Hanging basket for corrugated steel web plate construction and construction process

A technology of corrugated rigid web and base plate, applied in the field of composite beams, can solve the problem that the hanging basket cannot meet the simultaneous construction of the corrugated rigid web bridge, etc., and achieve the effect of improving the anti-overturning safety factor, reducing the total mass and large working space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

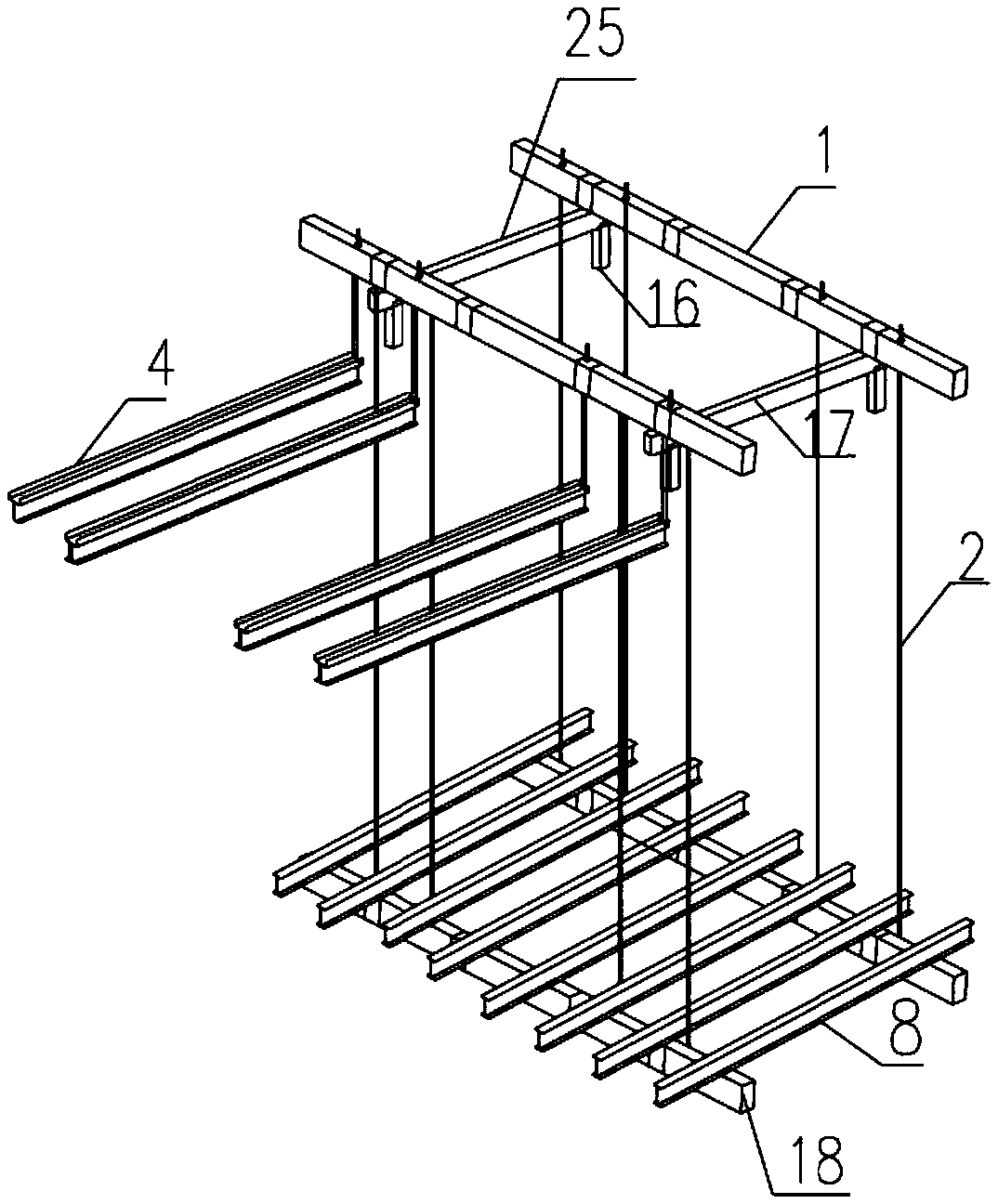

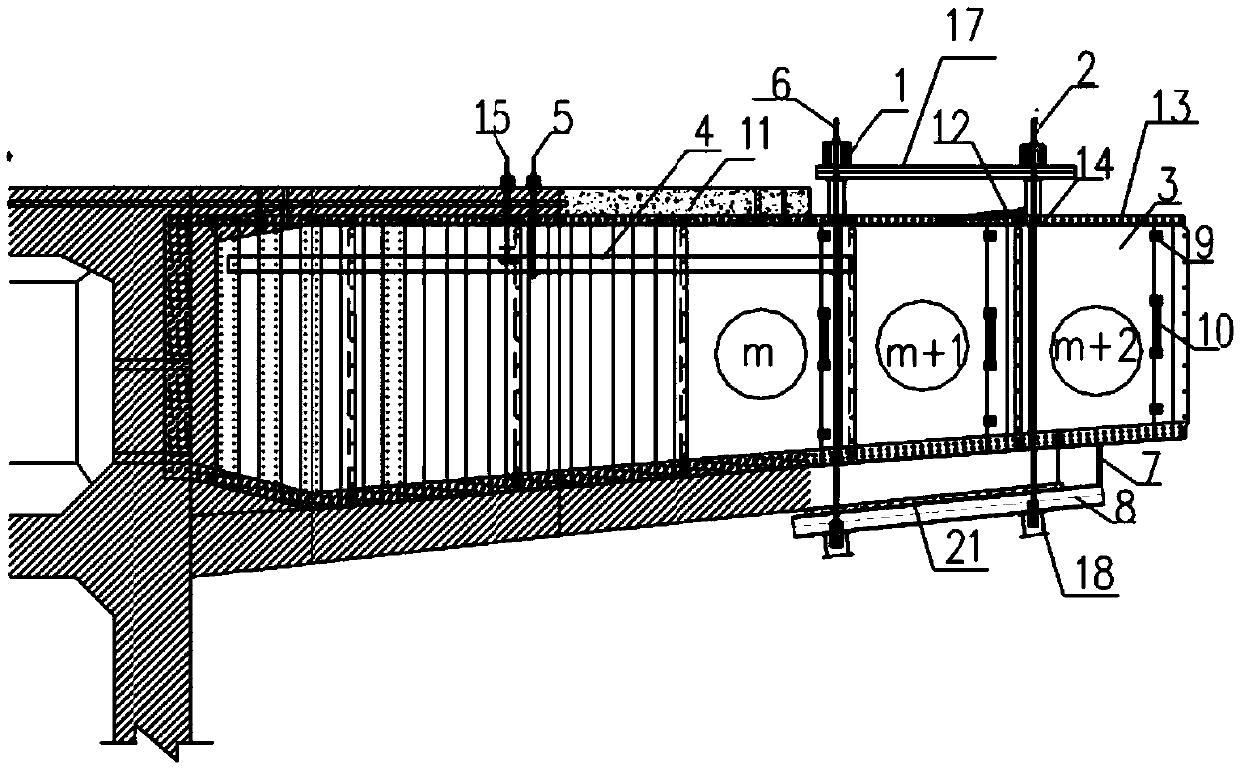

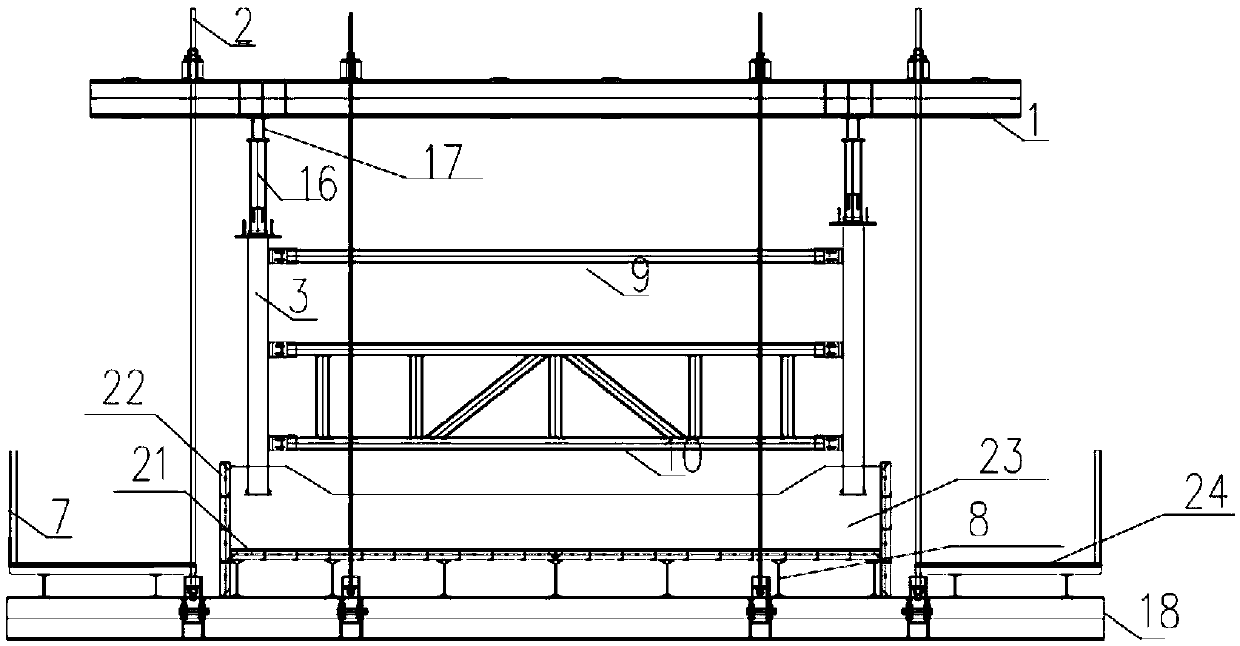

[0039] A corrugated rigid web hanging type construction hanging basket, such as figure 1 and 2 As shown, it is mainly composed of a load-bearing system, a hanging lifting system, a walking system, and a formwork system. The load-bearing system includes an upper beam 1, a lower longitudinal beam 8, and a corrugated rigid web 3; Middle fulcrum suspension rod 6, front fulcrum suspension rod 2. The walking system includes a hydraulic rod 12, a groove 13 arranged on the top of the corrugated rigid web 3, a PTFE slide plate 14, a sliding beam 4 and a walking trolley 15; the formwork system includes a top formwork, a bottom formwork, a sealing formwork and a working platform.

[0040] The support beam is embedded in the groove 13 of the corrugated rigid web, the threaded steel bar traverses the through hole and the support beam hole, and the bolts are anchored. The supporting beam 16 is fixed in the groove 13 . Thus, the supporting point of the hanging basket is anchored in the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com