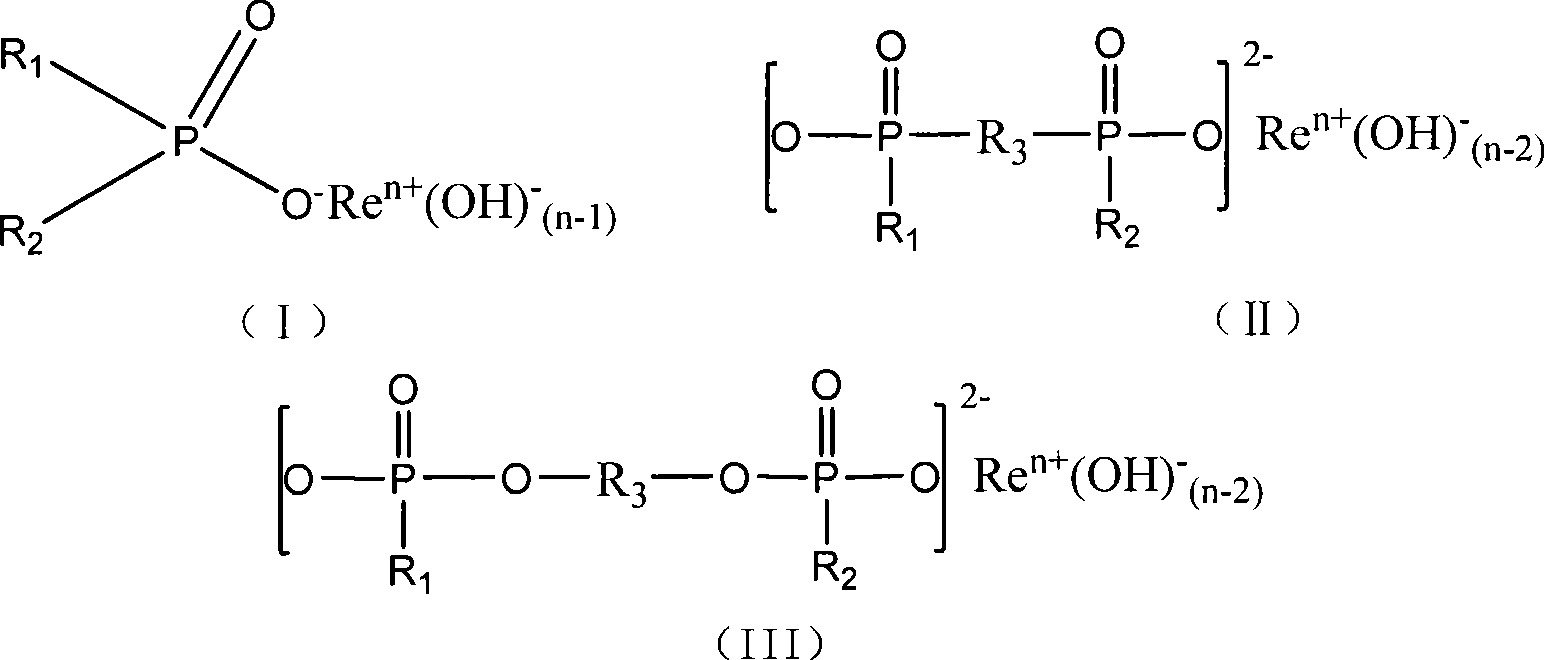

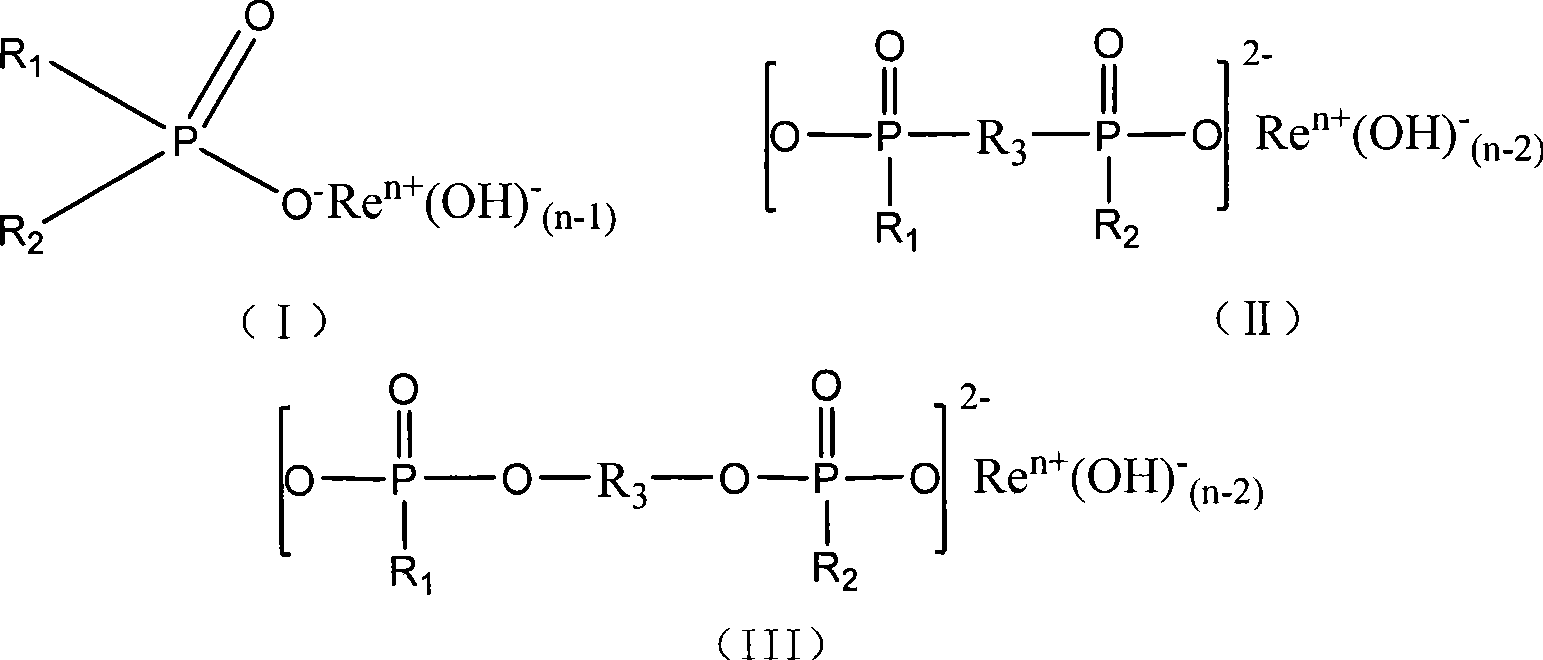

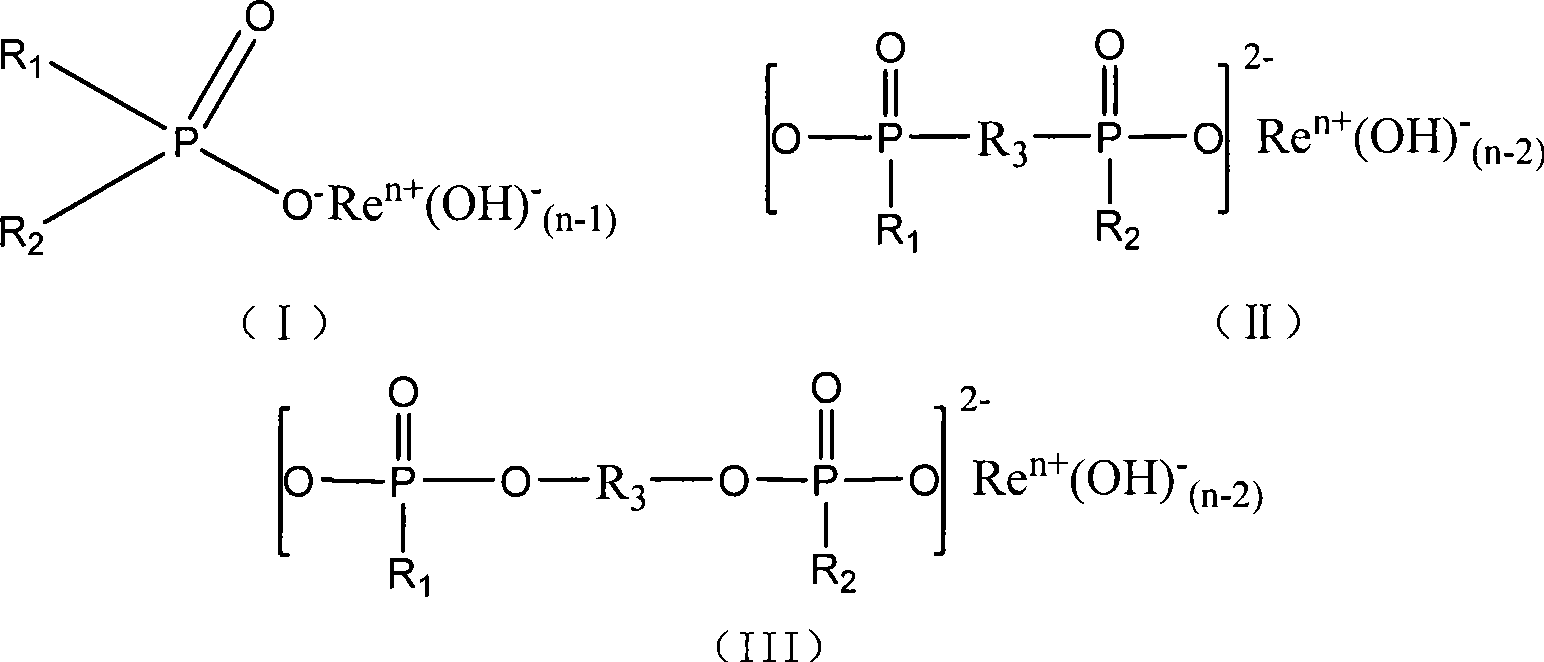

Rear earth organic phosphonate flame retardant, synthesizing method and use thereof

A synthesis method and organic phosphine technology are applied in the fields of fine chemicals and polymer materials to achieve the effects of wide synergy, high phosphorus content and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Embodiment 1, the synthesis of lanthanum bismethylphosphonate

[0064] Adding 94g bismethylphosphonic acid and 500ml concentration in the reactor is 15% ethanol aqueous solution, the bismethylphosphonic acid structural formula is as shown in general formula (IV), R 1 , R 2 For methyl. Under stirring, 20% sodium hydroxide aqueous solution containing 44 g of sodium hydroxide was added, and it was made to react at 70 degreeC for 2 hours. Then add 20% aqueous solution of lanthanum chloride containing 245.5g of lanthanum chloride, adjust the pH value of the solution to 7-8 with sodium hydroxide solution, and stir for 2 hours at 20-30°C. After the reaction, filter, dry, and pulverize to obtain 244.2 g of lanthanum bismethylphosphonate with a yield of 91.8%.

Embodiment 2

[0065] Embodiment 2, the synthesis of bis-tert-butylphosphonic acid gadolinium

[0066] Add 178g bis-tert-butylphosphonic acid and 1000ml concentration in the reactor and be 15% ethanol aqueous solution, bis-tert-butylphosphonic acid structural formula is as shown in general formula (IV), R 1 , R 2 For tert-butyl. Under stirring, 20% sodium hydroxide aqueous solution containing 44 g of sodium hydroxide was added, and it was made to react at 60 degreeC for 2 hours. Then add 20% gadolinium chloride aqueous solution containing 263.75g of gadolinium chloride, then adjust the pH value of the solution to 7-8 with sodium hydroxide solution, and stir at 60° C. for 2 hours. After the reaction, filter, dry, and pulverize to obtain 332.2 g of gadolinium bis-tert-butylphosphonate with a yield of 90.2%.

Embodiment 3

[0067] Embodiment 3, the synthesis of bisethoxylanthanum phosphate

[0068] Adding 154g diethoxy phosphoric acid and 800ml concentration in the reactor is 15% isopropanol solution, its structural formula is as shown in general formula (IV), R 1 , R 2 For ethoxy. Under stirring, 20% sodium hydroxide aqueous solution containing 44 g of sodium hydroxide was added, and it was made to react at 60 degreeC for 1 hour. Then add 15% lanthanum chloride aqueous solution containing 245.5g lanthanum chloride, then adjust the pH value of the solution to 7-8 with sodium hydroxide solution, and stir at 60°C for 2 hours. After the reaction, filter, dry, and pulverize to obtain 297.3 g of bisethoxylanthanum phosphate, with a yield of 91.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com