Patents

Literature

362 results about "Assembly (construction)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

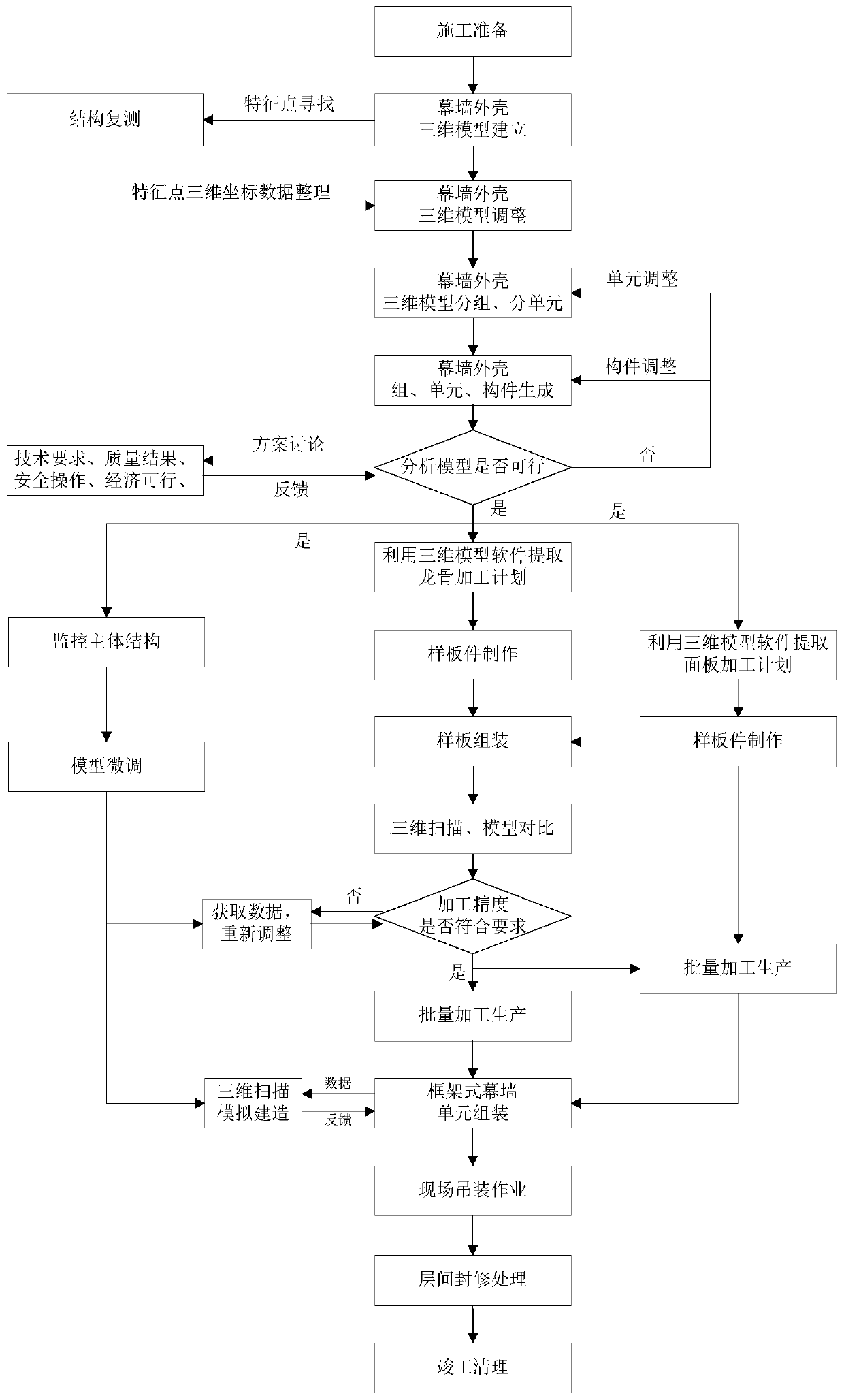

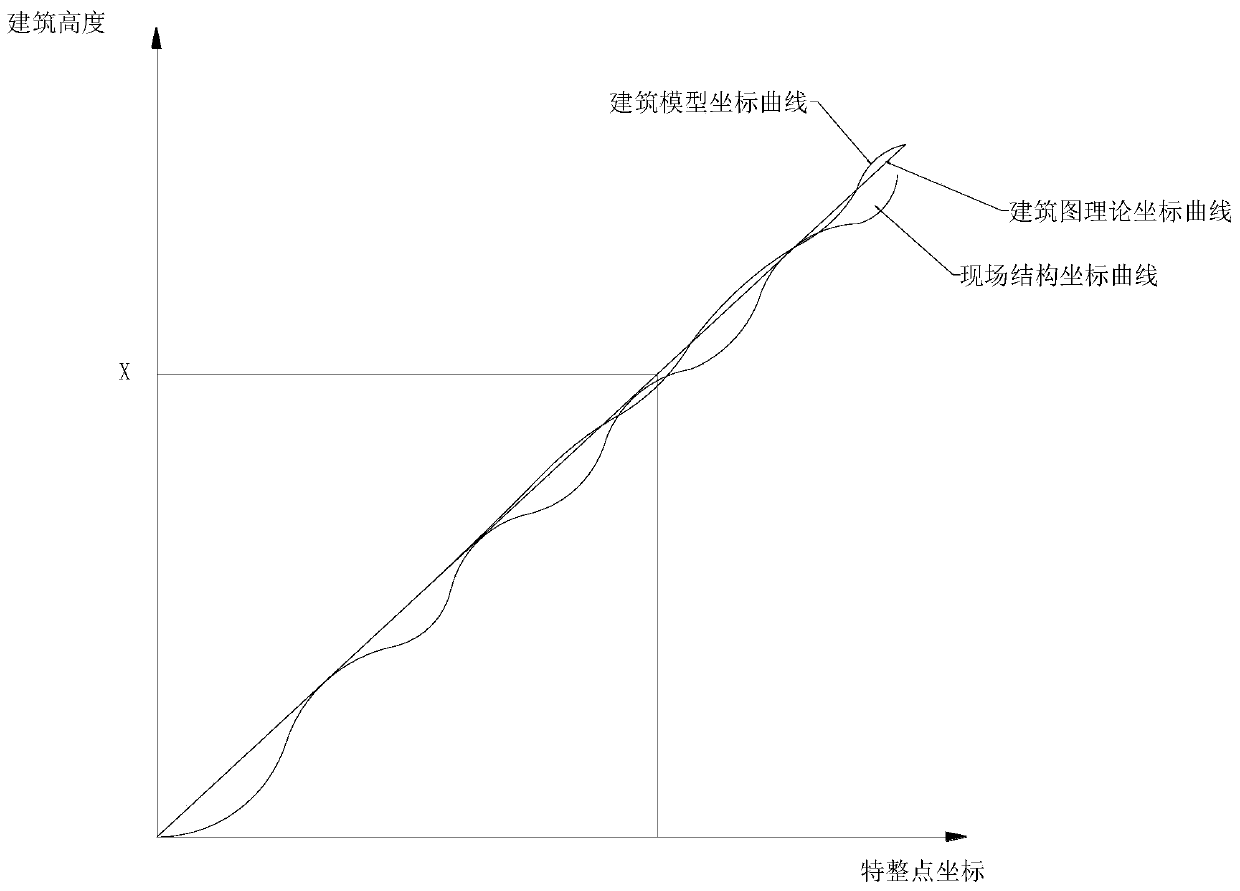

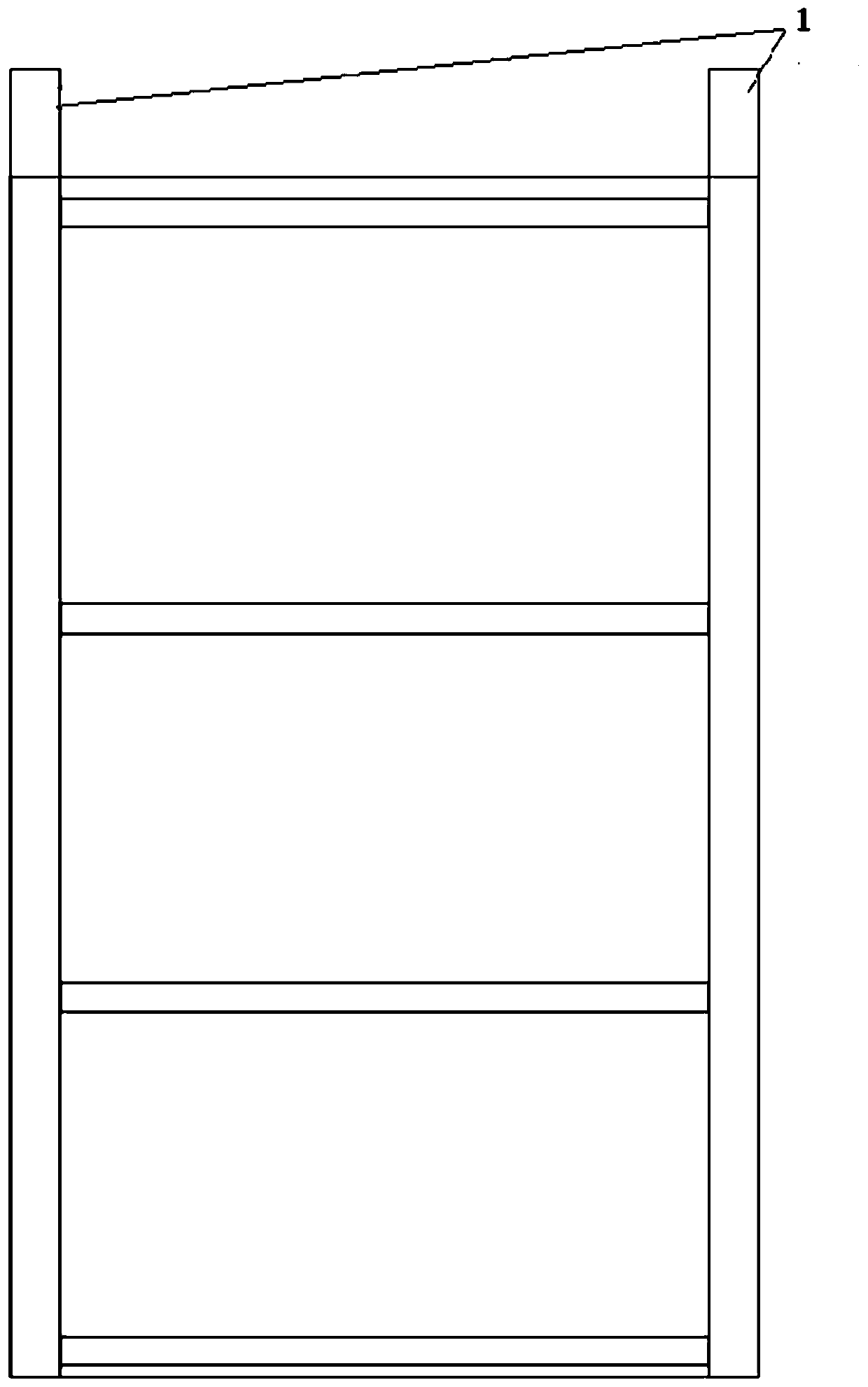

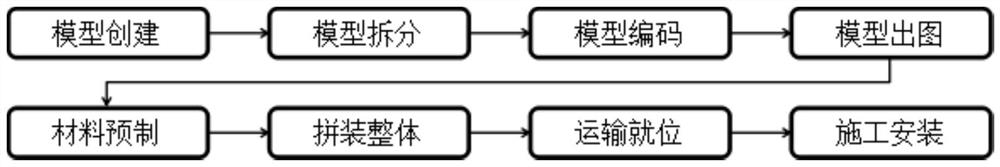

Frame-type curtain wall rapid assembly construction method and system based on BIM

InactiveCN110056106AFast and accurate generationSingle construction workWallsBuilding material handlingThree dimensional measurementHanging basket

The invention discloses a frame-type curtain wall rapid assembly construction method and system based on a BIM, and belongs to the field of curtain wall assembly construction. The to-be-solved technical problems are how to realize rapid assembly construction of a frame-type curtain wall and ensure the installation quality and performance of the curtain wall, according to the technical scheme, theframe-type curtain wall rapid assembly construction method includes the steps that three-dimensional model creation and adjustment of a curtain wall shell, curtain wall unit division, material component splitting and ordering are conducted through a BIM technology and a three-dimensional measurement technology, unit bodies of the frame-type curtain wall are assembled through centralized industrialprocessing, the processing quality of the frame-type curtain wall units is controlled by manufacturing standard parts, standard samples and using a three-dimensional scanning technology, site quick assembly construction of the frame-type curtain wall is completed through an integral hoisting technology, then treatment between layers is completed through a construction hanging basket or an elevating operating vehicle, and finally, rapid assembly construction operation of the frame-type curtain wall is realized. The invention further discloses the frame-type curtain wall rapid assembly construction system based on the BIM.

Owner:CHINA CONSTR EIGHTH ENG DIV

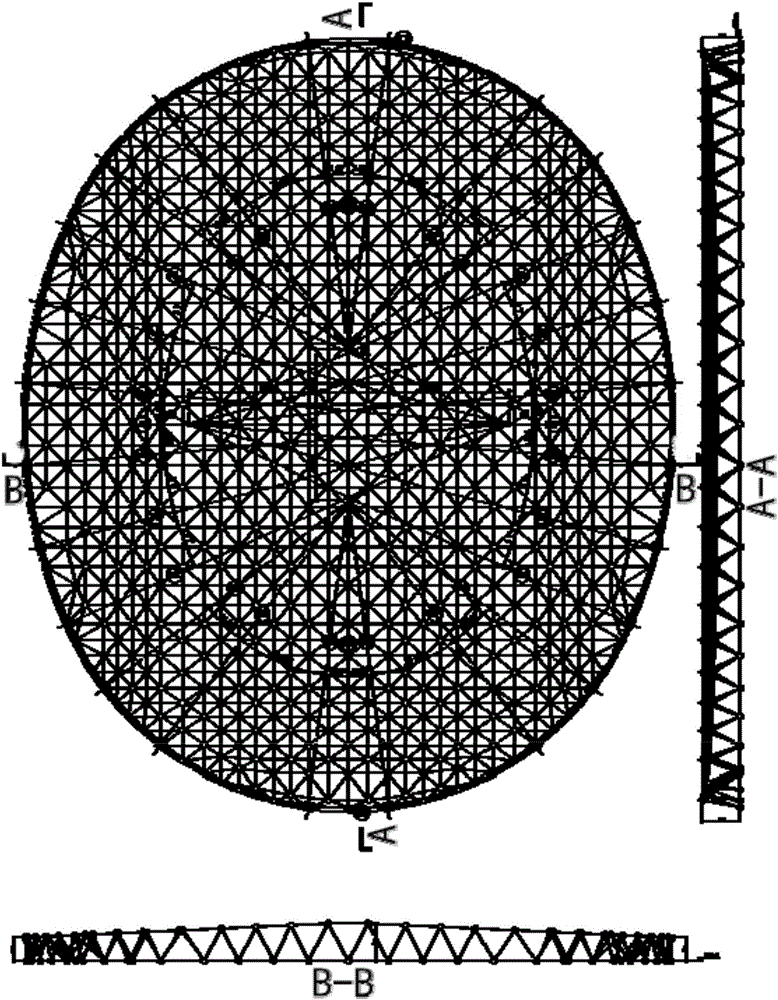

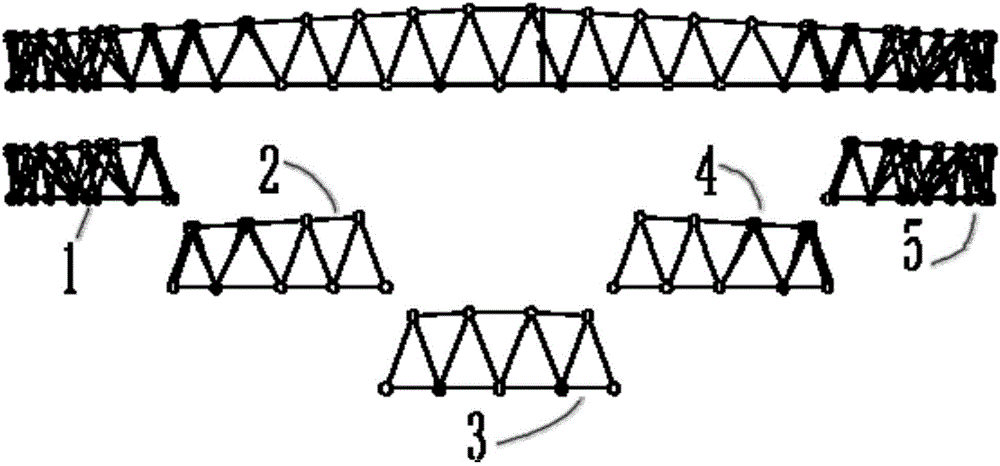

Construction method for roof steel grid frame

The invention discloses a construction method for a roof steel grid frame. The construction method comprises the following steps that A1, cranes are arranged along the oval plane circumference and the interior of the roof steel grid frame, and scaffold operation platforms are arranged; A2, segments of the roof steel grid frame are assembled, specifically, each steel grid frame body of the roof steel grid frame is spliced in a segmented mode symmetrically from the south and north directions to the center of a gymnasium, each steel grid frame body is divided into the corresponding five segments, namely the first segment, the second segment, the third segment, the fourth segment and the fifth segment to be spliced; A3, the segmenting-spliced segments of each steel grid frame body are spliced into the steel grid frame body symmetrically from the east and west directions to the center; and A4, the step A2 and the step A3 are repeated, the segmented splicing and hoisting method is stopped when only the middle steel grid frame body needs to be constructed, a high-altitude assembly construction method is adopted for a middle closing segment, and after the closing section is mounted, mounting and construction of the whole steel grid frame are completed. By combining high-altitude assembly and segmented hoisting, the advantages that safety is high, the construction occupied area is small, and the construction period is short and other advantages are achieved.

Owner:SHANGHAI CIVIL ENG GRP FIFTH

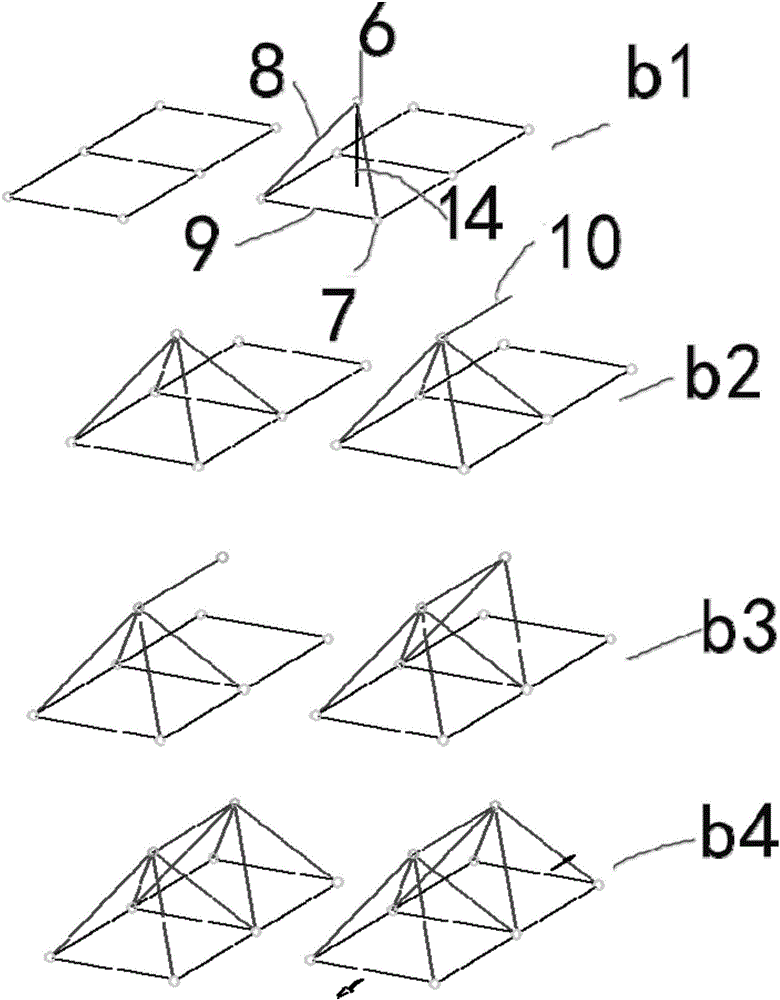

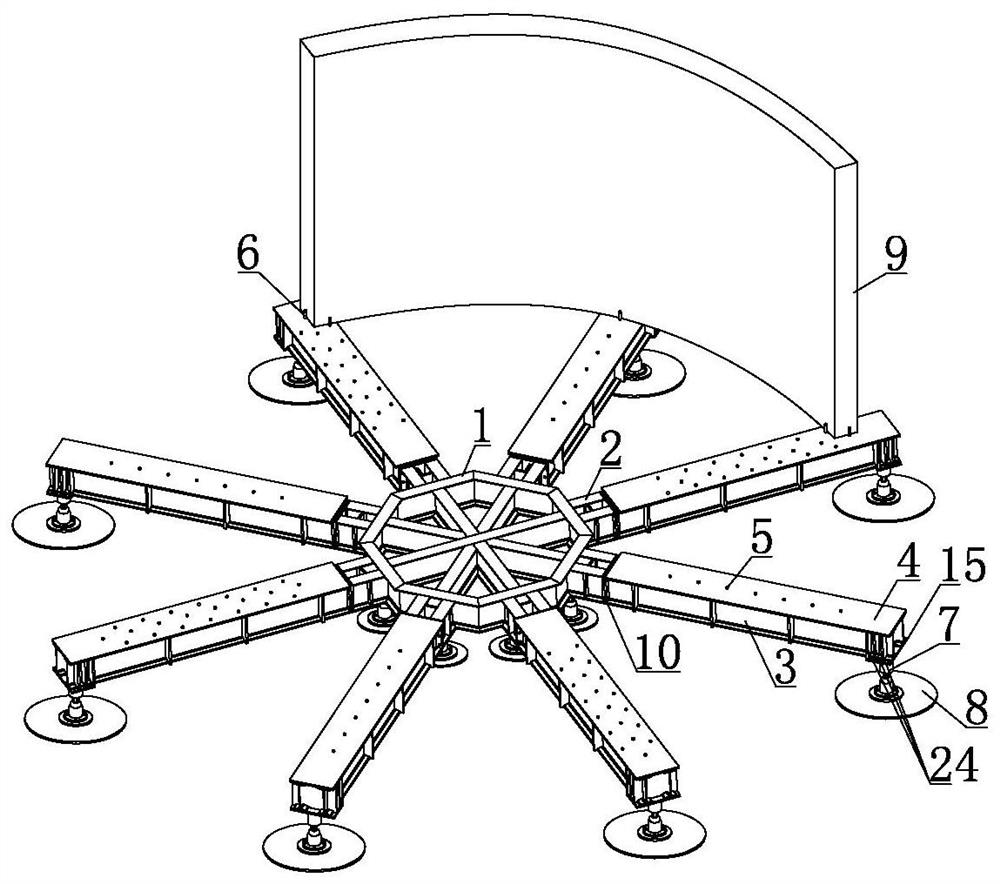

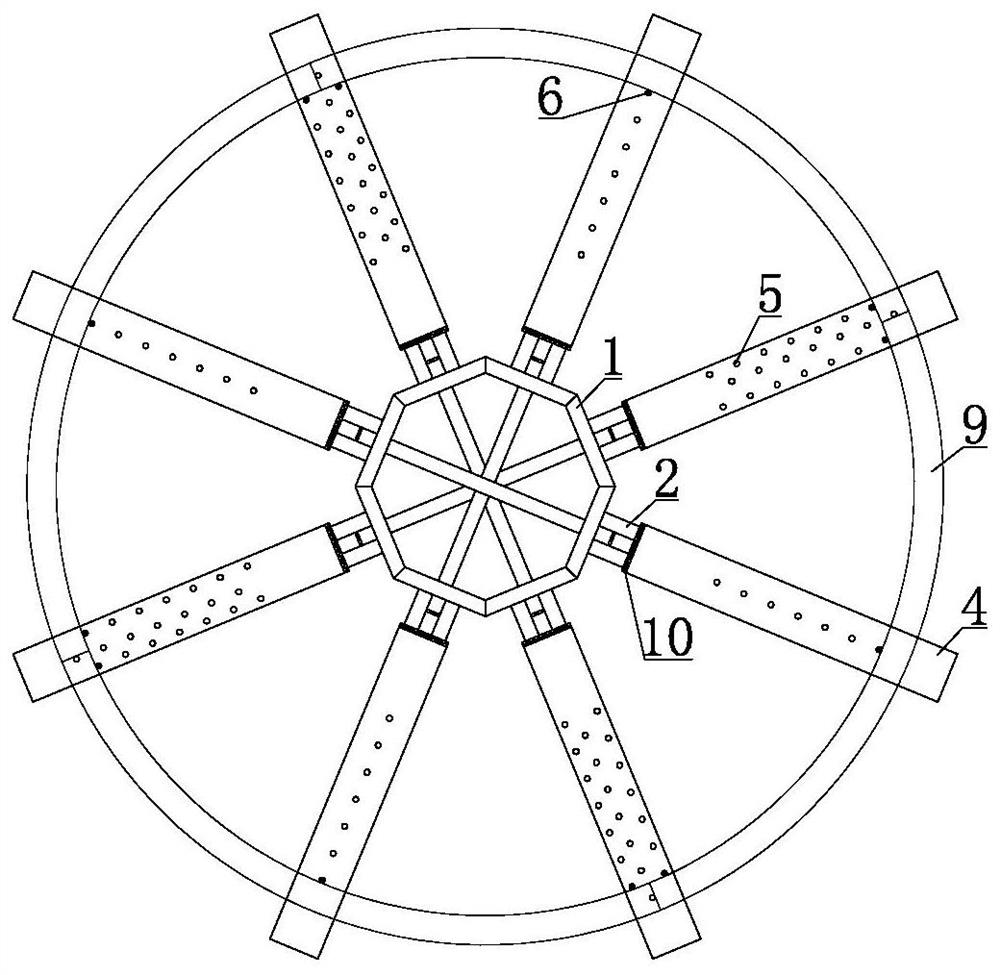

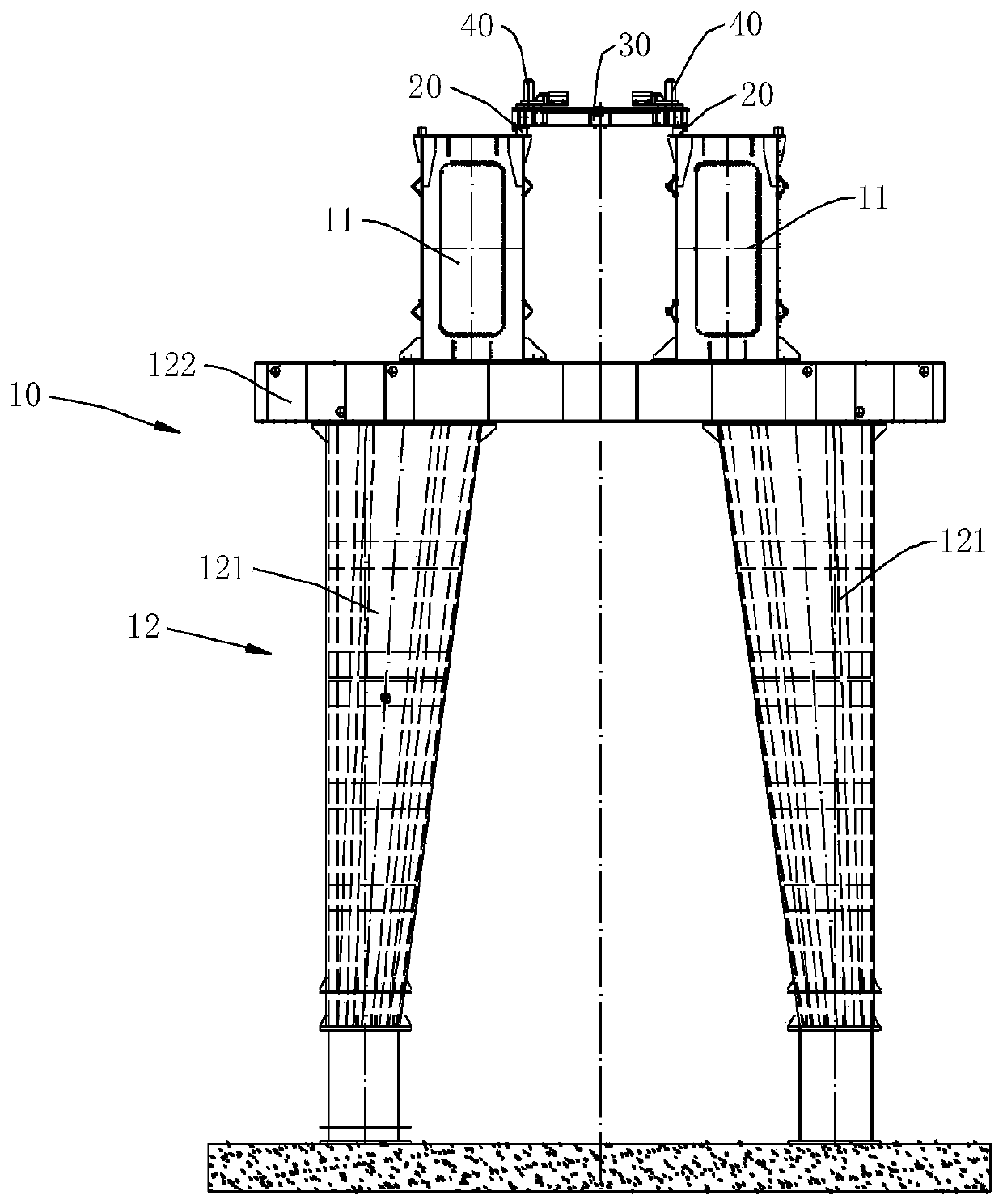

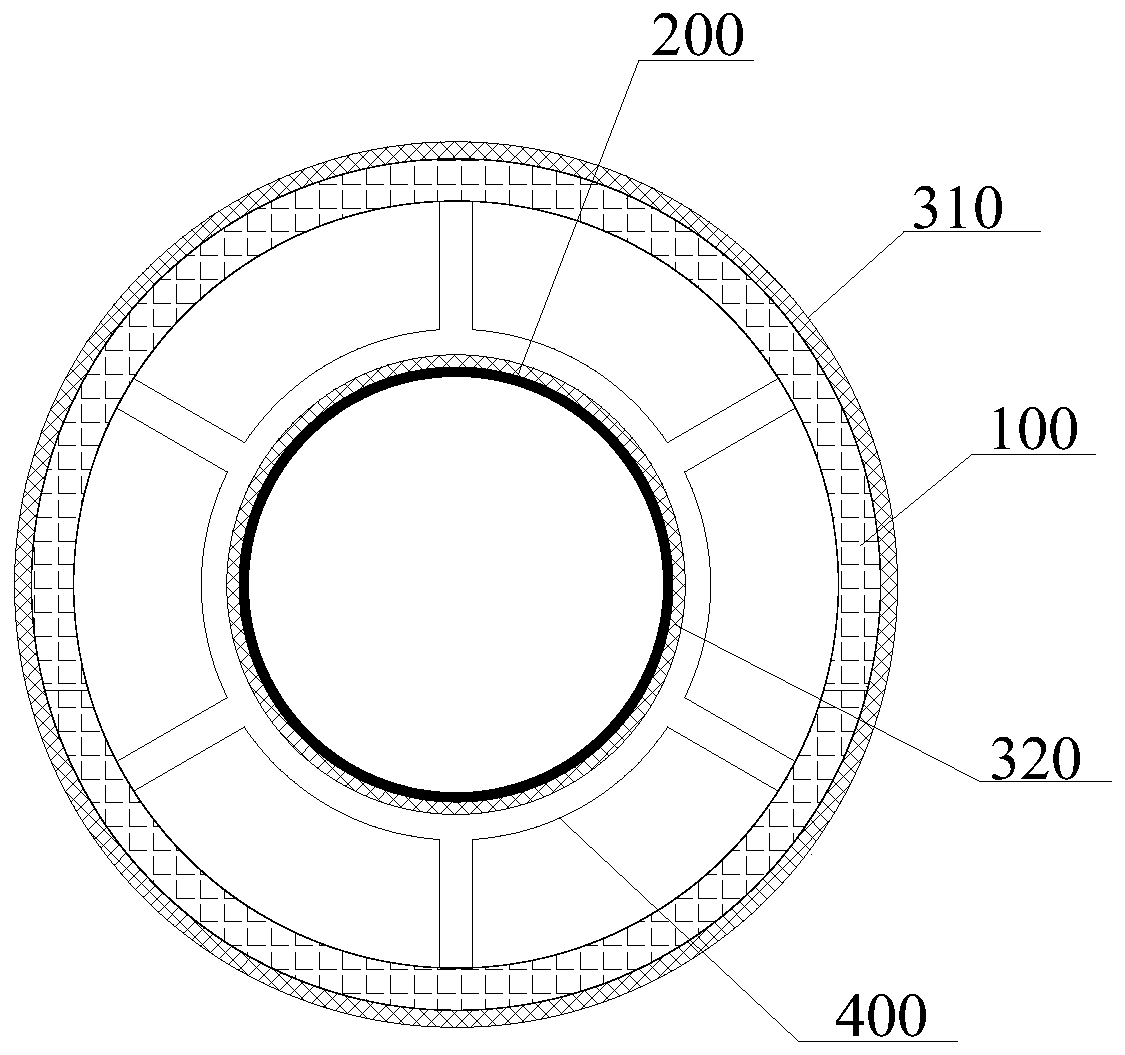

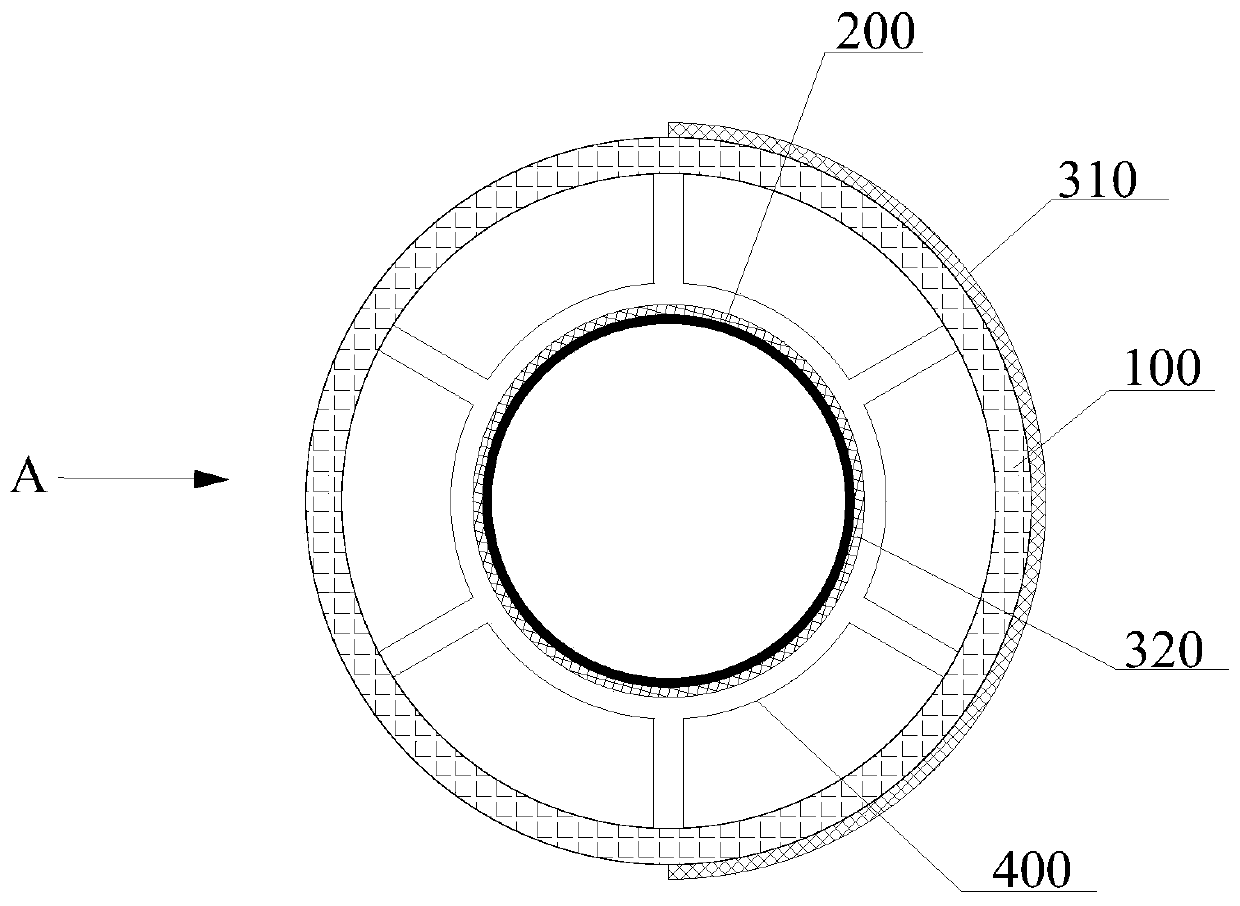

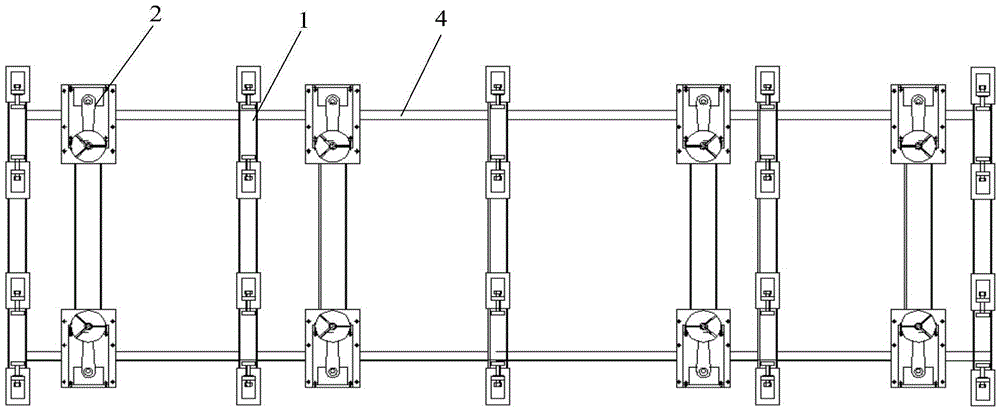

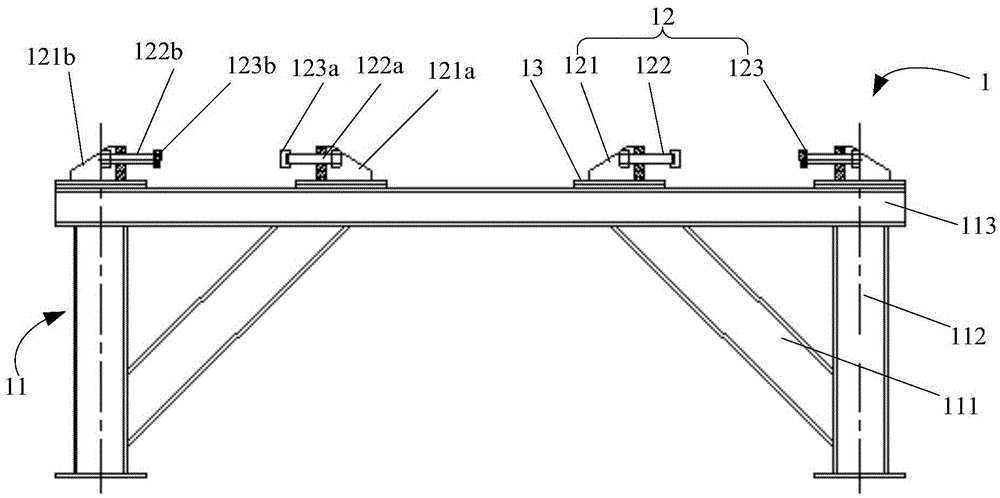

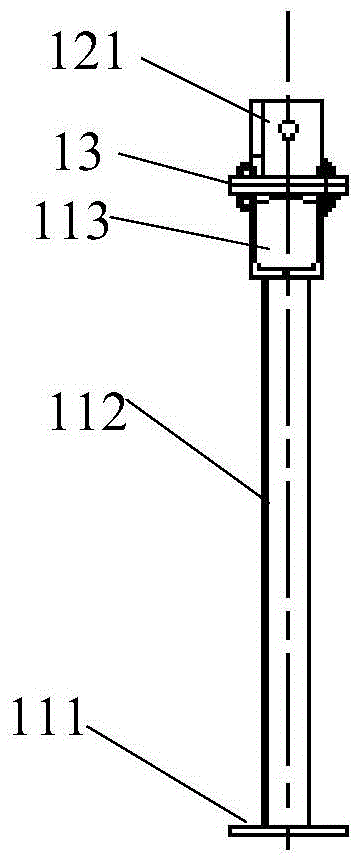

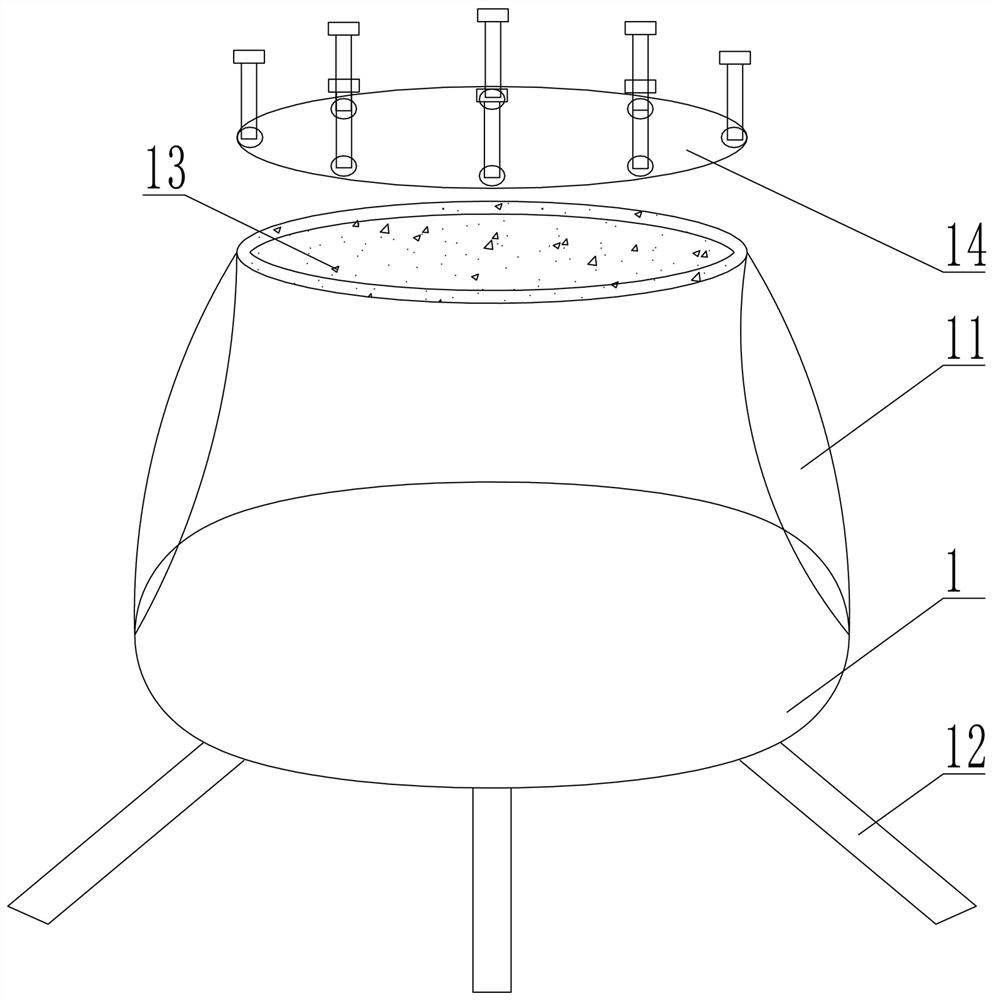

Fabricated concrete tower tube piece assembly platform and assembly method

ActiveCN111946555AReasonable structural designRealize precise positioning splicingWind motor assemblyWind motor supports/mountsArchitectural engineeringTower

The invention provides a fabricated concrete tower tube piece assembly platform and assembly method. The fabricated concrete tower tube piece assembly platform comprises a center frame, connecting sections, supporting beams, supporting panels, limiting positioning pin holes, positioning pins, leveling supporting feet, base plates and the like. The octagonal center frame and the eight supporting beams are connected through the connecting sections to form a spliced platform body structure. The supporting panels are welded to the top faces of the supporting beams, a series of limiting positioningpin holes are formed in the supporting panels, and the positioning pins are inserted to achieve rapid and accurate positioning of concrete tower tube pieces. The leveling supporting feet are arrangedat the bottoms of edge beams of the center frame and the bottoms of the outer ends of the supporting beams and serve as supporting supports and leveling devices of the platform. The base plates are arranged at the bottoms of the leveling supporting feet and used for dispersing upper concentrated loads and reducing local settlement of a foundation. According to the fabricated concrete tower tube piece assembly platform and assembly method, rapid and accurate assembly of the fabricated concrete tower tube pieces in the technical field of wind power can be realized, the concrete tower rapid construction concept of instant assembly and instant hoisting is embodied, and a quite excellent technical scheme for assembly construction of the fabricated concrete tower tube pieces prefabricated in afragmentation manner is achieved.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

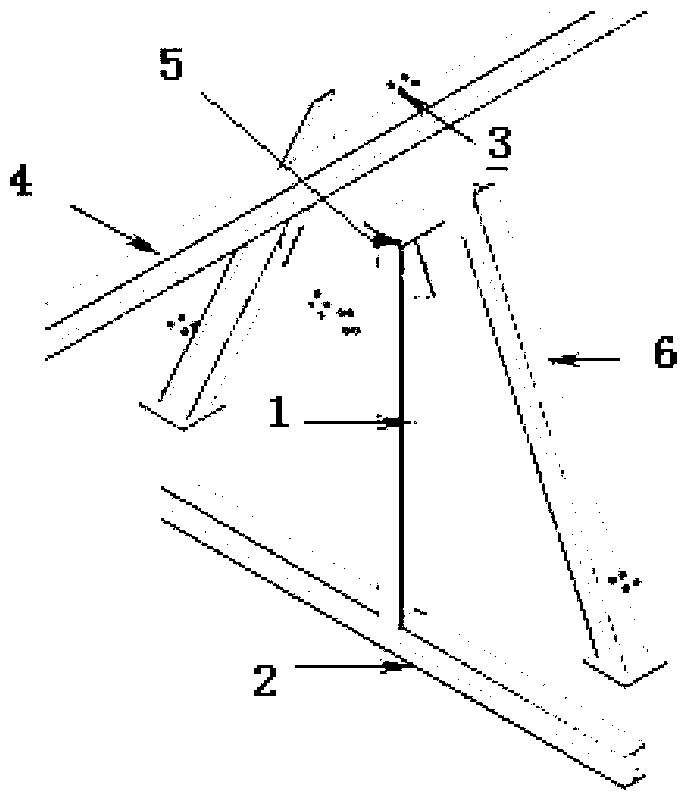

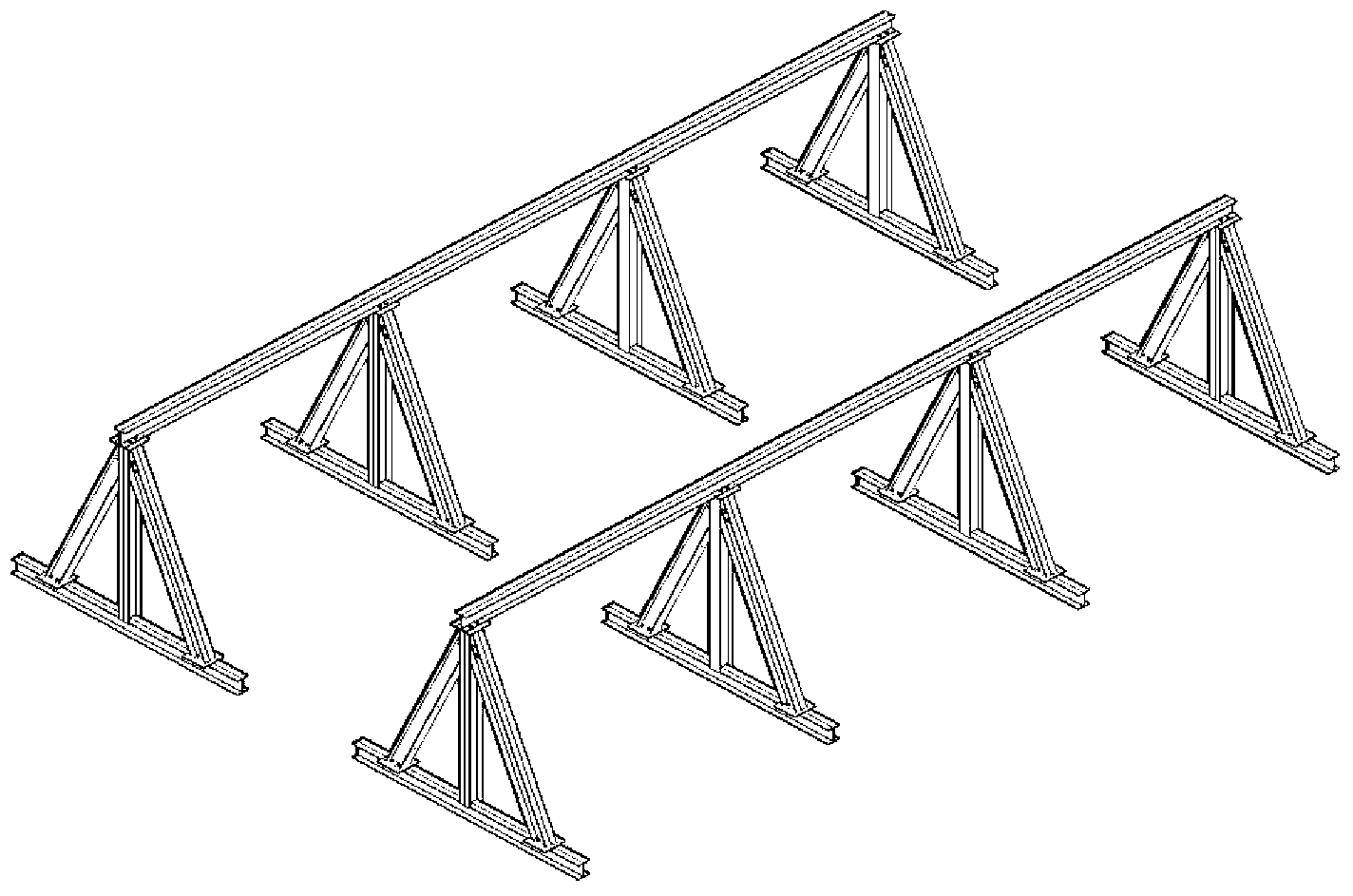

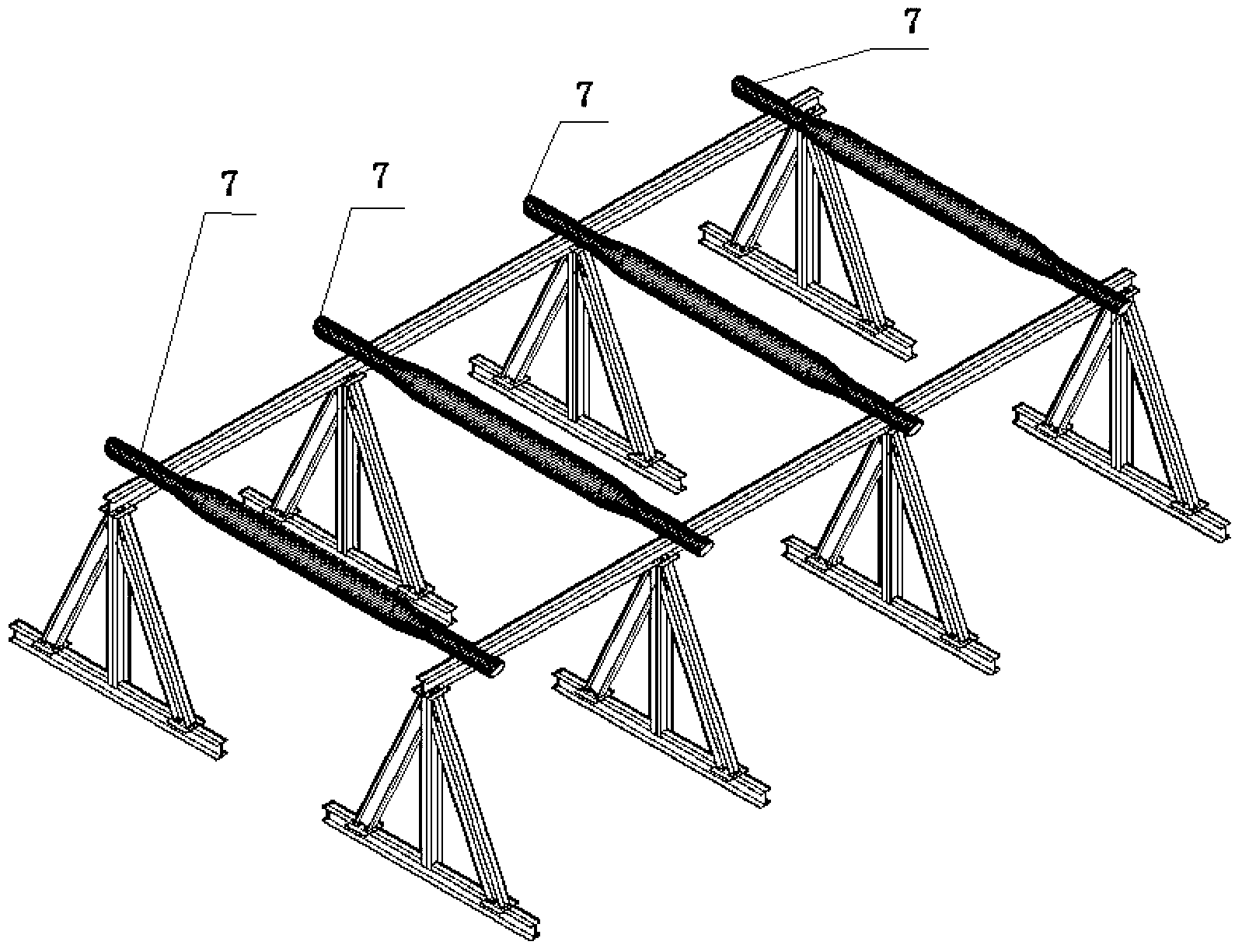

Detachable triangular scaffold and steel truss assembly construction method

InactiveCN103266778AMaintain stabilityEnsure stabilityBuilding material handlingShoresClassical mechanicsAssembly (construction)

The invention provides a detachable triangular scaffold and a steel truss assembly construction method. The scaffold is of a triangular connected structure, and comprises main vertical rods, bottom cross rods, top steel beams, connecting plates, diagonal rods, bolts and the like. The rods are connected by the bolts in a positioning manner, and positioning holes are reserved at the top of each steel beam and used for controlling the axis position of a steel truss. The detachable triangular scaffold is capable of achieving on-site repeated assembling of ultrahigh ultra-wide steel members, and can be widely applied to the field of steel structure assembly construction.

Owner:北京城建精工钢结构工程有限公司

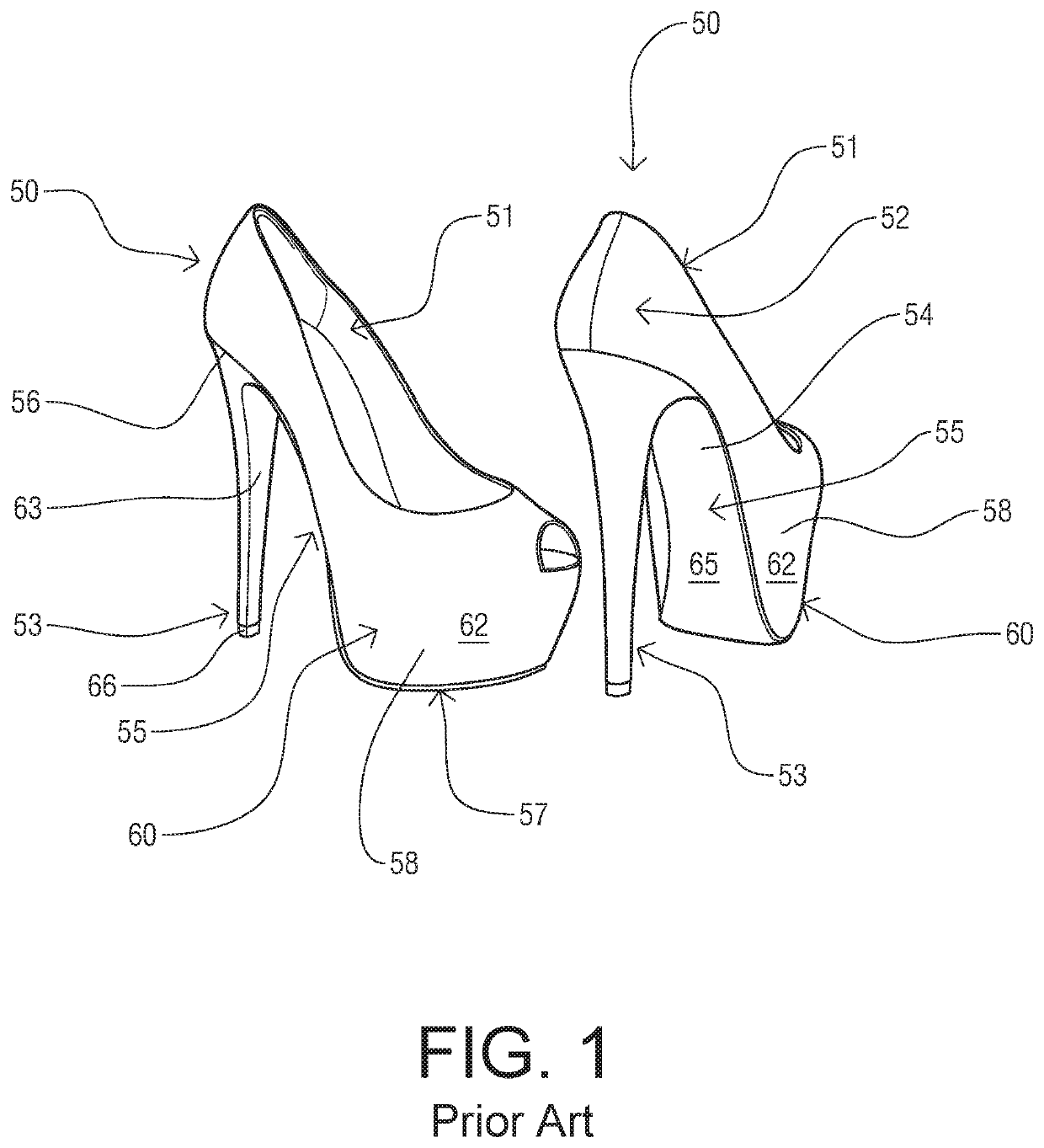

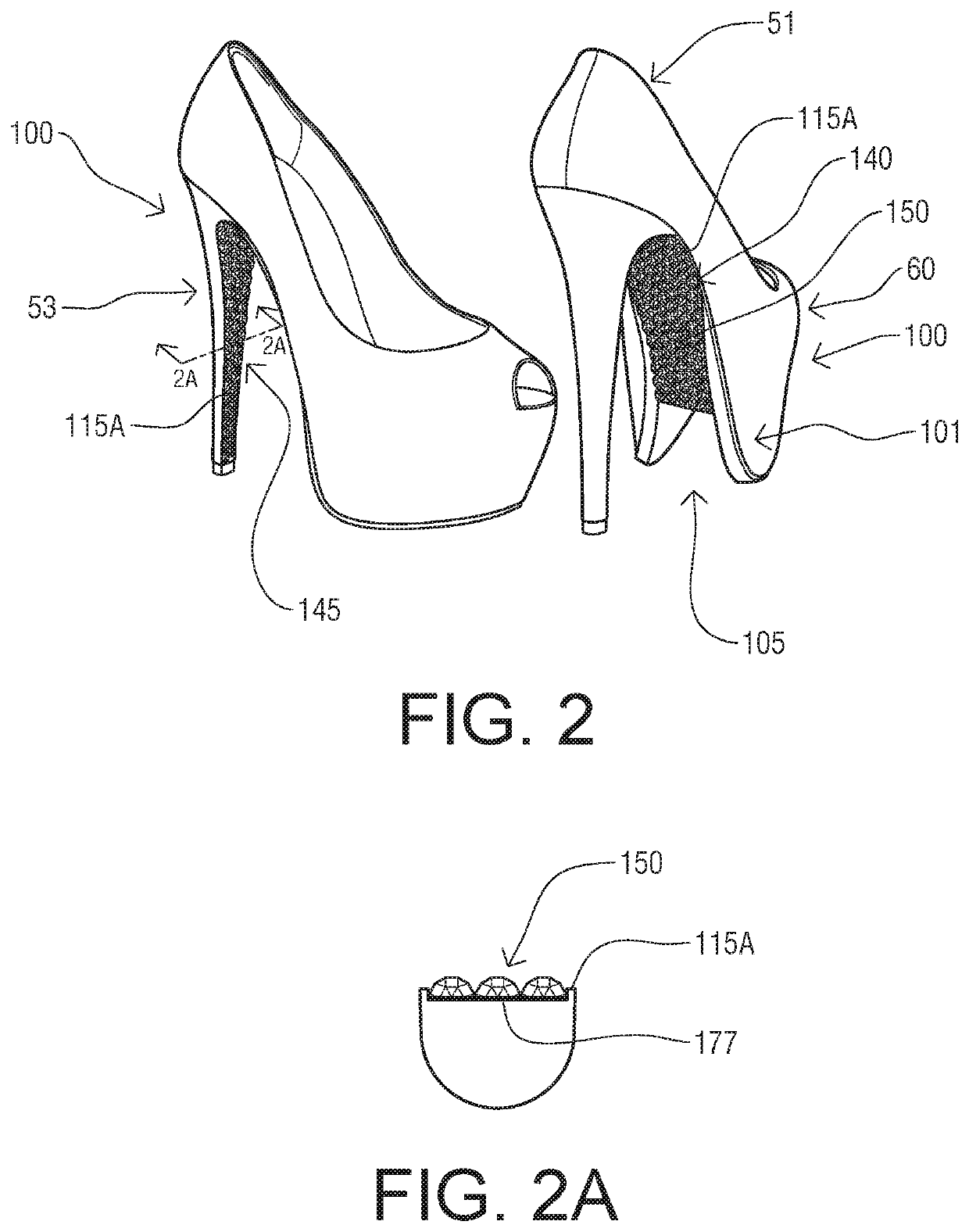

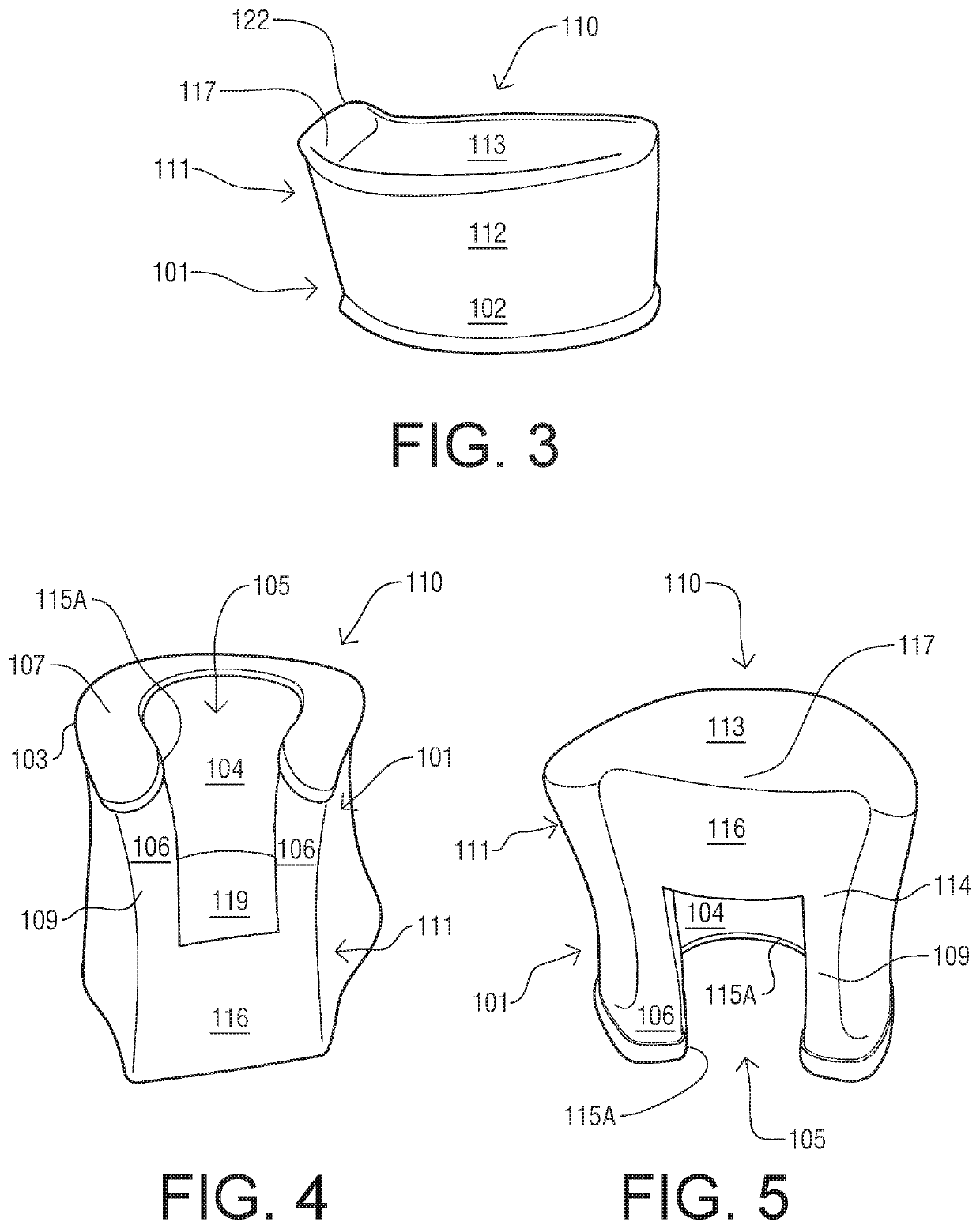

Construction unit and decorative component, and a shoe incorporating same

ActiveUS10729207B1Preventing damage and abrasionIncrease surface areaSolesUpperAssembly (construction)Foot arch

A footwear structural assembly construction unit including a construction unit and a decorative component is provided along with an embellished shoe that incorporates the footwear structural assembly. The construction unit comprises a unit body and a weight-bearing peripheral wall extending downwardly from the unit body, which together define an interior upraised area that accommodates at least a portion of the decorative component. Thus, the decorative component is elevated above the walking surface and protected from dirt and abrasion. The decorative component may optionally extend across the arch and / or down the inner heel.

Owner:FASHION LANE HOLDINGS LLC

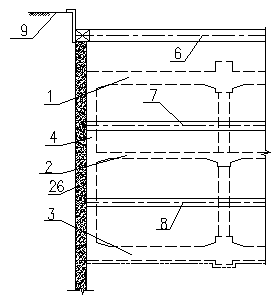

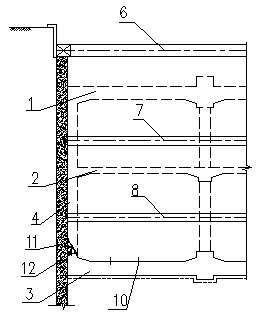

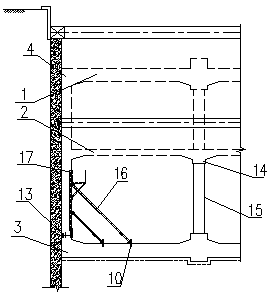

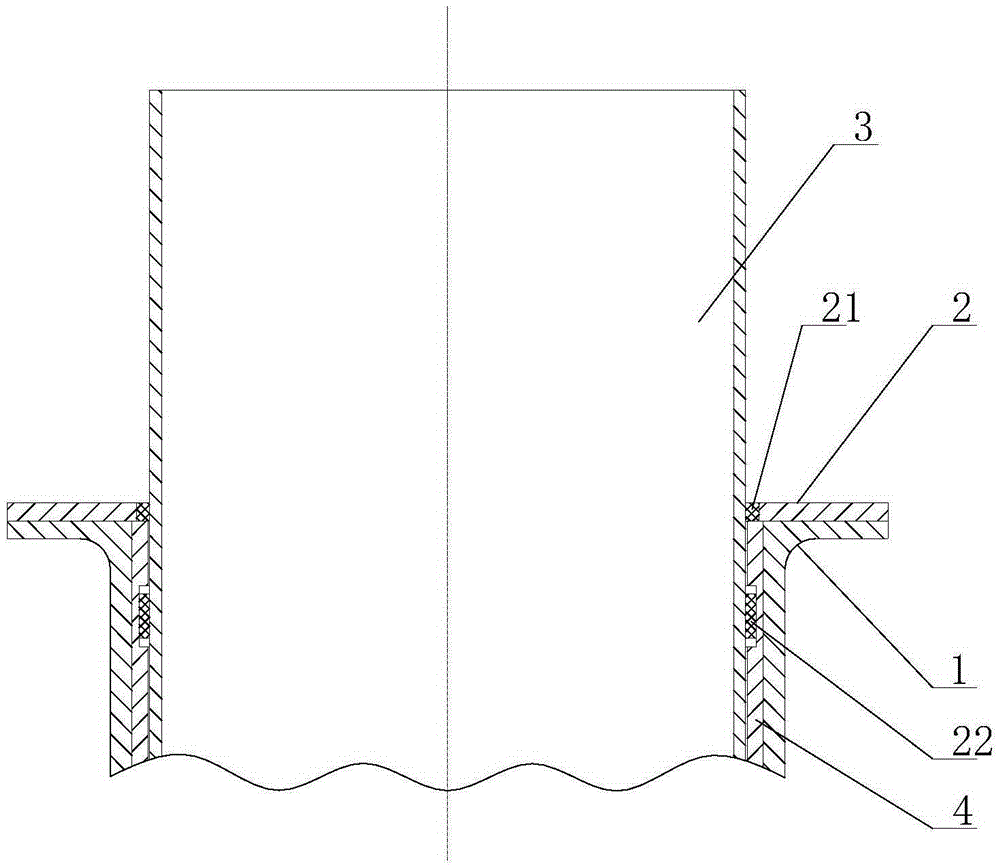

Superposed assembly type structure subway station and assembly construction method thereof

PendingCN111456088AImprove pouring qualityImprove self-waterproof qualityArtificial islandsProtective foundationReinforced concreteArchitectural engineering

The invention relates to a superposed assembly type structure subway station and an assembly construction method thereof. At present, when the station construction is carried out, a large number of formworks are needed, the field operation amount is large, and the construction period is long; environmental water pollution, noise pollution and air pollution can also be caused by the cast-in-place wetting operation, the superposed assembly type structure subway station comprises a top plate (1), a middle plate (2), a bottom plate (3), a heat exhaust air duct (5) and a side wall (4), and is characterized in that a construction joint from the bottom plate to the bottom of a negative second layer is of a cast-in-place reinforced concrete structure, and an exposed grouting sleeve is pre-buried at the construction joint and is connected with an upper side wall stress steel bar; the side wall inner skin is a precast block with truss bars and serves as an inner side formwork at the same time, the bottom of the side wall inner skin is inserted into the grouting sleeve, the stress steel bars are connected by pouring efficient grouting materials, a cast-in-place belt is arranged on the construction joint, side wall cavity concrete is poured, and a side wall overlapping structure is formed. The method thereof is applied to the field of subway construction.

Owner:CCCC FIRST HARBOR ENG +2

Segmental beam sliding assembly construction method

PendingCN111188276ALower requirementLow costBridge erection/assemblyAssembly (construction)Civil engineering

The invention discloses a segmental beam sliding assembly construction method. The construction method comprises the following steps: mounting a sliding bracket, mounting a sliding rail, mounting a beam moving trolley, lifting a beam to the beam moving trolley, transporting the beam by the beam moving trolley, splicing segmental beams, temporarily tensioning, tensioning internal prestressed tendons, repeating the mounting of the next segmental beam, constructing a mid-span closure segment, and dismounting the sliding bracket. According to the invention, the segmental beams are assembled by adopting a sliding assembly method, the segmental beams do not influence the passage or other operations at the lower part of the bracket during sliding assembly, the operating environment with passage requirements or limited topographic conditions can be met, the requirement on segmental beam hoisting equipment is lower by adopting the sliding method, and the cost of the installation equipment is effectively reduced.

Owner:CHINA CREC RAILWAY ELECTRIFICATION BUREAU GRP

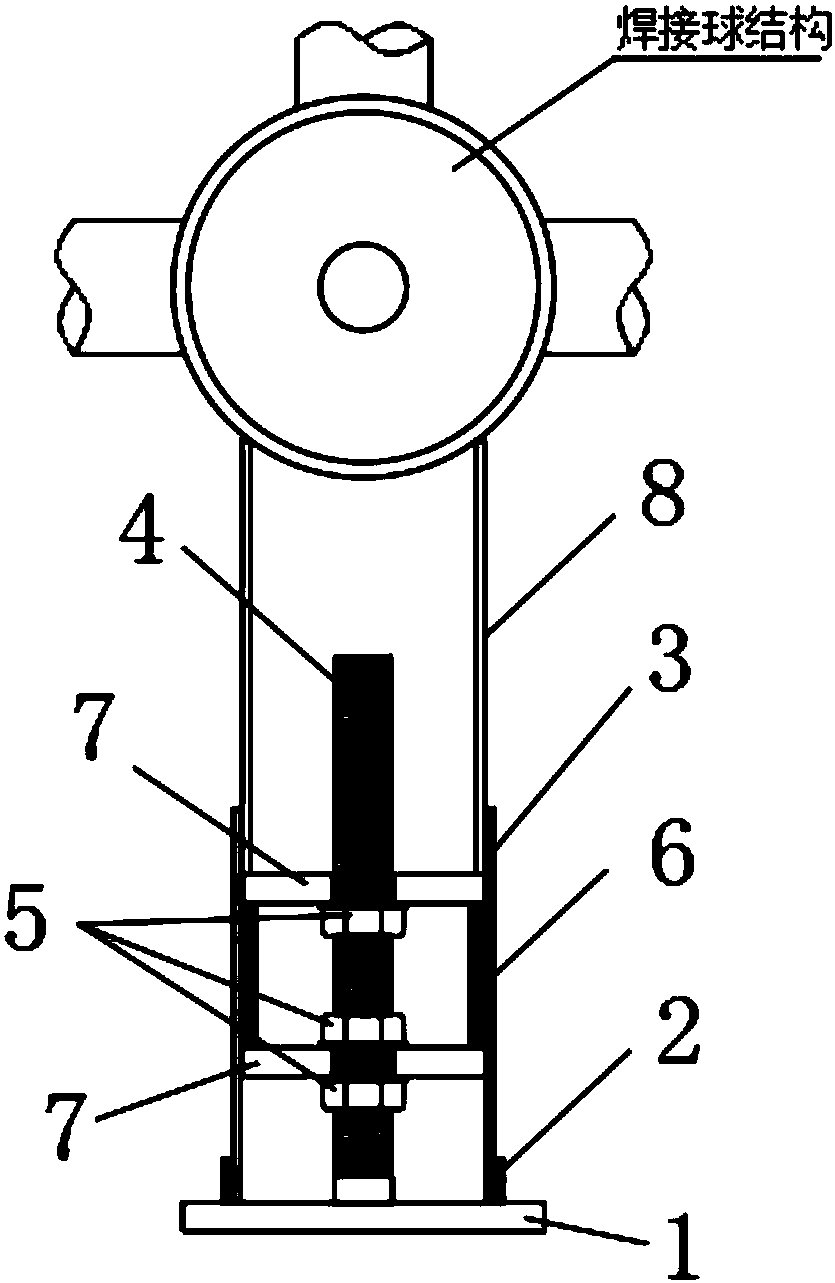

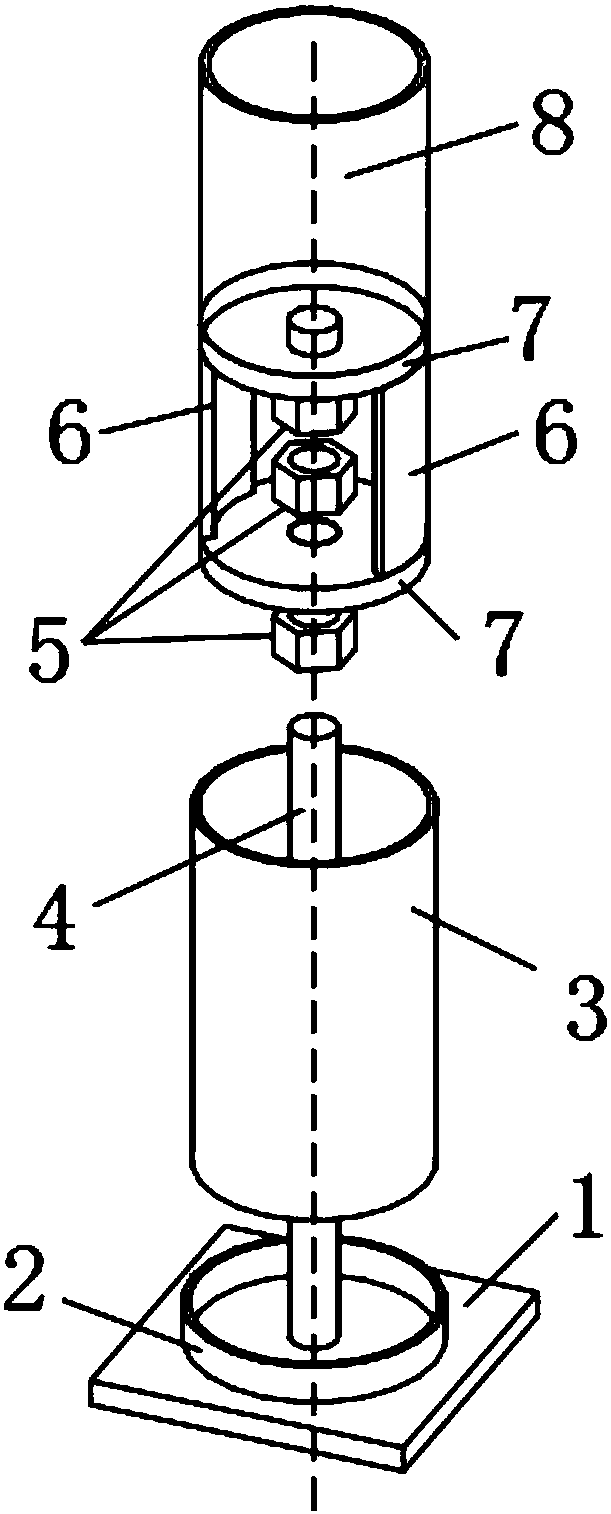

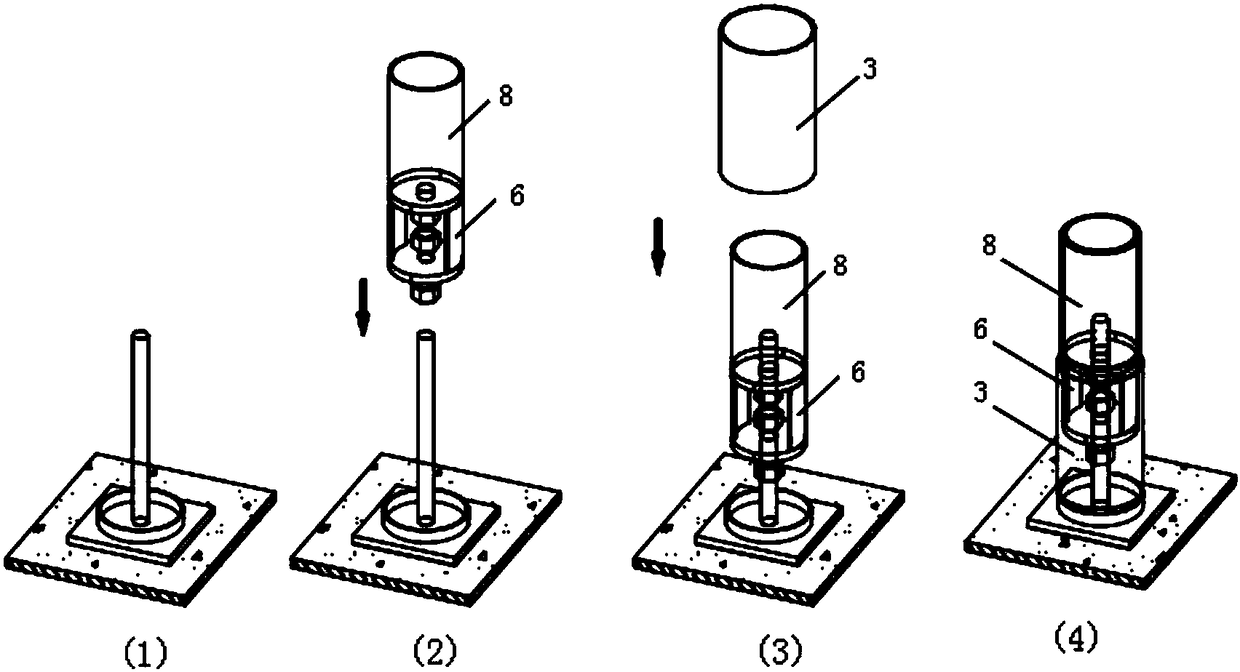

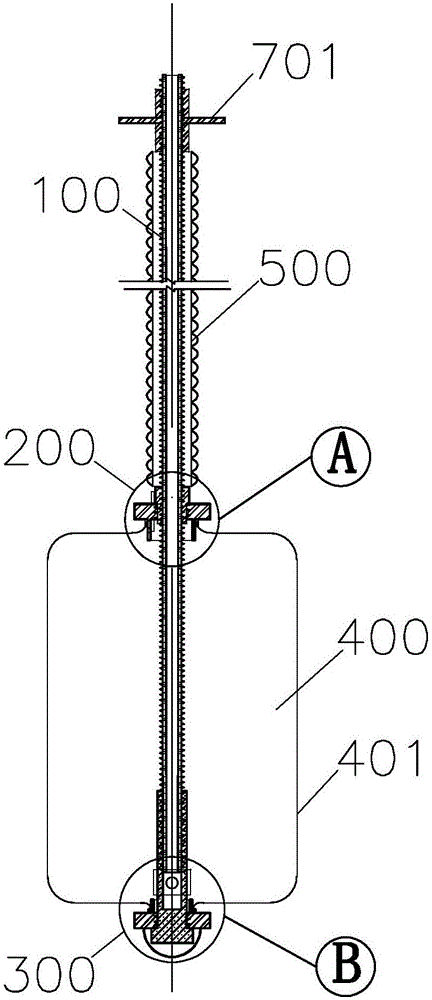

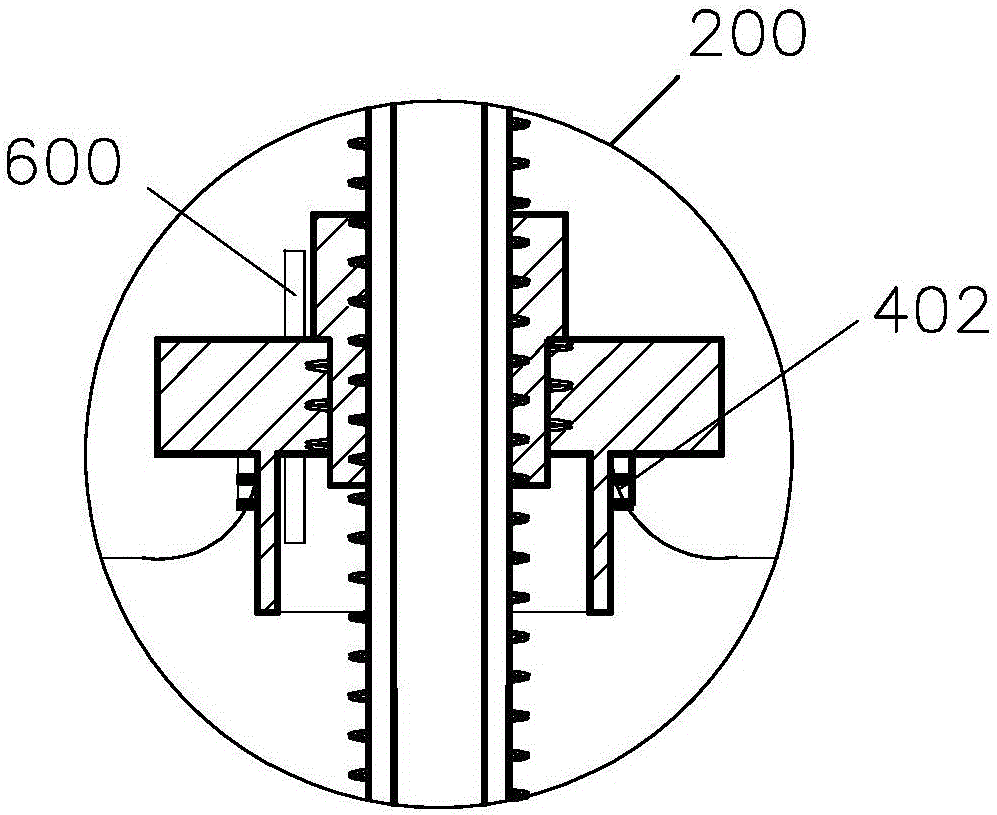

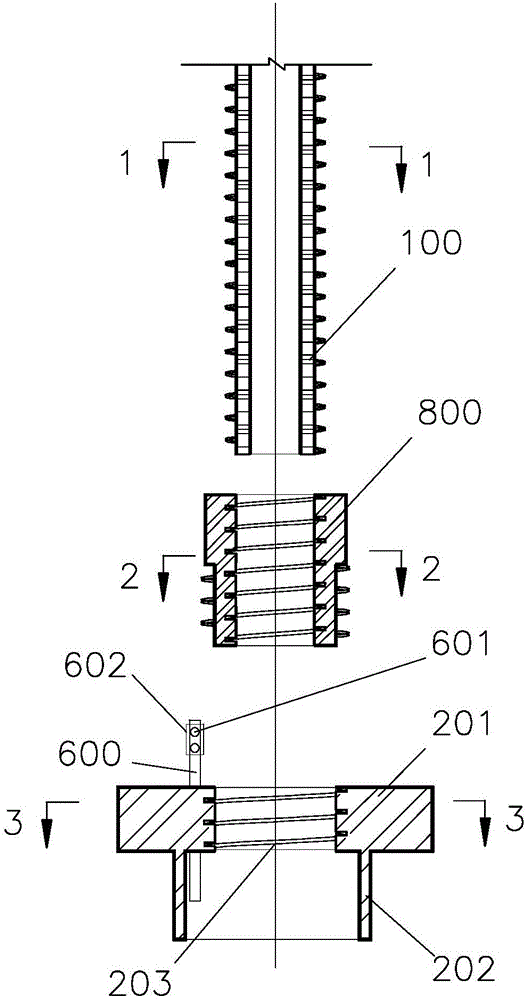

Wire frame sphere joint positioning rapid adjustment device and installation adjustment method thereof

PendingCN108590204ALimits eccentric compressionImprove assembly construction efficiencyBuilding material handlingArchitectural engineeringScrew thread

The invention discloses a wire frame sphere joint positioning rapid adjustment device. The wire frame sphere joint positioning rapid adjustment device comprises a base plate, a threaded round rod anda supporting steel pipe. A circular fixing hoop steel pipe is arranged on the surface of the base plate, and the threaded round rod is fixed to position, in the vertical axis direction of the fixing hoop steel pipe, of the base plate. Two curved plates are arranged on the outer side of the threaded round rod, and force transmitting plates are separately arranged on the upper and lower ends of thecurved plates. The supporting steel pipe is fixed to the force transmitting plate at the upper end. A movable hoop steel pipe is arranged between the supporting steel pipe and the fixing hoop steel pipe. Three hexagonal lock nuts are arranged on the threaded round rod, two of the hexagonal lock nuts are located between the two force transmission plates, another hexagonal lock nut is located belowthe force transmission plate at the lower part, and the hexagonal lock nuts are used for height adjustment and locking. The structural design of the wire frame sphere joint positioning rapid adjustment device is reasonable, and the upper and lower adjustment and rapid positioning and unloading can be realized, the assembly construction efficiency of a sphere joint wire frame is improved, the eccentric compression of the threaded round rod is reduced, the relative offset is not generated, and the fixation reliability is high.

Owner:THE SECOND CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU

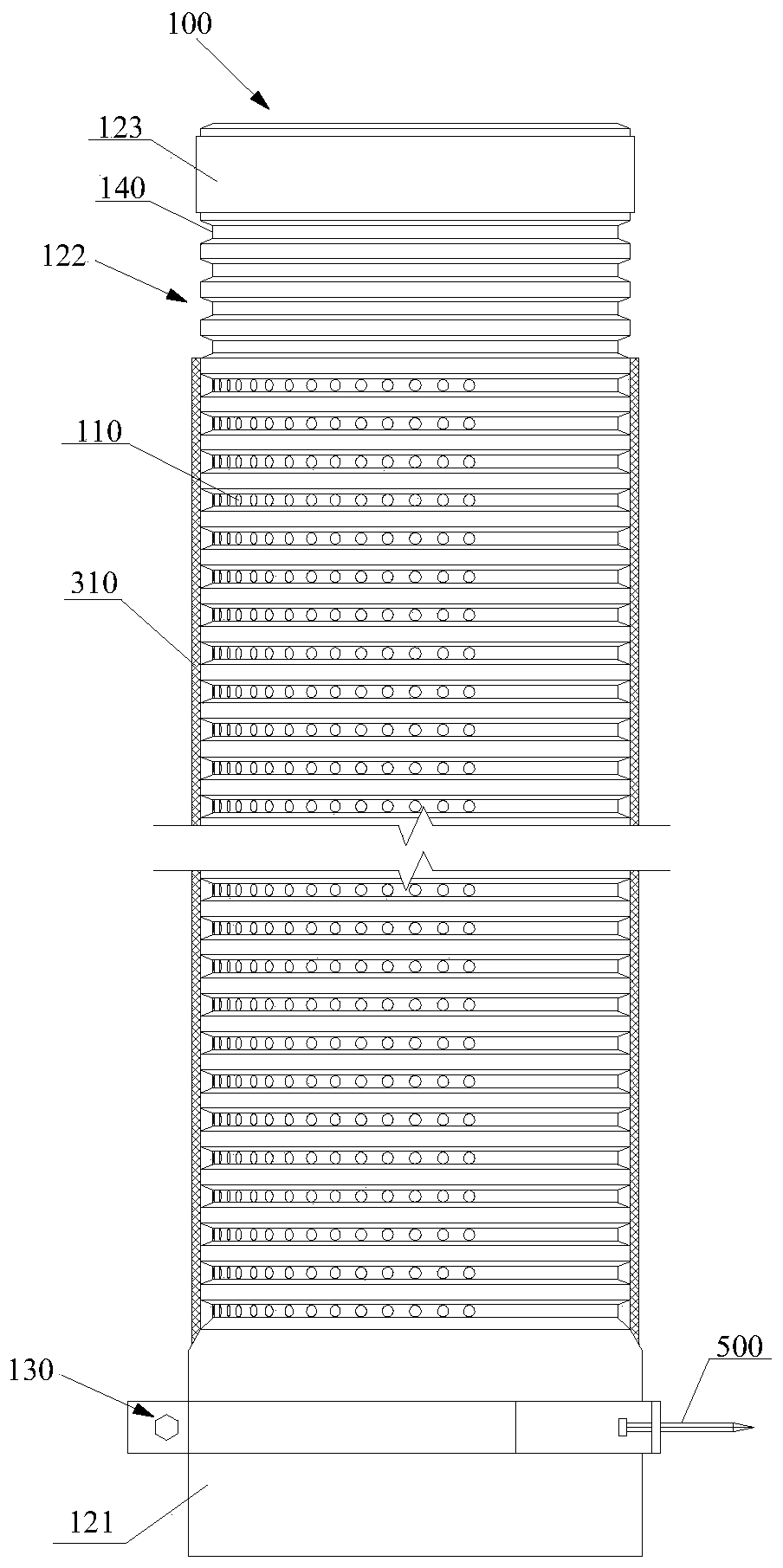

Wind-proof device used in inverted construction of large-size storage tanks and application method thereof

ActiveCN101446143AResistance to lateral loadsGuaranteed stabilityLarge containersBulk storage containerHydraulic cylinderAssembly disassembly

The invention provides a wind-proof device used in the inverted construction of large-size storage tanks and an application method thereof. The wind-proof device used in the inverted construction of large-size storage tanks comprises a tank wall and an expansive ring. A clamping bench is arranged on the tank wall. The expansive ring is rested against the clamping bench and is hoisted by a hydraulic cylinder. The wind-proof device used in the inverted construction of large-size storage tanks further comprises a tilted supporting rod and a vertical rod. The lower end of the tilted supporting rod is connected together with the base plate of the storage tank. The upper end of the tilted supporting rod is connected together with the upper end of the vertical rod. The lower end of the vertical rod is connected together with the base plate of the storage tank. The upper part of the vertical rod is mounted to the inner side of the expansive ring. The wind-proof device with the advantages of reasonable and compact structure, easy use, simple structure and convenience for assembly and disassembly can protect against the transverse load of wind during the inverted construction of large-size storage tanks, improve the lifting stability of the tank without affecting the smooth operation of vertically lifting the tank by the hydraulic cylinder, and facilitate the assembly and the construction of the storage tank; therefore, the invention has the characteristics of safety, simplification and low cost.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

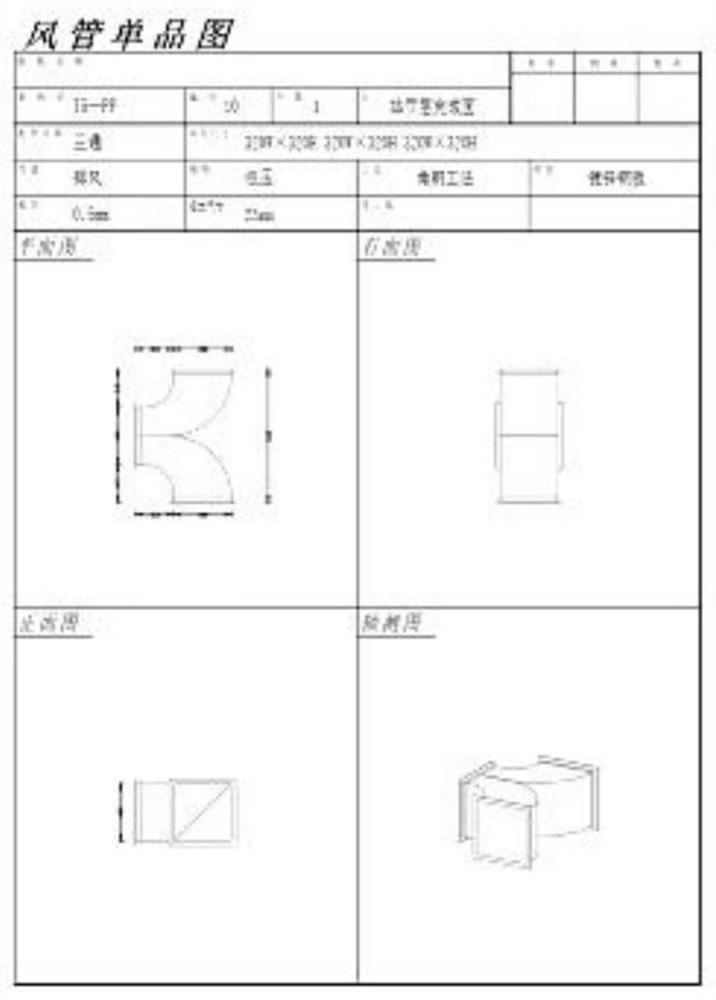

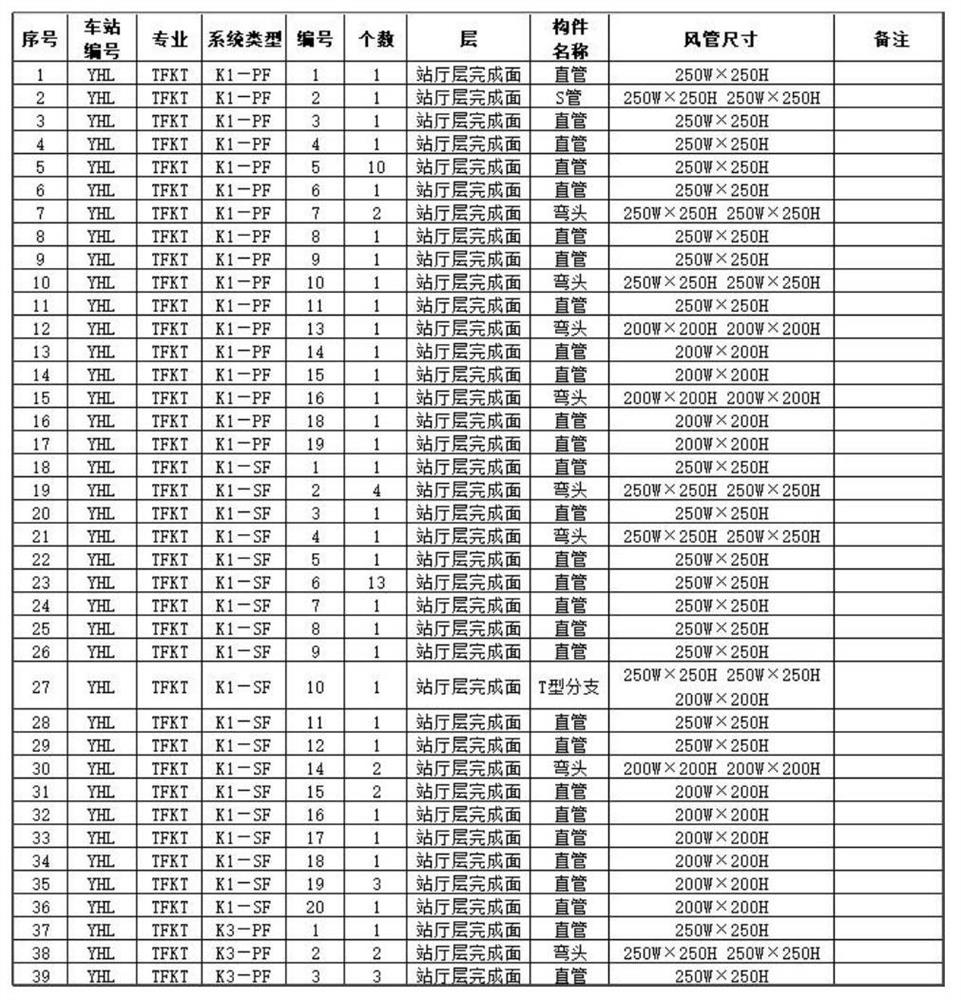

Integrated pipeline overall assembly method based on BIM technology

PendingCN112613100AReduce lossImprove efficiencyGeometric CADSpecial data processing applicationsProcess engineeringMaterial resources

The invention discloses a BIM technology-based integrated pipeline overall assembly method, which comprises the steps of creating a BIM model according to a drawing, then carrying out collision detection, and carrying out collision check by utilizing the BIM model, thereby being convenient, rapid, high in efficiency and low in error rate; carrying out three-dimensional visual disclosure on construction personnel by utilizing the BIM model, visually displaying the construction process, and ensuring that technical disclosure is in place; splitting the created model; after comprehensive pipeline segmentation is completed, carrying out pipeline and support coding, completing output of a material detail list and output of a machining drawing, carrying out accurate ordering according to the material detail list and the machining drawing, wherein material losses are low; enabling all pipelines to be subjected to factory prefabrication and assembly construction, so that the construction efficiency is improved; and transporting comprehensive pipelines in place at a time and installing the pipelines at a time, manpower, so that material resources and construction cost are saved, and the construction period is guaranteed.

Owner:中铁十一局集团电务工程有限公司 +1

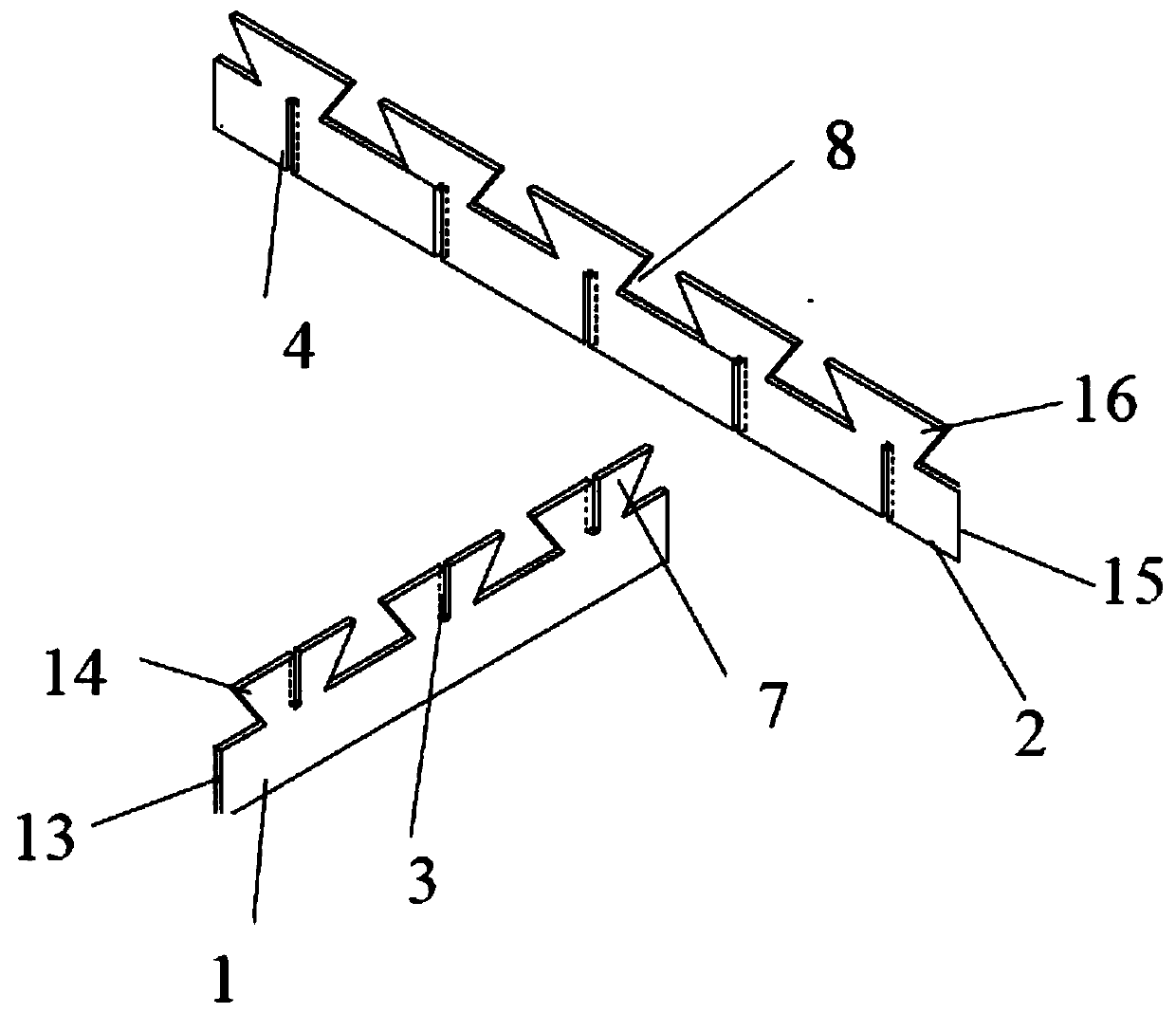

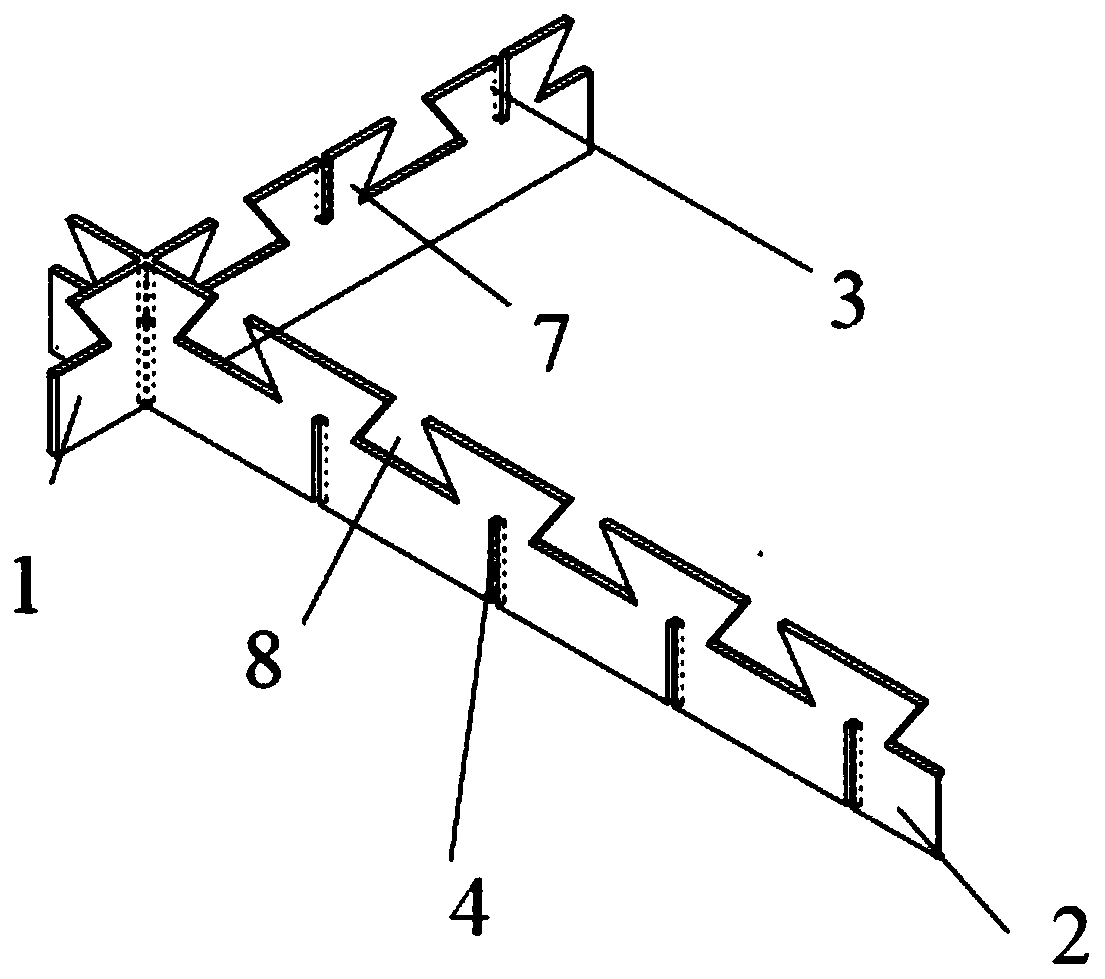

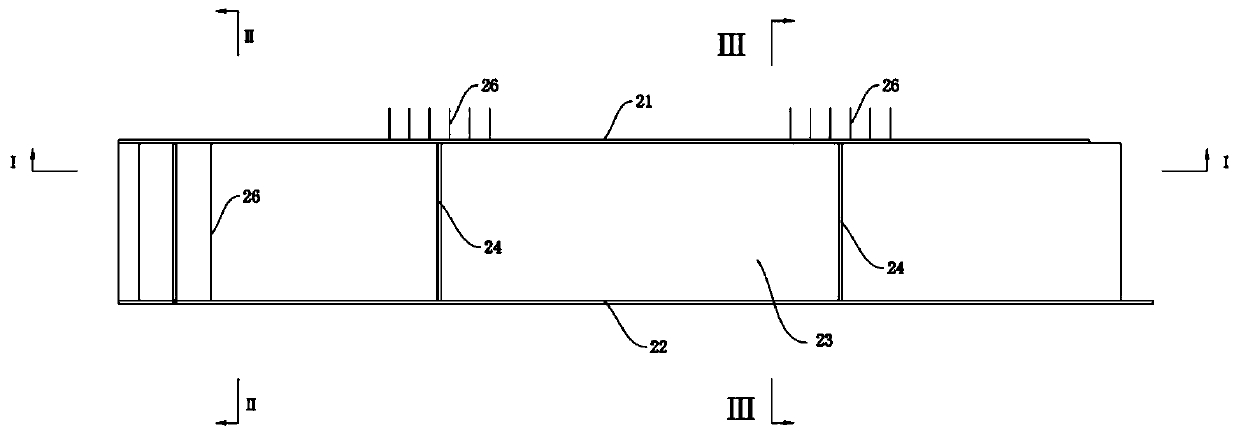

Shear connecting part, mounting structure and construction method of UHPC waffle slab combined beam bridge

ActiveCN110184896AEasy to processTake advantage ofBridge structural detailsBridge erection/assemblyCross connectionBeam bridge

The invention discloses a shear connecting part of a UHPC waffle slab combined beam bridge. The shear connecting part comprises a transverse tenon type standard part unit and a longitudinal tenon typestandard part unit, wherein the transverse tenon type standard part unit is composed of a plurality of transverse tenon type standard parts which are arranged at intervals, each transverse tenon typestandard part comprises a lower tenon joint slab body and an upper tenon joint slab body, and each upper tenon joint slab body is provided with an upper tenon joint hole; the longitudinal tenon typestandard part unit is composed of a plurality of longitudinal tenon type standard parts which are arranged at intervals, each longitudinal tenon type standard part comprises a lower tenon joint slab body and an upper tenon joint slab body, and each lower tenon joint slab body is provided with a lower tenon joint hole; and each lower tenon joint hole is inserted with the upper tenon joint hole in the corresponding transverse tenon type standard part, and the crossed connection positions between the transverse tenon type standard parts and the longitudinal tenon type standard parts are welded and fixed. According to the shear connecting part, the mounting structure and the construction method of the UHPC waffle slab combined beam bridge, materials are fully utilized, assembly construction isfacilitated, the defect that the shear rigidity of a flexible shear connecting part such as a stud is small is overcome, and the shear bearing capacity and the shear rigidity of the connecting part are remarkably improved.

Owner:天津大学前沿技术研究院

Assembly type expanded-base grouting anchoring structure device and assembly construction method

InactiveCN105714822AImprove anti-corrosion durabilityBoth functionsBulkheads/pilesCarrying capacityPull force

The invention relates to an assembly type expanded-base grouting anchoring structure device. The assembly type expanded-base grouting anchoring structure device comprises one or more hollow tubes and foldable unfolded bag sleeves. According to the assembly type expanded-base grouting anchoring structure device disclosed by the invention, the assembly type expanded-base grouting anchoring structure device which can bear pulling and pressing bidirectional loads as well as the assembly technology and construction method of the assembly type expanded-base grouting anchoring structure device are provided, bottom diameter expansion is performed in small-diameter pile holes or small-diameter anchor holes through a hole expansion technology, anchor rod piles or anchor rods, with expanded-base structures are generated, the carrying capacity of the expanded-base anchor rod piles or the expanded-base anchor rods can be increased in multiples, and besides, the expanded-base anchor rod piles or the expanded-base anchor rods are also suitable for bearing bidirectional loads of pressure and pulling force. According to the assembly type expanded-base grouting anchoring structure device disclosed by the invention, stress rod bodies are made from high-performance fiber reinforcement compound materials or steel products, and a hollow tube application technology is adopted, so that the stress rod bodies concurrently have grouting and carrying functions, the construction periods are shortened, materials are saved, the building cost is reduced, and besides, the construction is convenient and fast.

Owner:CHINA JINGYE ENG TECH CO LTD +1

Bridge reinforcing device based on load transfer

PendingCN110983993AIncreased durabilityShort construction periodBridge structural detailsBridge erection/assemblySupporting systemClassical mechanics

The invention discloses a bridge reinforcing device based on load transfer, which comprises a supporting system and a newly-added beam body, wherein the bottom of the newly-added beam body is mountedon the supporting system, the supporting system is mounted on a bent cap, the top of the newly-added beam body is propped against the bottom of a wet joint, and the top flange of the newly-added beambody is propped against the flange of an original beam body. The beneficial effects are that the new beam body is additionally arranged under the condition that the structure and the bearing capacityof the original beam body are not changed; part of the load borne by the original beam body is transferred to the new beam body, the original beam body is enabled to meet the standard of new design specifications, the original beam body and the newly-added beam body both meet the design benchmark period of 100 years, the newly-added beam body can achieve standardized design, industrialized production and field assembly construction, the construction period is short, and the engineering cost is low; and the newly-added beam body and the original beam body form a combined structure to jointly bear automobile loads on the bridge deck, and thus the bearing capacity of the bridge is improved.

Owner:汪小鹏

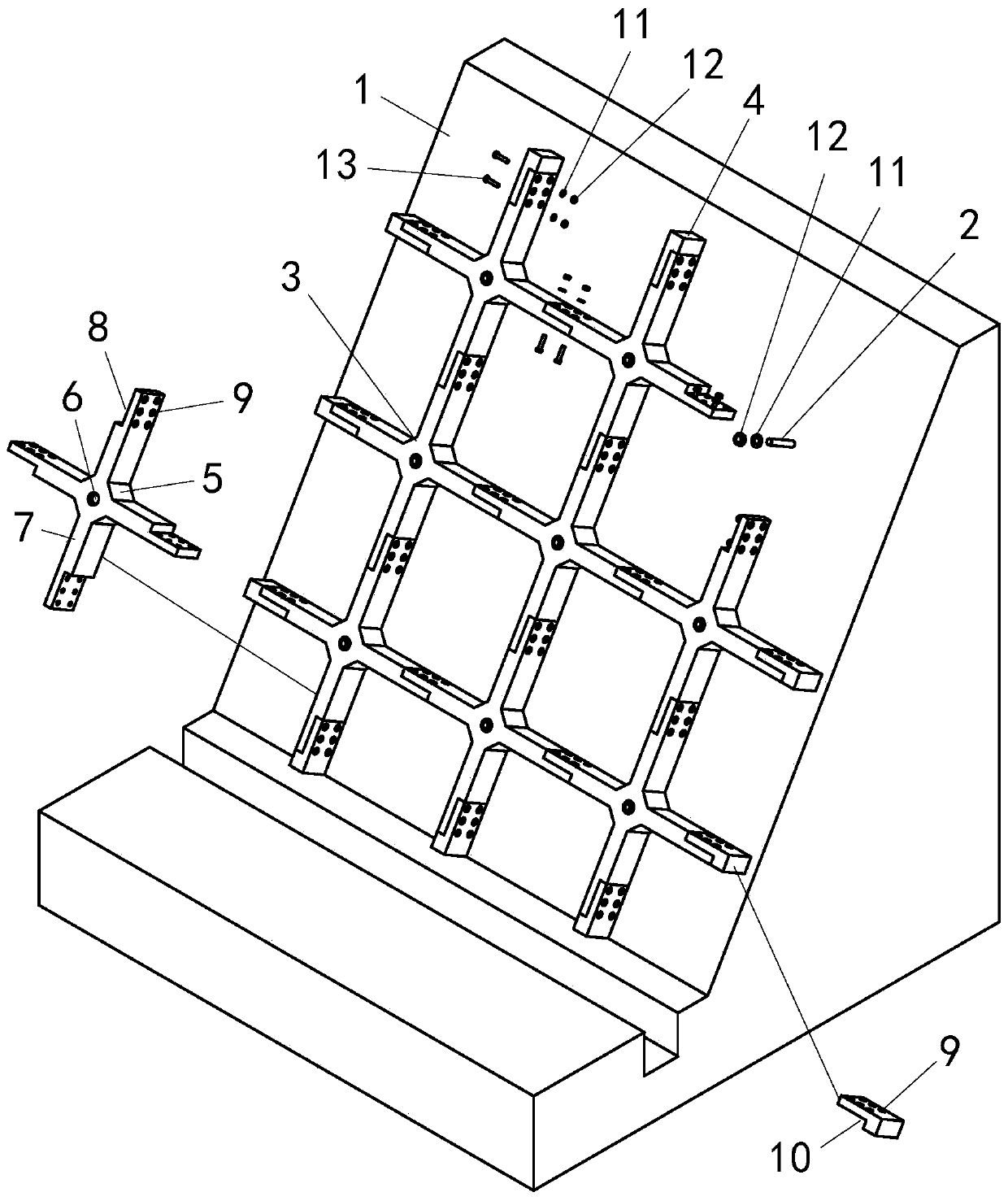

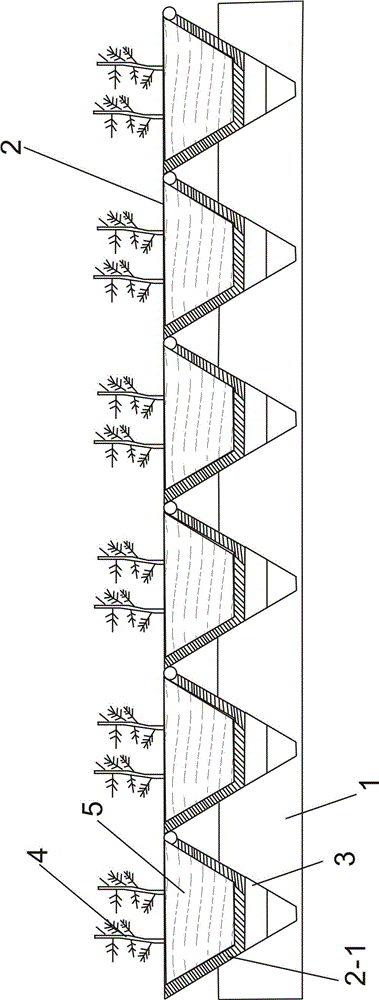

Construction method and structure of assembly anchor rod frame beam

PendingCN111270692AImprove ergonomicsMeet the requirements of protective safety regulationsExcavationsBulkheads/pilesArchitectural engineeringAssembly (construction)

The invention discloses a construction method and structure of an assembly anchor rod frame beam. The construction method is characterized in that an existing integral cast anchor rod frame beam is decomposed into two different prefabricated parts, namely cross prefabricated parts and sealing head prefabricated parts; during specific construction, the side slope protection working efficiency is improved by adopting a field assembly manner, and the side slope protection working efficiency is close to the side slope excavation working efficiency, so that the specification requirement for simultaneous excavation and protection of a side slop from top to bottom is achieved. According to the method, the prefabricated parts can be concentrated and prefabricated in a professional prefabricated field and then transported to a construction site for assembly construction, and due to the fact that formworks does not need to be erected as in the prior art, pouring of concrete and the time for waiting for the concrete to be consolidated are not needed, the side slope protection working efficiency is greatly improved. Therefore, requirements of side slope protection safety codes are met, the construction of simultaneous excavation and protection can be carried out from top to bottom, and the safety risks of landslides and falling objects to injure people are reduced.

Owner:中建四局贵州投资建设有限公司

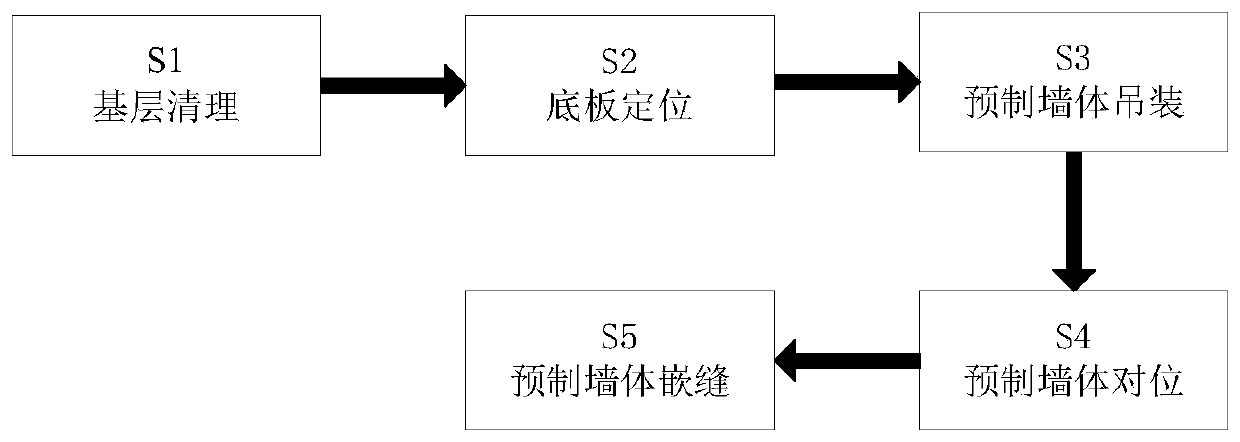

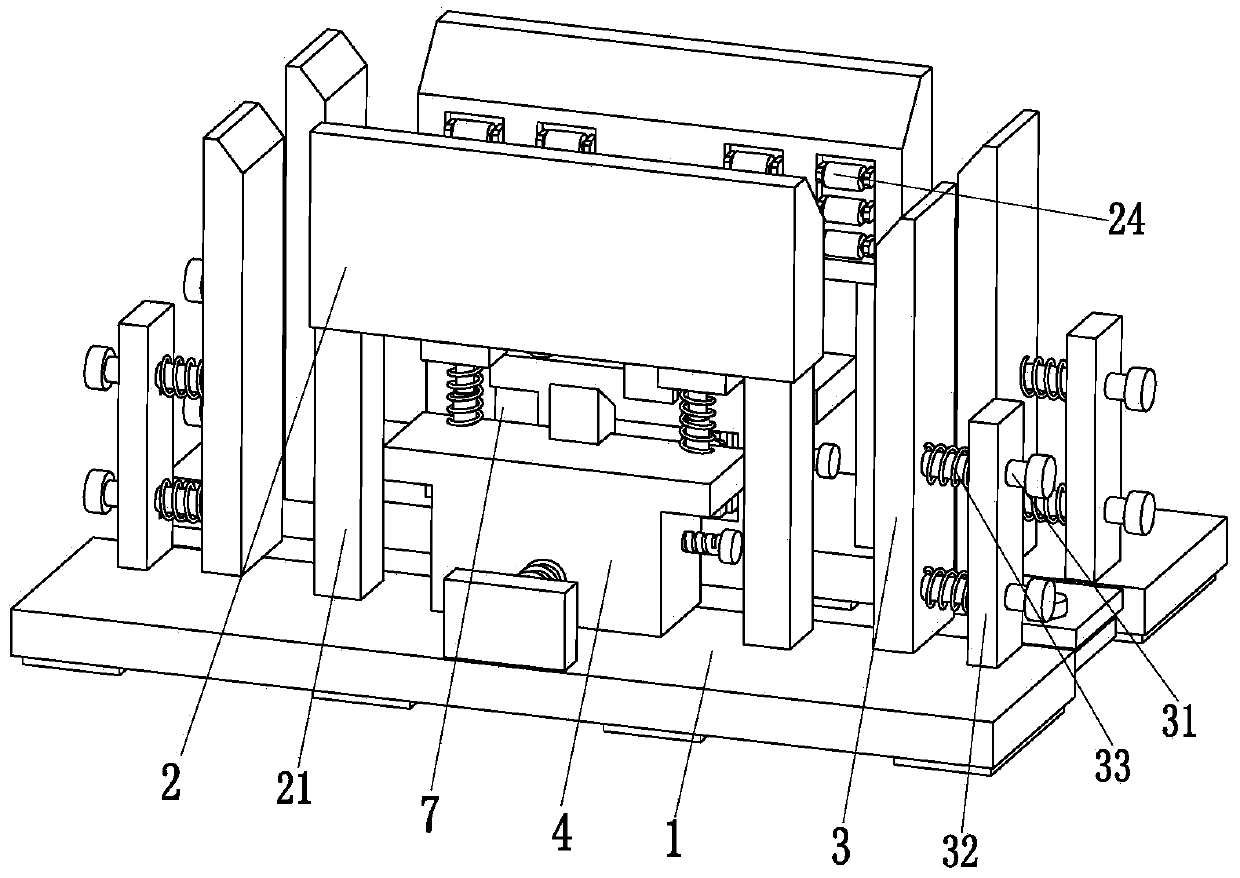

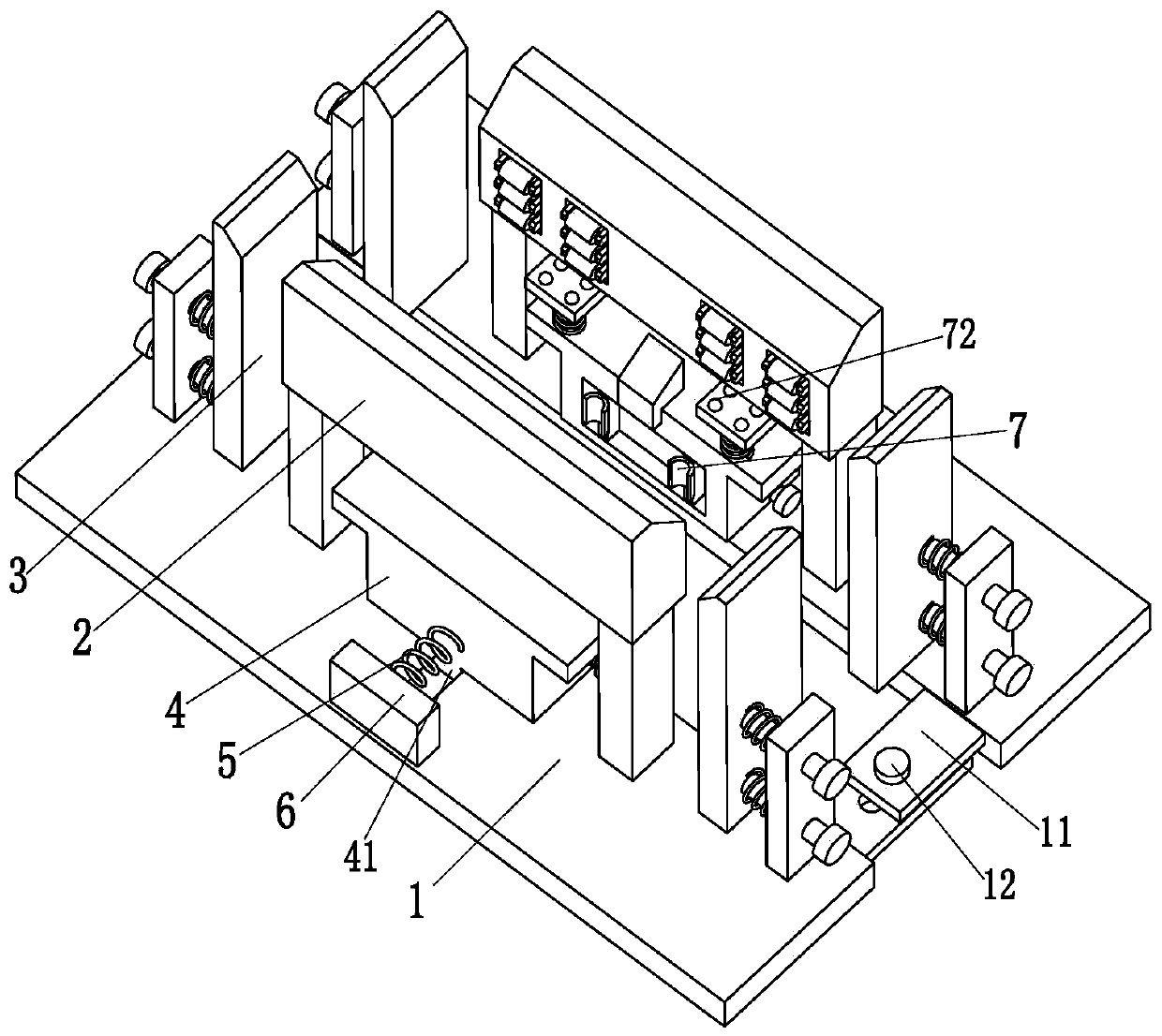

Site assembly and installation construction method for energy-saving reinforced concrete prefabricated wall bodies

ActiveCN111535597AImprove the installation effectImprove installation accuracyBuilding material handlingReinforced concreteArchitectural engineering

The invention relates to a site assembly and installation construction method for energy-saving reinforced concrete prefabricated wall bodies. A following prefabricated wall body assembly constructiondevice is adopted in the site assembly and installation construction method for the prefabricated wall bodies. The prefabricated wall body assembly construction device comprises bottom plates, transverse guide plates, longitudinal guide plates, buffer seats, externally-supporting springs, externally-supporting plates and buffer mechanisms. The construction method for site assembly and installation of the prefabricated wall bodies through the prefabricated wall body assembly construction device includes the following steps of S1, basic layer cleaning; S2, bottom plate positioning; S3, hoistingof the prefabricated wall bodies; S4, aligning of the prefabricated wall bodies; and S5, caulking of the prefabricated wall bodies. The problems that when the existing concrete prefabricated wall bodies are hoisted and put, the process of manually aligning the concrete prefabricated wall bodies is complex, and the concrete prefabricated wall bodies easily deviate, so that the concrete prefabricated wall bodies are damaged or preset rebars are bent can be solved.

Owner:华漾建设集团有限公司

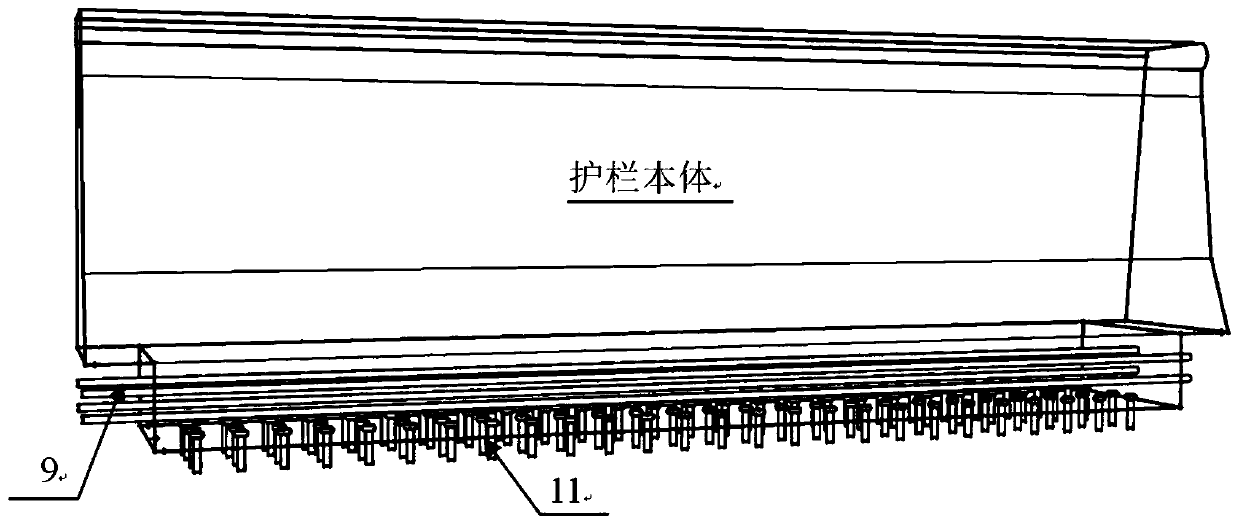

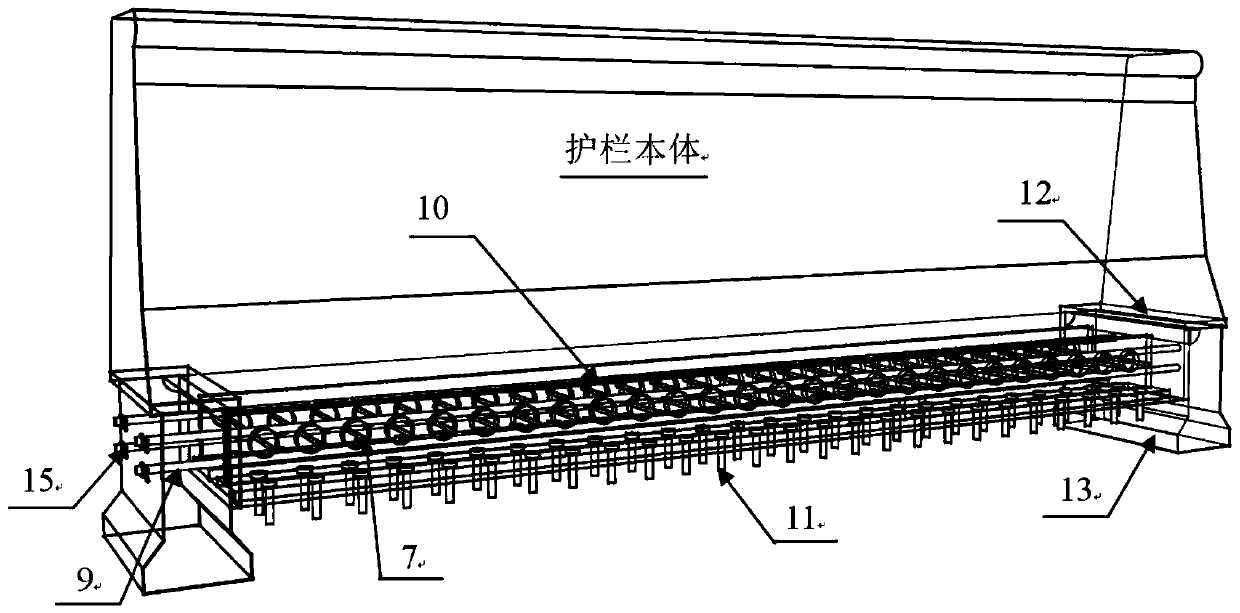

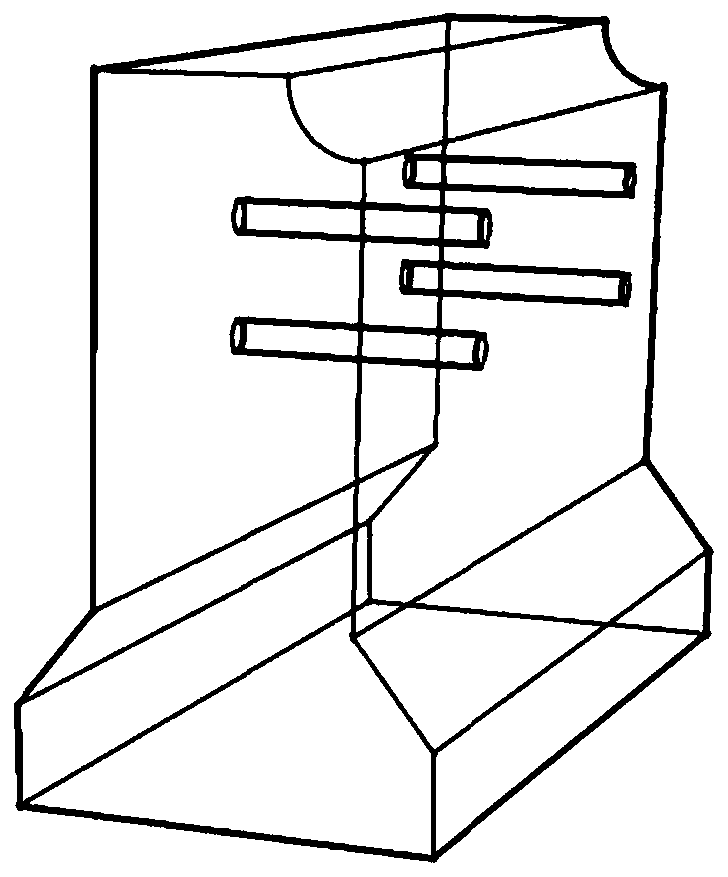

Connecting structure of fabricated steel bridge deck concrete crash barrier and complete set of construction method of connecting structure

ActiveCN111270606AAvoid stressAvoid residual deformationBridge structural detailsBridge erection/assemblyArchitectural engineeringBridge deck

The invention discloses a connecting structure of a fabricated steel bridge deck concrete crash barrier and a complete set of construction method of the connecting structure. The connecting structurecomprises a prefabricated concrete guardrail, the prefabricated concrete guardrail comprises embedded inverted-T-shaped perforated steel plate connecting pieces, embedded angle steel, embedded high-strength bolts, guardrail anti-collision steel bars and a guardrail body, the guardrail anti-collision steel bars, the embedded inverted-T-shaped perforated steel plate connecting pieces and the embedded angle steel are connected in a welded mode, and the concrete guardrail is prefabricated after the high-strength bolts are embedded. The precast concrete guardrail is reliably connected with the steel bridge deck through the high-strength bolts. The problems that in current steel bridge deck guardrail construction, welding residual stress is large, and construction procedures are complex are solved; and technical support is provided for assembly construction of the steel bridge deck concrete guardrail through the provided complete construction technology.

Owner:SHANDONG TRAFFIC PLANNING DESIGN INST

Assembled type double-pipe seepage and drainage blind ditch and construction method of roadbed seepage and drainage structure

ActiveCN110847321AGood drainageExtended service lifeFatty/oily/floating substances removal devicesSewerage structuresDrainage tubesDitch

The invention discloses an assembled type double-pipe seepage and drainage blind ditch and a construction method of a roadbed seepage and drainage structure. The assembled type double-pipe seepage anddrainage blind ditch comprises drainage units connected end to end; each drainage unit comprises a first drainage pipe, a first filter layer, a second drainage pipe and a second filtering layer, wherein the pipe wall of the first drainage pipe is provided with a first water seepage hole; the first filter layer is wrapped outside the first drainage pipe; the second drainage pipe is arranged insidethe first drainage pipe, and a second water seepage hole is formed in the pipe wall of the second drainage pipe; and the second filtering layer is wrapped outside of the second drainage pipe and forms a cavity between the inner wall of the first drainage pipe and the second filtering layer. The assembled type double-pipe seepage and drainage blind ditch has the advantages of simple structure, capability of being transported to a site after being assembled in advance in a factory, realization of the concept of assembly of all parts, higher assembly speed and efficiency, less labor required forassembly, shorter assembly construction period, lower construction cost and easier quality control.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

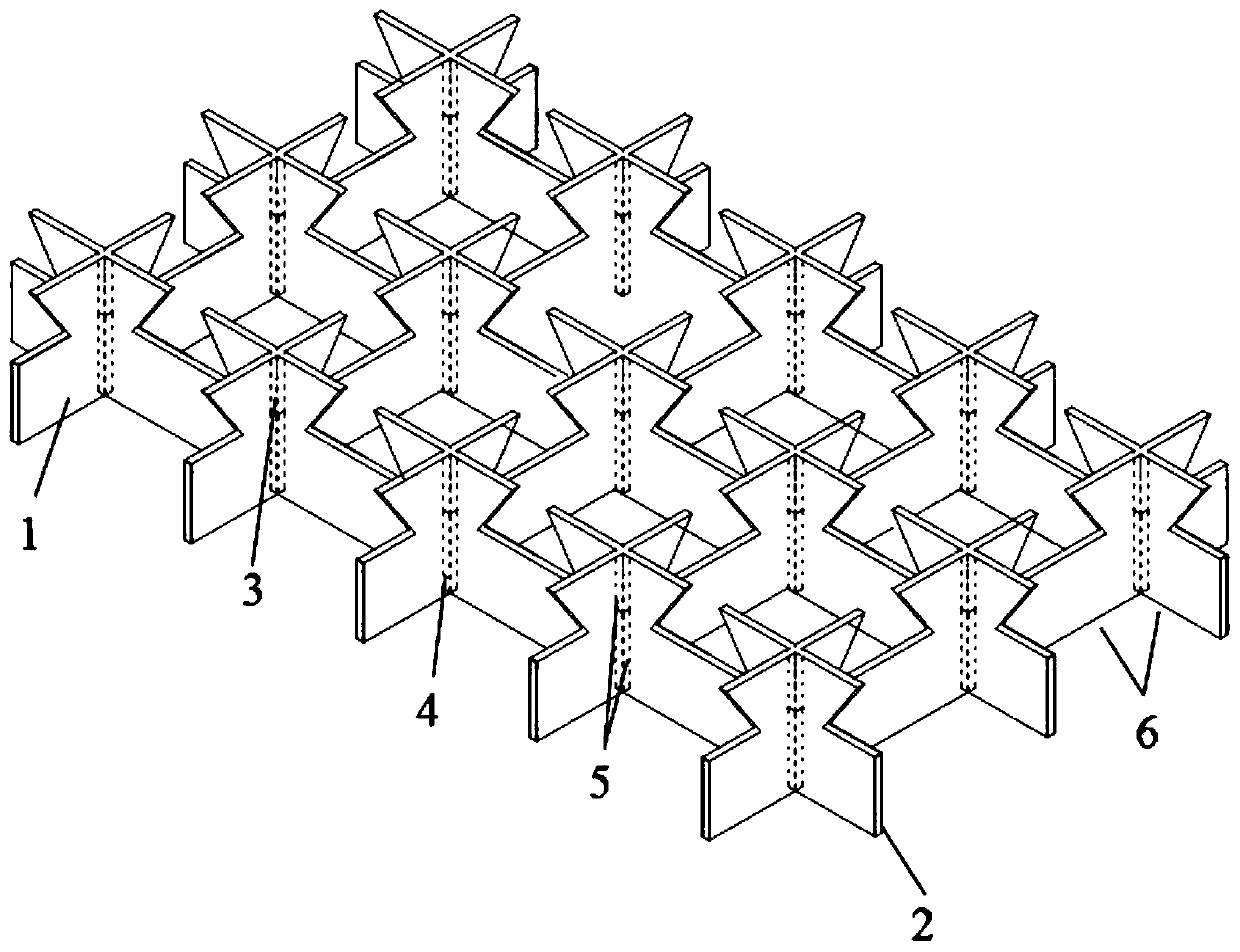

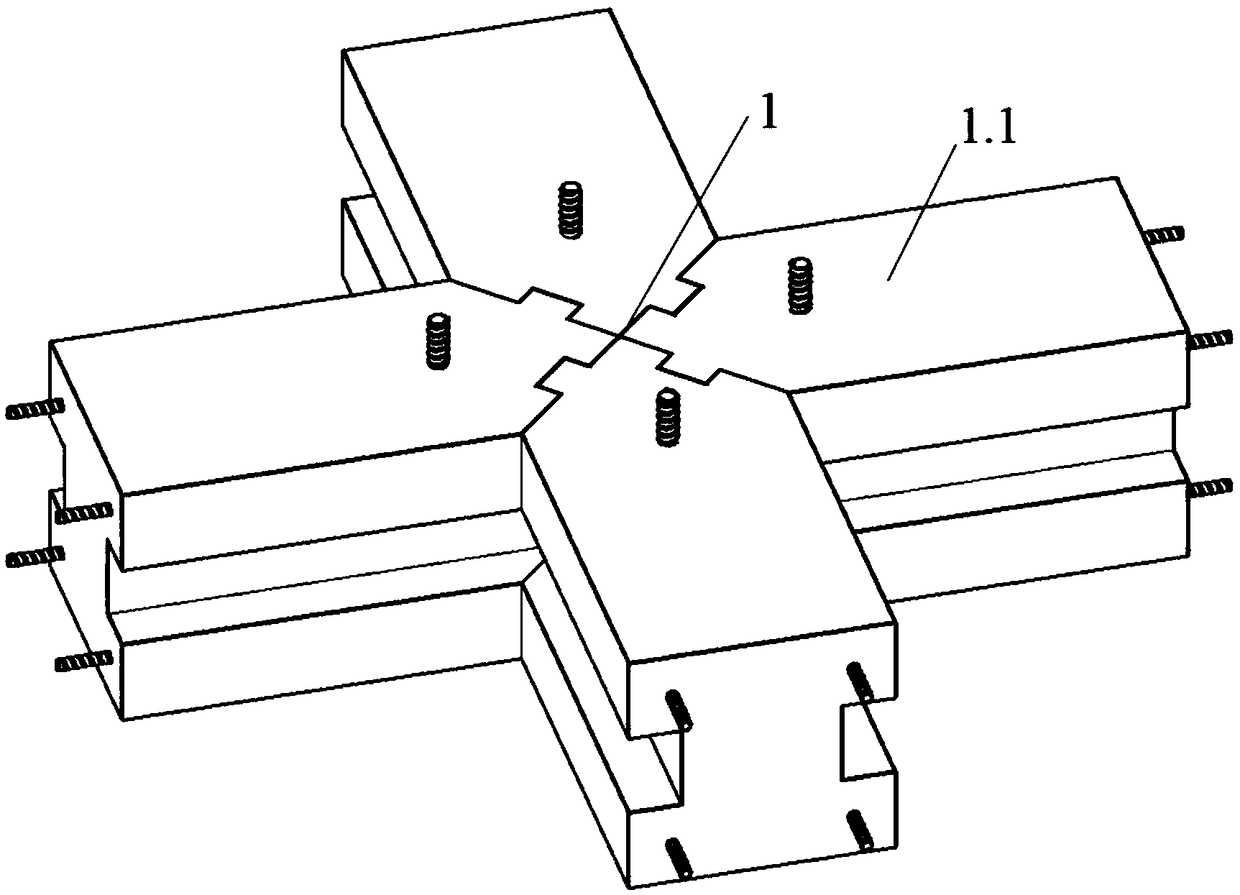

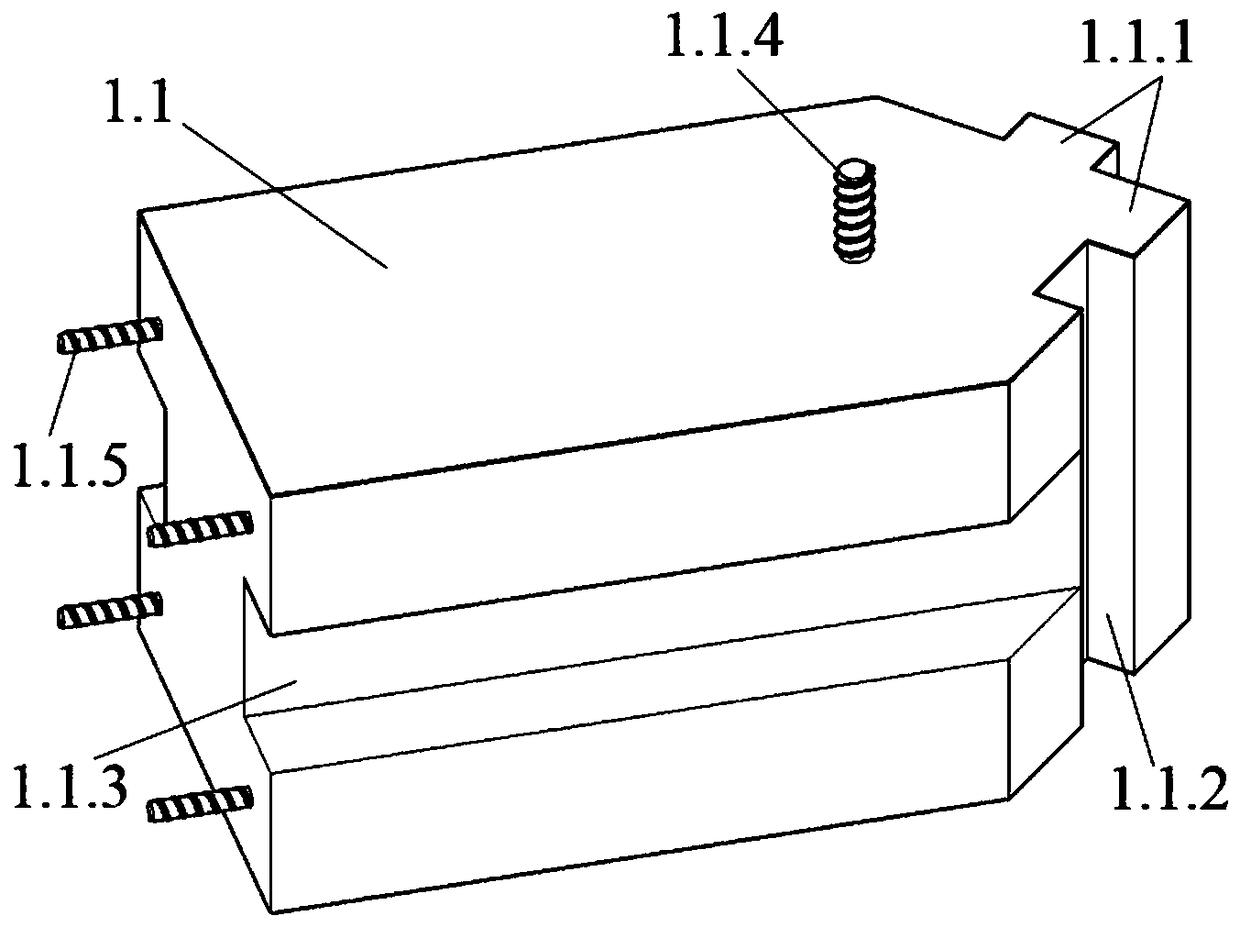

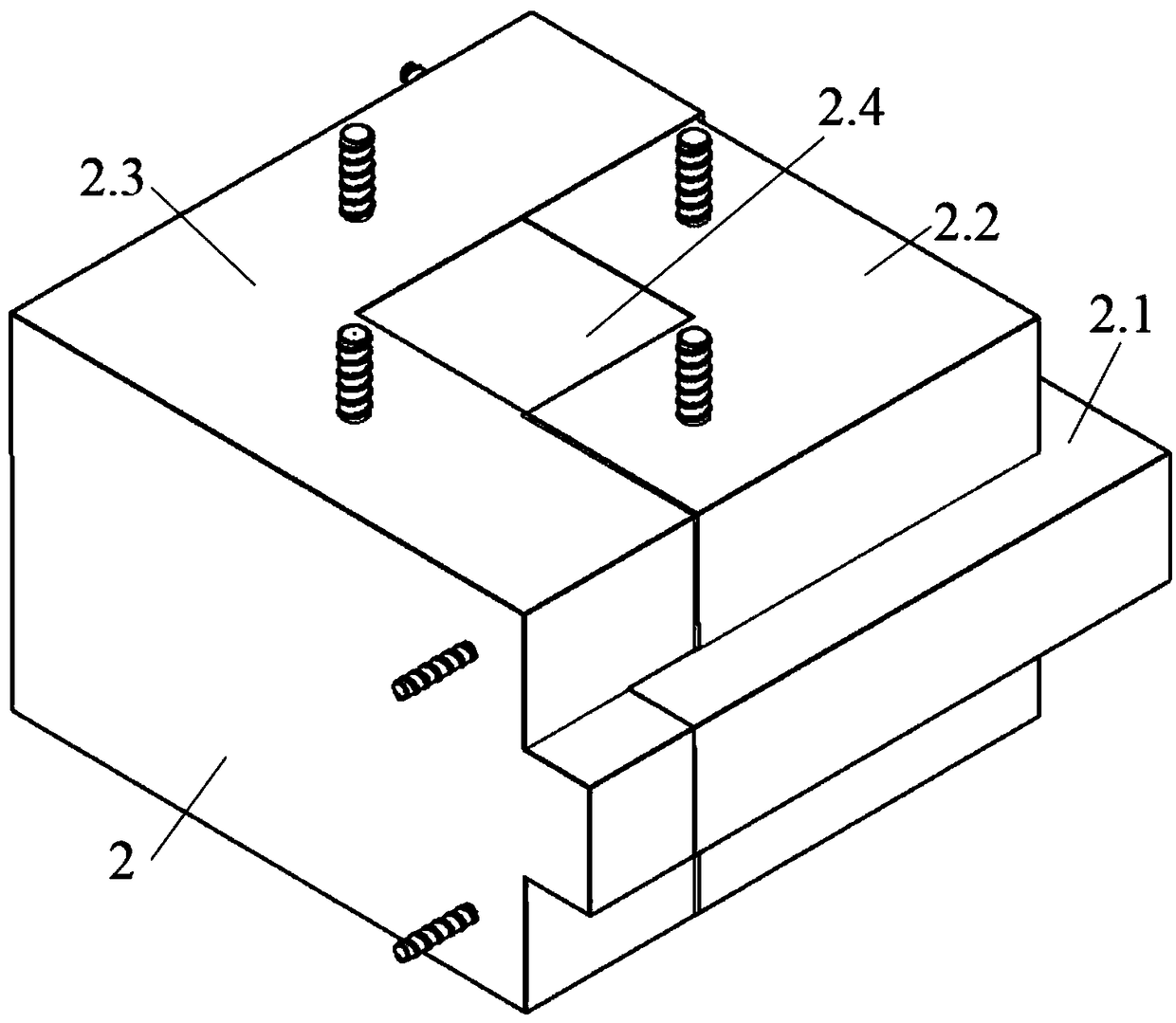

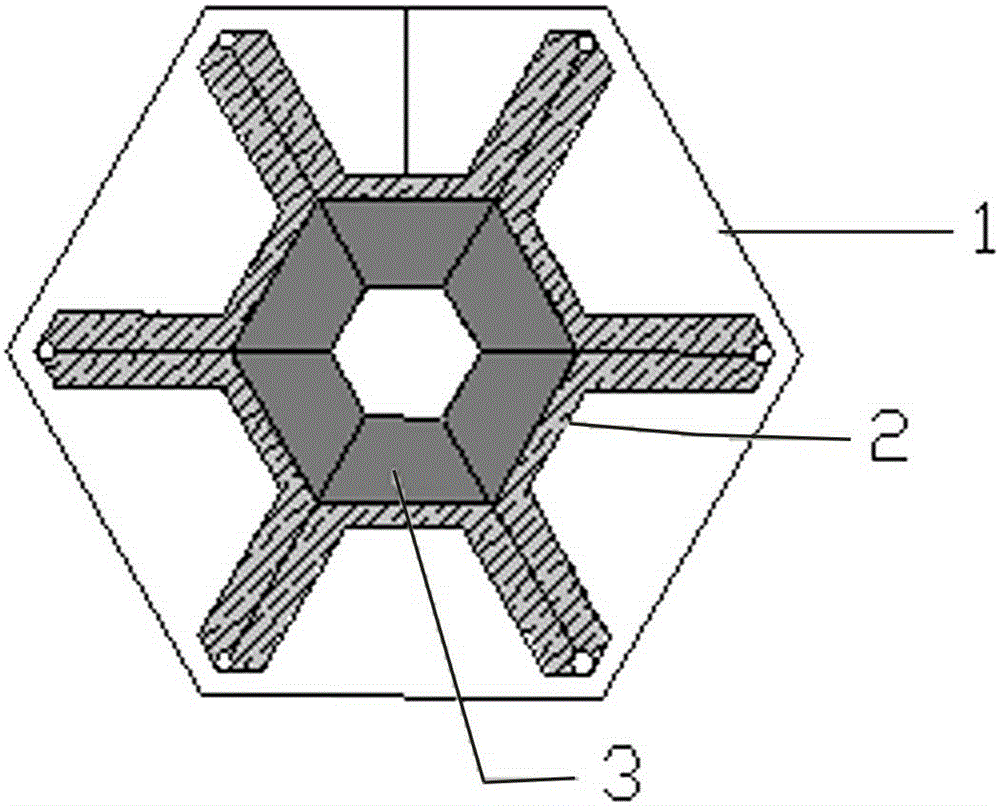

Assembly type power transmission line anchor rod static pressure miniature pile foundation and construction method thereof

ActiveCN108643219ASmall amount of workNo vibrationFoundation engineeringMaterial resourcesEngineering

The invention relates to an assembly type power transmission line anchor rod static pressure miniature pile foundation. The foundation comprises a first connecting main body and second connecting mainbodies, wherein the first connecting main body and the second connecting main bodies form a square bearing table, the first connecting main body is in a cross shape, and is formed by splicing the same four parts in a mutual embedding mode, the number of the second connecting main bodies is four, the four second connecting main bodies are distributed in a crossed grid of the first connecting mainbody and are spliced with the first connecting main body in a mutual embedding mode, each second connecting main body is in a concentric square shape and is formed by splicing two parts in a mutual embedding mode, and the two sides of each splicing joint between the side wall of the first connecting main body and the side wall of the corresponding second connecting main body are connected and fixed through a connecting steel plate, a pre-buried screw rod and a nut. All components of the assembly type power transmission line anchor rod static pressure miniature pile foundation with the design are prefabricated in factories and assembled on site, the construction is simple, convenient and fast, the influence on the environment is small, manpower and material resources are saved, and full-mechanical construction of the power transmission line foundation is realized.

Owner:HUAZHONG UNIV OF SCI & TECH +1

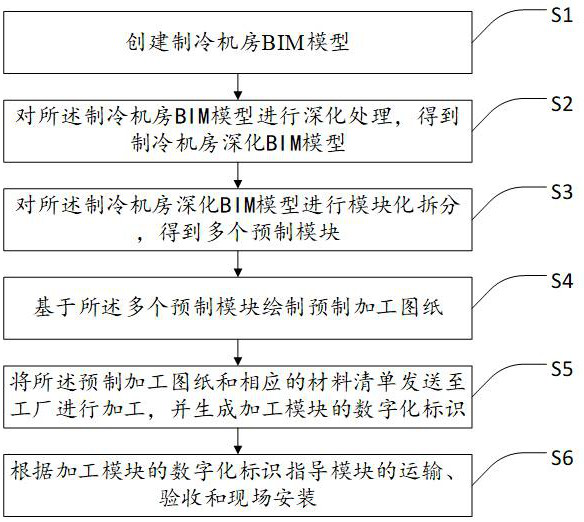

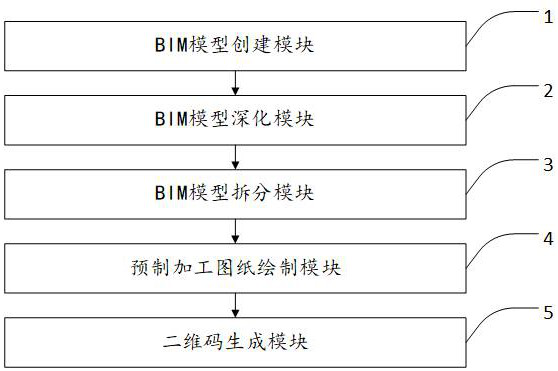

Prefabricated machine room assembly construction method and system based on BIM

PendingCN112651067AShorten the construction periodReduce productionGeometric CADDesign optimisation/simulationCode generationMachine

The invention discloses a prefabricated machine room assembly construction method and system based on BIM, and the method comprises the steps: building a refrigeration machine room BIM model, carrying out the deepening of the refrigeration machine room BIM model, obtaining a refrigeration machine room deepening BIM model, carrying out the modular splitting of the refrigeration machine room deepening BIM model, and obtaining a plurality of prefabricated modules; and drawing a prefabricated processing drawing based on the multiple prefabricated modules, sending the prefabricated processing drawing and the corresponding material list to a factory for processing, generating digital identifiers of the processing modules, and guiding transportation, acceptance and field installation of the modules according to the digital identifiers of the processing modules. The system comprises a BIM model creation module, a BIM model deepening module, a BIM model splitting module, a prefabricated processing drawing drawing module and a two-dimensional code generation module. By adopting a modular machine room assembly construction technology, the construction period of a machine room installation project can be effectively shortened, the field production efficiency and the construction quality are comprehensively improved, and theprefabricated machine room assembly construction method and system have important application value.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +1

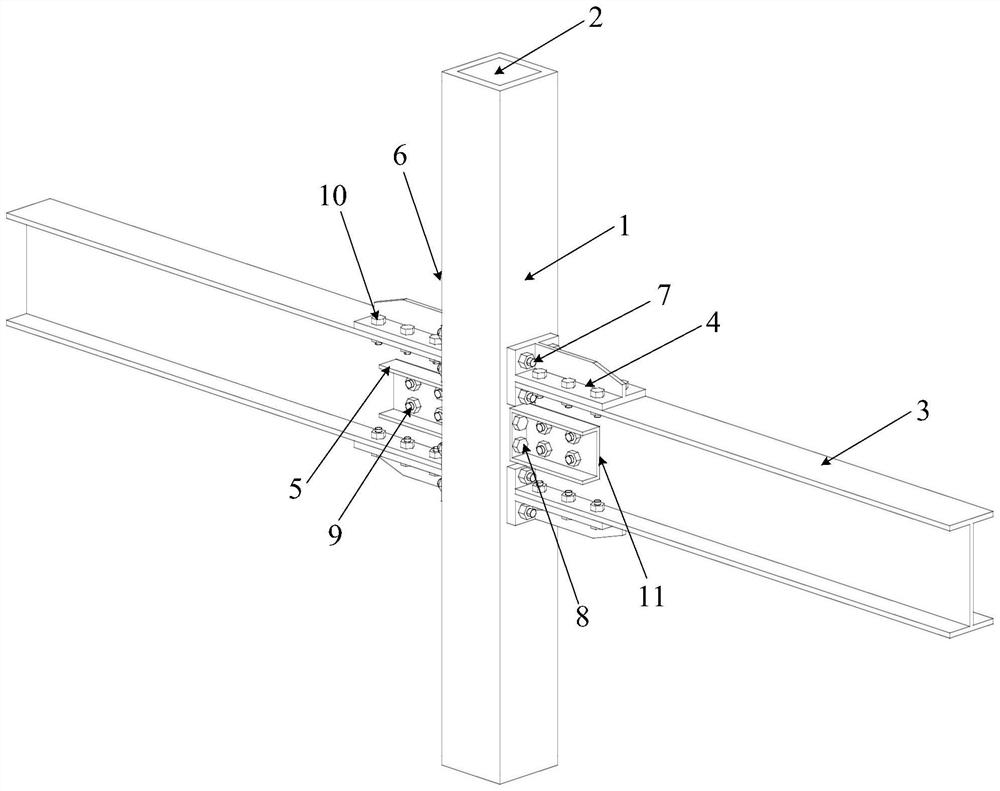

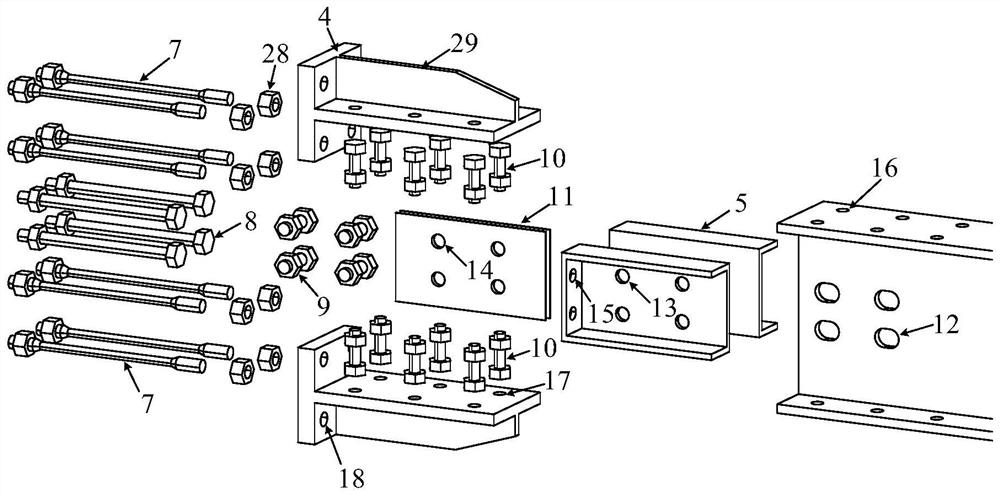

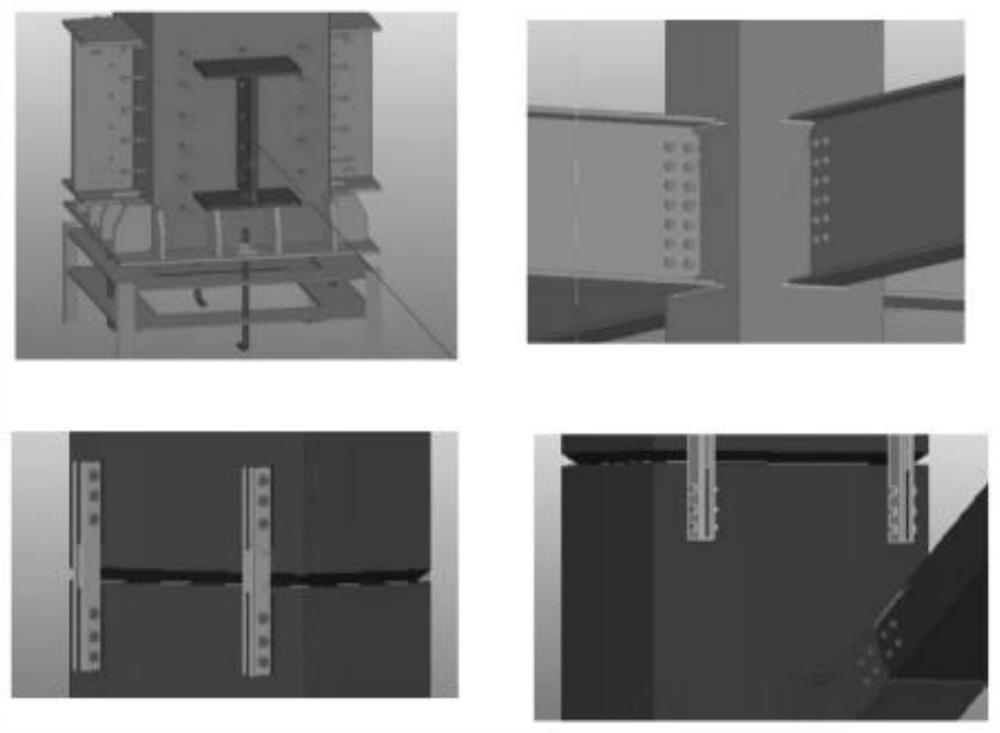

Self-resetting composite structure beam-column joint and construction method thereof

PendingCN114319590AEnsure self-resetting performanceThe node form is simpleBuilding material handlingAssembly (construction)Joint (building)

The invention discloses a self-resetting composite structure beam-column joint and a construction method thereof.The self-resetting composite structure beam-column joint comprises an I-shaped steel beam, T-shaped connecting pieces, friction components, a square steel tube concrete column and SMA screws, the I-shaped steel beam is horizontally arranged on the side edge of the square steel tube concrete column, and the T-shaped connecting pieces are symmetrically arranged on the outer side of the beam end of the I-shaped steel beam up and down; one end of the T-shaped connecting piece is fixed with a flange plate of the I-shaped steel beam through a third connecting bolt, and the other end of the T-shaped connecting piece is connected with the square steel tube concrete column through an SMA screw rod; the friction components are symmetrically arranged on the two sides of a web of the I-shaped steel beam, one end of each friction component is fixed to the side wall of the square steel tube concrete column through a first connecting bolt, and the other end of each friction component is connected with the web of the I-shaped steel beam through a second connecting bolt. According to the invention, the self-resetting capability is provided for the joint through the superelasticity of the SMA screw rod; friction components are used for providing good energy dissipation capacity, site welding is not needed in the joint assembly construction process, and the requirements for industrialization and assembly of a composite structure building are met.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Assembling and adjusting device and method thereof of F-shaped track panels

ActiveCN105525543APrecise positioningHigh precisionRailway track constructionEngineeringAssembly (construction)

Owner:SHANGHAI INSTALLATION ENG GRP

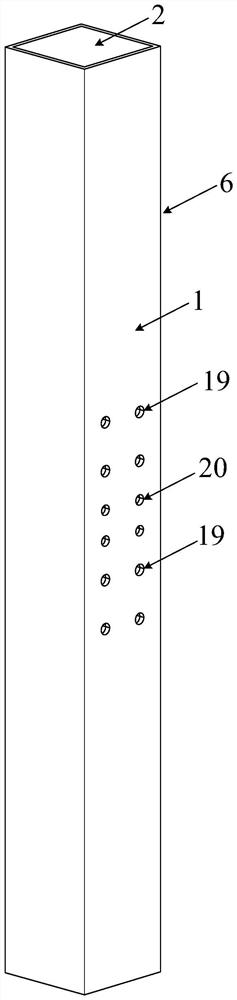

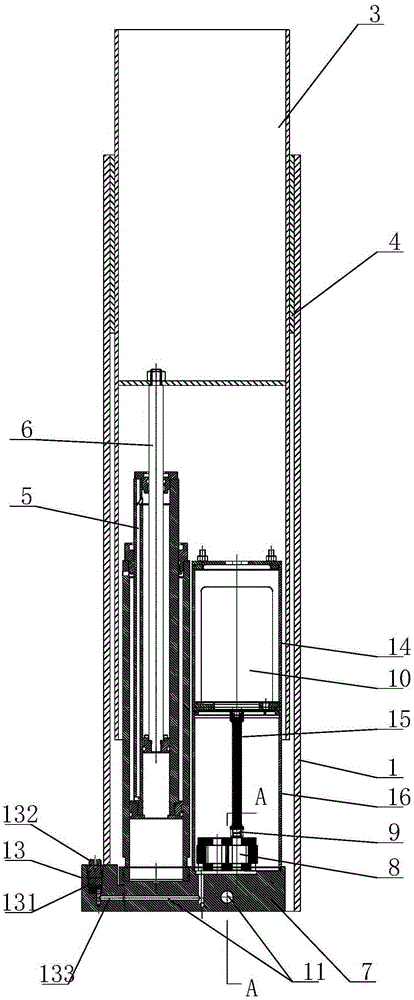

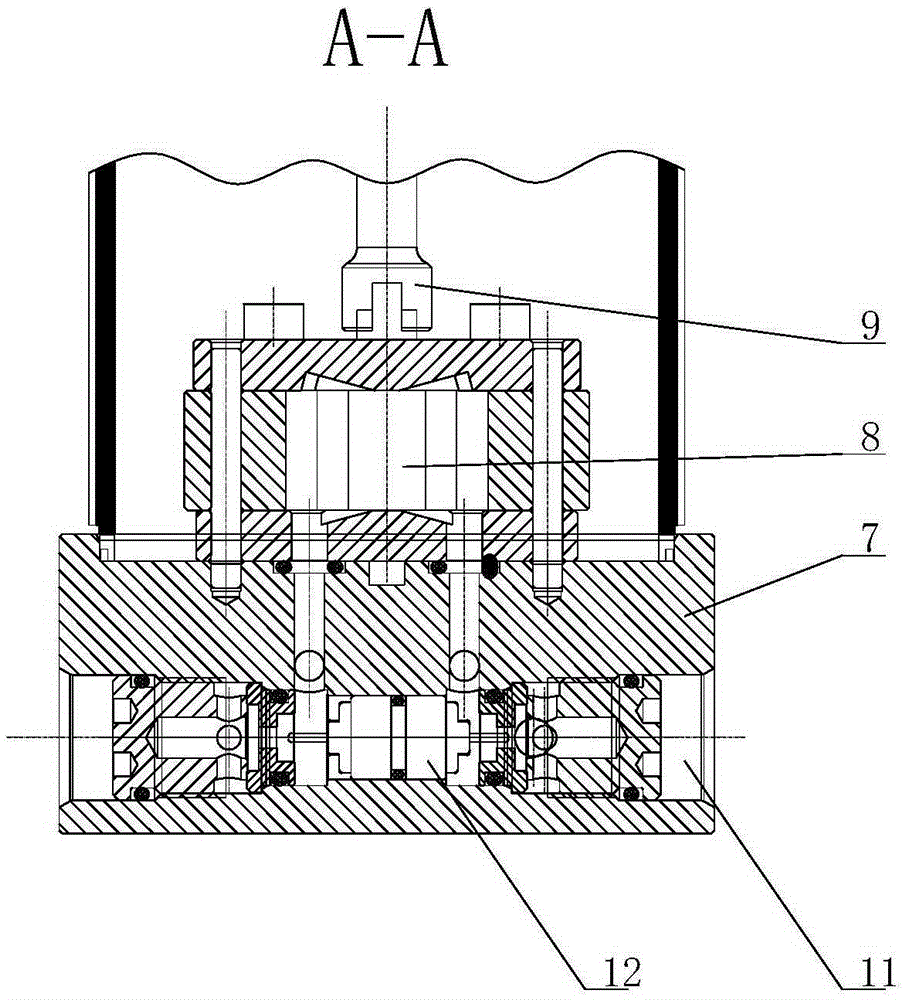

Integral hydraulic elevating road pile

ActiveCN105256737AReduce water seepageAvoid corrosion damageServomotor componentsServomotorsHydraulic cylinderCoupling

The invention relates to the technical field of elevating road piles and in particular relates to an integral hydraulic elevating road pile. The integral hydraulic elevating road pile comprises an external cylinder fixed underground. Over the external cylinder is provided a ground panel aligned to the construction ground; an internal cylinder accommodating an elevating road pile elevating cylinder is disposed in the external cylinder; the lower end of the elevating cylinder is connected with the upper end of a piston rod of a hydraulic cylinder; the lower end of the hydraulic cylinder is installed on a pedestal hydraulic pipeline module; the pedestal hydraulic pipeline module is further provided with a gear pump mechanism; the upper part of the gear pump mechanism is connected with a power output shaft of a motor via a coupler; the lower part of the gear pump mechanism is communicated with a hydraulic oil pipeline formed in the pedestal hydraulic pipeline module; a balance retaining vale is disposed in the hydraulic oil pipeline; one end of the hydraulic oil pipeline is communicated with a hydraulic cylinder communicated with one end of the gear pump mechanism. The integral hydraulic elevating road pile employs a modularized structure, thereby possessing convenient assembling and construction; and the hydraulic elevating road pile is integrally designed, thereby possessing great sealing property and prolonged service life.

Owner:山东金潮交通设施有限公司

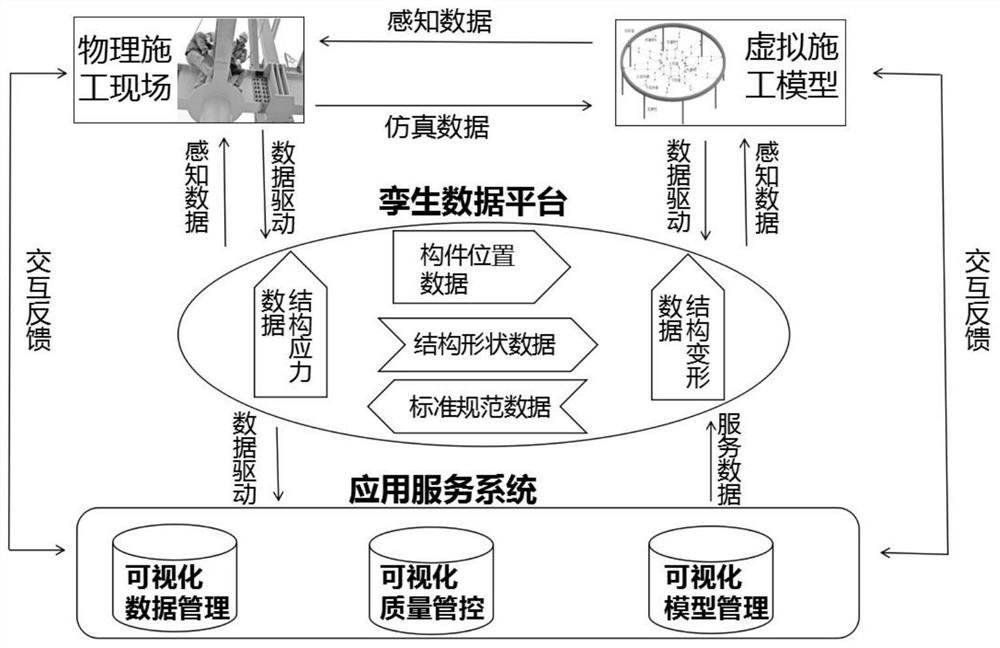

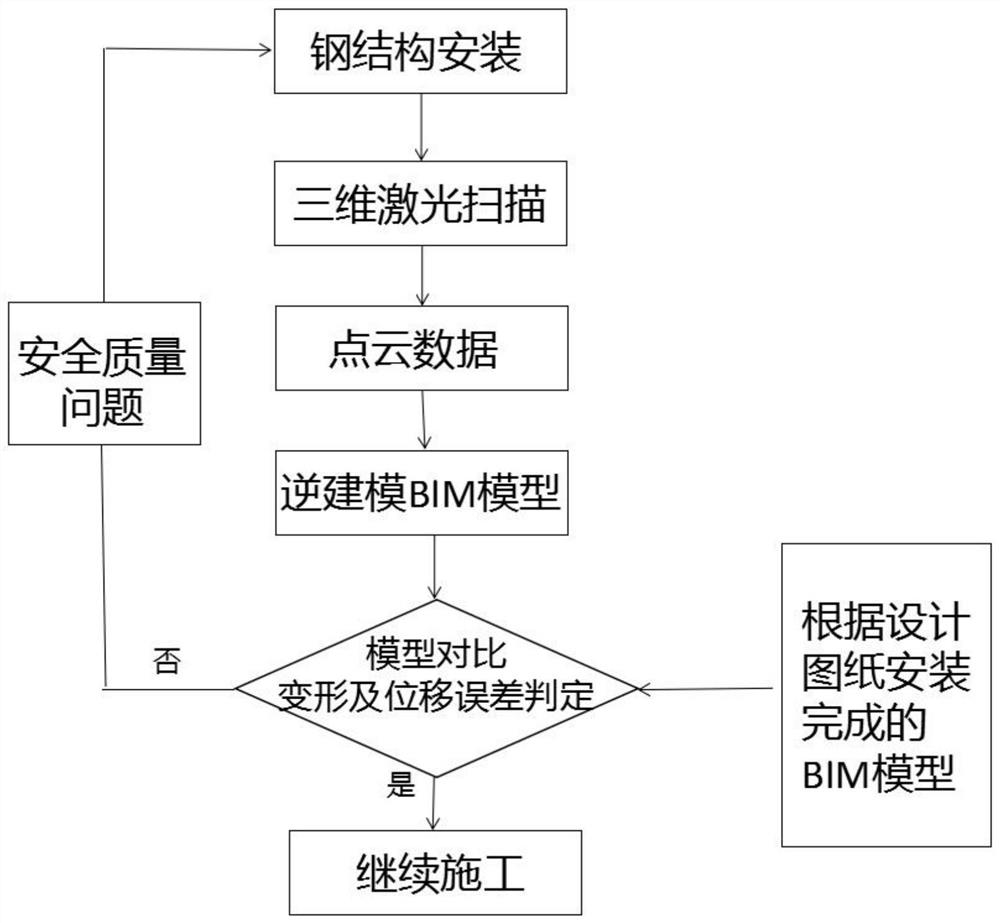

Intelligent steel structure installation method based on digital twin technology

ActiveCN111677294AImprove design efficiencyImprove the efficiency of technical disclosureOptically investigating flaws/contaminationBuilding material handlingLine sensorPoint cloud

The invention discloses an intelligent steel structure installation method based on digital twin technology. Before the steel structure is constructed, Revit is used for structural modeling to obtaina structure model. The structure model is imported into Ansys for mechanical performance analysis, and after the calculation is successful, detailed construction animation is made to complex nodes. The construction process is carried out by strictly following the model established by Revit, a 3D scanner will record each construction step in time to form point cloud data inverse modeling for comparison with the design model, and structural entities are adjusted to ensure that the construction is consistent with the design. After the assembling is completed, each connection node is equipped witha light sensor, and the construction quality problems can be checked in time through the data image of the sensors. In this way, from design to construction, each stage of monitoring realizes the mutual mapping of virtual reality to achieve a digital twin, which improves the quality and efficiency of construction. The intelligent steel structure installation method solves the problems such as poor assembly construction quality of complex steel structures and redundant node technology, and can be adapted to the installation of steel structure beams and columns.

Owner:BEIJING UNIV OF TECH

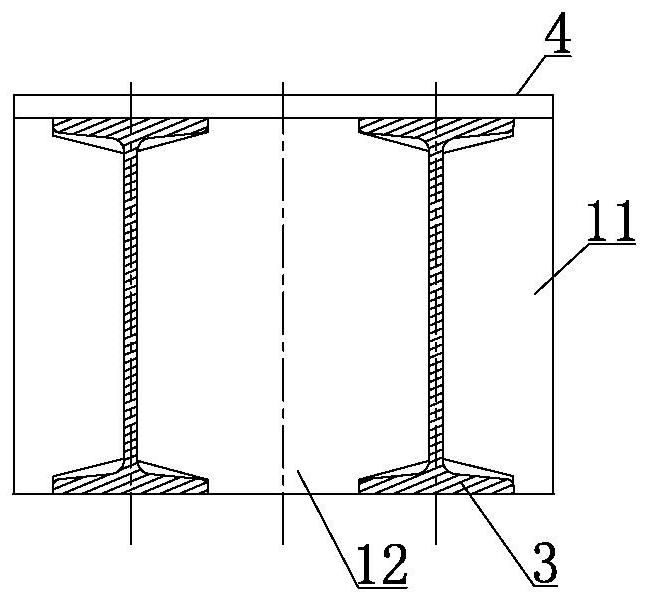

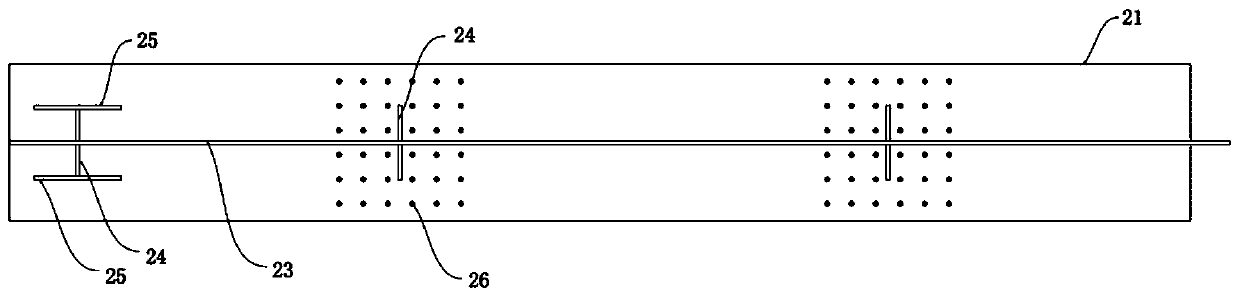

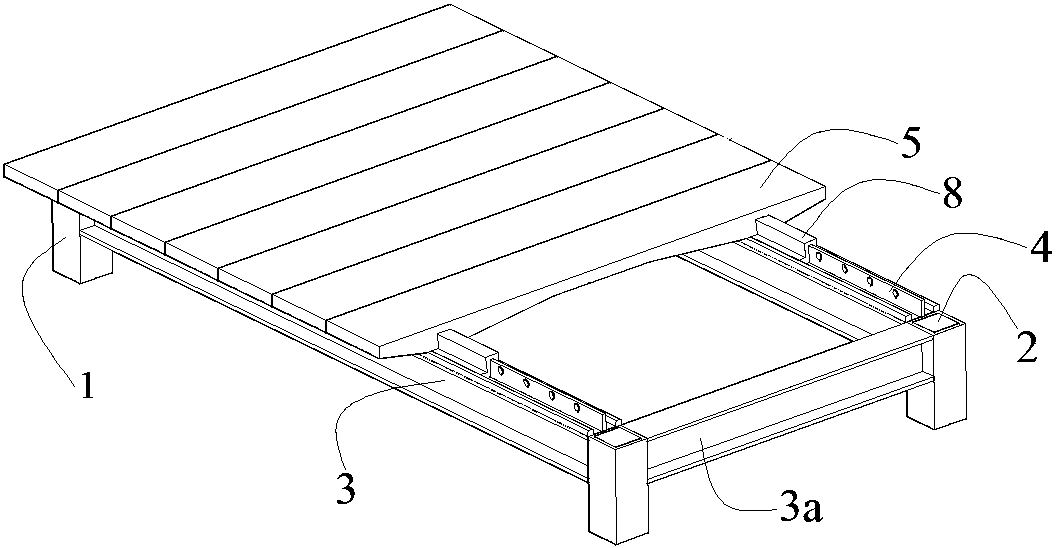

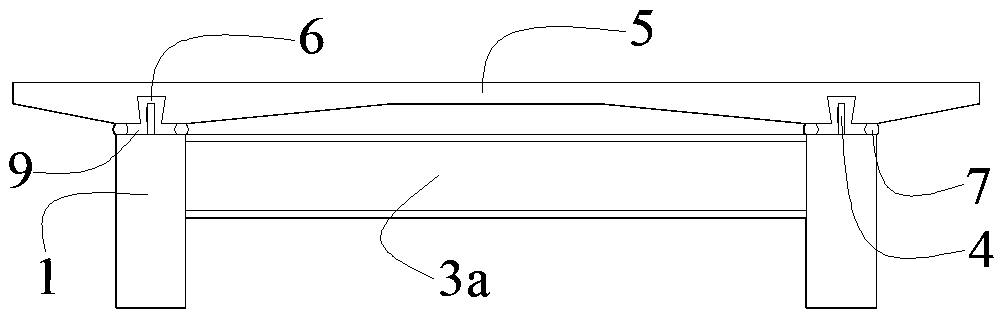

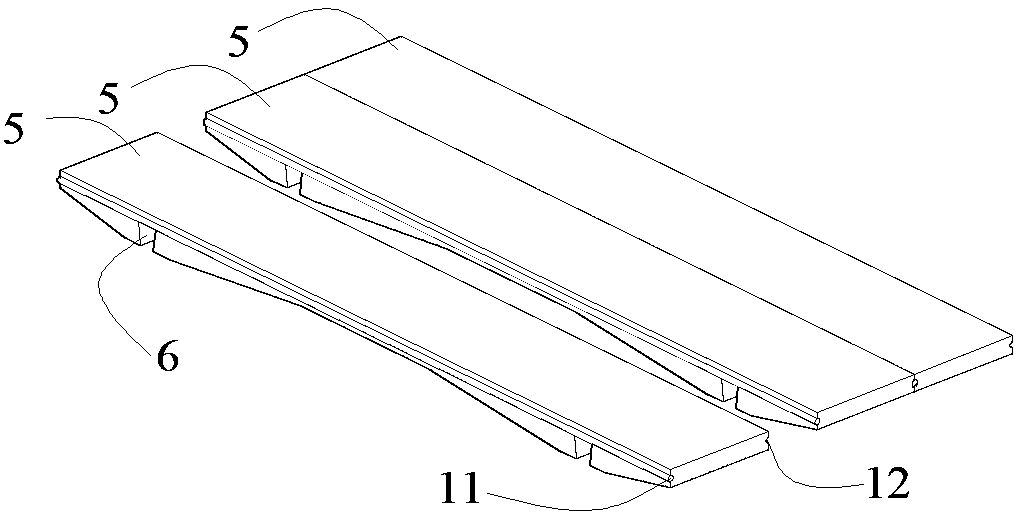

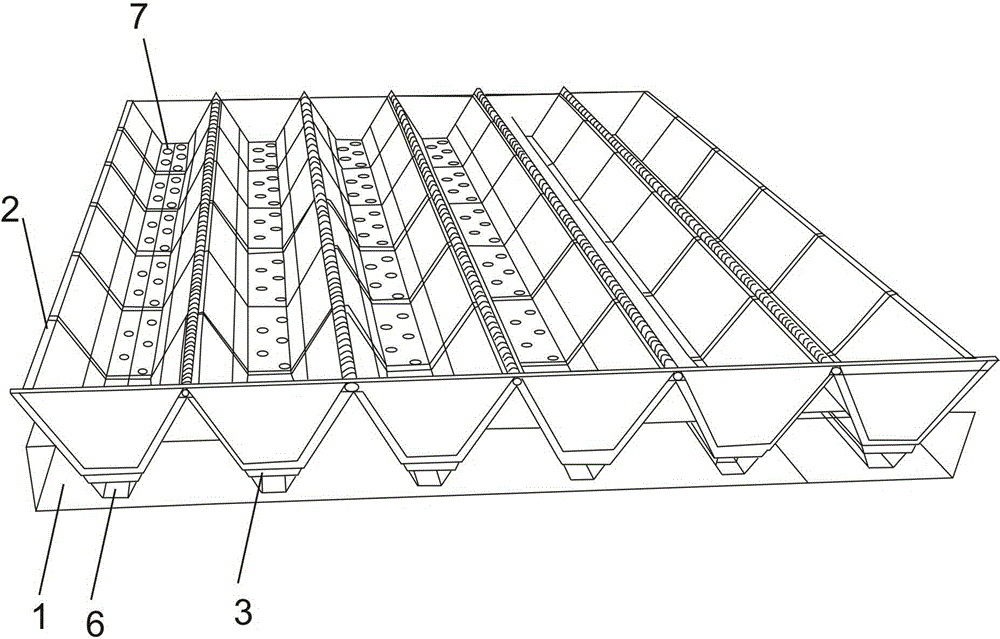

Prefabricated steel and concrete composite floor adopting self-locking connection and installation method

The invention relates to a prefabricated steel and concrete composite floor adopting self-locking connection and an installation method. The prefabricated steel and concrete composite floor comprisesa frame foundation, an H-shaped steel beam and prefabricated reinforced concrete panels. The H-shaped steel beam is composed of transverse beams and longitudinal beams, and upper flange plates of thelongitudinal beams are fixedly connected with rib plates. Channels matched with the rib plates are formed in the prefabricated reinforced concrete panels, and the bottom surfaces of the prefabricatedreinforced concrete panels, the upper flange plates of the longitudinal beams and the channels are filled with no-shrink self-compacting high-strength concrete filler. The installation method comprises the steps that firstly the frame foundation and the H-shaped steel beam are installed, and the rib plates are laid above the H-shaped steel beam; and then a rubber sealing material is bonded on theedges of the upper flange plates of the longitudinal beams, and the rib plates are just clamped into the channels by lifting the prefabricated reinforced concrete panels; and finally the non-shrink self-compacting high-strength concrete filler is subjected to pressure grouting through a slurry inlet. According to the prefabricated steel and concrete composite floor adopting the self-locking connection and the installation method, the connection strength is high, the assembly construction efficiency is high, and the problems of corrosion of connecting pieces and cracking of concrete and the like can be effectively solved.

Owner:NANJING HYDRAULIC RES INST

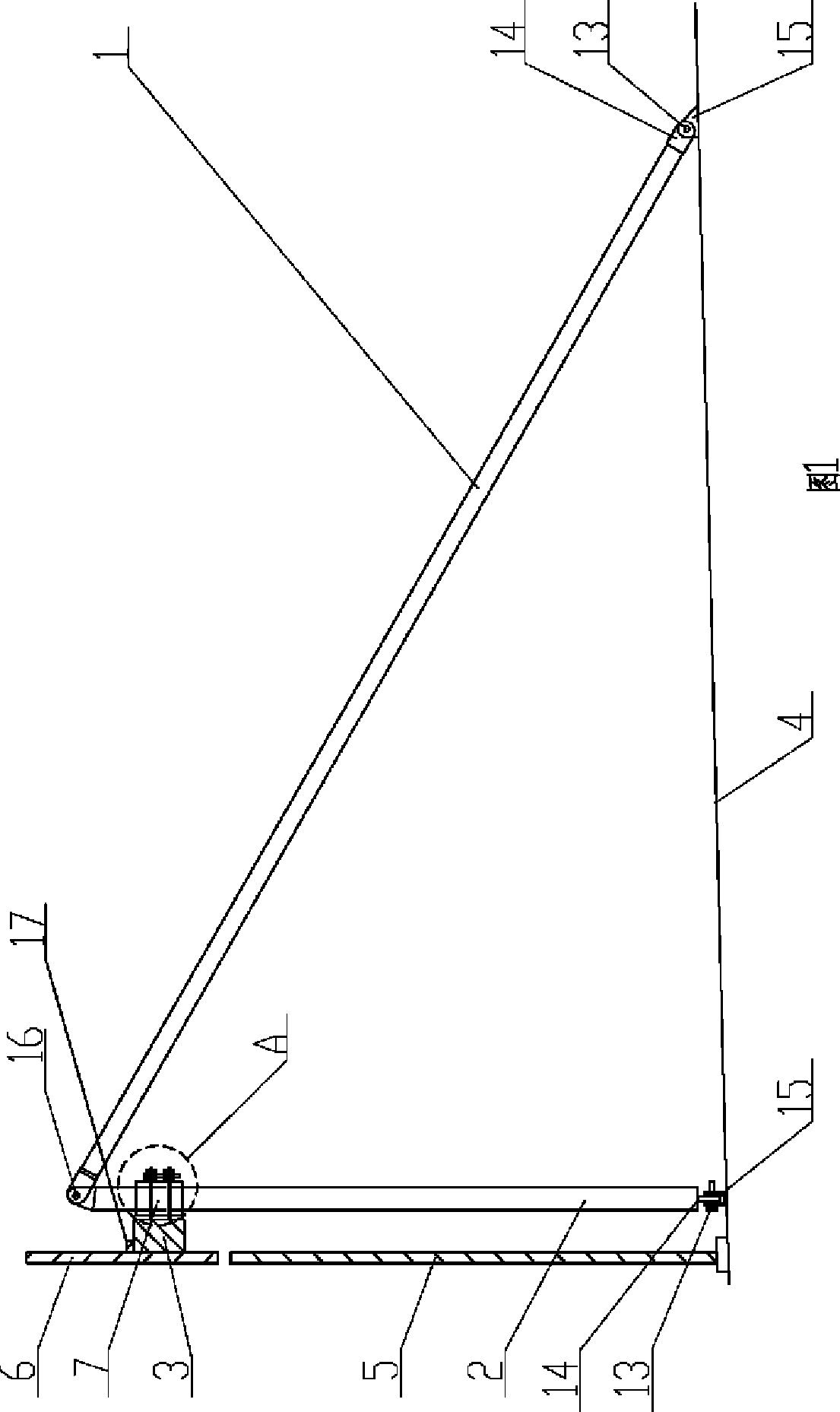

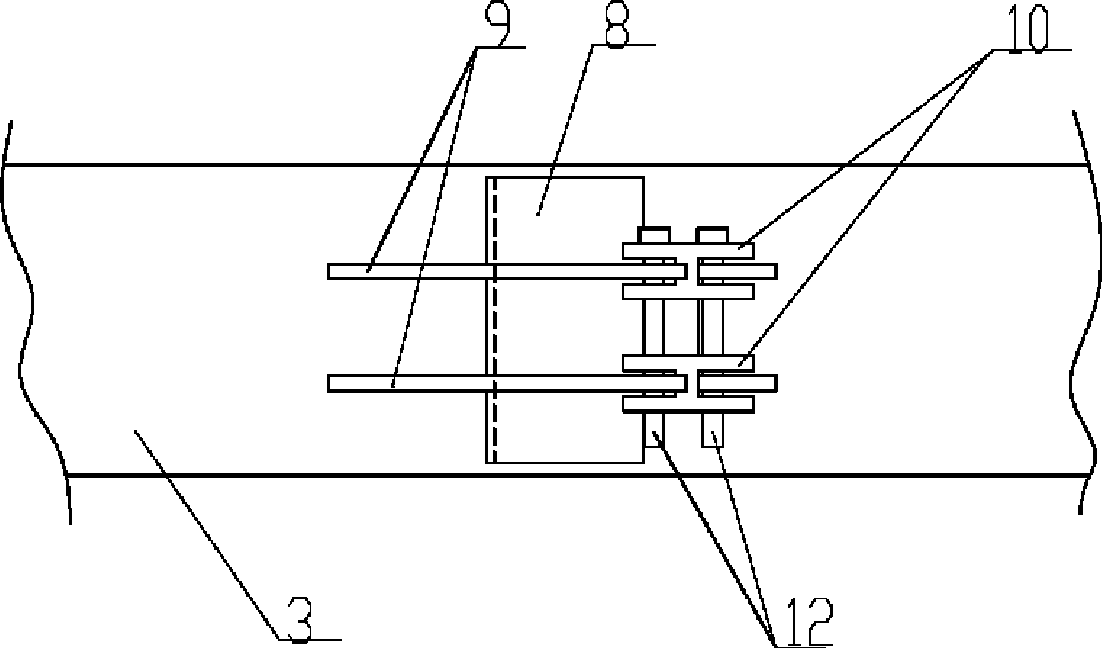

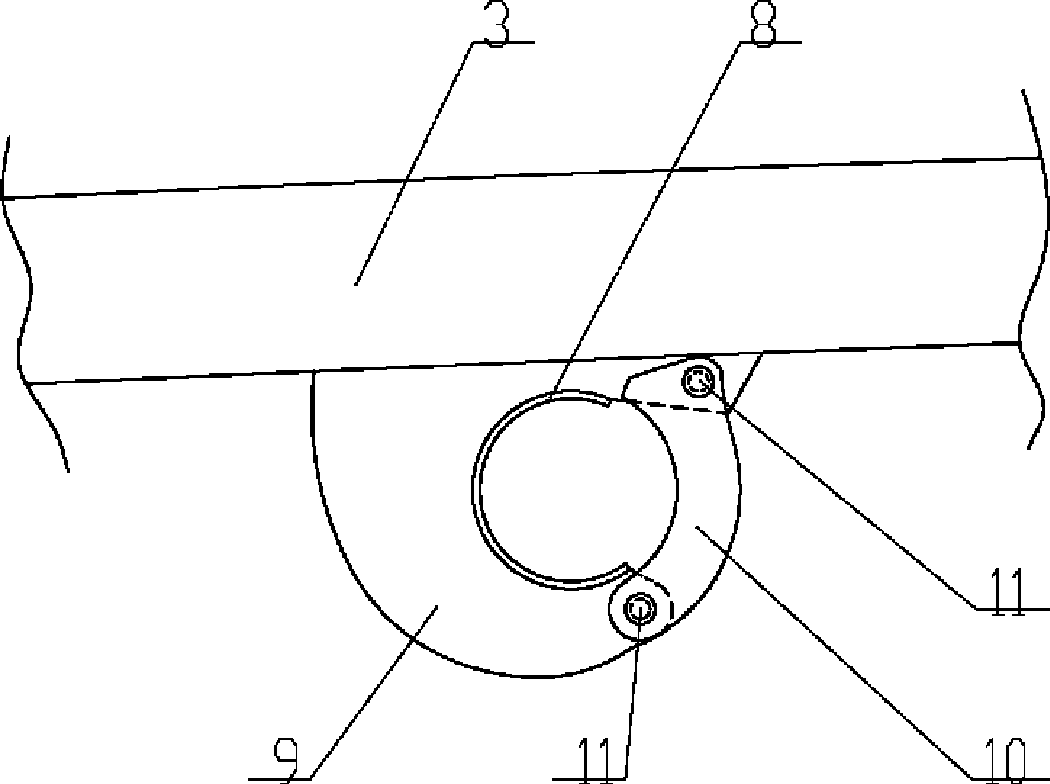

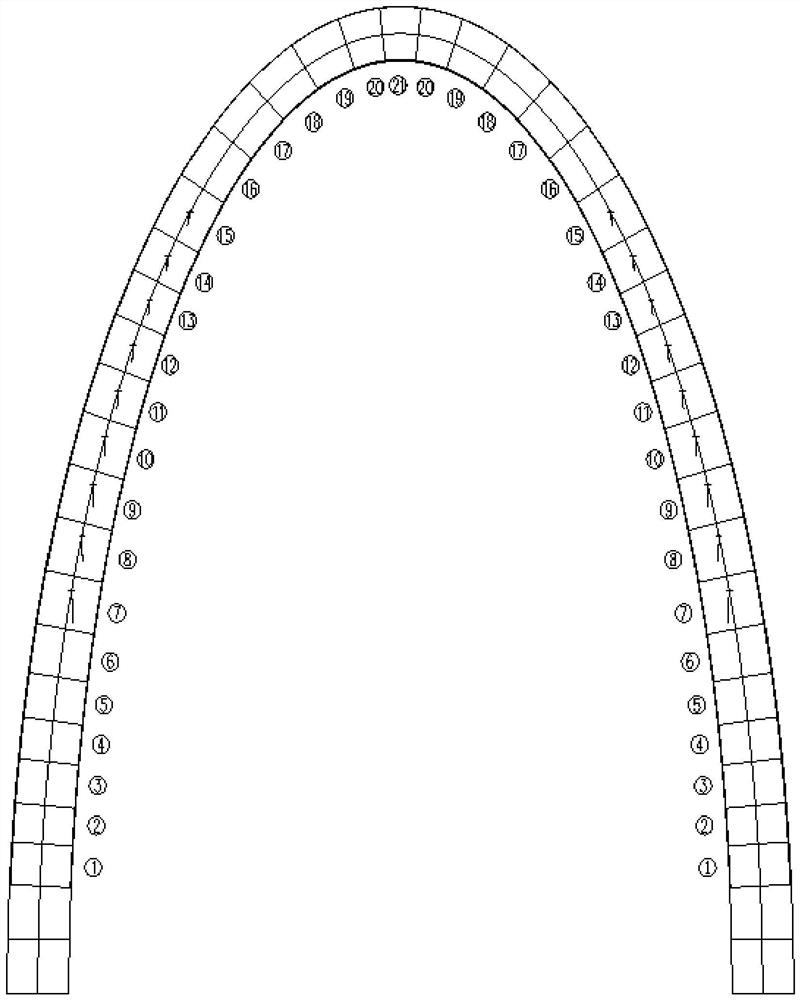

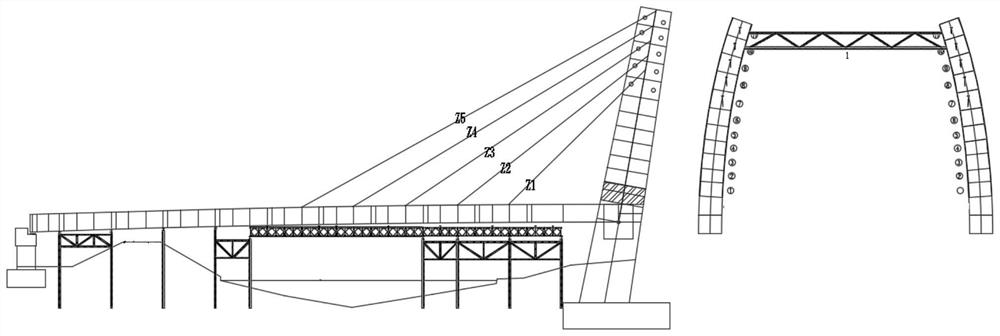

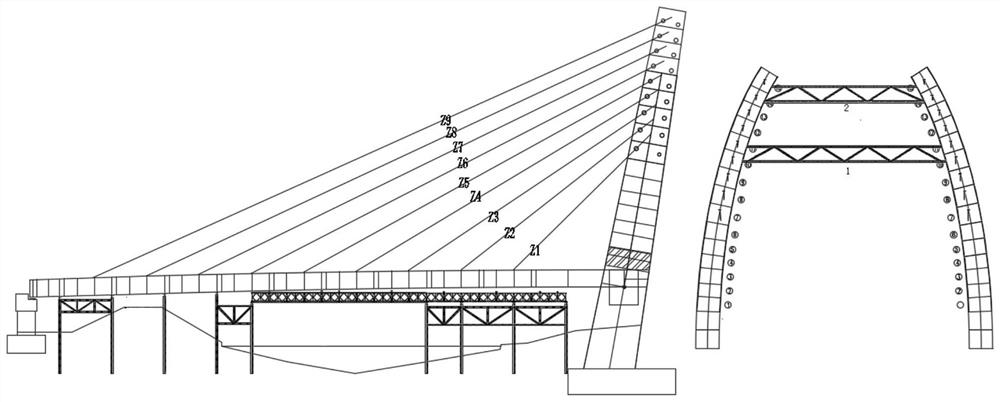

Small-angle inclined steel arch tower support-free in-situ assembly type asymmetric tensioning assembly construction method

ActiveCN111945569ASmall amount of workGuaranteed normal passageBridge structural detailsBridge erection/assemblyArchitectural engineeringTower

The invention discloses a small-angle inclined steel arch tower support-free in-situ assembly type asymmetric tensioning assembly construction method, which is characterized in that a traditional support method erection process is changed into a support-free assembly process in a bridge steel arch tower erection construction stage, and the quality of a steel arch tower is controllable; in addition, the construction difficulty is reduced, the work amount of auxiliary measures such as hoisting equipment, temporary supports and assembly sites is reduced, the construction period is shortened, thecost is reduced, passage of a navigation channel is guaranteed, and operation is convenient. The invention provides a small-angle inclined steel arch tower support-free in-situ assembly type asymmetric tensioning assembly construction method, which realizes factory manufacturing, transportation, hoisting and positioning of the steel arch tower, and solves the construction problems of limited bridge construction operation space, tight construction period and crossing of rivers with navigation requirements.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

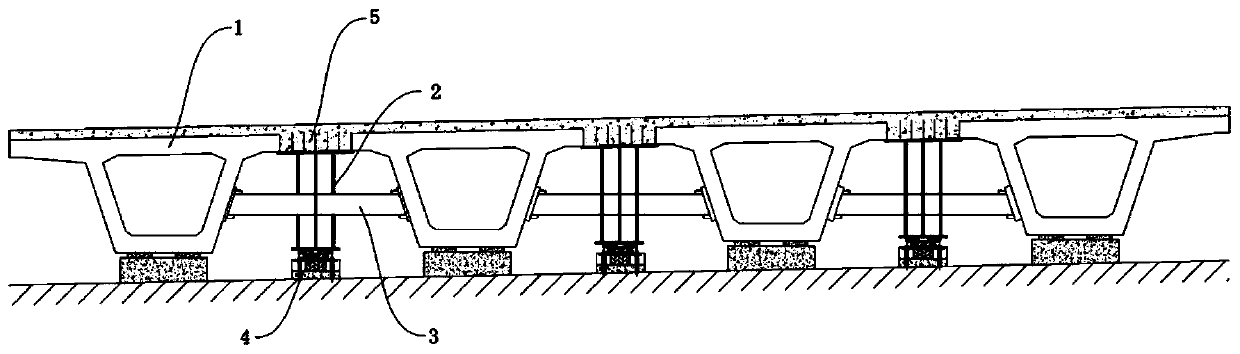

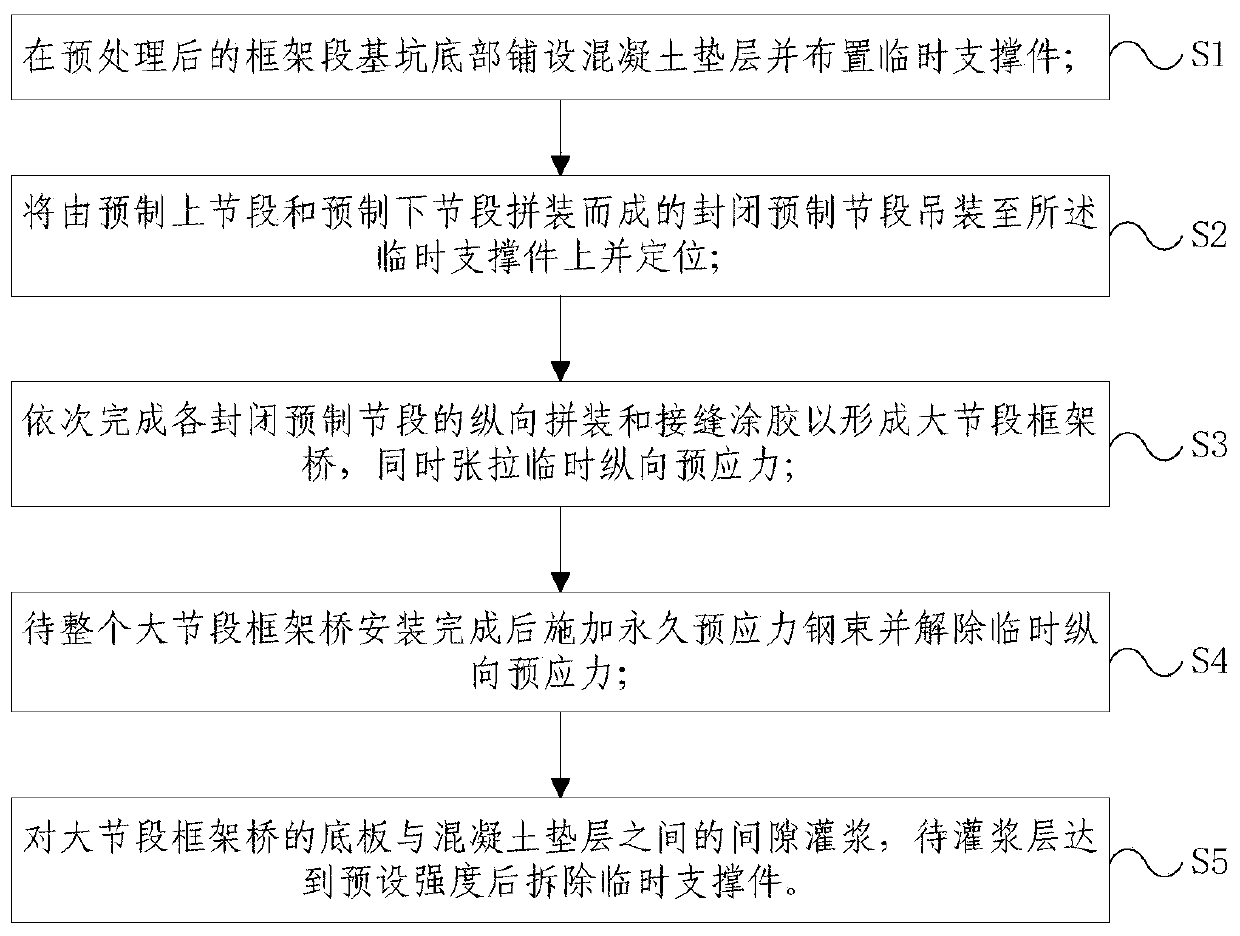

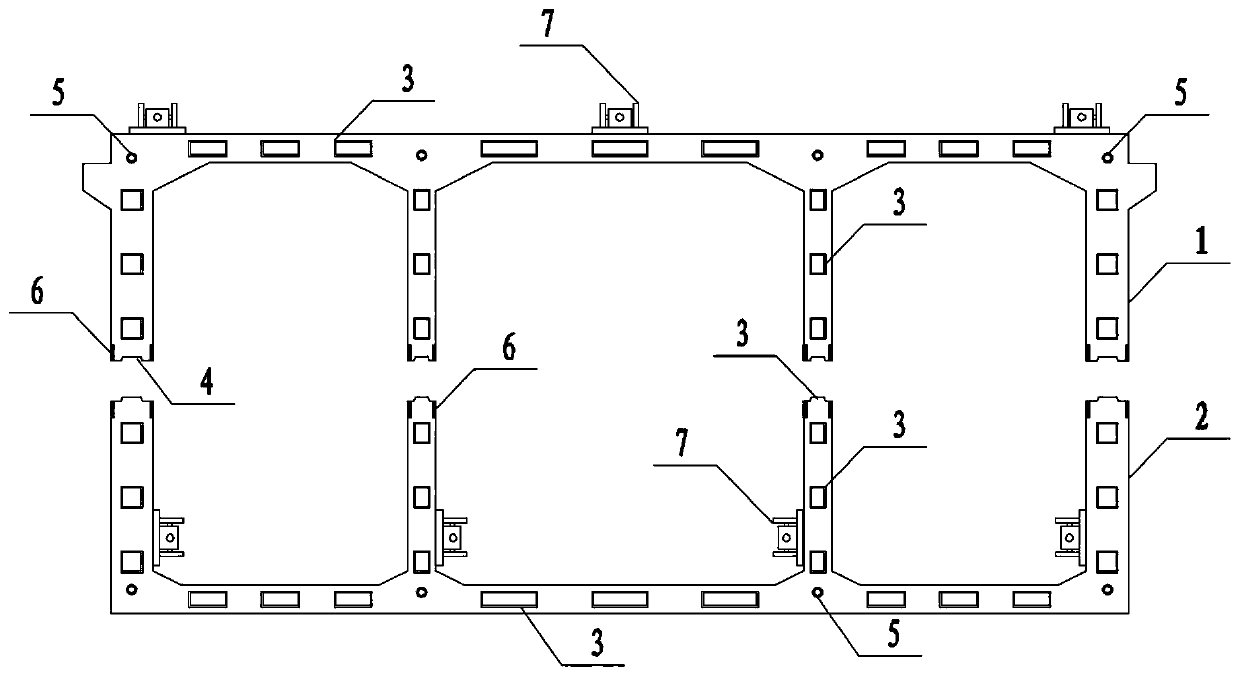

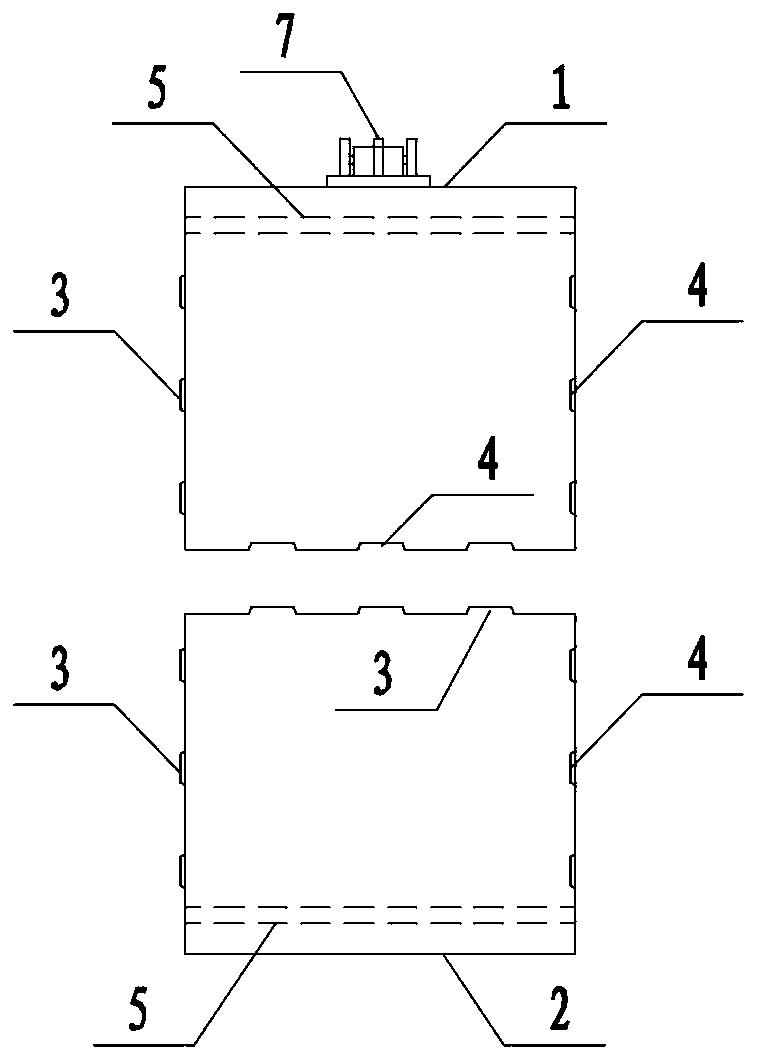

Porous frame bridge and assembly construction method thereof

InactiveCN110747903AReduce distractionsImprove construction progressArtificial islandsUnderwater structuresSocial benefitsReinforced concrete

The invention relates to the technical field of underground traffic engineering construction, and provides a porous frame bridge and an assembly construction method thereof. Block factory prefabrication is adopted, and synchronously conducted with excavation of a foundation pit. First, after upper and lower segments of a single prefabricated segment are assembled to form closed prefabricated segments, a large-segment frame bridge is formed by multi-direction longitudinal splicing of the multiple closed prefabricated segments, and longitudinal prestress is stretched; and in the splicing formingprocess of the whole large-segment frame bridge, site formwork erection, steel bar binding, concrete pouring and other processes are not needed, the construction progress is greatly accelerated, theinterference of construction vehicles and machines and tools on surrounding traffic is reduced to the maximum extent, dust and noise pollution to surrounding areas is lowered, and great economic and social benefits are achieved.

Owner:湖北建科国际工程有限公司

Rolling and spreading type roof greening structure and greening method thereof

ActiveCN105145165AEasy to storeEasy to transportCultivating equipmentsReceptacle cultivationIsosceles trapezoidWhole body

The invention provides a rolling and spreading type roof greening structure comprising a supporting base plate, a planting base groove and a root isolating plate, which are capable of being rolled and spread, wherein the supporting base plate consists of five base plate units and connecting units which are respectively positioned at two sides of a whole body composed of the five base plates; each base plate unit and each connecting unit are strip-shaped; the cross section of each base plate unit is in the shape of an isosceles trapezoid; the cross section of each connecting unit is in the shape of a right angle trapezoid; after right-angle sides of two connecting units are spliced, the cross section is consistent with that of each base plate unit; each base plate unit and each connecting unit are connected with each other to form a foldable whole body; and multiple vacancy grooves are formed between the five base plate units and the two connecting units. By adopting the rolling and spreading type roof greening structure and a greening method thereof provided by the invention, the problems of large occupied space and complex construction process can be solved, the structure is small in occupied space, is convenient to transport, and is convenient in assembly construction; and the roof greening construction efficiency and the greening effect are greatly improved.

Owner:CHINA THREE GORGES UNIV +2

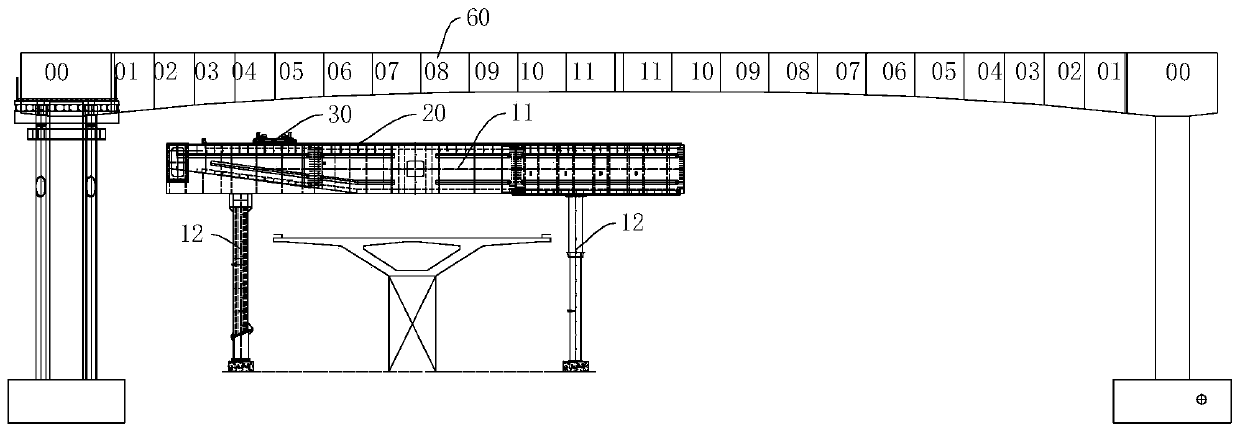

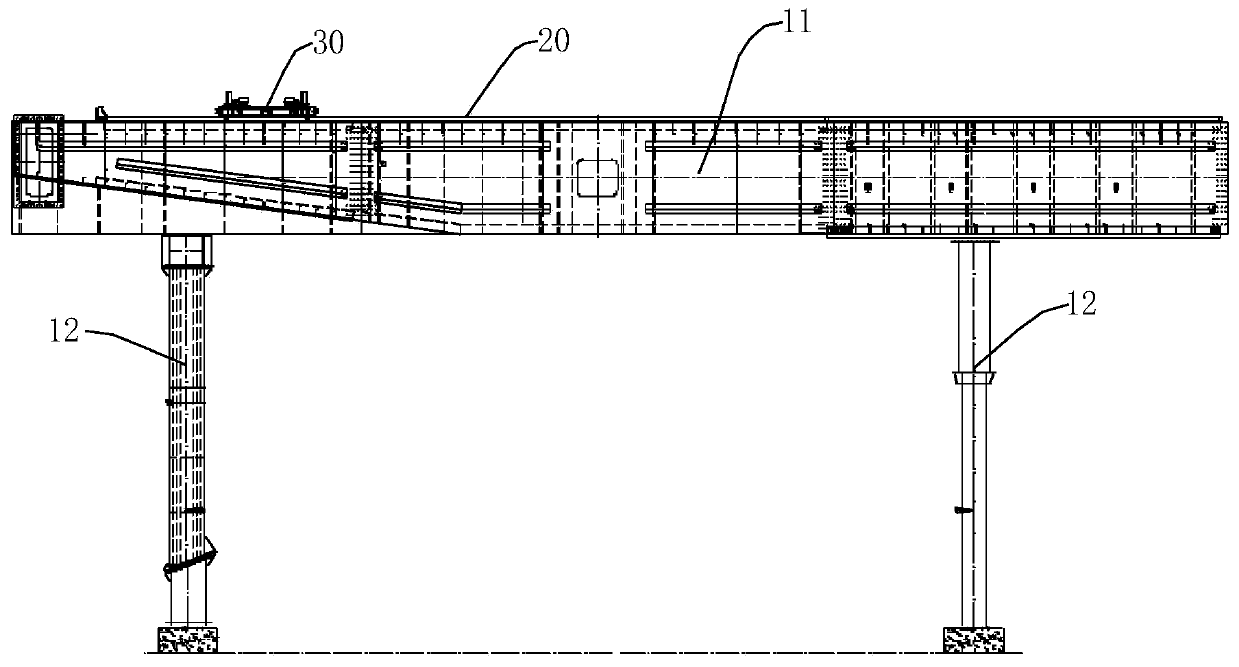

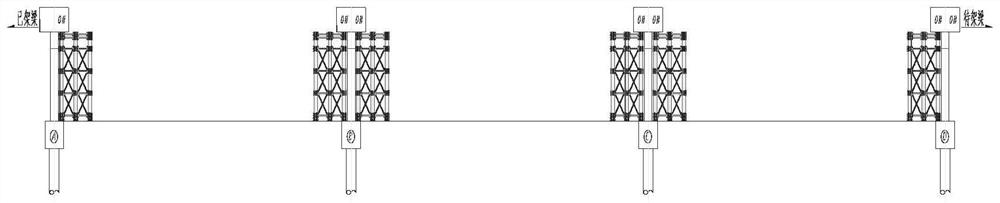

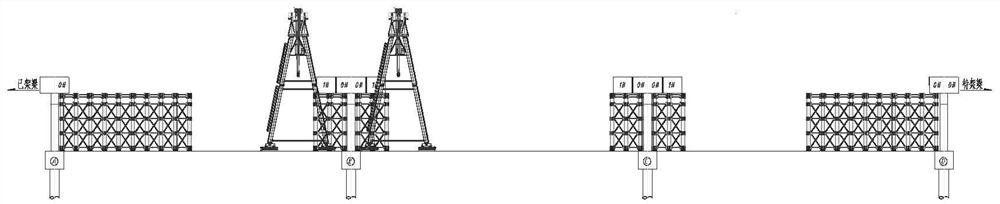

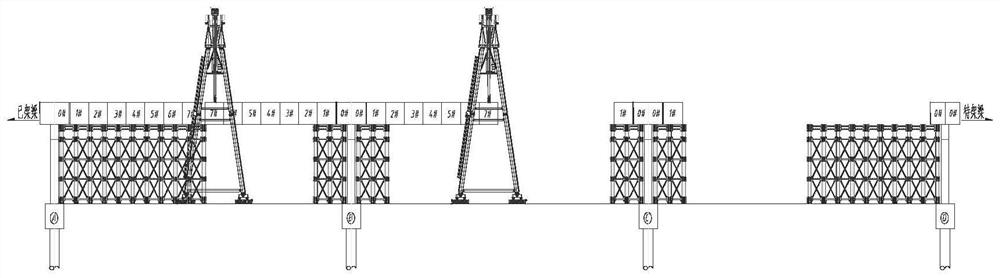

100t span pier gantry crane assembly type segmental beam assembly construction method

PendingCN114438896ALow usage feeImprove construction periodBridge erection/assemblyBridge materialsArchitectural engineeringMechanical equipment

The invention discloses a 100t cross-pier gantry crane assembly type segmental beam assembly construction method which is used for a municipal rapid engineering viaduct, according to the method, two 100t cross-pier gantry cranes are adopted for symmetrical cantilever assembly construction in prefabricated segmental beam assembly, operation is convenient, safety and reliability are achieved, the construction progress is high, the gantry cranes serve as beam erecting equipment, and the construction efficiency is high. Meanwhile, the device can also be used as middle transfer equipment for unloading and storing beams, and the universality of the device is well played in narrow sites of municipal bridge construction; and the use cost of beam unloading and storing mechanical equipment is reduced, and the construction period of staged beam erection is shortened.

Owner:中铁二十一局集团路桥工程有限公司

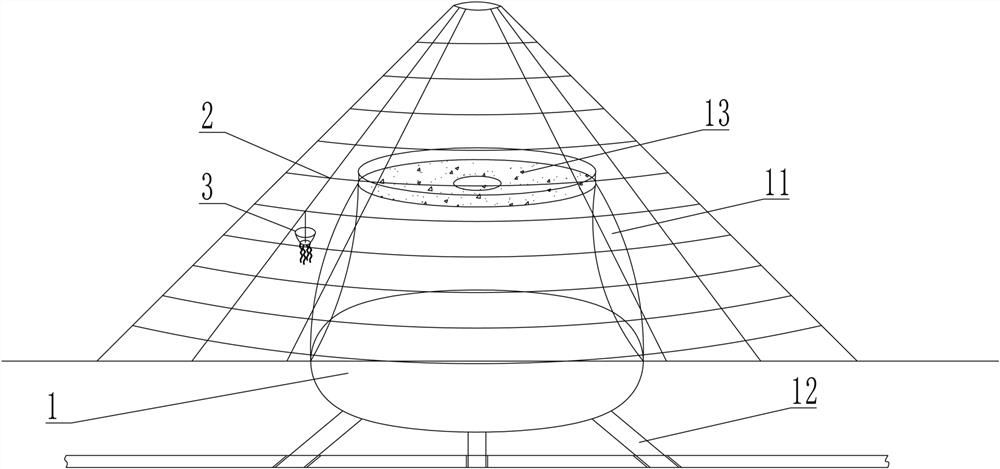

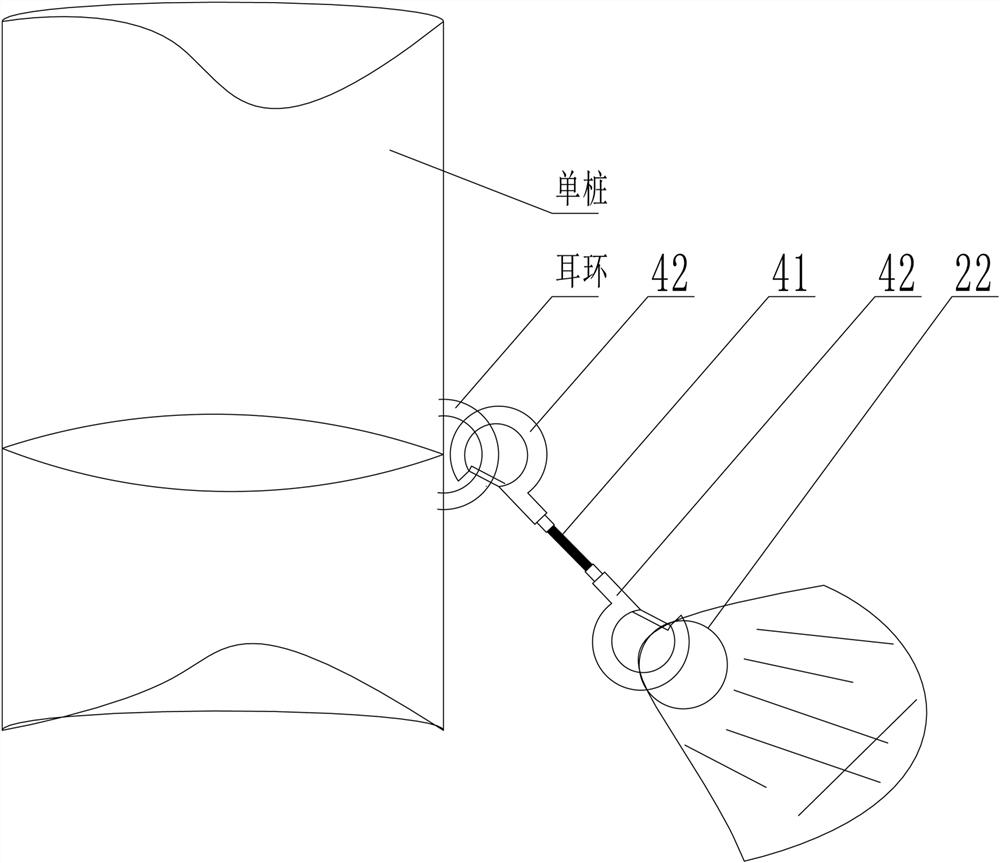

Rapidly-assembled and anti-scouring combined type offshore wind power foundation and method

ActiveCN112942405AQuick assemblyReduced stabilityWind motor supports/mountsFoundation engineeringOffshore wind powerAssembly (construction)

The invention relates to a rapidly-assembled and anti-scouring combined type offshore wind power foundation and a method. The rapidly-assembled and anti-scouring combined offshore wind power foundation comprises a foundation main body, an anti-scouring filter screen, a turbulent flow device and a connecting piece; the foundation main body is sleeved with the anti-scouring filter screen; supporting legs of the foundation main body are connected with a bottom plate of the anti-scouring filter screen; a single pile is connected with a cover plate at the upper end of the foundation main body; an inclined steel cable at the bottom of the anti-scouring filter screen is connected with the bottom plate and connected with a retaining ring at the upper end of the anti-scouring filter screen and a lug ring on the single pile through the two ends of the connecting piece respectively; and the turbulent flow device is connected with a node of the conical anti-scouring filter screen in a tightened state, overhangs in the anti-scouring filter screen and sinks into the bottom plate in a seabed rock hole through the foundation main body to make contact with the bottom of the hole. The problems that an original wind power single pile foundation is relatively low in protection performance and stability, long in construction period and high in cost are solved, and the combined type offshore wind power foundation has the advantages of being simple in structure, high in structural strength, good in stability, good in protection performance, capable of being rapidly assembled, short in construction period, easy and convenient to operate and low in maintenance cost.

Owner:CHINA THREE GORGES CORPORATION

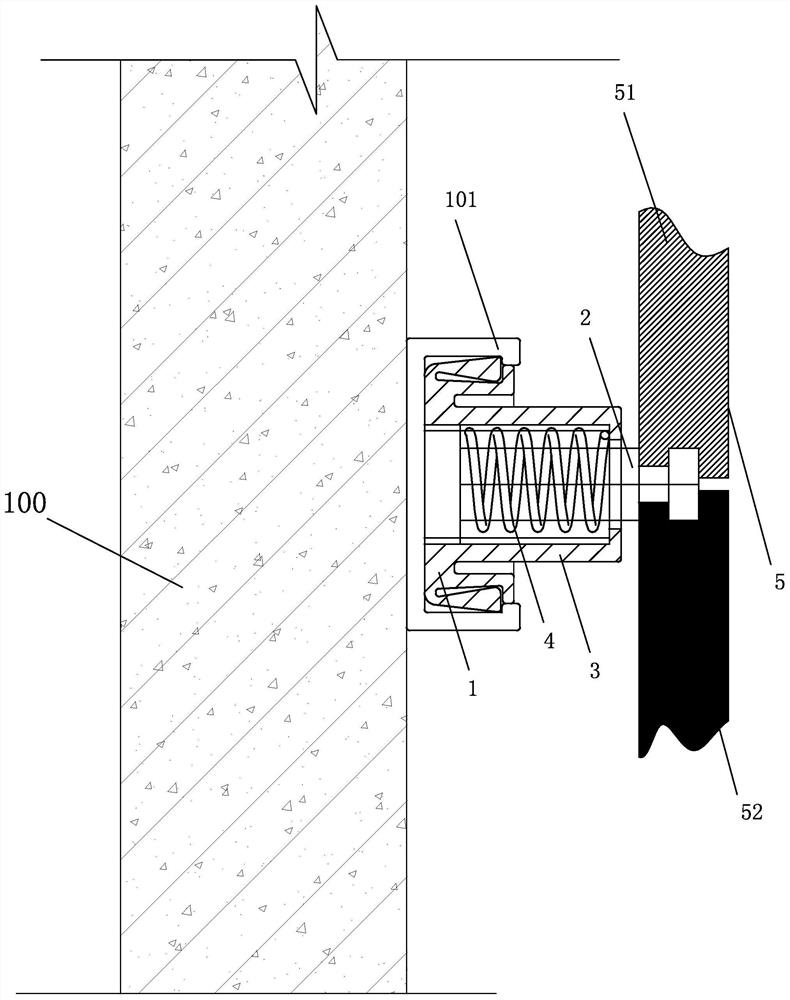

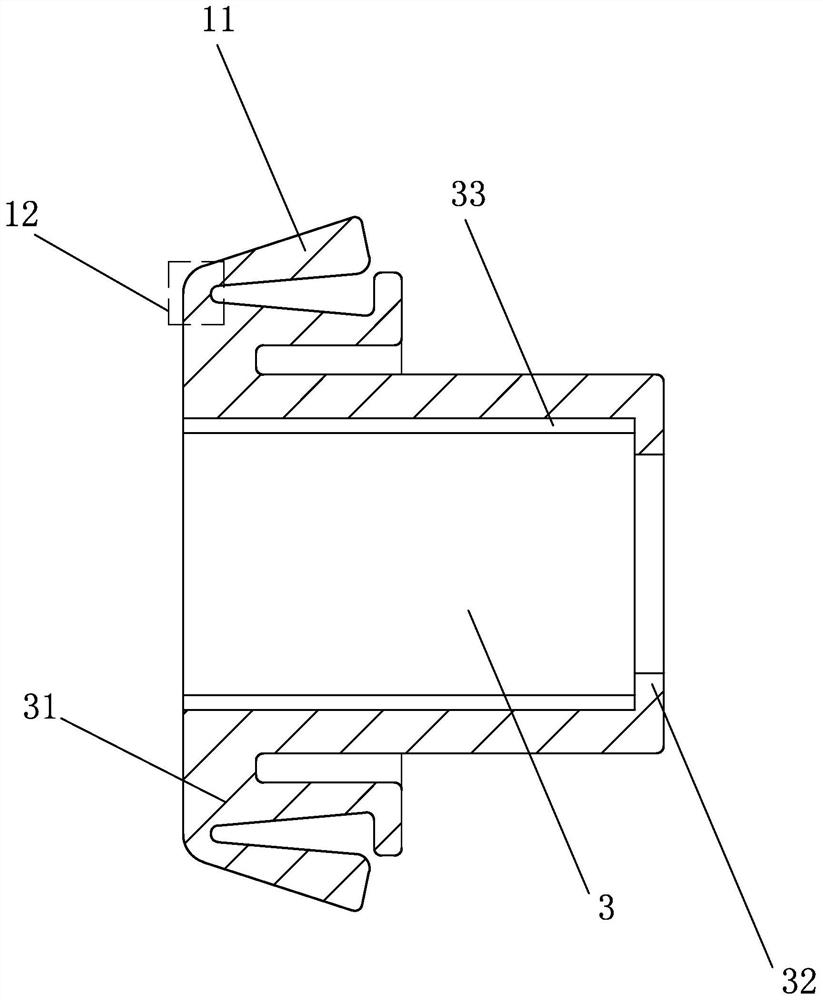

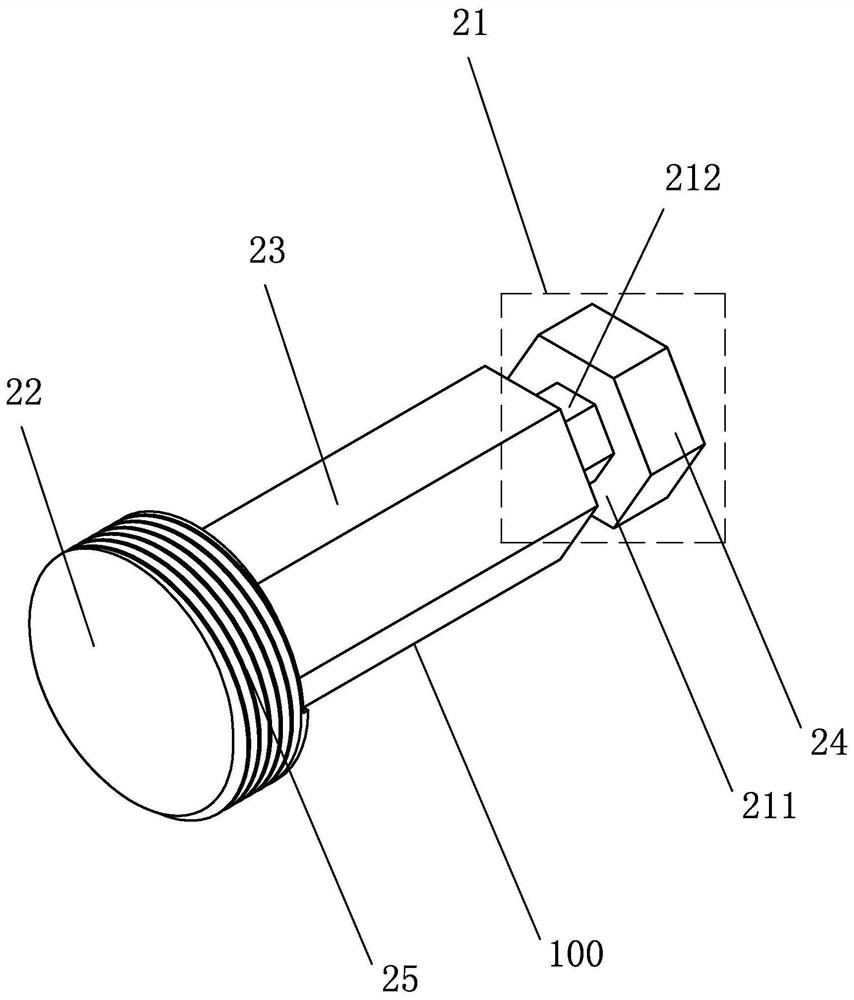

Self-leveling dry hanging assembly and mounting method thereof

PendingCN113152818AImprove heat transfer efficiencyWork efficiency is not idealCovering/liningsAssembly (construction)Industrial engineering

The invention discloses a self-leveling dry hanging assembly. The self-leveling dry hanging assembly comprises a leveling base and a leveling clamping piece, the leveling base is of a cylindrical structure, and a clamping wing part is arranged on the outer edge of the leveling base; the leveling clamping piece is arranged in the leveling base in a penetrating mode, the leveling clamping piece and the leveling base can move relatively, and a clamping part is arranged at the end, away from the leveling clamping piece, of the leveling clamping piece. The invention further discloses a mounting method of the self-leveling dry hanging assembly. By adjusting the relative distance between the leveling base provided with the clamping wing part and the leveling clamping piece arranged in a clamping ring groove, leveling of facing wallboards mounted on the clamping ring groove is completed while the distance is adjusted; and the multiple sets of leveling assemblies can be used in a combined mode, and the multiple facing wallboards of the whole wall surface are uniformly leveled, so that the parallelism can be ensured to be accurate and undifferentiated. Assembly construction is simple and convenient, and the structure compactness is good.

Owner:ZHEJIANG YASHA DECORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com