Foam platform for drilling on waterways

A platform and foam technology, applied in the field of water drilling foam platform, can solve the problems such as the influence of tidal, water level changes, poor buoyancy and bearing capacity sealing, unsolvable safety risks, etc. in the drilling operation site, so as to achieve convenient traffic road conditions, The combined type is easy to assemble and has the effect of high drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

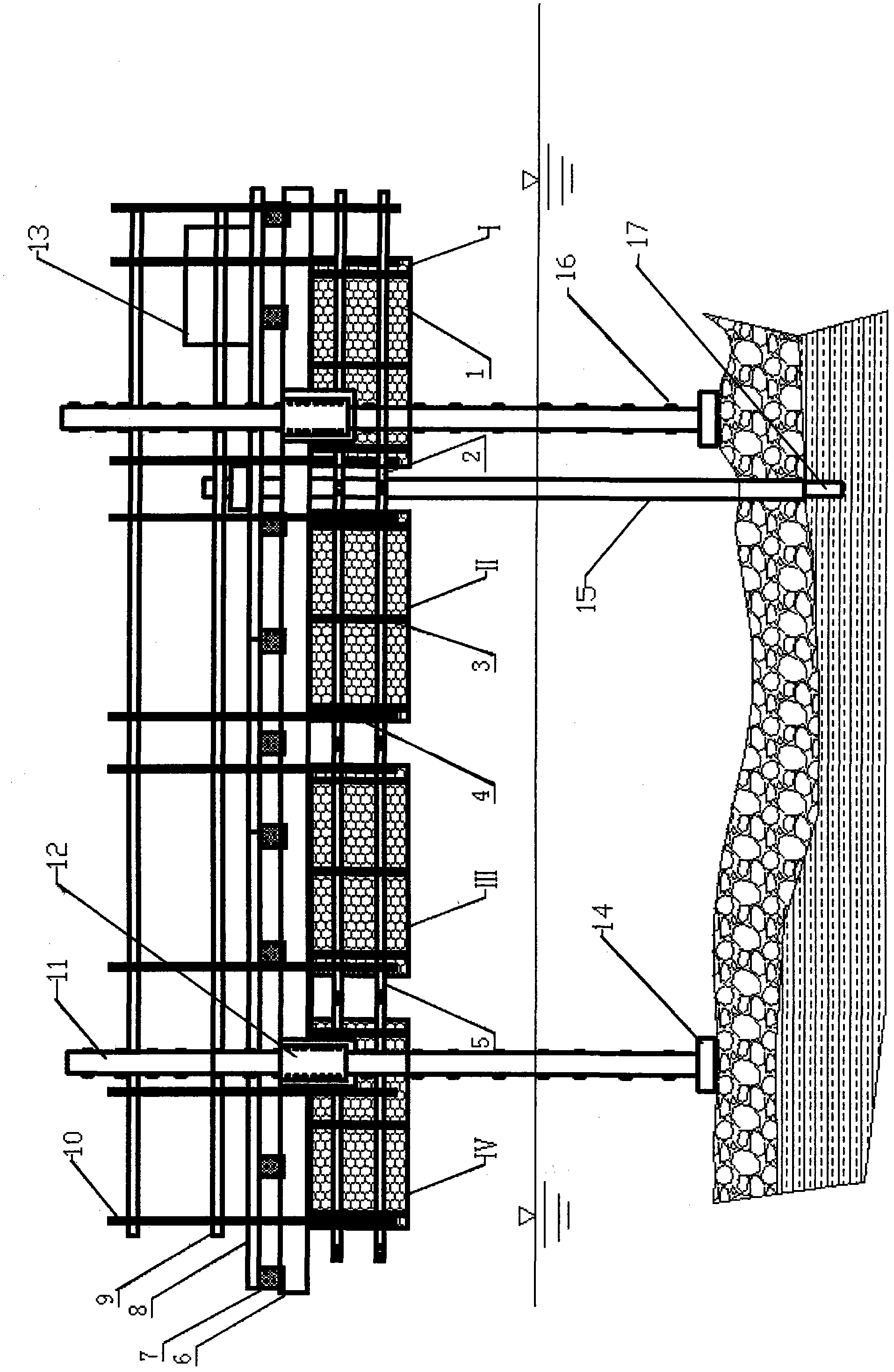

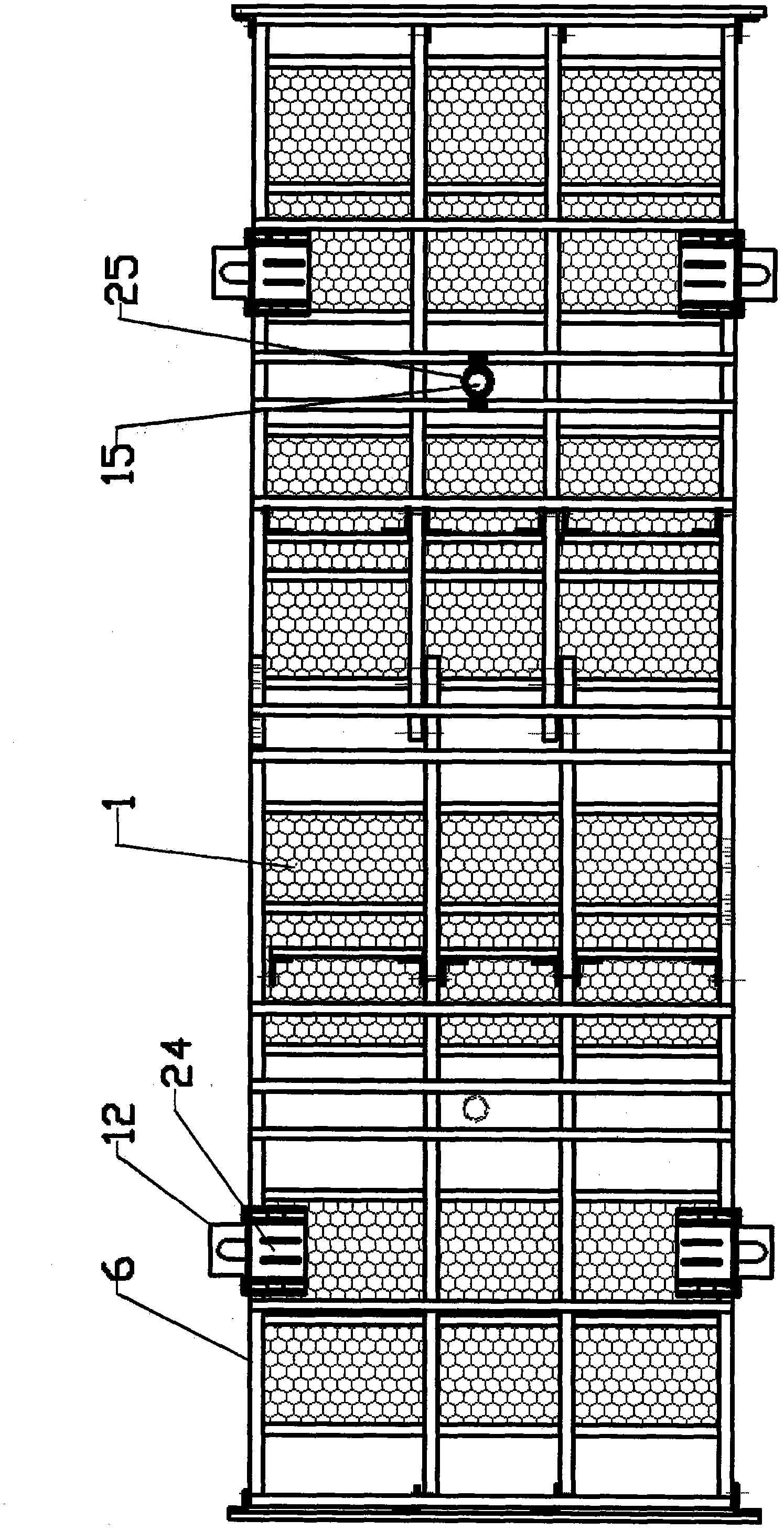

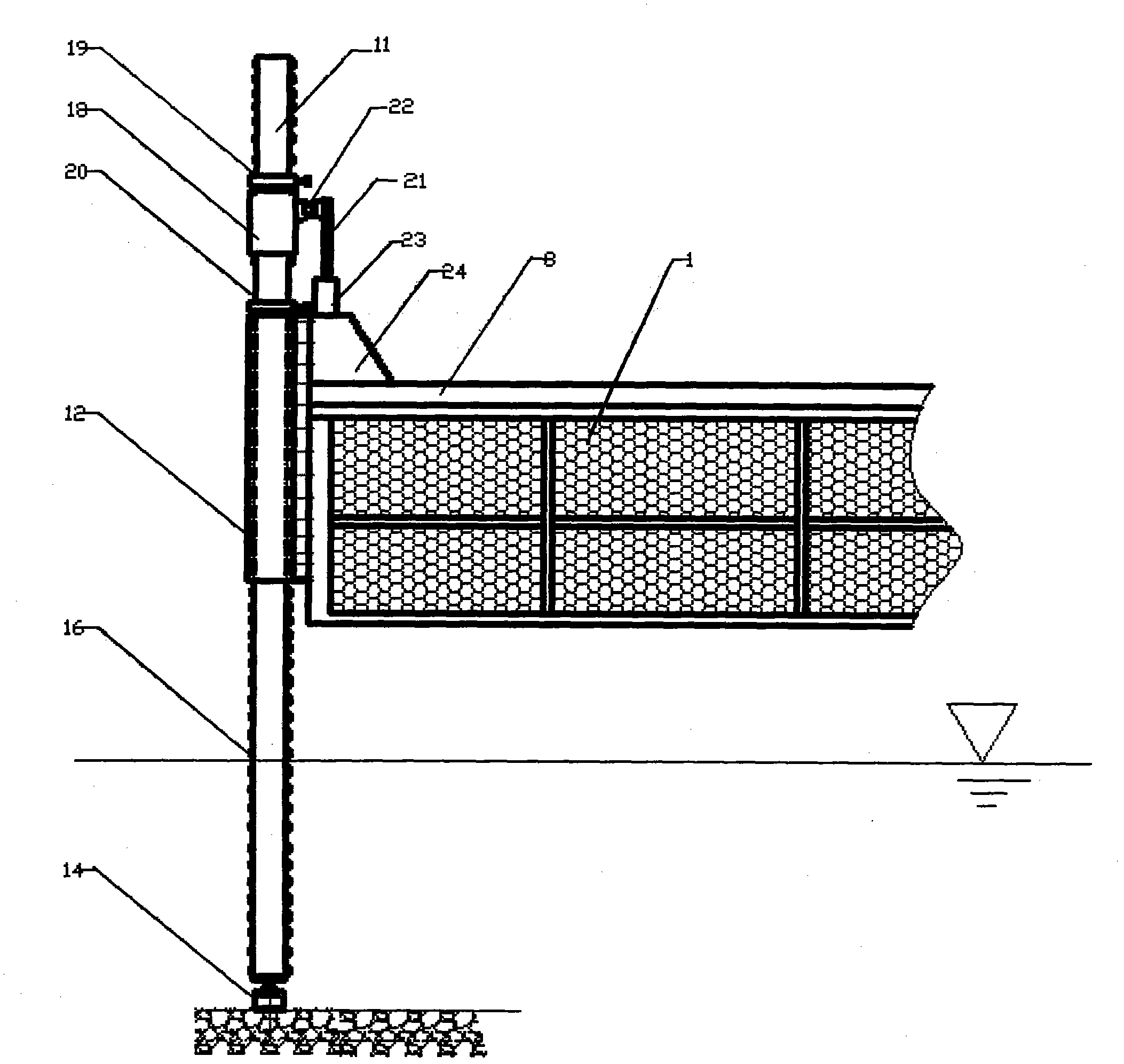

[0053] Below in conjunction with accompanying drawing, the above-water drilling foam platform of the present invention is further described:

[0054] figure 1 , figure 2 Shown is a structural schematic diagram of an embodiment of the foam platform for water drilling of the present invention. In this embodiment, the foam platform for water drilling of the present invention is composed of four steel frames with foam floats 1 placed thereon and splits I, II, III, and IV to form an integral foam platform. Wherein the steel frame 4 is formed by combining several horizontal connecting steels 2 and vertical connecting steels 3 through connecting fasteners. Adjacent steel frames are fastened to each other through removable connectors 5, and several longitudinal section steels 6 of the platform are fixed on the upper plane of the formed combination; on the plane formed by the several longitudinal section steels 6, the A plurality of square timbers 7 are fixed vertically to the dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com