Patents

Literature

142 results about "O-Phenylphenol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

2-Phenylphenol (ortho-phenylphenol, OPP), and sodium o-phenylphenate, SOPP, were first evaluated by the 1962 JECFA for their use for the post-harvest treatment of fruits and vegetables to protect against microbial damage during storage and distribution in commerce.

Application of 2-phenylphenol and derivatives thereof to medicine for treating epilepsia

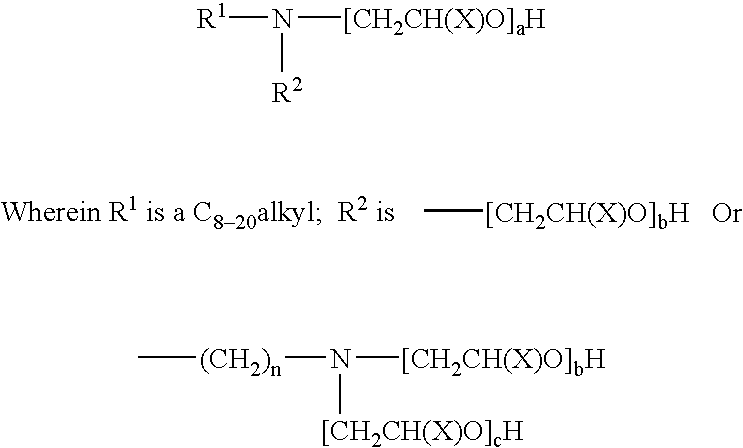

ActiveCN101804043ANo loss of consciousnessHigh affinityNervous disorderHydroxy compound active ingredientsO-PhenylphenolStructural formula

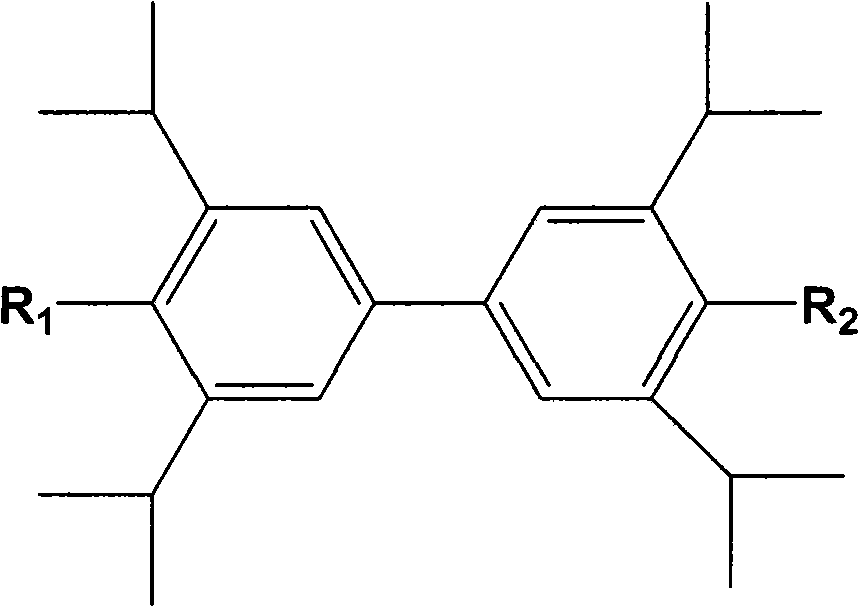

The invention belongs to the technical field of medicines and mainly relates to application of 2-phenylphenol and derivatives thereof to a medicine for treating epilepsia. The structural formula of the 2-phenylphenol derivatives is shown in the specification of the invetion, wherein R1 and R2 can be hydroxide groups, sulfhydryl groups at the same time or one is hydroxide radical and the other is sulfhydryl group; and R1 and R2 can be alkyls of C1-C6, alkenyls of C2-C6, alkyls and aryls of C2-C6 or acyls or alkenyls of C2-C6 and at least one of R1 and R2 is hydroxide group.

Owner:XIAN LIBANG PHARMA

9, 10- dihydro-9- oxa -10- phosphine hetero- phenanthrene -10- oxide compound and its derivant and method of preparing the same

InactiveCN101108864ALight colorHigh yieldGroup 5/15 element organic compoundsGlycol synthesisPhosphorus trichloride

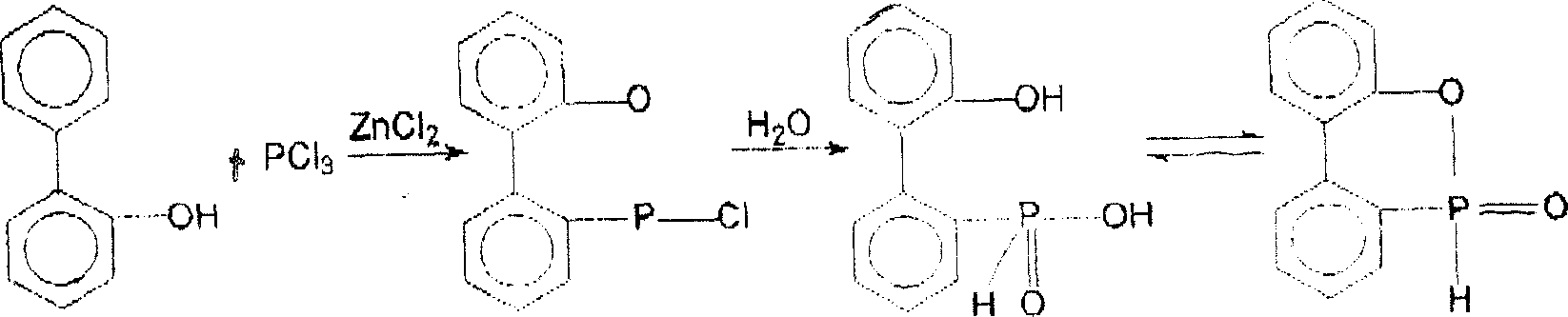

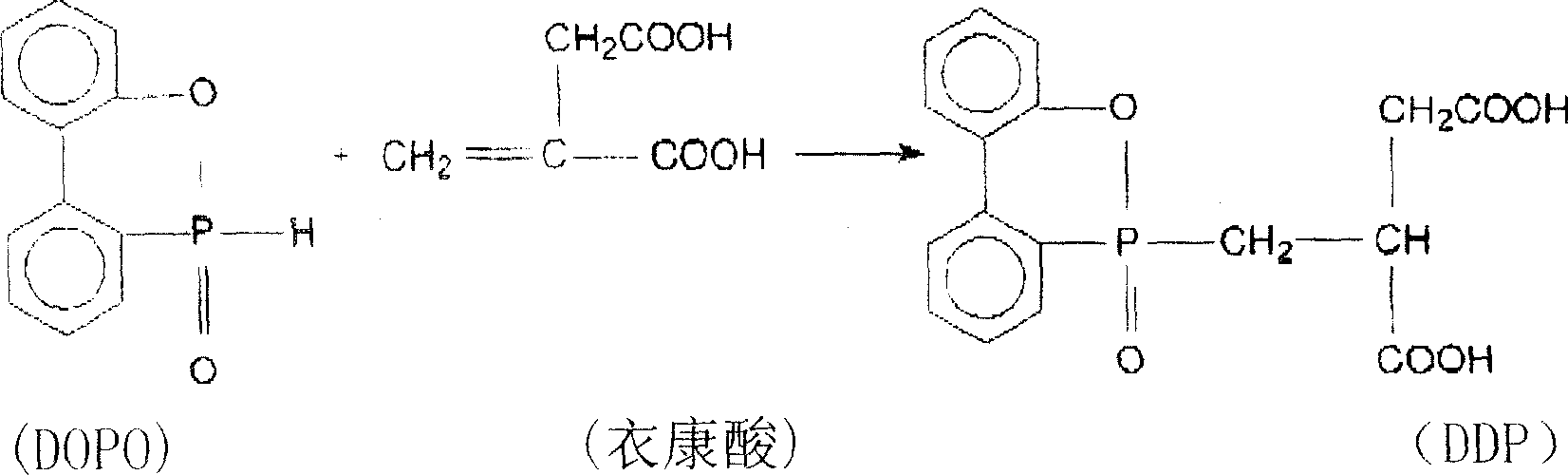

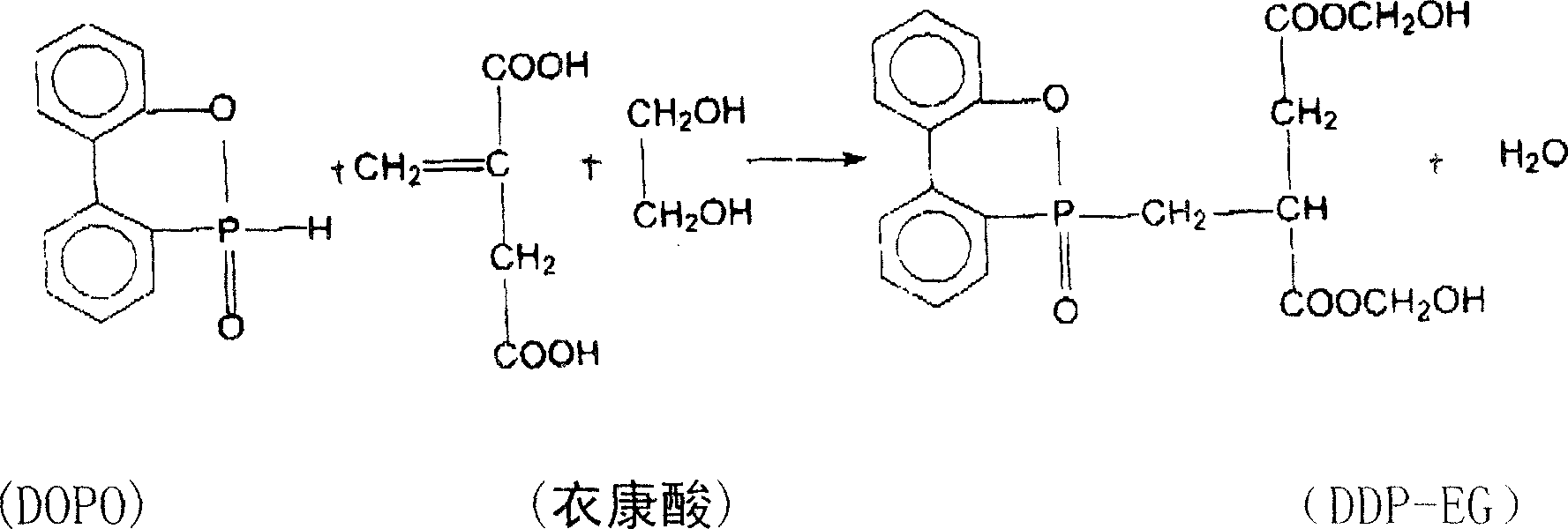

The invention discloses a preparation method of the 9, 10-dihydro-9-oxa-10-phosphahenanthrene-10-oxide and the derivatives DDP, DDP-EG and DOPO-BQ. The invention has three steps to synthesize the DOPO: (1) preparation of CDOP, the O-phenylphenol (OPP) reacts with the Phosphorus trichloride (PCl3) with ZnCl2 as the catalyst. (2) purification of CDOP, vacuum distillation is carried out. (3) DOPO with high purity and yield is gained through the hydrolysis and crystallization. The preparation materials comprises the O-phenylphenol, the Phosphorus trichloride, the toluene, the alcohol, the deionized water, the itaconic acid, the ethylene glycol, the p-benzoquinone and the acetone. The invention simplifies the process conditions, improves the product purity with good production stability and repeatability. The purity of the product reaches over 99.0 per cent, the content of the chloride is below 50ppm, the OPP is about 0.01 per cent, the color is about 10 (10 per cent solution of acetone), the zinc-ion is less than 10ppm. The preparation method of the derivatives DDP, DDP-EG, DOPO-BQ is simple, good in stability and high in yield.

Owner:魏铭杉

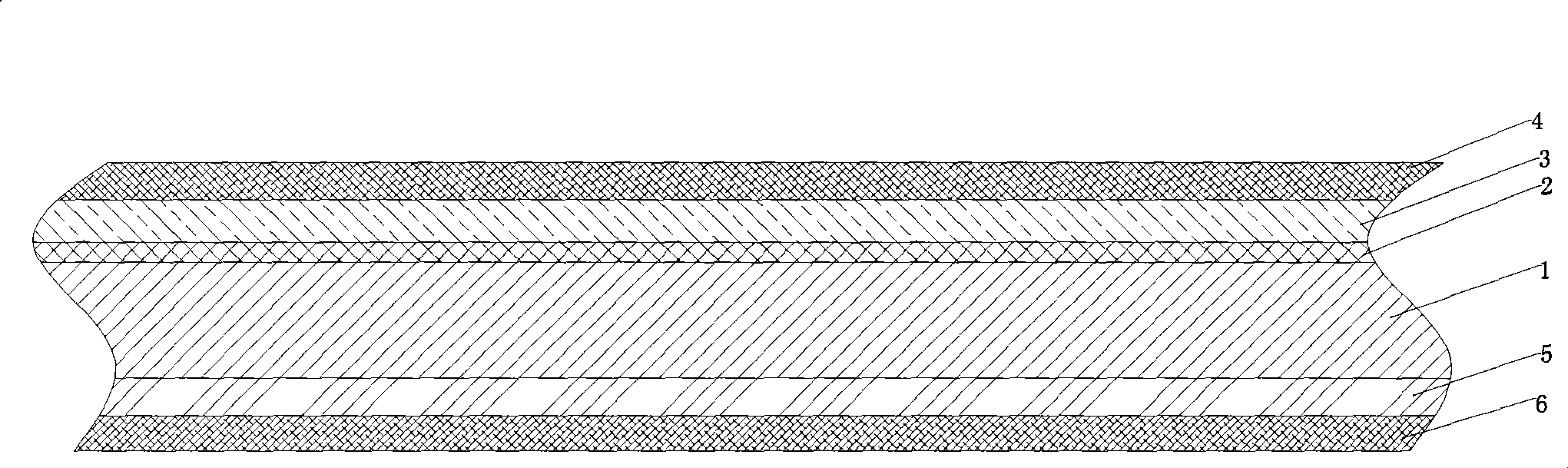

Fusible high-performance elastomer modified asphalt waterproof roll

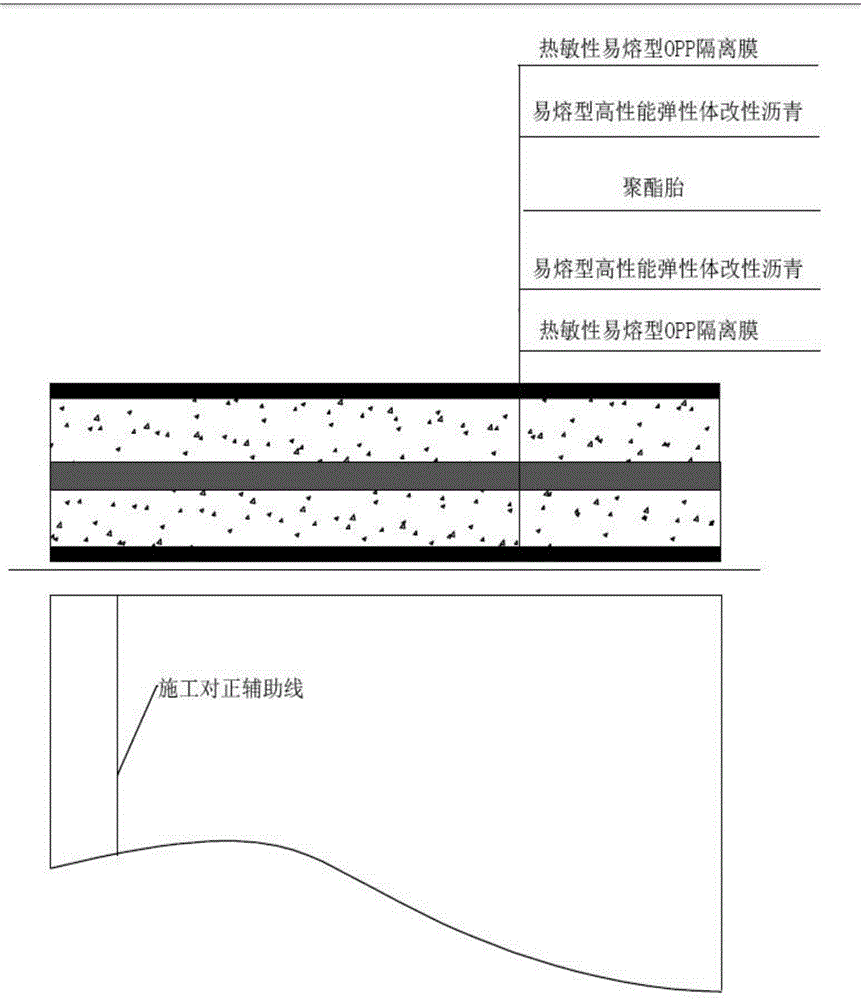

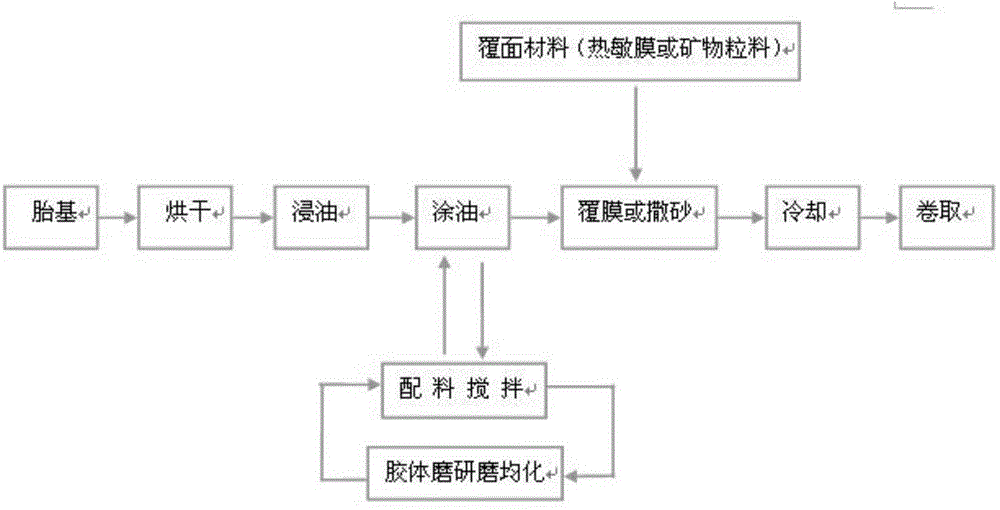

ActiveCN104553130AImprove construction rateExtended service lifeSynthetic resin layered productsBituminous layered productsSocial benefitsElastomer

The invention discloses a fusible high-performance elastomer modified asphalt waterproof roll. The fusible high-performance elastomer modified asphalt waterproof roll sequentially comprises a heat-sensitive fusible OPP (o-phenylphenol) isolating membrane, a fusible elastomer modified asphalt, a polyester reinforcement, fusible elastomer modified asphalt and a heat-sensitive fusible OPP isolating membrane from top to bottom. When the fusible high-performance elastomer modified asphalt waterproof roll is applied, the construction efficiency can be improved, the energy consumption is reduced, and the waterproof roll is energy-saving, environment-friendly and long in service life and has good economic benefits and social benefits. The experiment proves that the fusible high-performance elastomer modified asphalt waterproof roll disclosed by the invention has the advantage that the construction rate can be improved by 10-20 percent.

Owner:TANGSHAN DONGFANG YUHONG WATERPROOF TECH CO LTD +2

Wide spectrum disinfectant comprising an alcohol and disinfectant mixture

InactiveUS7338927B2Safe for userNot environmentally harmfulAntibacterial agentsBiocideAlcoholNonoxynols

The invention discloses methods of making and uses for wide spectrum disinfectants including as components an alcohol, O-phenylphenol, chlorhexidine gluconate, nonoxynol-9, benzalkonium chloride, and deionised double distilled water wherein on a weight / volume ratio the alcohol comprises from 50 to 80%, the O-phenylphenol comprises from 0.1% to 0.8%, the chlorhexidine gluconate comprises from 0.01 to 1%, the nonoxynol-9 comprises from 0.02 to 1%, and the benzalkonium chloride comprises from 0.15 to 1%.

Owner:ALDA PHARMA CORP

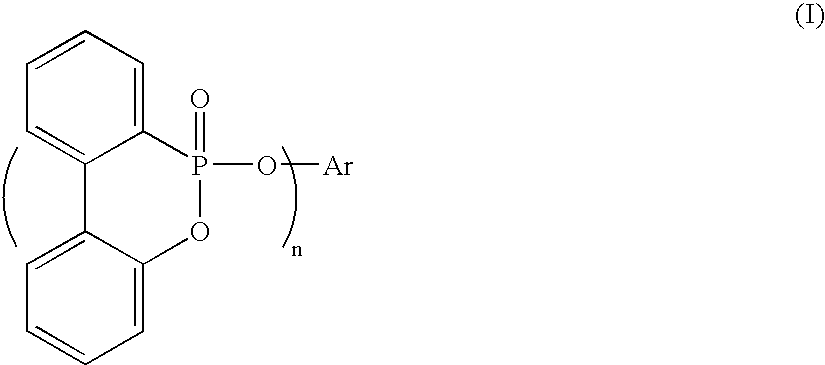

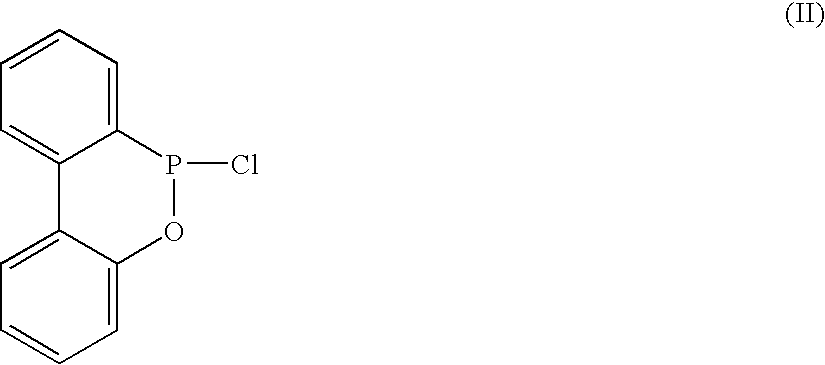

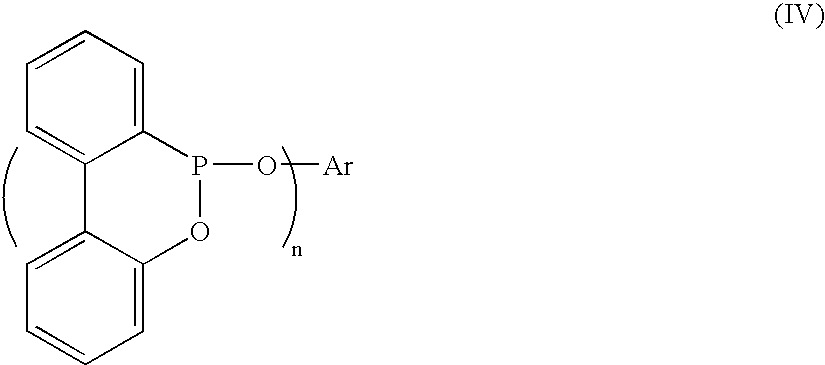

Method for preparing a biphenylphosphonate compound

A method for preparing a biphenylphosphonate compound of the following formula (I): wherein n is 2 or 3; Ar is a C6-C16 aromatic group; which comprising (a) reacting an o-phenylphenol with a phosphorus trichloride in the presence of a zinc chloride catalyst to form a 6-chloro-6H-dibenz [c,e][1,2] oxaphosphorin of the following formula (II); (b) reacting a polyhydroxybenzene compound of the formula (III) (HO)n—Ar (III) wherein n and Ar are defined the same as the above, with the compound of formula (II) to form a compound of the following formula (IV) wherein n and Ar are defined the same as the above; and (c) oxidizing the compound of formula (IV) in the presence of water and ozone to form the compound of formula (I).

Owner:NAT CHUNG SHAN INST SCI & TECH

Ultraviolet (UV) offset printing ink suitable for different film substrates and preparation method thereof

InactiveCN102898893ASmall smellEnergy saving and environmental protectionInksPolyethylene terephthalate glycolPolymer science

The invention discloses UV offset printing ink suitable for different film substrates and a preparation method thereof. The ink mainly comprises prepolymer, a reactive diluent, a photoinitiator, pigments, paddings and assistants. The ink contains no solvents, has zero discharge of volatile organic compounds (VOC), is small in odor, energy-saving, environment-friendly, high in drying speed and flexibility, high-temperature resistant, good in adhesion and bright in color; the defects of non-resistance to high temperature, poor adhesion on a printing stock and the like of the existing UV offset printing ink can be overcome; and the ink is printed through offset printing on different film substrates such as non-absorptive materials like acrylonitrile-butadiene-styrene (ABS), polyvinyl chloride (PVC), polypropylene (PP), polyethylene terephthalate (PET) and o-phenylphenol (OPP), is widely applied to various film substrate printing, and is high in peel strength which can reach above 5N / cm<2>.

Owner:深圳市深赛尔股份有限公司

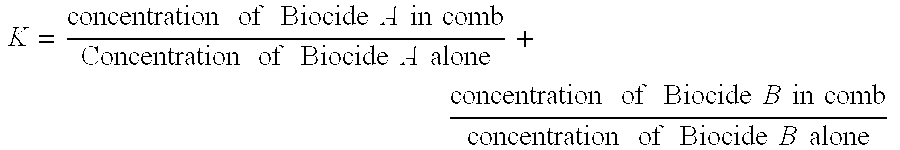

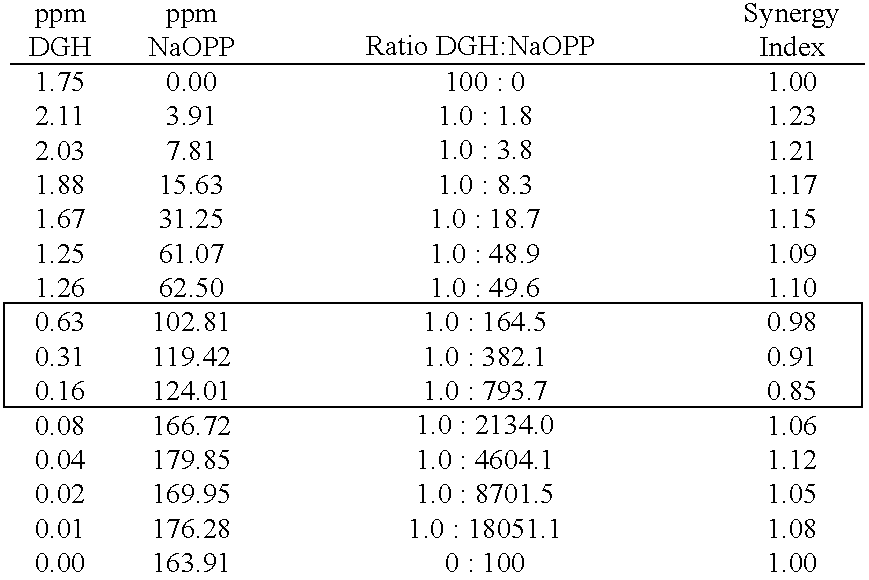

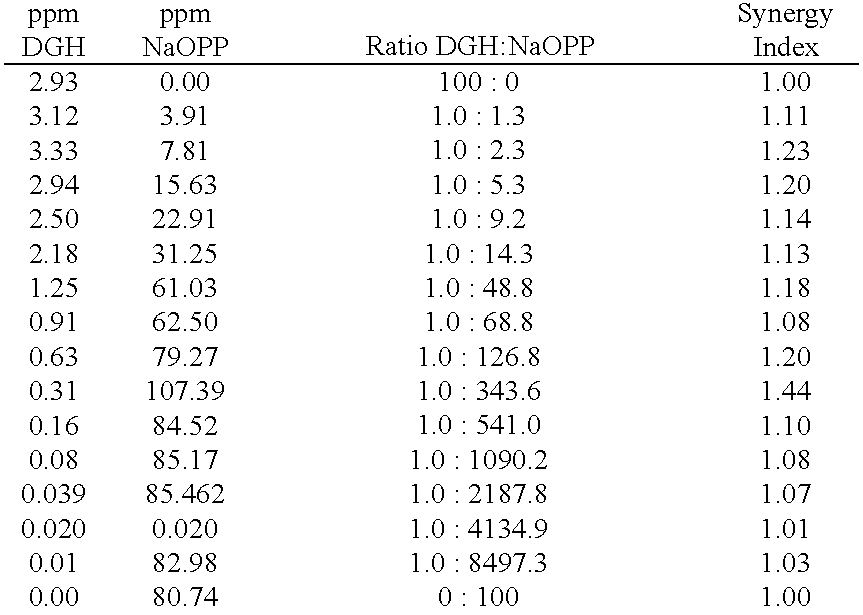

Synergistic Mixtures of O-Phenylphenol and Dazomet

InactiveUS20070203126A1Hydroxy compound active ingredientsNature of treatment waterO-PhenylphenolAntimicrobial compound

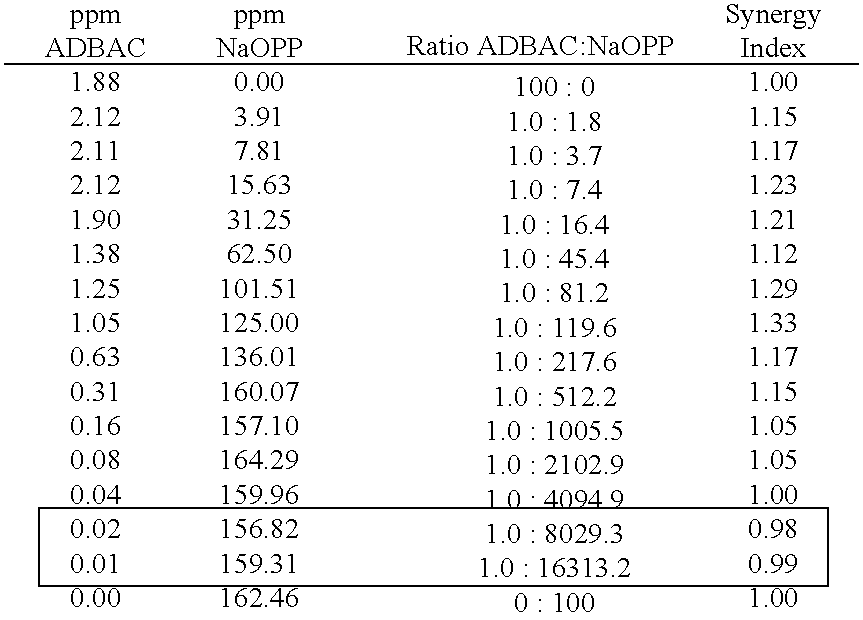

Ortho phenylphenol acts synergistically with various other antimicrobial compounds commonly used in industrial applications.

Owner:VERICHEM

Synergistic mixtures of o-phenylphenol and other nitrogen and aldehyde microbiocides

Ortho phenylphenol or its sodium salt is shown to form synergistic antimicrobial mixtures with nitrogen and aldehyde-containing microbiocides.

Owner:LENKSESS CORP

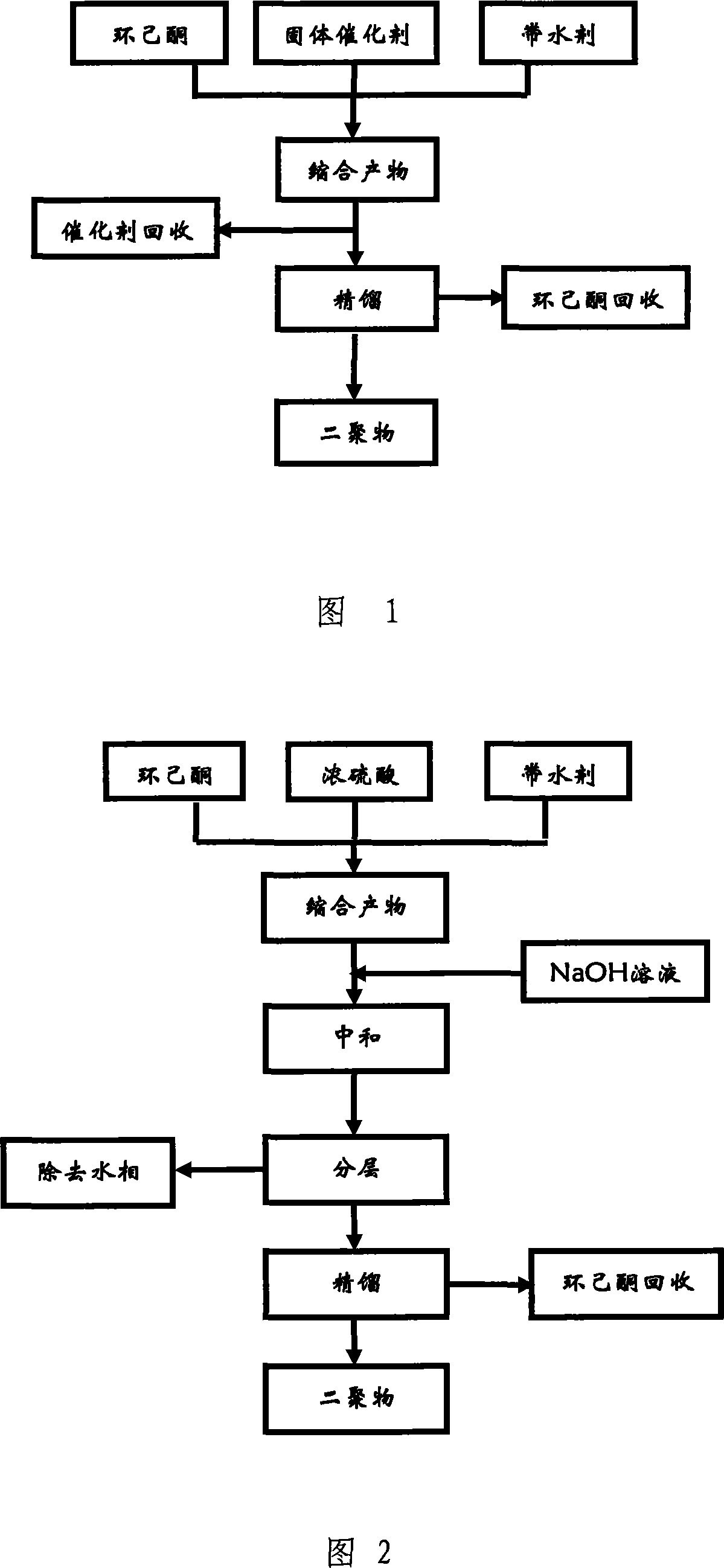

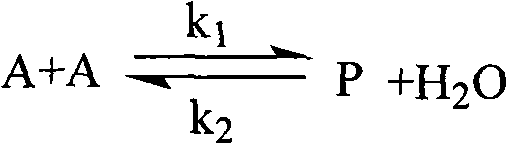

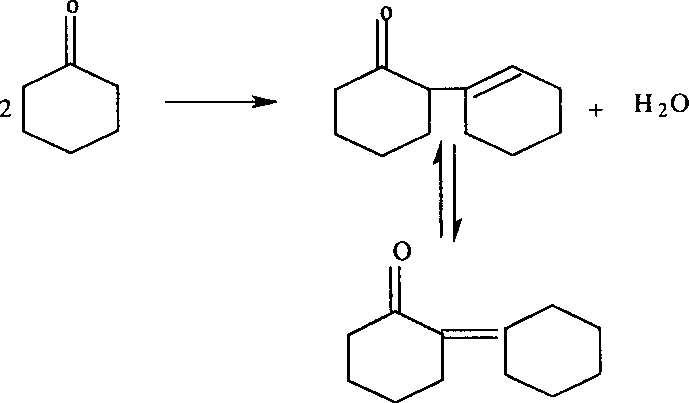

Utilization method of solid catalyst for cyclohexanone self-condensation reaction

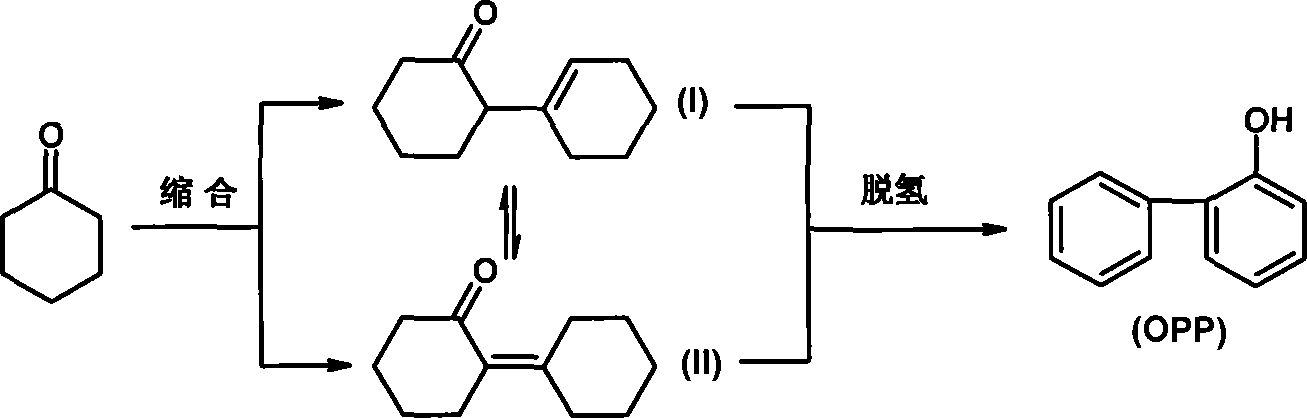

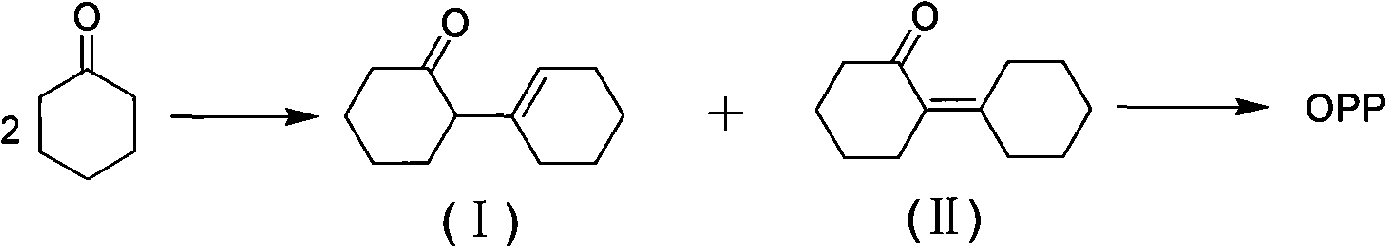

The invention relates to a method for using a solid catalyst for the self-condensing reaction of a cyclohexanone, which comprises the steps that an alumina-based solid catalyst is used in the first step of condensing and dehydrogenating the cyclohexanone to prepare the O-phenylphenol, namely the step of the self-condensing of the cyclohexanone, and a certain used amount of the appropriate water-carrying agents are used in the process of using the alumina-based solid catalyst for the condensation reaction of the cyclohexanone; wherein, the used amount of the solid catalysts corresponds to 2 per cent to 5 per cent of that of the cyclohexanone and the reaction time ranges from 4 to 8 hours; also that any water-carrying agents is unused is okay and the characteristic that the cyclohexanone carries water is utilized to accomplish the reaction; the cyclohexanone undergoes the self-condensing reaction so as to generate two resonance isomers, 2-(1-cyclohexenyl) (I) cyclohexanone and 2-cyclohexenyl alkylidene cyclohexanone (II), under the effect of the prepared solid catalysts, and two demeric products can be both used as the raw materials for carrying out the dehydrogenation to prepare the O-phenylphenol.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

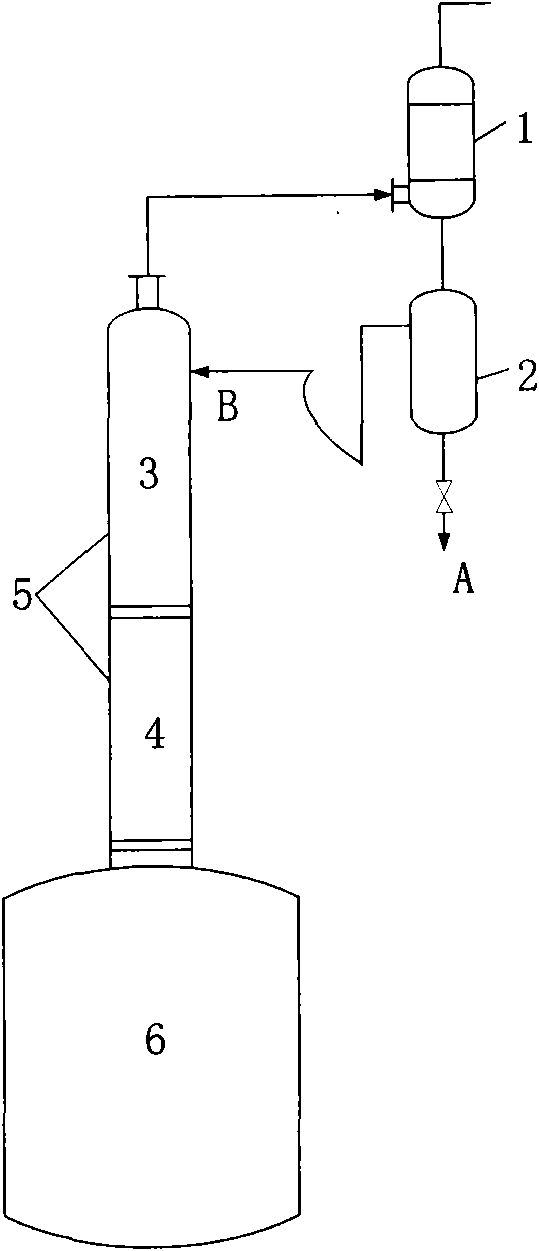

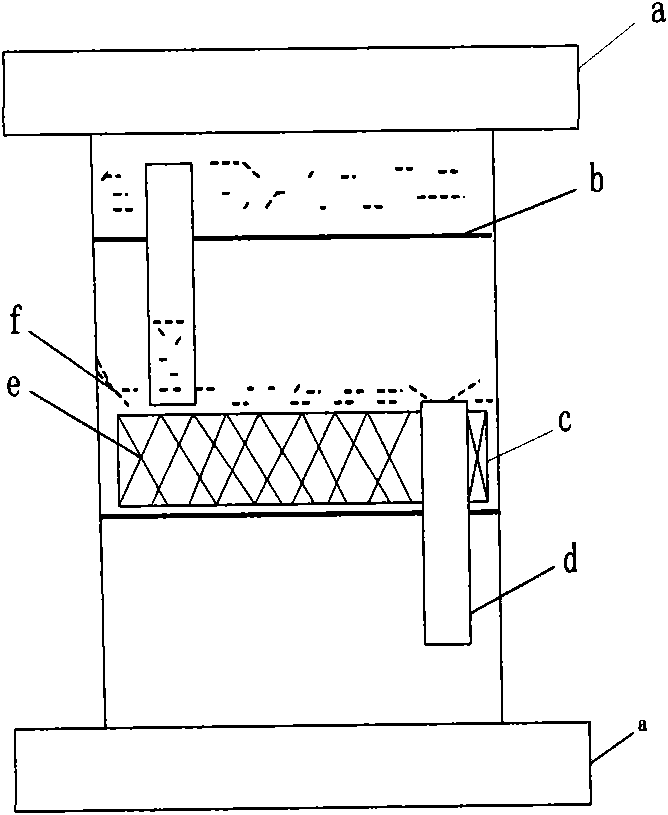

Device and method for preparing cyclohexenyl cyclohexanone

InactiveCN101613262AEmission reductionHigh selectivityOrganic compound preparationCarbonyl compound preparationCyclohexanoneLiquid layer

The invention relates to a device and a method for preparing cyclohexenyl cyclohexanone as an intermediate of o-phenylphenol. The device comprises a column bottom 6, a tower reactor 5, an all-reflex condenser 1 and an oil-water separator 2, wherein the reactor 5 consists of a reaction separation section 3 and a separation section 4; a catalyst bag is placed in a catalyst frame on a tower plate of the reaction separation section 3 of the tower separator, cyclohexanone in the column bottom is heated and steamed out and enters the tower plate of the reaction separation section 3 through the separation section 4 to form a liquid layer so that the catalyst in the catalyst frame is immersed in the cyclohexanone liquid, cyclohexanone undergoes a condensation reaction under the action of the catalyst to generate cyclohexenyl cyclohexanone and water, the cyclohexenyl cyclohexanone leaves the reaction section and moves towards the lower part of the tower under the separation action of the tower plate, and finally enters the column bottom, the generated water and cyclohexanone are steamed out together from the top of the tower and undergo phase splitting in the oil-water separator after being condensed. The once-through conversion of the cyclohexanone can reach over 95 percent and the selectivity of the cyclohexenyl cyclohexanone can reach over 98 percent.

Owner:江苏华派新材料科技有限公司 +1

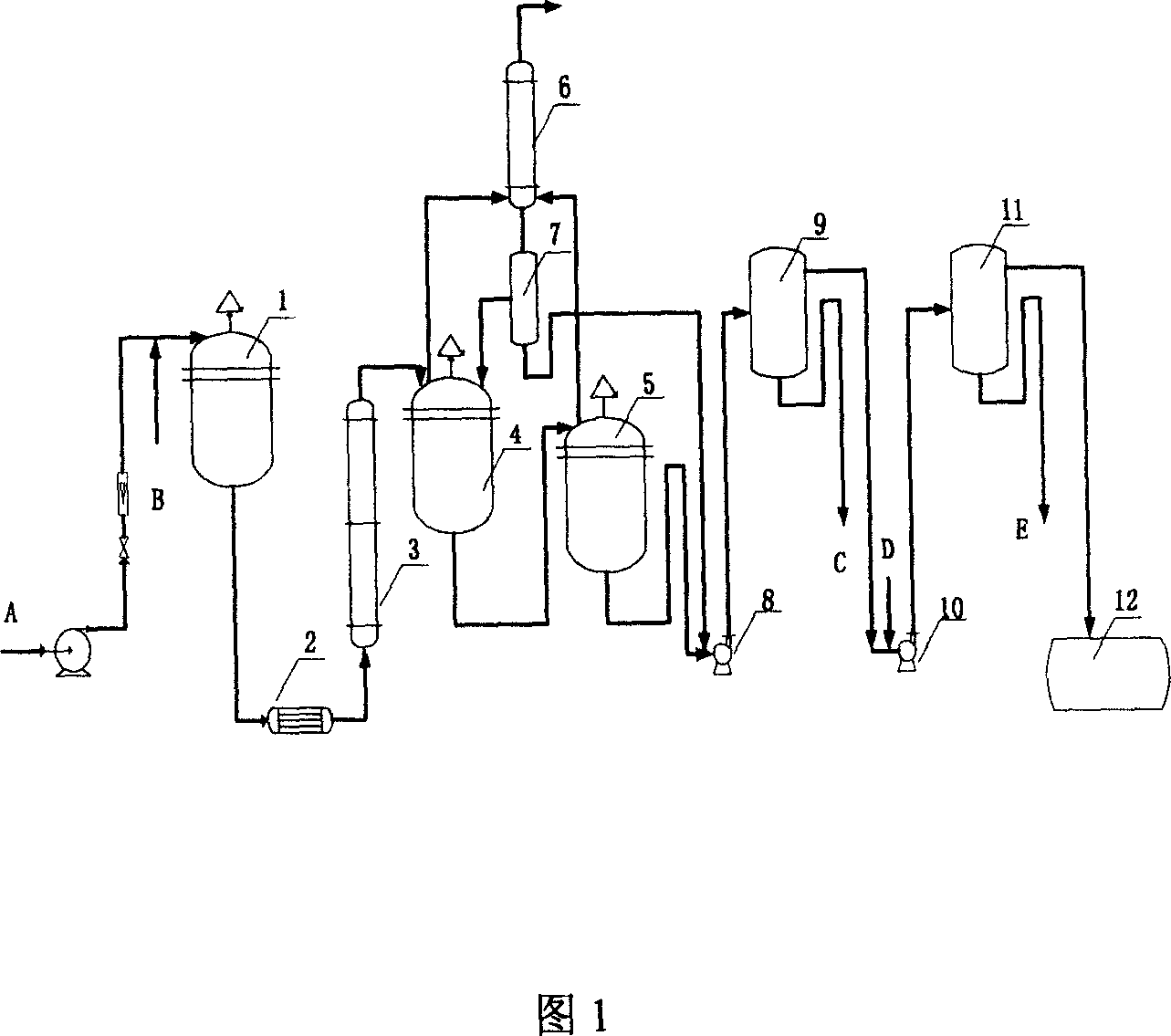

Method for producing cyclohexenyl anone from continuous condensating anone

InactiveCN101003471AReduce dosageRealize continuous industrial productionOrganic compound preparationCarbonyl compound preparationCyclohexanoneO-Phenylphenol

This invention relates to a method for producing cyclohexenyl cyclohexanone, an intermediate of 2-phenylphenol, from cyclohexanone by continuous condensation. The method comprises: premixing, preheating, performing multiple reactions, water washing, and alkali washing. The one-pass conversion rate of cyclohexanone is 50%, and the selectivity of cyclohexenyl cyclohexanone is higher than 96%.

Owner:江苏华派新材料科技有限公司 +1

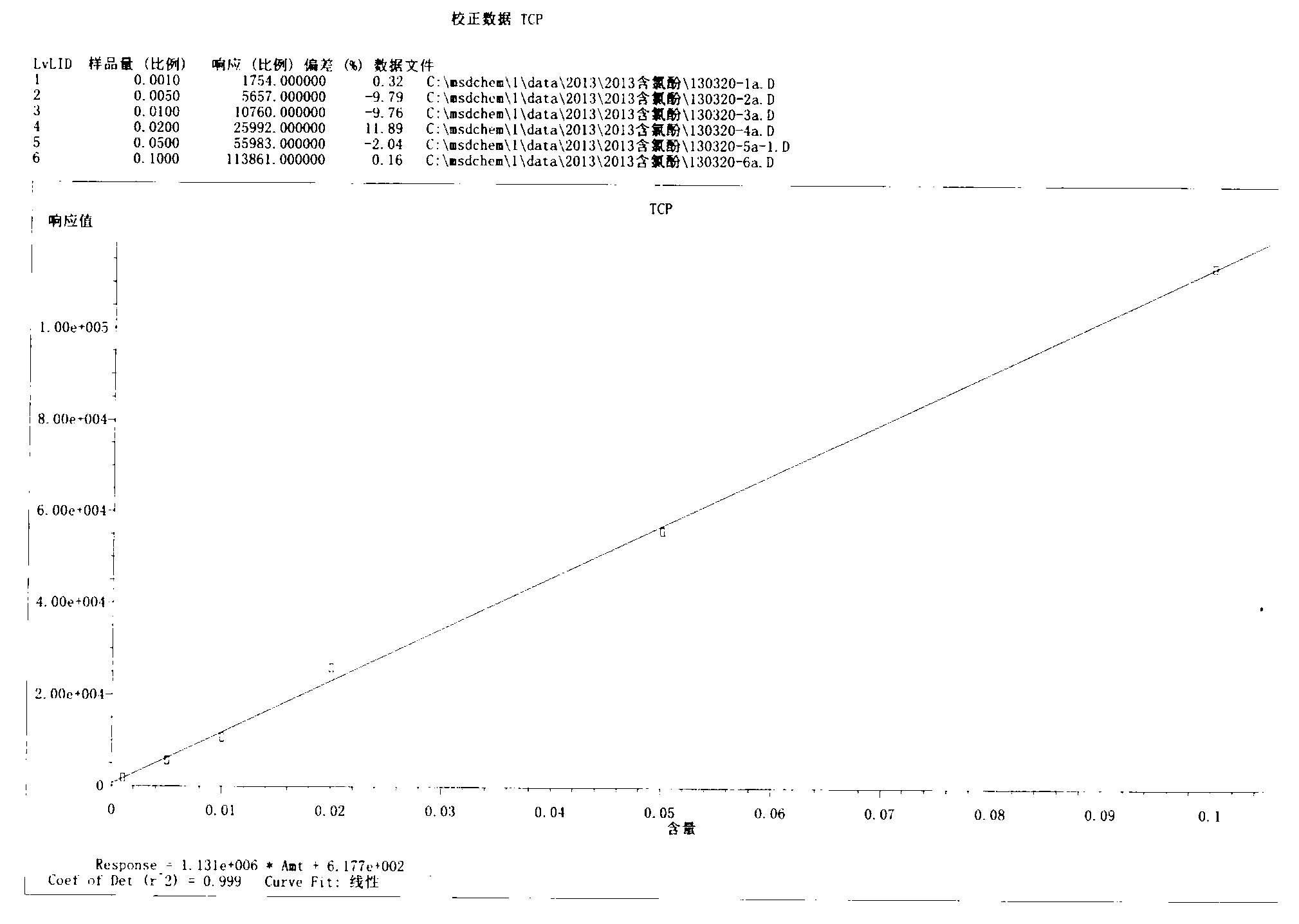

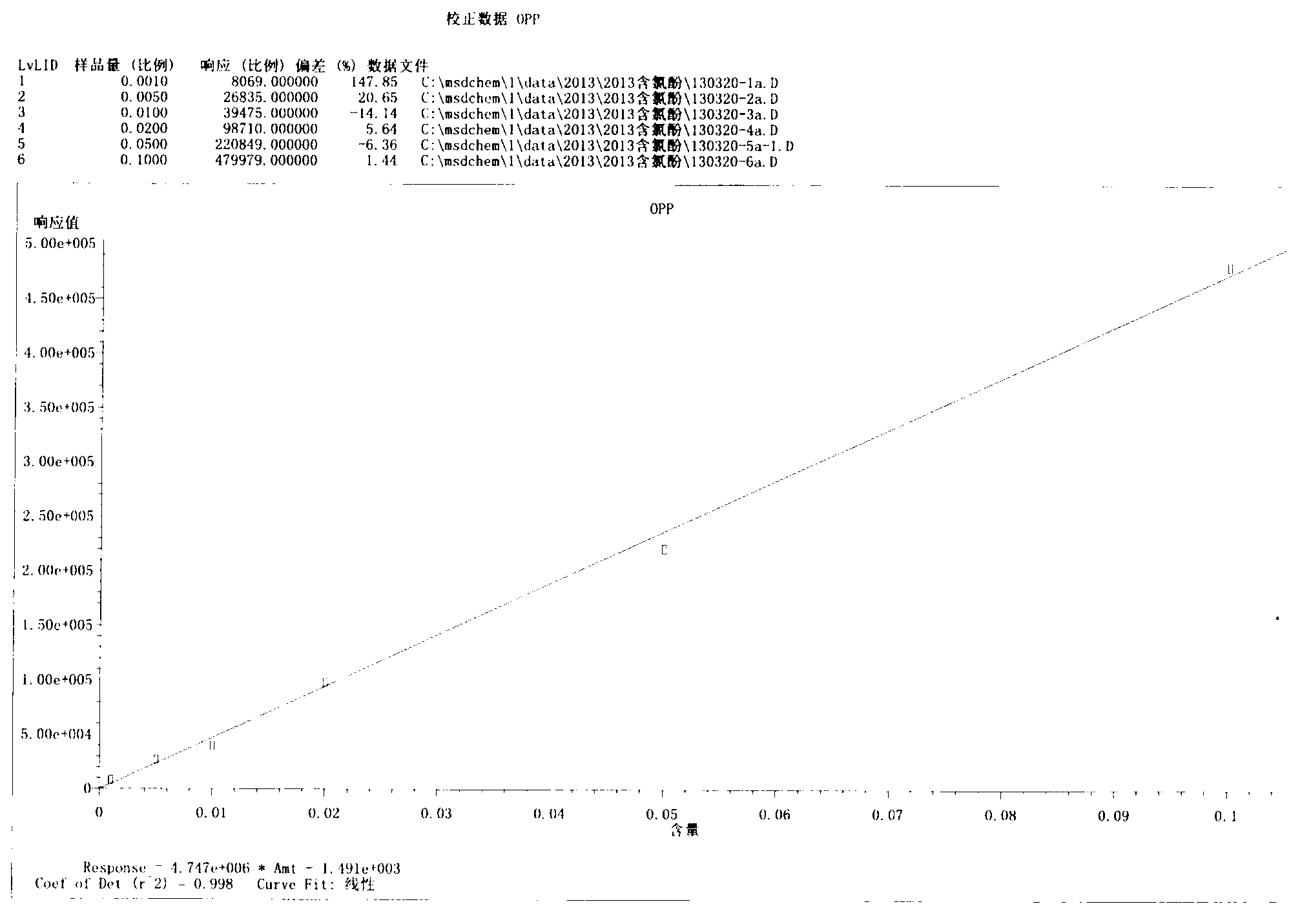

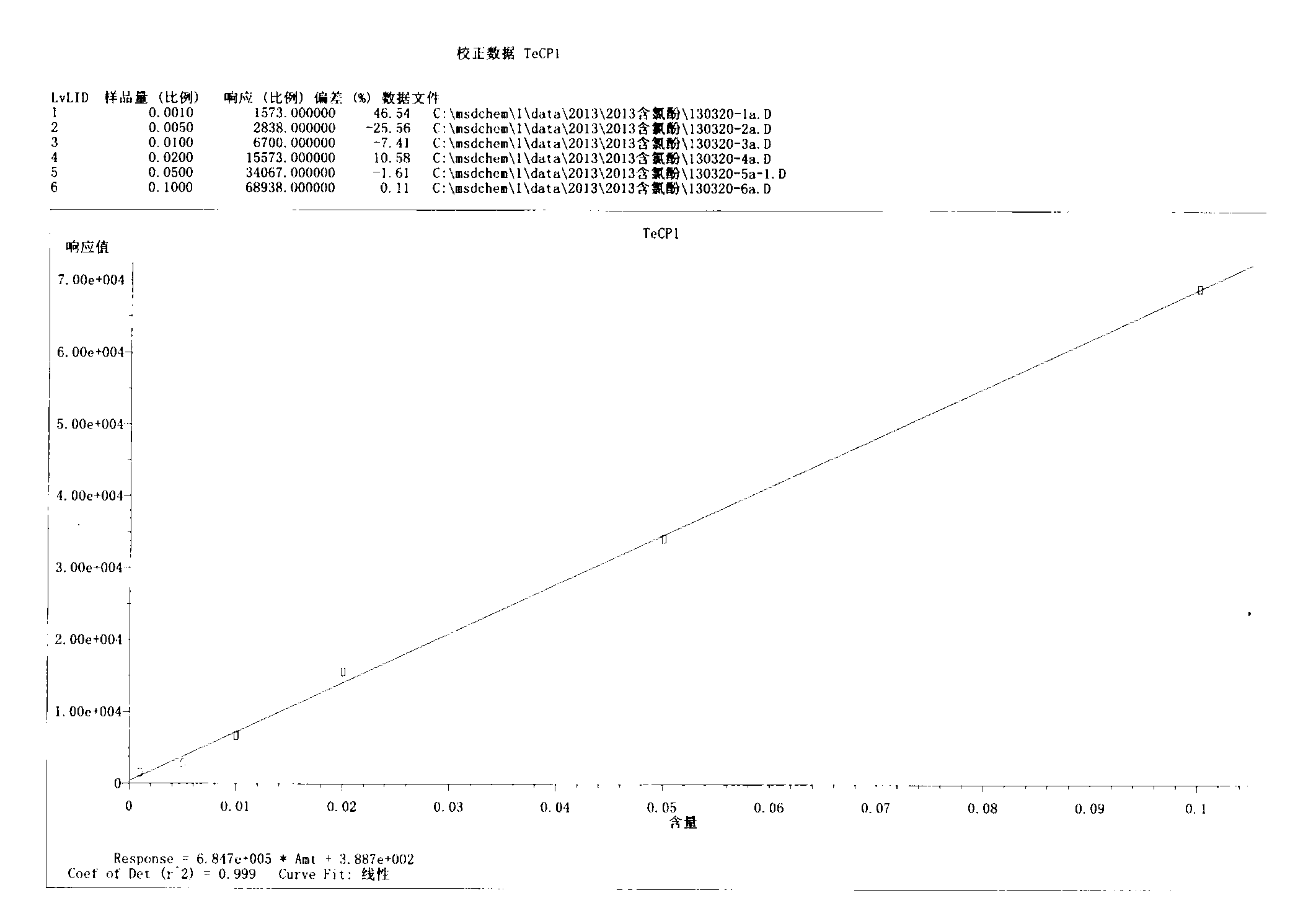

Method for detecting phenolic antibacterial agents in textiles through in-situ derivatization and dispersive liquid phase microextraction

The invention discloses a method for detecting phenolic antibacterial agents in textiles through the combined use of in-situ derivatization, dispersive liquid phase microextraction and gas chromatography / mass spectrometry. A technical program suitable for the simultaneous detection on five types of chlorinated phenols and o-phenylphenol in the textiles is established, a target compound is extracted by utilizing a dispersive liquid phase microextraction technology after being subjected to extraction and derivatization, and qualitative and quantitative analysis is carried out by using a gas chromatograph / mass spectrometer. The method can be applicable to the determination of the five types of chlorinated phenols and o-phenylphenol in the textiles such as clothes, fiber packing, yarns, clothing materials and household decoration products. The method is simple and rapid to operate, low in cost, environment-friendly and high in enrichment efficiency.

Owner:中华人民共和国苏州出入境检验检疫局

Wood-plastic composite environmentally-friendly decorative paper and production process thereof

InactiveCN101519861AGood finishWaterproofMechanical working/deformationSpecial paperSilicon moldPolyvinyl chloride

The invention relates to wood-plastic composite environmentally-friendly decorative paper. The wood-plastic composite environmentally-friendly decorative paper is produced in such a way that a decorative layer, a protective layer and a organic silicon mold release agent layer are sequentially attached to the surface of base paper, and a pressure-sensitive adhesive layer and a mold release paper layer are sequentially attached to the back surface of the base paper, wherein the protective layer can be an adhesive polythene (PE), polyethylene terephthalate (PET), bi-axially oriented polypropylene (BOPP), o-phenylphenol (OPP) or polyvinyl chloride (PVC) plastic film or sprayed polyethylene film. The wood-plastic composite environmentally-friendly decorative paper has favorable and obvious surface decorating effect, good ductibility and strong intensity of tension and is self-adhesive, waterproof and moistureproof and easy to paste and coat and does not deform, crack and bulge on surface when heated and cooled, thereby the wood-plastic composite environmentally-friendly decorative paper can be widely applied to food packing, decorative material and furniture material; in addition, the wood-plastic composite environmentally-friendly decorative paper is attractive in appearance and convenient to construct and manufacture, has clear patterns and characters and can be widely manufactured on a large scale in a factory with low cost, thereby being an larger improvement on surface decorating material.

Owner:杨建文

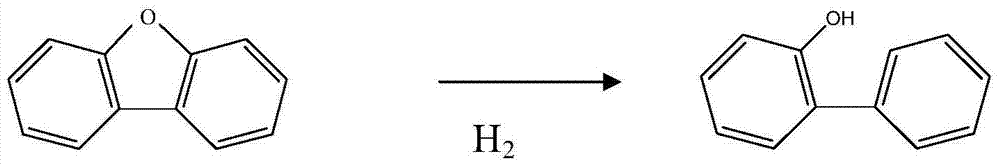

Catalyst composition and preparation method thereof, and method for preparing o-phenylphenol by using catalyst composition

ActiveCN104841421AHigh selectivityImprove adsorption capacityOrganic chemistryOrganic compound preparationActivated carbonO-Phenylphenol

The invention discloses a catalyst composition for catalyzing dibenzofuran for hydrogenation preparation of o-phenylphenol and a preparation method thereof, and a method for catalyzing dibenzofuran for hydrogenation preparation of o-phenylphenol by using the catalyst composition; the catalyst composition includes a hydrogenation catalyst active component and a carrier part, wherein an active substance in the catalyst active component is Pt or Pd; the carrier part is a solid carrier, and the solid carrier is selected from gamma-Al2O3, theta-Al2O3, SiO2 or activated carbon. The metal Pt or Pd having good catalytic performance on a hydrogenation reaction is subjected to preparation combination with the carrier such as gamma-Al2O3, theta-Al2O3, SiO2 or activated carbon, and the catalyst composition is applied in the reaction of catalyzing dibenzofuran for hydrogenation preparation of o-phenylphenol, and has better catalytic performance aiming at the reaction of dibenzofuran hydrogenation preparation of o-phenylphenol.

Owner:BEIJING RISUN TECH CO LTD

Wide spectrum disinfectant

The invention discloses methods of making and uses for wide spectrum disinfectants including as components an alcohol, O-phenylphenol, chlorhexidine gluconate, nonoxynol-9, benzalkonium chloride, and deionised double distilled water wherein on a weight / volume ratio the alcohol comprises from 50 to 80%, the O-phenylphenol comprises from 0.1% to 0.8%, the chlorhexidine gluconate comprises from 0.01 to 1%, the nonoxynol-9 comprises from 0.02 to 1%, and the benzalkonium chloride comprises from 0.15 to 1%.

Owner:ALDA PHARMA CORP

Antibacterial and mildew-proof treatment liquid of digital printing real-silk silk painting and antibacterial and mildew-proof post-treatment process

InactiveCN105421049AGood antibacterial and antifungal effectDoes not damage the structureBiochemical fibre treatmentAnimal fibresProtein structure2-Phenylphenol

The invention discloses components and a preparation method of antibacterial and mildew-proof treatment liquid of a digital printing real-silk silk painting and an antibacterial and mildew-proof post-treatment process. The treatment liquid is prepared from 2.00%-6.00% of phenyl salicylate, 0.10%-0.70% of dichlorophenol, 0.10%-0.40% of 2-phenylphenol, 0.10%-0.70% of N-octylisothiazolinone, 2.00%-6.00% of sodium alginate, 30.00%-45.00% of ethanol and 41.20%-65.70% of de-ionized water. All the components of the treatment liquid are added into a mixed solution of the ethanol and the de-ionized water and are stirred to be sufficiently dissolved; and the obtained liquid can be used for post-treatment process steps of starching a real-silk white blank of the digital printing real-silk silk painting, drying, drawing by spraying, steaming, washing with water, and impregnating by the antibacterial and mildew-proof treatment liquid and the like. The antibacterial and mildew-proof treatment liquid has a simple and convenient preparation process, has no toxicity and damages to human bodies and no any toxic side effect on the environment, does not damage a silk protein structure in a silk fabric and does not influence the real effect of the digital printing real-silk silk painting; and the difficulties that various bacteria are easily bred on the real-silk silk painting and the real-silk silk painting has mildew, so that the quality and service life of the painting are influenced are overcome.

Owner:SUZHOU SILKCUBE TEXTILE

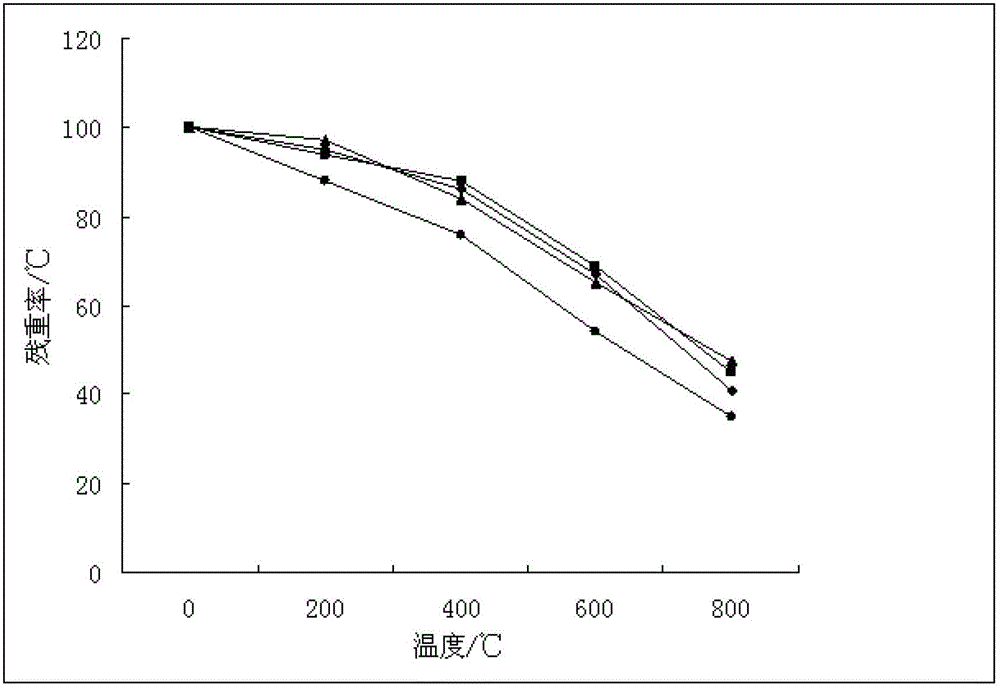

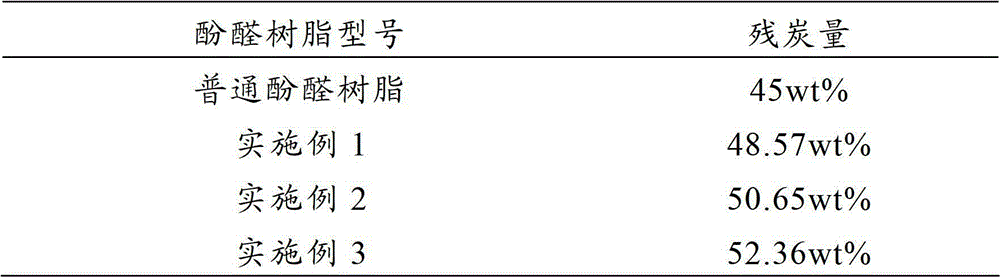

Preparation method of phenolic resin for refractory material

The invention provides a preparation method of phenolic resin for a refractory material. The method is as below: phenolic compounds, aldehyde compounds and o-phenylphenol are subjected to a polycondensation reaction under the action of an alkaline catalyst to obtain the phenolic resin. Through the polycondensation reaction of phenolic compounds, aldehyde compounds and o-phenylphenol, the o-phenylphenol is introduced into the phenolic resin; as aromatic ring is introduced into the phenolic resin, the phenolic resin gains increased carbon content; besides, the aromatic ring has high bond energy and stable structure, and is not easily broken for ablation under high temperature, so that the phenolic resin gains increased residual carbon content and high stability. The experiment results show that the phenolic resin prepared by the invention has residual carbon content of 48wt%-52.5wt%.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

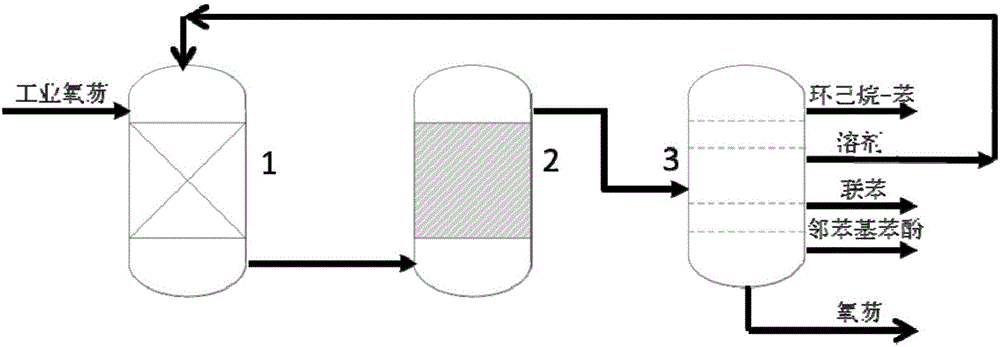

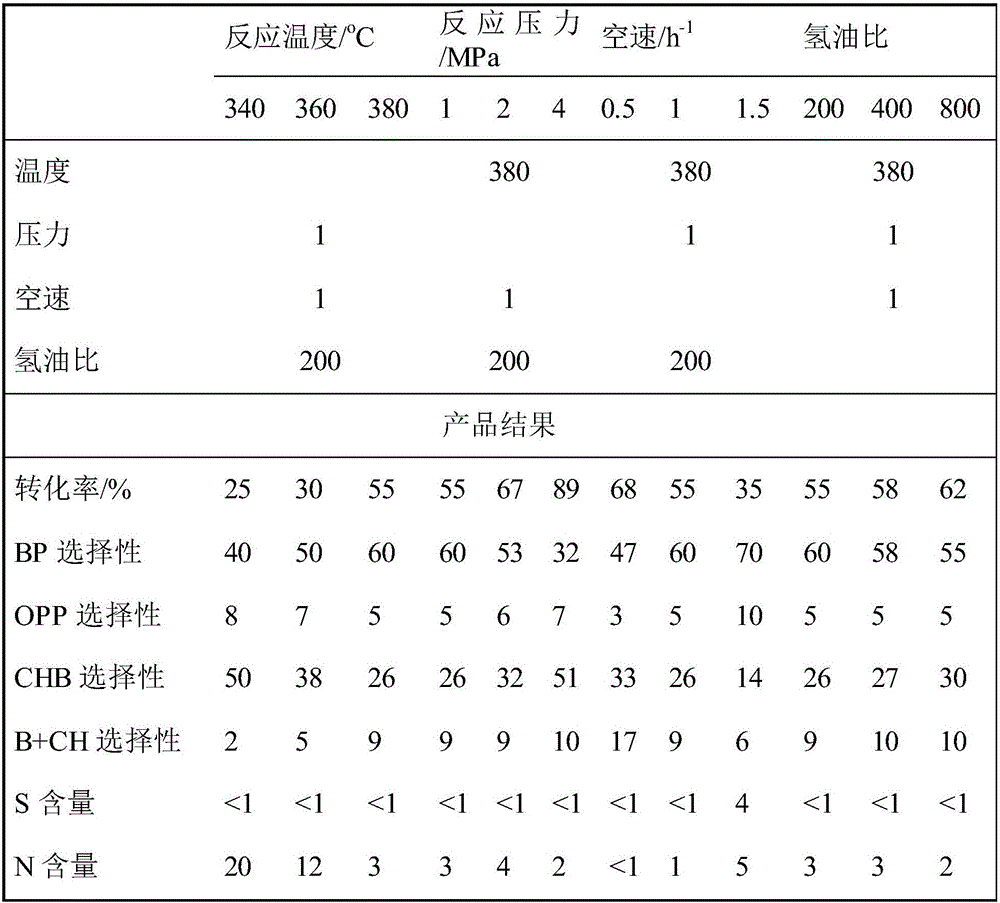

Preparation method for preparing biphenyl and o-phenylphenol by hydrofining industrial dibenzofuran

ActiveCN106495991AIncrease added valueHigh selectivityOrganic compound preparationHydrocarbon from oxygen organic compoundsComing outFixed bed

The invention provides a preparation method for preparing biphenyl and o-phenylphenol by hydrofining industrial dibenzofuran, and belongs to the field of fine chemical synthesis. The industrial dibenzofuran is dissolved in a dissolving kettle by a solvent, a dissolving temperature is 80-100 DEG C, and the industrial dibenzofuran organic solution after dissolving is injected into a fixed bed reactor loaded with a hydrofining catalyst and undergoes a hydrofining reaction; after the hydrofining reaction, the product directly enters a rectifying tower and is rectified, and cyclohexane and benzene come out of a tower top; according to the boiling point, an extracted solvent is circulated for re-dissolving the industrial dibenzofuran, the extracted biphenyl is directly granulated as a product, the extracted o-phenylphenol is directly granulated as a product, and refined dibenzofuran is extracted from a tower bottom; and the refined dibenzofuran as a raw material is used for production of o-phenylphenol. The biphenyl and the o-phenylphenol with high additional value are produced by the industrial dibenzofuran; the used catalyst has super high selectivity and relatively high hydrogenation activity. The method has good economic benefits and industrial application prospects.

Owner:DALIAN UNIV OF TECH

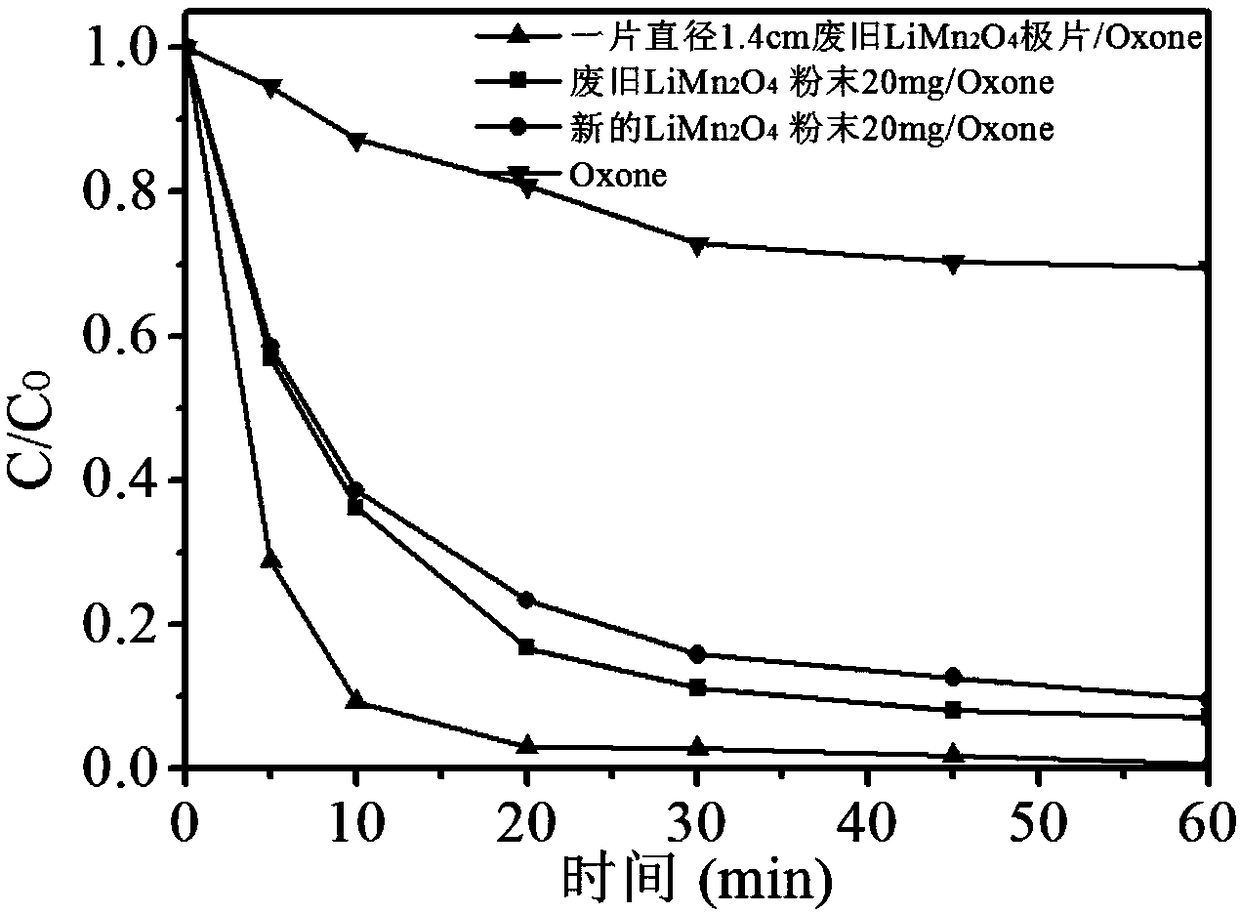

A method for recovering and reusing waste lithium ion battery

InactiveCN109244498AAvoid pollutionLow costReclaiming serviceable partsWaste accumulators reclaimingPotassium persulfateEngineering

The invention relates to a method for recovering and reusing waste lithium ion batteries, comprising the following steps: (1) placing the waste lithium ion batteries in an airtight box for disassembling to obtain an active positive electrode sheet; 2, collectING that active positive electrode sheet, and cleaning the active positive electrode sheet with deionize water and ethanol; (3) drying and recycling the washed materials; (4) at room temperature, adding appropriate amount of dried material into o-phenylphenol solution, and then adding a certain amount of potassium persulfate complex salt to generate SO4-. to oxidize and degrade o-phenylphenol. Compared with the prior art, the invention has the advantages of short aging time and simple operation, on the one hand, the problem of environmental pollution caused by waste lithium ion battery and secondary pollution caused by metal extraction is solved; On the other hand, it is used in the treatment of refractory sewage, which saves the cost of treatment and creates environmental benefits.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

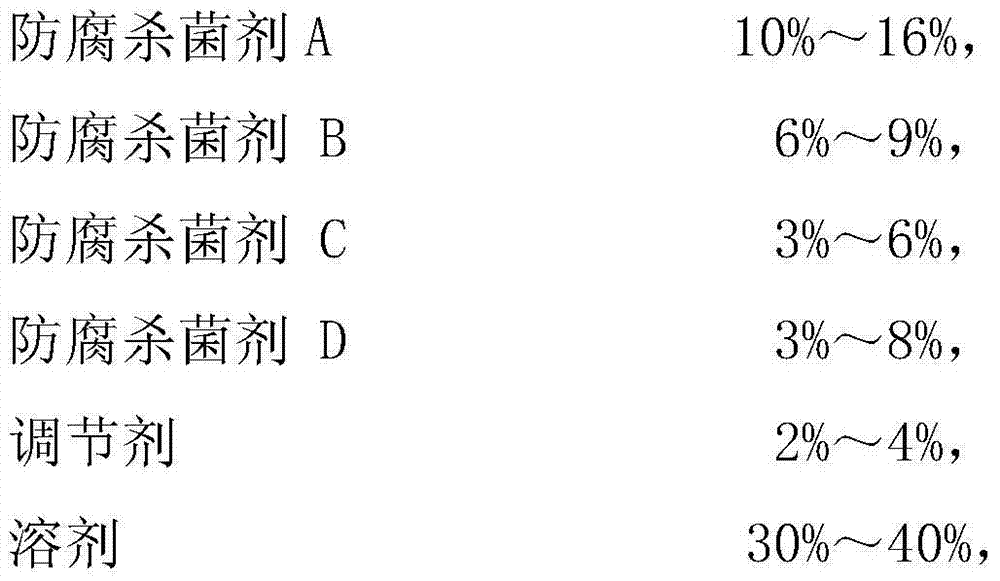

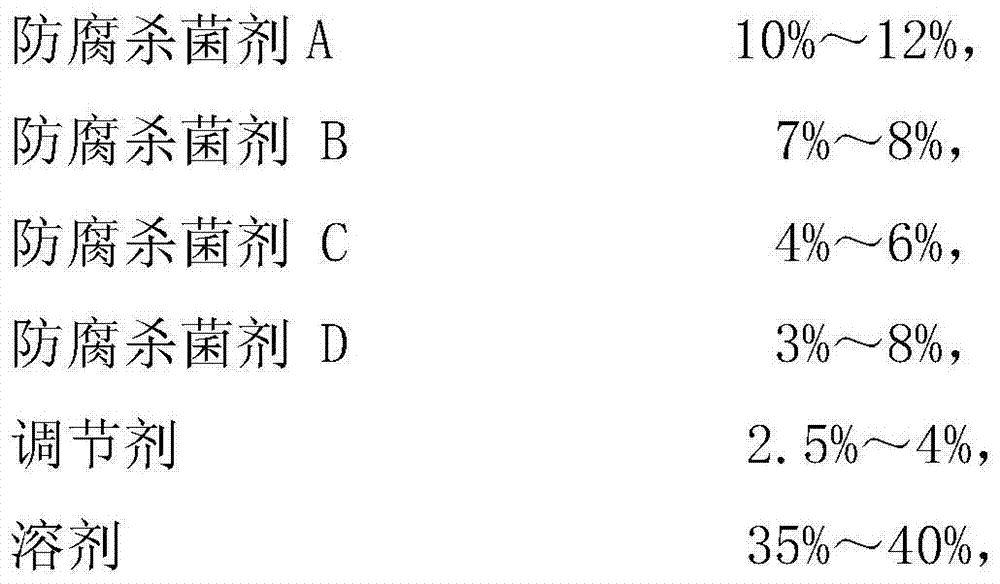

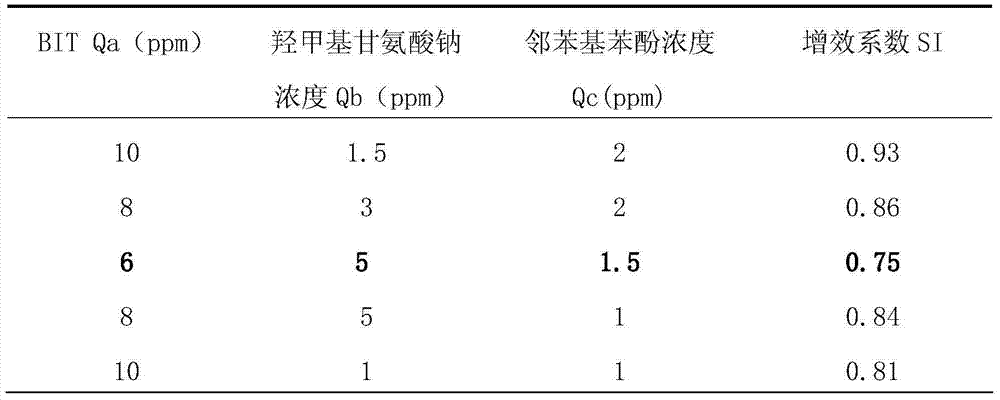

Composite synergistic bactericidal and preservative agent for organic foaming agents

ActiveCN103931627AExpand the scope of protectionHigh activityBiocideFungicidesSodium PyrithionePhenethyl alcohol

The invention relates to a composite synergistic bactericidal and preservative agent for organic foaming agents, which is prepared from 2-methylisothiazolinone and / or 1,2 benzisothiazolinone (BIT) and / or dichloroethylene based salicylamide, sodium pyrithione and / or sodium hydroxymethylglycinate, sodium dimethyldithiocarbamate and / or o-phenylphenol, phenethyl alcohol and / or phenylcarbinol, a regulator, a solvent and water. According to the invention, different bactericidal and preservative agents with various complementary bactericidal spectrums are composited, so that the products have the advantages of reasonable formula, comprehensive protection, strong synergism, good bactericidal and preservative effects and the like, and have a good application effect when being used in aqueous organic foaming agents containing large amounts of proteins and organic polysaccharides.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

O-phenylphenol/alkoxylated amine wood protection compositions

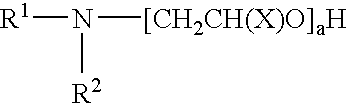

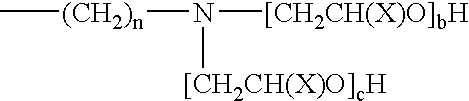

ActiveUS20060025308A1Improve protectionHigh activityBiocideDead plant preservationSolubilityO-Phenylphenol

A composition for protecting wood from decay, mildew and sapstain comprises o-phenylphenol in combination with an alkoxylated amine, wherein the weight ratio of alkoxylated amine to o-phenylphenol ranges from 1:1 to 10:1. Organic or inorganic acids may be added to enhance solubility of the alkoxylated amines.

Owner:U C COATINGS CORP

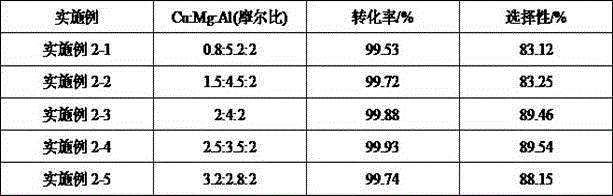

Preparation method of high-dispersion copper-based catalyst based on non-precious metal

ActiveCN103331160AReduce manufacturing costHigh activityOrganic chemistryOrganic compound preparationCyclohexanoneMagnesium salt

The invention discloses a preparation method of a high-dispersion copper-based catalyst based on non-precious metal, and relates to a production technique of a catalyst in medicine and a dye. The method comprises the steps of dissolving copper salt, magnesium salt and aluminum salt in deionized water, compounding a solution A, dissolving precipitators sodium carbonate and sodium hydroxide in the deionized water, compounding a solution B, dropwise adding the solution A and the solution B to the deionized water for ageing, transferring the aged mixed solution to a stainless steel hydrothermal reaction kettle for crystallization, filtering, washing, drying, roasting, conducting reduction activation, and obtaining the copper magaluma catalyst used for preparing o-phenylphenol. The method lowers the production cost of o-phenylphenol, and allows active components to achieve length dispersion, and the high-dispersion copper-based catalyst is adopted, so that a conversion rate of cyclohexenyl cyclohexanone reaches above 99.9%, and the selectivity of o-phenylphenol is about 90%.

Owner:YANGZHOU UNIV

Perfluoroelastomer composition and perfluoro rubber molded article

ActiveUS20070072973A1Good cross-linking effectEasy to processFibre treatmentConductive materialTetrafluoroethylenePolymer science

A perfluoroelastomer composition comprises a perfluoroelastomer (e.g., tetrafluoroethylene / perfluoro(methyl vinyl ether) copolymer), an organic peroxide (e.g., 2,5-dimethyl-2,5(tert-butylperoxy)hexane and a scorch retarder (e.g., o-phenylphenol), and the perfluoroelastomer composition is excellent in processability and unlikely to scorch. Furthermore, a perfluoro rubber molded article obtained by thermal crosslinking of the perfluoroelastomer composition is excellent in rubber physical properties such as tensile strength and elongation at break and in a compression set property.

Owner:ASAHI GLASS CO LTD

Catalyst used for preparing O-phenylphenol and its preparation method

InactiveCN1911508ALow costImprove conversion rateOrganic chemistryOrganic compound preparationCyclohexanonePolymer science

The present invention relates to one kind of catalyst for preparing o-phenyl phenol and its preparation process, and is especially one kind of Ni-Cu catalyst for preparing o-phenyl phenol and its preparation process. The catalyst has main catalyst component of metal Ni and Cu and co-catalyst component of Cr, K, etc supported onto active gamma-Al2O3 through a dipping process. The supported amounts of Ni, Cu, Cr and K are 1-20 wt%, 1-20 wt%, 4-8 wt% and 4-8 wt% separately. The catalyst of the present invention has cyclohexenyl cyclohexanone converting rate up to 98 %, and o-phenyl phenol selectivity of 90 %, as well as low cost and high stability.

Owner:NANJING UNIV OF TECH

Sterilized clean wet napkin and preparation method thereof

InactiveCN101953654AReduce pollutionBroad spectrumAbsorbent padsDomestic applicationsAlcoholO-Phenylphenol

The invention discloses a sterilized clean wet napkin and a preparation method thereof. The sterilized wet napkin comprises a sterilized clean solution and non-woven cloth adsorbing the sterilized clean solution and is characterized in that the sterilized clean solution comprises the following components by mass based on 100% by mass of sterilized clean wet napkin: (a) 0.25-0.35 percent of o-phenylphenol bactericide, (b) 0.02-0.04 percent of o-benzyl parachlorophenol bactericide, (c) 0.5-2.0 percent of surfactant, (d) 0.5-1.5 percent of alcohol solvent, (e) 0-0.5 percent of alkali auxiliary agent and (f) the balance of purified water. The sterilized clean wet napkin has wide bactericidal spectrum and is suitable for different materials; and the influence of environmental factors on the fungicidal effectiveness of the sterilized clean wet napkin is less.

Owner:TONGLING JIEYA BIOLOGIC TECH

High-strength food bag and preparation method thereof

InactiveCN104893262AImprove mechanical propertiesImprove antibacterial propertiesBio-packagingClimate change adaptationPolyethylene terephthalate glycolPolyethylene terephtalate

The invention discloses a high-strength food bag and a preparation method thereof. The preparation method comprises the following steps: (1) mixing raw materials, and carrying out thermal treatment, so as to form a mixture; (2) carrying out extrusion molding on the mixture, so as to prepare a plastic film; and (3) processing the plastic film into the high-strength food bag, wherein the raw materials include polyethylene terephthalate, o-phenylphenol, fillers, a coupling agent, natural silk, asbestos, white carbon black, fructus gleditsiae, fruticose dracaena leaves, diatomite, bran, hemp palm, bamboo clothing, starch, rhizoma alpiniae officinarum, rhizoma cimicifugae, clove and flos magnolia. The high-strength food bag prepared by virtue of the preparation method has excellent mechanical strength and mould resistance, and meanwhile, the raw materials in the preparation method are easily available, so that the industrial volume production of the high-strength food bag can be realized.

Owner:TONGLING FOUNDER PLASTICS TECH

Synthesis method of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide

ActiveCN102127115AReduce lossesLower requirementGroup 5/15 element organic compoundsHydrogenO-Phenylphenol

The invention discloses a synthesis method of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide. The method comprises the following steps: mixing o-phenylphenol and phosphorus trichloride according to a weight ratio of 1:0.75-0.85, adding catalyst to dissolve, reacting at 100-110 DEG C for 2.5-3.5 hours, then reacting at 120-130 DEG C for 5.5-6.5 hours, performing reflux reaction at 140-160 DEG C, dissolving, decoloring, hydrolyzing, removing solvent, performing atmospheric distillation in a distillation kettle at 125-135 DEG C, and then performing reduced pressure distillation under the conditions that the vacuum degree is no less than 0.09MPa and the inner temperature of the distillation kettle is 140-150 DEG C, to obtain the product 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide.

Owner:山东旭锐新材股份有限公司 +1

Synthetic method of o-phenylphenol

InactiveCN101555196APromotion of inhibition of decompositionHigh selectivityOrganic chemistryOrganic compound preparationAlkaline earth metalDecomposition

The invention discloses a synthetic method of o-phenylphenol. The method comprises the following steps: Pt / C catalyst modified by alkali metal carbonate or alkali earth metal carbonate and cyclohexanone dimer are added in a reaction vessel, nitrogen is charged for 2-3 times to replace the air in the reaction vessel, and then heating is conducted under stirring to temperature of 320 to 400 DEG C ; the reaction pressure is 0.6 to 2MPa, the reaction is stopped when the content of intermediate o-cyclohexyl alkylphenol in the reaction liquid is less than 2 percent, and the reaction liquid is cooled to the temperature of 60 to 70 DEG C and filtered to obtain the filtrate containing o-phenylphenol. The core of the method is that the active carbon carrier is modified by alkali metal carbonate or alkali earth metal carbonate so as to inhibit the promotion action of the acid center on the active carbon to the decomposition of the reaction material, namely, cyclohexanone dimer, and simultaneously provide proper alkaline condition for the generation of the o-phenylphenol, therefore, the selectivity of the catalyst is greatly improved. Moreover, the production efficiency of the catalyst in process unit is high, the recovery of the catalyst is convenient, and the method is beneficial to industrialization.

Owner:ZHEJIANG UNIV +1

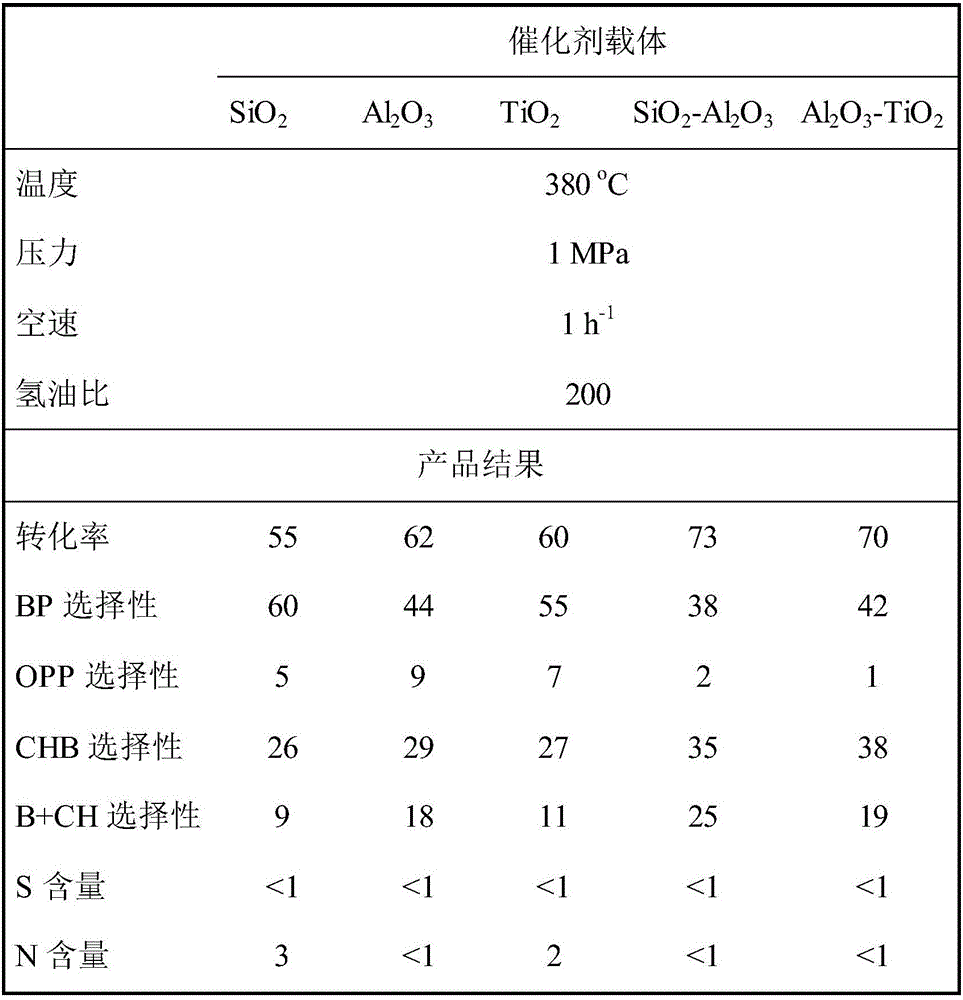

Preparation method of eggshell-type noble metal catalyst and method of using same for dibenzofuran hydrogenation ring opening to prepare o-phenylphenol

ActiveCN105879862AReduce dosageGood benefitOrganic chemistryOrganic compound preparationEggshellO-Phenylphenol

The invention provides a preparation method of an eggshell-type noble metal catalyst and a method of using the same for dibenzofuran hydrogenation ring opening to prepare o-phenylphenol and belongs to the technical field of industrial catalysis. The preparation method includes: adding a carrier into a platinum metal salt solution; controlling deposition of platinum nanoparticles on the surface of the carrier through quick reductive reaction and solution viscosity; filtering, washing, and heating for drying in an inert atmosphere to form an eggshell-type platinum catalyst which is stable. The preparation method has the advantages of simple process, controllable structure and low process energy consumption; platinum particles in the eggshell-type platinum catalyst prepared by the method are uniformly distributed on the surface of the carrier, so that consumption of metal platinum is lowered, cost of the catalyst is lowered effectively, and the eggshell-type platinum catalyst has good industrial application prospect. The eggshell-type platinum catalyst presents excellent catalysis performance and long service life in reaction for dibenzofuran hydrogenation ring opening to prepare o-phenylphenol.

Owner:DALIAN UNIV OF TECH +1

Preparation method of high-barrier CPP (casting polypropylene) aluminized film

InactiveCN105584183AGood alkali resistanceGood flexibilityLamination ancillary operationsSynthetic resin layered productsPolyethylene terephthalate glycolPolyethylene terephtalate

The invention discloses a preparation method of a high-barrier CPP (casting polypropylene) aluminized film, which comprises the following steps: step 1, preparation of a high-barrier film: completely mixing the following ingredients by weight parts: 35-50 parts of polyethylene terephthalate (PET), 5-10 parts of o-phenylphenol and 5-20 parts of polyvinylidene chloride, centrifuging the mixture in a high-speed centrifuge, performing polymerization reaction; then performing extrusion molding on the material after polymerization reaction with a twin-screw extruder, cooling and drying to obtain the high-barrier film; step 2, selecting a PET base film with haze of 55-59.8% and light transmittance of 86-89%; and pasting the high-barrier film obtained in step 1 on the PET base film to obtain a PET film; step 3, performing corona on the upper surface of the PET film obtained in step 2; step 4, paving a fiberglass mesh layer on the surface of the PET film after corona; and step 5, performing vacuum aluminizing on the surface of the fiberglass mesh layer of the PET film by a vacuum aluminizing machine to form an aluminized layer, so as to obtain the high-barrier CPP aluminized film.

Owner:嘉兴鹏翔包装材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com