Nitrogen, phosphorus and sulphur doping or co-doping carbon dot and batch controllable preparing method and application thereof

A technology of sulfur doping and co-doping, applied in the field of nanomaterials, can solve the problems of low yield, complicated process, and long synthesis time, and achieve the effects of good biocompatibility, simple process, and short synthesis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

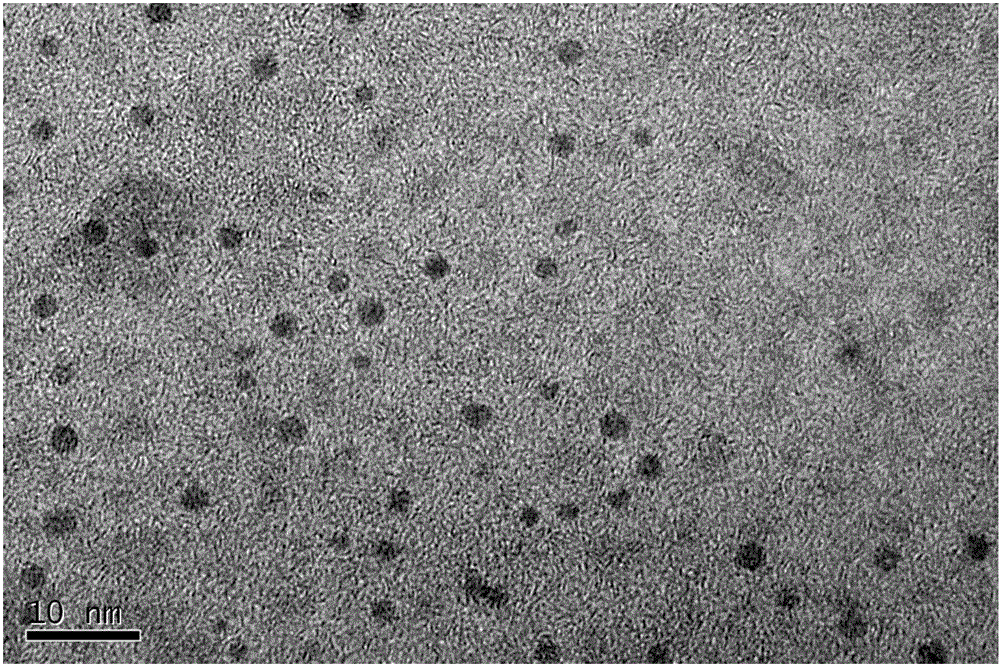

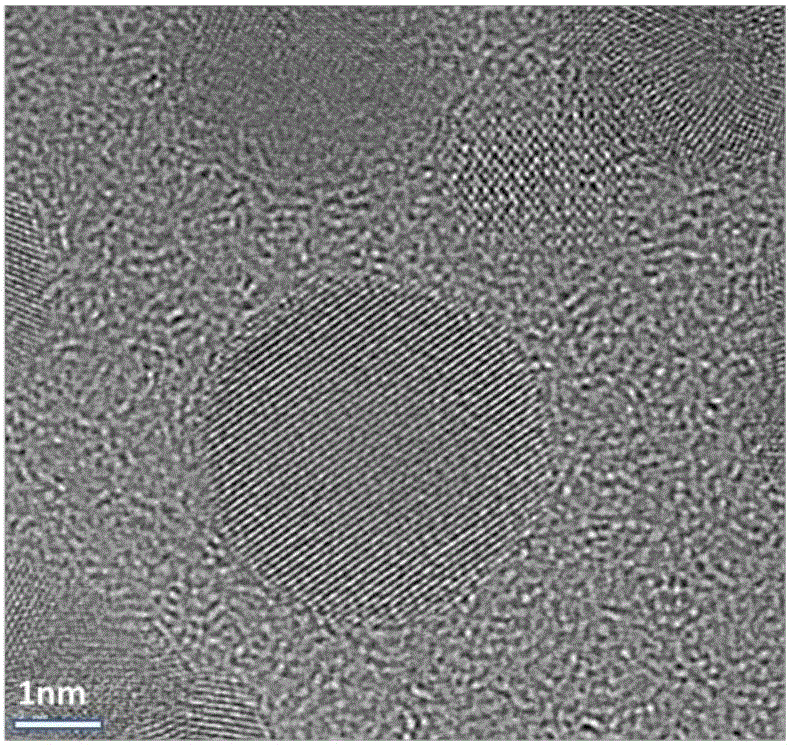

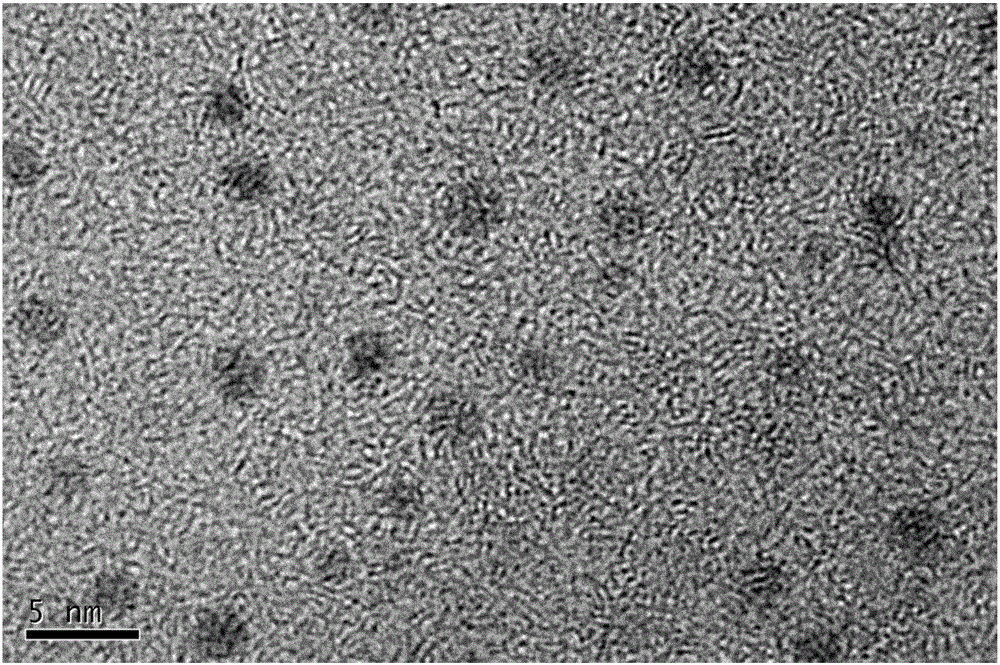

[0033] Example 1 Synthesis of nitrogen-doped carbon dots using amino acids as both carbon and nitrogen sources

[0034] Use 1 g of a mixture of glycine, alanine and valine as a nitrogen source and a carbon source at the same time, grind it into powder in an agate mortar and make it fully mixed, the molar ratio of C and N in the mixture is 1:0.3, and then Put the mixture into a 10mL glass test tube, put the test tube into an oil bath heated to 300°C in advance, the solid amino acid gradually begins to melt and turn yellowish brown until black, forming carbon dots, the reaction time is 10min, and then take it out of the oil bath The test tube was cooled naturally. The product was dissolved in water, filtered with a 22-micron membrane filter, and then dried in a vacuum oven at 40° C. for 12 hours. Then gradient column chromatography was performed using dichloromethane and methanol as developing solvents (4:1 volume ratio) to obtain nitrogen-doped fluorescent carbon dots.

[003...

Embodiment 2

[0036] Example 2 Preparation of nitrogen-sulfur co-doped carbon dots using cystine as carbon source, nitrogen source and sulfur source at the same time

[0037] Use 1g of cystine as nitrogen source, carbon source and sulfur source at the same time, wherein the molar ratio of C, N, and S is 1:0.333:0.333, put cystine into a 10mL glass test tube, put the test tube into the In an oil bath at 250°C, cystine gradually began to melt and turned yellowish brown until black, forming carbon dots. The reaction time was 25 minutes, and then the test tube was taken out of the oil bath to cool naturally. The product was dissolved in ethanol, filtered with a 22-micron membrane filter, and then dried in a vacuum oven at 40° C. for 12 hours. Then gradient column chromatography was carried out using dichloromethane and methanol as developing solvents (4:1 volume ratio) to obtain nitrogen-sulfur co-doped fluorescent carbon dots.

[0038] The raw material in this embodiment can also be the mixtu...

Embodiment 3

[0041] Example 3 Prepare nitrogen-doped carbon dots with tartaric acid and glycine as carbon source and nitrogen source respectively

[0042] Tartaric acid and glycine were mixed according to different mass ratios (respectively 9:1, 8:2, 7:3, 6:4, 5:5, 4:6, 3:7, 2:8, 1:9, 0:10 , that is, the molar ratio of C and N in the mixture is 1:(0.05~0.5)) mix evenly, each 1g, grind into powder in an agate mortar and mix well, then put each mixture into 10mL glass In the test tube, put the test tube into an oil bath heated to 200°C in advance, the mixture gradually begins to melt and turn yellowish brown until black, forming carbon dots, the reaction time is 3min, 5min, 8min, 15min, 22min, 30min, 37min , 45min, 52min, 60min, and then take out the test tube from the oil bath to cool naturally. The product was dissolved in water, filtered with a 22-micron membrane filter, and then dried in a vacuum oven at 40° C. for 12 hours. Then gradient column chromatography was performed to obtain n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com