Patents

Literature

50results about How to "Improve construction rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

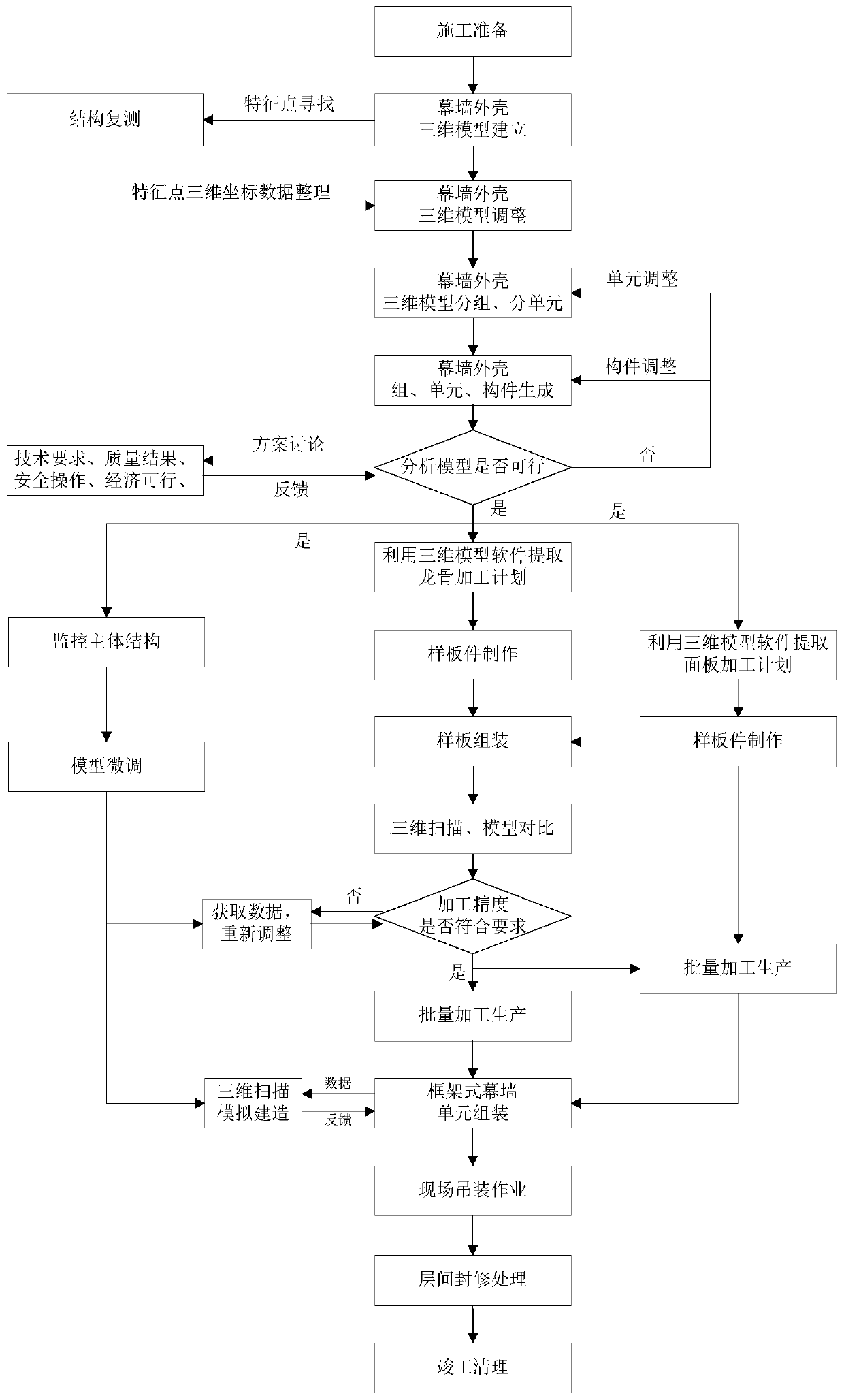

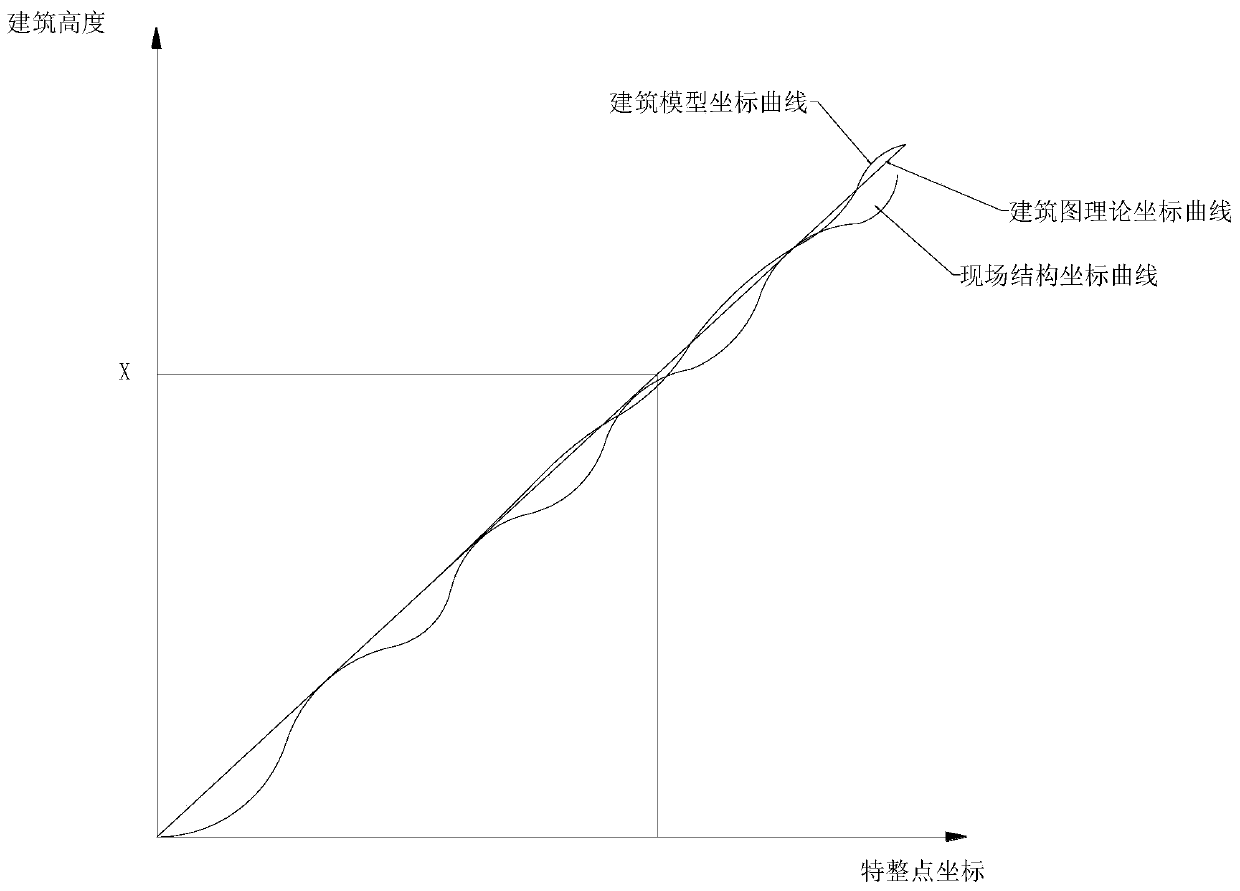

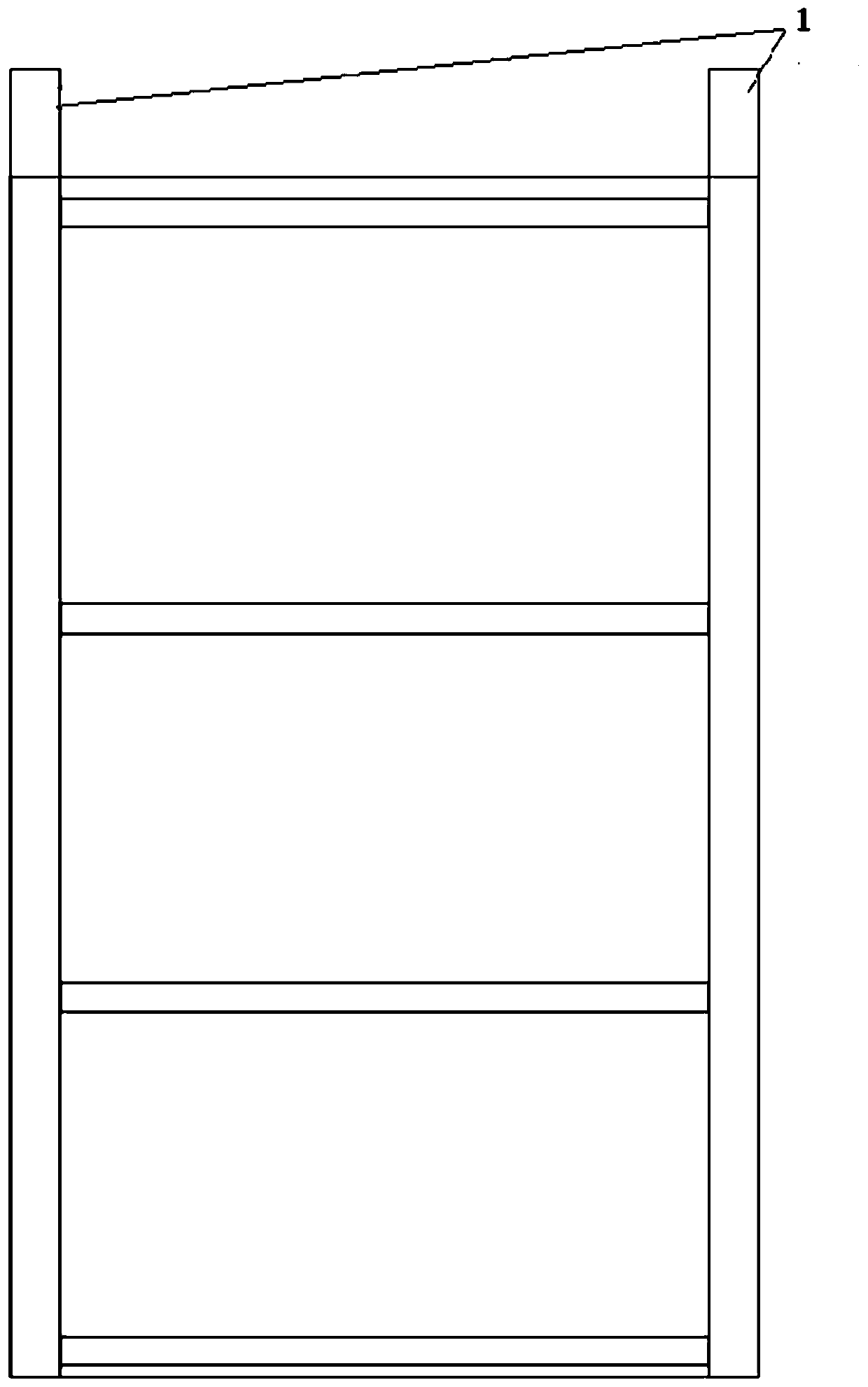

Frame-type curtain wall rapid assembly construction method and system based on BIM

InactiveCN110056106AFast and accurate generationSingle construction workWallsBuilding material handlingThree dimensional measurementHanging basket

The invention discloses a frame-type curtain wall rapid assembly construction method and system based on a BIM, and belongs to the field of curtain wall assembly construction. The to-be-solved technical problems are how to realize rapid assembly construction of a frame-type curtain wall and ensure the installation quality and performance of the curtain wall, according to the technical scheme, theframe-type curtain wall rapid assembly construction method includes the steps that three-dimensional model creation and adjustment of a curtain wall shell, curtain wall unit division, material component splitting and ordering are conducted through a BIM technology and a three-dimensional measurement technology, unit bodies of the frame-type curtain wall are assembled through centralized industrialprocessing, the processing quality of the frame-type curtain wall units is controlled by manufacturing standard parts, standard samples and using a three-dimensional scanning technology, site quick assembly construction of the frame-type curtain wall is completed through an integral hoisting technology, then treatment between layers is completed through a construction hanging basket or an elevating operating vehicle, and finally, rapid assembly construction operation of the frame-type curtain wall is realized. The invention further discloses the frame-type curtain wall rapid assembly construction system based on the BIM.

Owner:CHINA CONSTR EIGHTH ENG DIV

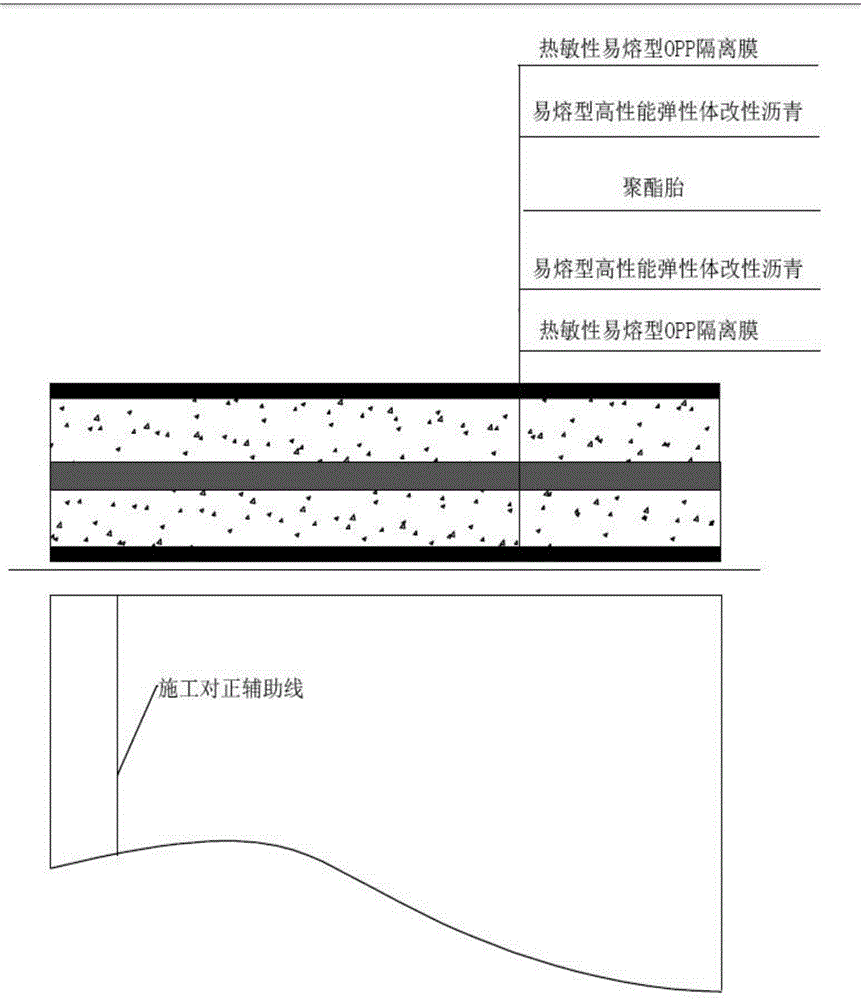

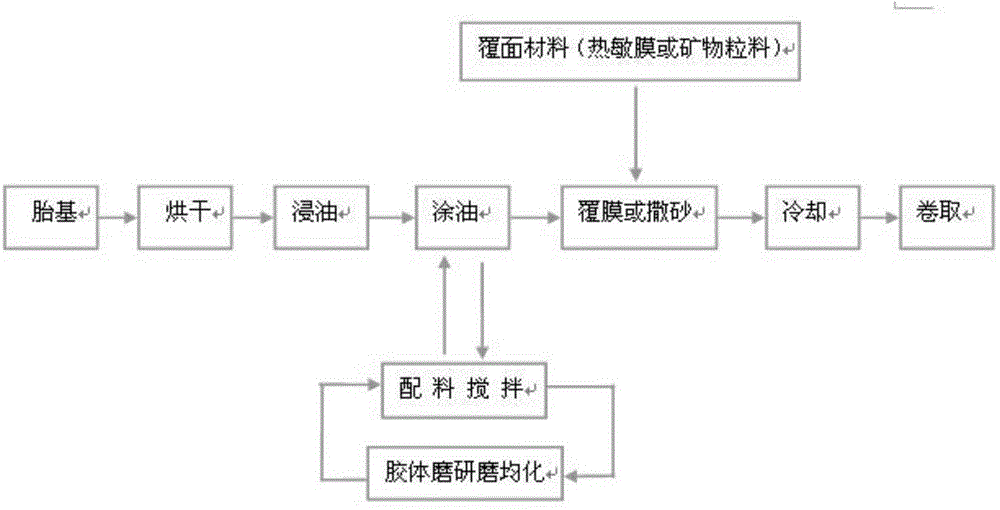

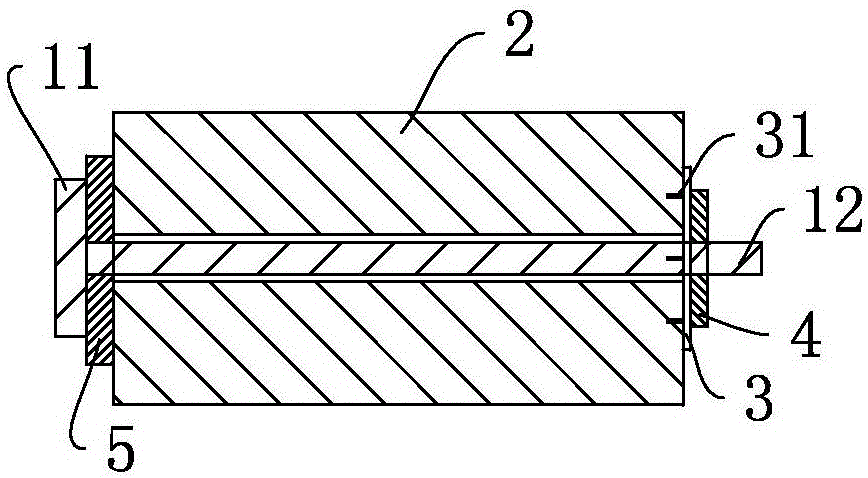

Fusible high-performance elastomer modified asphalt waterproof roll

ActiveCN104553130AImprove construction rateExtended service lifeSynthetic resin layered productsBituminous layered productsSocial benefitsElastomer

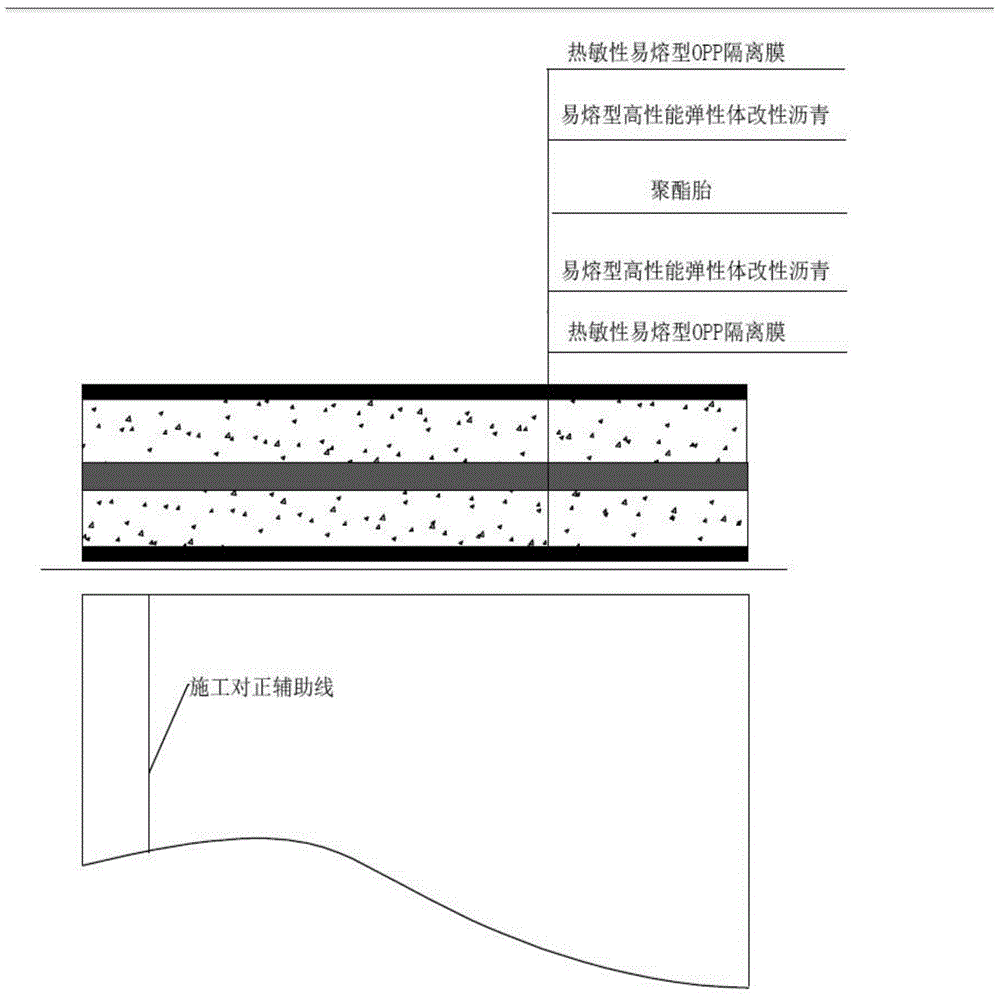

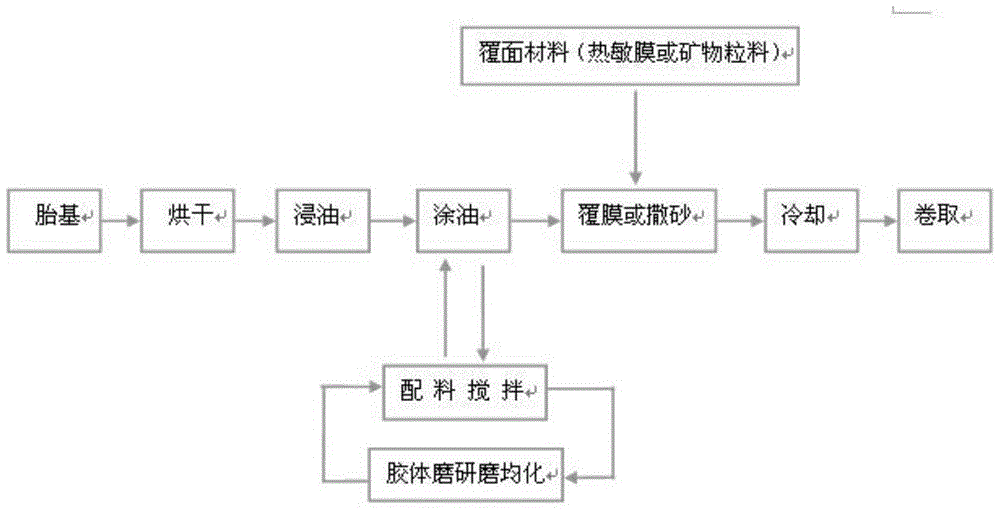

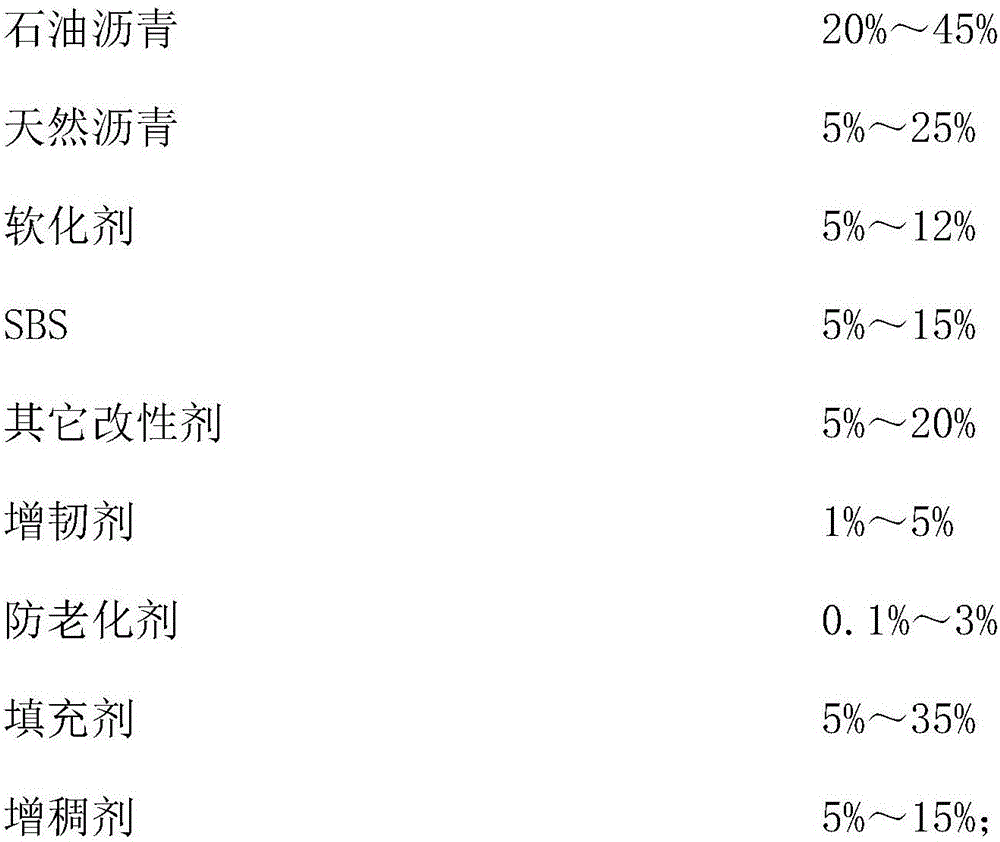

The invention discloses a fusible high-performance elastomer modified asphalt waterproof roll. The fusible high-performance elastomer modified asphalt waterproof roll sequentially comprises a heat-sensitive fusible OPP (o-phenylphenol) isolating membrane, a fusible elastomer modified asphalt, a polyester reinforcement, fusible elastomer modified asphalt and a heat-sensitive fusible OPP isolating membrane from top to bottom. When the fusible high-performance elastomer modified asphalt waterproof roll is applied, the construction efficiency can be improved, the energy consumption is reduced, and the waterproof roll is energy-saving, environment-friendly and long in service life and has good economic benefits and social benefits. The experiment proves that the fusible high-performance elastomer modified asphalt waterproof roll disclosed by the invention has the advantage that the construction rate can be improved by 10-20 percent.

Owner:TANGSHAN DONGFANG YUHONG WATERPROOF TECH CO LTD +2

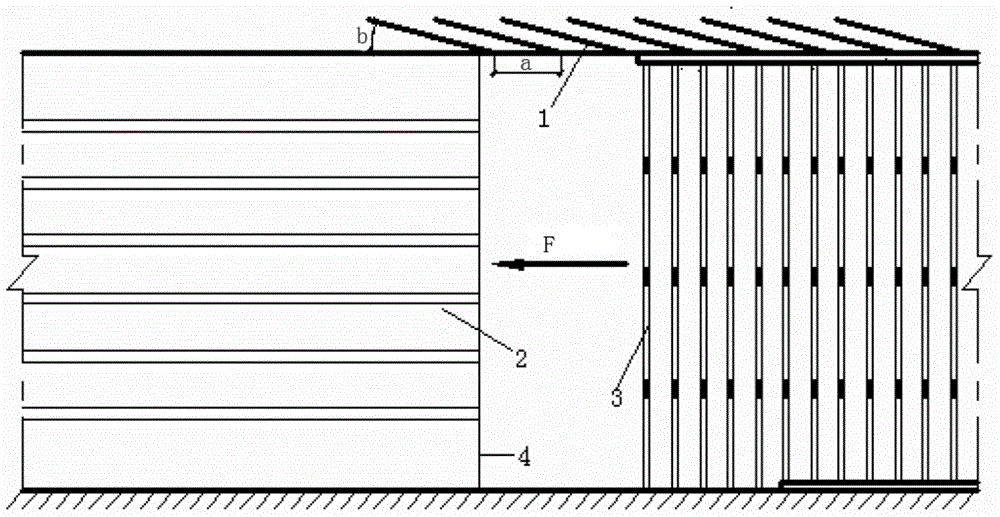

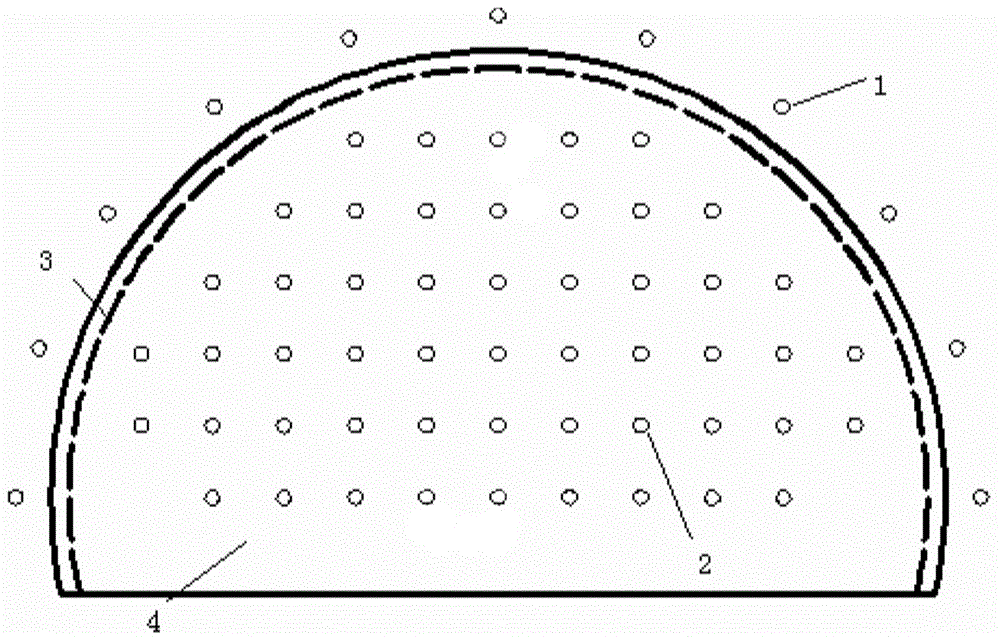

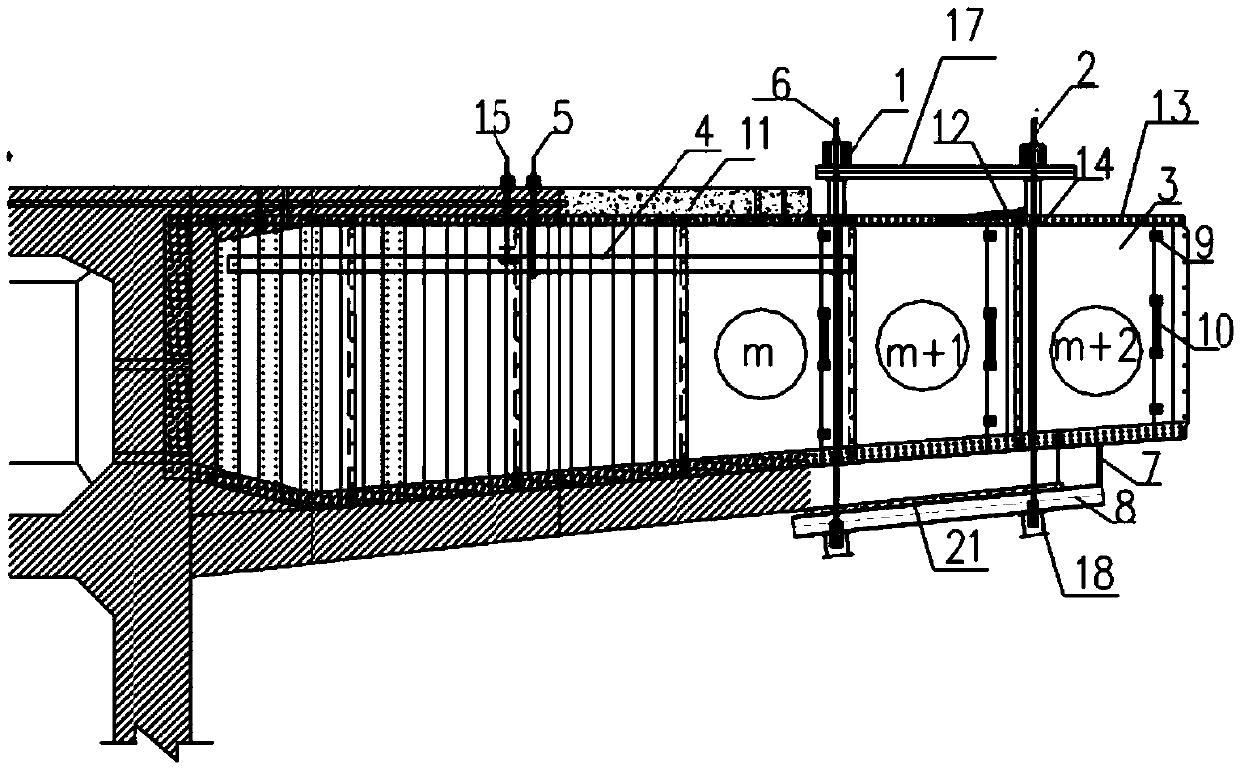

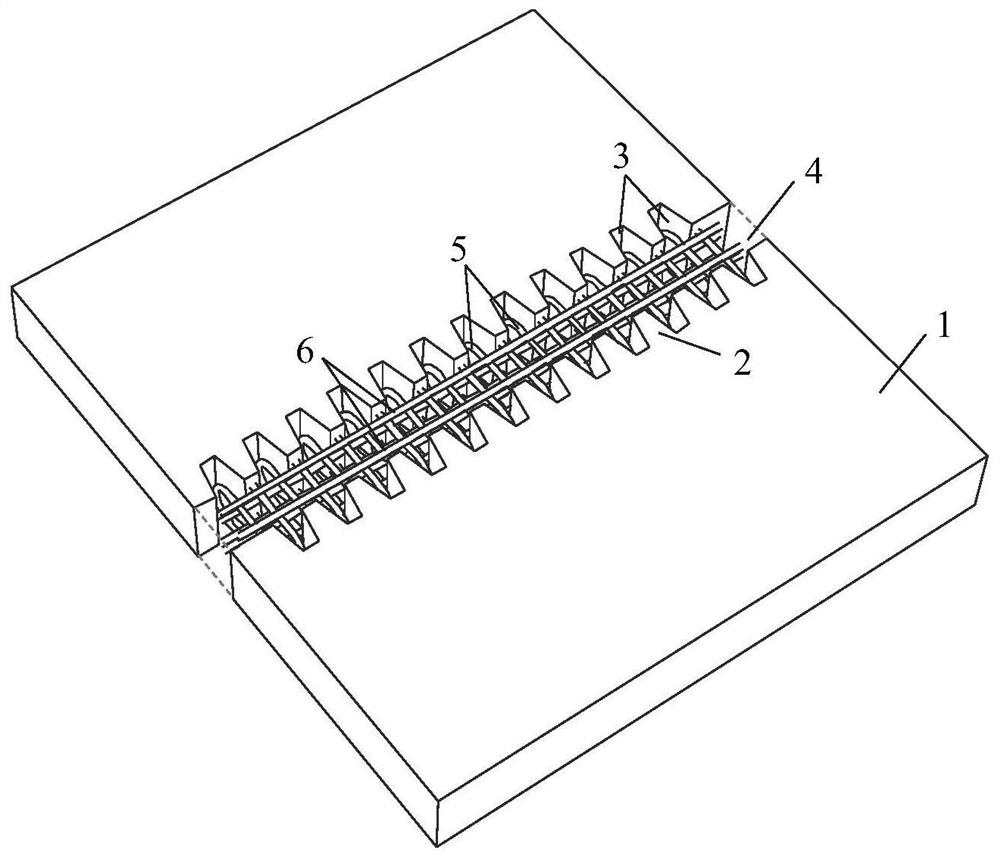

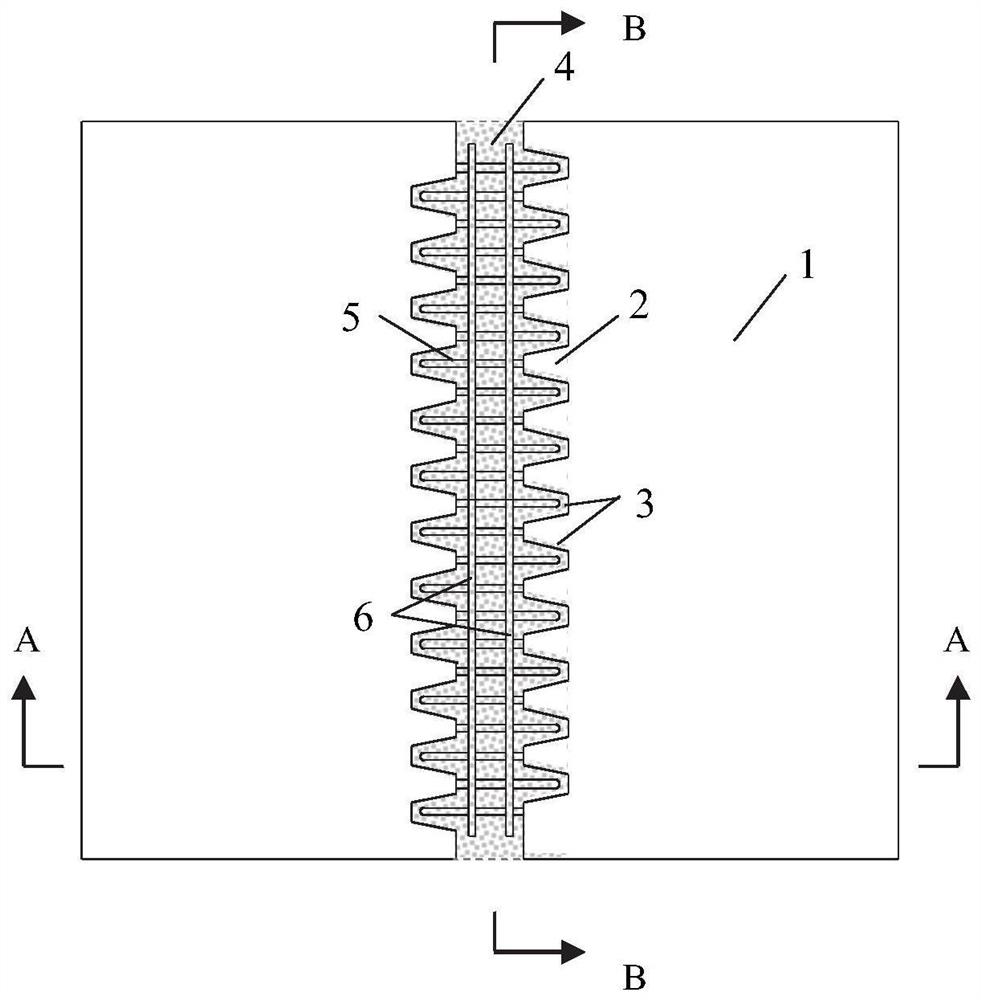

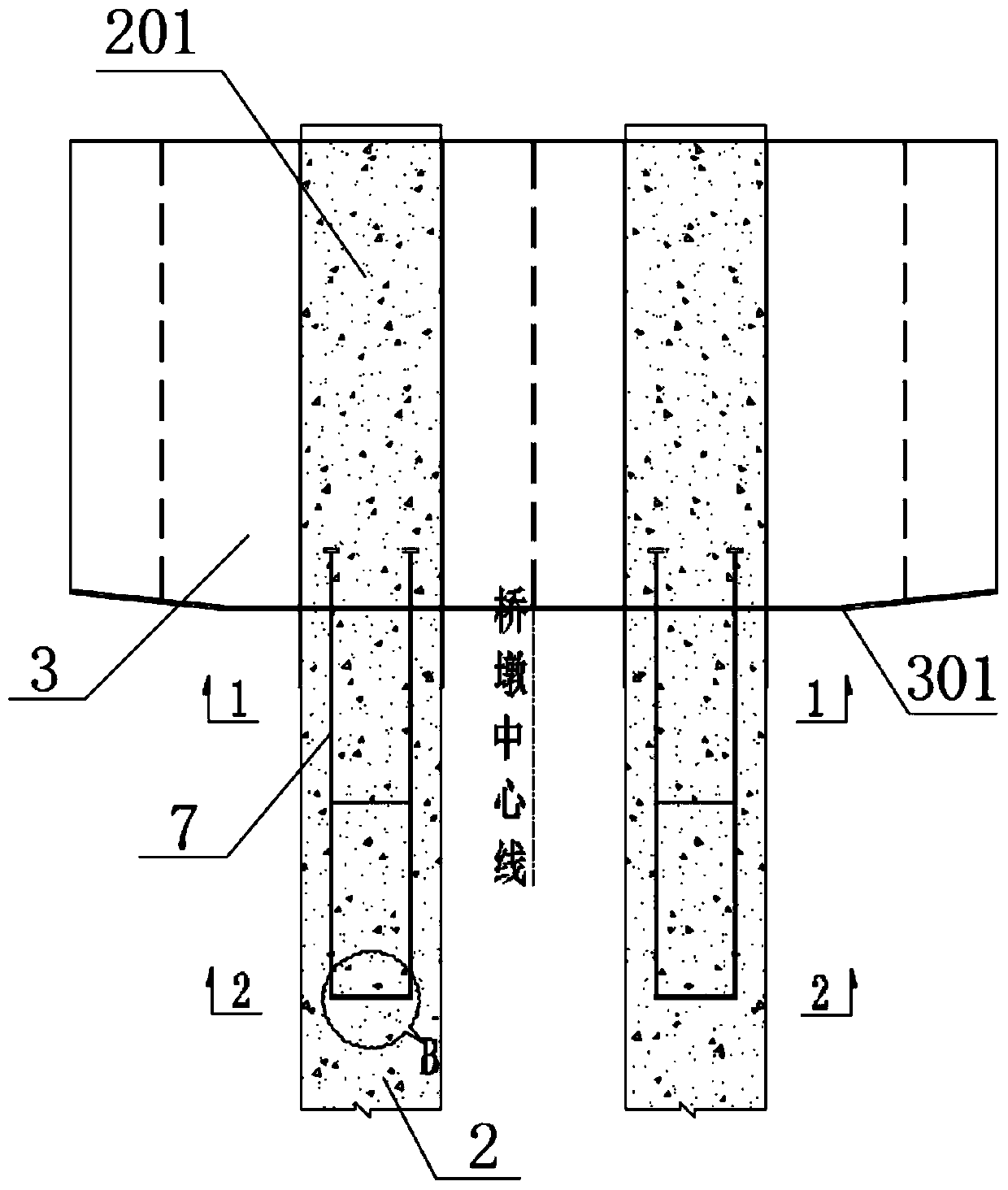

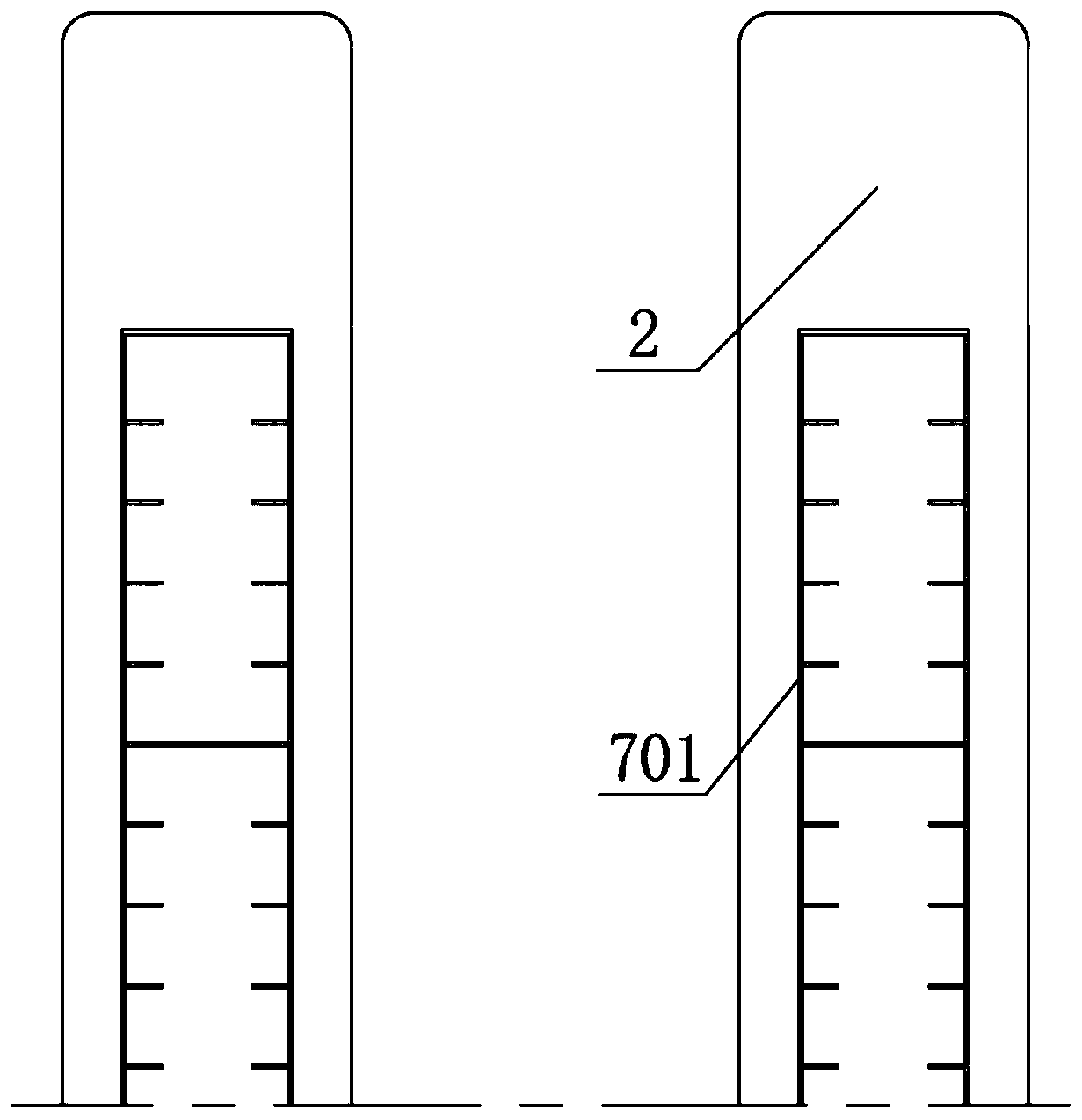

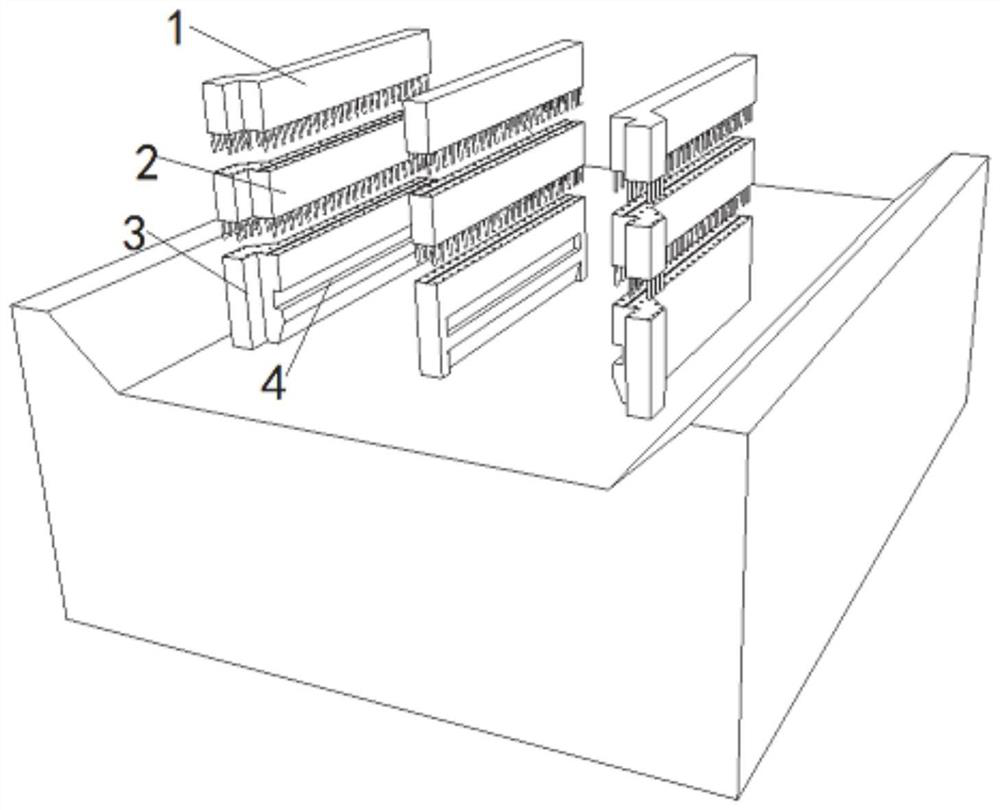

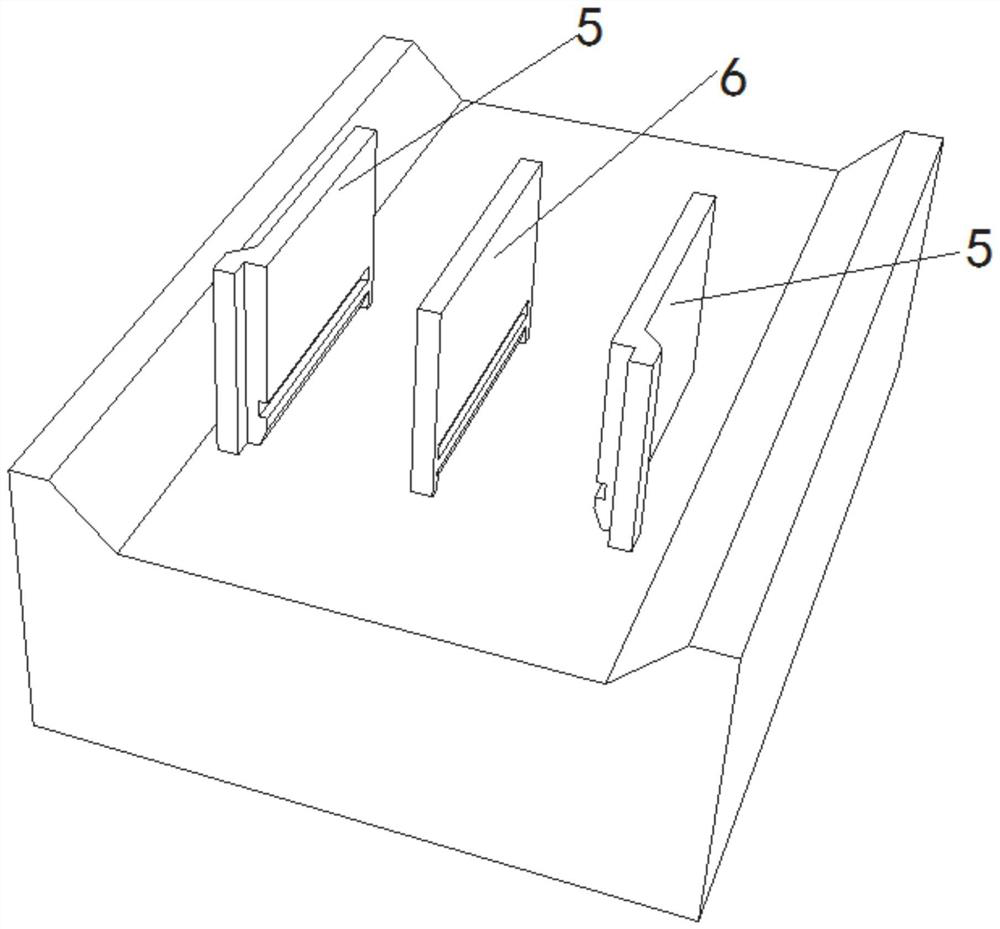

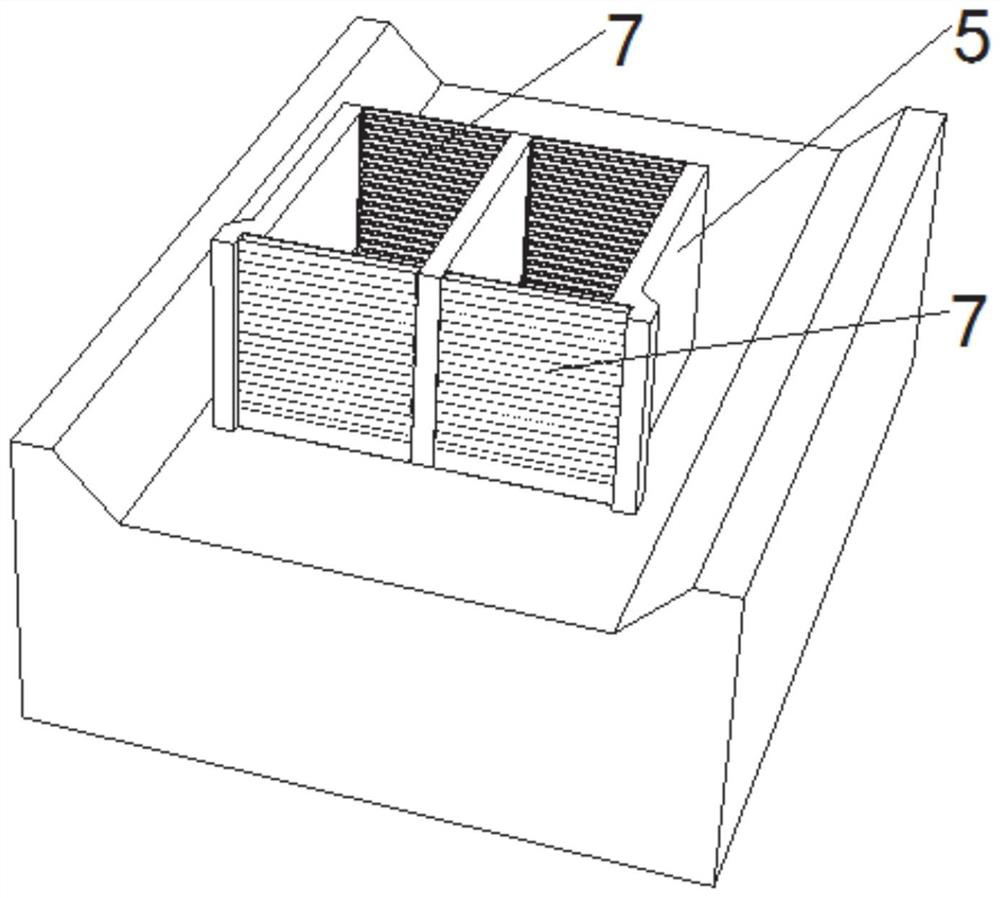

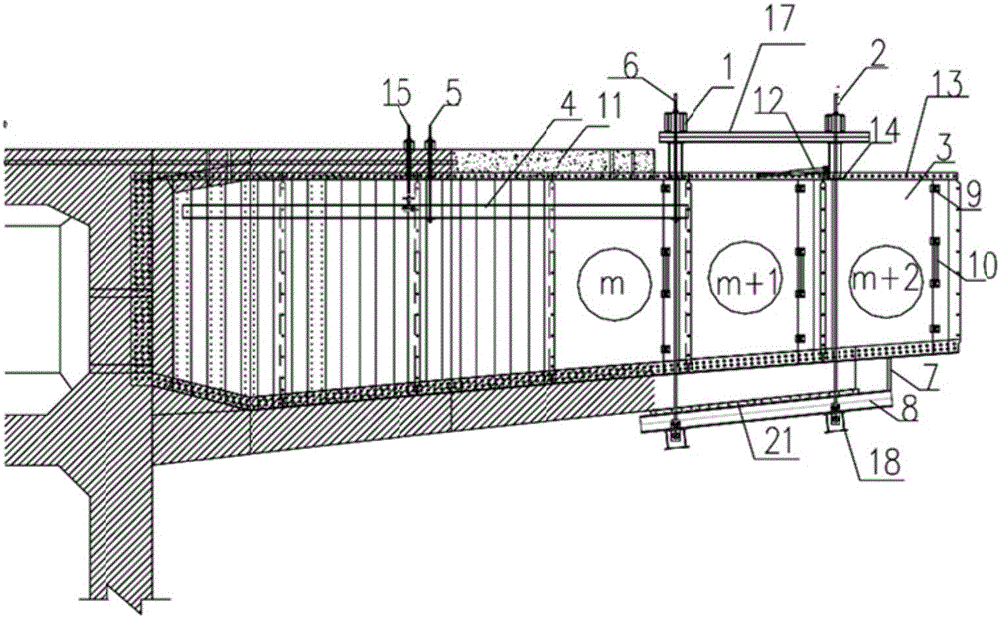

Pre-reinforcement method and pre-reinforcement structure for full section of tunnel

InactiveCN104314585ADoes not affect mechanical constructionImprove construction levelUnderground chambersTunnel liningConductor pipeContour line

The invention discloses a pre-reinforcement method and a pre-reinforcement structure for a full section of a tunnel. The method comprises the following steps: S1, arranging a plurality of conduits (1) in the surrounding rock of a to-be-excavated tunnel and along the contour line of a tunnel face (4), and grouting to the surrounding rock of the to-be-excavated tunnel through the conduits (1); S2, arranging a plurality of free-cutting anchor rods (2) in the to-be-excavated tunnel from the tunnel face (4); S3, excavating the tunnel face (4). The pre-reinforcement method and the pre-reinforcement structure disclosed by the invention are easy in field operation, reasonable in reinforcement cost, high in safety and good in reinforcement effect, and the problem that the working face of the tunnel collapses due to excessive extrusion deformation during a loess tunnel excavation and support process of full section excavation to influence the primary support stability is solved very well; as mechanized construction is not influenced by the free-cutting anchor rods during the construction process, so that the construction speed is quickened very well, the reasonable construction cost is kept, the construction safety, the construction quality, the construction period and the like are ensured, and the tunnel construction level is improved; the pre-reinforcement method and the pre-reinforcement structure have very good site construction value.

Owner:CHINA SHENHUA ENERGY CO LTD +1

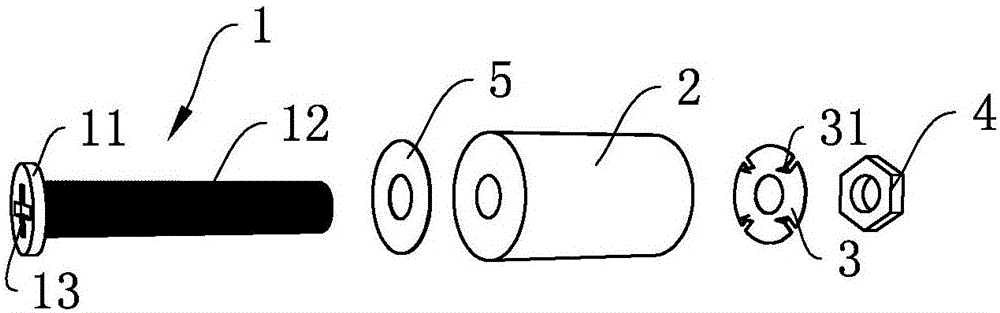

Rubber water stopping plug and construction method for plugging and stopping water of opposite-pull bolt hole of underground outer wall template

ActiveCN106639313AEliminate the risk of water leaksSolve the common quality problems of false blockingAuxillary members of forms/shuttering/falseworksBuilding material handlingLeaking waterPolyvinyl chloride

The invention discloses a rubber water stopping plug which is used for plugging a hole remained after an opposite-pull bolt is detached. A construction method comprises the following steps: after detaching an underground concrete outer wall template, eliminating a PVC (Polyvinyl Chloride) pipe with the depth which is not smaller than the length of the rubber water stopping plug by taking an outer wall as a starting point; carrying out mounting type plugging on the hole by utilizing the rubber water stopping plug; and coating an end close to the outer wall with a sealant, and densely plugging the end and a pipeline by adopting expanding type polymer cement waterproof mortar. The common quality problem that the opposite-pull bolt is not plugged tightly is solved and the risk of leaking water along the hole at a later period is eliminated.

Owner:WEIFANG HONGYUAN WATERPROOF MATERIAL

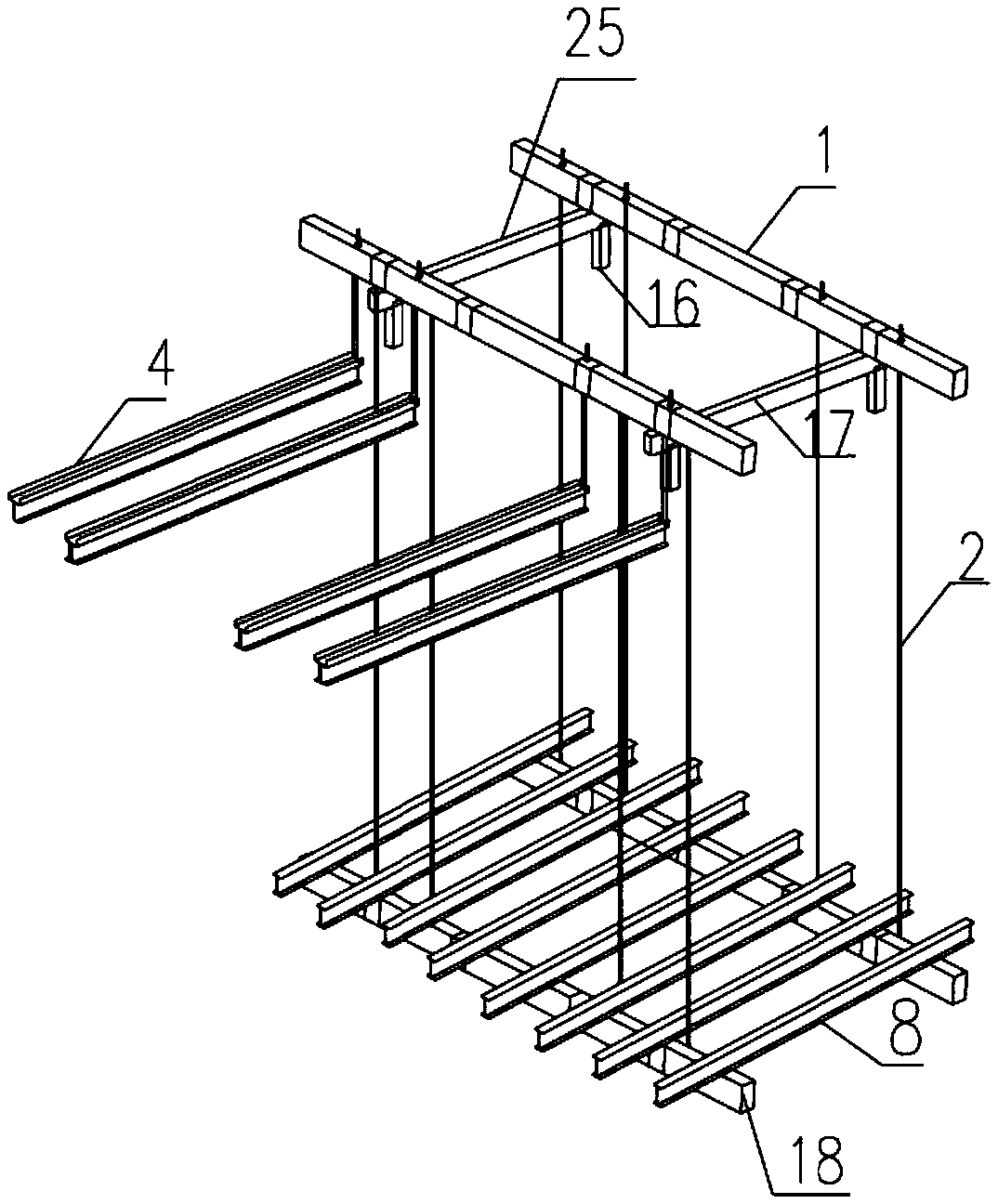

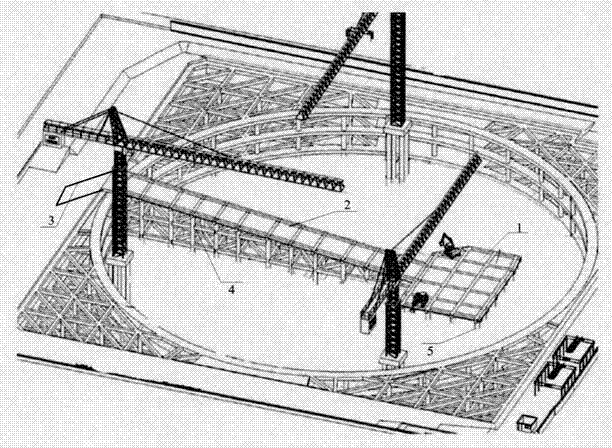

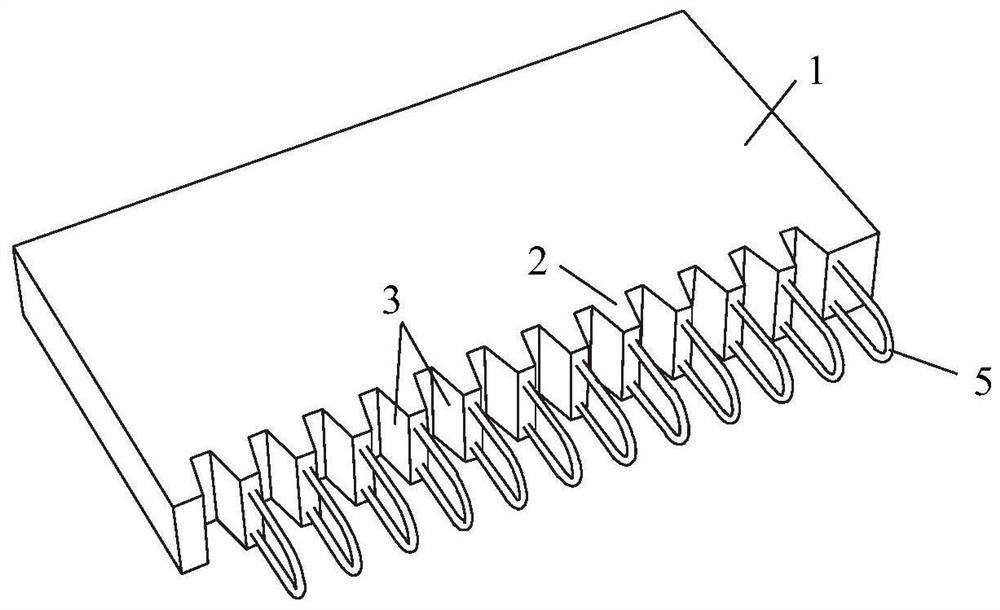

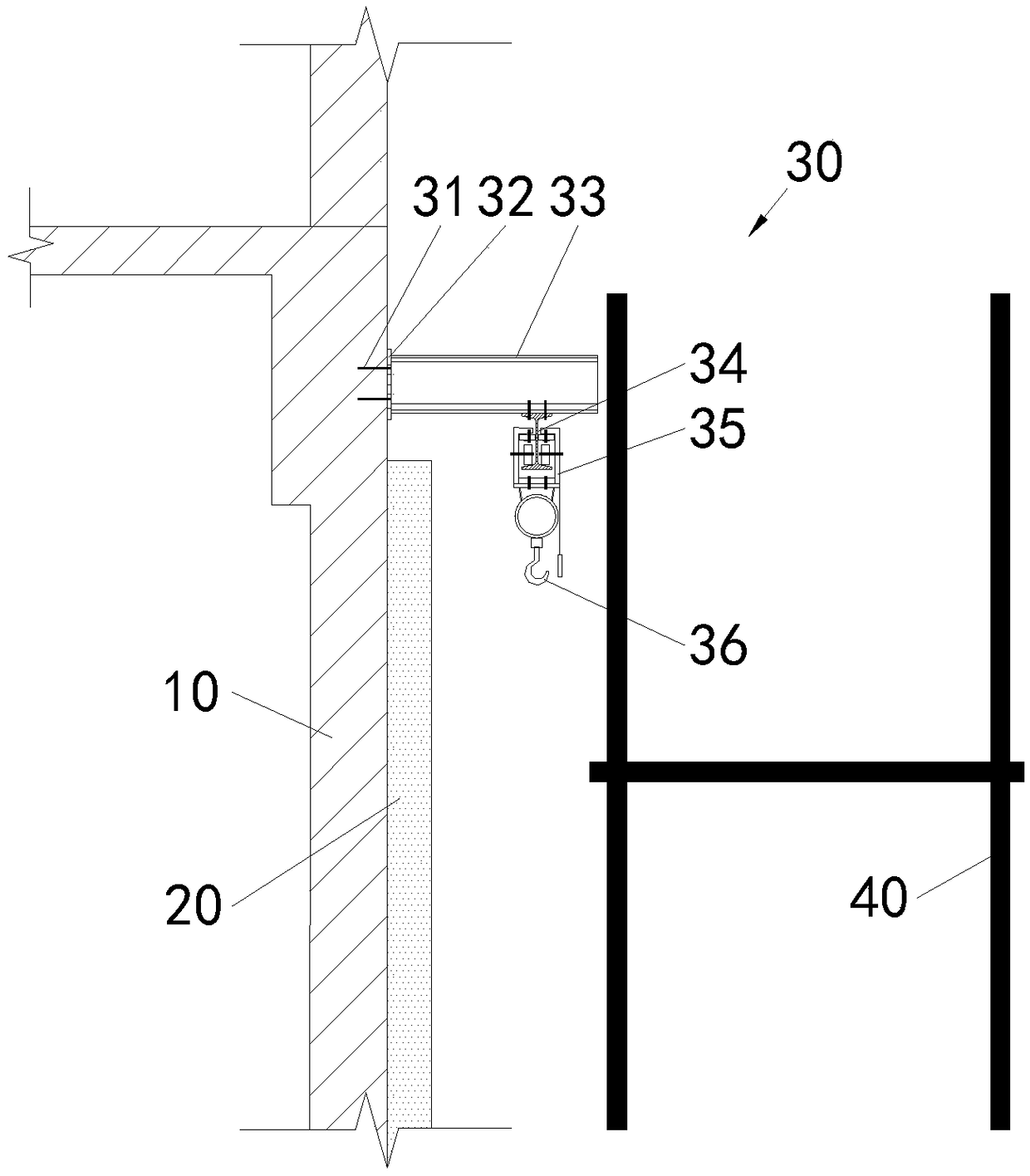

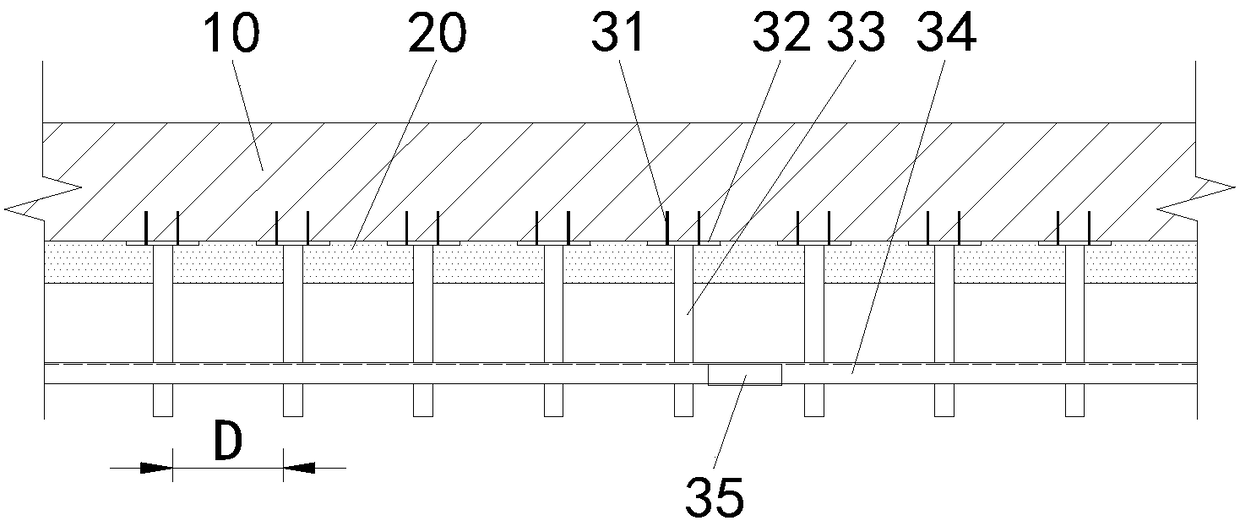

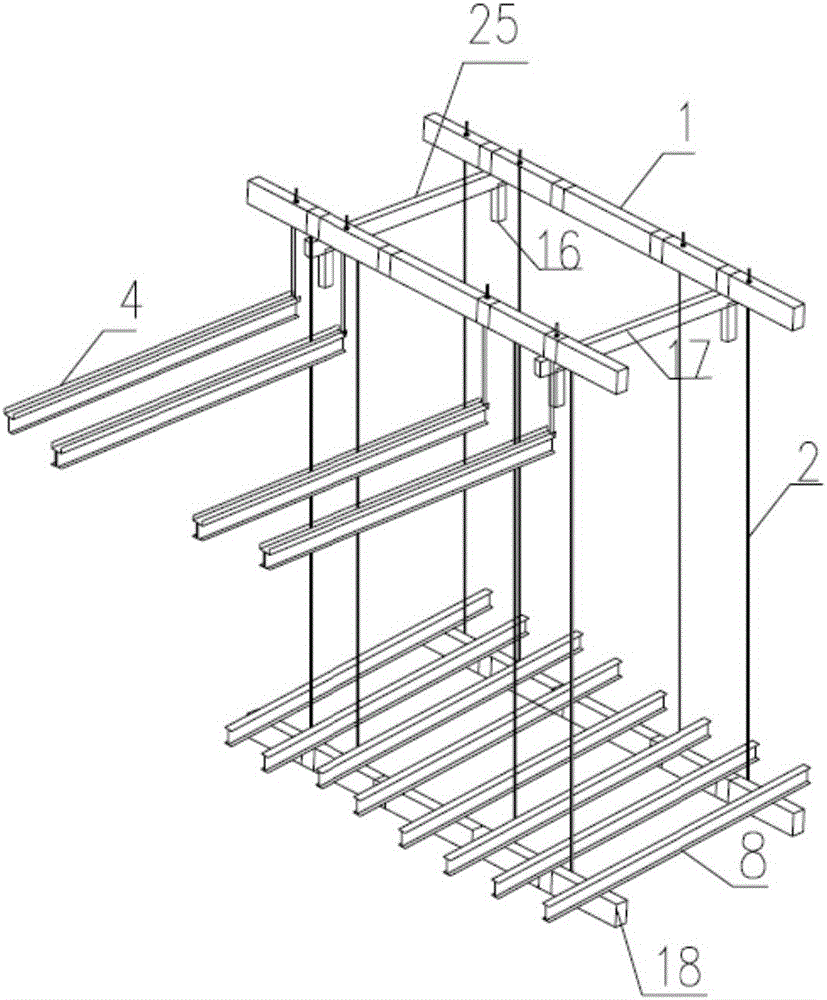

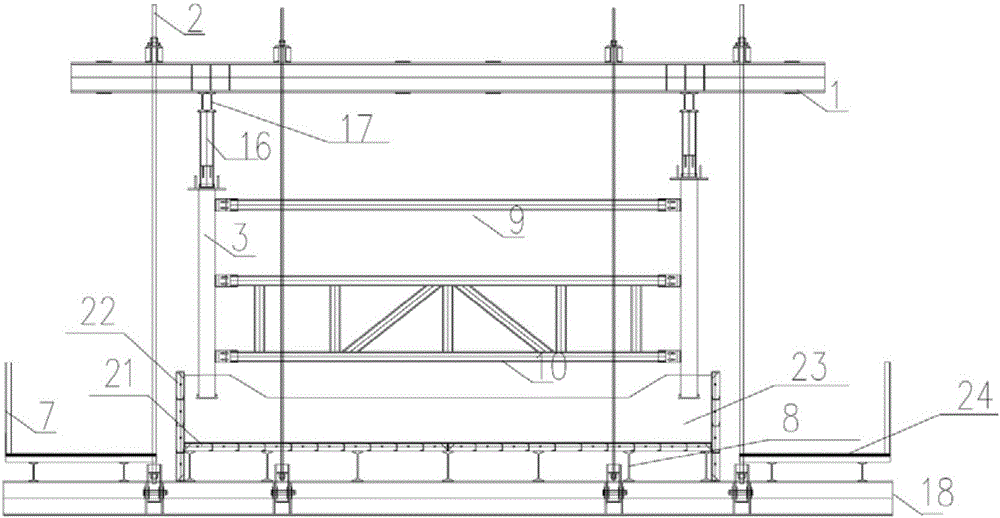

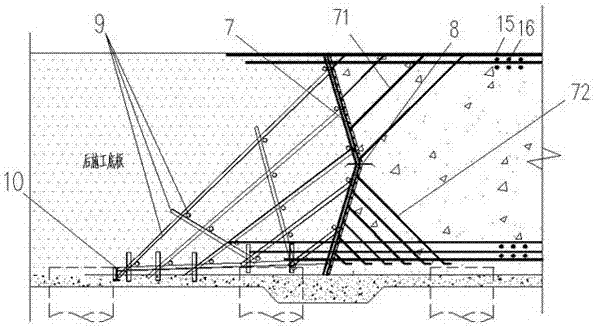

Hanging basket for corrugated steel web plate construction and construction process

InactiveCN105507165AReduce the total massIncrease the factor of safety against overturningBridge erection/assemblyArchitectural engineeringHanging basket

The invention discloses a hanging basket for corrugated steel web plate construction and a construction process. The hanging basket for construction comprises an upper beam assembly, a lower beam assembly and multiple groups of hanging rods for connecting the upper beam assembly and the lower beam assembly. A base plate bottom formwork and base plate side formworks are arranged above the lower beam assembly, the upper beam assembly is supported on the top end faces of two corrugated steel web plates through two groups of supporting beams, and thrusting devices are arranged between the supporting beams and the top ends of the corrugated steel web plates. The bottom ends of the corrugated steel web plates are arranged in a base plate concrete casting area. Top plate bottom formworks arranged above the upper beam assembly. Horizontally-arranged sliding beams are arranged on two sides of the corrugated steel web plates, and conveying devices for conveying the base plate bottom formwork, the base plate side formworks and the top plate bottom formworks to the positions to be cast are installed on the sliding beams. The self weight of the hanging basket for corrugated steel web plate construction can be effectively reduced, the security coefficient of the hanging basket can be improved, and the construction efficiency can be accelerated.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

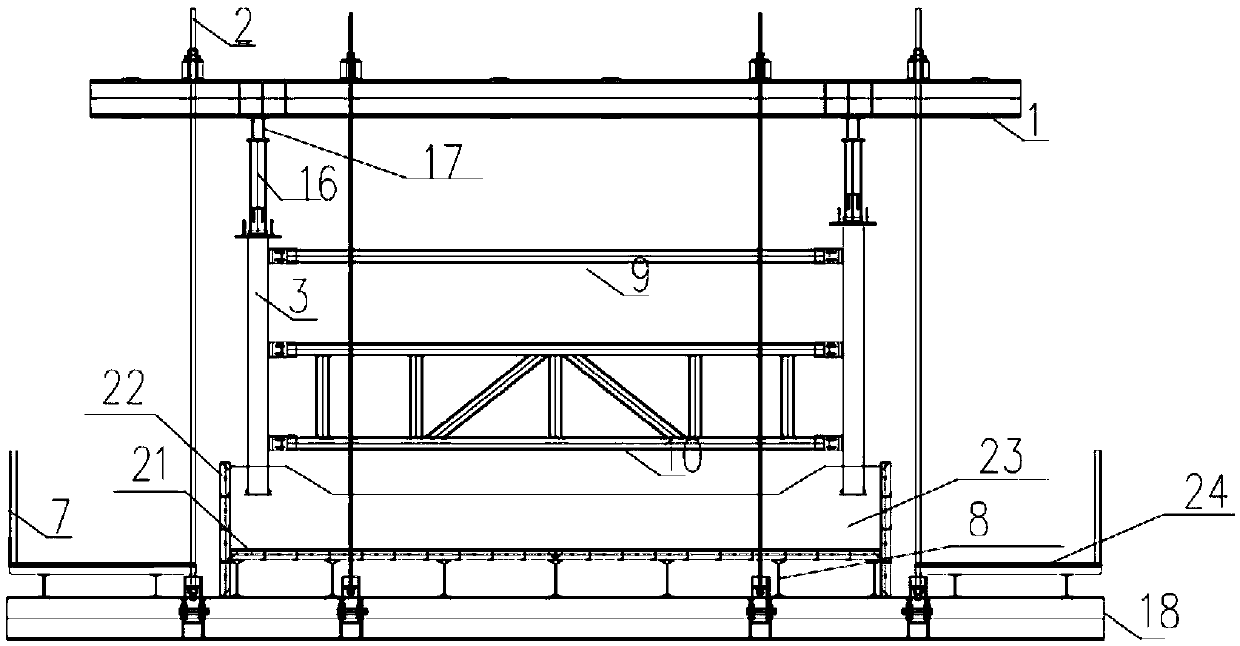

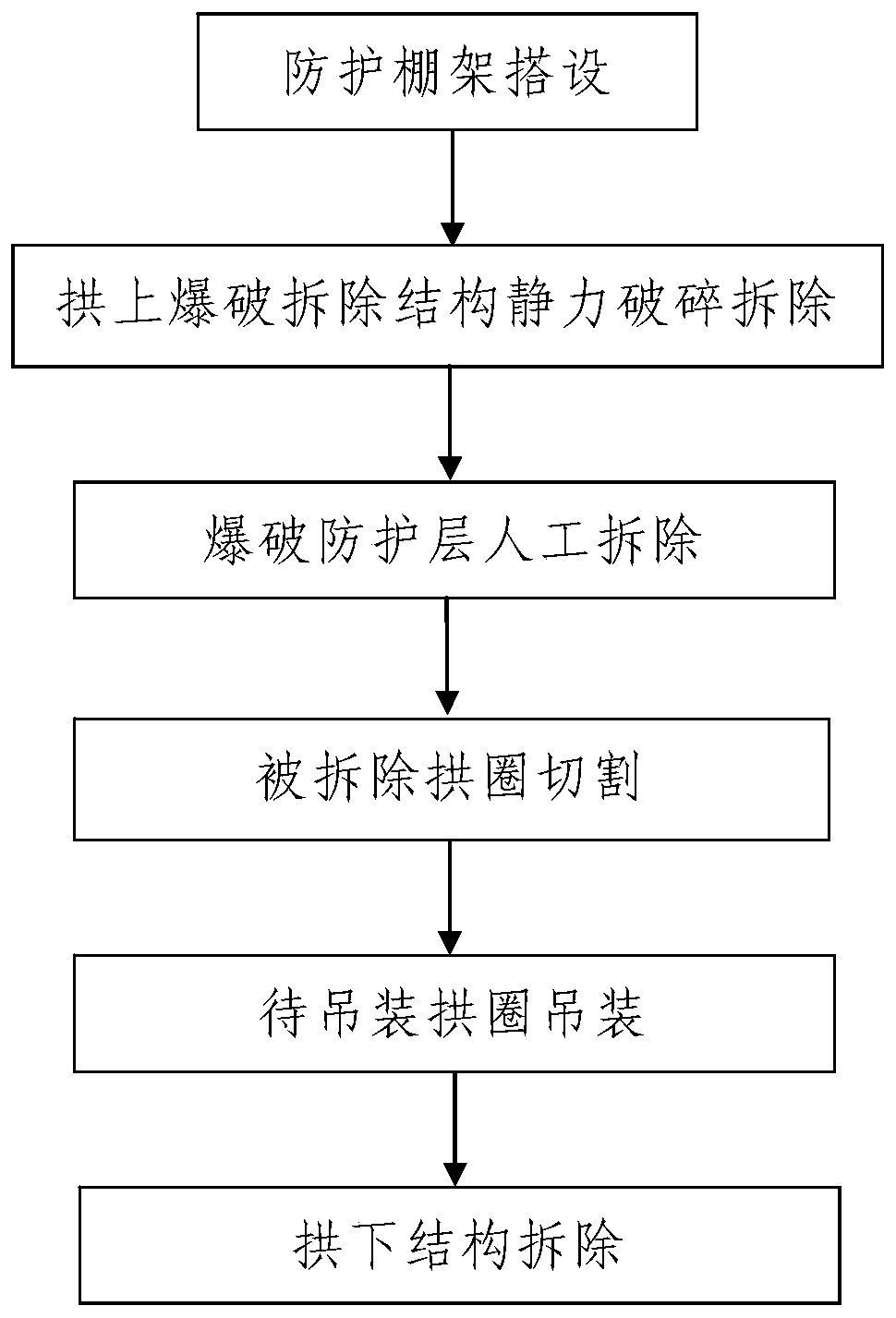

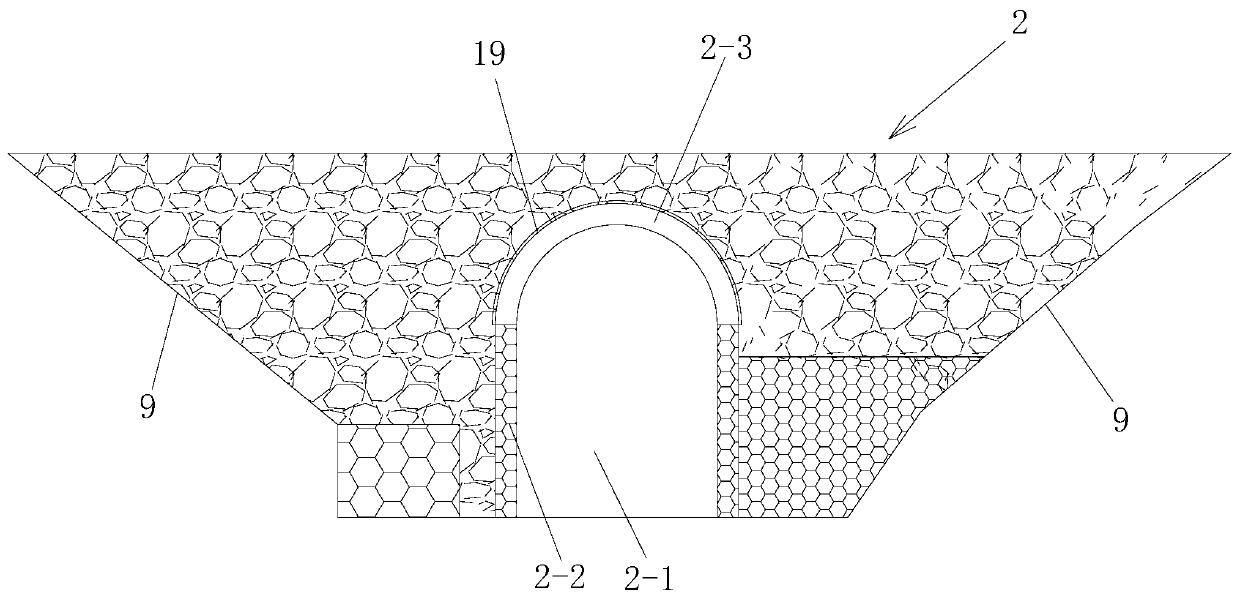

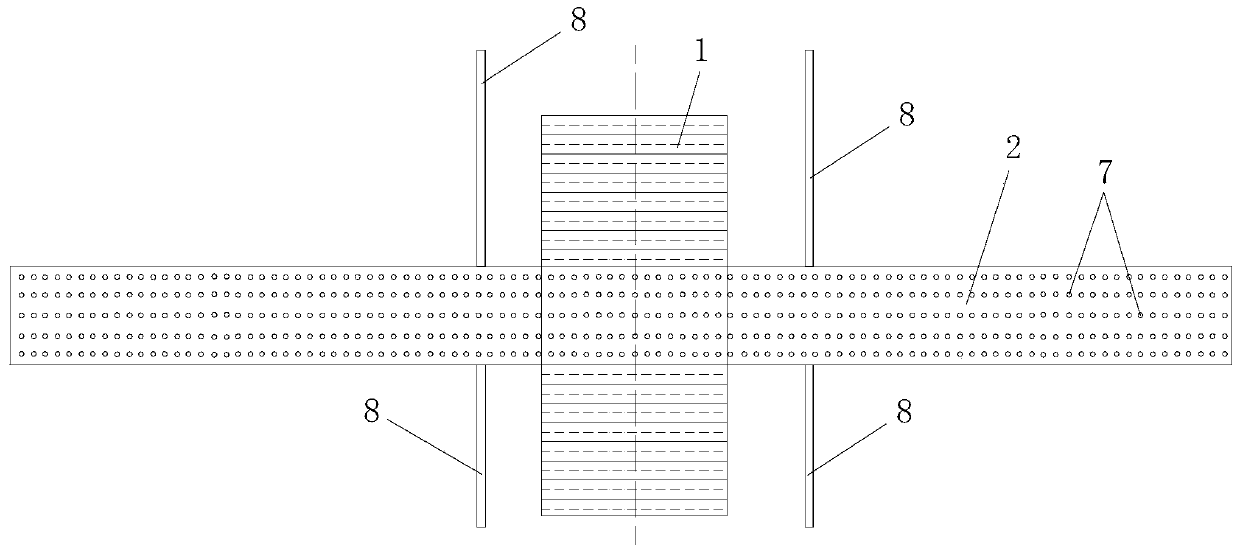

Demolition construction method for overpass existing line arch bridge

ActiveCN110904867AThe method steps are simpleReasonable designBuilding repairsBridge strengtheningArchitectural engineeringStructural engineering

The invention discloses a demolition construction method for an overpass existing line arch bridge. The demolition construction method comprises the steps: 1, erecting a protective shed frame; 2, carrying out static crushing demolition on the arch blasting demolition structure; 3, manually removing the blasting protection layer; 4, cutting the removed arch ring; 5, hoisting the arch ring to be hoisted; and 6, dismantling the under-arch structure. The method is simple, reasonable in design, easy and convenient to construct and good in using effect; the protection shed frames fixed to the frontside and the rear side of the removed arch bridge are adopted for effective protection, meanwhile, the structure on the arch of the removed arch bridge is removed in the mode that static crushing andmanual chiseling are combined, it is guaranteed that a plain concrete arch ring cannot be damaged in the static crushing process, and an existing spanned railway line cannot be disturbed. After the arch ring is exposed, the removed arch ring is cut and decomposed through a rope saw and then hoisted and removed, then the under-arch structures on the left side and the right side are rapidly removed,the construction period can be effectively shortened, the arch bridge removing efficiency is improved, and the removing process is safe and reliable.

Owner:THE FOURTH ENG CO LTD OF CHINA RAILWAYNO 20 BUREAU GRP

A Fusible Elastomer Modified Asphalt Waterproof Membrane

ActiveCN104553130BImprove construction rateExtended service lifeSynthetic resin layered productsBituminous layered productsSocial benefitsPolyester

The invention discloses a fusible high-performance elastomer modified asphalt waterproof roll. The fusible high-performance elastomer modified asphalt waterproof roll sequentially comprises a heat-sensitive fusible OPP (o-phenylphenol) isolating membrane, a fusible elastomer modified asphalt, a polyester reinforcement, fusible elastomer modified asphalt and a heat-sensitive fusible OPP isolating membrane from top to bottom. When the fusible high-performance elastomer modified asphalt waterproof roll is applied, the construction efficiency can be improved, the energy consumption is reduced, and the waterproof roll is energy-saving, environment-friendly and long in service life and has good economic benefits and social benefits. The experiment proves that the fusible high-performance elastomer modified asphalt waterproof roll disclosed by the invention has the advantage that the construction rate can be improved by 10-20 percent.

Owner:TANGSHAN DONGFANG YUHONG WATERPROOF TECH CO LTD +2

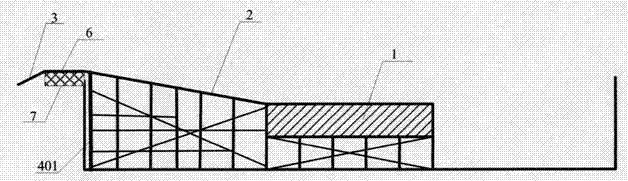

Concrete trestle and foundation pit connection joint structure and construction method thereof

InactiveCN106907024AQuick buildHigh strengthExcavationsShaping building partsReinforced concreteEngineering

The invention discloses a construction method of a concrete trestle and foundation pit connection joint structure. The construction method comprises the steps that firstly, a center area of a foundation pit is determined, and a trestle construction area is selected; secondly, a first supporting structure is constructed in the foundation pit; thirdly, a second supporting structure is constructed in the center area of the foundation pit, and then a horizontal platform is arranged above the second supporting structure; fourthly, a steel bar structure of a first slope ramp is constructed in the position, between the horizontal platform and the edge of the foundation pit, above the first supporting structure, then concrete is poured onto the steel bar structure to form the first slope ramp formed by the reinforced concrete, and antiskid strips are fixed on the upper surface of the first slope ramp; fifthly, a buffer platform parallel to the ground is arranged in the position, above the foundation pit, on the ground and connected with the first slope ramp; and sixthly, a second slope ramp is constructed between the buffer platform and the ground. The concrete trestle and foundation pit connection joint structure is firm in device and safe in driving, and the earthwork transportation efficiency is improved by 12%.

Owner:BEIJING NO 3 CONSTR ENG

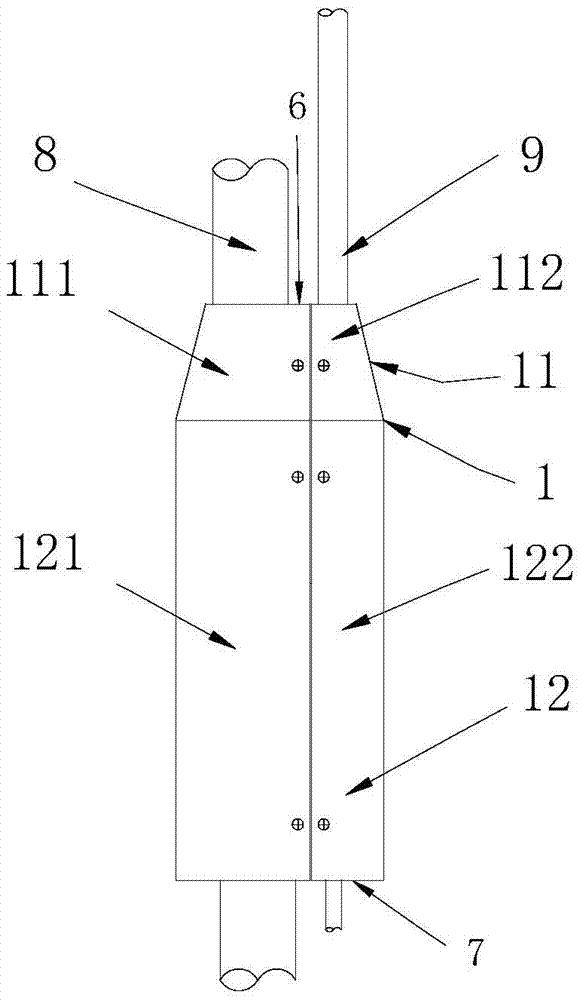

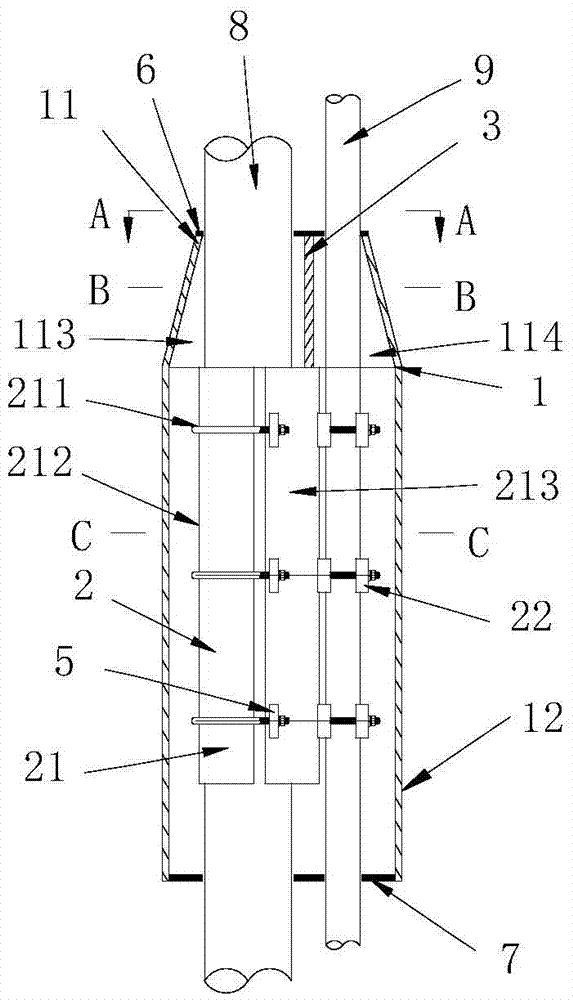

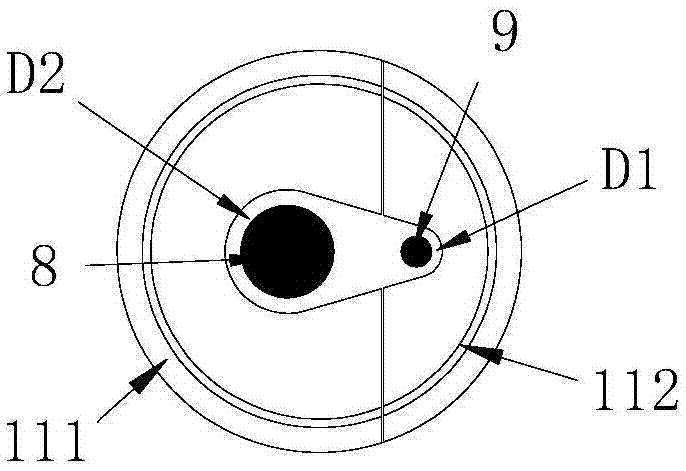

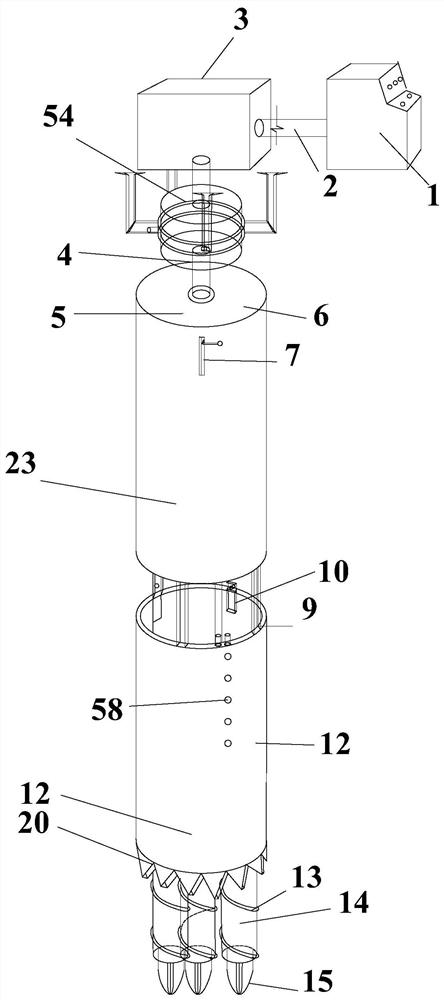

Vertical shaft traction cable clamp with guiding and avoiding functions

The invention provides a vertical shaft traction cable clamp with guiding and avoiding functions. The vertical shaft traction cable clamp comprises at least one group of clamp single-pieces, wherein each clamp single-piece comprises a hollow housing and a clamp body; the clamp body comprises a cable clamp and a steel wire rope clamp; a housing comprises a circular table body and a cylindrical barrel; each cable clamp comprises a U-shaped bolt, an arc-shaped board and angle steel; and each steel wire rope clamp comprises a single line clamp which is in one-to-one correspondence to the U-shaped bolt. According to the technical scheme applied by the invention, the vertical shaft traction cable clamp has the beneficial effects that: firstly, the integral structure is simplified, and space usage is small; secondly, the housing achieves the dual effects of protecting and guiding, i.e., the housing achieves the protecting effect for the clamp bodies arranged inside the vertical shaft traction cable clamp; and by virtue of the design of the circular table body, the housing can effectively avoid horizontal barriers along the conical surface of the housing, so that quick hoisting of cables is realized; and thirdly, by virtue of the structures of the cable clamps as well as a combined design of the cable clamps and the steel wire rope clamps, damages to the cables in a hoisting process can be reduced to the greatest extent, and the safety and hoisting speed in the hoisting process can be improved.

Owner:中建五局安装工程有限公司

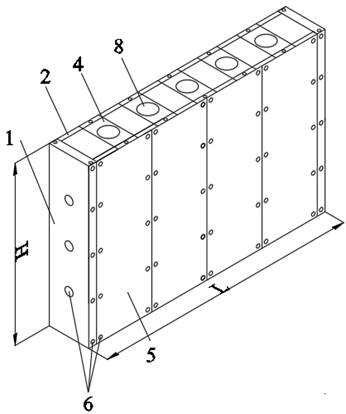

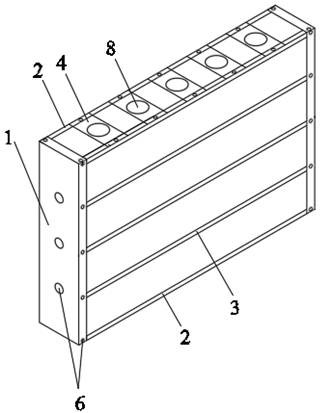

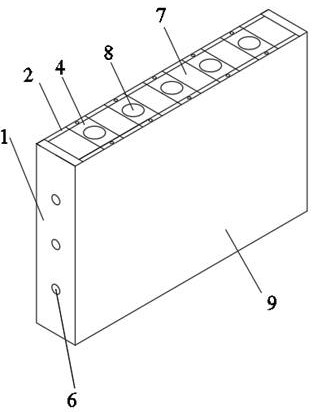

Small cable trench and construction method thereof

PendingCN110890736AGuarantee the appearance quality of moldingEliminate uneven settlementCable installations on groundArchitectural engineeringRebar

The invention provides a small cable trench. The cable trench comprises a cable trench cushion layer positioned below the ground plane, a prefabricated U-shaped cable trench is formed by a prefabricated U-shaped cable trench structural part, cable trench reinforcing steel bars are buried in the cable trench structural part, the tail ends of the cable trench reinforcing steel bars penetrate out ofthe top face of the U-shaped cable trench structural part and are buried in ground concrete 4, the ground concrete and the prefabricated U-shaped cable trench jointly form a trench inner wall, and angle steel is arranged on the edge of the trench. The invention further provides a construction method of the small cable trench. When the prefabricated U-shaped cable trench is prefabricated, trench wall steel bars are reserved; excavating and pouring a concrete cushion layer, installing and adjusting the prefabricated U-shaped cable trench, and arranging an expansion water stop strip at a horizontal construction joint before pouring the ground concrete; the angle steel is fixed on the ground reinforcing steel bars; and finally, the ground concrete is poured and formed. The scheme has the advantages that the efficiency is high; differential settlement of the ground and the cable trench is eliminated; the field use is reduced, and the forming appearance quality of the component can be guaranteed through factory prefabrication.

Owner:MCC TIANGONG GROUP

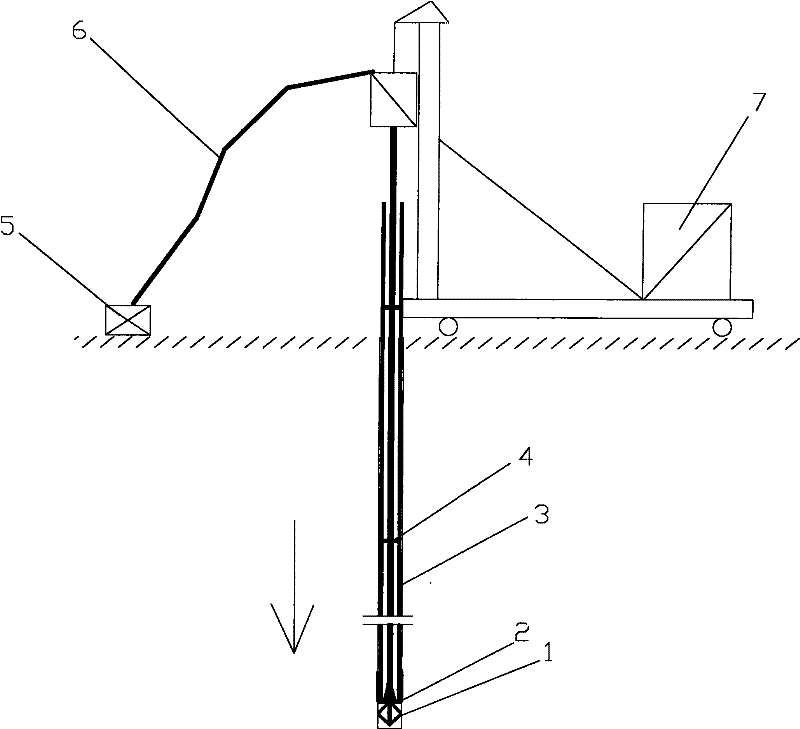

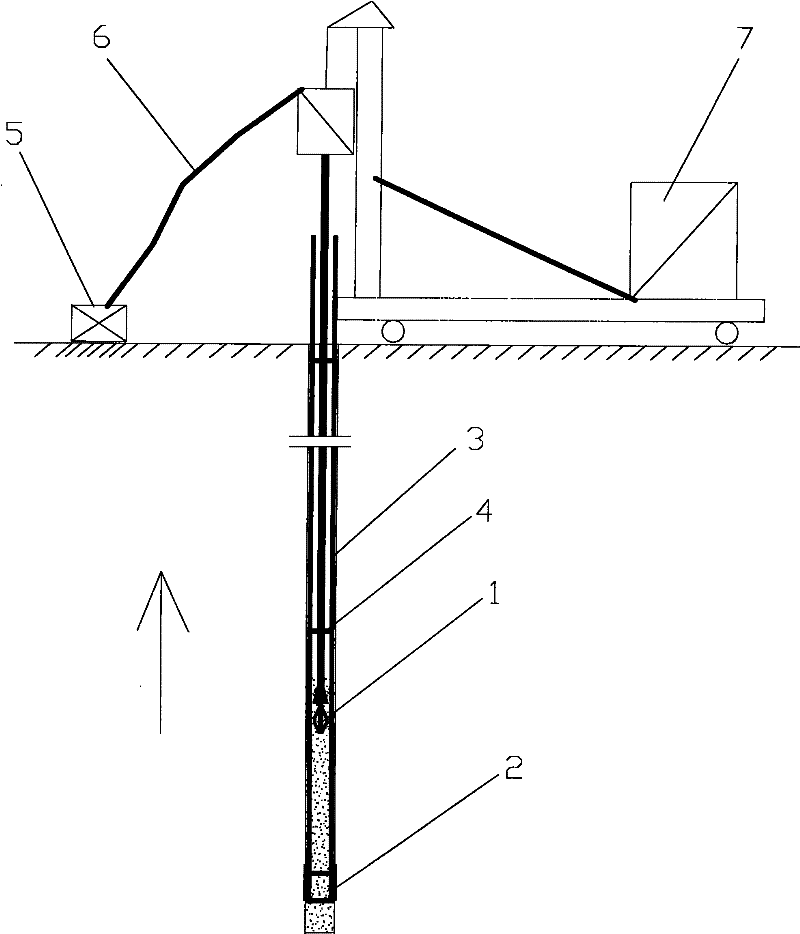

Construction Technology of Positive Circulation Straight-in Buried Pipe

InactiveCN102278809AAvoid clinging or twistingImprove continuityLighting and heating apparatusGeothermal energy generationEngineeringHeat transfer efficiency

The invention discloses a positive circulation direct-entry buried pipe construction technology, which can lower the heat exchange pipe together with the drill pipe into the drill hole when drilling. This construction process can lower the heat exchange tubes while drilling, integrate multiple processes together, reduce the process of sweeping holes, emptying and placing heat exchange tubes, and drill pipes for secondary lowering, which greatly improves the construction rate , the construction time can be shortened by about half; at the same time, the construction process can make the heat exchange tube close to the hole wall, avoiding the heat exchange tube being close or twisted together in the conventional buried pipe method, and improving the continuity and compactness of the filler , Compared with the conventional construction method, the heat exchange efficiency of the heat exchange system is greatly improved.

Owner:谢学军

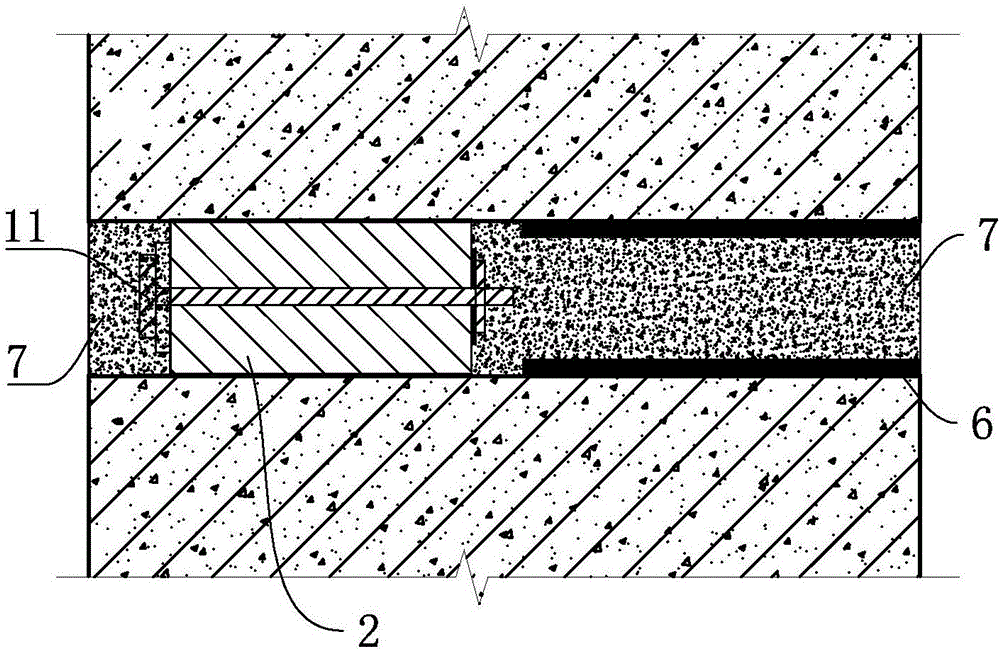

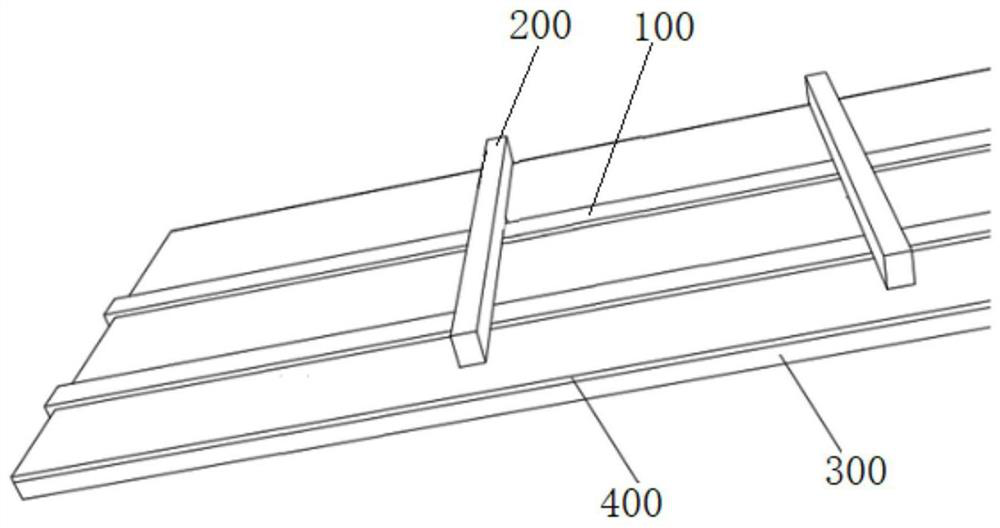

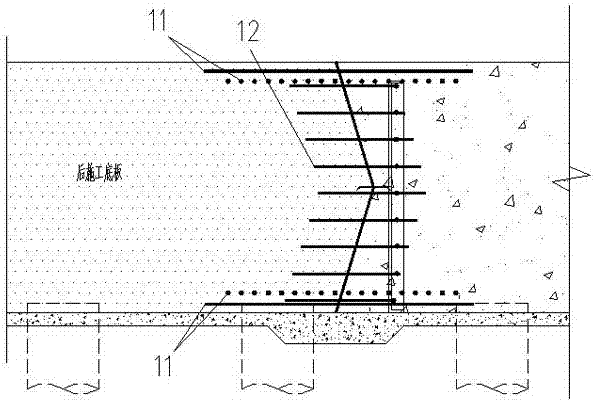

Prefabricated bridge deck slab wet joint connecting structure, prefabricated bridge and method

InactiveCN112127263AReduce on-site workloadImprove construction accuracyBridge structural detailsBridge erection/assemblyArchitectural engineeringBridge deck

The invention discloses a prefabricated bridge deck wet joint connecting structure, a prefabricated bridge and a method thereof. The technical proposal is as follows: prefabricating concrete bridge deck, a plurality of conical tooth grooves are formed in one side of the prefabricated concrete bridge deck and there is an annular connecting joint steel bar extending out from the end face of the prefabricated concrete bridge deck; the annular connecting joint steel bars between the two prefabricated concrete bridge decks are overlapped and staggered; transverse penetrating steel bars are arrangedon the inner sides and the outer sides of the annular connecting joint steel bars; concrete is filled between the oppositely-arranged conical tooth grooves to form a wet joint. The conical tooth grooves are formed in the connecting interface of the prefabricated concrete bridge deck slabs, the bridge deck slabs are connected through the annular steel bars. The invention has the advantages of simple structure, reasonable stress, reliable force transmission, capable of meeting various requirements of the concrete bridge deck slabs in the normal use and bearing capacity limit state; The on-sitepouring amount is small, and construction is convenient and fast.

Owner:SHANDONG TRAFFIC PLANNING DESIGN INST

Connecting structure of roof battens and counter battens and construction method thereof

PendingCN112196301AMake up for leaksSimplify the construction processRoof covering using tiles/slatesBuilding repairsRoof tileArchitectural engineering

In order to solve the problems of damage to a waterproof layer, low construction efficiency, low construction quality and the like in the construction process of the prior method, the invention provides a connecting structure of roof battens and counter battens. The connecting structure comprises a plurality of counter battens longitudinally and evenly arranged on a roof plate needing roof repairing work and a plurality of roof battens transversely and evenly arranged on the counter battens and used for hanging tiles. The two ends of the counter battens are hung at the two ends of roof platesrespectively. According to the connecting structure of the roof battens and the counter battens, the defect of waterproof layer leakage caused by traditional nailing can be overcome, the connecting positions and the connecting number of the roof battens and the counter battens can be adjusted according to the actual sizes of roof tiles, and therefore the usable range is wide; and in addition, theconstruction process of the structure is simple, and the construction speed can be greatly improved, so that the superiority in simplifying the process and improving the efficiency is stronger.

Owner:SHANGHAI NO 4 CONSTR

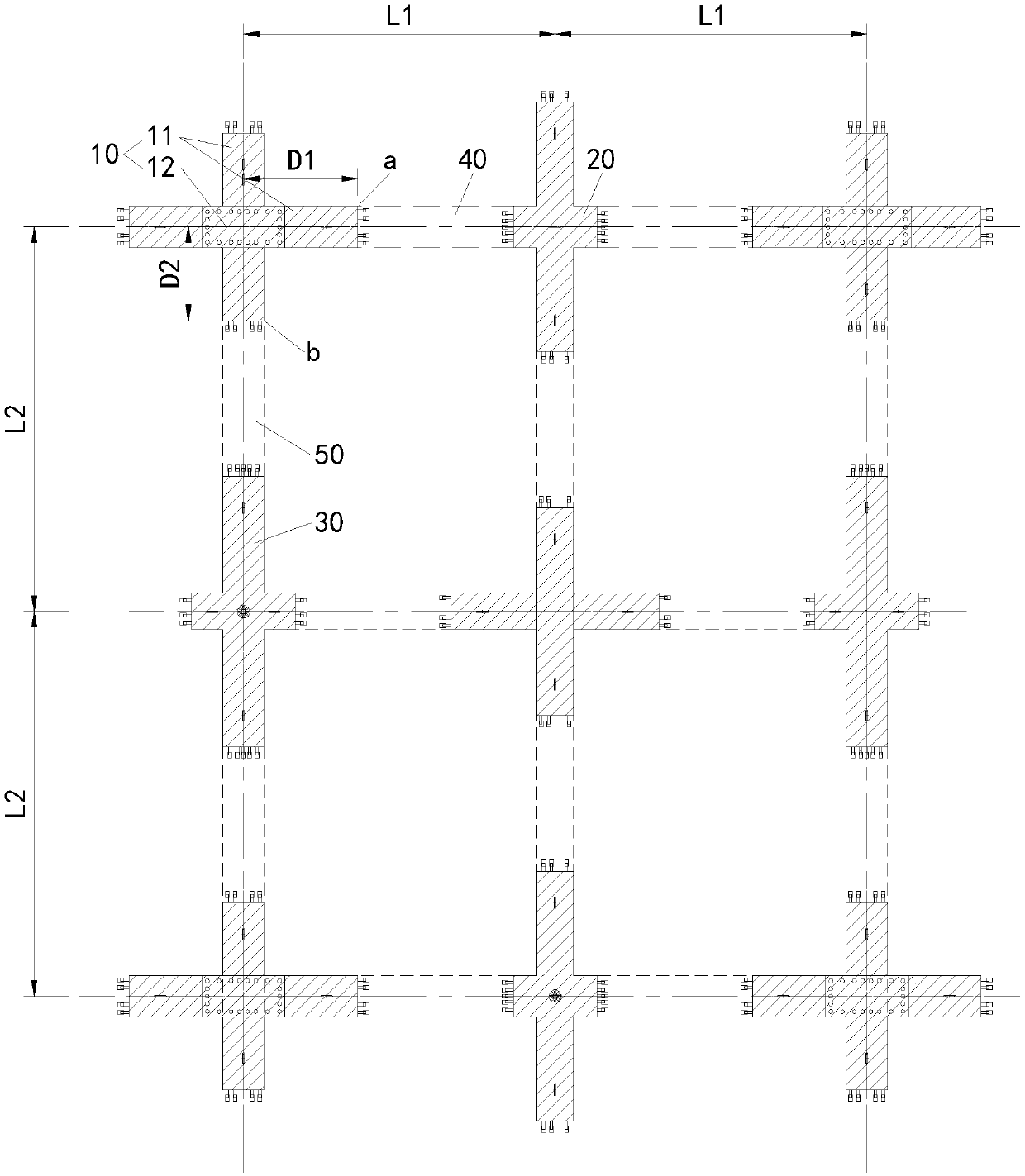

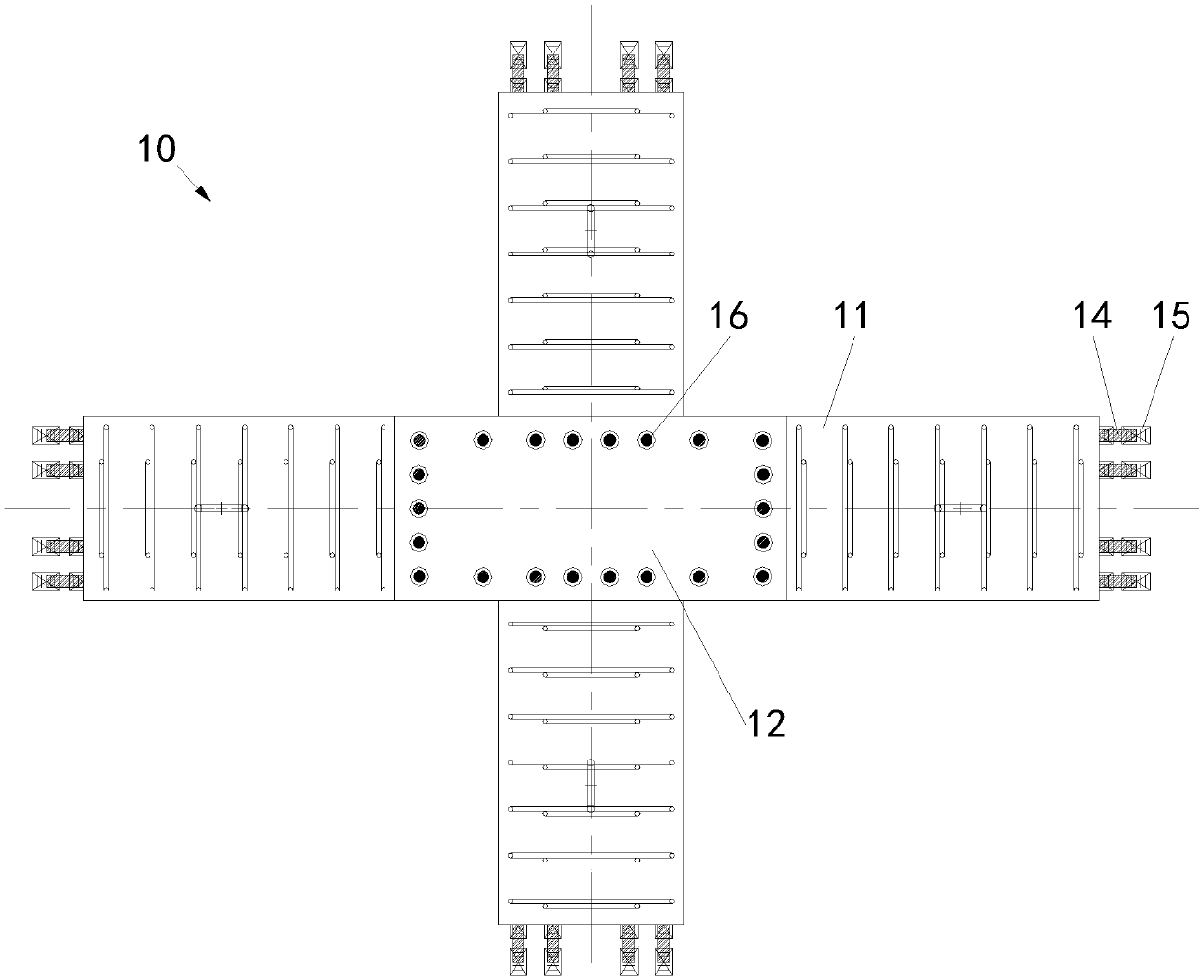

Assembled beam column structure and construction method thereof

PendingCN109518802AEnsure force safetyGuaranteed reasonablenessBuilding constructionsEngineeringBeam column

The invention relates to an assembled beam column structure and a construction method thereof and relate to the technical field of building structure design and construction, against the problem thatexisting prefabricated components of an prefabricated building and cast-in-place part connection nodes are disposed at the intersecting nodes of beam columns, so that the structural stress performanceis poor, resulting in unreasonable force. The assembled beam column structure includes a prefabricated section, a cast-in-place section and a plurality of structure columns, wherein the prefabricatedsection is at least one prefabricated primary beam and at least one support which are prefabricated to be a whole, or at least one prefabricated primary beam and at least one prefabricated secondarybeam which are prefabricated to be a whole; the cast-in-place section is connected between two adjacent prefabricated primary beams and / or prefabricated secondary beams, the cast-in-place section is formed by on-site concrete pouring, and the connecting node of the prefabricated section and the cast-in-place section has a distance of L / 4 to L / 3 from the center of the adjacent support or prefabricated primary beam; the structure columns are connected to the bottom of the support; and L is the calculated span of the beam.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

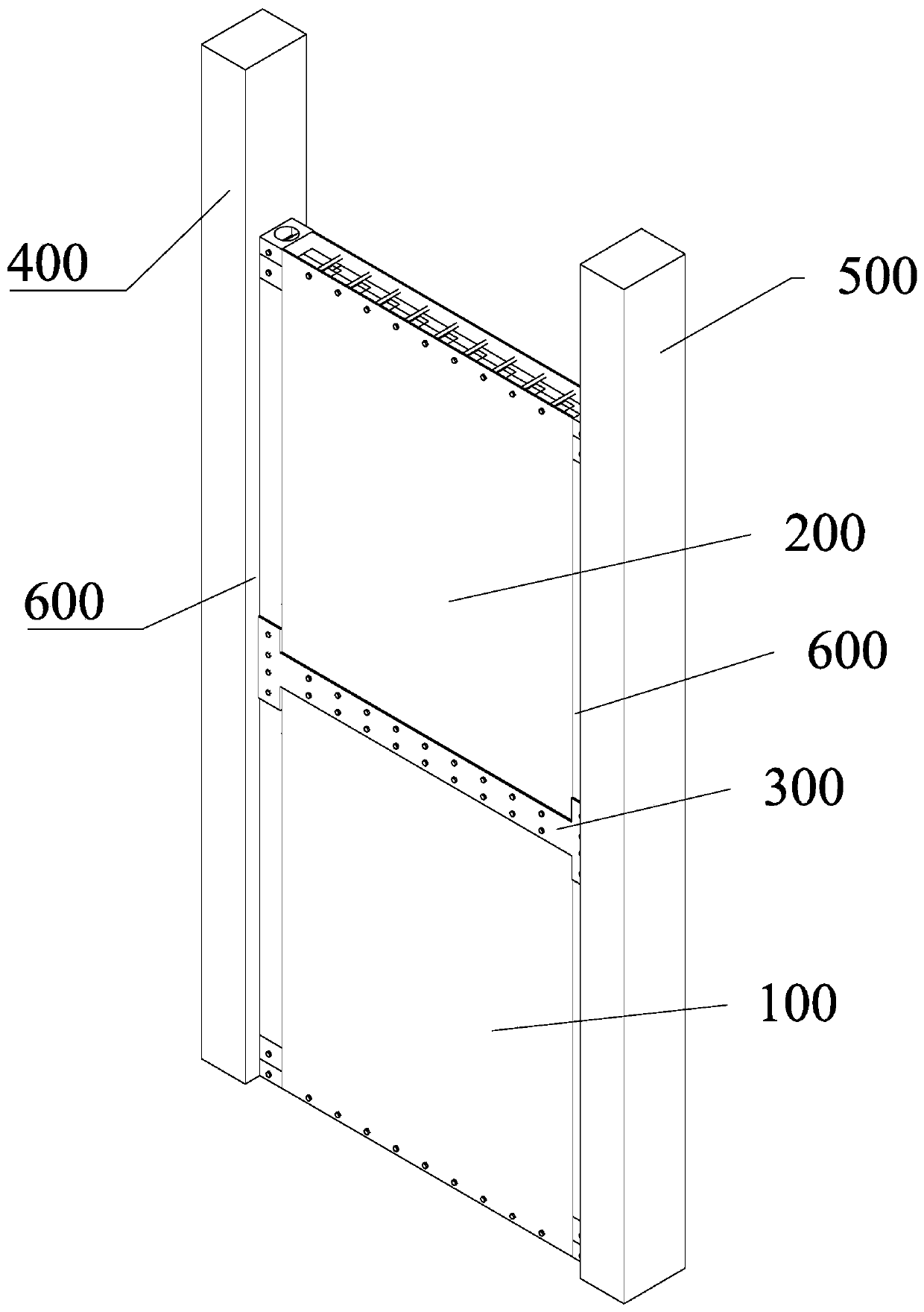

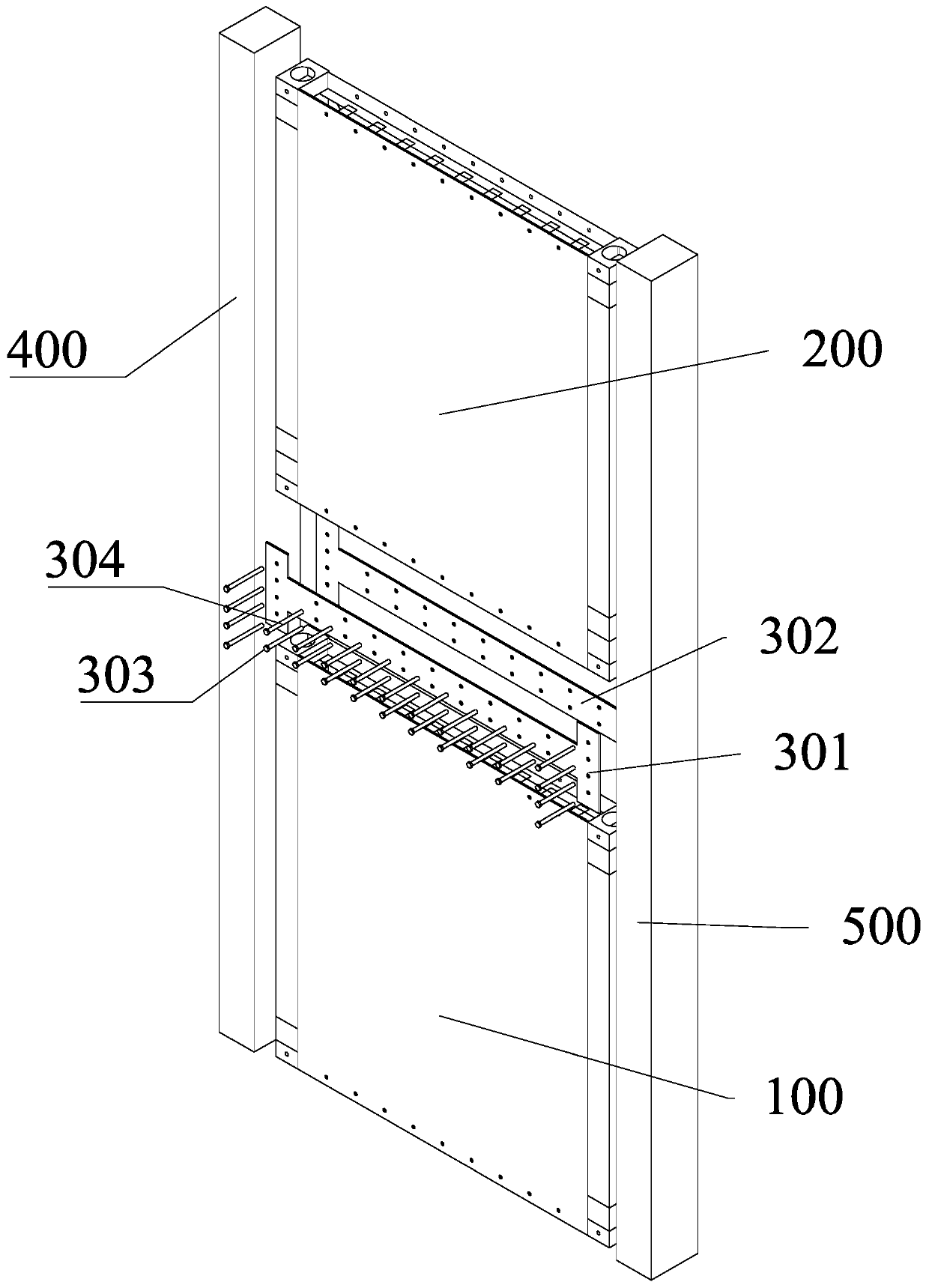

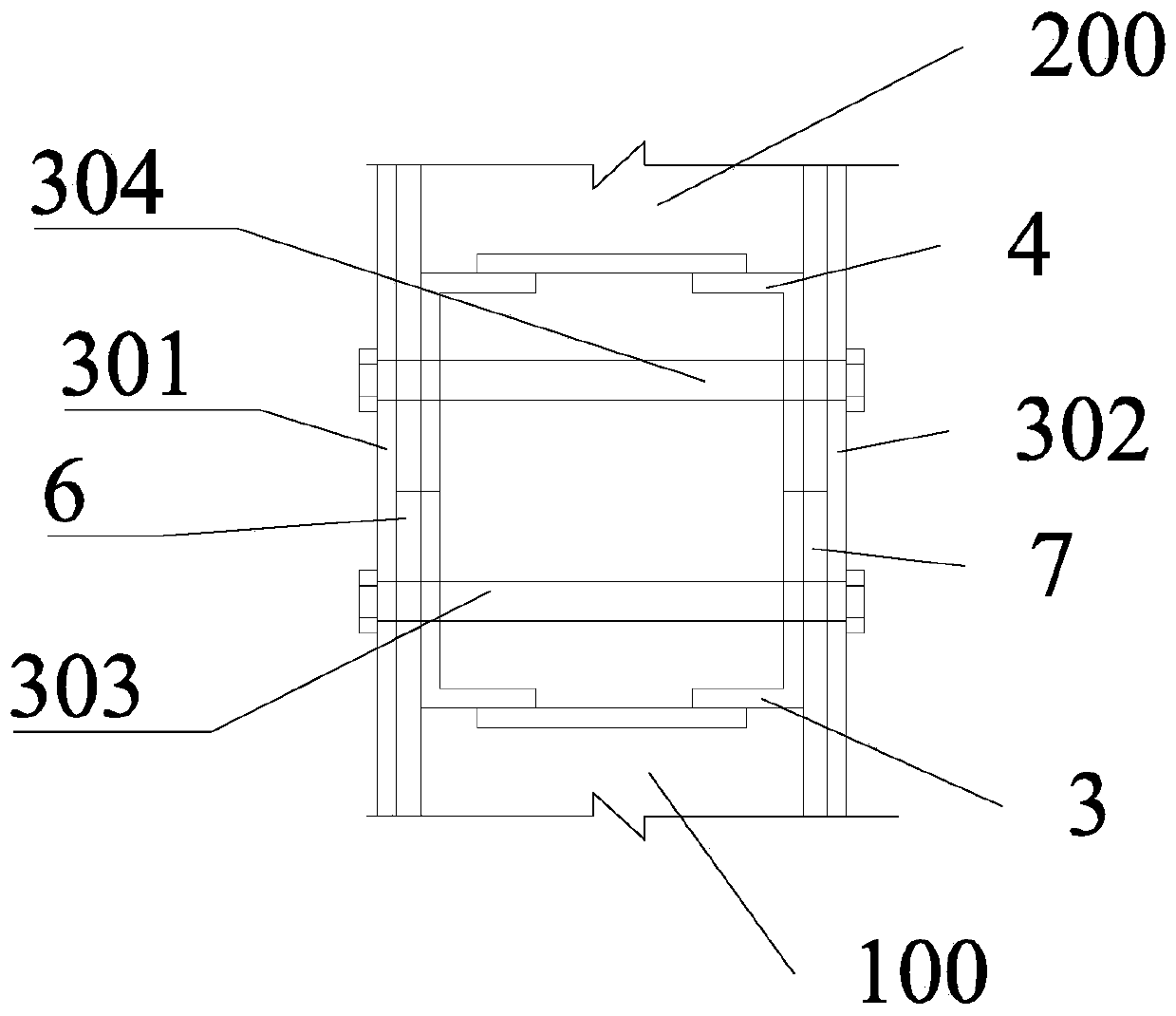

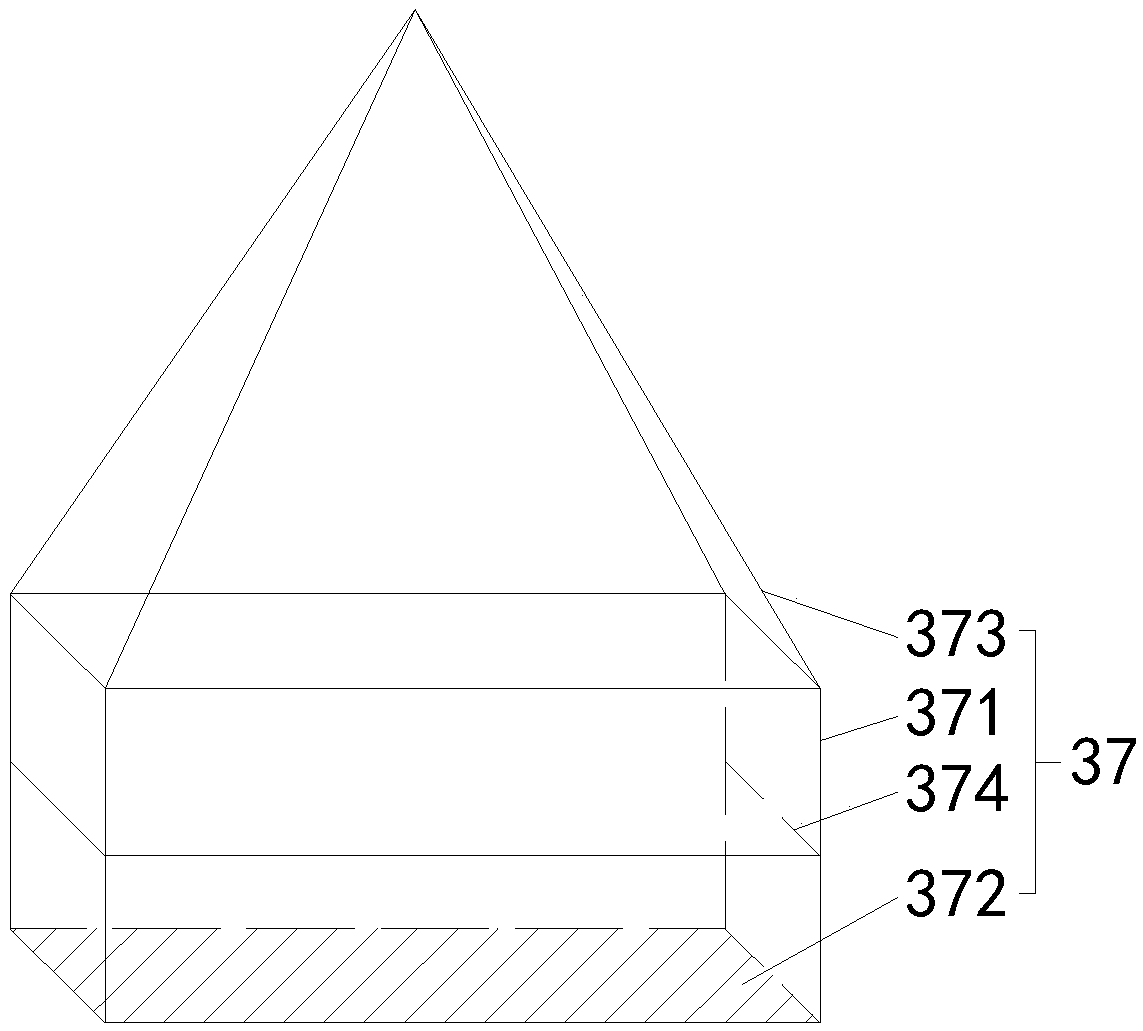

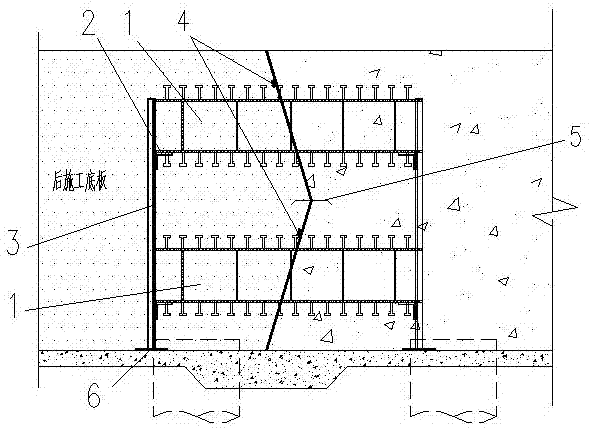

Fabricated shear wall with steel plate stud combined type diagonal bracing and construction method

PendingCN110512765AIncrease out-of-plane stiffnessIncrease height-to-thickness ratio limitWallsIn planeLateral stiffness

The invention discloses a fabricated shear wall with a steel plate stud combined type diagonal bracing and a construction method. The fabricated shear wall comprises a first shear wall unit and a second shear wall unit, wherein the first shear wall unit and the second shear wall unit are stacked up and down, and the first shear wall unit and the second shear wall unit are connected and fixed witha connecting mechanism; the first shear wall unit and the second shear wall unit are provided with shear wall structures; a shear wall frame is formed by enclosing a left concealed column, an upper concealed beam, a right concealed column and a lower concealed frame; a first facade steel plate and a second facade steel plate are fixed to the front side and the rear side of the shear wall frame; diagonal bracing members are fixed in the shear wall frame; and each diagonal bracing member comprises two steel plates, the two steel plates cross each other to form an X-shape structure, studs are arranged on the steel plates, and concrete is poured in the shear wall units. According to the fabricated shear wall with the steel plate stud combined type diagonal bracing and the construction method,the in-plane lateral stiffness, shear bearing capacity, bending bearing capacity, ductility and energy consumption of the shear wall are improved through the design of the diagonal bracing members, the shear wall units can be pre-installed in advance, and on-site construction is facilitated.

Owner:SOUTH CHINA UNIV OF TECH +2

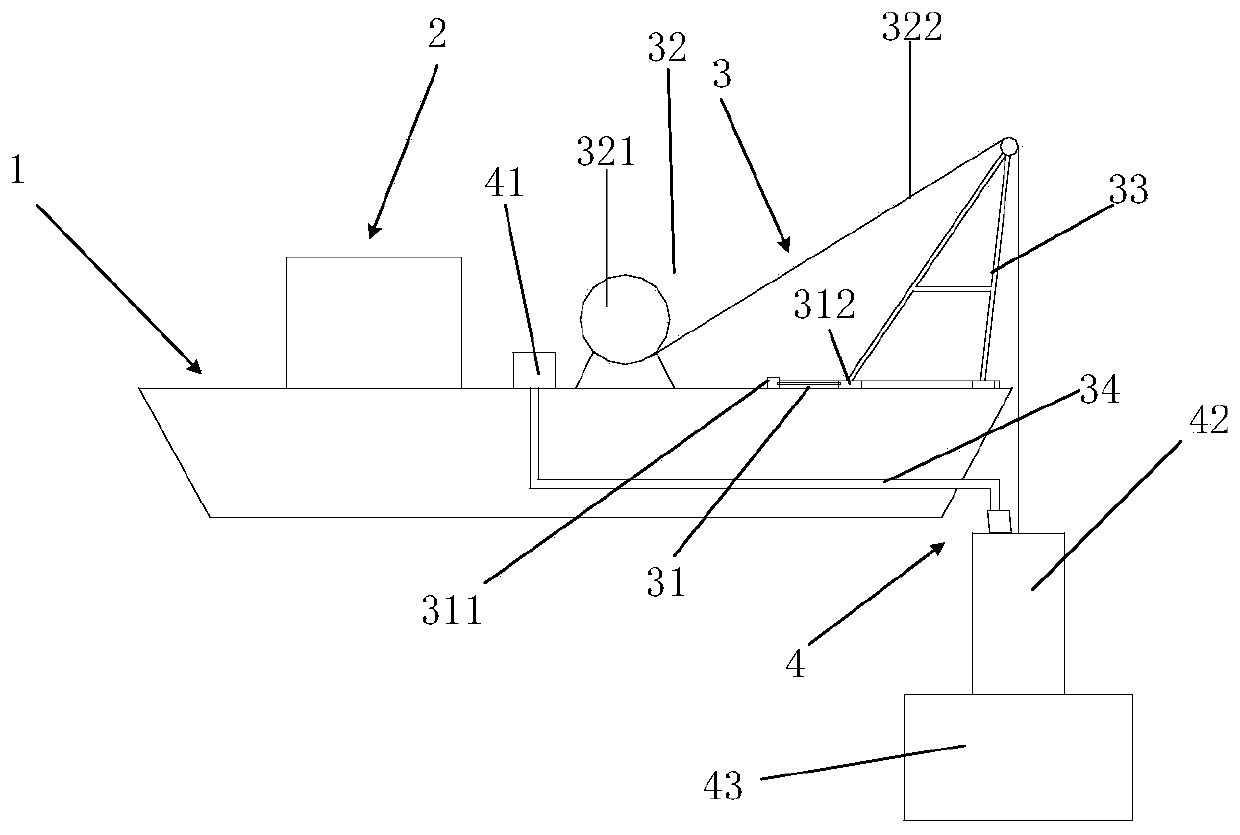

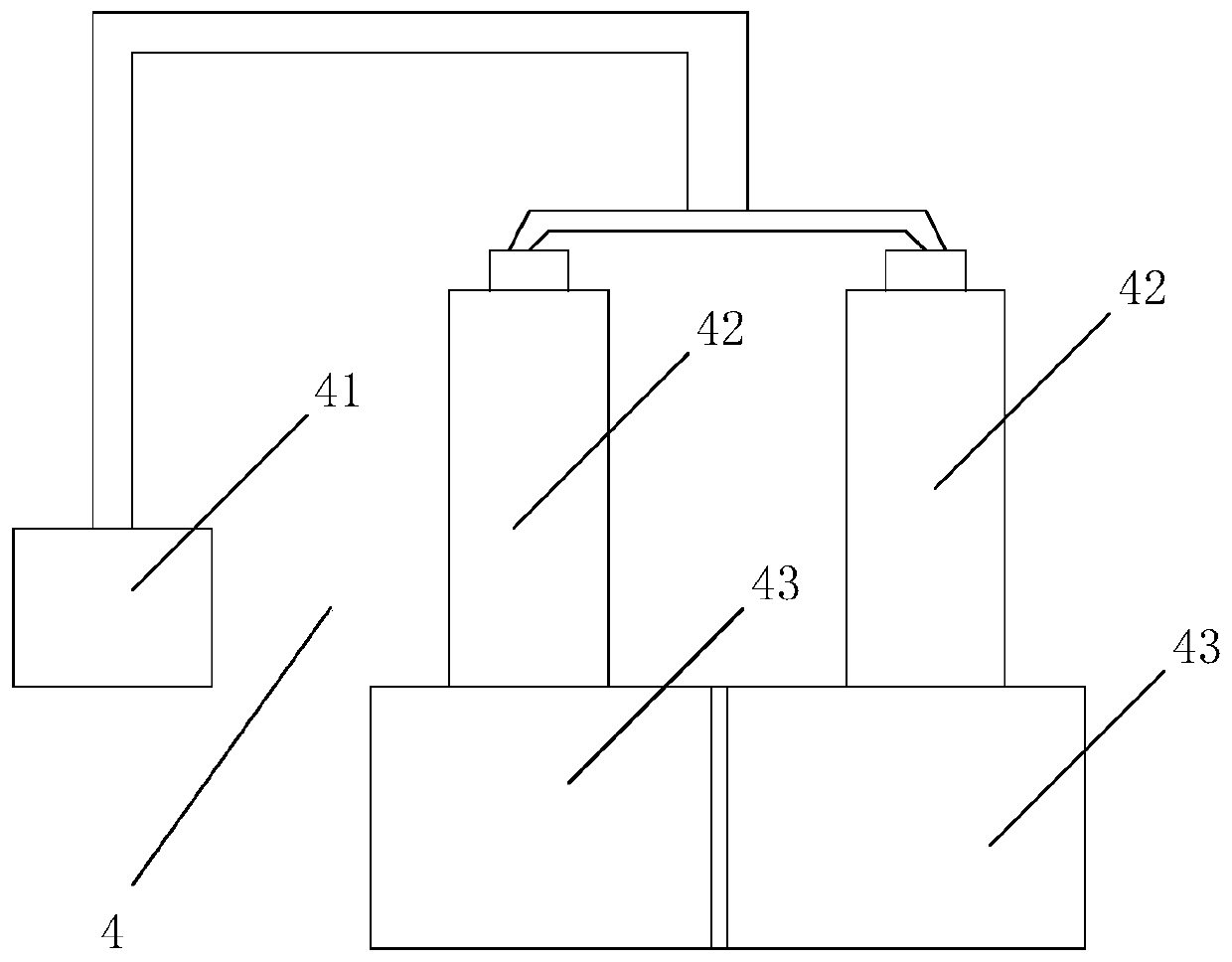

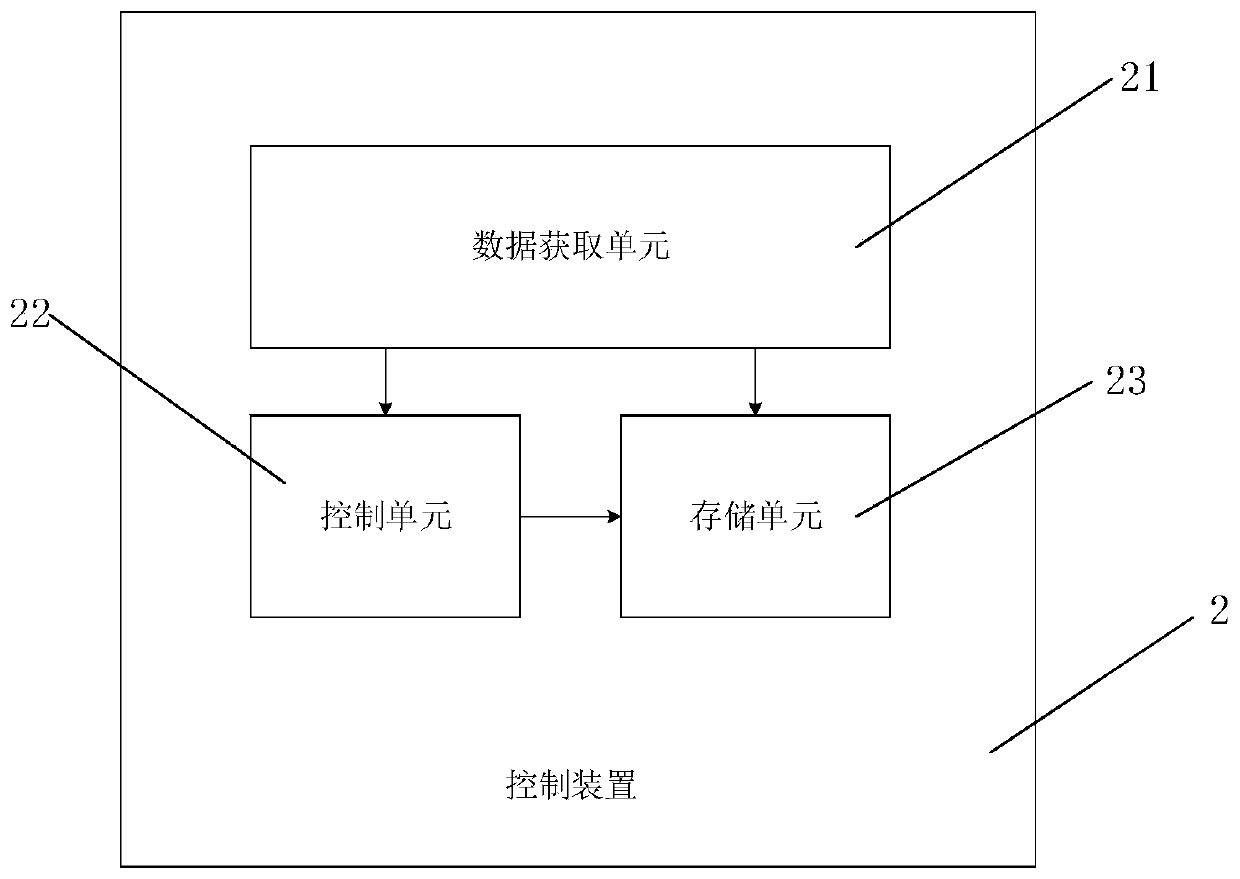

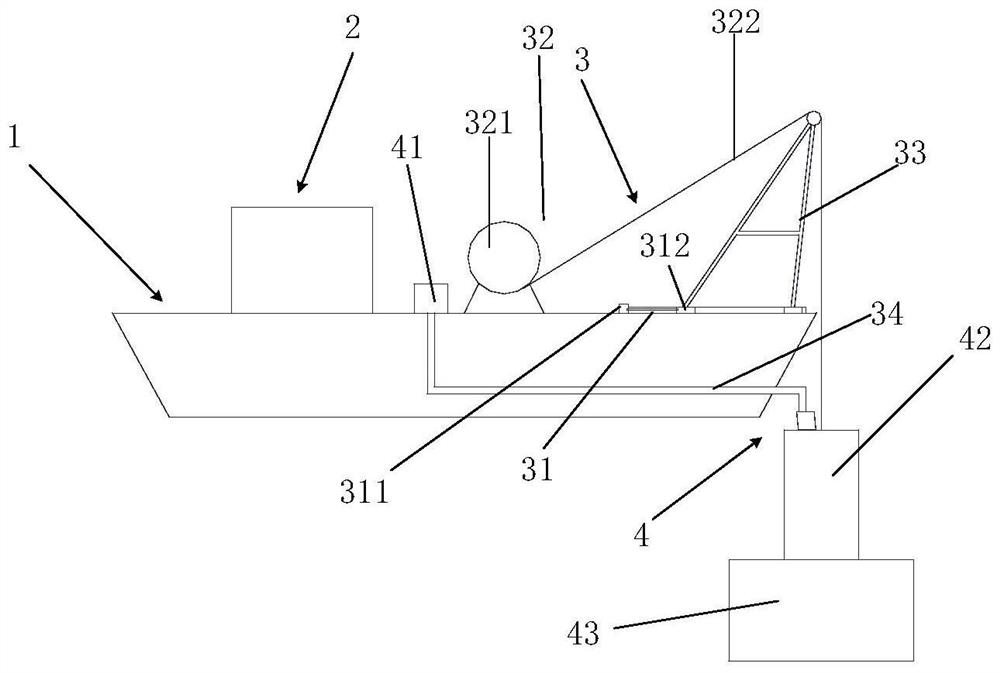

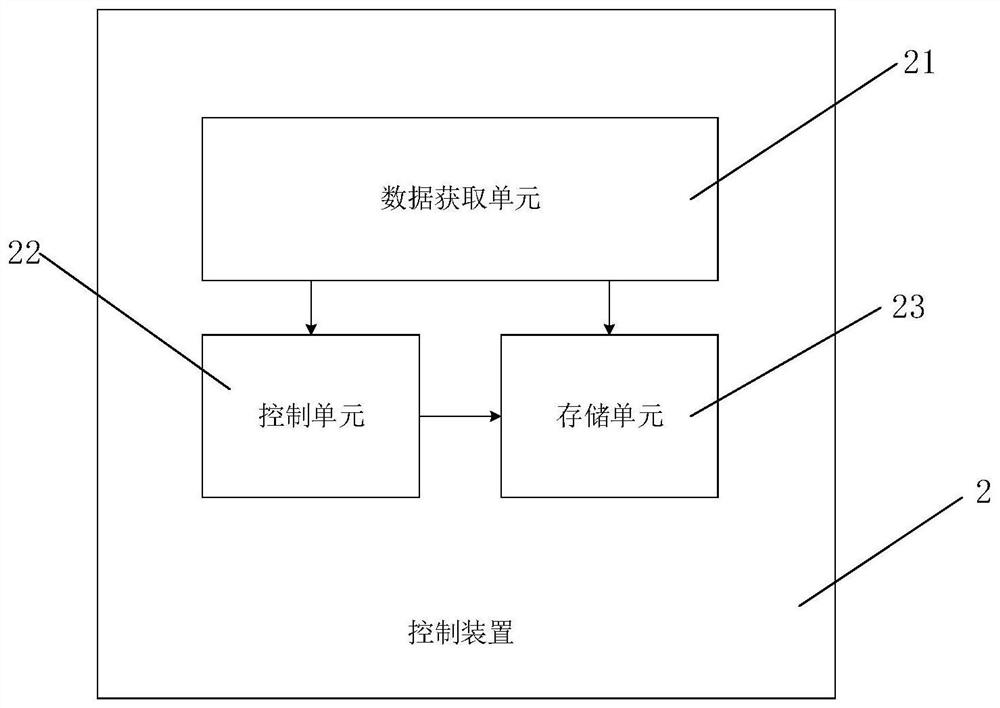

Single-unit hydraulic dredger

ActiveCN109826265AReduce difficultyImprove construction rateSoil-shifting machines/dredgersSludgeControl engineering

The invention provides a single-unit hydraulic dredger. The dredger comprises a hull, a control device, a driving mechanism and a water spraying device, wherein part of the control device is arrangedon the hull and used for computing preset angle and preset pressure intensity when high-pressure water spraying is conducted by the water spraying device and controlling the driving device to drive the water spraying device to move to a preset position to perform high-pressure impacting on sludge, the driving device is arranged on the hull and used for driving the water spraying device to synchronously move to a preset position according to a preset trajectory to ensure the water spraying device can perform high-pressure impacting on the sludge according to a preset angle, and part of the water spraying device is arranged on the hull and used for performing high-pressure water spraying according to the preset pressure intensity to flush away the sludge at the bottom of a port. The dredgerhas the advantages that the problems of lower cleaning efficiency and poorer cleaning effect when port sludge is cleaned by an existing dredger are solved.

Owner:王美玲

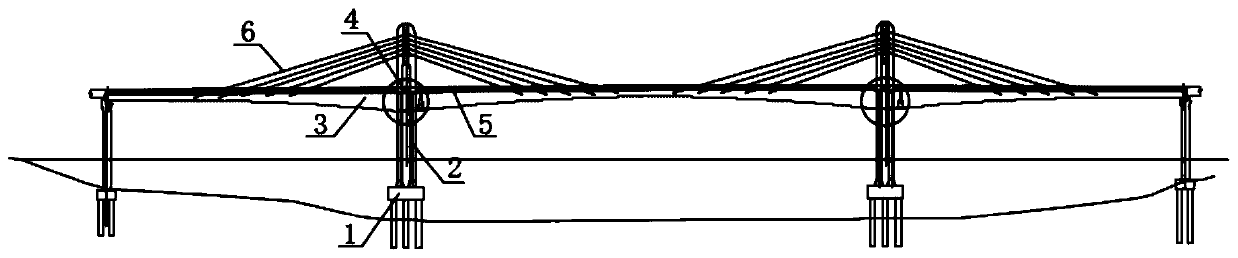

Steel box beam thin-walled pier rigid frame cable-stayed bridge suitable for straddle monorail

PendingCN109930469AIncrease stiffnessSufficient horizontal stiffnessCable-stayed bridgeBridge structural detailsCable stayedStraddle

The invention discloses a steel box beam thin-walled pier rigid frame cable-stayed bridge suitable for a straddle monorail. The bridge comprises a cap foundation (1), the cap foundation (1) is arranged longitudinally at interval in the bridge direction, the upper portion of the top is correspondingly provided with a pier, the pier comprises a side pier and a middle pier, the top of the pier is longitudinally provided with a steel main beam (3), pylons (4) are arranged corresponding to the top of the middle pier at the transverse sides above the steel main beam (3), the pylons (4) are providedwith cable fixing ends for fixing one end of a stay cable (6), and the other end of the stay cable (6) is sequentially fixed to the steel main beam (3) on both sides of the longitudinal direction of the pylons (4); the middle pier is at least two thin-walled piers (2) arranged at interval in the bridge direction, a pier beam consolidation system is adopted between the top of the middle pier and the steel main beam (3) to form a rigid frame structure with integral force, and the system releases the longitudinal temperature force of the steel main beam while satisfying the requirement of the straddle monorail to the rigidity of the bridge.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Curtain wall removal device and method

The invention provides a curtain wall removal device and method, and relates to the technical field of building construction. The problems that an existing curtain wall removal process has the defectssuch as high noise pollution, much construction dust, and high destructiveness to the surrounding environment are focused. The curtain wall removal device comprises a plurality of brackets, a track,and at least one winding engine and one hanging basket. The brackets are arranged at intervals, and one ends of the brackets are vertically connected to structural beams or structural columns in the area of curtain wall unit assemblies of an existing building. The horizontally arranged track is movably connected to the bottoms of the other ends of the brackets, and the extension direction of the track is parallel to the external wall of the existing building. The winding engines are connected to the track and can slide horizontally along the track. The hanging baskets are installed on liftinghooks on the bottoms of the winding engines correspondingly, and the hanging baskets are used for bearing the removed curtain wall unit assemblies and transporting the removed curtain wall unit assemblies to the ground.

Owner:SHANGHAI NO 4 CONSTR

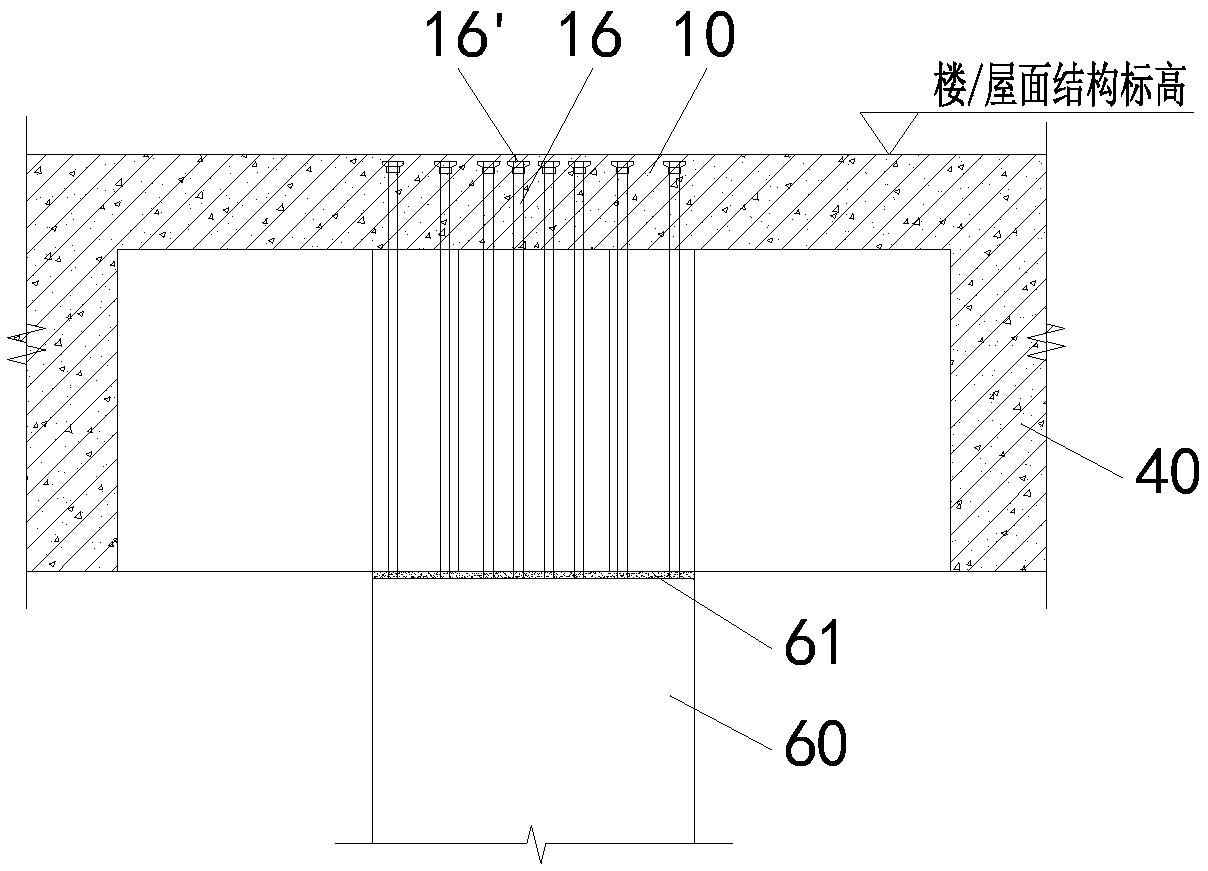

Cast-in-place gypsum hollow wall without removing formwork and construction method thereof

PendingCN114687484AImprove the tightnessGuaranteed flatnessWallsBuilding material handlingCalcium silicateFiberglass mesh

The invention relates to a cast-in-place gypsum hollow wall with a non-dismantling formwork and a construction method of the cast-in-place gypsum hollow wall with the non-dismantling formwork, the cast-in-place gypsum hollow wall with the non-dismantling formwork comprises the non-dismantling formwork, a cast-in-place gypsum hollow wall and a plastering layer, and the non-dismantling formwork is composed of a steel structure framework and a face plate which are assembled on site. The steel structure framework is composed of a vertical end plate, a transverse bottom plate, transverse reinforcing ribs and a hollow pipe positioning plate. The face plates are high-strength calcium silicate plates, bolt holes are formed in the high-strength calcium silicate plates in advance, the high-strength calcium silicate plates are arranged on the long face and the high face of the steel structure framework, the inner sides of the high-strength calcium silicate plates are coated with waterproof paint, and the cast-in-place gypsum hollow wall is located in the non-dismantling formwork. A hollow pipe is arranged in the cast-in-place gypsum hollow wall body, the plastering layer is located on the outer side of the face plate, glass fiber gridding cloth is arranged in the plastering layer, the steel structure framework and the face plate are prefabricated in a factory, the non-dismantling formwork is obtained through field assembly, transportation is convenient, and meanwhile the flatness of the wall body and the construction efficiency are improved.

Owner:赵训

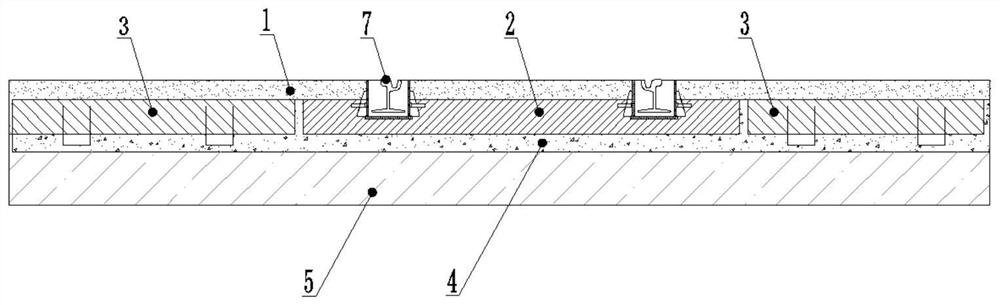

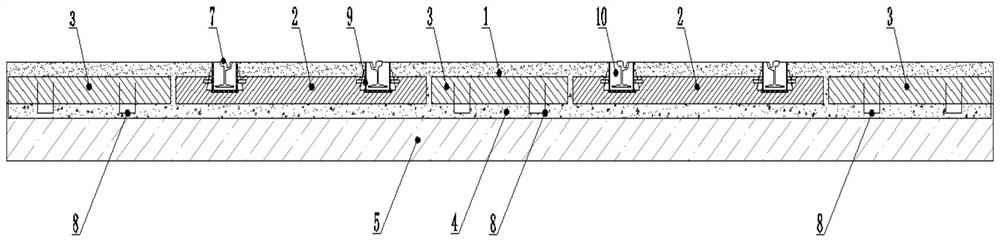

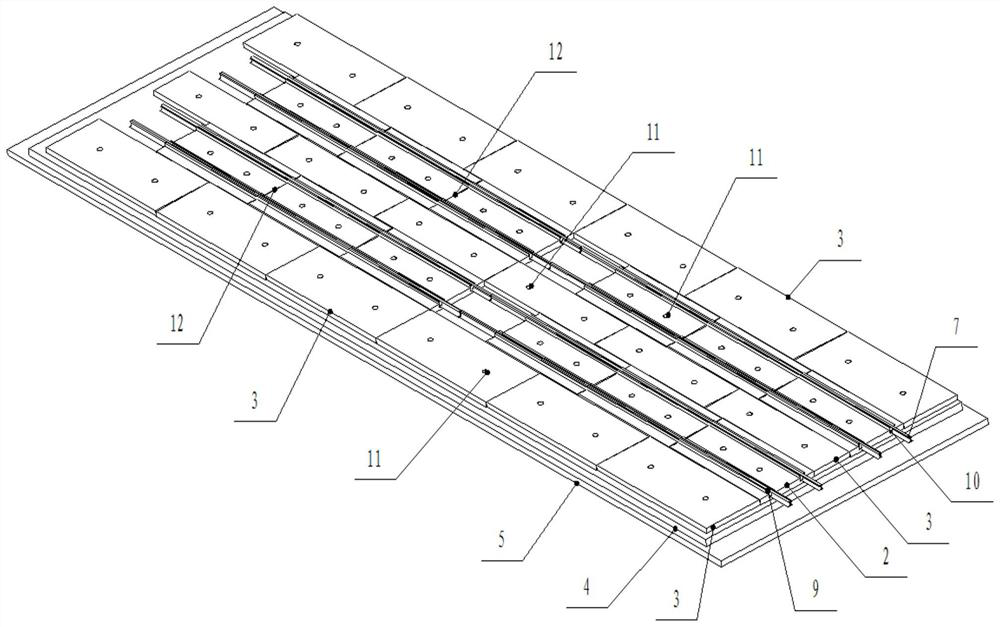

Level crossing rail rapid construction method

InactiveCN112281549AReduce the amount of cast-in-placeImprove construction rateBallastwayArchitectural engineeringLevel crossing

The invention discloses a rapid construction method for a level crossing rail, relates to the technical field of rail construction methods, and mainly adopts a prefabricated rail integration unit anda crossing plate to form most of rail structures in advance. In the construction site, implementation personnel only need to correspondingly construct the roadbed supporting layer, the mortar adjusting layer and the pavement paving layer, the cast-in-place amount of the whole construction site is reduced, and therefore the construction speed of a project is increased.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

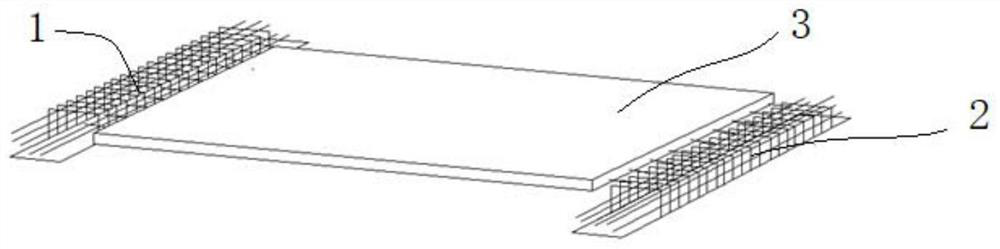

A kind of one-way laminated board construction and installation method

ActiveCN110359613BSave the docking installation processImprove construction rateFloorsGirdersArchitectural engineeringRebar

Owner:CHINA MCC5 GROUP CORP

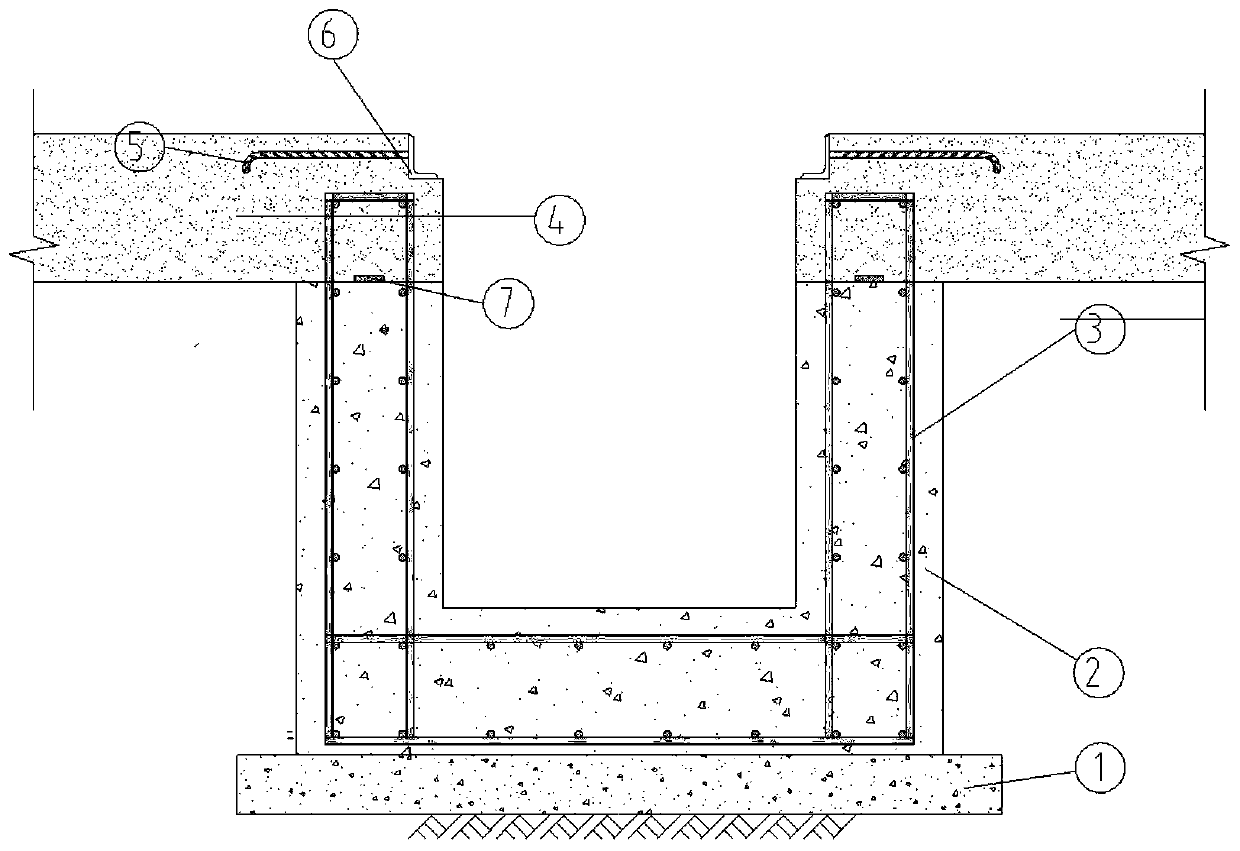

Fabricated underground structure and construction method

ActiveCN112814025AImprove protectionReduce constructionArtificial islandsExcavationsArchitectural engineeringPollution

The invention discloses a fabricated underground structure and a construction method. The problems that in the prior art, underground structure construction occupies a large space, and a large number of supporting structures are reserved are solved, and the beneficial effects that construction is convenient, the number of supporting structures is reduced, and environmental pollution is reduced are achieved. The fabricated underground structure comprises a plurality of sections, every two adjacent sections are connected, each section comprises side walls on the two sides, a bottom plate and a top plate, the bottom plates are arranged at the bottoms of the side walls, the top plates are arranged at the tops of the side walls, and each side wall comprises a plurality of prefabricated parts; and outward steps are formed on the side walls on the two sides of one end of each section, so that the other end, opposite to the steps, of the front section can be wrapped by the rear section, and every two adjacent sections are connected in a pouring mode.

Owner:JINAN MUNICIPAL ENG DESIGN & RES INSITITUTE GRP

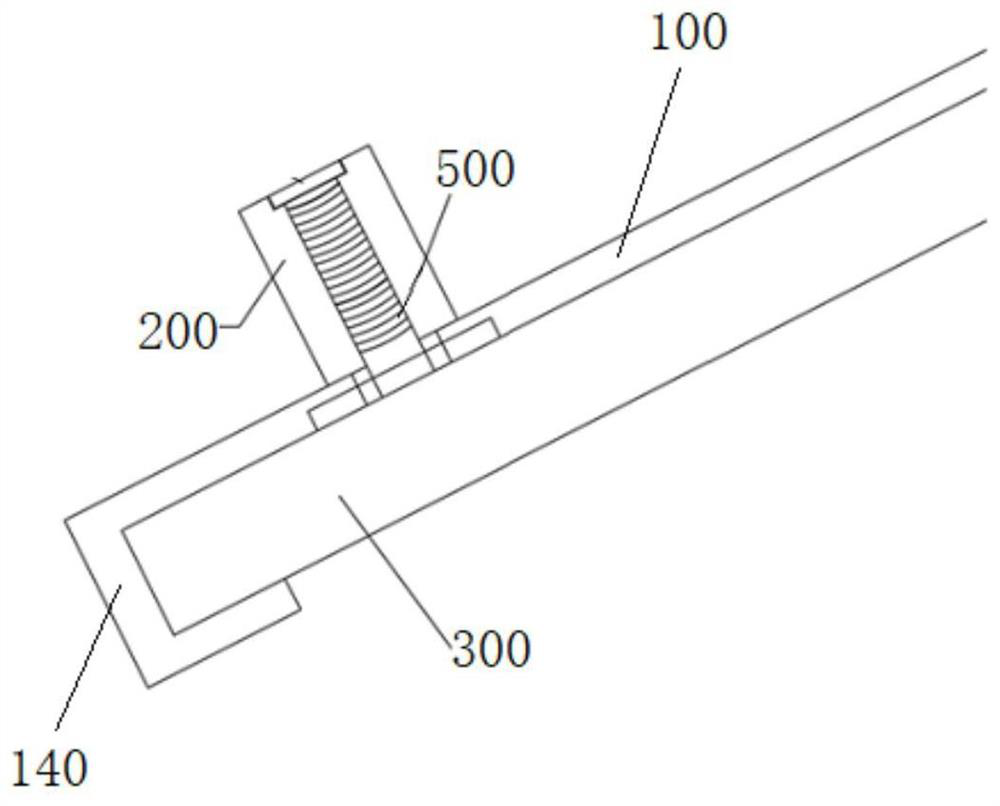

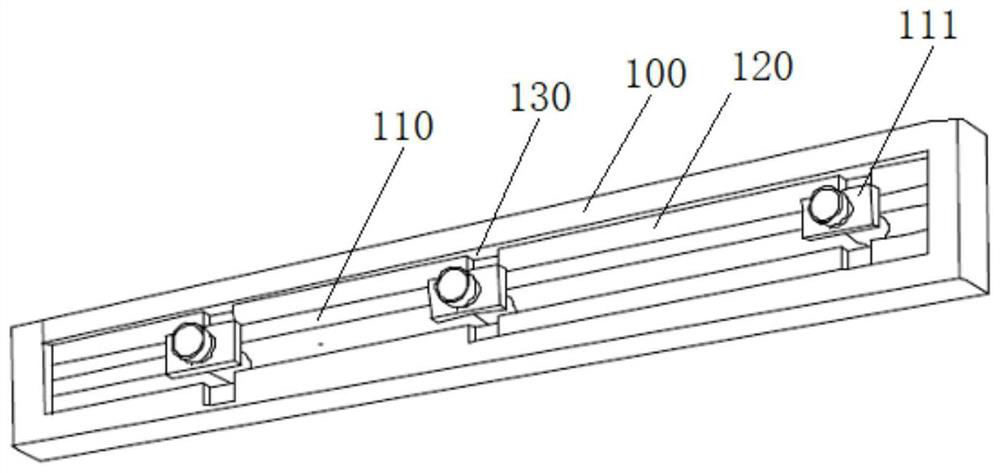

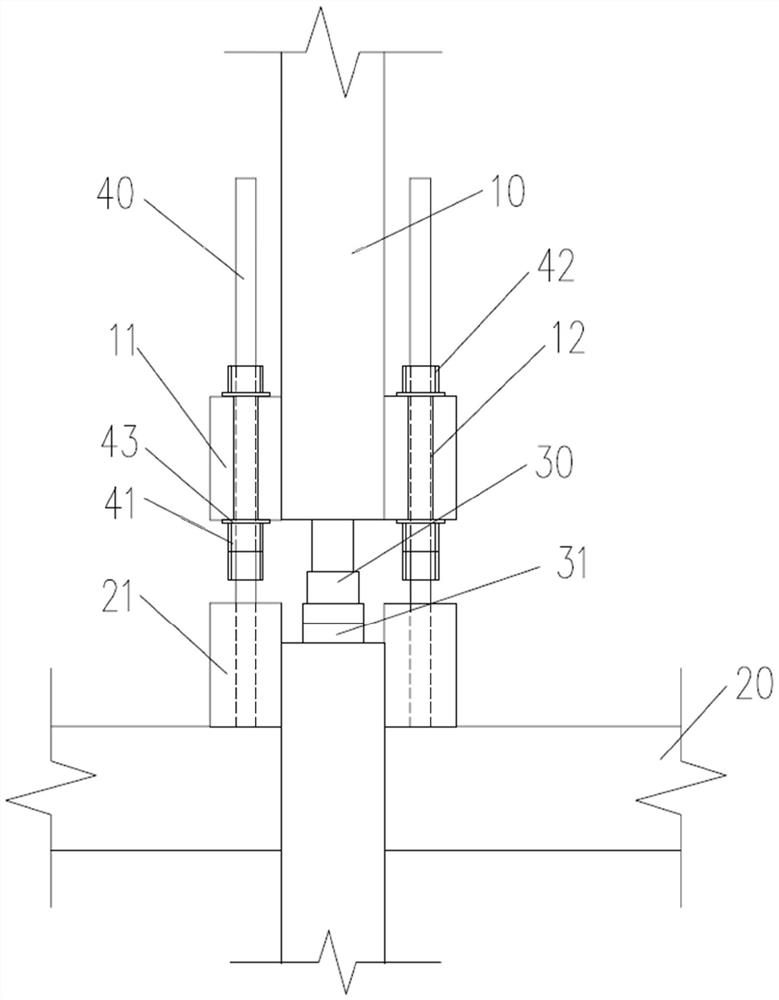

A frame building jacking device, an overall jacking method, and a jacking deviation correction method

ActiveCN112696050BReduce usageReduce cost inputBuilding repairsArchitectural engineeringScrew thread

The invention discloses a frame building jacking device, an overall jacking method and a jacking deviation correction method, which include a jack, a screw rod, a threaded sleeve, an upper limit nut and a lower pressure nut; There are 2 or 4 corbels symmetrically arranged, and 1~2 threaded steel pipes are pre-embedded in each corbel; the jack is placed on the ground beam directly below the center of the frame column; the bottom end of each screw is pre-buried in the ground beam In the center, the top ends pass through the corresponding threaded steel pipes to form a piercing end, the maximum length of which is not less than the jacking height of the frame building; the thread fit clearance between the screw rod and the inner wall of the threaded steel pipe does not exceed 1mm; under each corbel Each screw rod is provided with at least one lower bearing nut, and each screw rod above each corbel is provided with an upper limit nut. The invention can reduce the number of jacks used, greatly reduce the number of pads used, and speed up the construction speed. At the same time, during the jacking process, the verticality accuracy is high, and it can prevent tilting.

Owner:江苏建科土木工程技术有限公司

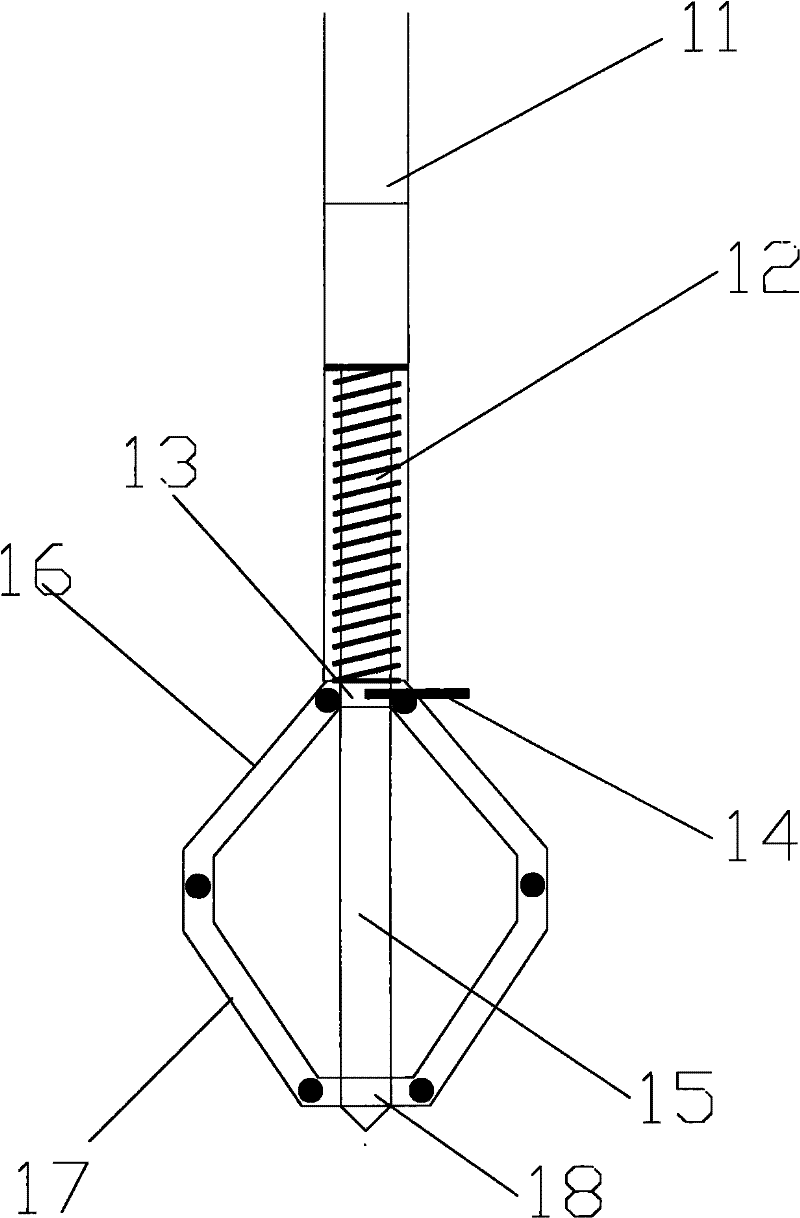

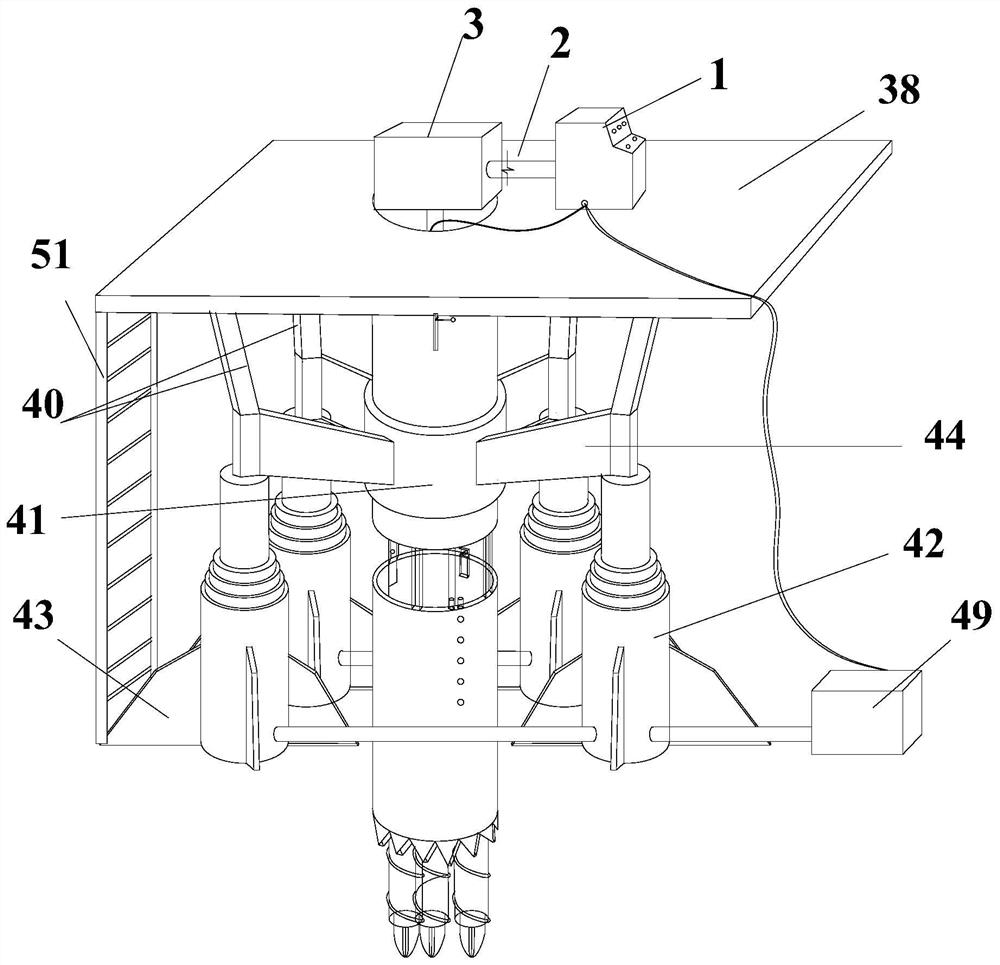

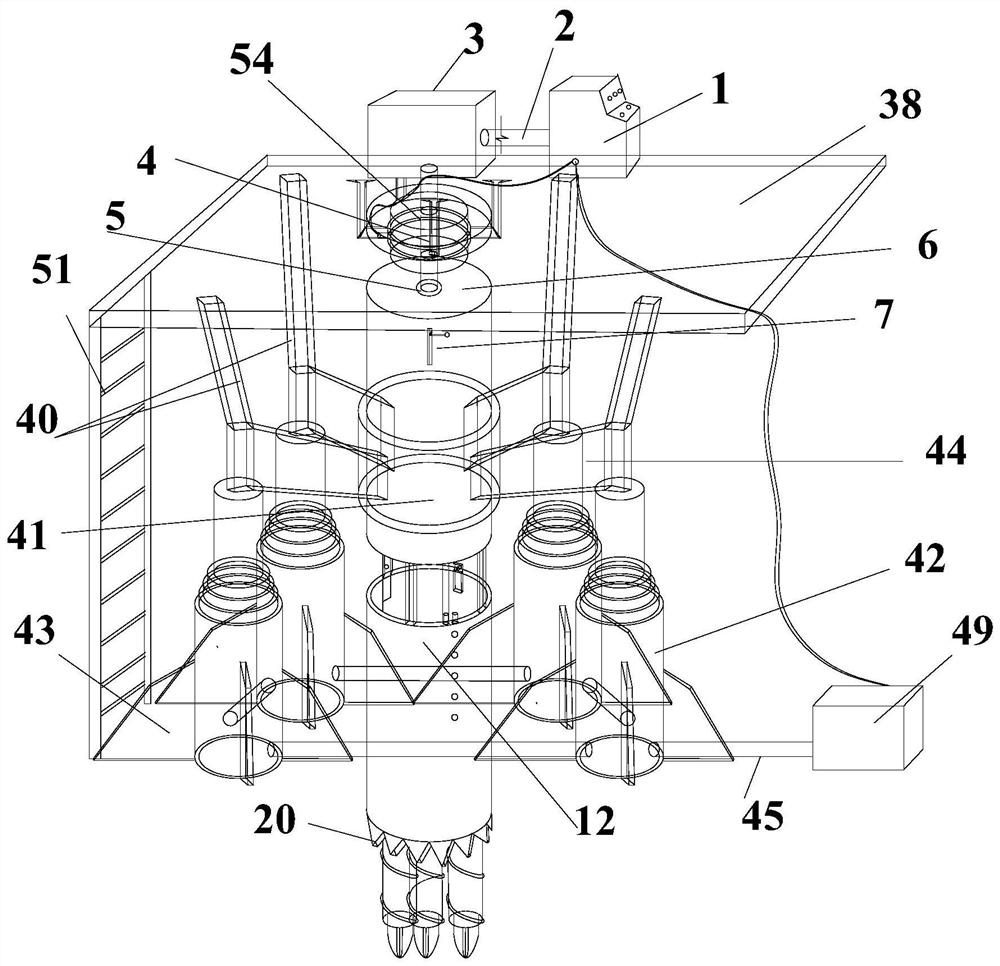

A multi-head soil dumper drill bit in hard soil area

ActiveCN111561267BReliable drilling degreeEasy to disassembleDrill bitsConstructionsAgricultural engineeringStructural engineering

The invention provides a drill bit for a multi-head soil dumper in a hard soil area, which includes a longitudinal transmission rod, an upper sleeve, several lower sleeves, a drill assembly, an electromagnetic exciter, and a lifting platform. The drill assembly is located at the The outer side of the longitudinal transmission rod, and cooperate with the longitudinal transmission rod, the upper sleeve is sleeved on the outer side of the longitudinal transmission rod, and the lower sleeve is connected with each other, and is sleeved on the The outer side of the drill bit assembly, the electromagnetic exciter is fixed on the longitudinal transmission rod, and is located above the upper sleeve, and the upper sleeve is fixed on the lifting platform. The drill bit of the multi-head soil dumper in the hard soil area of the present invention can be lifted and lowered, which facilitates the disassembly and installation of various structures and avoids the difficulty of device disassembly. At the same time, the operating platform can simultaneously control the lifting of the platform and the drilling of the drill bit, reducing personnel and operations. Simple.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

A corrugated rigid web construction hanging basket and construction technology

InactiveCN105507165BReduce the total massIncrease the factor of safety against overturningBridge erection/assemblyHanging basketEngineering

The invention discloses a hanging basket for corrugated steel web plate construction and a construction process. The hanging basket for construction comprises an upper beam assembly, a lower beam assembly and multiple groups of hanging rods for connecting the upper beam assembly and the lower beam assembly. A base plate bottom formwork and base plate side formworks are arranged above the lower beam assembly, the upper beam assembly is supported on the top end faces of two corrugated steel web plates through two groups of supporting beams, and thrusting devices are arranged between the supporting beams and the top ends of the corrugated steel web plates. The bottom ends of the corrugated steel web plates are arranged in a base plate concrete casting area. Top plate bottom formworks arranged above the upper beam assembly. Horizontally-arranged sliding beams are arranged on two sides of the corrugated steel web plates, and conveying devices for conveying the base plate bottom formwork, the base plate side formworks and the top plate bottom formworks to the positions to be cast are installed on the sliding beams. The self weight of the hanging basket for corrugated steel web plate construction can be effectively reduced, the security coefficient of the hanging basket can be improved, and the construction efficiency can be accelerated.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

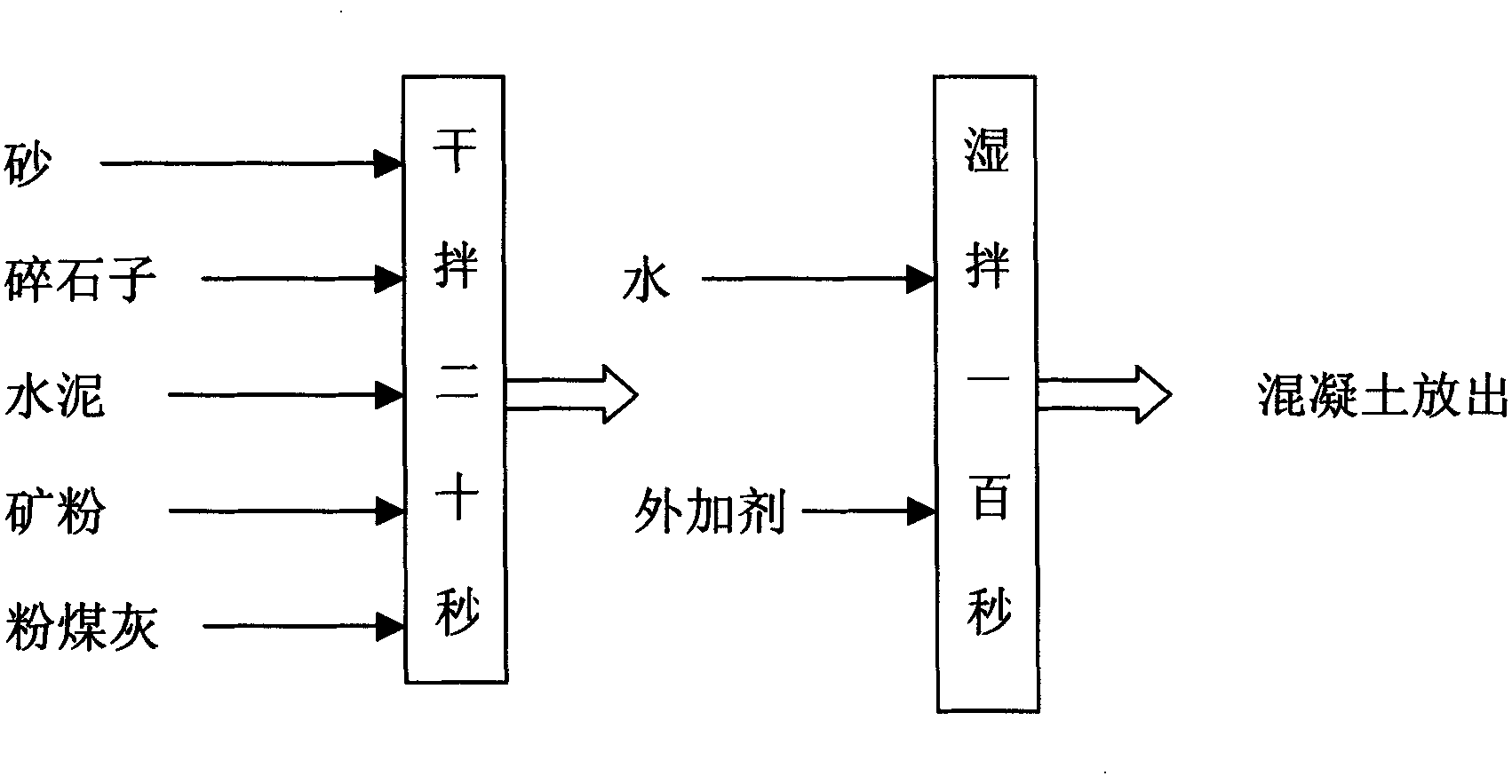

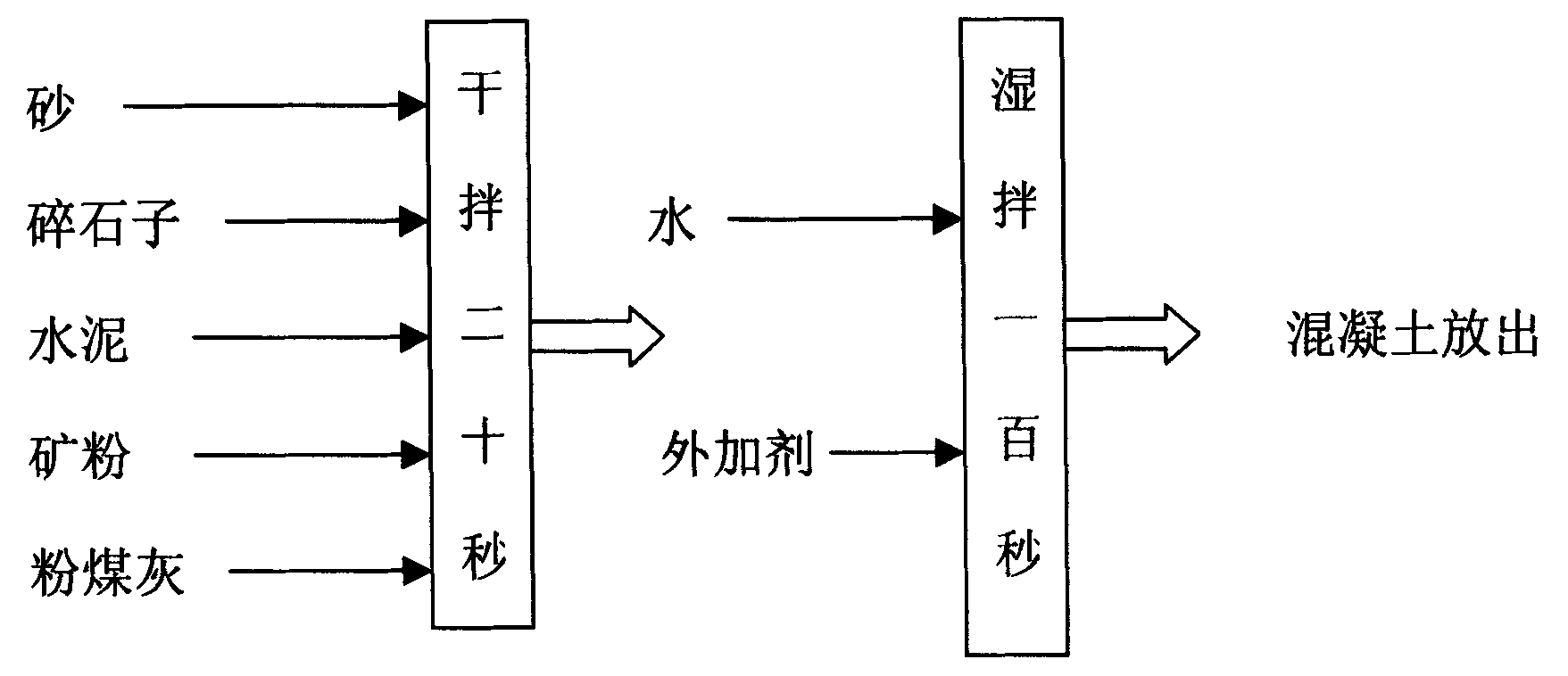

Autodensing concrete using polycarboxylic acid series additive and its technology

ActiveCN100999399BImprove plasticizing effectImprove slump retentionSolid waste managementPolyethylene oxidePolymer science

This invention relates to a self-compacting concrete that using polycarboxylate additive agent, mixed by aggregate, cementitious materials, additive agent and water. According to weight, sand rate of 45%, the total amount of slag and fly ash mixture is more than 30% of the total cementitious Materials, the water-cement ratio is not more than 0.4; select ordinary silicate cement of no less than 42.5; slag and fly ash ratio of 1:1; the Polycarboxylate, polyethylene oxide chain length of 10 ~ 300 Moore, the molar ratio of allyl part of 1 / 9 to 6 / 9, molecular weight of polymer is 30,000 to 80,000. It's Process: aggregate and cementitious materials by dry mixing 20 seconds later, add water and additive agent, wet mixing 00seconds then release concrete.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD

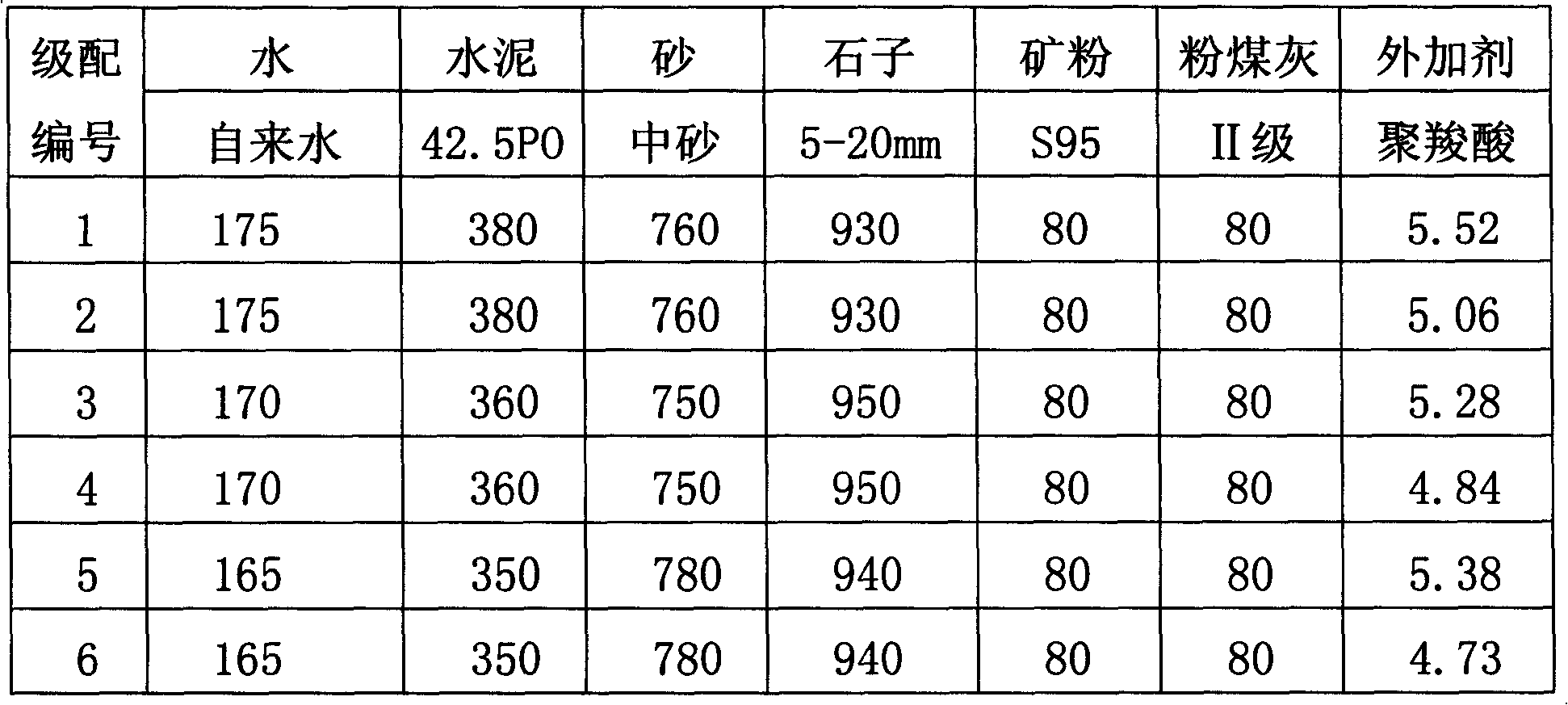

Sleeve wall construction method based on structural formwork

PendingCN113374482AImprove construction progressImprove construction rateShaft liningArchitectural engineeringRebar

Owner:CHINA COAL SCI & TECH GRP NANJING DESIGN & RES INST CO LTD

A construction method for vertical construction joints on the floor of a super high-rise core tube

ActiveCN105780938BReduce exposure timeReasonable designBuilding insulationsPunchingArchitectural engineering

The invention discloses a vertical construction seam construction method of a core tube bottom board for a super high-rise and relates to the field of building construction. The construction method includes the strengthening steel bar construction step, the punching-resistant H-shaped steel construction step, the lateral steel bar mesh construction step, the punching-resistant steel bar construction step, the rubber water stop construction step and the grouting construction step. The construction method is reasonable in design; the core tube bottom board of a tower is provided with vertical construction seams, and the core tube bottom board of the super high-rise is subjected to vertical sectional construction, so that the construction progress can be accelerated, the exposure time of a deep foundation pit is shortened, and risks are reduced; besides, the construction rate can be improved, and the labor input can be reduced; by using punching-resistant type steel as the primary punching bearing component and using punching-resistant steel bars, strengthening steel bars and a grouting system as auxiliaries, the high construction efficiency of the core tube bottom board for the super high-rise is guaranteed, and a powerful safety guarantee is provided for constructors.

Owner:THE SECOND CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU +3

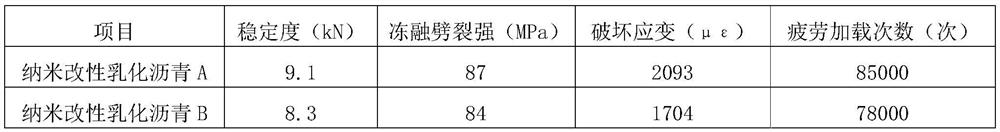

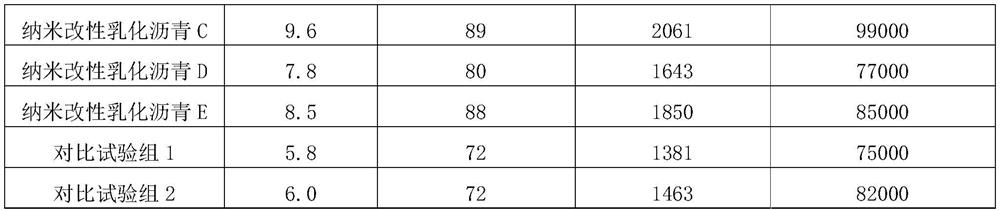

A kind of nano-modified emulsified asphalt and its preparation and use method

ActiveCN108559289BImprove road performanceImprove fatigue resistanceBuilding insulationsPolymer scienceBitumen emulsion

Owner:重庆路维康交通科技有限公司

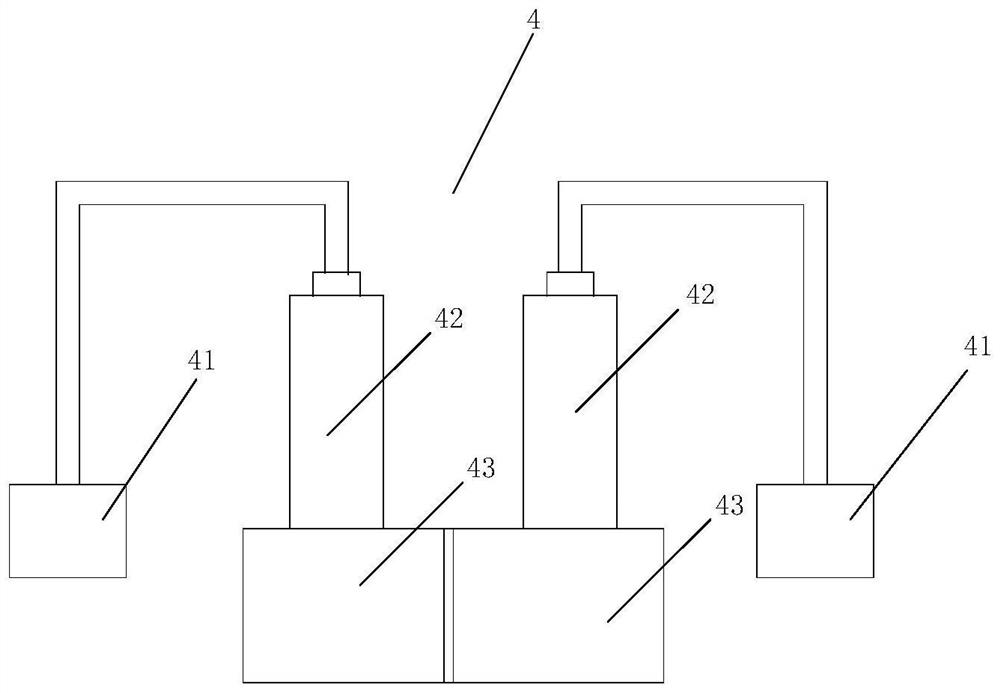

A double-unit hydraulic dredger

ActiveCN109826266BReduce difficultyImprove construction rateMechanical machines/dredgersSludgeHigh pressure water

The present invention provides a double-unit hydraulic dredger, comprising: a hull, a control device, a driving mechanism, and a water spray device; Calculate the preset angle and preset pressure when the water device performs high-pressure water spraying, and control the driving device to drive the water spraying device to move to the preset position to perform high-pressure impact on the sludge; the driving device is set at the on the hull, used to drive the water spray device to move synchronously to the preset position according to the preset trajectory, so as to ensure that the water spray device performs high-pressure impact on the silt according to a preset angle; the water spray device A part is arranged on the hull, and is used for high-pressure water spraying according to a preset pressure to wash away the silt at the bottom of the port. The double-unit hydraulic dredger provided by the invention solves the problems that the existing dredger has low cleaning efficiency and poor cleaning effect when cleaning port silt.

Owner:侍琳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com