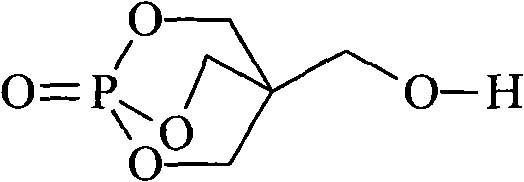

Caged bicyclic phosphate siloxane flame retardant and preparation method thereof

A technology of phosphate ester siloxane and phosphate ester, which is applied in the field of flame retardants, can solve the problems of large amount of addition, poor heat resistance, and easy precipitation, etc., and achieve the effect of mild reaction conditions, high thermal stability, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation of tris(2,6,7-trioxa-1-oxyphosphabicyclo[2.2.2]octane-4-methyleneoxy)silane (TRPSi): under the protection of nitrogen, the Add 180.0g (1.0mol) of PEPA, 79.1g (1.0mol) of pyridine and 200mL of acetonitrile into the reaction kettle with stirring, reflux condensing device, heating device and drying protection device, and raise the temperature to 30°C. After the PEPA is dissolved, use a constant pressure funnel to 44.4 g (0.33 mol) of trichlorosilane was added dropwise within 1 h. After the addition was completed, the reaction was carried out at 30° C. for 2 h, and then the temperature was raised to 82° C. for 5 h under reflux. Stop the reaction and cool to room temperature, filter, wash the filter residue with chloroform and water until there is no chloride ion, and obtain 156.9 g of the product after vacuum drying, with a yield of 84.0%.

[0036] product 1 HNMR (DMSO-d6), δ: 4.55~4.71 (18H, d, endomethylene), 3.76~3.89 (6H, d, exomethylene), 3.13~3.17 (1H...

Embodiment 2

[0038] Preparation of three (2,6,7-trioxa-1-oxyphosphabicyclo[2.2.2]octane-4-methyleneoxy)silane (TRPSi): under the protection of nitrogen gas, the Add 180.0g (1.0mol) of PEPA, 49.3g (0.30mol) of triethoxysilane, 500mL of dimethyl sulfoxide into the reaction kettle of mechanical stirring, distillation device, heating device and drying protection device, raise the temperature to 100°C, and The ethanol produced by the reaction was continuously collected. After 10 hours of reaction, the reaction was stopped and cooled to room temperature, and 200 mL of 1,4-dioxane was added and stirred to precipitate the product. The filter residue was washed with acetonitrile and water until there was no chloride ion, and 102.9 g of the product was obtained after vacuum drying with a yield of 60.6%.

[0039] product 1 H NMR (DMSO-d6), δ: 4.53~4.75 (18H, d, endomethylene), 3.75~3.93 (6H, d, exomethylene), 3.10~3.21 (1H, t, silicon atom ).

Embodiment 3

[0041] Preparation of methyltris (2,6,7-trioxa-1-oxyphosphabicyclo[2.2.2]octane-4-methyleneoxy)silane (MTPSi): under nitrogen protection, Add 180.0g (1.0mol) of PEPA, 79.1g (1.0mol) of pyridine, 1g of magnesium chloride and 500mL of chloroform into the reaction kettle with mechanical stirring, reflux condensing device, heating device and drying protection device. , Add 44.8g (0.3mol) methyltrichlorosilane dropwise within 1h with a constant pressure funnel, after the addition is complete, keep the reaction at 60°C for 1h, then raise the temperature to 62°C for reflux reaction for 8h. Stop the reaction and cool to room temperature, filter, wash the filter residue with chloroform and water until there is no chloride ion, and obtain 135.4 g of the product after vacuum drying, with a yield of 77.8%.

[0042] product 1H NMR (DMSO-d6), δ: 4.52~4.67 (18H, d, endomethylene), 3.79~3.94 (6H, d, exomethylene), 1.29~1.34 (3H, m, methyl ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com