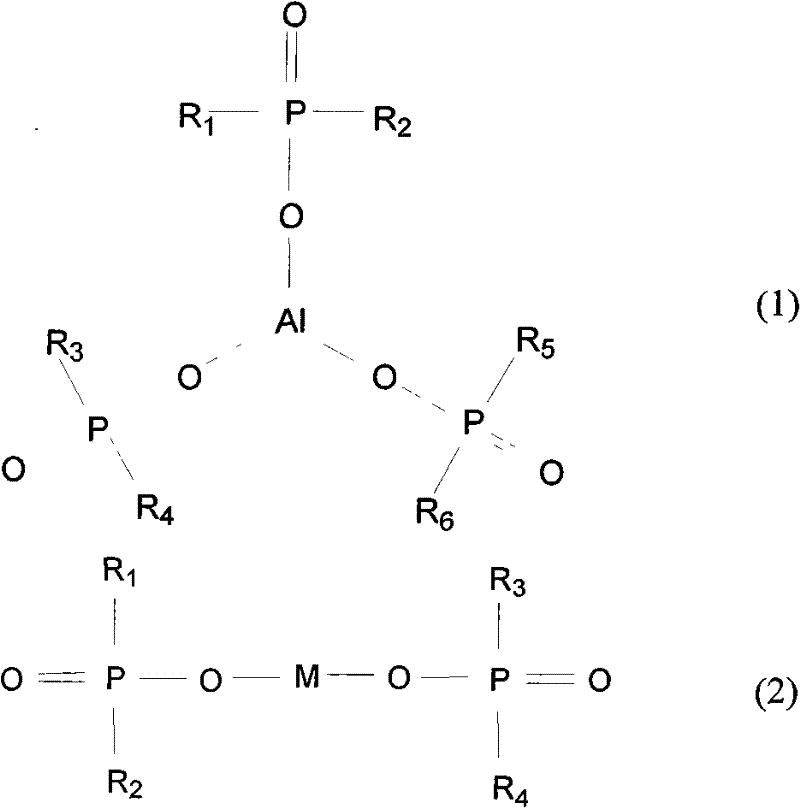

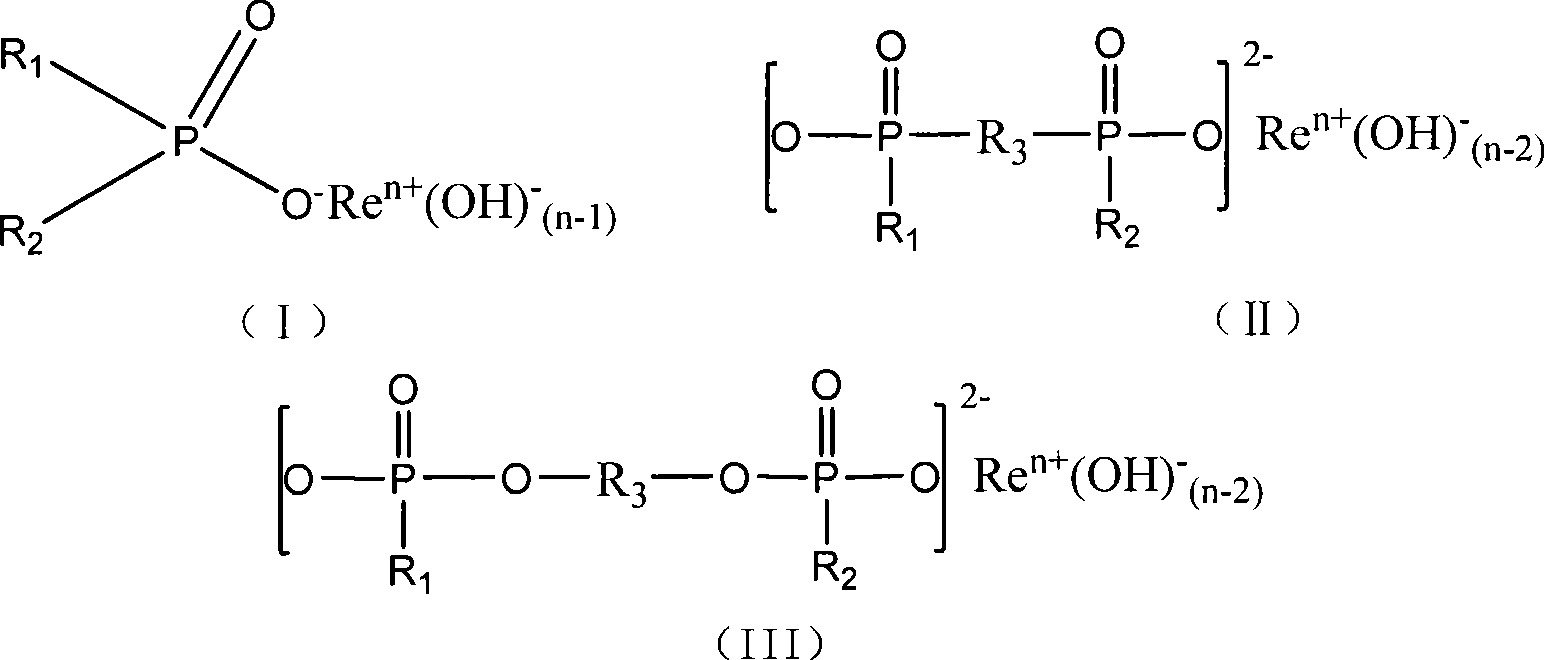

Rear earth organic phosphonate flame retardant, synthesizing method and use thereof

ActiveCN101475706AEffective structureStructure, and developed an efficient and feasible synthesis process for itGroup 5/15 element organic compoundsRare-earth elementOrganophosphorous compounds

The invention relates to organic phosphonic (phosphoric) acid rare-earth salt fire retardant and a synthetic method and application thereof, which belongs to the fields of fine chemical and macromolecular materials. The low-toxic, low-smoke, environment-friendly and efficient fire retardant is formed by combining with rare earth elements in organic phosphonic (phosphoric) acid structure. Compared with the organic phosphorous compound, the fire retardant has extremely high stability at normal temperature and plastic processing temperature; moreover, the use of rare earth elements ensures that the fire retardant and other components in macromolecular material are formed into a combination having better effects than Van Der Waals Force, hydrogen bond and the like; particularly, when mixed with other components of inflatable composite fire retardant, the fire retardant can obtain better synergic effects than currently used phosphinates such as aluminum phosphinate, zinc phosphinate and the like; moreover, the obtained macromolecular material can maintain better physical and mechanical properties.

Owner:广东华南精细化工研究院有限公司

Organic fertilizer and preparation method thereof

ActiveCN102951965AEliminate odorAvoid pollutionBio-organic fraction processingOrganic fertiliser preparationPhosphoric acidSugar

The invention relates to an organic fertilizer and a preparation method thereof. A formula of the organic fertilizer comprises by weight: 40%-60% of excrement, 3%-15% of straw, 5%-10% of deodorization strains, 4%-10% of calcium superphosphate, 4%-10% of oil cake, 2%-5% of sugar liquid, 1%-6% of ash, 1%-6% of a zeolite powder and 3%-9% of functional bacteria. The preparation method comprises the steps of fermentation and blending. The invention has the beneficial effects of effectively controlling stink of manure and reducing fermentation time to avoid environmental pollution, and reducing the production cost.

Owner:GUIZHOU DIBAO BIOTECH CO LTD

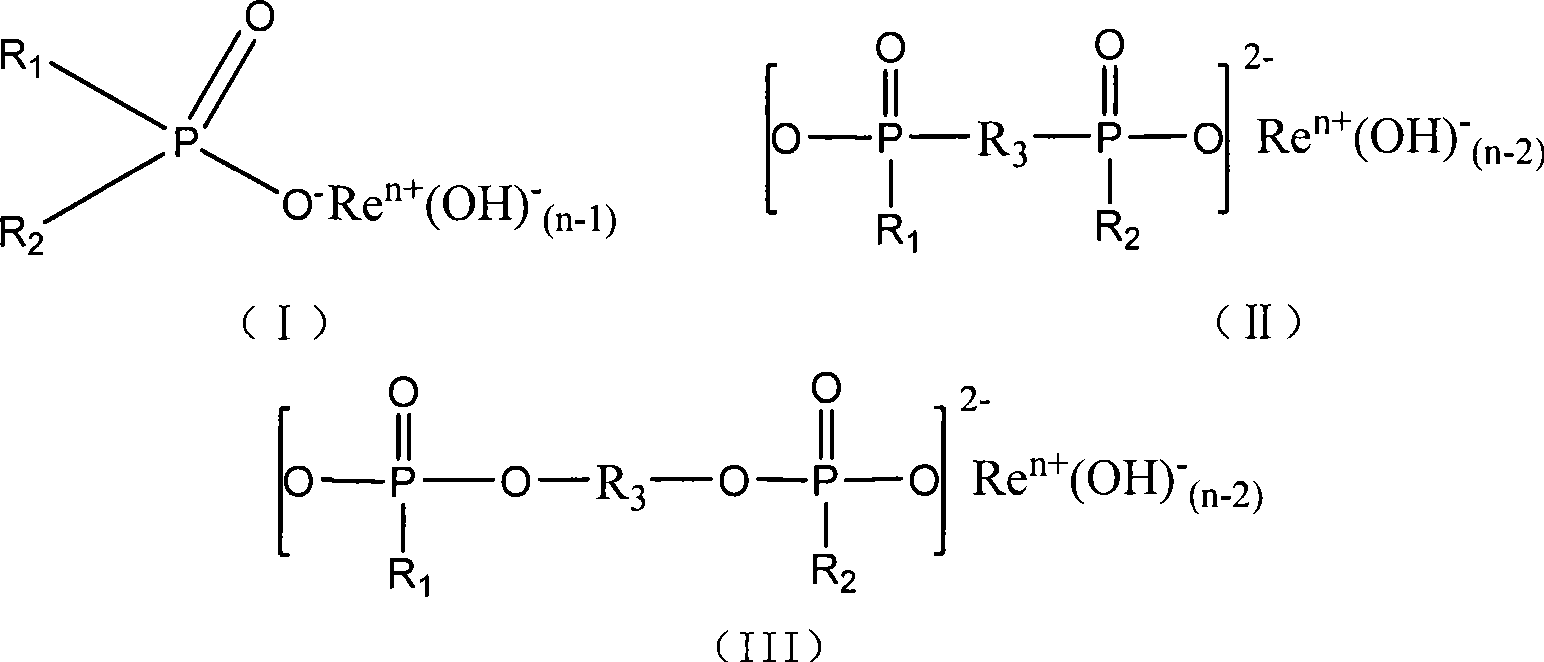

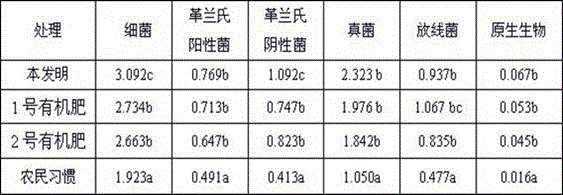

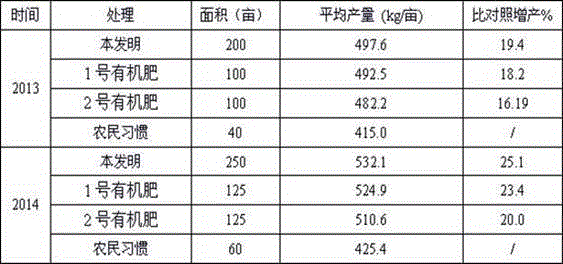

Composite microbial organic fertilizer for saline-alkali soil improvement and preparation method thereof

InactiveCN106008101APH dropReduce conductivityExcrement fertilisersBioloigcal waste fertilisersBacillus licheniformisAlkali soil

The invention relates to a composite microbial organic fertilizer for saline-alkali soil improvement. The composite microbial organic fertilizer for saline-alkali soil improvement comprises Bacillus subtilis, Bacillus licheniformis, Bacillus megaterium, silicate bacterium, mould fungus, fulvic acid, amino acids and bentonite. The preparation method comprises the following steps: screening, preparing a composite microbial inoculant, concentrating the fermentation liquid, drying, and carrying out high-temperature composting rotting fermentation. When the composite microbial organic fertilizer is used for improving the saline-alkali soil, the crop yield is increased by 19-40%, the soil pH is lowered by 0.2-0.8, the electric conductivity (EC) is lowered by 0.5-0.8, the available phosphorus content is increased by 2.0-4.4 mg / kg, the quick-acting potassium content is increased by 40-68 mg / kg, and the quantity and diversity of soil microbes are obviously increased.

Owner:SHANXI KINGSHINE FERTILIZER

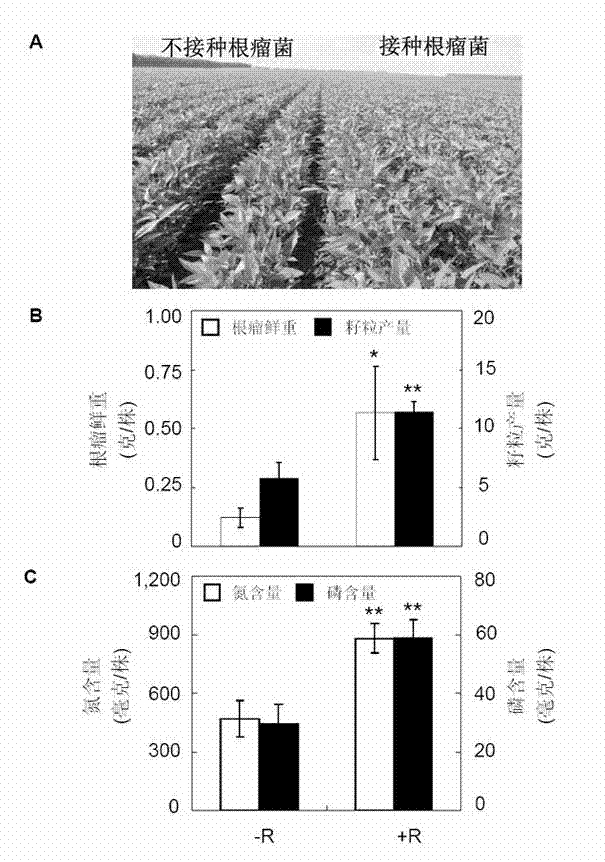

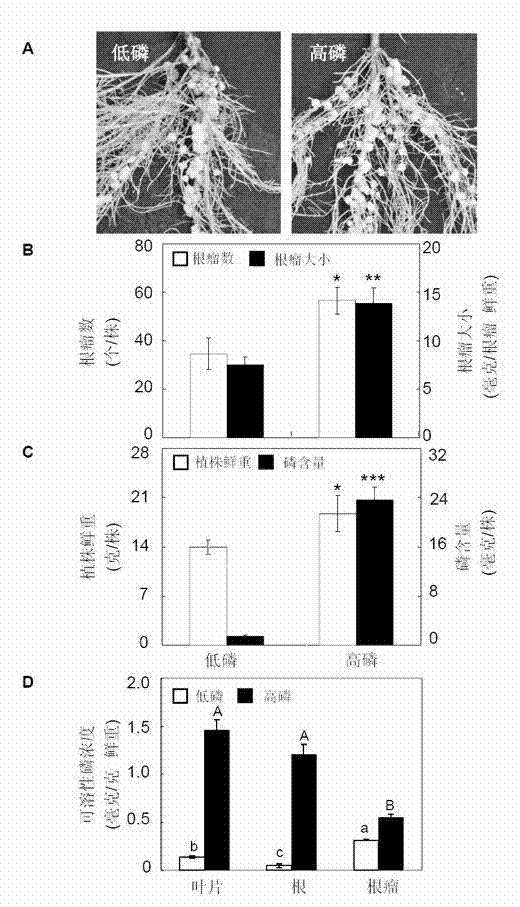

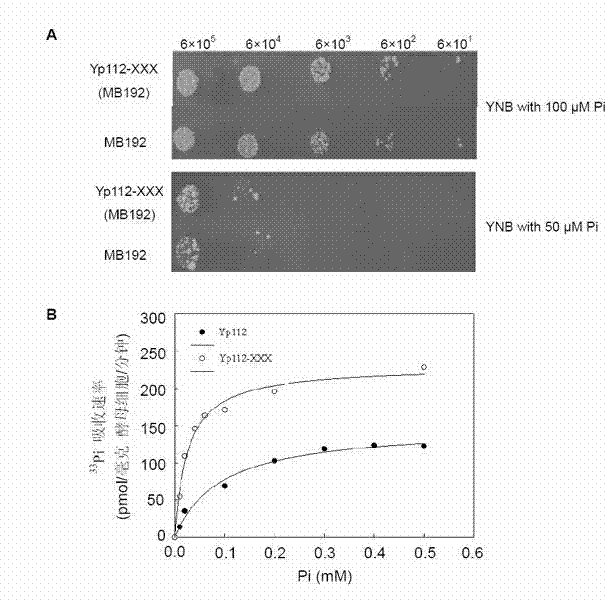

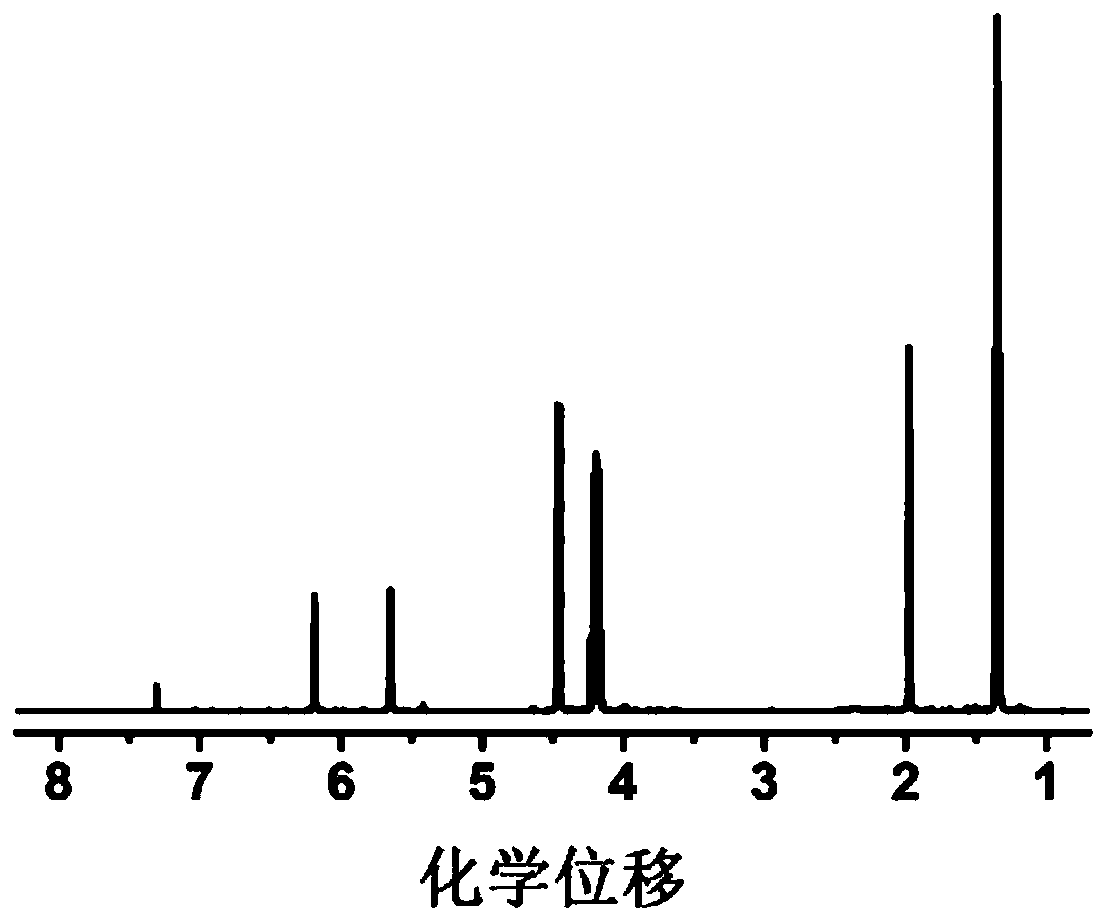

Phosphorus transportprotein gene GmPT5 related to phosphorus transport of soybean nodulation and application thereof

InactiveCN102757969AReduce sizeImprove absorption and utilization efficiencyFungiBacteriaNucleotideSoya bean

The invention discloses a phosphorus transportprotein gene GmPT5 related to phosphorus transport of soybean nodulation and application thereof. The phosphorus transportprotein gene GmPT5 related to the phosphorus transport of the soybean nodulation has a nucleotide sequence as shown in SEQ ID NO:1, and coded protein nucleotide sequence is shown as SEQ ID NO:2. The gene GmPT5 regulates and controls the phosphorus transport from a root part to the nodulation, furthermore, the overexpression of the gene is favorable for increasing the size of the soybean nodulation and the plant biomass as well as the nitrogen and phosphorus contents.

Owner:SOUTH CHINA AGRI UNIV

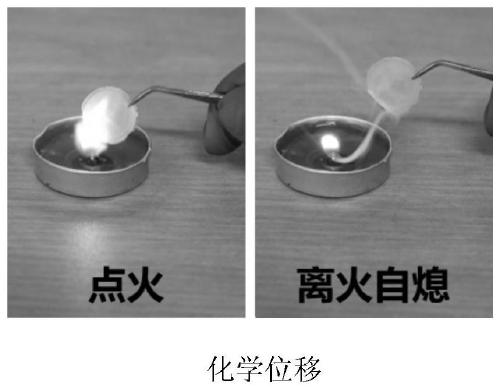

Non-combustible gel polymer electrolyte as well as preparation method and application thereof

ActiveCN111253523AHigh phosphorus contentSolve flammableFinal product manufactureLi-accumulatorsElectrical batteryPlasticizer

The invention discloses a non-combustible gel polymer electrolyte. The non-combustible gel polymer electrolyte is prepared by the steps: dissolving a vinyl phosphorus-containing compound, a vinyl compound and a lithium salt which are uniformly mixed into a plasticizer; and then adding an initiator, pouring into a mold, flattening or dropwise adding into a diaphragm assembled between a positive electrode and a negative electrode of a battery to infiltrate the diaphragm, and heating at the temperature of 50-80 DEG C for 3-24 h to polymerize the monomer in situ, and thus obtaining the non-combustible gel polymer electrolyte. The gel polymer electrolyte has relatively high phosphorus content, cannot be ignited when meeting open fire, and also has relatively high ionic conductivity, lithium iontransference number and electrochemical window at room temperature. When the electrolyte is applied to a lithium battery, side reaction caused by migration of a vinyl phosphorus-containing compound can be avoided, and damage to electrochemical performance can be reduced while incombustibility is achieved.

Owner:SICHUAN UNIV

Method for using arbuscular mycorrhizal fungi and organic fertilizer to reduce residue of lead and cadmium in tobacco

InactiveCN102577826AReduce poisonPromote growthHorticulture methodsBiotechnologyArbuscular mycorrhizal fungi

A method for using arbuscular mycorrhizal fungi and organic fertilizer to reduce residue of lead and cadmium in tobacco includes: preparing arbuscular mycorrhizal fungi inoculant, culturing mycorrhizal tobacco seedlings, and transplanting and managing the mycorrhizal seedlings. Tests show that arbuscular mycorrhizal fungi and cow dung added to soil coordinate to promote plant growth, increase phosphorus content of vegetation, lower poison and pollution of tobacco by lead and cadmium and promote tobacco growth, thereby reducing the residue of lead and cadmium in the tobacco.

Owner:HENAN UNIV OF SCI & TECH

Method for preparing modified coal ash phosphorus sorbent and uses thereof

InactiveCN101376094AAdsorption potential exertedIncrease surface areaOther chemical processesWater/sewage treatment by sorptionPhosphorSorbent

A preparation method for modified fly ash phosphor absorbent and application thereof is characterized in that uniformly mixing fly ash and water firstly; adding sulfuric acid with the thickness of 98%, and the weight ratio of the fly ash, the water and sulfuric acid is 100: (6-10): (2-50), and stirring uniformly; and at last curing for 0.5 to 5 hours at the temperature of 20 to 300 DEG C and getting the modified fly ash phosphor absorbent. The invention has the creative characteristics of making use of low-cost sulfuric aid modifier to largely dissolve substances with phosphor absorbing potential and further improving the surface area of the fly ash, thereby getting the absorbent with relatively high phosphor removing ability and maximally playing the phosphor removing potential of the fly ash. The invention eliminates the working procedures such as high-temperature roasting, acid solution and alkaline solution extraction, filtering, drying, etc. which are commonly used in fly ash modifying process, thereby realizing simple technology. The absorbent has relatively high speed of phosphor absorbing when put into sewage, and the maximum purification effect can be achieved in 5 minutes.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Catalyst component for olefin polymerization and catalyst thereof

The invention provides a catalyst component for olefin polymerization. The catalyst component is prepared by: mixing a magnesium compound, an organic alcohol compound and an inert solvent, and adding an assistant precipitation agent to obtain an alcohol adduct; contacting the alcohol adduct with a titanium compound solution, then adding an internal electron donor compound and leaving them to react, conducting filtration to separate solid particles; adding the solid particles into the titanium compound solution, carrying out stirring and leaving them to react, and conducting filtration to separate solid particles; washing the solid particles by the inert solvent, and performing drying. Specifically, a phosphorus-containing compound is added during the steps. And the phosphorus content of the catalyst component is 0.2-3.0wt%. The internal electron donor compound contains at least one diol ester compound selected from the following general formula (I). When the catalyst is used for olefin polymerization, especially propylene polymerization, a polymer with a high isotactic index and a high melt flow rate can be obtained. Particularly under a high hydrogen concentration, a polymer with a high melt flow rate and a high isotactic index can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

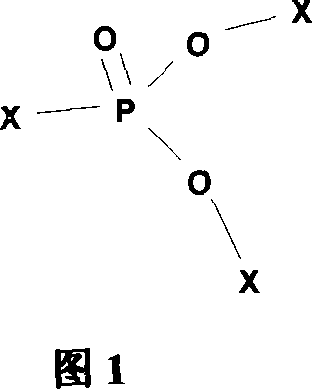

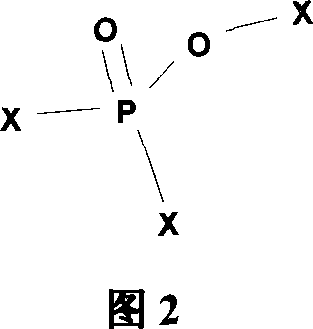

Catalyst component and catalyst for olefin polymerization

ActiveCN103059171AStrong Stereotropic AbilityGood hydrogen sensitivityPhosphorous acidElectron donor

The invention provides a catalyst component for olefin polymerization. The catalyst component is prepared by: mixing a magnesium compound, an organic alcohol compound and an inert solvent, and adding an precipitation assistant to obtain an alcohol adduct; contacting the alcohol adduct with a titanium compound solution, then adding an internal electron donor compound and allowing them to react, conducting filtration to separate solid particles; adding the solid particles into the titanium compound solution, carrying out stirring and allowing them to react, and conducting filtration to separate solid particles; washing the solid particles by the inert solvent, and performing drying. Specifically, a phosphorus-containing compound, which can be alkyl ester or halogenated alkyl ester of orthophosphoric acid or phosphorous acid, an alkyl or aryl phosphine compound or a mixture thereof, is added during the steps. And the phosphorus content of the catalyst component is 0.2-3.0wt%. When the catalyst is used for olefin polymerization, especially propylene polymerization, a polymer with a high isotactic index and a high melt flow rate can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Plant growth-promoting rhizobacteria and application thereof

ActiveCN103146610AIncrease profitImprove utilization efficiencyBiocidePlant growth regulatorsPlant rootsPhosphate

The invention belongs to the field of agricultural microbiology, and relates to plant growth-promoting rhizobacteria and an application thereof. The plant growth-promoting rhizobacteria (Pseudomonas fluorescens Y1) was collected in the General Microbiological Center of China Microbiological Culture Collection Management Committee on January 11th, 2013, and is named Pseudomonas fluorescens in a classified manner, and the collection number is CGMCC (China General Microbiological Culture Collection Center) NO. 7130. The strain utilizes insoluble phosphate as a phosphorus source for strong growth ability, can improve the utilization ratio of the fertilizer, promotes the development of plant roots and uptake of a fertilizer and increases the phosphorus content of the plant. The plant growth-promoting rhizobacteria disclosed by the invention has a good growth promoting effect for peanuts, and the efficient phosphate solubilisation of the strain promotes the growth and the development of the peanuts and the utilization ratio of a phosphorus fertilizer.

Owner:NANJING AGRICULTURAL UNIVERSITY

Catalyst component for olefin polymerization, catalyst and preparation method thereof

The invention provides a catalyst component for olefin polymerization. The catalyst component contains the reaction product of a magnesium compound, a titanium compound, a phosphorus-containing compound and a phosphorus-free internal electron donor compound. The phosphorus-containing compound is added in a step except the step of magnesium compound dissolution, and the catalyst component has a phosphorus content of 0.4-3.0wt%. The involved catalyst has strong stereospecificity and good hydrogen regulation sensitivity. When the catalyst is used for olefin polymerization, especially propylene polymerization, a product with a high isotactic index, a high melt flow rate and a low dimethylbenzene soluble substance content can be obtained simultaneously. Especially when the catalyst is used for propylene polymerization under a high hydrogen concentration condition, the obtained polymer can have a high melt flow rate, a high isotactic index and a low dimethylbenzene soluble substance content, and at the same time, the polymer has a relatively narrow molecular weight distribution.

Owner:CHINA PETROLEUM & CHEM CORP +1

Anti-fading treatment process for rattan for rattan-plaited handiwork

InactiveCN106003331AHigh carbon contentHigh phosphorus contentWood treatment detailsReed/straw treatmentWater contentChemistry

The invention provides an anti-fading treatment process for rattan for a rattan-plaited handiwork. The anti-fading treatment process comprises the following steps that an accelerant is applied to bamboo roots of rattan plants, and the rattan is felled 2 to 3 days after and put into a refrigeration house to be refrigerated at the temperature of 15 DEG C to 20 DEG C for 3 hours to 5 hours; high temperature treatment is conducted for 30 minutes to 50 minutes, the treatment temperature ranges from 130 DEG C to 150 DEG C, and then the rattan is put into an airtight pressure treatment tank and subjected to high-pressure treatment; and the rattan obtained after high-pressure treatment is conducted is polished through a polishing machine, the rattan is clipped according to the specification of the required rattan-plaited product, then the clipped rattan is dried, and the water content of the rattan is not larger than 3.5%. According to the anti-fading treatment process for the rattan for the rattan-plaited handiwork, quick growth of the rattan plants is promoted before the rattan is felled, the hardness of wood fiber of the rattan can be enhanced, the carbon content and the phosphorous content of the rattan are increased, the oxidation resistance of the wood fiber is enhanced, and the rattan fumigated by anti-fading steam cannot fade under the conditions of high temperature, oil soaking and acid-base corrosion.

Owner:FUNAN FANGLIU ARTS & CRAFTS CO LTD

Phosphaphenanthrene polyamide flame retardant and preparation and application thereof

ActiveCN104419003AHigh phosphorus contentEasy to useGroup 5/15 element organic compoundsThermoplasticPolymer science

The invention relates to a phosphaphenanthrene polyamide flame retardant and a preparation and an application thereof. The preparation method comprises the following steps: carrying out graft modification on novel unsaturated polyamide and a phosphorus-containing group; and carrying out additive reaction on 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) to prepare the polyamide flame retardant by using the reactivity of the unsaturated polyamide. The phosphaphenanthrene polyamide flame retardant has the characteristics of being halogen-free, low in smoke, low in toxicity, low in corrosion, good in fire resistance, good in processability and the like; the environmental protection index can meet the regulatory requirements of RoHS, IEC non-halogenation and Reach method of the European union; and compared with the previously known comparable DOPO derivative, the compound has a gas phase flame-retardant effect and a condensed phase flame-retardant effect, is high in efficiency, and can be applied to inflaming retarding of thermoplastic plastics and thermosetting materials.

Owner:GUANGZHOU SHINE POLYMER TECH

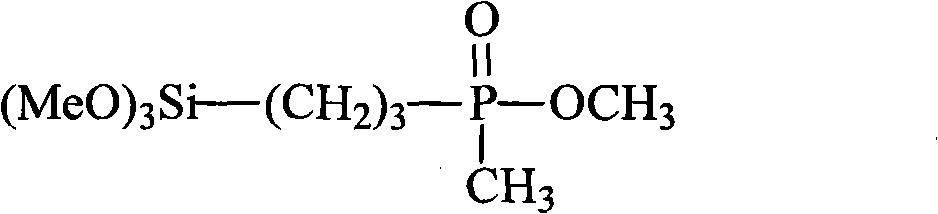

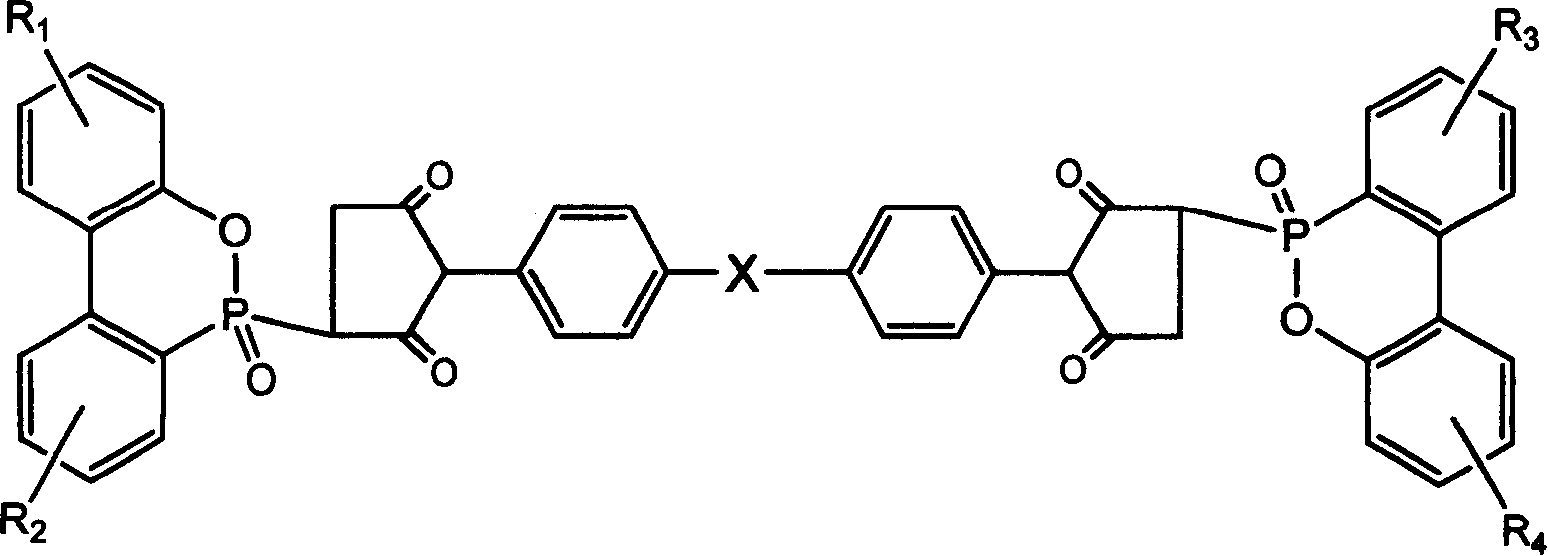

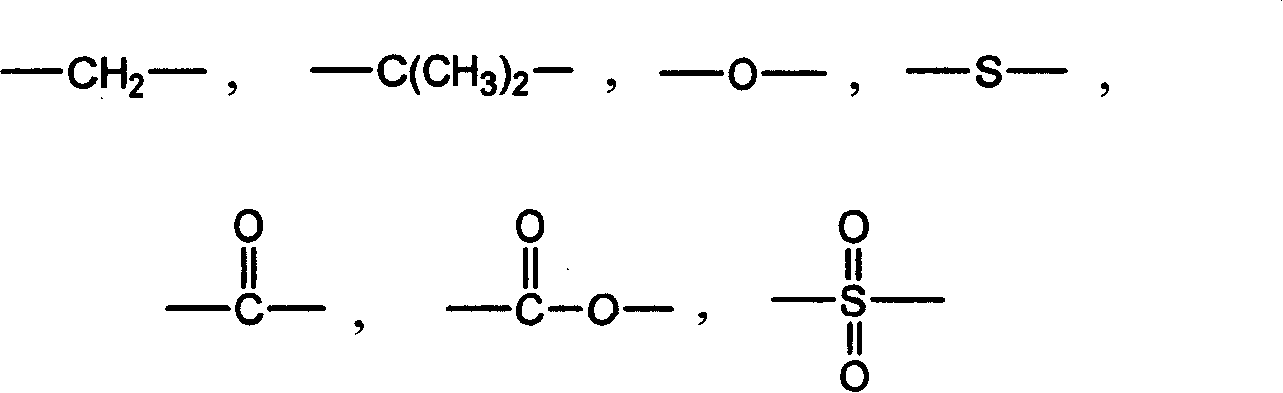

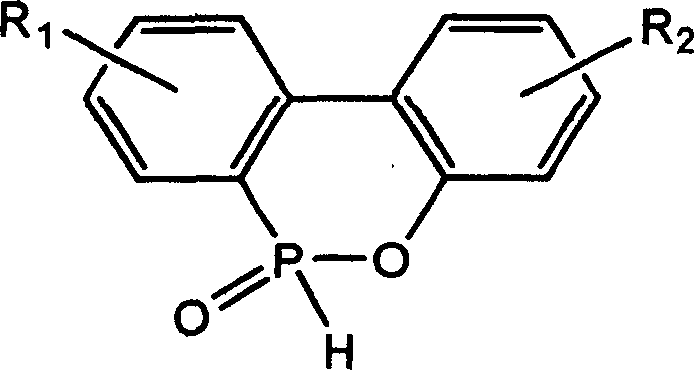

No-halogen fire-proof phosphorus-containing compound with high heat stability and its prepn

ActiveCN1887892AAchieving Synergistic Flame RetardancyMeet the requirements of halogen-free flame retardantGroup 5/15 element organic compoundsChemical structureHalogen

The present invention is no-halogen fireproof phosphorus-containing compound with high heat stability and its preparation process, and features that the phosphorus-containing compound is prepared with 9, 10-dihydro-9-oxa-10-phospha phenanthryl-10-oxide, bismaleimide and other material and through solution process or fusion process. This kind of the phosphorus-containing compound has high heat stability and high antiflaming efficiency, and may be used as flame retardant for preparing no-halogen fireproof resin. Its chemical structure is shown.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com