Non-combustible gel polymer electrolyte as well as preparation method and application thereof

A gel polymer and electrolyte technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve problems such as combustion and explosion of lithium batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

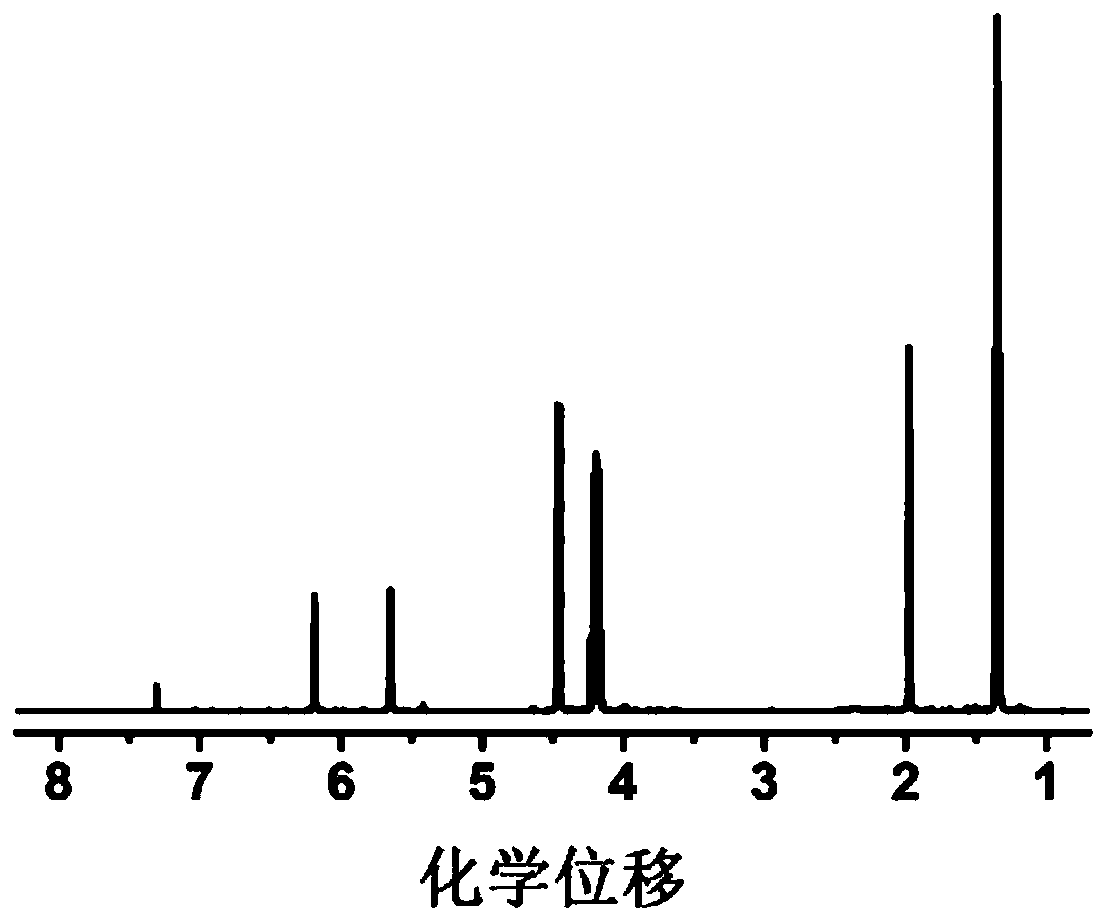

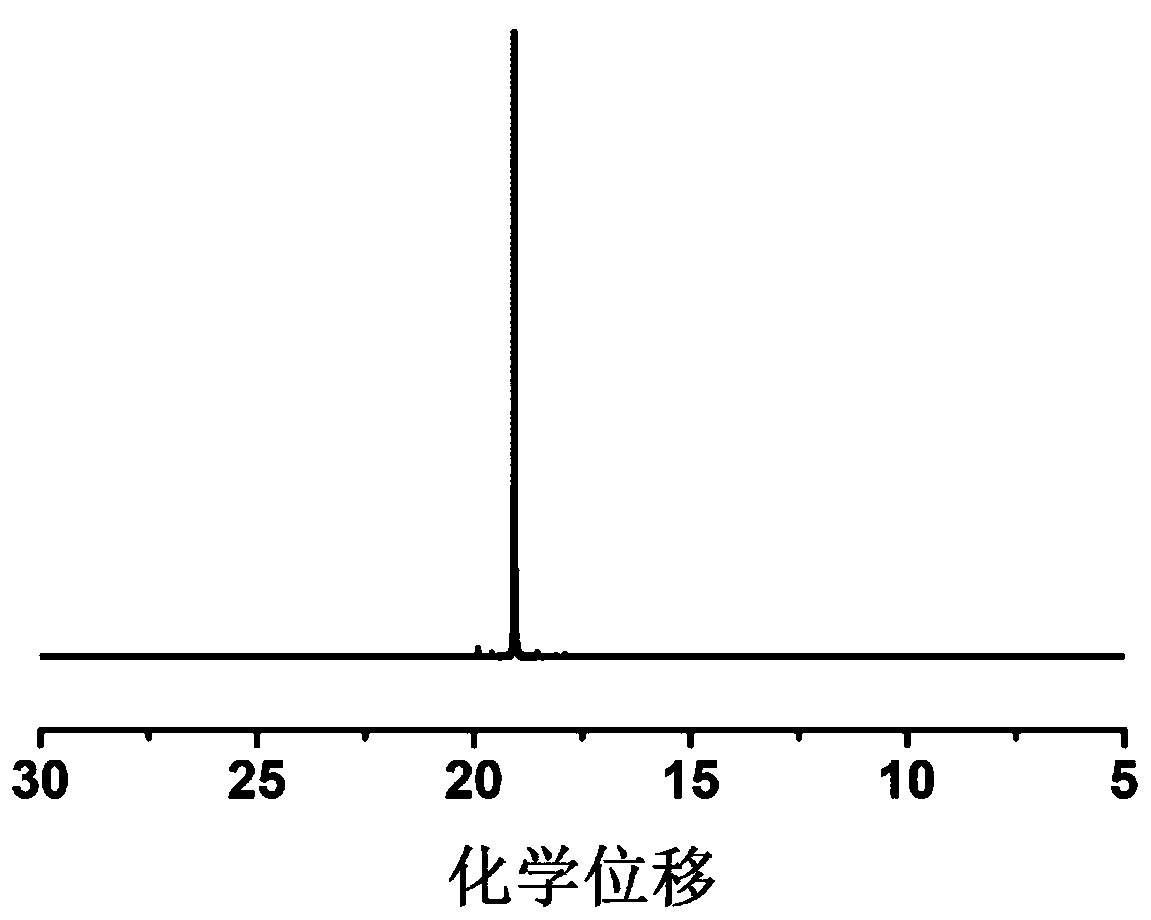

[0054] 4g of diethyl vinylphosphonate, 2g of acrylonitrile and 0.76g of LiPF 6 Dissolve in 5.234g EC and DMC (volume ratio 1:1), add 0.006g AIBN, stir until a homogeneous solution is formed, place it at 50°C for in-situ polymerization, and obtain a gel polymer electrolyte after 24 hours.

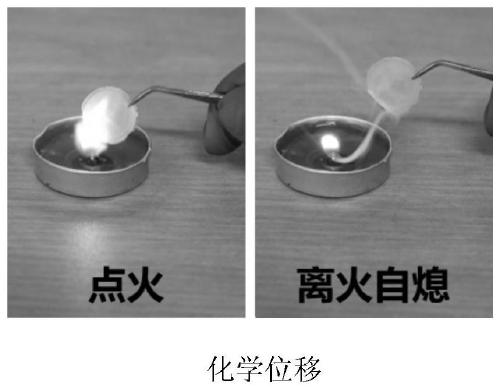

[0055] The prepared gel polymer is non-combustible in the ignition test, and the ion conductivity at room temperature is 2.5×10 -4 S cm -1 , the lithium ion migration number is 0.66, and the electrochemical window is 5.0V.

Embodiment 2

[0057] 4g of diethyl vinylphosphonate, 2g of acrylonitrile and 0.76g of LiPF 6 Dissolve in 5.234g EC and DMC (volume ratio 1:1), add 0.006g AIBN, stir until a homogeneous solution is formed, place it at 80°C for in-situ polymerization, and obtain a gel polymer electrolyte after 3 hours.

[0058] The prepared gel polymer is non-combustible in the ignition test, and the ion conductivity at room temperature is 2.8×10 -4 S cm -1 , the lithium ion migration number is 0.68, and the electrochemical window is 5.0V.

Embodiment 3

[0060] 4 g of diethyl vinylphosphonate, 2 g of methyl methacrylate and 0.76 g of LiPF 6 Dissolve in 5.234g EC and DMC (volume ratio 1:1), add 0.006g AIBN, stir until a homogeneous solution is formed, place it at 60°C for in-situ polymerization, and obtain a gel polymer electrolyte after 12 hours.

[0061] The prepared gel polymer is non-combustible in the ignition test, and the ion conductivity at room temperature is 1.9×10 -4 S cm -1, the lithium ion migration number is 0.38, and the electrochemical window is 4.2V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com