Oxa-phosphaphenanthrene flame retardant containing cyclotriphosphonitrile structure, and preparation method and application thereof

A technology of oxaphosphaphenanthrene and cyclotriphosphazene, which is applied in the field of phosphorus-nitrogen synergistic flame-retardant compounds, can solve the problems of high cost and inability to meet the processing temperature of polymer materials, and achieve high flame-retardant rate, easy industrial production, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

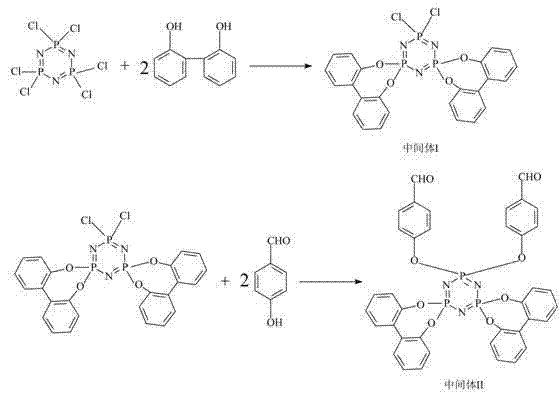

[0027] Compound A preparation method of oxaphosphaphenanthrene flame retardant containing cyclotriphosphazene structure, the steps are: dissolving 18.6 g (0.10 mmol) of 2,2'-biphenol in 300 mL of anhydrous acetone, N 2 Slowly added dropwise under protection to 17.4 g (0.05 mmol) and 27.6 g (0.20 mmol) of anhydrous K containing hexachlorocyclotriphosphazene 2 CO 3 100 mL acetone solution; reflux reaction for 2-3 h, after the completion of the reaction, filter, evaporate the solvent to obtain the crude product, the crude product was recrystallized with an equal volume of dichloromethane-petroleum ether mixed solvent to obtain intermediate I (white solid). The rate is 91.3%.

[0028] Weigh 11.1 g (0.08 mmol) of potassium carbonate and 9.76 g (0.08 mmol) of p-hydroxybenzaldehyde into a three-necked flask, add 150 mL of freshly distilled acetone and stir to dissolve, then slowly add 22.96 g (0.04 mmol) of intermediate I into the flask , reflux reaction for 10-12h, after the react...

Embodiment 2

[0031] Increase the 2,2'-diphenol to 19.53g (0.105mmol), and the other is the same as Example 1, and the yield of intermediate I is 92.1%.

Embodiment 3

[0033] Increase the 2,2'-diphenol to 19.46g (0.11mmol), and the other is the same as Example 1, and the yield of intermediate I is 92.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com