Fabricated concrete tower tube piece assembly platform and assembly method

A segment assembly and concrete technology, which is applied in the assembly of wind turbines, the configuration of installation/supporting wind turbines, wind power generation, etc., can solve the problems that the speed and accuracy of the assembly process affect the construction period and investment costs, and achieve convenient installation , Reasonable structural design, guaranteed accuracy and speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

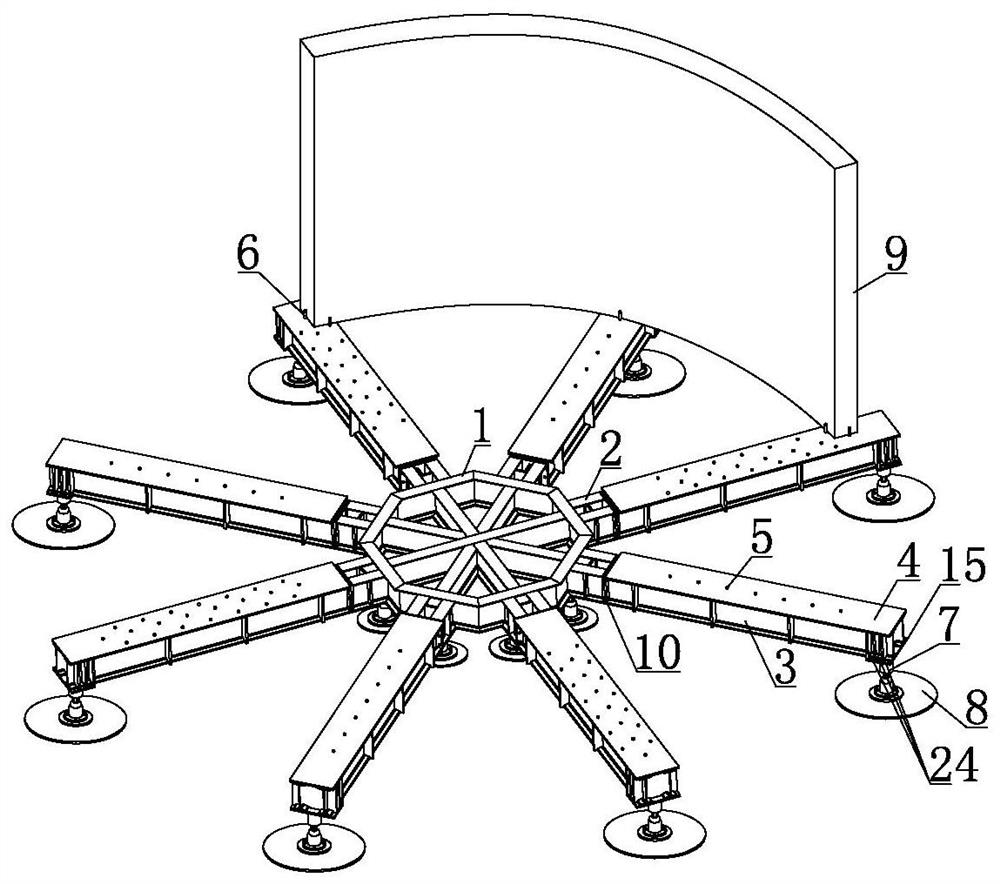

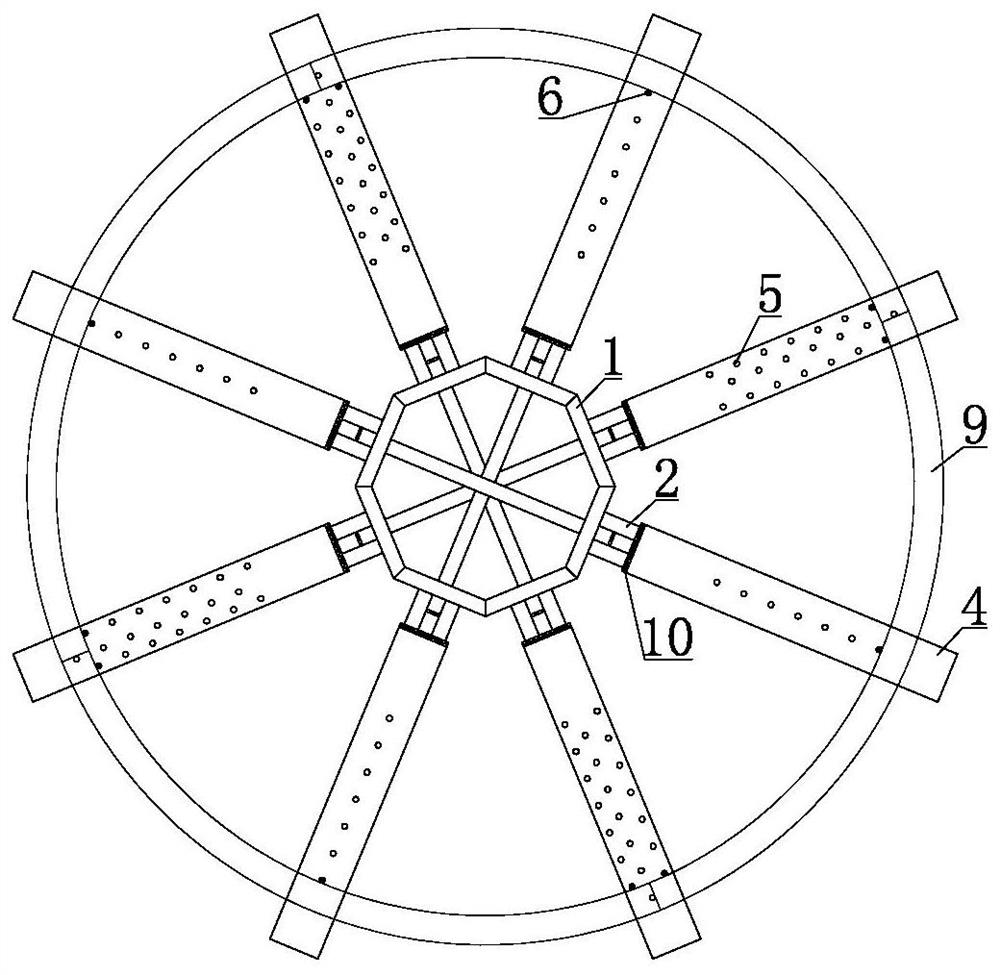

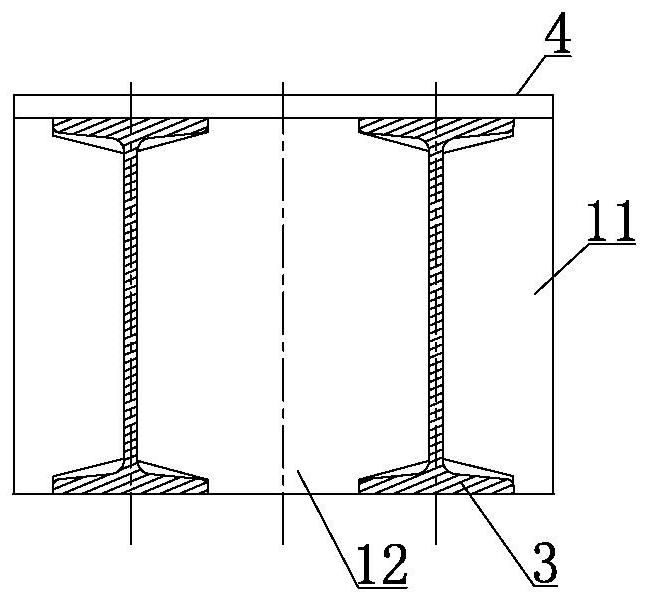

[0040] Such as Figure 1~2 As shown, a prefabricated concrete tower segment assembly platform includes a central frame 1, a connecting section 2, and a support beam 3. The inner end of the connecting section 2 is welded to the central frame 1, and the outer end is connected to the support beam 3 through flanges 10 bolts, and the three constitute the main structure of the device. A series of limiting and positioning pin holes 5 are arranged on the panel 4, and positioning pins 6 are inserted to form a limiting and positioning system of the device. The 16 said leveling feet 7 arranged at the bottom of the center frame and the support beam constitute the leveling system of the device. After the concrete tower segment 9 is hoisted onto the device, the leveling and assembling process of the tower segment can be quickly realized through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com