Cast-in-place gypsum hollow wall without removing formwork and construction method thereof

A technology that avoids demolition of formwork and gypsum. It is applied in the treatment of walls, buildings, and building materials. It can solve the problems of reducing market competitiveness, damage to blocks and plates, and poor wall flatness, so as to avoid fire-induced work, Ease of transportation and lower apparent density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementations.

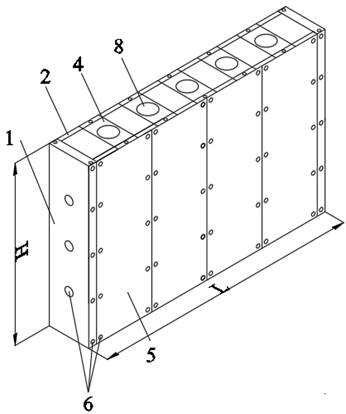

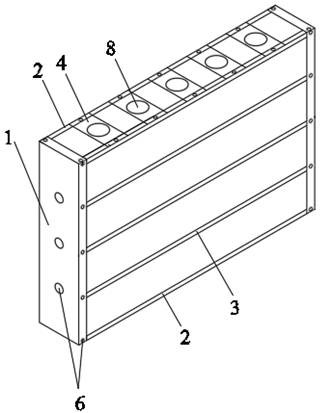

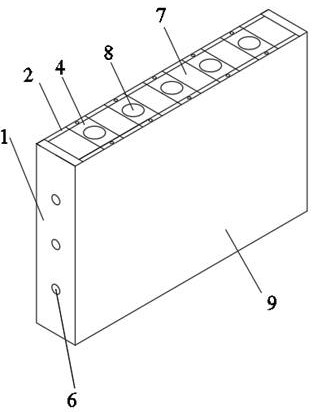

[0030] see example Figures 1~7 As shown in the figure, a cast-in-place gypsum hollow wall with a dismantling-free formwork includes a dismantling-free formwork, a cast-in-place gypsum hollow wall 7 and a plastering layer 9, and the dismantling-free formwork is composed of a steel structure skeleton and a panel 5 assembled on site, The steel structure skeleton is composed of vertical end plates 1, transverse bottom plates 2, transverse reinforcing ribs 3 and hollow tube positioning plates 4; the panel 1 is a high-strength calcium silicate board, which is pre-opened Bolt holes 6, the high-strength calcium silicate board is arranged on both sides of the steel structure skeleton with length L and height H, the inside of the high-strength calcium silicate board is coated with waterproof paint, and the cast-in-place gypsum hollow wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com