Patents

Literature

99results about How to "Increase carbon residue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

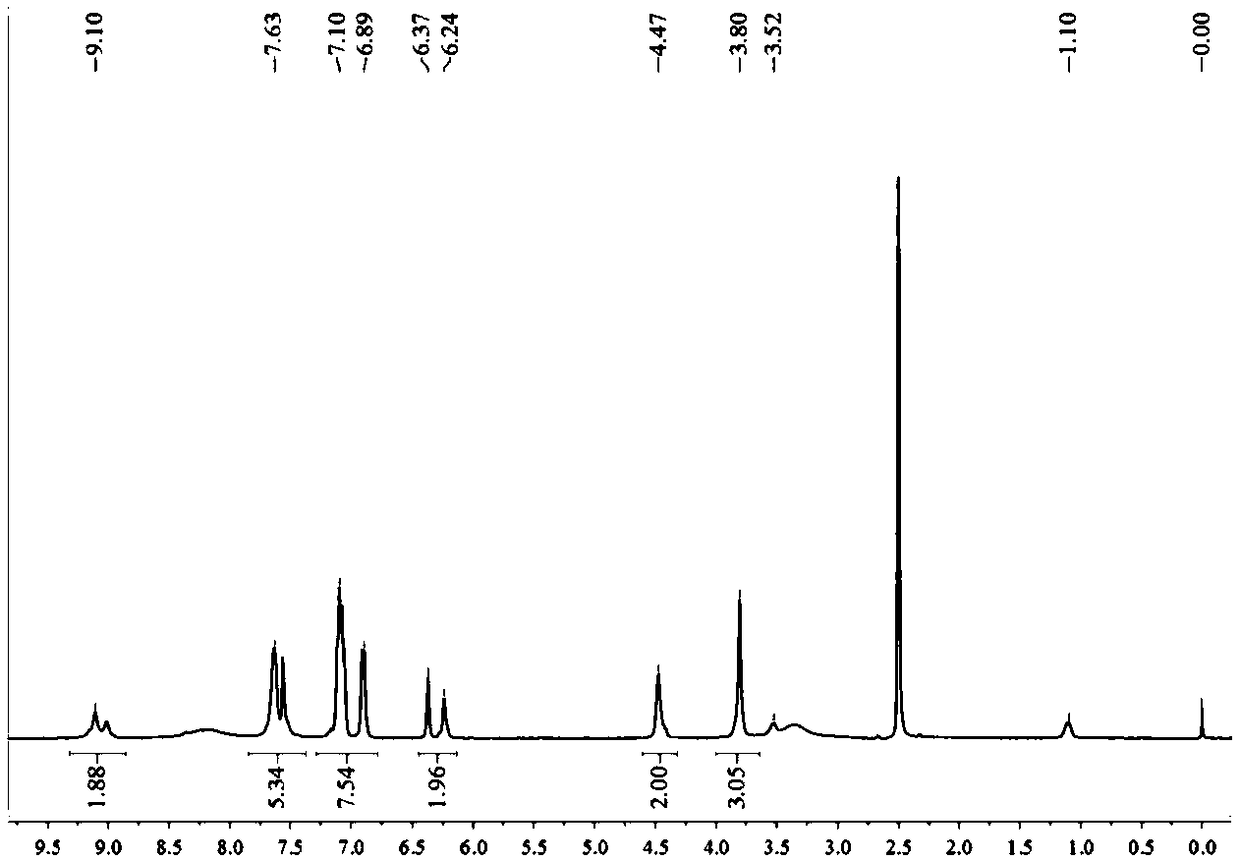

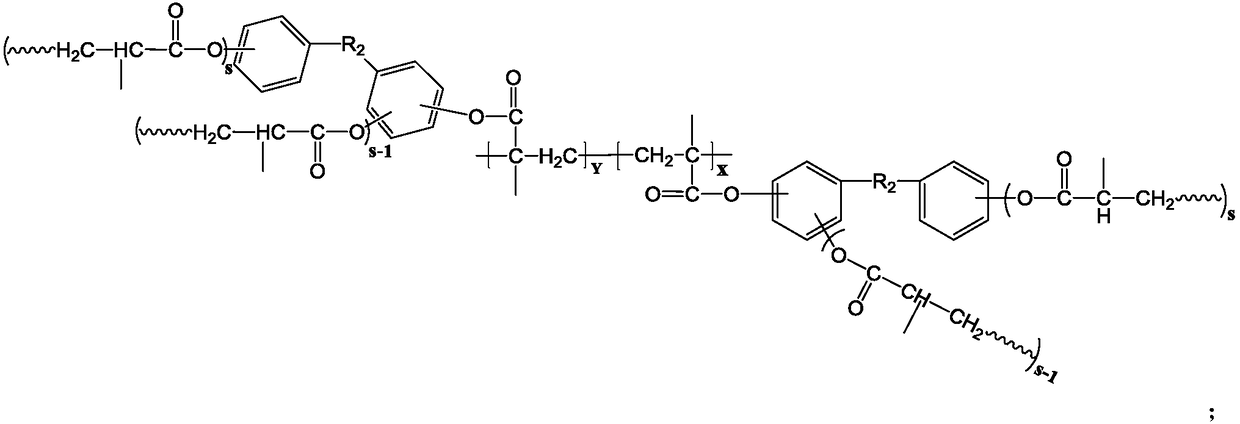

Phosphorus-containing Schiff base structured flame retardant and preparation method thereof

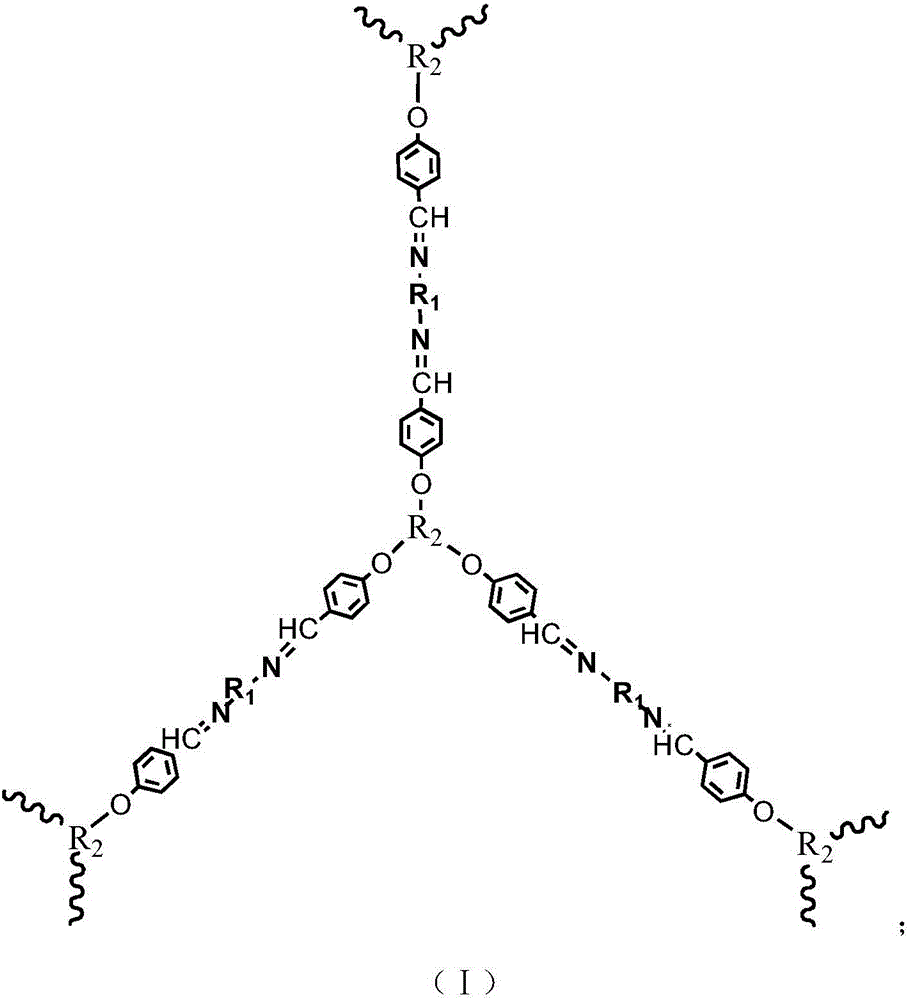

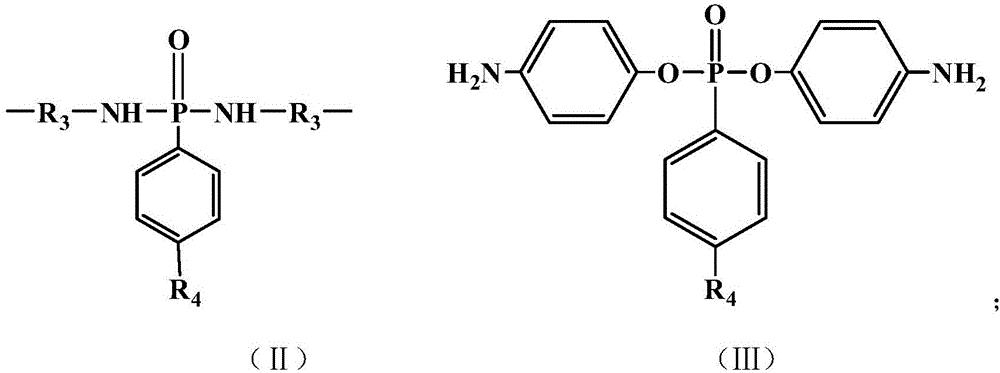

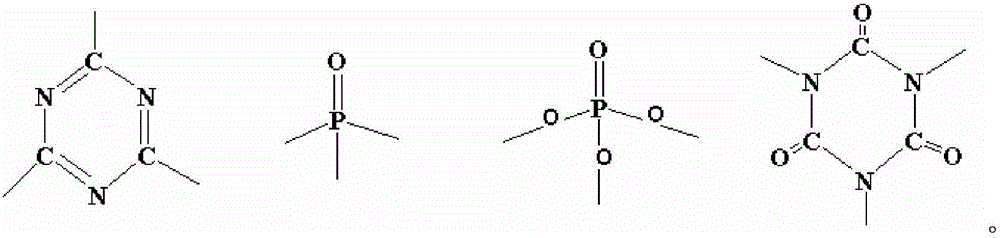

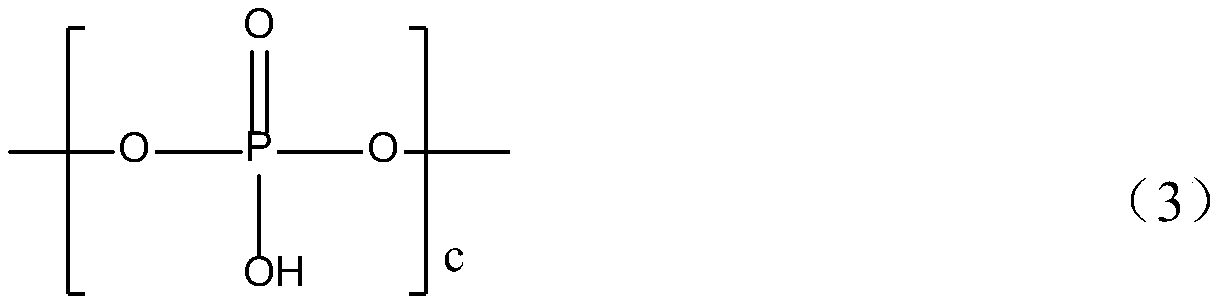

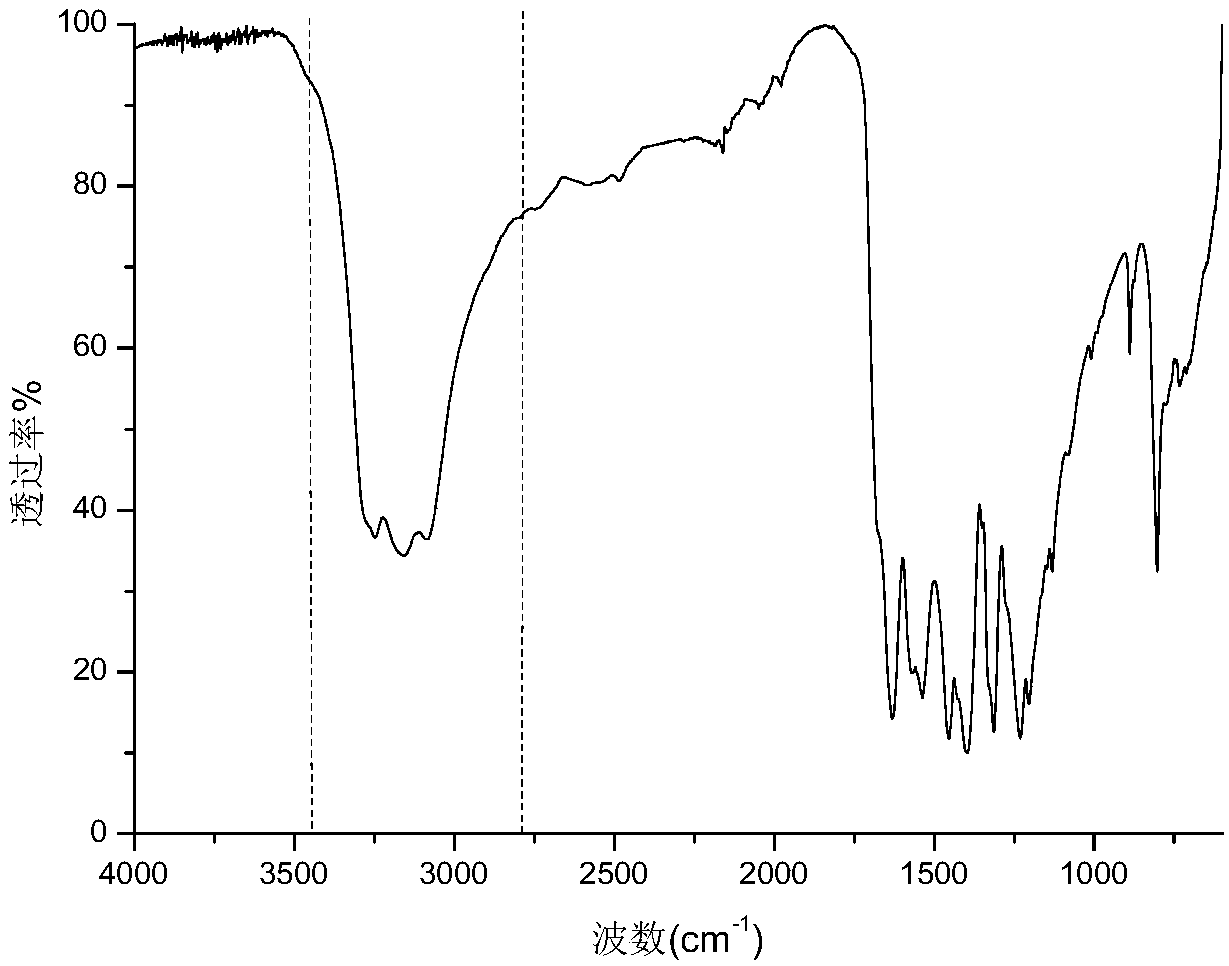

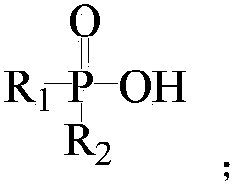

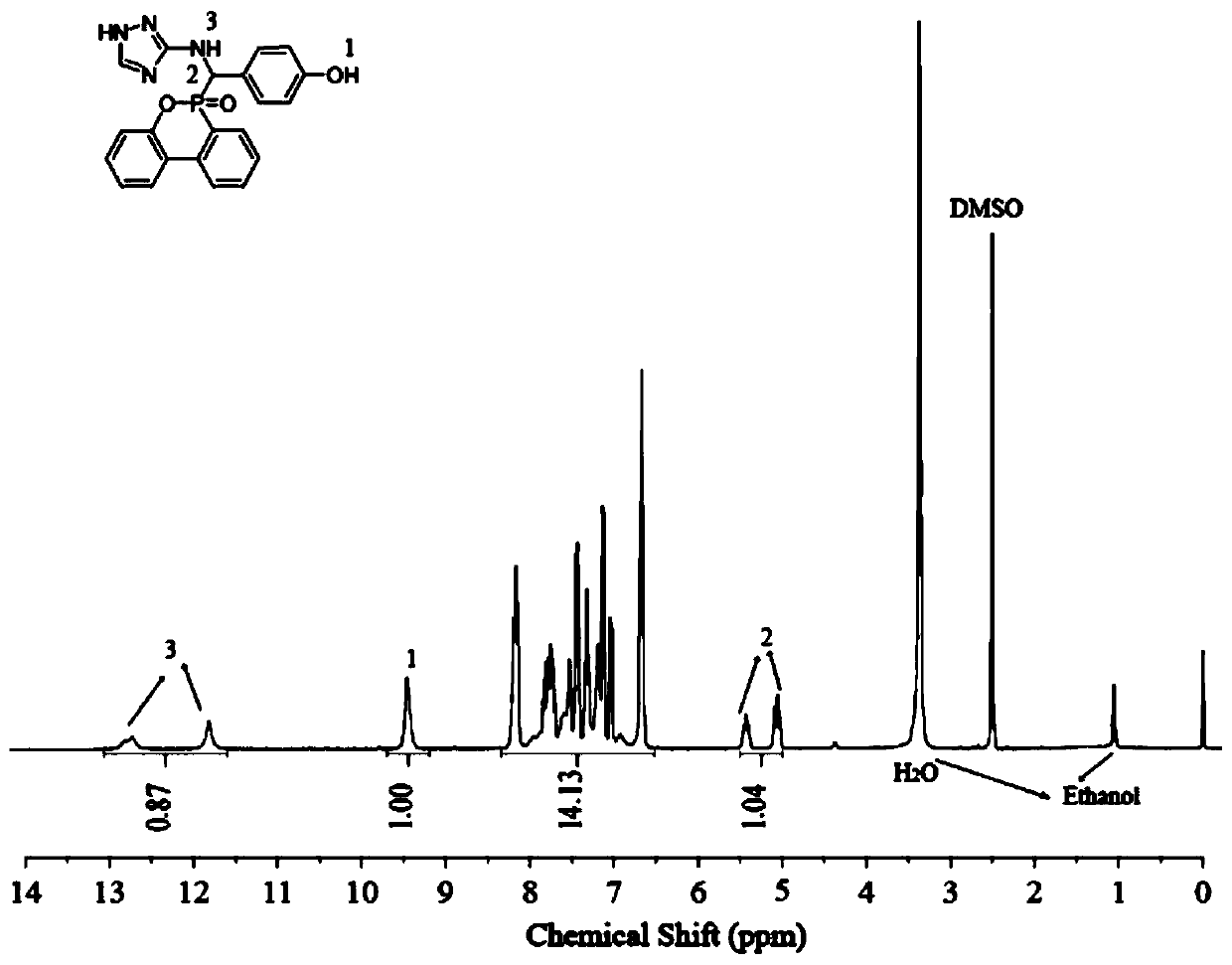

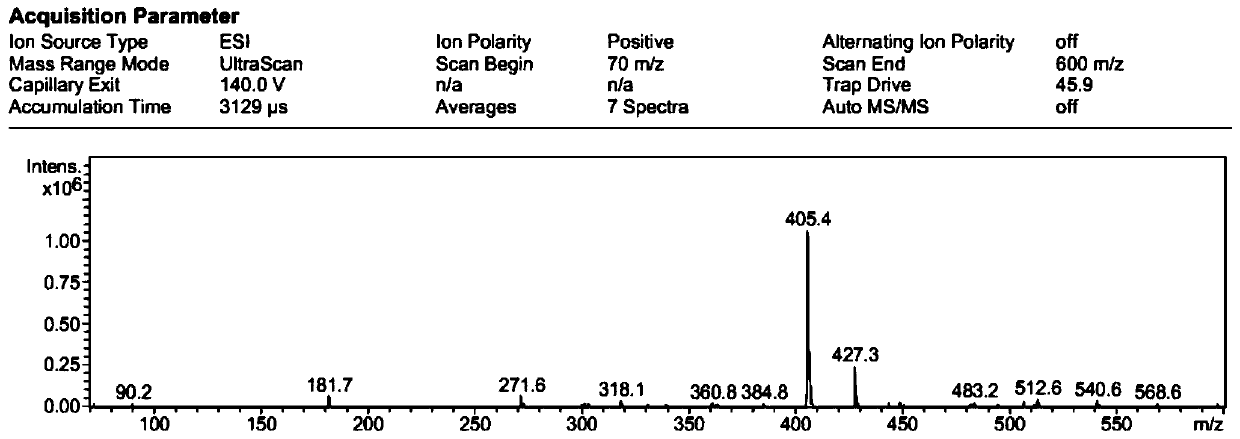

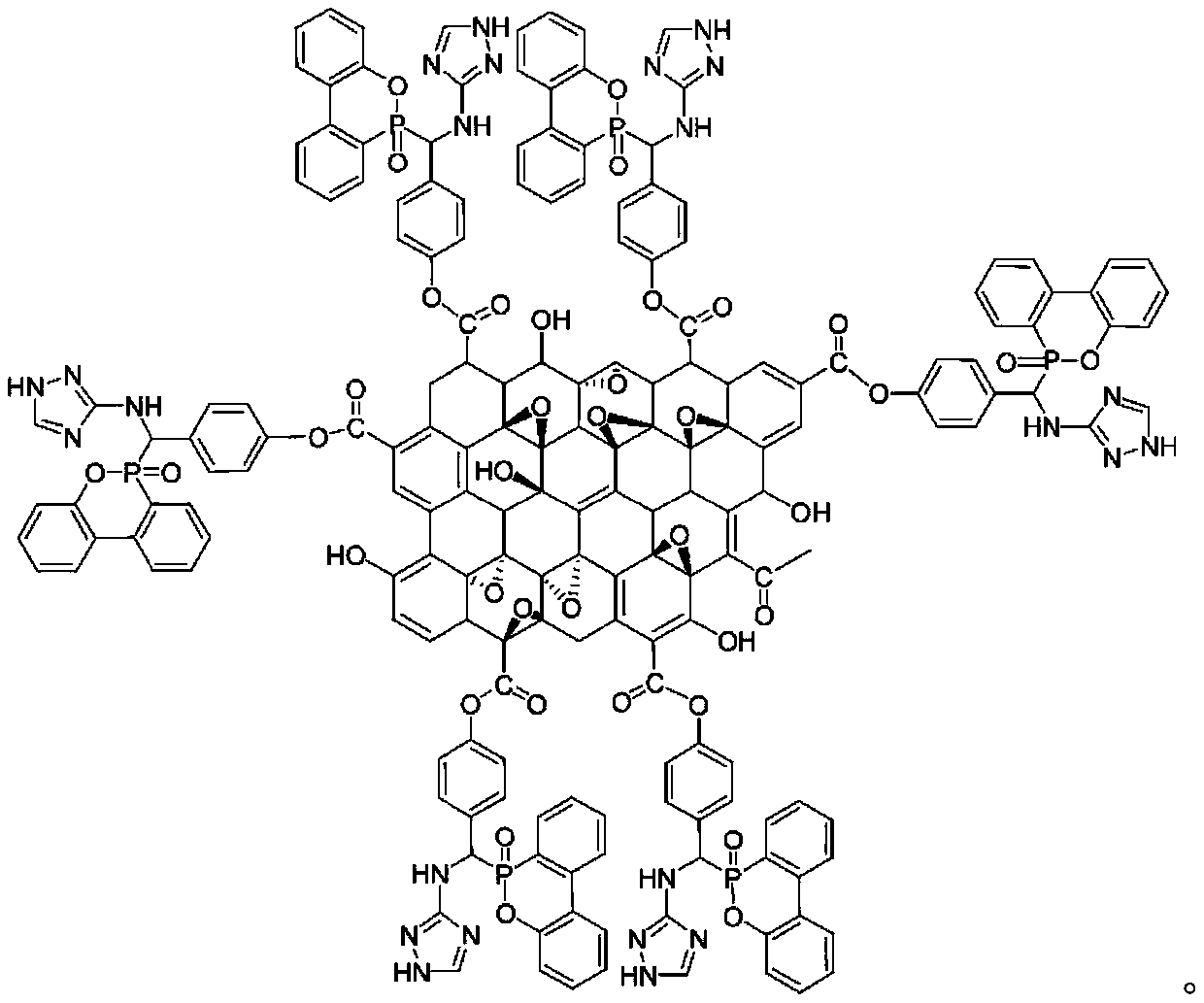

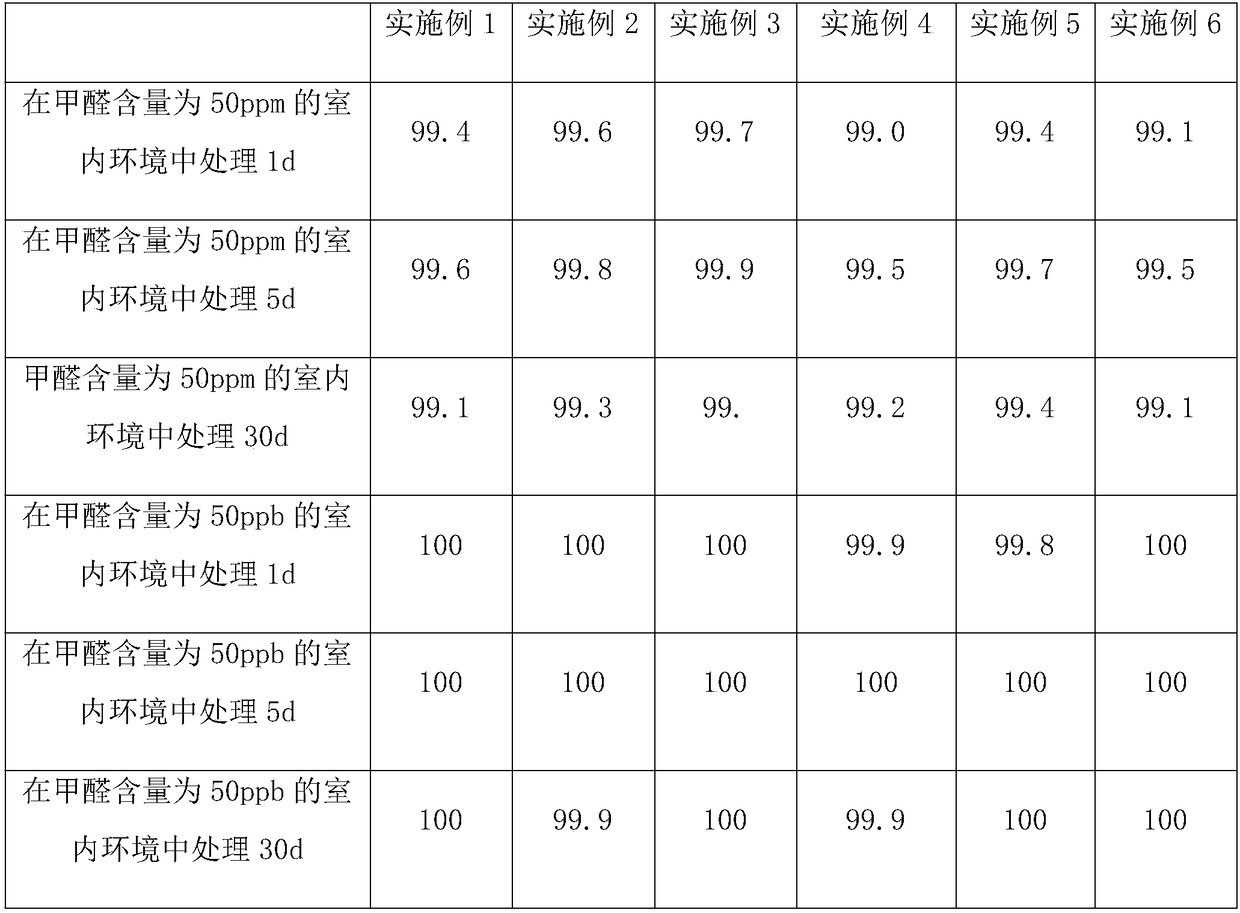

The invention discloses a phosphorus-containing Schiff base structured flame retardant and a preparation method thereof. The phosphorus-containing Schiff base structured flame retardant consists of hyperbranched macromolecules; a hyperbranched repeat unit is shown in the formula (I) as shown in the specification; in the formula, R1 is a phosphorus-containing structure, and R2 is a trifunctional structure; the molecular weight of the flame retardant is 500-100000. The flame retardant disclosed by the invention consists of hyperbranched macromolecules and is relatively large in molecular weight; when the flame retardant is used in polyurethane foams, the carbon residue amount of polyurethane can be greatly increased; the flame retardant disclosed by the invention is free of halogen and is a green and environment-friendly flame retardant; the flame retardant contains substances of a Schiff base structure, and due to existence of a C=N structure, very important chemical and biological significances can be achieved due to lone pair electrons on N atoms.

Owner:UNIV OF SCI & TECH OF CHINA

Ammonium polyphosphate flame retardant and preparing method thereof

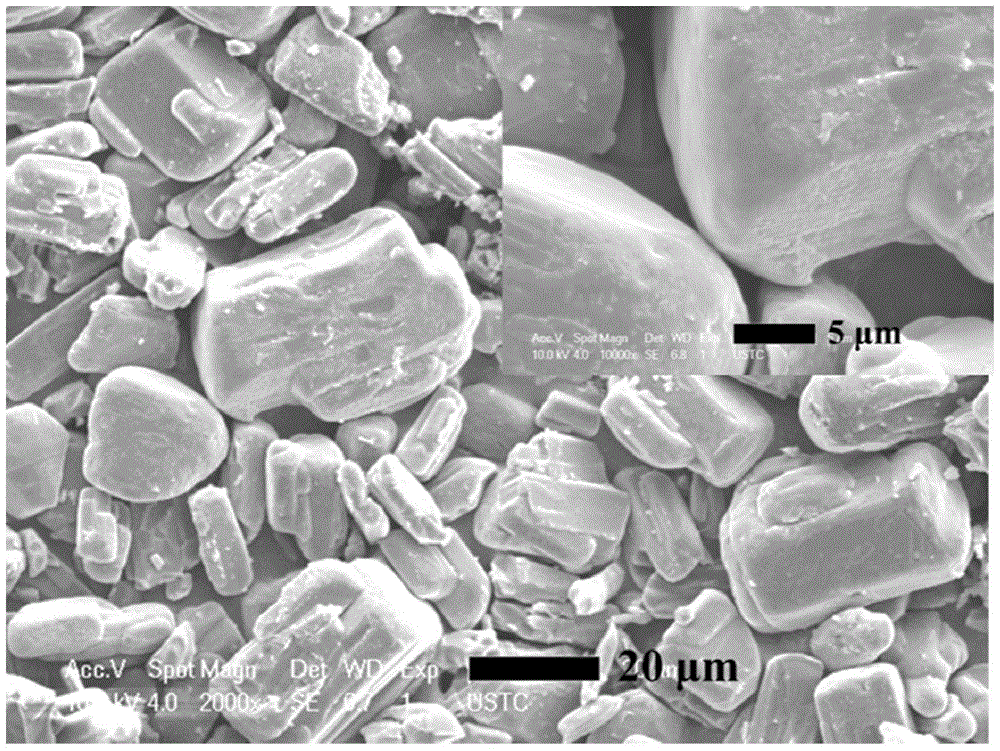

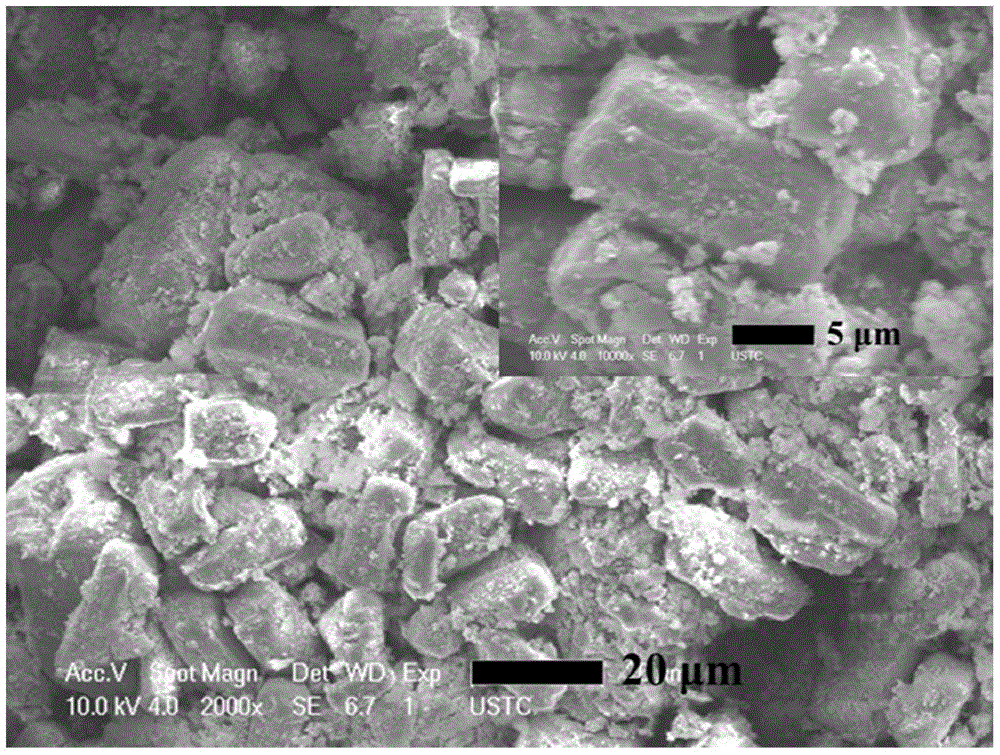

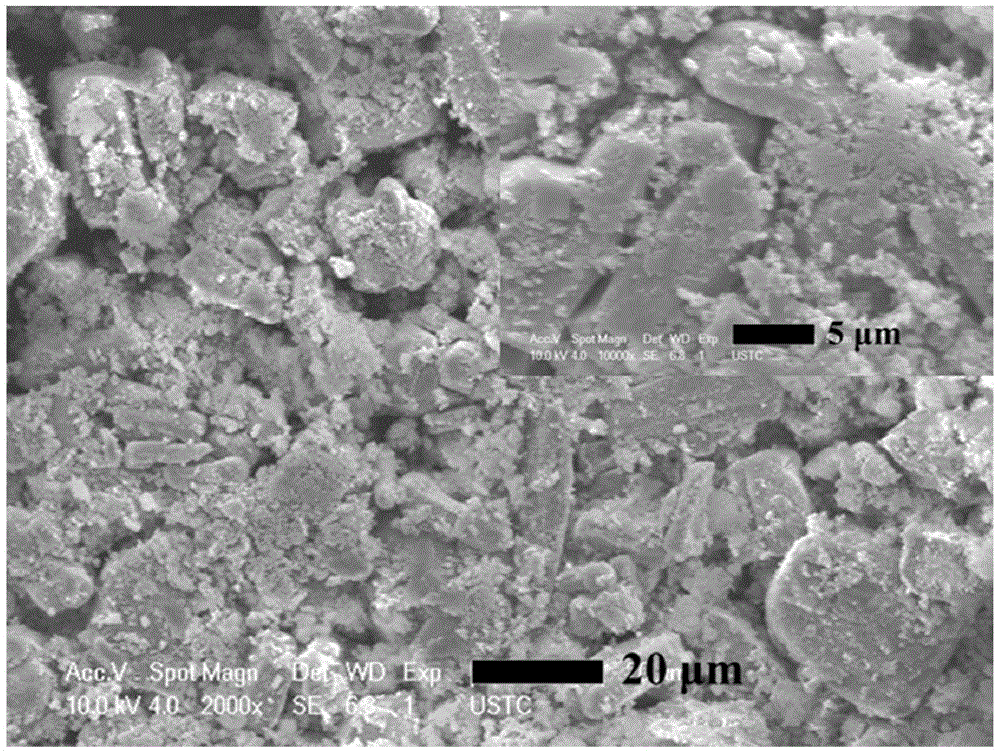

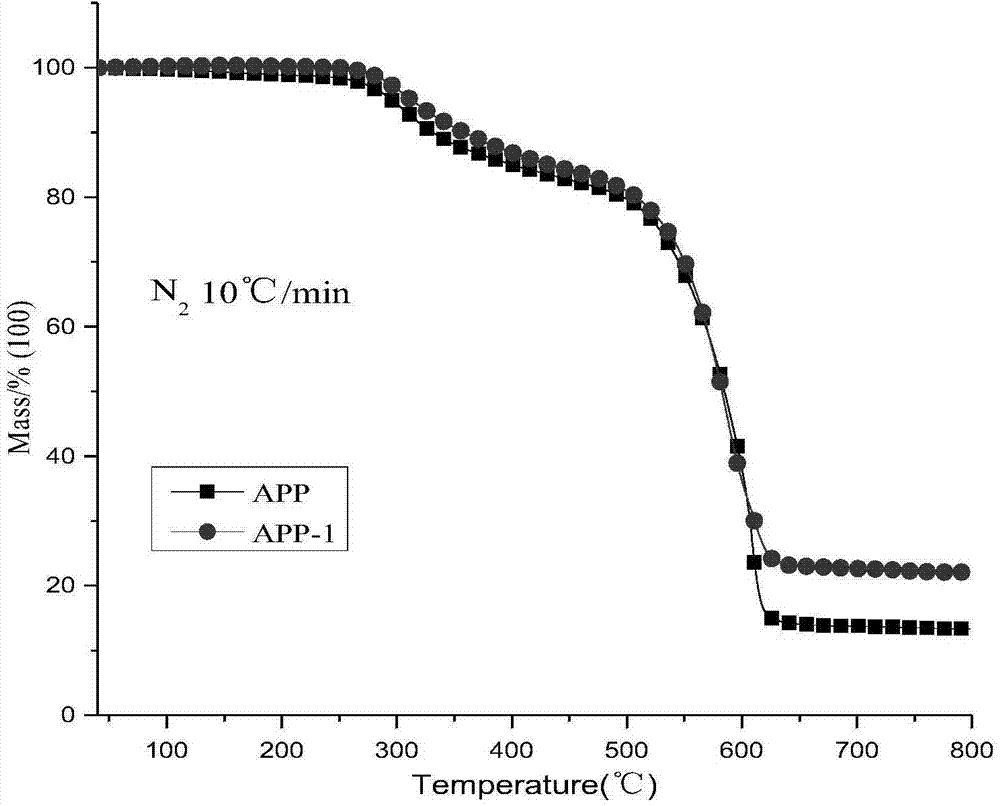

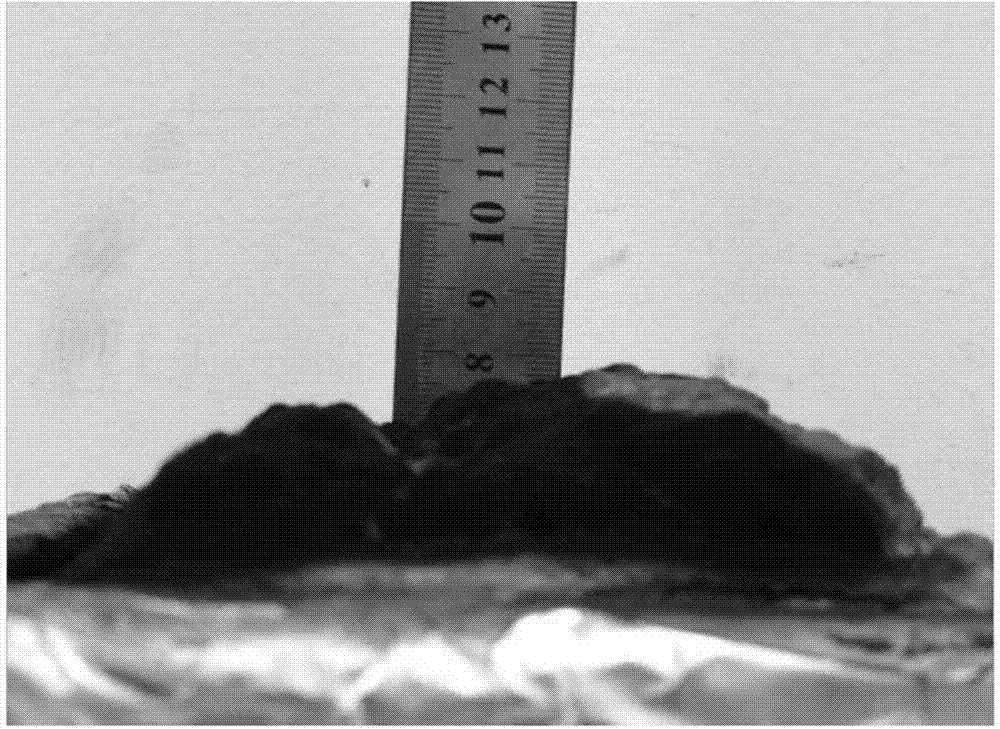

The invention provides an ammonium polyphosphate flame retardant. The ammonium polyphosphate flame retardant is characterized by comprising the ammonium polyphosphate flame retardant comprises carbon nitride and ammonium polyphosphate, and the mass percent of the carbon nitride and the ammonium polyphosphate is 0.05-0.45 to 1. The average grain size of the prepared compound halogen-free flame retardant is not obviously increased compared with that of ammonium polyphosphate, the carbon nitride on the surface layer is evenly scattered, the content of residual char is remarkably increased, and good heat stability is achieved; meanwhile, the ammonium polyphosphate flame retardant can be used as synergistic flame-retardant of polyolefin, polystyrene and other high polymer materials and has good compatibility, and flame retardant efficiency is improved obviously.

Owner:UNIV OF SCI & TECH OF CHINA

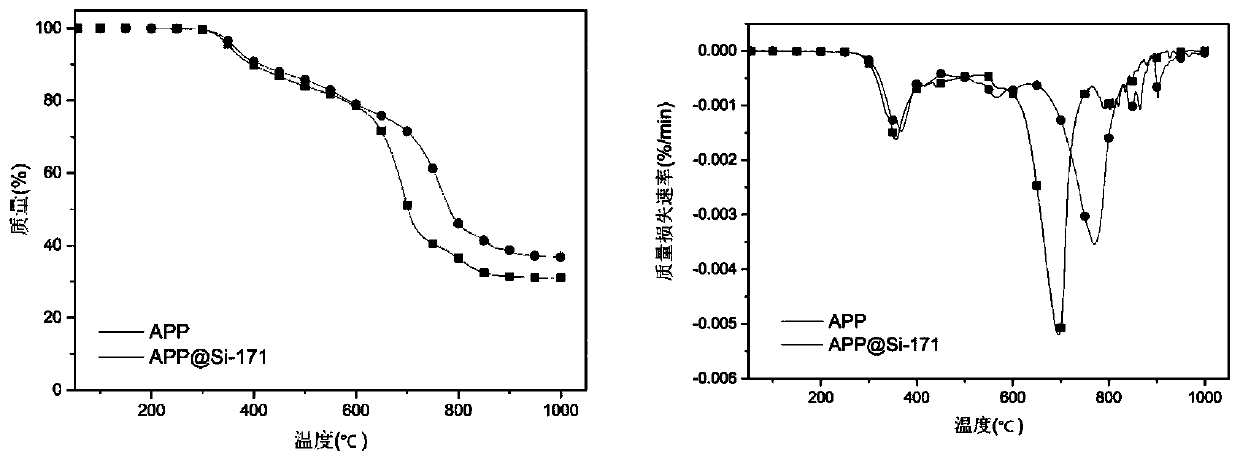

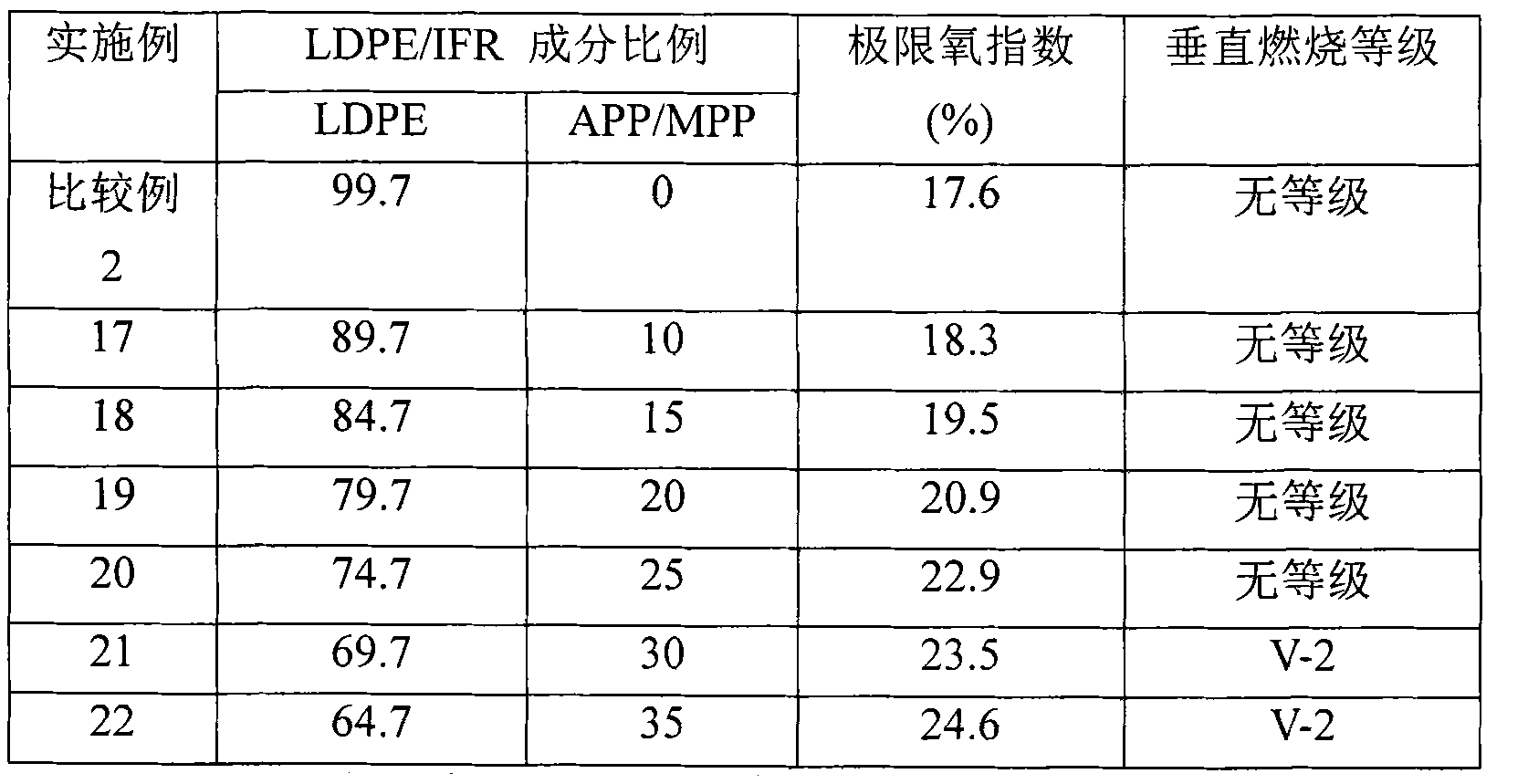

Synergistically modified APP (ammonium polyphosphate), preparation method for same and application to flame-retardant polypropylene

The invention belongs to the technical field of flame retardance, and relates to a synergistic modification technology for an inorganic phosphorus-containing flame retardant APP (ammonium polyphosphate), in particular to synergistically modified APP, a preparation method for the same and application to flame-retardant polypropylene. In a solution system, an aluminum-containing compound with different chemical properties is selected as a precursor of a surface layer modification material, reaction is performed on the surface of an APP particle to generate a layer of ultrafine water-insoluble substances in situ to improve the performance of the APP such as hygroscopicity, water resistance, flame retardance and compatibility with a polymer, a micron-nanometer composite particle employing the APP as a matrix and employing aluminum hydroxide as a surface layer is finally prepared, and in addition, the effects of ultrafine treatment, surface modification, flame-retardant synergism and the like of the APP are achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Flame-retardant elastic nanocellulose aerogel and preparation method thereof

ActiveCN106750550AImprove flame retardant performanceIncrease elasticitySimple Organic CompoundsCarboxylic acid

The invention discloses a flame-retardant elastic nanocellulose aerogel which is prepared from reactive organic compound and polybasic carboxylic acid-containing flame-retardant system by using biomass raw materials of the cellulose. The invention further discloses a preparation method of the aerogel. Compared with the traditional nanocellulose aerogel, the prepared aerogel has good flame-retardant performance, as well as excellent resilience performance, and the application potential and usage safety of the material in the fields of heat insulating field and the like can be greatly improved.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Ferrocene-DOPO biradical polyester type flame retarding and smoke suppressing agent, preparation method of ferrocene-DOPO biradical polyester type flame retarding and smoke suppressing agent, and application of ferrocene-DOPO biradical polyester type flame retarding and smoke suppressing agent to flame retarding polymer

The invention discloses a ferrocene-DOPO biradical polyester type flame retarding and smoke suppressing agent and a preparation method of the ferrocene-DOPO biradical polyester type flame retarding and smoke suppressing agent. The preparation method of the polymer is as follows: putting 10-(2,5-dyhydroxyl phenyl)-9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide into a reactor, adding a solvent,stirring for 5-10 minutes, adding an acid-binding agent; taking R1,R2'-ferrocene oxalyl chloride, adding the solvent, mixing, adding into the reactor dropwise, thermally insulating, stirring and reacting for 1-15 hours at the temperature of 0-50 DEG C under the protection of nitrogen after finishing adding dropwise; pouring a liquid obtained after the reaction into a precipitator while stirring, wherein the volume of the precipitator is 5-10 times that of the liquid, precipitating a yellow solid, carrying out suction filtration, washing a filter cake by using the precipitator, and drying to obtain the ferrocene-DOPO biradical polyester type flame retarding and smoke suppressing agent. The ferrocene-DOPO biradical polyester type flame retarding and smoke suppressing agent can be used to retard flame and suppress smoke of high polymer materials like polyolefins and epoxy resins.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Preparation method of phenolic resin for refractory material

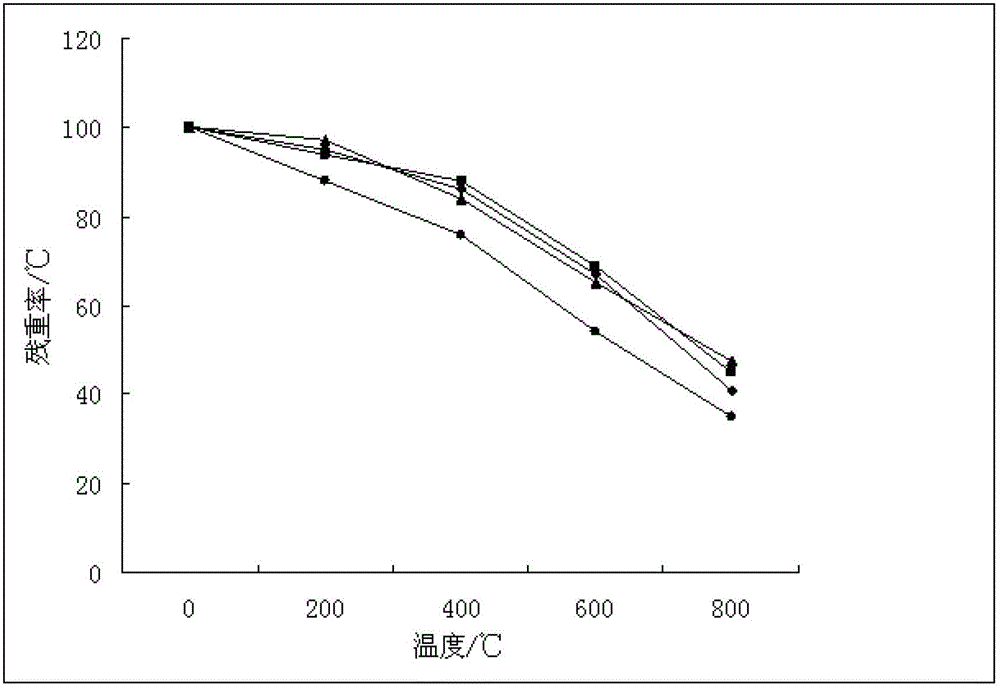

The invention provides a preparation method of phenolic resin for a refractory material. The method is as below: phenolic compounds, aldehyde compounds and o-phenylphenol are subjected to a polycondensation reaction under the action of an alkaline catalyst to obtain the phenolic resin. Through the polycondensation reaction of phenolic compounds, aldehyde compounds and o-phenylphenol, the o-phenylphenol is introduced into the phenolic resin; as aromatic ring is introduced into the phenolic resin, the phenolic resin gains increased carbon content; besides, the aromatic ring has high bond energy and stable structure, and is not easily broken for ablation under high temperature, so that the phenolic resin gains increased residual carbon content and high stability. The experiment results show that the phenolic resin prepared by the invention has residual carbon content of 48wt%-52.5wt%.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Flame-retardant high-impact polystyrene composite material and preparation method thereof

The invention provides a flame-retardant high-impact polystyrene composite material and a preparation method thereof. The flame-retardant high-impact polystyrene composite material comprises the following components in parts by mass: 85 parts of high-impact polystyrene, 3-15 parts of a modified phosphorus-based flame retardant, and 3-15 parts of a nano flame retardant. Wherein the modified phosphorus-based flame retardant is a silane coupling agent modified phosphorus-based flame retardant, and the mass ratio of the silane coupling agent to the phosphorus-based flame retardant is (2-7): 100. The phosphorus-containing flame retardant and the nano flame retardant have a synergistic effect in flame retardant effect, so that the flame retardant property of the composite flame retardant can beimproved, and the flame retardant property of the high-impact polystyrene composite material is enhanced. The preparation method is simple in process flow, wide in raw material source, non-toxic, harmless, green and environment-friendly, and has a good application prospect.

Owner:NANJING UNIV OF TECH

Halogen-free flame retardant polyester material and preparation method thereof

ActiveCN103173888AImprove adsorption capacityIncreasing the thicknessFlame-proof filament manufactureMonocomponent polyesters artificial filamentPolyesterPolymer science

The invention discloses a halogen-free flame retardant polyester material and a preparation method thereof. The halogen-free flame retardant polyester material is prepared from the following raw materials according to weight percent: 88%-94% of first polyesters and 6%-12% of flame retardant masterbatches, wherein the flame retardant masterbatches are prepared from the following raw materials according to weight percent: 50%-80% of polyethylene glycol modified polyesters and 20%-50% of a flame retardant. The halogen-free flame retardant polyester has a high flame retardant efficiency and is long in durability and good in hand feel or flexibility. The preparation method of the halogen-free flame retardant polyester material comprises the steps of mixing the polyethylene glycol modified polyesters with the flame retardant uniformly for extruding and granulating to obtain the flame retardant masterbatches, drying the flame retardant masterbatches, then blending the dried flame retardant masterbatches with the first polyesters for extruding and melt spinning, and winding the mixture to obtain the halogen-free flame retardant polyester material. The method is simple to operate and easy to control.

Owner:HANGZHOU CHANGXIANG CHEM FIBER

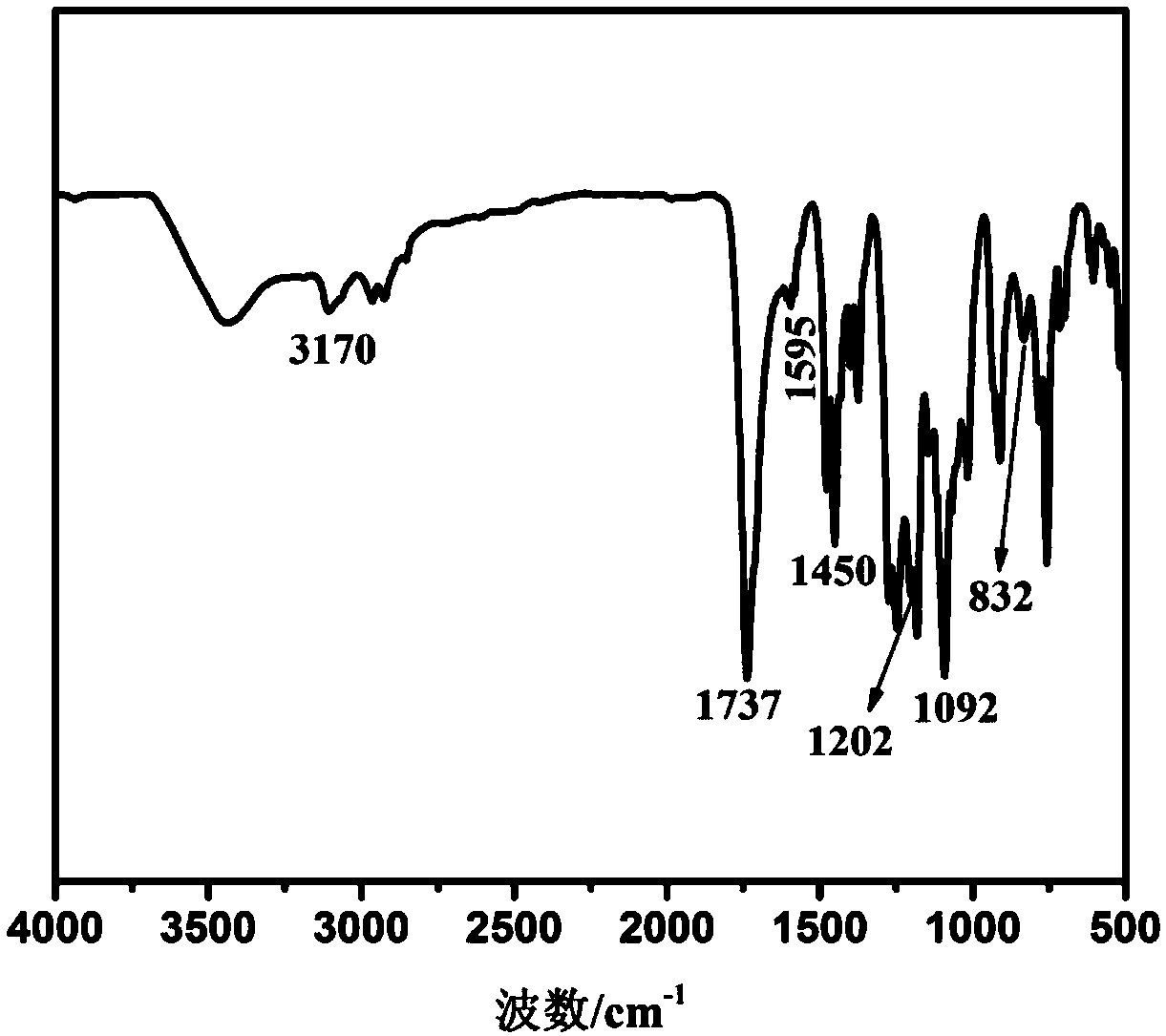

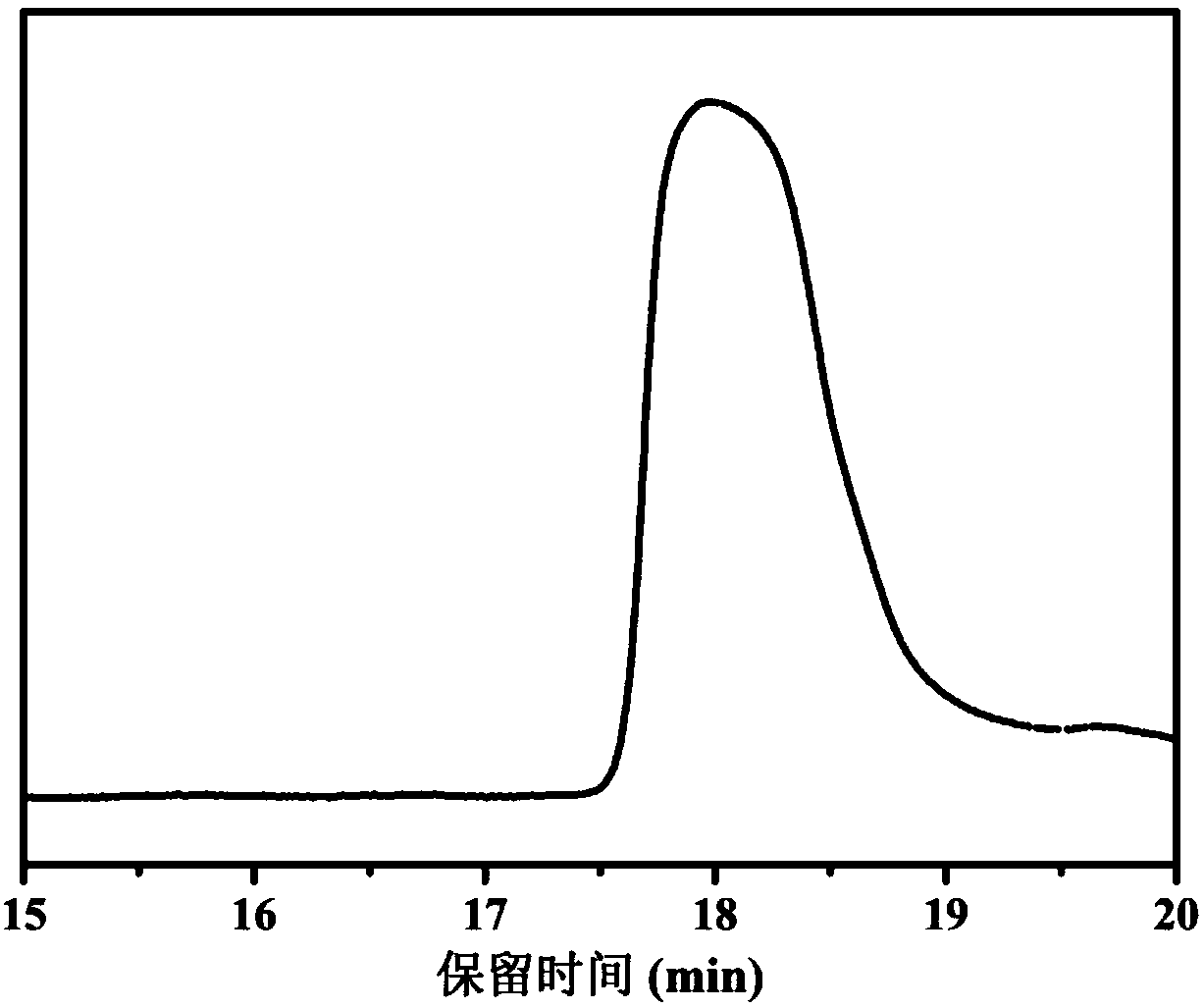

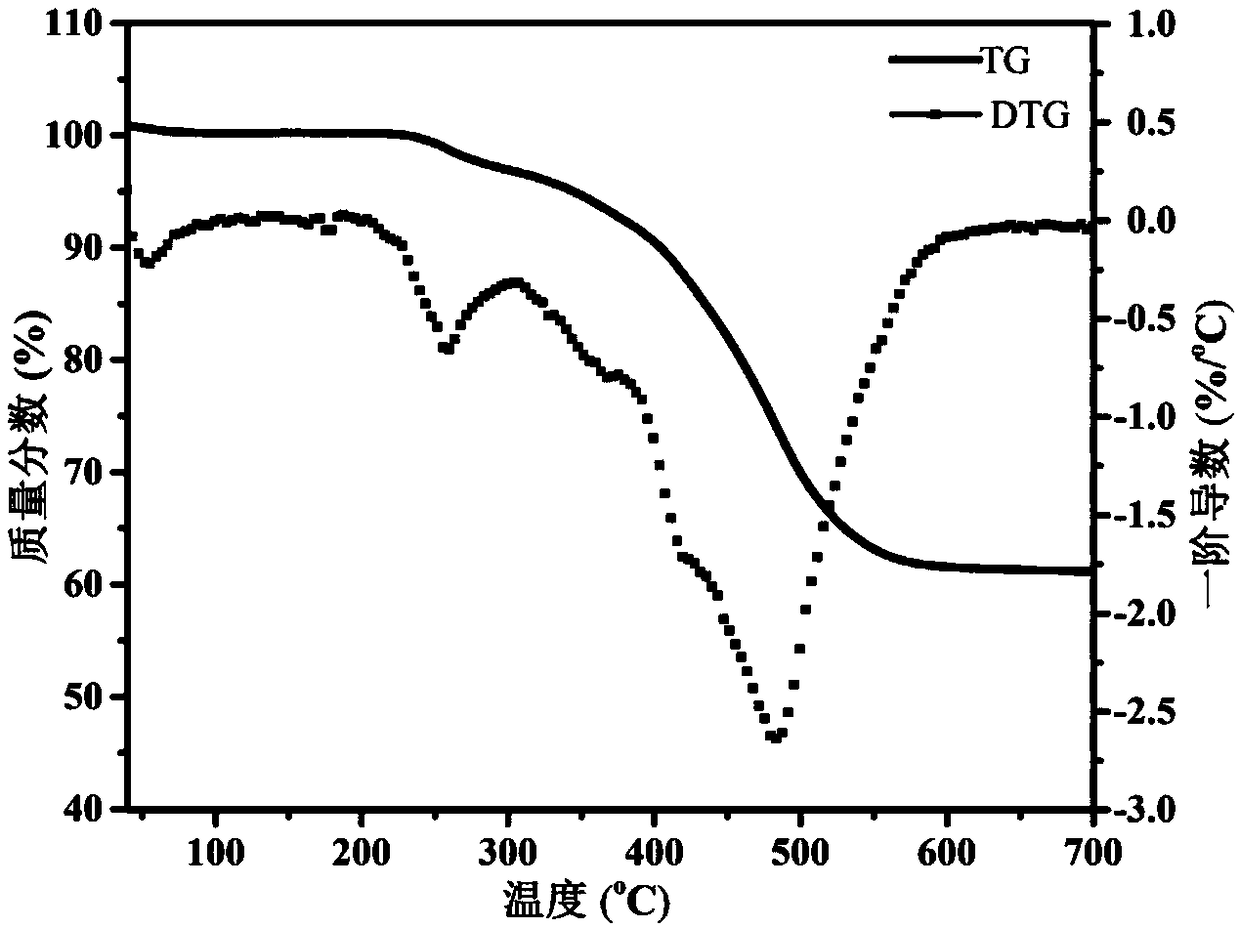

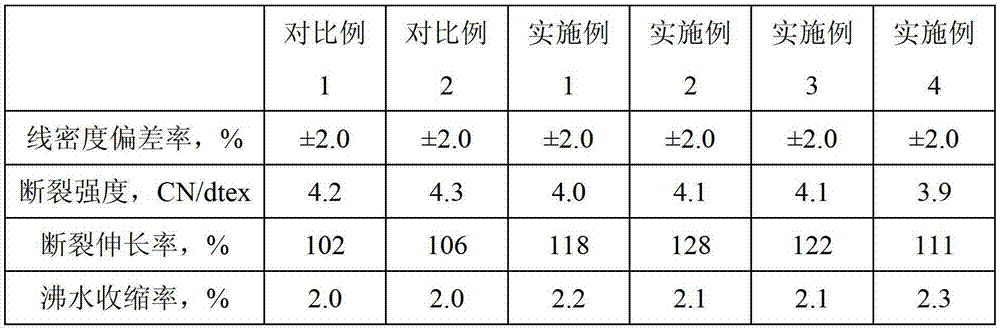

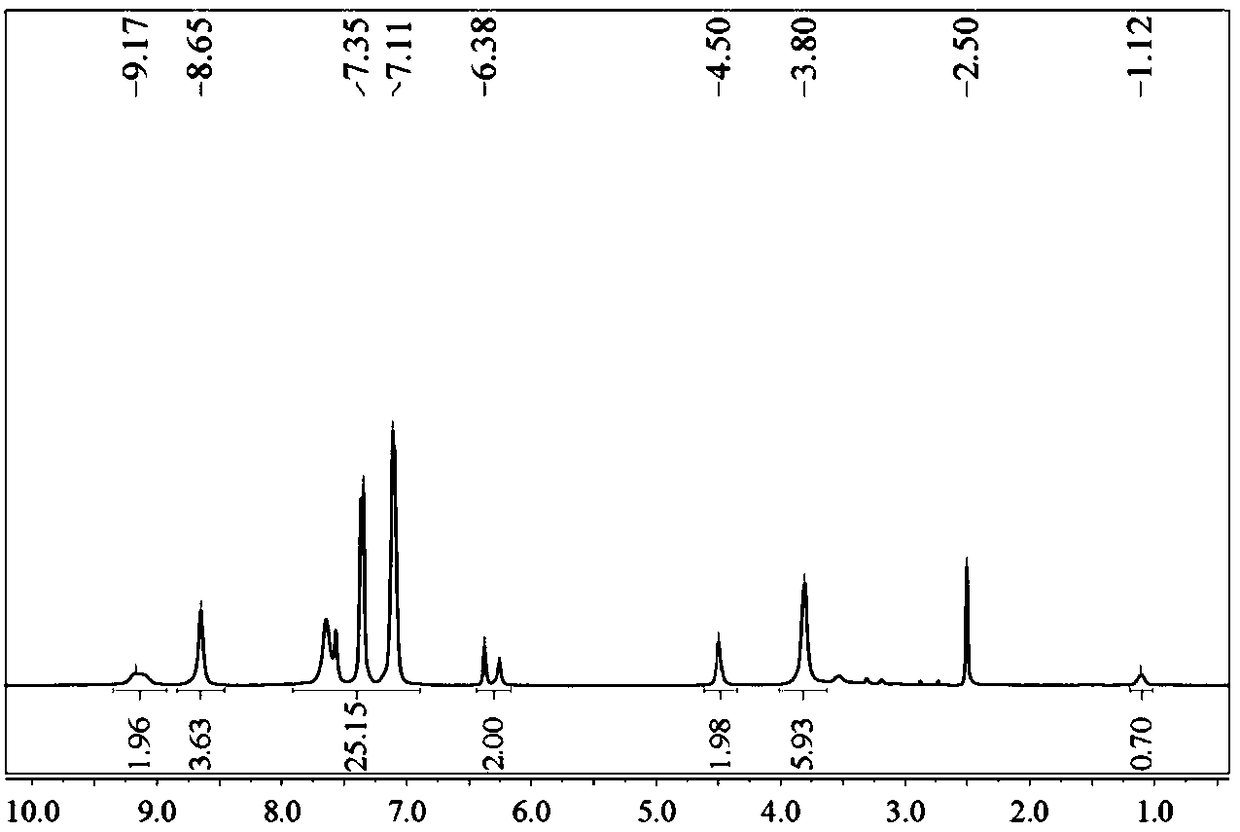

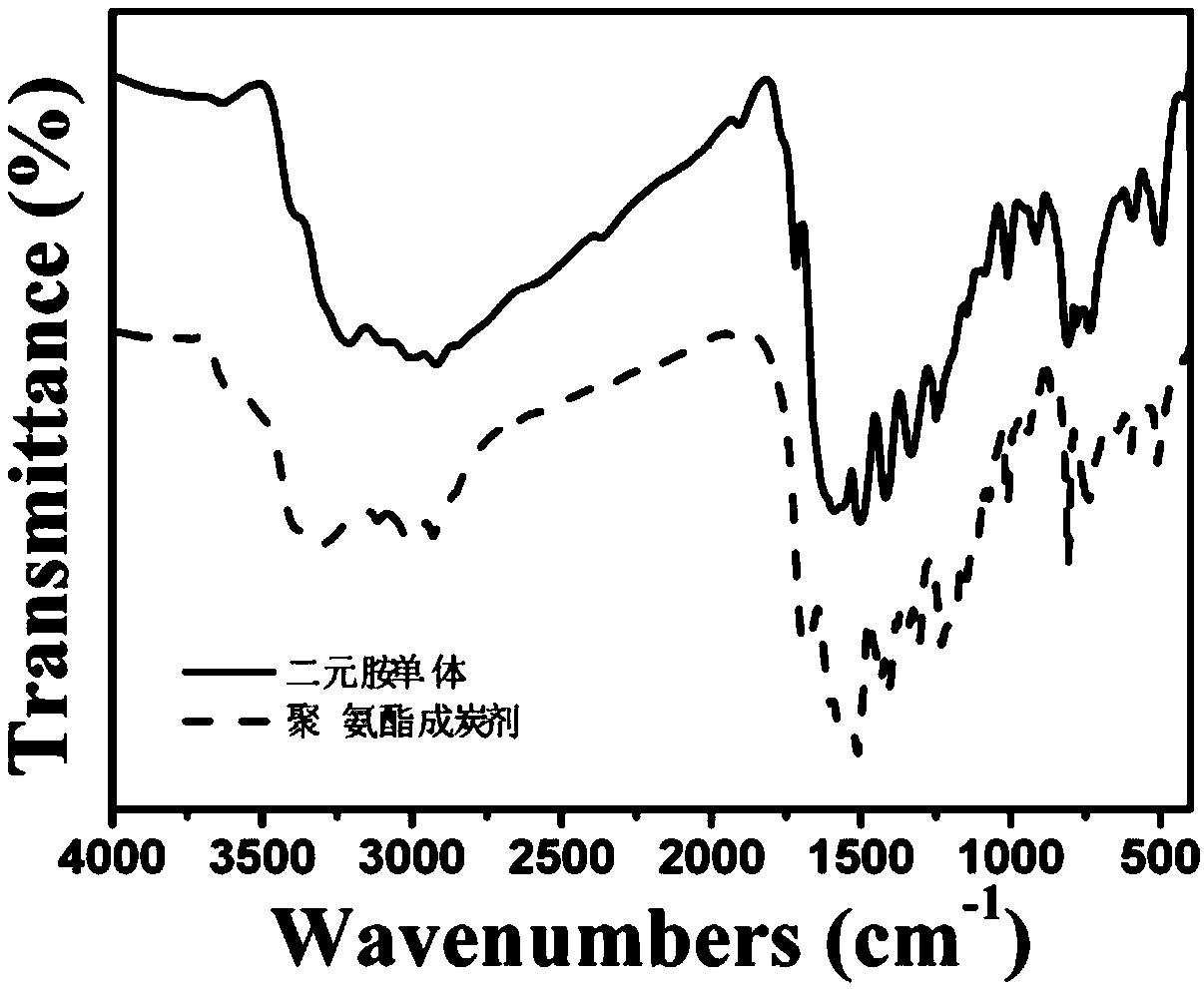

Triazine polyurethane carbon-forming agent containing furan ring side group and synthesis method thereof

ActiveCN109251293AHigh char formationPromote degradationBulk chemical productionFuranSynthesis methods

The invention discloses a triazine polyurethane carbon-forming agent containing a furan ring side group and a synthesis method thereof. According to the invention, a diamine or diol compound containing a furan ring side group and a triazine ring is firstly prepared; the diamine or diol compound and diisocyanate are subjected to prepolymerization under the action of a catalyst; and a chain extenderis added for polymerization to form the polyurethane material. The polyurethane material has excellent carbon forming performance. The method for preparing the polyurethane carbon-forming agent has the advantages of less side effect, high yield and simple operation, the introduced bio-based furan compound can help improve degradability of the polyurethane, and the introduction of the furan ring and the triazine ring can significantly improve the carbon forming performance of the polyurethane. Thereby, the polyurethane carbon-forming agent with good thermal stability, excellent carbon formingperformance and high residual carbon content is obtained, and the polyurethane carbon-forming agent has a good development prospect in the polymer intumescent flame retardant system.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

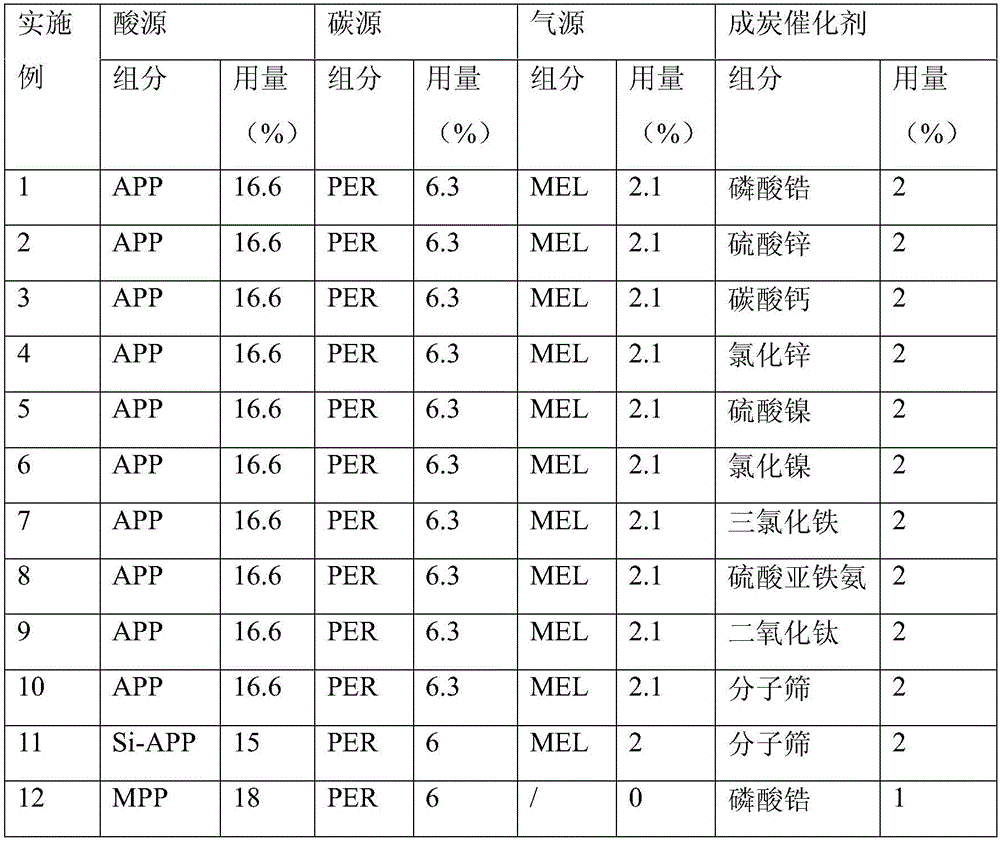

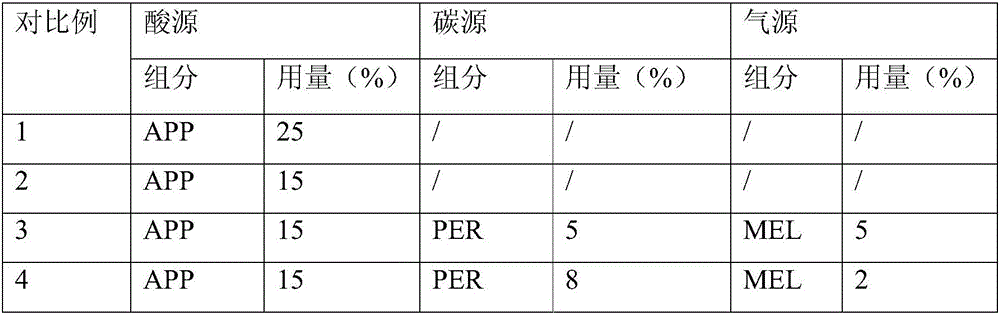

Catalysis carbonization intumescent flame-retardant system and application thereof

InactiveCN105839399AGood flame retardantIncrease carbon residueHeat resistant fibresHalogenCarbon source

The present invention relates to a catalytic carbonization expansion flame retardant system and its application. The system includes: an acid source, a carbon source, a gas source and a carbon forming catalyst; wherein, the mass percentage of the acid source in the flame retardant system is 15-30%; The mass ratio of acid source to gas source is 2-10:1; the mass ratio of acid source to carbon source is 2-10:1; the mass ratio of acid source to carbon-forming catalyst is 10-20:1. The catalytic carbonization expansion flame retardant system of the present invention is applied to the flame retardant post-finishing of polyester fabrics. The intumescent flame retardant system of the present invention does not contain halogen, and conforms to the development trend of less smoke and low toxicity of flame retardants, and is an environmentally friendly flame retardant system; the finished product has better flame retardant performance, and the finished polyester fabric has good flame retardant Anti-dripping.

Owner:DONGHUA UNIV

Modification method of halogen-free intumescent flame retardant and application of modified halogen-free intumescent flame retardant in flame-retardant polypropylene

ActiveCN102718987ALow water solubilityImprove thermal stabilityBulk chemical productionSolubilityPolymer science

The invention relates to a modification method of a halogen-free intumescent flame retardant, and application of the modified halogen-free intumescent flame retardant in flame-retardant polypropylene, which belong to the technical field of flame retardant materials. The modification method comprises the steps of: drying ammonium polyphosphate and a carbon source in a dryer, and compounding the ammonium polyphosphate and the carbon source with alkyl ester synergist and catalysts to obtain the IFR (intumescent flame retardant); dissolving modifying agent into dispersing agent, and adding water and acid in the modifying agent to obtain modifying agent solution; and adding the IFR in a flask, then adding the modifying agent solution in the flask, agitating and heating the mixture, performing decompression and suction filtration on the mixture, drying the mixture after removing the dispersing agent, and then crashing the mixture to obtain IFR powder with surface modified. The modification method has the advantages of mild preparation condition, easiness in control, high repeatability, high productivity and low cost; and the solubility in water of the prepared modified intumescent flame retardant is reduced, the thermal stability of the retardant is improved, and the quantity of carbon residues is increased. According to the invention, when the modified IFR is applied to the polypropylene flame-retardant system, the compatibility is imporoved, and the mechanical property, flame retardant property and the like of the flame-retardant polypropylene can be effectively improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Hybrid modified melamine salt, preparation method and application thereof

ActiveCN108424547AReduce thermal oxidationAvoid massive oxidationNitrogen and non-metal compoundsSolventChemistry

The invention relates to a hybrid modified melamine salt, a preparation method and application thereof. The preparation method includes: 1) dissolving a melamine salt in a solvent, adding amino-rich graphite carbon nitride nanosheets, and carrying out reaction at 30-150DEG C for 0.5-4h; and 2) at the end of the reaction, conducting filtering, drying and crushing to obtain the hybrid modified melamine salt. Specifically, the amino-rich graphite carbon nitride nanosheets have a nitrogen content of 66-68wt%, the chemical structure is rich in amino, the thickness is 0.5-50nm, and the nanosheets contain a graphite-like structure. The 5wt% thermal weight loss temperature of the product is 20-80DEG C higher than that of non-hybrid modified melamine salts. The product obtained by the invention isalso applied to the field of flame retardant materials, and the flame retardant performance and carbon residue amount are greatly improved. The production raw materials used by the invention are widely available, the synthesis process is simple, the equipment requirements are low, and the product has good thermal stability, good compatibility with a polymer matrix and good flame retardant effect,and has great application prospects.

Owner:DONGHUA UNIV

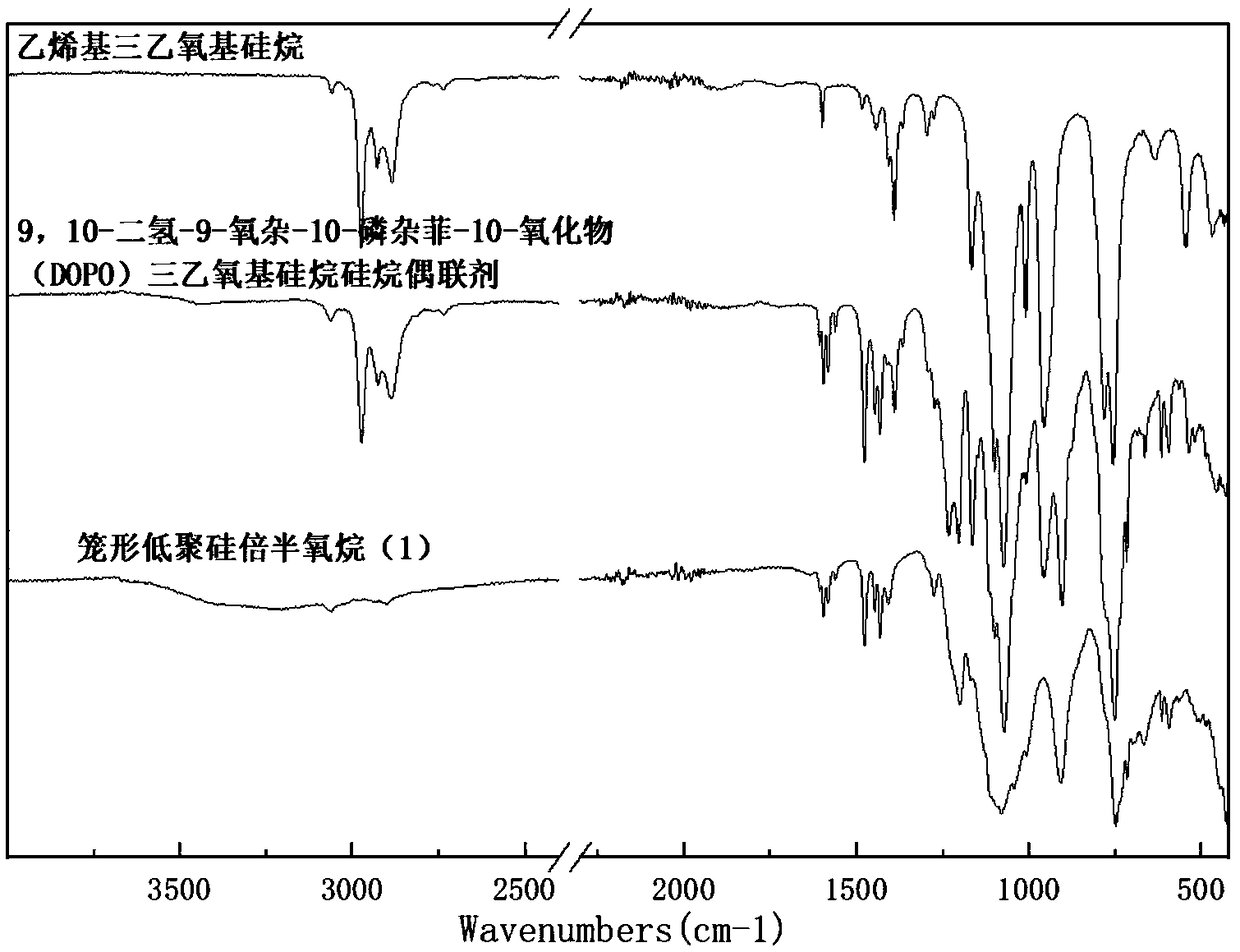

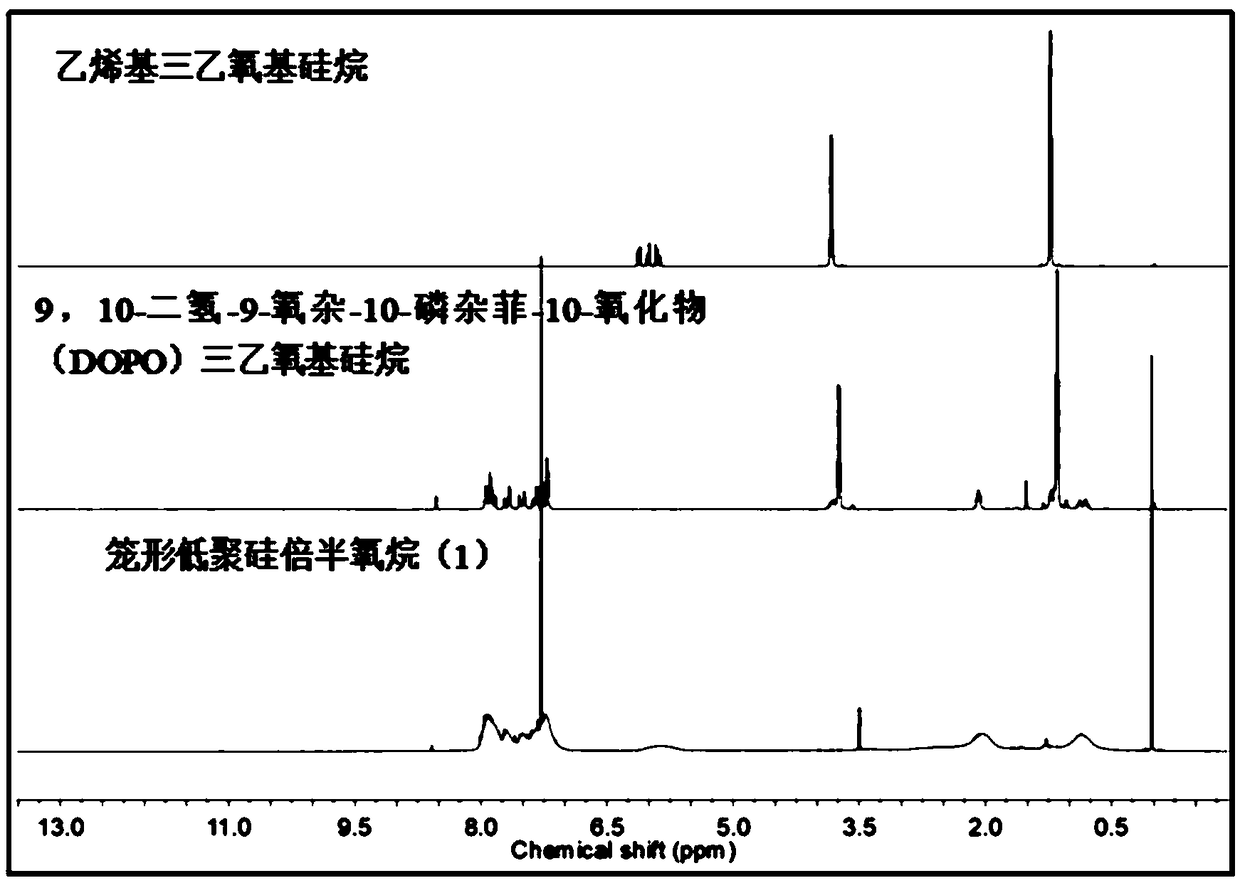

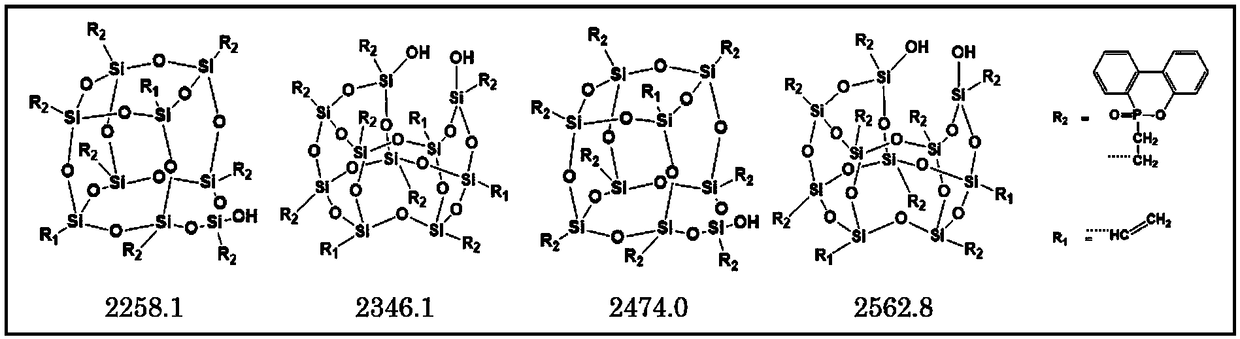

Cage-shaped oligomeric silsesquioxane flame-retardant polycarbonate as well as preparation method and application thereof

The invention provides cage-shaped oligomeric silsesquioxane flame-retardant polycarbonate and belongs to the field of flame retardance. According to the cage-shaped oligomeric silsesquioxane flame-retardant polycarbonate disclosed by the invention, the flame retardant is cage-shaped oligomeric silsesquioxane having phosphorus-containing groups and double bond groups, the ratio of the phosphorus-containing groups to the double bond groups in the flame retardant can be regulated according to different actual requirements, the types of the phosphorus-containing groups and the types of the doublebond groups can also be regulated, and the aim of controlling the phosphorus content and the amount of reactive groups is achieved. The double bond groups contained in the flame retardant can carry out a chemical reaction with multiple groups, the reactions of the double bond groups and corresponding groups can be regulated according to performance requirements of different polymers, and finallymulti-functionalization and high performance in the polymer material are realized; meanwhile, by utilizing the silicon phosphate synergistic effect of polysiloxane, high flame-retardant property underlow content can be realized; and moreover, the flame retardant provided by the invention is excellent in heat stability and high in residual carbon content, the flame retardant property of a PC composite material can be improved under the condition that the addition amount is very small, and the mechanical strength is excellent.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

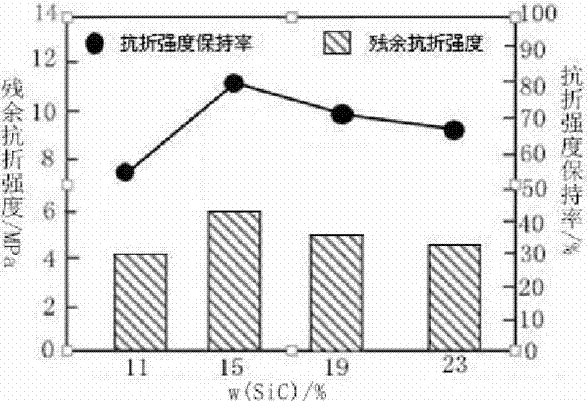

Environment-friendly high-iron-flux baking-free tapping channel ramming material and preparation method thereof

The invention relates to an environment-friendly high-iron-flux baking-free tapping channel ramming material and a preparation method thereof, belonging to the field of refractory materials. The environment-friendly high-iron-flux baking-free tapping channel ramming material is prepared from the following raw materials in parts by weight: 45-55 parts of brown corundum, 19-27 parts of dense corundum, 11-23 parts of SiC, 0-8 parts of Si powder, 0-12 parts of Si3N4, 3-6 parts of active alpha-Al2O3 powder, 1-5 parts of flake graphite and 3-8 parts of a bonding agent, wherein the total parts of all the other raw materials except the bonding agent is 100 parts; the bonding agent comprises the following components in parts by weight: 40-80 parts of carbon-containing resin, 10-40 parts of vegetable oil and fat, 5-15 parts of melamine urea-formaldehyde resin and 2-8 parts of carbon powder. An environment-friendly anhydrous tamping plug disclosed by the invention has the advantages that (1) the anhydrous tamping plug has small content of harmful substances, so that harms to the human body can not be caused; and (2) the anhydrous tamping plug does not have smoke and dust, so that the influence to the environment is small; (3) the anhydrous tamping plug has high iron flux and long service cycle, and can be used for reducing the labor intensity of workers.

Owner:渑池金华新材料有限公司

Residual oil modified fire retardation agent composition and fire retardation polyolefin material prepared from the same

The present invention discloses a phosphate ester fire retardation agent prepared through a residual oil modification reaction, and a method for preparing a fire retardation polyolefin composite material by adopting an intumescent fire retardation agent prepared through compounding of the phosphate ester fire retardation agent. According to the method, aromatic distillate is separated from residual oil, an organic phosphorus compound grafting reaction is performed to prepare a residual oil modified fire retardation agent, 10-30 parts by mass of the residual oil modified fire retardation agent, 30-50 parts by mass of ammonium polyphosphate, and 10-30 parts by mass of ammonium polyphosphate melamine are mixed, and the obtained mixture, 1-5 parts by mass of a synergist and 1-5 parts by mass of an antioxidant are subjected to a blending and melting composite process to prepare the intumescent fire retardation agent. According to the present invention, the residual oil modified fire retardation agent component is adopted as the charcoal source and the acid source, and the residual oil modified fire retardation agent component, the ammonium polyphosphate (acid source, gas source), and the ammonium polyphosphate melamine (air source) form the intumescent fire retardation agent so as to provide characteristics of no corrosive gas, low smoke, low toxicity, and good fire retardation; 10-35 parts by mass of the fire retardation agent composition is added to 90-65 parts by mass of the polyolefin, such that the fire retardation is significantly improved, and the mechanical property is not affected; and with the residual oil modification approach, the high added value utilization of the residual oil is achieved, and the new rich source is provided for the fire retardation agent.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

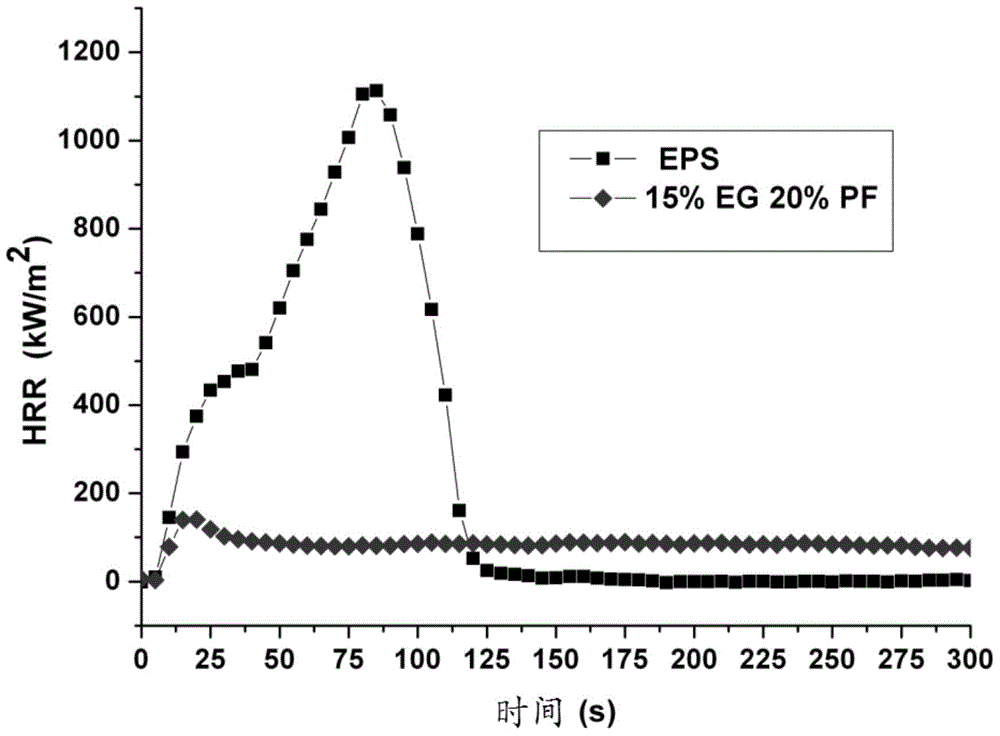

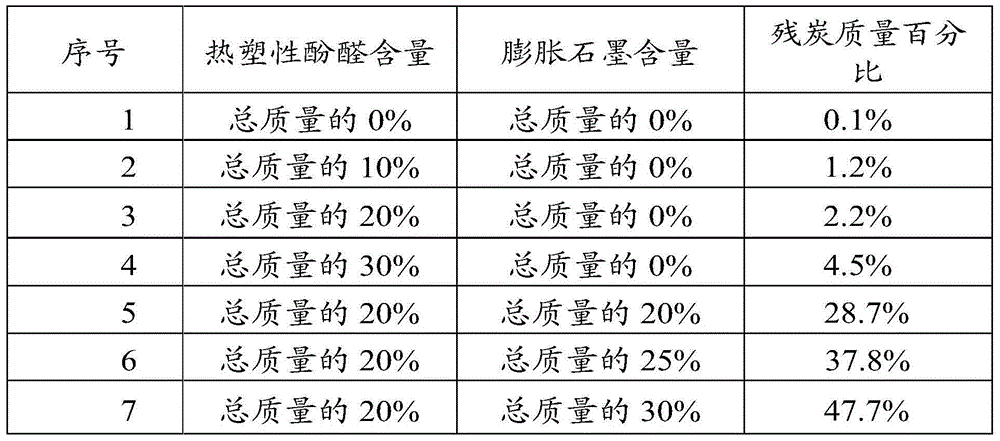

Polystyrene fire-retardant foam material and prepapration method thereof

InactiveCN104151729ASimple manufacturing methodIncrease carbon residueThermal insulationLimiting oxygen index

The invention relates to the field of polystyrene fire-retardant materials, and especially relates to a polystyrene fire-retardant foam material and a preparation method thereof. The polystyrene fire-retardant foam material is prepared from the raw materials of, by weight, 30-85% of expandable polystyrene particles, 5-40% of thermoplastic phenolic resin, and 10-50% of expansion graphite. According to the polystyrene fire-retardant foam material, when the added expansion graphite is heated, the volume thereof is rapidly increased, such that contact among pellets is inhibited. Also, expansion graphite has a good thermal insulation effect, such that internal heat transfer is reduced, polystyrene fire-retardant foam material pellet thermal degradation is inhibited, and material fire-retardant performance can be enhanced. The raw materials act synergetically. All the obtained polystyrene fire-retardant foam materials have limiting oxygen index values higher than 24%. The preparation method is simple and feasible, and cost is low. With the method, material fire-retardant property is effectively improved, and polystyrene fire-retardant foam material char residue amount is improved.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

High-toughness halogen-free flame-retardant reinforced PC (polycarbonate)/ASA (acrylonitrile styrene acrylate) alloy and preparation method thereof

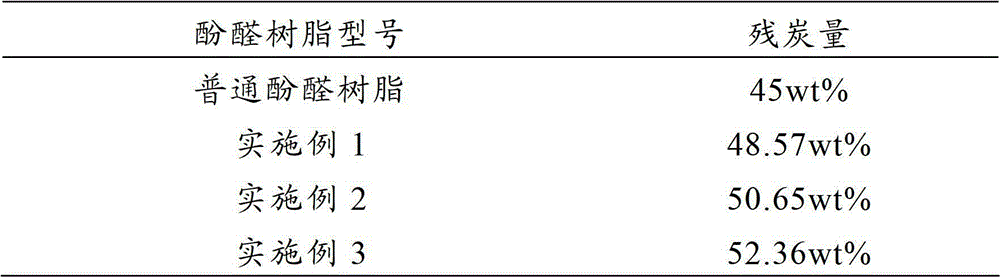

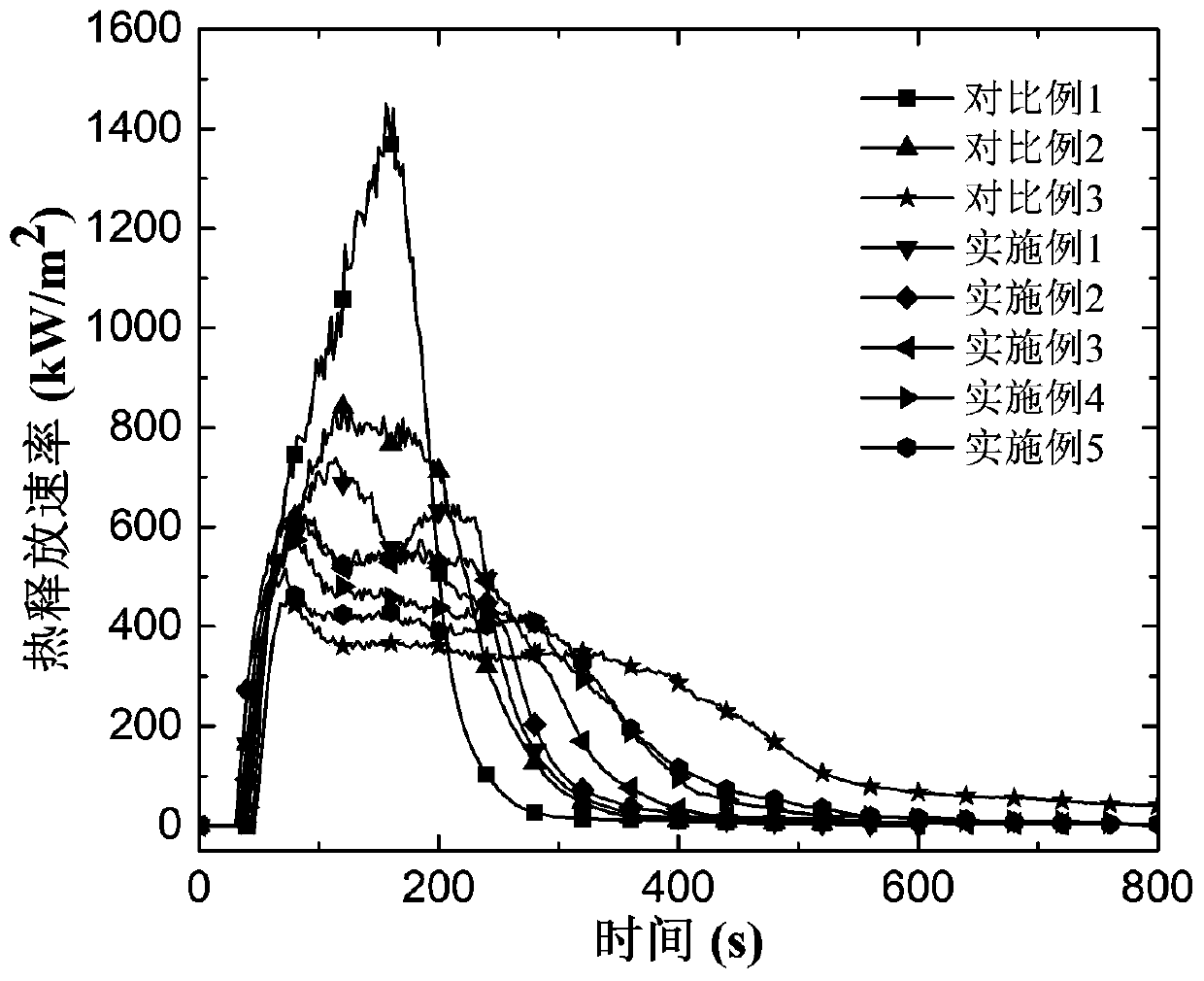

The invention relates to high-toughness halogen-free flame-retardant reinforced PC (polycarbonate) / ASA (acrylonitrile styrene acrylate) alloy and a preparation method thereof. The alloy is prepared from the following raw materials in parts by mass: 55 to 65 parts of PC, 10 to 20 parts of ASA, 3 to 8 parts of compatilizer, 4 to 7 parts of toughening agent, 15 to 20 parts of halogen-free composite flame retardant, 0.5 to 1 part of anti-drop agent, 0.1 to 0.5 part of lubricant and 0.1 to 0.5 part of antioxidant. The preparation method comprises the steps of weighing the raw materials according to the proportion, evenly mixing, putting the raw materials into a feeding opening of a twin-screw extruder, setting a rotation speed of the twin-screw extruder as 100 to 300r / min and extruding and granulating to obtain the high-toughness halogen-free flame-retardant reinforced PC / ASA alloy. The alloy material disclosed by the invention has the advantages of very good comprehensive mechanical property and flame retardance and low heat release rate, further avoids generating a lot of molten drops and smog and is a high-efficiency flame-retardant environment-friendly practical alloy material.

Owner:WUHAN UNIV OF TECH

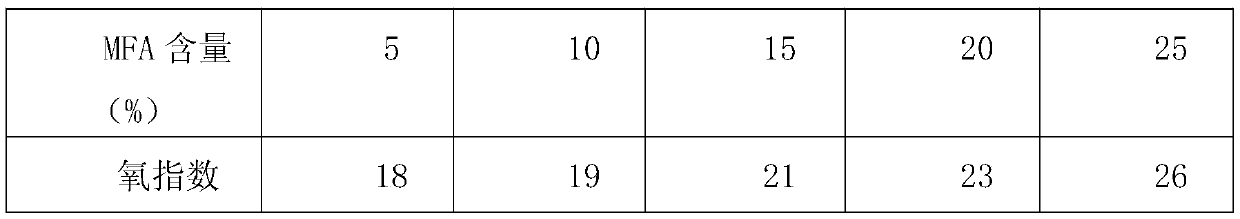

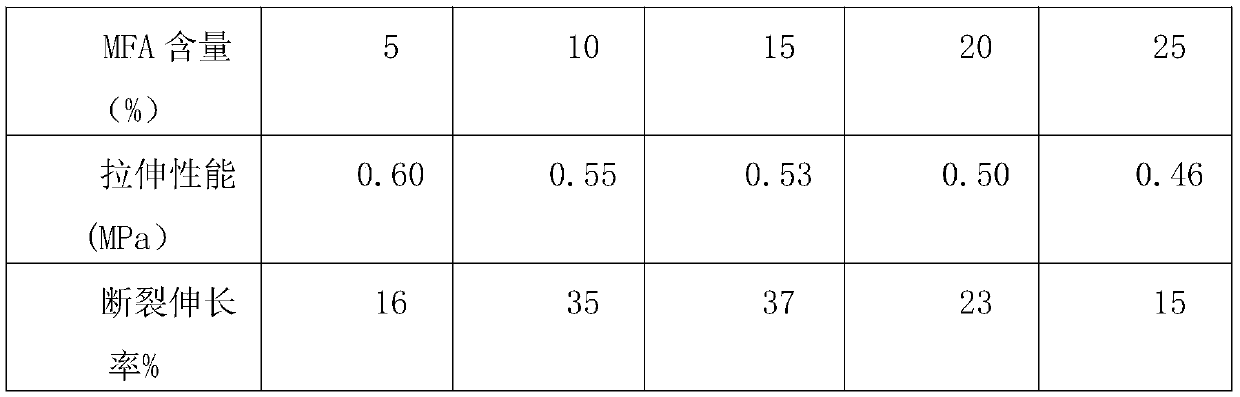

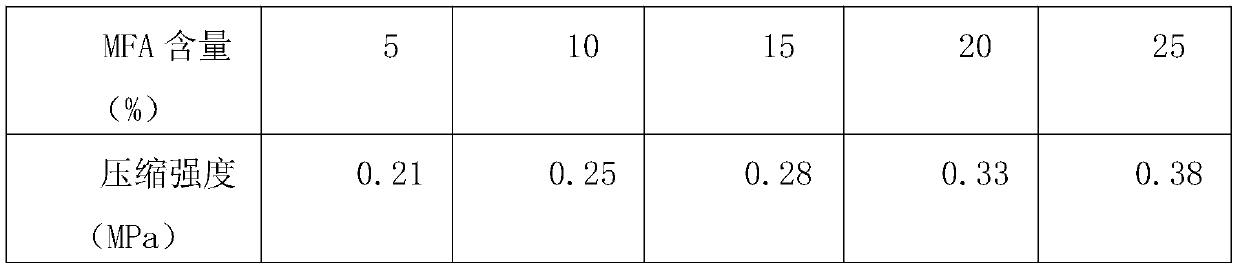

Flame retardant polyurethane rigid foamed plastic prepared based on microencapsulated fly ash

InactiveCN110746574AIncrease decomposition temperature and residual carbonImprove flame retardant performanceDiamineIsocyanate

The invention provides flame retardant polyurethane rigid foamed plastic prepared based on microencapsulated fly ash. The flame retardant polyurethane rigid foamed plastic is prepared from a componentA and a component B, the component A is prepared from the following raw material components in parts by weight: 60-80 parts of polyether polyol, 0.5-3 parts of a catalyst, 0.5-1.5 parts of a foam stabilizer, 0.6-1 part of deionized water, 6-30 parts of MFA and 0.06-0.1 part of triethylene diamine, and the component B is prepared from 60-100 parts of polymethylene polyphenyl polyisocyanate in parts by weight. The flame retardant polyurethane rigid foamed plastic prepared based on the microencapsulated fly ash has good heat resistance, high compressive strength, high limit oxygen index and goodflame retardant properties.

Owner:HAIYING ENTERPRISE GROUP

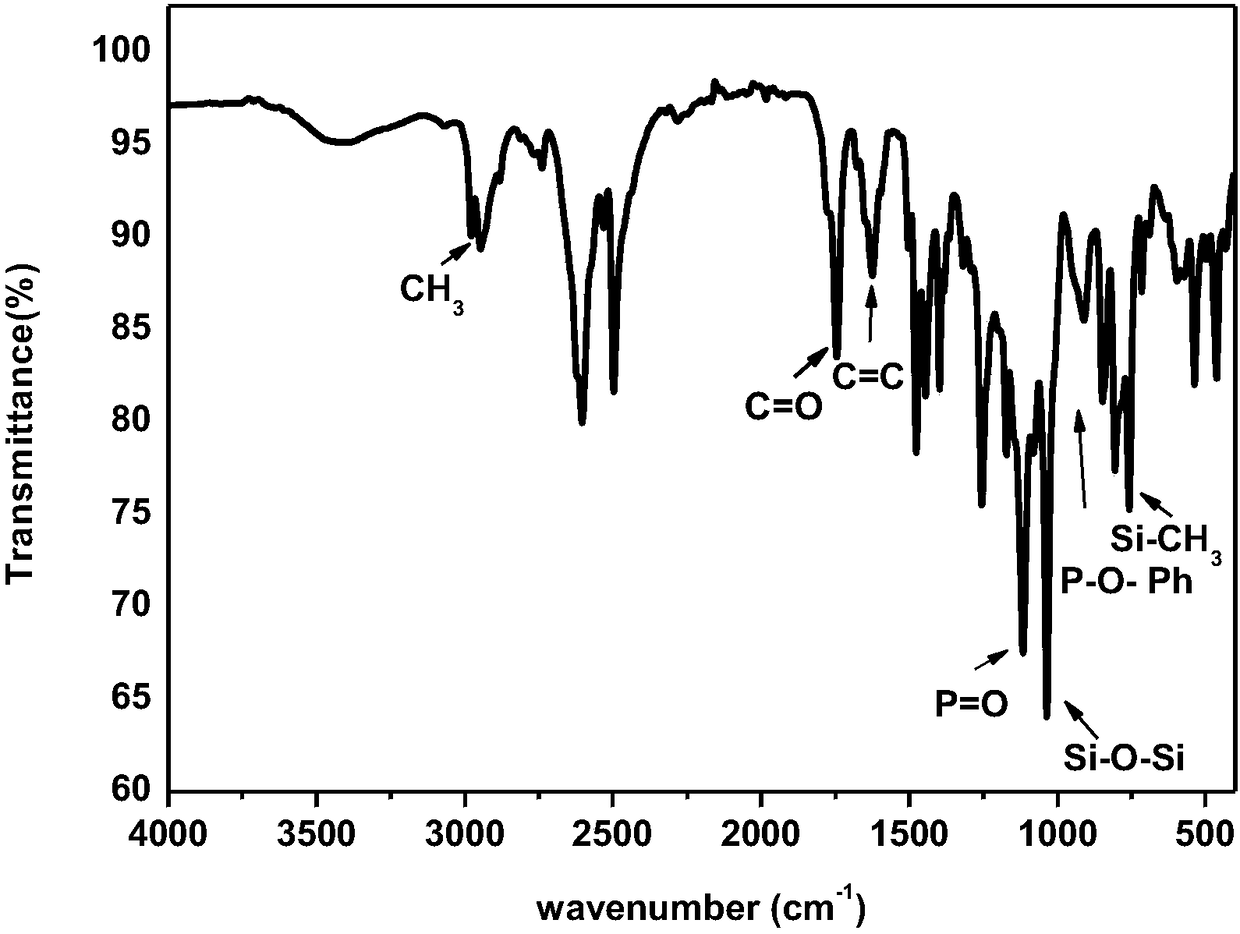

P-N-Si flame-retardant nanogel and preparation method and application thereof

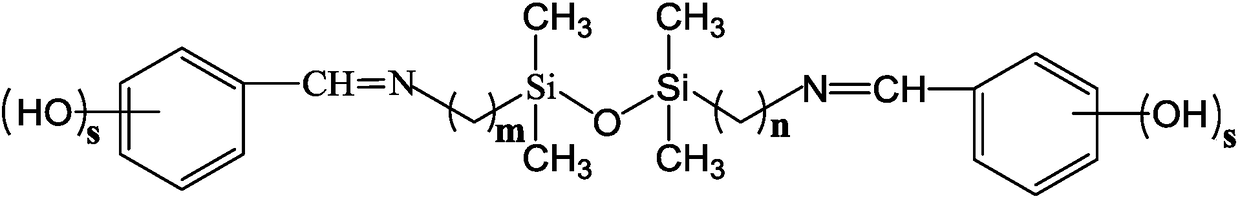

ActiveCN108586650AParticle size controllableImprove flame retardant performanceFlame-proof filament manufactureArtificial filaments from viscoseMicroparticleStructural formula

The invention relates to a P-N-Si flame-retardant nanogel and a preparation method and the application thereof. The P-N-Si flame-retardant nanogel adopts a structural formula as follows: FORMULA. Thepreparation method comprises the following steps: preparing an intermediate I, preparing an intermediate II, preparing an intermediate III, and preparing the P-N-Si flame-retardant nanogel. The P-N-Siflame-retardant nanogel is applied to the preparation of flame-retardant viscose fiber, lyocell fiber or other regenerated cellulose fiber. The flame-retardant nanogel is a halogen-free environment-friendly flame retardant which does not release formaldehyde, and incombustible gas decomposed by heat can enable a system to foam to produce a blow-out effect; the nanogel is in a form of nano-sized microparticles, the addition amount thereof into a spinning stock solution is reduced to 8-16%, and the technological cost can be effectively reduced.

Owner:DONGHUA UNIV

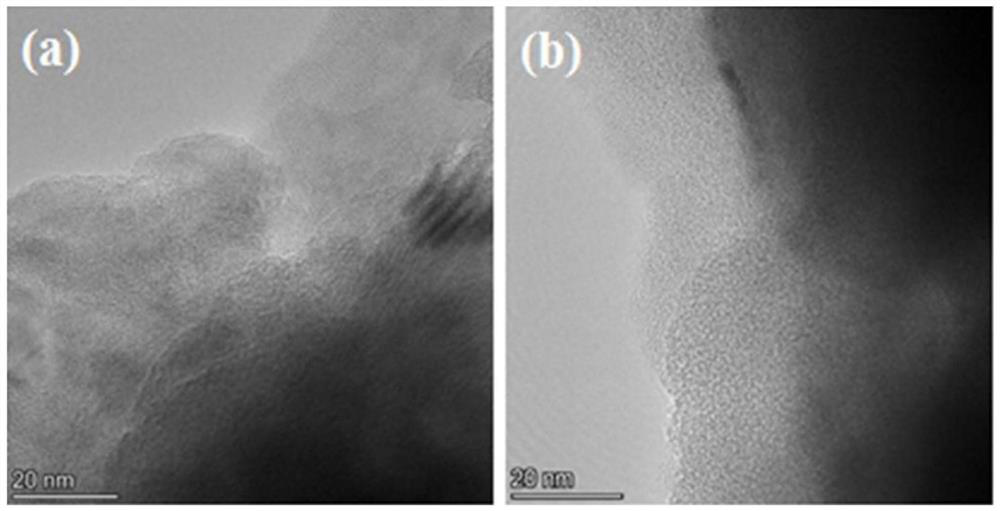

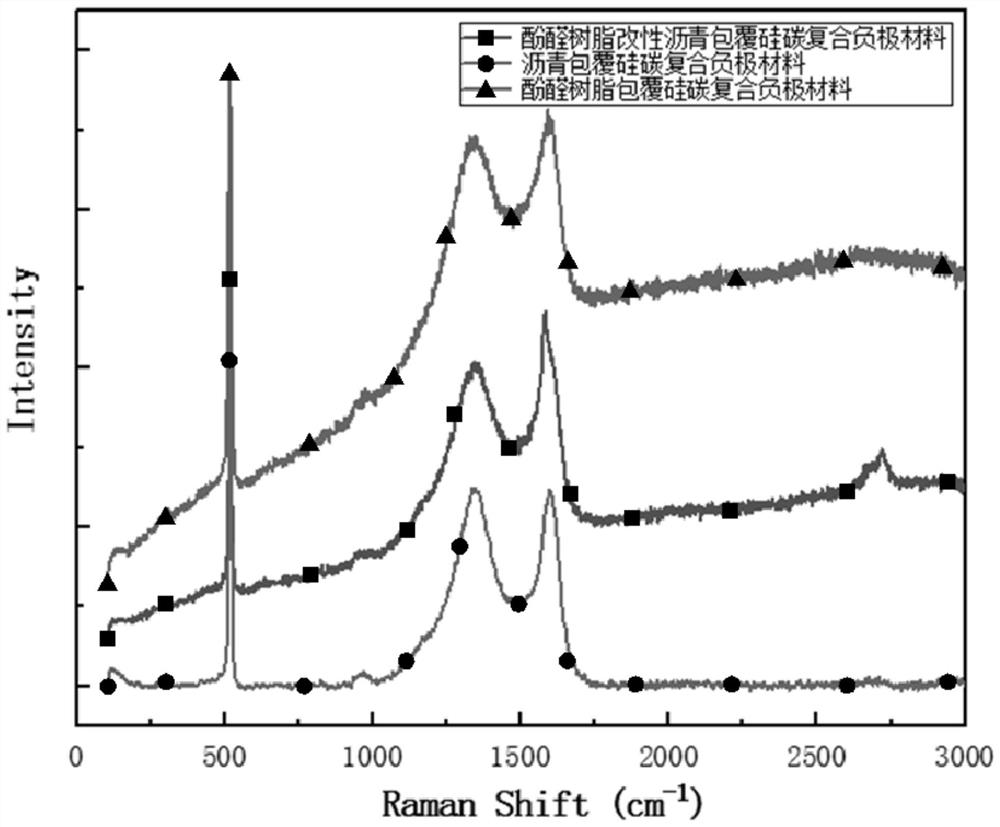

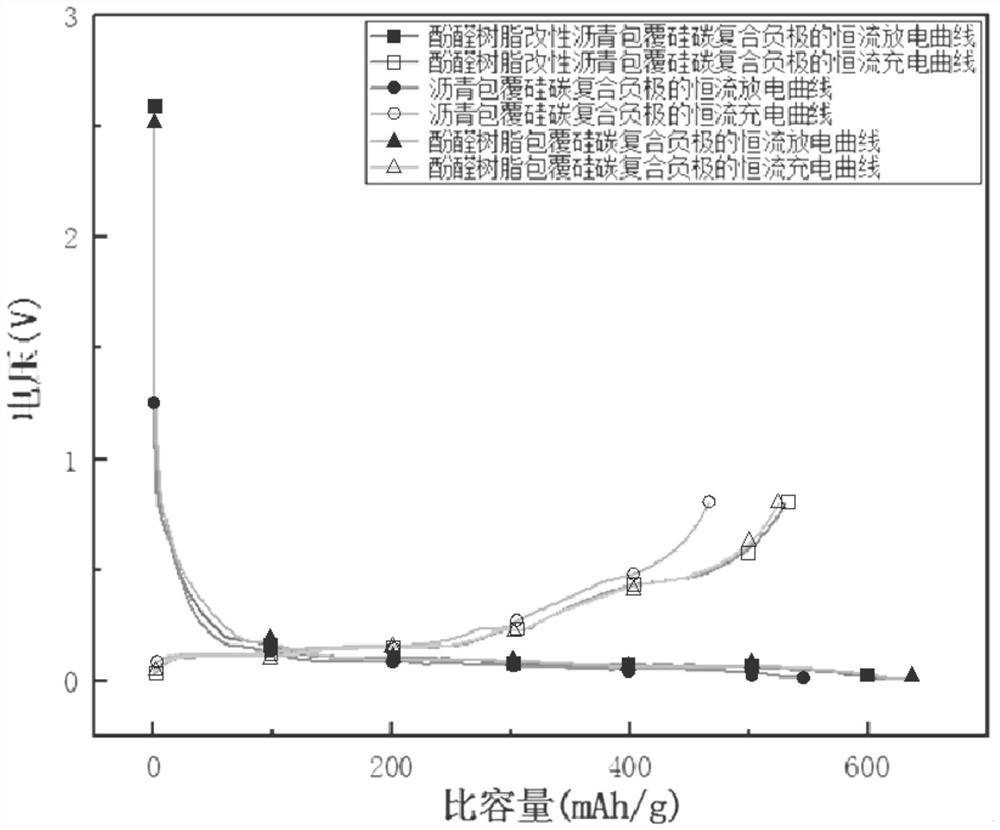

Modification method for coating silicon-carbon composite negative electrode material interface with modified asphalt

PendingCN112768644AHigh carbon residue rateHigh first rateSecondary cellsNegative electrodesCarbon compositesBattery capacity

The invention relates to the technical field of lithium battery materials, and in particular relates to a modification method for coating a silicon-carbon composite negative electrode material interface with modified asphalt. The asphalt-coated silicon-carbon composite negative electrode material is subjected to interface modification by utilizing specially selected phenolic resin, so that the silicon-carbon composite negative electrode material with high rate performance and high first rate is prepared. And a compact nano carbon coating layer with low pore defect degree is formed, so that the defects such as cracks and holes on the surfaces of nano silicon and graphite can be effectively repaired, irreversible consumption of a large number of active lithium ions in the charging and discharging process of a battery is avoided, and irreversible reduction of the battery capacity is remarkably reduced. Therefore, the asphalt-coated silicon-carbon composite negative electrode material is subjected to interface modification by utilizing the mutual synergistic effect of the phenolic resin and the asphalt, the capacity diving condition during high-current charging and discharging of the battery is obviously delayed, and the rate capability and coulombic efficiency of the material are improved.

Owner:西安英纳吉科技有限公司

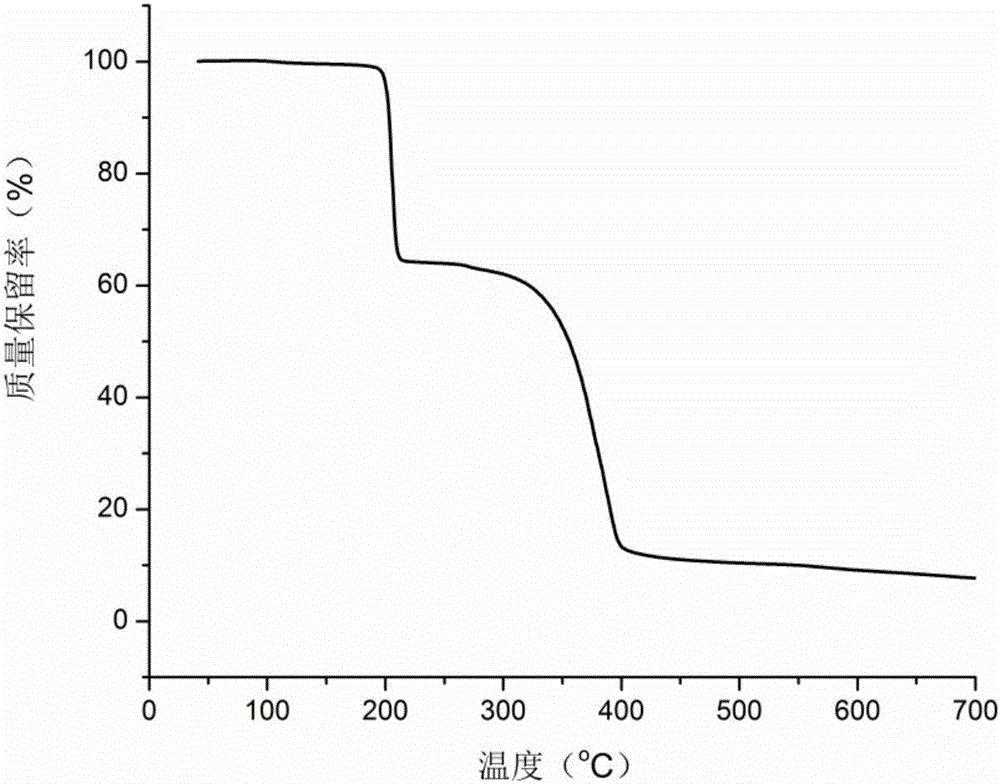

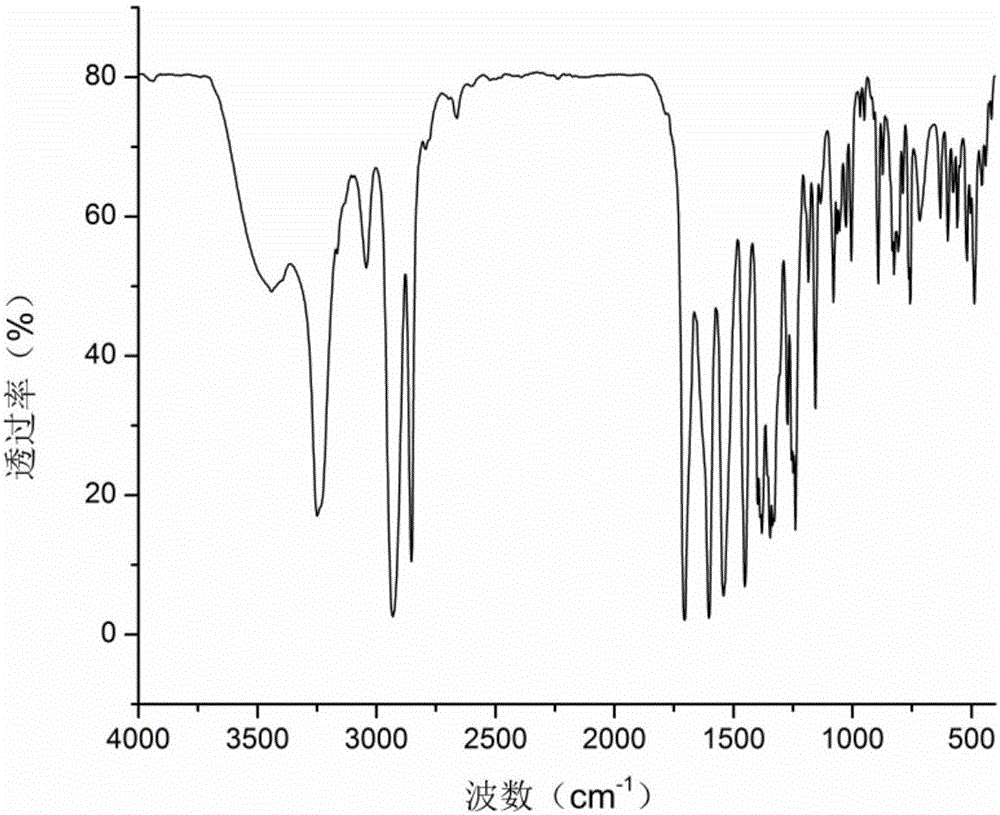

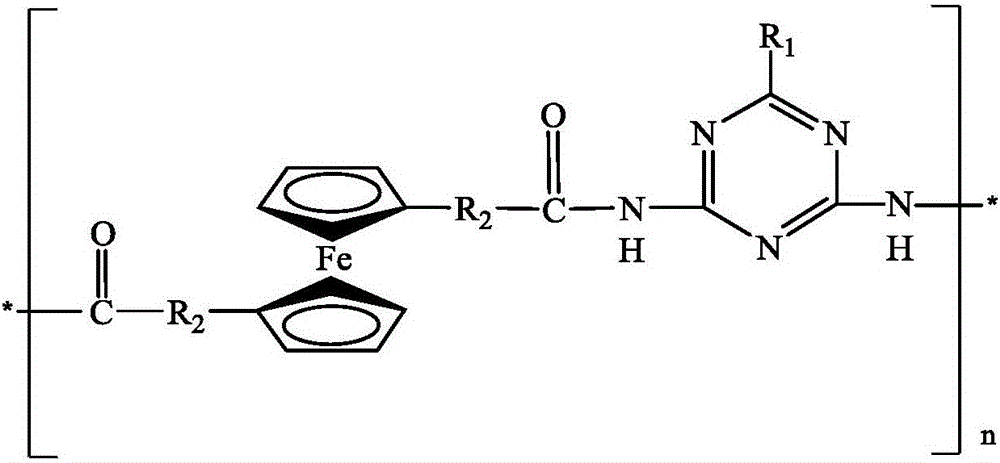

Ferrocene-thiotriazinone biradical polyamide synergistic charring agent and preparation method and application thereof

The invention discloses a ferrocene-thiotriazinone biradical polyamide synergistic charring agent shown in the formula (I) and a preparation method thereof.The preparation method of the polymer includes the steps that phenol, distilled water, an acid-binding agent I, cyanuric chloride, an organic solvent I and the like serve as raw materials and are prepared into an intermediate I through chemical reaction, the intermediate I, an acid-binding agent II, ammonia water, an organic solvent II and the like are prepared into an intermediate II through chemical reaction, and then the intermediate II, a raw material I, a dehydration agent, organic alkali, an organic solvent III and the like are prepared into the ferrocene-thiotriazinone biradical polyamide synergistic charring agent through chemical reaction.The polyamide synergistic charring agent is a polymerization type flame-retardant agent, can be used for flame retardance of plastic and other organic high polymer materials, can effectively improve heat stability and increase the residual carbon amount of a system, promotes matrix degradation cross-linking charring and compact carbon layer forming, and reduces release of smoke.The preparation method is simple and easy to control, and the polyamide synergistic charring agent is easy to obtain, good in performance and high in practicality.The formula (I) is as shown in the description.

Owner:SOUTHWEAT UNIV OF SCI & TECH

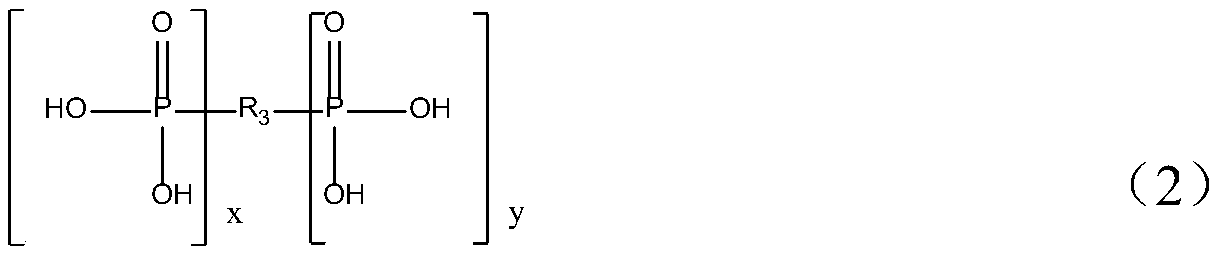

Novel organic phosphide flame retardant and preparation method and application thereof

ActiveCN111303207AAdd a small proportionHigh whitenessGroup 5/15 element organic compoundsO-Phosphoric AcidPhosphate

The invention relates to a novel organic phosphide flame retardant and a preparation method and application thereof. The flame retardant is prepared when at least one of soluble salt of dialkyl hypophosphorous acid or soluble salt of monoalkyl hypophosphorous acid and at least one of soluble salts of amino polyalkylene phosphoric acid, polyamine polyalkylene phosphoric acid, alkylene phosphoric acid, alkylene polyphosphoric acid, polyphosphoric acid and poly-metaphosphoric acid are dropwise added into a non-halogen soluble salt solution of 2-4 valence metals for reaction, or when at least oneof dialkyl hypophosphorous acid or monoalkyl hypophosphorous acid and at least one of amino polyalkylene phosphoric acid, polyamine polyalkylene phosphoric acid, alkylene phosphoric acid, alkylene polyphosphoric acid, polyphosphoric acid and poly-metaphosphoric acid are dropwise added into at least one of active metal oxide or metal hydroxide of 2-4 valence metals for reaction. The obtained flameretardant is high in whiteness, has a carbon residue rate higher than that of dialkyl hypophosphite, is excellent in flame retardance, and can be widely applied to the technical field of flame retardants.

Owner:WEIHAI HELEN NEW MATERIAL TECH CO LTD

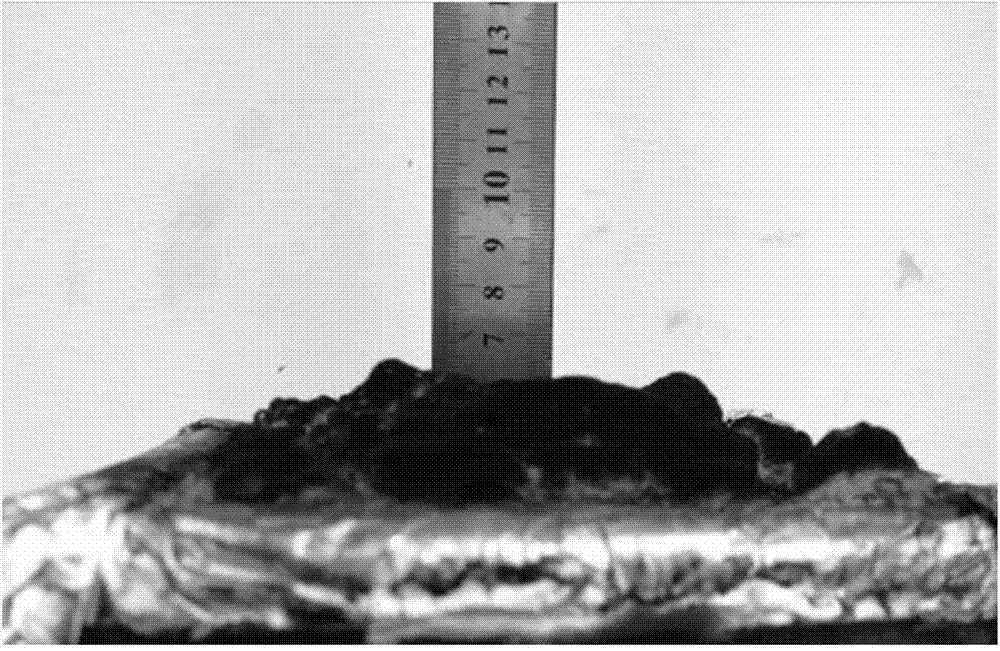

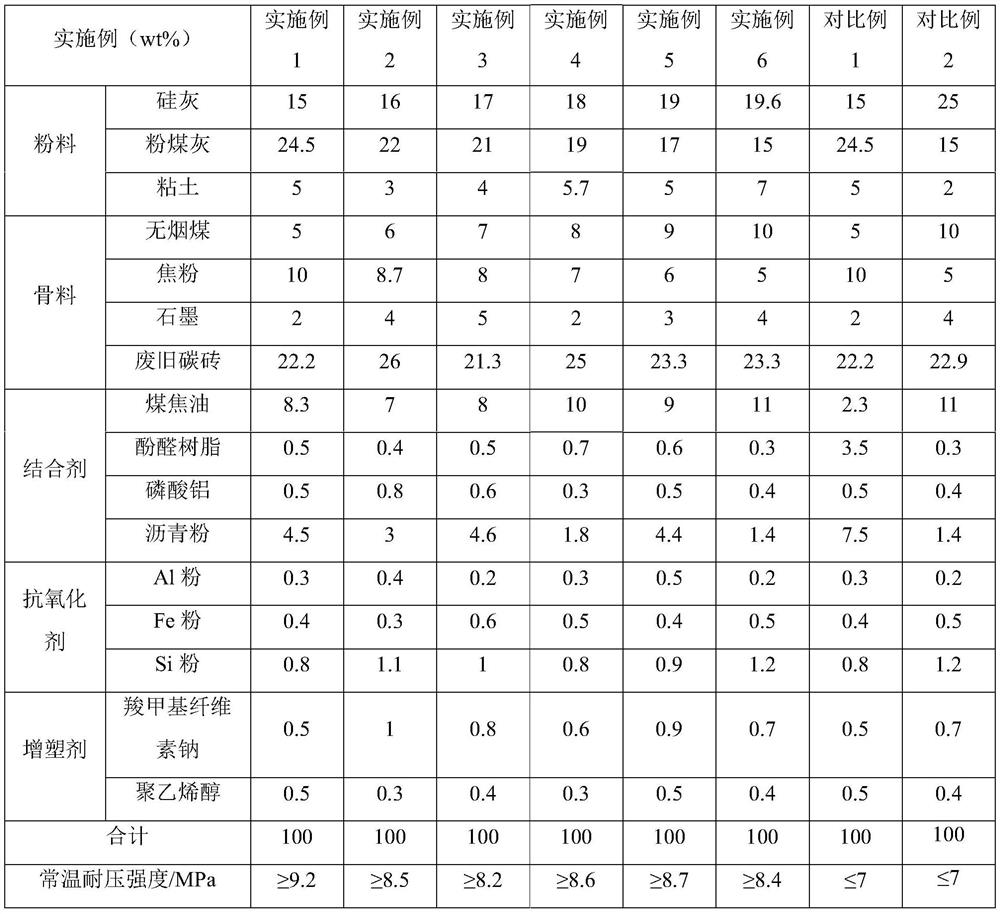

Self-repairing anhydrous stemming

The invention relates to the technical field of ferrosilicon production, in particular to self-repairing anhydrous stemming which comprises 41-45% of powder, 39-45% of aggregate, 11-14.5% of binding agent, 1.5-1.9% of antioxidant and 0.9-1.4% of plasticizer. The powder comprises silica fume, fly ash and clay, the aggregate comprises anthracite, coke powder, graphite and waste carbon bricks, the binding agent comprises coal tar, phenolic resin, aluminum phosphate and asphalt powder, the antioxidant comprises Al powder, Fe powder and Si powder, and the plasticizer comprises sodium carboxymethylcellulose and polyvinyl alcohol. The self-repairing anhydrous stemming is obtained by adjusting the components and the proportion, can be firmly combined with a furnace hole brick into a whole under the high-temperature condition, automatically repairs the gradually-enlarged furnace hole size, prolongs the repairing period and prolongs the service life of the furnace hole brick while meeting the iron notch plugging function.

Owner:内蒙古鄂尔多斯电力冶金集团股份有限公司

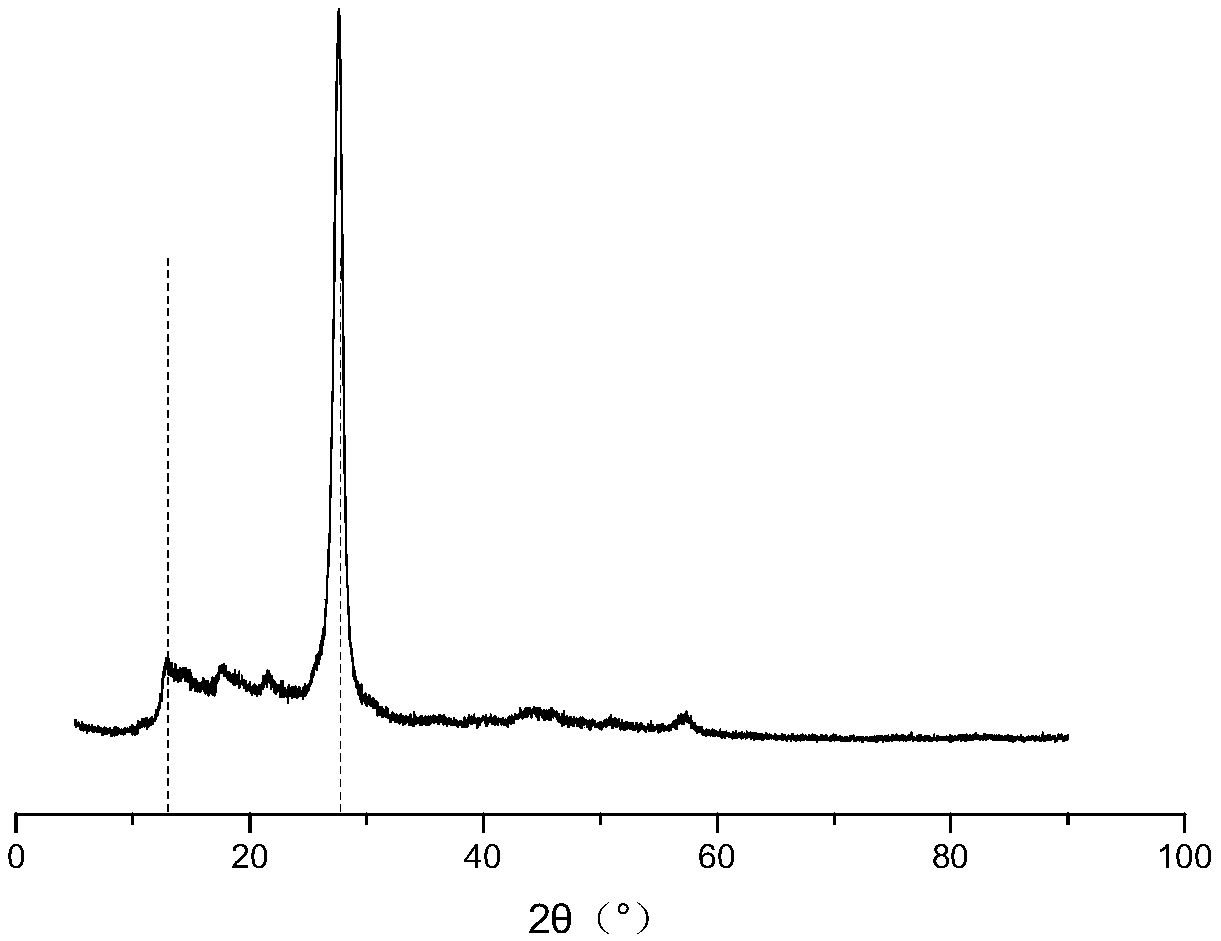

Hybrid modified salt of phosphorus-containing acid, preparation method and application thereof

ActiveCN108424546AImprove temperature stabilityImprove thermal stabilityNitrogen and non-metal compoundsChemical structureGraphite carbon

The invention relates to a hybrid modified salt of phosphorus-containing acid, a preparation method and application thereof. The preparation method includes: 1) dissolving a phosphorus-containing acidin a solvent, adding amino-rich graphite carbon nitride nanosheets, adjusting the PH value to 3-9, then adding a metal salt and carrying out reaction at 30-150DEG C for 2-12h; and 2) at the end of the reaction, conducting filtering, drying and crushing to obtain the hybrid modified salt of phosphorus-containing acid. The amino-rich graphite carbon nitride nanosheets in the obtained product have anitrogen element content of 66-68wt%, the chemical structure is rich in amino, the thickness is 0.5-50nm, and the nanosheets contain a graphite-like structure. The product prepared by the method provided by the invention also can be applied to the field of flame retardant materials, and the flame retardance and carbon residue amount are greatly enhanced. The production raw materials used by the invention are widely available, the synthesis process is simple, the equipment requirements are low, and the thermal stability is significantly improved than that of non-hybrid modified salts of phosphorus-containing acid, the prepared product has good compatibility with a polymer matrix, and has better flame retardant effect.

Owner:DONGHUA UNIV

Modified carbon foam phenolic resin and preparation method thereof

The invention relates to a modified carbon foam phenolic resin and a preparation method thereof. The modified carbon foam phenolic resin is prepared from the following raw materials: 100 mole fractions of phenol, 120-180 mole fractions of paraformaldehyde, 10-15 mole fractions of modifying agents, 0.1%-0.2% by weight of silane coupling agents relative to the weight percent of phenol and 2-4 mole fractions of catalysts. When the modified carbon foam phenolic resin is prepared, the method comprises the following steps of: adding the raw materials to a reaction kettle for uniform stirring; then heating to 70-80 DEG C, and then stopping heating; keeping temperature for 3-5 hours; and finally stopping reaction and reducing the temperature to acquire a finished product. The modified carbon foam phenolic resin disclosed by the invention is added with the silane coupling agents and increases the bonding force of a resin base and an inorganic substance, thereby enhancing the strength of a carbon foam product; and the modified carbon foam phenolic resin disclosed by the invention can be used for enhancing the toughness of synthetic resin and increasing the carbon residues of the synthetic resin by adding cyanamide and boride modifying agents and overcoming the defects of wastewater generation in a common preparation process, is favorable to environmental protection and has the characteristics of light weight, high strength, heat insulation, and the like by utilizing carbon foam materials prepared through the foaming ignition of the carbon foam resin.

Owner:苏州美克思科技发展有限公司

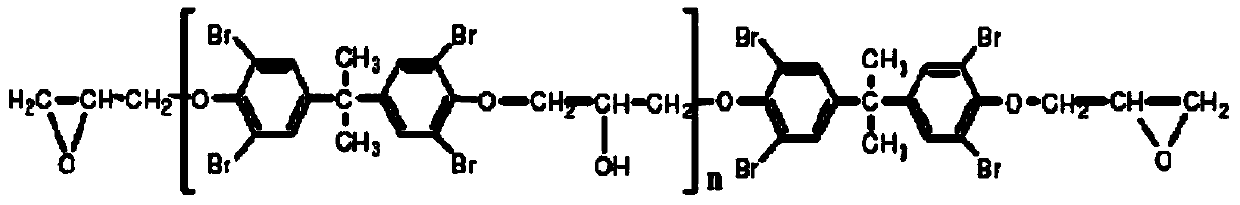

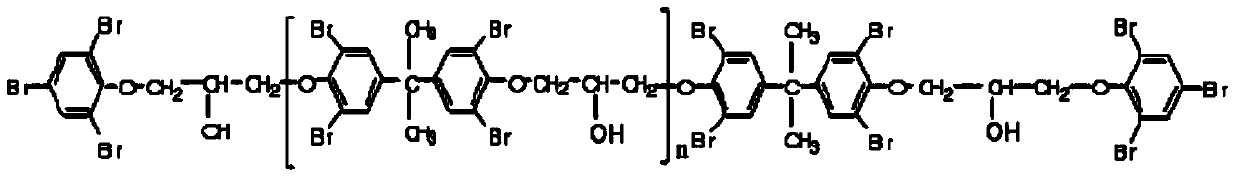

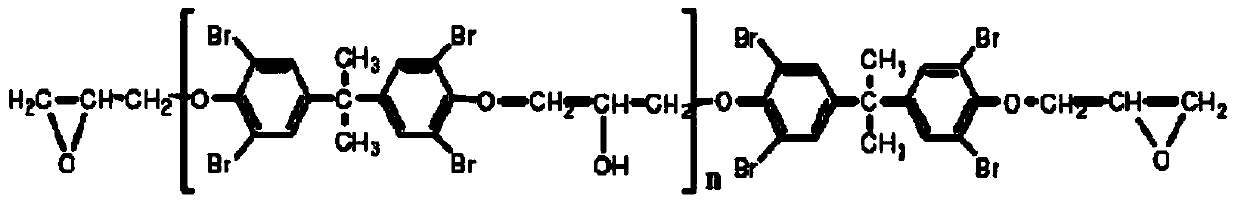

High-polymer bromine flame retardant/nano clay compound flame-retardant ABS (acrylonitrile-butadiene-styrene) resin and preparation method thereof

InactiveCN103992612AHigh flame retardant efficiencyImprove mechanical propertiesPolymer scienceBromine

The invention discloses a high-polymer bromine flame retardant / nano clay compound flame-retardant ABS (acrylonitrile-butadiene-styrene) resin and a preparation method thereof. The material is characterized by comprising the following components in percentage by weight: 52-70% of ABS resin, 20-25% of high-polymer bromine flame retardant, 5-10% of flame-retardant synergistic agent, 1-3% of nano clay and 4-10% of solubilizer. Since the high-polymer bromine flame retardant has favorable compatibility with the ABS resin matrix, the flame-retardancy-modified material has satisfactory melt flow rate and higher flame-retardant efficiency, and the material can be endowed with favorable flame retardancy, high ultraviolet stability, favorable mechanical properties and high heat stability; the flame retardant can not easily migrate, and the processed product can not easily bloom; and thus, the high-polymer bromine flame retardant / nano clay compound flame-retardant ABS resin is especially suitable for home appliances, electronics, automobiles and other industries with various strict performance requirements.

Owner:宁波泛塑新材料科技有限公司

Nitrogen-rich group functionalized graphene oxide and preparation method and application thereof

ActiveCN110510605AHas a high nitrogen contentImprove thermal stabilityCarbon compoundsEpoxyGas phase

The invention discloses a preparation method of nitrogen-rich group functionalized graphene oxide. A phosphorus and nitrogen compound is synthesized by a simple and convenient method. Through esterification reaction between phenolic hydroxyl groups on the compound and carboxyl groups on graphene oxide, an introduced phosphaphenanthrene functional group is expected to improve the dispersibility ofgraphene in an organic solvent, and secondary amine on the compound can also participate in the curing process of epoxy resin to improve the compatibility of the graphene in the epoxy resin. In the invention, phosphorus and nitrogen flame retardant elements are introduced into the graphene oxide to synthesize a flame retardant which can play a flame retardant role in a condensed phase and a gas phase, and is expected to improve the thermal stability of the epoxy resin. The flame retardant has mild reaction conditions, does not contain halogen elements, and is a novel environment-friendly flameretardant.

Owner:XIAMEN UNIV

Metal loaded activated carbon modified silk protein porous membrane and preparation and application methods thereof

InactiveCN108525646AImprove adsorption capacityPlay a fixed roleGas treatmentOther chemical processesFreeze-dryingCerium

The invention provides a metal loaded activated carbon modified silk protein porous membrane and preparation and application methods thereof. The metal loaded activated carbon modified silk protein porous membrane is composed of silk protein and loofah sponge sheet-like activated carbon materials loaded with gold, platinum, palladium, titanium, iron, manganese or cerium. The preparation process ofthe metal loaded activated carbon modified silk protein porous membrane comprises processing the peripheral fiber of loofah sponge into sheets, performing pretreatment through dilute alkali, and thoroughly immersing the raw materials into sugar alcohol solution containing metal salt; inletting nitrogen into the solution to form tiny bubble clusters, performing immersion treatment, extracting andthen squeezing the materials to remove superfluous sugar alcohol solution, and performing drying, curing and high-temperature carbonization treatment to obtain loofah sponge sheet-like activated carbon materials; mixing the loofah sponge sheet-like activated carbon materials with the silk protein solution; performing electrophoresis treatment to obtain hydrogel, freeze-drying the hydrogel in vacuum to obtain the metal loaded activated carbon modified silk protein porous membrane. The prepared metal loaded activated carbon modified silk protein porous membrane achieves absorption, oxidation catalysis and protein immobilization, and is significant in processing effects and free from the potential risk of secondary pollution.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

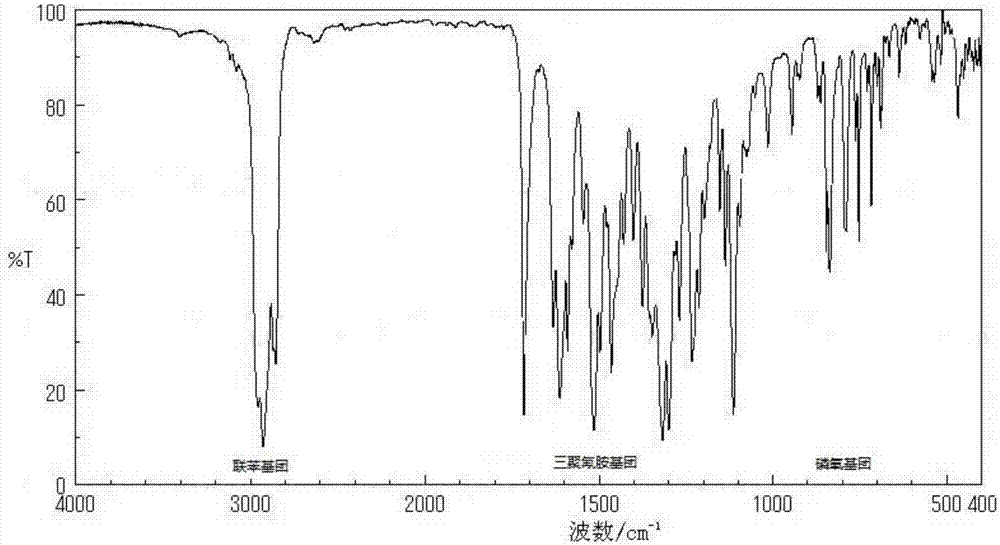

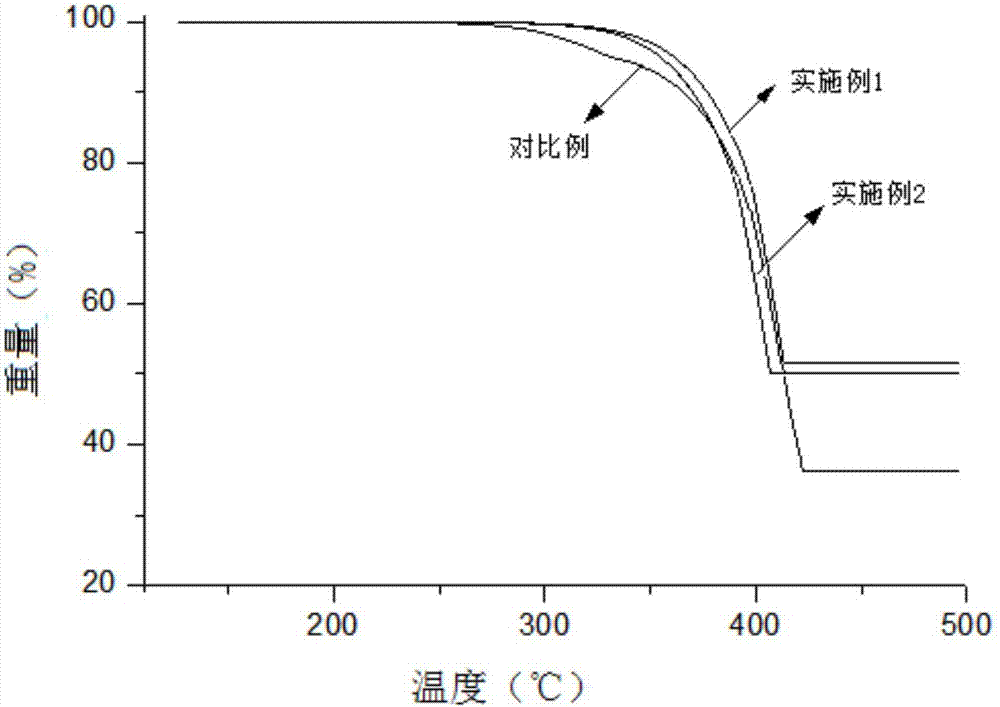

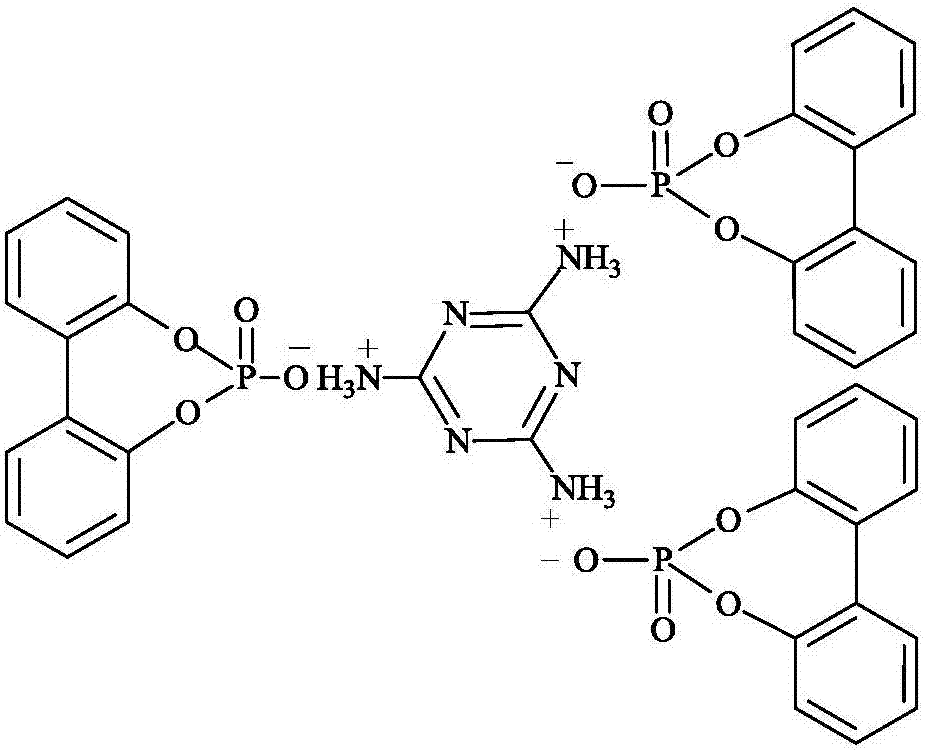

Triazine compound, as well as preparation method and application thereof

ActiveCN106892943AMild reaction conditionsLess side effectsGroup 5/15 element organic compoundsSolventCarbon source

The invention discloses a triazine compound, as well as a preparation method and application thereof. The novel triazine compound is prepared by taking 2,2'-dihydroxybiphenyl, phosphorus oxychloride, triethylamine and melamine as main raw materials, not only has a carbon source (biphenyl structure), but also has an acid source (phosphoric acid structure) and a gas source (melamine). The carbon forming agent has high carbon forming property, high thermal decomposition temperature, high stability and large residual carbon quantity. According to the preparation method provided by the invention, the reaction condition is mild, the side reaction is less, the operating flow is simple, the reaction cycle is greatly shortened, the used raw materials are safe and easily available, the use of an organic solvent is avoided because water serves as a reaction medium, the aftertreatment process is simplified, and industrialized production is facilitated. The solvent and the mother liquid can be recycled and reused, the operating flow of the process is simple, and the defects that the reaction time is too long and the use amount of the organic solvent is large in the existing process are overcome.

Owner:CHEM TECH ACAD OF SHANDONG PROVINCE

Binding agent for carbonic refractory material in magnesium texture

InactiveCN101050343AImprove performance indicatorsReduce manufacturing costAldehyde/ketone condensation polymer adhesivesPolyesterHigh carbon

This invention relates to a bonding agent for magnesium-based carbon-containing refractory material. The bonding agent is composed of: phenol formaldehyde resin 100 parts, aromatic polyester 30-60 parts, and solvent 17-32 wt. % of phenol formaldehyde resin and aromatic polyester. The bonding agent has such advantages as stable quality, high solid content and high carbon residue content, and can improve the properties of the refractory material.

Owner:周惠兴

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com