Preparation method of eggshell-type noble metal catalyst and method of using same for dibenzofuran hydrogenation ring opening to prepare o-phenylphenol

A noble metal catalyst, o-phenylphenol technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, preparation of organic compounds, chemical instruments and methods, etc., can solve the problem of decreased catalyst activity and selectivity, high catalyst cost , high equipment investment and other issues, to achieve good industrial application prospects, reduce catalyst costs, and evenly distribute the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

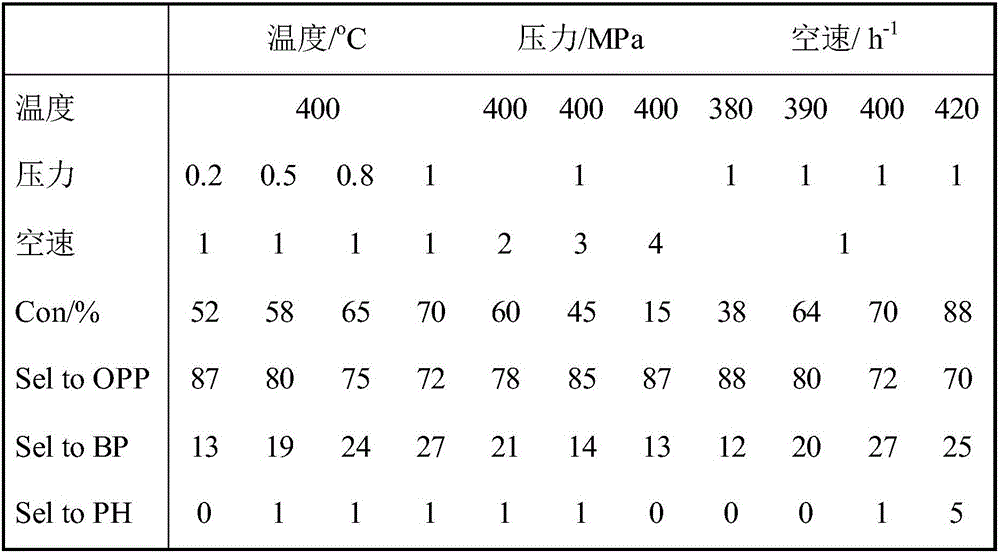

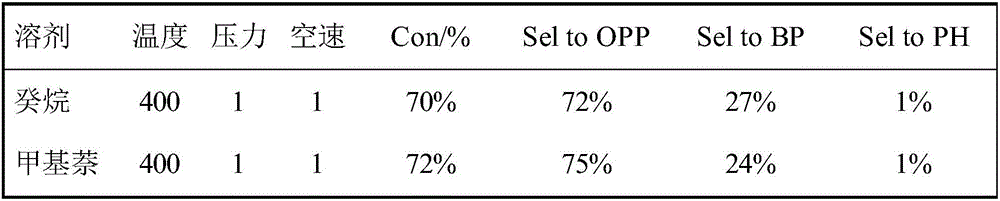

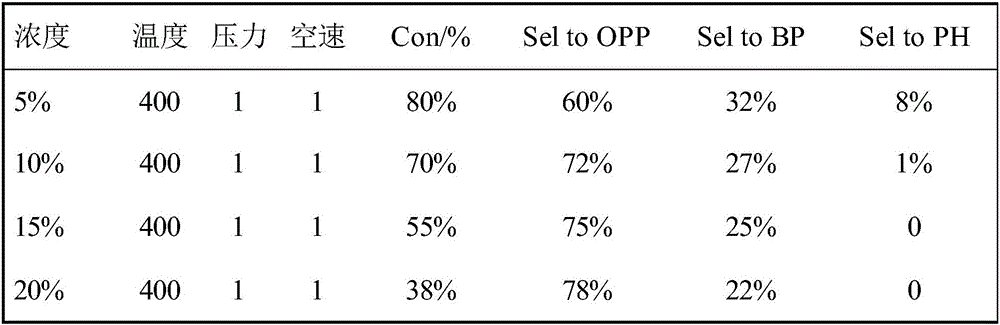

Embodiment 1

[0020] Embodiment 1: chloroplatinic acid and sodium acetate are dissolved in ethylene glycol respectively, the concentration of chloroplatinic acid is 0.01mol / L, the polyol solution aging of chloroplatinic acid is 30d, the concentration of sodium formate is 0.05mol / L, sodium formate The molar ratio of chloroplatinic acid and chloroplatinic acid is 5, spherical or columnar support MgO / SiO 2 Add it into the chloroplatinic acid solution, control the immersion time to 60s, and the solution viscosity to 15mPa.s, add the inducer solution, react at room temperature for 2 hours, filter, wash, and dry in an inert atmosphere to form a stable eggshell-type Pt catalyst, Pt The loading amount was 1.0%. The thickness of the generated Pt shell is 15 μm, and the particle size of Pt is 3.6 nm. The prepared eggshell-type platinum catalyst was used in the ring-opening reaction of oxyfluorene hydrogenation, and the reaction conditions were: reaction temperature 400°C, reaction pressure 1MPa, hyd...

Embodiment 2

[0021] Example 2: Dissolve chloroplatinic acid and sodium formate in ethylene glycol respectively, and compare the influence of the molar ratio of sodium formate and chloroplatinic acid on the preparation of eggshell catalysts. The concentration of chloroplatinic acid is 0.01mol / L, the polyol solution of chloroplatinic acid is aged for 30 days, the concentration of sodium formate is 0.05, 0.1, 0.35 and 0.7mol / L, and the molar ratios of sodium formate and chloroplatinic acid are 5 and 10 respectively. , 35, 70, spherical or columnar carrier MgO / SiO 2 Add it into the chloroplatinic acid solution, control the immersion time to 60s, add the inducer solution, react at room temperature for 2 hours at normal pressure, filter, wash, and dry in an inert atmosphere to form a stable eggshell-type Pt catalyst with a Pt loading of 1.0%. The thickness of the generated Pt shells was 15 μm, and the particle sizes of Pt were 3.6nm, 3.5nm, 2.2nm and 2.0nm, respectively. According to the hydrog...

Embodiment 3

[0022] Embodiment 3: chloroplatinic acid and sodium acetate are dissolved in ethylene glycol respectively, the concentration of chloroplatinic acid is 0.01mol / L, the polyol solution aging of chloroplatinic acid is 30d, the concentration of sodium formate is 0.05mol / L, sodium formate The molar ratio of chloroplatinic acid and chloroplatinic acid is 5, spherical or columnar support MgO / SiO 2 、MgO / Al 2 o 3 , ZrO 2 / SiO 2 , ZrO 2 / Al 2 o 3 Add it into the chloroplatinic acid solution, control the immersion time to 60s, and the solution viscosity to 15mPa.s, add the inducer solution, react at room temperature for 2 hours, filter, wash, and dry in an inert atmosphere to form a stable eggshell-type Pt catalyst, Pt The loading amount was 1.0%. The thickness of the generated Pt shell was 15 μm, and the particle sizes of Pt were 3.6nm, 3.8nm, 3.9nm, and 3.3nm, respectively. The prepared eggshell-type platinum catalyst was used in the ring-opening reaction of oxyfluorene hydrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com