Frame-type curtain wall rapid assembly construction method and system based on BIM

A construction method and frame-based technology, which are applied in the field of rapid assembly construction methods and systems for frame-type curtain walls based on BIM, can solve problems such as restricting the progress of the project, and achieve the effects of improving construction efficiency, ensuring construction quality, and accelerating construction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0103] The BIM-based frame-type curtain wall rapid assembly construction method of the present invention, the method uses BIM technology and three-dimensional measurement technology to create and adjust the three-dimensional model of the curtain wall shell, divide the curtain wall unit, disassemble and place orders for material components, and through factory centralized The processing operation realizes the unit assembly of the frame-type curtain wall. The quality control of the frame-type curtain wall unit processing is realized by making standard parts and standard samples and using three-dimensional scanning technology. The hanging basket or the climbing operation vehicle completes the interlayer treatment, and finally realizes the rapid assembly construction operation of the frame curtain wall, which specifically includes the following contents:

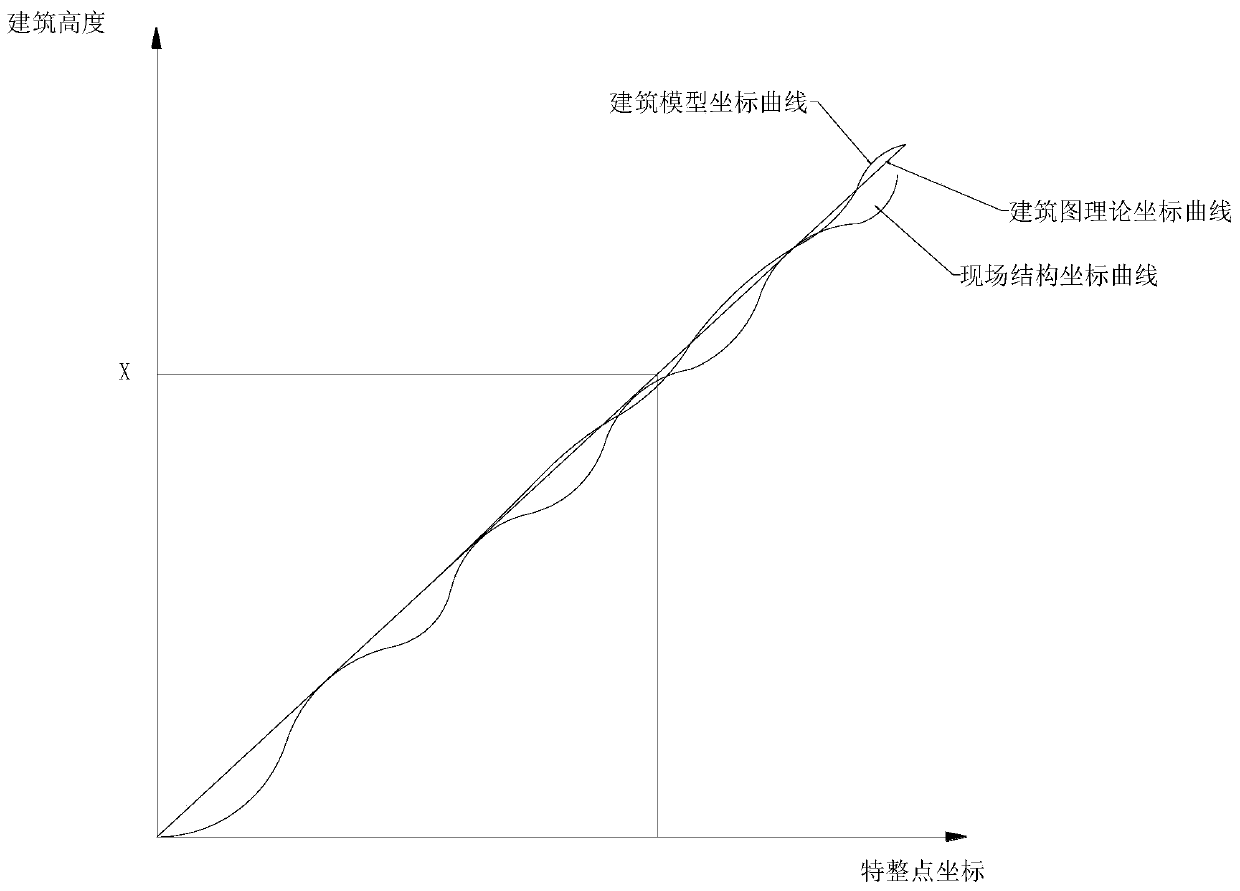

[0104] (1) Optimizing the 3D model of the curtain wall shell: using BIM technology and 3D laying out, by establishing, adjustin...

Embodiment 2

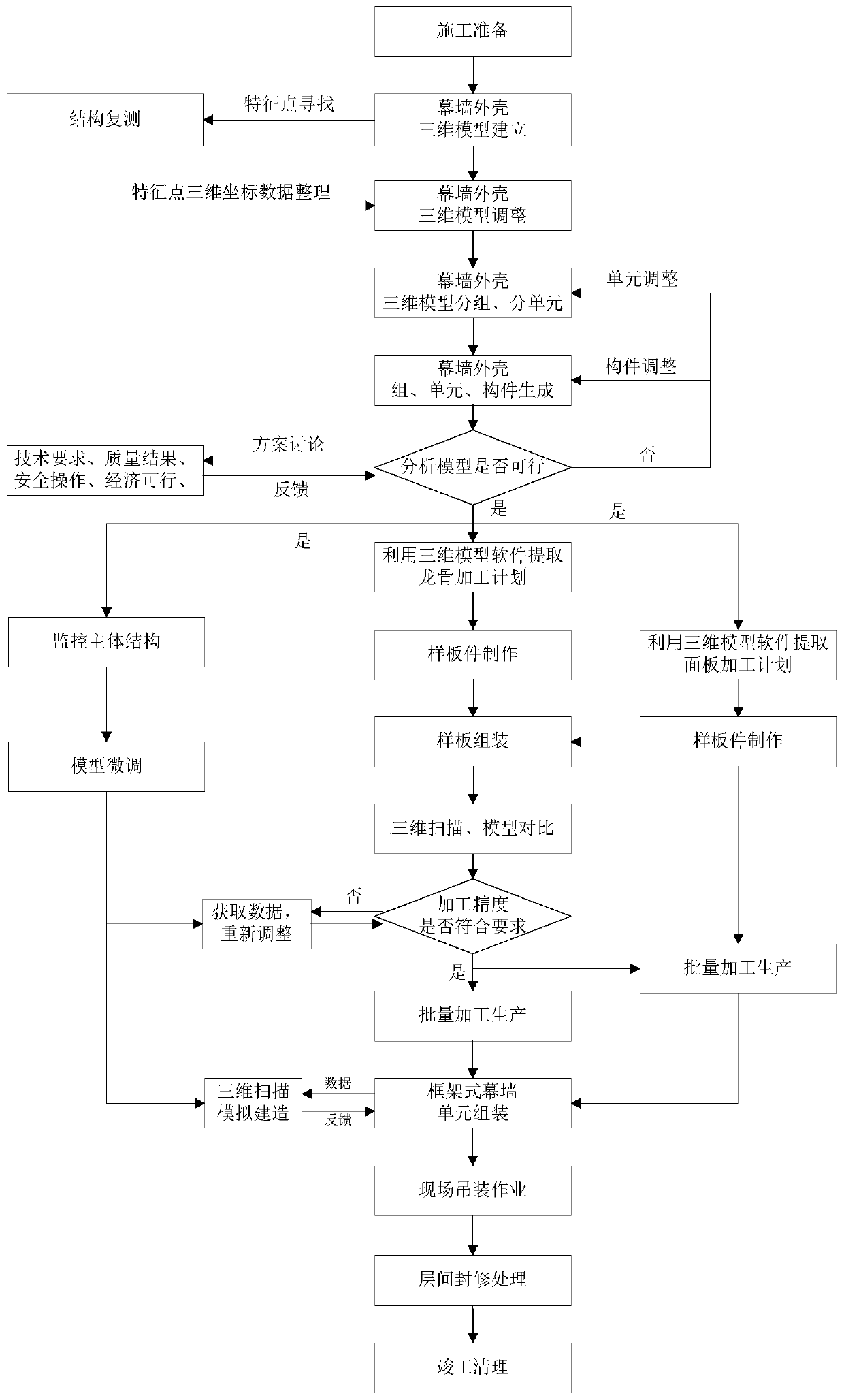

[0110] as attached figure 1 As shown, the construction process of the rapid assembly construction of the frame curtain wall is as follows:

[0111] S1. Construction preparation; specifically including technical preparation, data preparation, equipment and tool preparation and personnel preparation;

[0112] Technical preparation includes the preparation of special construction plans and safety plans, technical disclosure and safety disclosure to management personnel and construction operators;

[0113] Data preparation includes building, structural construction drawing, curtain wall construction drawing and Rhino model;

[0114] The preparation of equipment and tools includes measuring tools and construction machinery; measuring tools include checked theodolite, level, total station, steel ruler, turning ruler and other measuring instruments and tools; construction machinery includes truck cranes, truck-mounted cranes, construction cranes Baskets, aerial work vehicles, bench...

Embodiment 3

[0167] The BIM-based frame curtain wall rapid assembly construction system of the present invention, the system includes:

[0168] The building and optimization module of the 3D model of the curtain wall shell is used to use BIM technology and 3D laying-out. By establishing, adjusting, and optimizing the 3D model of the curtain wall shell and extracting data from the 3D model of the curtain wall shell, it guides the site setting-out positioning and embedded parts construction. Adjust the curtain wall model by the structural deviation value, and then analyze the positioning of the keel and embedded parts through the three-dimensional model of the curtain wall shell;

[0169] The frame-type curtain wall splitting module is used to unitize the frame-type curtain wall. The frame-type curtain wall is divided into units with the floor and the axis as the scale, and the overall hoisted curtain wall unit group is divided and intercepted from the 3D model of the curtain wall shell, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com