Device and method for preparing cyclohexenyl cyclohexanone

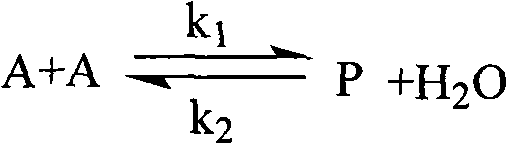

A technology for preparing cyclohexenyl cyclohexanone and a device, which is applied in the field of preparation of cyclohexenyl cyclohexanone with high selectivity, and can solve the problem of selectivity decline, increased chance of by-products, and single-pass conversion rate of cyclohexanone No high problems, to achieve the effect of reducing wastewater discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

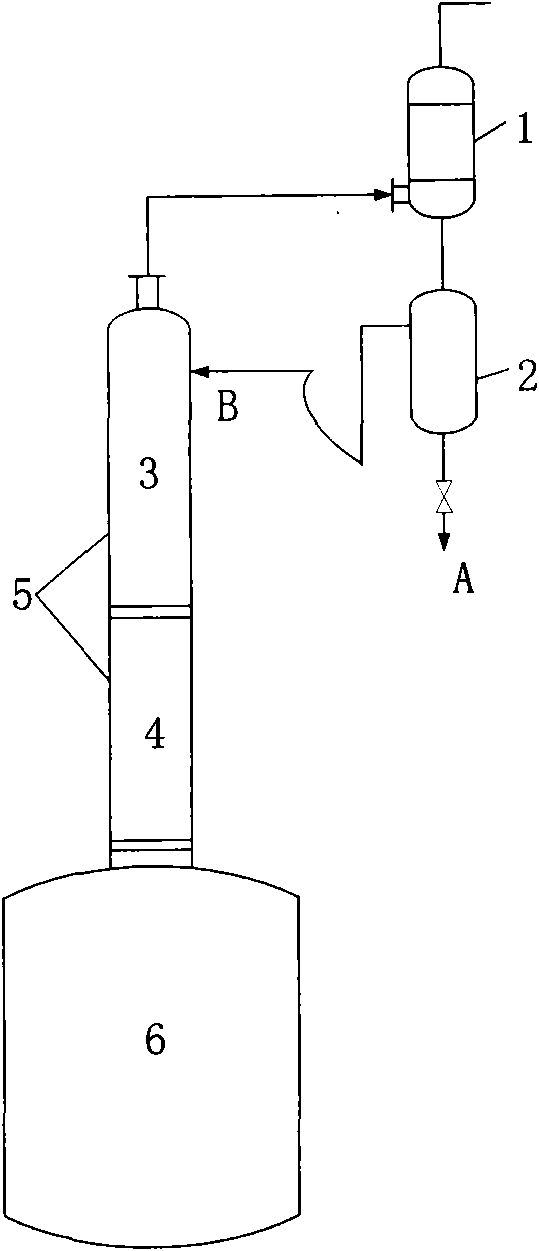

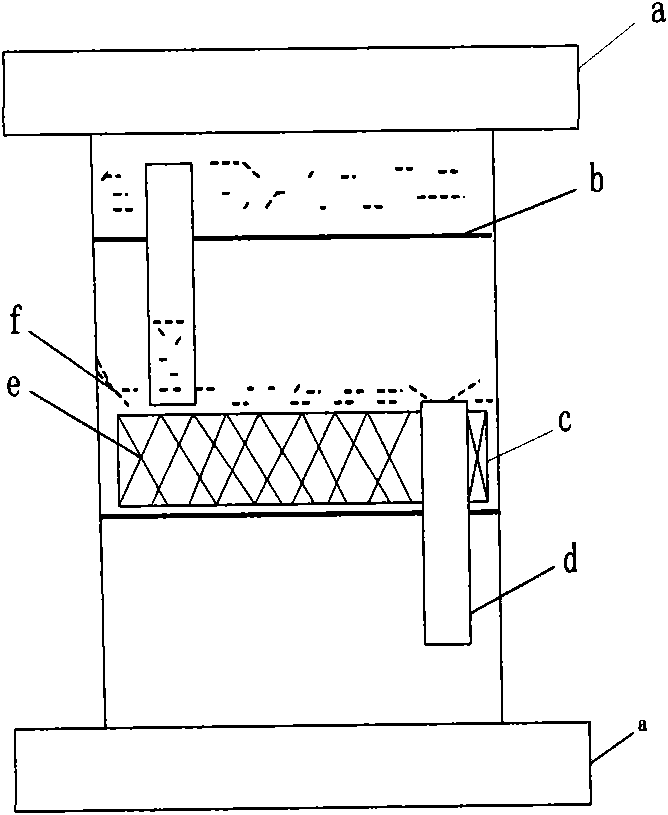

[0029] exist figure 1Coupling of cyclohexanone condensation and separation to prepare cyclohexenyl cyclohexanone The tower kettle is 1000L, heated with electricity; the inner diameter of the tower is Φ300mm, the separation section is filled with high-efficiency wire mesh corrugated packing, and the height is 3m; the reaction separation section has a total of 10 The first sieve plate is equipped with a catalyst frame on the 1st, 3rd, 5th, 7th, and 9th sieve plate from top to bottom. The catalyst frame is made of a 1mm thick perforated plate with an outer diameter of Φ290mm and a frame height of 8cm. The plate is 3cm, and the downcomer is 12cm high. Each frame is equipped with a catalyst package, and the catalyst package contains 1kg of phosphotungstic acid solid acid catalyst supported by 20-40 mesh activated carbon, and 5kg of catalyst is installed in five frames. Add 700 kg of cyclohexanone into the 1000 L tower kettle 1, and heat it to boiling under normal pressure. A liqu...

Embodiment 2

[0033] The same device as in Example 1, a catalyst bag is housed in each frame, and 20-40 mesh cationic resins are loaded with FeCl in the catalyst bag. 3 0.5kg of solid acid catalyst, 2.5kg of catalyst in five frames, and other conditions are the same.

[0034] After the reaction, the heating was stopped, and the gas chromatographic analysis was adopted for sampling and the condensation product was composed of: 3.0% cyclohexanone, 96.15% cyclohexenyl cyclohexanone, 0.85% polycondensate, and about 96.5% cyclohexanone single-pass conversion rate. The reaction selectivity is 98.8%, and the purity of cyclohexenyl cyclohexanone after direct distillation of the condensation product reaches 99.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com