Vertical shaft traction cable clamp with guiding and avoiding functions

A technology for cable clamps and shafts, applied in the direction of pipe supports, pipes/pipe joints/fittings, elevators, etc., can solve the problems of cable shaking, cable clamp falling off, high construction cost, etc., to increase friction and contact area, and simplify the overall structure , to meet the effect of simplifying parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

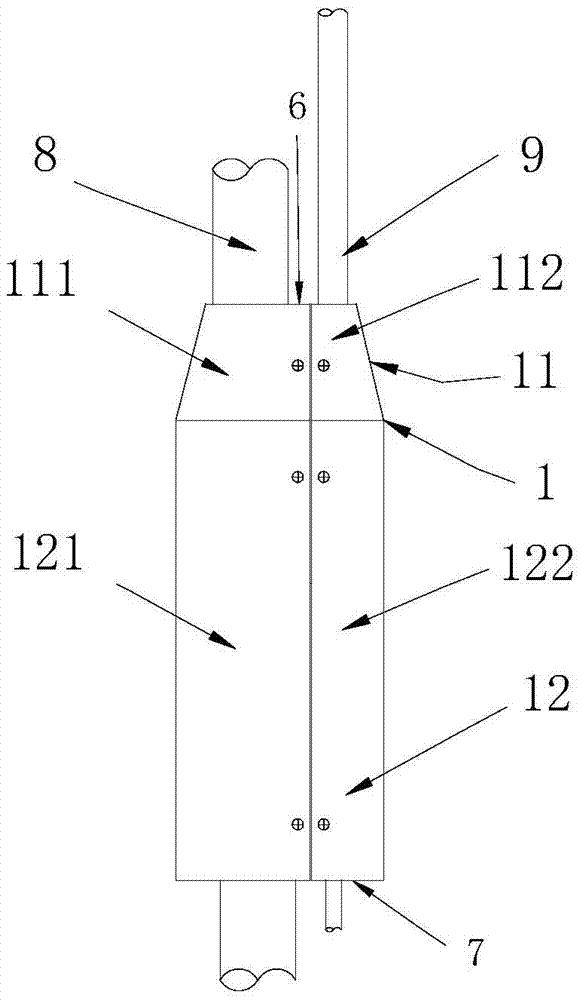

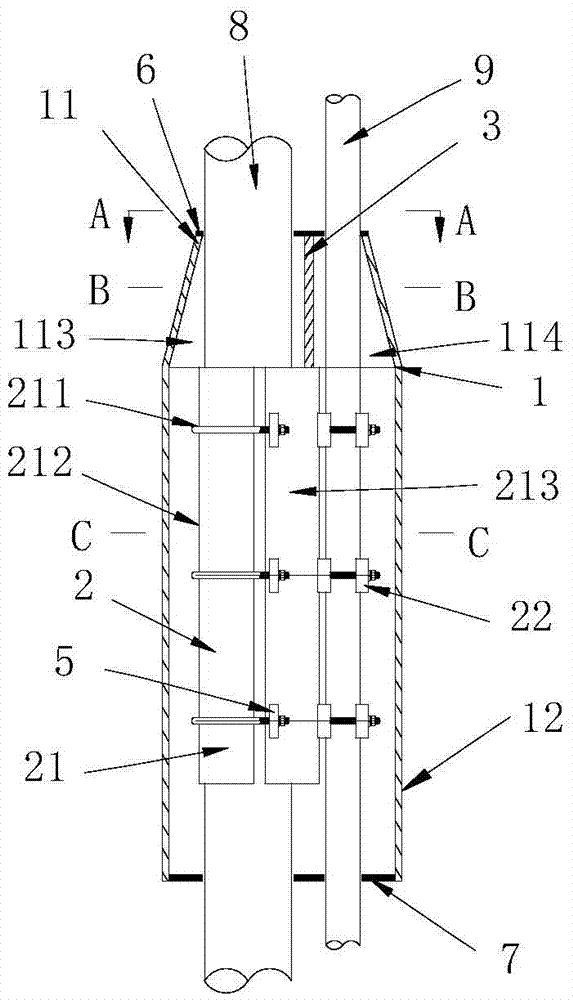

[0041] see figure 1 , figure 2 , image 3 , Figure 4 as well as Figure 5 , a shaft traction cable clamp with guidance and avoidance, including a set of single clamps (the single clamps can also be multiple groups, the specific number is selected according to actual needs), and the single clamps include a hollow shell 1 and a set The clamp body 2 is inside the housing 1 and includes a cable clamp 21 and a wire rope clamp 22 .

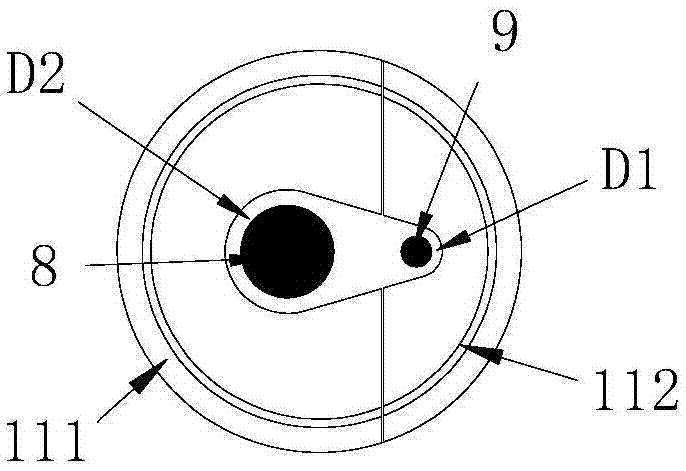

[0042] The housing 1 includes a frustum 11 that is wide at the bottom and narrow at the top and is arranged in the vertical direction, and a cylindrical barrel 12 that is arranged at the lower end of the frustum 11. The frustum 11 includes projections on the horizontal plane, respectively. It is a first arc-shaped body 111 of a three-quarter arc segment and a second arc-shaped body 112 of a quarter arc segment, and the cylindrical barrel 12 includes three-quarter projections on the horizontal plane The third arc body 121 of the arc segment and th...

Embodiment 2

[0056] A shaft traction cable clamp with guidance and avoidance, including two sets of single clamps, the structure of the single clamps is the same as that of Embodiment 1.

[0057] For a schematic diagram of the hoisting structure using the vertical shaft traction cable clamp with guidance and avoidance in this embodiment, see Figure 7 , the specific process is as follows:

[0058] (1) First, assemble two sets of clamps in sequence. The assembly process of a single set of clamps is as follows: first assemble the cable clamp 21 and the wire rope clamp 22 in the clamp body 2 respectively; pass the cable 6 through the cable clamp 21 Cavity 214 and adjust the size of cavity 214 by adjustable bolt 52 to clamp the cable; pass the steel wire rope 7 through the through hole of the single wire clamp 221 and adjust the bolt to fasten the steel wire rope 7; the first sealing plate and the second sealing plate The plates are respectively fixed on the upper end of the frustum of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com